Page 1

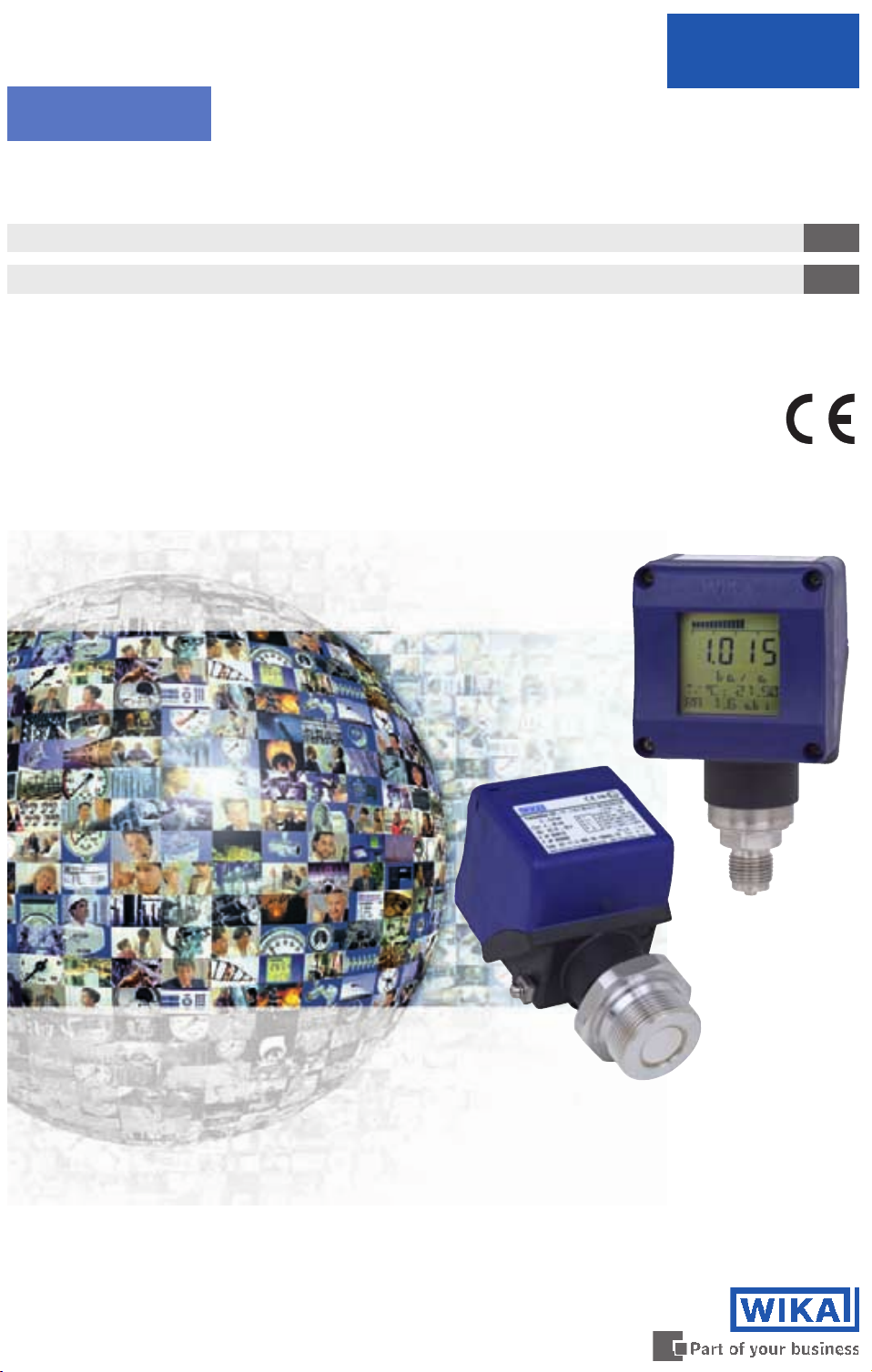

IUT-10 / IUT-11

Operating instructions

Betriebsanleitung

Universal transmitter for applications in hazardous environments

GB

GB

GBF

DUniversaltransmitter für den Einsatz in explosionsgefährdeten Bereichen

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/ Germany

Tel. (+49) 93 72/132-295

Fax (+49) 93 72/132-706

E-Mail support-tronic@wika.de

www.wika.de

IUT-10

IUT-11

Page 2

Universal IS Pressure Transmitter UniTrans

Contents

Contents

1 General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

2 Special Intrinsic Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . .80

2.1 Protection of diaphragm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

2.2 Special wiring advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

2.3 Connection to Zone 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

2.4 Special precaution for connection to Zone 0 and or Zone 20 . . . . . . . . . . . . . . . . 80

2.5 Instructions for temperature ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

2.6 Special instructions for dust explosion protection . . . . . . . . . . . . . . . . . . . . . . . . . 81

3 EC-Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

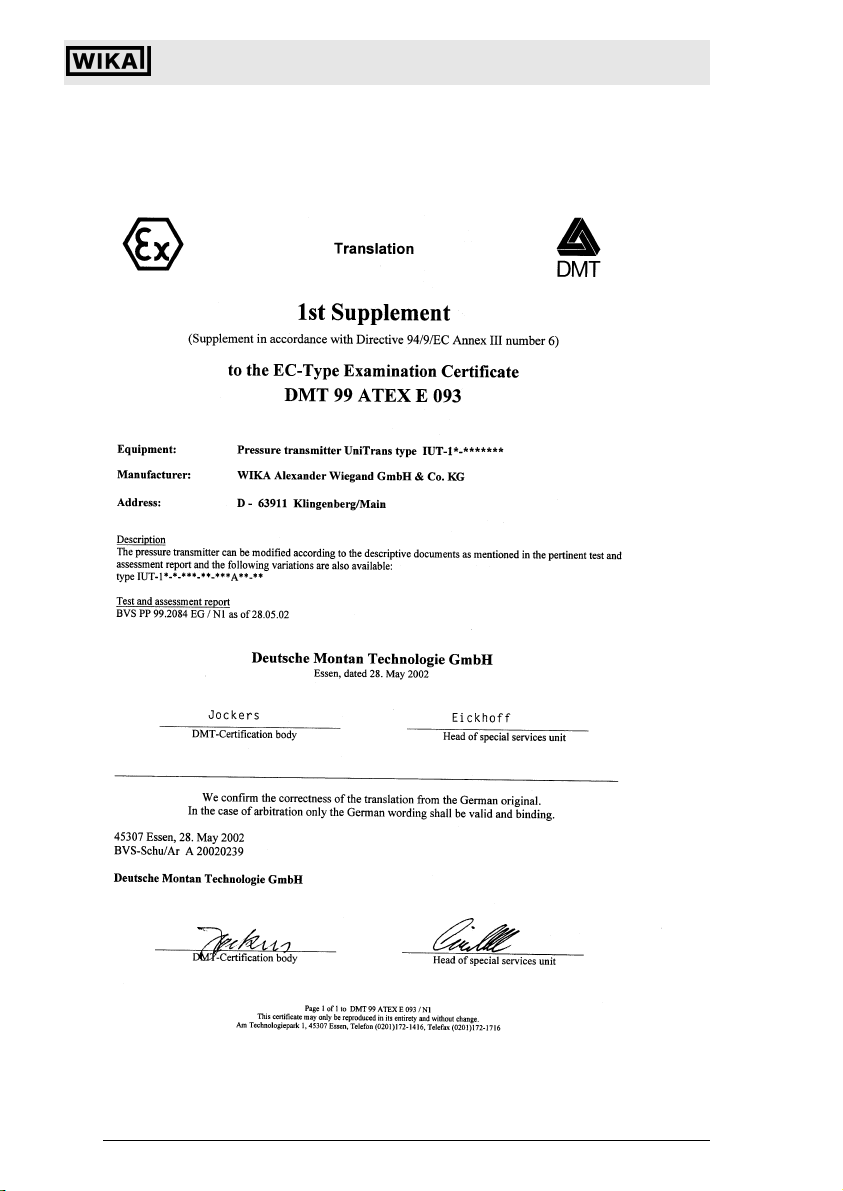

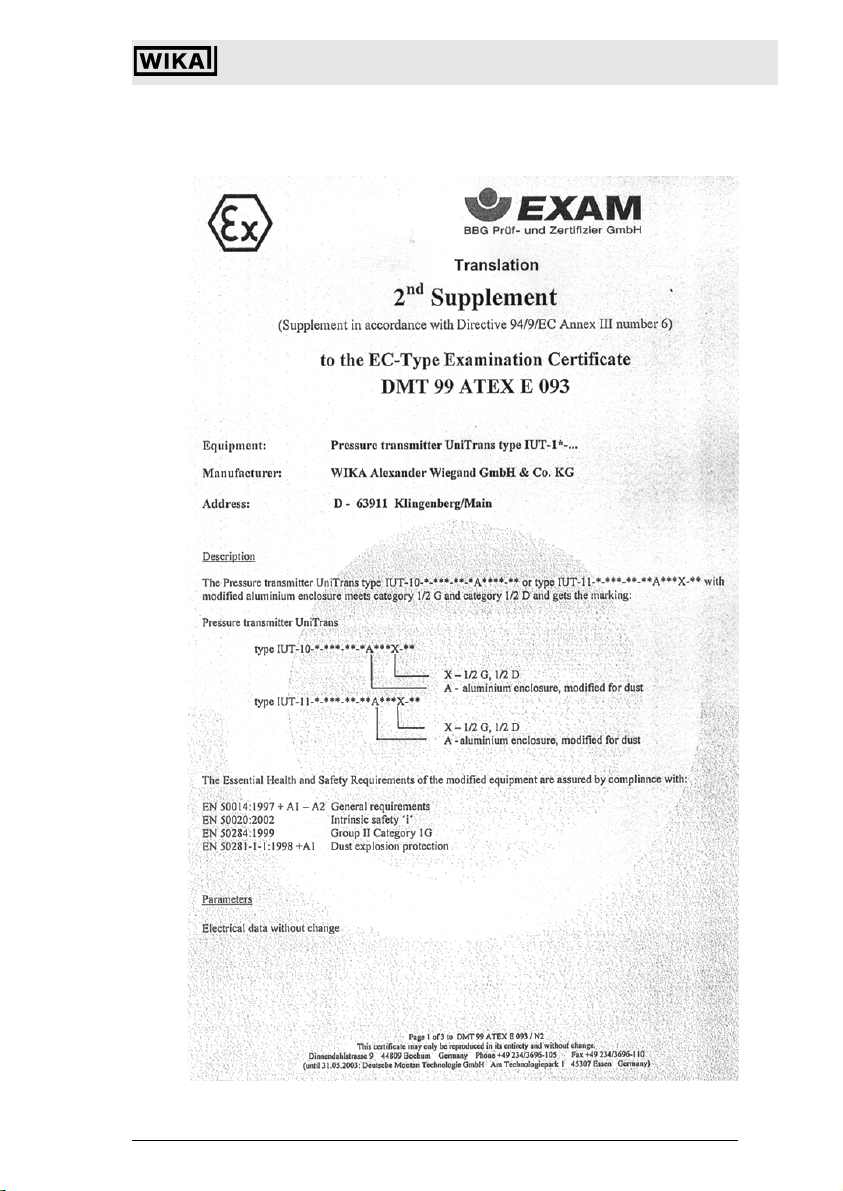

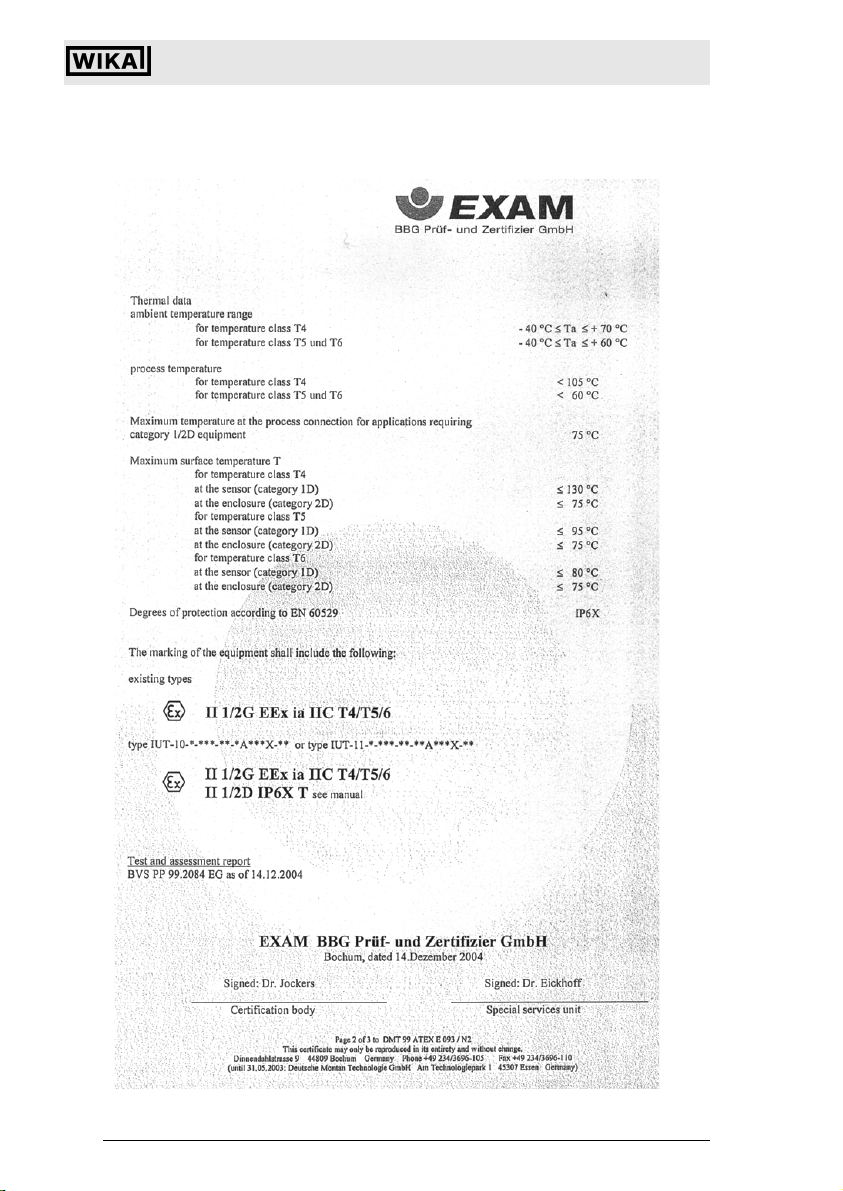

4 EC-Type Examination Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

5 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

5.1 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5.1.1 Pressure Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5.1.2 Processing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

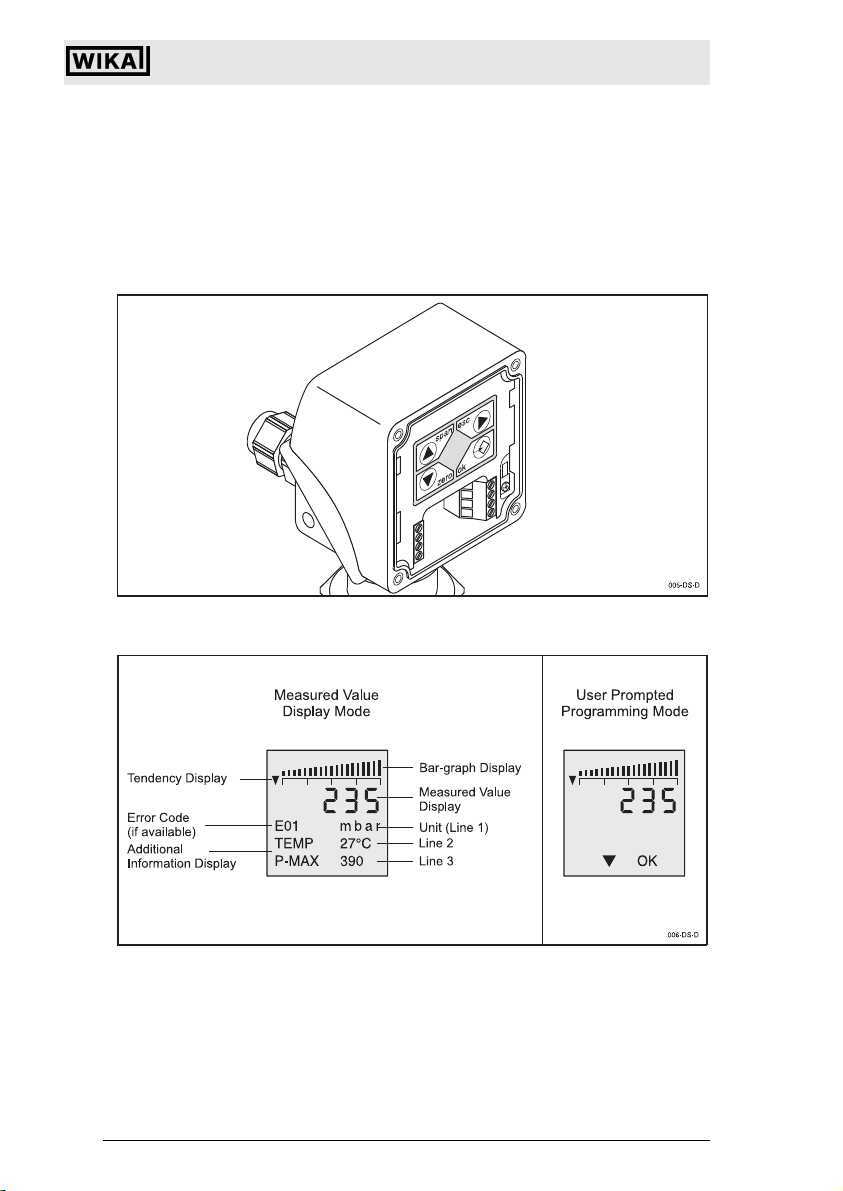

5.1.3 Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

5.2 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5.2.1 Functions of Transmitters without Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5.2.2 Functions of Transmitters with Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5.2.3 Functional features of transmitters with HART-Communication . . . . . . . . . . . . . 100

5.3 Installation Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.1 Input-values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.2 Output-values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.3 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.4 Auxilliary Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.5 Ambient Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.6 Process Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

6.7 Safety-related nominal values for IS protection conditions . . . . . . . . . . . . . . . . . 106

6.8 Product labels (example). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

7 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

7.1 Pressure Transmitter Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.2 Display Unit Upgrades. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.3 Housing Reconfiguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.4 Electrical Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

7.5 Pressure Compensation when using a Relative Pressure Sensor . . . . . . . . . . . 111

8 Operation of Devices without Displays . . . . . . . . . . . . . . . . . . . . . . .112

8.1 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

8.2 Key Functions (only for transmitters without display) . . . . . . . . . . . . . . . . . . . . . 112

2266939.05 D/GB 06/2006

8.3 Calibration with Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

77

Page 3

Universal IS Pressure Transmitter UniTrans

Contents

8.3.1 Zero Point Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

8.3.2 Span Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

8.4 Calibration without Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

8.4.1 Zero Point Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.4.2 Span Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.4.3 Mounting correction of the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.5 Integration Time (Damping) Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.6 Reset to Default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

9 Operation of Transmitters with Display. . . . . . . . . . . . . . . . . . . . . . . 118

9.1 The Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

9.2 Key Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

9.3 The Programming Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

9.4 Default Data (factory settings) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

9.5 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

9.5.1 Main Menu: Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

9.5.2 Main Menu: Calibration of zero and span (with / without pressure) . . . . . . . . . . . 124

9.5.3 Main Menu: Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

9.5.4 Main Menu: Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

9.5.5 Main Menu: Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

9.5.6 Main Menu: Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

10 Transmitter Operation with HART®-functionality . . . . . . . . . . . . . . 130

10.1 Possible HART® connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

10.1.1 Connection of the HART®- hand terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

10.1.2 Connecting the HART®-modem for PC operation . . . . . . . . . . . . . . . . . . . . . . . . 131

10.2 Operation via PC and the software PACTware‘ . . . . . . . . . . . . . . . . . . . . . . . . . . 132

10.2.1 Menu 'Device info'. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

10.2.2 Menu 'Description' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

10.2.3 Submenu 'Parameter' - Device info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

10.2.4 Submenu 'Parameter' - Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

10.2.5 Submenu 'Parameter' - Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

10.2.6 Submenu 'Parameter' - Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

10.2.7 Window 'Service'. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

10.2.8 Window 'Simulation' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

10.2.9 Window 'Measured value' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

10.2.10 Window 'Trend' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

10.2.11 Window 'Burst mode' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

10.2.12 Window 'Diagnosis'. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

11 Diagnostics and Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

12 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

13 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

13.1 Dimension Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

13.2 Model Key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

13.3 Warranty Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

13.4 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

13.5 Units of Pressure Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

78

2266939.05 D/GB 06/2006

Page 4

Universal IS Pressure Transmitter UniTrans

g

1 General Safety Instructions

• Select the appropriate pressure transmitter with regard to scale range,

performance and specific measurement conditions prior to installing and

Warnin

starting the instrument.

• Observe the relevant national regulations (e.g.: EN 50178, NEC, CEC)

and observe the applicable standards and directives for special

applications (e.g. with dangerous media such as oxygen, acetylene,

flammable gases or liquids and toxic gases or liquids and with

refrigeration plants or compressors).

If you do not observe the appropriate regulations, serious injuries

and/or damage can occur!

• Open pressure connections only after the system is without

pressure!

• Please make sure that the pressure transmitter is only used within the

overload threshold limit at all times!

• Observe the ambient and working conditions outlined in chapter 6

"Technical Data"

• Ensure that the pressure transmitter is only operated in accordance with

the provisions, i.e. as described in the following instructions.

• Do not interfere with or change the pressure transmitter in any other way

than described in these operating instructions...

• Remove the pressure transmitter from service and mark it to prevent it

from being used again accidentally, if it becomes damaged or unsafe for

operation..

• Take precautions with regard to remaining media in removed

pressure transmitter. Remaining media in the prsesure port may

be hazardous or toxic!

• Have repairs performed by the manufacturer only.

• Consider the details given in the EC-type examination certificate as well

as the respective specifications for explosion hazard use of the country

concerned (e.g.: IEC 60079, NEC, CEC). If you do not observe these

stipulations, serious injuries and/or damage can occur.

Other important safety guidelines can be found in the different sections of

this instruction manual.

Contents

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

79

Page 5

Universal IS Pressure Transmitter UniTrans

Special Intrinsic Safety Instructions

2 Special Intrinsic Safety Instructions

2.1 Protection of diaphragm

As soon as the diaphragm of an instrument gets damaged, absolutely no intrinsic

safety can be guaranteed any longer! Thus the diaphragm must not come in contact with abrasive substances! The diaphragm must be protected against pressure

Warning

peaks and must not be touched by tools! Information about material consistency

against corrosion and diffusion can be found in our WIKA Handbook, 'Pressure and

Temperature Measurement' (German: ISBN 3-9804074-0-3, English: ISBN 39804074-1-1).

2.2 Special wiring advice

The housing must always be connected to earth to protect the instrument against

electromagnetic fields and electrostatic charges.

Warning

The cables and wires must not be damaged.

Cables for applications in Zone 1 and 2 or Zone 21 and 22 must be checked with

a test voltage between conductor/earth, conductor/screen, screen/earth of more

than 500 V (AC).

Flying leads with fine wires must be covered by an end splice (cable preparation).

Both the internal capacity and inductivity must be considered.

Conductive screens may only be connected to earth one-sided and outside the

hazardous area.

2.3 Connection to Zone 0

(In general Zone 0 is given when the instrument is surrounded by a mixture of

explosive gases more than 1.000 hours per year = continuous hazard. The trans-

Warning

mitter may only be operated under Zone 0 conditions, as long as an atmospherical

pressure of 0.8 to 1.1 bar is guaranteed).

The circuits must be of type Ex ia.

The ingress protection must comply to IP 67 according to IEC 529.

2.4 Special precaution for connection to Zone 0 and or Zone 20

Make absolutely sure to follow the advice given in the IEC publication 60 529 for

connection to Zone 0 and/or Zone 20 for IP 67 pressure connections!

Warning

Warning

Installation in non-metallic vessels:

All metallic parts reaching into Zone 0 and/or Zone 20 must be grounded.

The intrinsically safe circuit must be decoupled from the regular circuit.

If the mounting position is less than 1m away from the transition into Zone 0 and/or

Zone 20 an overvoltage protection must be integrated. This can either be done

within the transmitter (option: overvoltage protection), or outside the transmitter by

the customer himself.

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexander- Wiegand-Str. · 6 3911 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: sup port-tronic@wika.d e ·

80

www.wika.de

2266939.05 D/GB 06/2006

Page 6

Universal IS Pressure Transmitter UniTrans

Special Intrinsic Safety Instructions

2.5 Instructions for temperature ranges

Observe the permissible surface temperatures applicable for this range according

to the defined temperature classes.

Warning

Warning

Observe the maximum temperature value (of the temperature range defined under

item 15.3. in the EC type test certificate at the hexagon of the process connection.

Protect the pressure transmitter against touching or affix a warning notice.

Insulate heat sources thermally from the pressure transmitter (e.g. pipes or tanks).

2.6 Special instructions for dust explosion protection

Ensure that under hazardous dust environments the pressure transmitter is mounted in a shielded section and protect it against shocks.

Warning

Warning

When installing the pressure transmitter or the cable gland into areas which require

category 1D equipment, ensure that ingress protection IP 6X according to IEC 60

529 is guaranteed.

Observe the EN 50281-1-2 in relation to e.g. dust deposits and temperature.

The permissible ambient temperatures as well as the maximum surface temperatures are to be taken from the EC type test certificate.

4

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexander- Wiegand-Str. · 6 3911 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-ma il: support-tronic@wik a.de ·

www.wika.de

81

Page 7

Universal IS Pressure Transmitter UniTrans

3 EC-Declaration of Conformity

EC-Declaration of Conformity

EG-Konformitäts-

erklärung

EC Declaration of

Conformity

Déclaration de

Conformité CE

Dokument Nr.: Document No.: Document No.:

11135212.01 11135212.01 11135212.01

Wir erklären in alleiniger

Verantwortung, dass die mit

gekennzeichneten Produkte

We declare under our sole

responsibility that the

marked products

Nous déclarons sous notre seule

responsabilité que les appareils

marqués

Typen: Models: Types:

IUT-10 / IUT-11 IUT-10 / IUT -11 IUT-10 / IUT-11

Beschreibung: Description: Description:

Universaltransmitter

UniTrans

Universal Pressure Transmitter

UniTrans

Transmetteur de pression

UniTrans

gemäß gültigem Datenblatt: according to the valid data-sheet: selon fiche technique valide:

PE 86.02 PE 86.02 PE 86.02

die grundlegenden Anforderungen

der folgenden Richtlinie(n)

erfüllen:

97/23/EG (DGRL)

89/336/EWG (EMV),

94/9/EG (ATEX)

Die Geräte wurden entsprechend

den folgenden Normen geprüft:

EN 61326:1997 +A1 +A2 +A3 EN 61326:1997 +A1 +A2 +A3 EN 61326:1997 +A1 +A2 +A3

EN 50014:1997 +A1 +A2 EN 50014:1997 +A1 +A2 EN 50014:1997 +A1 +A2

EN 50020:2002 EN 50020:2002 EN 50020:2002

EN 50281-1-1:1998 +A1 EN 50281-1-1:1998 +A1 EN 50281-1-1:1998 +A1

EN 20284:1999 EN 20284:1999 EN 20284:1999

(1)

PS > 200 bar:

Bewertungsverfahren Modul A

(2)

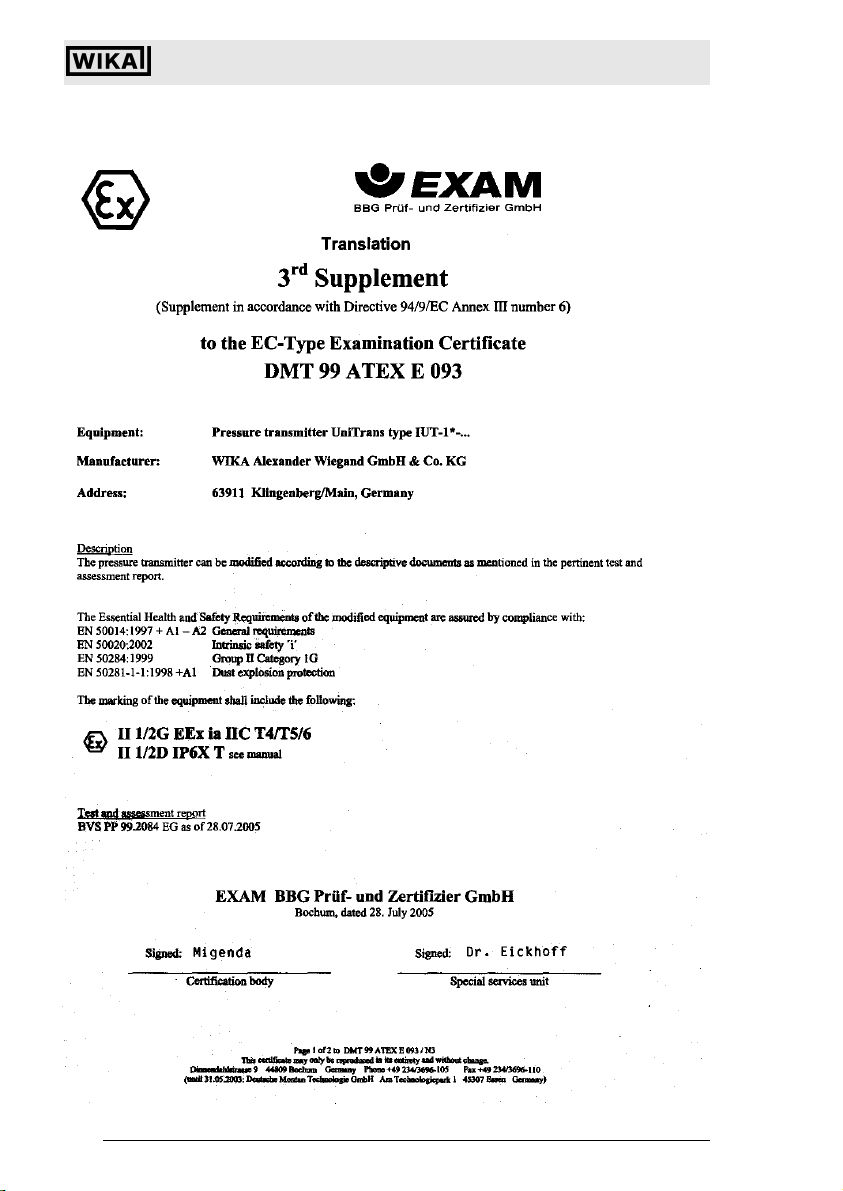

EG-Baumusterprüfbescheinigung

DMT 99 ATEX E 093 von EXAM BBG

Prüf- und Zertifizier GmbH, Bochum

(Reg.-Nr. 0158).

WIKA Alexander Wiegand GmbH & Co. KG

Klingenberg, 2006-05-08

Geschäftsbereich TRONIC

Company division TRONIC

Ressort TRONIC

(1)

,

(2)

are in conformity with the essential

requirements of the directive(s)

97/23/EC (PED)

89/336/EEC (EMC),

94/9/EC (ATEX)

The devices have been tested

according to the standards:

(1)

PS > 200 bar:

assessment procedure Module A

(2)

EC-type-examination certificate

DMT 99 ATEX E 093 of EXAM BBG

Prüf- und Zertifizier GmbH, Bochum

(reg. no. 0158).

(1)

,

(2)

Qualitätsmanagement TRONIC

Quality management TRONIC

Management de la qualité TRONIC

sont conformes aux exigences

essentielles de la (les) directive(s)

97/23/CE (DESP)

89/336/CEE (CEM),

94/9/CE (ATEX)

Les appareils ont été vérifiés

suivant les normes:

(1)

PS > 200 bar:

procédure d’évaluation Module A

(2)

Attestation d’examen CE de type

DMT 99 ATEX E 093 de EXAM BBG

Prüf- und Zertifizier GmbH, Bochum

(reg. no. 0158).

(1)

,

(2)

i. V. Stefan Richter

WIKA Alexander Wiegand Tel +49 · 93 72 · 132-0 Kommanditgesellschaft: Komplementärin: WIKA Alexander Wiegand Verwaltungs GmbH

GmbH & Co. KG Fax +49 · 93 72 · 132-406/414 Sitz Klingenberg Sitz Klingenberg

Alexander-Wiegand-Straße www.wika.de Amtsgericht Aschaffenburg Amtsgericht Aschaffenburg HRB 306

63911 Klingenberg · Germany info@wika.de HRA 1819 Geschäftsführer: Alexander Wiegand

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

82

i. A. Thomas Gerling

2266939.05 D/GB 06/2006

Page 8

Universal IS Pressure Transmitter UniTrans

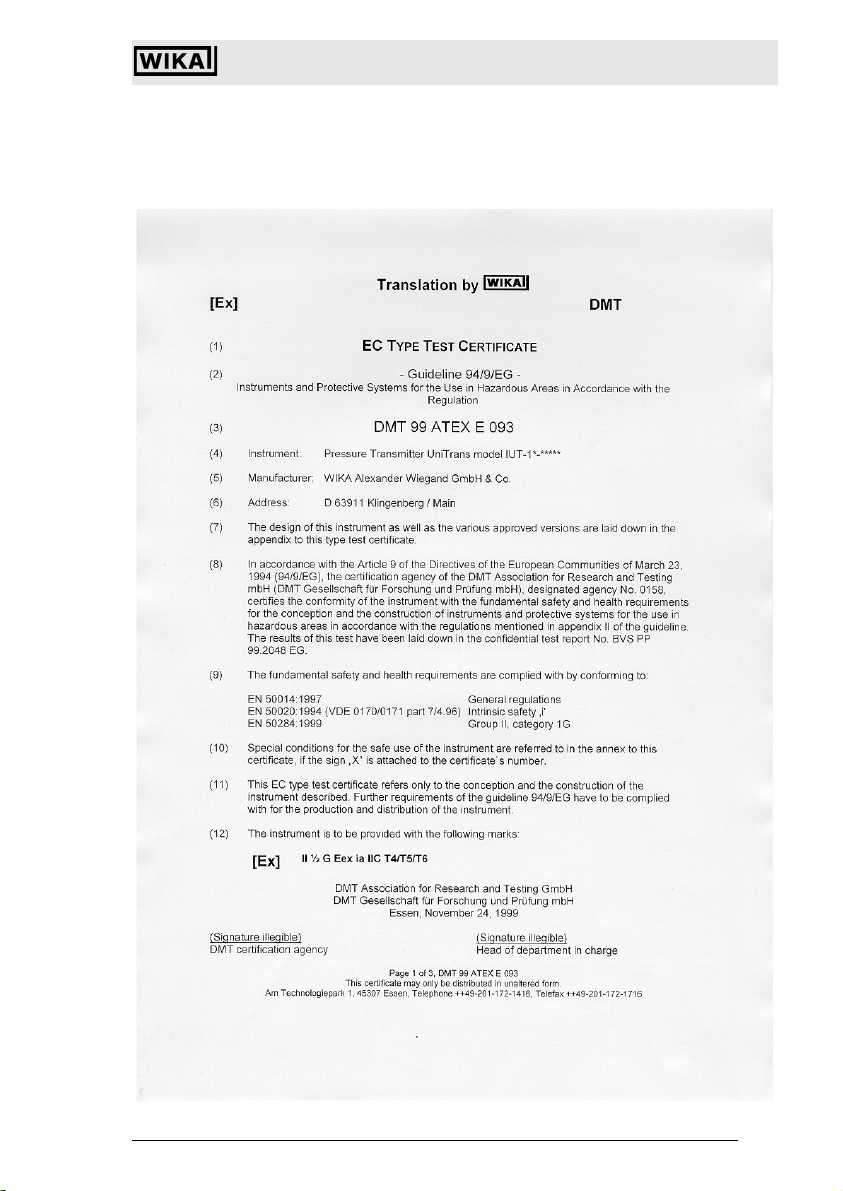

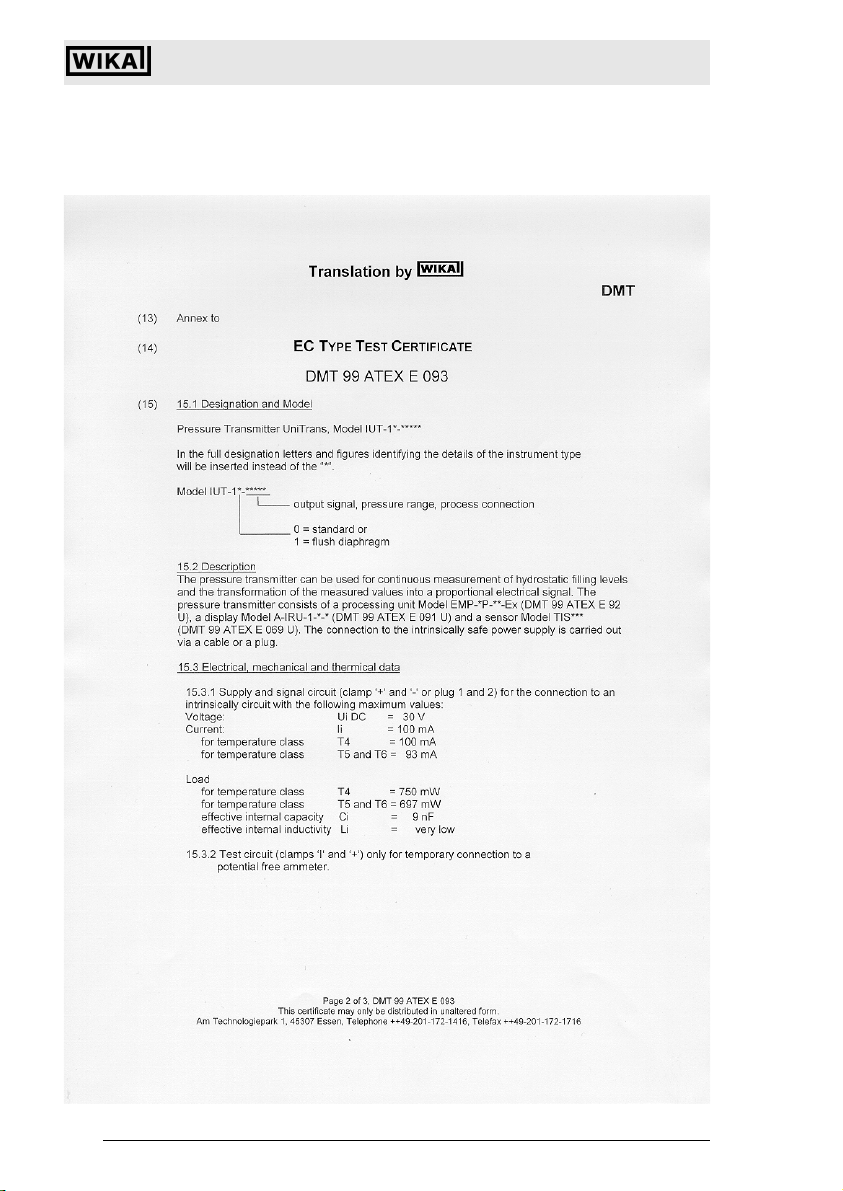

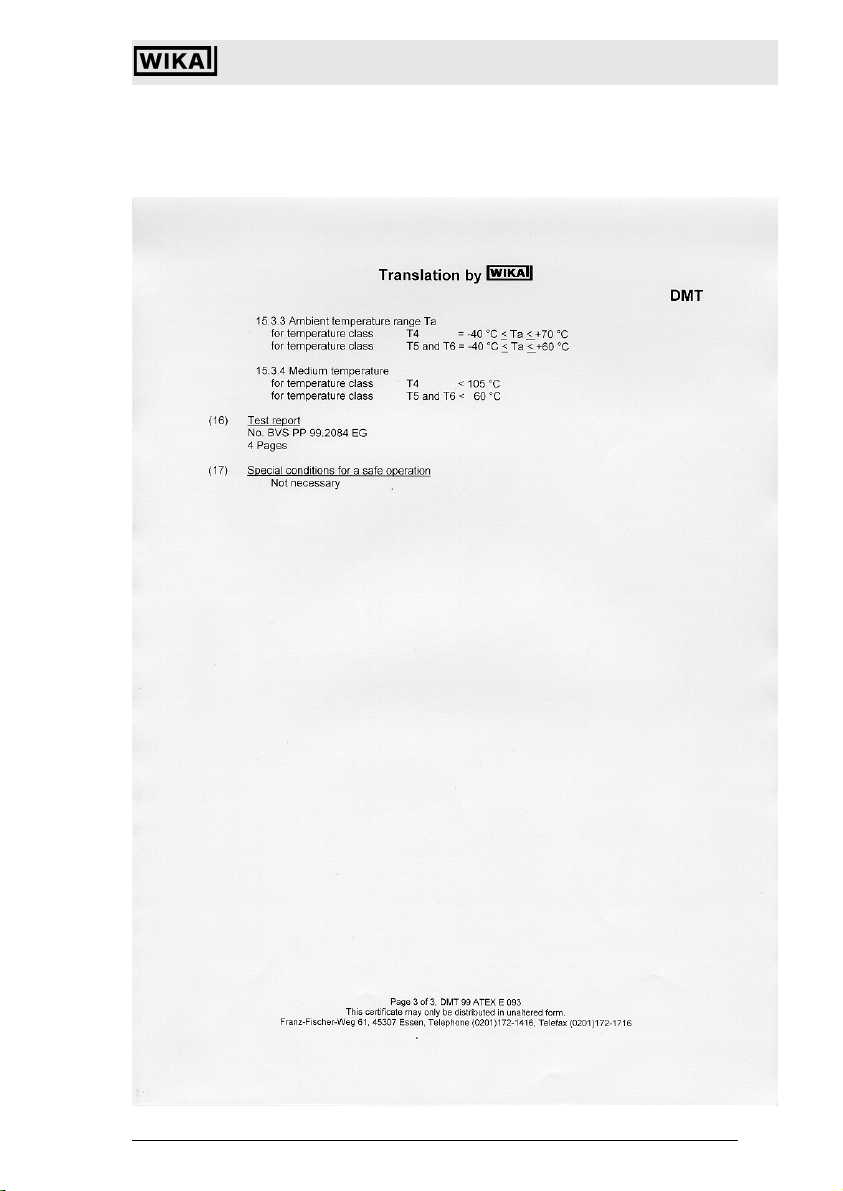

4 EC-Type Examination Certificate

EC-Type Examination Certificate

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

83

Page 9

Universal IS Pressure Transmitter UniTrans

EC-Type Examination Certificate

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

84

2266939.05 D/GB 06/2006

Page 10

Universal IS Pressure Transmitter UniTrans

EC-Type Examination Certificate

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

85

Page 11

Universal IS Pressure Transmitter UniTrans

EC-Type Examination Certificate

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

86

2266939.05 D/GB 06/2006

Page 12

Universal IS Pressure Transmitter UniTrans

EC-Type Examination Certificate

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

87

Page 13

Universal IS Pressure Transmitter UniTrans

EC-Type Examination Certificate

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

88

2266939.05 D/GB 06/2006

Page 14

Universal IS Pressure Transmitter UniTrans

EC-Type Examination Certificate

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

89

Page 15

Universal IS Pressure Transmitter UniTrans

EC-Type Examination Certificate

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

90

2266939.05 D/GB 06/2006

Page 16

Universal IS Pressure Transmitter UniTrans

EC-Type Examination Certificate

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

91

Page 17

Universal IS Pressure Transmitter UniTrans

EC-Type Examination Certificate

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

92

2266939.05 D/GB 06/2006

Page 18

Universal IS Pressure Transmitter UniTrans

EC-Type Examination Certificate

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

93

Page 19

Universal IS Pressure Transmitter UniTrans

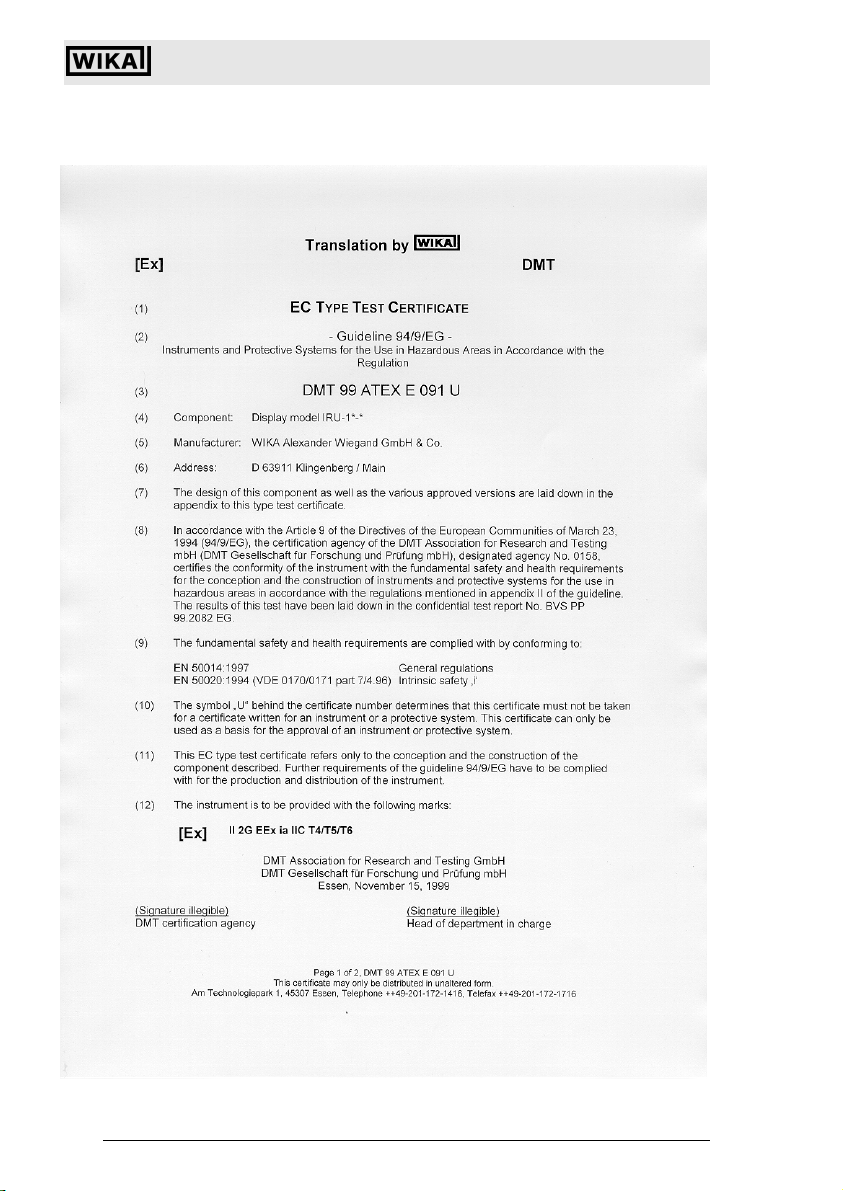

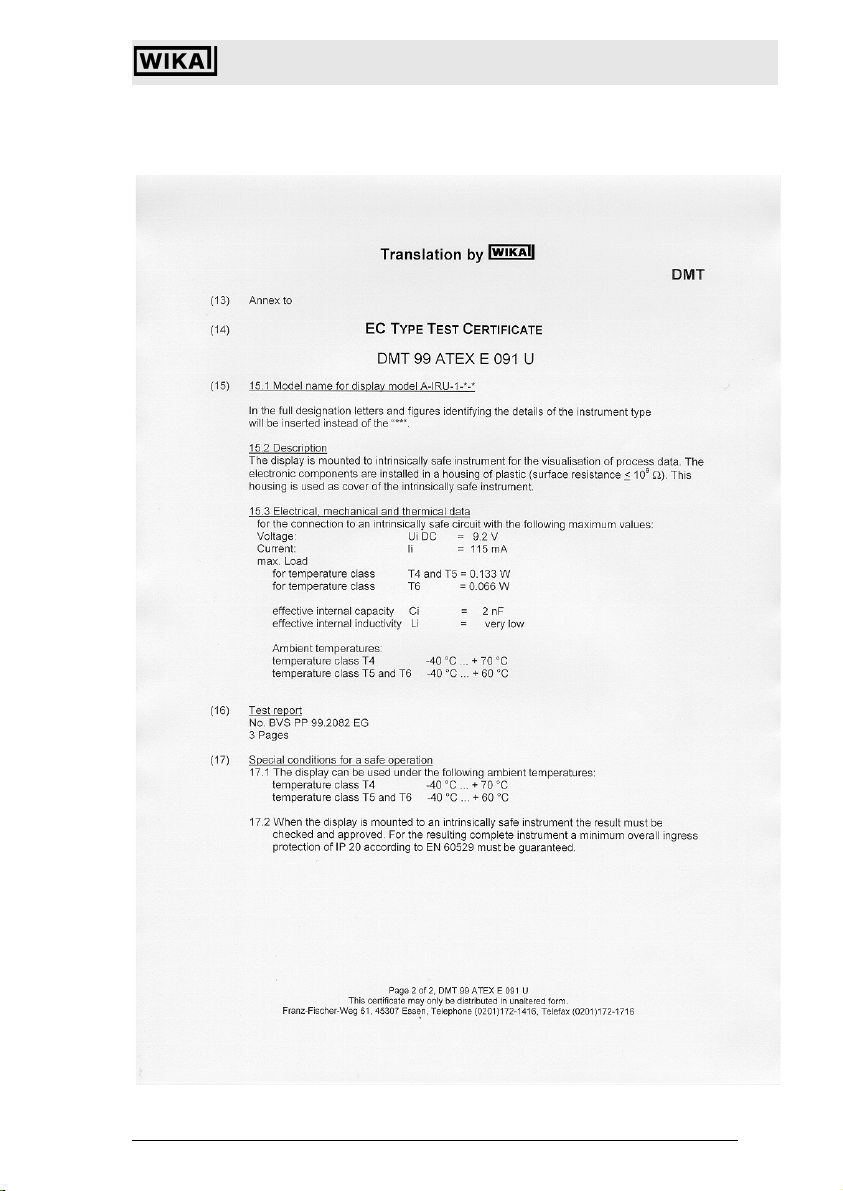

EC-Type Examination Certificate

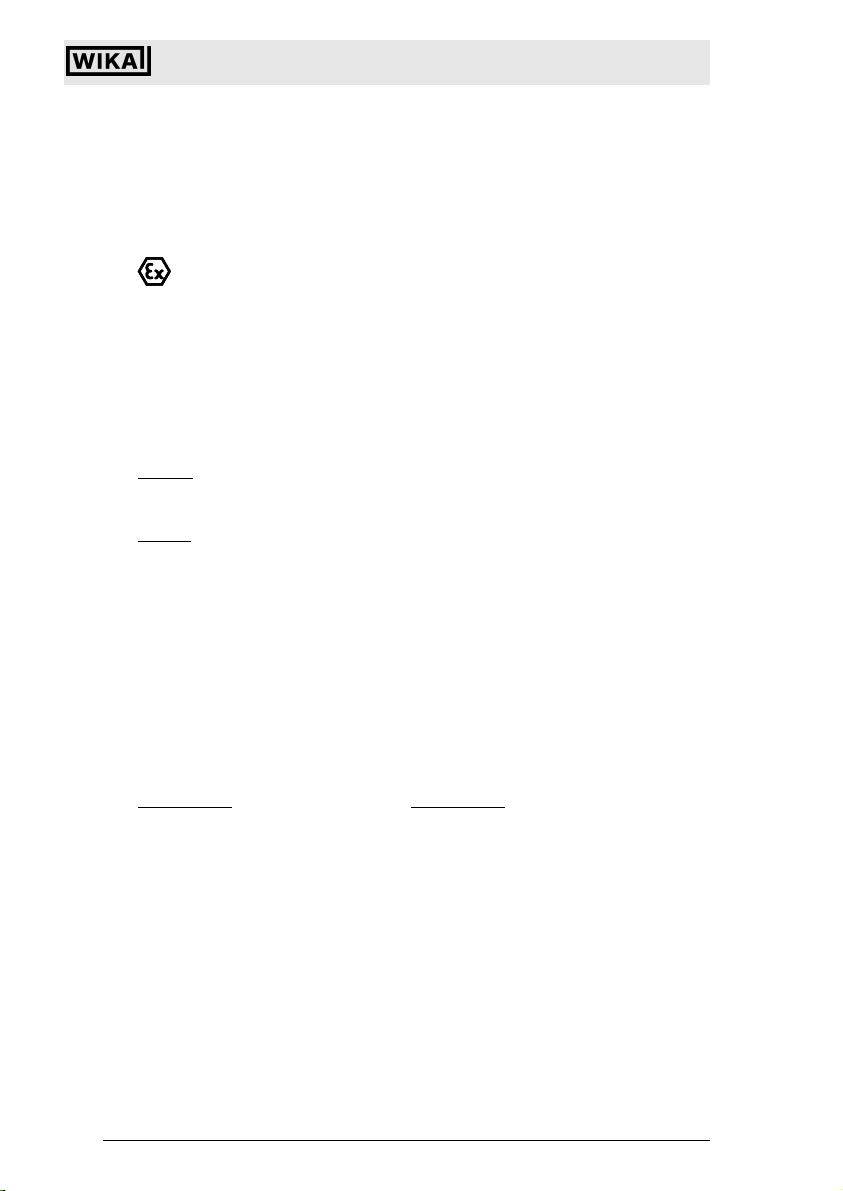

Translation by

g

DMT

st

Addendum

(addition according to Guideline 94/9/EG, appendix III, number 6)

to the EC T

1

YPE TEST CERTIFICATE

DMT 99 ATEX E 091 U

Component: Display model IRU-1*-*

Manufacturer: WIKA Alexander Wiegand GmbH & Co.

Address: D 63911 Klingenberg / Main

Description

The display can also be manufactured in compliance with the test documents mentioned in the related

test certificate No. BVS PP 99.2082 EG / N1

Test report

No. BVS PP 99.2082 EG / N1, edition 04/28/2000, 3 Pages

DMT Deutsche Montan Technologie GmbH

DMT Association for Research and Testing GmbH

(Signature illegible) (Signature illegible)

DMT certification agency Head of department in charge

Essen, April 24, 2000

Page 1 of 1, of the addendum to the DMT 99 ATEX E 091 U

Am Technologiepark 1, 45307 Essen, Telephone (0201)172-1416, Telefa (0201)172-1716

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

94

This certificate may only be distributed in unaltered form.

2266939.05 D/GB 06/2006

Page 20

Universal IS Pressure Transmitter UniTrans

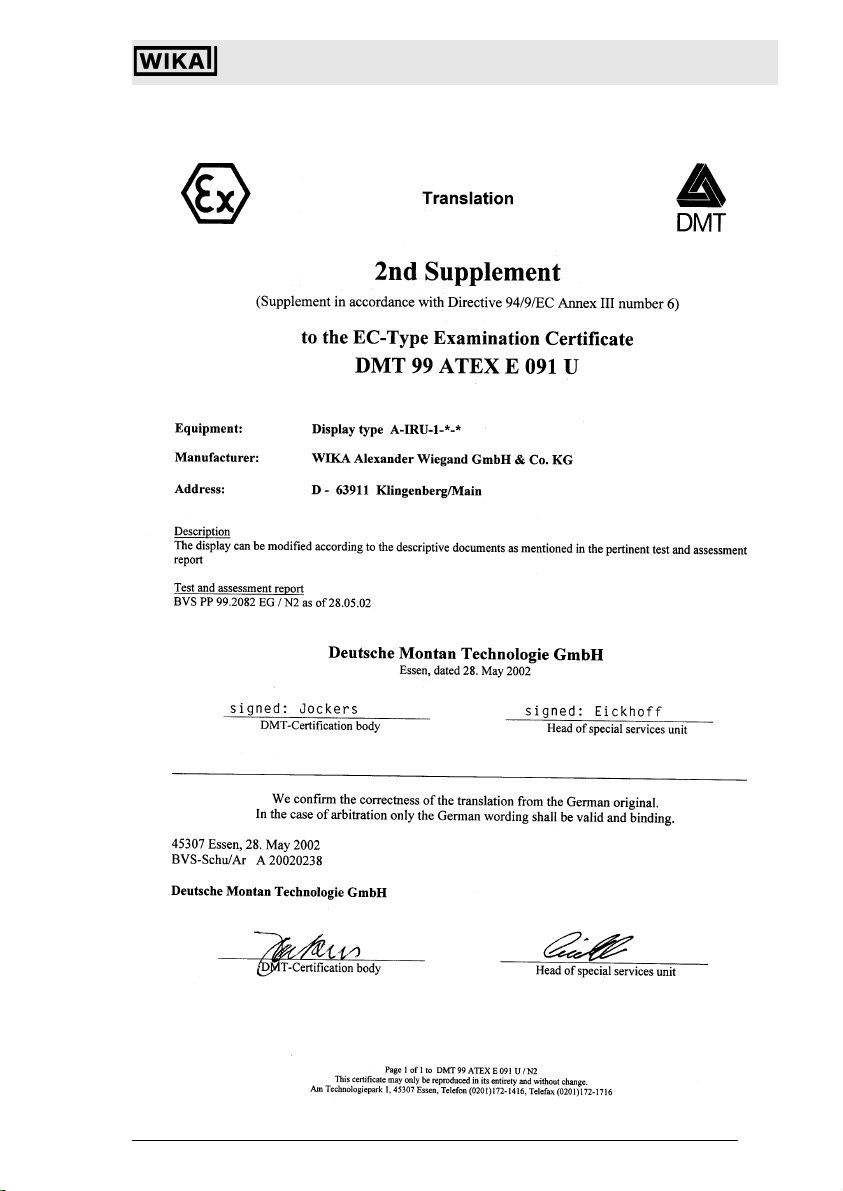

EC-Type Examination Certificate

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

95

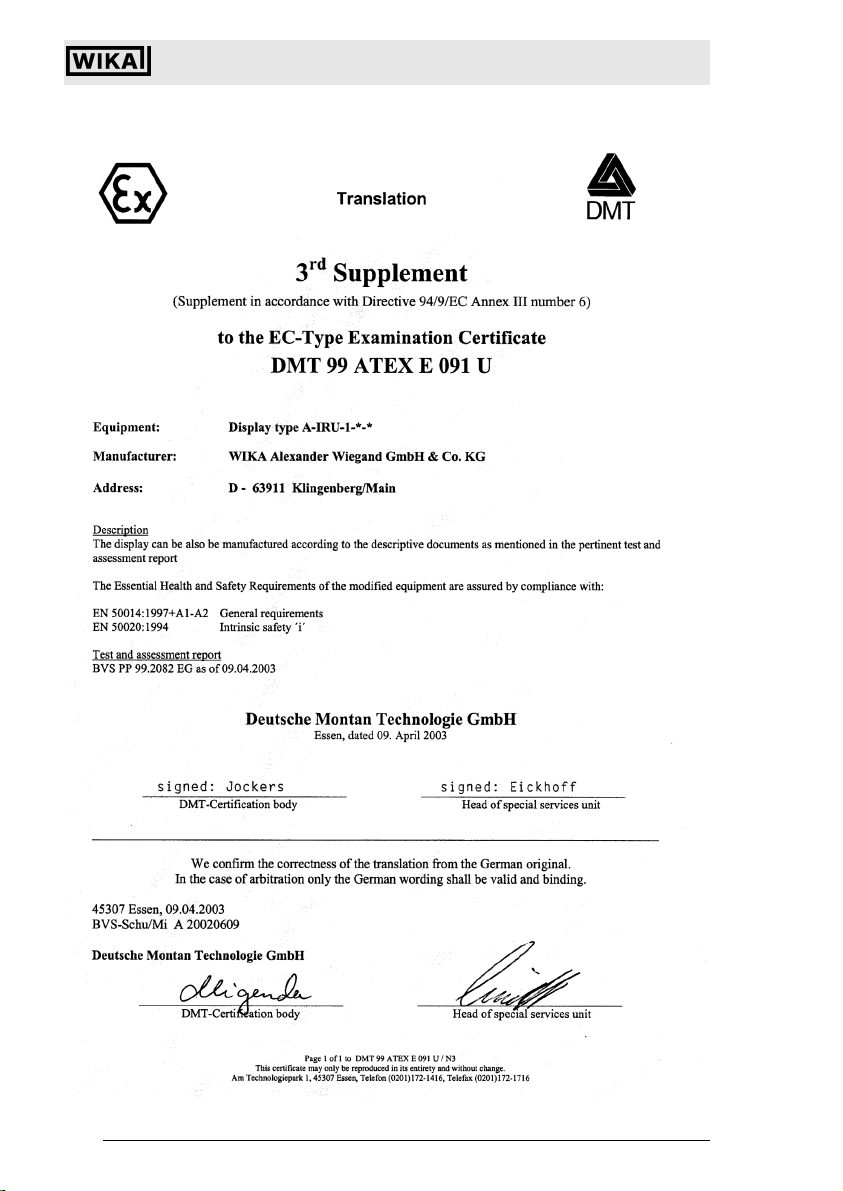

Page 21

Universal IS Pressure Transmitter UniTrans

EC-Type Examination Certificate

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

96

2266939.05 D/GB 06/2006

Page 22

Universal IS Pressure Transmitter UniTrans

Product Description

5 Product Description

The intrinsically safe pressure transmitter UniTrans can be used in level control

applications as well as for pressure measurement applications in process industry.

A variety of process connections, measurement ranges, main boards and display

options result in a product for a wide range of applications.

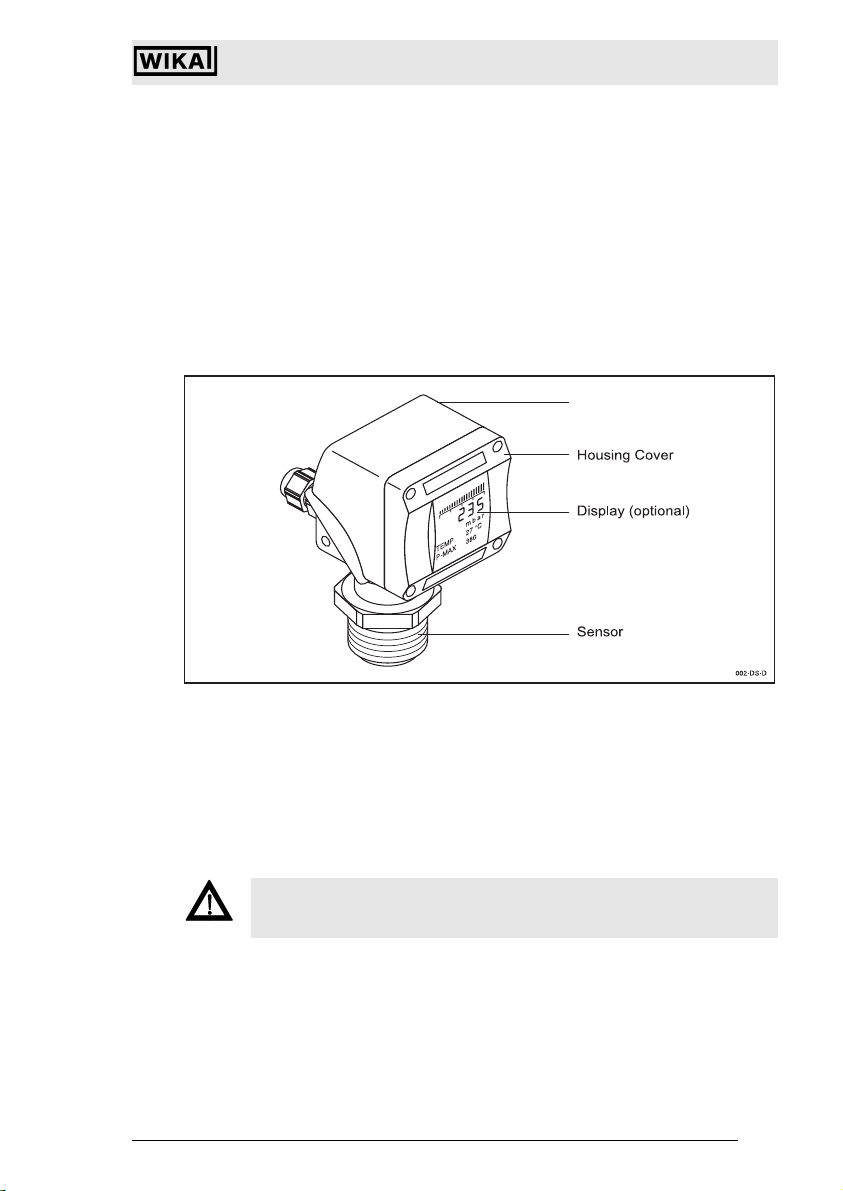

5.1 Construction

The UniTrans consists of a pressure sensor, a control interface unit and a housing

cover with optional display. Due to this modular design, different transmitter versions

can be mounted (see “Model Key” on page 151).

Direct Mounted

Processing Unit Housing

5.1.1 Pressure Transducer

The pressure transducer has a piezo-resistive or thinfilm measurement cell depending on the pressure range. The sensors are temperature compensated, and have a

hermetically welded membrane which is "helium" leak-tested. The pressure transducers do not have internal sealing elements.

Pressure transducers further distinguish themselves from one another based on their

pressure ranges and the different materials of wetted parts. Different process connections can be selected to serve a wide range of applications.

Never exceed the overpressure limit of the respective pressure transducer.

Warning

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

97

Page 23

Universal IS Pressure Transmitter UniTrans

Product Description

5.1.2 Processing Unit

The processing unit, which is integrated in the housing contains the terminal compartment and the keypad used for programming the transmitter. The four keys must be

activated (unlocked) before use. During normal operation the keypad is locked to protect data and functions previously entered. The keypad is automatically locked when

no key is hit for 10 minutes. The processing unit converts the digitalized signal from

the measuring unit into a standard 4...20 mA current signal.

Processing Unit

5.1.3 Display Unit

CALIBRATION

RANGE

The measured-value indicator has four digits (in a 7-segment display) + symbols. Below it, is line 1 (16-segment display) used to display error codes and the signal’s unit

of measure. The unit of measure can be selected by the operator. Measurements

over 9999 can not be correctly displayed. Please note this when choosing the unit

(e.g. 9999 Pascal = 0,09999 bar). Additional information is displayed in lines 2 and 3

(16-segment display). The operator can enter commands in the programming mode

on the display unit by means of menu guided, clear-text prompts.

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG· Alexander-Wiegand-Str. · 63911 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

98

2266939.05 D/GB 06/2006

Page 24

Universal IS Pressure Transmitter UniTrans

Product Description

Transmitters with displays offer a larger number of programming and processing options. These options include alarm status, damping, signal inversion, tank linearization and diagnostic messages.

Display units can be easily upgraded (see chapter 7.2).

5.2 Function

The pressure transducer converts the existing pressure into an electrical signal. Microelectronics further process the input signal and produce a proportional 4-20 mA

standard signal.

The display-version allows programming (parameterization) and the display of extended functions such as inversion, damping, alarm status and linearization.

5.2.1 Functions of Transmitters without Displays

• Calibration of zero and span under pressure (see 8.3)

• Calibration of zero and span without pressure (dry adjustment) (see 8.4)

• Setting the dampening / integration of the output signal 0-40 s (see 8.5)

• Reset to manufacturer’s default values (see 8.6)

• Mounting correction of the sensor (beginning with software version 1.05, see 8.4.3)

5.2.2 Functions of Transmitters with Displays

• Settable units of measurement (mbar, bar, psi, mA, %, m, mm WS) (see 9.5.1)

• Volume-related unit of measuring value can be set (l, kg, t, m

• Temperature and Min/Max values shown in display (see 9.5.1)

• Nominal pressure range of the sensor shown in display (see 9.5.1)

• Zero and span calibration (with/without pressure) (see 9.5.2)

• Setting of damping / integration of output signal 0-40 s (see 9.5.3)

• Inversion of the output current signal (see 9.5.3)

• Setting the output current value in case of alarm (3.6 mA or 21 mA) (see 9.5.3)

• Setting the limits of the output signal (see 9.5.3)

• Offset of the output signal (see 9.5.3)

• Mounting correction of the sensor (beginning with software version 1.05, see 8.4.3)

• Measuring circuit test function (see 9.5.4)

• Reset functions (see 9.5.4)

• Password activation (see 9.5.4)

• Selecting the language of the display (see 9.5.5)

• Entering of a table function for the linearization of the output signal (see 9.5.6)

• Entering the medium density (see 9.5.6)

3

, gal, lb) (see 9.5.1)

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

99

Page 25

Universal IS Pressure Transmitter UniTrans

Product Description

5.2.3 Functional features of transmitters with HART-Communication

Universal commands

• Displayed unit can be set (mbar, bar, psi, mA, %, m, mm WS ...)

(see chapter 10.2.3)

• Definition of measuring site description and tag number (see 10.2.3)

• Measuring circuit test function (see 10.2.8)

• Temperature and min. / max values can be displayed (see chapter 10.2.3)

• Nominal pressure range of sensor can be displayed (see chapter 10.2.3)

• Cyclic measurement and transmission of the measured value (see chapter 10.2.3)

Common commands

• Calibration of zero point and span (under/without pressure) (see chapter 10.2.4)

• Adjustment of damping/integration of the output signal 0 s ... 40 s

(see chapter 10.2.5)

Device-specific commands

• Inversion of output current signal (see chapter 10.2.5)

• Adjustment of alarm values for the output current (3.6 mA or 21 mA)

(see chapter 10.2.5)

• Adjustment of output signal limits (see chapter 10.2.5)

• Mounting correction of the sensor (see chapter 10.2.7)

• Reset functions (see chapter 10.2.7)

• Password activation (see chapter 10.2.7)

• Setting up a table function for a linearisation of the output signal (see 10.2.6)

• Entering the medium density (see chapter 10.2.6)

• Volume-related units of measured value can be set (l, kg, t, m3, gal, lb) (see 10.2.3)

• Display and graphical illustration of the measuring value over time (see 10.2.10)

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG· Alexander-Wiegand-Str. · 63911 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

100

2266939.05 D/GB 06/2006

Page 26

Universal IS Pressure Transmitter UniTrans

Product Description

5.3 Installation Examples

The UniTrans is primarily used to monitor the pressure in pipes, technical equipment

and tanks. Depending on the pressure range pressures between 20 mbar up to 4000

bar can be measured. The pressure is measured using absolute (against a vacuum)

or relative (against external or air pressure) measurement depending on the type of

sensor selected.

The UniTrans is also used for hydrostatic pressure measurement within liquid filled

pipes and containers.

Process Pressure Measurement: Process Pressure Measurement:

Used to measure pressure of liquids Used to measure container pressure.

or gases in pipelines.

Process Pressure Measurement: Process Pressure Measurement:

Installed behind feed pumps for Installed in front of and behind the filter.

process control or monitoring of pump Uses the pressure differential for moni-

functions. toring the function or accumulation of dirt

in the filter. Both output signals are pro-

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

cessed by a PLC or signal converter.

101

Page 27

Universal IS Pressure Transmitter UniTrans

Product Description

Level Control: Level Control:

Externally mounted Combined pressure and head pressure

(with front flat diaphragm) are measured by two externally mounted

pressure transducers. The two signals

are analyzed and the differential is cal-

culated by a PLC or suitable signal

converter.

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG· Alexander-Wiegand-Str. · 63911 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

102

2266939.05 D/GB 06/2006

Page 28

6 Technical Data

6.1 Input-values

Universal IS Pressure Transmitter UniTrans

Technical Data

Pressure Ranges

(Absolute pressure upon request)

6.2 Output-values

Output signal 4 ... 20 mA, two-wire, optionally with

Accuracy [% of span]

(incl. non-linearity, hysteresis, nonrepeatability, zero signal and full

scale error)

/ overpressure limit / Burst pressure

0 ... 0.4 bar 2 2.4

0 ... 1,6 bar 10 12

0 ... 6 bar 35 42

0 ... 16 bar 80 96

0 ... 40 bar 80 400

0 ... 100 bar 200 800

0 ... 250 bar 500 1200

0 ... 600 bar 1200 2400

0 ... 1.000 bar 1500 3000

0 ... 1,600 bar 2000 4000

0 ... 2,500 bar 3000 5000

0 ... 4,000 bar 4400 7000

-1 ... +0 bar* 2 2.4

-1 ... +0,6 bar* 10 12

-1 ... +3 bar* 35 42

-1 ... +5 bar* 35 42

-1 ... +15 bar* 80 96

* only relative pressure

Do not exceed the nominal pressure!

modulated HART signal

<

0.10 at ranges < 1000 bar

0.30 at ranges > 1000 bar

<

Non-linearity < 0.05% of span (BFSL) per IEC 61298-2

at ranges <

0.20% of span at ranges > 1000 bar

<

1000 bar

Turn down behavior: (1/k)

up to 1 : 5

1 : 5 to 1 : 20

no changes of deviation

the accuracy must be multiplied by the

factor (turn down / 5)

example for TD = 1:15, (k = 15)

accuracy = 0.10 * (15/5) = 0.3

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

103

Page 29

Universal IS Pressure Transmitter UniTrans

Technical Data

Overall deviation

(at +10 °C ... +40 °C)

Load R

Fault signal 3.6 mA or 21 mA, programmable

Integration time 0 s, 1 s, 5 s, 20 s, 40 s, programmable

Adjustment of the span Up to Turn Down 1 : 20

Integrated lightning protection optional

Zero point adjustment -2.5 ... 99 %

6.3 Construction

Process connections

Model IUT-10

better than 0.15 % of span for pressure

ranges of <

1000 bar

better than 0.6 % for pressure ranges of

> 1000 bar

< (UB–12 V)/0.023 A

A

with R

in Ohm and UB in Volt

A

G 1/2 per EN 837 (max. 1600 bar)

1/2 NPT per "nominal size for US

standard tapered pipe

thread NPT"

(max. 1600 bar)

M 16 x 1,5 with sealing cone

1600 bar)

(>

M 20 x 1,5 with sealing cone

(>

1600 bar)

9/16 - 18 UNF innen F 250-C

(>

1600 bar)

Model IUT-11

G 1 flush diaphragm with o-ring

(0 ... 0.4 up to 0 ... 1.6 bar)

G 1/2 flush diaphragm with o-ring

(0 ... 6 bis 0 ... 600 bar)

G 1 1/2 flush diaphragm with o-ring

(0 ... 0.4 bis 0 ... 16 bar)

Model IUT-11 EHEDG version

G 1 flush diaphragm with o-ring

(0...0.4 bis 0...16 bar)

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

104

2266939.05 D/GB 06/2006

Page 30

Universal IS Pressure Transmitter UniTrans

Materials

Housing

Wetted parts (IUT-10)

(IUT-11)

Wetted parts (IUT-11 EHEDG version)

Internal transmission fluid

Technical Data

highly resistive, fiberglass-enforced

plastic (PBT); optionally aluminium

CrNi-steel 1.4571 and 2.4711

CrNi-steel 1.4571, o-ring: NBR {Viton or

EPDM}; {Hastelloy C4}

CrNi-steel 1.4435

Standard {Halocarbon oil for oxygenapplications}; {FDA-approved}

Electrical connection

per EN 60 529/ IEC529

Electric protection Reverse polarity, overload and short cir-

6.4 Auxilliary Power

Power supply 12 ... 36 V DC

Attention

6.5 Ambient Conditions

Ambient temperature – 40 °C ... + 85 °C

M 20 x 1.5 cable gland with internal

terminal block. For the dust approval

version, only cable glands and blind plugs

with the appropriate ATEX approval may

be used.

M12x1 plug, 4-pin (pin allocation: 1+ 3-)

(not in conjunction with dust approval)

[3/4" NPT female conduit (only with

aluminum case)]

(see 7.4)

cuit protection

Please consider the safety related

values according to EC-Type

Examination Certificate (see chapter 3)

°F = (°C * 1.8) + 32

(– 20 °C ... 70 °C with display)

Please consider the safety related val-

ues according to EC-Type Examination

Attention

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

Certificate (see chapter 3)

105

Page 31

Universal IS Pressure Transmitter UniTrans

Storage temperature – 40 °C ... + 85 °C

(– 35 °C ... 80 °C with display)

Climate class D per DIN IEC 654-1

Technical Data

Ingress protection per EN 60 529 IP 65 for plastic case

IP 67 for aluminium case

EMC per EN 50 081-2, EN 50 082-2,

NAMUR NE 21

6.6 Process Conditions

Medium temperatures – 30 °C ... + 105 °C

Please consider the safety related

values according to EC-Type

Attention

Examination Certificate (see chapter 3)

6.7 Safety-related nominal values for IS protection conditions

-protection: The instruments are approved for IS zones, which require the

categories 1/2G, 2G,3G.

Dust approval 1/2D, 2D, 3D is available as an option.

Output signal 4 ... 20 mA, two-wire, optionally with

modulated HART signal

Ignition protection class

Available as an option

EEx ia IIC T4 EEx ia IIC T5 / T6

IP 6X T130°C / 95°C / 80°C

Certificate no. (display) (DMT 99 ATEX E 091 U)

°F = (°C * 1.8) + 32

Certificate no. (pressure transmitter) (DMT 99 ATEX E 093)

Power supply Ui 30 V DC 30 V DC

Short-circuit current Ii 100 mA 93 mA

Maximum load Pi 750 mW 697 mW

Medium temperature -40°C ... +105°C -40°C ... +60°C

Ambient temperature -40°C ... +70°C -40°C ... +60°C

Internal capacity Ci 9 nF

Internal inductivity Li very small

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

106

2266939.05 D/GB 06/2006

Page 32

Please pay attention to the information in chapter 7.4.

6.8 Product labels (example)

Universal IS Pressure Transmitter UniTrans

Technical Data

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wika. de

107

Page 33

Universal IS Pressure Transmitter UniTrans

7 Installation

The device should be installed/operated in accordance with the regulations of ElexV,

the Device Safety Regulation, this operating manual and generally recognized

industry standards.

Before mounting the transmitter make sure to read the operating manual,

as well as the EC-type examination certificate.

Warning

7.1 Pressure Transmitter Installation

The pressure transmitter’s diaphram should not come into contact with

hard or sharp objects.

Warning

Installation Using a Weld-on Adapter:

• Insert a filler piece (a pressure transmitter dummy) into the weld-on adapter.

• Weld the adapter into the container/pipe wall (section-weld process).

• Remove the filler piece.

• Install the pressure transmitter in the weld-on adapter.

7.2 Display Unit Upgrades

The display unit can be easily upgraded at any time.

• Remove the housing cover and the supporting string.

• Attach the display unit’s supporting string to the same place.

• Plug the display unit’s connector into the appropriate jack.

Installation

When installing the display unit, make sure that the connection cable

and the supporting string are not kinked or pinched. If the cable is

Warning

damaged, correct function may be impaired..

On Model IUT the Ex-protection of the transmitter will no longer exist.

Only the model A-IRU can be mounted as display for upgrading .

• The display unit can be mounted at 90° angles.

• Fasten the display unit with screws.

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

108

2266939.05 D/GB 06/2006

Page 34

Universal IS Pressure Transmitter UniTrans

Connection Cable

Supporting String

•

All functions are programmable once the pressure transmitter has been upgraded

with a display unit. The adjusted parameters are stored after the display unit is removed.

The display unit can be rotated in 300°, so that it can be read under various installation

conditions. The housing cover with built-in display can be fastened to the housing at

all four side positions.

7.3 Housing Reconfiguration

Rotate the housing of the display unit in order to be able to read the display from

above when the pressure transmitter is installed in an upright position.

• Loosen the 4 internal hexagonal screws.

• Lightly lift off the housing with the display unit.

• Carefully turn the housing by 180°.

• Re-tighten the screws.

When tightening the 4 hollow screws, make sure that they are

adequately and securely seated in order to ensure that the transmitter is

Warning

properly sealed.

Installation

When reconfiguring the housing, the spiral cable must not be damaged.

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wik a.de

109

Page 35

7.4 Electrical Connection

Universal IS Pressure Transmitter UniTrans

Installation

For the dust approval version, only cable glands and blind plugs with the

appropriate ATEX approval may be used. The M12x1 plug may not be used

Warning

in conjunction with dust approval.(See chapter 2.2)

Please observe local installation regulations (Germany: VDE-Standard).

The terminal voltage should not exceed 30 V.

The transmitter is only to be connected to approved intrinsically safe

measuring instruments.

The supply voltage is between 12 and 30 V. The power supply and the output signal

are transmitted via a two-wire cable (max. 12 mm outer diameter, max. 14 AWG) and

connected in accordance with the pin configuration.

When selecting a cable make sure that it complies with the capacity and

inductivity values as well as the voltage resistance values

Warning

(see “Technical Data” on page 103).

The given operating temperatures must not be exceeded.

For the connection of the cable the leads must be covered by end bushings. The cable must not be damaged.

Supply voltage can be supplied by a power unit, a transmitter power supply or by

means of a PLC connection.

It is suggested to use a model with integrated lightning protection for preventing

damage due to voltage peaks.

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

110

2266939.05 D/GB 06/2006

Page 36

Terminal Configuration

Universal IS Pressure Transmitter UniTrans

Installation

Hazardous (classified)areaNon-hazardous area

Legend

Ground

L- Negative

L+ Positive

I Test circuit; connect the ampere meter between terminals L+ and I

For transmitters with M12 x 1 circular connector, below are the wiring details:

1Positive

3 Negative

When connecting the clamps ’L+’ and ’I’ the safety-related nominal values

(See chapter 6.7) must be observed.

Warning

Only approved intrinsically safe ammeters may be connected to the test

circuit between the clamps ’L+’ and ’I’.

The internal resistance of the multimeter must be < 100

Ω.

The unit must be properly grounded in order to guarantee EMC resistance.

7.5 Pressure Compensation when using a Relative Pressure Sensor

A Goretex diaphram is used to compensate for the atmospheric pressure under the

IP 65 Protection Method.

A special cable with capillaries for relative pressurization is used for

Ingress Protection IP 67.

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wik a.de

111

Page 37

Universal IS Pressure Transmitter UniTrans

Operation of Devices without Displays

8 Operation of Devices without Displays

8.1 Preparation

This unit can be programmed before or after installation.

• Connect an ampere meter to the device’s output (between terminals I and L+).

• Note that after each action, a brief oscillation/deflection of 20 mA occurs (verification of a successful action).

The following functions can be programmed without a display unit:

• Zero point adjustment with a full or empty container (with/without pressure)

• Span adjustment with a full or empty container (with/without pressure)

• Integration time

• Mounting correction of the sensor (beginning with software version 1.05)

• Reset to manufacturer’s defaults

An error signal is caused by a current surge (21 mA or 3.6 mA; 5 sec) when

the zero point or span setting fall outside of the sensor’s nominal pressure

range during adjustments with existing pressure. No values are stored.

The keypad becomes inactive after 10 min. of disuse. All settings will default to previously stored values. Only settings that have been confirmed

with the "OK" function are stored.

8.2 Key Functions (only for transmitters without display)

Function 1 Function 2

Basic setting,

store span (2 s)

Action: upward,

increase value

Basic setting,

store zero point

Action: downward,

decrease value

(2 s)

Exit key or programming mode

(2 s)

Verification

(store 2 s)

Activate keys

(push simulta-

neously for 2 sec.)

Mounting correc-

tion of the sensor

(push simulta-

neously for 2 sec.)

Basic setting

Integration time/

damping (push

Reset to default

(push simulta-

neously for 2 sec.)

simultaneously for

2 sec.)

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

112

2266939.05 D/GB 06/2006

Page 38

8.3 Calibration with Pressure

8.3.1 Zero Point Calibration

Make sure that the pressure to be used as the zero point (P 0 %), is

present at the transmitterer diaphragm before calibration.

Calibration Value

(2 sec.)

Universal IS Pressure Transmitter UniTrans

Operation of Devices without Displays

Confirm

(2 sec.)

Function

(2 sec.)

meas

Zero point calibration

8.3.2 Span Calibration

Calibration of the measurement range (span).

Make sure that the pressure to be used as the span end-point (P 100 %) is

present at the transmitter diaphragm. The measuring range between zero

and end value of span is saved as span.

Calibration Value

Calibration of span

A change in the zero point has no effect on the calibrated span.

However, if the span end-point is higher than the peak value of the sensor’s nominal pressure range, then span end-point is fixed at this peak value and the span is reduced accordingly.

A change in the span setting has no effect on the zero point. The zero point

and span end-point must fall within the sensor’s nominal pressure range.

A mounting correction must not be carried out when making an adjustment

with pressure (wet adjustment). Otherwise, the mounting correction must

be carried out before saving the zero point and the end value of span.

024-DS-GB

Confirm

Function

(2 sec.)(2 sec.)

(2 sec.)

meas

025-DS-GB

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wik a.de

113

Page 39

Universal IS Pressure Transmitter UniTrans

Operation of Devices without Displays

8.4 Calibration without Pressure

Determine the current reference values for the zero point and the span to be entered

in the transmitter before calibration. This is done as follows:

8.4.1 Zero Point Calibration

• Determine the hydrostatic pressure of the liquid’s surface that meets the zero point.

• Adjust this pressure in proportion to the sensor’s nominal pressure range.

• Multiply this proportion by 16 mA and add 4 mA to the result.

This produces the calculated current (value I

and used to programm the zero point (0%).

Example:

A pressure transducer with 0 ... 400 mbar (nominal pressure) needs to be programmed.The liquid’s surface (with a density of 1) is 1 m above the diaphragm at the

zero point producing a pressure of 100 mbar.

Zero point pressure (0%) 100 mbar

-------------------------------------------------------------- ----------------------------------

calc

Sensors nominal pressure 400 mbar

This means that the device’s current value must be set to 8 mA when performing a dry

(empty) calibration.

), which is entered in the transmitter

calc

16 mA 4 mA

+⋅ 8 mA==

Calibration Value

calc

Calibration of zero point, without display, without pressure

(2 sec.)

(2 sec.)

... to I

... to I

Calibration Value

meas=Icalc

meas=Icalc

8.4.2 Span Calibration

• Determine the hydrostatic pressure of the liquid’s surface, which corresponds to the

span end-point.

• Calculate the difference of the pressure value between span end-point and zero

point and divide this difference by the nominal pressure range of the sensor.

• Multiply this proportion by 16 mA and add 4 mA to the result.

This produces the calculated current (value I

), which is entered in the transmitter

calc

and used to program the span end-point (100%).

The measurement range between zero point and span end-point will be stored as

span.

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

114

(2 sec.)

026-DS-GB

2266939.05 D/GB 06/2006

Page 40

Universal IS Pressure Transmitter UniTrans

Operation of Devices without Displays

Example:

A pressure transmitter with 0 ... 400 mbar (nominal pressure) is to be programmed.

The liquid’s surface (with a density of 1) is 1 m above the diaphragm at the zero point.

The maximum (span end-point) should be 3 m. The measuring range (span) is 200

mbar.

pressure difference (span) (300 mbar -100 mbar)

------------------- ------------------------------ --------------------------------- ----------------------------- ------------------ -

I

calc

Sensors nominal pressure 400 mbar

16 mA 4 mA

+⋅ 12 mA==

This means that the output must be set to 12 mA during programming.

Calculate

Calibration Value

I

=

calc

Activate

Keypad

(2 sec.)

Access

Function

(2 sec.)

Calibration of span, without display, without pressure

Enter

Value

current value increases

... to I

meas=Icalc

... to I

current value decreases

meas=Icalc

Calibration Value

A change in the zero point has no effect on the adjusted span.

However, if the span end-point is higher than the peak value of the

transmitter’s nominal pressure range, then the span end-point is fixed

at this peak value and the span is reduced accordingly.

A change in the span setting has no effect on the zero point. The zero

point and span end-point must fall within the transmitter’s nominal

pressure range.

A test / correction of the zero point is suggested after adjusting the

span in order to maintain optimum accuracy.

Important

A mounting correction should be carried out before or after making an

adjustment without pressure (dry adjustment) (see 8.4.3). The transmitter must therefore be placed in the reference position for the measurement (installation site) without pressure on the diaphragm.

Confirm

(2 sec.)

027-DS-GB

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wik a.de

115

Page 41

Universal IS Pressure Transmitter UniTrans

Operation of Devices without Displays

8.4.3 Mounting correction of the sensor

The position of the measuring cell is entered by simultaneously pressing (2 sec.) the

"zero" and "esc" buttons.

Calibration Value

(2 sec.)

Mounting correction of the sensor

(2 sec.)

8.5 Integration Time (Damping) Adjustment

The following integration time settings can be used: 0, 1, 5, 20 and 40 s.

The sensor’s measured values can then be averaged using the adjusted integration

time.

Calibration Value

(2 sec.)(2 sec.)

4 times

Function

(2 sec.)

049-DS-GB

Calibration Value

(2 sec.)

Calibration of the integration time

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

116

028-DS-GB

2266939.05 D/GB 06/2006

Page 42

Universal IS Pressure Transmitter UniTrans

Operation of Devices without Displays

8.6 Reset to Default

All default data settings are restored by simultaneously pressing the "zero", "esc" and

the "ok" buttons for 2 seconds (see chapter 9.4)

Calibration Value

Reset to default

Important

Function

(2 sec.)

(2 sec.)

(2 sec.)

050-DS-GB

Calibrated special measurement ranges i. e. 4 bar on a 6 bar transmitter can be adjusted by factory pre-setting. A reset to default will reset

the sensor back to its nominal range (i. e. 6 bar). The factory pre-setting

gets lost.

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wik a.de

117

Page 43

Universal IS Pressure Transmitter UniTrans

Operation of Transmitters with Display

9 Operation of Transmitters with Display

9.1 The Display

In order to program the device, remove the display with a screwdriver and re-attach it

to the housing as shown in the diagram below.

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

118

2266939.05 D/GB 06/2006

Page 44

Universal IS Pressure Transmitter UniTrans

Operation of Transmitters with Display

9.2 Key Functions

Button Functions

Main Menu Sub-menu Edit Functions

back to the previous

menu option

back to the previous

menu option

increase value

forward to next menu

option

back to value display

without saving

forward to next menu

option

back to main menu

without saving

decrease value

back without saving

to the sub-menu to the edit functions save value

activate keypad (push simultaneously; 2 s)

9.3 The Programming Mode

The transmitter can be programmed before or after installation.

The keypad is activated and the device can be programmed by simultaneously pressing the "esc" and "ok" keys (for 2 sec.). This method is used to access the main

menus. Each main menu has one or more sub-menus and each sub-menu, may have

its own sub-menus.

The keypad becomes inactive after 10 min. of disuse. All settings will default to previously stored values. Only settings that have been confirmed

with the "OK" function are stored.

A change in the starting measurement (zero point) has no effect on the

measurement span. Likewise, a change in the span has no effect on the

starting measurement.

An error signal occurs when the zero point or span settings fall outside of

the sensor’s nominal pressure range during calibration with pressure.

Nothing is saved.

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wik a.de

119

Page 45

Universal IS Pressure Transmitter UniTrans

Operation of Transmitters with Display

9.4 Default Data (factory settings)

Function Defaults

Display Unit of measurement

(Line 1)

Line 2

Line 3

Calibration zero 4 mA

span 20 mA

Output Damping

Inversion

Fault

Limits

I-offset

Service password no active password

Service mounting correction not activated

Language English

Evaluation linear

density

Calibrated special measurement ranges i. e. 4 bar on a 6 bar transmitter can be adjusted by factory pre-setting. A reset to default will reset

Important

the sensor back to its nominal range (i. e. 6 bar). The factory pre-setting

gets lost.

Pressure display (in bar)

Temperature display (in °C)

Sensor’s nominal pressure range (in bar)

nom. pressure range start

nom. pressure range end

0 s

no

21 mA (upscale)

3.8 ... 20.5 mA

0 mA

yes

1 g/cm

3

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

120

2266939.05 D/GB 06/2006

Page 46

9.5 Main Menu

Universal IS Pressure Transmitter UniTrans

Operation of Transmitters with Display

DISPLAY

OPTIONS

CALIBRATION

RANGE

see chapter 9.5.1

see chapter 9.5.2

OUTPUT

DEFINITION

EVALUATION

FUNCTION

LANGUAGE

OPTIONS

SERVICE

FUNCTIONS

see chapter 9.5.3

see chapter 9.5.4

see chapter 9.5.5

(not available for

transmitters with

HARTCommunication

option)

see chapter 9.5.6

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wik a.de

121

Page 47

9.5.1 Main Menu: Display

Universal IS Pressure Transmitter UniTrans

Operation of Transmitters with Display

DISPLAY

OPTIONS

*)The density of a medium must be

entered to calculate the correct filllevel when displaying or adjusting the

level in height units (e.g. mm, m, feet,

inch) (see 9.5.6). For ranges which

require over 4 digits see chapter

5.1.3.

**)For volume-based units it is necessary to enter the reference value

(100% = 0.0, value range 0 ...

3000).

*)

mbar

UNIT

DISPLAYED

DISPLAY

ROW 2

UNIT

UNIT

mmHG

UNIT

l

UNIT

lb

ROW 2

MEASURE

see *)

see **)

Units are set for the

measured value.

Units are set for the

measured value.

VOL_REF

100% = 0.0

OK

VOL_REF

100% = 0.0

OK

Second line

shows measured

value in %

Units are set for the

volume-related value.

Units are set for the

volume-related value.

bar

PSI

at

ROW 2

BLANK

Second line

remains empty

kg/cm²

mA

%

ROW 2

MIN VALUE

ROW 2

MEASUREMENT

Second line

shows minimum

values

mm

m starting with softinch ware version

1.05

feet

Pa

1)

hPa

kPa

ROW 2

MAX VALUE

ROW 2

TEMPERATUR

ROW 2

MEASUREMENT

TEMPERATU

TEMPERATURE

Second line

shows maximum

values

MPa

mmWS

mWS

1)

ROW 2

TEMPERATUR

TEMPERATU

mmHG

**)

TEMPERATURE

l

kg

ROW 2

TEMPERATURE

TEMPERATURE

in C

o

Second line

shows current

Tem p . in C

t starting with softm³ ware version

1.05

gal

lb

1) not available w. HART protocol

see chapter 5.1.3

ROW 2

CURRENT in mA

ROW 2

P-RANGE

TEMPERATURE

in F

o

Second line

shows present

current values

Merger of the

sensor's nominal

pressure range

Second line

shows current

Tem p . in F

display unit

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

122

o

o

Second line

shows minimum

o

Tem p . in C

Second line

shows minimum

o

Tem p . in F

Second line

shows maximum

o

Tem p . in C

Second line

shows maximum

o

Tem p . in F

031a1-DS-GB

2266939.05 D/GB 06/2006

Page 48

Universal IS Pressure Transmitter UniTrans

Operation of Transmitters with Display

DISPLAY

ROW 3

ROW 3

MEASURE %

ROW 3

BLANK

ROW 3

MIN VALUE

ROW 3

MAX VALUE

ROW 3

TEMPERATURE

ROW 3

CURRENT in mA

Third line

shows measured

value in %

Third line

remains empty

ROW 3

MEASUREMENT

ROW 3

TEMPERATURE

ROW 3

MEASUREMENT

ROW 3

TEMPERATURE

TEMPERATURE

o

in C

TEMPERATURE

o

in F

Third line

shows present

current value

Third line shows

minimum values

TEMPERATURE

in C

o

TEMPERATURE

o

in F

Third line shows

maximum values

TEMPERATURE

in C

o

TEMPERATURE

o

in F

Third line

shows current

o

Temp. in C

Third line

shows current

o

Temp. in F

Third line shows

minimum Temp.

o

in C

Third line shows

minimum Temp.

o

in F

Third line shows

maximum Temp.

o

in C

Third line shows

maximum Temp.

o

in F

ROW 3

P-RANGE

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wik a.de

Merger of the

sensors's nominal

pressure range

123

Page 49

Universal IS Pressure Transmitter UniTrans

Operation of Transmitters with Display

9.5.2 Main Menu: Calibration of zero and span (with / without pressure)

MAIN MENU

CALIBRATION

CALIBRATE

RANGE

Important

CALIBRATE

WITH PRESSURE

CALIBRATE

WITHOUT

PRESSURE

CALIBRATE

SET ZERO

CALIBRATE

SET SPAN

CALIBRATE

DEFINE ZERO

CALIBRATE

DEFINE SPAN

Adjustment

Zero Point

Adjustment

Span

DEFINE ZERO

DEFINE SPAN

Adjustment zero point via entry

of a pressure value within the

nominal pressure range

Adjustment span via entry

of a pressure value within the

nominal pressure range

A single pressure value is set for the zero point or the span end-point

within the sensor’s nominal pressure range, and assigned to the associated output current signal when making adjustments with existing pressure. An error signal occurs when the existing pressure lies outside of

the sensor’s nominal pressure range. The value is not saved in this

case.

A mounting correction should be performed before or after making an

adjustment without pressure (dry adjustment) (see 8.4.3). The sensor

must therefore be placed in the reference position for the measurement

(installation site) without pressure on the diaphragm.

A mounting correction is unnecessary when making an adjustment with

pressure (wet adjustment). Otherwise, the mounting correction must be

performed before saving the zero point and span end- point.

A test / correction of the zero point is suggested after adjusting the

span in order to maintain optimum accuracy.

Important

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexander Wiegand GmbH & Co. KG · Alexand er-Wiegand-Str. · 6391 1 Klingenberg · (09372) 132 - 710 · Fax - 706 · E-mail: support-tronic@wika.de · www.wika.de

124

2266939.05 D/GB 06/2006

Page 50

9.5.3 Main Menu: Output

Universal IS Pressure Transmitter UniTrans

Operation of Transmitters with Display

MAIN MENU

OUTPUT

OUTPUT

DEFINITION

OUTPUT

INVERSION

OUTPUT

DAMPING

OUTPUT

REVERSION

OUTPUT

ALARM/ERROR

OUTPUT

LIMITS

DAMPING

DAMPING

DAMPING

DAMPING

DAMPING

Output is inverted (20 mA ... 4 mA)

or not inverted (4 mA ... 20 mA)

LIMITS

Damping

40 s active

Damping

20 s active

Damping

5 s active

Damping

1 s active

Damping

0 s active

Alarm at 3.6 mA

(downscale)

Alarm at 21 mA

(upscale)

Measured value runs between 3.8 mA

and 20.5 mA. The current holds at the

limit when the sensing range is exceeded.

LIMITS

OUTPUT

CURRENT OFFSET

2266939.05 D/GB 06/2006

Subject to c hange due to techni cal modifications . © Copyright W IKA Alexander Wieg and GmbH & Co. KG / Germany

WIKA Alexand er Wiegand GmbH & Co. KG · Alexa nder-Wiegand-Str . · 63911 Klingen berg · (09372) 1 32 - 710 · Fax - 7 06 · E-mail: sup port-tronic@wik a.de · www.wik a.de

The current runs between 4 and 20 mA

Alarm condition when limits are reached;

It is necessary to restar t device by

using reset or by shutting down power

(see 8.5.6).

The output current is combined with an

assigned offset, which can have a maximum

of 0.4 mA.

Query routine for

additional safety.

033-DS-GB

125

Page 51

9.5.4 Main Menu: Evaluation

MAIN MENU

EVALUATION

Universal IS Pressure Transmitter UniTrans

Operation of Transmitters with Display

The level value and volume value

always be adjusted or verified in

order to store a value pair.

EVALUATION

FUCTIONS

EVALUATION

REF.TABLE

EVALUATION

LINEAR

EVALUATION

DENSITY

REF. POINT

INSERT

REF. POINT

DELETE

TABLE

EDIT

TABLE

ACTIVATE?

LINEAR

ACTIVATE?

l

d=

INSERT

DELETE