Page 1

Operating Instructions

Betriebsanleitung

Mode d´emploi

Magnetic operated float switches Model RSM and HIF

Schwimmer-Magnetschalter Typ RSM und HIF

Interrupteurs magnètiques à flotteur Type RSM et HIF

Magnetic operated float switch

Fig. left: Model RSM, Fig. right: Model HIF

GB

D

F

Page 2

Operating instructions magnetic operated float switches

GB

Model RSM and HIF Page 3-12

Betriebsanleitung Schwimmer-Magnetschalter

D

Typ RSM und HIF Seite 13-22

Mode d‘emploi interrupteurs magnètiques à flotteur

F

Type RSM et HIF Page 23-33

WIKA Operating instructions Magnetic operated float switches Model RSM and HIF

2

13333283.01 01/2010 GB/D/F

Page 3

Contents

Contents

Contents

1. Functional description 4

2. Area of application 4

3. Assembly 5

4. Electrical connection 6

5. Commissioning / function test 8

6. Maintenance 9

7. Notes 9

8. Technical data 10

9. Protective RC-Modules 11

WARNING!

Instructions for proper installation and use of magnetic

float switches. Disregard may lead to malfunction or destruction of reed contacts.

DANGER!

Instructions to avoid personal or property damage.

GB

ELECTRICAL INSTALLATIONS

Instructions for proper electrical installation.

WIKA Operating instructions magnetic operated float switches Model RSM and HIF

13333283.01 01/2010 GB/D/F

3

Page 4

1. Functional description / 2. Area of application

1. Functional description

Magnetic operated float switches operate according to the float

GB

principle with magnetic transmission. A reed contact built into the

slip pipe (5) or contact pipe (8) is activated by the magnetic field of a

permanent magnet on reaching a preset switching point. The permanent magnet is located in a float (7) which changes its height with

the level of the medium being monitored. The switching state of the

reed contact can be evaluated and processed by a series-connected

control unit.

The number and arrangement of the floats depends on the number

of preset switching points, their contacting function and the distance

apart of the switching points.

2. Area of application

Magnetic operated float switches are used exclusively for level

control and monitoring of liquid media.

The liquids may not be heavily contaminated and should not have

a tendency to crystallize. Make sure that the materials of the switch

(float, slip pipe) which come into contact with the medium being

monitored are suitably resistant.

WIKA Operating instructions Magnetic operated float switches Model RSM and HIF

4

13333283.01 01/2010 GB/D/F

Page 5

3. Assembly

3. Assembly

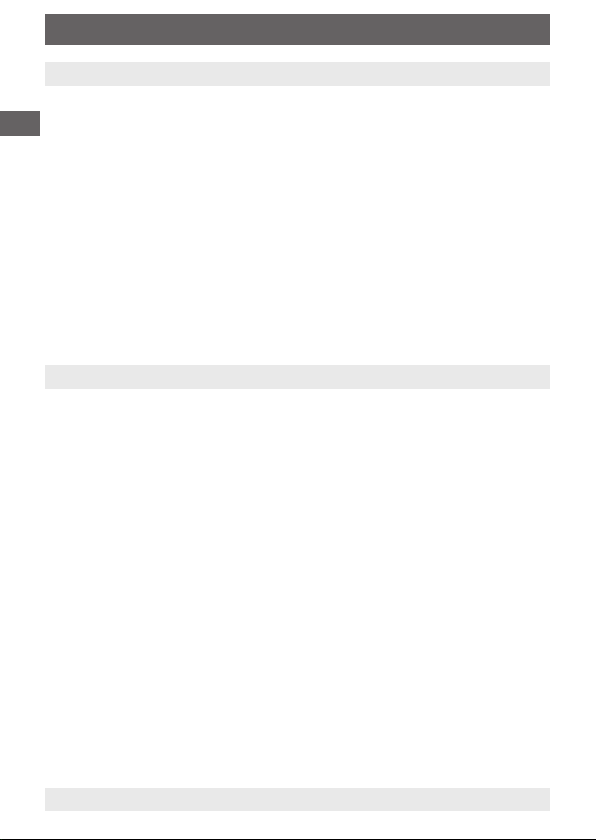

Versions for vertical installation (Fig. 1)

Install WIKA magnetic operated float switches according to their

model (flange or thread [3])

Use the screws and nuts suitable for the flange for flange models.

Fit a suitable gasket (4) for sealing. Make sure it is installed in the

right position. (max. deviation from the vertical ± 30°)

The float (7) must be removed before installation in openings with a

diameter smaller than the diameter of the float

Mark the position of the set collars (6) before removing

If top and bottom of the floats are not already marked, please do

so now

Replace the float inside the tank after installing the magnetic

operated float switch

Then fix the set collars (6) back in the same position

The number of floats and position of stop rings are dependent on

the switching positions and number of switch points

Versions for horizontal installation (Fig. 2)

Magnetic operated float switches for horizontal operation must be

installed as shown in figure 2.

Use the screws and nuts suitable for the flange for flange models. Fit

a suitable gasket (4) for sealing. Make sure it is installed in the right

position. (The float must be tilted downwards in the unactivated state).

When installing in the union, make sure that the tilting of the float is

not affected.

GB

WIKA Operating instructions magnetic operated float switches Model RSM and HIF

13333283.01 01/2010 GB/D/F

5

Page 6

3. Assembly / 4. Electrical connection

GB

When mounted inside ferromagnetic surroundings the

function could be restrained. This may cause a malfunction

and harm to goods.

The magnetic operated float switch must be mounted

outside ferromagnetic surroundings.

4. Electrical connection

When mounted inside ferromagnetic surroundings the

function could be restrained. This may cause a malfunction

and harm to goods.

The magnetic operated float switch must be mounted

outside ferromagnetic surroundings.

The electrical connection is made according to the wiring diagram

printed on the switch.

(Models with only one normally closed or normally open contact

contain no wiring diagram.)

The cable bushing (2) in the connection enclosure (1) must be sealed.

WIKA Operating instructions Magnetic operated float switches Model RSM and HIF

6

13333283.01 01/2010 GB/D/F

Page 7

4. Electrical connection

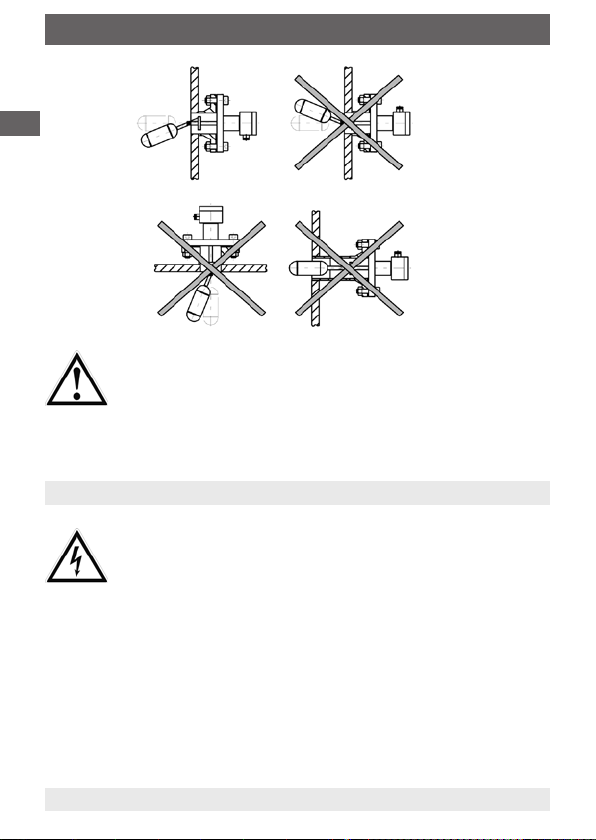

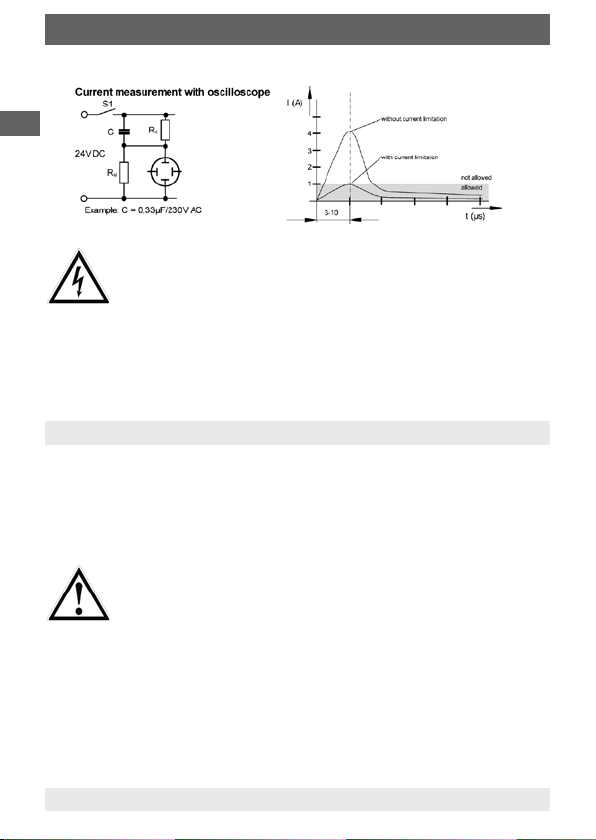

Use of magnetic float switches with inductive or capacitive

load may lead to the destruction of the reed switch. This

may cause a malfunction to the control circuitry and harm

to persons or goods.

With inductive load, magnetic switches have to be

connected to a RC Network (acc. to appendix).

With capacitive load, connecting cables longer than

50 m or connection to a PLC with capacitive input circuit,

a 22 Ω resp. 47 Ω (10 VA contacts) resistor is required to be

connected in series to limit current spikes. A 220 Ω resistor

shall be used when connected to an electronic timer.

GB

Overloading the magnetic float switches may lead to

the destruction of the reed switch, which may cause a

malfunction to the control circuitry and harm to persons or

goods. The maximum switch capacity values given in the

chapter "Technical data" and the Technical bulletin must

not be exceeded.

WIKA Operating instructions magnetic operated float switches Model RSM and HIF

13333283.01 01/2010 GB/D/F

7

Page 8

4. Electrical connection / 5. Commissioning / function test

GB

Magnetic float switches with connecting cable including no protective earth may be live under fault

conditions. Touching the housing may cause harm to

persons or even be lethal. These switches must only

be used with protective low voltage acc. to VDE 0100

(f. e. use a WIKA contact protection relay) or have to be

mounted in such way, that the switch is earthed.

5. Commissioning / function test

Switch on the power supply to the connected control unit. Fill the

vessel and check the function of the switching points of the magnetoperated float switch. The function test can also be conducted

manually on the removed switch.

Make sure that the function test does not accidentally set

any processes in motion.

WIKA Operating instructions Magnetic operated float switches Model RSM and HIF

8

13333283.01 01/2010 GB/D/F

Page 9

6. Maintenance / 7. Notes

6. Maintenance

The magnetic operated float switches operate free of maintenance

and wear when used properly.

The switch must be eye-checked within the scope of the necessary

inspections under extreme operating conditions.

7. Notes

The reed contacts must be operated on intrinsically safe circuits when

operating in „e“ areas of zone 1 or 2.

Float switches made of plastic may not be used in the „e“ areas of

zone 1 or 2.

Do not operate float switches in the immediate vicinity of strong

electromagnetic fields (distance away at least 1 m).

The switching points of the magnetic operated float switches cannot

be adjusted.

Magnetic operated float switches can only be used in media to which

the material of the slip pipe and the float is resistant.

The switches may not be exposed to heavy mechanical stresses

(shock, bending, vibrations).

GB

WIKA Operating instructions magnetic operated float switches Model RSM and HIF

13333283.01 01/2010 GB/D/F

9

Page 10

8. Technical data

8. Technical data

Switching behaviour: Norm close / Norm open

GB

Max. voltage: 250 V AC / DC

Max. current: 2 A AC / 1 A DC

Max. power: 100 VA, cosφ >0,7 / 50 W

Switching behaviour: Change over

Max. voltage: 250 V AC / DC

Max. current: 1 A AC / 0,5 A DC

Max. power: 40 VA, cosφ > 0,7 / 20 W

Magnet operated Mini Float Switches

Switching behaviour: Norm close / Norm open

Max. voltage: 250 V AC / DC

Max. current: 0,5 A AC / 0,25 A DC

Max. power: 10 VA , cosφ > 0,7 / 5 W

WIKA Operating instructions Magnetic operated float switches Model RSM and HIF

10

13333283.01 01/2010 GB/D/F

Page 11

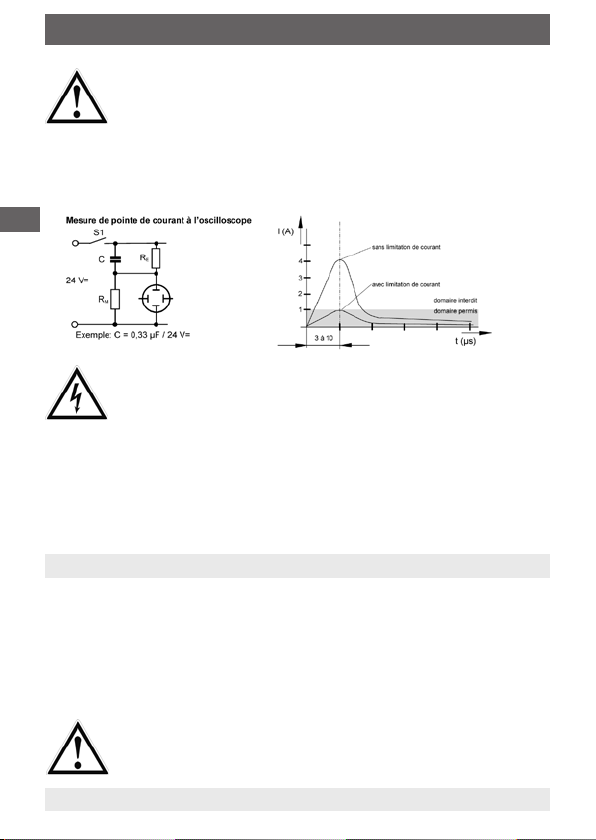

9. Protective RC-Modules

9. Protective RC-Modules

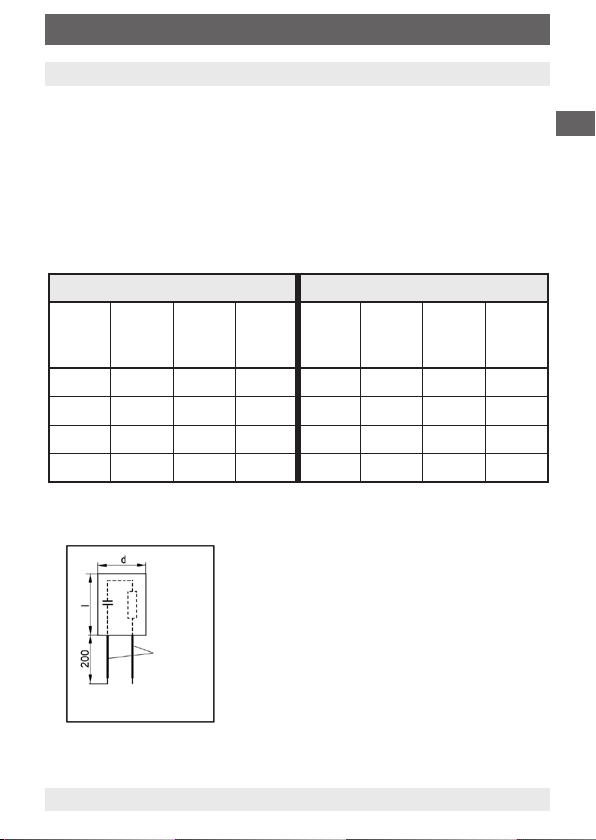

Please use RC-modules according to the table below. Rating of the

switches and supply voltage will determine the model to be used.

Other models might lead to destruction or lower service life of the

reed contacts.

For reed contacts 10-40 VA For reed contacts 40-100 VA

Capa-

citance

0,33 100 24 3/24 0,33 47 24 3/24

0,33 220 48 3/48 0,33 100 48 3/48

0,33 470 115 3/115 0,33 470 115 3/115

0,33 1500 230 3/230 0,33 1000 230 3/230

sistance

µF

Ohm

d = Ø16 ... Ø25 mm

I = 16 ... 58 mm

Re-

VoltageV~ModelACapa-

Wire

citance

µF

Re-

sistance

Ohm

VoltageV~Model

B

GB

WIKA Operating instructions magnetic operated float switches Model RSM and HIF

13333283.01 01/2010 GB/D/F

11

Page 12

GB

WIKA Operating instructions Magnetic operated float switches Model RSM and HIF

12

13333283.01 01/2010 GB/D/F

Page 13

Inhalt

Inhalt

Inhalt

1. Funktionsbeschreibung 14

2. Einsatzbereich 14

3. Montage 15

4. Elektrischer Anschluss 16

5. Inbetriebnahme / Funktionsprüfung 18

6. Wartung 19

7. Hinweise 19

8. Technische Daten 20

9. RC-Glieder zur Schutzbeschaltung 21

WARNUNG!

Hinweise zur fachgerechten Montage und den bestimmungsgemäßen Betrieb des Schwimmer-Magnetschalters.

Eine Nichtbeachtung kann zu Fehlfunktionen oder der

Zerstörung der Reedkontakte führen.

GEFAHR!

Hinweise zur Vermeidung von Personen- oder Sachschäden.

HINWEISE ZUR ELEKTRISCHEN INSTALLATION

Angaben für eine fachgerechte elektrische Installation.

D

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

13

Page 14

1. Funktionsbeschreibung / 2. Einsatzbereich

1. Funktionsbeschreibung

Schwimmer-Magnetschalter arbeiten nach dem Schwimmerprinzip

mit magnetischer Übertragung. Ein im Gleitrohr (5) bzw. Kontaktrohr (8) eingebauter Reedkontakt wird durch das Magnetfeld eines

D

Permanentmagneten bei Erreichen eines vorgegebenen Schaltpunktes

betätigt. Der Permanentmagnet befindet sich in einem Schwimmer (7),

der seine Höhenlage mit dem Pegel des zu überwachenden Mediums

verändert. Der Schaltzustand des Reedkontaktes kann durch eine

nachgeschaltete Steuereinrichtung ausgewertet und weiterverarbeitet

werden.

Die Anzahl und Anordnung der Schwimmer ist abhängig von der

Anzahl der vorgegebenen Schaltpunkte, deren Kontaktfunktion sowie

dem Abstand der Schaltpunkte.

2. Einsatzbereich

Schwimmer-Magnetschalter sind ausschließlich zur Füllstandssteuerung bzw. -überwachung von flüssigen Medien zu verwenden.

Die Flüssigkeiten dürfen keine starke Verschmutzungen oder Grobteile

aufweisen und nicht zum Auskristallisieren neigen. Es ist sicherzustellen, dass die medienberührenden Werkstoffe des Schalters (Schwimmer, Gleitrohr) gegen das zu überwachende Medium ausreichend

beständig sind.

14

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

Page 15

3. Montage

3. Montage

Ausführungen für vertikalen Einbau (Fig. 1)

WIKA Schwimmer-Magnetschalter entsprechend der Ausführung

(Flansch o. Gewinde [3]) einbauen

Bei Flanschausführungen sind die zum Flansch passenden Schrau-

ben und Muttern zu verwenden. Zum Abdichten ist eine geeignete

Dichtung (4) vorzusehen

Es ist auf korrekte Einbaulage zu achten. (max. Abweichung aus

der vertikalen ± 30°)

Bei Einbauöffnungen die kleiner als der Durchmesser des Schwim-

mers sind, ist der Schwimmer (7) vor dem Einbau des Schalters

abzunehmen

Die Position der Stellringe (6) ist vor dem Abnehmen zu markieren

(z. B. mit einem wasserfesten Stift)

Sofern die Schwimmer nicht gekennzeichnet sind, ist die Einbaula-

ge entsprechend zu kennzeichnen (z. B. „Oben“)

Nach dem Einbau des Schwimmer-Magnetschalters ist der

Schwimmer im Inneren des Tanks wieder aufzusetzen (Einbaulage

beachten!)

Die Stellringe (6) sind anschließend an den markierten Stellen

wieder zu befestigen

Die Anzahl der Schwimmer sowie die Position der Stellringe sind

vom Maß und der Anzahl der Schaltpunkte abhängig

Ausführungen für horizontalen Einbau (Fig. 2)

Schwimmer-Magnetschalter für horizontale Einbaulage sind gemäß

Fig. 2 einzubauen.

Bei Flanschausführungen sind die zum Flansch passenden Schrauben und Muttern zu verwenden. Zum Abdichten ist eine geeignete

Dichtung (4) vorzusehen. Es ist auf korrekte Einbaulage zu achten.

(Der Schwimmer muss im unbetätigten Zustand nach unten gekippt

sein). Beim Einbau in Stutzen muss gewährleistet sein, dass der

Schwimmer in seiner Kippbewegung nicht beeinträchtigt wird.

D

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

15

Page 16

3. Montage / 4. Elektrischer Anschluss

D

Beim Einbau in ferromagnetische Stutzen wird die Funktionsfähigkeit des Schalters beeinträchtigt. Gefahr von

Sachschäden durch fehlerhaftes Schaltverhalten des

Reedkontaktes.

Der Schwimmerschalter ist so einbauen, dass sich das

Kontaktrohr außerhalb eines ferromagnetischen Stutzens

befindet.

4. Elektrischer Anschluss

Der elektrische Anschluss ist entsprechend den im

Errichtungsland geltenden Errichtungsbestimmungen

durchzuführen und darf nur von Fachpersonal durchgeführt

werden.

Zur Erhöhung der Lebensdauer der Kontakte wird der

Betrieb an einem Kontaktschutzrelais empfohlen.

Der elektrische Anschluss ist entsprechend dem jeweiligen am

Schalter angebrachten Anschlussschema vorzunehmen.

(Ausführungen mit nur einem Öffner oder Schließerkontakt enthalten

kein Anschlussschema)

Die Kabeldurchführung (2) am Anschlussgehäuse (1) ist abzudichten

16

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

Page 17

4. Elektrischer Anschluss

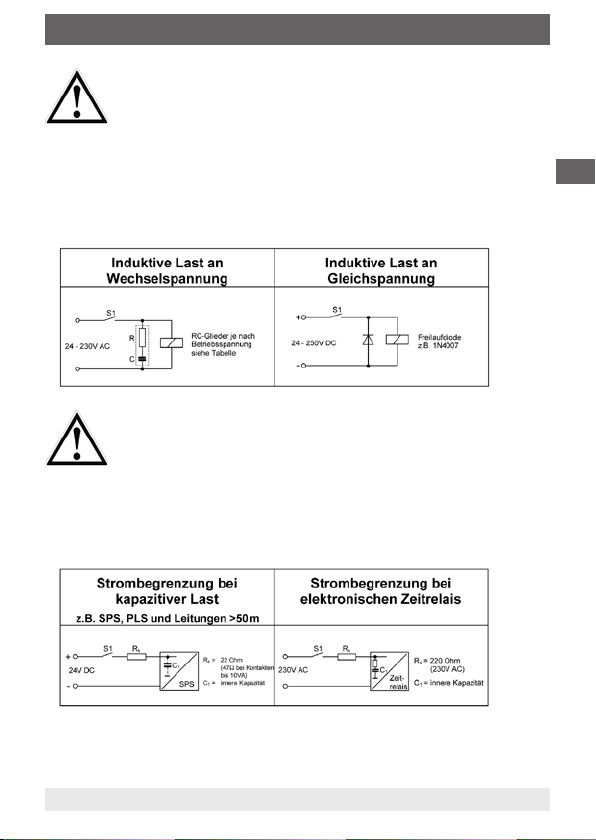

Der Betrieb der Schwimmer-Magnetschalter an induktiver

oder kapazitiver Last kann eine Zerstörung des Reedkontaktes zur Folge haben. Dies kann zu einer Fehlfunktion

der nachgeschalteten Steuerung und zu Personen- oder

Sachschäden führen.

Bei induktiver Belastung sind die Schwimmer-Magnetschalter durch Beschaltung mit einem RC-Glied gem.

Anhang bzw. einer Freilaufdiode zu schützen.

Bei kapazitiver Belastung, Leitungslängen über 50 m

oder dem Anschluss an Prozessleitsystemen mit kapazitivem Eingang ist zur Begrenzung des Spitzenstromes

ein Schutzwiderstand von 22 Ω bzw. 47 Ω (bei 10 VAKontakten) in Serie zu schalten.

Bei Anschluss an elektronische Zeitrelais muss ein Widerstand von 220 Ohm in Serie geschaltet werden.

D

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

17

Page 18

4. Elektrischer Anschluss / 5. Inbetriebnahme ...

Eine Überlastung des Schwimmer-Magnetschalters kann

eine Zerstörung des eingebauten Reedkontaktes zur Folge

haben. Dies kann zu einer Fehlfunktion der nachgeschalteten Steuerung und zu Personen- oder Sachschäden

führen. Die im Kapitel "Technische Daten" und im WIKA-

D

Datenblatt angegebenen Maximalwerte für die Schaltleistung sind einzuhalten.

Bei Schwimmer-Magnetschaltern mit Anschlusskabel ohne Schutzleiteranschluss kann der Schalter

im Fehlerfall spannungsführend sein. Bei Berührung

können schwere Körperschäden oder tödliche Verletzungen auftreten. Diese Schalter dürfen nur an Schutzkleinspannung nach VDE0100 betrieben werden (z.B.

an einem WIKA Kontaktschutzrelais) oder sind so zu

montieren, dass der Schwimmer-Magnetschalter mit

dem Potentialausgleich elektrisch verbunden ist.

5. Inbetriebnahme / Funktionsprüfung

Versorgungsspannung der angeschlossenen Steuerungseinrichtung

einschalten, Behälter füllen und die Schaltpunkte des SchwimmerMagnetschalters auf Funktion prüfen. Die Funktionsprüfung kann auch

manuell bei ausgebautem Schalter erfolgen.

Es ist sicherzustellen, dass durch die Funktionsprüfung

keine unbeabsichtigten Prozessabläufe eingeleitet werden.

18

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

Page 19

6. Wartung / 7. Hinweise

6. Wartung

Schwimmer-Magnetschalter arbeiten bei bestimmungsgemäßem

Gebrauch wartungs- und verschleißfrei.

Bei extremen Einsatzbedingungen sollte der Schalter im Rahmen der

durchzuführenden Revisionen einer Sichtkontrolle unterzogen werden.

7. Hinweise

Beim Betrieb im Ex-Bereich der Zone 1 oder 2 sind die

Reedkontakte an eigensicheren Stromkreisen zu betreiben.

Schwimmerschalter aus Kunststoff dürfen nicht im Ex-Bereich der

Zone 1 oder 2 eingesetzt werden.

Schwimmerschalter nicht in unmittelbarer Nähe von starken elektromagnetischen Feldern bzw. in unmittelbarer Nähe von Einrichtungen,

die durch Magnetfelder beeinflusst werden können, betreiben

(Abstand min. 1 m).

Die Schaltpunkte der Schwimmer-Magnetschalter können nicht

verstellt werden.

Schwimmer-Magnetschalter nur in Medien einsetzen gegen die der

Werkstoff des Gleitrohres und des Schwimmers beständig ist.

Die Schalter dürfen keinen starken mechanischen Belastungen (Stoß,

Verbiegen, Vibrationen) ausgesetzt werden.

D

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

19

Page 20

8. Technische Daten

8. Technische Daten

Kontaktfunktion: Öffner / Schließer

Max. Spannung: 250 V AC / DC

Schaltstrom: 2 A AC / 1 A DC

D

Schaltleistung: 100 VA, cosφ >0,7 / 50 W

Kontaktfunktion: Umschalter

Max. Spannung: 250 V AC / DC

Schaltstrom: 1 A AC / 0,5 A DC

Schaltleistung: 40 VA, cosφ > 0,7 / 20 W

Mini Schwimmerschalter

Kontaktfunktion: Öffner / Schließer

Spannung: 250 V AC / DC

Schaltstrom: 0,5 A AC / 0,25 A DC

Schaltleistung: 10 VA , cosφ > 0,7 / 5 W

20

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

Page 21

9. RC-Glieder zur Schutzbeschaltung

9. RC-Glieder zur Schutzbeschaltung

RC-Glieder sind, je nach Betriebsspannung, ausschließlich entsprechend untenstehender Tabelle zu verwenden.

Andere als die hier aufgeführten RC-Glieder führen zur Zerstörung

des Reedschalters.

Für Schutzgaskontakte von

10-40 VA

Kapa-

zität

µF

Wider-

stand

Ohm

Span-

nung

V~

TypAKapa-

0,33 100 24 3/24 0,33 47 24 3/24

0,33 220 48 3/48 0,33 100 48 3/48

0,33 470 115 3/115 0,33 470 115 3/115

0,33 1500 230 3/230 0,33 1000 230 3/230

Litze

d = Ø16 ... Ø25 mm

I = 16 ... 58 mm

Für Schutzgaskontakte von

40-100 VA

zität

µF

Wider-

stand

Ohm

Span-

nung

V~

Typ

B

D

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

21

Page 22

D

22

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

Page 23

Sommaire

Sommaire

Sommaire

1. Description du fonctionnement 24

2. Domaine d‘utilisation 24

3. Montage 25

4. Raccordement électrique 26

5. Mise en service / contrôle fonctionnel 29

6. Entretien 29

7. Remarques 30

8. Caractéristiques techniques 31

9. Circuits RC de protection de contacts 32

AVERTISSEMENT !

Instructions qui permettet le montage et l’utilisation correctes des régulateurs de niveau á flotteur. Un mépris de

ces instructions peut conduire au mauvais fonctionnement

ou á la detruction des contacts à lame souple.

DANGER !

Instructions qui permettet d’éviter de porter atteinte á des

personnes ou á des biens.

F

INSTALLATION ÉLECTRIQUE

Indications qui permettet une installation électrique

correcte.

WIKA Mode d‘emploi interrupteurs magnètiques à flotteur Type RSM et HIF

13333283.01 01/2010 GB/D/F

23

Page 24

1. Funktionsbeschreibung / 2. Einsatzbereich

1. Description fonctionnelle

Les interrupteurs magnétiques à flotteur fonctionnent suivant le principe des flotteurs à transfert magnétique. Un contact Reed logé dans

le tube de glissement (5) ou dans un tube de contact (8) est actionné

par le champ magnétique d‘un aimant permanent lorsqu‘un point de

commutation prédéterminé est atteint. L‘aimant permanent est monté

dans un flotteur (7) qui change sa position en hauteur avec le niveau

F

du milieu à surveiller. L‘état de commutation du contact Reed peut

être évalué et traité par un dispositif de commande monté en aval à

circuit de courant de commande à sécurité intrinsèque.

Le nombre et la disposition des flotteurs dépendent du nombre de

points de commutation prédéterminés et de leur fonction de contact

ainsi que de l‘écart des points de commutation.

2. Domaine d‘application

Les interrupteurs magnétiques à flotteur servent exclusivement

à commander ou à surveiller le niveau de remplissage de milieux

liquides.

Les liquides à surveiller ne doivent pas contenir de fortes pollutions

ou de particules grossières et ne doivent pas avoir tendance à se

cristalliser. Il faut s‘assurer que les matériaux de l‘interrupteur (flotteur,

tube de glissement) au contact du milieu résistent suffisamment au

milieu à surveiller.

WIKA Mode d‘emploi interrupteurs magnètiques à flotteur Type RSM et HIF

24

13333283.01 01/2010 GB/D/F

Page 25

3. Montage

3. Montage

Exécutions pour un montage à la verticale (fig. 1)

Monter les interrupteurs magnétiques à flotteur WIKA conformé-

ment à l‘exécution (bride ou filetage [3])

Pour les exécutions à bride, il convient d‘utiliser les vis et les

écrous adaptés à la bride. Pour étouper, il convient de prévoir un

joint adéquat (4)

Veiller à ce que la position de montage soit correcte. (Ecart

maximal par rapport à la verticale ± 30°)

En présence d‘ouvertures de montage plus petites que le dia-mètre

du flotteur, il convient d‘enlever le flotteur (7) avant le montage de

l‘interrupteur

Dans la mesure où les flotteurs ne portent pas de marquage, la

position de montage adéquate (par exemple en "haut") doit être

indiquée

Il convient de marquer la position des bagues de réglage (6) avant

l‘enlèvement

Après avoir monté l‘interrupteur magnétique à flotteur, il convient

de replacer le flotteur à l‘intérieur du réservoir

Les bagues de réglage (6) doivent être ensuite fixées de nouveau

au même endroit

Le nombre de flotteurs ainsi que la position des anneaux de règla-

ge dèpendent de la position et du nombre des contacts

Exécutions pour un montage à l‘horizontale (fig. 2)

Les interrupteurs magnétiques à flotteur destinés à un montage à

l‘horizontale doivent être montés conformément à la figure 2.

Pour les exécutions à bride, il convient d‘utiliser les vis et les écrous

adaptés à la bride. Pour étouper, il convient de prévoir un joint

adéquat (4). Veiller à ce que la position de montage soit correcte. (Le

flotteur doit être basculé vers le bas à l‘état non actionné).

Pour un montage dans des tubulures, il faut assurer que le flotteur ne

soit pas gêné dans son mouvement de basculement

F

WIKA Mode d‘emploi interrupteurs magnètiques à flotteur Type RSM et HIF

13333283.01 01/2010 GB/D/F

25

Page 26

1. Funktionsbeschreibung / 2. Einsatzbereich

F

Le montage dans des tubes ferromagnétiques entraîne

un mauvais fonctionnement du commutateur. Danger de

dommages matériels en raison de mauvaises commutations du contact reed.

Le commutateur du flotteur doit être monté de telle sorte

que la tubulure de contact se trouve à l‘extérieur d‘un tube

ferromagnétique.

4. Raccordement électrique

Il faut respecter les dispositions relatives aux installations électriques en vigueur dans le pays d‘exécution. Seul

le personnel spécialisé est autorisé à travailler sur les

installations électriques. our augmenter la durée de vie des

contacts, nous recommandons le fonctionnement avec un

relais de protection des contacts.

Le raccordement électrique doit être réalisé conformément au

schéma des connexions apposé sur l‘interrupteur.

(Les exécutions avec un seul contact d‘ouverture ou de fermeture

n‘ont pas de schéma des connexions.)

WIKA Mode d‘emploi interrupteurs magnètiques à flotteur Type RSM et HIF

26

13333283.01 01/2010 GB/D/F

Page 27

3. Montage

Il convient de s‘en tenir aux prescriptions en vigueur pour les installations électriques dans le pays d‘installation.

Il convient d‘étouper le passe-câble (2) sur le boîtier de raccordement

(1).

L‘utilisation des interrupteurs magnétiques á flotteur

sous charge inductive ou capacitive peut provoquer la

destruction du contact reed. Ceci peut entraîner le mauvais

fonctionnement de la commande située en aval ainsi que

des dommages corporels ou matériels.

Sous charge inductive, les interrupteurs magnétiques

doivent être protégés par un circuit RC (voir annexe) ou par

une diode de dérivation.

En cas de charge capacitive, de conduites de plus de 50

m de long ou de raccord à des systèmes d‘automatisme

industriel à entrée capacitive, il faut monter en série une

résistance protectrice de 22 ohms ou de 47 ohms (avec

des contacts de 10 VA) afin de limiter de courant de crête.

Une résistance de 220 Ohm montée en série doit être utilisée lors d’un raccordement à un minuteur éléctronique.

F

WIKA Mode d‘emploi interrupteurs magnètiques à flotteur Type RSM et HIF

13333283.01 01/2010 GB/D/F

27

Page 28

1. Funktionsbeschreibung / 2. Einsatzbereich

Une surcharge du commutateur magnétique peut provoquer la destruction du contact reed intégré. Ceci peut

entraîner le mauvais fonctionnement de la commande

située en avai ainsi que des dommages corporels ou

matériels. Il faut respecter les valeurs maximales de

puissance de rupture indiquée dans le chapitre „Données

techniques“ ainsi que dans la fiche technique WIKA.

F

Avec des interrupteurs magnétiques á flotteur à boîtier

métallique sans prise de terre, le boîtier peut être sous

tension en cas de perturbation. De graves lésions corporelles ou des blessures mortelles sont possibles en cas

de contact. Ces commutateurs ne peuvent être utilisés

qu‘avec une basse tension de protection selon VDE 0100

(WIKA relais de protection des contacts) ou bien doivent

être montés de telle sorte que le boîtier du interrupteur

magnétique á flotteur soit relié à une compensation de

potentiel.

5. Mise en service / contrôle fonctionnel

Mettre la tension d‘alimentation du dispositif de commande

raccordé en circuit. Remplir le réservoir et vérifier le fonctionnement

des points de commutation de l‘interrupteur magnétique à flotteur.

Le contrôle fonctionnel peut aussi être réalisé manuellement lorsque

l‘interrupteur est démonté. Ce faisant, il convient de veiller à ce

qu‘aucun déroulement de processus ne soit involontairement déclenché.

AVERTISSEMENT !

Il faut s‘assurer que le contrôle de fonctionnement ne

déclenche pas une étape de process involontaire.

WIKA Mode d‘emploi interrupteurs magnètiques à flotteur Type RSM et HIF

28

13333283.01 01/2010 GB/D/F

Page 29

3. Montage

6. Entretien

A condition d‘être utilisés de manière conforme, les interrupteurs

magnétiques à flotteur fonctionnent sans usure et ne nécessitent pas

d‘entretien.

En cas de conditions d‘utilisation extrêmes, l‘interrupteur devrait être

soumis à un contrôle visuel dans le cadre des révisions à réaliser.

7. Remarques

Pour une exploitation dans la zone explosive 1 ou 2, les contacts

Reed doivent être exploités sur des circuits de courant à sécurité

intrinsèque.

Les interrupteurs à flotteur en matière plastique n‘ont pas le droit

d‘être utilisés dans la zone explosive 1 ou 2.

Ne pas utiliser les interrupteurs à flotteur à proximité directe de

puissants champs électromagnétiques (distance minimale: 1 m).

Ne pas changer le positionnement des bagues de réglage ou ne pas

les enlever du tube de glissement.

Les points de commutation des interrupteurs magnétiques à flotteur

ne peuvent pas être déréglés.

Les interrupteurs magnétiques à flotteur ont uniquement le droit d‘être

utilisés dans des milieux contre lesquels le matériau du tube de glissement et du flotteur est résistant.

F

Les interrupteurs n‘ont pas le droit d‘être soumis à de fortes sollicitations mécaniques (chocs, torsion, vibration).

WIKA Mode d‘emploi interrupteurs magnètiques à flotteur Type RSM et HIF

13333283.01 01/2010 GB/D/F

29

Page 30

1. Funktionsbeschreibung / 2. Einsatzbereich

8. Caractéristiques techniques

Fonction de contact: ouverture / fermeture

Tension commutée: 250 V AC / DC

Courant commuté: 2 A AC / 1 A DC

Pouvoir de coupure: 100 VA, cosφ >0,7 / 50 W

Fonction de contact: inverseur

F

Tension commutée: 250 V AC / DC

Courant commuté: 1 A AC / 0,5 A DC

Pouvoir de coupure: 40 VA, cosφ > 0,7 / 20 W

Mini régulateurs de niveau

Fonction de contact: ouverture / fermeture

Tension commutée: 250 V AC / DC

Courant commuté: 0,5 A AC / 0,25 A DC

Pouvoir de coupure: 10 VA , cosφ > 0,7 / 5 W

WIKA Mode d‘emploi interrupteurs magnètiques à flotteur Type RSM et HIF

30

13333283.01 01/2010 GB/D/F

Page 31

3. Montage

9. Circuits RC de protection de contacts

Selon la tension d’alimentation, les circuits RC de protection de

contacts listés dans le tableau ci-dessous doivent être utilisés.

L’utilisation d’autres circuits RC conduit à la destruction des

contacts à lame souple.

F

Pour contacts à lame souple de

10 à 40 VA

Capa-

cité

µF

Rési-

stance

Ohm

Tensi-

on

V~

TypeACapa-

Pour contacts à lame souple de

40 à 100 VA

cité

µF

Rési-

stance

Ohm

Tensi-

on

V~

0,33 100 24 3/24 0,33 47 24 3/24

0,33 220 48 3/48 0,33 100 48 3/48

0,33 470 115 3/115 0,33 470 115 3/115

0,33 1500 230 3/230 0,33 1000 230 3/230

Fils de

raccordement

d = Ø16 ... Ø25 mm

I = 16 ... 58 mm

WIKA Mode d‘emploi interrupteurs magnètiques à flotteur Type RSM et HIF

13333283.01 01/2010 GB/D/F

Type

B

31

Page 32

F

WIKA Mode d‘emploi interrupteurs magnètiques à flotteur Type RSM et HIF

32

13333283.01 01/2010 GB/D/F

Page 33

Notes / Notizen / Notation

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

3333

Page 34

WIKA Global

Europe

Austria

WIKA Messgerätevertrieb Ursula

Wiegand GmbH & Co. KG, 1230 Wien

Phone: (+43) 1-86 91 631

E-mail: info@wika.at

www.wika.at

Benelux

WIKA Benelux, 6101 WX Echt

Phone: (+31) 475-535 500

E-mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD, 1309 Sofia

Phone: (+359) 2 82138-10

E-mail: t.antonov@wika.bg

Finland

WIKA Finland Oy, 00210 Helsinki

Phone: (+358) 9-682 49 20

E-mail: info@wika.fi

www.wika.fi

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Phone: (+33) 1-34 30 84 84

E-mail: info@wika.fr

www.wika.fr

Germany

WIKA Alexander Wiegand SE & Co. KG

63911 Klingenberg

Phone: (+49) 93 72-13 20

E-mail: info@wika.de

www.wika.de

Italy

WIKA Italia Srl & C. sas

20020 Arese (Milano)

Tel. (+39) 02 9386-11

Fax: (+39) 02 9386-174

E-Mail: info@wika.it

www.wika.it

34

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

Poland

WIKA Polska S.A., 87-800 Wloclawek

Phone: (+48) 542 30 11 00

E-mail: info@wikapolska.pl

www.wikapolska.pl

Romania

WIKA Instruments S.R.L., Bucuresti

Phone: (+40) 21-456 31 38

E-mail: m.anghel@wika.ro

Russia

ZAO WIKA MERA, 127015 Moscow

Phone: (+7) 495-648 01 80

E-mail: info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

11060 Belgrade

Phone: (+381) 11 27 63 722

E-mail: info@wika.co.yu

www.wika.co.yu

Spain

Instrumentos WIKA, S.A.

08280 Sabadell (Barcelona)

Phone: (+34) 90-290 25 77

E-mail: info@wika.es

www.wika.es

Switzerland

MANOMETER AG

6285 Hitzkirch

Phone: (+41) 41-919 72 72

E-mail: info@manometer.ch

www.manometer.ch

Ukraine

WIKA Pribor GmbH, 83016 Donetsk

Phone: (+38) 062 345 34 16

E-mail: info@wika.donetsk.ua

www.wika.donetsk.ua

13333283.01 01/2010 GB/D/F

Page 35

WIKA Global

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill RH13LG

Phone: (+44) 17 37 64 40 08

E-mail: info@wika.co.uk

www.wika.co.uk

North America

Canada

WIKA Instruments Ltd., Head Office

Edmonton, Alberta, T6N 1C8

Phone: (+1) 780-463 70 35

E-mail: info@wika.ca

www.wika.ca

Mexico

Instrumentos

Phone: (+52) 555 020 53 00

E-Mail ventas@wika.com.mx

www.wika.com.mx

USA

WIKA Instrument Corporation

Lawrenceville, GA 30043

Phone: (+1) 770-513 82 00

E-mail: info@wika.com

www.wika.com

South America

Argentina

WIKA Argentina S.A., Buenos Aires

Phone: (+54-11) 4730 18 00

E-mail: info@wika.com.ar

www.wika.com.ar

Brazil

WIKA do Brasil Ind. e Com. Ltda.

CEP 18560-000 Iperó - SP

Phone: (+55) 15-3266 16 55

E-mail: marketing@wika.com.br

www.wika.com.br

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

WIKA Mexico S.A. de C.V.

Africa/Middle East

Egypt

WIKA Alexander Wiegand GmbH &

Co. KG

Nasr City, Cairo

Phone: (+20) 2 2287 6219

E-mail: ahmed.azab@wika.de

South Africa

WIKA Instruments (Pty.) Ltd.

Gardenview, Johannesburg 2047

Phone: (+27) 11-621 00 00

E-mail: sales@wika.co.za

www.wika.co.za

United Arab Emirates

WIKA Middle East FZE

Jebel Ali, Dubai

Phone: (+971) 4 - 883 9090

E-mail: wikame@emirates.net.ae

Asia

China

WIKA International Trading

(Shanghai) Co., Ltd.

Phone: (+86) 21 - 5385 2573

E-mail: info@wika.com.cn

www.wika.com.cn

India

WIKA Instruments India Pvt. Ltd.

Village Kesnand, Wagholi

Pune - 412 207

Phone: (+91) 20 - 6629 3200

E-mail: sales@wika.co.in

www.wika.co.in

Japan

WIKA Japan K. K.

Tokyo 105-0023

Phone: (+81) 3-54 39 66 73

E-mail: t-shimane@wika.co.jp

3535

Page 36

WIKA Global

Kazakhstan

TOO WIKA Kazakhstan

050050 Almaty

Phone: (+7) 32 72 33 08 48

E-mail: info@wika.kz

Korea

WIKA Korea Ltd.

Seoul 153-023

Phone: (+82) 2 - 8 69 05 05

E-mail: info@wika.co.kr

Malaysia

WIKA Instrumentation (M) Sdn. Bhd.

Selangor Darul Ehsan

Phone: (+60) 3 - 56 36 88 58

E-mail: info@wika.com.my

www.wika.com.my

Weitere WIKA Niederlassungen weltweit finden Sie online unter www.wika.de.

Further WIKA subsidiaries worldwide can be found online at www.wika.de.

La liste des autres filiales WIKA dans le monde se trouve sur www.wika.de

Technical alteration rights reserved.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

Singapore

WIKA Instrumentation Pte. Ltd.

569625 Singapore

Phone: (+65) 68 44 55 06

E-mail: info@wika.com.sg

www.wika.com.sg

Taiwan

WIKA Instrumentation Taiwan Ltd.

Pinjen, Taoyuan

Phone: (+886) 034 20 60 52

E-mail: info@wika.com.tw

www.wika.com.tw

Turkey

WIKA Alexander Wiegand GmbH &

Co. KG

Türkiye irtibat bürosu

Maltepe - Istanbul

Phone: (+90) 216/305 4624

h.kizilkaya@wika.com.tr

http://www.wika.com.tr

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel (+49) 93 72/132-0

Fax (+49) 93 72/132-406

E-Mail info@wika.de

www.wika.de

36

WIKA Betriebsanleitung Schwimmer-Magnetschalter Typ RSM und HIF

13333283.01 01/2010 GB/D/F

Loading...

Loading...