Page 1

Operating instructions

Attachable indicator, model A-AI-2 GB

F

14014118.01 • V2.0 • 03/2011

Attachable indicator, model A-AI-2

Page 2

GB Operating instructions, model A-AI-2 Page 1 - 28

© 2010 WIKA Alexander Wiegand SE & Co. KG

All rights reserved.

WIKA® is a registered trademark in various countries .

Prior to starting any wo rk, read the operating instructions!

Keep for later use!

2 WIKA operating instructions, model A-AI-2

Page 3

Contents

1

General information .................................................................................................................... 4

2 Safety ...................... .................................................................................. ................................... 5

2.1 Intended use .................................................................................................................. ........ 5

2.2 Personnel qualification .................... ... ... ... .... ... ... ... ....... ... ... .... ... ... ... .... ...... .... ... ... ... .... ... ... ...... 6

2.3 Special hazards .................... ... ... .... ...... ... .... ... ... ... .... ... ... ....... ... ... ... .... ... ... .... ...... ... .... ... ... ...... 7

2.4 Labelling / Safety marks ........................................................................................................ 7

3 Specifications ............................................................................................................................. 8

4 Design and function ..................................... ............................................................................ 10

4.1 Description .......................................................................................................................... 10

4.2 Scope of delivery . ....... ... ... .... ... ... .... ... ...... .... ... ... ... .... ... ... ....... ... ... ... .... ... ... ... ....... ... .... ... ... .... 11

5 Transport, packaging and storage .................................. ...... .... ... ... ... .... ... ... ....... ... ... ... .... ... ... . 11

5.1 Transport ............................................................................................................................. 11

5.2 Packaging ............................................................................................................................ 11

5.3 Storage ................................................................................................................................ 11

6 Commissoning, operation ........................................................................................................ 11

6.1 Electrical connection ... ... .... ...... ... .... ... ... ... .... ...... ... .... ... ... ... .... ... ....... ... ... ... .... ... ... ... ....... ... .... 11

6.2 Configuration of the indicator ............................................................................................... 15

6.3 Switching points / alarm boundaries .................................................................................... 18

6.4 Offset and slope adjustment ......................................................................................... ....... 21

6.5 Min-/max-value storage ....................................................................................................... 22

7 Maintenance and cleaning ............................... ...... ... .... ... ... ... .... ... ...... .... ... ... ... .... ... ... ....... ... ... . 22

7.1 Maintenance ........................................................................................................................ 22

7.2 Cleaning .............................................................................................................................. 22

8 Faults ......................................................................................................................................... 23

9 Dismounting, return and disposal ...................................... ..................................................... 24

9.1 Demontage .......................................................................................................................... 24

9.2 Return....................................................................................................... ........................... 24

9.3 Disposal ............................................................................................................................... 24

10 Appendix ................................................................................................................................... 25

Declarations of conformity can be found online at www.wika.com.

WIKA operating instructions, model A-AI-2 3

Page 4

1 General information

1 General information

The instrument described in the operating instructions has been designed and manufactured

using state-of-the-art technology.

All compone nts are subject to str in ge nt qu ali t y and en vir o nm en t al cri ter ia during produ ction.

Our management systems are certified to ISO 9001 and ISO 14001.

These operating instructions contain important information on handling the instrument. Working

safely requires that all safety instructions and work instructions are observed.

Observe the relevant local accident prevention regulations and general safety regulations for

the instrument's range of use.

The operating instructions are part of the instrument and must be kept in the immediate vicini ty

of the instrument and readily accessib le to skilled personnel at any time.

Skilled personnel must have carefully read and understood the operating instructions, prior to

beginning any work.

The manufacturer's liability is void in the case of any damage caused by using the product

contrary to its intended use, non-compliance with these operating instruction s, assignment of

insufficiently qualified skilled personnel or unauthorised modifications to the instrument.

The general terms and conditions, contained in the sales documentation, shall apply.

Subject to technical modifications.

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: AC 80.08

- Application consultant: Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika. de

4 WIKA operating instructions, model A-AI-2

Page 5

2 Safety

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury or

death, if not avoided.

Information

... points out useful tips, recommendations and information for efficient and troublefree operation.

DANGER!

...identifies hazards caused by electric power. Should the safety instructions not be

observed, there is a risk of serious or fatal injury.

2 Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate

instrument has been selected in terms of measuring range, design and specific

measuring conditions.

Non-observance can result in serious injury and/or damage to equipment.

Further important safety instructions can be found in the individual chapters of these

operating instructions.

2.1 Intended use

The attachable indicator A-AI-2 is used for attaching between a transmitter and the according angular

plug.

The instrument has been designed and built solely for the intended use described here, and may only

be used accordingly.

If the instrument is transported from a cold into a warm environment, the formation of condensation

may result in the instrument malfunctioning. Before putting it back into operation, wait for the

instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary to the intended

use.

WIKA operating instruct io ns, mod e l A-AI-2 5

Page 6

2 Safety

This device was designed and tested considering the safety regulations for electronic measuring

devices.

Faultless operation and reliability in operation of the measuring device can only be assured if the

General Safety Measures and the devices specific safety regulation, mentioned in this operating

instructions, are considered.

1. Faultless operati on and reliability in operation of the measuring device can only be assured if

the device is used within the climatic conditions specified in the chapter “Specifications“.

2. Always disconnect th e device from its supply befo re opening it. Take care that nobody can

touch any of the unit‘s contacts after installing the device.

3. Standard regulations for operation and safety for electrical, light and heavy current equipment

have to be observed, with particular attention paid to the national safety regulations (e.g. VDE

0100).

4. When connecting the device to other devices (e.g. the PC) the interconnection has to be

designed most thoroughly, as internal connections in third-party devices (e.g. connection of

ground with protective earth) may lead to unwanted voltage potentials.

5. The device must be switched off and must be marked against using again, in case of obvious

malfunct i o ns of the de vi ce whi c h are e.g.:

visible damage

no prescripted working of the de vice

storing the device under inappropriate conditions for longer time

When not sure, the device should be s ent to the manufacturer for repairing or servicing.

6. In case of connecting lines lon ger than 30 m or in case of lines leaving the buildi ng an

additional suitable overvoltage protection shall be provided.

2.2 Personnel qualification

WARNING!

Risk of injury should qualificat ion be insufficient !

Improper handling can result in considerable injury and damage to equipment.

The activities described in these operating instructions may only be carried out

by skilled personnel who have the qualifications descr ibed below.

Keep unqualified personnel away from hazardous areas.

Skilled electrical personnel

Skilled electrical personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of

country-specific regulations, current standards and directives, are capable of carrying out work on

electrical systems and independently recognizing and avoiding potential hazards.

The skilled electrical personnel have been specifically trained for the work environment they are

working in and know the relevant standards and regulations.

The skilled electrical personnel must comply with current legal accident prevention regulations.

6 WIKA operating instructions, model A-AI-2

Page 7

2 Safety

2.3 Special hazards

DANGER!

Danger of death caused by electric current.

Upon contact with li ve parts, there is a direct danger of death.

Electrical instruments may only be installed and mounted by skilled electrical

personnel.

Operation usi n g a def ectiv e power s up ply unit (e.g. shor t cir c ui t fr om the main s

voltage to the output voltage) can result in life-threatening voltages at the

instrument!

WARNING!

Do NOT use this product as safety or emergency stopping device, or in any other

application where failure of the product could result in personal injury or material

damage.

Failure to comply with these instructions could result in death or serious injury and

material damage.

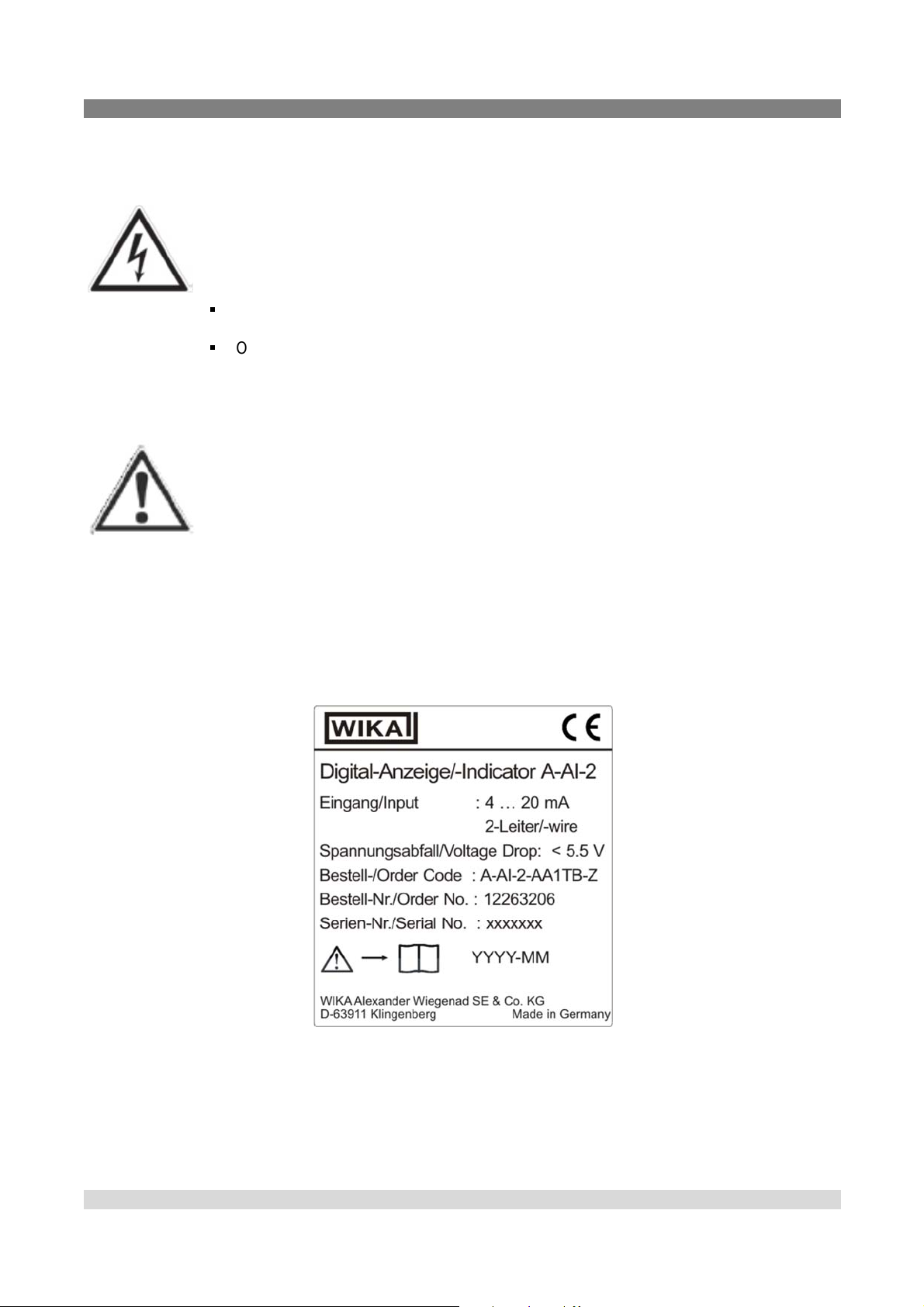

2.4 Labelling / Safety marks

Product label

WIKA operating instruct io ns, mod e l A-AI-2 7

Page 8

3 Specifications

Explanation of symbols

Before mounting and commi ss ioning the instrument, ensure y ou read the

operating instructions!

CE, Communauté Eur opéenne

Instruments bearing this mark comply with the relevant European

directives.

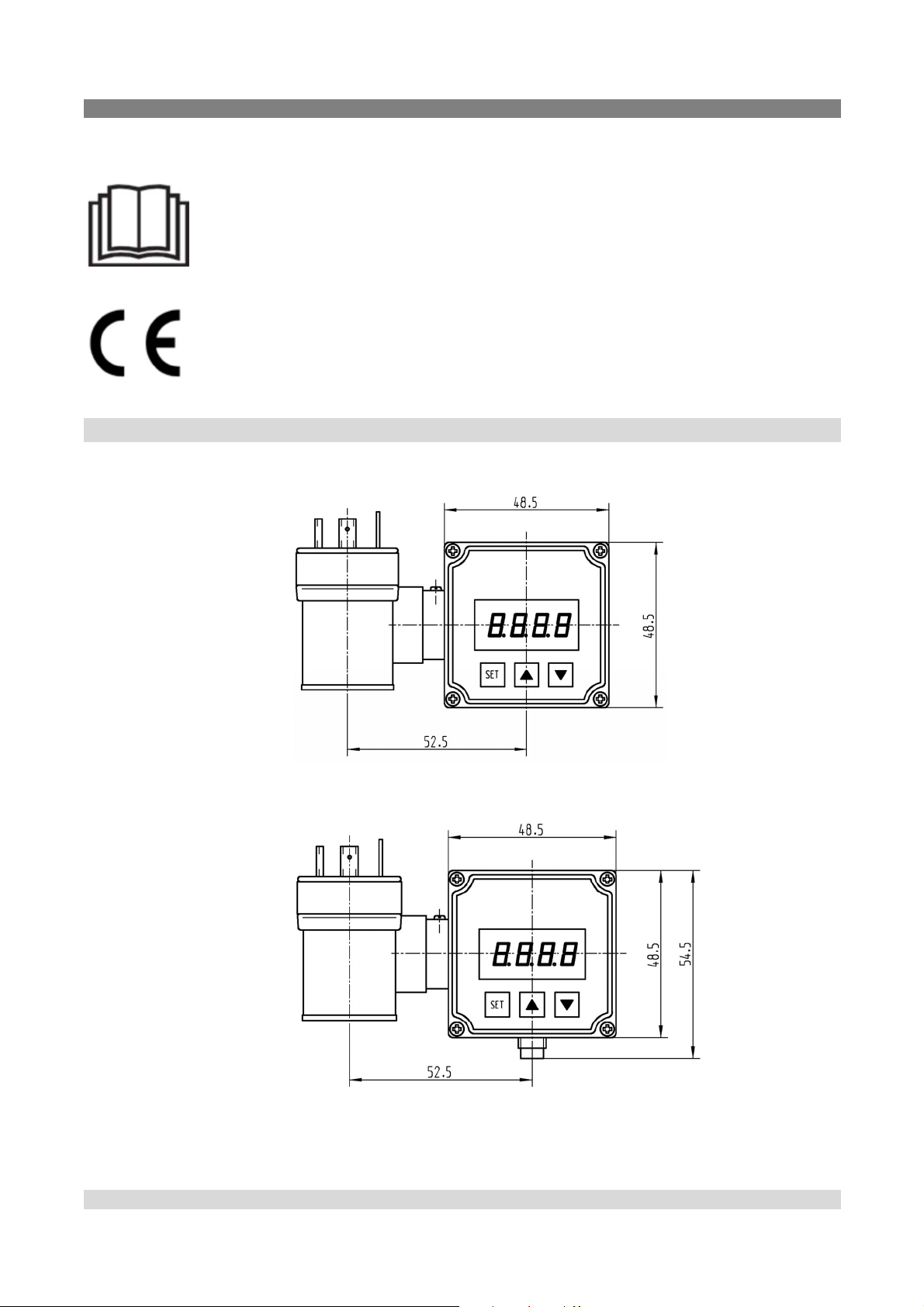

3 Specifications

Dimensions

A-AI-2-1:

A-AI-2-S:

8 WIKA operating instructions, model A-AI-2

Page 9

3 Specifications

Specifications

Display

■

Actual value LED, 4 -digit, character size 7 mm

■

Indication range -1999 ... +9999

■

Decimal point freely selectable

■

Accuracy ± 0.2 % of the meas uring span ± 1 digit

■

Sampling rate 50 measurements/sec

■

Operation membrane keypad on the front or push-buttons behind the

cover of the case

Input

■

Input signal 4 … 20 mA (2-wire)

■

Max. permissible input 25 mA (40 mA short term)

■

Voltage drop DC 5.5 V

Switching output

■

One output Open Collector, galv. isolated,

max. DC 28 V, load max. 20 mA, connection via angular

connector, no short-circuit protection

■

{two outputs} Open Collector, galv. isolated,

max. DC 28 V, load max. 1 A, connection via female M8connector, no short-circuit protection

■

Reaction time

■

switching point / hysteresise freely selectable

Equipment

■

Filter activatable, 3 filter stages

■

Min/Max value memory retrievable via keypad

■

Control characteristic ON/OFF (two-point control)

■

Alarm function Min-/Max alarm with settable time delay

Electrical connection to transmitter with 4 ... 20 mA and angular connector to DIN

CE-conformity

■

EMC directives 2004/108/EG, EN 61326 Emission (Group 1, Clas s B) and

Permissible

■

Operating temperat ure -25 ... +50 °C

■

Storage temperature -30 ... +85 °C

■

Humidity 0 ... 80 % relative humidity (no condensation)

Temperature effect on the indication 0.1% / 10 K

Case

■

Material ABS case, polycarbonate front panel, membrane keypad

■

Ingress protection IP 65 (when properly fitted)

■

Weight approx. 80 g

■

Dimensions in mm approx. 50.5 x 90 x 39.5 (L x B x T) incl. angular plug

■

Scope of delivery Attachable indicator, mounting screws, profile seali ng,

For further specifications see WIKA data sheet AC 80.08 and the order documentation.

≤

20 ms

43650, pol ari t y-f ree mounting

Immunity (industrial locations)

operating instructions

WIKA operating instructions, model A-AI-2 9

Page 10

4 Design and function

version

Order code

4 Design and function

4.1 Description

The attachable indicator A-AI-2 is a microprocessor controlled displaying, monitoring and controlling

device. In accordance to his type the device is supporting an input for standard signal 4…20 mA .

The device is available in two different versions. In the given operating instructions both versions are

described. If there is nothing other montioned, the declarations are for both versions.

A-AI-2-1 A-AI-2-AA1TB-Z

A-AI-2-S A-AI-2-AASTB-Z

version A-AI-2-1 (standard)

In according to his type the device is

supporting an input for standa rd

signals 4…20 mA. The device

features one switching output (npnoutput), which can be configured as

2-point-controll er or mi n/m a x ala rm

output. The state of the switching

output is displayed with the LED left

beneath the LED-display.

version A-AI-2-S (optional)

The device features two switching

outputs (npn-output), which can be

configur e d as 2-p oi nt - c ont roller, 3point-controller, 2-point-controller with

min./max.alarm or min./max. alarm

output ( common or individual). The

state of the switchi ng outputs is

displayed with 2 LED beneath the

LED-display. The left LED indicates

the state of the 1st output and the right

LED the state of the 2nd output.

When leaving our factory the A-AI-2 has been subjected to various inspection tests and is completely

calibrated.

Before the A-AI-2 can be used, it has to be configured for the customer’ s application.

10 WIKA operating instructions, model A-AI-2

Page 11

6 Commissoning, operation

4.2 Scope of delivery

The scope of delivery is:

Attachable indicator

Two mounting screws

Seal

Operating instructions

Cross-check scope of delivery with delivery note.

5 Transport, packaging and s to rage

5.1 Transport

Check instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting. Keep the packaging as it will provide optimum

protection during transport (e.g. change i n installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

Storage temperature: -30… +85 °C

Humidity: 0...80 % relative humidity (no condensation)

Avoid exposure to the following factors:

Direct sunlight or proximity to hot objects

Mechanical vibration, mechanical shock (putting it down hard)

Soot, vapour, dust and corrosive gases

Potentially explosive environments, flammable atmospheres

6 Commissoning, operation

6.1 Electrical connection

To connect the A-AI-2 it is simply plugged into an existing transmitter by means of a special adapter

for the cubic plug according to DIN 43650. An additional power supply is not necessary , because

device takes power directly fr om measuring current.

Electric connection and commissioning of the device must be carried out by trained and skilled

personnel.

Wrong connection may lead to destruction of the device, in which case we cannot assume any

warranty.

! Mind the maximum input current rating of 40mA under any circumstances!

WIKA operating instructions, model A-AI-2 11

Page 12

6 Commissoning, operation

contact number

wire colour

pin jack

6.1.1 Adju stment of the A-AI-2 connections

The assignment of the angular plug is designed for the most commonly used assignments of the

respective input signals .

As this is not a standardized assignment, your transmitter assignment may not correspond to the A-AI2 assignment.

Standard assignment of angular plug (A-AI-2-1)

1 blue indicator + indicator 2 red connected

3 black switching output + n.c.

4 yellow switching output - n.c.

n.c. = not connected

In the angular plug the male contact 2 is directly

connected 1:1 with the socket. The A-AI-2 is

located between the male contact 1 (+) and the

jack contact 1 (-). The male contact s 3 and 4 are

used for the switching output.

If the 'Signal/GND '-line in your transmitter is not as signed to c ontact 2 and if the '-Ub'-line is not

assigned to contact 1, please do not forget to adjust the A-AI-2 angle-type plug and the external angletype plug accordingly. To do so open the A-AI-2 angle-type plug and exchange the wire of contact 1

and contact 2 against the wire of the contact representing the connection in your transmitter.

Then exchange and rewire the two contacts in the angle-type plug of your connecting cable.

12 WIKA operating instructions, model A-AI-2

Page 13

6 Commissoning, operation

cont

a

ct number

wire colour

pin jack

assignment of the

M8

-

assignment of the connection

description

Standard assignment of angular plug (A-AI-2-S)

1 blue indicator + indicator 2 red connected

3 black connected

4 yellow connected

In the angle-type plug the male contacts 2, 3 and 4 are

directly connected 1:1 with the socket. Device is

located between the male contact 1 (+) and the jack

contact 1 (-).

-Ub

If the '

'-line is not assigned to contact 1, please do not forget to adjust the angle-type plug and the

external angle-type plug accordingly: To do so open the angle-type plug (refer to the “general

instructions for change ....”) and exchange the wire of contact 1 against the wire of the contact

representing the connection in your transmitter.

Then exchange and rewire the two contacts in the angle-type plug of your connecting cable.

General instruction for change of the angular plug assignment

Remove the coupling insert by means of a screw driver at th e position indicated (arrow). Change the

assignment according the notes of the respective input signal.

Latch coupling insert in cover. You have a choice between 4 different orientations – each of them

spaced 90°. Put on angel-type plug and connect plugs using the long screw delivered (do not forget

seals).

Terminal assignment of the switching outputs

connector

1 brown switching output 1 2 white switching output 1 +

3 blue switching output 2 4 black switching output 2 +

WIKA operating instruct io ns, mod e l A-AI-2 13

cable EBK401

Page 14

6 Commissoning, operation

6.1.2 Connection example

Please take care that you must not exceed the limits of the voltage and of the maximum current

of the switching outputs (not even for a short period of time).

Please take extreme care when switching induct ive loads (like coils or relays, etc.) because of their

high voltage peaks, protective m easures to limit these peaks have to be taken.

When switching large capaciti ve loads a series resistor for curre nt limitation needed, because of the

high turn-on-current of high capacitive loads. The same applies to incandescent lamps, whose turnon-current is also quite high due to their low cold resistance.

Connecting to current loop and switching of a relay (A-AI-2-1)

combined power suppl y for meas uremen t sect ion

and output section

separate power supply for measurement section and

output section

Connecting to current loop (A-AI-2-S)

14 WIKA operating instructions, model A-AI-2

Page 15

6 Commissoning, operation

Switching of a relay (A-AI-2-S)

connec tion as „LowSide“ contactor

6.2 Configuration of the indicator

connection as „HighSide“ contactor

Please note: The storage of a configuration value will be done by switching to the next

configuration value (via button 1).

When configuration is active and no button is pressed for more than 60 seconds the

configuration will be cancelled. Stored changes will not be lost!

Hint: The buttons 2 and 3 are f eatured with a ‘roll-function‘. When pressing the button

once the value will be raised (button 2) by one or lowered (button 3) by one. When

holding the button pressed for longer than 1 second the value starts cou nting up or

down, the counting speed will be raised after a short period of time.

6.2.1 Configuration of the input signal

Turn the device on and wait until it completed its built-in segment test.

Press button 2 for 1 sec ond, in the device displ ay appears ‚dP’ (decimal point).

Select the desired decimal point place by pre ssing button 2 respective button 3.

Validate the selected value by pressing button 1. The display shows ‚dP’ again.

Press button 1 again, the display will show “di.Lo“ (Display Low = low display value).

Use button 2 and button 3 to select the desired value the device should display when a 4mA

input signal is attached.

Validate the selected value by pressing button 1. The display shows “di.Lo“ again.

Press button 1 again, the display will show “di.Hi“ (Display High = high display value).

Use button 2 and button 3 to select the desired value the device should display when a 20mA

is attached.

Validate the selected value by pressing button 1. The display shows “di.Hi“ again .

Press button 1 again. The display will show “Li“ (Limit = Measuring range limit).

Use button 2 and button 3 to select the desired measuring range limit.

WIKA operating instruct io ns, mod e l A-AI-2 15

Page 16

6 Commissoning, operation

display

measuring range input

notes

off

on.Er

on.rG

display

description

0

1

2

deactivated Exceeding of the measuring

range limit is tolerable as of the

measuring limit (p.r.t. hint).

active, (displays an error) The meas. range limit is exactly

(on error)

aktiv, (di sp la ys th e se l e cte d

(on range)

Hint: When exceeding the measuring limit independently from the setting, the device will

always display an error message (“Err.1“ or “Err.2“).

The measuring limits are by 3.7 and 20.8 mA .

limit)

bounded by the input signal.

When exceedi n g or und er cu tt i n g

the input sign a l an error

message will be displayed.

The meas. range limit is exactly

bounded by the input signal.

When exceedi n g or und er cu tt i n g

the input sign a l the de vi ce will

display the selected lower/upper

display value.

[e.g. humidity: when

undercutting or exceeding, the

device will display 0 % or 100

%]

Press button 1 to validate the selection, the display shows “Li“ again.

When pressing button 1 again, the display will show “FiLt“ (Filter).

Use button 2 and button 3 to select the desired filter behavior

filter deactivat ed

filter stage 1:

suppresses jumping display values caused be smallest changes

filter stage 2:

additional suppression of measuring peaks (causes delayed reaction of switching

output)

Press button 1 to validate your value, the display shows “FiLt“ again.

The configuration of the device to the input signal is now completed. You now have to configure the

output of the device.

6.2.2 Selection of the outpu t function

When pressing button 1 again, the display will show “outP“. (Output)

Use button 2 and butt on 3 (middle or right button) to select the desired output-function.

16 WIKA operating instructions, model A-AI-2

Page 17

6 Commissoning, operation

description

to select as

output

(out)

see chapter

no

2P

AL

description

to select as

output

1 (out

1) output

2 (out

2) see chapter

no

2P

AL

3P

2P.AL

AL.F2

A-AI-2-1:

no output, device is

used as display

2-point-controller

Min/Max alarm

A-AI-2-S:

no output, device is

used as display

2-point-controller

Min-/Max-alarm,

common

3-point-controller

2-Punkt-Regler with

Min-/Max-alarm

Min-/Max-Alarm,

individual

output

output

off -switching function 6.3.1

min/max alarm, inverse 6.3.2

off off -switching

function

Min-/Max-alarm,

inverted

switching

function 1

switching

function 1

Max alarm,

inverted

off 6.3.1

off 6.3.2

switching

function 2

Min/Max alarm,

inverted

Min alarm,

inverted

6.3.1

6.3.1

6.3.2

Press button 1 to validate the selected output function. The display shows “outP“ again.

For output function = no the configuration is now finished. Press button 1 to finish the adjustment and

to switch over to display the measuring value.

If the output function was changed here, the delay and preferred state of switching function and the

switching points / alarm-bo un daries are to con figured in following.

Hint: The settings described in the following depend on the selected output function.

Depending on this setting therefore it is possible that more than one point is not

present in the following.

When pressing button 1 again, the device will display “1.dEL“ (delay = delay of switching

function 1).

Use button 2 and button 3 to set the desired val ue f or the swi t c hi n g- delay.

Hint: the selected value [0.01 ... 2.00] accords the switching delay in seconds.

Press button 1 to validate the selection. The display shows “1.dEL“ again.

When pressing button 1 again, the device will display “1.Err“ (error = preferred state of

switching function 1).

Use button 2 and button 3 to set the desire d init i al state in case of an erro r.

WIKA operating instructions, model A-AI-2 17

Page 18

6 Commissoning, operation

display

preferred state of switching

comment

off

on

function

Inactive in case of an error -Active in case of an error --

Press button 1 to validate the selection. The display shows “1.Err“ again.

A-AI-2-S: In case you selected a 3-point-controlle you have to make the following settings

similar to the settings you already made for output 1:

“2.dEL“ (delay = delay of switching function 2) and

“2.Err“ (error = preferred state of switching function 2).

The configuration of the output function is now completed. Depending on the selected output function

you have to make the settings for switching / alarm points. See description in chapter „switching

points/alarm-boundaries“ for further information.

Hint: The settings for the switching and alarm points can be made later in an extra menu

(see chapter 6.3)

6.3 Switching points / alarm boundaries

Please note: The storage of a configuration value will be done by switching to the next

configuration value (via button 1). When configurati on is active and no button is

pressed for more than 60 seconds the configuration will be cancelled. Stored

changes will not be lost!

Hint: The buttons 2 and 3 are featured with a ‘roll-function‘. When pressing the button

once the value will be raised (button 2) by one or lowered (button 3) by one. When

holding the button pressed for longer than 1 second the value starts counting up or

down, the counting speed will be raised after a short period of time.

When pressing button 1 for >2 seconds the menu to select the switching points and alarm-

boundaries will be called.

Depending on the configuration you have made in the „output“ menu you will get different

display values. Ple a se follow the specific chapter for further information.

6.3.1 2-point-controller (and 3-point-controller: A-AI-2-S)

This chapter describes how to configure the switching points as use the device for a 2-point- resp. 3point-controller. This instruction demands that you selected “2P“ resp. “3P“ as your desired output

function.

Press button 1 (when not already done).

The device will display “1.on“ (turn-on-poi nt of ou tp u t 1)

Use button 2 and button 3 to set the desired val ue, th e de vic e’ s out put sho ul d be t urn ing on.

Press button 1 to validate your selection. The display shows “1.on“ again.

When pressing button 1 again, the device will display “1.off“. (turn-off-point out output 1)

Use button 2 and button 3 to set the desired val ue, th e de vic e’ s out put 1 shoul d be t urn i n g off .

Press button 1 to validate your selection. The display shows “1.off“again.

18 WIKA operating instructions, model A-AI-2

Page 19

6 Commissoning, operation

Example: You want to control the temperature of a heating coil, with a hysteresis of +2°C, to

120°C. Therefore you will have to select the turn-on-point “1.on“ to 120°C and the

turn-off-point to “122°C“.

=> When your heating coil temperature falls below 120°C it will be turned on. When

the temperature rises above 122°C the heating coil will be turned off.

Note: Depending on the inertia of your heating coil an overshooting of the

temperature may be possible.

A-AI-2-S: When selected '2-point-controller' you finished configuring your de vice. Press button

1 to switch over to dis play the measuri ng val u e.

When sel ected '3-point-controller' you have to make the following settin gs similar to

the settings you already made for output 1:

“2.on“ (turn-on-point of output 2) and

“2.off“ (turn-off-point out output 2)

Now you finished configuring the switching point adjustment of your device. Press button 1 to finish

the adjustment and to switch over to display the measuring value

6.3.2 Min-/Max-Alarm (A-AI-2-1)

Min-/Max-Alarm (common or individual) (A-AI-2-S)

This chapter describes how to configure the device‘s alarm boundaries for min-/max-alarm-monitoring.

This instruction demands that you selected “AL“ (or “AL.2F” for A-AI-2-S) as your desired output

function.

Press button 1 (when not already done) , the device will display “AL.Hi“. (ma ximum alarm-

value)

Use button 2 and button 3 to set the desired value, the device should turn o n its maximum-

alarm.

Press button 1 to validate your selection. The display shows “AL.Hi“ again.

When pressing button 1 again, the device will display “AL.Lo“. (minimum alarm-value)

Use button 2 and button 3 to set the desired value, the device should turn o n its minimum-

alarm

Press button 1 to validate your selection. The display shows “AL.Lo“ again.

When pressing button 1 again, the device will display “A.dEL“. (delay of the alarm-function)

Use button 2 and button 3 to set the desired delay of the alarm-f u nc tion.

Note: the selected value [0 ... 9999] accords the alarm delay in seconds.

The device will turn on the alarm after minimum or maximum alarm value was active for the

del a y- tim e yo u h ave se t.

Press button 1 to validate the delay time. The display shows “A.dEL“ again.

Example: You want to have a temperature alarm-monitoring of a greenhouse. The alarm

should start when the temperature rises above 50 °C or falls below 15 °C. Therefore

your settings will be 50 °C for the maximum alarm-value “AL.HI“ and 15 °C for the

minimum alarm-value “AL.Lo“.

=> The alarm will be starting after the temperature rises above 50 °C and stays

above 50 °C for the entered delay time or after it had been falling below 15 °C and

stays below 15 °C for the entered delay time.

Please note that the alarm-outputs are inverted! This means, that the output will be active when there

is no alarm!

WIKA operating instructions, model A-AI-2 19

Page 20

6 Commissoning, operation

Now you finished configuring the alarm adjustment of your device. Press button 1 to finish the

adjustment and to switch over to display the measuring value.

6.3.3 2-point-controller with min-/max-alarm (A-AI-2-S)

This chapter describes how to configure the switching points as use the device for a 2-point-controller

with min-/max-alarm. This instruction demands that you selected “2P.AL“ as your desired output

function.

Press button 1 (when not already done).

The device will display “1.on“ (turn-on-poi nt of ou tp u t 1)

Use button 2 and button 3 to set the desired val ue, th e de vic e’ s out put sho ul d be t urn ing on.

Press button 1 to validate your selection. The display shows “1.on“ again.

When pressing button 1 again, the device will display “1.off“. (turn-off-point out output 1)

Use button 2 and button 3 to set the desired val ue, th e de vic e’ s out put 1 shoul d be t urn i n g off .

Press button 1 to validate your selection. The display shows “1.off“again.

When pressing button 1 again, the device will display “AL.Hi“. (maximum alar m- value)

Use button 2 and button 3 to set the desired value, the device should turn o n its maximum-

alarm.

Press button 1 to validate your selection. The display shows “AL.Hi“ again.

When pressing button 1 again, the device will display “AL.Lo“. (minimum alarm-value)

Use button 2 and button 3 to set the desired value, the device should turn o n its minimum-

alarm

Press button 1 to validate your selection. The display shows “AL.Lo“ again.

When pressing button 1 again, the device will display “A.dEL“. (delay of the alarm-function)

Use button 2 and button 3 to set the desired delay of the alarm-f u nc tion.

Note: the selected value [0 ... 9999] accords the alarm delay in seconds.

The device will turn on the alarm after minimum or maximum alarm value was active for the

del a y- tim e yo u h ave se t.

Press button 1 to validate the delay time. The display shows “A.dEL“ again.

Please note that the alarm-outputs are inverted! This means, that the output will be active when there

is no alarm!

Now you finished configuring the switching point and th e alarm adjustment of your device. Press

button 1 to finish the adjustment and to switch over to dis play the measuring value.

20 WIKA operating instructions, model A-AI-2

Page 21

6 Commissoning, operation

6.4 Offset and slope adjustment

The offset and slope- adjustment function can be used for compensating the tolerance of the used

sensor, resp. for vernier adjustment of t he used transducer / transmitter.

Please note: The storage of a configuration value will be occur by switching to the next

configuration value (via button 1). When configurati on is active and no button is

pressed for more than 60 seconds the configuration will be cancelled. Stored

changes will not be lost!

Hint: The buttons 2 and 3 are featured with a ‘roll-function‘. When pressing the button

once the value will be raised (button 2) by one or lowered (button 3) by one. When

holding the button pressed for longer than 1 second the value starts counting up or

down, the counting speed will be raised after a short period of time.

Turn on the device and wait after it finished its built-i n segment test.

Press button 3 > 2 seconds

The device will display “OFFS“ (Offset).

Use button 2 and button 3 for setting the des ir e d zero poi n t of f s et -v al ue.

The input of the offset value is in digit. The value that had been set will be subtracted from the

measured value. (see below for further information)

Press button 1 to validate your selection. The display shows “OFFS“ again.

When pressing button 1 again, the device will display “SCAL“. (scale = slope)

Use button 2 and button 3 to select the desir e d slo pe- a djustment.

The slope adjustment will be entered in %. The value displayed can be calculated like this:

Display = (measured value – offset – di.Lo) * (1 + slope adjustment [% / 100] ) + di.Lo

Example: The setting is 2.00 => the slope has risen 2.00 % => slope = 1 02%.

When measuring a value of 1000 (without slope-adjustment) the device would

display 1020 (with slope adjustment of 102 %)

Press button 1 to validate the selection of the slope-adjustment. The display shows “SCAL“

again.

Now you finished the offset and slope adjustment of your dev ice. Press button 1 to finish the

adjustment and to switch over to display the measuring value.

Exa m p le for O f fset and slo pe adj ustm e n t

Connecting of a pressure-transducer

The device displays th e following values (without offset- or slope-adjustment):

0.08 at 0.00 bar and 20.02 at 20.00 bar

Therefor e you ca l culated:

zero point: 0.08

slope: 20.02 – 0.08 = 19.94

deviation: 0.06 (= target-slope – actual-slope = 20.00 - 19.94)

WIKA operating instructions, model A-AI-2 21

Page 22

7 Maintenance and clean ing

Hi

CLr

You have to set:

offset = 0.08 (= zero point-deviation)

scale = 0.30 (= deviation/actual-slope=0.06/9.94=0.0030= 0.30%)

6.5 Min-/max-value storage

The device features a minimum/maximum-value storage. In this stor age the highest and lowest

performance data is saved. The storage is non-permanent so the saved values get lost in case of

voltage drop.

Calling of the minimum-v a lue press button 3 shortly

Calling of the maximum-value press button 2 shortly

Erasing of the min/max values press button 2 and 3 for 2 sec.

the device will display “Lo“

briefly, after that the min-value is

displayed for about 2 sec

the device will display “

briefly, after that the max-value

is displayed for about 2 sec.

The device will display “

briefly, after that the min/maxvalues are set to the cur-rent

displayed value.

“

“

7 Maintenance and cleaning

7.1 Maintenance

This instrument is mainten ance-free.

Repairs must only be carried out by the manufacturer.

7.2 Cleaning

CAUTION!

Before cleaning, correctly disconnect the instrument from the ma ins.

Clean the instrument with a moist cloth.

Electrical connections must not come into contact with moisture.

For information on returning the instrument see chapter "9.2 Return".

22 WIKA operating instructions, model A-AI-2

Page 23

8 Faults

Fehler

presumed cau s e

solution

Err.1

Err.2

Err.3

Err.4

Err.7

Err.11

8 Faults

When detecting an operating state which is not permissible, the device will display an error code. The

followin g err or c od es ar e def i n e d:

Input signal too hig h

Exceeding of the measuring

range

values below measuring range

display range has been

exceeded

values below display range

System error

value coul d not be cal c ula t e d

CAUTION!

If faults cannot be eliminated by means of the measures listed above, the instrument

must be shut down immediately, and it must be ensured that pressure and/or signal

are no longer present, and it must be prevented from being inadvertently put back

into service. In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter "9.2 Return".

Sensor shorted

Input signal zu low

Current below 4 mA

incorrect scale

incorrect scale

valid operation temperature

has been exceeded

defective device

incorrect scale

The input signal must be

within the limits

Check sensor,

transducer/transmitter

Check device configuration

The input signal must be

within the limits

Check sensor,

transducer/transmitter

Check device configuration

The input signal must be

within the limits

scale smaller indication

range

The input signal must be

within the limits

scale smaller indication

range

Stay within valid temperature

range

Exchange the defective

device

Check settings and input

signals

WIKA operating instruct io ns, mod e l A-AI-2 23

Page 24

9 Dismounting, return and disposal

9 Dismounting, return and disposal

WARNING!

Residual media in dismounted instruments ca n result in a risk to persons,

the environment and eq uipment. Take sufficient precautionary measures.

9.1 Demontage

First disconnect power supply, than open the screw which connects angular plug, indicator and

transmitter. Remove angular plug and indicator. After this attach the angular plug to transmitter and

fasten the screw. Ple ase use the screw which is from the scope of delivery of the transmitter. This

screw is smaller.

9.2 Return

WARNING!

Strictly observe when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous

substances (acids, bases, solutions, etc.).

When returning the instrument, use the original packagi ng or a suitable transport package.

Enclose the completed re turn for m with the ins trum ent .

The return form is available on the internet:

www.wika.de / Service / Return

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specific waste disposal regulations.

24 WIKA operating instructions, model A-AI-2

Page 25

10 Appendix

10 Appendix

WIKA operating instruct io ns, mod e l A-AI-2 25

Page 26

10 Appendix

26 WIKA operating instructions, model A-AI-2

Page 27

10 Appendix

WIKA operating instruct io ns, mod e l A-AI-2 27

Page 28

WIKA global

WIKA subsidiaries worldwide can be found online at www.wika.com.

WIKA Alexander Wiega nd SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. (+49) 9372/132-0

Fax (+49) 9372/132-406

E-Mail info@wika.de

www.wika.de

28 WIKA operating instructions, model A-AI-2

Loading...

Loading...