Page 1

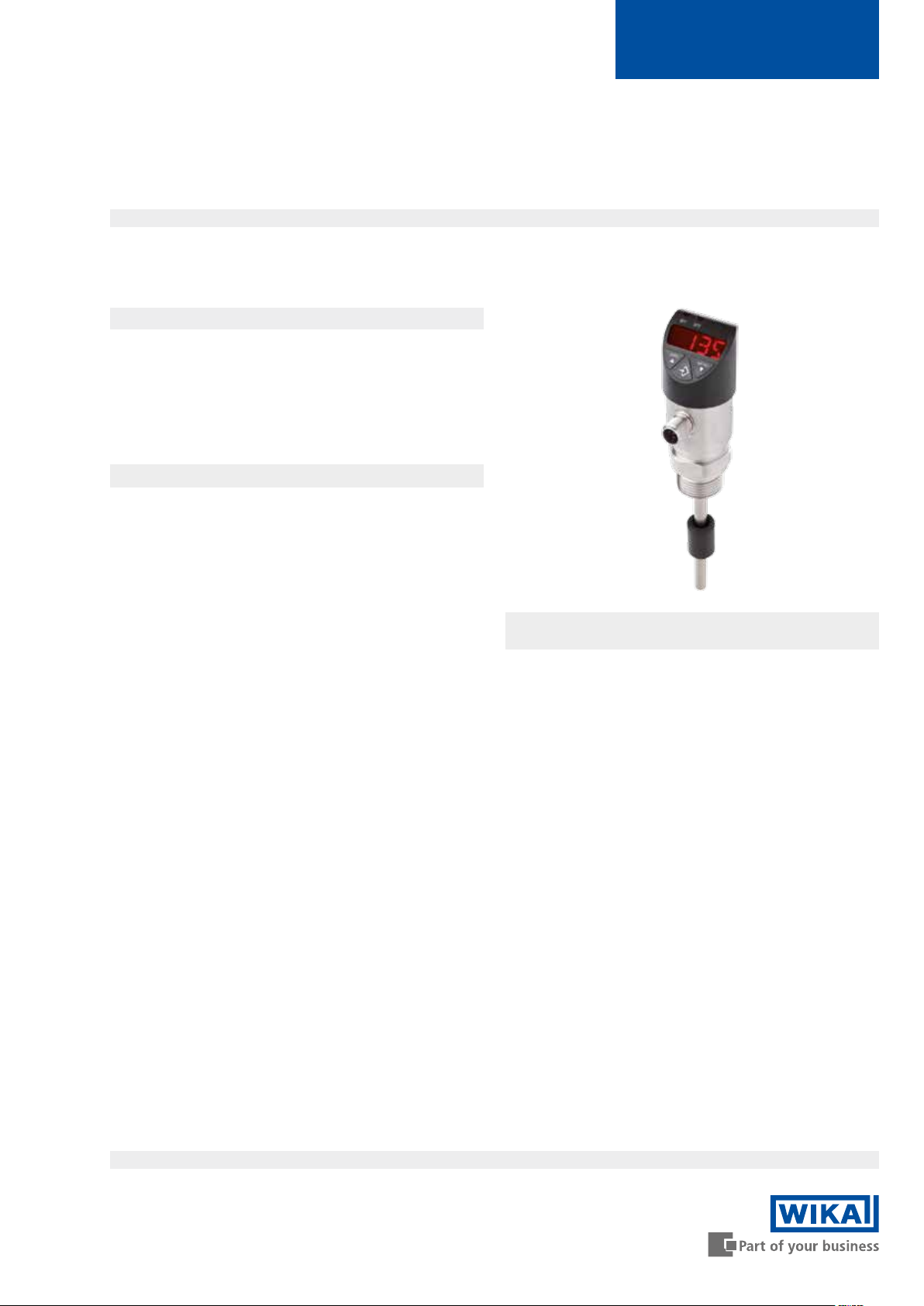

Electronic level switch with display

Model LSD-30

Applications

■

Machine tools

■

Hydraulic aggregates

■

Tank monitoring

■

Machine building

Special features

Level measurement

WIKA data sheet LM 40.01

■

Available with single or dual NPN or PNP solid state

user-programmable switches asily-readable, robust

display

■

High visibility, rugged 14-segment red LED display

■

Independent rotation between the M12x1 electrical

connection and the display to optimize installation position

■

User-friendly, intuitive 3-key operation

■

Programming menu meets VDMA Standards for user

friendly navigation

Description

Award-winning in design and functionality

The successful design and the excellent functionality of

the WIKA switch family were already conrmed by winning

the “iF product design award 2009” for the pressure switch

model PSD-30.

The robust LED display has been designed using 0.37"

(9 mm) high characters (the largest possible) and with a

slight incline in order to make reading the level as easy as

possible from a long way o. A 14-segment display has

been used, so alphanumeric messages are much easier

to understand.

The 3-key operation makes simple, intuitive menu navigation

possible, with no need for additional assistance. The menu

navigation is designed in accordance with the latest VDMA

standard. The VDMA standard for uid sensors (24574-4,

part 4 - level switches) has the aim of considerably simplifying the use of level switches by standardising menu navigation and display.

Electronic level switch with display

Model LSD-30

The control keys have been designed as large as possible

and are arranged ergonomically to ensure fast and easy

adjustments. Operation without any additional assistance is

made easier through the tactile feedback.

Customised installation

The installation of the model LSD-30 level switch can be

exibly adapted to the individual mounting situation. Due to

the almost unlimited rotation of the display and case by more

than 300°, the display can be adjusted independently of the

electrical connection. The display can thus always be aligned

to face the operator, and the M12 x 1 connection positioned

to suit the desired cable routing.

High quality

During development of the WIKA switch family a high

value was placed on a robust design and the selection

of appropriate materials suited for machine-building

applications. For this reason the case and the threaded

connection of the electrical connector are made from

stainless steel. Overwinding or tearing o the connector

is therefore virtually impossible.

Data sheets showing similar products:

Electronic pressure switch with display; model PSD-30; see data sheet PE 81.67

Electronic temperature switch with display; model TSD-30; see data sheet TE 67.03

Page 1 of 5WIKA data sheet LM 40.01 ∙ 01/2016

Page 2

Measuring ranges

Display

for process connection G ¾ A

Sensor length F (mm) 250 370 410 520 730

Measuring range (mm) 189 309 349 459 669

Measuring range (inch) 7.44 12.17 13.74 18.07 26.34

for process connection ¾ NPT

Sensor length F (mm) 250 370 410 520 730

Measuring range (mm) 205 325 365 475 684

Measuring range (inch) 8.07 12.80 14.37 18.70 26.93

Insertion lengths see “Dimensions in mm”

Specic gravity range of the medium

≥ 0.7 g/cm

3

Output signal

Switching output Analogue signal

SP1 SP2

PNP - 4 ... 20 mA (3-wire)

PNP - DC 0 ... 10 V (3-wire)

PNP PNP PNP PNP 4 ... 20 mA (3-wire)

PNP PNP DC 0 ... 10 V (3-wire)

Optionally also available with an NPN instead of a PNP

switching output.

Switching thresholds

Switch point 1 and 2 are both individually adjustable

14-segment LED, red, 4-digit, character size 0.37" (9 mm)

Display can be turned electronically through 180°

Update

200 ms

Voltage supply

Power supply U

DC 15 ... 35 V

Current consumption

Switching outputs with

■

Analog signal 4 ... 20 mA: 70 mA

■

Analog signal DC 0 ... 10 V: 45 mA

■

without analog signal: 45 mA

Total current consumption

max. 600 mA (incl. switching current)

+

Measuring element

Resistance measuring chain with reed switches and float

Resolution

< 0.24" (6 mm)

Response time

< 700 ms

Switching functions

Normally open, normally closed, window, hysteresis

Freely adjustable

Switching voltage

Power supply - 1 V

Switching current

max. 250 mA per switching output

Adjustment accuracy

0.1" (2.5 mm) steps

Response time

< 200 ms

Lettering (display and analogue signal)

Zero point: max. +25 % of span

Full scale: max. -25 % of span

Oset adjustment (display)

max. +1,500 mm

Load

■

Analogue signal 4 ... 20 mA: ≤ 500 Ω

■

Analogue signal DC 0 ... 10 V: > 10 kΩ

Maximum operating pressure

43.5 psi (3 bar)

Media compatibility

Test following ISO 7620, section 6, table 1

Medium Standard

Mineral oil HLP per DIN 51524

Aqueous solution HFC per VDMA 24317

Organic ester HFD-U per VDMA 24317

Triglyceride (rape oil) HETG per VDMA 24568

Synthetic ester HEES per VDMA 24568

Polyglycols HEPG per VDMA 24568

Accuracy data

Switching output

1 % of span

Display

1 % of span ±1 digit

Analogue signal

≤ ±0.5 % of span

WIKA data sheet LM 40.01 ∙ 01/2016Page 2 of 5

Page 3

Reference conditions

4

3

1

2

Electrical connections

Temperature: 50 ... 77 °F (15 ... 25 °C)

Atmospheric pressure: 13.8 ... 152 psi (950 ... 1,050 mbar)

Humidity: 45 ... 75 % r. h.

Nominal position:

Process connection lower mount (LM)

Power supply: DC 24 V

Load: see “Output signal”

Operating conditions

Permissible temperatures

Medium: -4 ... 176 °F (-20 ... +80 °C)

Ambient: -4 ... 176 °F (-20 ... +80 °C)

Storage: -4 ... 176 °F (-20 ... +80 °C)

Humidity

45 ... 75 % r. h.

Mounting position

vertical

Process connections

Available connections

Standard Thread

DIN 3852-E G ¾ A

ANSI / ASME B1.20.1 ¾ NPT

Other connections on request.

Details on the sensor dimensions see “Dimensions in mm”.

Sealings

for connections per DIN 3852-E

Standard NBR

Option Without

Option FPM/FKM

Materials

Wetted parts

Level sensor: Stainless steel 316Ti

Float: NBR (see “Media compatibility”)

Connections

■

Circular connector M12 x 1, 4-pin

■

Circular connector M12 x 1, 5-pin

1) Only for version with two switching outputs and additional analogue signal

1)

Ingress protection

IP 65 and IP 67

The stated ingress protection (per IEC 60529) only applies

when plugged in using mating connectors that have the

appropriate ingress protection.

Electrical safety

Short-circuit resistance: S

Reverse polarity protection: U

/ SP1 / SP2 vs. U

+

vs. U

-

+

-

Insulation voltage: DC 500 V

Overvoltage protection: DC 40 V

Connection diagram

Circular connector M12 x 1 (4-pin)

U

+

U

-

S

+

SP1 4

SP2 2

1

3

2

Circular connector M12 x 1 (5-pin)

U

+

U

-

S

+

SP1 4

SP2 2

Legend:

Power supply

U

+

U

Reference potential

-

SP1 Switching output 1

SP2 Switching output 2

S

Analogue output

+

1

3

5

Non-wetted parts

Case: Stainless steel 304

Keyboard TPE-E

Display window: PC

Display head: PC+ABS-Blend

WIKA data sheet LM 40.01 ∙ 01/2016

Page 3 of 5

Page 4

Dimensions in mm

CE conformity

Level switch

with M12 x 1 circular connector

4-pin / 5-pin

Process connections

EMC directive

2004/108/EC, EN 61326-2-3 emission (group 1, class B) and

interference immunity (industrial application)

RoHS conformity

2011/65/EU

Weight: approx. 0.3 kg

G1 L1

G ¾ A DIN 3852-E 16

Insertion lengths

Parallel thread

F M

250 189

370 309

410 349

520 459

730 669

G1 L1

¾ NPT 20

Tapered thread

F M

250 205

370 325

410 365

520 475

730 684

WIKA data sheet LM 40.01 ∙ 01/2016Page 4 of 5

Page 5

Accessories and spare parts

Sealings

Description Order no.

NBR prole sealing G 3/4 DIN 3852-E 1100378

FPM / FKM prole sealing G 3/4 DIN 3852-E 1158309

Connectors with moulded cable

Description Temperature range Cable diameter Order no.

Straight version, cut to length, 4-pin, 2 m PUR

cable, UL listed, IP 67

Straight version, cut to length, 4-pin, 5 m PUR

cable, UL listed, IP 67

Straight version, cut to length, 4-pin, 10 m PUR

cable, UL listed, IP 67

Straight version, cut to length, 5-pin, 2 m PUR

cable, UL listed, IP 67

Straight version, cut to length, 5-pin, 5 m PUR

cable, UL listed, IP 67

Straight version, cut to length, 5-pin, 10 m PUR

cable, UL listed, IP 67

Angled version, cut to length, 4-pin, 2 m PUR

cable, UL listed, IP 67

Angled version, cut to length, 4-pin, 5 m PUR

cable, UL listed, IP 67

Angled version, cut to length, 4-pin, 10 m PUR

cable, UL listed, IP 67

Angled version, cut to length, 5-pin, 2 m PUR

cable, UL listed, IP 67

Angled version, cut to length, 5-pin, 5 m PUR

cable, UL listed, IP 67

Angled version, cut to length, 5-pin, 10 m PUR

cable, UL listed, IP 67

-4 ... 176 °F

(-20 ... +80 °C)

-4 ... 176 °F

(-20 ... +80 °C)

-4 ... 176 °F

(-20 ... +80 °C)

-4 ... 176 °F

(-20 ... +80 °C)

-4 ... 176 °F

(-20 ... +80 °C)

-4 ... 176 °F

(-20 ... +80 °C)

-4 ... 176 °F

(-20 ... +80 °C)

-4 ... 176 °F

(-20 ... +80 °C)

-4 ... 176 °F

(-20 ... +80 °C)

-4 ... 176 °F

(-20 ... +80 °C)

-4 ... 176 °F

(-20 ... +80 °C)

-4 ... 176 °F

(-20 ... +80 °C)

4.5 mm 14086880

4.5 mm 14086883

4.5 mm 14086884

5.5 mm 14086886

5.5 mm 14086887

5.5 mm 14086888

4.5 mm 14086889

4.5 mm 14086891

4.5 mm 14086892

5.5 mm 14086893

5.5 mm 14086894

5.5 mm 14086896

01/2016 US

Ordering information

Model / Sensor length F / Output signal / Process connection / Sealing / Accessories and spare parts

© 2016 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modications to the specications and materials.

WIKA data sheet LM 40.01 ∙ 01/2016

WIKA Instrument, LP

1000 Wiegand Blvd.

Lawrenceville, GA 30043

Tel: 888-WIKA-USA • 770-513-8200

Fax: 770-338-5118

info@wika.com

www.wika.com

Page 5 of 5

Loading...

Loading...