Page 1

Operating Instructions

Digital Indicator Model A-RB-1

Page 2

2

Contents

Page Section Topic

4 1. General

5 2. Layout of front panel

5 2.1 LED display 'A'

5 2.2 MODE key 'H'

5 2.2.1 Real mode 'h'

5 2.2.2 HOLD mode 'h'

6 2.2.3 MIN mode (minimum memory) 'h'

6 2.2.4 MAX mode (maximum memory) 'h'

6 2.3 Set key descending value ( ) 'B'

6 2.4 Set key ascending value ( ) 'C'

6 2.5 Programming key PROG 'F'

(see also appendix A)

7 2.5.1 Programming the indication

Low end of scale

High end of scale

Decimal point

Input signal

Output signal

Damping

Reference for damping

Baud rate setting

10 2.5.2 Verification of programmed settings

10 2.5.3 Compensation of zero offset

11 2.6 Model A-RB-1-D with 2 alarms

(see also appendix B)

11 2.6.1 Setting of alarm 1

14 2.6.2 Setting of alarm 2

14 2.6.3 Verification of set points of alarm 1

14 2.6.4 Verification of set points of alarm 2

14 2.7 Reset key 'G'

14 2.7.1 Erase data memory

15 2.7.2 Exit programming mode

15 2.7.3 Exit verification mode

Page 3

3

Contents

Page Section Topic

15 3. Layout of back panel terminals

16 3.1 Layout of 15-pin plug 'J'

16 3.1.1 Opening the case

17 3.1.2 Scheme of line power settings

17 3.2 Layout of 9-pin plug 'K'

18 3.3 Wiring examples

19 3.4 Layout of 9-pin Sub-D plug 'L'

19 4. Option serial interface RS-232

20 4.1 Transfer of data and parameters

22 4.2 Programming of parameters

23 5. Error messages

24 5.1 Error messages E1/-E1

24 5.2 Error messages E2/-E2

24 5.3 Error messages E3/-E3

24 5.3.1 Error message E3

25 5.3.2 Error message -E3

26 6. Preparing for installation

26 7. Environment

26 8. Setting of physical unit

26 9. Maintenance

27 10. Specifications

28 App. A Schematic description of settings and data

transmission

32 App. B Schematic description of alarm settings

and verifications

34 App. C Dimensions

36 App. D Layout of front and back panel

Page 4

4

Safety Instructions

Preface

Many thanks for buying our digital indicator Model A-RB-1.

This operating manual includes instructions for the operation of the

digital indicator and information on its functionality. Read these operating instructions thoroughly prior to starting up the digital indicator. In

order to avoid any damage or injuries that might be caused by any nonobservance of the appropriate regulations, please ensure that the person

operating this digital indicator receives these operating instructions.

The appropriate national safety regulations (e.g. VDE 0100) must be

observed when mounting, starting up and operating these displays.

Serious injuries and/or damage can occur should the appropriate

regulations not be observed. Only appropriately qualified persons should

work on these instruments.

1. General

The digital indicators A-RB-1 are precision instruments for the measurement of current and voltage signals of pressure or other transmitters.

The instruments are normally DIN-Size panel mounting (96 x 48 x 190

mm) per IEC 61 554.

Indication is made via a 3 1/2 -digit LED display, covering a range from

-1999 to +1999 digits. The actual span to be indicated can be easily

programmed anywhere within this range. The same applies to decimal

point, signal input, analogue output damping and baud rate of the data

interface. All programming can be made while the instrument is

operative.

This versatility is achieved by means of a powerful microprocessor,

which also controls all other functions.

An inbuilt isolated transformer provides power supply of DC 24 V max.

30 mA to energise transmitters connected.

Analogue output of 0 … 10 V, 0 … 20 or 4 … 20 mA, adjustable

damping, as well as HOLD memory and MIN and MAX memory are serial

standard.

Page 5

5

Optionally available are 2 alarm contacts and also a serial RS-232

interface.

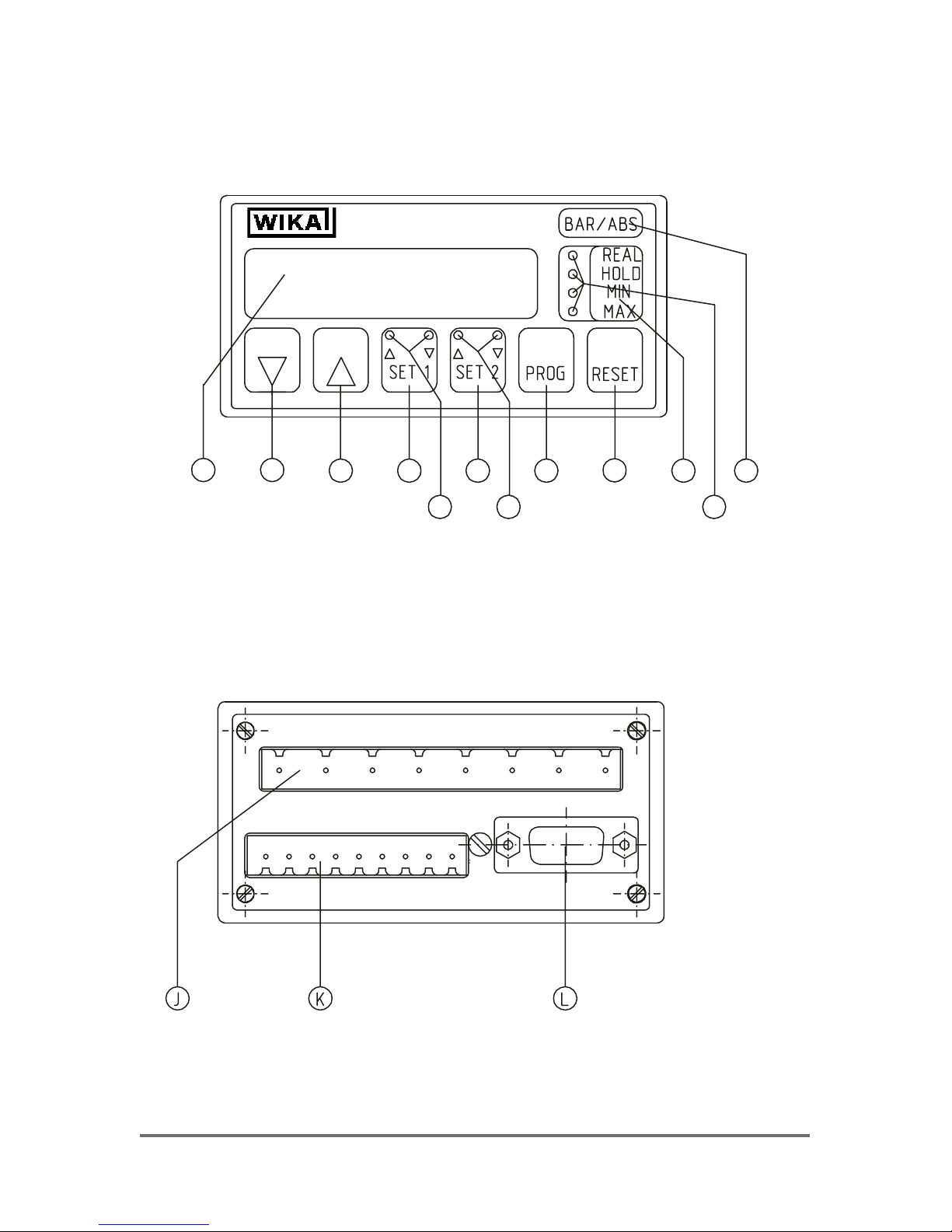

2. Layout of front panel

The position of the operation and connection elements is shown in

appendix C.

2.1 LED display 'A'

By means of the MODE key (see section 2.2), the display can be set to

optionally read the REAL value measured, or either one of the values

stored in the HOLD, MIN or MAX memory.

2.2 MODE key 'H'

The MODE key is found at the right-hand side next to the display,

indicated by REAL, HOLD, MIN and MAX. Hitting changes the modes in

consecutive order. A red LED indicates the active mode.

2.2.1 REAL mode 'h'

Indicates the current value measured.

2.2.2 HOLD mode 'h'

Hold the value indicated at the very moment the key is pressed.

Measurement continues in the background, meaning that the memories

of Minimum and Maximum as well as the alarm contacts continue to

operate. HOLD discontinues upon further hitting of the MODE key or

hitting of the RESET key (see 2.7).

Page 6

6

2.2.3 MIN mode (minimum memory) 'h'

The lowest value indicated since last hitting of the RESET key is

memorised and will be displayed in this mode. Measurement continues

in the background, meaning that the memories of MIN and MAX as well

as the alarm contacts continue to operate. MIN discontinues upon

further hitting of the MODE key. Hitting of the RESET key erases the

memory (see 2.7).

2.2.4 MAX mode (maximum memory) 'h'

The highest value indicated since last hitting of the RESET key is

memorised and will be displayed in this mode. Measurement continues

in the background, meaning, that the memories of MIN and MAX as well

as the alarm contacts continue to operate. MAX discontinues upon

further hitting of the MODE key. Hitting of the RESET key erases the

memory (see 2.7).

2.3 Set key descending value ( ) 'B'

Selects the next lower value or individual parameter during programming.

2.4 Set key ascending value ( ) 'C'

Selects the next higher value or individual parameter during programming.

2.5 Programming key PROG 'F'

Hitting of this key actuates the programming mode, at which all

operative parameters can be set and verified.

2.5.1 Programming the indication (see also appendix A)

All programming is made in consecutive order by initially holding the

PROG key pressed for approx. 5 seconds, until the message SCL (for

scaling) appears instead of PRO for programming.

Page 7

7

Press PROG once more: -A-appears, standing for "Low end of scale".

Press PROG once more: The "MIN" LED flashes and the corresponding

value is displayed. Change this value as desired by hitting the (

) and

(

) keys. Press PROG once more: The new value will be memorised.

This is indicated by 3 dashes "---" appearing for a few seconds.

The "MIN" LED extinguishes and -E-appears, standing for "High end of

scale". Press PROG once more: The "MAX" LED flashes and the

corresponding value is displayed. Change this value as desired by

hitting the (

) and ( ) keys. Press PROG once more: The new value

will be memorised. This is indicated by 3 dashes "---" appearing for a

few seconds.

The "MAX" LED extinguishes and dP appears, standing for "Decimal

point". Change the decimal point as desired by hitting the (

) and ( )

keys. Press PROG once more: The new position of the decimal point will

be memorised. This is indicated by 3 dashes "---" appearing for a few

seconds after which InX appears, standing for "Signal input X", where

"X" stands for figures 1 to 3 as explained below.

Change this value as desired by hitting the (

) and ( ) keys.

X = 1: In1 = Input signal voltage 0 ... 10 V

X = 2: In2 = Input signal current 0 ... 20 mA

X = 3: In3 = Input signal current 4 ... 20 mA

Press PROG once more: The new value will be memorised.

Page 8

8

This is indicated by 3 dashes "---" appearing for a few seconds after

which OuX appears, standing for "Output signal X", where "X" stands for

figures 1 to 3 as explained below. Change this value as desired by hitting

the (

) and ( ) keys.

X = 1: Ou1 = Output signal voltage 0 ... 10 V

X = 2: Ou2 = Output signal current 0 ... 20 mA

X = 3: Ou3 = Output signal current 4 ... 20 mA

Press PROG once more: The new value will be memorised .This is

indicated by 3 dashes "---" appearing for a few seconds.

Subsequently "-d- (damping)" appears automatically. After hitting the

key once more the current setting of the damping is displayed. The

damping can be set within a range of 0.1 s ... 50.0 s. The damping can

be changed in 0.1 s steps using the (

) and ( ) keys.

The damping is adapted from the behaviour of a capacitor. After the set

time (=t) has passed, approx. 63% of the changed value is applied. After

5 x t has passed, approx. 97% of the changed value is applied.

Press PROG once more: The new damping value will be memorised.

This is indicated by 3 dashes "---" appearing for a few seconds.

Then dXX (reference of damping) is displayed. XX stands for the selected

setting. The damping can be activated for the display, the analogue

output signal, the alarm contacts and the MIN / MAX memory in any

combination as specified in the following table:

Page 9

9

Setting Display Analogue Alarm MIN / MAX

d XX output contacts memory

d011000

d020100

d031100

d040010

d051010

d060110

d071110

d080001

d091001

d100101

d111101

d120011

d131011

d140111

d151111

(0: Damping deactivated, 1: Damping activated)

The value for dXX can be changed using the (

) and ( ) keys. Press

PROG once more: The new value will be memorised. This is indicated by

3 dashes "---" appearing for a few seconds.

With instruments not featuring the serial data interface, programming is

now complete and standard operating mode will be automatically

selected.

With instruments featuring the serial data interface, -b- appears. After

hitting the key once more the current setting of the Baud rate of the

serial interface (RS 232) is indicated. Change this value as desired by

hitting the (

) and ( ) keys.

Display Baud rate

01.2 1200 Baud

02.4 2400 Baud

04.8 4800 Baud

09.6 9600 Baud

19.2 19200 Baud

38.4 38400 Baud

Page 10

10

Press PROG once more: The new value will be memorised. This is

indicated by 3 dashes "---" appearing for a few seconds. Programming

is now complete and standard operating mode will be automatically

selected.

Programming can be terminated at any time by hitting the RESET key. In

this instance, only such changes are accepted that have been acknowledged by appearance of "---". Otherwise, previously set values remain in

effect.

2.5.2 Verification of programmed settings

(see also appendix A)

Short hitting of the PROG key initiates "Pro" to appear at the display,

followed by all current settings in consecutive order, where:

-A- Low end of scale

-E- High end of scale

dP Decimal point

InX Input signal

OuX Output signal

-d- Damping

dxx Reference of damping

-b- At digital interface: baud rate setting

Indication can be terminated at any time by hitting the RESET key. (see

also 2.7)

2.5.3 Compensation of zero offset

Despite careful calibration, the instrument may indicate a zero offset in

operation. This may be caused by a static head acting on the transmitter

or other process conditions. Preferably this should be compensated by

shifting the zero signal of the transmitter. If this cannot be accomplished,

true indication can be achieved by means of shifting low end and high

end indication correspondingly as per examples below.

Page 11

11

Example 1:

Scaling: 0 … 400 bar

Zero offset: 4 bar

Corrective: -4 … 396 bar

Example 2:

Scaling: 0 … 400 bar

Zero offset: -7 bar

Corrective: 7 … 407 bar

However, it is more favourable to compensate the offset by

adjustment the connected transmitter.

2.6 Model A-RB-1-D with 2 alarms

(see also appendix B)

The keys SET 1 (alarm 1) and SET 2 (alarm 2) actuate the programming

mode to enter and verify the settings of the alarms. The max. loading

capacity of the alarms is AC 250 V / 8 A.

2.6.1 Setting of alarm 1

(see also appendix B)

Programming of alarm 1 is made by initially holding the SET 1 key

pressed until SP1 (Set point 1) disappears and the message SE (Set

point makE) appears.

Press SET 1 once more: The red LED in the upper left hand corner of the

SET 1 key flashes and the corresponding value is displayed. Change this

value as desired by hitting the (

) and ( ) keys.

Press SET 1 once more: The new value will be memorised. This is

indicated by 3 dashes "---" appearing for a few seconds.

The LED extinguishes and SA appears, standing for "Set point breAk".

Press SET 1 once more: The red LED in the upper right corner of the

SET 1 key flashes and the corresponding value is displayed. Change this

value as desired by hitting the (

) and ( ) keys.

Page 12

12

Press SET 1 once more: The new value will be memorised. This is

indicated by 3 dashes "---" appearing for a few seconds and the LED

extinguishes.

Contact function can be selected to HIGH ALARM (meaning make on

rising value), or LOW ALARM (meaning make on falling value). This is

easily achieved by programming the make (SE) value either above or

below the corresponding break (SA) value.

Setting (SE) above (SA) means HIGH ALARM. (SE) will energise the alarm

circuit, which will remain energised until the display figure decreases to

reach the value of (SA).

Setting (SE) below (SA) means LOW ALARM. (SE) will energise the alarm

circuit, which will remain energised until the display figure increases to

reach the value of (SA).

The difference between (SE) and (SA) represents the hysteresis across

make and break points of the contact. (This must not be confused with

any hysteresis across approach of the set points with rising and falling

values. This sort of mechanical delay is not apparent with a digital

instrument).

Both values can be programmed without limitations, as the case

demands. Setting both, (SE) and (SA) at the same values, will automatically create HIGH ALARM function.

The LED's in the upper corners of the SET keys are intended to indicate

the alarm configuration together with the relay status. The left LED, when

lit, indicates energised alarm circuit at HIGH ALARM programmed. The

right LED, when lit, indicates energised alarm circuit at LOW ALARM

programmed.

SET 1 key corresponds to alarm 1, SET 2 key corresponds to alarm 2.

Programming of alarm contacts can be terminated at any time by hitting

the RESET key. In this instance, only such changes are accepted that

have been acknowledged by appearance of "---". Otherwise, previously

set values remain in effect.

Page 13

13

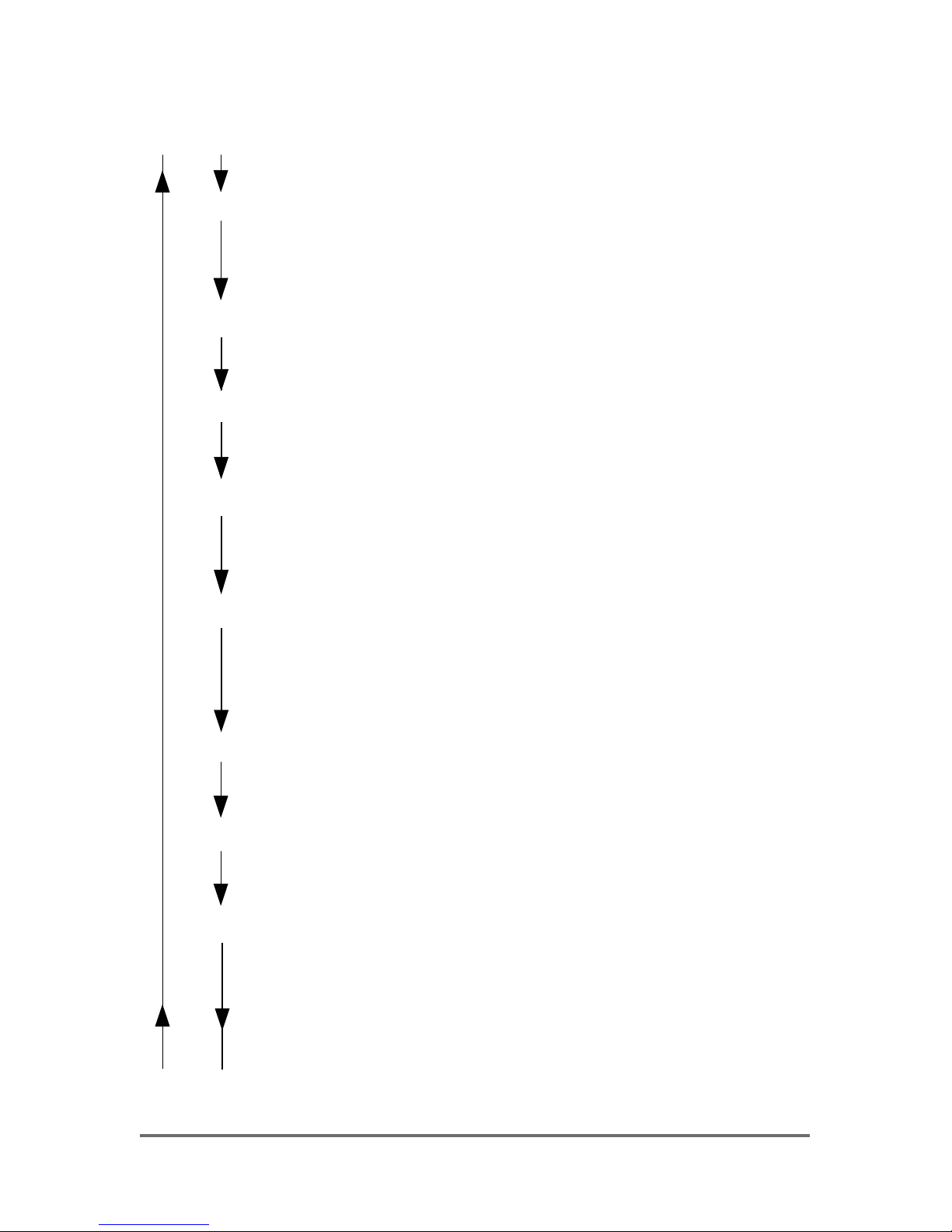

hysteresis

Relay on

Relay off

"-E-"

makE point

400

"-A-"

breAk point

500

value

"-A-"

breAk point

800

"-E-"

makE point

1000

hysteresis

Relay on

Relay off

value

Examples:

a) HIGH ALARM (make at 1000, break at 800)

The circuit relay is energised once the display value rises to 1000. It

remains energised until the display value falls to 800.

The left hand LED at the SET 1 key comes on at 1000 and is turned off

at 800.

b) LOW ALARM (make at 400, break at 500)

The circuit relay is energised once the display value falls to 400. It

remains energised until the display value rises to 500.

The right hand LED at the SET 1 key comes on at 400 and is turned off

at 500.

Page 14

14

2.6.2 Setting of alarm 2

(see also appendix B)

Programming of the alarm 2 contact is initiated by hitting key SET 2,

otherwise fully identically to the programming of no. 1.

2.6.3 Verification of set points of alarm 1

(see also appendix B)

Short hitting of the SET 1 key initiates "SP1" to appear at the display,

followed by the current settings of (SE) and (SA) of alarm contact no. 1

Indication can be terminated at any time by hitting the RESET key. (see

also 2.7)

2.6.4 Verification of set points of alarm 2

(see also appendix B)

Verification of the alarm 2 contact is initiated by hitting key SET 2,

otherwise fully identical to the verification of no. 1.

2.7 RESET key 'G'

The RESET key enables to - erase memories - exit programming mode exit verification mode.

2.7.1 Erase data memory

Hitting the RESET key while the instrument is operative erases the data

memories as explained below:

- When pressed in REAL mode (indication of value measured), the

MIN and MAX memories will be erased.

- When pressed in HOLD mode, this will reset the instrument into

REAL mode.

- When pressed in MIN mode, only the MIN memory will be erased.

- When pressed in MAX mode, only the MAX memory will be erased.

Page 15

15

2.7.2 Exit programming mode

(see also 2.5.1, 2.6.1 and 2.6.2)

Programming can be terminated at any time by hitting the RESET key. In

this instance, only such changes are accepted, that have been acknowledged by appearance of "---". Otherwise, previously set values remain in

effect.

2.7.3 Exit verification mode

(see also 2.5.2, 2.6.3 and 2.6.4)

The verification mode proceeds automatically and can be terminated at

any time by hitting the RESET key.

3. Layout of back panel terminals

(see illustration of appendix D)

The back panel features the 15-pin plug 'J', containing the terminals for

power supply and both alarm contacts, and the 9-pin plug 'K', containing the terminals of input signal, transmitter supply and analogue output.

Both racks are of the plug-terminal type for ease of wiring.

Every 2nd pin of the 15-pin plug remains blank to enable safe wiring of

the line voltage.

Instruments incorporating the serial interface will additionally feature a 9pin Sub-D plug 'L'.

Page 16

16

3.1 Layout of 15-pin plug 'J'

Pin Designation

1

3 Alarm 1 contact max. AC 250 V / 8 A

5

7

9 Alarm 2 contact max. AC 250 V / 8 A

11

13

15 AC 230 V ± 10 % or AC 115 V ± 10 %, 50 / 60 Hz

Internal jumpers provide adaption to line voltage AC 230 V

± 10 %, 50 / 60 Hz or AC 115 V ± 10 %, 50 / 60 Hz. To adjust,

open the enclosure and arrange jumpers next to the fuse as

indicated in the drawing. A replacement of the fuse is not

required.

3.1.1 Opening the case

Remember to disconnect the power supply prior

to opening the enclosure!

First strip the terminal blocks from the digital indicator. Then remove the

retaining screw in the centre of the case back and loosen the electronic

rack from the locking device by exerting a constant pressure on the 9pin female plug towards the front. Now you can pull the rack out of the

case.

For assembly please carry out these steps in reverse order.

Page 17

17

3.1.2 Scheme of line power settings

Power setting 230 VAC ± 10 %: Power setting 115 VAC ± 10 %:

3.2 Layout of 9-pin plug 'K'

Pin Designation

1+U

in

Voltage signal input

2-U

in

3+IinCurrent signal input

4-I

in

5 -out Common minus of current and voltage output

signal (pins 8 and 9)

6 +24 V Transmitter supply

7 -GND

8+U

out

Analogue output signal voltage

9+I

out

Analogue output signal current

Page 18

18

+ I-in 3

- I-in 4

GND 7

+ 24 V 6

+ signal

- power supply

+ power supply

+ U-in 1

- U-in 2

GND 7

+ 24 V 6

+ signal

- power supply

+ power supply

+ U-in 1

- U-in 2

GND 7

+ 24 V 6

+ signal

- signal

- power supply

+ power supply

+ I-in 3

- I-in 4

GND 7

+ 24 V 6

- terminal

+ terminal

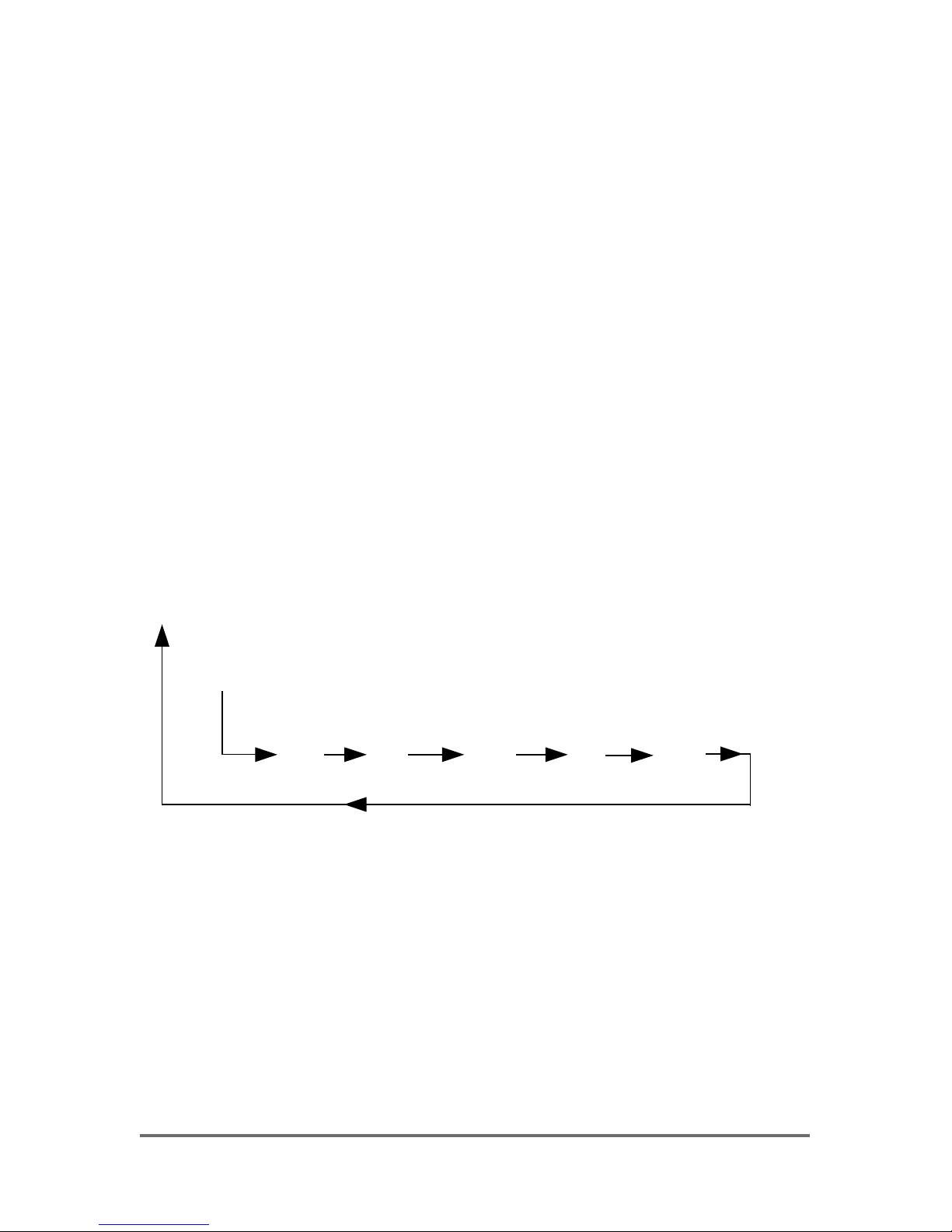

3.3 Wiring examples:

a) 2-wire, 4 ... 20 mA transmitter signal

Digital indicator Transmitter

b) 3-wire, 0 ... 20 mA transmitter signal

Digital indicator Transmitter

c) 3-wire, 0 ... 10 V transmitter signal

Digital indicator Transmitter

d) 4-wire, 0 ... 10 transmitter signal

Digital indicator Transmitter

Page 19

19

3.4 Layout of 9-pin Sub-D plug 'L'

Layout of the serial interface is identical to that of commonly found

Personal Computers. This simplifies data input into these widely used

machines.

Pin Designation

2 TX DATA

3 RX DATA

5 GROUND

4. Option serial interface RS-232

The instrument can be optionally equipped with a serial RS-232 data

interface. The interface transmits data measured as well as enabling

programming of the instrument.

Data transmission and programming follows the same rule in principle.

Data reading requires a 5-byte command. The instrument responds by

acknowledging the command together with the respective data.

Programming requires a 5-byte command followed by a word of 1 to 6

bytes length. All commands transmitted and received are followed by

<CR>, Dec 13, (↵) (carriage Return).

Page 20

20

4.1 Transfer of data and parameters

Com- Response Meaning

mand No. of byte

Example

RREAL Value active value measrued incl.

5 + 6 byte + ↵ sign and decimal point

RREAL+12.34

RMODE 1 = REAL mode status message, indicating

2 = HOLD mode current mode of instrument

3 = MIN mode

4 = MAX mode

5 + 1 byte + ↵

RMODE1

RMINM Min value contents of MIN memory incl.

5 + 6 byte + ↵ sign and decimal point

RMINM+01.23

RMAXM Max value contents of MAX memory incl.

5 + 6 byte + ↵ sign and decimal point

RMAXM+14.56

RST1E SE of alarm 1 starting point alarm 1, incl.

5 + 6 byte + ↵ sign and decimal point

RST1E+10.00

RST1A SA of alarm 1 end point alarm 1, incl.

5 + 6 byte + ↵ sign and decimal point

RST1A+09.50

RST2E SE of alarm 2 starting point alarm 2, incl.

5 + 6 byte + ↵ sign and decimal point

RST2E+08.00

RST2A SA of alarm 2 end point alarm 2, incl.

5 + 6 byte + ↵ sign and decimal point

RST2A+08.50

Page 21

21

Com- Response Meaning

mand No. of byte

Example

RSCLA Low scale low end of scale value incl.

5 + 6 byte + ↵ sign and decimal point

RSCLA+00.00

RSCLE High scale high end of scale value incl.

5 + 6 byte + ↵ sign and decimal point

RSCLE+16.00

RINPX 1 = 0 ... 10 V input signal selected

2 = 0 ... 20 mA

3 = 4 ... 20 mA

5 + 1 byte + ↵

RINPX3

ROUTX 1 = 0 ... 10 V output signal selected

2 = 0 ... 20 mA

3 = 4 ... 20 mA

5 + 1 byte + ↵

ROUTX3

RDAEM Damping set value of damping in seconds

5 + 4 byte + ↵

RDAEM00.1

RDBEZ Damping reference set reference of damping

5 + 2 byte + ↵

RDBEZ01

All commands transmitter to the instrument must

terminate with <CR> Dec. 13 (

↵↵

↵↵

↵ ). All date received

from the instrument will terminate with <CR> Dec.

13 (

↵↵

↵↵

↵ ).

Page 22

22

4.2 Programming of parameters

Com- Response Meaning

mand No. of byte

Example

PMODE 1 = REAL mode signal to set

2 = HOLD mode mode of instrument

3 = MIN mode

4 = MAX mode

5 + 1 byte + ↵

PMODE1

PMINM 0 = Reset erase MIN memory

5 + 1 byte + ↵

PMINM0

PMAXM 0 = Reset erase MAX memory

5 + 1 byte + ↵

PMAXM0

PST1E SE of alarm 1 set switch-on value alarm 1, incl.

5 + 6 byte + ↵ sign and decimal point

PST1E+10.00

PST1A SA of alarm 1 set switch-off value alarm 1, incl.

5 + 6 byte + ↵ sign and decimal point

PST1A+09.50

PST2E SE of alarm 2 set switch-on value alarm 2, incl.

5 + 6 byte + ↵ sign and decimal point

PST2E+08.00

PST2A SA of alarm 2 set switch-off value alarm 2, incl.

5 + 6 byte + ↵ sign and decimal point

PST2A+08.50

PSCLA Low scale set low end of scale value incl.

5 + 6 byte + ↵ sign and decimal point

PSCLA+00.00

Page 23

23

Com- Response Meaning

mand No. of byte

Example

PSCLE High scale set high end of scale value incl.

5 + 6 byte + ↵ sign and decimal point

PSCLE+16.00

PINPX 1 = 0 ... 10 V set input signal at instrument

2 = 0 ... 20 mA

3 = 4 ... 20 mA

5 + 1 byte + ↵

PINPX3

POUTX 1 = 0 ... 10 V set output signal (analogue output)

2 = 0 ... 20 mA at instrument

3 = 4 ... 20 mA

5 + 1 byte + ↵

POUTX3

PDAEM Damping set value in seconds for damping

5 + 4 byte + ↵

PDAEM00.1

PDBEZ Damping reference set reference of damping

5 + 2 byte + ↵

PDBEZ01

All commands transmitted to the instrument must

terminate with <CR> Dec. 13 (

↵↵

↵↵

↵ ). The decimal

point must be entered with both, low end and high

end scale values, where the last value entered will

determine the actual decimal point, irrespective

of this being the low or high end value. Note

correct decimal point when entering the alarm

contact settings.

Page 24

24

5. Error messages

Altogether 6 different error messages may be displayed:

5.1 Error messages E1/-E1

The error messages E1/-E1 will appear, if the actual input signal exceeds

the programmed maximum signal value (10 V or 20 mA) by more than

9% or if it falls below the minimum signal value (0 V, 0 mA or 4 mA) by

more than 9 % of the maximum signal value, because the inbuilt A/D

converter is overloaded. E1 indicates a too high signal, -E1 indicates a

too low signal. Below table indicates the actual values at which this error

message will appear:

Message Set input signal Actual signal

E1 0 ... 10 V > 10.9 V

0 ... 20 mA > 21.8 mA

4 ... 20 mA > 21.8 mA

-E1 0 ... 10 V < -0.9 V

0 ... 20 mA < -1.8 mA

4 ... 20 mA < 2.2 mA

5.2 Error messages E2/-E2

E2 appears if the input value exceeds the corresponding indication of

+1999 digits. -E2 appears if the input value exceeds the corresponding

indication of -1999 digits.

5.3 Error messages E3/-E3

5.3.1 Error message E3

E3 will appear, if the actual input signal exceeds the maximum signal

value (10 V or 20 mA) by more than 6 %. This is still within the capacity

of the inbuilt A/D converter (see also 5.1).

If the value to display is still within the capacity of the indicator, the value

and the respective error message will flash intermittently. If the value

exceeds ±1999, E3 will be displayed permanently.

Page 25

25

Below table indicates the actual values at which this error message will

appear:

Message Set input signal Actual signal

E3 flashes 0 ... 10 V > 10.6 V and < 10.9 V

intermittently 0 ... 20 mA > 21.2 mA and < 21.8 mA

with measured 4 ... 20 mA > 21.2 mA and < 21.8 mA

value

E3 0 ... 10 V > 10.6 V and < 10.9 V and

display > +1999 or < -1999

0 ... 20 mA > 21.2 mA and < 21.8 mA and

display > +1999 or < -1999

4 ... 20 mA > -21.2 mA and < 21.8 mA

display > +1999 or < -1999

5.3.2 Error message -E3

-E3 will appear, if the actual input signal is below the minimum signal

value (0 V, 0 mA or 4 mA) by more than 6 % of the maximum signal

value. This is still within the capacity of the inbuilt A/D converter (see

also 5.1). If the value to display is still within the capacity of the indicator,

the value and the respective error message will flash intermittently. If the

value exceeds ±1999, -E3 will be displayed permanently.

Below table indicates the actual values at which this error message will

appear:

Message Set input signal Actual signal

-E3 flashes 0 ... 10 V < -0.6 V and > -0.9 V

intermittently 0 ... 20 mA < -1.2 mA and > -1.8 mA

with measured 4 ... 20 mA < 2.8 mA and > 2.2 mA

value

-E3 0 ... 10 V < -0.6 V and > -0.9 V and

display > +1999 or < -1999

0 ... 20 mA < -1.2 mA and > -1.8 mA and

display > +1999 or < -1999

4 ... 20 mA < 2.8 mA and > 2.2 mA and

display > +1999 or < -1999

Page 26

26

6. Preparing for installation

The instrument is designed to fit panels of 40 mm maximum thickness.

Panel cut out per IEC 61 554, 92 +0.8 mm wide and 45 + 0.6 mm high.

Panel clamps are supplied with the instrument.

7. Environment

The front panel of the instrument is protected against moisture and dust

(IP65) by means of a sealed foil. Full ingress protection may be achieved

by fitting an appropriate gasket between panel and instrument.

The ambient operating temperature should be maintained within the

range 0 to 50 °C. When the permissible ambient temperature is exceeded make sure that there is sufficient ventilation.

8. Setting of physical unit

The instrument is supplied with a variety of labels to suit most commonly

used units of pressure and temperature. A number of blank labels may

be used to indicate customised units.

The pocket 'I' above the MODE key is intended to accept the unit label.

To insert the label, pry the pocket open with a tipped instrument. Take

care not to loosen or damage the protective foil.

9. Maintenance

No subject to wear and tear parts or components requiring any regular

maintenance are contained in the instrument. In case of obvious

malfunction, it is recommended that you return the instrument to an

authorised WIKA service for repair.

The front foil may be cleaned using a moist cloth and some non abrasive

household detergent.

Page 27

27

Display

- Design 7-Segment-LED, red, 3 1/2 -digit

- Size of digits 14.56 mm

- Indication range -1999 ... +1999

Accuracy ± 0.05 % of span ± 2 digit

Measuring rate 10 measurements/s, damping selectable in 100 ms steps up to max. 50.0 s

Error messages E1: A/D converter overflow

E2: Display overflow (measured value exceeds maximum possible display value)

E3: Input signal is below the minimum signal value or exceeds the maximum

signal value

Scaling adjustment Menu driven, initial value and final value free adjustable between -1999 and +1999;

Adjustable decimal point

Signal input Selectable as:

0 ... 20 mA, 4 ... 20 mA

0 ... 10 V

Analogue output Selectable as:

0 ... 20 mA, 4 ... 20 mA

0 ... 10 V

Response time 100 ms

(10 ... 90 %)

{Serial interface} RS-232

Transmitter supply DC 24 V ± 5 %, max. 30 mA, galvanically isolated, short-circuit proof (for

approx. 8 minutes)

{Alarm contacts}

- Number 2, independently settable

- Function MAX/MIN-alarm adjustable by setting of the switch-on and switch-off value

- Switching point Adjustable over the complete indication range

- Hysteresis Adjustable over the complete indication range

- Accuracy True value by means of digital control

- Contacts 1 potential-free relay change over contact for each alarm contact

- Load AC 250 V 8 A with resistive load;

AC 250 V 1 A with cos ϕ = 0.1

HOLD memory Displayed value is fix, measurement and control of MIN and MAX values as

well as alarm contacts goes on in the background.

MIN/MAX memory Two separately working memories for MIN and MAX values;

Individual or common reset enabled by pressing the RESET key;

Unlimited data storage by digital memory

Power supply AC 230 V, 50/60 Hz, ± 10 % or

AC 115 V, 50/60 Hz, ± 10 %, changeable by means of internal jumper

Electrical connection Detachable screw terminals

-Max. cable diameter 2.5 mm

2

Permissible ambient 0 °C ... 50 °C

temperature

CE Conformity Conformity in accordance with 89/336/EWG

Interference emission per EN 60 000-6-4

Interference compatibility per EN 61 000-6-2

For cable lengths of > 30 m, shielded cables are to be used

Case According to IEC 61 554

- Material PC, ABS-Blend, black

- Ingress protection Front: IP65; Back: IP00 (according to IEC 60 529 / EN 60 529)

- Mass Approx. 530 g

- Mounting Removable screw elements for a wall thickness up to 40 mm

10. Specifications

Specification Model A-RB-1

{ } Items in curved brackets are optional extras for additional price.

Page 28

28

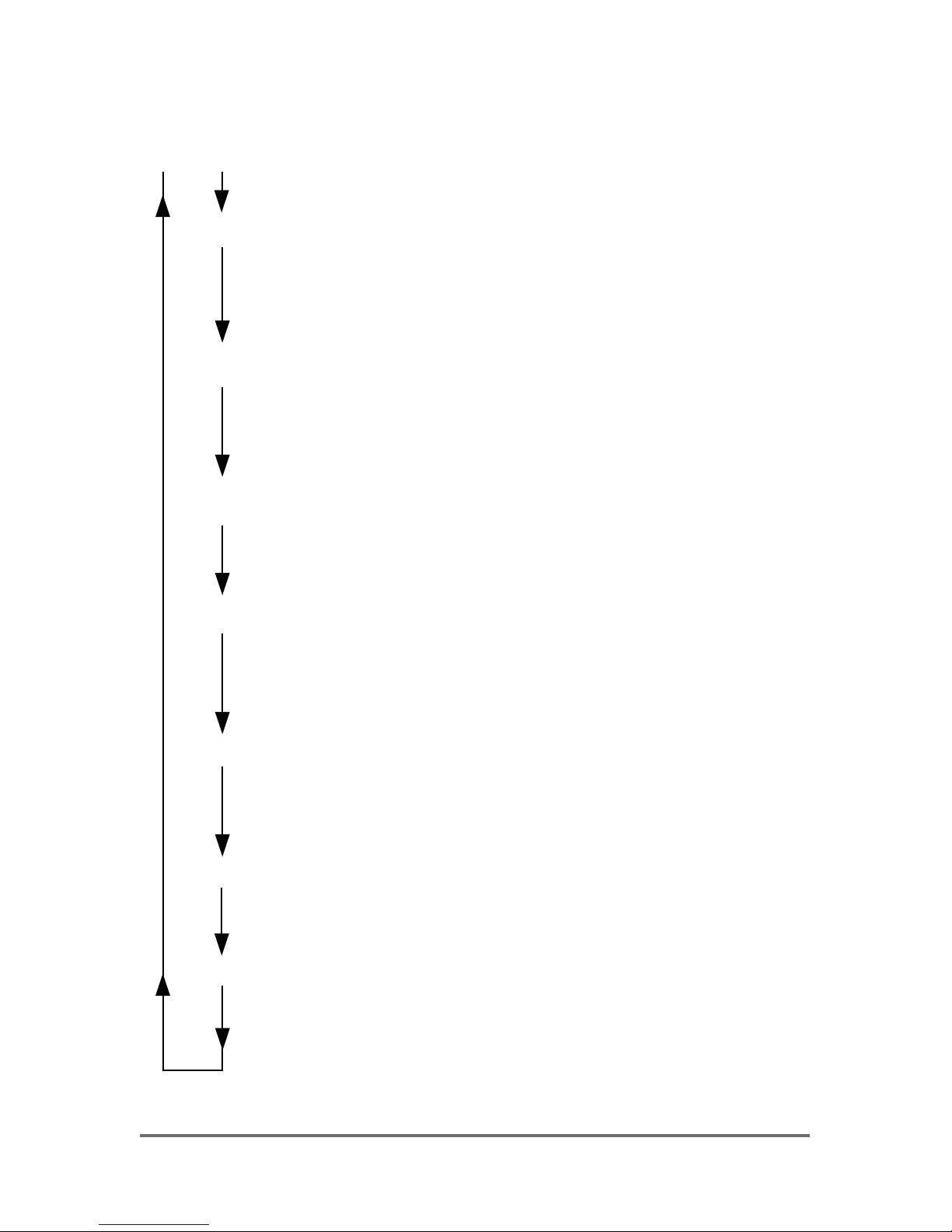

Appendix A Schematic description of settings and data transmission

Initial status: REAL mode

Press PROG and hold down

Pro appears at display and will change to

SCL indication programming mode.

Press PROG

- A- appears at display

Press PROG

current low scale value is displayed and MIN-LED flashs

Adjust value using (

) and ( ) keys

low scale value is changing.

Press PROG

- - - appears, indicating acceptance of new lower scale

value

-E- appears at display

Press PROG

current high scale value is displayed and MAX-LED flashs

Adjust value using (

) and ( ) keys

high scale value changes

Press PROG

- - - appears, indicating acceptance of new upper scale

value

dP. appears and current position of decimal point is

displayed

Page 29

29

Adjust value using ( ) and ( ) keys

decimal point changes

Press PROG

- - - appears, indicating acceptance of new decimal position

InX appears and current index of input signal is displayed

Adjust value using ( ) and ( ) keys

X index figure changes

Press PROG

- - - appears, indicating acceptance of new input signal

OuX appears at display

Adjust value using ( ) and ( ) keys

X index figure changes

Press PROG

- - - appears, indicating acceptance of new output signal

- d - appears at display

Press PROG

set value for damping in seconds appears

Adjust value using ( ) and ( ) keys

set time for damping is changed

Page 30

30

Press PROG

- - - appears, indicating acceptance of the time of damping

dXX appears automatically with the current reference of

damping

Adjust value using ( ) and ( ) keys

reference of damping changes

Press PROG

- - - acceptance of the reference of damping

with - b - appears at display

RS232

Press PROG

set baud rate appears

(values in kBaud).

Adjust value using ( ) and ( ) keys

stored value for the baud rate is

changed.

Press PROG

- - - appears, indicating acceptance of new

baud rate

Hitting RESET immediately terminates the programming mode at any

time. In this instance, the instrument resumes REAL mode.

Only such changes that have been acknowledged by appearance of

"---" will become effective. Otherwise, previously set values remain valid.

Page 31

31

Short hitting of the PROG key, while the instrument is in REAL mode,

initiates “PRO“ to appear at the display, followed by all current settings

in consecutive order.

Below flow diagram explains appearance of key words and values,

presuming settings of:

Examples:

Scale expansion: 0 ... 6.00 bar

Input signal: 4 ... 20 mA

Signal output: 0 ... 10 V

Damping

: 1.0 s

Reference of damping: Display

Baud rate 9600 baud

Initial status: REAL mode

Press PROG shortly

Pro SCL -A- 0.00 -E- 6.00

d.P In3 Ou1 -d- 01.0 d01

-b- 09.6

Hitting RESET immediately terminates verification mode at any time. In

this instance, the instrument resumes REAL mode.

Page 32

32

Appendix B Schematic description of alarm settings and verification

Initial status: REAL mode

Press SET 1 and hold down

SP1 appears at display and will change to

SE indicating programming mode

Press SET 1

current Set point make value no. 1 appears and the

- LED of alarm 1 flashs

Adjust value using (

) and ( ) keys

make value changes

Press SET 1

- - - appears, indicating acceptance of new Set point

make value

SA of alarm 1 appears at display

Press SET 1

current Set point break value no. 1 appears and the

- LED of alarm 1 flashs

Adjust value using (

) and ( ) keys

break value changes

Press SET 1

- - - appears, indicating acceptance of new Set point

break value

Page 33

33

Hitting RESET immediately terminates the programming mode at any

time. In this instance, the instrument resumes REAL mode.

Only such changes that have been acknowledged by appearance of

"---" will become effective. Otherwise, previously set values remain

valid.

Set points of alarm 2 are entered in the same manner.

Short hitting of the SET 1 (SET 2, respectively) key, while the instrument

is in REAL mode, initiates verification of the current settings of alarm 1

(2, respectively).

Example:

Set point make (SE): 4.00

Set point break (SA): 3.80

Initial status: REAL mode

Press SET 1 shortly

SP1 SE 4.00 SA 3.80

Hitting RESET immediately terminates verification mode at any time. In

this instance, the instrument resumes REAL mode.

Set points or alarm 2 are verified in the same manner.

Page 34

34

89.5

47.5

95.7

173.5

Appendix C Dimensions

Dimensions in mm

Page 35

35

8.9

42.3

45

+0.6

92

+0.8

Panel cutout in mm

Dimensions in mm

Page 36

36

AB CD EFG HI

d e h

Appendix D Layout of front and back panel

Page 37

37

A LED-display

B Decrease value key

C Increase value key

D Check / set contacts no. 1

d ∆ - LED = MAX value; ∇ - LED = MIN value

E Check / set contacts no. 2

e ∆ - LED = MAX value; ∇ - LED = MIN value

F Select programming mode. Continue with programming

G RESET memories, CANCEL programming

H Select display mode (toggle between LED’s)

h REAL = display true value

HOLD = hold value displayed

MIN = contents of minimum memory displayed

MAX = contents of maximum memory displayed

I Pocket window holding unit label

J Terminal block power supply and contacts output

K Terminal block signal input, signal output and transmitter supply

L Sub-D serial port (optional)

Page 38

38

For your notes

Page 39

39

For your notes

Page 40

40

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg / Germany

Phone (+49) 93 72/132-9986

Fax (+49) 93 72/132-217

E-Mail testequip@wika.de

www.wika.de

1287974 04/2005 GB

Loading...

Loading...