Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Transducer model LSO.06 and

switching amplier model LSO.25

Messwandler Typ LSO.06 und

Schaltverstärker Typ LSO.25

Transducteur de mesure type LSO.06 et

relais amplicateur type LSO.25

Transductor modelo LSO.06 y

amplicador de conmutación modelo LSO.25

GB

D

F

E

Switching amplier Transducer

model LSO.25 model LSO.06

Page 2

Operating instructions

GB

Models LSO.06, LSO.25 Page 3 - 34

Betriebsanleitung

D

Typen LSO.06, LSO.25 Seite 35 - 66

Mode d'emploi

F

Types LSO.06, LSO.25 Page 67 - 98

Manual de instrucciones

E

Modelos LSO.06, LSO.25 Página 99 - 130

© WIKA Alexander Wiegand SE & Co. KG 2010

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta posterior!

2

WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 10

4. Design and function 13

5. Transport, packaging and storage 19

6. Commissioning, operation 20

7. Conguration 26

8. Notes for mounting and operating in hazardous

areas 30

9. Maintenance, repair and cleaning 30

GB

10. Faults 32

11. Warranty 33

12. Dismounting, return and disposal 33

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 3

Page 4

1. General information

1. General information

■

GB

The instruments described in the operating instructions has been manufactured using

state-of-the-art technology.

All components are subject to stringent quality and environmental criteria during

production. Our management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument's range of use.

■

The operating instructions are part of the instrument and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions,

prior to beginning any work.

■

The manufacturer‘s liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions,

assignment of insuciently qualied skilled personnel or unauthorised modications to

the instrument

■

The general terms and conditions, contained in the sales documentation, shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: LM 31.10, LM 31.20

- Application consultant: Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation, which can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation, which can result in light

injuries or damage to equipment or the environment, if not avoided.

4 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 5

1. General information / 2. Safety

Information

... points out useful tips, recommendations and information for ecient and

trouble-free operation.

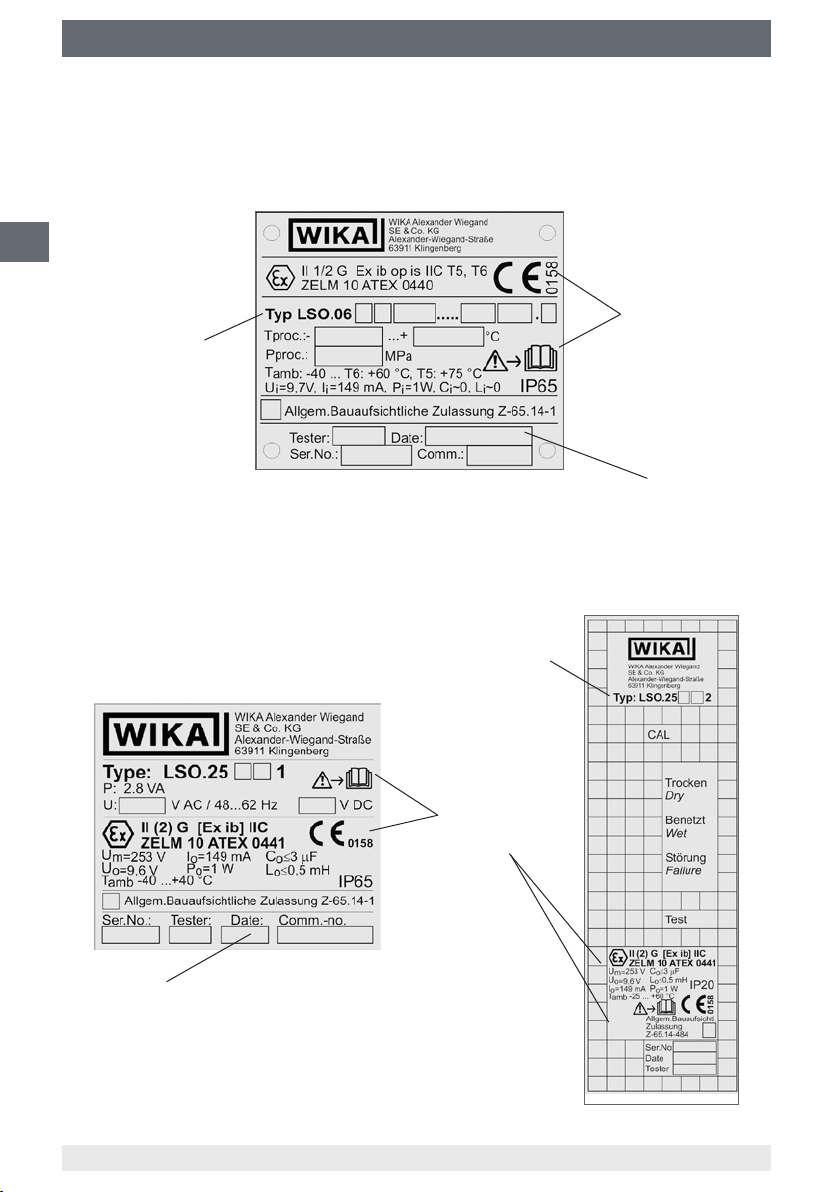

DANGER!

...identies hazards caused by electric power. Should the safety instructions

not be observed, there is a risk of serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation in a potentially explosive

atmosphere, resulting in serious injury or death, if not avoided.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the

appropriate instrument has been selected in terms of measuring range,

design and specic measuring conditions.

Serious injuries and/or damage can occur should these not be observed.

GB

Further important safety instructions can be found in the individual chapters

of these operating instructions.

2.1 Intended use

The model LSO.06 transducer is used for limit value detection in liquids. The

model LSO.25 switching amplier may be used in conjunction with the model LSO.06

transducer for overow control. The instruments are very robust and designed for rough

operating conditions.

These instruments have been designed and built solely for the intended use described

here, and may only be used accordingly.

The technical specications contained in these operating instructions must be observed.

Improper handling or operation of the transducer and the switching amplier outside of its

technical specications requires the instrument to be shut down immediately and inspected by an authorised WIKA service engineer.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 5

Page 6

2. Safety

2.2 Personnel qualication

WARNING!

GB

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and

knowledge of country-specic regulations, current standards and directives, are capable

of carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

2.3 Additional safety instructions for instruments with ATEX approval

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to

equipment.

■

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualications described

below.

■

Keep unqualied personnel away from hazardous areas.

WARNING!

■

Non-observance of these instructions and their contents may result in the

loss of explosion protection

■

Observe the European Use Directive (EN 60 079-10:1996 )

2.4 Special hazards

WARNING!

Observe the information given in the applicable type examination certicate

and the relevant country-specic regulations for installation and use

in potentially explosive atmospheres (e.g. IEC 60079-14, NEC, CEC).

Non-observance can result in serious injury and/or damage to equipment.

For additional important safety instructions for insturments with ATEX

approval see chapter "2.3 Additional safety instructions for instruments with

ATEX approval".

WARNING!

For hazardous media such as oxygen, acetylene, ammable or toxic gases

or liquids, and refrigeration plants, compressors, etc., in addition to all

standard regulations, the appropriate existing codes or regulations must also

be followed.

6 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 7

2. Safety

WARNING!

To ensure safe working on the instrument, the operating company must

ensure

■

that suitable rst-aid equipment is available and aid is provided whenever

required.

■

that the operating personnel are regularly instructed in all topics regarding

work safety, rst aid and environmental protection and knows the

operating instructions and, in particular, the safety instructions contained

therein.

DANGER!

Danger of death caused by electric current

Upon contact with live parts, there is a direct danger of death.

■

Electrical instruments may only be installed and mounted by skilled

electrical personnel.

■

Operation using a defective power supply unit (e.g. short circuit from the

mains voltage to the output voltage) may result in life-threatening voltages

on the instrument!

WARNING!

Residual media in dismounted instruments may result in a risk to people, the

environment and the system. Take sucient precautionary measures.

GB

Do not use this instrument in safety or Emergency Stop devices. Incorrect

use of the instrument can result in injury.

Should a failure occur, aggressive media with extremely high temperature

and under high pressure or vacuum may be present at the instrument.

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 7

Page 8

2. Safety

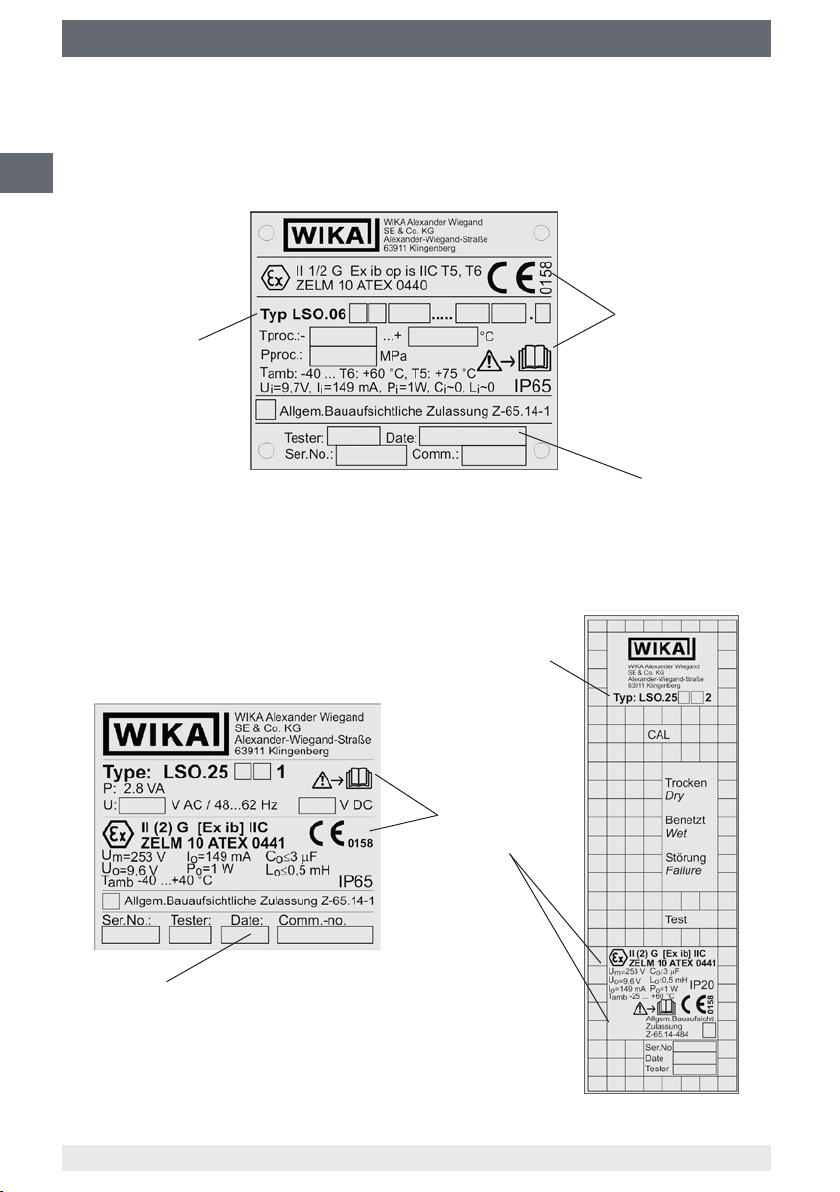

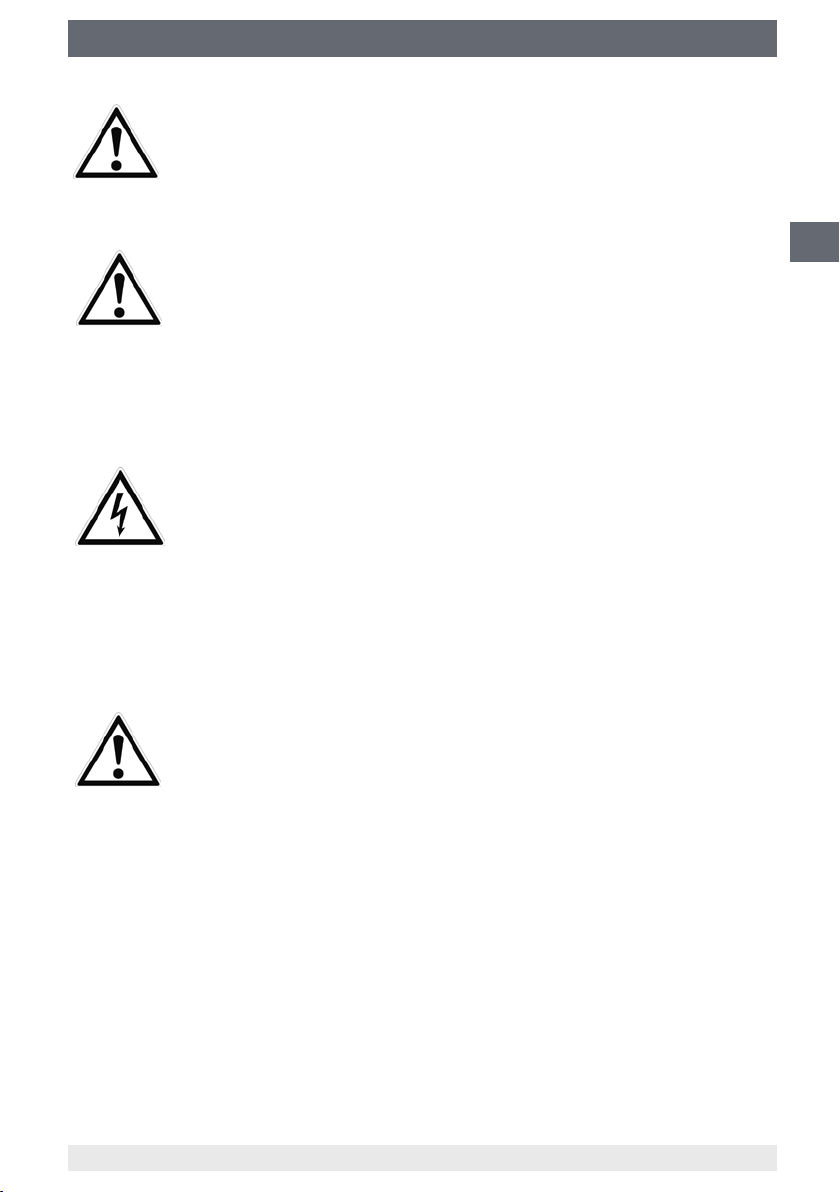

2.5 Labelling / safety marks

Product label

GB

■

Transducer model LSO.06

Model

■

Switching amplier model LSO.25

For an explanation of

symbols see page 9

Date of manufacture

19" plug-in card

In mounted case

For an explanation

of symbols see

page 9

Date of manufacture

Model

8 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 9

2. Safety

Explanation of symbols

Before mounting and commissioning the instrument, ensure you read

the operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

ATEX European Explosion Protection Directive

(Atmosphère = AT, explosible = Ex)

Instruments bearing this mark comply with the requirements of the European

Directive 94/9/EC (ATEX) on explosion protection.

GB

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 9

Page 10

3. Specications

3. Specications

3.1 Transducer model LSO.06

GB

General data

Measuring accuracy ±0.5 mm

Ambient light max. 100 Lux

Mounting position any

Weight

■

Standard version

■

High and low temperature version

1) ML = Measuring length

Design data

Medium temperature

■

Standard version

■

High and low temperature version

Ambient temperature -65 ... +95 °C

Working pressure 0 ... 25 MPa (0 ... 250 bar)

High pressure version 0 ... 50 MPa (0 ... 500 bar)

Materials

■

Sensor case

■

Light guide

■

Packing

■

Case

Ex ignition protection type II 1/2 G Ex ib op is IIC T5, T6

0.77 kg +9.3 g/cm ML

1.07 kg +9.3 g/cm ML

-65 ... +250 °C

-269 ... +400 °C

1.4571 (option: hastelloy, other materials on request)

clad core glass (option: quartz, sapphire (only max.

ML = 60 mm))

graphite

stainless steel

T6: to 60 °C, T5: to 75 °C

ZELM 10 ATEX 0440

1)

1)

Electrical data

Cable gland M20 x 1.5, Ex: blue

Terminal connection 3 x 2.5 mm²

Ingress protection IP 65 per EN 60529

For further specications see WIKA data sheet LM 31.10 and the order documentation.

10 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 11

3. Specications

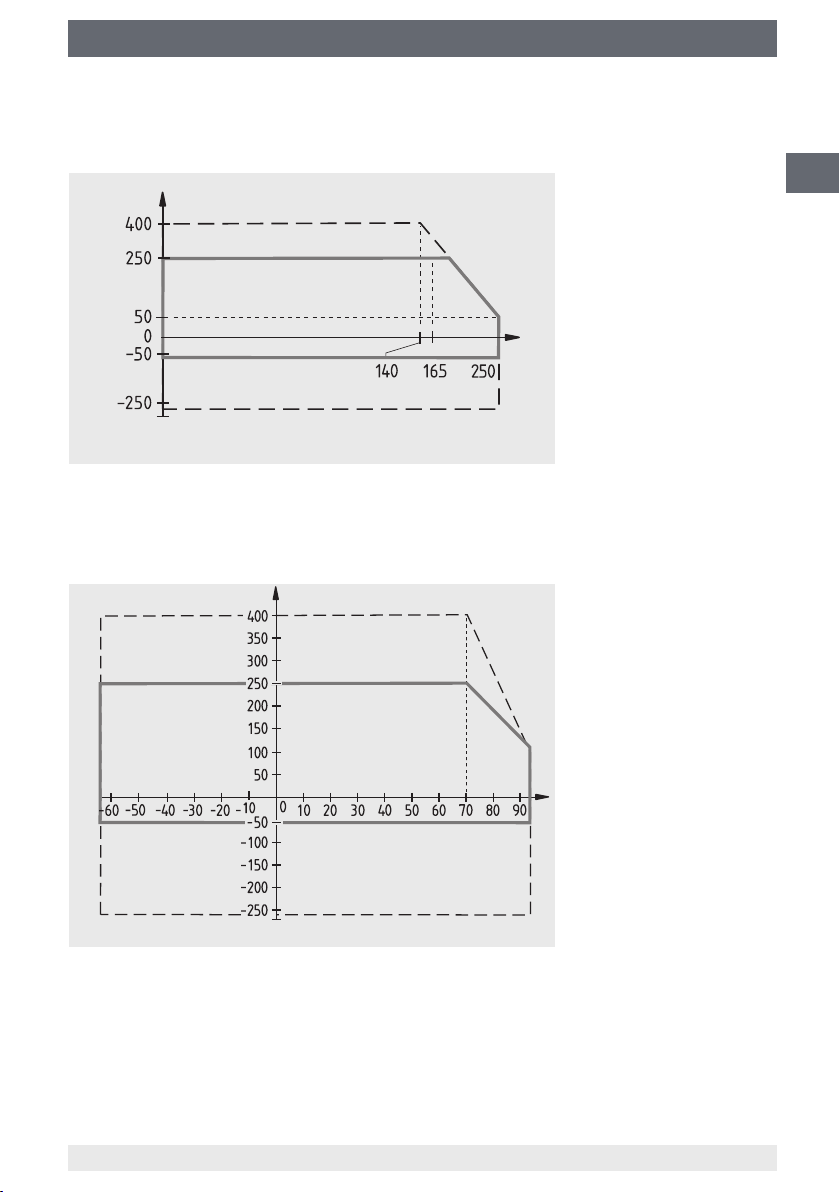

P-T Diagram

(Pressure / temperature limitation of application)

for mounting connection G ½ A per DIN 910

High temperature version

Standard version

Low temperature version

Medium temperature in °C

Working pressure in bar

Derating Diagram

(Temperature limitation of application)

GB

High temperature

version

Standard version

Medium temperature in °C

Ambient temperature in °C

13334603.01 09/2010 GB/D/F/E

Low temperature version

WIKA operating instructions models LSO.06, LSO.25 11

Page 12

3. Specications

3.2 Switching amplier model LSO.25

General data

GB

Functions

Monitoring

Weight

■

19" plug-in card

■

mounted case

Design data

Ambient temperature

■

19" plug-in card

■

mounted case

Ex ignition protection type II (2) G [Ex ib] IIC

Maximum external inductance L

Maximum external capacitance C

U

0

I

0

P

0

■

Selectable alarm direction

■

On-delay and drop-out delay for signal relay, each

adjustable up to approx. 8 s

■

Wire break signal circuit

■

Short-circuit signal circuit

■

Internal supply voltage, fail-safe

0.31 (0.36) kg

0.6 (0.73) kg

-25 ... +60 °C

-40 ... +40 °C

ZELM 10 ATEX 0441

max

0.5 mH

3 µF

max

≤ 9.6 V

≤ 149 mA

≤ 1.0 W

Electrical data

Supply voltage AC 230/115/120/24 V / DC 24 V

Power consumption 2.8 VA/3 W

Outputs

Cable glands M16 x 1.5 / M20 x 1.5 Ex: blue

Max. connection cross section 2.5 mm²

Cable length 175 ... 600 m (0.5 ... 1.5 mm²)

Ingress protection

■

19" plug-in card

■

mounted case

For further specications see WIKA data sheet LM 31.20 and the order documentation.

12 WIKA operating instructions models LSO.06, LSO.25

■

Signal relay, SPDT, 250 V/3 A/100 VA

■

Failure relay, SPDT, 250 V/3 A/100 VA

IP 20 per EN 60529

IP 65 per EN 60529

13334603.01 09/2010 GB/D/F/E

Page 13

4. Design and function

4. Design and function

4.1 Description

The transducer is used for measuring liquid level limits.

The conical tip of the sensor ensures really precise on-off performance level sensing.

Its reaction is independent of various physical parameters of the liquid such as density,

dielectric constant, conductivity, colour or refractive index. This allows the use for safe

level switching as well as for precise level control applications. If there is any foam you

even can decide whether to use the sensor for foam level or liquid level control, suppressing the influence of foam on switching.

If the sensor is supplied with a U-tip, it is able to sense changes in refractive index. So it

can be used for example as an interface level switch for liquids.

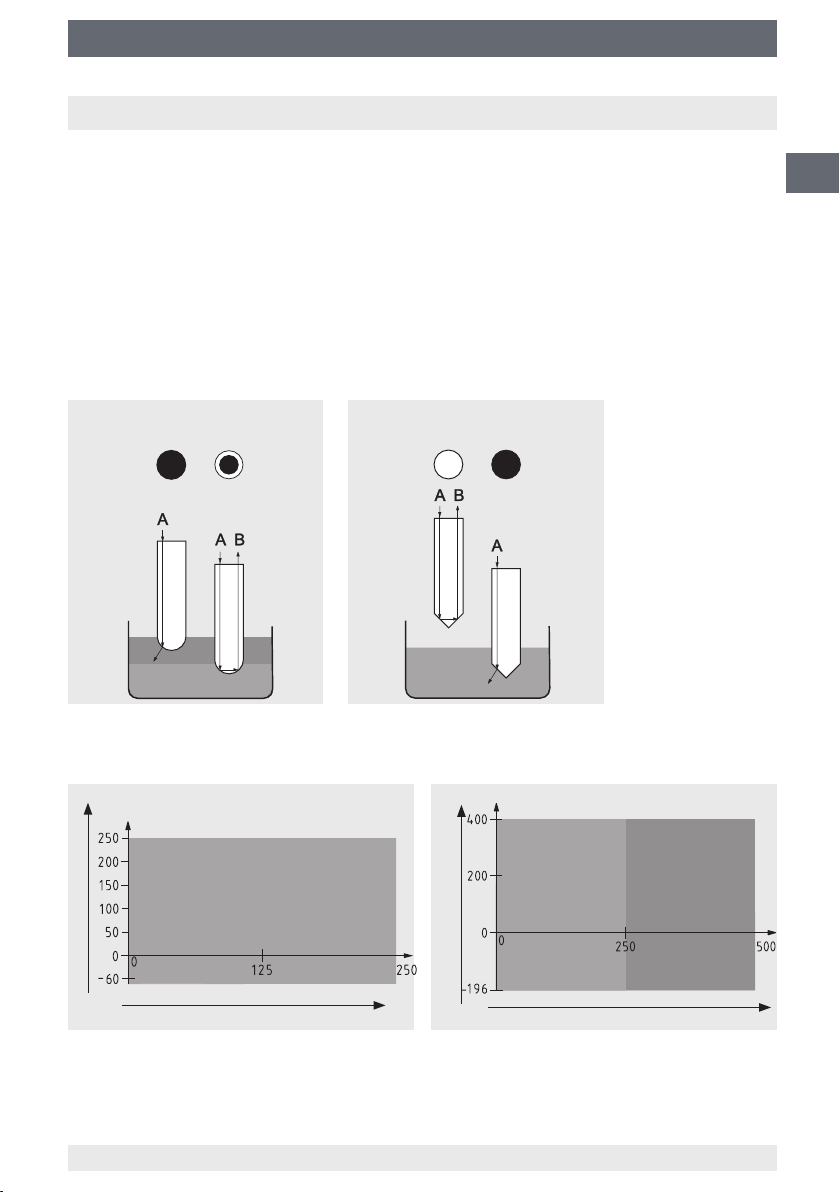

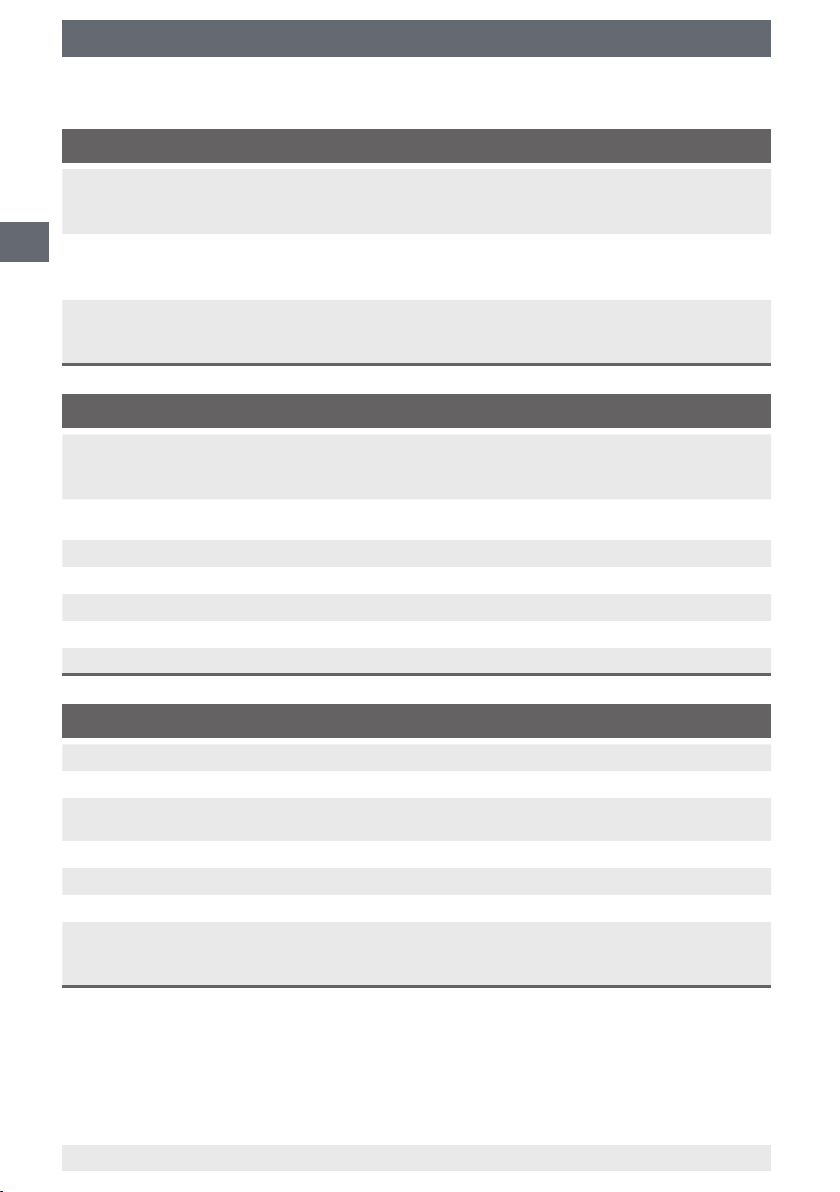

Principle of operation

Separation layer, U-tip

e.g. oil

e.g. water

Principle of operation

Level, conical tip

Gas

Liquid

GB

Application range

High pressure

version with

heatsink

threaded

connection G ½ A

Medium temperature in °C

Standard pressure version

without heatsink

threaded connection

Working pressure in bar

High pressure

version with

heatsink

threaded

connection NPT ½

Medium temperature in °C

Working pressure in bar

All typs of transducers need a switching ampliers model LSO.25 for power supply and

switch state signalling.

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 13

Page 14

4. Design and function

4.2 Instrument design

Each unit consists of a transducer and a controller (switch amplier). The transducer may

be of one-piece or multi-part design. Ex types are generally constructed as multi-part

GB

types. Multi-part transducers can be equipped with a heat-sink to expand the temperature

range.

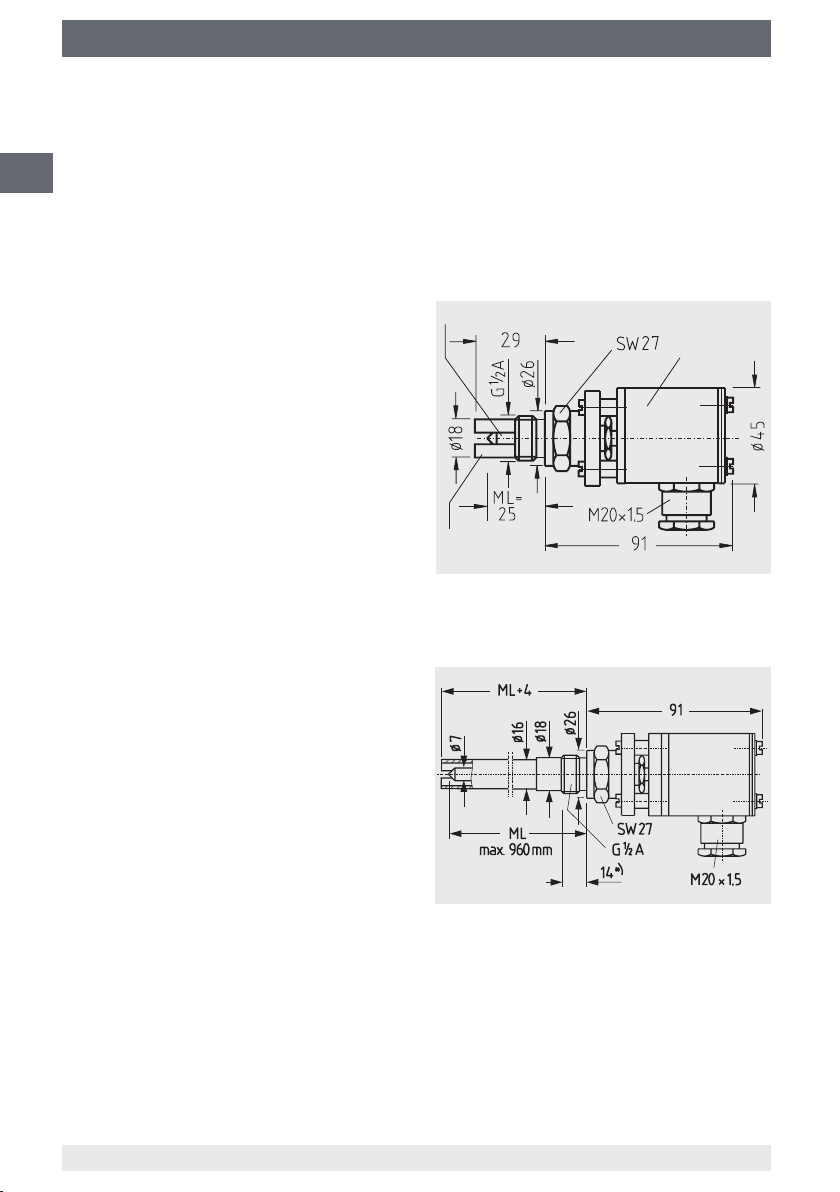

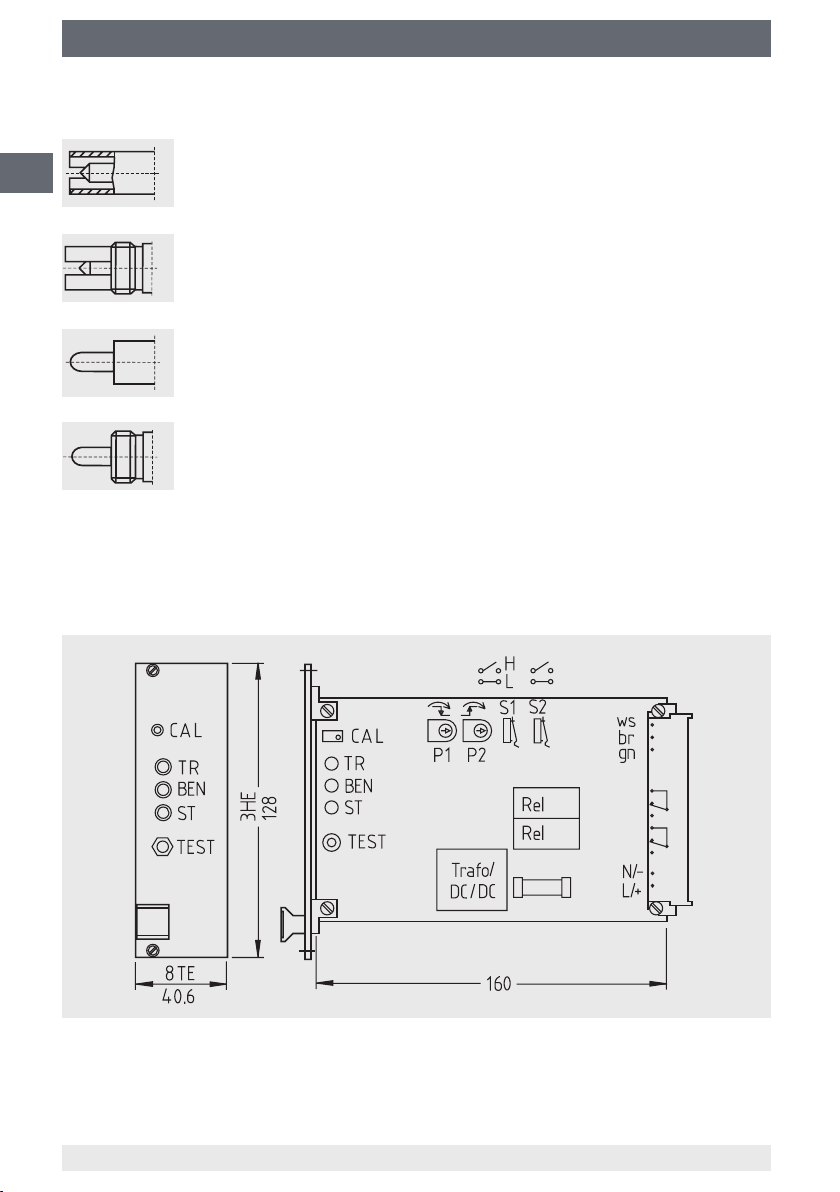

4.2.1 Transducer model LSO.06

■

Without extension

Fixed measuring length ML, no extension

possible. Protection ngers are part of the

sensor housing.

Light guide Ø 7

Sensor

housing

*) 20 for high pressure sensor

Sensor

body

■

With extension

Measuring length ML from 50 to 960 mm.

Extension tube screwed into sensor

housing.

Preferential measuring lengths:

50, 60, 80, 90, 100, 120, 150, 200, 300,

600 and 800 mm

Values between these can be delivered

using variable-length types

*) 20 for high pressure sensor

14 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 15

4. Design and function

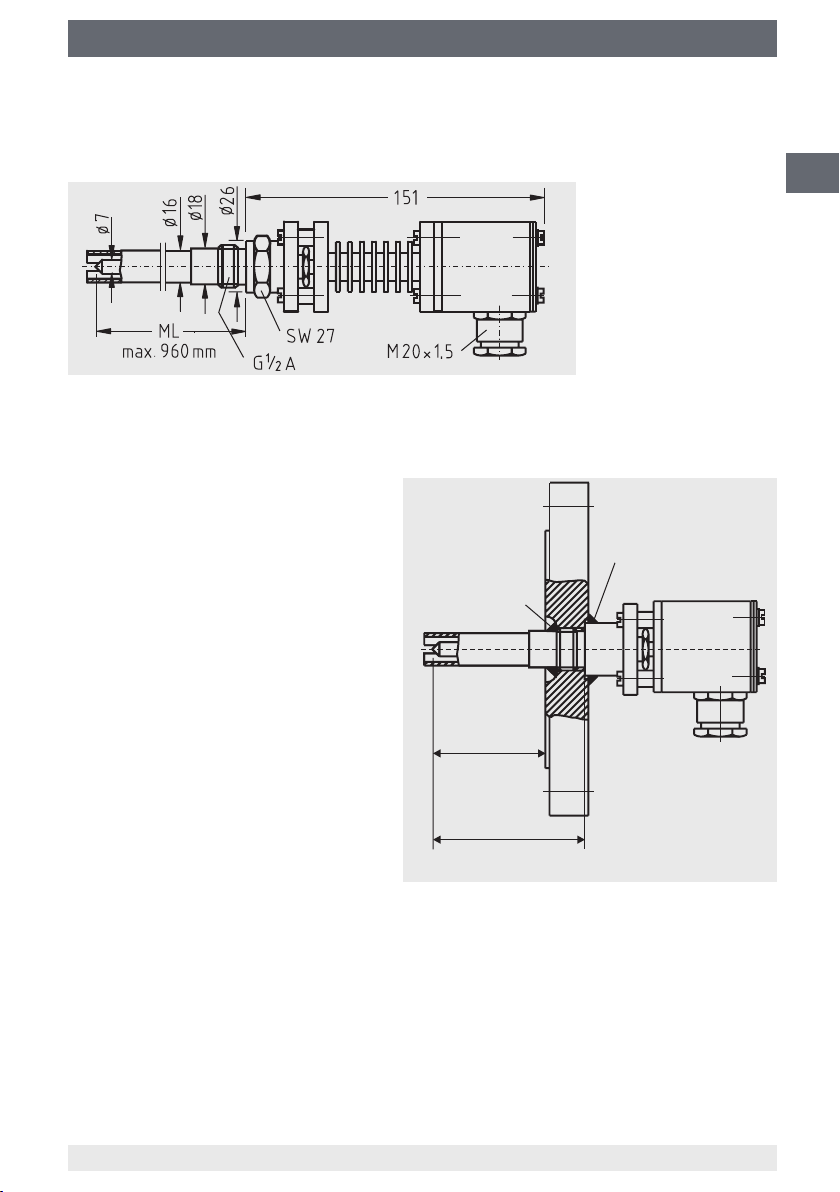

■

For increased temperature range

Extended temperature range with heatsink. This may be combined with xed ML 25

mm and with extended types.

heatsink

*) 20 for high pressure sensor

■

Fitted with ange

Design with ange from DN25 and

from PN6 or ANSI, all forms of the

sealing face. Explosion-protected

instruments are usually seal-welded

to the sensor component (in this case,

the hexagon is omitted).

seal weld

alternative

seal weld

GB

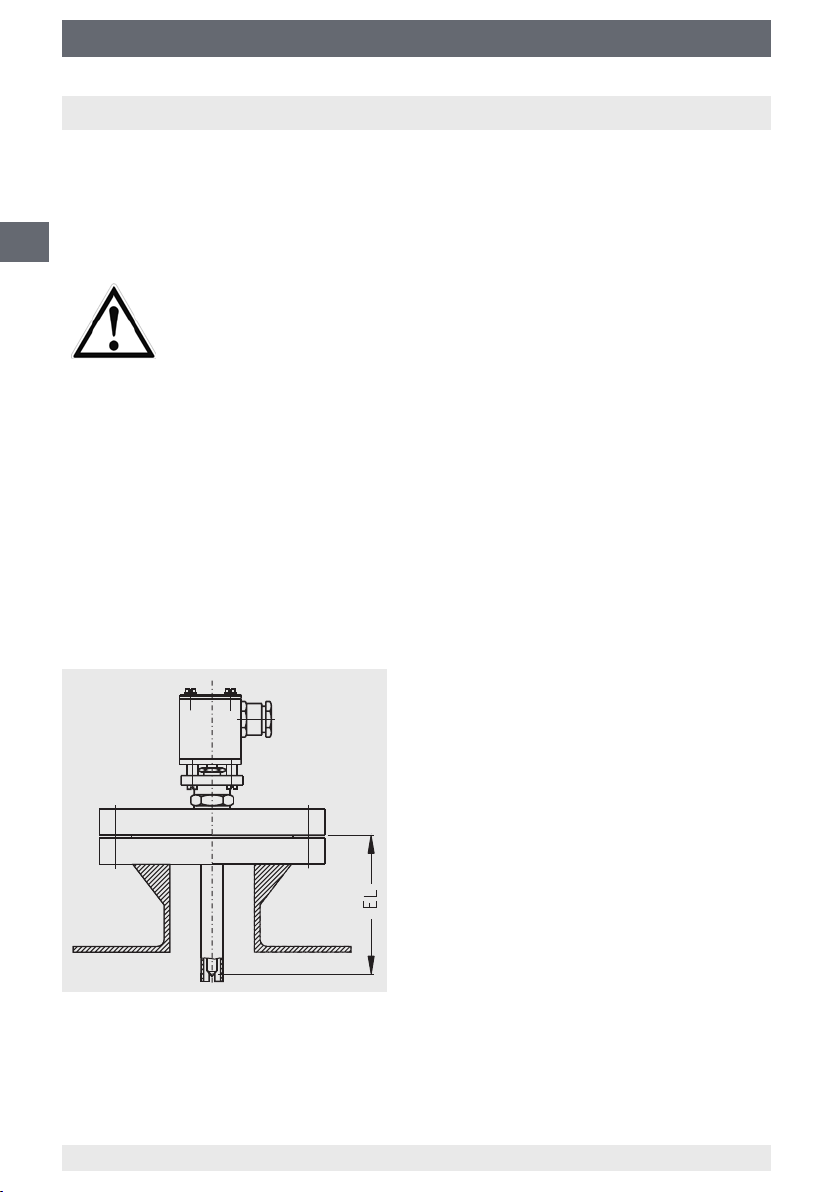

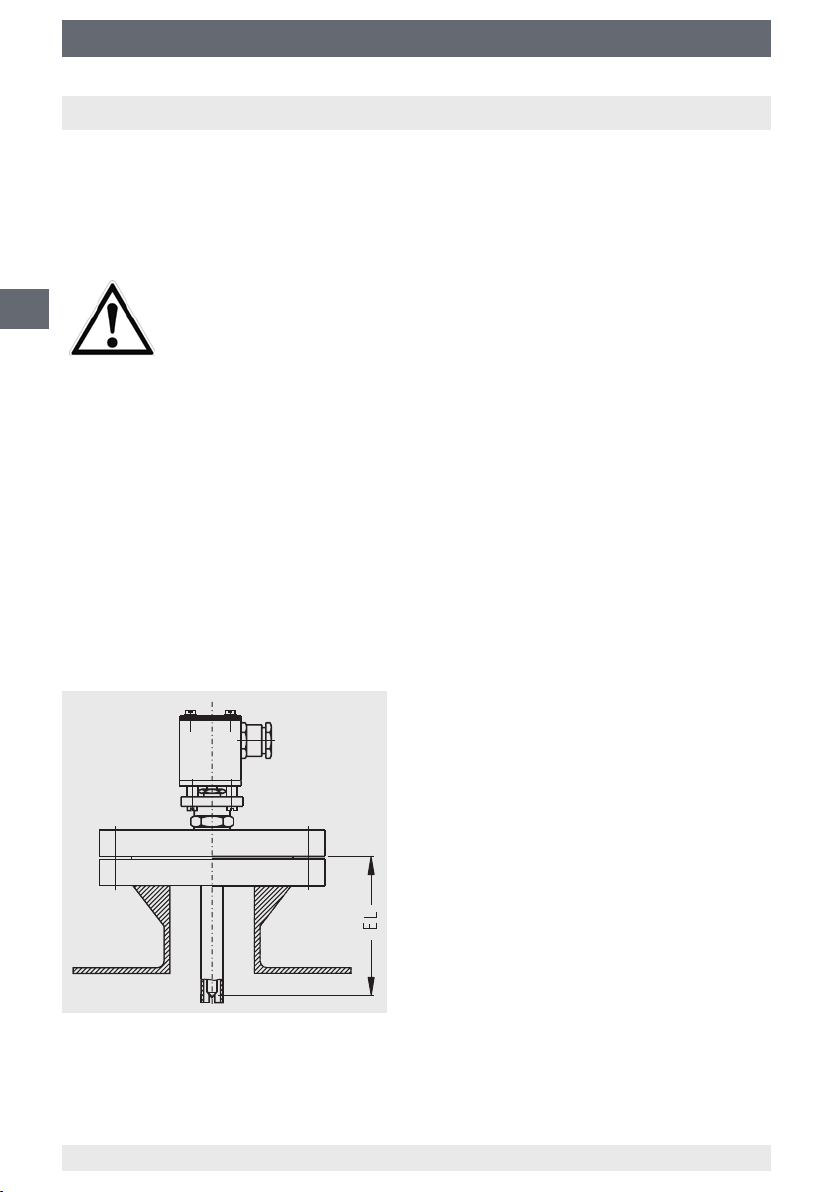

Insertion length EL =

ML-ange thickness

EL from

sealing face

ange

ML from

sealing face

sensor

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 15

Page 16

4. Design and function

■

Designs for level and separation layer

GB

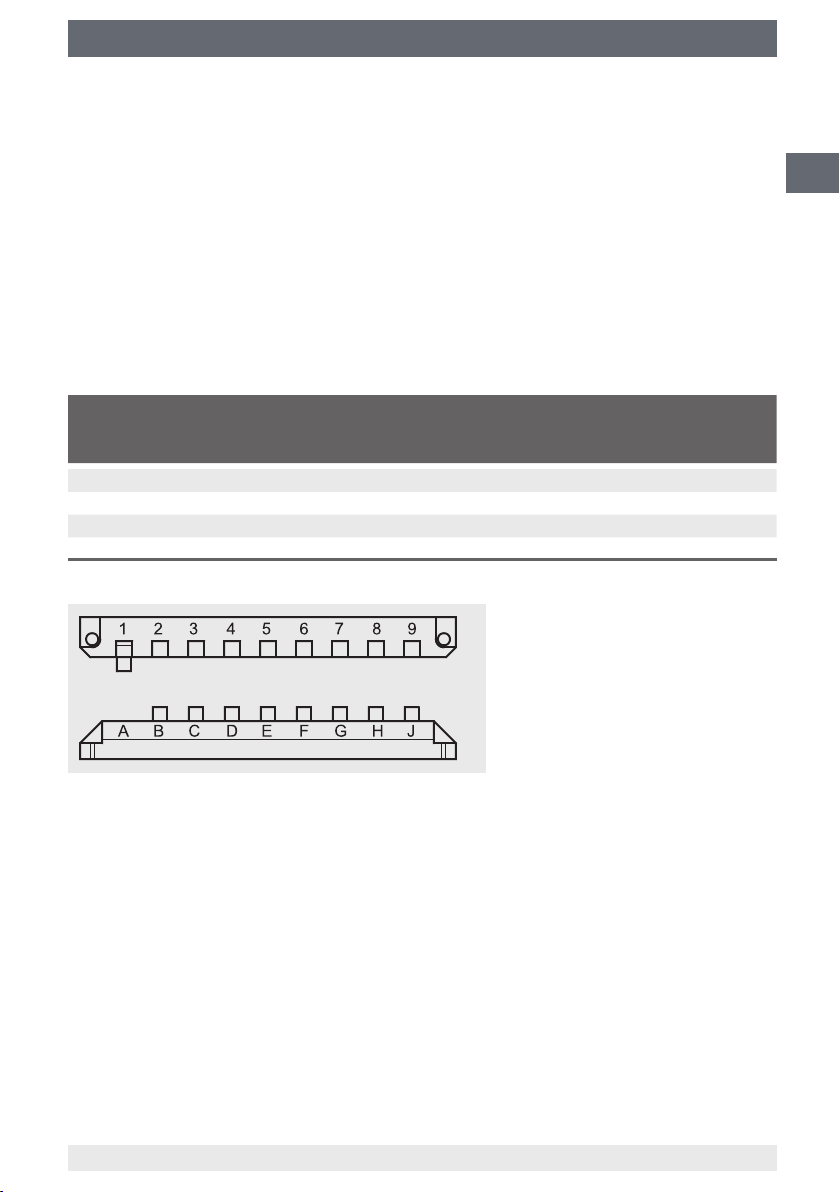

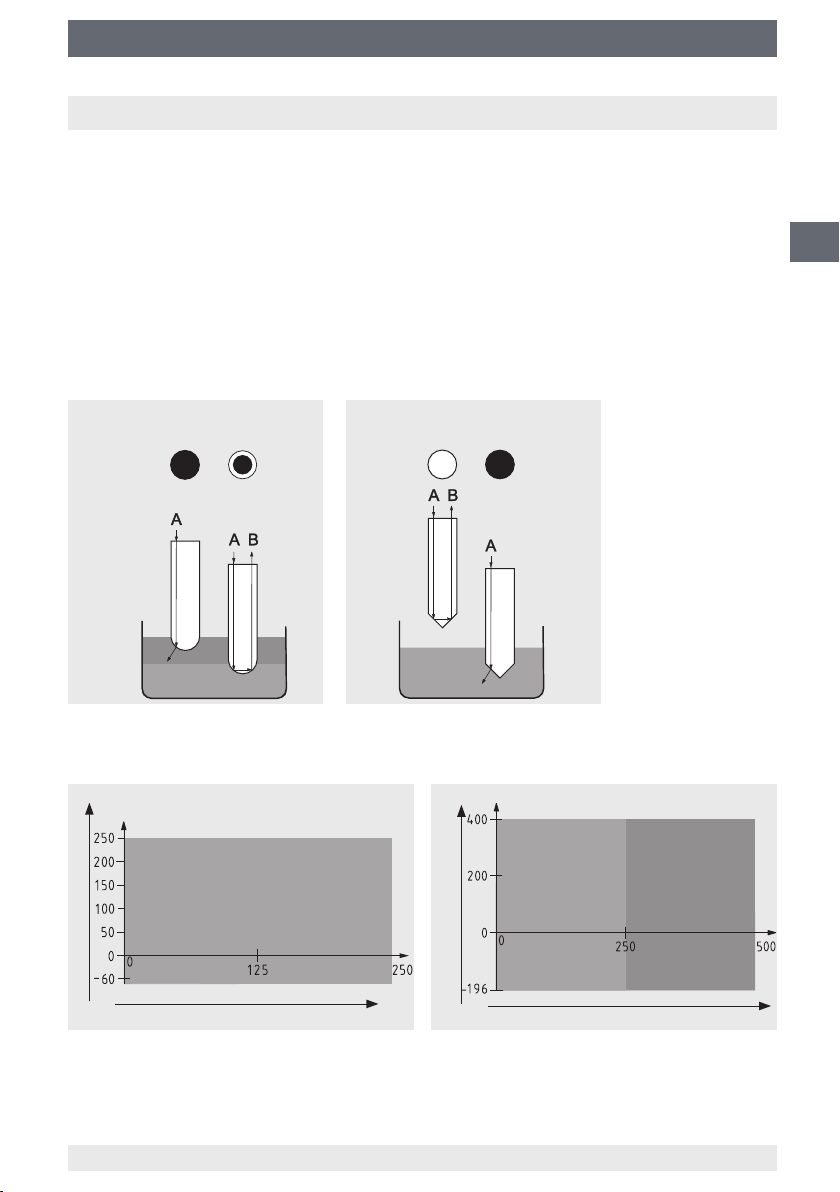

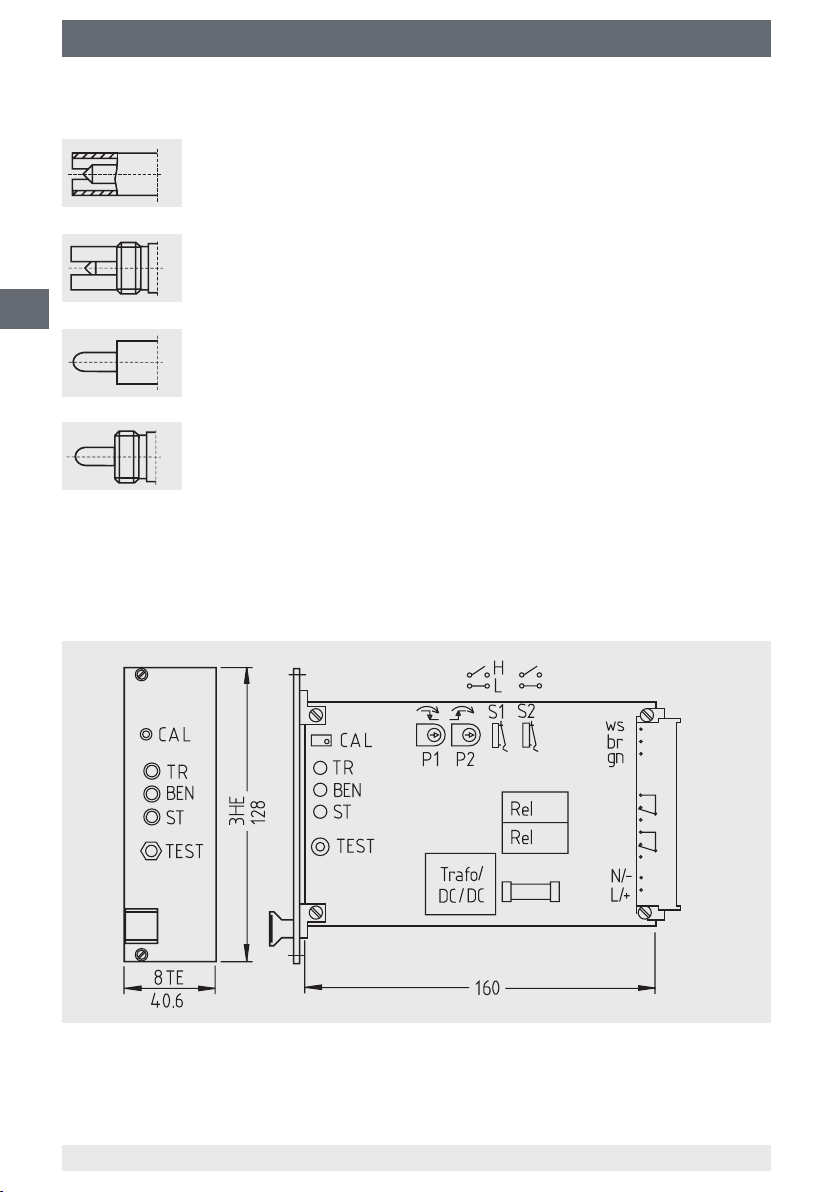

4.2.2 Switching amplier model LSO.25

■

19" plug-in card

Level measurement with conical tip and neck tube/thermowell, measuring

length ML 50 ... 960 mm

Level measurement with conical tip, xed measuring length ML 25 mm,

without neck tube

Separation layer measurement with U-tip, neck tube/thermowell,

measuring length ML 50 ... 960 mm

Separation layer measurement with U-tip, xed measuring length

ML 25 mm, without neck tube

time delay on

time delay o

Trans-

time delay

Fuse

16 WIKA operating instructions models LSO.06, LSO.25

ducer

Failure

Signal

Supply

13334603.01 09/2010 GB/D/F/E

Page 17

4. Design and function

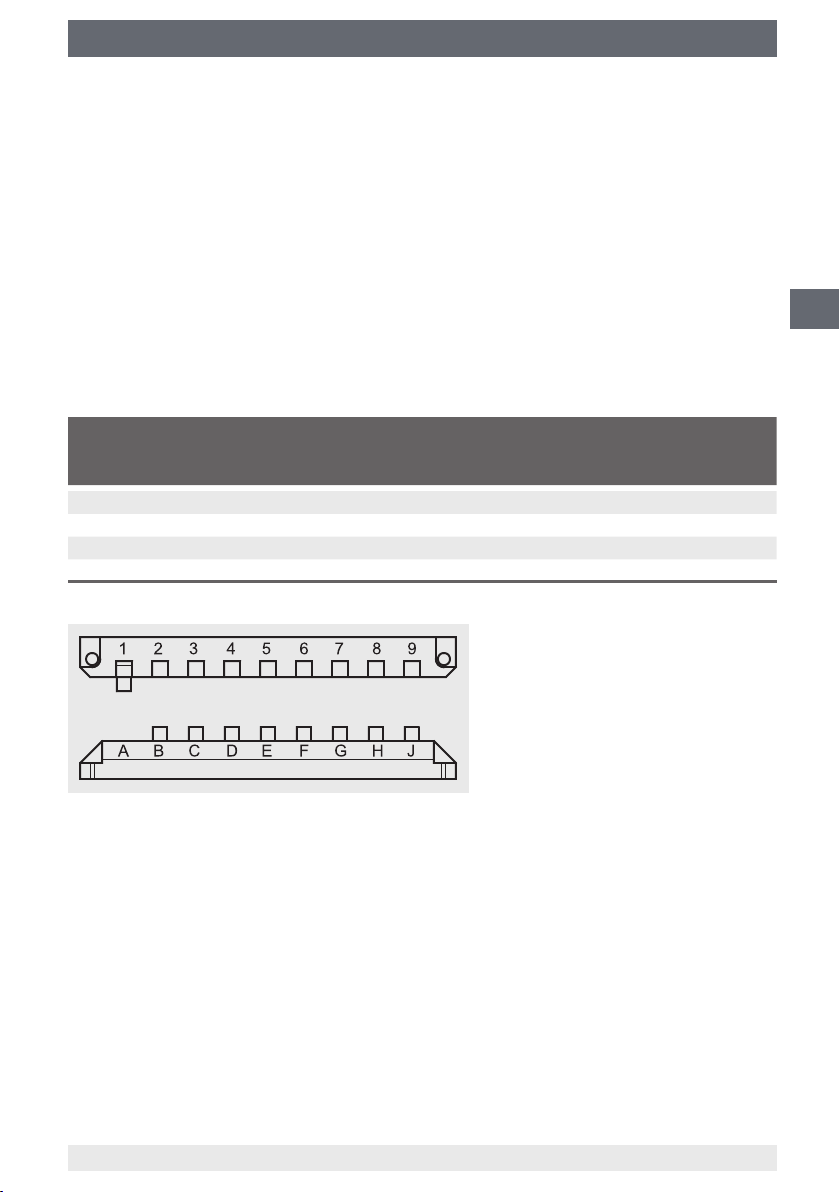

For explosion protected version please note the following

The amplier is designed as a plug-in card for a 19" plug-in card. The plug-in card alone

doesn't fulll the ingress protection IP 20 in accordance with EN 60529: 1991. It only is

intended for the installation into a suitable rack which guarantees the minimum ingress

protection IP 20. Not used plug-in places have if necessary to be covered with blind plates.

The distances and tracking distances particularly are between the individual plug-in cards

as well as the intrinsic safe and not intrinsic safe circuits, the requirements on the wiring as

well as the excess temperature and the dissipation power converted in the assemblies are

to take into account according to

ers are provided with an encoding system. It has to be made sure that the counter-strip is

executed availably and identically in the 19" rack.

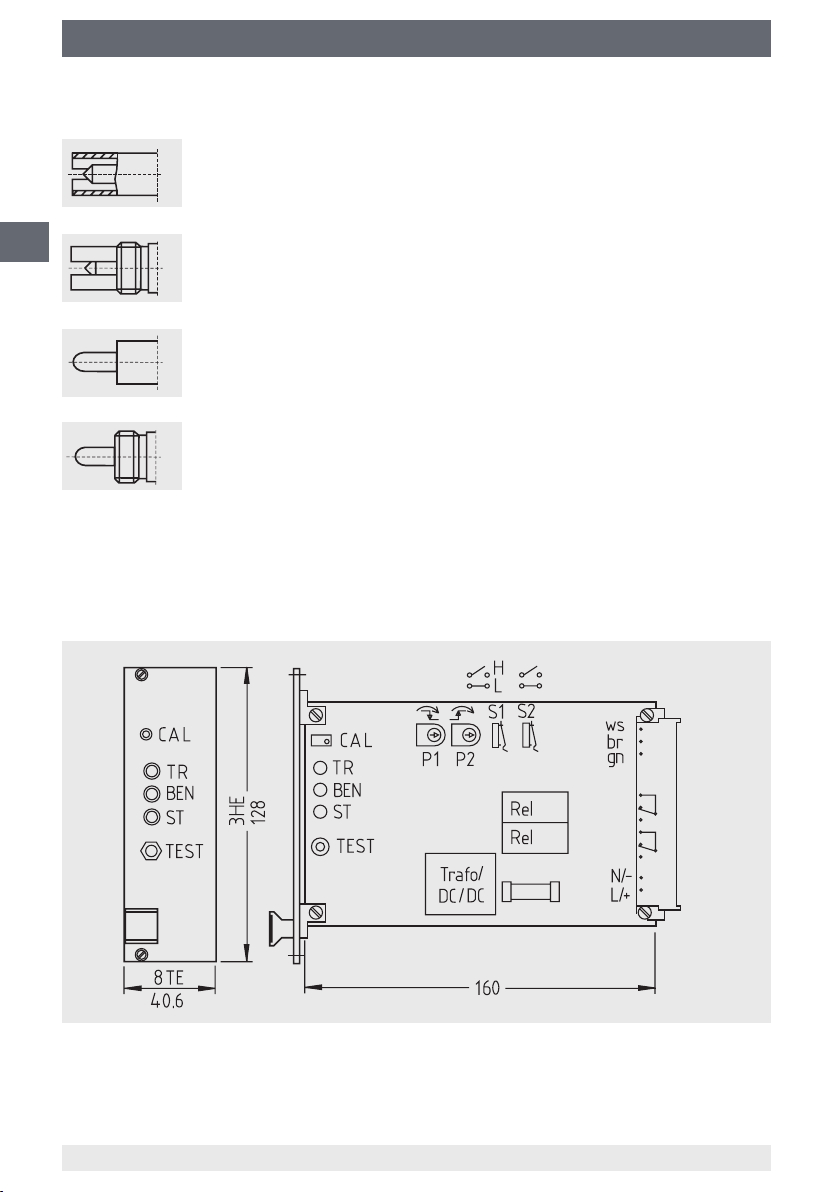

Default coding

Supply voltage

version

AC 230 V B-C-D-E-F-G-H-J 1

AC 115/120 V A, C-D-E-F-G-H-J 2

AC 24 V A-B, D-E-F-G-H-J 3

DC 24 V A-B-C, E-F-G-H-J 4

Encoder-strip rack,

provided at these positions

with coding pins

EN 60079-11:2007

. To avoid mistakes, the switch ampli-

Encoder-strip plug-in card,

provided at these positions with one

coding pin

:

Encoder-strip plug-in card

GB

Encoder-strip rack

Example: AC 230 V supply voltage version

We exclusively recommend the use of suitable racks for the guarantee of the requirements

to WIKA.

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 17

Page 18

4. Design and function

Alternatively the coding can take place directly in the female connector (rack side) and the

associated male connector (switching amplier side) after the following coding plan:

GB

The coding pin is inserted with a tool captive in the appropriate place in the female

connector and at the opposite side in the male connector is a drilling.

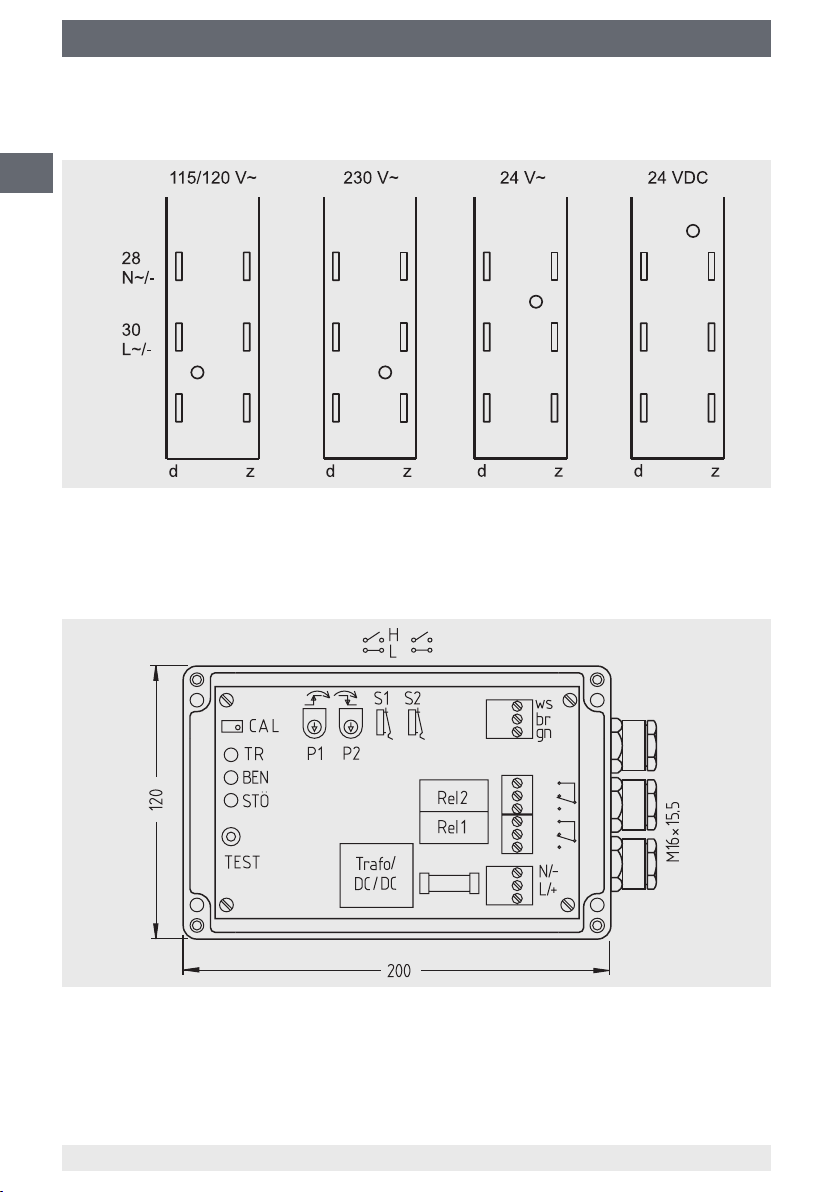

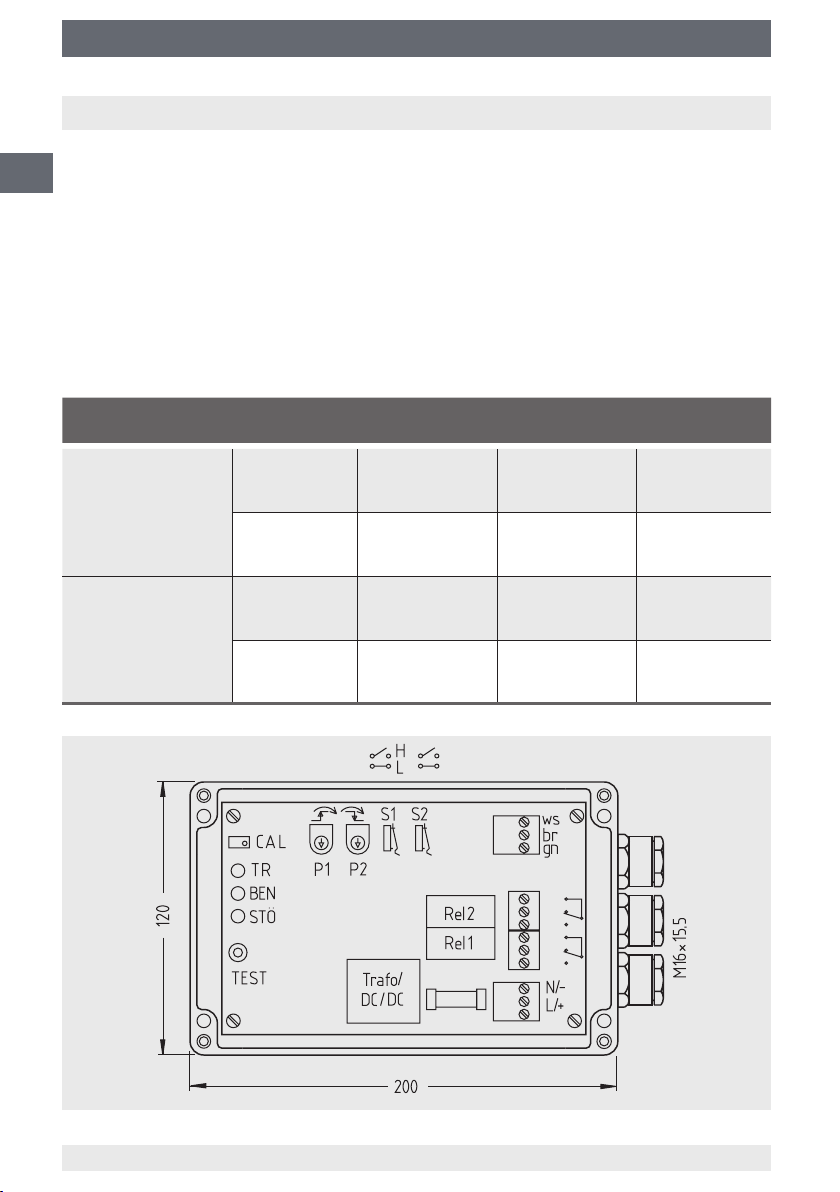

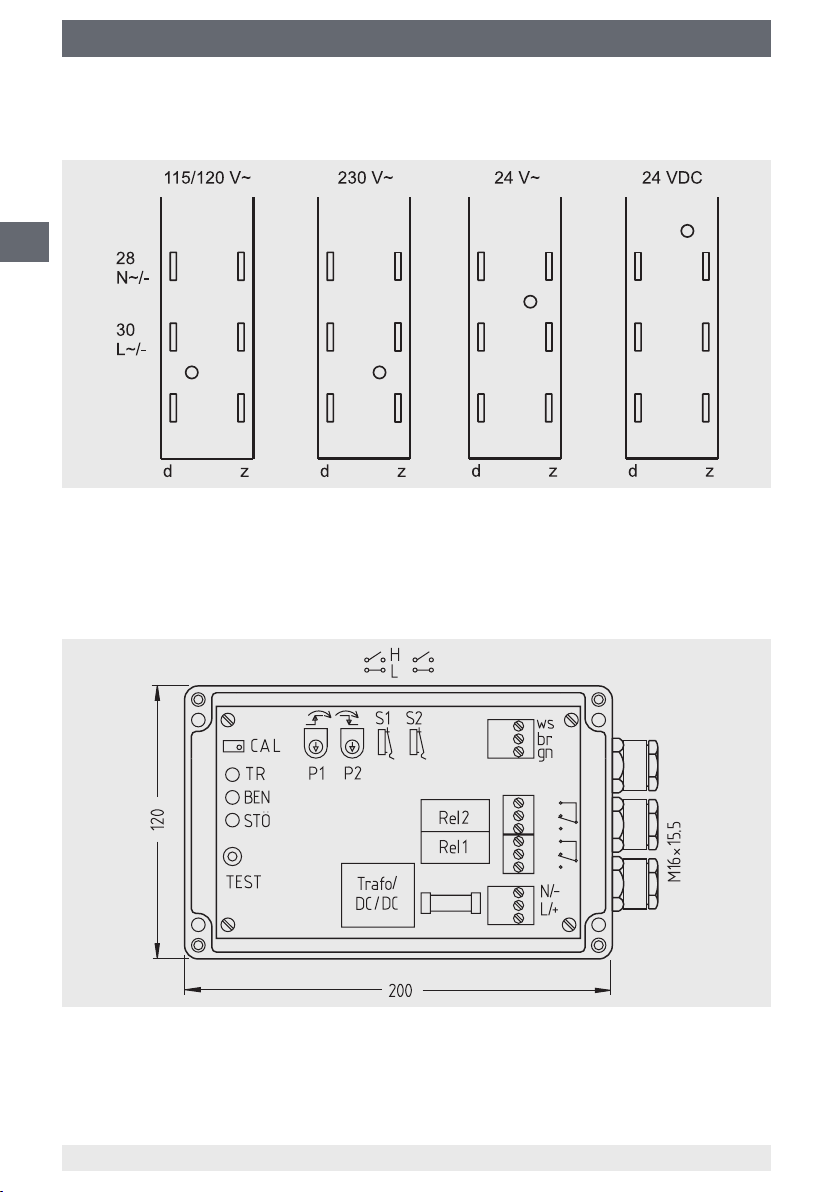

■

In mounted case

time delay on

time delay o

trans-

ducer

M20 x 1.5 or

time delay

Failure

Signal

Fuse

Supply

75 high

M16 x 1.5

4.3 Scope of delivery

Cross-check scope of delivery with delivery note.

18 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 19

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

Check instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -25 ... +70 °C

■

Humidity: 35 ... 85 % relative humidity (no condensation)

Avoidance of exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Potentially explosive environments, ammable atmospheres

Store the instrument in its original packaging in a location that fullls the conditions listed

above. If the original packaging is not available, package and store the instrument as

described below:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with shock-absorbent material, in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag, containing a

desiccant, inside the packaging.

GB

WARNING!

Before storing the instrument (following operation), remove any residual

media. This is of particular importance if the medium is hazardous to health,

e.g. caustic, toxic, carcinogenic, radioactive, etc.

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 19

Page 20

6. Commissioning, operation

6. Commissioning, operation

Before the installation a check of the function can be carried out. The device attached

GB

provisionally and the glass tip are one and from dived to this for the test in a glass with

liquid (adjustment if necessary, see chapter "7.2 Adjustment with CAL").

WARNING!

The electrical connection only be carried out by qualied skilled personnel.

Observe the appropriate VDE regulations.

6.1 Installation instructions transducer model LSO.06

The sensors may be installed in any direction, i. e. from top, bottom, sideways or inclined.

In some special applications it is recommended to use following hints:

■

High viscosity: sideways or from bottom

■

Dry Running protection for pumps:

■

Overll prevention devices: usually vertically from above

■

Vertical installation

if the pipes to or from the pump are installed

horizontally use top mounting for fast detection of

liquid

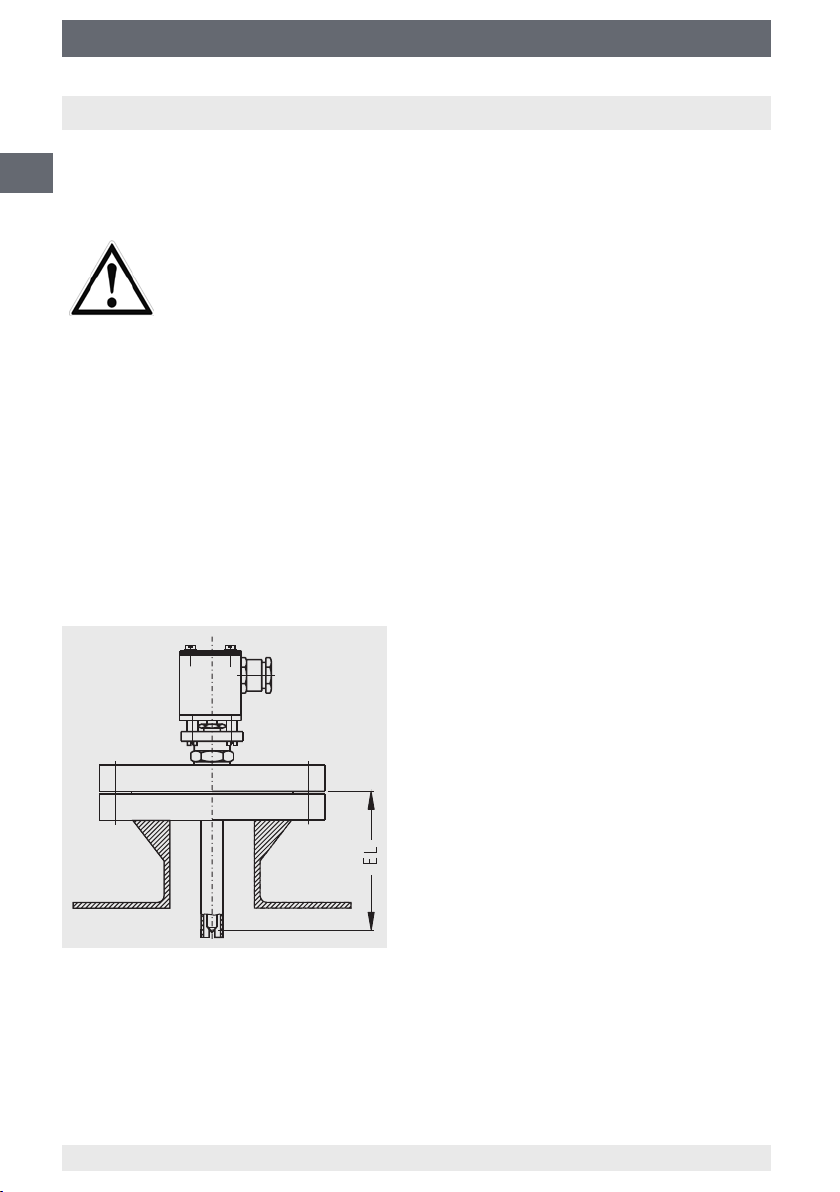

Installation model LSO.06 from top with ange

connection e. g. as overow control.

■

Insertion length EL from sealing face ange

■

DIN anges from DN25 PN6

■

ANSI anges

■

The sealing forms are freely selectable

Explosion-protected version:

■

Flanges seal-welded with the transducer

sensor component

■

If seal-welded: no hexagon on sensor

component

20 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 21

6. Commissioning, operation

■

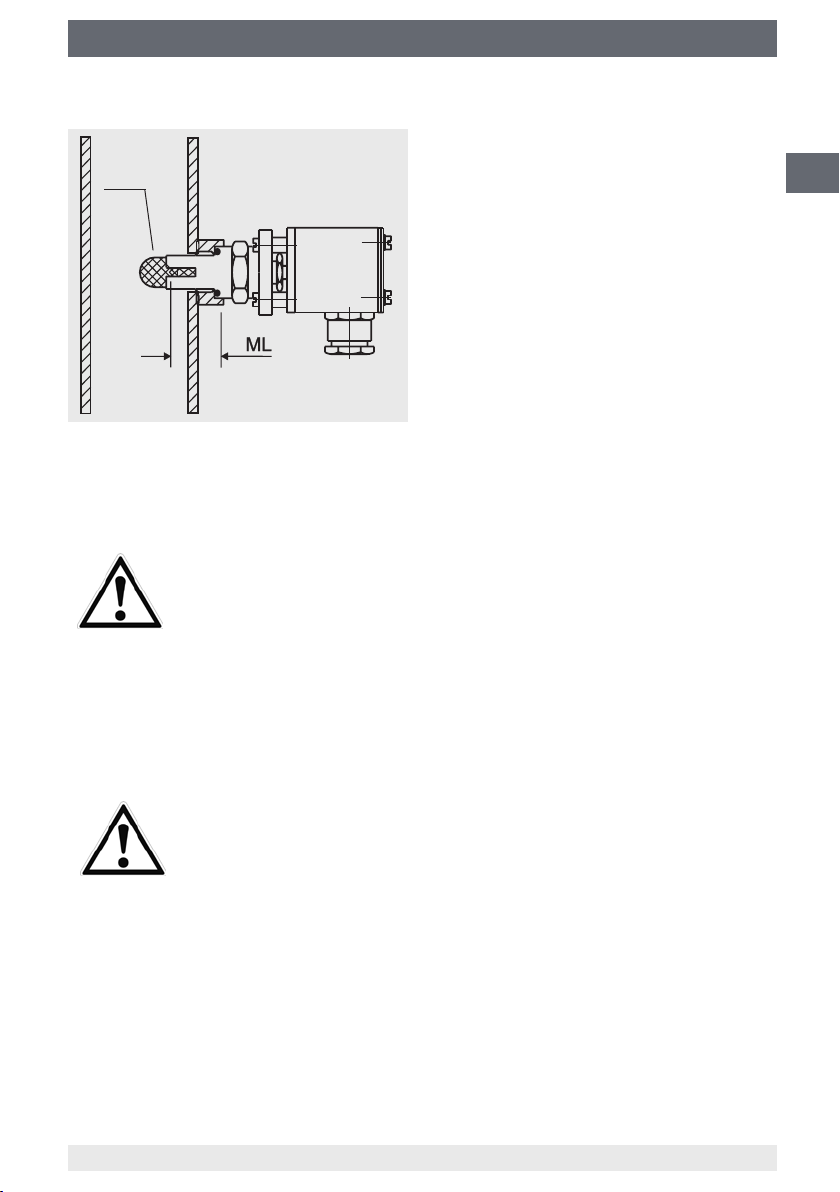

Lateral installation

Sieb

6.2 Mechanical installation

6.2.1 Transducer model LSO.06

CAUTION!

Carried out work only after a complete pressure balance.

Take corresponding safety and environmental protective measures.

Model LSO.06 built-in to pipe or tank wall

laterally, here, for example, as dry-run

protection into the suction or pressure line of

a pump, slightly oset from the centre and

provided with a screen so that it is unaected by gas bubbles.

In the model LSO.06 used here, the

measurement length ML is xed at 25 mm.

GB

The glass tip should have a distance of at least 10 mm to an opposite wall after assembly

having been carried out. This minimum distance can vary depending on geometry and

surface composition of the wall (e.g. with electropolished pipes 20 ... 30 mm).

Screw directly into the corresponding threaded coupling using a metallic seal or, with the

anged version, connect with a ange (observe DIN/ANSI).

CAUTION!

Assemble the transducer with caution and care, particularly respected on

the break risk of the glass. Take measures for the protection of the transducer head if a lateral load has to be expected. The operating company

has to provide the suitable choice of the seal diameters and materials. The

torque corresponds in the pipe line engineering for usual values. Install the

transducer unstressedly.

The transducer may not be charged at the side under any fuss when

installing and in the built-in condition at the sensor head (see chapter

"9.2 Repair"). When screwing into a connection thread do not use the

sensor head for turning.

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 21

Page 22

6. Commissioning, operation

Pressure and leage test

Every device is subjected to a pressure examination in the work. If in the plant still a

strength examination (system pressure examination) be required, pressure may not

GB

exceed the examining pressure means 1.5 times the indicated pressure on the type plate

and the ange.

CAUTION!

For all examinations and uses, in principle, these are indicated on the type

plate authoritatively!

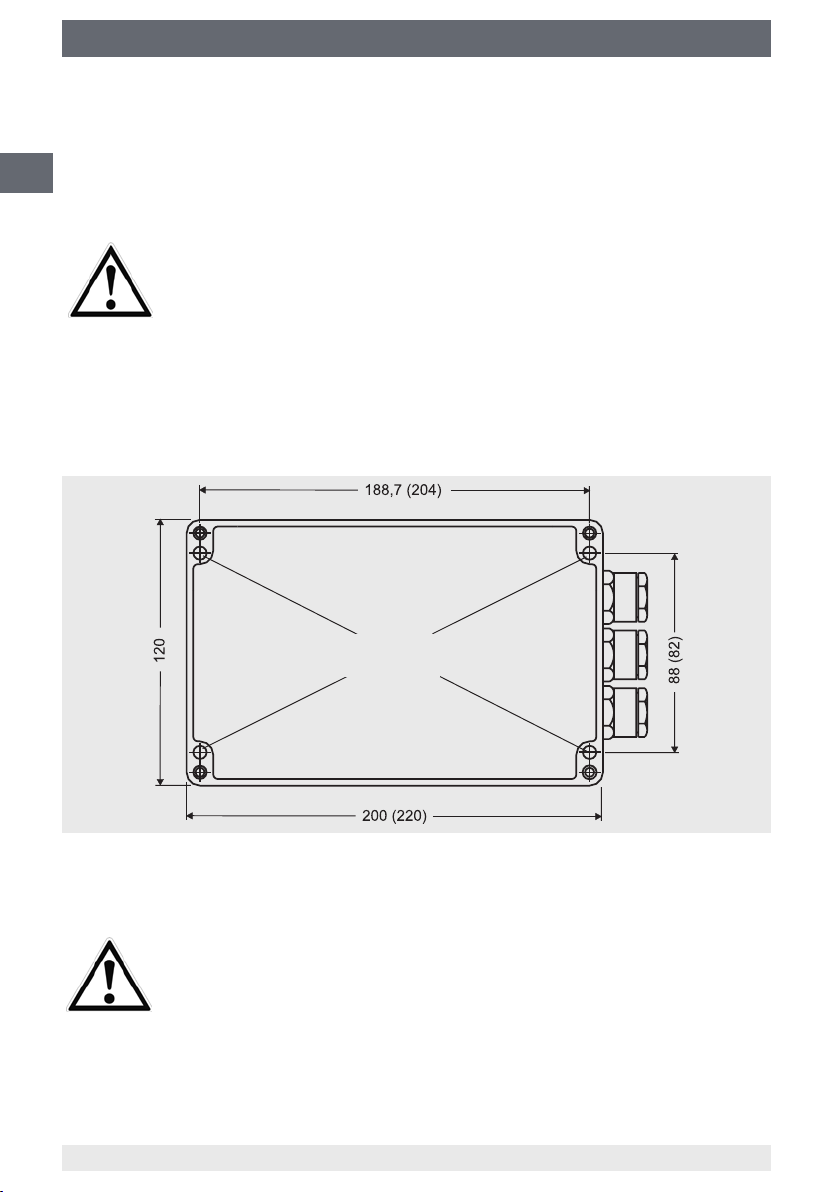

6.2.2 Switching amplier model LSO.25 (in makrolon housing)

■

Prepare mounting holes (see gure below)

■

Detach the clear cover from the housing

■

Insert mounting screws from cover side into the mounting holes

■

Tighten the mounting screws

mounting

holes

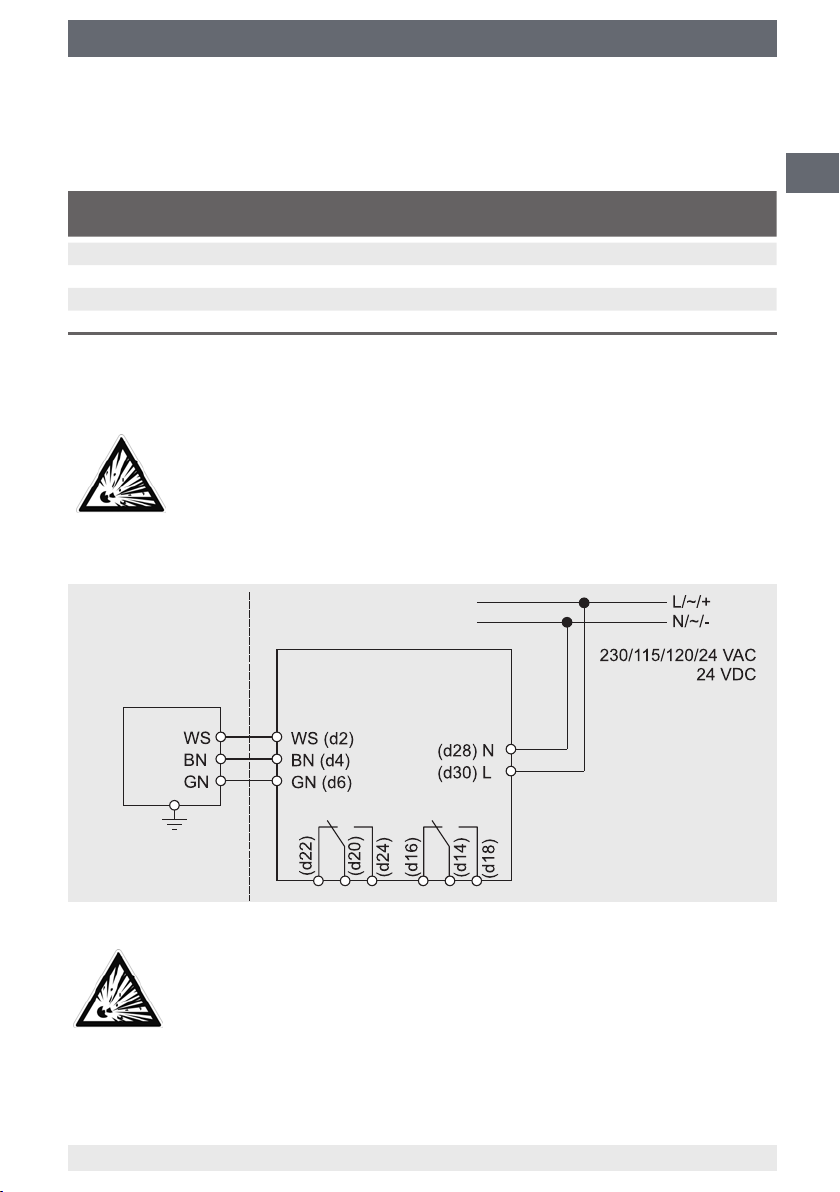

6.3 Electrical connection

WARNING!

For the electrical connection, comply with all relevant regulations.

The transducer and switching amplier connections are both marked with the colors WS

(white) respective 2d, BR (brown) respective 4d and GN (green) respective 6d. Connect

them according to the connection plan.

22 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 23

6. Commissioning, operation

The cable must not be shielded, however, should not be laid directly besides strong

electrical interference sources either. Including line resistance, contact resistance goes

the maximum line length and with that by the following table the maximum:

Wire cross section

in mm²

0.5 175 6.3

0.75 300 7.2

1.0 400 7.2

1.5 600 7.2

A complete resistance of 9 Ω, inclusive of contact resistances, should not be exceeded

since otherwise a failure signal is carried out.

In addition, for the explosion-protected version, a max. inductance of

L

≤ 0.5 mH and a max. capacitance of Ca ≤ 3 µF must be observed (incl.

a

switching amplier values).

Connection diagram transducer and switching amplier

Ex zone 0/1 Safe area

Wiring length

in m

Wiring resistance

in Ω

GB

Switching amplier model LSO.25

Transducer

model LSO.06

Signal Failure

The instrument can

be connected to

earth.

For the explosion-protected version, a light-blue cable or one marked

light-blue must be installed from the switching amplier to the transducer

(intrinsically safe circuit). The switching amplier is located in the

non-hazardous area and the measuring body of the transducer in a Zone 1

area.

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 23

Page 24

6. Commissioning, operation

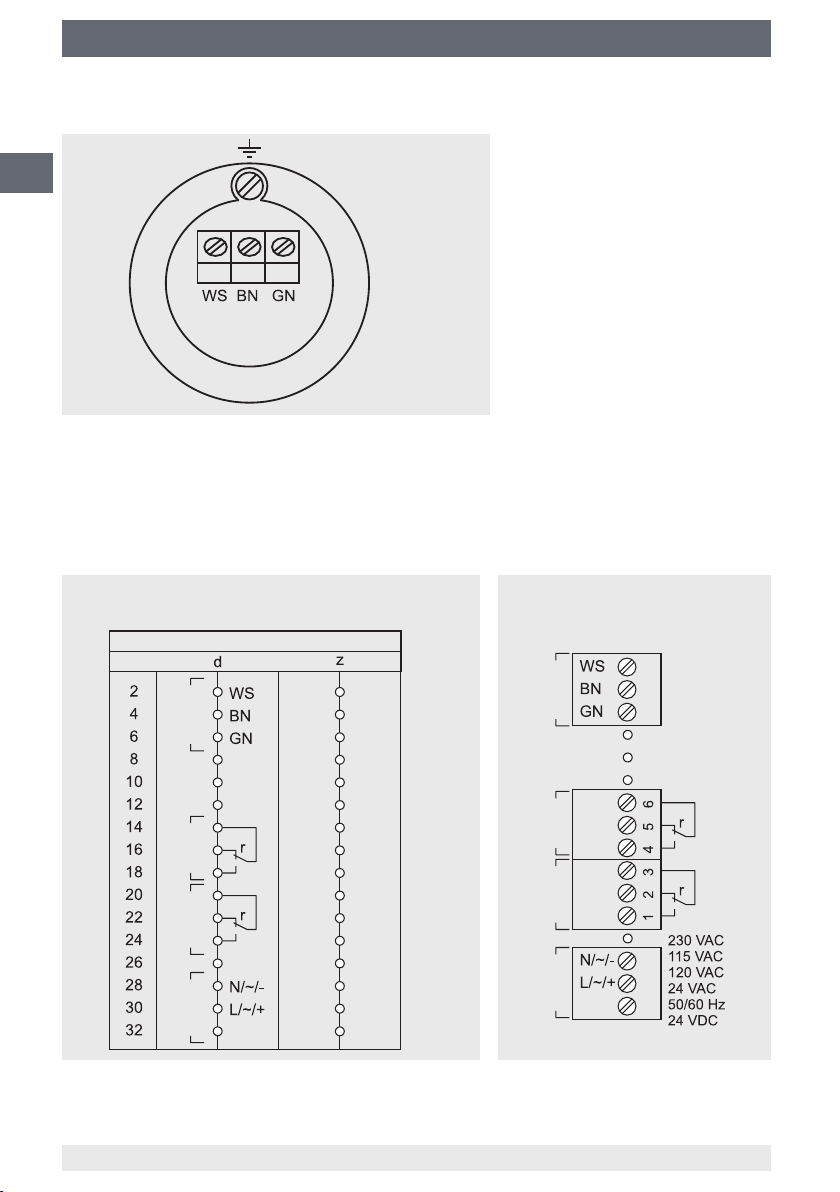

6.3.1 Transducer model LSO.06

GB

Earthing

Earth can be connected at the internal earthing screw (is not necessary for intrinsic safety)

or the connection is carried out via the metallic contact of the screwing thread with the

container.

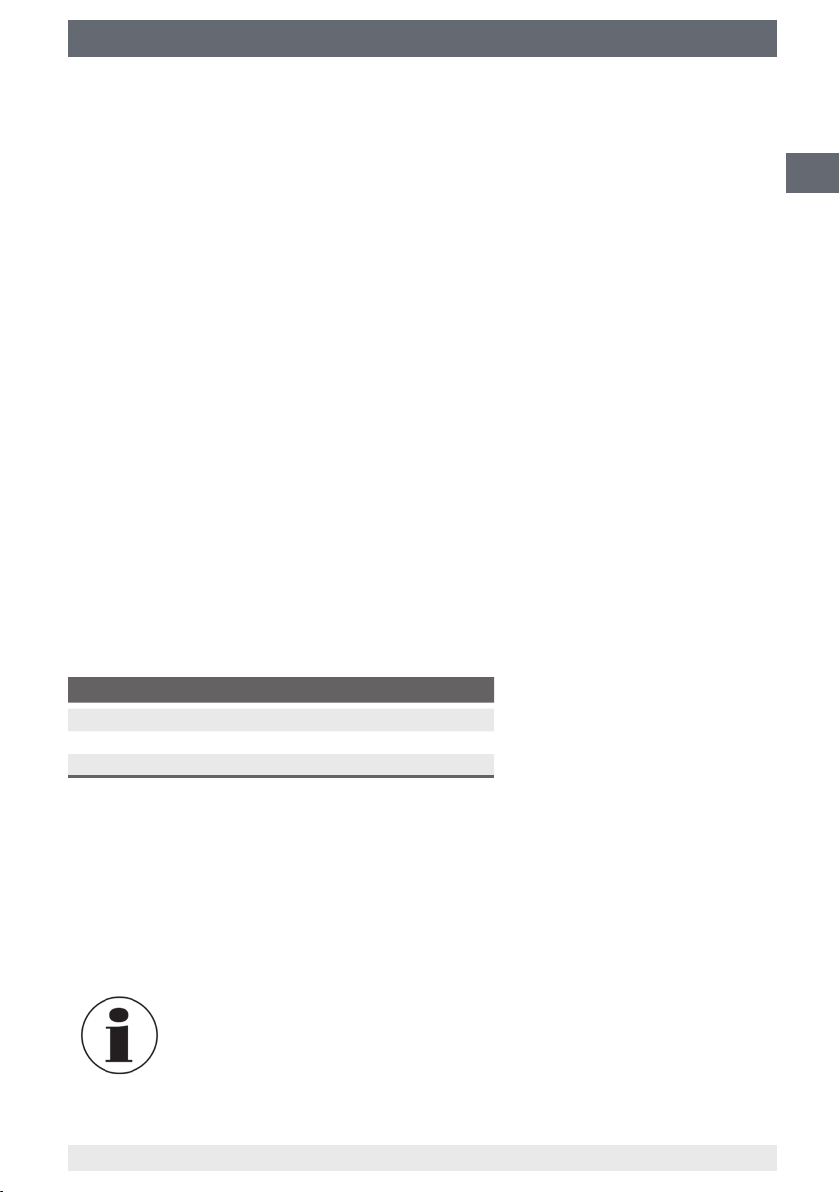

6.3.2 Switching amplier model LSO.25

19" plug-in card

male plug per DIN 41612

Male plug-connection side

row

Mounted case

screw terminals

Transd.Failure

Transd.

FailureSignal

Signal

Supply

Supply

24 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 25

6. Commissioning, operation

6.4 Connection supply

First check, if the existing supply voltage agrees with the voltage version of the switching

amplier should be checked rst (see marking on the circuit board).

230 V ~ LSO.25-X1X

115/120 V ~ LSO.25-X2X

24 V ~ LSO.25-X3X

24 V = LSO.25-X4X

24 V = without potential separation LSO.25-X7X (only for standard)

At the plastic case version the line terminals "supply" is marked with the operating

voltage in addition and it is the connection to see directly from the imprint. Carry out the

connection in accordance with "Connection diagram transducer and switching amplier"

on page 22.

Pin assignment of plug-in card

d 28 (c28) = N (-)

d 30 (c30) = L (+)

6.5 Connection relay

The signals "signal" and "failure" are provided for per a relay with change over contacts.

These are potential-free and can be used for every arbitrary application. At the mounting

case version the connections can be seen directly from the imprint on the pcboard.

GB

Pin assignment of plug-in card

Failure Signal Contact

4/d18 1/d24 NO

5/d16 2/d22 NC

6/d14 3/d20 root

6.6 Function control

After wiring been carried out and checked the supply can be switched on. One of the

yellow LED's should come on now. By pressing the button "test" at closed switch S2 (time

delay turned o) one of the two yellow LED shines approx. 1 s. After this the other yellow

LED is ashing as long as the test button remains pressed. This shows that wiring and

switch ampliers are all right. If this should not be the case, follow the justage instructions

see chapter "7.2 Adjustment with CAL".

Please observe the actions to be taken in the event of any faults that may

occur, see chapter "10. Troubleshooting".

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 25

Page 26

7. Conguration

7. Conguration

7.1 Setting of fail-safe direction with switch S1

GB

Switch S1 is a wire-hook switch which may be shortened by soldering or permanent

opened by cutting the switch wire.

High alarm: - S1 open,

- Signal relay released if sensor tip is immersed

Low alarm: - S1 closed

- Signal relay released if sensor tip is dry

Factory setting: - S1 open

Fault eect to dry/immersed

Operating status S1 Yellow LED

immersed

Immersed

sensor tip in

medium with higher

refractive index

open

H

High alarm

closed

ashing o released

permanent on o energized

L

Low alarm

Dry

sensor tip in

medium with lower

refractive index

open

H

High alarm

closed

o permanent on energized

o ashing released

L

Low alarm

Yellow LED

dry

Signal relay

time delay on

time delay o

Trans-

ducer

M20 x 1.5 or

time delay

Failure

Signal

Fuse

Supply

75 high

M16 x 1.5

26 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 27

7. Conguration

7.2 Adjustment with CAL

This is only required at the rst putting into operation or after the wiring to compensate for

all variable inuences of the measuring equipment.

Calibrate only when the sensor tip is in the medium with higher refractive index, e. g.:

■

Level liquid/gas = in the liquid

■

Separation layer e. g. water/oil = in oil

The photo transistor voltage can be measured between "GN" and "WS" of the transducer

connection with a voltage instrument (Ri ≥ 10 MOhm Messbereich 10 V=).

Voltage between GN / WS in V

1)

dry

Level (conical tip) 0.2 - 1.0

1) do not adjust, only check this value

2) 0.2 V at short measuring lengths and clean conical tip, up to 1.0 V at larger measuring lengths and

dirty conical tip.

3) adjust this value in the immersed condition only, the switching quality of the system transducer/

switching amplier can be inuenced by variation of this value:

■

approx. 4.5 V = less drop sensitive, foam insensitive

■

approx. 5.0 V = normal low viscous, clean application, no inuence of temperature uctuations

of

the medium up to ±25 °C

■

approx. 5.5 V = at strong temperature uctuations of the medium up to ±40 °C

■

approx. 6.0 V = detektion of condensation, foam (must have stable, reproducible qualitiy)

2)

immersed

3)

4.5 - 6

GB

Voltage between GN / WS in V

dry

(lower refractive index)

Separation layer (U-tip)

4) do not adjust, only check this value

5) the tension takes o two media and at this measuring of the refractive index dierence can therefore vary strongly.

6) adjust this value only when the sensor tip is immersed from the medium with higher refractive

index.The switching quality of the system sensor/amplier can be inuenced by variation of this

value.

To get a stable measuring it should be tried to adjust a dierence as big as possible between these

two values

13334603.01 09/2010 GB/D/F/E

0.2 - 3.0

5)

4)

immersed

(higher refractive index)

6)

4.5 - 6

WIKA operating instructions models LSO.06, LSO.25 27

Page 28

7. Conguration

7.3 Justage of time delay

The switch S2 is a wire-hook switch and is to or switch o the delay of the signal relay

which separated is adjustable for relay energize and release, e.g. at restless surface or

GB

strong fumigations or formations of bubbles in the liquid.

No time delay: ■ Close S2 or shorten by soldering

With time delay: ■ Time to energize relay ( _↑ ) with P1 as required (0 ... 8 s) adjust

■ Release time ( ↓_ ) with P1 as required (0 ... 8 s) adjust

Factory settings: ■ S2 open, P1 and P2 middle position (ca. 3 ... 4 s)

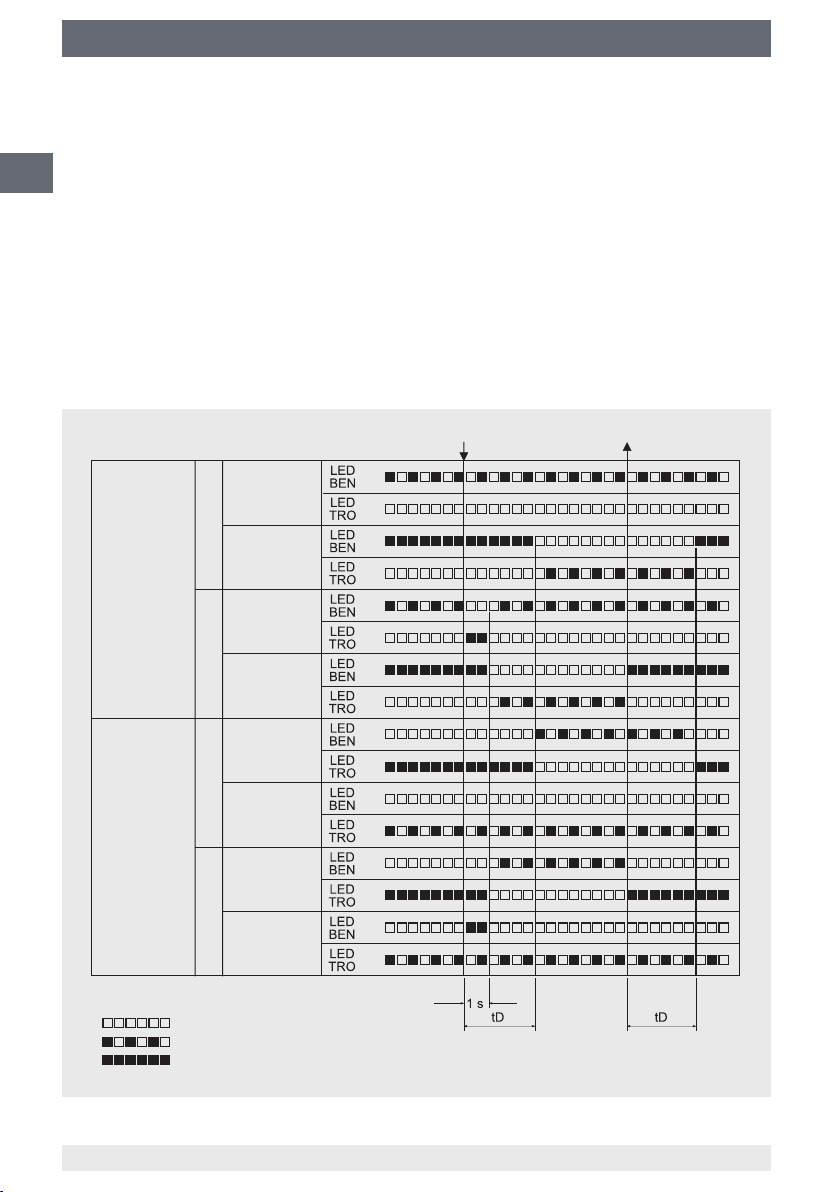

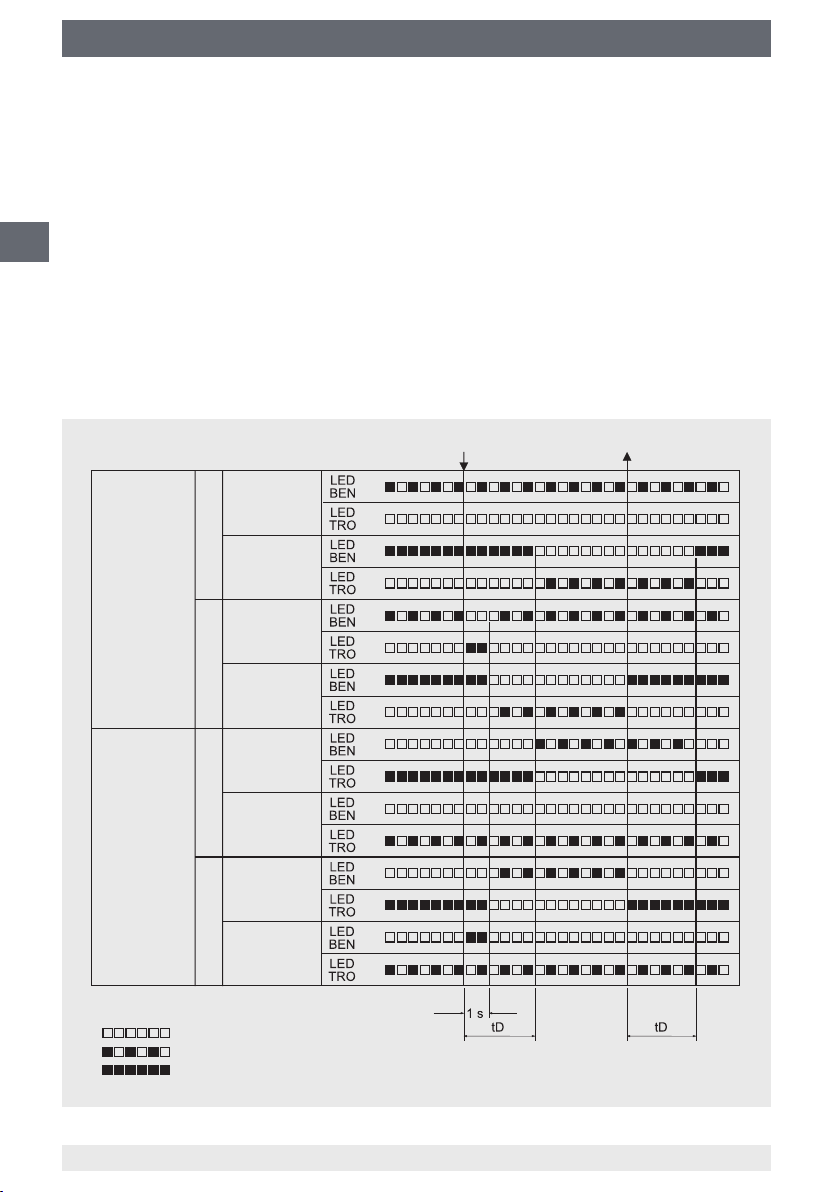

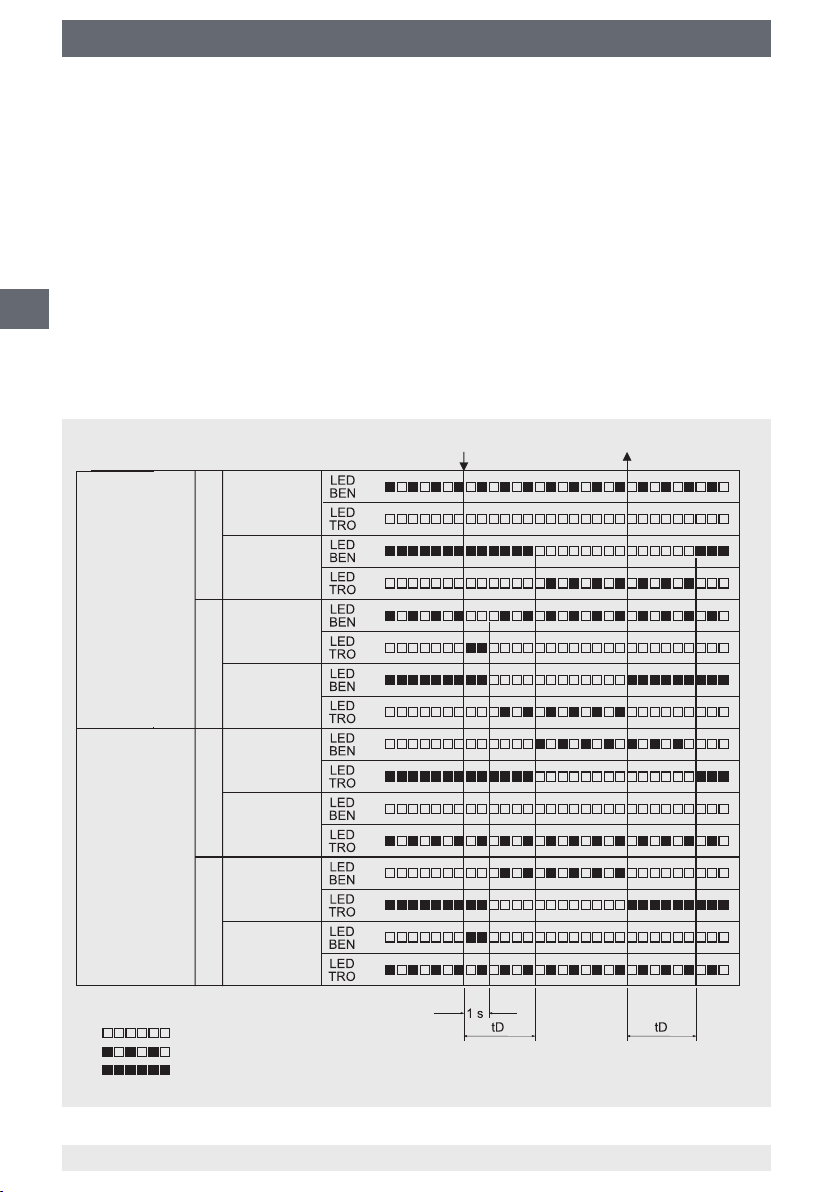

7.4 TEST Procedure

Test expiry when pressing the test button:

Test button pressed Test button released

S1 open

S2 openS2 closedS2 openS2 closed

Sensor tip

Transducer

immersed

S1 closed

S1 open

S1 closed

S1 open

Sensor tip

Transducer

dry

S1 closed

S1 open

S1 closed

LED o

LED ashes

LED permanent on

Legend:

BEN = immersed

TRO = dry

tD = delay time to adjust with P1 and P2

28 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 29

7. Conguration

Conditions:

■

P1 and P2 middle position, ca. 3 - 4 s time delay if P2 is open

■

Transducer correct connected and in function

■

No failure present

The time delay is, with S2 open, = switched on, must suciently be pushed for a long time

the button so that the complete test can go o. No test can go o, the alarm was already

entitled taken there is with S1 open, S2 open and sensor tip immersed. The same applies

S1 closed, S2 open and sensor tip dry. Failure, LED red and a yellow one ashes, can go

o no test at.

The test function makes possible a checking the measuring chain switching amplier

separately and e.g. post-connected signal amplier, signaling devices, control devices or a

correction device at a connected and operating transducer and a reliable information gives

about the proper function of the circuit board.

7.5 Operating characteristics relay SIGNAL

see table "Fault effect to dry/immersed", page 25

7.6 Operating characteristics relay FAILURE

The relay failure is energized in the normal operation and releases under the following

conditions (fail safe behavior):

■

The supply voltage breakes down (>100 ms)

■

The internal supply voltage for the intrinsic safe circuit breakes down

■

Short circuit (BR-WS) or interruption to infrared-LED (BR)

■

Short circuit (GN-WS) or interruption to phototransistor (GN)

Behavior

of the LED's see table

"Fault eect to dry/immersed", page 25

GB

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 29

Page 30

8. Notes for mounting and operating ... / Maintenance, ...

8. Notes for mounting and operating in hazardous areas

Zone 0 for Transducer model LSO.06

GB

If medium touched parts consist of titanium, the operator has to take care that no metallic

ttings can beat to the sensor parts and therefore could trigger a blow spark in the container. Perhaps a protection cage has to be attached outside the container around the sensor

head.

Ambient temperatures

If the transducer is installed vertically, the operating company has to provide it, the max.

temperatures indicated in the technical data do not exceed at all over, for Ex version

T6: +60 °C and T5: +75 °C.

CAUTION!

When a fault occurs, the repair should be by the manufacturer or by the

system operator and approved by a factory expert.

9. Maintenance, repair and cleaning

9.1 Maintenance

As a rule, these instruments are maintenance-free.

Stronger pollution is in the plant, however, recommends himself to make a maintenance

instruction. Perhaps this can conne himself to an electrical measuring of the voltage

between GN and WS of the transducer:

■

Immersed (BEN) in the rule 5 V *)

■

Dry (TRO) in the rule 0,2 ... 1 V *)

*) see table page 26 (separation layer) and table page 30

Repairs must only be carried out by the manufacturer.

At broken glass send in the transducer for repair see chapter "12.2 Return".

9.2 Repair

For repairs, only spare parts recommended by us are to be used. Repairs must be agreed

upon with us in writing, otherwise our warranty and responsibility will become void.

Transducer

It is not expected that the plant operator will carry out any repairs himself. If the system

operator wants to carry out a repair, at his own, he must obtain permission from the

manufacturer.

30 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 31

9. Maintenance, repair and cleaning

Replacing fuse of switching amplier

■

Switch net supply o

■

Taking fuse out

Use a new fuse only with the value printed on the circuit board

Supply voltage Model LSO.06

AC 230 V T 50 mA

AC 115/120 V T 100 mA

AC 24 V T 400 mA

DC 24 V with potential separation see marking on circuit board

DC 24 V without potential separation T 400 mA

■

Switch net supply on

At spare part orders indicate absolutely exact type, series no. and

commission no. the manufacturer.

9.2 Cleaning

If the glass tip becomes soiled, clean it carefully.

GB

CAUTION!

■

Before cleaning, correctly disconnect the instrument from the pressure

supply, switch it o and disconnect it from the mains.

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with moisture.

■

Wash or clean the dismounted instrument before returning it, in order to

protect sta and the environment from exposure to residual media.

■

Residual media in dismounted instruments can result in a risk to persons,

the environment and equipment. Take sucient precautionary measures.

For information on returning the instrument see chapter "12.2 Return".

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 31

Page 32

10. Faults

10. Faults

Faults Possible causes Measures

GB

No function Power supply been cancelled

Flashing of the red and a

yellow LED

LED changes, signal

relay changes, however

no reaction of the outer

circuit

The signal relay switches

none over despite level

change

Instrument reacts invers S1 in a wrong position S1 change position

Instrument reacts

apparently not or too

slowly to level change

Test button no reaction S2 open, P1, P2 on the right

Transducer not connected Transducer connect up

Cable interrupted to the

transducer

Cable short-circuited to the

transducer

Cal. P3 adjusted too far about

switching threshold

Contacts of the Relais REL 1

do not close/open

P3 adjusted wrongly, (under

switching point)

Transducer faulty

(mechanical defects)

Transducer faulty

(electrical defects)

Glass tip facing too near at

opposite surface

S2 open, P1, P2 on the right

stop, delay on

stop, delay on

Measure mains voltage, check

fuse, check terminal screws (not

soldering ends of the cable)

Check connections and cables

Check connections and cables

Adjusting in accordance with

instructions 7.2

Measure relay contacts

Adjusting in accordance with

instructions 7.2

Carrying out circuit board test.

Circuit board test faultless,

glass top on damage or dirt

approach search, clean or

exchange if under

Change transducer

see chapter 6.2.1

S2 close or P1, P2 turn aniticlockwise or wait until delay

time has passed

S2 close or P1, P2 on the left

stop shift and leave S2 open.

Pressing test button so long till

the delay time has passed

CAUTION!

If faults cannot be eliminated by means of the measures listed above, the

instrument must be shut down immediately, and it must be ensured that

pressure and/or signal are no longer present, and it must be prevented from

being inadvertently put back into service.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions see chapter

"12.2 Return".

32 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 33

11. Warranty / 12. Dismounting, return and disposal

11. Warranty

The warranty period is 24 months.

Condition is the proper treatment and the use as agreed

ance with these operating instructions. For consumable and spare parts the warranty is

restricted to faults in material or construction.

The manufacturer takes on the responsibility about the execution as agreed in accordance

with customer details. The customer takes on the responsibility about the assembly as

agreed and use.

and the intended use in accord-

12. Dismounting, return and disposal

WARNING!

Residual media in dismounted instruments can result in a risk to persons,

the environment and equipment. Take sucient precautionary measures.

12.1 Dismounting

WARNING!

Risk of burns!

Let the instrument cool down suciently before dismounting it!

When dismounting it, there is a risk that dangerously hot pressure media

may escape.

GB

Only disconnect the instruments once the system has been depressurised!

12.2 Return

WARNING!

Absolutely observe when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous

substances (acids, bases, solutions, etc.).

When returning the instrument, use the original packaging or a suitable transport package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with the shock-absorbent material, in the packaging.

Place shock-absorbent material evenly on all sides of the shipping box.

3. If possible, place a bag, containing a desiccant, inside the packaging.

4. Label the shipment as transport of a highly sensitive measuring instrument.

13334603.01 09/2010 GB/D/F/E

WIKA operating instructions models LSO.06, LSO.25 33

Page 34

12. Dismounting, return and disposal

Enclose the completed return form with the instrument.

GB

12.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal regulations.

The return form is available on the internet:

www.wika.de / Service / Return

34 WIKA operating instructions models LSO.06, LSO.25

13334603.01 09/2010 GB/D/F/E

Page 35

Inhalt

Inhalt

1. Allgemeines 36

2. Sicherheit 37

3. Technische Daten 42

4. Aufbau und Funktion 45

5. Transport, Verpackung und Lagerung 51

6. Inbetriebnahme, Betrieb 52

7. Konguration 58

8. Hinweise zu Montage und Betrieb im explosionsgefährdeten Bereich 62

9. Wartung, Instandsetzung und Reinigung 62

10. Störungen 64

11. Garantie 65

12. Demontage, Rücksendung und Entsorgung 65

D

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.25 35

Page 36

1. Allgemeines

1. Allgemeines

■

Die in der Betriebsanleitung beschriebenen Geräte werden nach den neuesten

Erkenntnissen gefertigt. Alle Komponenten unterliegen während der Fertigung strengen

Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und

ISO 14001 zertiziert.

D

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise

und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten

Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: LM 31.10, LM 31.20

- Anwendungsberater: Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder

zu schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen

kann, wenn sie nicht gemieden wird.

WIKA Betriebsanleitung Typen LSO.06, LSO.2536

13334603.01 09/2010 GB/D/F/E

Page 37

1. Allgemeines / 2. Sicherheit

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

ezienten und störungsfreien Betrieb hervor.

GEFAHR!

…kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung der Sicherheitshinweise besteht die Gefahr schwerer oder tödlicher

Verletzungen.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation im explosionsgefährdeten Bereich hin, die zum Tod oder zu schweren Verletzungen führt, wenn

sie nicht gemieden wird.

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige

Gerät hinsichtlich Messbereich, Ausführung und spezischen Messbedingungen ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

D

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen

Kapiteln dieser Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Der Messwandler Typ LSO.06 dient zur Grenzstanderfassung von Flüssigkeiten. Der

Schaltverstärker Typ LSO.25 kann zusammen mit dem Messwandler Typ LSO.06 als

Überfüllsicherung eingesetzt werden. Die Geräte sind sehr robust und für raue Industrieumgebung ausgelegt.

Diese Geräte sind ausschließlich für den hier beschriebenen bestimmungsgemäßen

Verwendungszweck konzipiert und konstruiert und dürfen nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Messwandlers und des Schaltverstärkers außerhalb der technischen Spezikationen macht die sofortige Stilllegung und

Überprüfung durch einen autorisierten WIKA-Servicemitarbeiter erforderlich.

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.25 37

Page 38

2. Sicherheit

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

2.2 Personalqualikation

D

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualikation durchführen

lassen.

■

Unqualiziertes Personal von den Gefahrenbereichen fernhalten.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der Messund Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landes-spezischen

Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen Arbeiten

auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

2.3 Zusätzliche Sicherheitshinweise für Geräte mit ATEX-Zulassung

WARNUNG!

■

Die Nichtbeachtung dieser Inhalte und Anweisungen kann zum Verlust

des Explosionsschutzes führen

■

Europäische Errichtungsbestimmungen einhalten (EN 60079-10:1996 )

2.4 Besondere Gefahren

WARNUNG!

Die Angaben der geltenden Baumusterprüfbescheinigung sowie die

jeweiligen landesspezischen Vorschriften zur Installation und Einsatz

in explosionsgefährdeten Bereichen (z. B. IEC 60079-14, NEC, CEC)

einhalten. Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise für Geräte mit ATEX-Zulassung siehe

Kapitel „2.3 Zusätzliche Sicherheitshinweise für Geräte mit ATEX-Zulassung“.

WIKA Betriebsanleitung Typen LSO.06, LSO.2538

13334603.01 09/2010 GB/D/F/E

Page 39

2. Sicherheit

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen, brennbaren oder giftigen Stoen, sowie bei Kälteanlagen, Kompressoren etc.

müssen über die gesamten allgemeinen Regeln hinaus die einschlägigen

Vorschriften beachtet werden.

WARNUNG!

Für ein sicheres Arbeiten am Gerät muss der Betreiber sicherstellen,

■

dass eine entsprechende Erste-Hilfe-Ausrüstung vorhanden ist und bei

Bedarf jederzeit Hilfe zur Stelle ist.

■

dass das Bedienpersonal regelmäßig in allen zutreenden Fragen von

Arbeitssicherheit, Erste-Hilfe und Umweltschutz unterwiesen wird, sowie

die Betriebsanleitung und insbesondere die darin enthaltenen Sicherheitshinweise kennt.

GEFAHR!

Lebensgefahr durch elektrischen Strom

Bei Berührung mit spannungsführenden Teilen besteht unmittelbare Lebensgefahr.

■

Einbau und Montage des elektrischen Gerätes dürfen nur durch das

Elektrofachpersonal erfolgen.

■

Bei Betrieb mit einem defekten Netzgerät (z. B. Kurzschluss von

Netzspannung zur Ausgangsspannung) können am Gerät lebensgefährliche Spannungen auftreten!

WARNUNG!

Messstoreste in ausgebauten Geräten können zur Gefährdung von

Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

D

Dieses Gerät nicht in Sicherheits- oder in Not-Aus-Einrichtungen benutzen.

Fehlerhafte Anwendungen des Gerätes können zu Verletzungen führen.

Am Gerät können im Fehlerfall aggressive Medien mit extremer Temperatur

und unter hohem Druck oder Vakuum anliegen.

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.25 39

Page 40

2. Sicherheit

2.5 Beschilderung / Sicherheitskennzeichnungen

Typenschild

■

Messwandler Typ LSO.06

D

Typ

■

Schaltverstärker Typ LSO.25

Symbolerklärung

siehe Seite 41

Herstellungsdatum

19"-Steckkarte

Im Aufbaugehäuse

Herstellungsdatum

Typ

Symbolerklärung

siehe Seite 41

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.2540

Page 41

2. Sicherheit

Symbolerklärung

Vor Montage und Inbetriebnahme des Gerätes unbedingt die

Betriebsanleitung lesen!

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den zutreenden

europäischen Richtlinien.

ATEX Europäische Explosionsschutz-Richtlinie

(Atmosphère = AT, explosible = Ex)

Geräte mit dieser Kennzeichnung stimmen überein mit den Anforderungen

der europäischen Richtlinie 94/9/EG (ATEX) zum Explosionsschutz.

D

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.25 41

Page 42

3. Technische Daten

3. Technische Daten

3.1 Messwandler Typ LSO.06

Allgemeine Daten

Messgenauigkeit ±0,5 mm

D

Umlicht max. 100 Lux

Einbaulage beliebig

Gewicht

■

Standardausführung

■

Hoch- und Tieftemperaturausführung

1) ML = Messlänge

Auslegungsdaten

Mediumstemperatur

■

Standardausführung

■

Hoch- und Tieftemperaturausführung

Umgebungstemperatur -65 ... +95 °C

Betriebsdruck 0 ... 25 MPa (0 ... 250 bar)

Hochdruckversion 0 ... 50 MPa (0 ... 500 bar)

Werkstoe

■

Sensorgehäuse

■

Lichtleiter

■

Packung

■

Gehäuse

Ex-Zündschutzart II 1/2 G Ex ib op is IIC T5, T6

0,77 kg +9,3 g/cm ML

1,07 kg +9,3 g/cm ML

-65 ... +250 °C

-269 ... +400 °C

1.4571 (Option: Hastelloy, andere Werkstoe auf Anfrage)

Kernmantelglas (Option: Quarz,

Saphir (nur max. ML = 60 mm))

Graphit

CrNi-Stahl

T6: bis 60 °C, T5: bis 75 °C

ZELM 10 ATEX 0440

1)

1)

Elektrische Daten

Kabelverschraubung M20 x 1,5, Ex: blau

Klemmenanschluss 3 x 2,5 mm²

Schutzart IP 65 nach EN 60529

Weitere technische Daten siehe WIKA Datenblatt LM 31.10 und Bestellunterlagen.

WIKA Betriebsanleitung Typen LSO.06, LSO.2542

13334603.01 09/2010 GB/D/F/E

Page 43

3. Technische Daten

P-T-Diagramm

(Druck- / Temperatureinsatzgrenzen)

für Montageanschluss G ½ A nach DIN 910

Hochtemperaturausführung

Standardausführung

Tieftemperaturausführung

Messstotemperatur in °C

Derating-Diagramm

(Temperatureinsatzgrenzen)

D

Betriebsdruck in bar

Hochtemperaturausführung

Standardausführung

Messstotemperatur in °C

Umgebungstemperatur in °C

13334603.01 09/2010 GB/D/F/E

Tieftemperaturausführung

WIKA Betriebsanleitung Typen LSO.06, LSO.25 43

Page 44

3. Technische Daten

3.2 Schaltverstärker Typ LSO.25

Allgemeine Daten

Funktionen

D

Überwachung

Gewicht

■

19"-Steckkarte

■

Aufbaugehäuse

Auslegungsdaten

Mediumstemperatur

■

19"-Steckkarte

■

Aufbaugehäuse

Ex-Zündschutzart II (2) G [Ex ib] IIC

Max. äußere Induktivität L

Max. äußere Kapazität C

U

0

I

0

P

0

max

max

■

Alarmrichtung wählbar

■

Anzugs-und Abfallverzögerung

für Signal-Relais jeweils bis ca. 8 s einstellbar

■

Drahtbruch Signalstromkreis

■

Kurzschluss Signalstromkreis

■

Interne Versorgungsspannung, fail-safe

0,31 (0,36) kg

0,6 (0,73) kg

-25 ... +60 °C

-40 ... +40 °C

ZELM 10 ATEX 0441

0,5 mH

3 µF

≤ 9,6 V

≤ 149 mA

≤ 1,0 W

Elektrische Daten

Versorgungsspannung AC 230/115/120/24 V / DC 24 V

Leistungsaufnahme 2,8 VA/3 W

Ausgänge

Kabelverschraubungen M16 x 1,5 / M20 x 1,5 Ex: blau

Max. Anschlussquerschnitt 2,5 mm²

Kabellänge 175 ... 600 m (0,5 ... 1,5 mm²)

Schutzart

■

19"-Steckkarte

■

Aufbaugehäuse

Weitere technische Daten siehe WIKA Datenblatt LM 31.20 und Bestellunterlagen.

■

Signal-Relais, Wechsler, 250 V/ 3 A/100 VA

■

Stör-Relais, Wechsler, 250 V/ 3 A/100 VA

IP 20 nach EN 60529

IP 65 nach EN 60529

WIKA Betriebsanleitung Typen LSO.06, LSO.2544

13334603.01 09/2010 GB/D/F/E

Page 45

4. Aufbau und Funktion

4. Aufbau und Funktion

4.1 Beschreibung

Der Messwandler dient zur Grenzstanderfassung von Flüssigkeiten.

Die kegelförmige Spitze des Fühlers bietet ein genaues, binäres Schaltverhalten. Dieses

ist unabhängig von physikalischen Eigenschaften der Flüssigkeiten wie Brechzahl, Farbe,

Dichte, Dielektrizitätskonstante und Leitfähigkeit, so dass z. B. präzise Niveauregelungen

durchgeführt werden können. Bei zur Schaumbildung neigenden Medien kann Schaum

wahlweise erkannt oder unterdrückt werden.

Ist der Fühler mit einer U-Spitze versehen, können alle Grenzwerte erfasst werden, die auf

Veränderung der Brechzahl beruhen. Der Hauptanwendungsbereich liegt bei der Erfassung von Flüssigkeitstrennschichten.

D

Funktionsprinzip

Trennschicht, U-Spitze

z. B. Öl

z. B. Wasser

Funktionsprinzip

Niveau, Kegelspitze

Gas

Flüssigkeit

Einsatzbereich

Hochdruck-

ausführung mit

Kühlrippenteil

Gewinde-

anschluss G ½ A

Messstotemperatur in °C

Normaldruckausführung

ohne Kühlrippenteil

Gewindeanschluss

Betriebsdruck in bar

Hochdruck-

ausführung mit

Kühlrippenteil

Gewinde-

anschluss NPT ½

Messstotemperatur in °C

Betriebsdruck in bar

Alle Messwandler-Typen benötigen einen Schaltverstärker Typ LSO.25 zur Auswertung

und Signalgabe.

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.25 45

Page 46

4. Aufbau und Funktion

4.2 Geräteaufbau

Jedes Gerät besteht grundsätzlich aus einem Messwandler und einem Schaltverstärker.

Beide Geräte können für den Standard- oder für den Ex-Bereich ausgelegt werden. Der

Temperaturbereich kann beim Messwandler durch ein zusätzliches Kühlrippenteil erweitert werden.

D

4.2.1 Messwandler Typ LSO.06

■

Ohne Verlängerung

Ausführung mit 25 mm Messlänge, d. h. es

kann kein Verlängerungsrohr/Schutzrohr

eingeschraubt werden. Die Schutznger

benden sich direkt am Messkörper.

Lichtleiter Ø 7

Sensorgehäuse

*) 20 bei Hochdrucksensor

Messkörper

■

Mit Verlängerung

Ausführung von 50 bis 960 mm,

Verlängerungsrohr/Schutzrohr wird in

Fühler eingeschraubt

Vorzugsmesslängen:

50, 60, 80, 90, 100, 120, 150, 200, 300,

600 und 800 mm

Zwischenwerte sind über längenvariable

Typen lieferbar

*) 20 bei Hochdrucksensor

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.2546

Page 47

4. Aufbau und Funktion

■

Für erhöhten Temperaturbereich

Ausführung mit Kühlrippenteil. Dieses kann sowohl an ein Gerät mit 25 mm ML als

auch an ein Gerät mit Verlängerungsrohr/Schutzrohr angebaut werden.

Kühl-

rippenteil

*) 20 bei Hochdrucksensor

■

Mit angebautem Flansch

Ausführung mit Flansch ab DN25

und ab PN6 oder ANSI, alle Formen

der Dichtäche. Bei Ex-Geräten in

der Regel mit dem Fühlerteil dichtverschweißt (in diesem Falle ist der

6-kant nicht vorhanden).

Dichtschweißung

alternativ

dichtgeschweißt

D

Einbaulänge EL = ML - Flanschdicke

EL ab

Dichtäche

Flansch

ML ab

Dichtäche

Fühler

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.25 47

Page 48

4. Aufbau und Funktion

■

Bauformen für Niveau und Trennschicht

Niveaumessung mit Kegelspitze und Verlängerungsrohr/Schutzrohr,

Messlänge ML 50 ... 960 mm

D

4.2.2 Schaltverstärker Typ LSO.25

■

19"-Steckkarte

Niveaumessung mit Kegelspitze, feste Messlänge ML 25 mm, ohne

Verlängerungsrohr

Trennschichtmessung mit U-Spitze, Verlängerungsrohr/Schutzrohr,

Messlänge ML 50 ... 960 mm

Trennschichtmessung mit U-Spitze, feste Messlänge ML 25 mm, ohne

Verlängerungsrohr

time delay

time delay on

time delay o

Mess-

wandler

Störung

Signal

Sicherung

Supply

WIKA Betriebsanleitung Typen LSO.06, LSO.2548

13334603.01 09/2010 GB/D/F/E

Page 49

4. Aufbau und Funktion

Bei explosionsgeschützter Ausführung zusätzlich beachten:

Der Schaltverstärker ist als Steckkarte für ein 19"-System ausgeführt. Die Steckkarte

erfüllt allein nicht den Schutzgrad IP 20 gemäß EN 60 529:1991. Er ist nur zum Einbau

in handelsübliche, dafür geeignete Baugruppenträger bestimmt, die den Mindestschutzgrad von IP 20 sicherstellen. Nötigenfalls sind nicht benutzte Steckplätze mit Blindplatten

abzudecken. Insbesondere sind die Abstände und Kriechstrecken zwischen den einzelnen Steckkarten sowie den eigensicheren und nichteigensicheren Stromkreisen

Anforderungen an die Verdrahtung sowie die Übertemperatur durch die in den Baugruppen

umgesetzte Verlustleistung gemäß EN 60079-11:2007 zu berücksichtigen. Um Verwechslungen zu vermeiden sind die Schaltverstärker mit einem Kodiersystem versehen. Es ist

sicherzustellen, dass die Gegenleiste im Baugruppenträger vorhanden und identisch

ausgeführt ist.

Standardmäßige Codierung

, die

D

Versorgungsspannungsausführung

AC 230 V B-C-D-E-F-G-H-J 1

AC 115/120 V A, C-D-E-F-G-H-J 2

AC 24 V A-B, D-E-F-G-H-J 3

DC 24 V A-B-C, E-F-G-H-J 4

Beispiel: AC 230 V Versorgungsspannungsversion

Zur Sicherstellung der Anforderungen empehlt sich ausschließlich die Verwendung von

geeigneten Baugruppenträgern von WIKA.

Codierleiste Rack

an diesen Postitionen mit

Codierstiften versehen

Codierleiste Steckkarte

an dieser Position mit

einem Codierstift versehen

Codierleiste Steckkarte

Codierleiste Rack

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.25 49

Page 50

4. Aufbau und Funktion

Alternativ kann die Codierung direkt in der Messerleiste (Schaltverstärker-Seite) und der

zugehörigen Buchsenleiste (Rack-Seite) nach folgendem Codierplan erfolgen:

D

Der Codierstift ist mit einem Werkzeug unverlierbar an der entsprechenden Stelle in

der Buchsenleiste eingesetzt. Auf der Gegenseite an der entsprechenden Stelle in der

Messerleiste bendet sich eine Bohrung

■

Im Aufbaugehäuse

time delay on

time delay o

time delay

Störung

Signal

Sicherung

4.3 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

WIKA Betriebsanleitung Typen LSO.06, LSO.2550

Supply

Mess-

wandler

75 hoch

M20 x 1,5 oder

M16 x 1,5

13334603.01 09/2010 GB/D/F/E

Page 51

5. Transport, Verpackung und Lagerung

5. Transport, Verpackung und Lagerung

5.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -25 ... +70 °C

■

Feuchtigkeit: 35 ... 85 % relative Feuchte (keine Betauung)

Vermeidung folgender Einüsse:

■

Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

Das Gerät in der Originalverpackung an einem Ort, der die oben gelisteten Bedingungen

erfüllt, lagern. Wenn die Originalverpackung nicht vorhanden ist, dann das Gerät wie folgt

verpacken und lagern:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der

Verpackung beilegen.

WARNUNG!

Vor der Einlagerung des Gerätes (nach Betrieb) alle anhaftenden Messstoreste entfernen. Dies ist besonders wichtig, wenn der Messsto gesundheitsgefährdend ist, wie z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

D

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.25 51

Page 52

6. Inbetriebnahme, Betrieb

6. Inbetriebnahme, Betrieb

Beim Auspacken des Messwandlers und des Schaltverstärkers alle Teile auf äußerliche

Beschädigungen überprüfen. Vor der Installation kann eine Überprüfung der Funktion

vorgenommen werden. Dazu wird das Gerät provisorisch angeschlossen und der Fühler

zum Test in einem Glas mit Flüssigkeit ein- und ausgetaucht (gegebenenfalls Justage

D

vornehmen, siehe Kapitel „7.2 Justage mit CAL“).

WARNUNG!

Den elektrischen Anschluss nur von qualiziertem Fachpersonal vornehmen. Dabei die einschlägigen VDE-Vorschriften beachten.

6.1 Einbauhinweise Messwandler Typ LSO.06

Die Einbaulage ist beliebig, d. h. senkrecht, waagerecht, von unten oder schräg.

Für einige Applikationen ergeben sich Vorzugsanordnungen:

■

Hochviskose Medien: waagerecht oder von unten

■

Trockenlaufschutz von Pumpen: senkrecht bei waagerechtem Teil der Saug-

oder Druckleitung, damit ein Leerlaufen

frühzeitig erkannt werden kann

■

Bei Überfüllsicherungen: in der Regel senkrecht von oben

■

Senkrechter Einbau

Einbau Typ LSO.06 senkrecht von oben in

Behälter über Flanschanschluss z. B als

Überfüllsicherung.

■

Einbaulänge EL ab Dichtäche Flansch

■

DIN-Flansche ab DN25 PN6

■

ANSI-Flansche

■

Dichtformen frei wählbar

Explosionsgeschützte Ausführung:

■

Flansche dichtverschweißt mit dem

Messwandler-Fühlerteil

■

Wenn dichtgeschweißt: 6-kant am

Fühlerteil entfällt

WIKA Betriebsanleitung Typen LSO.06, LSO.2552

13334603.01 09/2010 GB/D/F/E

Page 53

6. Inbetriebnahme, Betrieb

■

Seitlicher Einbau

Sieb

6.2 Mechanische Montage

6.2.1 Messwandler Typ LSO.06

VORSICHT!

Arbeiten erst nach vollständigem Druckausgleich durchführen.

Entsprechende Sicherheits- und Umweltschutzmaßnahmen treen.

Typ LSO.06 seitlich eingebaut in Rohrleitung

oder Behälterwand, hier z. B. als Trockenlaufschutz in der Saug- oder Druckleitung

einer Pumpe, etwas versetzt aus der Mitte

versehen mit Sieb um unempndlicher

gegenüber Gasblasen zu sein.

Die Messlänge ML ist beim hier verwendeten Typ LSO.06 mit 25 mm fest vorgegeben.

D

Die Fühlerspitze sollte nach erfolgter Montage einen Abstand von mindestens 10 mm zu

einer gegenüberliegenden Wandung haben. Dieser Mindestabstand kann je nach Geometrie und Oberächenbeschaenheit der Wandung variieren (z. B. bei elektropolierten

Rohren 20 ... 30 mm).

Direkt in den entsprechenden Gewindestutzen mit einer metallischen Dichtung einschrauben oder bei Flanschversion ananschen (DIN/ANSI beachten).

VORSICHT!

Den Messwandler mit Vorsicht und Sorgfalt montieren, insbesondere

auf Bruchgefahr der Glasspitze achten. Maßnahmen zum Schutz des

Messkörpers treen, falls eine seitliche Belastung zu erwarten ist.

Der Betreiber hat für die geeignete Auswahl der Dichtungsmaße- und

Materialien zu sorgen. Das Anzugsdrehmoment entspricht den im

Rohrleitungsbau üblichen Werten. Den Messwandler spannungsfrei

einbauen.

Den Messwandler unter keinen Umständen beim Einbauen und im eingebauten Zustand am Messkörper seitlich belasten (siehe Kapitel „9.2 Instandsetzung“). Beim Einschrauben in das Anschlussgewinde nicht am Messkörper drehen.

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.25 53

Page 54

6. Inbetriebnahme, Betrieb

Druck- und Dichtheitsprüfung

Jedes Gerät wird im Werk einer Druckprüfung unterzogen. Sollte bauseits nochmals eine

Festigkeitsprüfung (Systemdruckprüfung) erforderlich sein, so darf der Prüfdruck das

1,5-fache des auf dem Typenschild und auf dem Flansch angegebenen Nenndruckes

nicht überschreiten.

D

VORSICHT!

Für alle Prüfungen und Einsätze sind grundsätzlich die Angaben auf dem

Typenschild maßgebend!

6.2.2 Schaltverstärker Typ LSO.25 (im Makrolongehäuse)

■

Montagelöcher bohren (siehe Abbildung unten)

■

Deckel vom Gehäuse abschrauben

■

Schrauben von der Deckelseite in die Montagelöcher einführen

■

Gehäuse anschrauben

Montage-

bohrungen

6.3 Elektrischer Anschluss

WARNUNG!

Bei dem elektrischen Anschluss alle zutreenden Vorschriften einhalten.

Die Messwandleranschlüsse sind sowohl am Messwandler als auch am Schaltverstärker

gekennzeichnet mit den Farben WS (weiß) bzw. 2d, BR (braun) bzw. 4d und GN (grün)

bzw. 6d, und entsprechend dem Anschlussplan zu verbinden.

WIKA Betriebsanleitung Typen LSO.06, LSO.2554

13334603.01 09/2010 GB/D/F/E

Page 55

6. Inbetriebnahme, Betrieb

Das Kabel muss nicht abgeschirmt sein, sollte aber auch nicht direkt neben starken elektrischen Störquellen verleget werden. Die maximale Leitungslänge und damit der maximale Leitungswiderstand inklusive Kontaktwiderstand richtet sich nach folgender Tabelle:

Kabelquerschnitt

in mm²

0,5 175 6,3

0,75 300 7,2

1,0 400 7,2

1,5 600 7,2

Ein Gesamtwiderstand von 9 Ω inklusive Kontaktübergangswiderstände nicht überschreiten, da sonst eine Störmeldung erfolgt.

Bei Ex-Ausführung zusätzlich eine max. Induktivität von La ≤ 0,5 mH und

eine max. Kapazität von C

verstärkers).

Anschlussbild Messwandler und Schaltverstärker

Ex-Zone 0/1 Kein Ex-Bereich

Messwandler

Typ LSO.06

Leitungslänge

in m

≤ 3 µF einhalten (inkl. den Werten des Schalt-

a

Schaltverstärker Typ LSO.25

Leitungswiderstand

in Ω

D

Signal Störung

Erde kann

angeschlossen

werden

Bei Ex-Ausführung muss vom Schaltverstärker zum Messwandler ein

hellblaues bzw. hellblau gekennzeichnetes Kabel installiert werden

(eigensicherer Stromkreis). Der Schaltverstärker bendet sich im Nicht-ExBereich und der Messkörper des Messwandlers in Zone 1.

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.25 55

Page 56

6. Inbetriebnahme, Betrieb

6.3.1 Messwandler Typ LSO.06

D

Erdung

Erde kann an der internen Erdungsschraube aufgelegt werden (ist für Eigensicherheit

nicht unbedingt notwendig) oder die Kontaktierung erfolgt über den metallischen Kontakt

des Einschraubgewindes mit dem Behälter.

6.3.2 Schaltverstärker Typ LSO.25

19"-Steckkarte

Federleiste nach DIN 41612

Federleisten-Anschlussseite

Reihe

Aufbaugehäuse

Schraubklemmen

Messw

STÖSIGNAL

SUPPLY

Messw

STÖSIGNAL

SUPPLY

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.2556

Page 57

6. Inbetriebnahme, Betrieb

6.4 Anschluss Netzversorgung

Zuerst prüfen, ob die vorhandene Versorgungsspannung mit der Netzversion des Schaltverstärkers übereinstimmt (siehe Bedruckung auf der Platine).

230 V ~ LSO.25-X1X

115/120 V ~ LSO.25-X2X

24 V ~ LSO.25-X3X

24 V = LSO.25-X4X

24 V = ohne Potentialtrennung LSO.25-X7X (nur bei Standard)

Bei der Ausführung Kunststogehäuse ist zusätzlich die Anschlussgruppe „NETZ“ mit der

Betriebsspannung beschriftet und der Anschluss ist direkt auf dem Aufdruck zu ersehen.

Die Beschaltung gemäß „Anschlussbild Messwandler und Schaltverstärker“ auf Seite 55

vornehmen.

Anschlussbelegung der Steckkarte

d 28 (c28) = N (-)

d 30 (c30) = L (+)

6.5 Anschluss Relais

Für die Signalisierung „SIGNAL“ und „STÖRUNG“ ist je ein Relais mit Wechslerkontakten

vorgesehen. Diese sind potentialfrei und können für jede beliebige Anwendung verschaltet werden. Bei der Ausführung Aufbaugehäuse können die Anschlüsse direkt aus dem

Aufdruck entnommen werden.

D

Anschlussbelegung der Steckkarte

Störung Signal Kontakt

4/d18 1/d24 Arbeitskontakt

5/d16 2/d22 Ruhekontakt

6/d14 3/d20 Wurzel

6.6 Funktionskontrolle

Nach erfolgter und überprüfter Verdrahtung nun die Versorgung zuschalten. Eine

der gelben Leuchtdioden leuchtet nun auf. Durch Drücken der Taste „TEST“, bei

geschlossenem Schalter S2 (Zeitverzögerung ausgeschaltet), leuchtet eine der beiden

gelben LED's ca. 1 s lang. Danach wechselt die Anzeige auf Blinken der anderen

gelben LED, solange die Test-Taste gedrückt bleibt. Dies zeigt an, dass Verdrahtung und

Schaltverstärker in Ordnung sind. Sollte dies nicht der Fall sein, erst die Justageanleitung

siehe Kapitel „7.2 Justage mit CAL“ beachten.

Bei eventuell auftretenden Störungen Maßnahmen siehe Kapitel

„10. Störungen“ beachten.

13334603.01 09/2010 GB/D/F/E

WIKA Betriebsanleitung Typen LSO.06, LSO.25 57

Page 58

7. Konguration

7. Konguration

7.1 Einstellen der Alarmrichtung mit Schalter S1

Der Schalter S1 ist ein Drahtbrückenschalter, dessen Schaltdraht für eine bleibende

Einstellung entweder verlötet oder abgeschnitten werden kann.

D

Hochalarm: - S1 oen,

- Signalrelais abgefallen, wenn Fühler eintaucht

Tiefalarm: - S1 geschlossen

- Signalrelais abgefallen, wenn Fühler ausgetaucht

Werkseinstellung: - S1 oen

Störungsauswirkung zu Trocken/Benetzt

Betriebszustand S1 Gelbe LED

benetzt

Benetzt

Fühler im optisch

dichteren Medium

oen

H

Hochalarm

geschlossen

blinkt aus abgefallen

dauernd ein aus angezogen

L

Tiefalarm

Trocken

Fühler im optisch

dünneren Medium

oen

H

Hochalarm

geschlossen

aus dauernd ein angezogen

aus blinkt abgefallen

L

Tiefalarm