Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

EN

DE

FR

ES

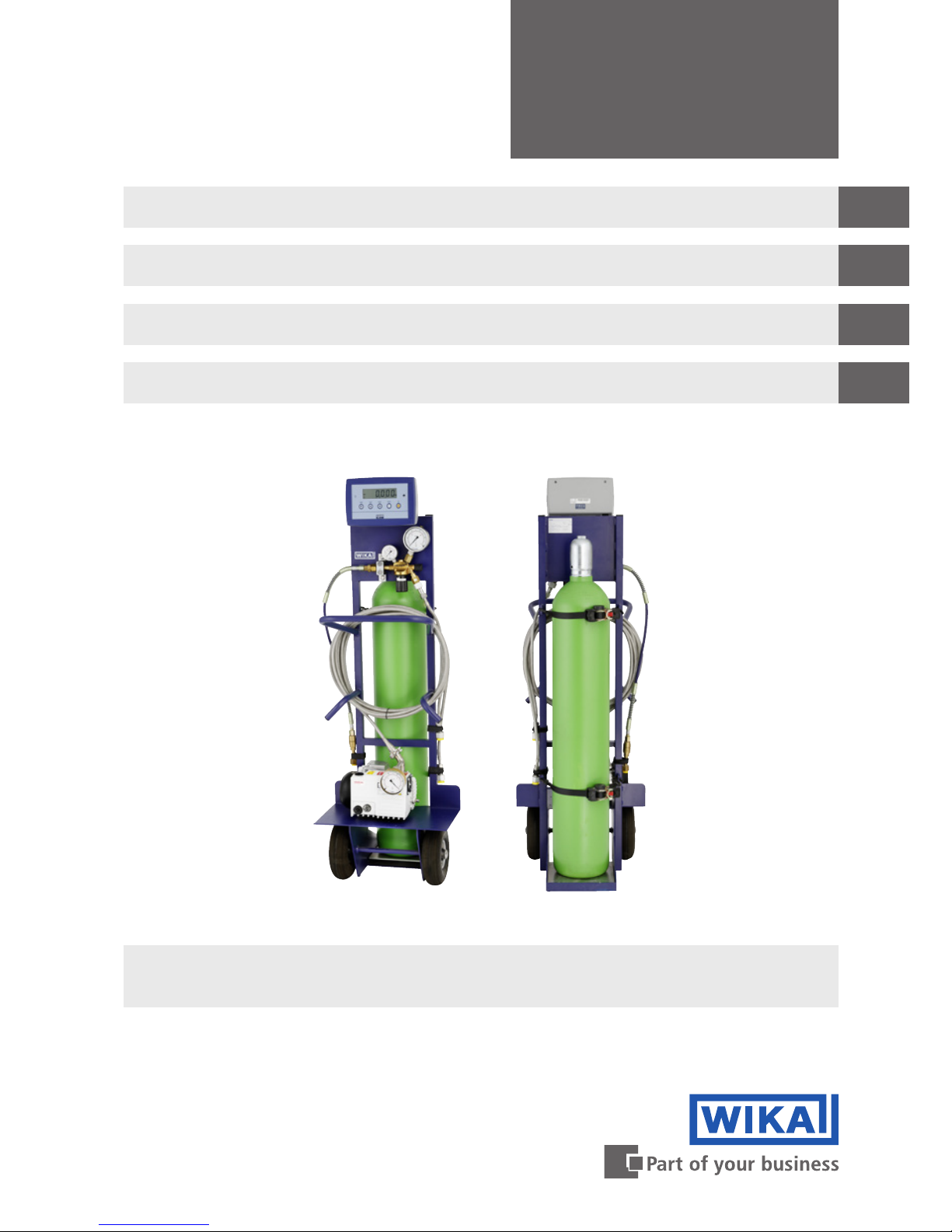

SF₆ gas filling cart, model GFU08

SF₆-Gas Füllwagen, Typ GFU08

Chariot de remplissage de gaz SF₆, type GFU08

Carro de servicio para gas SF₆, modelo GFU08

SF₆ gas filling cart, model GFU08

Page 2

2

14033074.01 11/2018 EN/DE/FR/ES

WIKA operating instructions SF₆ gas filling cart, model GFU08

EN

DE

FR

ES

Operating instructions model GFU08 Page 3 - 38

Betriebsanleitung Typ GFU08 Seite 39 - 74

Mode d'emploi type GFU08 Page 75 - 110

Manual de instrucciones modelo GFU08

Página 111 -146

© 11/2018 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA

®

is a registered trademark in various countries.

WIKA

®

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

Page 3

3

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

Contents

1. General information 4

2. Safety 5

3. Specications 16

4. Design and function 18

5. Transport, packaging and storage 19

6. Commissioning, operation 20

7. Display unit 24

8. Instrument messages during operation 33

9. Maintenance and cleaning 35

10. Faults 36

11. Dismounting and disposal 38

Contents

Page 4

4

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

1. General information

1. General information

■

The SF6 gas lling cart described in the operating instructions has been designed

and manufactured using state-of-the-art technology.All components are subject to

stringent quality and environmental criteria during production. Our management

systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the

instrument. Working safely requires that all safety instructions and work instructions

are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument’s range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by using

the product contrary to its intended use, non-compliance with these operating

instructions, assignment of insuciently qualied skilled personnel or unauthorised

modications to the instrument.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de/sf6, www.wika.com/sf6

- Relevant data sheet: SP 63.08

- Application consultant:

Tel.: (+49) 9372/132-8971

E-mail: sf6-sales@wika.de

Page 5

5

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

2. Safety

2. Safety

2.1 Importance of these operating instructions

■

These operating instructions contain important information on handling the SF6 gas

lling cart. Working safely requires that all safety instructions and work instructions

are observed. Non-compliance can lead to hazardous situations.

■

Pass the operating instructions on to the next operator or owner of the SF6 gas lling

cart.

■

Before any operation, the operator must ensure that personnel have carefully read

the operating instructions and material safety data sheets.

■

The safety instructions relevant for the task can be found at the start of the respective

chapters (e.g. transport, commissioning, ...)

2.2 Explanation of symbols

DANGER!

... indicates a directly dangerous situation resulting in serious injury or

death, if not avoided.

DANGER!

... identies hazards caused by electrical power. Should the safety

instructions not be observed, there is a risk of serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation that can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light

injuries or damage to property or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient

and trouble-free operation.

Page 6

6

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

2. Safety

Handling instructions

2. 3. Sequence of operations

Handling instructions must be carried out in the specied order.

▶

Handling instructions

Handling instructions without specied order.

⇒

Result

Describes the result of an operation.

→ Cross reference

Refers to another section in the operating instructions.

2.3 Intended use

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly. The manufacturer shall not be liable for claims of any

type based on operation contrary to the intended use.

Intended use

The SF

6

gas filling cart is used for filling and refilling SF6 gas into gas-tight tanks

provided and authorised for this purpose. The filling pressure can be set on the built-in

pressure reducer.

The model GFU08-W and GFU08-C SF

6

gas filling carts include, in addition, scales for

the measurement of the transferred mass of SF

6

gas.

Model GFU08-E or GFU08-C includes an additional vacuum pump, with which the gas

compartment can be evacuated before filling it.

Make sure that the vacuum pump is only used to pump out the air and not the SF

6

gas.

Application areas

Only use the SF₆ gas filling cart in applications that lie within its technical performance

limits (e.g. max. ambient temperature, material compatibility, ...).

→ For performance limits see chapter 3 “Specifications”.

The SF₆ gas filling cart is suitable for indoor and outdoor use. For safe operation, the

installation location must fulfil the following requirements:

■

Installation location is always supervised by skilled personnel or is not openly

accessible.

■

The foundation must be horizontal and level.

■

Non-explosive atmosphere.

■

Atmosphere must not be corrosion-inducing.

■

The atmosphere must not contain high levels of dust.

■

No operation outdoors during rain or electrical storms (IP20).

■

The installation location must offer sufficient space to enable safe operation.

Operating and maintenance personnel must be able to move freely around the

instrument.

■

The maximum permissible ambient temperature must not be exceeded.

Page 7

7

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

2. Safety

SF6 gas filling cart with scales (model GFU08-W or GFU08-C):

■

Handle electronic components with the required care (protect from humidity, impacts,

strong magnetic elds, static electricity and extreme temperatures, do not insert any

objects into the instrument or its openings). Plugs and sockets must be protected

from contamination.

■

If the instrument is transported from a cold into a warm environment, the formation

of condensation may result in instrument malfunction. Before putting it back into

operation, wait for the instrument temperature and the room temperature to equalise.

The technical specifications contained in these operating instructions must be

observed. Improper handling or operation of the instrument outside of its technical

specifications requires the instrument to be taken out of service immediately and

inspected by an authorised WIKA service engineer.Unauthorised alterations by the

operator are not permitted, especially on safety devices. Unauthorised alterations could

result in the improper functioning of safety equipment and result in life-threatening

situations.

WIKA is not liable for changes made by persons who have not been authorised by WIKA.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

Technical restrictions

The technical specications contained in these operating instructions must be

observed. Improper handling or operation of the instrument outside of its technical

specications requires the instrument to be taken out of service immediately and

inspected by an authorised WIKA service engineer.Technical specications:

→ Siehe Kapitel 3 “Specications”.

2.4 Responsibility of the operator

The instrument is used in the industrial sector. The operator is therefore responsible for

legal obligations regarding safety at work.

The safety instructions within these operating instructions, as well as the safety, accident

prevention and environmental protection regulations for the application area must be

maintained.

The operator is obliged to maintain the product label in a legible condition.

To ensure safe working on the instrument, the operating company must ensure

■

that suitable first-aid equipment is available and aid is provided whenever required.

■

that the operating personnel are regularly instructed in all topics regarding work

safety, first aid and environmental protection and know the operating instructions and

in particular, the safety instructions contained therein.

■

that the instrument is suitable for the particular application in accordance with its

intended use.

■

that personal protective equipment is available.

Page 8

8

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

2. Safety

2.5 Personnel qualification

All work on and with the SF

6

gas filling cart should only be carried out by trained and

authorised personnel.Observe the applicable national regulations, especially with

respect to hazardous materials and the qualification of personnel.

For training please contact the application consultant.

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

Transport

Observe the applicable national regulations, especially with respect to hazardous

materials and the qualication of personnel.

Operation

Observe the applicable national regulations, especially with respect to hazardous

materials and the qualication of personnel.

In Europe, operating personnel must be qualied in accordance with the following

regulations:

■

F-gas regulation (EU) 517/2014

■

Regulation (EC) 305/2008

Maintenance

The maintenance tasks described in these operating instructions must only be carried

out by personnel who have been authorised by the operator. Maintenance tasks which

are described in the operating instructions of sub-components should be carried out in

accordance with their specications and instructions.

Use in high-voltage plants

The plant operator must ensure that the handling of SF₆ gas is only carried out by

a qualified company or by qualified persons who have been specifically trained in

accordance with IEC 61634, section 4.3.1 or IEC 60480, section 10.3.1.

In the European Union, any activity related to fluorinated greenhouse gases must be

carried out by certified skilled personnel. The certification must be made in accordance

with Regulation (EC) No. 305/2008.

2.6 Additional safety instructions for use in switchgear

The operator must ensure that the SF

6

gas is handled by a company qualified for this or

by employees trained in accordance with IEC 61634 chapter 4.3.1 and IEC 60480

chapter 10.3.1.

Valid standards for SF

6

gas

■

Installation, construction, commissioning:

IEC 61634 (handling of SF

6

),

IEC 60376 (new SF

6

, technical SF6),

IEC 60480 (used SF

6

),

CIGRE report 276, 2005 (Practical SF

6

handling instructions)

Page 9

9

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

2. Safety

■

Leakages during operation:

IEC 60376 (new SF

6

, technical SF6),

IEC 60480 (used SF

6

),

CIGRE 2002 (“SF

6

in the Electric Industry”)

■

Repairs and maintenance:

IEC 61634 (Use and handling of SF

6

in high-voltage switchgear and control gear),

CIGRE 1991 (Handling of SF6),

CIGRE report 276, 2005 (Practical SF

6

handling instructions),

CIGRE report 163, 2000 (Guide for SF6 gas mixtures)

SF

6

is a colourless and odourless, chemically neutral, inert and

non-ammable gas which is approx. 5 times heavier than air, not toxic

and not harmful to the ozone layer. Detailed information is given in

IEC 60376 and IEC 61634.

2.7 Personal protective equipment

The personal protective equipment is designed to protect the personnel from hazards

that could impair their safety or health during work. When carrying out the various

tasks on and with the SF

6

gas filling cart, the personnel must wear personal protective

equipment.The personal protective equipment specified here is related exclusively

to the product described. Further requirements which arise from the environmental

conditions at the place of use, other products or linking with other products have not

been taken into consideration here.The requisite personal protective equipment must be

provided by the operating company.

The operator is in no way relieved of his obligations under labour law for the safety and

the protection of workers' health.

The design of the personal protective equipment must take into account all operating

parameters of the place of use.

For a safe handling of the SF

6

gas filling cart, the following personal protective

equipment is required:

Safety shoes

The safety shoes must be worn over the entire period when working on

gas containers (e.g. gas cylinders, tanks). The safety shoes protect the

feet from falling items and liquid splashes.

Safety goggles

The safety goggles must be worn over the entire period when working on

hoses or gas containers (e.g. gas cylinders, tanks).

The safety goggles protect the eyes from any flying particles, escaping

gas and liquid splashes.

Page 10

10

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

2. Safety

Protective gloves

Based on the gas properties, it is possible that the gas, due to the quick

expansion, gets very cold if the cylinder is opened very quickly.

Wear protective gloves to protect from freezing.

If, with an operator risk analysis, contaminated gases should be detected, for

any subsequent maintenance operations, protective measures appropriate to the

contamination should be taken.

Respirator

For maintenance work, the respirator must correspond to the protection

level specified for the corresponding gas in the material safety data sheet.

Protective suit

For maintenance operations, specific protective clothing must be worn

during the entire duration. The protective clothing protects the body from

contaminated SF₆ gas. The operator must select the specific protective

clothing correspondingly.

General safety instructions

Contents of the general safety instructions

This chapter deals with the general safety in the handling of SF

6

gas and the SF6 gas

lling cart. The safety instructions relevant for the task can be found at the start of the

respective chapters (e.g. transport, commissioning, ...) and must be followed.

Handling SF₆ gas

SF₆ gas is a greenhouse gas which is listed in the Kyoto Protocol. SF6 gas must not be

released into the atmosphere, but must be collected in suitable containers.

Properties of SF6 gas

■

Colourless and odourless

■

Chemically neutral

■

Inert

■

Not flammable

■

Five times heavier than air

■

Non-toxic

■

No damage to the ozone layer

Detailed information is given in IEC 60376 and IEC 61634.

Risk of asphyxiation through SF6 gas

High concentrations of SF₆ gas can lead to asphyxiation, since breathable air is

displaced from the lungs with the inhalation of SF₆ gas.Since SF₆ gas is heavier than air,

it collects, especially, at ground level or lower-lying rooms below the reference level (e.g.

cellars). This is particularly dangerous since SF6 gas is colourless and odourless and

thus may be imperceptable to people.

Page 11

11

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

2. Safety

Danger caused by decomposition products

SF₆ gas in electrical systems may contain decomposition products generated by electric

arcs:

■

Gaseous sulphur fluoride

■

Sulphur hexafluoride

■

Solid and atomized metal fluorides, metal sulfides, metal oxides

■

Hydrogen fluoride

■

Sulphur dioxide

Decomposition products can be harmful to health.

■

They can cause poisoning by inhalation, ingestion or contact with the skin.

■

They may be irritating to the eyes, the respiratory system or the skin and burn them.

■

Inhalation of large quantities may damage the lungs.

Observe the following safety instructions in order to avoid danger from SF₆ gas:

■

Wear personal protective equipment.

■

Read the material safety data sheet of the gas supplier.

■

Ensure good ventilation.

■

Ensure the leak tightness of the equipment with a gas detector (e.g. model GIR-10).

Use of accessories and spare parts

It is recommended to use original accessories and original spare parts from WIKA.

Using accessories and spare parts from third parties can lead to damage to the

instrument or accidents, due to quality defects or other reasons.WIKA assumes no

liability for damage or accidents caused by a malfunction or unsuitability of accessories

and spare parts which do not originate from WIKA (e.g. unsealed connecting parts). No

guarantee claims can be made which arise due to a malfunction or unsuitability of any

accessory or spare part from a third party.

Danger of tripping due to improper installation of connections

Improperly installed connections such as cables, hoses or pipelines can create tripping

hazards, and can cause serious injury.

Route the connections so that no tripping sources are present. Mark unavoidable

tripping sources with yellow and black marker tape.

2.8 Residual risks

What are residual risks?

The instrument has been designed so that no personnel are exposed to preventable

risks. Particular hazard points are protected through specific protective systems.

In the operating instructions, the safety instructions refer to these hazard points and the

necessary behaviour of the personnel in order to minimise risks arising from the hazard

points.

Page 12

12

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

2.9 Regular safety inspection

The operator is responsible for checking the instrument at least once a year or after

specific incidents. The checking should only be carried out by authorised and trained

personnel from WIKA or WIKA partner companies.

At the same time, a complete testing of the technical condition with respect to accident

safety must be carried out. In addition, the instrument, including all components, must

be thoroughly examined for damage.

The operator must ensure the immediate rectification of defects.

2. Safety

Page 13

13

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

2. Safety

2.10 Special hazards

DANGER!

Danger to life caused by electric current

Upon contact with live parts, there is a direct danger to life.

■

The instrument may only be installed and mounted by skilled

personnel.

■

Operation using a defective power supply unit (e.g. short circuit from

the mains voltage to the output voltage) can result in life-threatening

voltages at the instrument!

WARNING!

■

The wetted parts have been designed exclusively for SF6 gas or, if an

adapter (available as an option) is used, also for N

2

.

■

The lines with mounted lling hose are pre-lled with SF6 gas. The

pressure of the transport lling is approx. 200 mbar (2.9 psi) SF

6

gas.

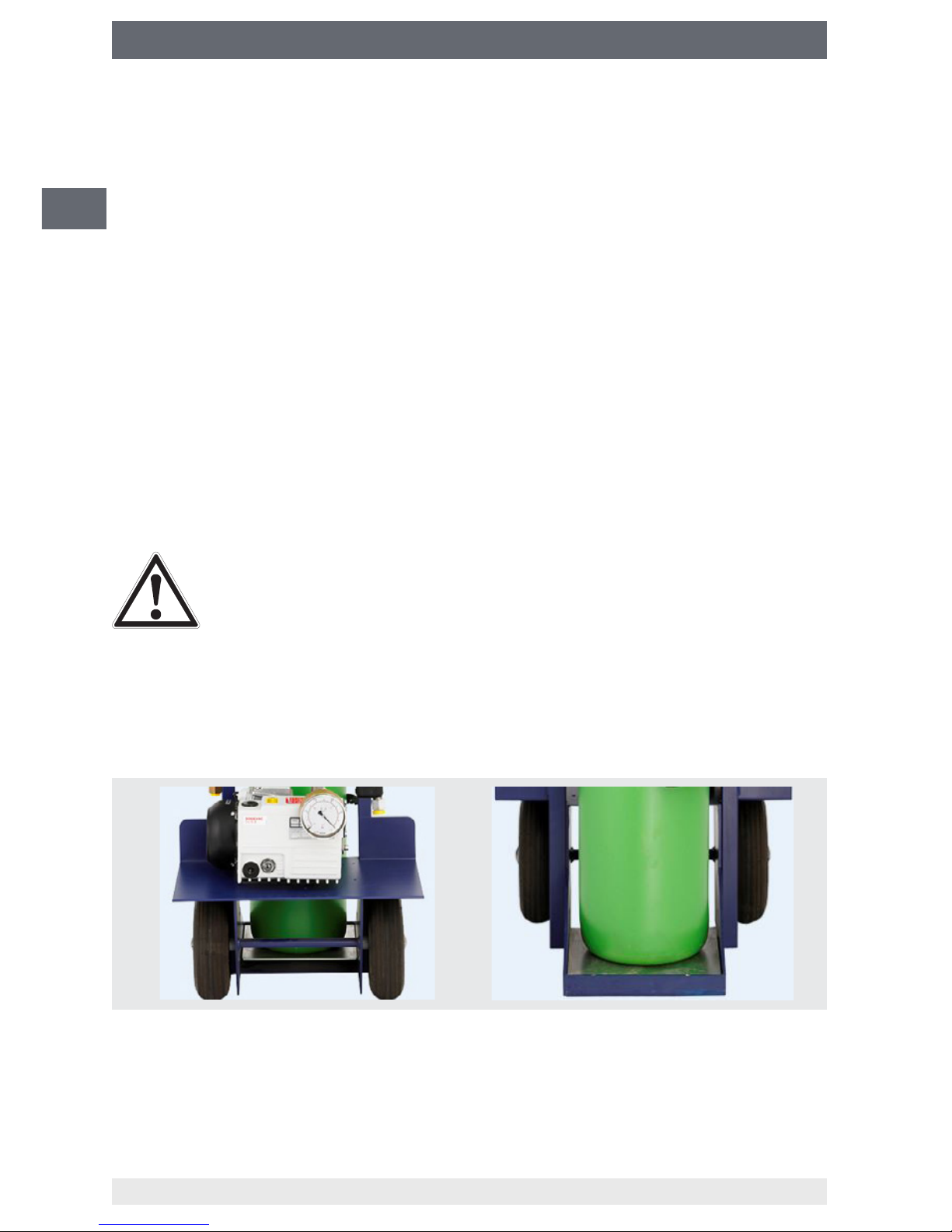

Models GFU08-E, GFU08-C

WARNING!

■

Only skilled electrical personnel are allowed to wire electrical

connections

■

After a correct commissioning, the SF6 gas lling cart should only be

moved in the upright position. Otherwise oil may leak out of the case.

■

For evacuation using the vacuum pump, only use the hose delivered

with the unit

■

Do not operate the SF6 gas lling cart in the rain or in a damp

environment

■

Check the oil level of the vacuum pump at regular intervals and adjust

it, if necessary

■

Do not use the vacuum pump to pump out SF6 gas

Page 14

14

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

2. Safety

Date of manufacture

Model GFU08-E: Filling cart with vacuum pump

Date of manufacture

■

To accelerate the lling process from the SF6 gas cylinder, the SF6 gas

cylinder can be heated up. Only use an appropriate cylinder heater.

■

To check the leak tightness of the cylinder connection, an SF6 gas leak

detector, e.g. model GIR-10, should be used at regular intervals

■

For the models GFU08-E and GFU08-C, an appropriate vacuum pump

oil (see operating instructions of the vacuum pump) must be stocked

up in order to maintain the required oil level by lling it up, if necessary.

2.11 Labelling / Safety marks

Product label model GFU08-B:

Model GFU08-W lling cart: Filling cart with scales

Model GFU08-C: Filling cart with scales and vacuum pump

Date of manufacture

Page 15

15

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

2. Safety

Model description Scales:

Article number

Rated load

Serial number

Maximum loading

Pressure reducer:

Battery type

Maximum input pressure Vacuum pump:

Maximum output pressure

Model description

Date of manufacture

Explanation of symbols

Before mounting and commissioning the instrument, ensure you

read the operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European

directives.

Page 16

16

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

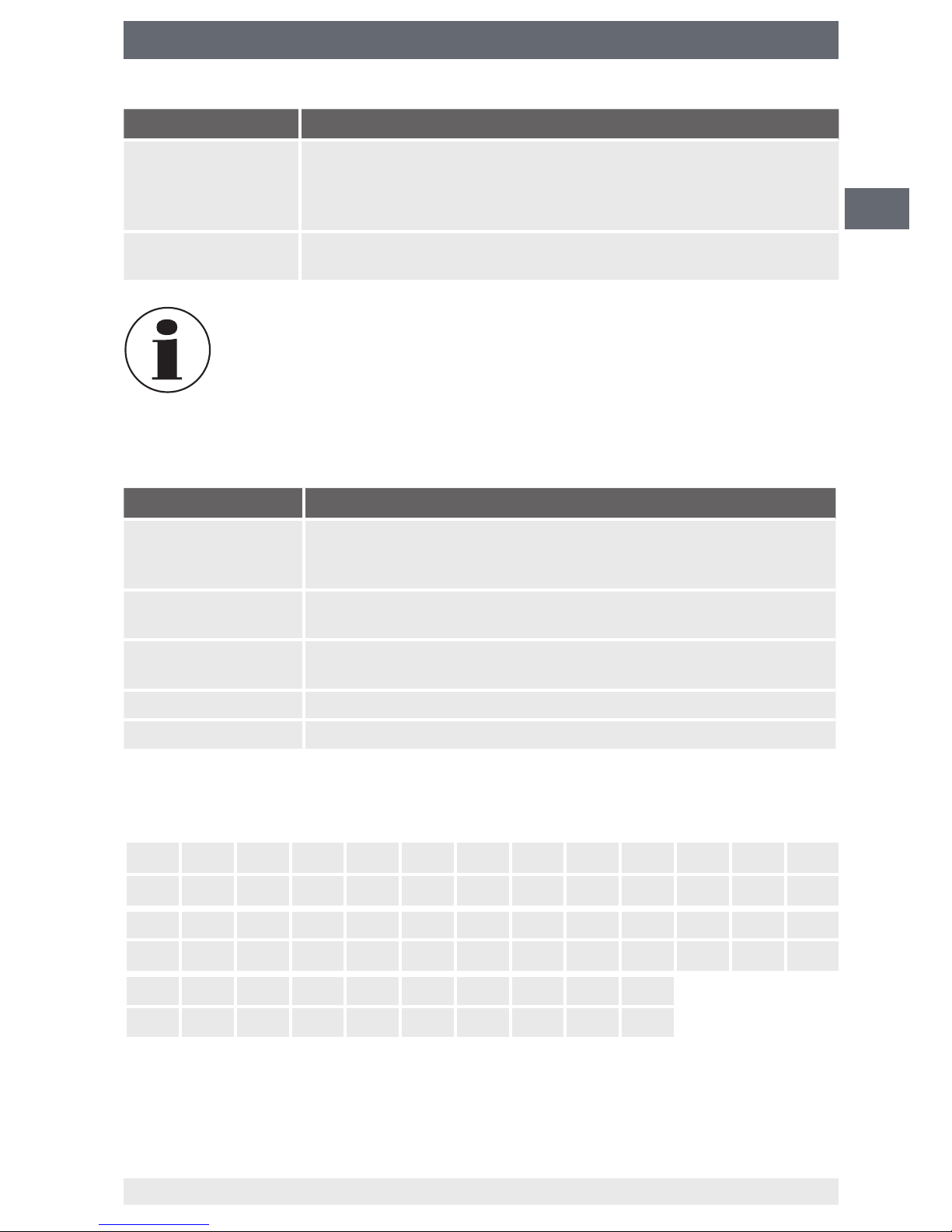

3. Specications

3. Specifications

Filling cart

Gas cylinder

connection

W 21.8 x 1/14" connector DIN 477 (others optional)

Connecting hose with bend protection; length 0.8 m (31.5")

Max. initial pressure 200 bar (2,900 psi)

Max. output pressure 10 bar (145 psi)

Gas cylinder tie-down 2 x self-storing ratchet strap 25 mm x 1.8 m (1" x 70"); marked per

EN 12195-2 for holding 250 daN each

optionally with chain

Filling hose 6 m (235") wire-braided stainless steel hose with DN 8 self-sealing

valves; other lengths optional

Rubber wheels Solid rubber 250 x 60 mm (9.8" x 2.4"); option:

Pneumatic tyres 260 x 85 mm (10.2" x 3.3")

Dimensions H x W x L: 1475 x 540 x 644 mm (58.1" x 21.3" x 25.4")

1)

Weight approx. 48 kg (105 lbs)

1) With models GFU08-W and GFU08-C: 1632 x 540 x 644 mm (64.3" x 21.3" x 25.4"), approx. 63 kg (138.9 lbs)

Models GFU08-W, GFU08-C

Scales

Rated load 125 kg (275 lbs)

Maximum load 200 kg (440 lbs)

Accuracy ±25 g (±0.02 % of the rated load), optionally ±10 g (±0.008 % of the rated

load)

Digital display 6-digit LCD display with LED backlighting

Rechargeable

battery

12 V battery pack (rechargeable NiMH)

Charger AC 110 ... 240 V, 50/60 Hz

Operating

environment

Ambient temperature: -10 ... +50 °C (14 ... 122 °F)

Air humidity: < 90 % non-condensing, IP65

Page 17

17

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

3. Specications

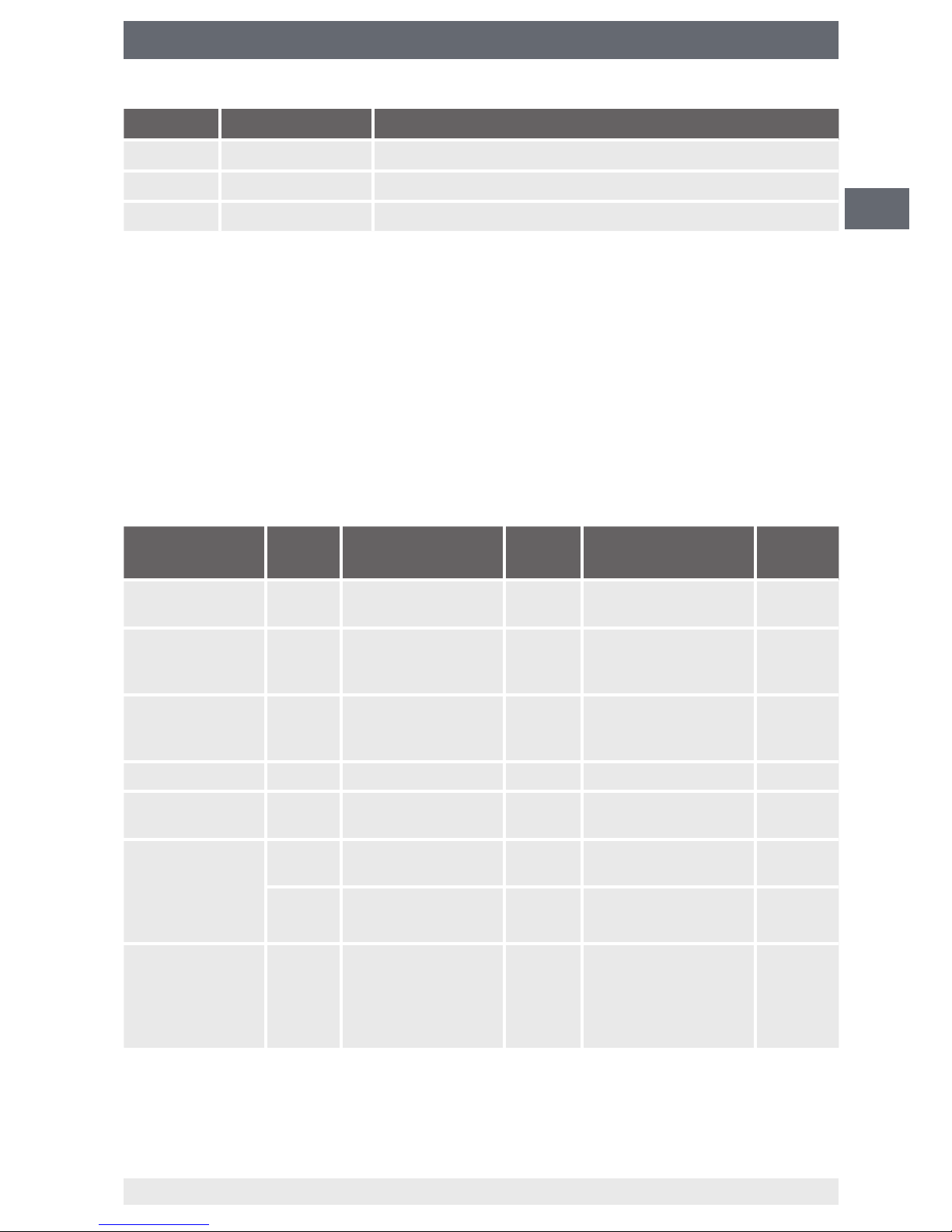

Models GFU08-E, GFU08-C

Vacuum pump

Model Working principle Nominal pumping

speed

Final partial pressure Weight

GVP-10

1)

Single-stage rotary

vane pump

9.0 m³/h

(5.9 cfm)

≤ 0.02 mbar

(≤ 0.015 Torr)

13 kg

(28.7 lbs)

S16

Single-stage rotary

vane pump

16.0 m³/h

(9.4 cfm)

≤ 1.0 mbar

(≤ 0.75 Torr)

20.5 kg

(45.3 lbs)

S25

Single-stage rotary

vane pump

26.0 m³/h

(15.3 cfm)

≤ 0.5 mbar

(≤ 0.4 Torr)

26.0 kg

(57.4 lbs)

S40

2)

Single-stage rotary

vane pump

44.0 m³/h

(25.9 cfm)

≤ 0.5 mbar

(≤ 0.4 Torr)

45.0 kg

(99.3 lbs)

D16

3)

Two-stage rotary vane

pump

18.9 m³/h

(11.1 cfm)

< 2.0 x 10-3 mbar

(< 1.5 x 10-3 Torr)

26.0 kg

(57.3 lbs)

D25

Two-stage rotary vane

pump

29.5 m³/h

(17.4 cfm)

< 2.0 x 10-3 mbar

(< 1.5 x 10-3 Torr)

32.0 kg

(70.6 lbs)

1) Standard

2) Model S40 only with three-phase supply (3-ph)

3) Photo on page 1 shows D16 + with oil lter and oil return

Voltage supply

Standard: 230 V, 50/60 Hz, 1-ph AC;

Option: 110 ... 120 V, 60 Hz 1-ph AC or 220 … 240/380 … 415 V, 50 Hz //

220 … 266/380 … 460 V, 60 Hz, 3-ph

Pressure measuring instrument

Robust pressure measuring instrument -1 … 0 bar, model 213.40 with forged brass case

Vacuum hose

6 m (235") wire-braided DN 8 stainless steel hose;

Optional: DN 20 hose and connections

other lengths optional

For further specications see WIKA data sheet SP 63.08 and the order documentation.

Page 18

18

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

4. Design and function

4. Design and function

4.1 Description

The GFU08 series of robust and modular gas cylinder transport carts are used for

the lling and relling of SF

6

gas in the required gas compartment. The modular

design enables worldwide application through the various mechanical and electrical

connections.

The model range is split into 4 versions:

■

Model GFU08-B: Filling cart

■

Model GFU08-W: Filling cart with scales

■

Model GFU08-E: Filling cart with vacuum pump

■

Model GFU08-C: Filling cart with scales and vacuum pump

Models GFU08-E and GFU08-C are tted with vacuum pumps. With these, the air is

extracted from the SF

6

gas compartments so that, afterwards, a professional SF6 gas

lling can be made. The 10 m³/h vacuum pump, built into the models GFU08-E and

GFU08-C as standard, enables a fast evacuation down to < 0.02 mbar (0.015 Torr).

For larger volumes, suction of up to 40 m³/h is available as an option. With 2-stage

pumps, the nal pressure can be reduced as far as 2 x 10

-3

mbar. The risk of either

too high humidity or air concentration in the SF

6

gas compartment is therefore not a

consideration.With the models GFU08-W and GFU08-C, gas cylinder scales are built

in, which enable the exact determination of the amount of SF

6

gas lled. Thus, the SF6

gas lling cart is an ideal tool for using the mass-balance method in accordance with the

IPCC directive for the preparation of emission reports.The special, at design of the load

cell under the gas cylinder allows easy loading and unloading of the heavy cylinder by

only one person.

4.2 Scope of delivery

Cross-check scope of delivery with delivery note.

Page 19

19

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

Check the SF

6

gas lling cart for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.Keep the packaging, as it provides

optimum protection during transport (e.g. change in operating site, sending for repair).

5.3 Storage

To store the optional components of vacuum pump or scales, the respective operating

instructions must be observed.

The SF

6

gas lling carts are tested for fault-free functioning and packed in our factory.

The connections are sealed with plastic protection caps or adhesive foil.

Unless otherwise stated, the protection caps and the adhesive foils must be removed

before commissioning.

■

Only store the SF6 gas lling cart in an upright position

■

Move the lling cart exclusively by means of the transport handle

Permissible conditions at the place of storage:

■

Storage temperature: 0 ... 60 °C

■

Humidity: 67 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, ammable atmospheres

Page 20

20

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

6. Commissioning, operation

6. Commissioning, operation

Commissioning must only be carried out by trained skilled personnel. The leak tightness

of the SF

6

gas filling cart has been completely checked ex works before delivery using

pure SF

6

gas at a transport pressure of approx. 200 mbar. This transport filling of approx.

200 mbar can be measured between the gas cylinder connection and initial pressure

gauge.

6.1 Explanation of terms

Self-storing

ratchet strap

Models GFU08-E, GFU08-C

Adapter

Connecting hose for

gas cylinders

Digital display

of the scales

(only model GFU08W/C)

Vacuum

pressure gauge

Initial pressure

gauge

Output pressure gauge

Handle for pressure

setting

Filling hose

Outlet valve

of pressure

reducer

Gas cylinder

valve

Vacuum suction

hose

Vacuum pump

Illustration with vacuum pump model D16,

other versions similar.

Page 21

21

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

6. Commissioning, operation

6.2 Commissioning the vacuum pump (models GFU08-E and GFU08-C)

The vacuum pump is delivered ex works without oil lling. Thus, before the rst start-up

of the vacuum pump, it should be lled with the accompanying oil. By unscrewing the oil

mist separator, the accompanying oil can be lled up to the height of the “middle sight

glass” in the vacuum pump which must be standing on the level.

The oil level must not lled beyond the “middle sight glass”. After lling the

oil, screw the oil mist separator back in.

To start the pump, the suction pipe must be opened. For this, remove the

cap (in addition, turn the stopcock to the setting “Flow”).

6.3 Evacuation of a gas compartment before filling it with SF

6

gas (models

GFU08-E and GFU08-C with vacuum pump)

■

Before switching on the vacuum pump, connect the vacuum suction hose to the

gas compartment and make sure that the connection is gas-tight and without leaks.

The gas compartment, lled with air, must not have a higher pressure than the

atmosphere.

■

In accordance with the operating instructions included from the manufacturer, the

vacuum pump must be operationally safe (oil level, power supply).

■

After switching on the vacuum pump, the pressure display will show the negative

pressure range smaller than 0 bar after a few seconds. If the pressure does not drop

below 0 bar, the vacuum pump must be switched o immediately.

→ See chapter 10 “Faults” for this.

■

Seal the gas compartment after the required nal pressure has been reached or after

the required pump-o time and make sure that it is gas-tight. Afterwards, switch the

vacuum pump o.

■

After switching o the vacuum pump, there should be no vacuum over a longer

period at the suction joint of the vacuum pump. Dismount the vacuum hose and

ventilate it.

6.4 Preparation of the SF

6

gas filling

6.4.1 Mounting the gas cylinder

CAUTION!

Use only appropriate adapters for the cylinder types to be connected! Risk

of accidents if unsuitable adapters are used.

■

After a successful evacuation, the gas outlet on the SF6 gas cylinder can be

connected properly and without leakage to the connecting hose of the gas cylinder

on the SF

6

gas lling cart by means of an adapter.

Page 22

22

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

6. Commissioning, operation

■

Protect the gas cylinder valve by an appropriate valve protection.

■

To test the leak tightness, a model GIR-10 leak detector or a comparable leak

detector must be used.

■

Close the outlet valve at the pressure reducer.

■

After opening the gas cylinder valve, the initial pressure is available at the pressure

reducer.

6.5 Filling and refilling of SF

6

gas

6.5.1 Connecting the filling hose

Establish a gas-tight connection between the SF

6

gas lling cart and the gas

compartment to be lled using the lling hose included.

6.5.2 Adjusting the pressure reducer

Use the pressure setting handle to set the pressure reducer to the desired output

pressure. For this, read the pressure on the output pressure gauge.

6.5.3 Weighing the quantity of the filled SF

6

gas (models GFU08-W and GFU08-C

with scales)

CAUTION!

Place the gas cylinder without the shunt forces of the fastening elements

(ratchet strap or chain) on the scale plate.

Secure the gas cylinder against falling over!

Place the SF

6

gas lling cart level on solid ground in order to make a precise weight

measurement.

Correct position of the gas cylinder on the scale plate:

Page 23

23

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

MODE

TARE

Press the TARE button on the digital display. The display shows 0.000 kg or 0.00 lbs,

depending on the set unit or number of decimal places.

6. Commissioning, operation

6.5.4 SF6 gas flows into the gas compartment

CAUTION!

Wear suitable gloves to protect your hands against frostbite.

■

Slowly open the outlet valve on the pressure reducer so that the SF6 gas can ow into

the gas compartment provided for this. Based on the gas properties, it is possible

that the gas, due to the quick expansion, gets very cold if the cylinder is opened very

quickly.

■

Fill the gas compartment according to the lling parameters indicated by the

manufacturer. Use suitable measuring devices.

■

Remove the lling hose from the gas compartment after having reached the lling

parameters.

6.5.5 Reading the filled gas quantity (models GFU08-W and GFU08-C with scales)

After the lling process, the quantity lled into the gas compartment is displayed with

negative sign on the digital display of the scales.

The MODE button can be used to switch between the complete weight and the TARE

weight (GROSS/NET).

Further information on the digital display of the scales: → See chapter 7 “Display unit”.

Page 24

24

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

7. Display unit

7.1 Display

7. Display unit

Lights up with external voltage supply

MODE button

Digital display

TARE button

C button

ZERO button

ENTER/PRINT button

Control light

Button Function

C/i

■

Switches the display unit on/off.

■

With numeric input, the current value is set to zero.

■

In SETUP: Leaves the step without confirming any change.

■

Displays the metric information: Capacity, graduations, minimum

weight for each configured range.

ENTER/PRINT

■

Enables the execution of a specific function, dependent on the

functionality selected in SETUP.

■

Numeric input: Confirmation of the input or change

■

In SETUP: Confirmation of the input, opening a parameter for

changing.

MODE

■

Enables the operating mode previously selected in SETUP.

■

With numeric input, one selects the value to be altered, from left to

right.

Page 25

25

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

Button Function

TARE

■

With a short press, the semi-automatic tare function will be executed.

■

After a longer press, a manual input can be made.

■

Annuls the negative tare value.

■

With numeric input, the figure will be increased.

ZERO

■

Annuls the negative tare value.

■

With a numeric entry, this reduces the number to be changed.

Settings in SETUP can only be carried out by WIKA personnel.

7.1.1 Numeric input

Via the five buttons of the display unit, a numeric value can be entered as follows:

Button Function

C/i

■

Short press: Displayed value will be set to zero.

■

Longer press: Return to weighing mode - without saving the

changes.

ENTER/PRINT

■

Confirms the entered value.

■

Quit input phase.

MODE

■

Select the figure to be changed (blinking).

■

Cursor moves from left to right.

TARE

■

Increases the selected figure.

ZERO

■

Reduces the selected figure.

7.1.2 Display

The letters and numbers on the display are represented as follows:

A B C D E F G H I J K L M

A B C D E F g h I J K L N

N O P Q R S T U V W X Y Z

n o P Q R S T u V W H Y 2

0 1 2 3 4 5 6 7 8 9

0 1 2 3 4 5 6 7 8 9

7. Display unit

Page 26

26

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

7.1.3 Automatic zero setting on start

If, during the start, a weight of ± 10 % of the nominal load/weighing capacity is

determined, an automatic zero setting is carried out. If the weight lies outside of this

range, the display on the display unit shows the current weight after a few moments.

7.1.4 Keylock

In order to prevent unwanted entries, the buttons of the display unit can be locked. The

settings for the keylock are made in SETUP.

Automatic keylock

The keypad will be locked after 15 seconds of inactivity in the weighing status (the

display indicates “LoC.key”).

Functions with keylock:

■

Switch the display unit off by pressing the C button for 10 seconds. Switches the

display unit back on.

■

Unlocking the keypad: Press the ZERO and ENTER/PRINT buttons one after the

other. (Display shows the message “unl.key”). By pressing any other button, the

display shows the message “Press Zero to unlock”. By pressing the ZERO

button, the display shows the message “now Press Print to unlock”.

Keylock via optional input

The keypad will be locked on closing the input and only unlocked again after opening it.

The display shows no message on locking/unlocking. If a button is pressed, the display

shows the message “LoCkin”.

7.2 Switching the display unit on

To switch the display unit on, press the C button until the display unit switches on.

Release the button.

Indication on the display after switching on:

Step Display Description

1

HH.YY

Indicates the installed software version.

2 Indicates all segments and symbols in the display.

3

NAH HHH.HHH

Weighing capacity of channel 1.

or

Naster

by selecting the function range “Nastr”.

or

ripE

by selecting the function range “rEpE”.

4

bt HHH

Indicates the charge status of the battery - “H” corresponds to

a number from 0 to 100.

5 Display of weighing capacity and scale divisions.

7. Display unit

Page 27

27

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

Step Display Description

6

hirES

Non-calibratable display unit.

or

LEGAL

Calibratable display unit.

7 Display unit performs countdown for self-checking.

7.2.1 Switching off

Keep the C button pressed until the message “-off-” is shown in the display.

In order to the switch the display unit off and then on again, keep the C button pressed

for 8 seconds. The display unit switches off and then automatically switches back on.

7.3 Zeroing the scales

If the gross weight lies within ± 2 % of the nominal load, it is possible to set the display

unit to zero by pressing the ZERO button. The display no longer indicates any weight

and the power-on lamp lights up, and symbols are shown on the display.

7.4 Function of the MODE button

Operating

modes

Button

Effect Button Effect Button

STANDARD MODE Change units

between kg and lb

NET/GROSS MODE Switching between

gross and net

weight

SETPOINT ENTER With model GFU-08

SF

6

gas lling cart,

without function

IN/OUT MODE Input weight ENTER Output weight

ALIBI MEMORY MODE Input of recall

number

ENTER Input of ID number ENTER

TOLERANCE

CHECK

MODE Input of target

weight

ENTER Input of minus

tolerance weight

>>>>>

ENTER Input of plus

tolerance weight

ENTER Input of minimum

weight

ENTER

PERCENT MODE Input of % value ENTER MODE button:

a) Changes % to

weight

MODE button 2 sec.:

b) Piece

7. Display unit

Page 28

28

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

Operating

modes

Button

Effect Button Effect Button

DISPLAY x 10 MODE Activates/deactiva-

tes the 10 x higher

resolution

HOLD MODE Activates/deactiva-

tes the weight/hold

function

PEAK MODE Activates/deactiva-

tes the peak value

display

TOTALISER MODE Total

Individual weighing

ENTER Total

ENTER 2 seconds: Overall

total

NUMBER OF

ITEMS

MODE Enters the number

of parts

ENTER MODE button:

a) Changes pieces to

weight

MODE button 2 sec.:

b) Piece

7.5 Tare function

With the tare function, before filling, the weight of the gas cylinder can be tared. With

this, the exact filling weight can be read off the display unit.

7.5.1 Semi-automatic taring

By pressing the TARE button, the weight resting on the scales is tared. The display

indicates “tArE” for a moment and then “0” (net weight). Semi-automatic taring only

occurs when the weight is at least one digit, is stable, and has a valid value, i.e. no

overload condition is allowed.

7.5.2 Taring via the keypad

1. Press the TARE button for a few seconds.

⇒

On the display is indicated: “- tn -”, then “000000”.

2

.

Enter the required value via the buttons.

→ see chapter 6.1.1 “Numerical input”.

3

.

Confirm with ENTER/PRINT button.

⇒

The value will be subtracted from the applied weight. The control light lights up.

7. Display unit

Page 29

29

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

7.5.3 Deleting the tare

The tare value can be cleared in the following ways:

■

Remove the load from the scales and press the TARE button (only with net weight at

zero and not negative)

■

Unload the scales and press the ZERO button

■

When using the tare function several times, one after the other, load the scales in

stages (each time press the TARE button once)

■

Press button C without unloading the scales

■

Enter “0” as the manual tare value

■

Tare value is deleted automatically (→ see chapter 6.5.4 “Tare locked/unlocked/

deactivated”)

7.5.4 Tare locked / unlocked / deactivated

Press the MODE button twice, one after the other, in order to set the tare type:

Display Description

loCK

Tar e locked:

If the tare value has been entered, on unloading the scales, the display shows

the value of the tare with a minus sign.With manual input of the tare value, or

adopting the value from memory, the net weight before the unloading of the

scales must be stable to at least two digits.

unloCk

Tar e unlocked:

The tare value will be deleted for each loading of the scales.

Auto

Automatic tare:

If a weight is placed on the empty scales, it is tared automatically only if there is

no existing tare and a stable gross weight of at least 5 g is present.

disAblE

Tar e deactivated:

All tare processes are deactivated.

The display stores the last values selected.

7.5.5 Limitations of the tare functions

For scales with a nominal load of 100 kg, all tare functions are switched off.

For scales with a nominal load/weighing capacity over 100 kg:

■

The value of the semi-automatic taring cannot, with a manual tare or from the

memory, be changed, i.e. the manual tare or from the memory can only be entered

for unladen scales and when the tare is 0.

■

The value of the taring can only be deleted with unladen scales if the ZERO button is

pressed or a manual taring of 0 is entered.

7. Display unit

Page 30

30

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

7.6 Automatic power-off

The “Automatic power-off” function is activated/deactivated via SETUP.

If the weighing platform is unladen, if the load is not moved or if, in the set time period

(1 to 255 minutes), no button is pressed, the display will show a blinking “-oFF-”. After

an audible signal, the display unit will automatically switch off.

7.7 Automatic stand-by function

The “Auto stand-by” function is activated/deactivated via SETUP.

The display unit is generally in stand-by mode (the display is switched off, except for the

decimal point). On pressing any button, the message “- on -” will be shown briefly. The

weight on the scales will be displayed for 30 seconds. After this time, the display unit will

return to the stand-by mode.

7.8 Setting the date/time

The display unit can be fitted with the date/time option or it could already be fitted. As

soon as the display unit is (for the first time) switched on, the display shows “CloCK”.The

setting of date and time is made in the SETUP area.

7.9 Print

If a printer is connected, there is the possibility to print the programmed weight data,

such as:

■

4 headers, each of 24 characters

■

Gross weight

■

Net weight

■

Number of print document

■

Hour and date (optional or as standard, depending on model)

■

Barcode from model 39

It is also possible to send the weight data to a PC via the printer port. This is achieved

via standard or extended string (parameter “ALL.Std/ALL.EHt o PrPC.St/PrPC.EH in

Pr.NodE”).

■

The print is confirmed by the display of the “PRinT” message in the display, or the

message “-tot-” in the case of totalising.

■

If the printing is no longer activated, the display shows the message “no.0.un.5”.

■

For unstable weights, the display shows the message “unStAb”.

■

If the gross or net weight is smaller than the required minimum load, after pressing

the ENTER/PRINT button, the display shows the error message “LoW”.

■

If the display unit has an under or overload, after pressing the ENTER/PRINT button,

the display shows the error message “un.oVEr”

.

7. Display unit

Page 31

31

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

7.9.1 Restoring the printing and display functions

During the use of the display unit, it is possible that the error “no.0.un5” is shown on

the display and a signal tone sounds. This means that the printing or the function to be

carried out must be re-enabled (in order to prevent unwanted applications).This function

is very useful in order to, for example, prevent a duplicate data output on the printer

or PC, or even a double summation.It is possible to define this restoration in different

ways in the SETUP area: “Returning the net weight over 0”, “Instability of the weight” or

“always”.

7.9.2 Display of the metric data

The display unit is fitted with the function “inFO”. Through this it is possible to display the

metric data of the scales:

▶

hold the C button down until the word “inFO” is shown on the display or

▶

press the MODE + C buttons

7.10 Selecting the operating mode

In addition to the standard weighing mode, tare deduction and the output of data, the

display unit can be switched to the following operating modes:

■

Changing over weight unit

■

Switching between gross/net

■

Input/output (“inout”)

7.10.1 Changing over the weight unit

By pressing the MODE button, it switches between kg and lb and vice versa.

▶

The calculation is carried out for the weight unit that is set during the

calibration.

▶

After changing the weight units over, the display unit must be

recalibrated.

7.10.2 Switching between GROSS/NET

If a tare has been entered, by pressing the MODE button, the gross weight is shown

on the display for 3 seconds.During the display of the gross weight, no printing can be

made.

7. Display unit

Page 32

32

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

7.10.3 Input/output (“inout”)

Simple weighing function in input/output mode: The operator selects two weight values

which the display acquires as input weight and as output weight. The electronics

calculate the difference between these two values and automatically prints out the data

(when a printer is connected).

In this operating mode, all tare procedures are deactivated

Performing the weighing function

1. Press the MODE button for the first weighing

⇒

Shown on the display: “--I---” accompanied by a long tone

2

.

Carry out the weighing.

3

.

Press the MODE button again for the second weighing.

⇒

Shown on the display: “--2---” accompanied by a long tone

4 Carry out the weighing.

5

⇒

Data is printed.

Annulling the weighing process

How to interrupt the weighing cycle:

1. Press the ENTER/PRINT button after completing the first weighing.

⇒

Shown on the display: “CLEARP” accompanied by a long tone

2

.

Press the ENTER/PRINT button in order to confirm the deletion of the first weighing.

OR

press any other button to continue with the second weighing - without deletion.

7. Display unit

Page 33

33

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

8. Instrument messages during operation

Display Description

2ERO

The scales are trying to effect a zero setting

AL.Err

The alibi memory is selected, but on starting the scales, no alibi memory is connected or the data communication between the display and the keypad is faulty.

Er I.b.H

A function is linked to input X (from 1 to 4) and is not “present”. See SETUP area

under “input5”.

Er.r.b.H

In a switch point function, the relay X (from 1 to 4) has been set and is not “present”.

See SETUP area under “output”.

busy

Printing is in progress (serial connection PRN is busy) or the display unit is waiting to

be able to send a print to the PC.

unstAb

Printing attempt with an unstable weight.

un.oUEr

Printing attempt in over or underload condition, i.e. with a weight that is 9 scale divisions greater than the nominal load or 100 scale divisions under the gross zero.

LoW

The net weight is less than the minimum load required for printing or totalling, or less

than the minimum weight for transferring a data string by pushbutton.

no.0..un5

Weight has not passed net 0 or was not unstable (depending on configuration).

ConU.

On legally calibrated instruments, an attempt was made to print in the standard

setting while the instrument was adjusting the weight unit.

no in

In the input/output function (activated as “in .out”), a second attempt was made to

acquire the input weight.

no out

In the input/output function (activated as “in .out”), a second attempt was made to

acquire the output weight.

no 1

In the input/output function (activated as “G.t.” or “1St.2nd”), a second attempt was

made to acquire the input weight.

no 2

In the input/output function (activated as “G.t.” or “1St.2nd”), a second attempt was

made to acquire the output weight.

Er.Not

Unstable weight.

Error

In counting mode, the reference determination was not or not properly performed, or

a larger reference quantity is required. During the comparison procedure, the load

cell with which the comparison is performed does not correspond to the rated load or

values have not been entered or have been entered in the wrong order.

E9..Err

Is displayed when the execution of the comparison was not possible.

StorE

Is displayed when data has been stored in the permanent memory of the instrument

(switch points, tare, updated record, etc.)

Err.Clk

Problem with the date/time cards. Setting of “F.NodE” >> “Clock” in SETUP.

SEt.Clk

Date/Time not set. Setting of “F.NodE” >> “Clock” in SETUP.

PrEC.

Is displayed when attempting to perform the zero calibration without first confirming

the number of calibration points.

8. Instrument messages during operation

Page 34

34

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

Display Description

Er.Pnt

During the acquisition of a calibration point, an invalid value is read from the transducer.

Err.rF

Is displayed if, during the selection of the function “NAStEr” and the activation of

the power-saving mode of the indicator, a SLAVE instrument is not found after 60

seconds. This message is displayed if the radio module is activated.This message is

displayed for 3 seconds and then the display is switched off.

Er 11

Calibration error: Too low a comparison weight has been used; it is recommended to

use a weight that corresponds to at least half the nominal load of the scales.

Er 12

Calibration error: The acquired calibration point (“tP1” or “tP2” or “tP3”) is the same as

the zero point (“tP0”).

Er 37

The number of points of the transducer for the subdivision of the scales is less than

two. Carry out the calibration again (correctly), paying attention to the nominal load

and the scale divisions.

Er 39

Occurs when the instrument is not yet initialised and calibrated.

When the instrument displays “ER 39”, press the TARE button, in order to access

the SETUP area. Carry out the initialisation of the display unit (Parameter “dEFAu”),

the selection of the keypad type (parameter “keyb”), the programming of all parame-

ters of the SETUP area and the calibration of the instrument.

ER 85

Occurs when the instrument has been initialised, but not yet calibrated.

When the instrument displays “ER 85”, press the TARE button, in order to access

the SETUP area.

C.Er.36

During calibration, internal, negative points have been calculated:

■

The calibration point lies below the zero point.

■

The signal is negative (check the cable connections to the load cell).

undEr

(blinking)

The scale is in underload (i.e. the weight on the scale is ≤ 100 scale divisions under

the gross zero, when the instrument is legally calibrated). This message is accompanied by an acoustic signal.

oVEr

(blinking)

The scales are in overload (i.e. the weight on the scales is 9 scale divisions greater

than the nominal load/weighing capacity). This message is accompanied by an

acoustic signal.

Eco H

Is shown for a moment when the master instrument manages to connect to the slave

instrument X. When the connection is not possible, the message persists and the

master instrument emits an acoustic signal.

tilt

The connected tilt sensor is preventing a weighing process.

The message is displayed when the tilt of a pallet truck is greater than 2 % or, with a

fork-lift truck, is greater than 5 %.The activation of the “TILT alarm” is carried out with

approx. 3 seconds delay.

8. Instrument messages during operation

Page 35

35

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

9. Maintenance and cleaning

9.1 Maintenance

The SF

6

gas lling cart is maintenance-free. Information on the maintenance of the

optional vacuum pump components see chapter “Vacuum pump”.

Vacuum pump (models GFU08-E and GFU08-C)

The most important maintenance factor for a vacuum pump is the oil. This must be

replaced when it is strongly contaminated (dark or cloudy oil). After the evacuation of

contaminated refrigerant, the oil must also be replaced. In particular, moisture/water

which remains in the pump until the next use can lead to damage of the pump through

corrosion.

Contaminated oil can damage the vacuum pump.

Process for oil change:

1. Let the pump run warm to the working temperature, then switch o and pull out the

mains plug.

2

.

Unscrew the oil mist separator.

3

.

Drain the oil by opening the outlet plug, or pour it out through the hole of the oil mist

separator by tilting the pump.

4. Plug in the mains plug - switch the pump on. Let it run for approx. 5-10 seconds with

the suction pipe open, so the residual oil is forced out of the pressure stages.

5. Switch the pump o - pull out the mains plug.

6. Drain or pour out the residual oil.

7. Screw the oil drain plug back in tightly.

8. Fill the new oil back to the ll level “middle sight glass”.

9. Screw in the oil mist separator. Briey switch on the pump for a few seconds.

With heavily contaminated oil, it is recommended to repeat the oil change

after about 30 minutes running in order to rinse out all of the contamination.

In order to achieve the specied performance and to not damage the pump, only ever

use WIKA oil.

The used oil must be disposed of properly by the pump operator in

accordance with regulations!

Repairs must only be carried out by the manufacturer.

9. Maintenance and cleaning

Page 36

36

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

9.2 Cleaning

CAUTION!

■

Clean the instrument with a moist cloth.

■

Do not use aggressive cleaning agents

■

Do not use any pointed or hard objects for cleaning.

10. Faults

In the event of leaks on lines lled with SF6 gas, the system must be stopped immediately

by closing the gas cylinder valve and the leaks must be eliminated by skilled personnel.

The SF

6

gas lling cart can, following successful leak testing, e.g. with a WIKA model

GIR-10, be put back into service.

Faults in the display unit

Faults Causes Measures

Display unit without function. Display unit not switched on. Switch on the display unit.

Battery empty. Charge the battery.

Display unit indicates no

value, even though there is a

weight on the scales.

Defective connection cable/

cable break.

Check the connection of the

display unit with the scales.

If complaint is unjustified, we will charge you the complaint processing fees.

Faults in the vacuum pump

Faults Causes Measures

Pump is dicult to start. The

speed is too low.

Oil too cold. Place the pump in a warm

environment.

Third-party oil is too viscous. Replace with original oil.

Pump is dirty. Carry out the oil change.

Motor windings defective. Ask customer service.

The connection cable is too

long.

Use a shorter connection

cable.

Mains voltage is too low. Pump is designed for mains

voltage ± 10 %.

Motor will not start. Capacitor defective. Replace capacitor.

Switch defective. Replace switch.

Motor too hot. Allow it to cool.

Cable defective. Replace cable.

9. Maintenance and cleaning / 10. Faults

Page 37

37

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

Faults Causes Measures

Engine hums - pump

blocked.

Pump contaminated. Pump

silted up.

Replace the pressure stage.

Ask customer service.

Motor is running ⇒ No power Coupling pin broken. Ask customer service.

Oil splashes on the oil mist

separator.

Oil reservoir is overlled. Oil level to “middle sight

glass”. Drain o excess oil.

Oil mist formation Operating pressure = atmos-

pheric pressure

Oil mist reduces after the

build up of suction pressure.

Oil level not visible. Oil volume too low. Rell with oil.

Oil contaminated/cloudy. Dirty refrigerant/oil sucked in. Carry out the oil change.

Pump does not achieve

vacuum.

Open the gas ballast valve. Turn the gas ballast valve to

closed.

Loosen the cap on the intake

port.

Screw the cap tight.

O-ring in the cap of the intake

port is defective.

Replace the O-ring.

Oil level too low. Rell with oil.

Oil silted up or contaminated. Change oil.

Line leaking. Check line, seal it.

Pump is worn after long

usage.

Repair or replace the pump.

Pump generates noise Motor bearings defective. Ask customer service.

Ventilator defective. Replace the ventilator.

Pump is losing oil. Oil housing sealing defect. Replace the O-ring.

Oil drain plug leaking. Replace drain plug.

Sight glass sealing defective. Replace the sight glass.

Oil housing tting leaking. Replace the seals of the oil

housing tting.

Shaft seal defective. Ask customer service.

10. Faults

Page 38

38

WIKA operating instructions SF6 gas lling cart, model GFU08

14033074.01 11/2018 EN/DE/FR/ES

EN

11. Dismounting and disposal

WARNING!

Residual media in the dismounted SF

6

gas lling cart can result in a risk

to persons, the environment and equipment.

Take sucient precautionary measures.

11.1 Dismounting

Only disconnect the SF

6

gas lling cart once the system has been depressurised!

11.2 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal regulations.

11. Dismounting and disposal

Page 39

39

WIKA Betriebsanleitung SF6-Gas Füllwagen, Typ GFU08

DE

14033074.01 11/2018 EN/DE/FR/ES

Inhalt

1. Allgemeines 40

2. Sicherheit 41

3. Technische Daten 52

4. Aufbau und Funktion 54

5. Transport, Verpackung und Lagerung 55

6. Inbetriebnahme, Betrieb 56

7. Anzeigeeinheit 60

8. Gerätemeldungen während der Nutzung 69

9. Wartung und Reinigung 71

10. Störungen 72

11. Demontage und Entsorgung 74

Inhalt

Page 40

40

WIKA Betriebsanleitung SF6-Gas Füllwagen, Typ GFU08

DE

14033074.01 11/2018 EN/DE/FR/ES

1. Allgemeines

1. Allgemeines

■

Der in der Betriebsanleitung beschriebene SF6-Gas-Füllwagen wird nach den

neuesten Erkenntnissen konstruiert und gefertigt. Alle Komponenten unterliegen

während der Fertigung strengen Qualitäts- und Umweltkriterien. Unsere

Managementsysteme sind nach ISO 9001 und ISO 14001 zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät.

Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen

Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen

Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige

Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend

qualizierten Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de/sf6, www.wika.com/sf6

- zugehöriges Datenblatt: SP 63.08

- Anwendungsberater:

Tel.: (+49) 9372/132-8971

E-Mail: sf6-sales@wika.de

Page 41

41

WIKA Betriebsanleitung SF6-Gas Füllwagen, Typ GFU08

DE

14033074.01 11/2018 EN/DE/FR/ES

2. Sicherheit

2. Sicherheit

2.1 Bedeutung dieser Betriebsanleitung

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem SF6-GasFüllwagen. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen

Sicherheitshinweise und Handlungsanweisungen. Zuwiderhandlungen können zu

gefährlichen Situationen führen.

■

Betriebsanleitung an nachfolgende Benutzer oder Besitzer des SF6-Gas-Füllwagens

weitergeben.

■

Vor allen Arbeiten muss der Betreiber sicherstellen, dass das Personal die Betriebsanleitung und Sicherheitsdatenblätter sorgfältig durchgelesen hat.

■

Die aufgabenbezogen Sicherheitshinweise sind am Anfang der jeweiligen Kapitel zu

nden (z. B. Transport, Inbetriebnahme, ...)

2.2 Symbolerklärung

GEFAHR!

... weist auf eine unmittelbar gefährliche Situation hin, die zum Tod oder

zu schweren Verletzungen führt, wenn sie nicht gemieden wird.

GEFAHR!

... kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung der Sicherheitshinweise besteht die Gefahr schwerer oder tödlicher

Verletzungen.

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die zum Tod

oder zu schweren Verletzungen führen kann, wenn sie nicht gemieden

wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden

führen kann, wenn sie nicht gemieden wird.

Information

... hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

ezienten und störungsfreien Betrieb hervor.

Page 42

42

WIKA Betriebsanleitung SF6-Gas Füllwagen, Typ GFU08

DE

14033074.01 11/2018 EN/DE/FR/ES

2. Sicherheit

Handlungsanweisungen

2. 3. Handlungssequenz

Handlungsanweisungen sind in vorgegebener Reihenfolge durchzuführen.

▶

Handlungsanweisung

Handlungsanweisungen ohne vorgegebene Reihenfolge.

⇒

Resultat

Beschreibt das Resultat einer Handlung.

→ Querverweis

Verweist auf eine weitere Stelle in der Betriebsanleitung.

2.3 Bestimmungsgemäße Verwendung

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet

werden. Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung

sind ausgeschlossen.

Verwendungszweck

Der SF

6

-Gas-Füllwagen dient der Füllung bzw. Nachfüllung von SF6-Gas in dafür vorgesehene und zugelassene gasdichte Behälter. Dabei kann der Fülldruck am eingebauten

Druckminderer eingestellt werden.

Der SF

6

-Gas-Füllwagen Typ GFU08-W bzw. GFU08-C enthält zusätzlich eine Waage

zur Messung der transferierten Masse SF

6

-Gas.

Der Typ GFU08-E bzw. GFU08-C enthält zusätzlich eine Vakuumpumpe, mit der der

Gasraum vor der Füllung evakuiert werden kann.

Es ist darauf zu achten, dass die Vakuumpumpe nur zum Abpumpen von Luft und nicht

von SF

6

-Gas verwendet wird.

Einsatzbereiche

Den SF₆-Gas Füllwagen nur in Anwendungen verwenden, die innerhalb seiner technischen Leistungsgrenzen liegen (z. B. max. Umgebungstemperatur, Materialverträglichkeit, ...).

→ Leistungsgrenzen siehe Kapitel 3 „Technische Daten“.

Der SF₆-Gas Füllwagen eignet sich für den Innen- und Außeneinsatz. Für einen siche-

ren Betrieb muss der Aufstellort folgende Vorraussetzungen erfüllen:

■

Aufstellort ist jederzeit durch Fachpersonal beaufsichtigt oder nicht allgemein

zugänglich.

■

Der Untergrund ist stets waagerecht und eben.

■

Nicht-explosionsfähige Atmosphäre.

■

Nicht-korrosionsverursachende Atmosphäre.

■

Keine stark staubhaltige Atmosphäre.

■

Kein Betrieb im Außenbereich bei Regen oder Gewitter (IP20).

Page 43

43

WIKA Betriebsanleitung SF6-Gas Füllwagen, Typ GFU08

DE

14033074.01 11/2018 EN/DE/FR/ES

2. Sicherheit

■

Der Aufstellort muss genügend Platz aufweisen, damit ein sicherer Betrieb möglich

ist. Das Bedien- und Wartungspersonal muss sich frei um das Gerät bewegen

können.

■

Max. zulässige Umgebungstemperatur wird nicht überschritten.

SF

6

-Gas-Füllwagen mit Waage (Typ GFU08-W bzw. GFU08-C):

■

Elektronische Komponenten mit erforderlicher Sorgfalt behandeln (vor Nässe,

Stößen, starken Magnetfeldern, statischer Elektrizität und extremen Temperaturen

schützen, keine Gegenstände in das Gerät bzw. Önungen einführen). Stecker und

Buchsen vor Verschmutzung schützen.

■

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann

durch Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur

abwarten.

Die technischen Spezifikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen Spezifikationen macht die sofortige Stilllegung und Überprüfung durch einen

autorisierten WIKA-Servicemitarbeiter erforderlich.

Eigenmächtige Umbauten durch den Betreiber sind nicht gestattet, insbesondere an

Sicherheitseinrichtungen. Eigenmächtige Umbauten können dazu führen, dass Sicherheitseinrichtungen nicht ordnungsgemäß funktionieren und lebensgefährliche Situationen daraus resultieren.

WIKA haftet nicht für Änderungen, welche von Personen vorgenommen werden, die

nicht durch WIKA autorisiert sind.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

Technische Einschränkungen

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der techni-

schen Spezikationen macht die sofortige Stilllegung und Überprüfung durch einen

autorisierten WIKA-Servicemitarbeiter erforderlich.

Technische Spezikationen:

→ Siehe Kapitel 3 „Technische Daten“.

2.4 Verantwortung des Betreibers

Das Gerät wird im gewerblichen Bereich eingesetzt. Der Betreiber unterliegt daher den

gesetzlichen Pflichten zur Arbeitssicherheit.

Die Sicherheitshinweise dieser Betriebsanleitung, sowie die für den Einsatzbereich des

Gerätes gültigen Sicherheits-, Unfallverhütungs- und Umweltschutzvorschriften einhalten.

Page 44

44

WIKA Betriebsanleitung SF6-Gas Füllwagen, Typ GFU08

DE

14033074.01 11/2018 EN/DE/FR/ES

2. Sicherheit

Der Betreiber ist verpflichtet, das Typenschild lesbar zu halten.

Für ein sicheres Arbeiten am Gerät muss der Betreiber sicherstellen,

■

dass eine entsprechende Erste-Hilfe-Ausrüstung vorhanden ist und bei Bedarf jederzeit Hilfe zur Stelle ist.

■

dass das Bedienpersonal regelmäßig in allen zutreffenden Fragen von Arbeitssicherheit, Erste Hilfe und Umweltschutz unterwiesen wird, sowie die Betriebsanleitung

und insbesondere die darin enthaltenen Sicherheitshinweise kennt.

■

dass das Gerät gemäß der bestimmungsgemäßen Verwendung für den Anwendungsfall geeignet ist.

■

dass die persönliche Schutzausrüstung verfügbar ist.

2.5 Personalqualifikation

Alle Arbeiten an und mit dem SF

6

-Gas-Füllwagen dürfen nur durch geschultes und

autorisiertes Personal erfolgen.Es sind die jeweils gültigen nationalen Vorschriften zu

beachten, speziell zu Gefahrengut und Qualifikation des Personals.