Page 1

Operating instructions

Betriebsanleitung

Mode d‘emploi

Manual de instrucciones

Shut-o valves and valve manifolds

Models IV10, IV11, IV20, IV21, IV30, IV31, IV50, IV51

Absperrventile und Ventilblöcke

Typen IV10, IV11, IV20, IV21, IV30, IV31, IV50, IV51

Vannes d'arrêt et manifolds

Types IV10, IV11, IV20, IV21, IV30, IV31, IV50, IV51

Válvulas de cierre y manifolds

Modelos IV10, IV11, IV20, IV21, IV30, IV31, IV50, IV51

Model IV10, needle valve Model IV11, multiport valve

Model IV20, block-and-bleed valve Model IV51, 5-valve manifold

EN

DE

FR

ES

Page 2

Operating instructions

EN

Shut-o valves and valve manifolds

Betriebsanleitung

DE

Absperrventile und Ventilblöcke

Mode d‘emploi

FR

Vannes d'arrêt et manifolds

Manual de instrucciones

ES

Válvulas de cierre y manifolds

© 10/2019 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

Page 3 - 26

Seite 27 - 50

Page 51 - 75

Página 76 - 98

2

Operating instructions shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 3

Contents

Contents

1. General information 4

2. Design and function 5

3. Safety 6

4. Transport, packaging and storage 11

5. Commissioning, operation 12

6. Faults 17

7. Maintenance, repair and cleaning 19

8. Dismounting, return and disposal 21

9. Specications 24

EN

14294094.01 10/2019 EN/DE/FR/ES

WIKA operating instructions, shut-o valves and valve manifolds

3

Page 4

1. General information

1. General information

■

The valves described in the operating instructions have been

designed and manufactured using state-of-the-art technology. All

EN

components are subject to stringent quality and environmental

criteria during production. Our management systems are certied to

ISO 9001.

■

These operating instructions contain important information on

handling the product. Working safely requires that all safety

instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and

general safety regulations for the product's range of use.

■

The operating instructions are part of the product and must be kept

in the immediate vicinity of the valve and readily accessible to skilled

personnel at any time. Pass the operating instructions on to the next

operator or owner of the product.

■

Skilled personnel must have carefully read and understood the

operating instructions prior to beginning any work.

■

The general terms and conditions contained in the sales

documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheets: AC 09.19, AC 09.22, AC 09.23

4 WIKA operating instructions, shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 5

2. Design and function

2. Design and function

2.1 Functional description

The products described below have built-in bonnets for shutting o,

venting and compensating process pressures for pressure measuring

instruments. The functions of the models described here can be found in

the table on the following page.

Bonnet (standard version)

Gland nut

Seal bush

Spindle tip

1)

Dust cap colour code

Blue: Shut o

Red: Vent

Green: Compensate

T-bar handle

Coloured dust cap

Counter nut

Valve spindle

Sealing packing

Bonnet body

EN

Valve body

Locking pin

1) Optionally other handle designs are available

14294094.01 10/2019 EN/DE/FR/ES

WIKA operating instructions, shut-o valves and valve manifolds

Sealing ring

5

Page 6

2. Design and function / 3. Safety

Model Number of bonnets

Shut o Vent

IV10 1 - -

IV11 1 - -

EN

IV20, IV21 1 1 -

IV30, IV31 2 - 1

IV50, IV51 2 2 1

1) Venting with bonnet, for further venting options (e.g. via vent screw) see data sheet

1)

2.2 Scope of delivery

Cross-check scope of delivery with delivery note.

3. Safety

3.1 Explanation of symbols

DANGER!

... indicates a directly dangerous situation resulting in serious

injury or death, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result in

serious injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result

in light injuries or damage to equipment or the environment, if

not avoided.

Information

... points out useful tips, recommendations and information for

ecient and trouble-free operation.

Compensate

6 WIKA operating instructions, shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 7

3. Safety

3.2 Intended use

These valves are used for the separation of measuring instruments from

the process by means of shut-o, venting and pressure compensating

function(s) They are designed for use in applications with clean gaseous

and liquid media that are not highly viscous or crystallising.

The product must only be used with media which are not harmful to

the wetted parts over the entire operating range of the instrument. Any

change in the state of the matter or any decomposition of unstable media

is not permitted.

Only use the product in applications that lie within its technical performance limits (e.g. max. ambient temperature, material compatibility, ...).

→ For performance limits see chapter 9 “Specications”.

Improper handling or operation of the product outside of its technical

specifications requires the instrument to be taken out of service

immediately and inspected by an authorised service engineer.

These valves do not have their own potential ignition source. The

responsibility for the safe use in hazardous areas in accordance with

the accepted standards of technology rests with the operator.

For the reasons mentioned above, these valves are not marked and do

not have their own certification.

The product has been designed and built solely for the intended use

described here, and may only be used accordingly.

The manufacturer shall not be liable for claims of any type based on

operation contrary to the intended use.

EN

3.3 Improper use

Improper use is dened as any application that exceeds the technical

performance limits or is not compatible with the materials.

14294094.01 10/2019 EN/DE/FR/ES

WIKA operating instructions, shut-o valves and valve manifolds

7

Page 8

3. Safety

WARNING!

Injuries through improper use

Improper use of the product can lead to hazardous situations

and injuries.

EN

Any use beyond or dierent to the intended use is considered as

improper use.

3.4 Responsibility of the operator

The product is used in the industrial sector. The operator is therefore

responsible for legal obligations regarding safety at work.

The safety instructions within these operating instructions, as well as the

safety, accident prevention and environmental protection regulations for

the application area must be maintained.

The operator is obliged to maintain the product label in a legible condition.

To ensure safe working on the product, the operating company must

ensure the following:

■

The operating personnel are regularly instructed in all topics

regarding work safety, rst aid and environmental protection

and know the operating instructions and in particular, the safety

instructions contained therein.

■

The operating personnel have read the operating instructions and

taken note of the safety instructions contained therein.

■

The intended use for the application is complied with.

■

Following testing, improper use of the product is excluded.

▶

Refrain from unauthorised modifications to the product.

▶

Do not use the product with abrasive or viscous media.

8 WIKA operating instructions, shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 9

3. Safety

3.5 Personnel qualication

WARNING!

Risk of injury should qualication be insucient

Improper handling can result in considerable injury and

damage to equipment.

▶

The activities described in these operating instructions

may only be carried out by skilled personnel who have the

qualications described below.

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be

personnel who, based on their technical training, knowledge of measurement and control technology and on their experience and knowledge

of country-specic regulations, current standards and directives, are

capable of carrying out the work described and independently recognising potential hazards.

Operating personnel

The personnel trained by the operator are understood to be personnel

who, based on their education, knowledge and experience, are capable of carrying out the work described and independently recognising

potential hazards.

Special operating conditions require further appropriate knowledge, e.g.

of aggressive media.

3.6 Personal protective equipment

The personal protective equipment is designed to protect the skilled

personnel from hazards that could impair their safety or health during

work. When carrying out the various tasks on and with the product, the

skilled personnel must wear personal protective equipment.

EN

Follow the instructions displayed in the work area regarding

personal protective equipment!

The requisite personal protective equipment must be provided by the

operating company.

14294094.01 10/2019 EN/DE/FR/ES

WIKA operating instructions, shut-o valves and valve manifolds

9

Page 10

3. Safety

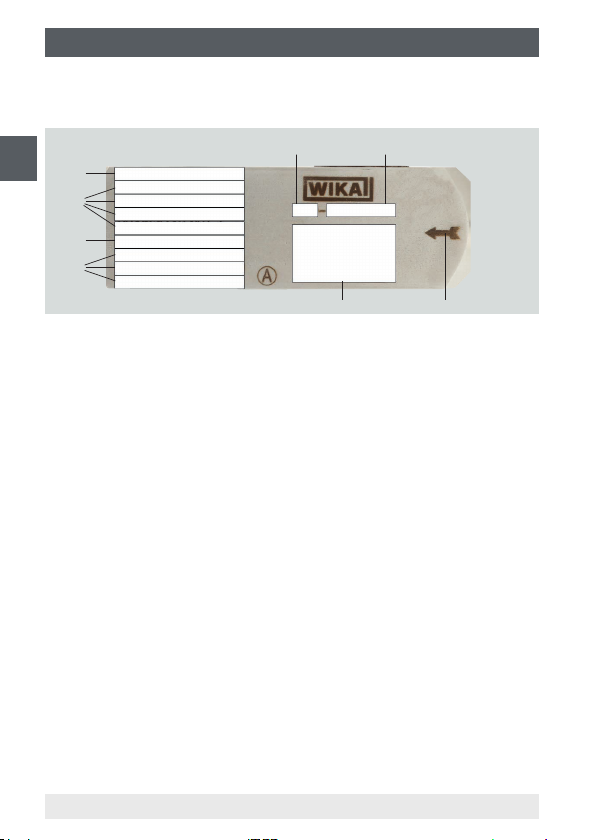

3.7 Labelling, safety marks

Product marking

EN

Article number

Model

ID number

Article description (thread denition, material, etc.)

Permissible operating pressure

Product traceability information (production date, lot number etc.)

Functional diagram

Flow direction

10 WIKA operating instructions, shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 11

4. Transport, packaging and storage

4. Transport, packaging and storage

4.1 Transport

Check the product for any damage that may have been caused by transport. Obvious damage must be reported immediately.

CAUTION!

With improper transport, a high level of damage to

property can occur.

▶

When unloading packed goods upon delivery as well as

during internal transport, proceed carefully.

▶

With internal transport, observe the instructions in chapter

4.2 “Packaging and storage”.

4.2 Packaging and storage

Do not remove packaging until just before commissioning.

Keep the packaging as it will provide optimum protection during transport

(e.g. change in installation site, sending for repair).

Permissible conditions at the place of storage:

■

Storage temperature: -60 ... +70 °C (-76 ... +158 °F)

■

Humidity: 35 ... 85 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, ammable atmospheres

EN

Store the product in its original packaging in a location that fulls the

conditions listed above. If the original packaging is not available and if

the product is stored for a prolonged period of time (more than 30 days),

place a bag containing a desiccant inside the packaging.

14294094.01 10/2019 EN/DE/FR/ES

WIKA operating instructions, shut-o valves and valve manifolds

11

Page 12

5. Commissioning, operation

5. Commissioning, operation

Personnel: Skilled personnel

Tools and mounting material:

EN

■

Torque spanner set, open-ended spanner set (17 ... 32 mm)

■

Allen key set

■

Screwdriver

■

Suitable lubricants for sealing elements and bolts

■

Suitable sealing material for threaded connections

Before installation, commissioning and operation, ensure that the appropriate product has been selected in terms of operating conditions, design

and specic measuring conditions.

Only use original parts.

Always observe the mounting and operating instructions of accessories

when commissioning them.

WARNING!

Physical injuries and damage to property and the

environment caused by hazardous media

Upon contact with hazardous media (e.g. with ammable

or toxic substances), harmful media (e.g. corrosive, toxic,

carcinogenic, radioactive), and also with refrigeration plants

and compressors, there is a danger of physical injuries and

damage to property and the environment.

Aggressive media with extremely high temperature and under

high pressure may be present at the product.

▶

For these media, in addition to all standard regulations,

the appropriate existing codes or regulations must also be

followed.

▶

Wear the requisite protective equipment (see chapter 3.6

“Personal protective equipment”).

12 WIKA operating instructions, shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 13

5. Commissioning, operation

WARNING!

Physical injuries and damage to property and the

environment caused by media escaping under high

pressure

With the pressurisation of the product, as a result of poor

sealing of the connections, media under high pressure can

escape.

Due to the high energy of the media that can escape in

the event of a failure, the possibility of physical injuries and

damage to property exists.

▶

The sealing of the connections must be carried out expertly

and checked for leak tightness.

WARNING!

Physical injuries and damage to property and the

environment caused by improper handling.

Incorrect opening or closing of a valve can lead to the

escape of media.

▶

The operator must be aware of the consequences prior to

changing the state to a specic valve position.

5.1 Mounting

■

When unpacking, check all components for any external damage.

If a return is needed, please follow the instructions given in chapter

8.2 “Return”.

■

Ensure that all unused connections are closed. Plug screws for vent

connections are included in delivery, though not pre-tted.

■

The valve may only be carried by the valve body, not by the handle

■

Check the product marking for correctness (see chapter 3.7 “Labelling, safety marks”).

■

Before mounting, ensure that the process line has been depressurised using the main valve.

■

Mount the measuring instrument at the right connection. Ensure that

the ow direction arrow points from the process connection towards

the measuring instrument.

EN

14294094.01 10/2019 EN/DE/FR/ES

WIKA operating instructions, shut-o valves and valve manifolds

13

Page 14

5. Commissioning, operation

■

Remove the protection caps of the required process connections.

■

Ensure that the sealing faces are clean and do not show any mechanical damage.

■

The correct sealing element must be used for the respective

EN

connection.

Threaded connection

To screw in threaded connections the appropriate tool must only be

applied through the spanner ats provided for this purpose.

The tightening torque is dependent on the process connection and

sealing element used.

Flange connection

Applicable models: IV20, IV21, IV30, IV31, IV50, IV51

Use only the bolts and sealing rings included in delivery:

Models IV20, IV21: 2 bolts, 1 sealing ring

Models IV30, IV31, IV50, IV51: 4 bolts, 2 sealing rings

Instructions for correct process connection mounting can be

found in the relevant standards e.g. IEC 61518

1. Fix the instrument for valve mounting on the workbench.

2. Apply a small amount of grease on the bolts.

3. Apply a small amount of grease to each sealing ring to hold it in

place.

4. Position the valve manifold on the instrument.

5. To ease the mounting for ange connections with 4 screws, place

two centring pins opposite each other.

6. Screw in 2 bolts and tighten them by hand.

7. If applicable, remove the centring pins used before.

8. Then screw in the other 2 bolts and tighten them by hand.

9. Use the torque spanner and tighten the bolts opposite each other

with an initial torque of 34 Nm.

10. Use the torque spanner and tighten the bolts opposite each other

with the nal torque depending on the material.

Final torque for stainless steel: 72 Nm.

Final torque for carbon steel: 87 Nm.

14 WIKA operating instructions, shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 15

5. Commissioning, operation

5.2 Commissioning and operation

To close the valve, turn the handle in a clockwise direction as far as the

stop. To open the valve, turn the handle anticlockwise as far as the stop.

It will take approximately 4 turns from open to closed and vice versa.

The ow can be controlled by not totally opening/closing the valve.

Please note that the handle may present a slight play and

spin freely up to a quarter turn when in the depressurised

state. This is due to the constructive design.

■

The valve, especially the handle, must not be subjected to any external loading (e.g. use as a climbing aid, support for objects).

■

The handle may only be used by hand; the use of tools is not

accepted.

■

The torque on reaching the valve stop must only be hand-tight.

■

Ensure that all valves of the product are closed prior to opening the

main valve of the process line.

EN

14294094.01 10/2019 EN/DE/FR/ES

WIKA operating instructions, shut-o valves and valve manifolds

15

Page 16

5. Commissioning, operation

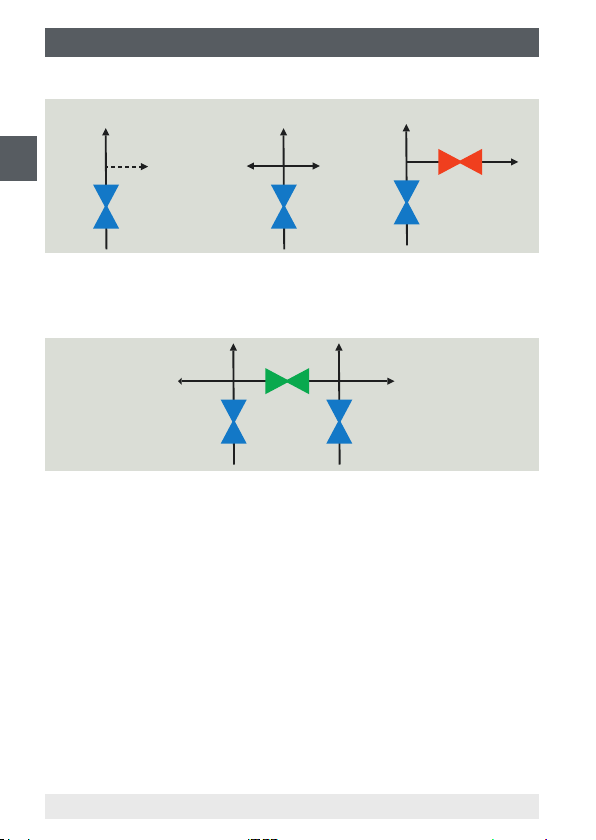

Models IV10, IV11, IV20, IV21

Model IV10 Model IV11 Models IV20, IV21

EN

To avoid pressure surges, open the shut-o valve (blue) slowly.

The pressure is at the instrument connection now.

Models IV30, IV31

1. Open compensating valve (green).

2. To avoid pressure surges, open the shut-o valves (blue) slowly.

The pressure is at the instrument connection now.

3. Close compensating valve (green).

16 WIKA operating instructions, shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 17

5. Commissioning, operation / 6. Faults

Models IV50, IV51

1. Close vent valves (red).

2. Open compensating valve (green).

3. To avoid pressure surges, open the shut-o valves (blue) slowly.

The pressure is at the instrument connection now.

4. Close compensating valve (green).

6. Faults

The following table contains the most frequent causes of

faults and the necessary countermeasures.

Faults Causes Measures

Dicult handle

operation

Leakage at the

spindle

Lubrication problem due to

unchanged valve position for a

long time period

Defective parts due to

corrosion, process conditions,

age

Overtightened gland nut,

defective sealing packing

Leaking sealing packing See chapter 7.2 “Repair”

Perform a functional test

as described in chapter

“Maintenance” and

7.1

shorten inspection interval

as appropriate

Replace product

Replace product

EN

14294094.01 10/2019 EN/DE/FR/ES

WIKA operating instructions, shut-o valves and valve manifolds

17

Page 18

6. Faults

Faults Causes Measures

No ow or

restricted ow of

process media

EN

CAUTION!

Physical injuries and damage to property and the

environment

If faults cannot be eliminated by means of the listed

measures, the product must be taken out of operation

immediately.

WARNING!

Physical injuries and damage to property and the

environment caused by hazardous media

Upon contact with hazardous media (e.g. oxygen, acetylene,

ammable or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic, radioactive), and also with refrigeration plants and compressors, there is a danger of physical

injuries and damage to property and the environment.

Should a failure occur, aggressive media with extremely high

temperature and under high pressure or vacuum may be

present at the product.

Valve closed or partially open Ensure that that valve is

Incorrect mounting Ensure that that valve is

Clogging by unsuitable

process media

▶

Ensure that there is no longer any pressure present and

protect against being put into operation accidentally.

▶

Contact the supplier.

▶

If a return is needed, please follow the instructions given in

chapter 8.2 “Return”.

▶

For these media, in addition to all standard regulations,

the appropriate existing codes or regulations must also be

followed.

▶

Wear the requisite protective equipment (see chapter 3.6

“Personal protective equipment”).

open

correctly mounted

Check compatibility of

process media

18 WIKA operating instructions, shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 19

7. Maintenance, repair and cleaning

7. Maintenance, repair and cleaning

7.1 Maintenance

When used properly, the valves work maintenance-free. They must be

checked within the context of regular maintenance.

Inspection interval

Depending on the process, the ambient conditions and the number of

operations, the required inspection interval may vary from daily to several

weeks.

Recommended inspection interval: ≤ 3 months

Inspection checklist

1. Leak test of the process and instrument connections

2. Leak test between bonnet and valve body

3. Functional test for correct opening and closing

In case the leak test of item 2 fails, proceed with the adjustment of the

sealing packing described below.

7.2 Repair

Adjustment of the sealing packing

This adjustment is required when a leak can be detected at the valve

spindle, directly below the handle, or when during operation there is no

torque or resistance when turning the handle.

1. Loosen the counter nut

2. Increase the packing compression through the gland nut applying a

torque of ≥13 … ≤ 18 Nm (18 … 25 lbs ft)

3. Fix the gland nut with the counter nut

EN

If after the adjustment of the sealing packing the leakage problem

persists, the packing must be returned for repair.

Perfect functioning of the product can only be guaranteed

when original accessories and spare parts are used.

14294094.01 10/2019 EN/DE/FR/ES

WIKA operating instructions, shut-o valves and valve manifolds

19

Page 20

7. Maintenance, repair and cleaning

7.3 Cleaning

CAUTION!

EN

1. Prior to cleaning, properly disconnect the product from the process.

2. Clean the product carefully with a moist cloth.

Physical injuries and damage to property and the

environment

Improper cleaning may lead to physical injuries and damage

to property and the environment. Residual media in the

dismounted product can result in a risk to persons, the

environment and equipment.

▶

Rinse or clean the dismounted product.

▶

Take sucient precautionary measures.

CAUTION!

Damage to property

Improper cleaning may lead to damage to the product!

▶

Do not use any aggressive cleaning agents.

▶

Do not use any hard or pointed objects for cleaning.

20 WIKA operating instructions, shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 21

8. Dismounting, return and disposal

8. Dismounting, return and disposal

8.1 Dismounting

Before starting the disassembly, you must ensure that the main valve of

the process line is closed.

WARNING!

Risk of burns

During dismounting there is a risk of dangerously hot media

escaping.

▶

Let the product cool down suciently before dismounting it!

WARNING!

Physical injury

When dismounting, there is a danger from aggressive media

and high pressures.

▶

Wear the requisite protective equipment (see chapter 3.6

“Personal protective equipment”).

▶

Observe the information in the material safety data sheet

for the corresponding medium.

▶

Only disconnect the valve once the system has been

depressurised.

WARNING!

Physical injuries and damage to property and the

environment through residual media

Upon contact with hazardous media (e.g. oxygen, acetylene,

ammable or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic, radioactive), and also with refrigeration plants and compressors, there is a danger of physical

injuries and damage to property and the environment.

▶

Wear the requisite protective equipment (see chapter 3.6

“Personal protective equipment”).

▶

Observe the information in the material safety data sheet

for the corresponding medium.

▶

Before storage of the dismounted product (following

use) wash or clean it, in order to protect persons and the

environment from exposure to residual media.

EN

14294094.01 10/2019 EN/DE/FR/ES

WIKA operating instructions, shut-o valves and valve manifolds

21

Page 22

8. Dismounting, return and disposal

Models IV10, IV11

1. To avoid pressure surges, open the shut-o valve (blue) slowly.

2. In case the valve is equipped with a vent connection, open this

connection with a suitable tool. Remove plug screw/vent screw (if

EN

available).

The valve can be dismounted now.

Models IV20, IV21

1. To avoid pressure surges, open the shut-o valve (blue) slowly.

2. Open the vent connection with a suitable tool. Remove plug screw/

vent screw (if available).

3. Open the vent valve slowly (red) to depressurise the valve.

The valve can be dismounted now.

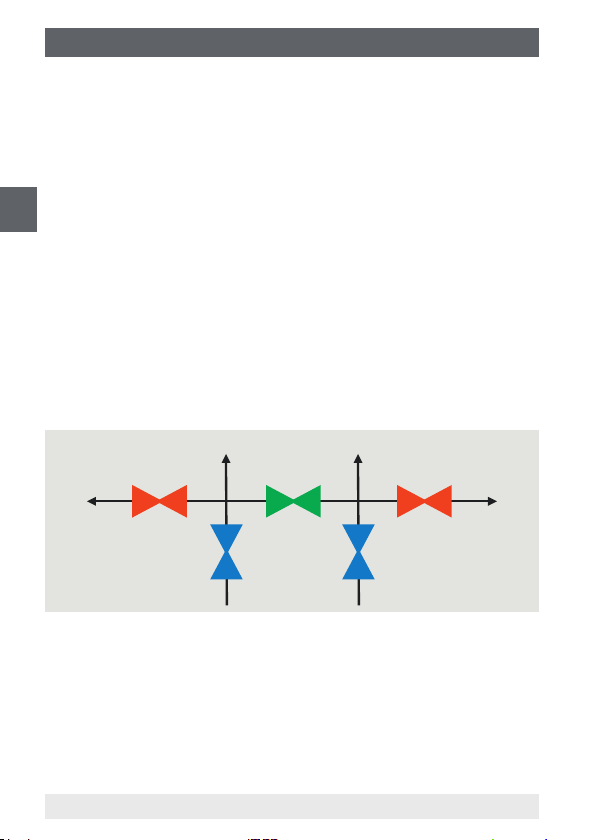

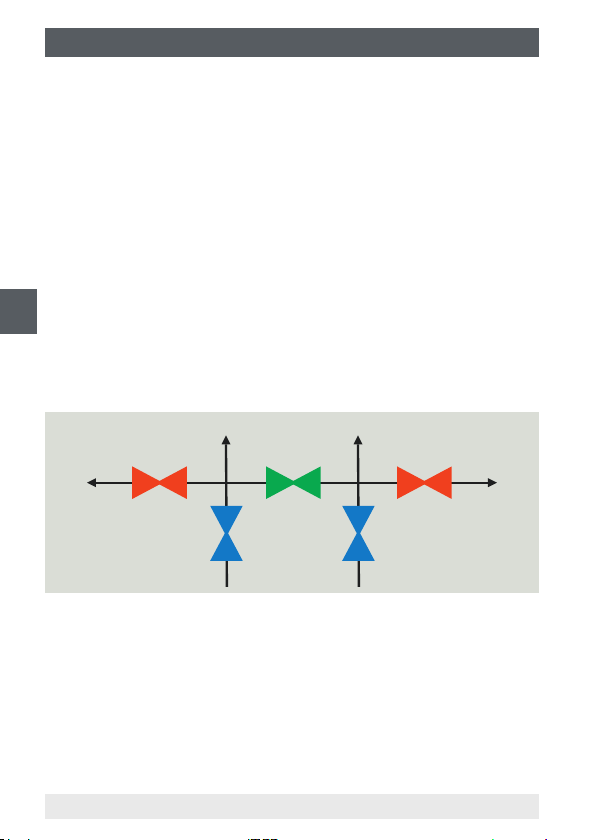

Models IV30, IV31, IV50, IV51

Vent (red)

Models IV5x only

Shut o

(blue)

Compensate

(green)

Shut o

(blue)

Vent (red)

Models IV5x only

1. Open compensating valve (green).

2. To avoid pressure surges, close the shut-o valves (blue) slowly.

3. Remove plug screws/vent screws (if available).

4. Only for models IV5x: Open vent valves (red) slowly.

The valve can be dismounted now.

22 WIKA operating instructions, shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 23

8. Dismounting, return and disposal

8.2 Return

Strictly observe the following when shipping the product:

All products delivered to WIKA must be free from any kind of hazardous

substances (acids, bases, solutions, etc.) and must therefore be cleaned

before being returned.

WARNING!

Physical injuries and damage to property and the

environment through residual media

Residual media in the dismounted product can result in a risk

to persons, the environment and equipment.

▶

With hazardous substances, include the material safety

data sheet for the corresponding medium.

▶

Clean the instrument, see chapter 7.2 “Cleaning”.

When returning the product, use the original packaging or a suitable

transport packaging.

Information on returns can be found under the heading

“Service” on our local website.

8.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of product components and packaging materials in an environ-

mentally compatible way and in accordance with the country-specic

waste disposal regulations.

EN

14294094.01 10/2019 EN/DE/FR/ES

WIKA operating instructions, shut-o valves and valve manifolds

23

Page 24

9. Specications

9. Specications

For the illustrated location of the parts mentioned below, see chapter 2.1

“Functional description”.

EN

Specication

Spindle tip Non-rotating, low-wear

Valve seat Metal seat

Valve bore size 4 mm (0.16 in)

Material Standard Option

Wetted parts

■

Valve body Stainless steel 316/316L

Bonnet body

Spindle tip

Sealing packing PTFE Graphite

Non-wetted parts

Handle Stainless steel 304 Stainless steel 316/316L

Gland nut Stainless steel 316/316L

Counter nut

Valve spindle

Seal bush

Monel 400

■

Hastelloy 276

■

Others on request

24 WIKA operating instructions, shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 25

9. Specications

Operating conditions

Sealing material Max. permissible operating pressure in bar

at temperature in °C

PTFE 689 bar at 38 °C

276 bar at 204 °C

Graphite 420 bar at 38 °C

209 bar at 538 °C

EN

Sealing material Max. permissible operating pressure in psi

at temperature in °F

PTFE 10,000 psi at 100 °F

4,000 psi at 400 °F

Graphite 6,000 psi at 100 °F

3,030 psi at 1,000 °F

The minimum design temperature is -54 °C (-65 °F).

For permanently low operating temperatures of ≤ -54 °C (≤ -65 °F), a

special design is required.

The following diagram must be used to ensure that the permissible

pressure-temperature rating is met during operation depending on the

sealing material used.

For further specifications see data sheets AC 09.19, AC 09.21,

AC 09.23.

14294094.01 10/2019 EN/DE/FR/ES

WIKA operating instructions, shut-o valves and valve manifolds

25

Page 26

9. Specications

Pressure-temperature diagram

700

(10153)

EN

600

(8702)

500

(7252)

400

(5802)

300

(4351)

200

Pressure in bar (psi)

(2901)

100

(1450)

0

PTFE

Graphite

Temperature in °C (°F)

26 WIKA operating instructions, shut-o valves and valve manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 27

Inhalt

Inhalt

1. Allgemeines 28

2. Aufbau und Funktion 29

3. Sicherheit 30

4. Transport, Verpackung und Lagerung 35

5. Inbetriebnahme, Betrieb 36

6. Störungen 41

7. Wartung, Instandsetzung und Reinigung 43

8. Demontage, Rücksendung und Entsorgung 45

9. Technische Daten 48

14294094.01 10/2019 EN/DE/FR/ES

WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

DE

27

Page 28

1. Allgemeines

1. Allgemeines

■

Die in der Betriebsanleitung beschriebenen Ventile werden nach

dem aktuellen Stand der Technik konstruiert und gefertigt. Alle

Komponenten unterliegen während der Fertigung strengen Qualitätsund Umweltkriterien. Unsere Managementsysteme sind nach

ISO 9001 zertiziert.

DE

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem

Produkt. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller

angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Produktes geltenden

örtlichen Unfallverhütungsvorschriften und allgemeinen

Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in

unmittelbarer Nähe des Ventils für das Fachpersonal jederzeit

zugänglich aufbewahrt werden. Betriebsanleitung an nachfolgende

Benutzer oder Besitzer des Produktes weitergeben.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller

Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Es gelten die allgemeinen Geschäftsbedingungen in den

Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- Zugehörige Datenblätter: AC 09.19, AC 09.22, AC 09.23

28 WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

14294094.01 10/2019 EN/DE/FR/ES

Page 29

2. Aufbau und Funktion

2. Aufbau und Funktion

2.1 Funktionsbeschreibung

Bei den im Folgenden beschriebenen Produkten sind Ventiloberteile zum

Absperren, Entlüften bzw. Ausgleichen von Prozessdrücken für Druckmessgeräte eingebaut. Die Funktionen der hier beschriebenen Typen ist

der Tabelle auf der Folgeseite zu entnehmen.

Ventiloberteil (Standardausführung)

T-Gristange

Farbige Staubkappe

Stopfbuchsenmutter

Kontermutter

Ventilspindel

Dichtbuchse

Dichtpackung

Ventiloberteil-Gehäuse

Spindelspitze

1)

Farbkennung Staubkappe

Blau: Absperren

Rot: Entlüften

Grün: Ausgleichen

DE

Ventilgehäuse

Verschlussstift

1) Optional sind weitere Griausführungen lieferbar

14294094.01 10/2019 EN/DE/FR/ES

WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

Dichtring

29

Page 30

2. Aufbau und Funktion / 3. Sicherheit

Ty p Anzahl Ventiloberteile

Absperren Entlüften

IV10 1 - -

IV11 1 - -

IV20, IV21 1 1 -

IV30, IV31 2 - 1

DE

IV50, IV51 2 2 1

1) Entlüftung mit Ventiloberteil, weitere Optionen zur Entlüftung (z. B. über Entlüftungsschraube) siehe Datenblatt

1)

Ausgleichen

2.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

3. Sicherheit

3.1 Symbolerklärung

GEFAHR!

... weist auf eine unmittelbar gefährliche Situation hin, die

zum Tod oder zu schweren Verletzungen führt, wenn sie nicht

gemieden wird.

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die

zum Tod oder zu schweren Verletzungen führen kann, wenn

sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die

zu geringfügigen oder leichten Verletzungen bzw. Sach- und

Umweltschäden führen kann, wenn sie nicht gemieden wird.

Information

... hebt nützliche Tipps und Empfehlungen sowie Informa-

tionen für einen ezienten und störungsfreien Betrieb hervor.

30 WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

14294094.01 10/2019 EN/DE/FR/ES

Page 31

3. Sicherheit

3.2 Bestimmungsgemäße Verwendung

Diese Ventile dienen dazu, Messgeräte mit Hilfe von Abschalt-, Entlüftungs- und Druckausgleichsfunktion(en) vom Prozess zu trennen. Sie

sind konzipiert für den Einsatz in Anwendungen mit sauberen gasför-

migen und üssigen Messstoen, die nicht hochviskos sind und nicht

kristallisieren.

Das Produkt darf nur mit Messstoen betrieben werden, die im gesamten Einsatzbereich des Produktes als unbedenklich für die messstobe-

rührten Teile gelten. Eine Änderung des Aggregatszustandes oder die

Zersetzung instabiler Messstoe ist nicht zulässig.

Das Produkt nur in Anwendungen verwenden, die innerhalb seiner

technischen Leistungsgrenzen liegen (z. B. max. Umgebungstemperatur,

Materialverträglichkeit, ...).

→ Leistungsgrenzen siehe Kapitel 9 „Technische Daten“.

Eine unsachgemäße Handhabung oder ein Betreiben des

Produktes außerhalb der technischen Spezifikationen macht die

sofortige Stilllegung und Überprüfung durch einen autorisierten

Servicemitarbeiter erforderlich.

Diese Armaturen besitzen keine eigene potentielle Zündquelle. Die

Verantwortung für den sicheren Einsatz in explosionsgefährdeten

Bereichen, nach den anerkannten Regeln der Technik, trägt der

Betreiber.

Aus oben genannten Gründen erhalten diese Armaturen keine

Kennzeichnung und haben keine eigene Zertifizierung.

Das Produkt ist ausschließlich für den hier beschriebenen

bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert

und darf nur dementsprechend verwendet werden.

DE

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer

Verwendung sind ausgeschlossen.

3.3 Fehlgebrauch

Als Fehlgebrauch gilt jede Verwendung, die die technischen Leistungs-

grenzen überschreitet oder mit den Werkstoen unverträglich ist.

14294094.01 10/2019 EN/DE/FR/ES

WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

31

Page 32

3. Sicherheit

WARNUNG!

Verletzungen durch Fehlgebrauch

Fehlgebrauch des Produktes kann zu gefährlichen

Situationen und Verletzungen führen.

▶

Eigenmächtige Umbauten am Produkt unterlassen.

▶

Produkt nicht für abrasive und viskose Messstoffe

DE

Jede über die bestimmungsgemäße Verwendung hinausgehende oder

andersartige Benutzung gilt als Fehlgebrauch.

3.4 Verantwortung des Betreibers

Das Produkt wird im gewerblichen Bereich eingesetzt. Der Betreiber

unterliegt daher den gesetzlichen Pichten zur Arbeitssicherheit.

Die Sicherheitshinweise dieser Betriebsanleitung, sowie die für den

Einsatzbereich des Gerätes gültigen Sicherheits-, Unfallverhütungs- und

Umweltschutzvorschriften einhalten.

Der Betreiber ist verpichtet, das Typenschild lesbar zu halten.

Für ein sicheres Arbeiten am Produkt muss der Betreiber Folgendes

sicherstellen:

■

Bedienpersonal wird regelmäßig in allen zutreenden Fragen von

Arbeitssicherheit, Erste Hilfe und Umweltschutz unterwiesen, sowie

die Betriebsanleitung und insbesondere die darin enthaltenen

Sicherheitshinweise sind bekannt.

■

Bedienpersonal hat Betriebsanleitung gelesen und insbesondere die

darin enthaltenen Sicherheitshinweise zur Kenntnis genommen.

■

Die bestimmungsgemäße Verwendung für den Anwendungsfall wird

eingehalten.

■

Nach Prüfung ist ein Fehlgebrauch des Produktes ausgeschlossen.

verwenden.

32 WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

14294094.01 10/2019 EN/DE/FR/ES

Page 33

3. Sicherheit

3.5 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation

Unsachgemäßer Umgang kann zu erheblichen Personenund Sachschäden führen.

▶

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten

nur durch Fachpersonal nachfolgend beschriebener Quali-

kation durchführen lassen.

Fachpersonal

Das vom Betreiber autorisierte Fachpersonal ist aufgrund seiner

fachlichen Ausbildung, seiner Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen Vorschriften, geltenden Normen und Richtlinien in der Lage, die

beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig zu erkennen.

Bedienpersonal

Das vom Betreiber geschulte Personal ist aufgrund seiner Bildung,

Kenntnisse und Erfahrungen in der Lage, die beschriebenen Arbeiten

auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes

Wissen, z. B. über aggressive Messstoe.

3.6 Persönliche Schutzausrüstung

Die persönliche Schutzausrüstung dient dazu, das Fachpersonal gegen

Gefahren zu schützen, die dessen Sicherheit oder Gesundheit bei der

Arbeit beeinträchtigen könnten. Beim Ausführen der verschiedenen

Arbeiten an und mit dem Produkt muss das Fachpersonal persönliche

Schutzausrüstung tragen.

DE

Im Arbeitsbereich angebrachte Hinweise zur persönlichen Schutzausrüstung befolgen!

Die erforderliche persönliche Schutzausrüstung muss vom Betreiber zur

Verfügung gestellt werden.

14294094.01 10/2019 EN/DE/FR/ES

WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

33

Page 34

3. Sicherheit

3.7 Beschilderung, Sicherheitskennzeichnungen

Produktkennzeichnung

DE

Artikelnummer

Typ

ID-Nummer

Artikelbeschreibung (Anschlussgewinde, Werksto usw.)

Zulässiger Betriebsdruck

Informationen zur Rückverfolgbarkeit des Produktes (Herstellungsdatum,

Losnummer usw.)

Funktionsschema

Strömungsrichtung

34 WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

14294094.01 10/2019 EN/DE/FR/ES

Page 35

4. Transport, Verpackung und Lagerung

4. Transport, Verpackung und Lagerung

4.1 Transport

Produkt auf eventuell vorhandene Transportschäden untersuchen. Oensichtliche Schäden unverzüglich mitteilen.

VORSICHT!

Bei unsachgemäßem Transport können Sachschäden in

erheblicher Höhe entstehen.

▶

Beim Abladen der Packstücke bei Anlieferung sowie innerbetrieblichem Transport vorsichtig vorgehen.

▶

Bei innerbetrieblichem Transport die Hinweise unter Kapitel

4.2 „Verpackung und Lagerung“ beachten.

4.2 Verpackung und Lagerung

Verpackung erst unmittelbar vor der Inbetriebnahme entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem

Transport einen optimalen Schutz (z. B. wechselnder Einbauort,

Reparatursendung).

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -60 ... +70 °C (-76 ... +158 °F)

■

Feuchtigkeit: 35 ... 85 % relative Feuchte (keine Betauung)

Folgende Einüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

Das Produkt in der Originalverpackung an einem Ort lagern, der die

oben gelisteten Bedingungen erfüllt. Wenn die Originalverpackung nicht

vorhanden ist und bei längerer Einlagerung (mehr als 30 Tage) einen

Beutel mit Trocknungsmittel der Verpackung beilegen.

DE

14294094.01 10/2019 EN/DE/FR/ES

WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

35

Page 36

5. Inbetriebnahme, Betrieb

5. Inbetriebnahme, Betrieb

Personal: Fachpersonal

Werkzeug und Befestigungsmaterial:

■

Drehmomentschlüsselsatz, Gabelschlüsselsatz (17 ... 32 mm)

■

Inbusschlüsselsatz

■

Schraubendreher

DE

■

Geeignete Schmiermittel für Dichtelemente und Schraubbolzen

■

Geeignete Dichtungswerkstoe für Gewindeanschlüsse

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige Produkt hinsichtlich Einsatzbedingungen, Ausführung und spezischen Messbedingungen ausgewählt wurde.

Nur Originalteile verwenden.

Zur Inbetriebnahme von Zubehör unbedingt die jeweilige Montage- und

Betriebsanleitung beachten.

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch

gefährliche Messstoe

Bei Kontakt mit gefährlichen Messstoen (z. B. bei brennbaren oder giftigen Stoen), gesundheitsgefährdenden

Messstoen (z. B. ätzend, giftig, krebserregend, radioaktiv)

besteht die Gefahr von Körperverletzungen, Sach- und

Umweltschäden.

Am Produkt können aggressive Messstoe mit extremer

Temperatur und unter hohem Druck anliegen.

▶

Bei diesen Messstoen müssen über die gesamten

allgemeinen Regeln hinaus die einschlägigen Vorschriften

beachtet werden.

▶

Notwendige Schutzausrüstung tragen (siehe Kapitel 3.6

„Persönliche Schutzausrüstung“).

36 WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

14294094.01 10/2019 EN/DE/FR/ES

Page 37

5. Inbetriebnahme, Betrieb

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch

unter hohem Druck austretende Messstoe

Bei der Druckbeaufschlagung des Produktes kann aufgr-

und schlechter Abdichtung der Anschlüsse Messsto unter

hohem Druck entweichen.

Durch die hohe Energie des im Fehlerfall austretenden

Messstoes besteht die Gefahr von Körperverletzungen und

Sachschäden.

▶

Die Abdichtung der Anschlüsse muss fachgerecht

ausgeführt und auf Dichtheit überprüft werden.

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch

unsachgemäße Handhabung

Falsches Önen oder Schließen eines Ventils kann zum

Austreten von Messstoen führen.

▶

Der Bediener muss sich vor dem Ändern einer bestimmten Ventilstellung der daraus folgenden Konsequenzen

bewusst sein.

5.1 Montage

■

Beim Auspacken alle Teile auf äußerliche Beschädigungen überprüfen. Bei notwendiger Rücksendung die Hinweise unter Kapitel

8.2 „Rücksendung“ beachten.

■

Sicherstellen, dass sämtliche nicht verwendeten Verbindungen

verschlossen sind. Verschlussschrauben für Entlüftungsanschlüsse

im Lieferumfang enthalten, jedoch nicht vormontiert.

■

Das Ventil darf nur am Ventilgehäuse getragen werden, nicht am Gri

■

Überprüfen Sie die Produktkennzeichnung auf Richtigkeit (siehe

Kapitel 3.7 „Beschilderung, Sicherheitskennzeichnung“).

■

Vor der Montage sicherstellen, dass die Prozessleitung mit dem

Hauptventil drucklos gemacht wurde.

■

Das Messgerät am richtigen Anschluss montieren. Sicherstellen,

dass der Durchussrichtungspfeil vom Prozessanschluss in Richtung

Messgerät zeigt.

14294094.01 10/2019 EN/DE/FR/ES

WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

DE

37

Page 38

5. Inbetriebnahme, Betrieb

■

Die Schutzkappen der benötigten Prozessanschlüsse entfernen.

■

Sicherstellen, dass die Dichtächen sauber sind und keine mechanische Beschädigung aufweisen.

■

Für den jeweiligen Anschluss muss das richtige Dichtelement

verwendet werden.

Gewindeanschluss

DE

Zum Einschrauben von Gewindeanschlüssen darf das entsprechende

Werkzeug nur durch die dafür vorgesehenen Schlüsselächen aufgebracht werden.

Das Anzugsdrehmoment ist abhängig vom verwendeten Prozessanschluss und Dichtelement.

Flanschanschluss

Zutreende Typen: IV20, IV21, IV30, IV31, IV50, IV51

Nur die im Lieferumfang enthaltenen Schraubbolzen und Dichtringe

verwenden:

Typen IV20, IV21: 2 Schraubbolzen, 1 Dichtring

Typen IV30, IV31, IV50, IV51: 4 Schraubbolzen, 2 Dichtringe

Anweisungen zur korrekten Montage von

Prozessanschlüssen nden Sie in den entsprechenden

Normen, z. B. IEC 61518

1. Instrument für die Ventilmontage auf der Werkbank befestigen.

2. Eine kleine Menge Fett auf die Schraubbolzen auftragen.

3. Eine kleine Menge Fett auf jeden Dichtring auftragen, damit dieser

nicht verrutschen kann.

4. Den Ventilblock auf dem Gerät positionieren.

5. Zwei Zentrierstifte einander gegenüber einsetzen, um die Montage

der Flanschverbindungen mit 4 Schraubbolzen zu erleichtern.

6. Zwei Schraubbolzen eindrehen und mit der Hand anziehen.

7. Gegebenenfalls die beiden zuvor verwendeten Zentrierstifte entfernen.

8. Dann die beiden anderen Schraubbolzen eindrehen und mit der

Hand anziehen.

9. Mit dem Drehmomentschlüssel die einander gegenüberliegenden

Schraubbolzen mit einem Anfangsdrehmoment von 34 Nm anziehen.

38 WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

14294094.01 10/2019 EN/DE/FR/ES

Page 39

5. Inbetriebnahme, Betrieb

10. Mit Hilfe des Drehmomentschlüssels die einander gegenüberliegenden Schraubbolzen mit dem materialabhängigen Enddrehmoment

nachziehen.

Enddrehmoment für CrNi-Stahl: 72 Nm.

Enddrehmoment für Kohlenstostahl: 87 Nm.

5.2 Inbetriebnahme und Betrieb

Zum Schließen des Ventils den Gri im Uhrzeigersinn bis zum Anschlag

drehen. Zum Önen des Ventils den Gri gegen den Uhrzeigersinn

bis zum Anschlag drehen. Um von der geöneten in die geschlossene

Stellung und umgekehrt zu wechseln, sind ungefähr 4 Umdrehungen

notwendig.

Der Durchuss kann gesteuert werden, indem das Ventil nicht vollständig geönet/geschlossen wird.

Bitte beachten, dass der Gri im drucklosen Zustand ein

leichtes Spiel aufweisen und sich bis zu einer Vierteldrehung

frei drehen kann. Diese Eigenschaft ist konstruktionsbedingt.

■

Das Ventil, insbesondere der Gri, darf von außen keinerlei Belastungen ausgesetzt werden (z. B. Nutzung als Steighilfe, Ablage von

Gegenständen).

■

Der Gri darf nur mit der Hand bedient werden; Werkzeuge dürfen

nicht verwendet werden.

■

Das Drehmoment beim Erreichen des Ventilanschlags darf nur

handfest sein.

■

Sicherstellen, dass alle Ventile des Produkts geschlossen sind, bevor

das Hauptventil der Prozessleitung geönet wird.

DE

14294094.01 10/2019 EN/DE/FR/ES

WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

39

Page 40

5. Inbetriebnahme, Betrieb

Typen IV10, IV11, IV20, IV21

Typ IV10 Typ IV11 Typen IV20, IV21

DE

Zur Vermeidung von Druckstößen das Absperrventil (blau) langsam

önen.

Der Druck ist nun am Geräteanschluss vorhanden.

Typen IV30, IV31

1. Ausgleichsventil önen (grün).

2. Zur Vermeidung von Druckstößen die Absperrventile (blau) langsam

önen.

Der Druck ist nun am Geräteanschluss vorhanden.

3. Ausgleichsventil schließen (grün).

40 WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

14294094.01 10/2019 EN/DE/FR/ES

Page 41

5. Inbetriebnahme, Betrieb / 6. Störungen

Typen IV50, IV51

1. Entlüftungsventile (rot) schließen.

2. Ausgleichsventil önen (grün).

3. Zur Vermeidung von Druckstößen die Absperrventile (blau) langsam

önen.

Der Druck ist nun am Geräteanschluss vorhanden.

4. Ausgleichsventil schließen (grün).

6. Störungen

In der folgenden Tabelle sind die häugsten Fehlerursachen

und erforderliche Gegenmaßnahmen aufgeführt.

Störungen Ursachen Maßnahmen

Gri

schwergängig

Leckage an der

Spindel

14294094.01 10/2019 EN/DE/FR/ES

WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

Schmierproblem aufgrund

einer über längere Zeit

unveränderten Ventilstellung

Defekte Teile aufgrund

von Korrosion,

Prozessbedingungen, Alter

Stopfbuchsenmutter zu stark

angezogen, defekte Dichtpackung

Undichte Dichtpackung Siehe Kapitel 7.2

Funktionstest wie in

Kapitel 7.1 „Wartung

beschrieben durchführen

und eventuell das

Inspektionsintervall

verkürzen

Produkt ersetzen

Produkt ersetzen

„Instandsetzung“

DE

”

41

Page 42

6. Störungen

Störungen Ursachen Maßnahmen

Kein oder

eingeschränkter

Durchuss der

Prozessmedien

DE

Können Störungen mit Hilfe der aufgeführten Maßnahmen

nicht beseitigt werden, Produkt unverzüglich außer Betrieb

setzen.

Bei Kontakt mit gefährlichen Messstoen (z. B. Sauersto,

Acetylen, brennbaren oder giftigen Stoen), gesundheitsgefährdenden Messstoen (z. B. ätzend, giftig, krebserre-

gend, radioaktiv) sowie bei Kälteanlagen, Kompressoren

besteht die Gefahr von Körperverletzungen, Sach- und

Umweltschäden.

Am Produkt können im Fehlerfall aggressive Messstoe mit

extremer Temperatur und unter hohem Druck oder Vakuum

anliegen.

42 WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

Ventil geschlossen oder

teilweise oen

Fehlerhafte Montage Sicherstellen, dass das

Verstopfung durch

ungeeignete Prozessmedien

Sicherstellen, dass das

Ventil geönet ist

Ventil richtig montiert ist

Kompatibilität der

Prozessmedien

überprüfen

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden

▶

Sicherstellen, dass kein Druck mehr anliegt und gegen

versehentliche Inbetriebnahme schützen.

▶

Kontakt mit dem Lieferanten aufnehmen.

▶

Bei notwendiger Rücksendung die Hinweise unter Kapitel

8.2 “Rücksendung” beachten.

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch

gefährliche Messstoe

▶

Bei diesen Messstoen müssen über die gesamten

allgemeinen Regeln hinaus die einschlägigen Vorschriften

beachtet werden.

▶

Notwendige Schutzausrüstung tragen (siehe Kapitel 3.6

„Persönliche Schutzausrüstung“).

14294094.01 10/2019 EN/DE/FR/ES

Page 43

7. Wartung, Instandsetzung und Reinigung

7. Wartung, Instandsetzung und Reinigung

7.1 Wartung

Die Ventile arbeiten bei bestimmungsgemäßem Gebrauch wartungsfrei.

Sie sind im Rahmen der regulären Wartung zu überprüfen.

Kontrollintervall

Abhängig von dem Prozess, den Umgebungsbedingungen und der

Anzahl der Betätigungen können die Kontrollintervalle zwischen täglich

oder mehreren Wochen liegen.

Empfohlenes Kontrollintervall: ≤ 3 Monate

Kontrollcheckliste

1. Dichtheitsprüfung der Prozess- und Geräteanschlüsse

2. Dichtheitsprüfung zwischen Ventiloberteil und Ventilgehäuse

3. Funktionstest im Hinblick auf korrektes Önen und Schließen

Bei einem negativen Ergebnis der Dichtheitsprüfung von Punkt 2 die im

Folgenden beschriebene Justage der Dichtpackung durchführen.

7.2 Instandsetzung

Justage der Dichtpackung

Diese Justage ist erforderlich, wenn direkt unter dem Gri eine Leckage

an der Ventilspindel zu erkennen ist oder wenn während des Betriebs

kein Drehmoment oder Widerstand bei Drehung des Gries vorhanden

ist.

1. Kontermutter lösen

2. Packungskompression mit einem Drehmoment von ≥ 13 … ≤ 18 Nm

(18 … 25 lbs ft) auf die Stopfbuchsenmutter erhöhen

3. Stopfbuchsenmutter mit der Kontermutter xieren

DE

Wenn das Problem der Leckage nach der Justage der Dichtpackung

weiterhin besteht, muss eine Rücksendung zur Reparatur beauftragt

werden.

Die Funktion des Produktes kann nur bei Verwendung von

Originalzubehör und Ersatzteilen gewährleistet werden.

14294094.01 10/2019 EN/DE/FR/ES

WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

43

Page 44

7. Wartung, Instandsetzung und Reinigung

7.3 Reinigung

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden

Eine unsachgemäße Reinigung führt zu Körperverletzungen,

Sach- und Umweltschäden. Messstoreste im ausgebauten

DE

1. Vor der Reinigung das Produkt ordnungsgemäß vom Prozess trennen.

2. Das Produkt vorsichtig mit einem feuchten Tuch reinigen.

Produkt können zur Gefährdung von Personen, Umwelt und

Einrichtung führen.

▶

Ausgebautes Produkt spülen bzw. säubern.

▶

Ausreichende Vorsichtsmaßnahmen ergreifen.

VORSICHT!

Sachbeschädigung

Eine unsachgemäße Reinigung führt zur Beschädigung des

Produktes!

▶

Keine aggressiven Reinigungsmittel verwenden.

▶

Keine harten und spitzen Gegenstände zur Reinigung

verwenden.

44 WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

14294094.01 10/2019 EN/DE/FR/ES

Page 45

8. Demontage, Rücksendung und Entsorgung

8. Demontage, Rücksendung und Entsorgung

8.1 Demontage

Vor Beginn der Demontage sicherstellen, dass das Hauptventil der

Prozessleitung geschlossen ist.

WARNUNG!

Verbrennungsgefahr

Beim Ausbau besteht Gefahr durch austretende, gefährlich

heiße Messstoe.

▶

Vor dem Ausbau das Produkt ausreichend abkühlen

lassen!

WARNUNG!

Körperverletzung

Bei der Demontage besteht Gefahr durch aggressive Messst-

oe und hohe Drücke.

▶

Notwendige Schutzausrüstung tragen (siehe Kapitel 3.6

„Persönliche Schutzausrüstung“).

▶

Angaben im Sicherheitsdatenblatt für den entsprechenden

Messsto beachten.

▶

Ventil nur im drucklosen Zustand demontieren.

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch

Messstoreste

Bei Kontakt mit gefährlichen Messstoen (z. B. Sauersto,

Acetylen, brennbaren oder giftigen Stoen), gesundheitsgefährdenden Messstoen (z. B. ätzend, giftig, krebserre-

gend, radioaktiv) sowie bei Kälteanlagen, Kompressoren

besteht die Gefahr von Körperverletzungen, Sach- und

Umweltschäden.

▶

Notwendige Schutzausrüstung tragen (siehe Kapitel 3.6

„Persönliche Schutzausrüstung“).

▶

Angaben im Sicherheitsdatenblatt für den entsprechenden

Messsto beachten.

▶

Vor der Einlagerung das ausgebaute Produkt (nach

Betrieb) spülen bzw. säubern, um Personen und Umwelt

vor Gefährdung durch anhaftende Messstoreste zu

14294094.01 10/2019 EN/DE/FR/ES

WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

schützen.

DE

45

Page 46

8. Demontage, Rücksendung und Entsorgung

Typen IV10, IV11

1. Zur Vermeidung von Druckstößen das Absperrventil (blau) langsam

schließen.

2. Wenn das Ventil mit einem Entlüftungsanschluss ausgestattet ist,

diesen mit einem geeigneten Werkzeug önen. Verschlussschraube/

Entlüftungsschraube (falls vorhanden) entfernen.

Das Ventil kann nun demontiert werden.

DE

Typen IV20, IV21

1. Zur Vermeidung von Druckstößen das Absperrventil (blau) langsam

schließen.

2. Den Entlüftungsanschluss mit einem geeigneten Werkzeug önen.

Verschlussschraube/Entlüftungsschraube (falls vorhanden)

entfernen.

3. Entlüftungsventil (rot) langsam önen, um das Ventil drucklos zu

machen.

Das Ventil kann nun demontiert werden.

Typen IV30, IV31, IV50, IV51

Entlüften (rot)

Nur Typen IV5x

Absperren

(blau)

Ausgleichen

(grün)

Absperren

(blau)

Entlüften (rot)

Nur Typen IV5x

1. Ausgleichsventil önen (grün).

2. Zur Vermeidung von Druckstößen die Absperrventile (blau) langsam

schließen.

3. Verschlussschrauben/Entlüftungsschrauben (falls vorhanden)

entfernen.

4. Nur bei den Typen IV5x: Entlüftungsventile (rot) langsam önen.

Das Ventil kann nun demontiert werden.

46 WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

14294094.01 10/2019 EN/DE/FR/ES

Page 47

8. Demontage, Rücksendung und Entsorgung

8.2 Rücksendung

Beim Versand des Produktes unbedingt beachten:

Alle an WIKA gelieferten Produkte müssen frei von Gefahrstoen

(Säuren, Laugen, Lösungen, etc.) sein und sind daher vor der Rücksendung zu reinigen.

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch

Messstoreste

Messstoreste im ausgebauten Produkt können zur Gefährdung von Personen, Umwelt und Einrichtung führen.

▶

Bei Gefahrstoen das Sicherheitsdatenblatt für den

entsprechenden Messsto beilegen.

▶

Gerät reinigen, siehe Kapitel 7.2 „Reinigung“.

Zur Rücksendung des Produktes die Originalverpackung oder eine

geeignete Transportverpackung verwenden.

Hinweise zur Rücksendung benden sich in der Rubrik

„Service“ auf unserer lokalen Internetseite.

8.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Produktkomponenten und Verpackungsmaterialien entsprechend den

landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften

umweltgerecht entsorgen.

14294094.01 10/2019 EN/DE/FR/ES

WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

DE

47

Page 48

9. Technische Daten

9. Technische Daten

Eine Abbildung der Positionen der nachfolgend genannten Teile nden

Sie in Kapitel 2.1 „Funktionsbeschreibung“.

Spezikation

Spindelspitze Nichtdrehend, verschleißarm

DE

Ventilsitz Metallsitz

Ventilbohrungsgröße 4 mm (0,16 in)

Werksto Standard Option

Messstoberührte Teile

■

Ventilgehäuse CrNi-Stahl 316/316L

Ventiloberteil-Ge-

häuse

Spindelspitze

Dichtpackung PTFE Graphit

Nicht-messstoberührte Teile

Gri CrNi-Stahl 304 CrNi-Stahl 316/316L

Stopfbuchsenmutter CrNi-Stahl 316/316L

Kontermutter

Ventilspindel

Dichtbuchse

Monel 400

■

Hastelloy 276

■

Weitere auf Anfrage

48 WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

14294094.01 10/2019 EN/DE/FR/ES

Page 49

9. Technische Daten

Einsatzbedingungen

Dichtungswerksto Max. zulässiger Betriebsdruck in bar bei

Temperatur in °C

PTFE 689 bar bei 38 °C

276 bar bei 204 °C

Graphit 420 bar bei 38 °C

209 bar bei 538 °C

DE

Dichtungswerksto Max. zulässiger Betriebsdruck in psi bei

Temperatur in °F

PTFE 10.000 psi bei 100 °F

4.000 psi bei 400 °F

Graphit 6.000 psi bei 100 °F

3.030 psi bei 1.000 °F

Die minimale Auslegungstemperatur beträgt -54 °C (-65 °F).

Für dauerhaft niedrige Betriebstemperaturen von ≤ -54 °C (≤ -65 °F) ist

eine spezielle Ausführung erforderlich.

Mit Hilfe des folgenden Diagramms muss sichergestellt sein, dass

während des Betriebes die zulässige Druck-Temperatur-Zuordnung in

Abhängigkeit des eingesetzten Dichtungswerkstoes eingehalten wird.

Weitere technische Daten siehe Datenblätter AC 09.19, AC 09.21,

AC 09.23.

14294094.01 10/2019 EN/DE/FR/ES

WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

49

Page 50

9. Technische Daten

Druck-Temperatur-Diagramm

700

(10153)

DE

600

(8702)

500

(7252)

400

(5802)

300

(4351)

Druck in bar (psi)

200

(2901)

100

(1450)

0

PTFE

Graphit

Temperatur in °C (°F)

50 WIKA-Betriebsanleitung Absperrventile und Ventilblöcke

14294094.01 10/2019 EN/DE/FR/ES

Page 51

Sommaire

Sommaire

1. Généralités 52

2. Conception et fonction 53

3. Sécurité 54

4. Transport, emballage et stockage 59

5. Mise en service, utilisation 60

6. Dysfonctionnements 65

7. Entretien, réparation et nettoyage 67

8. Démontage, retour et mise au rebut 69

9. Spécications 72

FR

14294094.01 10/2019 EN/DE/FR/ES

Mode d'emploi WIKA pour vannes d'arrêt et manifolds

51

Page 52

1. Généralités

1. Généralités

■

Les vannes décrites dans le mode d'emploi sont conçues et

fabriquées selon les dernières technologies en vigueur. Tous les

composants sont soumis à des exigences environnementales et de

qualité strictes durant la fabrication. Nos systèmes de gestion sont

certiés selon ISO 9001.

■

Ce mode d'emploi donne des indications importantes concernant

l'utilisation du produit. Il est possible de travailler en toute sécurité

FR

avec ce produit en respectant toutes les consignes de sécurité et

d'utilisation.

■

Respecter les prescriptions locales de prévention contre les

accidents et les prescriptions générales de sécurité en vigueur pour

le domaine d'application du produit.

■

Le mode d'emploi fait partie de l'instrument et doit être conservé à

proximité immédiate de la vanne et accessible à tout moment pour

le personnel qualié. Coner le mode d'emploi à l'utilisateur ou

propriétaire ultérieur du produit.

■

Le personnel qualié doit, avant de commencer toute opération, avoir

lu soigneusement et compris le mode d'emploi.

■

Les conditions générales de vente mentionnées dans les documents

de vente s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site Internet : www.wika.fr

- Fiches techniques correspondantes : AC 09.19, AC 09.22,

AC 09.23

52 Mode d'emploi WIKA pour vannes d'arrêt et manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 53

2. Conception et fonction

2. Conception et fonction

2.1 Description fonctionnelle

Les produits décrits ci-dessous sont munis de robinets intégrés

permettant la fermeture, la mise à l'atmosphère et la compensation des

pressions de process pour des instruments de mesure de pression. Vous

trouverez les fonctions des types décrits ici dans le tableau à la page

suivante.

Chapeau de vanne (version standard)

Poignée en T

Capuchon anti-poussière de

Ecrou de presse-étoupe

Contre-écrou

Tige de vanne

Presse-étoupe d'étanchéité

Garniture d'étanchéité

Corps du chapeau de vanne

Extrémité de la tige

1)

couleur

Corps

Broche de verrouillage

1) En option, d'autres exécutions de poignée sont disponibles

14294094.01 10/2019 EN/DE/FR/ES

Mode d'emploi WIKA pour vannes d'arrêt et manifolds

Code couleur du capuchon

anti poussière

Bleu : fermeture

Rouge : mise à l'atmosphère

Vert : compenser

Joint d'étanchéité

FR

53

Page 54

2. Conception et fonction / 3. Sécurité

Type Nombre de robinets

Fermeture Mise à

l'atmosphère

IV10 1 - -

IV11 1 - -

IV20, IV21 1 1 -

IV30, IV31 2 - 1

IV50, IV51 2 2 1

FR

1) Mise à l'atmosphère avec robinet, pour d'autres options de mise à l'atmosphère, (par exemple par vis de mise

à l'atmosphère), voir che technique

1)

Compenser

2.2 Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

3. Sécurité

3.1 Explication des symboles

DANGER !

... indique une situation dangereuse pouvant entraîner la mort

ou des blessures graves si elle n'est pas évitée.

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles

de provoquer la mort ou des blessures graves si elle n'est pas

évitée.

ATTENTION !

… indique une situation potentiellement dangereuse et

susceptible de provoquer de légères blessures ou des

dommages matériels et pour l'environnement si elle n'est pas

évitée.

Information

... met en exergue les conseils et recommandations utiles de

même que les informations permettant d'assurer un fonction-

nement ecace et normal.

54 Mode d'emploi WIKA pour vannes d'arrêt et manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 55

3. Sécurité

3.2 Utilisation conforme à l'usage prévu

Ces vannes sont utilisées pour isoler des instruments de mesure du

process au moyen de fonctions de fermeture, de mise à l'atmosphère et

de compensation de pression. Elles sont conçues pour un emploi dans

des applications avec des uides gazeux et liquides propres qui ne sont

pas hautement visqueux ni cristallisants.

Le produit doit seulement être utilisé avec des uides qui ne sont pas

nocifs pour les parties en contact avec le uide sur la totalité de la plage

de fonctionnement de l'instrument. Tout changement d'état de la matière

ou toute décomposition de uides instables sont interdits.

Utiliser le produit uniquement dans des applications qui se trouvent dans

les limites de ses performances techniques (par exemple température

ambiante maximale, compatibilité de matériau, ...).

→ Pour les limites de performance, voir chapitre 9 “Spécications”.

En cas d'utilisation non conforme ou de fonctionnement du produit en

dehors des spécifications techniques, un arrêt et contrôle doivent être

immédiatement effectués par un collaborateur autorisé du service.

Ces vannes n'ont pas leur source d'ignition de potentiel propre. La

responsabilité d'un usage en toute sécurité en zone explosive en

conformité avec les standards technologiques reconnus incombe à

l'opérateur.

Pour les raisons mentionnées ci-dessus, ces vannes ne sont pas

marquées et ne possèdent pas de certification propre.

Le produit est conçu et construit exclusivement pour une utilisation

conforme à l'usage prévu décrit ici, et ne doit être utilisé qu'à cet effet.

FR

Aucune réclamation ne peut être recevable en cas d'utilisation non

conforme à l'usage prévu.

3.3 Utilisation inappropriée

On dénit un usage impropre comme étant toute application qui excède

les limites techniques de performance ou étant incompatible avec les

matériaux.

14294094.01 10/2019 EN/DE/FR/ES

Mode d'emploi WIKA pour vannes d'arrêt et manifolds

55

Page 56

3. Sécurité

AVERTISSEMENT !

Blessures causées par une utilisation inappropriée

Une utilisation inappropriée du produit peut conduire à des

situations dangereuses et à des blessures.

▶

S'abstenir de modifications non autorisées sur le produit.

▶

Ne pas utiliser le produit avec un fluide abrasif ou

visqueux.

Toute utilisation diérente ou au-delà de l'utilisation prévue est

considérée comme inappropriée.

FR

3.4 Responsabilité de l'opérateur

Le produit est prévu pour un usage dans le domaine industriel.

L'opérateur est de ce fait responsable des obligations légales en matière

de sécurité du travail.

Les instructions de sécurité de ce mode d'emploi comme les réglementations liées à la sécurité, à la prévention des accidents et à la protection

de l'environnement pour le domaine d'application doivent être respectées.

L'opérateur doit s'assurer que la plaque signalétique reste lisible.

An de travailler en toute sécurité sur le produit, la société exploitante

doit s'assurer que les points suivants sont respectés :

■

Le personnel opérationnel est formé à intervalles réguliers sur tous

les sujets concernant la sécurité du travail, les premiers secours et

la protection de l'environnement et il connaît le mode d'emploi et

particulièrement les consignes de sécurité contenues dans celui-ci.

■

Le personnel opérationnel doit avoir lu le mode d'emploi et pris note

des instructions de sécurité qu'il contient.

■

L'utilisation prévue de l'application a été respectée.

■

A la suite des essais, une utilisation impropre du produit est exclue.

56 Mode d'emploi WIKA pour vannes d'arrêt et manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 57

3. Sécurité

3.5 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante

Une utilisation non conforme peut entraîner d'importants

dommages corporels et matériels.

▶

Les opérations décrites dans ce mode d'emploi ne doivent

être eectuées que par un personnel ayant la qualication

décrite ci-après.

Personnel qualié

Le personnel qualié, autorisé par l'opérateur, est, en raison de sa

formation spécialisée, de ses connaissances dans le domaine de

l'instrumentation de mesure et de régulation et de son expérience,

de même que de sa connaissance des réglementations nationales et

des normes en vigueur, en mesure d'eectuer les travaux décrits et

d'identier de façon autonome les dangers potentiels.

Personnel opérationnel

Le personnel formé par l'opérateur est, en raison de sa formation et de

son expérience en mesure d'eectuer les travaux décrits et de reconnaître de façon autonome les dangers potentiels.

Les conditions d'utilisation spéciales exigent également une connaissance adéquate, par ex. des liquides agressifs.

3.6 Equipement de protection individuelle

L'équipement de protection individuelle sert à protéger le personnel

qualié contre les dangers pouvant entraver la sécurité et la santé de ce

dernier durant le travail. Le personnel qualié doit porter l'équipement

de protection individuelle lors de l'exécution des diérents travaux sur et

avec le produit.

FR

Respecter les indications concernant l'équipement de protection

individuelle dans la zone de travail !

L'équipement de protection individuelle requis doit être mis à disposition

par l'utilisateur.

14294094.01 10/2019 EN/DE/FR/ES

Mode d'emploi WIKA pour vannes d'arrêt et manifolds

57

Page 58

3. Sécurité

3.7 Etiquetage, marquages de sécurité

Marquage de produit

FR

Numéro d'article

Type

Numéro d'identication

Description d'article (dénition du letage, matériau, etc.)

Pression de service admissible

Informations concernant la traçabilité du produit (date de production, numéro de lot, etc.)

Schéma de fonctionnement

Sens de l'écoulement

58 Mode d'emploi WIKA pour vannes d'arrêt et manifolds

14294094.01 10/2019 EN/DE/FR/ES

Page 59

4. Transport, emballage et stockage

4. Transport, emballage et stockage

4.1 Transport

Vérier si le produit a été endommagé pendant le transport. Communiquer immédiatement les dégâts constatés.

ATTENTION !

Un transport inapproprié peut donner lieu à des

dommages importants.

▶

Lors du déchargement des colis à la livraison comme lors

du transport des colis en interne après réception, il faut

procéder avec soin.

▶

Lors du transport en interne après réception, observer les

instructions du chapitre 4.2 “Emballage et stockage”.

4.2 Emballage et stockage

N'enlever l'emballage qu'avant la mise en service.

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection

optimale (par ex. changement de lieu d'utilisation, renvoi pour

réparation).

Conditions admissibles sur le lieu de stockage :

■

Température de stockage : 0 ... 70 °C

■

Humidité : 35 ... 85 % d'humidité relative (sans condensation)

Eviter les inuences suivantes :

■

Lumière solaire directe ou proximité d'objets chauds

■

Vibrations mécaniques, chocs mécaniques (mouvements brusques

en le posant)

■

Suie, vapeur, poussière et gaz corrosifs

■

Environnements dangereux, atmosphères inammables

FR

Conserver le produit dans l'emballage original dans un endroit qui satisfait aux conditions susmentionnées. Si l'emballage d'origine n'est pas

disponible et si le produit est entreposé pendant une période prolongée

(plus de 30 jours), mettre également un sachet absorbeur d'humidité

dans l'emballage.

14294094.01 10/2019 EN/DE/FR/ES

Mode d'emploi WIKA pour vannes d'arrêt et manifolds

59

Page 60

5. Mise en service, utilisation

5. Mise en service, utilisation

Personnel : personnel qualié

Outillage et matériel d'installation

■

Jeu de clés dynamométriques, jeu de clés plates (17 ... 32 mm)

■

Jeu de clés à six pans creux

■

Tournevis

■

Lubriants adéquats pour les éléments d'étanchéité et les boulons

■

Matériau d'étanchéité adéquat pour les raccords letés

FR

Avant le montage, la mise en service et le fonctionnement, s'assurer que

le produit a été choisi de façon adéquate, en ce qui concerne l'étendue

de mesure, la version et les conditions de mesure spéciques.

Utiliser uniquement des pièces d'origine.

Toujours respecter le manuel d'installation et le mode d'emploi des

accessoires avant de les mettre en service.

AVERTISSEMENT !

Blessures physiques et dommages aux équipements et