Page 1

Operating Instructions

Indicating and adjustment module for IPT-1* sensors

Page 2

Contents

Contents

1 About this document

1.1 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Symbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 For your safety

2.1 Authorised personnel . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Warning about misuse . . . . . . . . . . . . . . . . . . . . . . .

2.4 General safety instructions . . . . . . . . . . . . . . . . . . . .

2.5 Safety approval markings and safety tips . . . . . . . . . .

2.6 CE conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Compatibility according to NAMUR NE 53 . . . . . . . . .

2.8 Safety instructions for Ex areas . . . . . . . . . . . . . . . . .

3 Product description

3.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Packaging, transport and storage . . . . . . . . . . . . . . .

4 Mounting

4.1 Mounting steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Set up

5.1 Adjustment system . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 General functions . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Special functions - 4 … 20 mA/HART . . . . . . . . . . . .

5.4 Special functions - Profibus PA . . . . . . . . . . . . . . . . .

5.5 Menu schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Menu schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Menu schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3

3

4

4

4

4

4

4

5

5

6

7

7

8

9

11

12

18

20

23

26

28

6 Maintenance and fault rectification

6.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Instrument repair . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Dismounting

7.1 Dismounting steps . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Supplement

8.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Indicating and adjustment module for IPT-1* sensors

30

30

31

31

32

33

31549-EN-081211

Page 3

1 About this document

1 About this document

1.1 Function

This operating instructions manual provides all the information you

need for mounting, connection and setup as well as important

instructions for maintenance and fault rectification. Please read this

information before putting the instrument into operation and keep this

manual accessible in the immediate vicinity of the device.

1.2 Target group

This operating instructions manual is directed to trained qualified

personnel. The contents of this manual should be made available to

these personnel and put into practice by them.

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or malfunctions can

result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

l List

The dot set in front indicates a list with no implied sequence.

à Action

This arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 3

Page 4

2 For your safety

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual must be

carried out only by trained specialist personnel authorised by the plant

operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Appropriate use

The pluggable indicating and adjustment module is used for remote

measured value indication and parameter adjustment for IPT-1*

pressure transmitters.

2.3 Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to

application-specific hazards, e.g. vessel overfill or damage to system

components through incorrect mounting or adjustment.

2.4 General safety instructions

This is a high-tech instrument requiring the strict observance of

standard regulations and guidelines. The user must take note of the

safety instructions in this operating instructions manual, the countryspecific installation standards as well as all prevailing safety

regulations and accident prevention rules.

The instrument must only be operated in a technically flawless and

reliable condition. The operator is responsible for trouble-free

operation of the instrument.

During the entire duration of use, the user is obliged to determine the

compliance of the required occupational safety measures with the

current valid rules and regulations and also take note of new

regulations.

2.5 Safety approval markings and safety tips

The safety approval markings and safety tips on the device must be

observed.

2.6 CE conformity

This device fulfills the legal requirements of the applicable EC

guidelines. By attaching the CE mark, VEGA provides a confirmation

of successful testing.

4 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 5

2 For your safety

2.7 Compatibility according to NAMUR NE 53

With respect to compatibility, NAMUR recommendation NE 53 is met.

The parameter adjustment of the basic sensor functions is indepen-

dent of the software version. The range of available functions depends

on the respective software version of the individual components.

2.8 Safety instructions for Ex areas

Please note the Ex-specific safety information for installation and

operation in Ex areas. These safety instructions are part of the

operating instructions manual and come with the Ex-approved

instruments.

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 5

Page 6

1

2

3 Product description

3 Product description

3.1 Configuration

Scope of delivery

Equipment

The scope of delivery encompasses:

l Indicating and adjustment module

l Documentation

- this operating instructions manual

The indicating and adjustment module is equipped with a display with

full-dot matrix as well as four keys for adjustment. An integrated

backlight can be switched via the adjustment menu. The following

hardware versions are necessary:

l Indicating and adjustment module …- 01 or higher

l Sensor electronics 4 … 20 mA …- 02 or higher

l Sensor electronics P rofibus PA or Foundation Fieldbus …- 03 or

higher

l

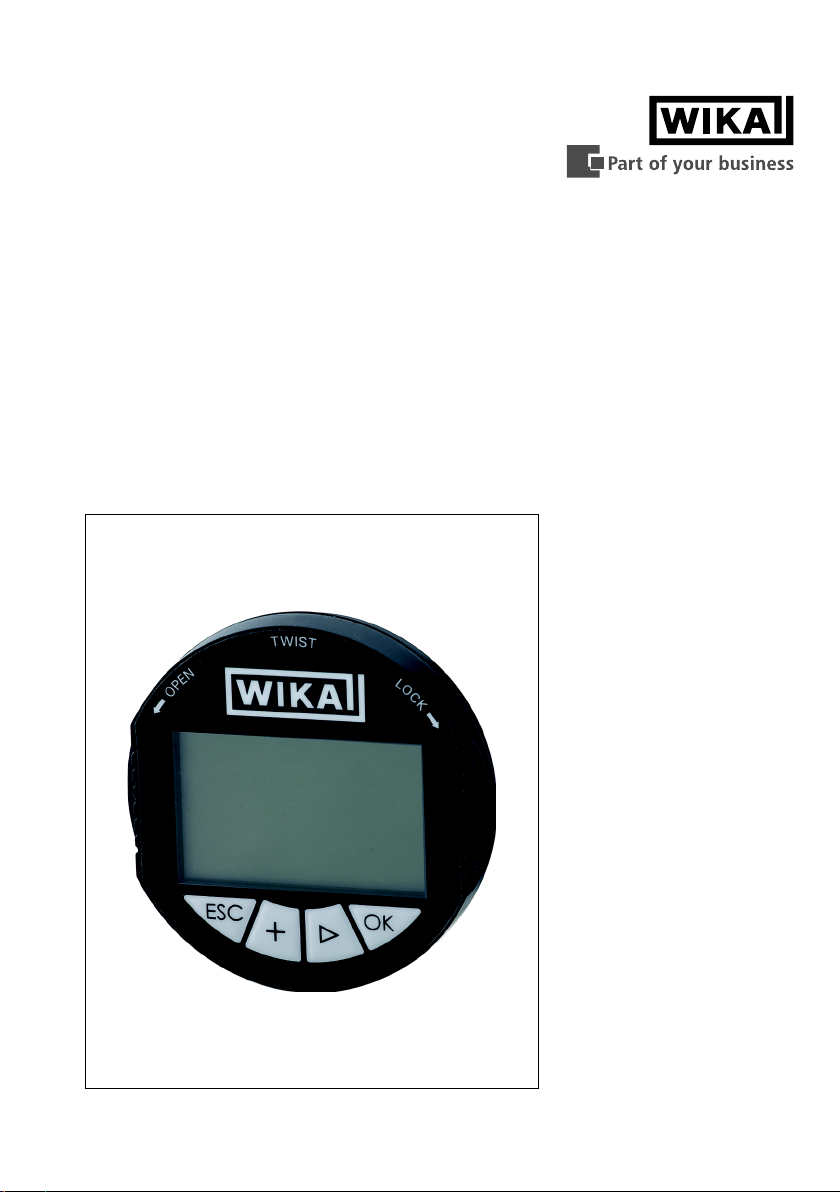

Fig. 1: Indicating and adjustment module

1 Display

2 Keys

6 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 7

1

2

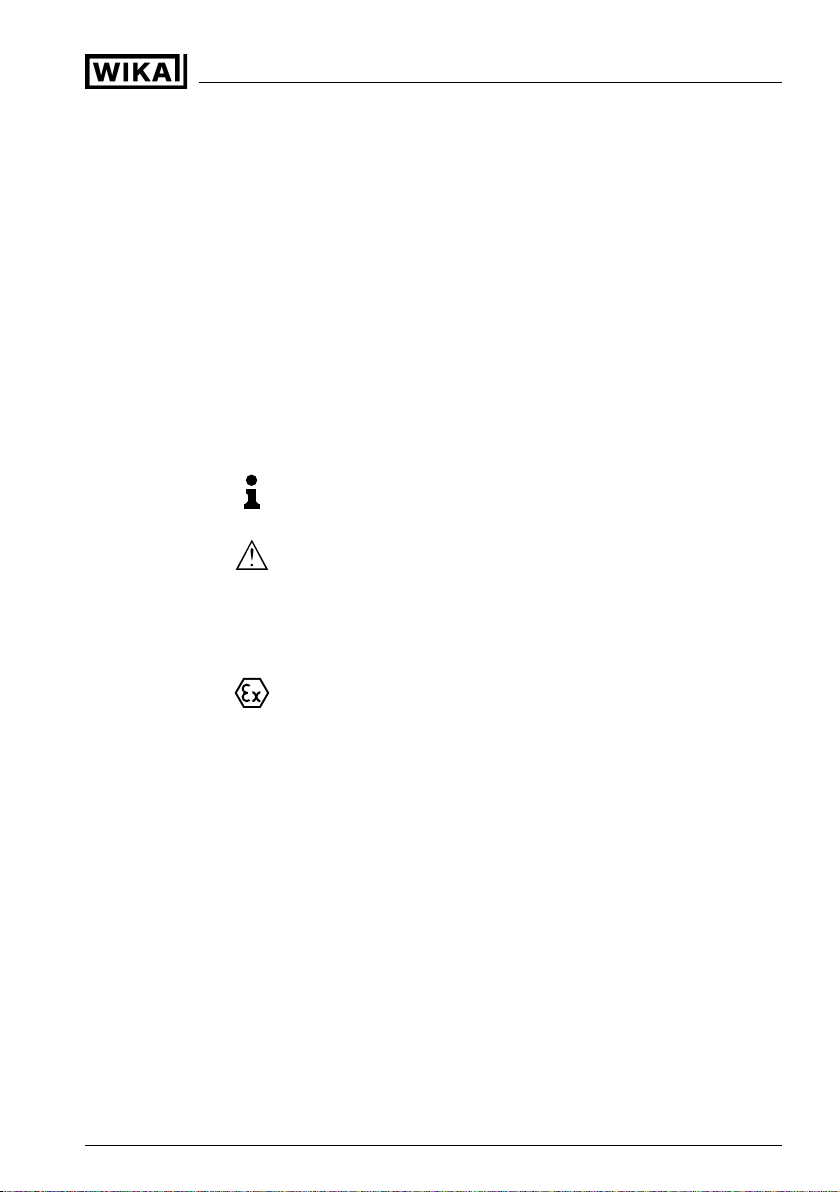

Fig. 2: Rear of the indicating/adjustment module

1 Integrated seal ring

2 Gold plated contact paths

3.2 Principle of operation

3 Product description

Application area

The indicating and adjustment module is used for measured value

indication, adjustment, and diagnostics for the following WIKA

sensors:

l IPT-10 vers. 2.0 (ceramic sensor)

l IPT-1* vers. 3.0 (metallic sensor)

l IPT-11 vers. 4.0 (ceramic sensor)

The indicating and adjustment module is mounted into the respective

sensor housing or into the external housing. After mounting, the sensor

and the external housing are also splash water proof without housing

cover.

The operation of two indicating and adjustment modules in parallel in

the sensor and in the external housing is not supported.

Power supply

Power supply directly via the respective sensor or the external

housing. An additional connection is not necessary.

3.3 Operation

The adjustment is carried out via the integrated keys. The entered

parameters are generally saved in the respective sensor. A copy

function enables loading of the parameters into the indicating and

adjustment module.

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 7

®

Page 8

3 Product description

3.4 Packaging, transport and storage

Packaging

Transport

Transport inspection

Storage

Storage and transport

temperature

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

according to DIN EN 24180.

The packaging of standard instruments consists of environmentfriendly, recyclable cardboard. For special versions, PE foam or PE foil

is also used. Dispose of the packaging material via specialised

recycling companies.

Transport must be carried out under consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or

concealed defects must be appropriately dealt with.

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

l Not in the open

l Dry and dust free

l Not exposed to corrosive media

l Protected against solar radiation

l Avoiding mechanical shock and vibration

l Storage and transport temperature see chapter "Supplement -

Technical data - Ambient conditions"

l Relative humidity 20 … 85 %

8 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 9

4 Mounting

4.1 Mounting steps

4 Mounting

Mount/Dismount indicating and adjustment

module

The indicating and adjustment module can be inserted or removed at

any time. It is not necessary to interrupt the voltage supply.

For mounting, proceed as follows:

1 Unscrew the housing cover

2 Place the indicating/adjustment module in the requested position

on the electronics

Information:

Four different positions are possible, each displaced by 90°.

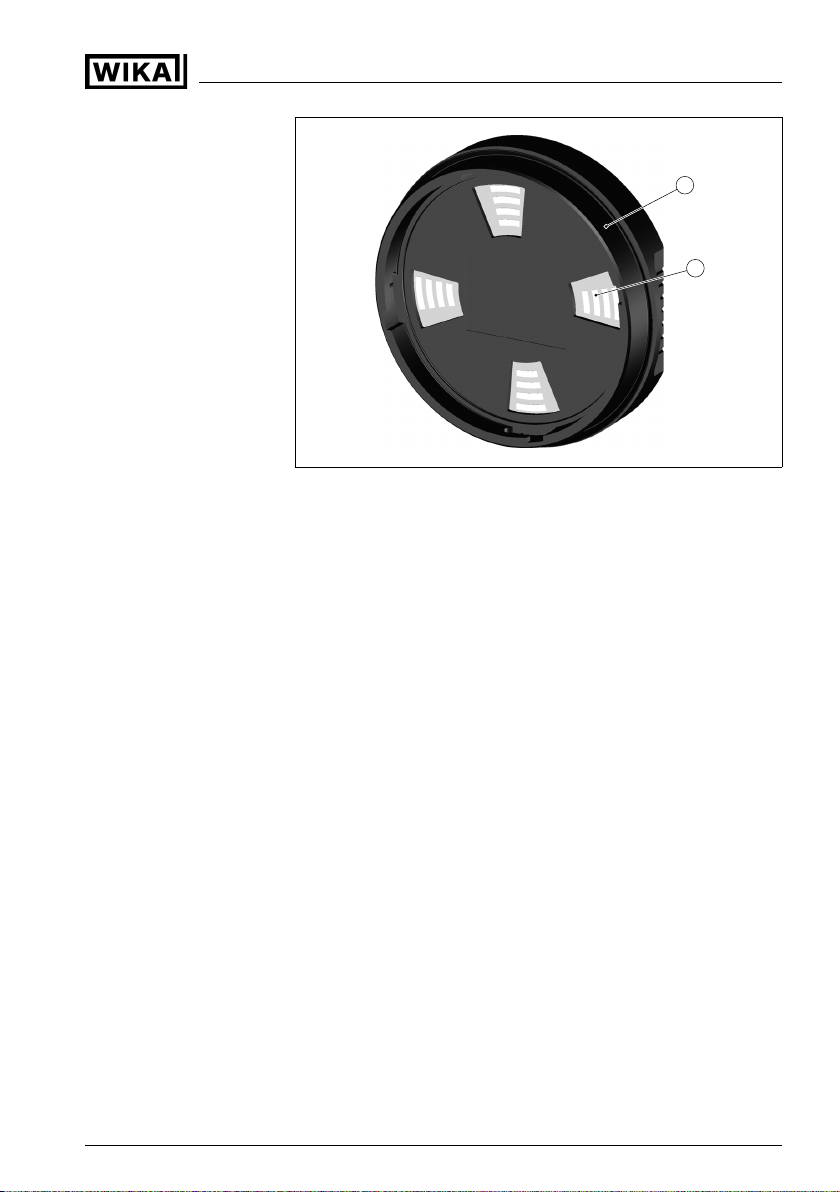

Fig. 3: Mounting the indicating and adjustment module

3 Press the indicating/adjustment module lightly onto the electronics

and turn it to the right until it snaps in

4 Screw housing cover with inspection window tightly back on

Note:

If you intend to retrofit the instrument with an indicating and adjustment

module for continuous measured value indication, a higher cover with

an inspection glass is required.

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 9

Page 10

4 Mounting

Dismounting is carried out in reverse order.

10 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 11

5 Set up

1.1

2

3

1

5.1 Adjustment system

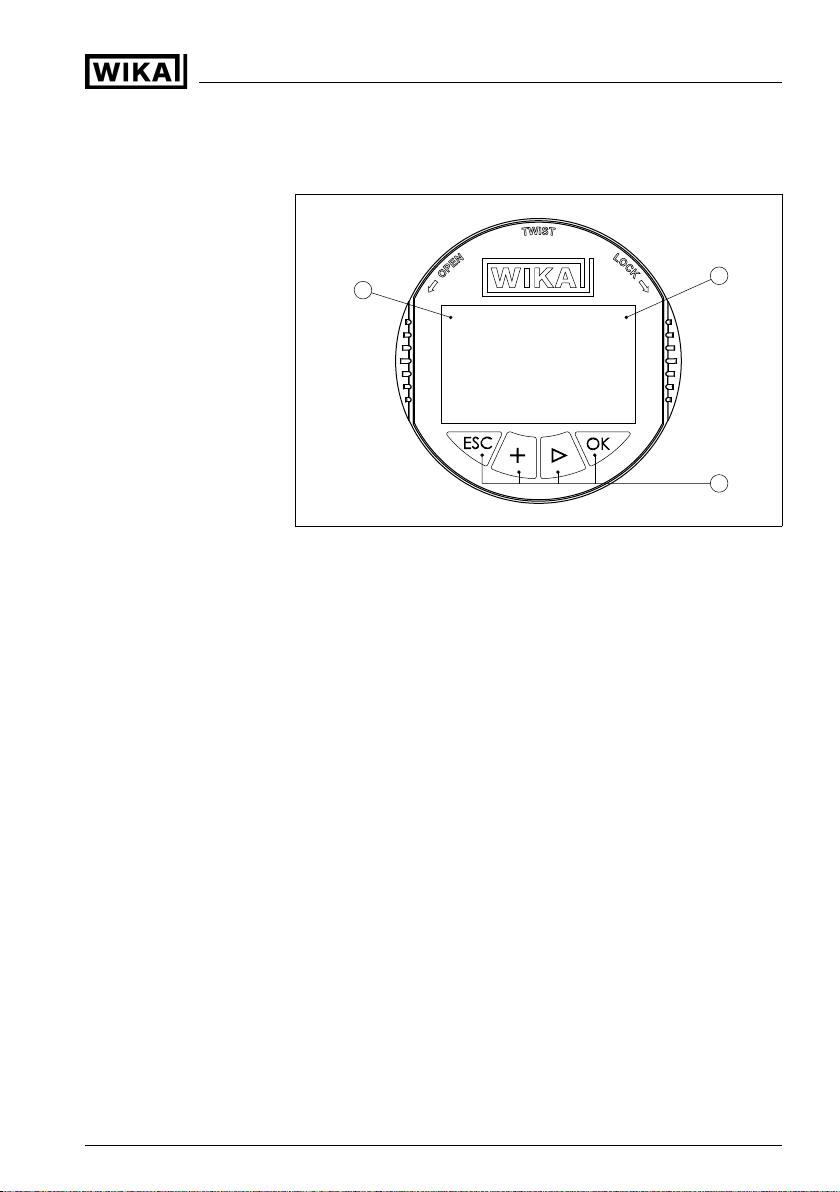

Fig. 4: Indicating and adjustment elements

1 LC display

2 Indication of the menu item number

3 Adjustment keys

5 Set up

Key functions

l [OK] key:

- Move to the menu overview

- Confirm selected menu

- Edit parameter

- Save value

l [->] key to select:

- menu change

- list entry

- Select editing position

l [+] key:

- Change value of the parameter

l [ESC] key:

- interrupt input

- jump to the next higher menu

Adjustment system

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 11

The sensor is adjusted via the four keys of the indicating and

adjustment module. The LC display indicates the individual menu

items. The functions of the individual keys are shown in the above

illustration. Approx. 10 minutes after the last pressing of a key, an

automatic reset to measured value indication is triggered. Any values

not confirmed with [OK] will not be sa ved.

Page 12

5 Set up

5.2 General functions

Introduction

Measured value indica-

tion

Menu overview

IPT-1* pressure transmitters have various functions. Hence they can

be adapted to the respective application.

Some of these functions are sensor-specific. These are described in

the operating instructions manual of the corresponding sensor. Other

functions, however, have a general character, i.e. they are available in

different sensors.

The general functions are described in this paragraph. The functions of

the indicating/adjustment module are determined by the sensor and

correspond to the respective software version of the sensor.

The following presentations are available in the measured value

display:

l Level or pressure as digital value, sensor-TAG

l Level or pressure as digital value and bar graph, sensor TAG

l Level or pressure as digital value, temperature value

With [->] you select the different presentations of the measured value.

You can reach the menu overview from any presentation with [OK].

With [ESC] you return from the menu overview to the measured value

display.

In the menu overview you select the appropriate menu with [->] and

open it with [OK]. Then the individual menu items are available.

▶

Basic adjustment

Display

Diagnostics

Service

Info

Menu section, basic adjustment

Damping

To damp process-dependent measured value fluctuations, you have to

set an integration time of 0 … 999 s in this menu item.

Depending on the sensor type, the factory setting is 0 s or 1 s.

Damping

0 s

Linearisation curve

In this menu item you select the linearization curve:

l linear

l Cylindrical tank

l Spherical tank

l User programmable

User programmable means: Switching on a linearization curve

programmed via PC and PACTware

12 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 13

5 Set up

The linearization curve creates a correlation between height and

volume. It takes into account the vessel geometry for the displayed

measured value and current output.

Factory setting is linear.

Linearisation curve

linear

Edit sensor TAG

Lighting

In the menu item "Sensor-TAG" you edit a 12-digit measurement loop

name. An unambiguous designation can hence be assigned to the

sensor, e.g. the measurement loop name or the tank or product

designation. In digital systems and in the documentation of larger

plants, a singular designation should be entered for exact identification

of individual measuring sites.

The available digits comprise:

l Letters from A … Z

l Numbers from 0 … 9

l Special characters +, -, /, -

Factory setting is "Sensor".

Sensor-TAG

Sensor

Menu section, display

An integrated background lighting can be switched via the adjustment

menu. The following version is necessary:

l Indicating and adjustment module …- 01 or higher

l Sensor electronics 4 … 20 mA …- 01 or higher

l Sensor electronics pressure transmitter 4 … 20 mA …- 02 or

higher

l Sensor electronics P rofibus PA or Foundation Fieldbus …- 03 or

higher

The version is stated on the type label of the indicating and adjustment

module or the sensor electronics. The function depends also on the

height of the supply voltage, see operating instructions manual of the

respective sensor.

In the default setting, the lightning is switched off.

Pointer

Min. and max. measured values are saved in the sensor. The values

are displayed in the menu item "Peak values".

l Min. and max. pressure

1)

Pressure: -50 … +150 % of the nominal measuring range.

1)

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 13

Page 14

5 Set up

Sensor status

Curve presentation

l Min. and max. temperature

Pointer

2)

In this menu item, the device status is displayed. If the sensor detects

a fault, "OK" will be displayed. If a fault is detected, a flashing failure

message is outputted sensor-specifically, e.g. "E013". The fault is also

displayed in clear text, e.g. "No measurement value".

Information:

The fault message as well as the clear text indication are also carried

out in the measured value display.

Meas. reliability

Sensor status

Available with the trend curve:

l "X-Zoom": Resolution in minutes, hours or days

l "Stop/Start": Interrupt a recording or start a new recording

l "Unzoom": Reset the resolution to minutes

Trend curve

Menu section, service

Simulation of

measured values

In this menu item you simulate a user-defined level or pressure value

via the current output. This allows you to test the signal path, e.g.

through connected indicating instruments or the input card of the

control system.

The following simulation variables are available:

l Percent

l Current

l Pressure

With Profibus PA sensors, the selection of the simulated value is made

via the "Channel" in the menu "Basic adjustments".

How to start the simulation:

2)

Temperature: -50 … +150 °C.

14 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 15

5 Set up

1 Push [OK]

2 Select the requested simulation variable with [->] and confirm with

[OK]

3 Set the requested value with [+] and [->].

4 Push [OK]

The simulation is now running, with 4 … 20 mA/HART a current is

outputted and with Profibus PA or Foundation Fieldbus a digital value.

How to interrupt the simulation:

à Push [ESC]

Information:

The simulation is terminated automatically 10 minutes after the last key

has been pushed.

Simulation

Start simulation?

Reset

Unit of measurement

With the reset function, modified values are reset. Three subfunctions

are available:

l Basic adjustment

- Reset the values modified with the indicating and adjustment

module to the basic setting

l Factory setting

- As basic adjustment, but also reset of special parameters to

the delivery status

l Peak values measured value and temperature

- Reset the min./max. values of pressure and temperature to the

current values

Reset

Select reset?

For pressure transmitters more comprehensive units are available.

They are described in the operating instructions manual of the

respective sensor in the menu "Basic adjustments".

Unit of measurement

bar

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 15

Page 16

5 Set up

Language

Copy sensor data

The sensor is already set to the ordered national language. In this

menu item you can change the language. The following languages are

available, e.g. in software version 3.50:

l Deutsch

l English

l Français

l Espanõl

l Pycckuu

l Japanese

l Italiano

l Netherlands

l Japanese

l Chinese

Language

Deutsch

With this function

l Load parameter adjustment data from the sensor into the

indicating and adjustment module

l Write p arameter adjustment data from the indicating and adjust-

ment module into the sensor

The data are permanently saved in an EEPROM memory in the

indicating and adjustment module and remain there even in case of

power failure. From there, they can be written in one or several

sensors or kept as backup for a probable sensor exchange.

Kind and volume of the copied data is stated in the operating

instructions manual of the respective sensor.

Information:

Before writing the data into the sensor, it is checked if the data fit the

sensor. If data do not fit, a fault signal is triggered or the function is

blocked. When writing data into the sensor, you will see from which

instrument type the data originate and which TAG-no. this sensor had.

The following items are checked:

l Software version

l WHG approval

l SIL activated

l Measuring principle

l Signal output

l Pressure measuring range

16 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 17

5 Set up

PIN

Info

In this menu item, the PIN is activated/deactivated permanently.

Entering a 4-digit PIN protects the sensor data against unauthorized

access and unintentional modifications. If the PIN is activated

permanently, it can be deactivated temporarily (i.e. for approx. 60 min.)

in any menu item. The instrument is delivered with the PIN set to 0000.

PIN

Disable permanently?

Only the following functions are permitted with activated PIN:

l Select menu items and show data

l Read data from the sensor into the indicating/adjustment module.

Menu section, info

In this menu item the most important sensor information can be

displayed:

l Sensor type

l Serial number: 8-digit number, e.g. 12345678

Sensor type

Serial number

12345678

l Date of manufacture: Date of the factory calibration, e.g. 10.

January 2008

l Software version: Edition of the sensor software, e.g. 3.50

Date of manufacture

10. January 2008

Software version

3.50

l Date of last change using PC: Date of the last change of sensor

parameters via PC, e.g. 10. January 2008

Last change using PC

10. January 2008

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 17

Page 18

5 Set up

l Sensor details, e.g. approval, process fitting, seal, measuring cell,

measuring range, electronics, housing, cable entry, plug, cable

length etc.

Sensor characteristics

Display now?

5.3 Special functions - 4 … 20 mA/HART

Introduction

Display

The 4 … 20 mA/HART special functions are briefly described in this

paragraph. The respective range of functions of the indicating and

adjustment module is determined by the sensor and the sensor

software version.

In the menu item "Display" you can define how the measured value

should be presented on the display.

The following indication values are available:

l Height

l Pressure (only with pressure transmitters)

l Current

l Scaled

l Percent

l Lin. percent

l Temperature

The selection "scaled" opens the menu items "Display unit" and

"Scaling". In "Display unit" there are the following options:

l Height

l Mass

l Flow

l Volume

l Without unit

Depending on selection, the different units are in turn available.

In the menu item "Scaling", the requested numerical value with

decimal point is entered for 0 % and 100 % of the measured value.

There is the following relation between the indication value in the menu

"Display" and the adjustment unit in the menu "Basic adjustment":

l With pressure, displayed value "Pressure" or " Height" means:

presentation of the measured value in the selected adjustment

unit, e.g. bar or m.

Displayed value

31549-EN-081211

Scaled

18 Indicating and adjustment module for IPT-1* sensors

Page 19

Current output

5 Set up

Display unit

Volume

l

Scaling

0 % = 0.0 l

100 % = 100.0 l

Menu section, service

In the menu item "Current output" you determine the behaviour of the

current output during operation and in case of failure. The following

options are available:

Current output

Characteristics curve 4 … 20 mA

Failure mode

Min. current

Max. current

3)

4)

5)

20 … 4 mA

Hold value

20.5 mA

22 mA

< 3.6 mA

3.8 mA

4 mA

20 mA

20.5 mA

The values in bold font represent the data of the factory setting.

In HART multidrop mode, the current is constantly 4 mA. This value

does not change even in case of failure.

Current output

Functional safety (SIL)

Output mode: 4-20 mA

Failure mode: 22 mA

Min. current 3 .8 mA

The functional safety is already activated Ex factory for instruments

▼

▼

▼

with SIL qualification. For instruments Ex factory without SIL

qualification, the functional safety must be activated by the user f or

applications according to SIL via the indicating and adjustment

module. The SIL factory setting cannot be deactivated by the user.

The activation of SIL has the following impact:

3)

Value of the current output in case of failure, e.g. if no valid measured value

is delivered.

4)

This value is not underrun during operation.

5)

This value is not exceeded during operation.

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 19

Page 20

5 Set up

l In the menu item "Failure mode" under "Current output", the

parameters "Hold value" and "20.5 mA" are blocked

l In the menu item "HART mode", the function "Multidrop" is blocked

Note:

For such applications, it is absolutely necessary to take note of "Safety

Manual".

HART mode

Introduction

Sensor address

HART offers standard and multidrop mode.

The mode standard with the fixed address 0 means output of the

measured value as 4 … 20 mA signal.

In Multidrop mode, up to 15 sensors can be operated on one two-wire

cable. An address between 1 and 126 must be assigned to each

6)

sensor.

In this menu item you determine the HART mode and enter the

address for multidrop.

HART mode

Standard

Address 0

The default setting is standard with address 0.

5.4 Special functions - Profibus PA

The Profibus PA special functions are briefly described in this

paragraph. The respective range of functions of the indicating and

adjustment module is determined by the sensor and the sensor

software revision.

Menu section, basic adjustment

Level and pressure sensors operate as slaves on the Profibus PA. To

be identified as a bus participant, each sensor must have a unique

address. Each instrument is delivered with address 126. With this

address, it can at first be connected to an existing bus. However, the

address must be changed. This can be done in this menu item.

Sensor address

126

6)

The 4 … 20 mA signal of the HART sensor is switched off. The sensor

consumes a constant current of 4 mA. The measuring signal is transmitted

exclusively as digital HART signal.

20 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 21

5 Set up

Channel

Display

The channel is the input selector switch for function block (FB) of the

sensor. Within the function block, additional scalings (Out-Scale) are

carried out. In this menu item, the value fir the function block is

selected:

l SV1 (Secondary Value 1):

- Pressure or height

l SV2 (Secondary Value 2):

- Percent

l PV (Primary Value):

- Linearised percentage value

Channel

PV lin. value

A pressure transmitter delivers the following measured values:

l SV1 (Secondary Value 1): P ressure or height value before

adjustment

l SV2 (Secondary Value 2): P ercentage value after the adjustment

l PV (Primary Value): Linearised percentage value

l PA-Out (value after passing the function block): PA output

l Temperature

In the menu item "Display" you can define which measured value

should be presented on the display.

Displayed value

PA-Out

Additional PA value

Profibus transmits two values cyclically. The first value is determined in

the menu item "Channel". The additional cyclical value is selected in

the menu item "Additional PA value".

With pressure transmitters the following values are available:

l SV1 (Secondary Value 1): P ressure or height value before

adjustment

l SV2 (Secondary Value 2): P ercentage value after the adjustment

l PV (Primary Value): Linearised percentage value

Additional PA value

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 21

Page 22

5 Set up

Determine Out-Scale

Here, you determine the unit and scaling for PA-Out. These settings

also apply to the values displayed on the indicating and adjustment

module if in the menu item "Displayed value" PA-Out was selected.

In the menu item "PV-Out-Scale", the requested numerical value with

decimal point is entered for 0 % and 100 % of the measured value.

Out-Scale-Unit

PV-Out-Scale

7)

7)

The following display values are available in "Out-Scale-Unit": Pressure,

height, mass, flow, volume, others (without unit, %, mA).

22 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 23

Basic adjustment

P

▶

Basic adjustment

Display

Diagnostics

Service

Info

5 Set up

5.5 Menu schematic

Information:

Depending on the version and application, the highlighted menu

windows are not always available.

1

Unit

Unit of measurement

Temperature unit

°C

▼

Damping

Display

Basic adjustment

▶

Display

Diagnostics

Service

Info

Displayed value

Pressure

Lighting

Switched off

bar

2

Position correction

Offset

=

0.2 mbar

0000 mbar

Linearisation curve

linear

▼

Displayed value

Scaled

1.2

1.6

▼

2.1

1.1

▼

1.5

1 s

2.1

▼

2.4

Min. adjustment

000.0 %

=

0.0 mbar

0.0 mbar

Sensor-TAG

Sensor

Display unit

Volume

▼

l

▼

1.3

1.7

2.2

Max. adjustment

100.00 %

=

100.00 mbar

0.0 mbar

Scaling

0 % = 0.0

l

100 % = 100.0

l

1.4

2.3

▼

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 23

Page 24

5 Set up

Diagnostics

Basic adjustment

Display

▶

Diagnostics

Service

Info

3

Pointer

p-min.: -5.8 mbar

p-max.: 167.5 mbar

T-min.: -12.5 °C

T-max.: +85.5 °C

Service

Basic adjustment

Display

Diagnostics

▶

Service

Info

Current output

Output mode: 4-20 mA

Fail.mode: < 3.6 mA

Min. current: 3.8 mA

max. current: 20.5 mA

SIL

Deactivated!

Application

▼

Level

3.1

4.1

▼

Sensor status

OK

4

Simulation

Start simulation

3.2

4.2

▼

Trend curve

Start trend curve?

Reset

Select reset

3.3.1

4.3

▼

Language

Deutsch

4.4

▼

▼

▼

▼

4.5

▼

4.9

HART mode

Standard

Address 0

4.6

Copy sensor data

Copy sensor data?

4.7

PIN

4.8

Enable?

Info

Basic adjustment

Display

Diagnostics

Service

▶

Info

Sensor type

Serial number

12345678

5.1

5

Date of manufacture

e.g. 16. May 2008

Software version

e.g. 3.50

5.2

Last change using PC

e.g. 16. May 2008

5.3

Sensor characteristics

Display now?

5.4

24 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 25

5 Set up

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 25

Page 26

P

5 Set up

Basic adjustment

▶

Basic adjustment

Display

Diagnostics

Service

Info

5.6 Menu schematic

Information:

Depending on the version and application, the highlighted menu

windows are not always available.

1

Sensor address

126

Max. adjustment

100.00 %

=

100.00 mbar

0.0 mbar

Display

Basic adjustment

▶

Display

Diagnostics

Service

Info

Displayed value

PA-Out

Diagnostics

Basic adjustment

Display

▶

Diagnostics

Service

Info

1.1

1.4

2.1

2

3

Unit

Unit of measurement

bar

▼

Temperature unit

°C

▼

Damping

0 s

Lighting

Switched off

▼

1.1

1.5

2.4

Position correction

Offset

=

0.2 mbar

0000 mbar

Linearisation curve

linear

▼

1.2

1.6

Min. adjustment

000.0 %

=

0.0 mbar

0.0 mbar

Sensor-TAG

Sensor

1.3

1.7

Pointer

p-min.: -5.8 mbar

p-max.: 167.5 mbar

T-min.: -12.5 °C

T-max.: +85.5 °C

3.1

Sensor status

OK

3.2

Trend curve

Start trend curve?

3.3.1

26 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 27

Service

Basic adjustment

Display

Diagnostics

▶

Service

Info

5 Set up

4

Additional PA value

Secondary Value 1

Reset

Select reset

Application

Level

▼

Info

Basic adjustment

Display

Diagnostics

Service

▶

Info

Sensor type

Serial number

12345678

5

Out-Scale-Unit

Volume

l

Language

Deutsch

Date of manufacture

e.g. 16. May 2008

Software version

e.g. 3.50

4.2

4.6

5.2

4.1

4.3

▼

4.9

5.1

PA-Out-Scale

100.00 lin %

= 0.0 l

0.00 lin %

= 100.0 l

Copy sensor data

Copy sensor data?

Last change using PC

e.g. 16. May 2008

4.3

4.7

5.3

Simulation

Start simulation

PIN

Enable?

Sensor characteristics

Display now?

4.2

▼

4.8

5.4

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 27

Page 28

P

5 Set up

Basic adjustment

▶

Basic adjustment

Display

Diagnostics

Service

Info

5.7 Menu schematic

Information:

Depending on the version and application, the highlighted menu

windows are not always available.

1

Unit

Unit of measurement

bar

Temperature unit

°C

▼

Damping

Display

Basic adjustment

▶

Display

Diagnostics

Service

Info

Displayed value

AI-Out

Diagnostics

Basic adjustment

Display

▶

Diagnostics

Service

Info

2

3

Position correction

Offset

=

0.2 mbar

0000 mbar

Linearisation curve

linear

▼

Lighting

Switched off

▼

1.2

1.6

2.4

1.1

▼

1.5

0 s

2.1

Min. adjustment

000.0 %

=

0.0 mbar

0.0 mbar

Sensor-TAG

Sensor

1.3

1.7

Max. adjustment

100.00 %

=

100.00 mbar

0.0 mbar

1.4

Pointer

p-min.: -5.8 mbar

p-max.: 167.5 mbar

T-min.: -12.5 °C

T-max.: +85.5 °C

3.1

Sensor status

OK

3.2

Trend curve

Start trend curve?

3.3.1

28 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 29

Service

Basic adjustment

Display

Diagnostics

▶

Service

Info

5 Set up

4

Simulation

Start simulation

PIN

Info

Basic adjustment

Display

Diagnostics

Service

▶

Info

Device-ID

Sensor-TAG

Sensor characteristics

Display now?

Enable?

4.2

▼

4.5

5.1

5.4

Reset

Select reset

Application

Level

5

Sensor type

Serial number

12345678

4.3

▼

4.6

5.2

Language

Deutsch

Date of manufacture

e.g. 16. May 2008

Software version

e.g. 3.50

4.3

5.2

Copy sensor data

Copy sensor data?

Last change using PC

e.g. 16. May 2008

4.4

5.3

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 29

Page 30

6 Maintenance and fault rectification

6 Maintenance and fault rectification

6.1 Maintenance

When used in the correct way, no special maintenance is required in

normal operation.

6.2 Instrument repair

You can download a return form (24 KB) in the Internet from our

homepage

If a repair is necessary, please proceed as follows:

l Print and fill out one form per instrument

l If necessary, state a contamination

l Clean the instrument and pack it damage-proof

l Attach the completed form and probably a safety data sheet to the

instrument

l Please contact the agency serving you for the address of the

return shipment

By doing this you help us carry out the repair quickly and without

having to call back for needed information.

www.wika.com under the item "Service".

30 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 31

7 Dismounting

7 Dismounting

7.1 Dismounting steps

Warning:

Before dismounting, be aware of dangerous process conditions such

as e.g. pressure in the vessel, high temperatures, corrosive or toxic

products etc.

Take note of chapters "Mounting" and "Connecting to power supply"

and carry out the listed steps in reverse order.

7.2 Disposal

The indicating and adjustment module consists of materials which can

recycled by specialised recycling companies. We have purposely

designed the components to be easily separable.

WEEE directive 2002/96/EG

This indicating and adjustment module is not subject to the WEEE

directive 2002/96/EG and the respective national laws (in Germany, e.

g. ElektroG). Pass the indicating and adjustment module directly on to

a specialised recycling company and do not use the municipal

collecting points. They may only be used for privately used products

according to the WEEE directive.

Correct disposal avoids negative effects to persons and environment

and ensures recycling of useful raw materials.

Materials: see chapter "Technical data"

If you have no possibility to dispose of the old instrument

professionally, please contact us concerning return and disposal.

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 31

Page 32

8 Supplement

8 Supplement

8.1 Technical data

General data

Weight approx. 150 g (0.33 lbs)

Ambient conditions

Ambient temperature -15 … +70 °C (+5 … +158 °F)

Storage and transport temperature -40 … +80 °C (-40 … +176 °F)

Indicating and adjustment module

Voltage supply and data transmission through the sensor

Indication LC display in dot matrix

Adjustment elements 4 keys

Protection

- unassembled IP 20

- mounted into the sensor without cover IP 40

Materials

- Housing ABS

- Inspection window Polyester foil

32 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 33

8.2 Dimensions

27,6mm

(1

3

/

32

")

ø66,3mm

(2

39

/

64

")

45,1mm

(1

25

/

32

")

9,7mm

(

3

/

8

")

Indicating and adjustment module

8 Supplement

Fig. 5: Indicating and adjustment module

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 33

Page 34

8 Supplement

34 Indicating and adjustment module for IPT-1* sensors

31549-EN-081211

Page 35

8 Supplement

31549-EN-081211

Indicating and adjustment module for IPT-1* sensors 35

Page 36

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Phone +49 9372 132295

Fax +49 9372 132706

e-mail: support-tronic@wika.de

www.wika.de

Printing date::

All statements concerning scope of delivery, application,

practical use and operating conditions of the sensors and

processing systems correspond to the information avail-

able at the time of printing.

Subject to change without prior notice 31549-EN-081211

Loading...

Loading...