Page 1

Operating instructions

Betriebsanleitung

Mode d‘emploi

Manual de instrucciones

Gas density monitor, model GDM-100-TI/TA

Gasdichtewächter, Typ GDM-100-TI/TA

Densimètre, type GDM-100-TI/TA

Densimetro, modelo GDM-100-TI/TA

EN

DE

FR

ES

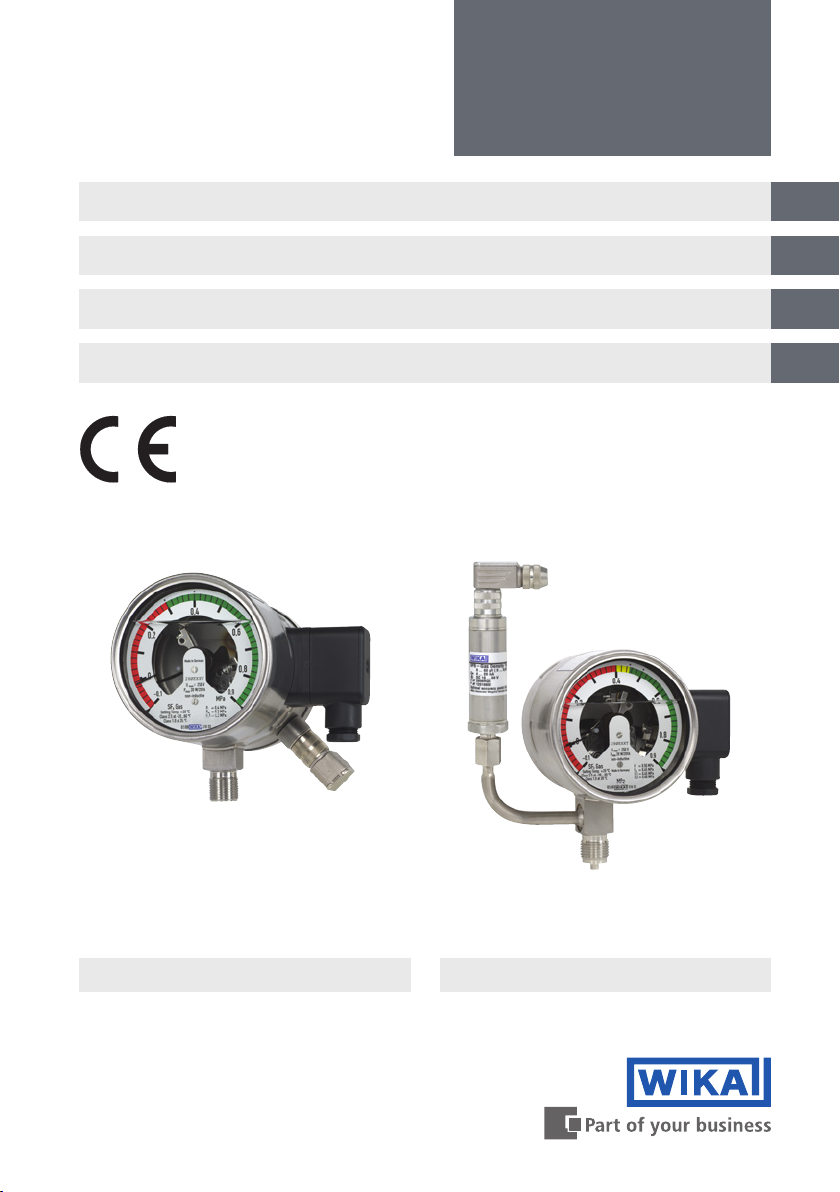

Model GDM-100-TI

Model GDM-100-TA

Page 2

Operating instructions model GDM-100-TI/TA Page 3 - 24

EN

Betriebsanleitung Typ GDM-100-TI/TA Seite 25 - 46

DE

Mode d‘emploi type GDM-100-TI/TA Seite 47 - 68

FR

Betriebsanleitung modelo GDM-100-TI/TA Seite 69 - 91

ES

© 04/2019 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions, models GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 3

Contents

Contents

1. General information 4

2. Design and function 5

3. Safety 6

4. Transport, packaging and storage 11

5. Commissioning, operation 12

6. Faults 17

7. Maintenance, cleaning and recalibration 19

8. Dismounting, return and disposal 20

9. Specifications 21

Declarations of conformity can be found online at www.wika.com.

EN

14300398.01 04/2019 EN/DE/FR/ES

3WIKA operating instructions, models GDM-100-TI, GDM-100-TA

Page 4

1. General information

1. General information

■

The instrument described in the operating instructions has been designed and

manufactured using state-of-the-art technology. All components are subject to strin-

EN

gent quality and environmental criteria during production. Our management systems

are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working safely requires that all safety instructions and work instructions are

observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument’s range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time. Pass

the operating instructions on to the next operator or owner of the instrument.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modifications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheets:

SP 60.05 Model GDM-100-TI

SP 60.06 Model GDM-100-TA

- Application consultant: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

4

WIKA operating instructions, models GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 5

2. Design and function

2. Design and function

2.1 Overview

Gas density monitor with integrated transmitter

Model GDM-100-TI

Product label

Electrical connection, cable socket

Transmitter

Process connection, spanner flats

Process connection, thread

Gas density monitor with built-in transmitter

Model GDM-100-TA

Electrical connection, transmitter

Electrical connection, switch contacts

Process connection, spanner flats

Process connection, thread

Extension for transmitter

Product label, transmitter

Product label, gas density monitor

EN

2.2 Description

Switch contacts

The switch contacts permanently installed in the gas density monitor close or open at

set limit values, depending on the switching function. Switching functions are: Normally

closed, normally open, change-over contact.

The magnetic snap-action contacts are auxiliary current switches which open or close

connected electric circuits via a contact arm which is moved by the instrument pointer.

2.3 Scope of delivery

Cross-check scope of delivery with delivery note.

14300398.01 04/2019 EN/DE/FR/ES

5WIKA operating instructions, models GDM-100-TI, GDM-100-TA

Page 6

3. Safety

3. Safety

3.1 Explanation of symbols

EN

3.2 Intended use

Wherever the gas density of SF₆ gas has to be indicated locally and, at the same time,

circuits need to be switched, the model GDM-100 gas density monitor finds its use. The

transmitter transmits the measured gas density as an electrical signal.

Gas density monitors are modified contact pressure gauges, specially developed for the

use of SF₆ gas. Temperature influences acting on the enclosed SF₆ gas are compensated by a compensation system.

The gas density monitors are specially designed for the respective application in switch-

gear (pure SF₆ gas, gas mixtures, calibration pressure, switch points ...). Before use,

check whether this instrument is suitable for the intended application.

WARNING!

... indicates a potentially dangerous situation that can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries

or damage to property or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for efficient

and trouble-free operation.

Only use the instrument in applications that lie within its technical performance limits

(e.g. max. ambient temperature, material compatibility, ...).

→ For performance limits see chapter 9 “Specifications”.

This instrument is not permitted to be used in hazardous areas!

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

6

WIKA operating instructions, models GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 7

3. Safety

The technical specifications contained in these operating instructions must be

observed. Improper handling or operation of the instrument outside of its technical

specifications requires the instrument to be taken out of service immediately and

inspected by an authorised WIKA service engineer.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

3.3 Improper use

WARNING!

Injuries through improper use

Improper use of the instrument can lead to hazardous situations and

injuries.

▶

Refrain from unauthorised modifications to the instrument.

▶

Do not use the instrument within hazardous areas.

Any use beyond or different to the intended use is considered as improper use.

3.4 Responsibility of the operator

The instrument is used in the industrial sector. The operator is therefore responsible for

legal obligations regarding safety at work.

The safety instructions within these operating instructions, as well as the safety,

accident prevention and environmental protection regulations for the application area

must be maintained.

EN

The operator is obliged to maintain the product label in a legible condition.

To ensure safe working on the instrument, the operating company must ensure

■

that suitable first-aid equipment is available and aid is provided whenever required.

■

that the operating personnel are regularly instructed in all topics regarding work

safety, first aid and environmental protection and know the operating instructions and

in particular, the safety instructions contained therein.

■

that the instrument is suitable for the particular application in accordance with its

intended use.

■

that personal protective equipment is available.

14300398.01 04/2019 EN/DE/FR/ES

7WIKA operating instructions, models GDM-100-TI, GDM-100-TA

Page 8

3. Safety

3.5 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient

EN

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be personnel who,

based on their technical training, knowledge of measurement and control technology

and on their experience and knowledge of country-specific regulations, current standards and directives, are capable of carrying out the work described and independently

recognising potential hazards.

Specically when using SF₆ gas

The plant operator must ensure that the handling of SF

qualied company or by qualied persons who have been specially trained in accordance with IEC 61634, section 4.3.1 or IEC 60480, section 10.3.1.

3.6 Personal protective equipment

The personal protective equipment is designed to protect the skilled personnel from

hazards that could impair their safety or health during work. When carrying out the

various tasks on and with the instrument, the skilled personnel must wear personal

protective equipment.

Improper handling can result in considerable injury and damage to equipment.

▶

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualifications described

below.

gas is only carried out by a

6

Follow the instructions displayed in the work area regarding personal protective

equipment!

The requisite personal protective equipment must be provided by the operating company.

Safety goggles in accordance with EN 166, class 2, mechanical

strength class S

The safety goggles must be worn over the entire period when working on

hoses or gas containers (e.g. gas cylinders, tanks).

The safety goggles protect the eyes from any flying particles, escaping

gas and liquid splashes.

Protective gloves against heat in accordance with EN ISO 13732-1

and against cold in accordance with EN ISO 13732-3

The protective gloves must be worn over the entire period when working

on hoses, gas containers (e.g. gas cylinders, tanks) or components which

heat up to over 60 °C.

8

WIKA operating instructions, models GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 9

3. Safety

3.7 Handling of insulating gases and gas mixtures

SF₆ gas is a greenhouse gas which is listed in the Kyoto Protocol. SF₆ gas must not be

released into the atmosphere, but must be collected in suitable containers.

Properties of insulating gases

■

Colourless and odourless

■

Chemically neutral

■

Inert

■

Not flammable

■

Heavier than air

■

No toxicity

■

No damage to the ozone layer

Detailed information is given in IEC 60376 and IEC 61634.

Danger of suocation caused by insulating gases and gas mixtures

High concentrations of gases can lead to asphyxiation, since breathable air is displaced

from the lungs with the inhalation of gas.

Since SF₆ gas is heavier than air, it collects, especially, at ground level or lower-lying

rooms below the reference level (e.g. cellars). This is particularly dangerous since SF₆

gas is colourless and odourless and thus may be imperceptible to people.

3.8 Danger caused by decomposition products

Insulating gas in electrical systems may contain decomposition products generated by

electric arcs:

■

Gaseous sulphur fluorides

■

Sulphur hexafluorides

■

Solid and atomized metal fluorides, metal sulfides, metal oxides

■

Hydrogen fluoride

■

Sulphur dioxide

Decomposition products can be harmful to health.

■

They can cause poisoning by inhalation, ingestion or contact with the skin.

■

They may be irritating to the eyes, the respiratory system or the skin and burn them.

■

Inhalation of large quantities may damage the lungs.

EN

Observe the following safety instructions in order to avoid danger from insulating gas:

■

Wear personal protective equipment.

■

Read the material safety data sheet of the gas supplier.

■

With large leaks, evacuate the area quickly.

■

Ensure good ventilation.

■

Ensure the leak tightness of the equipment with a leak detector (e.g. model GIR-10).

14300398.01 04/2019 EN/DE/FR/ES

9WIKA operating instructions, models GDM-100-TI, GDM-100-TA

Page 10

3. Safety

3.9 Applicable standards and directives for installation, assembly, commissioning

■

BGI 753 (SF₆ plants and equipment in Germany)

■

IEC 61634 (Handling of SF₆ gas)

■

IEC 60376 (New SF₆ gas, technical grade SF₆ gas)

■

EN

IEC 60480 (Used SF₆ gas)

■

CIGRE report 276, 2005 (Practical SF₆ gas handling instructions)

Leaks during operation:

■

IEC 60376 (New SF₆ gas, technical grade SF₆ gas)

■

IEC 60480 (Used SF₆ gas)

■

CIGRE 2002 (“SF₆ gas in the electrical industry”)

SF

is a colourless and odourless, chemically neutral, inert and non-am-

6

mable gas which is approx. ve times heavier than air, non-toxic and not

harmful to the ozone layer.

Detailed information is given in IEC 60376 and IEC 61634.

3.10 Labelling, safety marks

Product label (gas density monitor)

Dichtewächter mit Kontakteinrichtung

Density monitor with alarm contacts

Schaltzustand bei Skalenanfangswert / Status of switch at minimum scale value Made in Germany

Model designation

Pin assignment

Case filling

P# Product No.

Date of manufacture

Switching thresholds

Electrical characteristics

Model designation of the switch contact

10

14300398.01 04/2019 EN/DE/FR/ES

WIKA operating instructions, models GDM-100-TI, GDM-100-TA

Page 11

3. Safety / 4. Transport, packaging and storage

Product label (transmitter)

Model designation

Measuring range

Output signal

Power supply

S# Article No.

P# Product No.

Pin assignment

Date of manufacture

EN

4. Transport, packaging and storage

4.1 Transport

Check the instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, a high level of damage to property can occur.

▶

When unloading packed goods upon delivery as well as during internal

transport, proceed carefully and observe the symbols on the packaging.

▶

With internal transport, observe the instructions in chapter 4.2 “Packaging and storage”.

4.2 Packaging and storage

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change

in installation site, sending for repair).

14300398.01 04/2019 EN/DE/FR/ES

11WIKA operating instructions, models GDM-100-TI, GDM-100-TA

Page 12

4.Transport, ... / 5. Commissioning, operation

WARNING!

Physical injuries and damage to property and the environment

caused by hazardous decomposition products

Before storing the instrument, any residual decomposition products must

EN

Permissible conditions at the place of storage:

■

Storage temperature: -40 ... +60 °C

■

Humidity: 45 ... 75 % r.h. (non-condensing)

Avoid exposure to the following factors:

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, flammable atmospheres

Store the instrument in its original packaging in a location that fulfils the conditions

listed above. If the original packaging is not available, pack and store the instrument as

described below:

1. Place the instrument, along with the shock-absorbent material, in the packaging.

2. If stored for a prolonged period of time (more than 30 days), place a bag containing

a desiccant inside the packaging.

be removed.

▶

For cleaning, see chapter 7.2 “Cleaning”

5. Commissioning, operation

5.1 Mechanical mounting

CAUTION!

Physical injuries and damage to property and the environment

through faulty instrument

Prior to commissioning, the instrument must be subjected to a visual

inspection. Only use the instrument if it is in perfect condition with respect

to safety.

5.1.1 Requirements for the installation point

■

For outdoor applications, the selected installation location has to be suitable for the

specified ingress protection, so that the instrument is not exposed to impermissible

weather conditions.

■

The sealing faces at the instrument and at the measuring point have to be undamaged and clean.

12

WIKA operating instructions, models GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 13

5. Commissioning, operation

5.1.2 Installation

■

With transport or storage, it can occur that gas density monitors warm up or cool down

and this results in pointer movements. These pointer movements are caused by the

compensation system. To make sure that the instruments have adapted sufficiently to

ambient temperature, at least 2 hours at 20 °C must be allowed for adaptation to the

temperature. Then, in the depressurised state, the pointer will sit within the tolerance

bar.

■

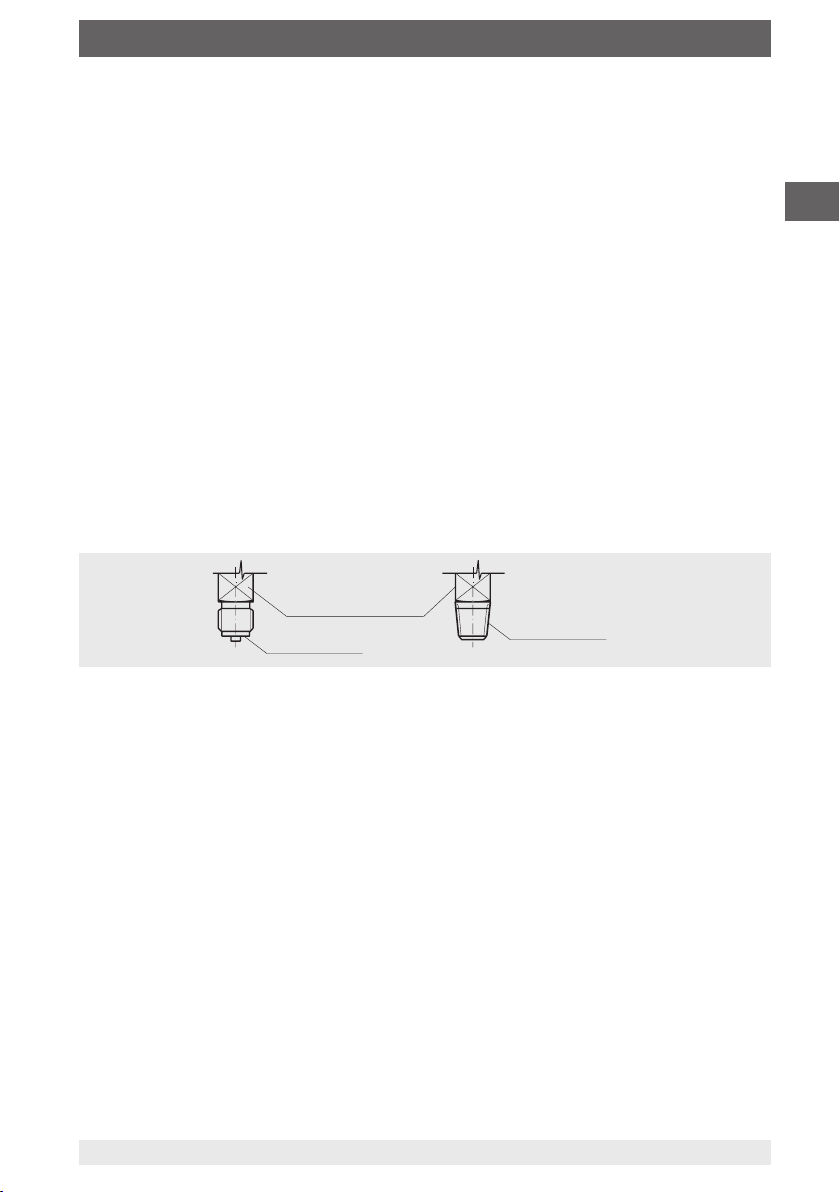

Corresponding to the general technical rules for pressure gauges (e.g. EN 837-2

“Selection and installation recommendations for pressure gauges”) when screwing in

the instrument, the force required to do this must not be applied through the case, but

only through the spanner flats provided for this purpose and using a suitable tool.

■

When screwing in, do not tilt the threads.

For parallel threads, use flat gaskets, lens-type sealing rings or WIKA profile sealings

at the sealing face . With tapered threads (e.g. NPT threads), sealing is made in the

threads , using a suitable sealing material (EN 837-2).

The tightening torque depends on the sealing used. In order to orientate the measuring

instrument so that it can be read as well as possible, a connection with LH-RH union or

union nut should be used. When a blow-out device is fitted to an instrument, it must be

protected against being blocked by debris and dirt.

Spanner ats

Sealing face

Sealing in the thread

EN

5.1.3 Temperature load

The installation of the instrument should be made in such a way that the permissible

operating temperature, also considering the effects of convection and thermal radiation,

neither exceeds nor falls below the permissible limits.

The influence of temperature on the indication and measurement accuracy must be

observed.

5.2 Electrical mounting of the gas density monitor

■

The instrument must be grounded via the process connection.

■

For cable outlets, make sure that no moisture enters at the cable end.

■

Select a cable diameter that matches the cable bushing of the connector. Make sure

that the cable gland of the mounted plug has a tight fit and that the seals are present

and undamaged. Tighten the threaded connection and check that the sealing is

correctly seated, in order to ensure the ingress protection.

■

Connection details and switching functions are given on the product label. Connection terminals and ground terminal are appropriately marked.

14300398.01 04/2019 EN/DE/FR/ES

13WIKA operating instructions, models GDM-100-TI, GDM-100-TA

Page 14

5. Commissioning, operation

5.2.1 Limit values for the contact load with resistive load

gas-filled instruments liquid-filled instruments

EN

Maximum rated operating

voltage Ueff

Rated operating current

Switch-on current 1 A 1 A

Switch-off current 1 A 1 A

Continuous current 0.6 A 0.6 A

Maximum switching power 30 W, 50 VA 20 W, 20 VA

Do not exceed the limit values. In order to permanently ensure safe operation, the

following load values are recommended:

AC 250 V AC 250 V

Voltage

gas-filled instruments liquid-filled instruments

(per IEC 38)

resistive load inductive

load

DC/AC DC AC cos ϕ >0.7 DC AC cos ϕ >0.7

230 V 100 mA 120 mA 65 mA 65 mA 90 mA 40 mA

110 V 200 mA 240 mA 130 mA 130 mA 180 mA 85 mA

48 V 300 mA 450 mA 200 mA 190 mA 330 mA 130 mA

24 V 400 mA 600 mA 250 mA 250 mA 450 mA 150 mA

resistive load inductive load

The switching current must not be less than 20 mA with low voltages for switching reliability reasons.

For higher loads, and for instruments with liquid-lled cases, WIKA model

905.1X contact protection relays are recommended

Overcurrent protectors

The instruments do not provide for incorporated overcurrent protectors. Should protectors be required, the following values in accordance with EN 60 947-5-1 are to be

recommended.

■

Voltage 24 V: 2 A

■

Voltage 250 V: 1 A

14

WIKA operating instructions, models GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 15

5. Commissioning, operation

5.2.2 Contact protection measures

Mechanical contacts must not exceed the specified electrical values for switching

current, switching voltage and switching power independent of each other, not even for

a short time only.

For capacitive or inductive loads we recommend one of the following protective circuits:

Inductive load with DC voltage

With DC voltage the contact protection can be achieved via a free-wheeling diode,

connected in parallel to the load. The polarity of the diode must be arranged so that it

closes when the operating voltage is on.

Example:

Contact protection

measure with freewheeling diode

Contact

EN

Diode

Load

Inductive load with AC voltage

With AC voltage two protection measures are possible:

Example:

Contact protection

measure with

voltage-dependent

resistor VDR

Example:

Contact protection

measure with RC

element

Load

Load

14300398.01 04/2019 EN/DE/FR/ES

15WIKA operating instructions, models GDM-100-TI, GDM-100-TA

Page 16

U

U

+

-

U

A

UB+/Sig+

0V/Sig-

5. Commissioning, operation

Capacitive load

With capacitive loads elevated switch-on currents arise. These can be reduced by

series-connecting resistors in the supply line.

EN

Examples: Contact protection measure with current-limiting resistor

B

R

1

Load Load

B

R

1

5.3 Electrical mounting of the transmitter

Requirements for voltage supply

Power supply: DC 10 ... 30 V

The supply must be made via an energy-limited circuit in accordance with IEC 61010-1.

Requirements for electrical connection

■

Cable diameter matches the cable bushing of the mating connector.

■

Cable gland and seals of the mating connector are correctly seated.

■

With cable outlets, no humidity can ingress at the cable end.

Requirement for shielding and grounding

The transmitter is grounded via the process connection of the gas density monitor. The

transmitter is connected with the process connection of the gas density monitor via the

mounting.

Pin assignment

Transmitter, angular connector (2-pin)

16

WIKA operating instructions, models GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 17

5. Commissioning, operation / 6. Faults

5.4 Switch point setting

The switch points have a fixed setting as standard and cannot be adjusted. Thus, an

undesired adjustment of the switch points is excluded.

With customer-specific, adjustable switch points, with the accompanying adjustment

key, the desired set point can be set via the adjustment lock in the window.

6. Faults

CAUTION!

Physical injuries and damage to property and the environment

If faults cannot be eliminated by means of the listed measures, the instrument must be taken out of operation immediately.

▶

Ensure that pressure or signal is no longer present and protect against

accidental commissioning.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the instructions given in chapter 9.2

“Return”.

EN

For contact details see chapter 1 “General information” or the back page

of the operating instructions.

14300398.01 04/2019 EN/DE/FR/ES

17WIKA operating instructions, models GDM-100-TI, GDM-100-TA

Page 18

EN

6. Faults

Faults Causes Measures

Contact is no longer

switching in line with the

specification

Switching status remains

unchanged despite

reaching the switch point/

reset point

No pointer movement

despite change in pressure

Pointer movement, even

though depressurised

No output signal Cable break Replace connection cable

Deviating zero point signal Overpressure limit exceeded Observe the permissible

Constant output signal

upon change in pressure

Signal span varies EMC interference sources in

Signal span varies/

inaccurate

Signal span drops/too

small

Electrical connection is

interrupted.

Electrical load unsuitable for

the switch contact model.

Contact contaminated.

Contacts defective (e.g. fused

contact zone).

Movement blocked. Replace instrument.

Warming or cooling of the

measuring instrument (no

damage)

Too high/low working temperature

Mechanical overload caused

by overpressure

the environment; for example,

frequency converter

Too high/low working

temperature

Mechanical overload caused

by overpressure

Carry out a continuity test on

the electrical connection lines.

Maintain the permissible

electrical loads for the switch

contact model.

Replace instrument. Before

recommissioning the

new instrument, provide

a protective circuit for the

contact.

Let the instrument settle for 2

hours at 20 °C.

overpressure limit

Observe the permissible

temperatures

Replace instrument; if it

fails repeatedly, contact the

manufacturer

Shield instrument; cable

shield; remove source of

interference

Observe the permissible

temperatures

Replace instrument; if it

fails repeatedly, contact the

manufacturer

For claims, the serial and product numbers must be stated. The serial number is printed

on the dial, the product number on the product label. With claims, the atmospheric

pressure and the temperature during the measurement must be given, as well as the

data on the reference standard (model, class).

18

WIKA operating instructions, models GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 19

7. Maintenance, cleaning and recalibration

7. Maintenance, cleaning and recalibration

7.1 Maintenance

These gas density monitors are maintenance-free.

The indication and switching function should be checked once or twice every year. For

this the instrument must be disconnected from the gas compartment to check with a

pressure testing device.

Repairs must only be carried out by the manufacturer.

The instruments must not be opened, since this can lead to indication and switch point

errors.

7.2 Cleaning

CAUTION!

Physical injuries and damage to property and the environment

Improper cleaning may lead to physical injuries and damage to property

and the environment. Decomposition products in the dismounted instrument can result in a risk to persons, the environment and equipment.

▶

Carry out the cleaning process as described below.

1. Before cleaning, correctly disconnect the instrument from the pressure supply and

switch o the current.

2. Use the requisite protective equipment.

3. Clean the instrument with a moist cloth.

Electrical connections must not come into contact with moisture!

EN

CAUTION!

Damage to the instrument

Improper cleaning may lead to damage to the instrument!

▶

Do not use any aggressive cleaning agents.

▶

Do not use any hard or pointed objects for cleaning.

4. Wash or clean the dismounted instrument, in order to protect people and the environment from exposure to residual decomposition products.

Information on returns can be found under the heading “Service” on our

local website.

7.3 Calibration

The gas density monitor can be calibrated via a special calibration system for gas densi-

ty measuring instruments (e.g. WIKA BCS-10).

The gas density monitor must be dismounted professionally. In this case, it may be

necessary to take the entire system temporarily out of service.

14300398.01 04/2019 EN/DE/FR/ES

19WIKA operating instructions, models GDM-100-TI, GDM-100-TA

Page 20

8. Dismounting, return and disposal

8. Dismounting, return and disposal

8.1 Dismounting

EN

Before dismantling the instrument, evacuate the gas filling.

Only dismount the instrument when it is depressurised and free from current.

8.2 Return

When returning the instrument, use the original packaging or a suitable transport

packaging.

To avoid damage:

1. Place the instrument, along with the shock-absorbent material, in the packaging.

Place shock-absorbent material evenly on all sides of the transport packaging.

2. If possible, place a bag containing a desiccant inside the packaging.

WARNING!

Physical injuries and damage to property and the environment

caused by hazardous decomposition products

Upon contact with hazardous decomposition products, there is a danger

of physical injuries and damage to property and the environment.

▶

Wear the requisite protective equipment (see chapter 3.6 “Personal

protective equipment”).

WARNING!

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazard-

ous substances (e.g. decomposition products) and must therefore be

cleaned before being returned.

Information on returns can be found under the heading “Service” on our

local website.

8.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specific waste disposal regulations.

20

WIKA operating instructions, models GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 21

9. Specifications

9. Specifications

Measuring ranges

Nominal size in mm 100

Measuring range Vacuum and overpressure range with measuring span of 1.6 ... 25 bar

(at an ambient temperature of 20 °C and gaseous phase)

Pressure element

Leak rate ≤ 1 · 10 -8 mbar · l / s

Test method Helium mass spectrometry

Output signals

Output signal 4 ... 20 mA, 2-wire

Permissible max. load

R

A

Switch contacts

Number of contacts Max. 4 magnetic snap-action contacts

Switching function Normally open, normally closed, change-over contact (max. 2 switch

Switch point setting secured switch points, not adjustable (option: Adjustable switch

Switching power For cases with gas filling: 30 W / 50 VA, max. 1 A

RA ≤ (UB - 10 V) / 0.02 A with RA in ohms and UB in volts

points)

points)

With cases with filling liquid: 20 W / 20 VA, max. 1 A

EN

Voltage supply

Power supply DC 10 ... 30 V

Accuracy specifications

Mechanical display ±1 % at an ambient temperature of 20 °C [68 °F]

±2.5 % at an ambient temperature of -20 … +60 °C and with

calibration pressure in accordance with reference isochore (reference

diagram KALI-Chemie AG, Hanover, prepared by Dr. Döring 1979)

Transmitter

Point of optimal

density

14300398.01 04/2019 EN/DE/FR/ES

-40 °C: 3 % of span

20 °C: 1 % of span

60 °C: 2.3 % of span

21WIKA operating instructions, models GDM-100-TI, GDM-100-TA

Page 22

9. Specifications

Accuracy specifications

Start and end of the

measuring range

EN

Stability per year ≤ 0.3 % of span

Switch contacts Switching accuracy in the temperature range -20 … +60 °C

Operating conditions

Permissible temperature range

Ambient -20 ... +60 °C (gaseous phase)

Storage -40 ... +60 °C

Ingress protection per

IEC/EN 60529

Intended medium pure SF

High-voltage test 100 % 2 kV, 50 Hz, 1 s (wiring against case)

Electromagnetic

compatibility (EMC) to

IEC 61000-4

-40 °C: 4 % of span

20 °C: 2 % of span

60 °C: 3.3 % of span

Switch point = calibration pressure P

specification

Switch point ≠ calibration pressure PE: Parallel to the reference iso-

chore of the calibration pressure

IP65

gas, further gas mixtures on request

6

IEC 61000-4-2 (ESD): Test level 4 (8 kV)

IEC 61000-4-3 (Field): Test level 3 (10 V/m)

IEC 61000-4-4 (Burst): Test level X (±2 kV)

IEC 61000-4-5 (Surge): Test level 2 (±1 kV)

IEC 61000-4-6 (Conducted RFI): Test level 3 (10 V)

: In accordance with customer

E

Process connections

Process connection G ½ B per EN 837, lower mount

Spanner flats 22 mm

(Option: Flange connection)

other connections and connection locations on request

Electrical connection

Switch contacts Cable socket with M20 x 1.5 cable gland

Wire cross-section max. 2.5 mm²

(Option: Plug-in cable box)

Transmitter With built-in transmitter: Cable outlet

With built-in transmitter: Angular connector (2-pin), IP67 (option:

Field case, stainless steel, IP67)

Electrical safety Protection against reverse polarity and overvoltage

22

WIKA operating instructions, models GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 23

9. Specifications

Materials

Movement Stainless steel

Bimetal link (temperature compensation)

Dial Aluminium, red, yellow, green area as specified in the order

Pointer Aluminium, black

Case Stainless steel, with silicone oil or nitrogen filling

Gas-tight: Leak rate ≤ 1 · 10-5 mbar · l / s

Switch contacts 80 % Ag / 20 % Ni, gold-plated

Transmitter Stainless steel

Window Laminated safety glass (option: Clear non-splintering plastic win-

dow)

Ring Bayonet ring, stainless steel, secured by means of 3 welding

spots

Process connection Stainless steel

Internal transmission

fluid

Media chamber with pro-

cess connection (wetted)

Pressure element Stainless steel, welded

Synthetic oil

Stainless steel 316Ti (1.4571)

EN

Approvals

Logo Description Country

EU declaration of conformity

■

EMC directive

■

Pressure equipment directive

■

Low voltage directive

EAC

■

EMC directive

■

Pressure equipment directive

■

Low voltage directive

■

Machinery directive

■

Gas appliances directive

For further specifications, see the order documentation.

14300398.01 04/2019 EN/DE/FR/ES

European Union

Eurasian Economic

Community

23WIKA operating instructions, models GDM-100-TI, GDM-100-TA

Page 24

9. Specifications

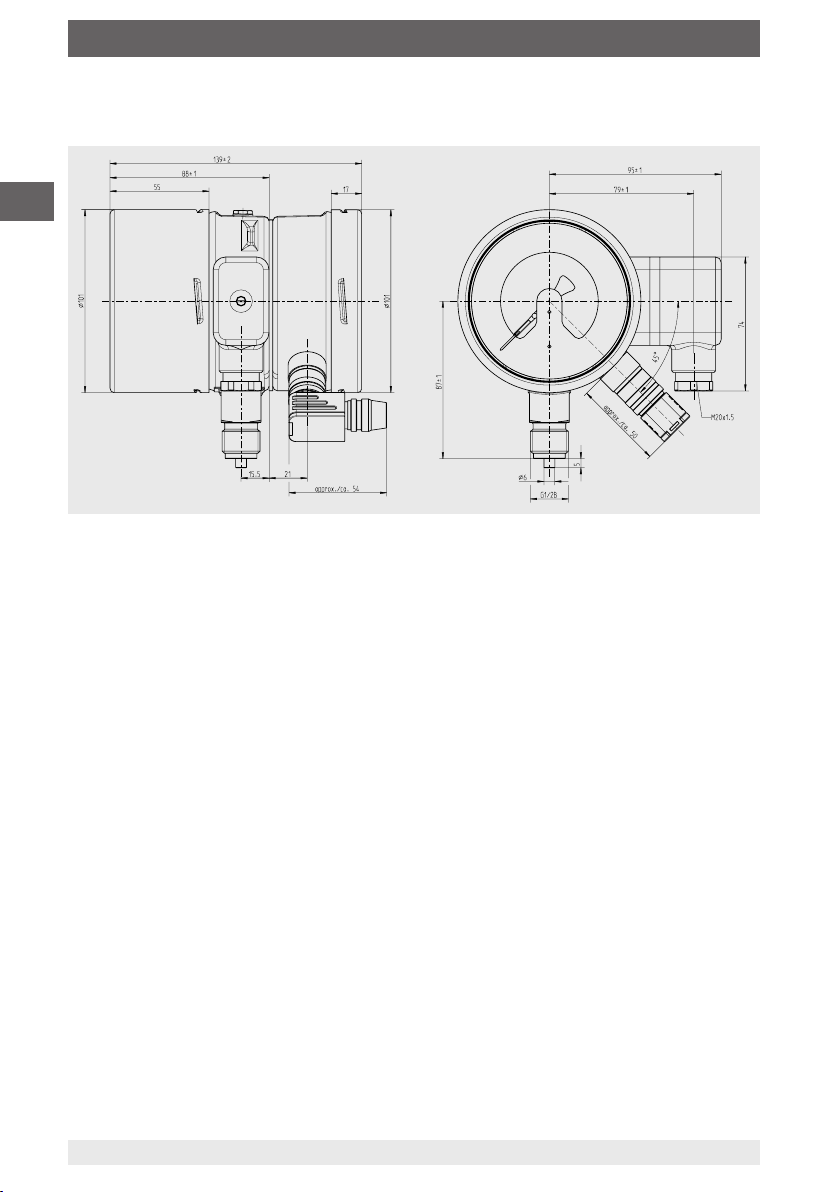

Dimensions in mm

EN

Weight: approx. 1.2 kg

24

WIKA operating instructions, models GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 25

Inhalt

Inhalt

1. Allgemeines 26

2. Aufbau und Funktion 27

3. Sicherheit 28

4. Transport, Verpackung und Lagerung 33

5. Inbetriebnahme, Betrieb 34

6. Störungen 39

7. Wartung, Reinigung und Rekalibrierung 41

8. Demontage, Rücksendung und Entsorgung 42

9. Technische Daten 43

Konformitätserklärungen finden Sie online unter www.wika.de.

DE

14300398.01 04/2019 EN/DE/FR/ES

25WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

Page 26

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Gerät wird nach dem aktuellen Stand der

Technik konstruiert und gefertigt. Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind

nach ISO 9001 und ISO 14001 zertifiziert.

DE

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät.

Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen

Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen

Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden. Betriebsanleitung an nachfolgende Benutzer oder Besitzer des Gerätes weitergeben.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehörige Datenblätter:

SP 60.05 Typ GDM-100-TI

SP 60.06 Typ GDM-100-TA

- Anwendungsberater: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

26

WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 27

2. Aufbau und Funktion

2. Aufbau und Funktion

2.1 Überblick

Gasdichtewächter mit integriertem Transmitter

Typ GDM-100-TI

Typenschild

Elektrischer Anschluss, Kabeldose

Transmitter

Prozessanschluss, Schlüsselfläche

Prozessanschluss, Gewinde

Gasdichtewächter mit angebautem Transmitter

Typ GDM-100-TA

Elektrischer Anschluss, Transmitter

Elektrischer Anschluss, Schaltkontakte

Prozessanschluss, Schlüsselfläche

Prozessanschluss, Gewinde

Anbau für Transmitter

Typenschild, Transmitter

Typenschild, Gasdichtewächter

DE

2.2 Beschreibung

Schaltkontakte

Die im Gasdichtewächter fest eingebauten Schaltkontakte schließen oder öffnen

bei eingestellten Grenzwerten je nach Schaltfunktion. Schaltfunktionen sind: Öffner,

Schließer, Wechsler.

Die Magnetspringkontakte sind Hilfsstromschalter, die angeschlossene elektrische

Stromkreise über einen vom Gerätezeiger bewegten Kontaktarm öffnen oder schließen.

2.3 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

14300398.01 04/2019 EN/DE/FR/ES

27WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

Page 28

3. Sicherheit

3. Sicherheit

3.1 Symbolerklärung

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die zum Tod

DE

3.2 Bestimmungsgemäße Verwendung

Überall dort, wo die Gasdichte von SF₆-Gas vor Ort angezeigt werden muss und gleichzeitig Stromkreise geschaltet werden sollen, findet der Gasdichtewächter Typ GDM-100

seinen Einsatz. Der Transmitter überträgt die gemessene Gasdichte als elektrisches

Signal.

Gasdichtewächter sind abgewandelte Kontaktmanometer, die speziell für die Verwen-

dung von SF₆-Gas entwickelt wurden. Temperatureinflüsse die auf das eingeschlossene

SF₆-Gas wirken, werden durch ein Kompensationssystem ausgeglichen.

oder zu schweren Verletzungen führen kann, wenn sie nicht gemieden

wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen

kann, wenn sie nicht gemieden wird.

Information

... hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

effizienten und störungsfreien Betrieb hervor.

Die Gasdichtewächter sind speziell für den jeweiligen Einsatzfall in der Schaltanlage

ausgelegt (reines SF₆-Gas, Gasgemische, Eichdruck, Schaltpunkte ...). Vor der Verwendung überprüfen, ob das vorliegende Gerät für den vorgesehenen Einsatzfall geeignet

ist.

Das Gerät nur in Anwendungen verwenden, die innerhalb seiner technischen Leistungs-

grenzen liegen (z. B. max. Umgebungstemperatur, Materialverträglichkeit, ...).

→ Leistungsgrenzen siehe Kapitel 9 „Technische Daten“.

Dieses Gerät ist nicht für den Einsatz in explosionsgefährdeten Bereichen zugelassen!

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen

Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

28

WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 29

3. Sicherheit

Die technischen Spezifikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen Spezifikationen macht die sofortige Stilllegung und Überprüfung durch einen

autorisierten WIKA-Servicemitarbeiter erforderlich.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

3.3 Fehlgebrauch

WARNUNG!

Verletzungen durch Fehlgebrauch

Fehlgebrauch des Gerätes kann zu gefährlichen Situationen und Verletzungen führen.

▶

Eigenmächtige Umbauten am Gerät unterlassen.

▶

Gerät nicht in explosionsgefährdeten Bereichen einsetzen.

Jede über die bestimmungsgemäße Verwendung hinausgehende oder andersartige

Benutzung gilt als Fehlgebrauch.

3.4 Verantwortung des Betreibers

Das Gerät wird im gewerblichen Bereich eingesetzt. Der Betreiber unterliegt daher den

gesetzlichen Pflichten zur Arbeitssicherheit.

DE

Die Sicherheitshinweise dieser Betriebsanleitung, sowie die für den Einsatzbereich des

Gerätes gültigen Sicherheits-, Unfallverhütungs- und Umweltschutzvorschriften einhalten.

Der Betreiber ist verpflichtet das Typenschild lesbar zu halten.

Für ein sicheres Arbeiten am Gerät muss der Betreiber sicherstellen,

■

dass eine entsprechende Erste-Hilfe-Ausrüstung vorhanden ist und bei Bedarf jederzeit Hilfe zur Stelle ist.

■

dass das Bedienpersonal regelmäßig in allen zutreffenden Fragen von Arbeitssicherheit, Erste Hilfe und Umweltschutz unterwiesen wird, sowie die Betriebsanleitung

und insbesondere die darin enthaltenen Sicherheitshinweise kennt.

■

dass das Gerät gemäß der bestimmungsgemäßen Verwendung für den

Anwendungsfall geeignet ist.

■

dass die persönliche Schutzausrüstung verfügbar ist.

14300398.01 04/2019 EN/DE/FR/ES

29WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

Page 30

3. Sicherheit

3.5 Personalqualifikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualifikation

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden führen.

▶

DE

Fachpersonal

Das vom Betreiber autorisierte Fachpersonal ist aufgrund seiner fachlichen Ausbildung,

seiner Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen sowie

Kenntnis der landesspezifischen Vorschriften, geltenden Normen und Richtlinien in der

Lage, die beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig zu

erkennen.

Speziell beim Einsatz von SF₆-Gas

Der Betreiber muss sicherstellen, dass die Handhabung von SF

qualiziertes Unternehmen oder von gemäß IEC 61634 Abschnitt 4.3.1 bzw. IEC 60480

Abschnitt 10.3.1 geschulten Mitarbeitern durchgeführt wird.

3.6 Persönliche Schutzausrüstung

Die persönliche Schutzausrüstung dient dazu, das Fachpersonal gegen Gefahren

zu schützen, die dessen Sicherheit oder Gesundheit bei der Arbeit beeinträchtigen

könnten. Beim Ausführen der verschiedenen Arbeiten an und mit dem Gerät muss das

Fachpersonal persönliche Schutzausrüstung tragen.

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualifikation durchführen

lassen.

-Gas durch ein hierzu

6

Im Arbeitsbereich angebrachte Hinweise zur persönlichen Schutzausrüstung

befolgen!

Die erforderliche persönliche Schutzausrüstung muss vom Betreiber zur Verfügung

gestellt werden.

Schutzbrille nach EN 166 Klasse 2, mechanische Festigkeit Klasse S

Die Schutzbrille muss bei Arbeiten an Schläuchen oder Gasbehältern (z.

B. Gaszylinder, Tanks) über die gesamte Dauer hinweg getragen werden.

Die Schutzbrille schützt die Augen vor umherfliegenden Teilen, austretendem Gas und Flüssigkeitsspritzern.

Schutzhandschuhe gegen Wärme nach EN ISO 13732-1 und gegen

Kälte nach EN ISO 13732-3

Die Schutzhandschuhe müssen bei Arbeiten an Schläuchen, Gasbehältern (z. B. Gaszylinder, Tanks) oder Teilen die sich auf über 60 °C erwärmen über die gesamte Dauer hinweg getragen werden.

30

WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 31

3. Sicherheit

3.7 Umgang mit Isoliergasen und Gasgemischen

SF₆-Gas ist ein Treibhausgas, das im Kyoto-Protokoll gelistet ist. Das SF₆-Gas darf

nicht in die Atmosphäre gelangen, sondern muss in geeigneten Behältern gesammelt

werden.

Eigenschaften von Isoliergasen

■

Farb- und geruchlos

■

Chemisch neutral

■

Inert

■

Nicht entflammbar

■

Schwerer als Luft

■

Keine Toxizität

■

Nicht ozonschädigend

Detaillierte Angaben benden sich in der IEC 60376 und IEC 61634.

Erstickungsgefahr durch Isoliergase und Gasgemische

Hohe Konzentrationen von Gasen können zur Erstickung führen, da beim Einatmen von

Gas die Atemluft aus den Lungen verdrängt wird.

Da SF₆-Gas schwerer ist als Luft, sammelt es sich insbesondere in Bodennähe oder

tiefer gelegenen Räumen unterhalb des Bezugsniveaus an (z. B. Kellerräume). Dies ist

besonders gefährlich, da SF6-Gas farb- und geruchlos ist und somit vom Menschen

nicht wahrgenommen wird.

3.8 Gefährdung duch Zersetzungsprodukte

Isoliergas in elektrischen Anlagen kann durch Lichtbogeneinwirkung Zersetzungsprodukte enthalten:

■

Gasförmige Schwefelflouride

■

Schwefeloxyfluoride

■

Feste staubförmige Metallfluoride, -sulfide und -oxide

■

Fluorwasserstoff

■

Schwefeldioxid

DE

Zersetzungsprodukte können gesundheitsschädlich sein.

■

Durch Einatmen, Verschlucken oder Hautberührung kann es zu einer Vergiftung

kommen.

■

Augen, Atmungsorgane oder die Haut kann gereizt und verätzt werden.

■

Durch Einatmen größerer Mengen kann die Lunge geschädigt werden.

Folgende Sicherheitshinweise beachten, um Gefahren durch Isoliergas zu vermeiden:

■

Persönliche Schutzausrüstung tragen.

■

Das Sicherheitsdatenblatt des Gaslieferanten lesen.

■

Bei großen Leckagen schnell den Ort verlassen.

■

Für gute Belüftung sorgen.

■

Dichtigkeit der Betriebsmittel mit Lecksuchgerät sicherstellen (z. B. Typ GIR-10).

14300398.01 04/2019 EN/DE/FR/ES

31WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

Page 32

3. Sicherheit

3.9 Geltende Normen und Richtlinien für Installation, Errichtung, Inbetriebnahme

■

BGI 753 (SF₆-Anlagen und Betriebsmittel in Deutschland)

■

IEC 61634 (Handhabung von SF₆-Gas)

■

IEC 60376 (neues SF6-Gas, technisches SF₆-Gas)

■

IEC 60480 (gebrauchtes SF₆-Gas)

■

CIGRE report 276, 2005 (Practial SF₆ gas handling instructions)

DE

Leckagen während des Betriebs:

■

IEC 60376 (neues SF₆-Gas, technisches SF₆-Gas)

■

IEC 60480 (gebrauchtes SF₆-Gas)

■

CIGRE 2002 („SF₆ gas in the electrical industry“)

SF

-Gas ist farb- und geruchlos, chemisch neutral, inert, nicht entamm-

6

bar und etwa fünfmal schwerer als Luft, nicht toxisch und nicht ozonschädigend.

Detaillierte Angaben benden sich in der IEC 60376 und IEC 61634.

3.10 Beschilderung, Sicherheitskennzeichnungen

Typenschild (Gasdichtewächter)

Schaltzustand bei Skalenanfangswert / Status of switch at minimum scale value Made in Germany

Typbezeichnung

Anschlussbelegung

Gehäusefüllung

P# Erzeugnis-Nr.

Herstelldatum

Schaltschwellen

Elektrische Kennwerte

Typbezeichnung des Schaltkontakts

32

Dichtewächter mit Kontakteinrichtung

Density monitor with alarm contacts

WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 33

3. Sicherheit / 4.Transport, Verpackung und Lagerung

Typenschild (Transmitter)

Typbezeichnung

Messbereich

Ausgangssignal

Hilfsenergie

S# Artikel-Nr.

P# Erzeugnis-Nr.

Anschlussbelegung

Herstelldatum

DE

4. Transport, Verpackung und Lagerung

4.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Offensichtliche Schäden unverzüglich mitteilen.

VORSICHT!

Beschädigungen durch unsachgemäßen Transport

Bei unsachgemäßem Transport können Sachschäden in erheblicher Höhe

entstehen.

▶

Beim Abladen der Packstücke bei Anlieferung sowie innerbetrieblichem

Transport vorsichtig vorgehen und die Symbole auf der Verpackung

beachten.

▶

Bei innerbetrieblichem Transport die Hinweise unter Kapitel 4.2 „Verpackung und Lagerung“ beachten.

4.2 Verpackung und Lagerung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

14300398.01 04/2019 EN/DE/FR/ES

33WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

Page 34

4.Transport, ... / 5. Inbetriebnahme, Betrieb

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch gefährliche

Zersetzungsprodukte

Vor der Einlagerung müssen alle anhaftenden Zersetzungsprodukte

entfernt werden.

▶

Reinigung siehe Kapitel 7.2 „Reinigung“

DE

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -40 ... +60 °C

■

Feuchtigkeit: 45 ... 75 % r. F. (nicht kondensierend)

Folgende Einflüsse vermeiden:

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

Das Gerät in der Originalverpackung an einem Ort lagern, der die oben gelisteten

Bedingungen erfüllt. Wenn die Originalverpackung nicht vorhanden ist, dann das Gerät

wie folgt verpacken und lagern:

1. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

2. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der

Verpackung beilegen.

5. Inbetriebnahme, Betrieb

5.1 Mechanische Montage

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden durch defektes

Gerät

Vor der Inbetriebnahme das Gerät optisch prüfen. Das Gerät nur in

sicherheitstechnisch einwandfreiem Zustand einsetzen.

5.1.1 Anforderungen an die Einbaustelle

■

Bei Anwendungen im Freien ist ein für die angegebene Schutzart geeigneter Aufstellort zu wählen, damit das Gerät keinen unzulässigen Witterungseinflüssen ausgesetzt

ist.

■

Dichtflächen am Gerät und an der Messstelle müssen unbeschädigt und frei von

Verschmutzungen sein.

5.1.2 Installation

■

Beim Transport oder der Lagerung kann es vorkommen, dass sich Gasdichtewächter

erwärmen oder abkühlen und dies in Zeigerbewegungen resultiert. Diese Zeigerbewegungen werden durch das Kompensationssystem hervorgerufen. Um sicherzustellen, dass sich die Geräte ausreichend der Umgebungstemperatur angepasst haben,

müssen sie min. 2 Std. bei 20 °C temperiert werden. Danach steht der Zeiger im

drucklosen Zustand innerhalb des Toleranzbalkens.

34

WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 35

5. Inbetriebnahme, Betrieb

■

Entsprechend den allgemeinen technischen Regeln für Manometer (z.B. EN 837-2

„Auswahl und Einbauempfehlungen für Druckmessgeräte“) darf beim Einschrauben des Gerätes die dazu erforderliche Kraft nicht über das Gehäuse aufgebracht

werden, sondern nur mit geeignetem Werkzeug über die dafür vorgesehene

Schlüsselfläche.

■

Beim Einschrauben die Gewindegänge nicht verkanten.

Für zylindrische Gewinde sind an der Dichtfläche Flachdichtungen, Dichtlinsen oder

WIKA-Profildichtungen einzusetzen. Bei kegeligen Gewinden (z. B. NPT-Gewinde)

erfolgt die Abdichtung im Gewinde , mit geeignetem Dichtungswerkstoff (EN 837-2).

Das Anzugsmoment ist von der eingesetzten Dichtung abhängig. Um das Messgerät

in die Stellung zu bringen, in der es sich am besten ablesen lässt, ist ein Anschluss mit

Spannmuffe oder Überwurfmutter zu empfehlen. Sofern ein Gerät eine Ausblasvorrichtung besitzt, muss diese vor Blockierung durch Geräteteile oder Schmutz geschützt

sein.

Schlüsseläche

Dichtäche

Abdichtung im Gewinde

5.1.3 Temperaturbelastung

Die Anbringung des Gerätes ist so auszuführen, dass die zulässige Betriebstemperatur,

auch unter Berücksichtigung des Einflusses von Konvektion und Wärmestrahlung,

weder unter- noch überschritten wird.

Der Temperatureinfluss auf die Anzeige- bzw. Messgenauigkeit ist zu beachten.

5.2 Elektrische Montage des Gasdichtewächters

■

Das Gerät über den Prozessanschluss erden.

■

Beim Kabelausgang sicherstellen, dass am Ende des Kabels keine Feuchtigkeit

eintritt.

■

Den Kabeldurchmesser passend zur Kabeldurchführung des Steckers wählen.

Darauf achten, dass die Kabelverschraubung des montierten Steckers korrekt sitzt

und dass die Dichtungen vorhanden und nicht beschädigt sind. Die Verschraubung

festziehen und den korrekten Sitz der Dichtungen überprüfen, um die Schutzart zu

gewährleisten.

■

Die Belegung der Anschlüsse und die Schaltfunktionen sind auf dem Typenschild

am Gerät angegeben und die Anschlussklemmen sowie die Erdungsklemme sind

entsprechend gekennzeichnet.

DE

14300398.01 04/2019 EN/DE/FR/ES

35WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

Page 36

5. Inbetriebnahme, Betrieb

5.2.1 Grenzwerte für die Kontaktbelastung bei ohmscher Belastung

gasgefüllte Geräte flüssigkeitsgefüllte

Geräte

Maximale Nennbetriebsspannung Ueff

DE

Nennbetriebsstrom

Einschaltstrom 1 A 1 A

Ausschaltstrom 1 A 1 A

Dauerstrom 0,6 A 0,6 A

Maximale Schaltleistung 30 W, 50 VA 20 W, 20 VA

Die Grenzwerte nicht überschreiten. Um dauerhaft eine sichere Funktion zu gewährleisten, werden folgende Belastungswerte empfohlen:

AC 250 V AC 250 V

Spannung

gasgefüllte Geräte flüssigkeitsgefüllte Geräte

(nach IEC 38)

ohmsche

Belastung

DC/AC DC AC cos ϕ >0,7 DC AC cos ϕ >0,7

230 V 100 mA 120 mA 65 mA 65 mA 90 mA 40 mA

110 V 200 mA 240 mA 130 mA 130 mA 180 mA 85 mA

48 V 300 mA 450 mA 200 mA 190 mA 330 mA 130 mA

24 V 400 mA 600 mA 250 mA 250 mA 450 mA 150 mA

induktive

Belastung

ohmsche

Belastung

induktive

Belastung

Bei niedrigen Spannungen darf der Schaltstrom aus Gründen der Schaltsicherheit nicht

kleiner als 20 mA sein.

Für höhere Belastungen, sowie für Geräte mit üssigkeitsgefüllten

Gehäusen, werden WIKA-Kontaktschutzrelais Typen 905.1X empfohlen

Überstrom-Schutzeinrichtungen

In den Geräten sind keine Überstrom-Schutzeinrichtungen eingebaut. Falls Schutzeinrichtungen gefordert werden, sind folgende Werte nach EN 60 947-5-1 zu empfehlen.

■

Spannung 24 V: 2 A

■

Spannung 250 V:1 A

36

WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 37

5. Inbetriebnahme, Betrieb

5.2.2 Kontaktschutzmaßnahmen

Mechanische Kontakte dürfen die angegebenen elektrischen Werte für Schaltstrom,

Schaltspannung und Schaltleistung unabhängig voneinander, auch kurzzeitig, nicht

überschreiten.

Für kapazitive oder induktive Lasten empfehlen wir eine der folgenden Schutzbeschaltungen:

Induktive Last bei Gleichspannung

Bei Gleichspannung kann der Kontaktschutz durch eine parallel zur Last geschalteten Freilaufdiode erzielt werden. Die Polung der Diode muss so erfolgen, dass sie bei

angelegter Betriebsspannung sperrt.

Beispiel:

Kontaktschutzmaßnahme mit Freilaufdiode

Kontakt

Diode

Last

Induktive Last bei Wechselspannung

Bei Wechselspannung gibt es zwei mögliche Schutzmaßnahmen:

Beispiel:

Kontaktschutzmaßnahme mit Spannungsabhängigem

Widerstand VDR

Last

DE

Beispiel:

Kontaktschutzmaßnahme mit

RC-Glied

14300398.01 04/2019 EN/DE/FR/ES

Last

37WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

Page 38

U

U

+

-

U

A

UB+/Sig+

0V/Sig-

5. Inbetriebnahme, Betrieb

Kapazitive Last

Bei kapazitiven Lasten treten erhöhte Einschaltströme auf. Diese können durch Reihenschalten von Widerständen in der Zuleitung verringert werden.

Beispiele: Kontaktschutzmaßnahme mit Widerstand zur Strombegrenzung

DE

B

R

1

Last Last

B

R

1

5.3 Elektrische Montage des Transmitters

Anforderungen an Spannungsversorgung

Hilfsenergie: DC 10 ... 30 V

Die Versorgung muss durch einen energiebegrenzten Stromkreis gemäß IEC 61010-1

erfolgen.

Anforderungen an elektrische Verbindung

■

Kabeldurchmesser passt zur Kabeldurchführung des Gegensteckers.

■

Kabelverschraubung und Dichtungen des Gegensteckers sitzen korrekt.

■

Bei Kabelausgängen kann keine Feuchtigkeit am Kabelende eindringen.

Anforderung an Schirmung und Erdung

Der Transmitter wird über den Prozessanschluss des Gasdichtewächters geerdet. Der

Transmitter ist über den Anbau elektrisch mit dem Prozessanschluss des Gasdichtewächters verbunden.

Anschlussbelegung

Transmitter, Winkelstecker (2-polig)

38

WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 39

5. Inbetriebnahme, Betrieb / 6. Störungen

5.4 Schaltpunkteinstellung

Die Schaltpunkte sind standardmäßig fest eingestellt und können nicht verstellt werden.

Dadurch ist ein ungewolltes Verstellen der Schaltpunkte ausgeschlossen.

Bei kundenspezifischen verstellbaren Schaltpunkten, lässt sich mittels mitgelieferten

Verstellschlüssels der gewünschte Sollwert über das Verstellschloss in der Sichtscheibe

einstellen.

6. Störungen

DE

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden

Können Störungen mit Hilfe der aufgeführten Maßnahmen nicht beseitigt

werden, Gerät unverzüglich außer Betrieb setzen.

▶

Sicherstellen, dass kein Druck bzw. Signal mehr anliegt und gegen

versehentliche Inbetriebnahme schützen.

▶

Kontakt mit dem Hersteller aufnehmen.

▶

Bei notwendiger Rücksendung die Hinweise unter Kapitel 9.2

„Rücksendung“ beachten.

Kontaktdaten siehe Kapitel 1 „Allgemeines“ oder Rückseite der Betriebs-

anleitung.

14300398.01 04/2019 EN/DE/FR/ES

39WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

Page 40

6. Störungen

Störungen Ursachen Maßnahmen

Kontakt schaltet nicht mehr

gemäß Spezifikation.

DE

Schaltzustand bleibt

trotz Erreichen des

Schaltpunktes/Rückschaltpunktes unverändert.

Keine Zeigerbewegung

trotz Druckänderung.

Zeigerbewegung obwohl

drucklos.

Kein Ausgangssignal Leitungsbruch Anschlusskabel tauschen

Abweichendes Nullpunkt-

Signal

Gleichbleibendes

Ausgangssignal bei

Druckänderung

Signalspanne schwankend EMV-Störquellen in Umge-

Signalspanne schwankend/

ungenau

Signalspanne fällt ab/zu

klein

Elektrische Verbindung ist

unterbrochen.

Elektrische Last für den

Schaltkontakt-Typ ungeeignet.

Kontakt verunreinigt.

Kontakte defekt (z. B. Kontakt-

zone verschmolzen).

Messwerk blockiert. Gerät austauschen.

Erwärmung oder Abkühlung

des Messgerätes (keine Stö-

rung)

Überlast-Druckgrenze überschritten

Zu hohe/niedrige Einsatztemperatur

Mechanische Überlastung

durch Überdruck

bung, z. B. Frequenzumrichter

Zu hohe/niedrige Einsatztemperatur

Mechanische Überlastung

durch Überdruck

Durchgangsprüfung der elektrischen Verbindungsleitungen

durchführen.

Zulässige elektrische Lasten

des Schaltkontakt-Typs einhalten.

Gerät austauschen. Vor erneuter Inbetriebnahme des neuen

Gerätes Schutzbeschaltung

für den Kontakt vorsehen.

Gerät 2 Stunden bei 20 °C

temperieren.

Zulässige Überlast-Druckgrenze einhalten

Zulässige Temperaturen einhalten

Gerät austauschen; bei

wiederholtem Ausfall Rücksprache mit Hersteller

Gerät abschirmen; Leitungsabschirmung; Störquelle entfernen

Zulässige Temperaturen einhalten

Gerät austauschen; bei

wiederholtem Ausfall Rücksprache mit Hersteller

Bei Reklamationen sind die Fertigungs- und Erzeugnisnummern anzugeben. Die

Fertigungsnummer ist auf dem Ziffernblatt angebracht, die Erzeugnisnummer auf dem

Typenschild. Bei Reklamationen ist stets der Luftdruck und die Temperatur während der

Messung anzugeben, ebenso die Daten des Vergleichsnormals (Typ, Klasse).

40

WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 41

7. Wartung, Reinigung und Rekalibrierung

7. Wartung, Reinigung und Rekalibrierung

7.1 Wartung

Diese Gasdichtewächter sind wartungsfrei.

Eine Überprüfung der Anzeige und der Schaltfunktion sollte etwa 1 bis 2 mal pro Jahr

erfolgen. Dazu ist das Gerät vom Gasraum zu trennen und mit einer Druckprüfvorrichtung zu kontrollieren.

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

Die Geräte dürfen nicht geöffnet werden, da dadurch Anzeige- und Schaltpunktfehler

entstehen.

7.2 Reinigung

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden

Eine unsachgemäße Reinigung führt zu Körperverletzungen, Sach- und

Umweltschäden. Zersetzungsprodukte im ausgebauten Gerät können zur

Gefährdung von Personen, Umwelt und Einrichtung führen.

▶

Reinigungsvorgang wie folgt beschrieben durchführen.

1. Vor der Reinigung das Gerät ordnungsgemäß von der Druckversorgung trennen und

stromlos schalten.

2. Notwendige Schutzausrüstung verwenden.

3. Das Gerät mit einem feuchten Tuch reinigen.

Elektrische Anschlüsse nicht mit Feuchtigkeit in Berührung bringen!

DE

VORSICHT!

Beschädigung des Gerätes

Eine unsachgemäße Reinigung führt zur Beschädigung des Gerätes!

▶

Keine aggressiven Reinigungsmittel verwenden.

▶

Keine harten und spitzen Gegenstände zur Reinigung verwenden.

4. Ausgebautes Gerät spülen bzw. säubern, um Personen und Umwelt vor Gefährdung

durch anhaftende Zersetzungsprodukte zu schützen.

Hinweise zur Rücksendung befinden sich in der Rubrik „Service“ auf

unserer lokalen Internetseite.

7.3 Kalibrierung

Der Gasdichtewächter kann über ein spezielles Kalibriersystem für Gasdichtemessge-

räte (z. B. WIKA BCS-10) kalibriert werden.

Der Gasdichtewächter muss fachgerecht demontiert werden. Hierbei kann es nötig sein,

die gesamte Anlage vorübergehend außer Betrieb zu nehmen.

14300398.01 04/2019 EN/DE/FR/ES

41WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

Page 42

8. Demontage, Rücksendung und Entsorgung

8. Demontage, Rücksendung und Entsorgung

8.1 Demontage

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch gefährliche

DE

Vor der Demontage des Gerätes die Gasfüllung evakuieren.

Das Gerät nur im druck- und stromlosen Zustand demontieren.

8.2 Rücksendung

Zur Rücksendung des Gerätes die Originalverpackung oder eine geeignete

Transportverpackung verwenden.

Zersetzungsprodukte

Bei Kontakt mit gefährlichen Zersetzungsprodukten besteht die Gefahr

von Körperverletzungen, Sach- und Umweltschäden.

▶

Notwendige Schutzausrüstung tragen (siehe Kapitel 3.6 „Persönliche

Schutzausrüstung“).

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoen (z.B.

Zersetzungsprodukten) sein und sind daher vor der Rücksendung zu

reinigen.

Um Schäden zu vermeiden:

1. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

2. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung beifügen.

Hinweise zur Rücksendung befinden sich in der Rubrik „Service“ auf

unserer lokalen Internetseite.

8.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den

landesspezifischen Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht

entsorgen.

42

WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 43

9. Technische Daten

9. Technische Daten

Messbereiche

Nenngröße in mm 100

Messbereich Vakuum- und Überdruckbereich mit Messspanne 1,6 ... 25 bar

(bei einer Umgebungstemperatur von 20 °C und Gasphase)

Messglied

Leckrate ≤ 1 · 10-8 mbar · l / s

Prüfmethode Heliummassenspektrometrie

Ausgangssignale

Ausgangssignal 4 ... 20 mA, 2-Leiter

Zulässige max. Bürde

R

A

Schaltkontakte

Anzahl Kontakte Max. 4 Magnetspringkontakte

Schaltfunktion Schließer, Öffner, Wechsler (max. 2 Schaltpunkte)

Schaltpunkteinstellung gesicherte Schaltpunkte, nicht verstellbar (Option: verstellbare

Schaltleistung Bei Gehäuse mit Gasfüllung: 30 W / 50 VA, max. 1 A

RA ≤ (UB - 10 V) / 0,02 A mit RA in Ohm und UB in Volt

Schaltpunkte)

Bei Gehäuse mit Füllflüssigkeit: 20 W / 20 VA, max. 1 A

DE

Spannungsversorgung

Hilfsenergie DC 10 ... 30 V

Genauigkeitsangaben

Mechanische Anzeige ±1 % bei einer Umgebungstemperatur von 20 °C [68 °F]

±2,5 % bei einer Umgebungstemperatur von -20 … +60 °C und bei

Eichdruck nach Referenzisochore (Referenzdiagramm KALI-Chemie

AG, Hannover, erstellt von Dr. Döring 1979)

Transmitter

Punkt der optimalen

Dichte

14300398.01 04/2019 EN/DE/FR/ES

-40 °C: 3 % der Spanne

20 °C: 1 % der Spanne

60 °C: 2,3 % der Spanne

43WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

Page 44

9. Technische Daten

Genauigkeitsangaben

Anfang und Ende

des Messbereiches

Stabilität pro Jahr ≤ 0,3 % der Spanne

DE

Schaltkontakte Schaltgenauigkeit im Temperaturbereich -20 … +60 °C

Einsatzbedingungen

Zulässiger Temperaturbereich

Umgebung -20 ... +60 °C (Gasphase)

Lagerung -40 ... +60 °C

Schutzart nach

IEC/EN 60529

Vorgesehener Messstoff reines SF

Hochspannungstest

100 %

Elektromagnetische Ver-

träglichkeit (EMV) nach

IEC 61000-4

-40 °C: 4 % der Spanne

20 °C: 2 % der Spanne

60 °C: 3,3 % der Spanne

Schaltpunkt = Eichdruck P

Schaltpunkt ≠ Eichdruck PE: Parallel zur Referenzisochore des Eich-

druckes

IP65

-Gas, weitere Gasgemische auf Anfrage

6

2 kV, 50 Hz, 1 s (Verdrahtung gegen Gehäuse)

IEC 61000-4-2 (ESD): test level 4 (8 kV)

IEC 61000-4-3 (Field): test level 3 (10 V/m)

IEC 61000-4-4 (Burst): test level X (±2 kV)

IEC 61000-4-5 (Surge): test level 2 (±1 kV)

IEC 61000-4-6 (Conducted RFI): test level 3 (10 V)

: Nach Kundenspezifikation

E

Prozessanschlüsse

Prozessanschluss G ½ B nach EN 837, unten

Schlüsselfläche 22 mm

(Option: Flanschanschluss)

weitere Anschlüsse und Anschlusslagen auf Anfrage

Elektrischer Anschluss

Schaltkontakte Kabeldose mit Kabelverschraubung M20 x 1,5

Aderquerschnitt max. 2,5 mm²

(Option: Steckbare Kabelbox)

Transmitter Bei eingebautem Transmitter: Kabelausgang

Bei angebautem Transmitter: Winkelstecker (2-polig), IP67 (Option: Feldgehäuse CrNi-Stahl, IP67)

Elektrische Sicherheit Verpolungs- und Überspannungsschutz

44

WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 45

9. Technische Daten

Werkstoffe

Zeigerwerk CrNi-Stahl

Bimetallzugstange (Temperaturkompensation)

Zifferblatt Aluminium, Rot-, Gelb-, Grünbereich nach Bestellspezifikation

Zeiger Aluminium, schwarz

Gehäuse CrNi-Stahl, mit Silikonöl oder Stickstofffüllung

Gasdicht: Leckrate ≤ 1 · 10-5 mbar · l / s

Schaltkontakte 80 % Ag / 20 % Ni, vergoldet

Transmitter CrNi-Stahl

Sichtscheibe Mehrschichten-Sicherheitsglas (Option: Acrylglas Sichtscheibe)

Ring Bajonettring, CrNi-Stahl, mit 3 Schweißpunkten gesichert

Prozessanschluss CrNi-Stahl

Interne

Übertragungsflüssigkeit

Messstoffraum mit

Prozessanschluss (messstoffberührt)

Messglied CrNi-Stahl, geschweißt

Zulassungen

Synthetisches Öl

CrNi-Stahl 316Ti (1.4571)

DE

Logo Beschreibung Land

EU-Konformitätserklärung

■

EMV-Richtlinie

■

Druckgeräterichtlinie

■

Niederspannungsrichtlinie

EAC

■

EMV-Richtlinie

■

Druckgeräterichtlinie

■

Niederspannungsrichtlinie

■

Maschinenrichtlinie

■

Gasgeräterichtlinie

Weitere technische Daten siehe Bestellunterlagen.

14300398.01 04/2019 EN/DE/FR/ES

Europäische Union

Eurasische

Wirtschaftsgemeinschaft

45WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

Page 46

9. Technische Daten

Abmessungen in mm

DE

Gewicht: ca. 1,2 kg

46

WIKA Betriebsanleitung, Typen GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 47

Sommaire

Sommaire

1. Généralités 48

2. Conception et fonction 49

3. Sécurité 50

4. Transport, emballage et stockage 55

5. Mise en service, utilisation 56

6. Dysfonctionnements 61

7. Entretien, nettoyage et réétalonnage 63

8. Démontage, retour et mise au rebut 64

9. Spécifications 65

Déclarations de conformité disponibles sur www.wika.fr.

FR

14300398.01 04/2019 EN/DE/FR/ES

47WIKA mode d'emploi types GDM-100-TI, GDM-100-TA

Page 48

1. Généralités

1. Généralités

■

L'instrument décrit dans le mode d'emploi est conçu et fabriqué selon les dernières

technologies en vigueur. Tous les composants sont soumis à des exigences environnementales et de qualité strictes durant la fabrication. Nos systèmes de gestion sont

certifiés selon ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant l'utilisation de l'ins-

FR

trument. Il est possible de travailler en toute sécurité avec ce produit en respectant

toutes les consignes de sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents et les

prescriptions générales de sécurité en vigueur pour le domaine d‘application de

l'instrument.

■

Le mode d'emploi fait partie de l'instrument et doit être conservé à proximité

immédiate de l'instrument et accessible à tout moment pour le personnel qualifié.

Confier le mode d'emploi à l'utilisateur ou propriétaire ultérieur de l'instrument.

■

Le personnel qualifié doit, avant de commencer toute opération, avoir lu soigneusement et compris le mode d'emploi.

■

Les conditions générales de vente mentionnées dans les documents de vente

s'appliquent.

■

Sous réserve de modifications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site Internet : www.wika.fr

- Fiches techniques correspondantes :

SP 60,05 Type GDM-100-TI

SP 60,06 Type GDM-100-TA

- Conseiller applications : Tél. : +33 1 787049-46

Fax : 0 891 03 58 91

info@wika.fr

48

WIKA mode d'emploi types GDM-100-TI, GDM-100-TA

14300398.01 04/2019 EN/DE/FR/ES

Page 49

2. Conception et fonction

2. Conception et fonction

2.1 Vue générale

Densimètre avec transmetteur intégré

Type GDM-100-TI

Plaque signalétique

Raccordement électrique, prise de câble

Transmetteur

Raccord process, six pans

Raccord process, filetage

Densimètre avec transmetteur rattaché

Type GDM-100-TA

Raccordement électrique, transmetteur

Raccordement électrique, contacts

électriques

Raccord process, six pans

Raccord process, filetage

Extension pour le transmetteur

Plaque signalétique, transmetteur

Plaque signalétique, densimètre

FR

2.2 Description

Contacts électriques

Les contacts électriques installés dans le densimètre se ferment ou s'ouvrent à des

valeurs limites réglées, en fonction de la fonction de commutation. Les fonctions de

commutation sont : normalement ouvert, normalement fermé, contact inverseur.

Les contacts secs magnétiques sont des contacts auxiliaires qui ouvrent ou ferment des

circuits électriques au moyen d'un bras de contact déplacé par l'aiguille de l'instrument.

2.3 Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

14300398.01 04/2019 EN/DE/FR/ES

49WIKA mode d'emploi types GDM-100-TI, GDM-100-TA

Page 50

3. Sécurité

3. Sécurité

3.1 Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer

la mort ou des blessures graves si elle n'est pas évitée.

FR

3.2 Utilisation conforme à l'usage prévu

Le densimètre type GDM-100 peut être utilisé partout où la densité de gaz SF₆ doit être

affichée localement et où il est nécessaire en même temps de commuter des contacts.

Le transmetteur envoie la densité de gaz mesurée sous forme de signal électrique.

Les densimètres sont des manomètres à contact modifiés développés spécialement

pour l'utilisation avec du gaz SF₆. Les influences de la température sur le gaz SF₆ confiné sont compensées par un système de compensation.

Les densimètres sont conçus spécialement pour les applications concernées liées aux

disjoncteurs (gaz SF₆ pur, mélanges de gaz, pression d'étalonnage, points de seuil ...).

Avant l'utilisation, vérifier si cet l'instrument est adapté à l'application prévue.

Utiliser l'instrument uniquement dans des applications qui se trouvent dans les limites

de ses performances techniques (par exemple température ambiante maximale,

compatibilité de matériau, ...).

ATTENTION !