Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Pressure transmitter, model HP-2

Druckmessumformer, Typ HP-2

Transmetteur de pression, type HP-2

Transmisor de presión, modelo HP-2

GB

D

F

E

Pressure transmitter for highest pressure, model HP-2

Page 2

GB

Operating instructions model HP-2 Page

3 - 22

D

Betriebsanleitung Typ HP-2 Seite

F

Mode d'emploi type HP-2 Page

Manual de instrucciones modelo HP-2 Página

E

© 2012 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

23 - 42

43 - 62

63 - 82

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions pressure transmitter, model HP-2

11379180.03 09/2013 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 8

4. Design and function 10

5. Transport, packaging and storage 10

6. Commissioning, operation 11

7. Adjustment of zero point and span 14

8. Spare part kit 15

9. Maintenance and cleaning 18

10. Faults 19

GB

11. Dismounting, return and disposal 20

12. Accessories 21

Appendix 1: Declaration of conformity for model HP-2 22

Declarations of conformity can be found online at www.wika.com.

11379180.03 09/2013 GB/D/F/E

WIKA operating instructions pressure transmitter, model HP-2

3

Page 4

1. General information

1. General information

■

The pressure transmitter described in the operating instructions has been designed

and manufactured using state-of-the-art technology. All components are subject

GB

to stringent quality and environmental criteria during production. Our management

systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working safely requires that all safety instructions and work instructions are

observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions, assignment of insuciently qualied skilled personnel or unauthorised modications to the instrument.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: PE 81.53

- Application consultant:

Tel.: +49 9372 132-8976

Fax: +49 9372 132-8008976

support-tronic@wika.de

4

WIKA operating instructions pressure transmitter, model HP-2

11379180.03 09/2013 GB/D/F/E

Page 5

1. General information / 2. Safety

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury

or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries

or damage to equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient and

trouble-free operation.

WARNING!

... indicates a potentially dangerous situation that can result in burns, caused

by hot surfaces or liquids, if not avoided.

Abbreviations

2-wire The two connection lines are used for the voltage supply.

The measurement signal also provides the supply current.

3-wire Two connection lines are used for the voltage supply.

One connection line is used for the measurement signal.

U

, +5V Positive power supply

B

0V, GND Reference potential

S+ Positive output terminal

D+ ,D- Data link USB 2.0

GB

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate pressure transmitter has been selected in terms of measuring range,

design and specic measuring conditions.

The operator must ensure the compatibility of the uid with the material

used. Where the medium is hydrogen, contact the manufacturer.

Non-observance can result in serious injury and/or damage to the equipment.

11379180.03 09/2013 GB/D/F/E

WIKA operating instructions pressure transmitter, model HP-2

5

Page 6

2. Safety

WARNING!

■

Open the connections only after the system has been depressurised.

■

Observe the working conditions in accordance with chapter 3 “Specications”.

■

GB

2.1 Intended use

The pressure transmitter is used to convert pressure into an electrical signal.

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The technical specications contained in these operating instructions must be

observed. Improper handling or operation of the instrument outside of its techni-

cal specications requires the instrument to be taken out of service immediately and

inspected by an authorised WIKA service engineer.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

Always operate the pressure transmitter within the overpressure limit.

Further important safety instructions can be found in the individual chapters

of these operating instructions.

2.2 Personnelqualication

WARNING!

Riskofinjuryshouldqualicationbeinsucient!

Improper handling can result in considerable injury and damage to equipment.

The activities described in these operating instructions may only be carried

out by skilled personnel who have the qualications described below.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowl-

edge of country-specic regulations, current standards and directives, are capable of

carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

6

WIKA operating instructions pressure transmitter, model HP-2

11379180.03 09/2013 GB/D/F/E

Page 7

2. Safety

2.3 Special hazards

WARNING!

For hazardous media such as oxygen, acetylene, ammable or toxic gases

or liquids, and refrigeration plants, compressors, etc., in addition to all standard regulations, the appropriate existing codes or regulations must also be

followed.

WARNING!

No plant conditions are permitted that could lead to the formation of atomic

hydrogen in the connection channel of the pressure transmitter.

WARNING!

Residual media in the dismounted pressure transmitter can result in a risk to

persons, the environment and equipment.

Take sucient precautionary measures.

Do not use this instrument in safety or emergency stop devices. Incorrect use

of the instrument can result in injury.

Should a failure occur, aggressive media with extremely high temperature and

under high pressure or vacuum may be present at the instrument.

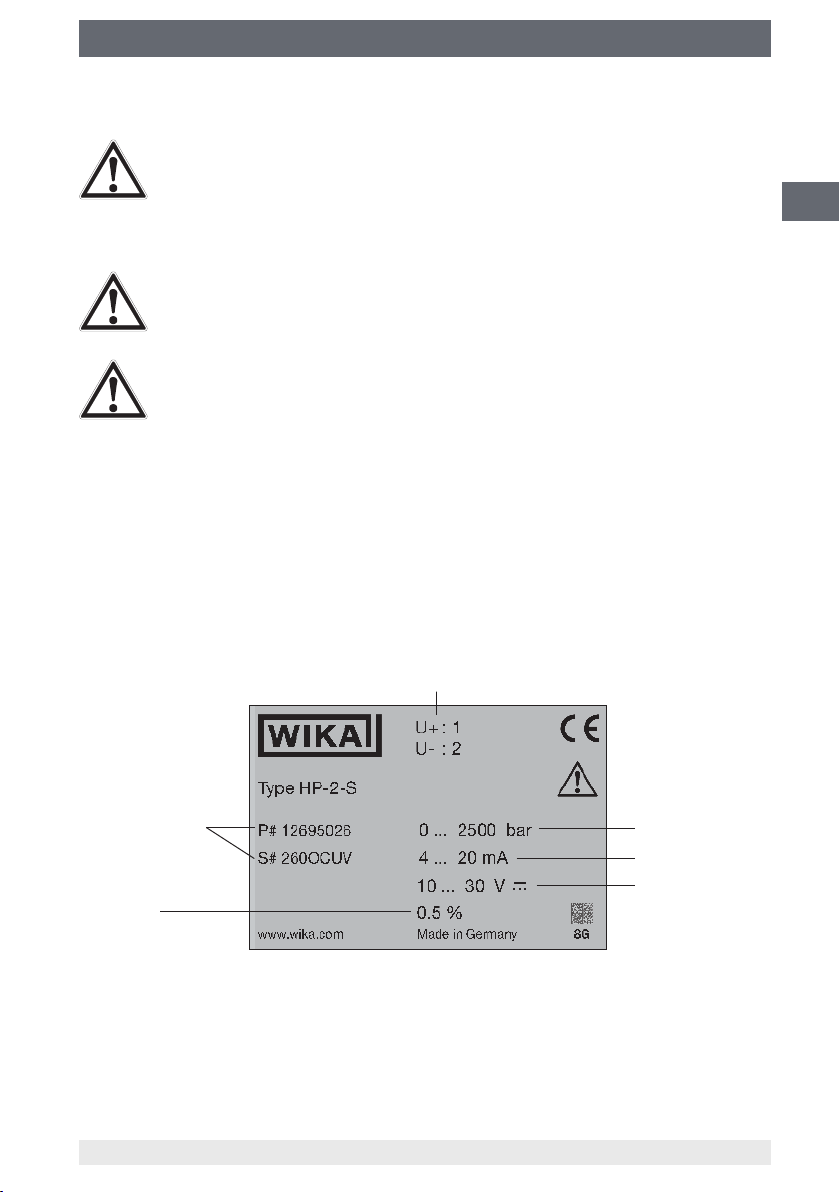

2.4 Labelling, safety marking

GB

Product label

Pin assignment

P# Product no.

S# Serial no.

Accuracy

Measuring range

Output signal

Power supply

If the serial number becomes illegible due to mechanical damage or overpainting, traceability will no longer be possible.

11379180.03 09/2013 GB/D/F/E

WIKA operating instructions pressure transmitter, model HP-2

7

Page 8

2.Safety/3.Specications

Explanation of symbols

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

GB

3. Specications

WARNING!

When designing the system, please note that the values given (e.g. burst

pressure, overpressure limit) are dependent upon the material and thread

used.

Measuring ranges

Relative pressure

bar Measuring range 0 ... 1,600 0 ... 2,500 0 ... 4,000 0 ... 5,000

Overpressure limit 2,300 3,500 5,000 6,000

Burst pressure 4,000 6,000 8,000 10,000

Measuring range 0 ... 6,000 0 ... 7,000 0 ... 8,000 0 ... 10,000

Overpressure limit 7,000 8,000 10,000 11,000

Burst pressure 11,000 11,000 12,000 12,000

Measuring range 0 ... 12,000 0 ... 15,000

Overpressure limit 12,500 15,500

Burst pressure 14,000 16,000

psi Measuring range 0 ... 23,000 0 ... 36,000 0 ... 58,000 0 ... 72,000

Overpressure limit 33,300 50,500 72,500 87,000

Burst pressure 58,000 87,000 116,000 145,000

Measuring range 0 ... 87,000 0 ... 100,000 0 ... 115,000 0 ... 145,000

Overpressure limit 101,500 116,000 145,000 159,000

Burst pressure 159,500 159,500 174,000 174,000

Service life

On request, since the service life depends on the actual pressure prole.

Despite its excellent load cycle stability a permanent load cycle stability is only given

conditionally. This is due to the extreme loadings faced by the highly pressurised

materials. This applies particularly to dynamic applications. Accordingly, the pressureloaded parts of the HP-2 are considered as wear parts that are not covered by the

warranty.

8

WIKA operating instructions pressure transmitter, model HP-2

11379180.03 09/2013 GB/D/F/E

Page 9

3.Specications

Output signals

Signal type Signal

Current (2-wire) 4 ... 20 mA

Voltage (3-wire) DC 0 ... 5 V

USB USB 2.0

Power supply

The power supply depends on the selected output signal

■

4 ... 20 mA: DC 10 ... 30 V

■

DC 0 ... 5 V: DC 10 ... 30 V

■

DC 0 ... 10 V: DC 14 ... 30 V

■

USB 2.0: DC 5 V

LoadinΩ

■

Current output (2-wire): ≤ (power supply - 10 V) / 0.02 A

■

Voltage output (3-wire): > maximum output signal / 1 mA

Ingress protection (per IEC 60529)

■

Angular connector DIN 175301-803 A: IP 65

■

Circular connector M12 x 1 (4-pin): IP 67

■

USB connector type A: Instrument: IP 67, connector: IP 20

■

Cable outlet: IP 67

DC 0 ... 10 V

GB

The stated ingress protection only applies when plugged in using mating connectors

that have the appropriate ingress protection.

Permissible temperature ranges

■

Medium: 0 ... +80 °C

■

Ambient: -20 ... +80 °C

■

Storage: -40 ... +85 °C

CE conformity

■

EMC directive 2004/108/EC, EN 61326 emission (group 1, class B) and immunity

(industrial application)

With USB signal output and strong electromagnetic disturbances in the frequency

range 650 … 750 MHz, the accuracy can be inuenced by up to 1 %.

■

Pressure equipment directive 97/23/EC

RoHS conformity

Yes

For special model numbers, e.g. HP-20000, please note the specications stated on the

delivery note.

For further specications see WIKA data sheet PE 81.53 and the order documentation.

11379180.03 09/2013 GB/D/F/E

WIKA operating instructions pressure transmitter, model HP-2

9

Page 10

4. Design and function / 5. Transport, packaging and ...

4. Design and function

4.1 Short description

The prevailing pressure is measured at the sensor element through the deformation of

a diaphragm. By supplying power, this deformation of the diaphragm is converted into

GB

an electrical signal. The output signal from the pressure transmitter is amplied and

standardised.

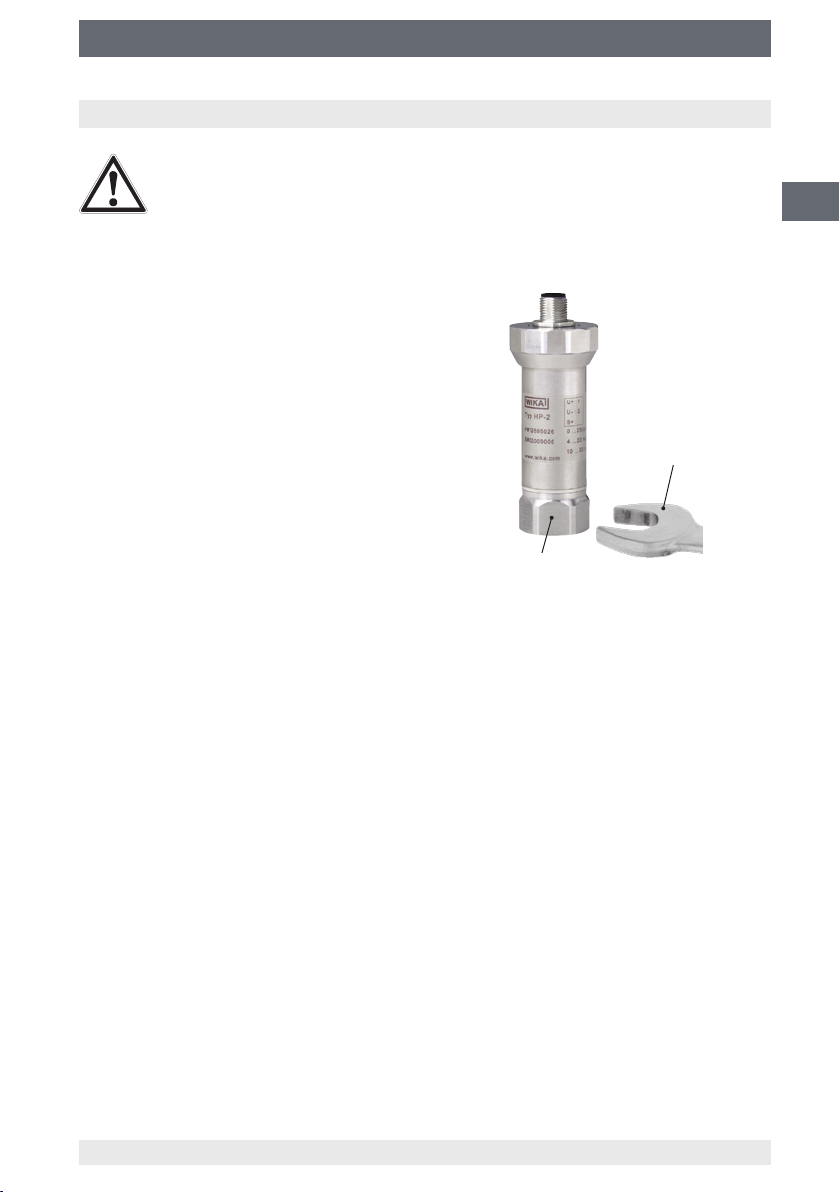

4.2 Scope of delivery

Cross-check scope of delivery with delivery note.

5. Transport, packaging and storage

5.1 Transport

Check the pressure transmitter for any damage that may have been caused during

transportation.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change

in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

see chapter 3 “Specications”

Store the pressure transmitter in its original packaging in a location that fulls the condi-

tions listed above.

WARNING!

Before storing the instrument (following operation), remove any residual

media. This is of particular importance if the medium is hazardous to health,

e.g. caustic, toxic, carcinogenic, radioactive, etc.

10

WIKA operating instructions pressure transmitter, model HP-2

11379180.03 09/2013 GB/D/F/E

Page 11

6. Commissioning, operation

6. Commissioning, operation

CAUTION!

Prior to commissioning, the pressure transmitter must be subjected to a

visual inspection.

Only use the pressure transmitter if it is in perfect condition with respect to

safety.

6.1 Mechanical mounting

■

The sealing faces at the instrument have to be

undamaged and clean.

■

When screwing the instrument in, the force

required to do this must not be applied through

the case, but only through the spanner ats

provided for this purpose and using a suitable

tool.

For the installation point, the valid values for

tightening torque and maximum pressure

should be taken from the high-pressure pipe

supplier's documentation.

GB

Open-ended spanner

(spanner width 27)

Spanner ats

■

When screwing in, do not cross the threads.

■

For information on tapped holes and welding sockets, see Technical information

IN 00.14 at www.wika.com.

6.2 Electrical mounting

■

The instrument must be grounded via the process connection.

■

Use the pressure transmitter with shielded cable, and ground the shield on at least

one end of the lead, if the lines are longer than 30 m (3- or 4-wire) or leave the building.

■

Select a cable diameter that matches the cable gland of the plug. Make sure that

the cable gland of the mounted plug has a tight t and that the seals are present and

undamaged. Tighten the threaded connection and check that the seal is correctly

seated, in order to ensure the ingress protection.

■

For cable outlets, make sure that no moisture enters at the cable end.

■

Observe the specications in accordance with chapter 3 “Specications”.

11379180.03 09/2013 GB/D/F/E

WIKA operating instructions pressure transmitter, model HP-2

11

Page 12

6. Commissioning, operation

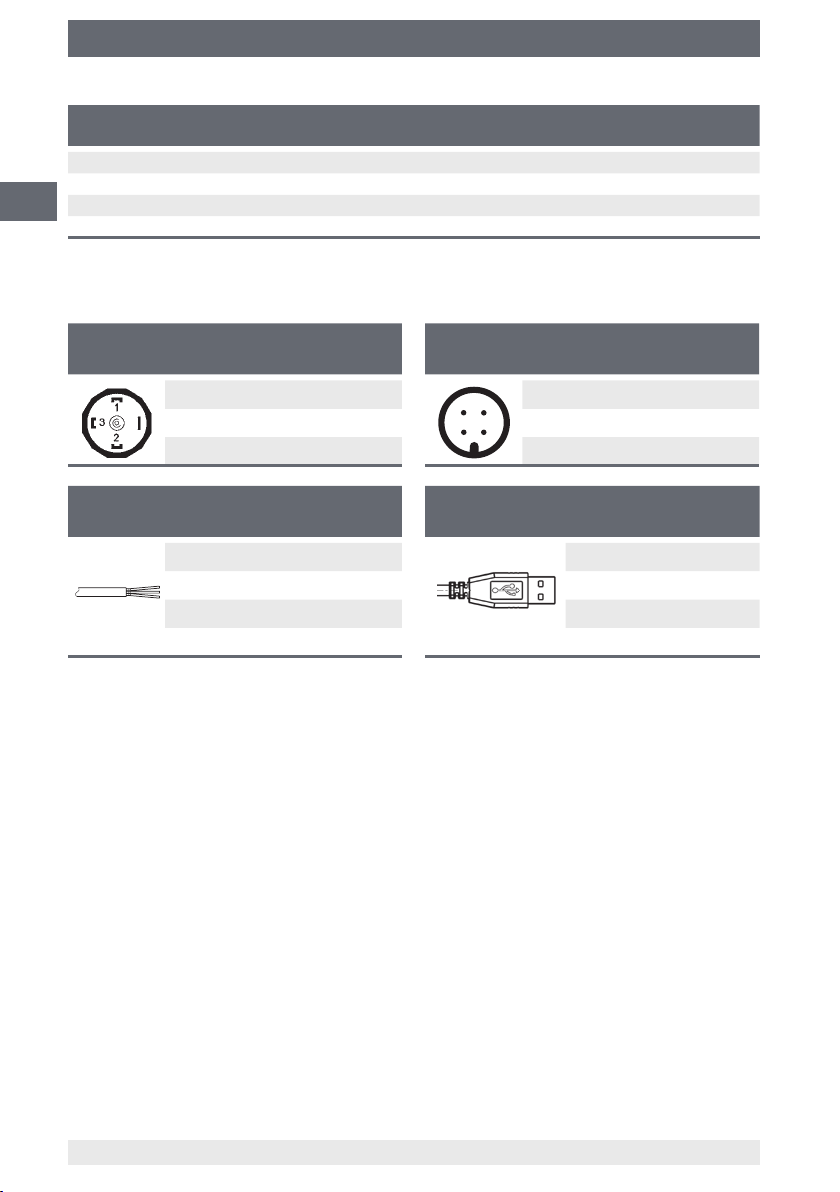

Electrical connection Wire cross-section Cable∅ Cable

Angular connector DIN 175301-803 A max. 1.5 mm

Circular connector M12 x 1 (4-pin) - - -

GB

USB connector type A - - 2 m

Cable outlet 0.5 mm

2

2

(AWG 20) 6.8 mm 1.5 m

6 ... 8 mm -

Connection diagrams

For abbreviations see page 5

Angular connector DIN 175301-803 A

2-wire 3-wire

UB1 1

0V 2 2

S+ - 3

Cable outlet

2-wire 3-wire

UBbrown brown

0V green green

S+ - white

Circular connector M12 x 1 (4-pin)

2-wire 3-wire

4

1

0V 3 3

2

S+- 4

UB1 1

3

USB connector type A

lengths

+5V 1

GND 4

D+ 3

D- 2

12

WIKA operating instructions pressure transmitter, model HP-2

11379180.03 09/2013 GB/D/F/E

Page 13

6. Commissioning, operation

Fitting the DIN 175301-803 angular connector

1.

Loosen the screw .

2.

Loosen the cable gland .

3.

Pull the angled socket + from the instrument.

4.

Via the mounting hole , lever the terminal block

out of the case .

5. Pass the cable with the appropriate cable outer

diameter through the cable gland , ring ,

sealing and the case .

6. Connect the cable ends to the connection terminals on the terminal block in accordance with the

pin assignment (see “Connection diagrams” for the

pin assignment).

7.

Press the terminal block into the case .

8.

Tighten the cable gland around the cable.

Make sure that the cable gland and seal are not

damaged and that they are assembled correctly in

order to ensure ingress protection.

Mounting hole

GB

9.

Place the at, square gasket over the pressure

transmitter's connection pins.

10.

Slide the assembled angled socket + onto

the pressure transmitter's connection pins.

11.

Using the screw , screw the angled socket to the

pressure transmitter, hand-tight.

6.3 Commissioning of USB instruments

■

For installing the driver, administrator rights are required.

■

Connect the USB connector to a USB 2.0 port at your computer.

■

Install the driver via the InstallWizard of the product software.

■

For further operation the P-3x data logger software is available (for details see

instruction manual P-3x data logger).

■

Details on the interface protocol or the DLL (Dynamic Link Library) are available on

the software CD and in the download section at www.wika.com.

For the model HP-2, model P-30 software must be used. All les and

documents are available for download at www.wika.com.

11379180.03 09/2013 GB/D/F/E

WIKA operating instructions pressure transmitter, model HP-2

13

Page 14

7. Adjustment of zero point and span

7. Adjustment of zero point and span

Only adjust the span-setting potentiometer if calibration equipment is avail-

GB

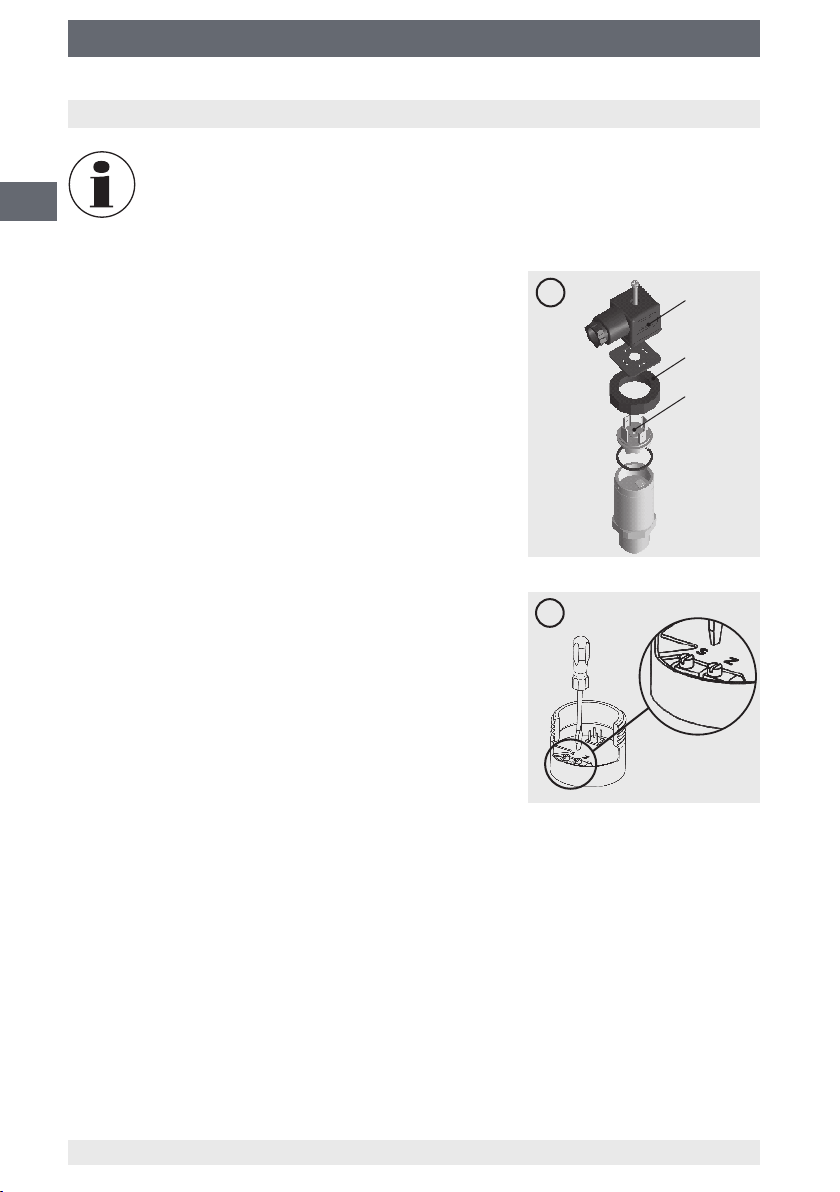

7.1 Preparation(gureA)

To gain access to the potentiometers, open the instrument as follows:

■

Disconnect the electrical connection from the

instrument.

■

Remove the clamping nut .

■

Carefully pull the instrument connector from the

instrument.

■

Connect the instrument connector to the power

supply and a display unit (e.g. ammeter, voltmeter)

according to the connection diagram.

7.2 Adjustmentofzeropoint(gureB)

■

Go to the start of the measuring range.

■

Using potentiometer “Z”, adjust the minimum output

signal (e.g. 4 mA).

7.3 Settingthespan(gureB)

■

Go to the end of the measuring range.

■

Using potentiometer “S”, adjust the maximum output

signal (e.g. 20 mA).

■

Check the zero point and if there is any deviation,

re-adjust it.

■

Repeat the procedure until the zero point and the

span are set correctly.

able which has at least three times the accuracy of the pressure transmitter.

A

B

7.4 Finishtheadjustment(gureA)

■

Disconnect the instrument connector from the power supply and the display unit.

■

Carefully push the instrument connector onto the instrument, without damaging the

wires or the seals. The seals must be clean and undamaged in order to guarantee the

given ingress protection.

■

Tighten the clamping nut .

After the adjustment, check that the system is functioning correctly.

Recommended recalibration cycle: Half-yearly

14

WIKA operating instructions pressure transmitter, model HP-2

11379180.03 09/2013 GB/D/F/E

Page 15

8. Spare part kit

8. Spare part kit

The spare part kit is used for the exchange of process connections and the bae

plate of the models HP-2-D and HP-2-E. It is not compatible with the standard version,

model HP-2-S.

8.1 Contents of the spare part kit

Clamping jawExchangeable process connection

BaeplateforDIPSorEPC O-ring

DIPS EPC

GB

8.2 Tools required

Vice

11379180.03 09/2013 GB/D/F/E

WIKA operating instructions pressure transmitter, model HP-2

Torque spanner

Tweezers

15

Page 16

8. Spare part kit

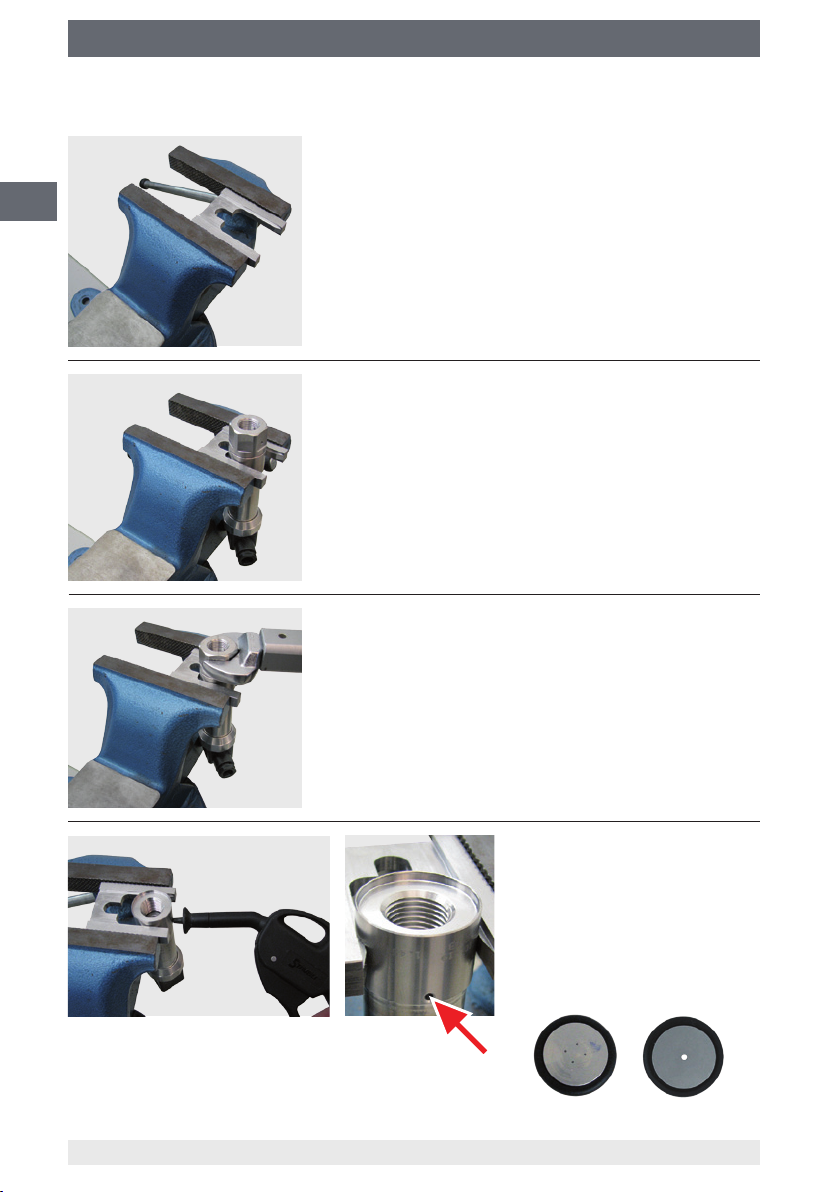

8.3 Mounting

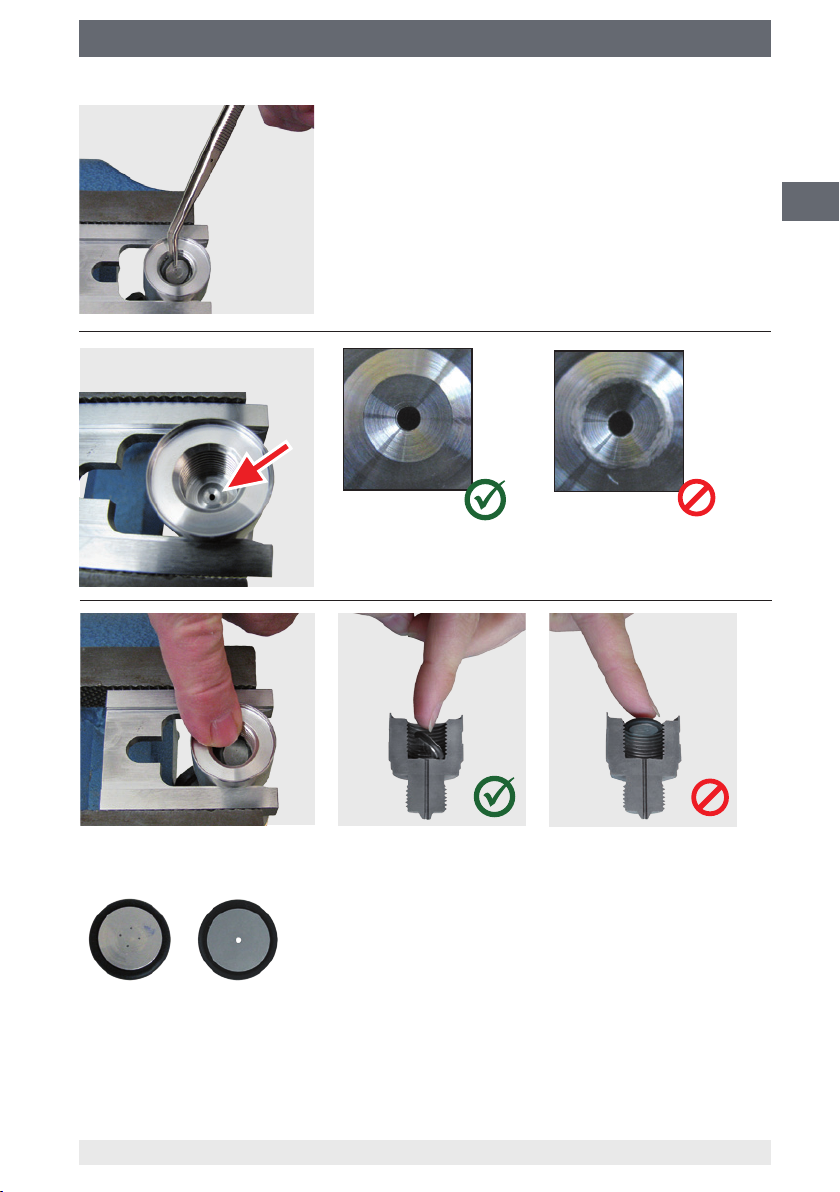

GB

Secure the clamping jaw in the vice as shown, so that

this cannot come loose.

Slide the pressure transmitter between the clamping

jaw, using the groove milled into the process connection.

Loosen the process connection using the torque

spanner.

16

Dry the bae plate incl. the

O-ring using compressed air.

For access, there is a bore

on the process connection.

Bae plate

DIPS EPC

11379180.03 09/2013 GB/D/F/E

WIKA operating instructions pressure transmitter, model HP-2

Page 17

8. Spare part kit

Remove the dry bae plate incl. the O-ring using the

tweezers.

GB

Check the sealing cone for damage.

If the sealing cone is damaged, the entire instrument

must be replaced.

Insert the new bae plate with O-ring at an angle, and press down, taking care not to

damage the surface of the bae plate and the O-ring.

DIPS EPC

11379180.03 09/2013 GB/D/F/E

WIKA operating instructions pressure transmitter, model HP-2

17

Page 18

8. Spare part kit / 9. Maintenance and cleaning

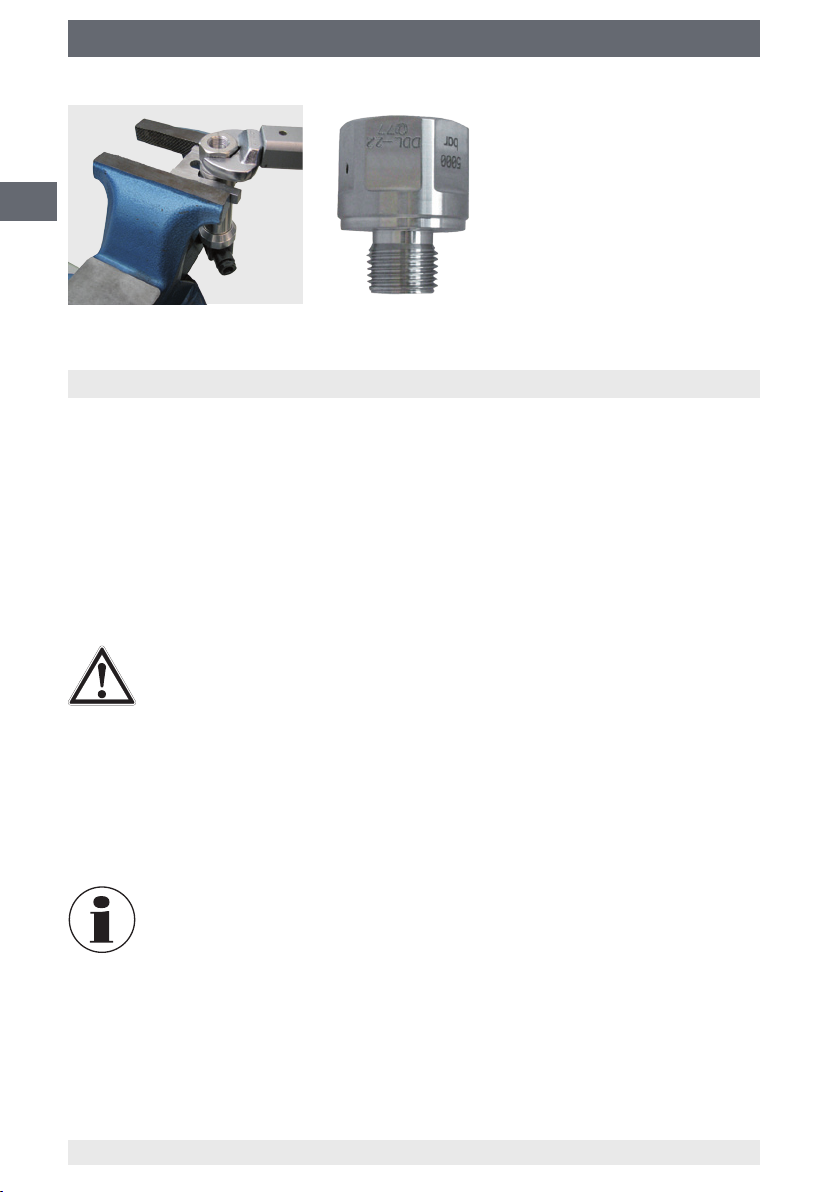

Tighten the exchangeable

process connection using the

torque spanner.

GB

On the torque spanner, set

the tightening torque to

130 Nm.

9. Maintenance and cleaning

9.1 Maintenance

Repairs must only be carried out by the manufacturer.

When a leak is suspected, as a result of hairline cracks in the process connection, as

described in chapter 8 “Spare part kit”, replace it.

For the order number for the spare part kit see chapter 12 “Accessories”

9.2 Cleaning

CAUTION!

■

Before cleaning, correctly disconnect the pressure transmitter from the

pressure supply, switch it o and disconnect it from the voltage supply.

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with moisture.

■

Wash or clean the dismounted instrument before returning it, in order to

protect persons and the environment from exposure to residual media.

■

Residual media in the dismounted pressure transmitter can result in a risk

to persons, the environment and equipment. Take sucient precautionary

measures.

18

For information on returning the instrument see chapter 11.2 “Return”.

11379180.03 09/2013 GB/D/F/E

WIKA operating instructions pressure transmitter, model HP-2

Page 19

10. Faults

10. Faults

In the event of any faults, rst check whether the pressure transmitter is mounted

correctly, mechanically and electrically.

Faults Causes Measures

No output signal Cable break Replace connecting cable

No/wrong power supply Correct the power supply

No/wrong output signal Wiring error Rectify the wiring in accordance

Constant output signal upon

change in pressure

Deviating output signal Zero point change through

Signal span too high Pressure spikes, cavitations Use instrument with cavitation and

Signal span too small Wrong power supply Rectify the power supply

Signal span varies EMC interference sources in the

Leakage at the process connection Hairline crack in the pressure port Consult with manufacturer, if

Wrong power supply Replace instrument

dynamic pressure

environment

Instrument not grounded Ground the instrument

Strongly varying pressure of the

medium

with the connection diagram

Re-adjust zero point

pressure-spike protection

Shield the instrument and cables,

remove source of interference

Damping (consulting by the

manufacturer)

required, replace instrument.

GB

If complaint is unjustied, the handling costs will be charged.

CAUTION!

If faults cannot be eliminated by means of the measures listed above, shut

down the pressure transmitter immediately, and ensure that pressure and/or

signal are no longer present, and secure the instrument from being put back

into operation inadvertently.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter

11.2 “Return”.

11379180.03 09/2013 GB/D/F/E

WIKA operating instructions pressure transmitter, model HP-2

19

Page 20

11. Dismounting, return and disposal

11. Dismounting, return and disposal

WARNING!

GB

11.1 Dismounting

Only disconnect the pressure gauge once the system has been depressurised!

11.2 Return

Residual media in the dismounted pressure transmitter can result in a risk to

persons, the environment and equipment.

Take sucient precautionary measures.

WARNING!

Risk of burns!

Let the instrument cool down suciently before dismounting it!

During dismounting there is a risk of dangerously hot pressure media

escaping.

WARNING!

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous

substances (acids, bases, solutions, etc.).

When returning the instrument, use the original packaging or a suitable transport

package.

Information on returns can be found under the heading “Service” on our local

website.

11.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal regulations.

20

WIKA operating instructions pressure transmitter, model HP-2

11379180.03 09/2013 GB/D/F/E

Page 21

12. Accessories

12. Accessories

Accessories and spare parts

Mating connector

Designation Order number

without cable with 2 m cable with 5 m cable

Angular connector DIN 175301-803 A

■

with cable gland, metric 11427567 11225793 11250186

■

with cable gland, conduit 11022485 - -

Circular connector M12 x 1, 4-pin

■

straight 2421262 11250780 11250259

■

angled 2421270 11250798 11250232

Sealings for mating connectors

Designation Order number

Angular connector DIN 175301-803 A 1576240

Spare part kit for models HP-2-D and HP-2-E

Consisting of a replacement connection thread, replacement sealing disc and a mounting aid.

Spare part kit suitable for the following process connections:

Process connection Order number

Model HP-2-D Model HP-2-E

M16 x 1.5 female 14039895 14050403

M20 x 1.5 female 13319923 14050404

Software

The full software is available to download as freeware from the following path.

www.wika.com / Download / Software / Electronic pressure measurement

GB

11379180.03 09/2013 GB/D/F/E

WIKA operating instructions pressure transmitter, model HP-2

21

Page 22

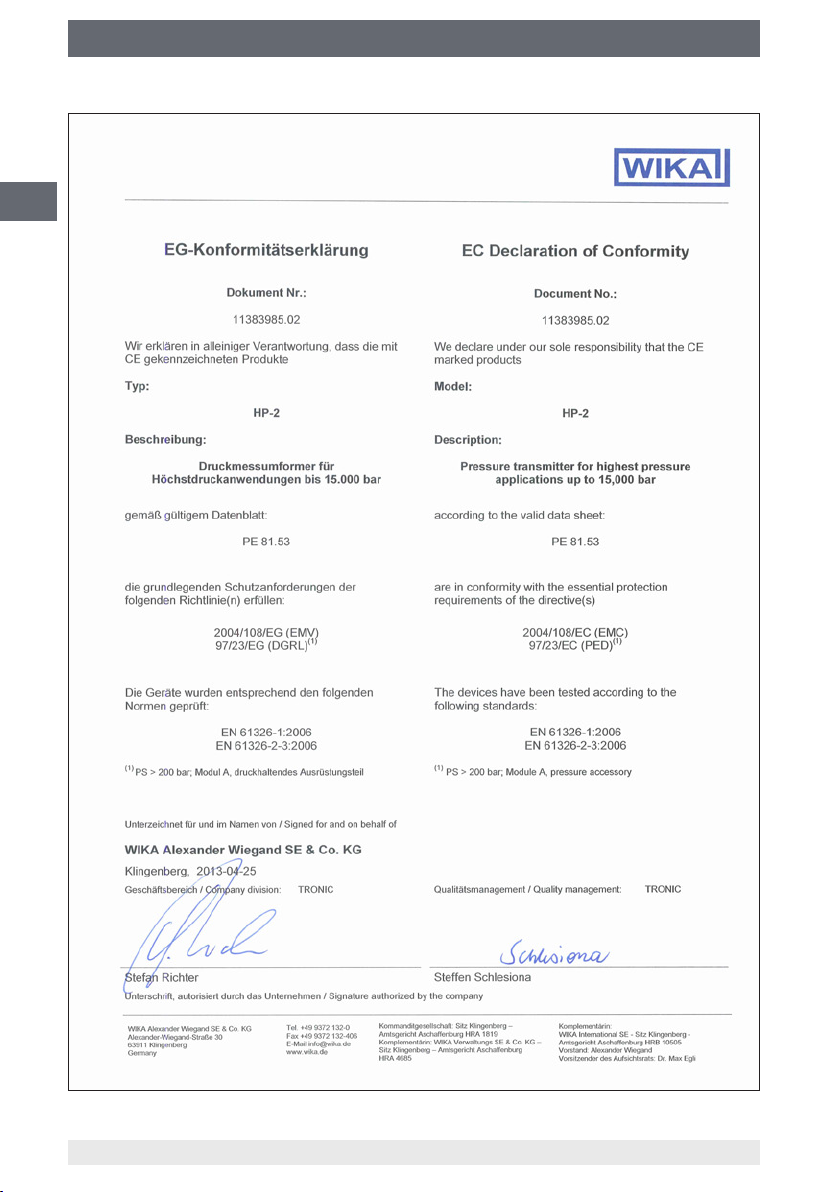

Appendix 1: Declaration of conformity for model HP-2

GB

22

WIKA operating instructions pressure transmitter, model HP-2

11379180.03 09/2013 GB/D/F/E

Page 23

Inhalt

Inhalt

1. Allgemeines 24

2. Sicherheit 25

3. Technische Daten 28

4. Aufbau und Funktion 30

5. Transport, Verpackung und Lagerung 30

6. Inbetriebnahme, Betrieb 31

7. Einstellung Nullpunkt und Spanne 34

8. Ersatzteilkit 35

9. Wartung und Reinigung 38

10. Störungen 39

D

11. Demontage, Rücksendung und Entsorgung 40

12. Zubehör 41

Anlage 1: Konformitätserklärung Typ HP-2 42

Konformitätserklärungen nden Sie online unter www.wika.de

11379180.03 09/2013 GB/D/F/E

23WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

Page 24

1. Allgemeines

1. Allgemeines

■

Der in der Betriebsanleitung beschriebene Druckmessumformer wird nach dem

aktuellen Stand der Technik konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und

Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001

zertiziert.

D

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwen-

dung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten

Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: PE 81.53

- Anwendungsberater:

Tel.: +49 9372 132-8976

Fax: +49 9372 132-8008976

support-tronic@wika.de

24 WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

11379180.03 09/2013 GB/D/F/E

Page 25

1. Allgemeines / 2. Sicherheit

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder

zu schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen

kann, wenn sie nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

ezienten und störungsfreien Betrieb hervor.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die durch heiße

Oberächen oder Flüssigkeiten zu Verbrennungen führen kann, wenn sie

nicht gemieden wird.

Abkürzungen

2-Leiter Die zwei Anschlussleitungen dienen zur Spannungsversorgung.

Der Speisestrom ist das Messsignal.

3-Leiter Zwei Anschlussleitungen dienen zur Spannungsversorgung.

Eine Anschlussleitung dient für das Messsignal.

U

, +5V Positive Hilfsenergie

B

0V, GND Bezugspotential

S

+

,D

D

+

Positiver Messanschluss

Datenleitung USB 2.0

-

2. Sicherheit

D

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass der richtige

Druckmessumformer hinsichtlich Messbereich, Ausführung und spezischen Messbedingungen ausgewählt wurde.

Der Betreiber muss die Verträglichkeit des Fluides mit dem eingesetzen

Werksto sicherstellen. Bei Medium Wassersto den Hersteller kontaktieren.

Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

11379180.03 09/2013 GB/D/F/E

25WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

Page 26

2. Sicherheit

WARNUNG!

■

Anschlüsse nur im drucklosen Zustand önen.

■

Betriebsparameter gemäß Kapitel 3 „Technische Daten“ beachten.

■

Druckmessumformer immer innerhalb der Überlast-Druckgrenze betreiben.

D

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen

Kapiteln dieser Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Der Druckmessumformer dient zum Umwandeln von Druck in ein elektrisches Signal.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der techni-

schen Spezikationen macht die sofortige Stilllegung und Überprüfung durch einen

autorisierten WIKA-Servicemitarbeiter erforderlich.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

VerletzungsgefahrbeiunzureichenderQualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden führen.

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualikation durchführen lassen.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der

Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezi-

schen Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen

Arbeiten auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

26 WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

11379180.03 09/2013 GB/D/F/E

Page 27

2. Sicherheit

2.3 Besondere Gefahren

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen, brennbaren

oder giftigen Stoen, sowie bei Kälteanlagen, Kompressoren etc. müssen

über die gesamten allgemeinen Regeln hinaus die einschlägigen Vorschriften beachtet werden.

WARNUNG!

Es sind keine Anlagenzustände gestattet, die zur Bildung von atomarem

Wassersto im Anschlusskanal des Druckmessumformers führen können.

WARNUNG!

Messstoreste im ausgebauten Druckmessumformer können zur Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

Dieses Gerät nicht in Sicherheits- oder in Not-Aus-Einrichtungen benutzen.

Fehlerhafte Anwendungen des Gerätes können zu Verletzungen führen

Am Gerät können im Fehlerfall aggressive Medien mit extremer Temperatur

und unter hohem Druck oder Vakuum anliegen.

D

.

2.4 Beschilderung, Sicherheitskennzeichnungen

Typenschild

Anschlussbelegung

P# Erzeugnis-Nr.

S# Serien-Nr.

Genauigkeit

Messbereich

Ausgangssignal

Hilfsenergie

Wird die Seriennummer durch mechanische Beschädigung oder Übermalen unleserlich,

ist eine Rückverfolgbarkeit nicht mehr möglich.

11379180.03 09/2013 GB/D/F/E

27WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

Page 28

2. Sicherheit / 3. Technische Daten

Symbolerklärung

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den zutreenden

europäischen Richtlinien.

D

3. Technische Daten

WARNUNG!

Bei der Auslegung der Anlage ist zu beachten, dass die angegebenen Werte

(z. B. Berstdruck, Überlast-Druckgrenze) in Abhängigkeit vom verwendeten

Material und Gewinde gelten.

Messbereiche

Relativdruck

bar Messbereich 0 ... 1.600 0 ... 2.500 0 ... 4.000 0 ... 5.000

Überlast-Druckgrenze 2.300 3.500 5.000 6.000

Berstdruck 4.000 6.000 8.000 10.000

Messbereich 0 ... 6.000 0 ... 7.000 0 ... 8.000 0 ... 10.000

Überlast-Druckgrenze 7.000 8.000 10.000 11.000

Berstdruck 11.000 11.000 12.000 12.000

Messbereich 0 ... 12.000 0 ... 15.000

Überlast-Druckgrenze 12.500 15.500

Berstdruck 14.000 16.000

psi Messbereich 0 ... 23.000 0 ... 36.000 0 ... 58.000 0 ... 72.000

Überlast-Druckgrenze 33.300 50.500 72.500 87.000

Berstdruck 58.000 87.000 116.000 145.000

Messbereich 0 ... 87.000 0 ... 100.000 0 ... 115.000 0 ... 145.000

Überlast-Druckgrenze 101.500 116.000 145.000 159.000

Berstdruck 159.500 159.500 174.000 174.000

Lebensdauer

Auf Anfrage, da die Lebensdauer vom tatsächlichen Druckverlauf abhängt.

Trotz seiner hervorragenden Lastwechselfestigkeit ist eine Dauerlastwechselfestigkeit

nur bedingt gegeben. Grund dafür sind die extremen Belastungen, denen die

hochdruckbeaufschlagten Materialien ausgesetzt sind. Dies gilt insbesondere für

dynamische Anwendungen. Dementsprechend handelt es sich bei den druckbelasteten

Teilen des HP-2 um Verschleißteile, die nicht unter die Gewährleistung fallen.

28 WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

11379180.03 09/2013 GB/D/F/E

Page 29

3. Technische Daten

Ausgangssignale

Signalart Signal

Strom (2-Leiter) 4 ... 20 mA

Spannung (3-Leiter) DC 0 ... 5 V

USB USB 2.0

DC 0 ... 10 V

Hilfsenergie

Die Hilfsenergie ist abhängig vom gewählten Ausgangssignal

■

4 ... 20 mA: DC 10 ... 30 V

■

DC 0 ... 5 V: DC 10 ... 30 V

■

DC 0 ... 10 V: DC 14 ... 30 V

■

USB 2.0: DC 5 V

BürdeinΩ

■

Stromausgang (2-Leiter): ≤ (Hilfsenergie - 10 V) / 0,02 A

■

Spannungsausgang (3-Leiter): > maximales Ausgangssignal / 1 mA

Schutzarten (nach IEC 60529)

■

Winkelstecker DIN 175301-803 A: IP 65

■

Rundstecker M12 x 1 (4-polig): IP 67

■

USB-Stecker Typ A: Gerät: IP 67, Stecker: IP 20

■

Kabelausgang: IP 67

Die angegebenen Schutzarten gelten nur im gesteckten Zustand mit Gegensteckern

entsprechender Schutzart.

Zulässige Temperaturbereiche

■

Medium: 0 ... +80 °C

■

Umgebung: -20 ... +80 °C

■

Lagerung: -40 ... +85 °C

D

CE-Konformität

■

EMV-Richtline

2004/108/EG

EN 61326 Emission (Gruppe 1, Klasse B)

und Störfestigkeit (industrieller Bereich)

Bei Signalausgang USB und starken elektromagnetischen Störungen im Frequenz-

bereich 650 … 750 MHz können Beeinussungen der Genauigkeit bis 1 % auftreten.

■

Druckgeräterichtlinie 97/23/EG

RoHS-Konformität

Ja

Bei Sondertypennummer, z. B. HP-20000 Spezikationen gemäß Lieferschein beachten.

Weitere technische Daten siehe WIKA-Datenblatt PE 81.53 und Bestellunterlagen.

11379180.03 09/2013 GB/D/F/E

29WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

Page 30

4. Aufbau und Funktion / 5. Transport, Verpackung und ...

4. Aufbau und Funktion

4.1 Kurzbeschreibung

Der anstehende Druck wird mittels Membranverformung am Sensorelement gemessen.

Unter Zuführung von Hilfsenergie wird diese Membranverformung in ein elektrisches

Signal umgewandelt. Das vom Druckmessumformer ausgegebene Signal ist verstärkt

und standardisiert.

D

4.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

5. Transport, Verpackung und Lagerung

5.1 Transport

Den Druckmessumformer auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

siehe Kapitel 3 „Technische Daten“

Den Druckmessumformer in der Originalverpackung an einem Ort lagern, der die oben

gelisteten Bedingungen erfüllt.

WARNUNG!

Vor der Einlagerung des Gerätes (nach Betrieb) alle anhaftenden Messstoreste entfernen. Dies ist besonders wichtig, wenn der Messsto gesund-

heitsgefährdend ist, wie z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

30 WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

11379180.03 09/2013 GB/D/F/E

Page 31

6. Inbetriebnahme, Betrieb

6. Inbetriebnahme, Betrieb

VORSICHT!

Vor der Inbetriebnahme den Druckmessumformer optisch prüfen.

Den Druckmessumformer nur in sicherheitstechnisch einwandfreiem

Zustand einsetzen.

6.1 Mechanische Montage

■

Dichtächen am Gerät und an der Messstelle

müssen unbeschädigt und frei von Verschmutzungen sein.

■

Beim Einschrauben des Gerätes darf die dazu

erforderliche Kraft nicht über das Gehäuse

aufgebracht werden, sondern nur mit geeignetem

Werkzeug über die dafür vorgesehene Schlüssel-

äche.

Die für die Montagestelle gültigen Werte für

Anzugsmoment und Maximaldruck sind aus den

Unterlagen des Hochdruckrohr-Lieferanten zu

entnehmen.

D

Maulschlüssel

(Schlüsselweite 27)

Schlüsseläche

■

Beim Einschrauben die Gewindegänge nicht verkanten.

■

Angaben zu Einschraublöchern und Einschweißstutzen siehe Technische Information

IN 00.14 unter www.wika.de.

6.2 Elektrische Montage

■

Das Gerät über den Prozessanschluss erden.

■

Den Druckmessumformer mit geschirmter Leitung betreiben und den Schirm auf

mindestens einer Leitungsseite erden, wenn die Leitungen länger als 30 m (3- bzw.

4-Leiter) sind oder das Gebäude verlassen.

■

Den Kabeldurchmesser passend zur Kabeldurchführung des Steckers wählen.

Darauf achten, dass die Kabelverschraubung des montierten Steckers korrekt sitzt

und dass die Dichtungen vorhanden und nicht beschädigt sind. Die Verschraubung

festziehen und den korrekten Sitz der Dichtungen überprüfen, um die Schutzart zu

gewährleisten.

■

Beim Kabelausgang sicherstellen, dass am Ende des Kabels keine Feuchtigkeit

eintritt.

■

Technische Daten gemäß Kapitel 3 „Technische Daten“ einhalten.

11379180.03 09/2013 GB/D/F/E

31WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

Page 32

6. Inbetriebnahme, Betrieb

Elektrischer Anschluss Aderquerschnitt Kabel-∅ Kabellängen

Winkelstecker DIN 175301-803 A max. 1,5 mm

Rundstecker M12 x 1 (4-polig) - - USB-Stecker Typ A - - 2 m

Kabelausgang 0,5 mm

Anschlussschemen

D

Abkürzungen siehe Seite 25

2

2

(AWG 20) 6,8 mm 1,5 m

6 ... 8 mm -

Winkelstecker DIN 175301-803 A

2-Leiter 3-Leiter

UB1 1

0V 2 2

S+ - 3

Kabelausgang

2-Leiter 3-Leiter

UBbraun braun

0V grün grün

S+ - weiß

Rundstecker M12 x 1 (4-polig)

2-Leiter 3-Leiter

4

1

0V 3 3

2

S+- 4

UB1 1

3

USB-Stecker Typ A

+5V 1

GND 4

D+ 3

D- 2

32 WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

11379180.03 09/2013 GB/D/F/E

Page 33

6. Inbetriebnahme, Betrieb

Montage des Winkelsteckers DIN 175301-803

1.

Die Schraube lösen.

2.

Die Kabelverschraubung lösen.

3.

Die Winkeldose + vom Gerät abziehen.

4.

Über die Montageönung den Klemmblock

aus dem Gehäuse hebeln.

D

5. Das Kabel mit passendem Leitungsaußendurchmesser durch Kabelverschraubung , Ring ,

Dichtung und das Gehäuse schieben.

6. Die Kabelenden entsprechend der Belegung in den

Anschlussklemmen des Klemmblocks anschließen (Belegung siehe „Anschlussschemen“).

7.

Den Klemmblock in das Gehäuse drücken.

8.

Das Kabel über die Kabelverschraubung

verschrauben. Darauf achten, dass die Kabelverschraubung und Dichtung unbeschädigt ist und

korrekt sitzt, um die Schutzart zu gewährleisten.

9.

Die quadratische Flachdichtung über die

Anschlusspins des Druckmessumformers legen.

10.

Die montierte Winkeldose + auf die Anschlusspins des Druckmessumformers schieben.

11.

Über die Schraube die Winkeldose am Druckmessumformer handfest verschrauben.

6.3 Inbetriebnahme USB-Geräte

■

Zur Installation des Treibers werden Administratorrechte benötigt.

■

USB-Stecker mit einem USB 2.0 Port mit dem Rechner verbinden.

■

Den Treiber über den InstallWizard der Produktsoftware installieren.

■

Für den weiteren Betrieb steht die P-3x Datenlogger-Software zur Verfügung (Details

siehe Bedienungsanleitung P-3x Datenlogger).

■

Details bezüglich des Schnittstellenprotokolls oder der DLL (Dynamic Link Library)

stehen auf der

gung.

Software-CD und im Downloadbereich unter www.wika.de zur Verfü-

Montageönung

Für den Typ HP-2 ist die Software des Typ P-30 zu verwenden. Alle Dateien

und Dokumente stehen zum Download unter www.wika.de zur Verfügung.

11379180.03 09/2013 GB/D/F/E

33WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

Page 34

7. Einstellung Nullpunkt und Spanne

7. Einstellung Nullpunkt und Spanne

Das Potentiometer zur Spanneeinstellung nur verstellen, wenn eine Kalibrierausstattung vorhanden ist, die mindestens die dreifache Genauigkeit des

Druckmessumformers aufweist.

7.1 Vorbereitung (Abbildung A)

D

Um Zugang zu den Potentiometern zu erhalten, das

Gerät wie folgt önen:

■

Den elektrischen Anschluss vom Gerät trennen.

■

Den Griring lösen.

■

Den Gerätestecker vorsichtig aus dem Gerät

ziehen.

■

Den Gerätestecker gemäß Anschlussschema mit

der Hilfsenergie und einer Anzeigeeinheit (z. B. Strommessgerät, Spannungsmessgerät) verbinden.

7.2 Einstellung Nullpunkt (Abbildung B)

■

Den Messbereichsanfang anfahren.

■

Über das Potentiometer „Z“ das minimale Ausgangssignal justieren (z. B. 4 mA).

A

7.3 Einstellung Spanne (Abbildung B)

■

Den Messbereichsendwert anfahren.

■

Über das Potentiometer „S“ das maximale

B

Ausgangssignal justieren (z. B. 20 mA).

■

Den Nullpunkt überprüfen und bei Abweichung erneut

justieren.

■

Den Vorgang solange wiederholen bis Nullpunkt und

Spanne korrekt eingestellt sind.

7.4 Einstellung abschließen (Abbildung A)

■

Den Gerätestecker von der Hilfsenergie und Anzeigeeinheit trennen.

■

Den Gerätestecker vorsichtig in das Gerät stecken, ohne Litzen und Dichtungen zu

beschädigen. Die Dichtungen müssen sauber und unbeschädigt sein, um die angegebene Schutzart sicherzustellen.

■

Den Griring festziehen.

Nach dem Justieren die korrekte Arbeitsweise des Systems überprüfen.

Empfohlener Nachkalibrierzyklus: halbjährlich

34 WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

11379180.03 09/2013 GB/D/F/E

Page 35

8. Ersatzteilkit

8. Ersatzteilkit

Das Ersatzteilkit dient dem Austausch des Prozessanschlusses und der Prallplatte der

Typen HP-2-D und HP-2-E. Es ist nicht kompatibel zur Standardausführung Typ HP-2-S.

8.1 Inhalt des Ersatzteilkits

SpannbackeAustauschbarer Prozessanschluss

Prallplatte für DIPS oder EPC O-Ring

DIPS EPC

D

8.2 Benötigtes Werkzeug

Schraubstock

11379180.03 09/2013 GB/D/F/E

Drehmomentschlüssel

Pinzette

35WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

Page 36

8. Ersatzteilkit

8.3 Montage

D

Die Spannbacke wie abgebildet in den Schraubstock

einspannen, sodass diese nicht verrutschen kann.

Den Druckmessumformer, über die am Prozessanschluss eingefräste Nut, zwischen die Spannbacke

schieben.

Den Prozessanschluss mittels Drehmomentschlüssel

lösen.

Die Prallplatte inkl. O-Ring

mittels Druckluft trocknen.

Als Zugang dient eine

Bohrung am Prozessanschluss

Prallplatte

DIPS EPC

36 WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

11379180.03 09/2013 GB/D/F/E

Page 37

8. Ersatzteilkit

Die trockene Prallplatte inkl. O-Ring mittels Pinzette

entfernen.

D

Den Dichtkonus auf Beschädigung überprüfen.

Bei beschädigtem Dichtkonus ist das komplette Gerät

zu ersetzen.

Die neue Prallplatte mit O-Ring schräg einlegen und nach unten drücken, dabei die

Oberäche der Prallplatte und den O-Ring nicht beschädigen.

DIPS EPC

11379180.03 09/2013 GB/D/F/E

37WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

Page 38

8. Ersatzteilkit / 9. Wartung und Reinigung

D

9. Wartung und Reinigung

9.1 Wartung

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

Den austauschbaren Prozessanschluss mit dem Drehmomentschlüssel anziehen.

Am Drehmomentschlüssel

den Anzugsmoment auf

130 Nm einstellen.

Bei Verdacht auf Undichtigkeit wegen

Haarrissen den Prozessanschluss, wie in Kapitel 8

„Ersatzteilkit“ beschrieben, austauschen.

Die Bestellnummer für das Ersatzteilkit siehe Kapitel 12 „Zubehör“

9.2 Reinigung

VORSICHT!

■

Vor der Reinigung den Druckmessumformer ordnungsgemäß von der

Druckversorgung trennen, ausschalten und von der Spannungsversorgung trennen.

■

Das Gerät mit einem feuchten Tuch reinigen.

■

Elektrische Anschlüsse nicht mit Feuchtigkeit in Berührung bringen.

■

Ausgebautes Gerät vor der Rücksendung spülen bzw. säubern, um

Personen und Umwelt vor Gefährdung durch anhaftende Messstoreste

zu schützen.

■

Messstoreste im ausgebauten Druckmessumformer können zur Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

Hinweise zur Rücksendung des Gerätes siehe Kapitel 11.2 „Rücksendung“.

38 WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

11379180.03 09/2013 GB/D/F/E

Page 39

10. Störungen

10. Störungen

Bei Störungen zuerst überprüfen, ob der Druckmessumformer mechanisch und elektrisch korrekt montiert ist.

Störungen Ursachen Maßnahmen

Kein Ausgangssignal Leitungsbruch Anschlussleitung austauschen

Keine/Falsche Hilfsenergie Hilfsenergie korrigieren

Kein/Falsches Ausgangssignal Verdrahtungsfehler Verdrahtung gemäß Anschluss-

Gleichbleibendes Ausgangssignal

bei Druckänderung

Abweichendes Ausgangssignal Nullpunktänderung durch Druck-

Signalspanne zu hoch Druckspitzen, Kavitationen Gerät mit Kavitations- und Druck-

Signalspanne zu klein Falsche Hilfsenergie Hilfsenergie korrigieren

Signalspanne schwankend EMV-Störquellen in der Nähe Gerät und Leitungen abschirmen,

Leckage am Prozessanschluss Haarriss im Druckkanal Beratung durch Hersteller,

Falsche Hilfsenergie Gerät austauschen

dynamik

Gerät nicht geerdet Gerät erden

Stark schwankender Druck des

Messstoes

schema korrigieren

Nullpunkt nachjustieren

spitzenschutz einsetzen

Störquelle entfernen

Dämpfung (Beratung durch

Hersteller)

evtl. Gerät austauschen

D

Im unberechtigten Reklamationsfall werden die Bearbeitungskosten berechnet.

VORSICHT!

Können Störungen mit Hilfe der oben aufgeführten Maßnahmen nicht

beseitigt werden, ist der Druckmessumformer unverzüglich außer Betrieb zu

setzen, sicherzustellen, dass kein Druck bzw. Signal mehr anliegt und gegen

versehentliche Inbetriebnahme zu schützen.

In diesem Falle Kontakt mit dem Hersteller aufnehmen.

Bei notwendiger Rücksendung die Hinweise unter Kapitel 11.2 „Rücksendung“ beachten.

11379180.03 09/2013 GB/D/F/E

39WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

Page 40

11. Demontage, Rücksendung und Entsorgung

11. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste im ausgebauten Druckmessumformer können zur Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

D

11.1 Demontage

WARNUNG!

Verbrennungsgefahr!

Vor dem Ausbau das Gerät ausreichend abkühlen lassen!

Beim Ausbau besteht Gefahr durch austretende, gefährlich heiße Messstoe.

Druckmessgerät nur im drucklosen Zustand demontieren!

11.2 Rücksendung

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoen (Säuren,

Laugen, Lösungen, etc.) sein.

Zur Rücksendung des Gerätes die Originalverpackung oder eine geeignete Transportverpackung verwenden.

Hinweise zur Rücksendung benden sich in der Rubrik „Service“ auf unserer

lokalen Internetseite.

11.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

40 WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

11379180.03 09/2013 GB/D/F/E

Page 41

12. Zubehör

12. Zubehör

Zubehör und Ersatzteile

Gegenstecker

Bezeichnung Bestellnummer

ohne Kabel mit 2 m Kabel mit 5 m Kabel

Winkelstecker DIN 175301-803 A

■

mit Verschraubung, metrisch

■

mit Verschraubung, conduit

Rundstecker M12 x 1, 4-polig

■

gerade

■

gewinkelt

Dichtungen für Gegenstecker

Bezeichnung Bestellnummer

Winkelstecker DIN 175301-803 A 1576240

Ersatzteilkit für die Typen HP-2-D und HP-2-E

Bestehend aus Ersatzanschlussgewinde, Ersatzdichtscheibe und einer Montagehilfe.

Ersatzteilkit passend zu folgenden Prozessanschlüssen:

Prozessanschluss Bestellnummer

M16 x 1,5 Innengewinde 14039895 14050403

M20 x 1,5 Innengewinde 13319923 14050404

11427567 11225793 11250186

11022485 - -

2421262 11250780 11250259

2421270 11250798 11250232

Typ HP-2-D Typ HP-2-E

D

Software

Die komplette Software steht als Freeware unter folgendem Pfad zum Download bereit.

www.wika.de / Download / Software / Elektronische Druckmesstechnik

11379180.03 09/2013 GB/D/F/E

41WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

Page 42

Anlage 1: Konformitätserklärung Typ HP-2

D

42 WIKA Betriebsanleitung Druckmessumformer, Typ HP-2

11379180.03 09/2013 GB/D/F/E

Page 43

Sommaire

Sommaire

1. Généralités 44

2. Sécurité 45

3. Spécications 48

4. Conception et fonction 50

5. Transport, emballage et stockage 50

6. Mise en service, exploitation 51

7. Réglage du point zéro et étendue 54

8. Kit de pièces de rechange 55

9. Entretien et nettoyage 58

10. Dysfonctionnements 59

11. Démontage, retour et mise au rebut 60

12. Accessoires 61

Annexe 1 : Déclaration de conformité pour le type HP-2 62

Déclarations de conformité se trouve sur www.wika.fr.

F

11379180.03 09/2013 GB/D/F/E

43WIKA mode d’emploi Transmetteur de pression, type HP-2

Page 44

1. Généralités

1. Généralités

■

Le transmetteur décrit dans le mode d'emploi est conçu et fabriqué selon les

dernières technologies en vigueur. Tous les composants sont soumis à des critères

de qualité et d'environnement stricts durant la fabrication. Nos systèmes de gestion

sont certiés selon ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant l'utilisation de l'instrument. Il est possible de travailler en toute sécurité avec ce produit en respectant

F

toutes les consignes de sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents et les

prescriptions générales de sécurité en vigueur pour le domaine d'application de

l'instrument.

■

Le mode d'emploi fait partie de l'instrument et doit être conservé à proximité

immédiate de l'instrument et accessible à tout moment pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération, avoir lu soigneuse-

ment et compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de dommages provoqués par une utilisation non conforme à l'usage prévu, de non respect de ce mode

d'emploi, d'utilisation de personnel peu qualié de même qu'en cas de modications

de l'instrument eectuées par l'utilisateur.

■

Les conditions générales de vente mentionnées dans les documents de vente

s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site Internet : www.wika.fr

- Fiche technique correspondante : PE 81.53

- Conseiller applications :

Tél. : +33 1 343084-84

Fax : +33 1 343084-94

info@wika.fr

44 WIKA mode d'emploi Transmetteur de pression, type HP-2

11379180.03 09/2013 GB/D/F/E

Page 45

1. Généralités / 2. Sécurité

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer

la mort ou des blessures graves si elle n'est pas évitée.

ATTENTION !

… indique une situation potentiellement dangereuse et susceptible de

provoquer de légères blessures ou des dommages matériels et pour l'environnement si elle n'est pas évitée.

Information

… met en exergue les conseils et recommandations utiles de même que les

informations permettant d'assurer un fonctionnement ecace et normal.

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer

des brûlures dues à des surfaces ou liquides chauds si elle n'est pas évitée.

Abréviations

2 ls Les deux lignes de raccordement servent à l'alimentation en tension.

Le signal de mesure fournit également le courant d'alimentation.

3 ls Deux lignes de raccordement servent à l'alimentation en tension.

Un câble de raccordement est utilisé pour le signal de mesure.

U

, +5V Alimentation positive

B

0V, GND Potentiel de référence

S+ Borne de sortie positive

D+ ,D- Connexion USB 2.0 pour transmission de données

F

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement, s'assurer que

le transmetteur de pression a été choisi de façon adéquate, en ce qui

concerne l'étendue de mesure, la version et les conditions de mesure spéci-

ques.

L'opérateur doit veiller à ce que le uide soit compatible avec le matériau

utilisé. Lorsque le uide est de l'hydrogène, contacter le fabricant.

Un non respect de cette consigne peut entraîner des blessures corporelles

graves et/ou des dégâts matériels.

11379180.03 09/2013 GB/D/F/E

45WIKA mode d’emploi Transmetteur de pression, type HP-2

Page 46

2. Sécurité

AVERTISSEMENT !

■

N'ouvrez les connexions qu'après que le système ait été dépressurisé.

■

Observez les conditions de fonctionnement conformément au chapitre 3

“Spécications”.

■

Ne faites fonctionner le transmetteur de pression que dans les limites de

surpression.

Vous trouverez d'autres consignes de sécurité dans les sections indivi-

F

2.1 Utilisation conforme à l'usage prévu

Le transmetteur de pression permet de convertir la pression en un signal électrique.

L'instrument est conçu et construit exclusivement pour une utilisation conforme à l'usage

prévu décrit ici et ne doit être utilisé qu'en conséquence.

Les spécications techniques mentionnées dans ce mode d'emploi doivent être respectées. En cas d'utilisation inadéquate ou de fonctionnement de l'instrument en dehors

des spécications techniques, un arrêt et contrôle doivent être immédiatement eectués par un collaborateur autorisé du service de WIKA.

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à l'usage

prévu.

duelles du présent mode d'emploi.

2.2 Qualicationdupersonnel

AVERTISSEMENT !

Dangerdeblessureencasdequalicationinsusante!

Une utilisation non conforme peut entraîner d'importants dommages corporels

et matériels.

Les opérations décrites dans ce mode d'emploi ne doivent être eectuées

que par un personnel ayant la qualication décrite ci-après.

Personnelqualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses connaissances

dans le domaine de la technique de mesure et de régulation et de ses expériences de

même que de sa connaissance des prescriptions nationales, des normes et directives

en vigueur, en mesure d'eectuer les travaux décrits et de reconnaître automatiquement

les dangers potentiels.

Les conditions d'utilisation spéciales exigent également une connaissance adéquate

par exemple des liquides agressifs.

46 WIKA mode d'emploi Transmetteur de pression, type HP-2

11379180.03 09/2013 GB/D/F/E

Page 47

2. Sécurité

2.3 Dangers particuliers

AVERTISSEMENT !

Dans le cas de uides de mesure dangereux comme notamment l'oxygène,

l'acétylène, les substances combustibles ou toxiques, ainsi que dans le cas

d'installations de réfrigération, de compresseurs etc., les directives appropriées existantes doivent être observées en plus de l'ensemble des règles

générales.

AVERTISSEMENT !

Toutes conditions d'installation pouvant entraîner la formation d'hydrogène

atomique dans le canal de raccordement du transmetteur de pression sont

interdites.

AVERTISSEMENT !

Les restes de uides se trouvant dans le transmetteur de pression démonté

peuvent mettre en danger les personnes, l'environnement ainsi que l'installation.

Prendre des mesures de sécurité susantes.

Ne pas utiliser cet instrument dans des dispositifs de sécurité ou d'arrêt

d'urgence. Une utilisation incorrecte de l'instrument peut occasionner des

blessures.

En cas d'erreur, des uides agressifs peuvent être présents à une température extrême et sous une pression élevée ou sous vide au niveau de l'instrument.

2.4 Etiquetage, marquages de sécurité

Plaque signalétique

Conguration du raccordement

F

P# N° Produit

S# N° Série

Incertitude

Etendue de mesure

Signal de sortie

Alimentation

Si le numéro de série devient illisible à cause de dommages mécaniques ou de peinture,

aucune traçabilité n'est plus possible.

11379180.03 09/2013 GB/D/F/E

47WIKA mode d’emploi Transmetteur de pression, type HP-2

Page 48

2.Sécurité/3.Spécications

Explication des symboles

CE, Communauté Européenne

Les instruments avec ce marquage sont conformes aux directives

européennes pertinentes.

3. Spécications

F

AVERTISSEMENT !

Lors de la conception du système, noter que les valeurs indiquées (par ex.

pression d'éclatement, limite de surpression) dépendent du matériau et du

letage utilisés.

Etendues de mesure

Pression relative

bar Etendue de mesure 0 ... 1.600 0 ... 2.500 0 ... 4.000 0 ... 5.000

Limite de surpression 2.300 3.500 5.000 6.000

Pression d'éclatement 4.000 6.000 8.000 10.000

Etendue de mesure 0 ... 6.000 0 ... 7.000 0 ... 8.000 0 ... 10.000

Limite de surpression 7.000 8.000 10.000 11.000

Pression d'éclatement 11.000 11.000 12.000 12.000

Etendue de mesure 0 ... 12.000 0 ... 15.000

Limite de surpression 12.500 15.500

Pression d'éclatement 14.000 16.000

psi Etendue de mesure 0 ... 23.000 0 ... 36.000 0 ... 58.000 0 ... 72.000

Limite de surpression 33.300 50.500 72.500 87.000

Pression d'éclatement 58.000 87.000 116.000 145.000

Etendue de mesure 0 ... 87.000 0 ... 100.000 0 ... 115.000 0 ... 145.000

Limite de surpression 101.500 116.000 145.000 159.000

Pression d'éclatement 159.500 159.500 174.000 174.000

Durée de vie

Sur demande, car la durée de fonctionnement dépend du cycle de pression réelle.

Malgré son excellente stabilité de cycle de charge, une stabilité permanente de cycle

de charge est relative. Cela est dû aux contraintes extrêmes auxquelles sont soumis

les matériaux hautement pressurisés. Cela vaut en particulier pour les applications

dynamiques. Les pièces sous pression du HP-2 sont donc des pièces d'usure qui ne

sont pas couvertes par la garantie.

48 WIKA mode d'emploi Transmetteur de pression, type HP-2

11379180.03 09/2013 GB/D/F/E

Page 49

3.Spécications

Signaux de sortie

Type de signal Signal

Courant (2 ls) 4 ... 20 mA

Tension (3 ls) 0 ... 5 VDC, 0 ... 10 VDC

USB USB 2.0

Alimentation

L'alimentation dépend du signal de sortie choisi

■

4 ... 20 mA : 10 ... 30 VDC

■

0 ... 5 VDC : 10 ... 30 VDC

■

0 ... 10 VDC : 14 ... 30 VDC

■

USB 2.0 : 5 VDC

ChargeenΩ

■

Sortie courant (2 ls) : ≤ (alimentation - 10 V) / 0,02 A

■

Sortie tension (3 ls) : Signal de sortie max. / 1 mA

Indice de protection (selon CEI 60529)

■

Connecteur coudé DIN 175301-803 A : IP 65

■

Connecteur circulaire M12 x 1 (4 broches) : IP 67

■

Connecteur USB type A : Instrument : IP 67, connecteur : IP 20

■

Sortie câble : IP 67

F

L'indice de protection mentionné n’est valable que lorsque le contre-connecteur

possède également l'indice de protection requis.

Plages de température admissibles

■

Fluide : 0 ... +80 °C

■

Ambiante : -20 ... +80 °C

■

Stockage : -40 ... +85 °C

Conformité CE

■

Directive CEM 2004/108/CE, EN61326 émission (groupe 1, classe B) et résistance

aux perturbations (domaine industriel)

Avec un signal de sortie USB et de fortes perturbations électromagnétiques

comprises dans la plage de fréquences 650 … 750 MHz, la précision peut être

inuencée de 1 % au maximum.

■

Directive relative aux équipements sous pression 97/23/EC

Conformité RoHS

Oui

Pour les numéros de type spéciaux, par exemple HP-20000, prière de tenir compte des

spécications gurant sur la notice de livraison. Pour les autres spédications, voir che

technique WIKA PE 81.53 et les documents de commande.

11379180.03 09/2013 GB/D/F/E

49WIKA mode d’emploi Transmetteur de pression, type HP-2

Page 50

4. Conception et fonction / 5. Transport, emballage et ...

4. Conception et fonction

4.1 Brève description

La pression de référence est mesurée sur l'élément capteur par la déformation d'une

membrane. En fournissant du courant, on convertit cette déformation de la membrane

en un signal électrique. Le signal de sortie en provenance du transmetteur de pression

est amplié et standardisé.

4.2 Détail de la livraison

F

Comparer le détail de la livraison avec le bordereau de livraison.

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur le transmetteur de pression liés au transport.

Communiquer immédiatement les dégâts constatés.

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection optimale (par ex.

changement de lieu d'utilisation, renvoi pour réparation).

5.3 Stockage

Conditions admissibles sur le lieu de stockage :

voir chapitre 3 “Spécications”

Conserver le transmetteur de pression dans l'emballage original dans un endroit qui

satisfait aux conditions susmentionnées.

AVERTISSEMENT !

Enlever tous les restes de uides adhérents avant l'entreposage de l'instrument (après le fonctionnement). Ceci est particulièrement important lorsque

le uide représente un danger pour la santé, comme p. ex. des substances

corrosives, toxiques, cancérogènes, radioactives etc.

50 WIKA mode d'emploi Transmetteur de pression, type HP-2

11379180.03 09/2013 GB/D/F/E

Page 51

6. Mise en service, exploitation

6. Mise en service, exploitation

ATTENTION !

Avant la mise en service, le transmetteur de pression doit être soumis à un

contrôle visuel.

Le transmetteur de pression ne doit être utilisé qu'en parfait état de sécurité

technique.

6.1 Montage mécanique

■

Les surfaces d'étanchéité sur l'instrument

doivent être non-endommagées et propres.

■

Lors du vissage de l'instrument, le couple de

serrage ne doit pas être appliqué sur le boîtier

mais seulement sur les surfaces prévues et ce

avec un outil approprié.

Clé à fourche

(clé d'une largeur de 27)

Pour le point d'installation, les valeurs valables

pour le couple de serrage et la pression

maximale doivent être celles indiquées dans

la documentation du fournisseur de tuyauterie

Surface de clé

haute pression.

■

Lorsque vous vissez, ne pas croiser les lets.

■

Pour obtenir des informations concernant les trous taraudés et les embases à

souder, voir les Informations techniques IN 00.14 sur www.wika.fr.

6.2 Montage électrique

■

L'instrument doit être mis à la terre par le raccord process.

■

Utiliser le transmetteur de pression avec un câble blindé, et mettre le blindage à la

terre à une extrémité du l de sortie au moins, si les lignes sont longues de plus de

30 m (3 ou 4 ls) ou sortent du bâtiment.

F

■

Choisir un diamètre de câble qui correspond au passe-câble de la prise. Vérier que

le passe-câble de la prise montée est bien serré et que les joints sont bien présents

et intacts. Serrer la liaison letée et vérier que le joint est bien xé pour assurer

l'indice de protection.

■

Protéger les départs de câble contre la pénétration d'humidité.

■

Respectez les spécications conformément au chapitre 3 “Spécications”.

11379180.03 09/2013 GB/D/F/E

51WIKA mode d’emploi Transmetteur de pression, type HP-2

Page 52

6. Mise en service, exploitation

Raccordement électrique Section du conducteur ∅decâble Longueurs de

câble

Connecteur coudé DIN 175301-803 A max. 1,5 mm

Connecteur circulaire M12 x 1 (4-plots) - - Connecteur USB type A - - 2 m

Sortie câble 0,5 mm

2

2

(AWG 20) 6,8 mm 1,5 m

6 ... 8 mm -

Diagrammes de connexion

Pour les abréviations, se référer à la page 45.

F

Connecteur coudé DIN 175301-803 A

2ls 3ls

UB1 1

0V 2 2

S+ - 3

Sortie câble

2ls 3ls

UBmarron marron

0V vert vert

S+ - blanc

Connecteur circulaire M12 x 1 (4-plots)

2ls 3ls

4

1

0V 3 3

2

S+- 4

UB1 1

3

Connecteur USB type A

+5V 1

GND 4

D+ 3

D- 2

52 WIKA mode d'emploi Transmetteur de pression, type HP-2

11379180.03 09/2013 GB/D/F/E

Page 53

6. Mise en service, exploitation

Pose du connecteur coudé DIN 175301-803

1.

Desserrer la vis .

2.

Desserrer le passe-câble .

3.

Enlever la prise coudée + de l'instrument.

4.

Par le trou de montage , hisser le bloc terminal

hors du boîtier .

5. Passer le câble ayant le diamètre extérieur qui

convient à travers le presse-étoupe , la bague ,

le joint d'étanchéité et le boîtier .

6. Relier les extrémités de câble aux bornes de

raccordement correspondantes situées sur le bloc

terminal en respectant la distribution des plots

(voir “Diagrammes de connexion” pour la distribution

des plots).

7.

Presser le bloc terminal dans le boîtier .

8.

Serrer le passe-câble autour du câble. Assurezvous que les joints ne sont pas endommagés et

que le passe-câble et les joints sont assemblés

correctement pour obtenir une protection contre

l'intrusion.

Trou de montage

F

9.

Placer le joint plat et carré sur les ches de

connexion du transmetteur de pression.

10.

Glisser l'embase coudée assemblée + sur les

plots de raccordement du transmetteur de pression.

11.

Au moyen de la vis , visser la prise coudée sur le

transmetteur de pression, serrer à la main.

6.3 Mise en service des instruments USB

■

Des droits d'administrateur sont nécessaires pour l'installation du pilote.

■

Raccordez la prise USB avec un port USB 2.0 à l'ordinateur.

■

Installez le pilote au moyen du logiciel InstallWizard du produit.

■

Pour aller plus loin, le logiciel enregistreur de données P-3x est disponible (pour plus

de détails, voir le manuel d'instructions de l'enregistreur de données P-3x).

■

Des détails sur le protocole d'interface ou la DLL (Dynamic Link Library) sont disponible sur le CD du logiciel et peuvent être téléchargés à www.wika.com.

Pour le type HP-2, le logiciel du type P-30 doit être utilisé. Tous les chiers et

documents peuvent être téléchargés sous www.wika.com.

11379180.03 09/2013 GB/D/F/E

53WIKA mode d’emploi Transmetteur de pression, type HP-2

Page 54

7. Réglage du point zéro et étendue

7. Réglage du point zéro et étendue

N'ajuster le potentiomètre qui règle l'échelle que si on dispose d'un équipement d'étalonnage ayant au moins trois fois la précision du transmetteur de

pression.

7.1 Préparation(gureA)

Pour accéder au potentiomètre, ouvrir l'instrument

F

comme suit :

■

Déconnecter l'alimentation électrique de l'instru-

A

ment.

■

Retirer l'écrou de serrage .

■

Retirer soigneusement la prise d'instrument .

■

Raccorder la prise de l'instrument à l'alimentation

électrique et une unité d'achage (par exemple,

ampèremètre, voltmètre) suivant le diagramme de

connexion.

7.2 Réglagedupointzéro(gureB)

■

Aller sur le démarrage de l'étendue de mesure.

■

Au moyen du potentiomètre “Z”, régler le signal de

sortie minimum (par exemple 4 mA).

B

7.3 Réglagedel'échelle(gureB)

■

Aller sur le n de l'étendue de mesure.

■

Au moyen du potentiomètre “S”, régler le signal de

sortie maximum (par exemple 20 mA).

■

Vériez le point zéro et s'il y a un écart, corrigez-le.

■

Répéter la procédure jusqu'à ce que le point zéro et

l'échelle soient réglés correctement.

7.4 Finirleréglage(gureA)

■

Débrancher la prise d'instrument et l'unité d'achage de l'alimentation électrique.

■

Poussez soigneusement la prise d'instrument sur l'instrument sans endommager les

ls ou les joints d'étanchéité. Les joints d'étanchéité doivent être propres et en bon état

pour pouvoir garantir l'indice de protection annoncé.

■

Serrer l'écrou de serrage .

Après le réglage, vériez que le système fonctionne correctement.

Fréquence de réétalonnage recommandée : deux fois par an

54 WIKA mode d'emploi Transmetteur de pression, type HP-2

11379180.03 09/2013 GB/D/F/E

Page 55

8. Kit de pièces de rechange

8. Kit de pièces de rechange

Le kit de pièces de rechange est utilisé pour l'échange de raccords process et d'écran

réducteur de pression des types HP-2-D et HP-2-E. Il n'est pas compatible avec la

version standard, le type HP-2-S.

8.1 Contenu du kit de pièces de rechange.

Mâchoire de serrageRaccord process échangeable

Chicane pour DIPS ou EPC Joint torique

DIPS EPC

F

8.2 Outils requis

Etau

11379180.03 09/2013 GB/D/F/E

Clé dynamométrique

Pinces

55WIKA mode d’emploi Transmetteur de pression, type HP-2

Page 56

8. Kit de pièces de rechange

8.3 Installation

F

Fixer la mâchoire de serrage dans l'étau comme illustré, de telle sorte qu'elle ne puisse pas bouger.

Glisser le transmetteur de pression entre les mâchoires

de serrage en utilisant la rainure du raccord process.

Desserrer le raccord process en utilisant la clé

dynamométrique.

Sécher la chicane y compris

le joint torique en utilisant de

l'air comprimé.