Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

UHP pressure gauge

UHP-Druckmessgerät

Manomètre UHP

Manómetro UHP

GB

D

F

E

HYDRA-Gauge

HYDRA-Gauge

in-line are

HYDRA-Gauge

dead-end are

HYDRA-Gauge incl.

contacts in-line are

Page 2

Operating instructions HYDRA-Gauge Page 3 - 12

GB

D

Betriebsanleitung HYDRA-Gauge Seite 13 - 22

Mode d’emploi HYDRA-Gauge Page 23 - 32

F

Manual de instrucciones HYDRA-Gauge Página 33 - 42

E

© 2013 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions HYDRA-Gauge

9015329.01 08/2013 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 6

4. Design and function 7

5. Transport, packaging and storage 8

6. Commissioning, operation 8

7. HYDRA-Gauge with switch contacts 9

8. Maintenance and cleaning 12

9. Dismounting and disposal 12

GB

9015329.01 08/2013 GB/D/F/E

WIKA operating instructions HYDRA-Gauge 3

Page 4

1. General information

1. General information

■

GB

The pressure gauge described in the operating instructions has been designed and

manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria during produc-

tion. Our management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument’s range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The manufacturer’s liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions,

assignment of insuciently qualied skilled personnel or unauthorised modications to

the instrument.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: SP 99.20

- Application consultant:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.com

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury

or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or

damage to equipment or the environment, if not avoided.

Information

… points out useful tips, recommendations and information for ecient and

trouble-free operation.

4 WIKA operating instructions HYDRA-Gauge

9015329.01 08/2013 GB/D/F/E

Page 5

2. Safety

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate

pressure gauge has been selected in terms of measuring range, design and

specic measuring conditions.

Non-observance can result in serious injury and/or damage to the equipment.

Further important safety instructions can be found in the individual chapters of

these operating instructions.

2.1 Intended use

These pressure gauges are used for measuring pressure in UHP applications, e.g. in the

semiconductor industry or for UHP chemicals distribution systems.

The pressure gauge has been designed and built solely for the intended use described

here and may only be used accordingly.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to equipment.

■

The activities described in these operating instructions may only be carried

out by skilled personnel who have the qualications described below.

GB

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowl-

edge of country-specic regulations, current standards and directives, are capable of

carrying out the work described and independently recognising potential hazards.

2.3 Special hazards

WARNING!

Residual media in dismounted instruments can result in a risk to persons, the

environment and equipment.

Take sucient precautionary measures.

9015329.01 08/2013 GB/D/F/E

WIKA operating instructions HYDRA-Gauge 5

Page 6

2. Safety / 3. Specications

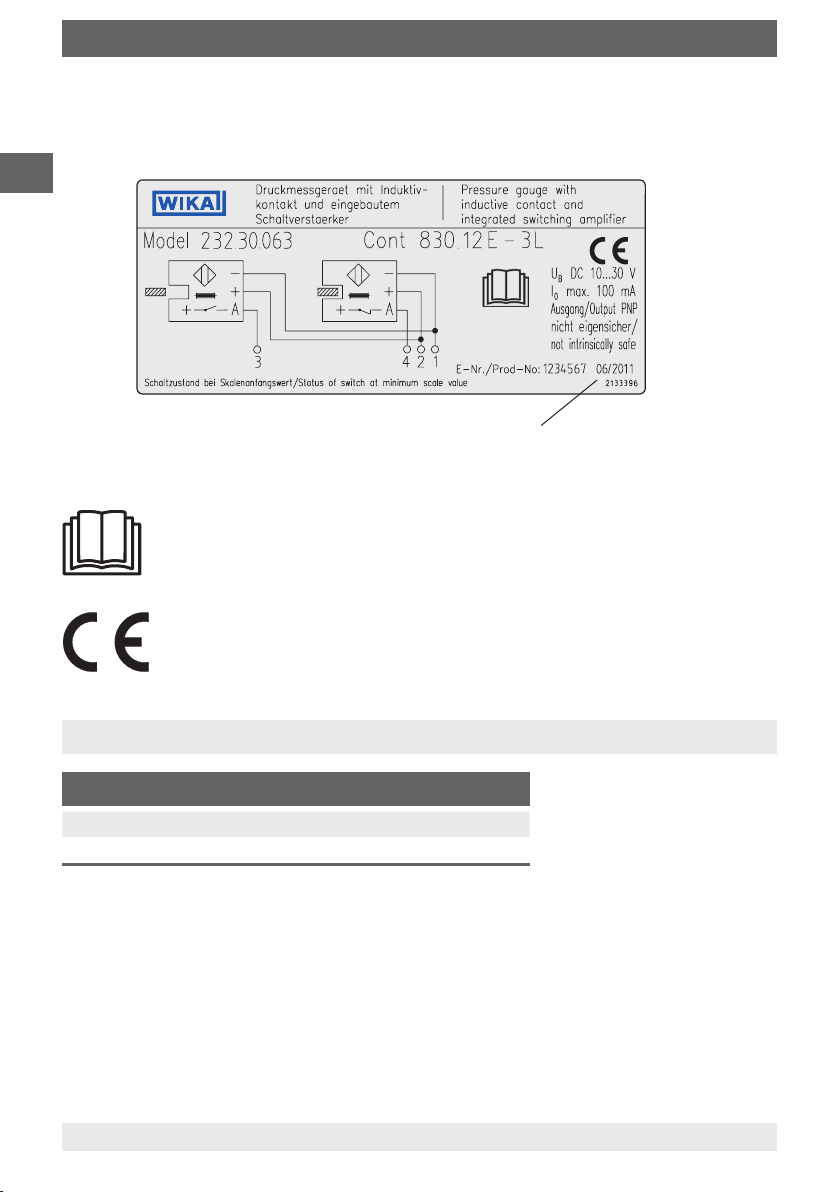

2.4 Labelling / Safety marks

Product label (HYDRA-Gauge with switch contacts)

GB

Explanation of symbols

Before mounting and commissioning the instrument with electronic contacts,

ensure you read the operating instructions!

Date of manufacture

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

3. Specications

Permissible working conditions

Ambient temperature +5 ... 60 °C

Process temperature +5 ... 60 °C

■

The mechanical pressure gauge of the HYDRA-Gauge is overpressure safe up to the

full scale value for a short term. However working pressure should not exceed 2/3 of the

measuring range to guarantee a long service life of the pressure gauge.

■

In any case the maximum pressures and temperatures of the process connection

according to the following chart must not be exceeded. The resulting maximum

permissible working pressures might be lower than the instrument's measuring range.

6 WIKA operating instructions HYDRA-Gauge

9015329.01 08/2013 GB/D/F/E

Page 7

3. Specications / 4. Design and function

Permissible process pressure

1/4" and 3/8"

1/2"

Pressure in bar

Temperature in °C

■

The HYDRA-Gauge is not appropriate for strong vibrations, pulsations and pressure

surges, e.g. at measuring points directly behind a pump. Appropriate pulsation dampers

and restrictor segments may be necessary.

■

The HYDRA-Gauge must not be used with aggressive ambient conditions (e.g. HCl

vapours). This may result in corrosion of the metallic parts of the HYDRA-Gauge.

For further specications see WIKA data sheet SP 99.20 and the order documentation.

3/4"

1"

1 1/4"

only up to

25 °C

GB

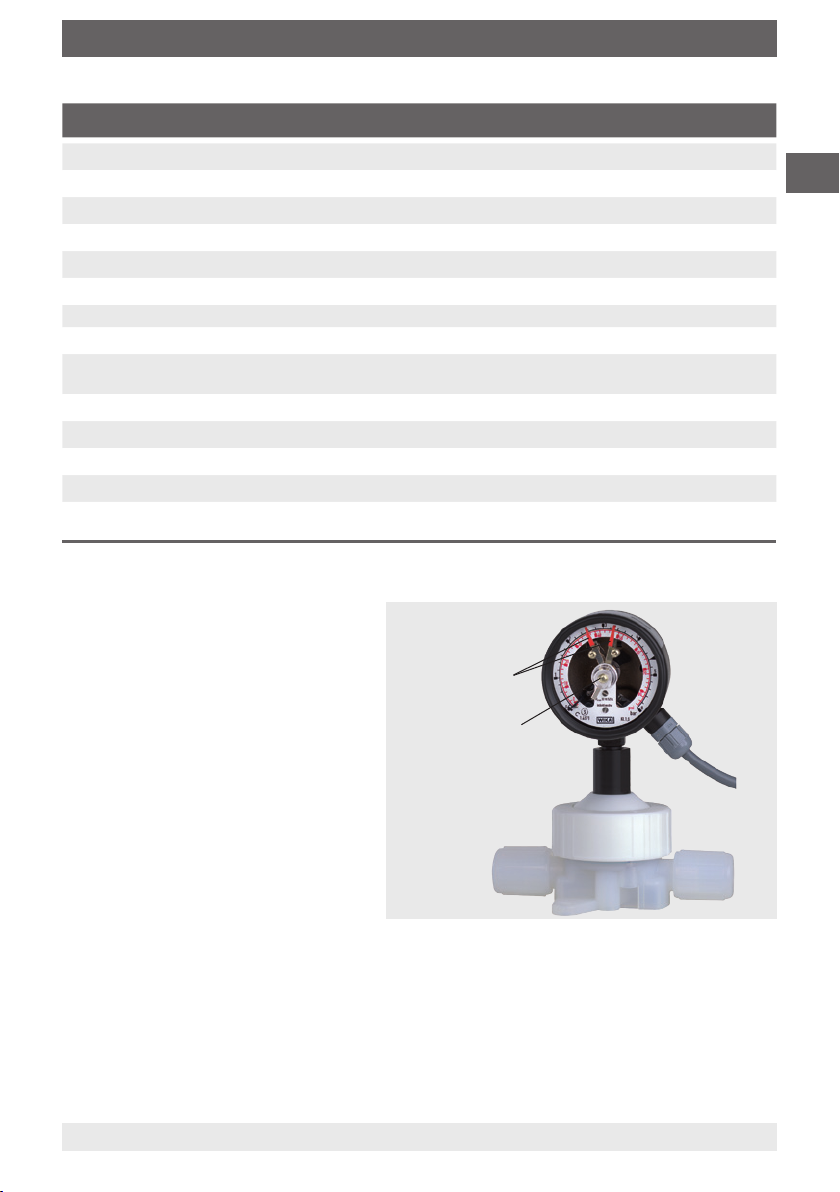

4. Design and function

4.1 Description

HYDRA-Gauge is a mechanical pressure gauge of nominal size 63 in accordance with

EN 837-1. With a special diaphragm seal system it has been adapted to the special

requirements of ultrapure media distribution systems. All wetted parts are made of PFA

or TFM (modied PTFE). Final assembly, adjustment and packaging is eected under

Laminar-Flow Class 100. Standard system ll uid is KN 75, a 50/50 mixture of DI water and

isopropyl alcohol (IPA). Optionally DI water (KN 64) is used. Pressure gauge and diaphragm

seal are one unit and may never ever be separated as this may cause the system ll uid to

leak, thus destroying the measuring assembly.

4.2 Scope of delivery

Cross-check scope of delivery with the delivery note.

9015329.01 08/2013 GB/D/F/E

WIKA operating instructions HYDRA-Gauge 7

Page 8

5. Transport, packaging ... / 6. Commissioning, operation

5. Transport, packaging and storage

5.1 Transport

GB

Check the instrument for any damage that may have been caused during transportation.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -20 ... +60 °C (standard, KN 75)

+5 ... +60 °C (optional, KN 64)

6. Commissioning, operation

Installation instructions

The recommendations of EN 837-2 regarding selection and installation of pressure

gauges are to be observed. Installation and commissioning may only be carried out by

trained and qualied personnel. When tightening the process connections, observe the

relevant instructions and the advice of the ttings' manufacturers. The measuring instru-

ment's central nut, which is sealed with a colour point, and the threaded connection of the

pressure gauge to the diaphragm seal must not be loosened at any rate. This would cause

the destruction of the measuring assembly and the leakage of the process medium.

8 WIKA operating instructions HYDRA-Gauge

9015329.01 08/2013 GB/D/F/E

Page 9

6. Commissioning ... / 7. HYDRA-Gauge with switch contacts

After installation the pressure gauge may

be turned by hand in order to get an optimal

read-o position.

A pressure measuring instrument with the option of an electrical contact must be

connected in accordance with the connection diagram on the instrument.

For further information see data sheet AC 08.01

360°

7. HYDRA-Gauge with switch contacts

When using the HYDRA-Gauge pressure measuring assemblies with model 830 E

electronic contacts, observe the following:

7.1 Description, application

Direct switching of small capacities which are usually required in connection with a PLC

can be realised by the inductive contact with integrated switching amplier, which is

factory-installed directly into the measuring instrument.

GB

The familiar advantages with inductive contacts, such as an especially safe contact

operation, no wear at all by proximity contact operation as well as virtually no reaction

on the measuring system, thus enabling the accuracy of the indication, are used in this

context, too.

An additional control unit is not required.

The electronic contact with 3-wire design is realised with a PNP output. The operating

voltage is DC 10 ... 30 V. The maximum switching current is 100 mA.

The model 830 E is not intrinsically safe and therefore not suitable for applications in

hazardous areas!

9015329.01 08/2013 GB/D/F/E

WIKA operating instructions HYDRA-Gauge 9

Page 10

7. HYDRA-Gauge with switch contacts

7.2 Special requirements for the installation point

To avoid, amongst other things, switch signal "chatter", it must be ensured that the instruments are mounted free of vibration.

GB

7.3 Electrical connection

The electrical connection must only be made by qualied skilled personnel. The permissible electrical data, connection details and switching functions are given on the product

label axed to the instrument.

The connection cables are appropriately marked.

■

To connect a PLC control unit or for direct switching of small capacities

■

PNP transistor

With PNP switching apparatus, the switched output is a connection towards PLUS. The

load RL between the switched ouput and the MINUS should be selected in a way not to

exceed the maximum switching current of 100 mA.

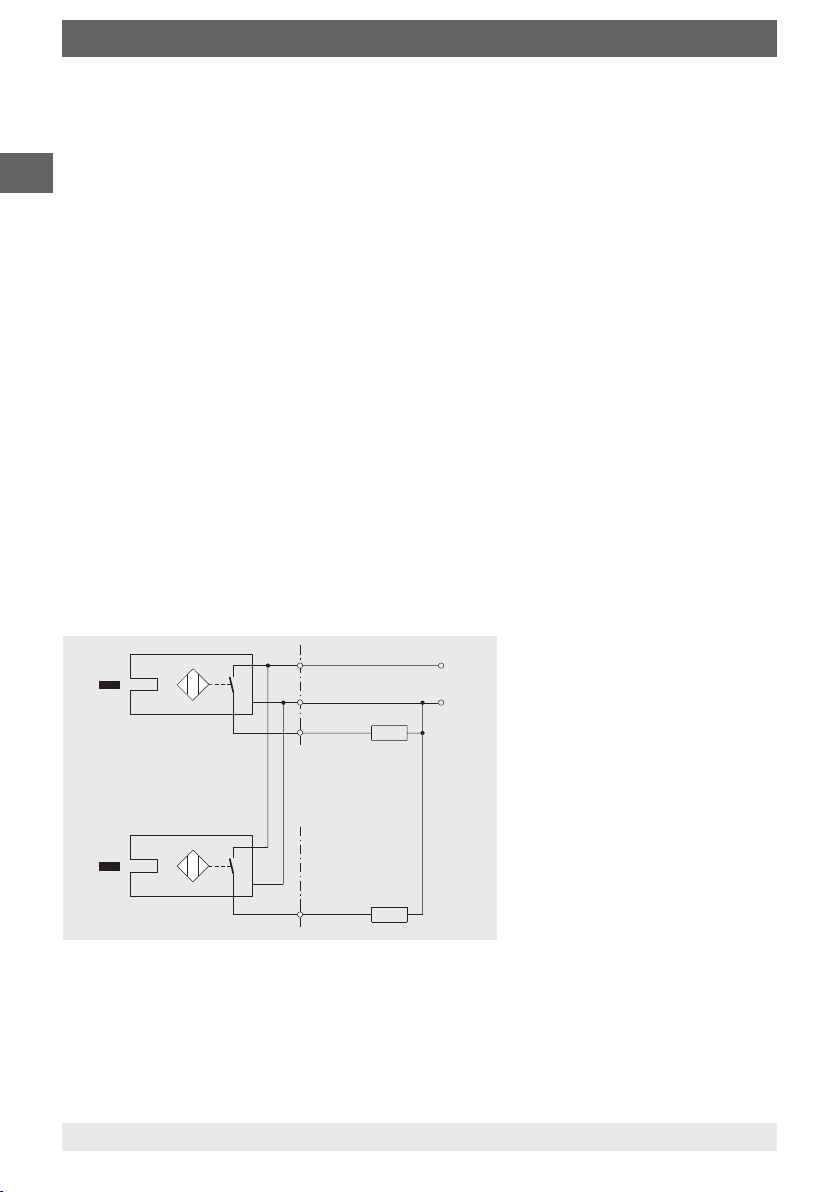

Connection and function circuit diagrams for electronic contact model 830 E,

3-wire system,

control and switching electronics in the sensor,

electrical connection via ying leads

■

Flag emerges from slot

sensor:

Contact open

(output not active)

■

Flag retreats into slot sensor:

Contact closed (output active)

PNP

With double contact

2nd contact

PNP

2

1

3

RL (load)

RL (2nd load)

4

+ U

_

B

10 WIKA operating instructions HYDRA-Gauge

9015329.01 08/2013 GB/D/F/E

Page 11

7. HYDRA-Gauge with switch contacts

7.4 Specications

Range of operating voltage DC 10 ... 30 V

Residual ripple max. 10 %

No-lead current ≤ 10 mA

Switching current ≤ 100 mA

Leakage current ≤ 100 mA

Function of switching element Normally open

Type of output PNP transistor

Voltage drop (with I max.) ≤ 0.7 V

Reverse polarity protection conditional U

Anti-inductive protection 1 kV, 0.1 ms, 1 kΩ

Oscillator frequency approx. 1000 kHz

EMC per EN 60947-5-2

Ambient conditions and temperature in accordance with measuring instrument

Installation installed directly in the measuring instrument at the factory,

Electronic contact model 830 E

(the output 3 or 4 switch must never be set

directly to minus)

maximum 2 switch contacts per measuring instrument

B

7.5 Adjusting the set pointers

The adjustment of the set points is

achieved using the adjustment lock

in the window with the aid of the

Set pointer

adjustment key (included in delivery).

Adjustment lock

GB

The set pointers for the limit switches are freely adjustable over the full scale range. For

reasons of switching accuracy and service life of the mechanical measuring systems, the

switch points should be between 10 % and 90 % of the measuring range.

9015329.01 08/2013 GB/D/F/E

WIKA operating instructions HYDRA-Gauge 11

Page 12

8. Maintenance and cleaning / 9. Dismounting and disposal

8. Maintenance and cleaning

8.1 Maintenance

GB

HYDRA-Gauge pressure measuring assemblies are maintenance-free.

The indicator and switching function should be checked once or twice every year.

The instrument must be disconnected from the process to check the indication and switching function with a pressure testing device.

The HYDRA double diaphragm system prevents contamination of the process medium

even in case of mechanical damage of the wetted diaphragm. In this case the process

medium will penetrate the lateral leakage bore. The instrument must be exchanged as soon

as possible.

For safety reasons repairs of already installed instruments are not possible.

8.2 Cleaning

CAUTION!

■

The HYDRA-Gauge may only be cleaned by rinsing. Any mechanical

cleaning inside the process connection may damage the separating

diaphragms.

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with moisture.

9. Dismounting and disposal

WARNING!

Residual media in dismounted instruments can result in a risk to persons, the

environment and equipment.

Take sucient precautionary measures.

9.1 Dismounting

Only disconnect the pressure gauge once the system has been depressurised!

9.2 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal regulations.

12 WIKA operating instructions HYDRA-Gauge

9015329.01 08/2013 GB/D/F/E

Page 13

Inhalt

Inhalt

1. Allgemeines 14

2. Sicherheit 15

3. Technische Daten 16

4. Aufbau und Funktion 17

5. Transport, Verpackung und Lagerung 18

6. Inbetriebnahme, Betrieb 18

7. HYDRA-Gauge mit Schaltkontakten 19

8. Wartung und Reinigung 22

9. Demontage und Entsorgung 22

D

9015329.01 08/2013 GB/D/F/E

WIKA Betriebsanleitung HYDRA-Gauge 13

Page 14

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Druckmessgerät wird nach dem aktuellen

Stand der Technik konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und Umwelt-

kriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001 zertiziert.

D

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise

und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwen-

dung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten

Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: SP 99.20

- Anwendungsberater:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder

zu schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen

kann, wenn sie nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

ezienten und störungsfreien Betrieb hervor.

WIKA Betriebsanleitung HYDRA-Gauge14

9015329.01 08/2013 GB/D/F/E

Page 15

2. Sicherheit

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige

Druckmessgerät hinsichtlich Messbereich, Ausführung und spezischen

Messbedingungen ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen Kapiteln

dieser Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Diese Druckmessgeräte dienen zum Messen von Druck bei UHP-Anwendungen z. B. in

der Halbleiterindustrie oder für Reinstchemieversorgungssysteme.

Das Druckmessgerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen

Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet

werden.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

D

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden

führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualikation durchführen

lassen.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der Mess-

und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen

Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen Arbeiten

auszuführen und mögliche Gefahren selbstständig zu erkennen.

2.3 Besondere Gefahren

WARNUNG!

Messstoreste in ausgebauten Geräten können zur Gefährdung von

Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

9015329.01 08/2013 GB/D/F/E

WIKA Betriebsanleitung HYDRA-Gauge 15

Page 16

2. Sicherheit / 3. Technische Daten

2.4 Beschilderung / Sicherheitskennzeichnungen

Typenschild (HYDRA-Gauge mit Schaltkontakten)

D

Symbolerklärung

Vor Montage und Inbetriebnahme des Gerätes mit Elektronik-Kontakten

unbedingt die Betriebsanleitung lesen!

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den zutreenden

europäischen Richtlinien.

Herstellungsdatum

3. Technische Daten

Zulässige Betriebsparameter

Umgebungstemperatur +5 ... 60 °C

Prozesstemperatur +5 ... 60 °C

■

Das mechanische Druckmessgerät des HYDRA-Gauge ist kurzzeitig bis zum

Skalenendwert belastbar. Um eine lange Lebensdauer des Druckmessgerätes zu

gewährleisten, sollte der Betriebsdruck jedoch nicht mehr als 2/3 des Messbereiches

betragen.

■

In jedem Fall dürfen die Maximaldrücke und Temperaturen des Prozessanschlusses

entsprechend dem folgendem Diagramm nicht überschritten werden. Die sich daraus

ergebenden maximal zulässigen Betriebsdrücke können unter Umständen niedriger

sein als der Messbereich.

WIKA Betriebsanleitung HYDRA-Gauge16

9015329.01 08/2013 GB/D/F/E

Page 17

3. Technische Daten / 4. Aufbau und Funktion

Zulässiger Prozessdruck

1/4" und 3/8"

1/2"

Druck in bar

Temperatur in °C

■

Das HYDRA-Gauge ist nicht geeignet bei Auftreten von starken Vibrationen,

3/4"

1"

1 1/4" nur bis 25 °C

Pulsationen und Druckstößen, wie sie z.B. bei Messstellen direkt hinter einer Pumpe

auftreten. Gegebenenfalls sind geeignete Pulsationsdämper und Drosselstrecken

vorzusehen.

■

Das HYDRA-Gauge ist nicht geeignet bei aggressiven Umgebungsbedingungen

(z. B. HCl-Dämpfe). Hier kann es zu Korrosion der metallischen Bauteile von HYDRAGauge kommen.

Weitere technische Daten siehe WIKA Datenblatt SP 99.20 und Bestellunterlagen.

4. Aufbau und Funktion

4.1 Beschreibung

Bei HYDRA-Gauge handelt es sich um ein mechanisches Druckmessgerät der

Nenngröße 63 entsprechend den Vorschriften der EN 837-1. Dieses ist durch ein spezielles

Druckmittlersystem an die besonderen Anforderungen in der Reinstmedienversorgung

angepasst worden. Alle messstoberührten Teile sind aus PFA oder TFM (modiziertes

PTFE). Endmontage, Justage und Verpackung erfolgt unter Laminar-Flow Class 100. Die

Standard-Druckübertragungsüssigkeit ist KN 75, eine Mischung aus 50 % DI-Wasser und

50 % Isopropylalkohol (IPA). Optional wird DI-Wasser (KN 64) eingesetzt. Druckmessgerät

und Druckmittler sind eine Einheit und dürfen auf keinen Fall getrennt werden. Dies würde

zu einem Austritt von Druckübertragungsüssigkeit und somit zu einer Zerstörung der

Druckmessanordnung führen.

D

4.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

9015329.01 08/2013 GB/D/F/E

WIKA Betriebsanleitung HYDRA-Gauge 17

Page 18

5. Transport, Verpackung ... / 6. Inbetriebnahme, Betrieb

5. Transport, Verpackung und Lagerung

5.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

D

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -20 ... +60 °C (Standard, KN 75)

+5 ... +60 °C (optional, KN 64)

6. Inbetriebnahme, Betrieb

Montagehinweise

Die Empfehlungen der EN 837-2 zur Auswahl und Einbau von Druckmessgeräten sind

einzuhalten. Die Montage und Inbetriebnahme darf nur von entsprechend qualiziertem

Fachpersonal durchgeführt werden. Beim Verschrauben der Prozessanschlüsse sind die

einschlägigen Vorschriften sowie die Empfehlungen der Fittinghersteller einzuhalten. Die

mit einem Farbpunkt versiegelte Zentralmutter des Messgerätes sowie die Verschraubung

des Manometers mit dem Druckmittler dürfen auf keinen Fall gelöst werden. Dies führt zu

einer Zerstörung der Messanordnung und zum Austreten von Prozessmedium.

9015329.01 08/2013 GB/D/F/E

WIKA Betriebsanleitung HYDRA-Gauge18

Page 19

6. Inbetriebnahme ... / 7. HYDRA-Gauge mit Schaltkontakten

Nach der Montage kann das Druckmessgerät von Hand verdreht werden, um ihn in eine

zum Ablesen optimale Position zu bringen.

Ist das Druckmessgerät mit der Option elektrischer Kontakt versehen, so ist dieser

entsprechend dem auf dem Gerät angebrachten Anschlussplan anzuschließen.

Weitere Informationen siehe Datenblatt AC 08.01

360°

7. HYDRA-Gauge mit Schaltkontakten

Bei Einsatz von HYDRA-Gauge Druckmessanordnungen mit Elektronik-Kontakt Typ 830 E

ist Folgendes zu beachten:

7.1 Beschreibung, Einsatz

Durch den werkseitig direkt in das Messgerät eingebauten Induktivkontakt mit integriertem

Schaltverstärker Typ 830 E können kleine Leistungen, wie beispielsweise bei speicherprogrammierbaren Steuerungen (SPS) üblich, direkt geschaltet werden.

D

Die von den Induktivkontakten bekannten Vorteile, wie besonders sichere Kontaktgabe,

keinerlei Verschleiß durch berührungslose Kontaktgabe sowie praktisch keine Rückwirkungen auf das Messsystem, werden auch hier genutzt.

Ein zusätzliches Steuergerät ist nicht erforderlich.

Der Elektronik-Kontakt ist in 3-Leiter-Technik mit einem PNP-Ausgang realisiert, wobei der

Betriebsspannungsbereich DC 10 ... 30 V beträgt und der maximale Schaltstrom 100 mA

ist.

Elektronik-Kontakt Typ 830 E ist nicht eigensicher und deshalb nicht geeignet für Anwendungen in explosionsgefährdeten Bereichen!

9015329.01 08/2013 GB/D/F/E

WIKA Betriebsanleitung HYDRA-Gauge 19

Page 20

7. HYDRA-Gauge mit Schaltkontakten

7.2 Besondere Anforderungen an die Einbaustelle

Um u.a. ein „Flattern“ des Schaltsignals zu vermeiden, ist dafür zu sorgen, dass die Geräte

erschütterungsfrei montiert sind.

7.3 Elektrischer Anschluss

D

Der elektrische Anschluss darf nur durch qualiziertes Personal erfolgen. Die zulässigen

Anschlusswerte, Belegung der Anschlüsse und die Schaltfunktionen sind dem Typenschild, welches am Gerät angebracht ist, zu entnehmen.

Die Anschlusskabel sind entsprechend gekennzeichnet.

■

Zum Anschluss einer SPS-Steuereinheit bzw. zum direkten Schalten kleiner Leistungen

■

PNP-Transistor

Bei PNP-schaltenden Geräten stellt der geschaltete Ausgang eine Verbindung nach

PLUS dar. Die Last R

wählen, dass der max. Schaltstrom von 100 mA nicht überschritten wird.

Anschluss- und Funktionsschaltbild für Elektronik-Kontakt Typ 830 E,

3-Leiter-Ausführung,

Steuer- und Schaltelektronik im Initiator,

elektrischer Anschluss über freies Kabelende

zwischen dem geschalteten Ausgang und dem MINUS ist so zu

L

PNP

Bei Zweifachkontakt

2. Kontakt

PNP

2

1

3

RL (Last)

RL (2. Last)

4

+ U

_

WIKA Betriebsanleitung HYDRA-Gauge20

■

Steuerfahne aus dem

B

Schlitzinitiator:

Kontakt oen

(Ausgang nicht aktiv)

■

Steuerfahne im

Schlitzinitiator:

Kontakt geschlossen

(Ausgang aktiv)

9015329.01 08/2013 GB/D/F/E

Page 21

7. HYDRA-Gauge mit Schaltkontakten

7.4 Technische Daten

Betriebsspannungsbereich DC 10 ... 30 V

Restwelligkeit max. 10 %

Leerlaufstrom ≤ 10 mA

Schaltstrom ≤ 100 mA

Reststrom ≤ 100 mA

Schaltelementefunktion Schließer

Ausgangsart PNP-Transistor

Spannungsabfall (bei I max.) ≤ 0,7 V

Verpolungsschutz bedingt U

Induktionsschutz 1 kV, 0,1 ms, 1 kΩ

Oszillatorfrequenz ca. 1000 kHz

EMV gemäß EN 60947-5-2

Umgebungsbedingungen und

-temperatur

Einbau werkseitig direkt in das Messgerät,

Elektronik-Kontakt Typ 830 E

(der geschaltete Ausgang 3 oder 4 darf niemals

direkt auf Minus gelegt werden)

entsprechend Messgerät

maximal 2 Schaltkontakte je Messgerät

B

7.5 Einstellen der Sollwertzeiger

Das Einstellen der Sollwerte

erfolgt über das Verstellschloss

in der Sichtscheibe mit Hilfe des

Sollwertzeiger

Verstellschlüssels (gehört zum

Lieferumfang).

Verstellschloss

D

Die Sollwertzeiger der Grenzwertschalter sind im gesamten Skalenbereich frei

einstellbar. Aus Gründen der Schaltgenauigkeit und der Lebensdauer der mechanischen

Messsysteme sollen die Schaltpunkte zwischen 10 % und 90 % der Messspanne liegen.

9015329.01 08/2013 GB/D/F/E

WIKA Betriebsanleitung HYDRA-Gauge 21

Page 22

8. Wartung und Reinigung /

9. Demontage und Entsorgung

8. Wartung und Reinigung

8.1 Wartung

HYDRA-Gauge Druckmessanordnungen sind wartungsfrei.

Eine Überprüfung der Anzeige und der Schaltfunktion sollte etwa 1 bis 2 mal pro Jahr

D

erfolgen.

Zur Prüfung von Anzeige und Schaltfunktion ist das Gerät vom Prozess zu trennen und mit

einer Druckprüfvorrichtung zu kontrollieren.

Das HYDRA-Doppelmembransystem verhindert auch bei einer mechanischen Beschädi-

gung der messstoberührenden Membran eine Kontamination des Prozessmediums. In

diesem Fall tritt Prozessmedium zur seitlichen Leckagebohrung aus. Das Gerät ist dann

schnellstmöglich auszuwechseln.

Aus Sicherheitsgründen sind Reparaturen von bereits vor Ort eingebauten Geräten nicht

möglich.

8.2 Reinigung

VORSICHT!

■

Eine Reinigung von HYDRA-Gauge darf nur durch Ausspülen erfolgen.

Jegliche mechanische Reinigung im Inneren des Prozessanschlusses

kann zu einer Beschädigung der Trennmembranen führen.

■

Das Gerät mit einem feuchten Tuch reinigen.

■

Elektrische Anschlüsse nicht mit Feuchtigkeit in Berührung bringen.

9. Demontage und Entsorgung

WARNUNG!

Messstoreste in ausgebauten Geräten können zur Gefährdung von

Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen sind zu ergreifen.

9.1 Demontage

Druckmessgerät nur im drucklosen Zustand demontieren!

9.2 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezischen

Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

WIKA Betriebsanleitung HYDRA-Gauge22

9015329.01 08/2013 GB/D/F/E

Page 23

Sommaire

Sommaire

1. Généralités 24

2. Sécurité 25

3. Spécications 26

4. Conception et fonction 27

5. Transport, emballage et stockage 28

6. Mise en service, exploitation 28

7. HYDRA-Gauge avec contacts électriques 29

8. Entretien et nettoyage 32

9. Démontage et mise au rebut 32

F

9015329.01 08/2013 GB/D/F/E

WIKA mode d'emploi HYDRA-Gauge 23

Page 24

1. Généralités

1. Généralités

■

Le manomètre décrit dans le présent mode d’emploi est conçu et fabriqué selon les

dernières technologies en vigueur. Tous les composants sont soumis à des critères de

qualité et d’environnement stricts durant la fabrication. Nos systèmes de gestion sont

certiés selon ISO 9001 et ISO 14001.

■

Ce mode d’emploi donne des indications importantes concernant l’utilisation de

l’instrument. Il est possible de travailler en toute sécurité avec ce produit en respectant

F

toutes les consignes de sécurité et d’utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents et les

prescriptions générales de sécurité en vigueur pour le domaine d’application de

l’instrument.

■

Le mode d’emploi fait partie de l’instrument et doit être conservé à proximité immédiate

de l’instrument et accessible à tout moment pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération, avoir lu soigneusement

et compris le mode d’emploi.

■

La responsabilité du fabricant n’est pas engagée en cas de dommages provoqués par

une utilisation non conforme à l’usage prévu, de non respect de ce mode d’emploi,

d’utilisation de personnel peu qualié de même qu’en cas de modications de

l’instrument eectuées par l’utilisateur.

■

Les conditions générales de vente mentionnées dans les documents de vente

s’appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d’autres informations:

- Consulter notre site internet : www.wika.fr

- Fiche technique correspondante : SP 99.20

- Conseiller applications :

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer

la mort ou des blessures graves si elle n'est pas évitée.

Tel. : +33 1 343084-84

Fax : +33 1 343084-94

info@wika.fr

ATTENTION !

… indique une situation potentiellement dangereuse et susceptible de

provoquer de légères blessures ou des dommages matériels et pour

l'environnement si elle n'est pas évitée.

Information

… met en exergue les conseils et recommandations utiles de même que les

informations permettant d'assurer un fonctionnement ecace et normal.

WIKA mode d'emploi HYDRA-Gauge24

9015329.01 08/2013 GB/D/F/E

Page 25

2. Sécurité

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement, s'assurer que

l'indicateur de pression portable et le capteur de pression ont été choisi de

façon adéquate, en ce qui concerne la plage de mesure, la version et les

conditions de mesure spéciques.

Un non-respect de cette consigne peut entraîner des blessures corporelles

graves et/ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les sections individuelles

du présent mode d'emploi.

2.1 Utilisation conforme à l'usage prévu

Ces manomètres permettent de mesurer la pression dans des applications UHP, par

exemple dans l'industrie des semi-conducteurs ou pour des systèmes de distribution de

produits chimiques ultra-purs.

Le manomètre est conçu et construit exclusivement pour une utilisation conforme à l'usage

prévu décrit ici et ne doit être utilisé qu'en conséquence.

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à l'usage prévu.

F

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants dommages

corporels et matériels.

■

Les opérations décrites dans ce mode d'emploi ne doivent être eectuées

que par un personnel ayant la qualication décrite ci-après.

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses connaissances

dans le domaine de la technique de mesure et de régulation et de ses expériences de

même que de sa connaissance des prescriptions nationales, des normes et directives en

vigueur, en mesure d'eectuer les travaux décrits et de reconnaître automatiquement les

dangers potentiels.

2.3 Dangers particuliers

AVERTISSEMENT !

Les restes de uides se trouvant dans les instruments démontés peuvent

mettre en danger les personnes, l'environnement ainsi que l'installation.

Prendre des mesures de sécurité susantes.

9015329.01 08/2013 GB/D/F/E

WIKA mode d'emploi HYDRA-Gauge 25

Page 26

2. Sécurité / 3. Spécications

2.4 Etiquetage / Marquages de sécurité

Plaque signalétique (HYDRA-Gauge avec contacts électriques)

F

Date de fabrication

Explication des symboles

Lire impérativement le mode d'emploi avant le montage et la mise en service

de l'instrument avec contacts électriques !

CE, Communauté Européenne

Les instruments avec ce marquage sont conformes aux directives

européennes pertinentes.

3. Spécications

Conditions de travail admissibles

Température ambiante +5 ... 60 °C

Température process +5 ... 60 °C

■

Le manomètre mécanique du HYDRA-Gauge est résistant à la surpression pour une

période courte, et ce jusqu'à la valeur de pleine échelle. La pression de travail ne doit

cependant pas excéder les 2/3 de la plage de mesure an de garantir une longue durée

de vie au manomètre.

■

Dans tous les cas, les pressions et températures maximales du raccord process

selon le diagramme suivant ne doivent pas être dépassées. Les pressions de travail

maximales admissibles en résultant pourraient être inférieures à la plage de mesure de

l'instrument.

WIKA mode d'emploi HYDRA-Gauge26

9015329.01 08/2013 GB/D/F/E

Page 27

3. Spécications / 4. Conception et fonction

Pression de traitement admissible

1/4" et 3/8"

1/2"

Pression en bar

Température en °C

■

Le HYDRA-Gauge n'est pas approprié pour des vibrations, pulsations et variations

de pression fortes, par exemple, aux points de mesure placés directement derrière

une pompe. Des amortisseurs de pulsation et des segments restricteur pourraient être

nécessaires.

■

Le HYDRA-Gauge ne doit pas être utilisé dans des conditions ambiantes

agressives (par exemple, des vapeurs de HCI). Cela peut se traduire par une

corrosion des pièces métalliques du HYDRA-Gauge.

Pour de plus amples spécications, voir la che technique WIKA SP 99.20 et la

documentation de commande.

3/4"

1"

1 1/4"

seulement jusqu'à

25 °C

F

4. Conception et fonction

4.1 Description

Le HYDRA-Gauge est un manomètre mécanique de taille nominale 63 conformément à la

norme EN 837-1. Il a été adapté, avec un système spécial de séparateur, aux exigences

particulières des systèmes de distribution de uides ultra-purs. Toutes les pièces en contact

sont en PFA ou en TFM (PTFE modié). Le montage nal, l'ajustement et l'emballage sont

eectués sous écoulement laminaire, classe 100. Le liquide de remplissage du système

standard est KN 75, un mélange 50/50 d'eau DI et d'alcool isopropylique (IPA). En option,

de l'eau DI (KN 64) peut être utilisée. Le manomètre et le séparateur forment une seule

unité et ne doivent jamais être séparés car ceci peut amener le liquide de transmission de

pression à fuir et ainsi à détruire le dispositif de mesure.

4.2 Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

9015329.01 08/2013 GB/D/F/E

WIKA mode d'emploi HYDRA-Gauge 27

Page 28

5. Transport, emballage ... / 6. Mise en service, exploitation

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur l'instrument liés au transport.

Communiquer immédiatement les dégâts constatés.

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

F

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection optimale (par ex.

changement de lieu d'utilisation, renvoi pour réparation).

5.3 Stockage

Conditions admissibles sur le lieu de stockage :

■

Température de stockage: -20 ... +60 °C (standard, KN 75)

+5 ... +60 °C (optionnel, KN 64)

6. Mise en service, exploitation

Instructions d'installation

Les recommandations de la norme EN 837-2 concernant la sélection et l'installation de

manomètres sont à respecter. L'installation et la mise en service ne doivent être eectuées

que par du personnel spécialisé et qualié. Lors du vissage des raccords process, il

est nécessaire de suivre les instructions pertinentes et les conseils des fabricants des

installations. L'écrou central de l'instrument de mesure scellé par un point de couleur ainsi

que la connexion letée du manomètre avec le séparateur ne doivent en aucun cas être

desserrés. Ceci provoque la destruction du dispositif de mesure et une fuite du uide de

process.

9015329.01 08/2013 GB/D/F/E

WIKA mode d'emploi HYDRA-Gauge28

Page 29

6. Mise en service ... / 7. HYDRA-Gauge avec contacts ...

Après l'installation, le manomètre peut être

tourné à la main an d'obtenir la meilleure

position pour la lecture.

Un instrument de mesure de pression pourvu de l'option d'un contact électrique doit être

connecté conformément au diagramme de connexion appliqué sur l'instrument.

Voir che technique AC 08.01 pour plus d'informations

360°

7. HYDRA-Gauge avec contacts électriques

Lors de l'utilisation des dispositifs de mesure de pression avec des contacts électroniques

type 830 E, observez les points suivants:

7.1 Description, application

Une commutation directe de petites charges requises habituellement en raccordement

avec un PLC peut être réalisée par le contact inductif avec amplicateur de commutation

intégré installé en usine directement dans l'instrument de mesure.

F

Les avantages bien connus des contacts inductifs, tels qu'un fonctionnement de contact

spécialement sûr, aucune usure due à un fonctionnement de contact de proximité de

même qu'une absence virtuelle de réaction sur le système de mesure, permettant ainsi

une grande précision de l'indication, sont utilisés aussi dans ce contexte.

Une unité de commande supplémentaire n'est pas nécessaire.

Le contact électronique avec exécution à trois ls est muni d'une sortie PNP. La tension de

fonctionnement est de 10 à 30 VDC. Le courant de commutation maximum est de 100 mA.

Le type 830 E n'est pas intrinsèquement sûr et donc ne convient pas à des applications

dans des zones dangereuses !

9015329.01 08/2013 GB/D/F/E

WIKA mode d'emploi HYDRA-Gauge 29

Page 30

7. HYDRA-Gauge avec contacts électriques

7.2 Exigences particulières relative au point de montage

Pour éviter, entre autres, un "bégaiement" des signaux de commutation, on doit s'assurer

que les instruments sont montés de manière à éliminer toute vibration.

7.3 Raccordement électrique

Les travaux de raccordement électrique ne doivent être eectués que par des personnels

qualiés. Les données électriques autorisées, les détails de raccordement et les fonctions

de commutation sont indiqués sur l'étiquette du produit apposée sur l'instrument.

F

Les câbles de raccordement sont marqués en conséquence.

■

Pour raccorder une unité de contrôle PLC ou pour une commutation directe de petites

charges

■

Transistor PNP

Avec un équipement de contrôle PNP, la sortie commutée est un raccordement vers

le PLUS. La charge RL entre la sortie commutée et le MOINS devra être choisie de

manière à ne pas dépasser le courant de commutation maximum de 100 mA.

Diagrammes de raccordement et de circuit de fonctionnement pour le

contact électronique type 830 E, système à 3 ls,

électronique de contrôle et de commutation dans le capteur,

raccordement électrique par conducteurs volants

PNP

Avec double contact

2ème contact

PNP

2

1

3

RL (charge)

RL (2ème

charge)

4

+ U

_

■

Un drapeau sort du capteur à

B

fente :

contact ouvert

(sortie pas active)

■

Le drapeau se replie dans le

capteur à fente :

contact fermé (sortie active)

9015329.01 08/2013 GB/D/F/E

WIKA mode d'emploi HYDRA-Gauge30

Page 31

7. HYDRA-Gauge avec contacts électriques

7.4 Spécications

Plage de tension admissible 10 ... 30 VDC

Ondulation résiduelle 10 % maximum

Courant non-conducteur ≤ 10 mA

Courant de commutation ≤ 100 mA

Courant de fuite ≤ 100 mA

Fonctionnement de l'élément de

commutation

Type de sortie Transistor PNP

Baisse de tension (avec I max.) ≤ 0,7 V

Protection contre l'inversion de

polarité

Protection anti-inductive 1 kV, 0,1 ms, 1 kΩ

Fréquence d'oscillateur env. 1000 kHz

EMC selon EN 60947-5-2

Conditions et température ambiantes selon l'instrument de mesure

Installation Installation directement dans l'instrument de mesure en

Contact électrique type 830 E

Normalement ouvert

U

conditionnelle (le commutateur de sortie 3 ou 4 ne doit

B

jamais être réglé directement sur moins)

usine, au maximum 2 contacts électriques par instrument

de mesure

7.5 Réglage de la valeur de

consigne

Le réglage des valeurs de consigne

s'eectue via l'orice de réglage dans

le cadran à l‘aide de la clef de réglage

(fournie avec l'instrument).

Indicateur de

la valeur de

consigne

Orice de réglage

F

Les indicateurs de la valeur de consigne pour les interrupteurs de n de course sont

librement réglables sur toute l'échelle de mesure. Pour des raisons de précision et

de sécurité de commutation, et an de ne pas porter préjudice à la durée de vie des

instruments, il est recommandé de xer les points de commutation entre 10 % et 90 % de

l'étendue de mesure.

9015329.01 08/2013 GB/D/F/E

WIKA mode d'emploi HYDRA-Gauge 31

Page 32

8. Entretien et nettoyage / 9. Démontage et mise au rebut

8. Entretien et nettoyage

8.1 Entretien

Les dispositifs de mesure de pression HYDRA-Gauge sont sans entretien.

Un contrôle de l’achage et de la fonction de commutation est recommandé 1 à 2 fois/an.

Pour contrôler l'achage et la fonction de commutation, l'instrument doit être isolé du

processus de mesure et contrôlé à l'aide d'un dispositif de contrôle de la pression.

F

Le système de membrane double HYDRA empêche la contamination du uide de process,

même dans le cas d'un dommage mécanique de la membrane en contact. Dans ce cas, le

uide de process pénétrera l'orice de fuite latéral. L'instrument doit être remplacé le plus

vite possible.

Pour des raisons de sécurité, il n'est pas possible de réparer des instruments déjà

installés.

8.2 Nettoyage

ATTENTION !

■

Le HYDRA-Gauge ne doit être nettoyé que par rinçage. Tout nettoyage

mécanique dans le raccord process endommagerait les membranes de

séparation.

■

Nettoyer l'instrument avec un chion humide.

■

Eviter tout contact des raccordements électriques avec l'humidité.

9. Démontage et mise au rebut

AVERTISSEMENT !

Les restes de uides se trouvant dans les instruments démontés peuvent

mettre en danger les personnes, l'environnement ainsi que l'installation.

Prendre des mesures de sécurité susantes.

9.1 Démontage

Déconnecter le manomètre uniquement une fois que le système a été mis hors pression.

9.2 Mise au rebut

Une mise au rebut inadéquate peut entraîner des dangers pour l'environnement.

Eliminer les composants des instruments et les matériaux d'emballage conformément

aux prescriptions nationales pour le traitement et l'élimination des déchets et aux lois de

protection de l'environnement en vigueur.

WIKA mode d'emploi HYDRA-Gauge32

9015329.01 08/2013 GB/D/F/E

Page 33

Contenido

Contenido

1. Información general 34

2. Seguridad 35

3. Datos técnicos 36

4. Diseño y función 37

5. Transporte, embalaje y almacenamiento 38

6. Puesta en servicio, funcionamiento 38

7. HYDRA-Gauge con contactos eléctricos 39

8. Mantenimiento y limpieza 42

9. Desmontaje y eliminación 42

E

9015329.01 08/2013 GB/D/F/E

WIKA manual de instrucciones HYDRA-Gauge 33

Page 34

1. Información general

1. Información general

■

El manómetro descrito en el manual de instrucciones está construido y fabricado

según el estado actual de la técnica. Todos los componentes están sujetos a rigurosos

criterios de calidad y medio ambiente durante la producción. Nuestros sistemas de

gestión están certicados según ISO 9001 y ISO 14001.

■

Este manual de instrucciones proporciona indicaciones importantes acerca del manejo

del instrumento. Para un trabajo seguro, es imprescindible cumplir con todas las

instrucciones de seguridad y manejo indicadas.

■

E

Cumplir siempre las normativas sobre la prevención de accidentes y las normas de

seguridad en vigor en el lugar de utilización del instrumento.

■

El manual de instrucciones es una parte integrante del instrumento y debe guardarse

en la proximidad del mismo para que el personal especializado pueda consultarlo en

cualquier momento.

■

El personal especializado debe haber leído y entendido el manual de instrucciones

antes de comenzar cualquier trabajo.

■

El fabricante queda exento de cualquier responsabilidad en caso de daños causados

por un uso no conforme a la nalidad prevista, la inobservancia del presente manual

de instrucciones, un manejo por personal insucientemente cualicado así como una

modicación no autorizada del instrumento.

■

Se aplican las condiciones generales de venta incluidas en la documentación de venta.

■

Modicaciones técnicas reservadas.

■

Para obtener más informaciones consultar:

- Página web: www.wika.es

- Hoja técnica correspondiente: SP 99.20

- Servicio técnico:

Explicación de símbolos

Tel.: +34 933 938-630

Fax: +34 933 938-666

info@wika.es

¡ADVERTENCIA!

... indica una situación probablemente peligrosa que pueda causar la muerte

o lesiones graves si no se evita.

¡CUIDADO!

... indica una situación probablemente peligrosa que pueda causar lesiones

leves o medianas o daños materiales y medioambientales si no se evita.

Información

... destaca consejos y recomendaciones útiles así como informaciones para

una utilización ecaz y libre de fallos.

WIKA manual de instrucciones HYDRA-Gauge34

9015329.01 08/2013 GB/D/F/E

Page 35

2. Seguridad

2. Seguridad

¡ADVERTENCIA!

Antes del montaje, la puesta en servicio y el funcionamiento asegurarse de

que se haya seleccionado el manómetro adecuado con respecto a rango de

medida, versión y condiciones de medición especícas.

El no respetar las instrucciones puede generar lesiones graves y/o daños

materiales.

Los distintos capítulos de este manual de instrucciones contienen otras

importantes indicaciones de seguridad.

2.1 Uso conforme a lo previsto

Estos manómetros son adecuados para medir la presión en aplicaciones UHP, como p. Ej.

en la industria de semiconductores, o para sistemas de alimentación de química purísima.

El manómetro ha sido diseñado y construido únicamente para la nalidad aquí descrita y

debe utilizarse en conformidad a la misma.

No se admite ninguna reclamación debido a un manejo no adecuado.

2.2 Cualicación del personal

¡ADVERTENCIA!

¡Riesgo de lesiones debido a una insuciente cualicación!

Un manejo no adecuado puede causar considerables daños personales y

materiales.

■

Las actividades descritas en este manual de instrucciones deben

realizarse únicamente por personal especializado con la consiguiente

cualicación.

Personal especializado

Debido a su formación profesional, a sus conocimientos de la técnica de regulación

y medición así como a su experiencia y su conocimiento de las normativas, normas y

directivas vigentes en el país de utilización el personal especializado es capaz de ejecutar

los trabajos descritos y reconocer posibles peligros por sí solo.

E

2.3 Riesgos especícos

¡ADVERTENCIA!

Restos de medios en instrumentos desmontados pueden causar riesgos para

personas, medio ambiente e instalación.

Tomar adecuadas medidas de precaución.

9015329.01 08/2013 GB/D/F/E

WIKA manual de instrucciones HYDRA-Gauge 35

Page 36

2. Seguridad / 3. Datos técnicos

2.4 Rótulos / Marcados de seguridad

Placa indicadora (HYDRA-Gauge con contactos eléctricos)

E

Fecha de fabricación

Explicación de símbolos

¡Es absolutamente necesario leer el manual de instrucciones antes del

montaje y la puesta en servicio del instrumento con contactos eléctricos!

CE, Communauté Européenne

Los instrumentos con este marcaje cumplen las directivas europeas

aplicables.

3. Datos técnicos

Parámetros de servicio admisibles

Temperatura ambiental +5 ... 60 °C

Temperatura de proceso +5 ... 60 °C

■

El manómetro mecánico de HYDRA-Gauge puede cargarse brevemente hasta el valor

nal de escala. Sin embargo, a n de garantizar una larga vida útil del manómetro, la

presión de servicio no debe superar 2/3 del rango de medida.

■

En todo caso, no deben sobrepasarse las presiones máximas y temperaturas de la

conexión al proceso conforme al siguiente diagrama. Las presiones máximas de servicio admisibles resultantes de ello pueden ser ocasionalmente inferiores al rango de

medida

WIKA manual de instrucciones HYDRA-Gauge36

9015329.01 08/2013 GB/D/F/E

Page 37

3. Datos técnicos / 4. Diseño y función

Presión de proceso admisible

1/4" et 3/8"

1/2"

Presión en bar

Temperatura en °C

■

El HYDRA-Gauge no es adecuado para aplicaciones con fuertes vibraciones,

pulsaciones y golpes de presión, como p. ej. en puntos de medición situados

directamente en el dorso de una bomba. En caso necesario deben montarse

amortiguadores de pulsación y dispositivos de obturación.

■

El HYDRA-Gauge no es apto para aplicaciones en condiciones (p. Ej. vapores

de HCl). Aquí puede producirse corrosión de los componentes metálicos del

instrumento.

3/4"

1"

1 1/4" sólo hasta 25 °C

E

Para más datos técnicos véase la hoja técnica de WIKA SP 99.20 y la documentación de

pedido.

4. Diseño y función

4.1 Descripción

El HYDRA-Gauge es un manómetro mecánico de diámetro nominal 63 conforme a las

prescripciones de la norma EN 837-1. El mismo ha sido adaptado a los requerimientos de

procesos con medios de alta pureza mediante un sistema de separadores. Todas las partes

en contacto con el medio a medir son de PFA o TFM (PTFE modicado). Montaje nal,

ajuste y embalaje se realizan bajo Laminar-Flow Class 100. El líquido transmisor de presión

estándar es KN 75, una mezcla de 50 % de agua destilada y 50 % de alcohol isopropílico

(IPA). Opcionalmente se emplea agua destilada (KN 64). Manómetro y transmisor de

presión forman una unidad y de ninguna manera deben separarse. Ello provocaría una

pérdida de líquido transmisor de presión y por lo tanto una destrucción de la disposición de

medición de presión.

4.2 Volumen de suministro

Comparar mediante el albarán si se han entregado todas las piezas.

9015329.01 08/2013 GB/D/F/E

WIKA manual de instrucciones HYDRA-Gauge 37

Page 38

5. Transporte, embalaje ... / 6. Puesta en servicio ...

5. Transporte, embalaje y almacenamiento

5.1 Transporte

Comprobar si el instrumento presenta eventuales daños causados en el transporte.

Noticar de inmediato cualquier daño evidente.

5.2 Embalaje

No quitar el embalaje hasta justo antes del montaje.

Guardar el embalaje ya que es la protección ideal durante el transporte (por ejemplo si el

lugar de instalación cambia o si se envía el instrumento para posibles reparaciones).

E

5.3 Almacenamiento

Condiciones admisibles en el lugar de almacenamiento:

■

Temperatura de almacenamiento: -20 ... +60 °C (estándar, KN 75)

+5 ... +60 °C (opcional, KN 64)

6. Puesta en servicio, funcionamiento

Indicaciones de montaje

Deben seguirse las recomendaciones de la norma EN 837-2 para la selección y el

montaje de manómetros. Montaje y puesta en servicio deben estar exclusivamente a

cargo del personal técnico debidamente cualicado. Al atornillar las conexiones al proceso

deben observarse las prescripciones pertinentes, así como las recomendaciones del

fabricante de las piezas de conexión. De ninguna manera debe aojarse la tuerca central

del manómetro, marcada con un punto de color, como tampoco la unión atornillada

del manómetro con el transmisor de presión. Esto ocasionaría una destrucción de la

disposición de medición y un escape del medio de proceso.

9015329.01 08/2013 GB/D/F/E

WIKA manual de instrucciones HYDRA-Gauge38

Page 39

6. Puesta en servicio ... / 7. HYDRA-Gauge con contactos ...

Tras el montaje puede girarse el manómetro

con la mano a n de llevarlo a una posición

óptima para su lectura.

Si el manómetro está dotado de la opción de contacto eléctrico, éste debe conectarse

conforme al esquema de conexión que se encuentra en el instrumento.

Para mas informaciones véase la hoja técnica AC 08.01

360°

7. HYDRA-Gauge con contactos eléctricos

Al utilizar disposiciones de medición HYDRA-Gauge con contacto electrónico tipo 830 E

debe tenerse en cuenta lo siguiente:

7.1 Descripción, utilización

Debido al contacto inductivo con amplicador de conmutación incorporado, modelo 830

E, integrado directamente en fábrica en el instrumento de medición, se pueden conmutar

directamente leves potencias habituales, por ejemplo en controles lógicos programables

(PLC).

E

Aquí se aprovechan las conocidas ventajas de los contactos inductivos, como la conmuta-

ción able sin desgaste, provocado por efectos redundantes al sistema de medición.

Un equipo de adicional de control no es necesario.

El contacto electrónico está disponible con 3 conmutadores con salida PNP. El rango de

tensiones de servicio es de DC 10 ... 30 V, y la corriente de conmutación máxima de

100 mA.

¡El contacto electrónico 830 E no es de seguridad intrínseca y por lo tanto no es

adecuado para el uso en atmósferas potencialmente explosivas!

9015329.01 08/2013 GB/D/F/E

WIKA manual de instrucciones HYDRA-Gauge 39

Page 40

7. HYDRA-Gauge con contactos eléctricos

7.2 Requerimientos especiales en el lugar de instalación

Para prevenir, por ejemplo la oscilación de la señal de conmutación, asegurarse de que

los instrumentos estén montados libre de vibraciones.

7.3 Conexión eléctrica

La conexión eléctrica sólo la puede realizar personal cualicado. Consultar la placa

indicadora de tipo del instrumento para los valores de conexión permitidos, la asignación

de pin y las funciones de conmutación.

Los cables de conexión están debidamente identicados.

E

■

Para conectar una unidad de control PLC o para conmutar potencias bajas

directamente

■

Transistor PNP

En combinación con transistores PNP, la salida representa una conexión con el polo

POSITIVO. Seleccione la carga RL entre la salida conmutada y el polo NEGATIVO de

tal forma que no se exceda la corriente máxima de conmutación de 100 mA.

Esquema de conexiones y funciones para contactos electrónicos del modelo 830

E, versión de 3 conductores, sistema electrónico de control y conmutación en el

sensor de proximidad, conexión eléctrica mediante cable pelado

PNP

Con contacto doble

2º contacto

PNP

2

1

3

RL (carga)

4

RL

(2a carga)

WIKA manual de instrucciones HYDRA-Gauge40

+ U

_

■

La bandera de control se

B

encuentra en el exterior

de la ranura del iniciador:

El contacto está abierto

(salida desactivada).

■

La bandera de control se

encuentra en el interior

de la ranura del iniciador:

El contacto está cerrado

(salida activada)

9015329.01 08/2013 GB/D/F/E

Page 41

7. HYDRA-Gauge con contactos eléctricos

7.4 Datos técnicos

Rango de tensiones de servicio DC 10 ... 30 V

Ondulación residual máx. 10 %

Corriente en vacío ≤ 10 mA

Corriente de conmutación ≤ 100 mA

Corriente residual ≤ 100 mA

Función del elemento de

conmutación

Tipo de salida Transistor PNP

Caída de tensión (con I máx.) ≤ 0,7 V

Protección contra inversión de

polaridad

Antiinducción 1 kV, 0,1 ms, 1 kΩ

Frequencia de oscilación aprox. 1000 kHz

CEM conforme a EN 60947-5-2

Condiciones ambientales y

temperatura ambiente

Instalación en la fábrica directamente en el instrumento de medición,

Contacto electrónico modelo 830 E

Contacto normalmente abierto

condiciona U

directamente al polo negativo)

dependiendo del instrumento de medición

máx. 2 contactos eléctricos por instrumento de medición

(nunca conectar las salidas 3 ó 4

B

7.5 Ajuste de los indicadores de

valor nominal

El ajuste de los valores nominales se

hace a través del cierre de ajuste en

la mirilla, utilizando la llave de ajuste

(incluido en el suministro).

Indicador de

valor nominal

Cierre de ajuste

E

Los indicadores de valor nominal de los contactos de alarma pueden ajustarse en toda la

escala. Por razones de precisión de conmutación y vida útil de los sistemas mecánicos

de medición, se recomienda jar los puntos de conmutación entre el 10 % y el 90 % del

alcance de medición.

9015329.01 08/2013 GB/D/F/E

WIKA manual de instrucciones HYDRA-Gauge 41

Page 42

8. Mantenimiento y limpieza / 9. Desmontaje y eliminación

8. Mantenimiento y limpieza

8.1 Mantenimiento

Las disposiciones de medición de presión HYDRA-Gauge no requieren mantenimiento.

Controlar el instrumento y la función de conmutación una o dos veces al año.

Para la revisión del instrumento y la comprobación de la función de conmutación hay que

desconectar el instrumento del proceso y controlarlo con un dispositivo de control de

presión.

El sistema de doble membrana HYDRA previene una contaminación del medio de proceso

E

incluso en caso de un deterioro mecánico de la membrana en contacto con el medio de

medición. En tal caso, se produce un escape del medio de proceso hacia el taladro de

fuga lateral. El instrumento debe reemplazarse entonces lo más rápido posible.

Por razones de seguridad no es posible efectuar reparaciones en instrumentos montados

ya in situ.

8.2 Limpieza

¡CUIDADO!

■

La limpieza del HYDRA-Gauge debe realizarse solamente mediante una

purga. Cualquier limpieza mecánica en el interior de la conexión al proceso

puede provocar un deterioro de las membranas de separación.

■

Limpiar el instrumento con un trapo húmedo.

■

Asegurarse de que las conexiones eléctricas no se humedecen.

9. Desmontaje y eliminación

¡ADVERTENCIA!

Restos de medios en instrumentos desmontados pueden causar riesgos

para personas, medio ambiente e instalación.

Tomar adecuadas medidas de precaución.

9.1 Desmontaje

¡Desmontar el manómetro sólo si no está sometido a presión!

9.2 Eliminación de residuos

Una eliminación incorrecta puede provocar peligros para el medio ambiente.

Eliminar los componentes de los instrumentos y los materiales de embalaje conforme a

los reglamentos relativos al tratamiento de residuos y eliminación vigentes en el país de

utilización.

WIKA manual de instrucciones HYDRA-Gauge42

9015329.01 08/2013 GB/D/F/E

Page 43

WIKA global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand GmbH & Co.

KG

Perfektastr. 83

1230 Vienna

Tel. +43 1 8691631

Fax: +43 1 8691634

info@wika.at

www.wika.at

Belarus

WIKA Belrus

Ul. Zaharova 50B, Oce 3H

220088 Minsk

Tel. +375 17 2945711

Fax: +375 17 2945711

info@wika.by

www.wika.by

Benelux

WIKA Benelux

Industrial estate De Berk

Newtonweg 12

6101 WX Echt

Tel. +31 475 535500

Fax: +31 475 535446

info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

Akad.Ivan Geshov Blvd. 2E

Business Center Serdika

1330 Soa

Tel. +359 2 82138-10

Fax: +359 2 82138-13

info@wika.bg

www.wika.bg

Croatia

WIKA Croatia d.o.o.

Hrastovicka 19

10250 Zagreb-Lucko

Tel. +385 1 6531-034

Fax: +385 1 6531-357

info@wika.hr

www.wika.hr

9015329.01 08/2013 GB/D/F/E

Finland

WIKA Finland Oy

Melkonkatu 24

00210 Helsinki

Tel. +358 9 682492-0

Fax: +358 9 682492-70

info@wika.

www.wika.

France

WIKA Instruments s.a.r.l.

Parc d‘Aaires des Bellevues

8 rue Rosa Luxembourg

95610 Eragny-sur-Oise

Tel. +33 1 343084-84

Fax: +33 1 343084-94

info@wika.fr

www.wika.fr

Germany

WIKA Alexander Wiegand SE

& Co. KG

Alexander-Wiegand-Str. 30

63911 Klingenberg

Tel. +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

www.wika.de

Italy

WIKA Italia S.r.l. & C. S.a.s.

Via G. Marconi 8

20020 Arese (Milano)

Tel. +39 02 93861-1

Fax: +39 02 93861-74

info@wika.it

www.wika.it

Poland

WIKA Polska S.A.

Ul. Legska 29/35

87-800 Wloclawek

Tel. +48 54 230110-0

Fax: +48 54 230110-1

info@wikapolska.pl

www.wikapolska.pl

Romania

WIKA Instruments Romania

S.R.L.

050897 Bucuresti

Calea Rahovei Nr. 266-268

Corp 61, Etaj 1

Tel. +40 21 4048327

Fax: +40 21 4563137

m.anghel@wika.ro

www.wika.ro

Russia

ZAO WIKA MERA

Wjatskaya Str. 27, Building 17

Oce 205/206

127015 Moscow

Tel. +7 495-648018-0

Fax: +7 495-648018-1

info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

Sime Solaje 15

11060 Beograd

Tel. +381 11 2763722

Fax: +381 11 753674

info@wika.rs

www.wika.rs

Spain

Instrumentos WIKA S.A.U.

C/Josep Carner, 11-17

08205 Sabadell Barcelona

Tel. +34 933 9386-30

Fax: +34 933 9386-66

info@wika.es

www.wika.es

Switzerland

MANOMETER AG

Industriestrasse 11

6285 Hitzkirch

Tel. +41 41 91972-72

Fax: +41 41 91972-73

info@manometer.ch

www.manometer.ch

Turkey

WIKA Instruments Istanbul

Basinc ve Sicaklik Ölcme

Cihazlari

Ith. Ihr. ve Tic. Ltd. Sti.

Bayraktar Bulvari No. 17

34775 Yukari Dudullu - Istanbul

Tel. +90 216 41590-66

Fax: +90 216 41590-97

info@wika.com.tr

www.wika.com.tr

Ukraine

TOV WIKA Prylad

M. Raskovoy Str. 11, A

PO 200

02660 Kyiv

Tel. +38 044 4968380

Fax: +38 044 4968380

info@wika.ua

www.wika.ua

43WIKA operating instructions HYDRA-Gauge

Page 44

WIKA global

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill RH13LG

Tel. +44 1737 644-008

Fax: +44 1737 644-403

info@wika.co.uk

www.wika.co.uk

North America

Canada

WIKA Instruments Ltd.

Head Oce, 3103 Parsons

Road

Edmonton, Alberta, T6N 1C8

Tel. +1 780 4637035

Fax: +1 780 4620017

info@wika.ca

www.wika.ca

Mexico

Instrumentos WIKA Mexico

S.A. de C.V.

Viena 20 Ofna 301

Col. Juarez, Del. Cuauthemoc

06600 Mexico D.F.

Tel. +52 55 50205300

Fax: +52 55 50205300

ventas@wika.com

www.wika.com.mx

USA

WIKA Instrument, LP

1000 Wiegand Boulevard

Lawrenceville, GA 30043

Tel. +1 770 5138200

Fax: +1 770 3385118

info@wika.com

www.wika.com

WIKA Process Solutions, LP.

950 Hall Court

Deer Park, TX 77536

Tel. +1 713 47500-22

Fax: +1 713 47500-11

info@wikahouston.com

www.wika.com

Mensor Corporation

201 Barnes Drive

San Marcos, TX 78666

Tel. +1 512 396-4200

Fax: +1 512 396-1820

sales@mensor.com

www.mensor.com

Latin America

Argentina

WIKA Argentina S.A.

Gral. Lavalle 3568

(B1603AUH) Villa Martelli

Buenos Aires

Tel. +54 11 47301800

Fax: +54 11 47610050

info@wika.com.ar

www.wika.com.ar

Brazil

WIKA do Brasil

Av. Ursula Wiegand, 03

CEP 18560-000 Iperó - SP

Tel. +55 15 34599700

Fax: +55 15 32661650

vendas@wika.de

www.wika.com.br

Chile

WIKA Chile S.p.A.

Av. Coronel Pereira 72, Ocina

101

Las Condes - Santiago de Chile

Tel. +56 2 365-1719

info@wika.cl

www.wika.cl

Ind. e Com. Ltda.

Further WIKA subsidiaries worldwide can be found online at www.wika.com.

Weitere WIKA-Niederlassungen weltweit nden Sie online unter www.wika.de.

La liste des autres liales WIKA dans le monde se trouve sur www.wika.fr.

Otras sucursales WIKA en todo el mundo puede encontrar en www.wika.es.

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

44 WIKA operating instructions HYDRA-Gauge

9015329.01 08/2013 GB/D/F/E

Loading...

Loading...