Page 1

IS-20-S, IS-21-S, IS-20-F, IS-21-F, IS-20-H

Operating instructions

Betriebsanleitung

Mode d'emploi

Pressure Transmitter

Druckmessumformer

Transmetteur de pression

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/ Germany

Tel. (+49) 93 72/132-295

Fax (+49) 93 72/132-706

E-Mail support-tronic@wika.de

www.wika.de

2132926.02 GB/D/F 01/2006

IS-21-S

IS-20-F

GB

GB

GB

IS-20-H

D

F

Page 2

Operating instructions

Betriebsanleitung

Mode demploi

IS-20-S, IS-21-S

IS-20-F, IS-21-F

IS-20-H

Pressure transmitter /

Druckmessumformer /

Transmetteur de pression

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg

Phone (+49) 93 72/132-295

Fax (+49) 93 72/132-706

E-Mail support-tronic@wika.de

www.wika.de

2132926.02 GB/D/F 01/2006

/Germany

IS-21-S

IS-20-H

IS-20-F

Page 3

Contents / Inhalt / Contenu

Contents Page 3-20

1. Important details for your information

2. A quick overview for you

3. Abbreviations, signs and symbols

4. Function and accessories

5. For your safety

6. Packaging

7. Starting, operation

8. Maintenance, spare parts

9. Trouble shooting

10. Storage, disposal

11. EC declaration of conformity

Inhalt Seite 21-39

1. Wichtiges zu Ihrer Information

2. Der schnelle Überblick für Sie

3. Zeichenerklärungen, Abkürzungen

4. Funktion und Zubehör

5. Zu Ihrer Sicherheit

6. Verpackung

7. Inbetriebnahme, Betrieb

8. Wartung, Ersatzteile

9. Störbeseitigung

10. Lagerung, Entsorgung

11. EG-Konformitätserklärung

2

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

GB

Contenu Page 40-59

1. Informations inportantes

2. Aperçu rapide

3. Explication des symboles,abréviations

4. Fonction et accessoires

5. Pour votre sécurité

6. Emballage

7. Mise en service, exploitation

8. Entretien, Pièces de rechange

9. Elimination de perturbations

10. Stockage, mise au rebus

11. Déclaration de conformité CE

Contents/Inhalt/Contenu

D

12. Control Drawing FM, CSA 60

Current terms and conditions apply.

Details are available on

www.wika.de

Es gelten unsere aktuellen Verkaufs- und

Lieferbedingungen siehe unter

www.wika.de

Toute commande est assujettie à nos

conditions de ventes et de fournitures dans

leur dernière version en vigueur, voir sous

www.wika.de

S -S, IS-2 S -F, IS-20-H

GB

FDGB

F

1. Important details for your information

1. Important details for your information

GB

Read these operating instructions before installing and starting the pressure transmitter. Keep

the operating instructions in a place that is accessible to all users at any time.

The following installation and operating instructions have been compiled by us with great care

but it is not feasible to take all possible applications into consideration. These installation and

operation instructions should meet the needs of most pressure measurement applications. If

questions remain regarding a specific application, you can obtain further information (data

sheets, instructions, etc.) via our Internet address (www.wika.de / www.wika.com ) or contact

WIKA for additional technical support (see section7 Starting, Operation/Further information).

The product data sheet is designated as PE 81.50 / PE 81.51

WIKA pressure transmitters are carefully designed and manufactured using state-of-the-art

technology. Every component undergoes strict quality inspection before assembly and each

instrument is fully tested prior to shipment.

Use of the product in accordance with the intended use IS-2S-S, IS-2S-F, IS-20-H:

Use the intrinsically safe pressure transmitter for pressure measurement in hazardous areas.

D

F

Certificate ATEX: Pressure transmitter for operation in hazardous areas in compliance

with the respective certificate (see attached EC-type examination certificate

BVS 04 ATEX E 068 X).

ATEX Approval ratings: Gases and mist connection to Zone 0, Zone 1, Zone 2.

Dust connection to Zone 20, Zone 21, Zone 22 (not for IS-20-H).

Mining Category M1, M2.

Certificate FM/CSA: Pressure transmitter for operation in hazardous areas in compliance

with the respective certificate (see Control drawing No. 2323880, section 13).

FM / CSA Approval ratings: Intrinsically Safe with entity approval for Class I, II

and III Division 1, Groups A, B, C, D, E, F, G and Class I, Zone 0, AEx ia IIC

Dust-ignitionproof for Class II and III, Division 1, Groups E, F, and G.

Non-incendive for Class I Division 2 Groups A, B, C and D

FM standards according to FMRC 3600, 3610, 3611, 3810 (including

supplement #1), ISA-S12.0.01, IEC60529 (including amendment #1)

CSA Standard C22.2 No. 0-M1991 / 94-M1991 / 142-M1987 / 157-M1992

UL 50, Eleventh Edition / UL 508, Seventeenth Edition / UL 913, Sixth Edition

2132926.02 GB/D/F 01/2006

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

S -S, IS-2 S -F, IS-20-H

3

Page 4

2. A quick overview for you / 3. Abbreviations, signs and symbols

GB GB

Knowledge required: Install and start the pressure transmitter only if you are familiar with the

relevant regulations and directives of your country and if you have the qualification required.

You have to be acquainted with the rules and regulations on hazardous areas, measurement

and control technology and electric circuits, since this pressure transmitter is electrical

equipment as defined by EN 50178. Depending on the operating conditions of your

application you have to have the corresponding knowledge, e.g. of aggressive media.

2. A quick overview for you

If you want to get a quick overview, read Chapters 3, 5, 7 and 10. There you will get some

short safety instructions and important information on your product and its starting. Read

these chapters in any case. Get some more detailed information on this product in Chapters

4 Function and accessories and 6 Packaging. Read Chapter 8 for Maintenance. In the

case of failures please refer to Chapter 9.

3. Abbreviations, signs and symbols

!

Warning

Warning

Caution

4

Potential danger of life or of

severe injuries.

Potential danger of life or of

severe injuries due to catapulting

parts.

Potential danger of burns due to

hot surfaces.

Notice, important information,

malfunction.

The product complies with the

applicable European directives.

Power supply

Load (e.g. display)

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

The product complies with the requirements of the European directive 94/9/EC (ATEX) on explosion

protection.

The product was tested and certified by FM Approvals. It complies

with the applicable US-American

standards on safety (including

explosion protection).

The product was tested and certified by CSA International. It complies with the applicable Canadian

and US-American standards on

safety (including explosion protection).

S -S, IS-2 S -F, IS-20-H

3. Abbreviations, signs and symbols / 4. Function and accessories

With a line transformer you realise the mandatory galvanic isolation of the voltage

and current supply between hazardous and non-hazardous areas and ensure the

safety connection data.

2-wire Two connection lines are intended for the voltage supply.

The supply current is the measurement signal.

UB+/Sig+ Positive supply / measurement connection

OV/Sig- Negative supply / measurement connection

ATEX European guideline for explosion protection (Atmosphäre=AT, Explosion=EX)

CSA Canadian Standard Association

EHEDG European Hygienic Equipment Design Group

FDA Food and Drug Administration

FM Factory Mutual

4. Function and accessories

IS-20: Standard pressure connection (intrinsically safe).

IS-21: Pressure connection with flush diaphragm (intrinsically safe) for highly viscous

S

-S Pressure transmitter (intrinsically safe), version with electrical connector or flying

IS-2

S

-F Pressure transmitter (intrinsically safe), field case version.

IS-2

IS-20-H Pressure transmitter

Function: With the pressure transmitter you measure the pressure of your application, which

is trans-formed into an electric signal. This electric signal changes in proportion to the

pressure and can be evaluated correspondingly.

Accessories: For details about the accessories, please refer to WIKAs price list, WIKAs

product catalog on CD or WIKAs web site www.wika.de. Please refer to our data sheet

Pressure gauge sealing washers AC 09.08 in WIKAs product catalog Pressure and

Temperature Measurement or our web site www.wika.de for details about sealing washers.

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

or solids entrained media which might clog the pressure port.

leads.

(intrinsically safe), highest pressure version.

S -S, IS-2 S -F, IS-20-H

5

Page 5

5. For your safety

5. For your safety

n Select the appropriate pressure transmitter with regard to scale range,

!

Warning

n Open pressure connections only after the system is without pressure!

n Please make sure that the pressure transmitter is only used within the overload

n Observe the ambient and working conditions outlined in section 7 Technical data.

n Ensure that the pressure transmitter is only operated in accordance with the

n Do not interfere with or change the pressure transmitter in any other way than

n Remove the pressure transmitter from service and mark it to prevent it from being

n Take precautions with regard to remaining media in removed pressure

n Have repairs performed by the manufacturer only.

n Consider the details given in the EC-type examination certificate as well as the

Information about material consistency against corrosion and diffusion can be found in our

WIKA-Handbook, 'Pressure and Temperature Measurement'.

6

performance and specific measurement conditions prior to installing and

starting the instrument.

n Observe the relevant national regulations (e.g.: EN 50178, NEC, CEC) and

observe the applicable standards and directives for special applications

(e.g. with dangerous media such as oxygen, acetylene, flammable gases or

liquids and toxic gases or liquids and with refrigeration plants or compressors).

If you do not observe the appropriate regulations, serious injuries and/or

damage can occur!

threshold limit at all times!

provisions, i.e. as described in the following instructions.

described in these operating instructions

used again accidentally, if it becomes damaged or unsafe for operation.

transmitter. Remaining media in the pressure port may be hazardous or toxic!

respective specifications for explosion hazard use of the country concerned

(e.g.: IEC 60079, NEC, CEC). If you do not observe these stipulations, serious injuries

and/or damage can occur.

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

.

S -S, IS-2 S -F, IS-20-H

GB

5. For your safety

Special advice for intrinsic safety

n Protect the diaphragm against any contact with abrasive substances and

!

Warning

Measurement of process media with higher temperatures than the media temperature ranges

specified in the tables of the EC-type examination certificate under item 15.1.2 is permissible,

if special cooling elements are used (not for IS-20-H).

!

Warning

n Ensure an unhindered air circulation at the cooling element.

n Protect the pressure transmitter against touching or affix a warning notice.

n Insulate heat sources thermally from the pressure transmitter (e.g. pipes or tanks)

n Protect the cooling element against contamination and dust deposits.

Special wiring advice

!

Warning

n Connect the shield to ground exclusively in safe (i.e. non-hazardous) areas in

n Consider both the internal capacitance and inductance.

n Consider that cables for use in zones 1 and 2 must be checked with a test voltage

n Cover flying leads with fine wires by an end splice (cable preparation).

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

pressure peaks and do not touch it with tools. If you damage the diaphragm,

no intrinsic safety can be guaranteed (ATEX, FM, CSA)!

n Ensure that under hazardous dust ennvironment the pressure transmitter is

mounted in a shielded section and protect it against shocks.

n Observe the permissible surface temperatures applicable for this range

according to the defined temperature classes.

n Observe the maximum temperature value (of the temperature range defined

under item 15.1.2 in the EC-type examination certificate) at the hexagon of the

tubular case.

n The bayonet-connector is made of light metal, a material which is not

permissible for group I applications (mining).

n Always connect the case to earth to protect the pressure transmitter against

electromagnetic fields and electrostatic charges.

accordance with EN 60079-14. Ensure that with flying leads the shield is always

connected to ground on the instrument side by the manufacturer.

between conductor/earth, conductor/screen, screen/earth of more than 500V (AC).

S -S, IS-2 S -F, IS-20-H

GB

.

7

Page 6

5. For your safety / 6. Packaging

Installation in / connection to zone 0 and zone 20 (zone 20 not with IS-20-H)

(In general Zone 0 is given when the pressure transmitter is surrounded by a mixture of

explosive gases more than 1.000 hours per year = continuous hazard).

n For the seperation of the zones the pressure transmitter or the cable gland

!

Warning

in the wall must have the ingress protection according to IEC 60 529

namely for zone 0: IP 67 and for zone 20: IP 6X.

n Observe the technical data for the use of the pressure transmitter in

connection with aggressive / corrosive media and for the avoidance of

mechanical hazards.

n Lay out the circuits according to type Ex ia.

6. Packaging

n Inspect the pressure transmitter for possible damage during transportation.

Should there be any obvious damage, inform the transport company and WIKA

without delay.

n Keep the packaging, as it offers optimal protection during transportation

(e.g. changing installation location, shipment for repair).

n Keep the protection cap of the pressure connection thread and the diaphragm

for later storage or transport.

In order to protect the diaphragm, the pressure connection of the instrument IS-21-S, -F is

provided with a special protection cap.

n Remove this protection cap only just before installing the pressure transmitter

in order to prevent any damage to the diaphragm.

n Mount the protection cap when removing and transporting the instrument.

n Ensure that the pressure connection thread and the connection contacts will

not be damaged.

8

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

S -S, IS-2 S -F, IS-20-H

GB

7. Starting, operation

7. Starting, operation

Has everything been supplied?

Check the scope of supply:

n Completely assembled pressure transmitters; with flush version IS-21-S, -F

including pre-assembled sealings and protection cap.

n EC-type examination certificate

Required tools: wrench (flats 27), screw driver

Diaphragm test for your safety

It is necessary that before starting the pressure transmitter you test the diaphragm, as this is

a safety-relevant component.

n Pay attention to any liquid leaking out, for this points to a diaphragm damage

(not necessary for IS-20-H).

n Check the diaphragm visually for any damage.

n Use the pressure transmitter only if the diaphragm is undamaged.

n Use the pressure transmitter only if it is in a faultless condition as far as the

safety-relevant features are concerned.

n Remove the protection cap only just before installation and absolutely avoid

any damage to the diaphragm during installation as well.

n Ensure that the cable diameter you select fits to the cable gland of the

connector. Ensure that the cable gland of the mounted connector is positioned

correctly and that the sealings are available and undamaged. Tighten the

threaded connection and check the correct position of the sealings in order to

ensure the ingress protection.

n When mounting the instrument, ensure that the sealing faces of the instrument

and the measuring point are clean and undamaged.

n Screw in or unscrew the instrument only via the flats using a suitable tool and

and the prescribed torque. Do not use the case as working surface for

screwing in or unscrewing the instrument.

n When screwing the transmitter in, ensure that the threads are not jammed.

S -S, IS-2 S -F, IS-20-H

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

!

Warning

Installation

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

GB

9

Page 7

7. Starting, operation

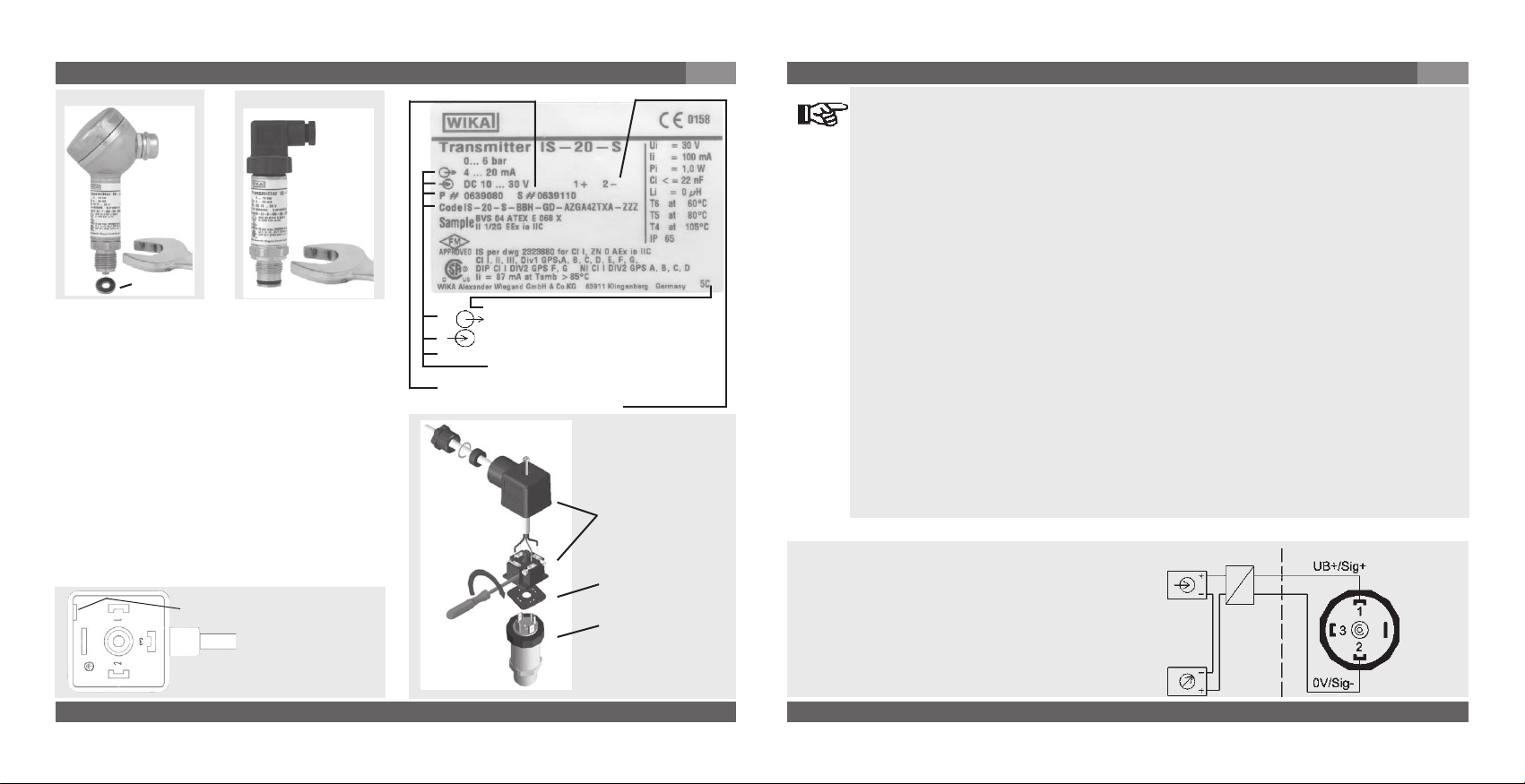

IS-20-F , IS-21-F

max.

50Nm

Sealing

For Model IS-20-S/-F the sealing ring is available as an optional extra. For Model IS-21-S/-F

the sealing ring is included in delivery.

For tapped holes and welding sockets

please see Technical Information IN 00.14

for download at www.wika.de -Service

Wiring: Ingress protection per IEC 60529

(The ingress protection classes specified only

apply while the pressure transmitter is

connected with female connectors that

provide the corres-ponding ingress

protection). Please make sure that the ends

of cables with flying leads do not allow any

ingress of moisture.

(D) Mounting hole

IS-20-S, IS-21-S

max.

50Nm

Product label (example)

Coded manufacture date

Signal

Power Supply

P #

Product No.

Order code

Serial No.

S #

PIN assignment

(2)

(3)

(4)

(1)

(5)

Female

connector

(6)

Sealing

Clamping nut,

Male connector,

Case with

pressure connection

GB

7. Starting, operation

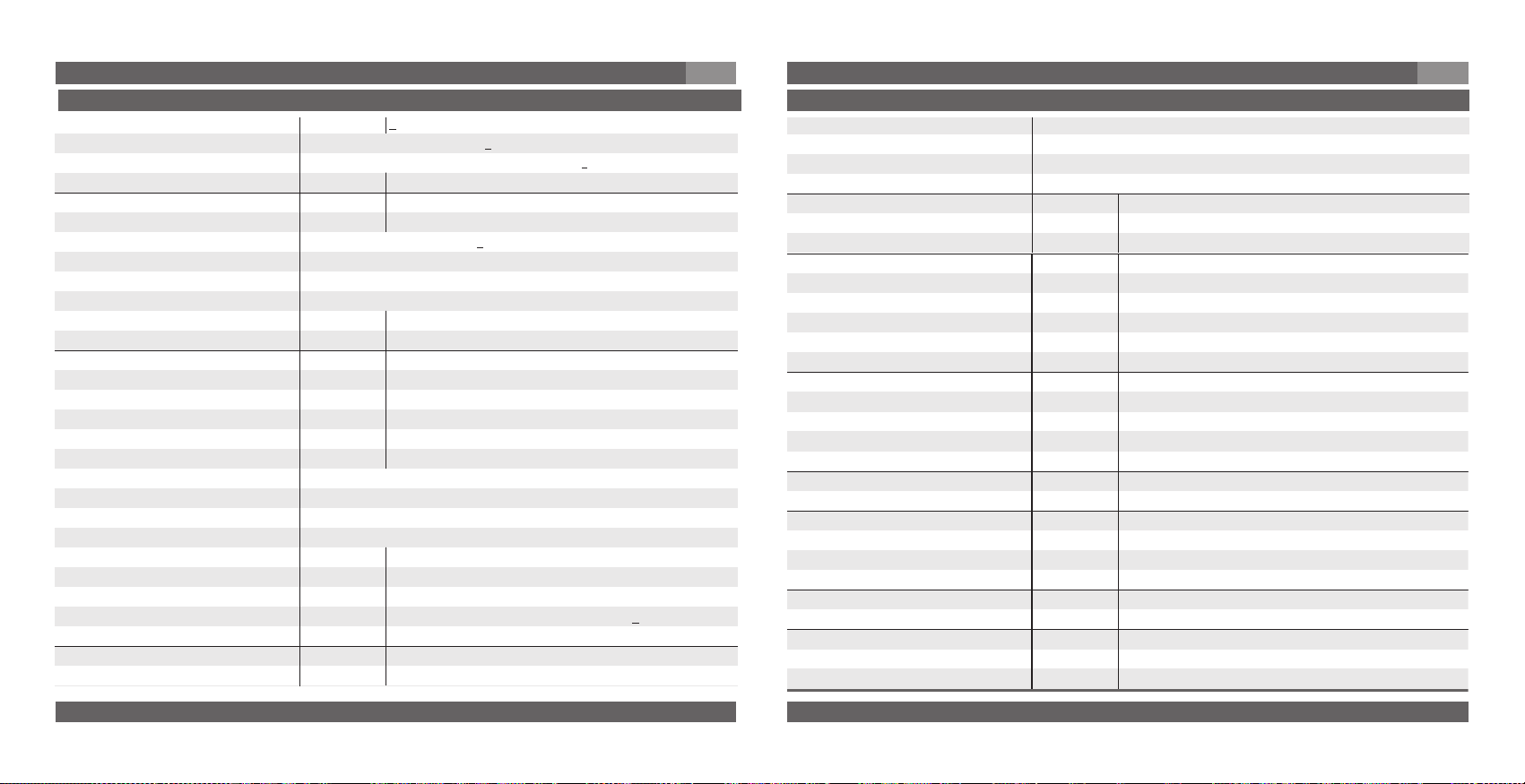

1. Loosen the screw (1).

2. Loosen the cable gland (2).

3. Pull the angle housing (5), with the terminal block (6) inside, away from the

instrument.

4. Using the head of a small screwdriver in the mounting hole (D), lever the

terminal block (6) out of the angle housing (5). In order not to damage the

sealing of the angle housing, do not try to push the terminal block (6) out using

the screw hole (1) or the cable gland (2).

5. Ensure that the conducteur outer diameter you select is matched to the angle

housings cable gland. Slide the cable through the cable gland nut (2), washer

(3), gland seal (4) and angle housing (5).

6. Connect the flying leads to the screw terminals on the terminal block (6) in

accordance with the pin-assignment drawing.

7. Press the terminal block (6) back into the angle housing (5).

8. Tighten the cable gland (2) around the cable. Make sure that the sealing isnt

damaged and that the cable gland and seals are assembled correctly in order

to ensure ingress protection.

9. Place the flat, square gasket over the connection pins on the top of the instrument housing.

10. Slide the terminal block (6) onto the connection pins.

11. Secure the angle housing (5) and terminal block (6) to the instrument with the

screw (1).

Model IS-20-S, IS-21-S, IS-20-H 2-wire

L-Connector, DIN EN 175301-803, Form A,

for conducter cross section up to max. 1.5 mm²,

conducter outer diameter 6 to 8 mm

(ship approval: 10 to 14 mm), IP 65,

Order code: A4 and G (ship approval)

Non hazardous area Hazardous (classified) area

GB

10

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

S -S, IS-2 S -F, IS-20-H

2132926.02 GB/D/F 01/2006

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

S -S, IS-2 S -F, IS-20-H

11

Page 8

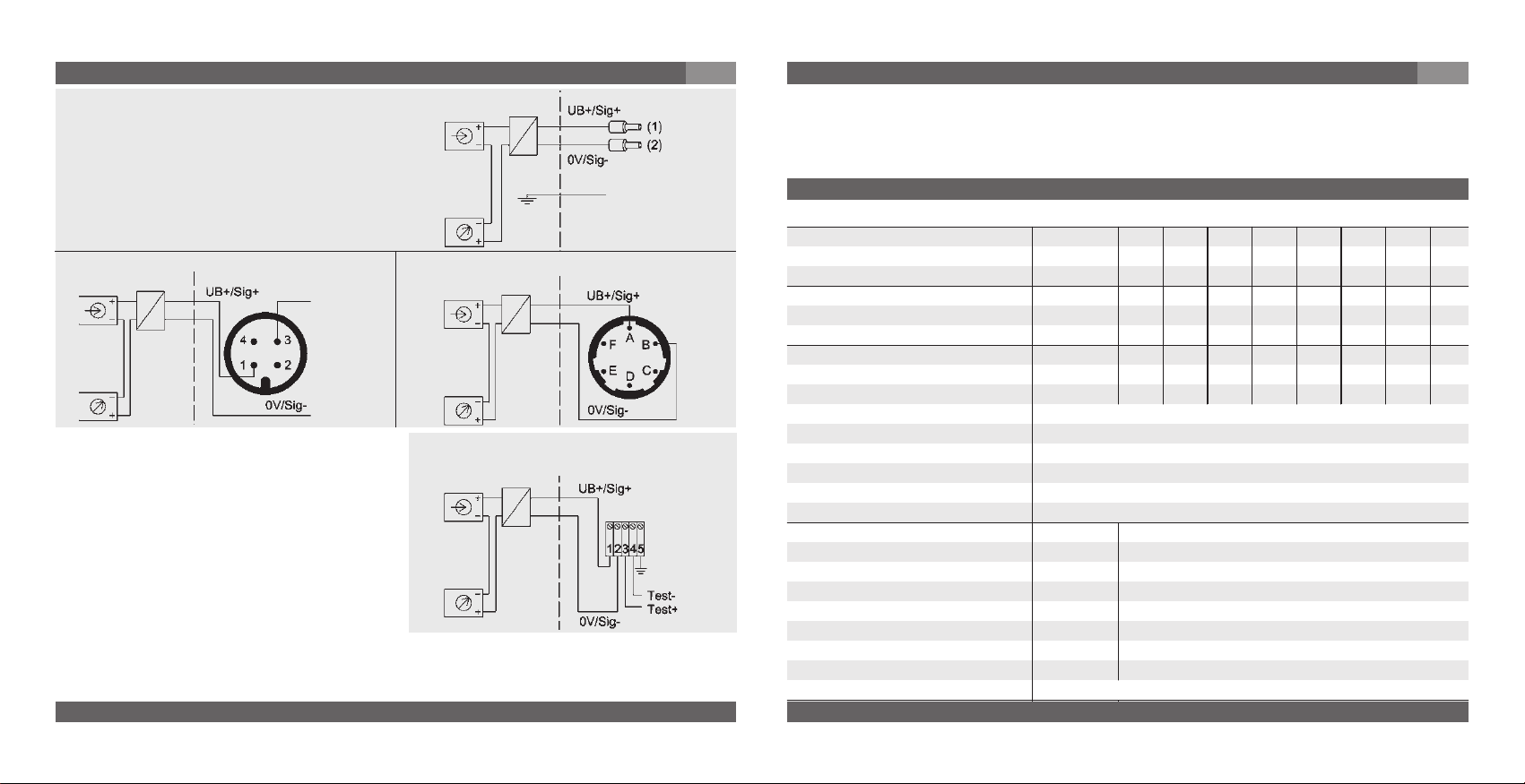

7. Starting, operation

Flying leads, conducter cross section up

to max. 0.5 mm ²/AWG 20 with end splices,

Non hazardous area

Hazardous (classified) area

brown

GB

conducter outer diameter 6.8 mm,

IP67, Order-Code: DL /

zero/span not adjustable, IP68,Order-Code:EM/

zero/span adjustable, IP68, Order-Code: XM

Circular connector M 12x1, IP 67, Order-Code: M4

Non hazardous area Hazardous (classified) area

Cable connection in the spring clip terminal

n Cover the stripped wire ends with end splices.

n Unscrew the case cover.

Bayonet-connector, IP 67 / Order-Code: C6

Non hazardous area Hazardous (classified) area

Model IS-20-F, IS-21-F, IS-20-H with field case

Order-Code: FC, FH

Non hazardous area

green

screen

Hazardous (classified) area

n Loosen the cable gland using an open-end

wrench, wrench size 24.

n Lead the cable through the cable gland into

the opened case head.

n Press the corresponding plastic lever at the

spring clip terminal down using a screw

driver, so that the clamped contact will be

released.

n Lead the prepared flying lead into the opening and let go of the plastic lever, so that the

flying lead will be squeezed inside the spring clip terminal.

n After connecting the individual wires, tighten the cable gland and screw down the case over.

12

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

S -S, IS-2 S -F, IS-20-H

7. Starting, operation

Function of the test circuit for 2-wire: By means of the test circuit the current can be metered during normal operation without having to disconnect the instrument. For that purpose

you have to connect an ammeter (for applications in hazardous areas; internal resistance

< 15 Ohm) to the test +/- terminals.

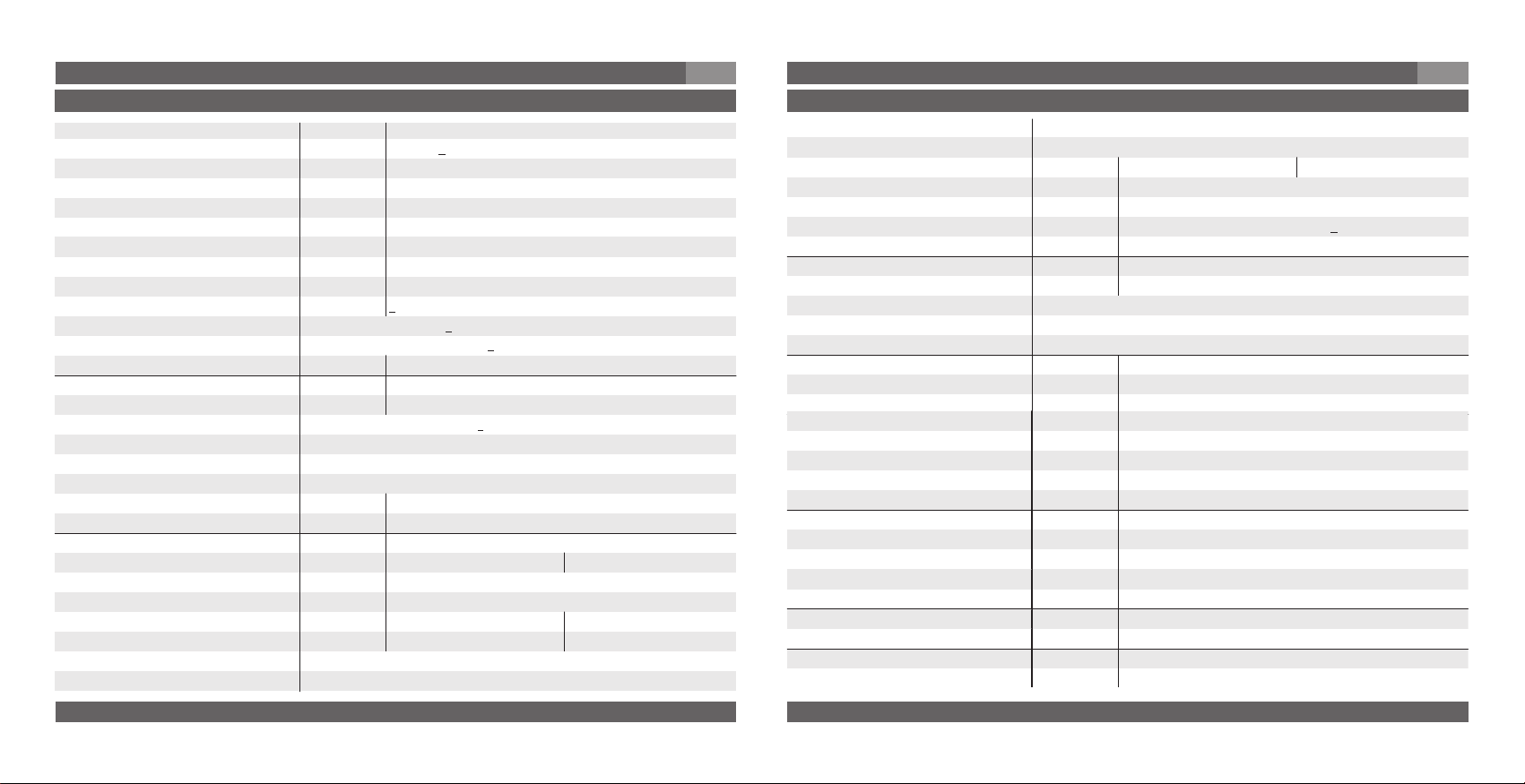

Specifications Model IS-20-S, IS-21-S, IS-20-F, IS-21-F, IS-20-H

Specifications without model designation apply for all models.

Pressure ranges *) IS-2

Over pressure safety IS-2

Burst pressure IS-2

Pressure ranges *)IS-2

Over pressure safety IS-2

Burst pressure IS-2

Pressure ranges *) IS-2

Over pressure safety IS-2

Burst pressure IS-2

Materials

Wetted parts

n

Model IS-20-S, IS-20-F, IS-20-H *

Ø

Model IS-21-S, IS-21-F

Ø

n Case Stainless steel

Internal transmission fluid

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

S

S

S

S

S

S

S

S

S

3)

-S, IS-2

-S, IS-2

-S, IS-2

-S, IS-2

-S, IS-2

-S, IS-2

-S, IS-2

-S, IS-2

-S, IS-2

S

-F bar 0.1 0.16 0.25 0.4 0.6 1 1.6 2.5

S

-F bar 1 1.5 2 2 4 5 10 10

S

-F bar 2 2 2.4 2.4 4.8 6 12 12

S

-F bar 4 6 10 16 25 40 60 100

S

-F bar 17 35 35 80 50 80 120 200

S

-F bar 20.5 42 42 96 96 400 550 800

S

-F bar 160 250 400 600 1000

S

-F bar 320 500 800 1200 1500

S

-F bar 1000 1200 17002)24002)3000

Pressure ranges for IS-20-H see additional operating

instructions 11126418 High pressure

{Vacuum, gauge pressure, compound range, absolute pressure are available}

1)

Only Model IS-20-S, IS-20-F.

2)

For model IS-21-S, IS-21-F: the value specified in the table applies only when sealing is

realised with the sealing ring underneath the hex. Otherwise max. 1500 bar applies.

)

3)

Not for model IS-20-S, IS-20-F with pressure ranges > 25 bar and IS-20-H

(other materials see WIKA diaphragm seal program)

Stainless steel

Stainless steel {Hastelloy C4}

O-ring: NBR {FPM/FKM or EPDM}

Synthetic oil {Halocarbon oil for oxygen applications}

{Listed by FDA for Food & Beverage}

S -S, IS-2 S -F, IS-20-H

1)

GB

13

Page 9

7. Starting, operation

)

GB

7. Starting, operation

GB

Specifications Model IS-20-S, IS-21-S, IS-20-F, IS-21-F, IS-20-H Specifications Model IS-20-S, IS-21-S, IS-20-F, IS-21-F, IS-20-H

8)

Power supply U

B

UB in DC V

10 < U

30

≤

B

(11 < UB < 30 with model IS-2

-F and IS-20-H with field case)

S

Signal output and 4 ... 20 mA, 2-wire

maximum load R

Model IS-2

Ø

Model IS-2

Ø

A

S

-S

S

-F, IS-20-H with

RA in Ohm

RA ≤ (UB–10 V) / 0.02 A–(length of flying leads in m x0,14Ohm

≤ (UB – 11 V) / 0.02 A

R

A

field case

S

Test circuit signal and maximum load RA < 15 (only model IS-2

Adjustability zero/span %

Response time (10 ... 90 %) ms < 1

4)

Response time IS-20-S/-F: < 10 ms at medium temp. Below <-30°C for pressure ranges

up to 25 bar. Response time IS-21: < 10 ms at medium temp. below < -30 °C (-22°F).

10 using potentiometers inside the instrument

±

4)

-F, IS-20-H with field case)

Dielectric strength Insulation complies with EN 50020, 6.4, 12

Accuracy % of span

% of span

5)

Accuracy

6

)

Including non-linearity, hysteresis, non-repeatability, zero signal and full scale error

(corresponds to error of measurement per IEC 61298-2).

Adjusted in vertical mounting position with lower pressure connection.

Non-linearity % of span

1-year stability % of span

Permissible temperature of

n Medium 7)

9) *)

0.25 {0.125}

≤

0.5 {0.25}

≤

for pressure ranges > 0.25 bar, not for IS-20-H

{ }

0.2 (BFSL) according to IEC 61298-2

≤

0.2 (at reference conditions)

≤

-20 ... +80 °C

5) 6)

8)

6)

(BFSL)

-4 ... +176 °F

(Extended temperature ranges see chapter 7 „Relation of

medium temperature to ambient temperature“)

-20 ... +80 °C

8)

-4 ... +176 °F

-30 ... +105 °C -22 ... +221 °F

n Ambience 7)

n Storage

7)

9)

7)

Also complies with EN 50178, Tab. 7, Operation (C) 4K4H, Storage (D) 1K4,

Transport (E) 2K3

Compensated temp range 0 ... +80 °C 32 ... +176 °F

Temperature coefficients within

compensated temp range

n Mean TC of zero % of span

Mean TC of range % of span

n

d

- protection

Ignition protection type EEx ia I/II C T4, EEx ia I/II C T5, EEx ia I/II C T6

– protection

Ex

Ignition protection type Instrinsic safe Class I, II, III Division 1,

a

- conformitiy

FM, CSA FM standards according to FMRC 3600, 3610, 3611

8)

8)

HF-immunity V/m 10

BURST KV 2

Shock resistanceØ Model IS-2

Model IS-2

Ø

S

-S g 1000 according to IEC 60068-2-27 (mechanical shock)

S

-F g 600 according to IEC 60068-2-27 (mechanical shock)

Other temperature ranges are possible, depending on the electrical connection; see

EC-type examination certificate, e.g. -30…+105 °C / -22 ... +221 °F

0.2 / 10 K (< 0,4 for pressure range < 250 mbar)

≤

0.2 / 10 K

≤

ATEX Category 9) 1G, 1/2G, 2G, 1D

9)

the operating conditions and safety-relevant data in the

Read

EC-type examination certificate in any case

10)

Not for IS-20-H

10)

10)

, 2D

10)

, M1, M2

, 1/2D

(BVS 04 ATEX E 068 X)

FM, CSA Class I, II and III

Group A, B, C, D, E, F, G and Class I, Zone 0 AEx ia II C

89/336/EEC interference emission and immunity see

EN 61 326, interference emission limit class A and B

ATEX EN 50 014 (general part),

EN 50 020 (instrinsic safety), {EN 50 284 (Zone 0)},

{EN 50 281-1 (dust -Ex)}, {EN 50 303 (mining industry)}

(including supplement #1), ISA-S12.0.01, IEC 60 529

(including amendment #1), CSA standard C22.2

No. 0-M1991 / 142-M1987 / 157-M1992, UL 50, Eleventh

Edition / UL 508, Seventeenth Edition / UL 913, Sixth Edition

14

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

S -S, IS-2 S -F, IS-20-H

2132926.02 GB/D/F 01/2006

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

S -S, IS-2 S -F, IS-20-H

15

Page 10

7. Starting, operation

GB

Specifications Model IS-20-S, IS-21-S, IS-20-F, IS-21-F, IS-20-H

Vibration resistanceØ Model IS-2

Model IS-2

Ø

Wiring protection Protected against reverse polarity and short circuiting on the

Mass

*) In an oxygen version model IS-21 is not available. In an oxygen version model IS-20 is only available in gauge pressure ranges > 0.25 bar

with media temperatures between -20 … +60 °C / -4 … +140 °F and using stainless steel or Elgiloy® wetted parts.

{ } Items in curved brackets are optional extras for additional price.

Model IS-2

Ø

Model IS-2

Ø

Model IS-20-H

Ø

S

-S g 20 according to IEC 60068-2-6 (vibration resonance)

S

-F g 10 according to IEC 60068-2-6 (vibration resonance)

instrument side

S

-S kg Approx. 0.2

S

-F kg Approx. 0.35

kg Approx. 0.3 (approx. 0.45 with version field case)

When designing your plant, take into account that the stated values (e.g. burst pressure, over

pressure safety) apply depending on the material, thread and sealing element used.

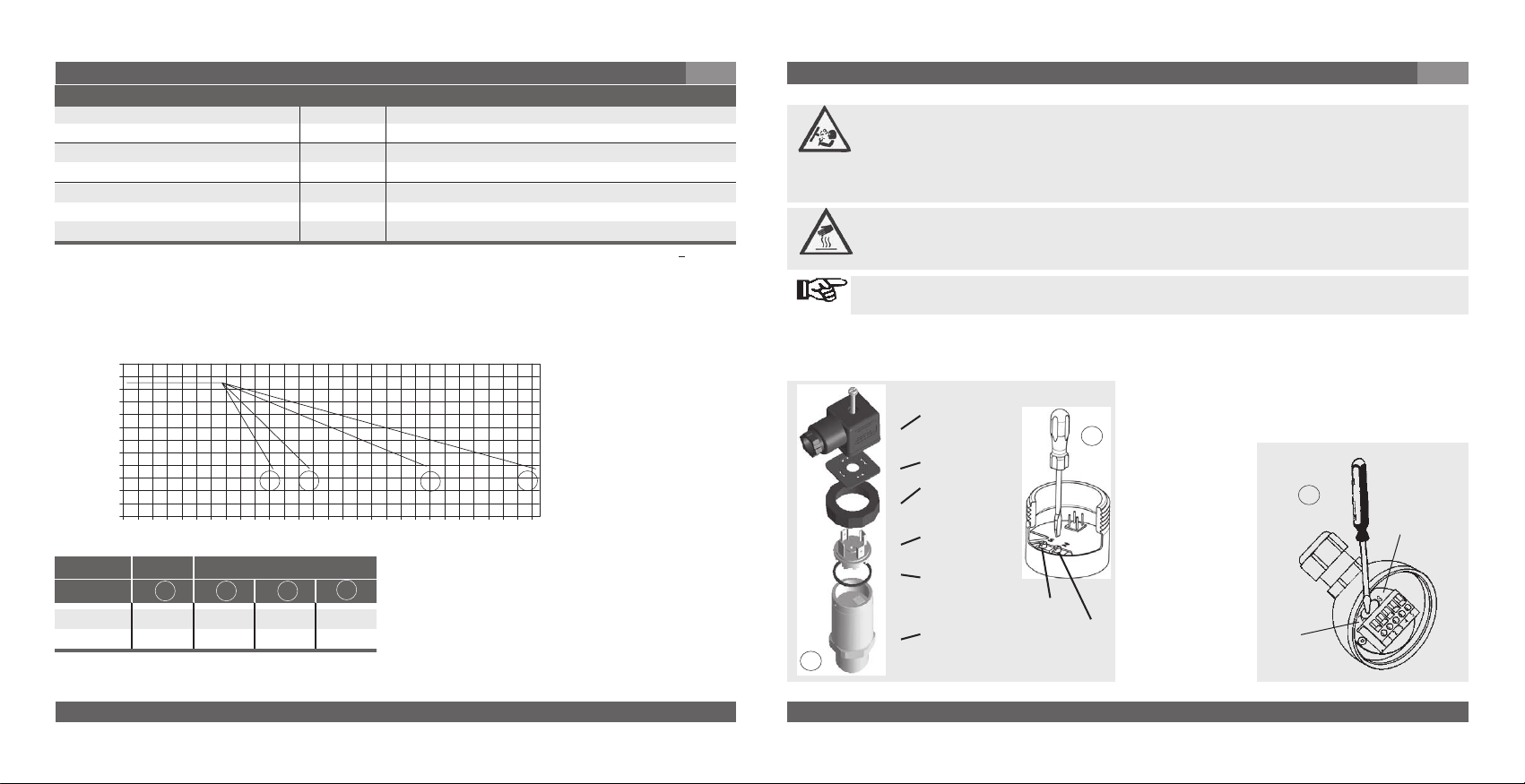

Relation of medium temperature to ambient temperature

120

110

100

90

80

70

60

50

40

30

20

10

0

40 80 120 160 200 240 280 320

Temperature of ambient [°C]

Model

Version

Cooling fin - 2 3 5

Constant K 0.34 0.47 0.68 0.76

IS-20-H IS-2

A B

Calculation of max. temperature of ambience:

= T

16

+ (TB - T

med

T

amb

) / K

med

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

A

5

-S/ -F

C

B

C

D

Temperature of medium [°C]

Calculation of cooling element:

T

= T

- (T

- T

B

med

D

T

B

T

med

T

amb

K = Constant of cooling element

med

= Operation temperature of transmitter

= max. temperature of process medium

= max. temperature of ambience

) x K

amb

S -S, IS-2 S -F, IS-20-H

7. Starting, operation

Functional test

Warning

Caution

Adjustment of zero point/span (only for pressure transmitter with clamping nut and field case)

IS-20-S, IS-21-S, IS-20-H:

A

A

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

n Open pressure connections only after the system is without pressure!

n Observe the ambient and working conditions outlined in section 7 Technical

data.

n Please make sure that the pressure transmitter is only used within overload

threshold limit at all times!

When touching the pressure transmitter, keep in mind that the surfaces of the

instrument components might get hot during operation.

The output signal must be proportional to the pressure. If not, this might point to

a damage of the diaphragm. In that case refer to chapter 9 Troubleshooting.

IS-20-F, IS-21-F, IS-20-H

with field case:

Female

connector

Sealing

Clamping

nut

Male

connector

Sealing

S = Span

Case with

pressure

connection

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

C

B

Z = Zero

Z = Zero

S -S, IS-2 S -F, IS-20-H

GB

S = Span

17

Page 11

e

q

7. Starting, operation / 8. Maintenance, spare parts

S -S, IS-2 S -F, IS-20-H with field case:

IS-2

GB

n Make sure using a pressure standard with adequate accuracy. Pressure standard with

adequate accuracy means with an accuracy that is at least 3x more accurate than the

accuracy indicated for the instrument.

n Please make sure that no braids get torn or pinched during the assembly / disassembly of

the connectors.

n Remove the female connector. Open the pressure transmitter by detaching the clamping

nut (see Fig. A ). Carefully remove the male connector from the case.

Open the pressure transmitter by twisting off the field case cover (see Fig. B ).

n Adjust the zero point (Z) (see Fig. B + C ) by generating the lower limit of the pressure

range.

n Adjust the span (S) by generating the higher limit of the pressure range.

n Check the zero point.

n If the zero point is incorrect, repeat procedure as required.

n Close the pressure transmitter carefully.Make sure that the sealings are notdamaged and

check their correct position in order to ensure the ingress protection.

Recommended recalibration cycle: 1 year

8. Maintenance, spare parts

WIKA pressure transmitters require no maintenance!

For further information (+49 9372/132-295)

n Open pressure connections only after the system is without pressure!

Warning

n Take precautions with regard to remaining media in removed pressure

!

Warning

transmitters. Remaining media in the pressure port may be hazardous or toxic!

n Remove the pressure transmitter from service and mark it to prevent it from

being used again accidentally, if it becomes damaged or unsafe for operation.

n Have repairs performed by the manufacturer only.

Do not insert any pointed or hard objects into the pressure port for cleaning to

prevent damage to the diaphragm of the pressure connection.

Spare parts: For spare part details refer to our current stock price list, the CD catalog or

contact our sales department.

18

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

S -S, IS-2 S -F, IS-20-H

9. Trouble shooting

GB

9. Trouble shooting

Problem Possible cause Remedy

No output Power supply failure Check power supply

Open wiring Check continuity

Wiring reversed Correct polarity

No pressure or port blocked Check pressure port

transmitter failure due to wrong

Supply voltage or power surge Replace transmitter

Output steady as pressure Pressure port blocked Check pressure port

changes Transmitter over-pressurized Replace transmitter

Transmitter failure due to wrong

supply voltage or power surge Replace Transmitter

Full span output low Supply voltage too low Check supply voltage

Load impedance too high or too low Adjust load or supply voltage

Transmitter over-pressurized Recalibrate Transmitter

Replace Transmitter *)

Zero signal too low or too high Transmitter over-pressurized Recalibrate Transmitter

Replace Transmitter *)

Non-linear output Transmitter over-pressurized Replace Transmitter

*) For transmitters with non accessible adjustment potentiometers, or instruments that cannot be recalibrated using the

zero and span potentiometers, adjusting the controller or display device can usually compensate for small changes or

drifts in the output signal. Test the system for proper operation after adjustments are made. An excessive change in th

output signal that cannot be corrected by calibration indicates possible transmitter damage. This may cause the output

to be non-linear, re

If the problem persists, contact our sales department.

USA, Canada

If the problem continues, contact WIKA or an authorized agent for assistance. If the pressure

transmitter must be returned obtain an RMA (return material authorization) number and

shipping instructions from the place of purchase. Be sure to include detailed information

about the problem. Pressure

not be accepted.

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

uiring transmitter replacement.

transmitters received by WIKA without a valid RMA number will

S -S, IS-2 S -F, IS-20-H

19

Page 12

10. Storage, disposal / 11. EC declaration of conformity

10. Storage, disposal

When storing or disposing of the pressure transmitter, take precautions with

!

Warning

regard to remaining media in removed pressure transmitters. Remaining media

in the pressure port may be hazardous or toxic!

Storage

Mount the protection cap when storing the pressure transmitter in order to

prevent any damage to the diaphragm.

Disposal

Dispose of instrument components and packaging materials in accordance

with the respective waste treatment and disposal regulations of the region or

country to which the instrument is supplied.

11. EC declaration of conformity

The devices have been tested according

to the norm:

EC Declaration of Conformity

Document No.:

We declare under our sole responsibility,

that the

Model: IS-20-S, IS-21-S

IS-20-F, IS-21-F

IS-20-H

Description:

Intrinsically safe pressure transmitter

according to the valid datasheet:

PE 81.50, PE 81.51

fulfills the essential requirements of the

directive(s)

- 89/336/EEC (EMC)

- 94/9/EC (ATEX)

6005601

a

marked products

WIKA reserves the right to alter these technical specifications.

20

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

EMC: EN 61326:2002

ATEX: EN 50014:1997+A1+A2

ATEX: EN 50020: 2002

ATEX: EN 50284:1999

ATEX: EN 50303:2000

ATEX: EN 50281-1-1:1998+A1

WIKA Alexander Wiegand GmbH & Co.

KG

Klingenberg, 23.09.2004

Company division TRONIC

i. V. Stefan Richter

Quality management TRONIC

i. A. Thomas Gerling

GB

S -S, IS-2 S -F, IS-20-H

1. Wichtiges zu Ihrer Information

1. Wichtiges zu Ihrer Information

Lesen Sie diese Betriebsanleitung vor Montage und Inbetriebnahme des Druckmessgerätes.

Bewahren Sie die Betriebsanleitung an einem für alle Benutzer jederzeit zugänglichen Ort auf.

Die nachfolgenden Einbau- und Betriebshinweise haben wir mit Sorgfalt zusammengestellt. Es

ist jedoch nicht möglich, alle erdenklichen Anwendungsfälle zu berücksichtigen. Sollten Sie

Hinweise für Ihre spezielle Aufgabenstellung vermissen, können Sie über unsere InternetAdresse (www.wika.de / www.wika.com) weitere Informationen (Datenblätter, Hinweise, etc.)

erhalten oder sich mit einem unserer Anwendungsberater in Verbindung setzen (siehe Punkt 7

Inbetriebnahme, Betrieb/ Rückfragen).

Das zugehörige Produkt-Datenblatt hat die Bezeichnung PE 81.50, PE 81.51

Die in der Betriebsanleitung beschriebenen WIKA-Druckmessgeräte werden nach den neuesten Erkenntnissen konstruiert und gefertigt. Alle Komponenten unterliegen während der

Fertigung strengen Qualitätskriterien.

Bestimmungsgemäße Produktverwendung IS-2

Verwenden Sie den eigensicheren Druckmessumformer zum Messen von Druck in explosionsgefährdeten Bereichen.

Zulassung ATEX: Druckmessgerät zur bestimmungsgemäßen Verwendung in explosions-

gefährdeten Bereichen (siehe beiliegende EG-Baumusterprüfbescheinigung

BVS 04 ATEX E 068 X). ATEX Zulassungseigenschaften:

für Gase und Nebel Anbau an Zone 0, Zone 1, Zone 2. Stäube Anbau an

Zone 20, Zone 21, Zone 22 (nicht für IS-20-H). Bergbau Kategorie M1, M2.

Zulassung FM/CSA: Druckmessgerät zur bestimmungsgemäßen Verwendung in

explosionsgefährdeten Bereichen(siehe Control drawing Nr. 2323880, Punkt 13)

FM / CSA Zulassungseigenschaften: Intrinsically Safe mit Gerätezulassung für

Class I, II und III Division 1, Gruppe A, B, C, D, E, F, G und Class I, Zone 0,

AEx ia IIC. Dust-ignitionproof für Class II und III, Division 1, Gruppe E, F und G.

Non-incendive für Class I Division 2 Gruppe A, B, C und D

FM Standards nach FMRC 3600, 3610, 3611, 3810 (einschließlich Anhang #1),

ISA-S12.0.01, IEC60529 (einschließlich Zusatz #1)

CSA Standard C22.2 Nr. 0-M1991 / 94-M1991 / 142-M1987 / 157-M1992

UL 50, 11. Ausgabe / UL 508, 17. Ausgabe / UL 913, 6. Ausgabe

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

S

-S, IS-2S-F, IS-20-H

S -S, IS-2 S -F, IS-20-H

D

21

Page 13

1. Wichtiges / 2. Der schnelle Überblick für Sie / 3. Zeichenerklärungen

D

Ihre erforderlichen Kenntnisse: Montieren und nehmen Sie das Druckmessgerät nur in Be-

trieb, wenn Sie mit den zutreffenden landesspezifischen Richtlinien vertraut sind und die entsprechende Qualifikation besitzen. Sie müssen mit den Vorschriften und Kenntnissen für explosionsgefährdete Bereiche, Mess- und Regeltechnik sowie elektrische Stromkreise vertraut

sein, da das Druckmessgerät ein elektrisches Betriebsmittel nach EN 50178 ist. Je nach Einsatzbedingung müssen Sie über entsprechendes Wissen verfügen,z.B.

über agressive Medien.

2. Der schnelle Überblick für Sie

Wollen Sie sich einen schnellen Überblick verschaffen, lesen Sie Kapitel 3, 5, 7 und 10. Dort

erhalten Sie kurz Hinweise zu Ihrer Sicherheit und wichtige Informationen über Ihr Produkt

und zur Inbetriebnahme. Lesen Sie diese unbedingt. Informieren Sie sich detaillierter über

dieses Produkt in Kapitel 4 Funktion und Zubehör und 6 Verpackung. Lesen Sie Kapitel 8

zum Thema Wartung. Bei Auftreten von Störungen lesen Sie bitte im Kapitel 9 weiter.

3. Zeichenerklärungen, Abkürzungen

!

Warnung

Warnung

Vorsic ht

22

Mögliche Gefahr für Ihr Leben

oder schwerer Verletzungen.

Mögliche Gefahr für Ihr Leben

oder schwerer Verletzungen

durch wegschleudernde Teile.

Mögliche Gefahr von

Verbrennungen durch heisse

Oberflächen.

Hinweis, wichtige Information,

Funktionsstörung.

Das Produkt stimmt mit den

zutreffenden europäischen

Richtlinien überein.

Spannungsversorgung

Verbraucher

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

Das Produkt stimmt überein mit

den Anforderungen der europäischen Richtlinie 94/9/EG (ATEX)

zum Explosionsschutz.

Das Produkt wurde von FM

Approvals geprüft und zertifiziert.

Es stimmt überein mit den anwendbaren US-amerikanischen Normen

zur Sicherheit (einschließlich

Explosionsschutz).

Das Produkt wurde durch CSA International geprüft und zertifiziert.

Es stimmt überein mit den anwendbaren kanadischen und US-amerikanischen Normen zur Sicherheit

(einschließlich Explosionsschutz).

S -S, IS-2 S -F, IS-20-H

3. Zeichenerklärungen, Abkürzungen / 4. Funktion und Zubehör

Mit einem Speisetrenner realisieren Sie die zwingend nötige galvanische Trennung

der Spannungs- und Stromversorgung zwischen Ex- und Nicht-Ex-Bereich und

stellen die sicherheitstechnischen Anschlussdaten sicher.

2-Leiter Zwei Anschlussleitungen dienen zur Spannungsversorgung.

Der Speisestrom ist das Mess-Signal.

UB+/Sig+ Positiver Versorgungs- / Messanschluss

OV/Sig- Negativer Versorgungs- / Messanschluss

ATEX Europäische Explosionsschutz-Richtlinie (Atmosphäre=AT, Explosion=EX)

CSA Canadian Standard Association

EHEDG European Hygienic Equipment Design Group

FDA Food and Drug Administration

FM Factory Mutual

4. Funktion und Zubehör

IS-20: Druckanschluss Standardausführung (eigensicher)

IS-21: Druckanschluss mit frontbündiger Membrane (eigensicher) für hochviskose

oder kristallisierende Medien, die die Bohrung des Druckanschlusses zusetzen

S

IS-2

-S Druckmessgerät (eigensicher) Ausführung mit Stecker- bzw. Kabelanschluss

S

-F Druckmessgerät (eigensicher) Ausführung Feldgehäuse

IS-2

IS-20-H Druckmessgerät (eigensicher) Ausführung Höchstdruck

Funktion: Mit dem Druckmessgerät messen Sie den in Ihrer Anwendung anstehenden Druck,

der in ein elektrisches Signal umgewandelt wird. Dieses elektrische Signal verändert sich

proportional zum Druck und kann entsprechend ausgewertet werden.

Zubehör: Hinweise zu Zubehör entnehmen Sie bitte der WIKA-Preisliste, dem WIKA Product

Catalog auf CD-Rom oder unserer Internet-Seite unter www.wika.de. Hinweise zu Dichtungen

entnehmen Sie bitte unserer Information Zubehör Dichtungen AC 09.08 im Gesamtkatalog

Druck- und Temperaturmesstechnik oder unserer Internet-Seite unter www.wika.de.

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

können.

S -S, IS-2 S -F, IS-20-H

D

23

Page 14

5. Zu Ihrer Sicherheit

5. Zu Ihrer Sicherheit

n Wählen Sie das richtige Druckmessgerät hinsichtlich Messbereich, Ausführung

!

Warnung

n Öffnen Sie Anschlüsse nur im drucklosen Zustand!

n Betreiben Sie das Druckmessgerät immer innerhalb des Überlastgrenzbereiches!

n Beachten Sie die Betriebsparameter gemäß Punkt 7 Technische Daten.

n Stellen Sie sicher, dass das Druckmessgerät nur bestimmungsgemäß -also wie in der

n Unterlassen Sie unzulässige Eingriffe und Änderungen am Druckmessgerät, welche

n Setzen Sie das Druckmessgerät außer Betrieb und schützen Sie es gegen versehent-

n Ergreifen Sie Vorsichtsmaßnahmen für Messstoffreste in ausgebauten Druck-

n Lassen Sie Reparaturen nur vom Hersteller durchführen.

n Beachten Sie die Angaben der geltenden Baumusterprüfbescheinigung sowie die

Angaben zu Korrosions- bzw. Diffusionsbeständigkeit der Gerätewerkstoffe entnehmen Sie

bitte unserem WIKA-Handbuch zur Druck- und Temperaturmesstechnik.

24

und spezifischen Messbedingungen vor Montage oder Inbetriebnahme.

n Halten Sie die entsprechenden landesspezifischen Vorschriften ein

(z. B.: EN 50178, NEC, CEC) und beachten Sie bei speziellen Anwendungen

die geltenden Normen und Richtlinien (z. B. bei gefährlichen Messstoffen wie

Sauerstoff, Acetylen, brennbaren oder giftigen Stoffen sowie bei Kälteanlagen

und Kompressoren).

Wenn Sie die entsprechenden Vorschriften nicht beachten, können

schwere Körperverletzungen und Sachschäden entstehen!

folgenden Anleitung beschrieben- betrieben wird.

nicht in dieser Betriebsanleitung beschrieben sind.

liche Inbetriebnahme, wenn Sie Störungen nicht beseitigen können.

messgeräten. Messstoffreste können zur Gefährdung von Menschen, Umwelt

und Einrichtung führen!

jeweiligen landesspezifischen Vorschriften bezüglich Ex-Einsatz (z.B.: IEC 60079, NEC,

CEC).

Wenn Sie diese nicht beachten, können schwere Körperverletzungen und Sachschäden entstehen.

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

S -S, IS-2 S -F, IS-20-H

D

5. Zu Ihrer Sicherheit

Besondere Ex-Schutz Hinweise

Warnung

Die Messung von Prozessmedien mit höheren Temperaturen als der in den Tabellen der EGBaumusterprüfbescheinigung unter Punkt 15.1.2 beschriebenen Medientemperaturbereichen

ist mit speziellen Kühlstrecken zulässig (nicht für IS-20-H).

Warnung

n Stellen Sie durch waagrechte Montage eine ungehinderte Luftzirkulation am Kühl-

n Schützen Sie das Gerät vor Berührungen oder bringen Sie ein Warnhinweis an.

n Isolieren Sie Wärmequellen thermisch gegenüber dem Druckmessumformer

n Schützen Sie die Kühlstrecken vor Verschmutzung und Staubablagerung.

Besondere Maßnahmen beim elektrischen Anschluss

Warnung

n Erden Sie gemäß EN 60079-14 den Schirm nur im sicheren (also Nicht-Ex-Bereich).

n Beachten Sie die innere wirksame Kapazität und Induktivität.

n Beachten Sie, dass bei Kabeln für den Einsatz in Zone 1 und 2 die Prüfspannung

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

n Schützen Sie die Membran vor Kontakt mit abrasiven Medien und gegen

!

!

!

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

Schläge. Wenn Sie die Membran beschädigen, ist kein Explosionsschutz

gewährleistet (ATEX, FM, CSA)!

n Sorgen Sie in Staub-Ex-Bereichen für eine geschützte Anordnung des Druck-

messgerätes und schützen Sie es vor Schlägen.

n Halten Sie die zulässigen Oberflächentemperaturen ein, die für diesen Bereich

auf Grund der festgelegten Temperaturklassen gelten.

n Halten Sie den maximalen Temperaturwert (des unter Punkt 15.1.2 in der EG-

Baumusterprüfbescheinigung festgelegten Temperaturbereichs) am Sechskant

des rohrförmigen Gehäuses ein.

element sicher.

(z.B. Rohre oder Tanks).

n Der Bajonett-Rundsteckverbinder ist aus Leichtmetall-Werkstoff, welcher nicht

für Gruppe I-Anwendungen (Bergbau) zugelassen ist.

n Erden Sie das Gehäuse immer gegen elektromagnetische Felder und

elektrostatische Aufladungen.

Beachten Sie dabei, daß bei Kabelausgang der Schirm vom Hersteller immer

geräteseitig geerdet ist.

Leiter/Erde, Leiter/Schirm, Schirm/Erde > 500V Wechselspannung betragen muss.

S -S, IS-2 S -F, IS-20-H

D

25

Page 15

5. Zu Ihrer Sicherheit / 6. Verpackung

n Versehen Sie feindrahtige Leiterenden mit Aderendhülsen (Kabelkonfektio-

!

Warnung

Ein- und -Anbau an Zone 0 und Zone 20 (Zone 20 nicht bei IS-20-H): (Zone 0 bedeutet,

dass explosionsfähiges Gasgemisch >1000 Stunden pro Jahr am Druckmessgerät vorliegt)

!

Warnung

nierung).

n Das Druckmessgerät oder die Kabeldurchführung in der Wand zur Trennung

der Zonen, muss einer Schutzart nach IEC 60 529 entsprechen, und zwar

für die Zone 0: IP 67, für die Zone 20: IP 6X.

n Beachten Sie die Technischen Daten zur Verwendung des Druckmessgerätes

in Verbindung mit agressiven / korrosiven Medien und zur Vermeidung von

mechanischen Gefährdungen.

n Legen Sie die Stromkreise nach Typ Ex ia aus.

D

6. Verpackung

n Untersuchen Sie das Druckmessgerät auf eventuell entstandene Transport-

schäden.

Sind offensichtlich Schäden vorhanden, teilen Sie dies dem Transportunternehmen und WIKA unverzüglich mit.

n Bewahren Sie die Verpackung auf, denn diese bietet bei einem Transport einen

optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

n Bewahren Sie die Schutzkappe des Druckanschluss-Gewindes und der Mem-

bran zur späteren Lagerung oder Transport auf.

Zum Schutz der Membran ist der Druckanschluss des Gerätes IS-21-S, -F mit einer speziellen Schutzkappe versehen.

n Entfernen Sie diese Schutzkappe erst kurz vor dem Einbau, damit die

Membran nicht beschädigt wird.

n Montieren Sie die Schutzkappe bei Ausbau und Transport des Gerätes.

n Achten sie darauf, dass das Druckanschluss-Gewinde und die Anschlusskon-

takte nicht beschädigt werden.

26

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

S -S, IS-2 S -F, IS-20-H

7. Inbetriebnahme, Betrieb

7. Inbetriebnahme, Betrieb

Wurde alles geliefert?

Überprüfen Sie den Lieferumfang:

Komplett montierte Druckmessgeräte; bei frontbündiger Ausführung

IS-21-S, -F mit vormontierten Dichtungen und Schutzkappe.

Baumusterprüfbescheinigung.

Benötigtes Werkzeug: Maulschlüssel SW 27, Schraubendreher

Membran-Prüfung zu Ihrer Sicherheit

Es ist erforderlich, dass Sie vor Inbetriebnahme des Druckmessgerätes die Membran prüfen,

denn sie ist ein sicherheitsrelevantes Teil.

Warnung

Montage

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

n Achten Sie auf auslaufende Flüssigkeit, denn sie ist ein Hinweis auf eine

!

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

Membranbeschädigung (nicht nötig bei IS-20-H).

n Prüfen Sie die Membran optisch auf Beschädigung.

n Setzen Sie das Druckmessgerät nur ein, wenn die Membran unbeschädigt ist.

n Setzen Sie das Druckmessgerät nur in sicherheitstechnisch einwandfreiem

Zustand ein.

n Entfernen Sie die Schutzkappe erst kurz vor dem Einbau und achten Sie

unbedingt darauf, dass die Membran auch während des Einbaus nicht beschädigt wird.

n Wählen Sie den Kabeldurchmesser passend zur Kabeldurchführung des

Steckers. Achten Sie darauf, dass die Kabelverschraubung des montierten

Steckers korrekt sitzt und dass die Dichtungen vorhanden und nicht beschädigt sind. Ziehen Sie die Verschraubung fest und überprüfen Sie den korrekten

Sitz der Dichtungen, um die Schutzart zu gewährleisten.

n Achten Sie bei der Montage auf saubere und unbeschädigte Dichtflächen am

Gerät und Messstelle.

n Schrauben Sie das Gerät nur über die Schlüsselflächen mit einem geeigneten

Werkzeug und dem vorgeschriebenen Drehmoment ein bzw. aus.

Verwenden Sie zum Ein- bzw. Ausschrauben nicht das Gehäuse als

Angriffsfläche. Verkanten Sie nicht die Gewindegänge beim Einschrauben.

S -S, IS-2 S -F, IS-20-H

D

27

Page 16

7. Inbetriebnahme, Betrieb

Typenschild

(Beispiel):

IS-2

-S

5

max.

50Nm

Bei Typ IS-20-S/-F ist der Dichtring optional erhältlich. Bei Typ IS-21-S/-F ist der Dichtring im Lieferumfang enthalten.

Angaben zu Einschraublöchern und

Einschweißstutzen entnehmen Sie bitte

unserer Technischen Information IN 00.14

unter www.wika.de -Service

Elektrischer Anschluss

Schutzart IP nach IEC 60 529 (Die angegebenen Schutzklassen gelten nur im gesteckten

Zustand mit Leitungsteckern Buchsen

entsprechender Schutzart). Stellen Sie bei

Kabelausgängen sicher, dass am Ende des

Kabels keine Feuchtigkeit eintritt.

IS-2

-F

5

max.

50Nm

Dichtung

((D) Montageöffnung

(2)

(3)

Codiertes Herstelldatum

Signal

Spannungsversorgung

Erzeugnis-Nr.

P #

Bestellcode

S #

Fabrik-Nr.

Anschlussbelegung

(1)

(4)

(5)

(6)

Leitungsstecker

(Buchse)

Dichtung

D

7. Inbetriebnahme, Betrieb

1. Lösen Sie die Schraube (1).

2. Lösen Sie die Kabelverschraubung (2).

3. Ziehen Sie Winkelgehäuse (5) mit Klemmblock (6) vom Gerät ab.

4. Hebeln Sie mit dem Schraubendreher in die Montageöffnung (D), so dass Sie

den Klemmblock (6) aus dem Winkelgehäuse (5) herausdrücken. Drücken Sie

nicht den Klemmblock (6) durch die Schraubenöffnung (1) bzw. Kabelverschraubung (2) heraus, sonst beschädigen Sie die Dichtungen des Winkelgehäuses.

5. Wählen Sie den Leitungsaußendurchmesser passend zur Kabeldurchführung

des Winkelgehäuses. Schieben Sie das Kabel durch Kabelverschraubung (2),

Ring (3), Dichtung (4) und Winkelgehäuse (5).

6. Schließen Sie die Kabelenden entsprechend der Belegungszeichnung in den

Anschlussklemmen des Klemmblocks (6) an.

7. Drücken Sie das Winkelgehäuse (5) auf den Klemmblock (6).

8. Verschrauben Sie das Kabel mit der Kabelverschraubung (2). Achten Sie

darauf, dass die Dichtungen unbeschädigt sind und Kabelverschraubung und

Dichtungen korrekt sitzen, um die Schutzart zu gewährleisten.

9. Legen Sie die quadratische Flachdichtung über die Anschlusspins im Gehäuse.

10. Schieben Sie den Klemmblock (6) auf die Anschlusspins im Gehäuse.

11. Verschrauben Sie mit der Schraube (1) das Winkelgehäuse (5) mit dem Klemmblock (6) im Gerät.

D

Griffring,

Gerätestecker(Stift),

Gehäuse mit

Druckanschluss

28

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

S -S, IS-2 S -F, IS-20-H

2132926.02 GB/D/F 01/2006

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

S -S, IS-2 S -F, IS-20-H

29

Page 17

7. Inbetriebnahme, Betrieb

Typ IS-20-S, IS-21-S, IS-20-H 2-Leiter

Winkelsteckverbinder DIN 175301-803, Form A

für Leitungsquerschnitt bis max. 1,5 mm

außendurchmesser 6 - 8 mm (Schiffszulassung: 10 - 14 mm), IP 65, Bestellcode: A4

und G (Schiffszulassung)

Nicht Ex-Bereich

Ex-Bereich

Rundsteckverbinder M12x1, IP 67 /

Bestellcode: M4

Nicht Ex-Bereich

30

Ex-Bereich

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2

, Leitungs-

Kabelausgang mit 1,5 m Länge, Leitungsquerschnitt 0,5 mm² / AWG 20 mit Aderendhülsen,

Leitungsaußendurchmesser 6,8 mm.

IP 67, Bestellcode: DL /

IP 68, ohne Zugang zu Nullpunkt und SpannePotentiometer, Bestellcode: EM /

IP 68, mit Zugang zu Nullpunkt und SpannePotentiometer, Bestellcode: XM

Nicht Ex-Bereich

Ex-Bereich

braun

grün

Schirm

Bajonett-Rundsteckverbinder, IP 67 /

Bestellcode: C6

Nicht Ex-Bereich Ex-Bereich

S -S, IS-2 S -F, IS-20-H

D

7. Inbetriebnahme, Betrieb

Kabelanschluss im Federklemmblock

n Konfektionieren Sie die abgemantelten

Aderenden mit Aderendhülsen.

n Schrauben Sie den Gehäusedeckel auf.

n Lösen Sie mit einem Maulschlüssel SW24

die Kabelverschraubung.

n Führen Sie das Kabel durch die Kabel-

verschraubung in den geöffneten

Gehäusekopf.

n Drücken Sie den entsprechenden

Kunststoffhebel am Federklemmblock

mit einem Schraubendreher herunter, damit sich der Klemmkontakt öffnet.

n Führen Sie das konfektionierte Kabelende in die Öffnung ein und lassen den Kunststoff-

hebel los, so dass das Kabelende im Federklemmblock eingeklemmt wird.

n Nach Anschließen der einzelnen Adern ziehen Sie die Kabelverschraubung fest und ver-

schrauben den Gehäusedeckel.

Funktion des Testkreises für 2-Leiter

Anhand des Testkreises ist es möglich, während des normalen Betriebes eine Strommessung

durchzuführen ohne das Gerät abzuklemmen. Sie müssen hierzu ein Amperemeter (für ExAnwendungen; Innenwiderstand < 15 Ohm) an die Klemmen Test +/- anschließen.

Technische Daten Typen IS-20-S, IS-21-S, IS-20-F, IS-21-F, IS-20-H

Technische Daten ohne Typenkennzeichnung gelten typübergreifend.

Messbereich *)IS-2

Überlastgrenze IS-2

Berstdruck IS-2

Messbereich *)IS-2

Überlastgrenze IS-2

Berstdruck IS-2

Messbereich *)IS-2

Überlastgrenze IS-2

Berstdruck IS-2

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

-S, IS-2

S

-S, IS-2

S

-S, IS-2

S

-S, IS-2

S

-S, IS-2

S

-S, IS-2

S

-S, IS-2

S

-S, IS-2

S

-S, IS-2

S

-F bar 0,1 0,16 0,25 0,4 0,6 1 1,6 2,5

S

-F bar 1 1,5 2 2 4 5 10 10

S

-F bar 2 2 2,4 2,4 4,8 6 12 12

S

-F bar 4 6 10 16 25 40 60 100

S

-F bar 17 35 35 80 50 80 120 200

S

-F bar 20,5 42 42 96 96 400 550 800

S

-F bar 160 250 400 600 1000

S

-F bar 320 500 800 1200 1500

S

-F bar 1000 1200 17002)24002)3000

S

Typ IS-20-F, IS-21-F, IS-20-H mit Feldgehäuse

Bestellcode: FC, FH

Feldgehäuse (innenliegende Federklemmen),IP68

Nicht Ex-Bereich

S -S, IS-2 S -F, IS-20-H

Ex-Bereich

1)

D

31

Page 18

7. Inbetriebnahme, Betrieb

D

Technische Daten Typen IS-20-S, IS-21-S, IS-20-F, IS-21-F, IS-20-H

Druckbereiche für IS-20-H siehe ZusatzBetriebsanleitung 11126418 Höchstdruck

{Unterdruck, Überdruck, +/- , Absolutdruck erhältlich}

1)

Nur für Typ IS-20-S, IS-20-F gültig.

2)

Bei Typen IS-21-S, IS-21-F: Der Tabellenwert gilt ausschließlich bei Abdichtung mittels

Dichtring unterhalb vom Sechskant. Andernfalls gilt max. 1500 bar.

Werkstoff

Messstoffberührte Teile

n

Typen IS-20-S, IS-20-F, IS-20-H *

Ø

Typen IS-21-S, IS-21-F

Ø

n Gehäuse CrNi-Stahl

Interne Übertragungsflüssigkeit

Hilfsenergie U

B

)

3)

3)

Nicht vorhanden bei IS-20-S, IS-20-F für Messbereichen > 25 bar und IS-20-H

UB in DC V

Ausgangssignal und RA in Ohm 4 ... 20 mA, 2-Leiter

zulässige max. Bürde R

Typen IS-2

Ø

Typen IS-2

Ø

A

S

-S, IS-20-H

S

-F, IS-20-H mit

Feldgehäuse

Testkreissignal und zulässige Bürde RA < 15 (nur bei Typen IS-2

Einstellbarkeit Nullpunkt/Spanne %

Einstellzeit (10 ... 90 %) ms < 1

4)

Einstellzeit bei IS-20-S/-F: < 10 bei Messstofftemp.< -30 °C für Messbereiche bis 25 bar.

Einstellzeit bei IS-21-S/-F: < 10 bei Messstofftemp.< -30 °C.

Spannungsfestigkeit Isolierung entspricht EN 50020, 6.4, 12

(andere Werkstoffe siehe WIKA Druckmittler-Programm)

CrNi-Stahl

CrNi-Stahl {Hastelloy C4}

O-Ring: NBR {FPM/FKM oder EPDM}

Synthetisches Öl {Halocarbonöl für Sauerstoff-Ausführungen}

{FDA-gelistet für Nahrungsmittelindustrie}

10 < U

30

≤

B

(11 < UB < 30 bei Typen IS-2

S

-F, IS-20-H mit Feldgehäuse)

RA ≤ (UB – 10 V) / 0,02 A – (Länge der Kabelausführung in m

x 0,14 Ohm)

RA ≤ (UB – 11 V) / 0,02 A

S

-F, IS-20-H mit Feldgehäuse)

10 durch Potentiometer im Gerät

±

4)

7. Inbetriebnahme, Betrieb

D

Technische Daten Typen IS-20-S, IS-21-S, IS-20-F, IS-21-F, IS-20-H

Genauigkeit % d. Spanne

% d. Spanne

5)

Genauigkeit

6)

Einschließlich Nichtlinearität, Hysterese, Nichtwiederholbarkeit, Nullsignal- und

Endwertabweichung (entspricht Messabweichung nach IEC 61298-2).

Kalibriert bei senkrechter Einbaulage Druckanschluss nach unten.

Nichtlinearität % d. Spanne

Stabilität pro Jahr % d. Spanne

Zulässige Temperaturbereiche

n Messstoff

n Umgebung

n Lagerung

7) 9) *)

7) 9)

7)

°C -20 ... +808)(Erweiterte Temperaturbereiche siehe unter

°C -20 ... +80

°C -30 ... +105

7)

Erfüllt auch EN 50178, Tab. 7, Betrieb (C) 4K4H, Lagerung (D) 1K4, Transport (E) 2K3

8

)

Weitere Temperaturbereiche in Abhängigkeit der elektrischen Anschlüsse, siehe

EG-Baumusterprüfbescheinigung, z.B. -30 … +105 °C

0,25 {0,125}

≤

0,5 {0,25}

≤

für Messbereiche > 0,25 bar. Nicht möglich bei IS-20-H.

{ }

0,2 (Toleranzbandeinstellung, BFSL) nach IEC 61298-2

≤

0,2 (bei Referenzbedingungen)

≤

Kompensierter Temperaturbereich °C 0 ... +80

Temperaturkoeffizienten im

kompensierten Temperaturbereich

n Mittlerer TK des Nullpunktes % d. Spanne

Mittlerer TK der Spanne % d. Spanne

n

d

-Schutz

Zündschutzart EEx ia I/II C T4, EEx ia I/II C T5, EEx ia I/II C T6

Schutz

Ex -

ATEX Kategorie 9) 1G, 1/2G , 2G, 1D

9)

Lesen Sie unbedingt

Daten in der

10)

Nicht für IS-20-H

FM, CSA Class I, II und III

0,2 / 10 K (< 0,4 für Messbereiche < 250 mbar)

≤

0,2 / 10 K

≤

EG-Baumusterprüfbescheinigung

Zündschutzart Eigensicher Class I, II, III Division 1,

5)

(Toleranzbandeinstellung, BFSL)

5) 6)

Punkt 7. Inbetriebnahme, Betrieb: “Bezug

Medientemperatur zu Umgebungstemperatur“)

8)

10)

10)

, 2D

10)

, M1, M2

, 1/2D

die Einsatzbedingungen und sicherheitstechnischen

nach (BVS 04 ATEX E068 X)

32

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

S -S, IS-2 S -F, IS-20-H

2132926.02 GB/D/F 01/2006

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

S -S, IS-2 S -F, IS-20-H

33

Page 19

7. Inbetriebnahme, Betrieb

D

Technische Daten Typen IS-20-S, IS-21-S, IS-20-F, IS-21-F, IS-20-H

a

-Kennzeichen

FM, CSA FM Standards gemäss FMRC 3600, 3610, 3611

HF-Immunität V/m 10

BURST KV 2

Schockbelastbarkeit

VibrationsbelastbarkeitØ Typ IS-2

Elektrische Schutzarten Verpolungs- und Kurzschlussschutz geräteseitig

Masse

*) In Sauerstoff-Ausführung ist Typ IS-21 nicht erhältlich. In Sauerstoff-Ausführung ist Typ IS-20 nur möglich mit Überdruck-Messbereich

0,25 bar, Messstofftemperatur -20 … +60 °C und messstoffberührte Teile in CrNi-Stahl oder Elgiloy

≥

{ } Angaben in geschweiften Klammern beschreiben gegen Mehrpreis lieferbare Sonderheiten.

Ø

Ø

Ø

Ø

Ø

Ø

S

Typ IS-2

Typ IS-2

Typ IS-2

Typ IS-2

Typ IS-2

Typ IS-20-H kg Ca. 0,3 (ca. 0,45 in Ausführung Feldgehäuse)

-S g 1000 nach IEC 60068-2-27 (Schock mechanisch)

S

-F g 600 nach IEC 60068-2-27 (Schock mechanisch)

S

-S g 20 nach IEC 60068-2-6 (Vibration bei Resonanz)

S

-F g 10 nach IEC 60068-2-6 (Vibration bei Resonanz)

S

-S kg Ca. 0,2

S

-F kg Ca. 0,35

89/336/EWG Störemission und Störfestigkeit nach

EN 61 326, Störemission Grenzwertklasse A und B

ATEX EN 50 014 (allgemeiner Teil),

EN 50 020 (Eigensicherheit), {EN 50 284 (Zone 0)},

{EN 50 281-1 (Staub-Ex)}, {EN 50 303 (Bergbau)}

(einschliesslich Anhang #1), ISA-S12.0.01, IEC 60 529

(einschliesslich Zusatz #1), CSA Standard C22.2

No. 0-M1991 /142-M1987 / 157-M1992, UL 50,11. Ausgabe/

UL 508, 17. Ausgabe / UL 913, 6. Ausgabe

®

.

Beachten Sie bei der Auslegung Ihrer Anlage, dass die angegebenen Werte (z. B. Berstdruck,

Überlastgrenze) in Abhängigkeit vom verwendeten Material, Gewinde und Dichtung gelten.

34

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

S -S, IS-2 S -F, IS-20-H

7. Inbetriebnahme, Betrieb

Bezug Mediumstemperatur zu Umgebungstemperatur

120

110

100

90

80

70

60

50

40

30

20

10

0

40 80 120 160 200 240 280 320

Umgebungstemperatur [°C]

Typ

Ausführ.

Kühlrippen - 2 3 5

Konstante K 0,34 0,47 0,68 0,76

IS-20-H IS-2

A B

Max. zulässige Umgebungstemperatur:

= T

T

amb

+ (TB - T

med

med

Funktionsprüfung

n Öffnen Sie Anschlüsse nur im drucklosen Zustand!

n Beachten Sie die Betriebsparameter gemäß Punkt 7Technische Daten.

Warnung

n Betreiben Sie das Druckmessgerät immer innerhalb des Überlastgrenzbereichs.

Beachten Sie beim Berühren des Druckmessgerätes, dass die Oberflächen der

Gerätekomponenten während des Betriebes heiß werden können.

Vorsic ht

Das Ausgangssignal muss sich dem anstehenden Druck proportional verhalten.

Wenn dies nicht so ist, kann das ein Hinweis auf eine Beschädigung der

Membran sein. Lesen Sie in diesem Fall in Kapitel 9 Störbeseitigung nach.

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

) / K

A

B

5

-S/ -F

C

D

C

Berechnung der Kühlstrecke:

T

D

= T

B

T

B

T

med

T

amb

K = Kühlstrecken-Konstante

D

Medientemperatur [°C]

- (T

- T

med

med

= Betriebstemperatur Messumformer

amb

) x K

= max. Temperatur Prozessmedium

= max. Temperatur Umgebung

S -S, IS-2 S -F, IS-20-H

35

Page 20

7. Inbetriebnahme, Betrieb

Einstellung Nullpunkt / Spanne

(nur bei Geräten mit Griffring und Feldgehäuse)

IS-20-S, IS-21-S, IS-20-H:

Leitungsstecker

(Buchse)

Dichtung

Griffring

Gerätestecker

(Stift)

Dichtung

A

Gehäuse

mit Druckanschluss

S = Spanne

IS-20-F, IS-21-F, IS-20-H mit Feldgehäuse:

B

Z = Nullpunkt

36

S = Spanne

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

C

Z = Nullpunkt

D

n Stellen Sie ausreichend genaue Druck-

referenz ein. Ausreichend genaue Druck

referenz bedeutet mindestens 3x genauer

als die angegebene Kennlinienabweichung.

n Achten Sie bei der Steckerdemontage /-

montage darauf, dass keine Litzen abgerissen bzw. eingequetscht werden.

n Ziehen Sie den Leitungstecker(Buchse)

ab. Öffnen Sie das Druckmessgerät,

indem Sie den Griffring lösen (siehe

Abbildung A ). Ziehen Sie vorsichtig den

Gerätestecker(Stift) aus dem Gehäuse.

n Stellen Sie den Nullpunkt (Z) ein (siehe

Abbildung B und C ), indem Sie den

Druckanfangswert anfahren.

n Stellen Sie die Spanne (S) ein, indem

Sie den Druckendwert anfahren.

n Überprüfen Sie den Nullpunkt.

n Wenn der Nullpunkt nicht stimmt ggf.

Prozedur wiederholen.

n Schließen Sie das Druckmessgerät

wieder sorgfältig. Achten Sie darauf, dass

die Dichtungen unbeschädigt und sauber

sind und auf die korrekte Lage der Dichtungen, um die Schutzart zu gewährleisten.

Empfohlener Nachkalibrier-Zyklus: 1 Jahr

Bei Rückfragen (+49) 9372/132-295

S -S, IS-2 S -F, IS-20-H

8. Wartung, Ersatzteile / 9. Störbeseitigung

8. Wartung, Ersatzteile

WIKA Druckmessgeräte sind wartungsfrei !

Öffnen Sie Anschlüsse nur im drucklosen Zustand!

Warnung

n Ergreifen Sie Vorsichtsmaßnahmen für Messstoffreste in ausgebauten Druck-

!

Warnung

messgeräten. Messstoffreste können zur Gefährdung von Menschen, Umwelt

und Einrichtung führen!

n Setzen Sie das Druckmessgerät außer Betrieb und schützen Sie es gegen

versehentliche Inbetriebnahme, wenn Sie Störungen nicht beseitigen können.

n Lassen Sie Reparaturen nur vom Hersteller durchführen.

Verwenden Sie keine spitzen bzw. harten Gegenstände zur Reinigung, denn die

Membran des Druckanschlusses darf nicht beschädigt werden.

Ersatzteile

Entnehmen Sie bitte Ersatzteilangaben unserer aktuellen Lagerpreisliste, dem CD-Katalog

oder setzen Sie sich mit unserem Vertriebsmitarbeiter in Verbindung.

9. Störbeseitigung

Störung Mögliche Ursache Maßnahme

Kein Ausgangssignal Keine Versorgungsspannung Spannungsversorgung überprüfen

Leitungsbruch Durchgang überprüfen

Leitungsverpolung Polung korrigieren

Kein Druck oder Druckkanal blockiert Druckkanal überprüfen

Messumformer defekt wegen falscher

Versorgungsspannung oder Stromstoß Messumformer austauschen

Gleichbleibendes Ausgangssignal Druckkanal blockiert Druckkanal überprüfen

bei Druckänderung Mechanische Überbelastung Messumformer austauschen

Messumformer defekt wegen falscher

Versorgungsspannung oder Stromstoß Messumformer austauschen

2132926.02 GB/D/F 01/2006

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

2132926.02 GB/D/F 01/2006

S -S, IS-2 S -F, IS-20-H

D

37

Page 21

9. Störbeseitigung / 10. Lagerung, Entsorgung

Störung Mögliche Ursache Maßnahme

Signalspannung zu klein Versorgungsspannung zu niedrig Versorgungsspannung überprüfen

Bürde zu hoch oder zu niedrig Bürde bzw. Versorgungsspannung

korrigieren

Mechanische Überbelastung Messumformer neu kalibrieren

Messumformer austauschen *)

Nullpunktsignal zu niedrig oder zu hoch Mechanische Überbelastung Messumformer neu kalibrieren

Messumformer austauschen *)

Signalkennlinie unlinear Mechanische Überbelastung Messumformer austauschen

*) Bei Messumformern ohne Zugang zu den Justage-Potentiometern oder bei Instrumenten, die mittels des Nullpunkt-

Und Spanne-Potentiometers nicht neu kalibriert werden können, kann normalerweise eine Justage des Reglers oder

des Anzeigegeräts kleine Änderungen oder Verschiebungen des Ausgangssignals ausgleichen. Überprüfen Sie nach

dem Justieren die korrekte Arbeitsweise des Systems. Eine extreme Änderung des Ausgangssignals, die durch eine

Kalibrierung nicht korrigiert werden kann, deutet auf eine mögliche Beschädigung des Messumformers hin. Diese

könnte die Ursache für ein unlineares Ausgangssignal sein und den Austausch des Messumformers erforderlich

machen.

D

11. EG-Konformitätserklärung

11. EG-Konformitätserklärung

Wenn das Problem bestehen bleibt, setzen Sie sich mit unserem Vertriebsmitarbeiter in

Verbindung.

10. Lagerung, Entsorgung

Ergreifen Sie bei Lagerung oder Entsorgung Vorsichtsmaßnahmen für

!

Warnung

Lagerung

Entsorgung

38

Messstoffreste in ausgebauten Druckmessgeräten. Messstoffreste können zur

Gefährdung von Menschen, Umwelt und Einrichtung führen!

Montieren Sie die Schutzkappe bei Lagerung des Druckmessgerätes, damit die

Membran nicht beschädigt wird.

Entsorgen Sie Gerätekomponenten und Verpackungsmaterialien entsprechend

den einschlägigen landesspezifischen Abfallbehandlungs- und Entsorgungsvorschriften des Anliefergebietes.

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

S -S, IS-2 S -F, IS-20-H

Technische Änderungen vorbehalten.

2132926.02 GB/D/F 01/2006

2132926.02 GB/D/F 01/2006

Die Prüfung der Geräte wurde

entsprechend den Normen

EG-Konformitätserklärung

Dokument Nr.:

Wir erklären in alleiniger Verantwortung,

dass die mit

Produkte

Typ: IS-20-S, IS-21-S

IS-20-F, IS-21-F

IS-20-H

6005601

a

gekennzeichneten

EMV: EN 61326:2002

ATEX: EN 50014:1997+A1+A2

ATEX: EN 50020: 2002

ATEX: EN 50284:1999

ATEX: EN 50303:2000

ATEX: EN 50281-1-1:1998+A1

durchgeführt.

WIKA Alexander Wiegand GmbH & Co.

KG

Klingenberg, 23.09.2004

Beschreibung:

Eigensicherer Druckmessumformer

gemäß gültigem Datenblatt:

PE 81.50, PE 81.51

die grundlegenden Anforde-rungen der

folgenden Richtlinie(n) erfüllen:

- 89/336/EWG (EMV)

- 94/9/EG (ATEX)

WIKA Operating instructions / Betriebsanleitung / Mode d'emploi IS-2

Geschäftsbereich TRONIC

i. V. Stefan Richter

Qualitätsmanagement TRONIC

i. A. Thomas Gerling

S -S, IS-2 S -F, IS-20-H

D

39

Page 22

1. Informations importantes

F

1. Informations inportantes

Veuillez lire ce mode demploi avant le montage et la mise en service de transmetteur de pression. Conservez ce mode demploi dans un endroit accessible en tout temps pour tous les

utilisateurs. Les instructions de montage et de service présentées ci-après ont été établi avec

grand soin. Il reste toutefois impossible denvisager tous les cas dapplications possibles.

Dans le cas où vous constateriez des lacunes dans ces instructions pour les tâches spéciales

quil vous faut exécuter, vous avez la possibilité de recevoir des compléments dinformations

(fiches de caractéristiques, remarques etc.) sous notre adresse internet (www.wika.de /

www.wika.com) ou par contact direct avec notre conseiller applications(voir chapitre 7 Mise

en service, exploitation/ En cas de problèmes). La fiche technique de ce produit a la désignation PE 81.50, PE 81.51. La conception et la fabrication des transmetteurs de mesure WIKA,