Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Manuale d'uso

Dierential pressure transmitter model A2G-50

Dierenzdrucktransmitter Typ A2G-50

Transmetteur de pression diérentielle type A2G-50

Transmisor de presión diferencial modelo A2G-50

Trasmettitore di pressione dierenziale modello A2G-50

Dierential pressure transmitter model A2G-50

GB

D

F

E

I

Page 2

GB

Operating instructions model A2G-50 Page 3-12

D

Betriebsanleitung Typ A2G-50 Seite 13-22

F

Mode d'emploi type A2G-50 Page 23-32

E

Manual de instrucciones modelo A2G-50 Página 33-42

I

Manuale d'uso modello A2G-50 Pagina 43-52

© 2009 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

Prima di iniziare ad utilizzare lo strumento, leggere il manuale d'uso!

Conservare per future consultazioni!

2

WIKA operating instructions air2guide model A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 6

Design and function

4.

5. Transport, packaging and storage 9

6. Commissioning, operation 9

7. Zero point adjustment 11

8. Options and accessories 12

9. Maintenance and cleaning 12

10. Disposal 12

8

GB

40202780.02 05/2012 GB/D/F/E/I

WIKA operating instructions air2guide model A2G-50

3

Page 4

1. General information

1. General information

■

The dierential pressure transmitter described in the operating

instructions has been designed and manufactured using state-of-theart technology. All components are subject to stringent quality and

GB

environmental criteria during production. Our management systems

are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on

handling the instrument. Working safely requires that all safety

instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and

general safety regulations for the instrument’s range of use.

■

The operating instructions are part of the product and must be kept

in the immediate vicinity of the instrument and readily accessible to

skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the

operating instructions, prior to beginning any work.

■

The manufacturer’s liability is void in the case of any damage caused

by using the product contrary to its intended use, non-compliance

with these operating instructions, assignment of insuciently

qualied skilled personnel or unauthorised modications to the

instrument.

■

The general terms and conditions contained in the sales

documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

www.air2guide.com

- Relevant data sheet: SP 69.03

4

WIKA operating instructions air2guide model A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 5

1. General information / 2. Safety

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can

result in serious injury or death, if not avoided.

Information

… points out useful tips, recommendations and

information for ecient and trouble-free operation.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure

that the appropriate dierential pressure transmitter has

been selected in terms of measuring range, design and

specic measuring conditions.

Non-observance can result in serious injury and/or damage

to the equipment.

Further important safety instructions can be found in the

individual chapters of these operating instructions.

2.1 Intended use

This dierential pressure transmitter is used for:

■

Monitoring the dierential pressure of air and other non-inammable

and non-aggressive gases

■

Monitoring of air lters, blowers in ventilation ducts

■

Control of air and re dampers and for overpressure monitoring in

clean rooms and laboratories

GB

The instrument has been designed and built solely for the intended use

described here, and may only be used accordingly.

40202780.02 05/2012 GB/D/F/E/I

WIKA operating instructions air2guide model A2G-50

5

Page 6

2. Safety / 3. Specications

The manufacturer shall not be liable for claims of any type based on

operation contrary to the intended use.

2.2 Personnel qualication

GB

Skilled personnel

Skilled personnel are understood to be personnel who, based on their

technical training, knowledge of measurement and control technology

and on their experience and knowledge of country-specic regulations,

current standards and directives, are capable of carrying out the work

described and independently recognising potential hazards.

Explanation of symbols

3. Specications

WARNING!

Risk of injury if qualication is insucient!

Improper handling can result in considerable injury and

damage to equipment.

■

The activities described in these operating instructions

may only be carried out by skilled personnel who have

the qualications described below.

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant

European directives.

Process connection

Connecting nozzle (ABS), for hoses with inner diameter 4 or 6 mm

Measuring element

Piezo measuring cell

Case

Plastic (ABS)

6

WIKA operating instructions air2guide model A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 7

3. Specications

Electrical connection

Cable gland M16, Screw terminals, max. 1.5 mm

Output signal

4 ... 20 mA or 0 … 10 V, 3-wire

Supply voltage

AC 24 V or DC 24 V ±10 %

Power < 1 W (1.5 W with 20 mA) 3-wire models

Long-term stability

0 ... 2,500 Pa ±8 Pa per year

0 ... 7,000 Pa ±24 Pa per year

-250 ... +250 Pa ±3 Pa per year

±1 Pa with automatic zero adjustment (option)

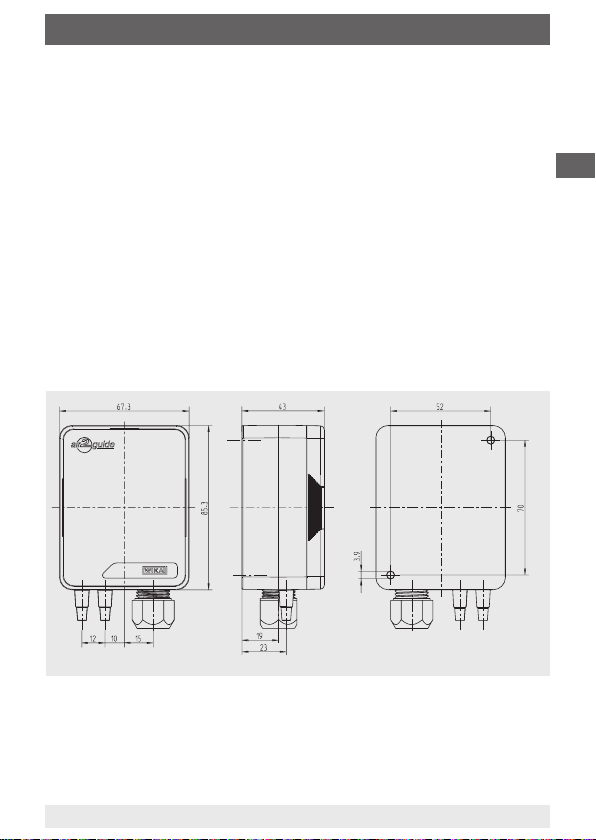

Dimensions in mm

2

GB

Weight

150 g

Ingress protection

IP 54 per EN 60529 / lEC 529

For further specications see WIKA data sheet SP 69.03 and the order

documentation.

40202780.02 05/2012 GB/D/F/E/I

WIKA operating instructions air2guide model A2G-50

7

Page 8

4. Design and function

4. Design and function

4.1 Description

Design

CE conformity:

GB

2004/108/EG Electromagnetic compatibility (EMC)

2002/95/EC RoHS (restriction of the use of certain hazardous

substances in electrical and electronic equipment)

Accuracy

±1.5 %

(with measuring range -250 ... +250 Pa: ±3 %)

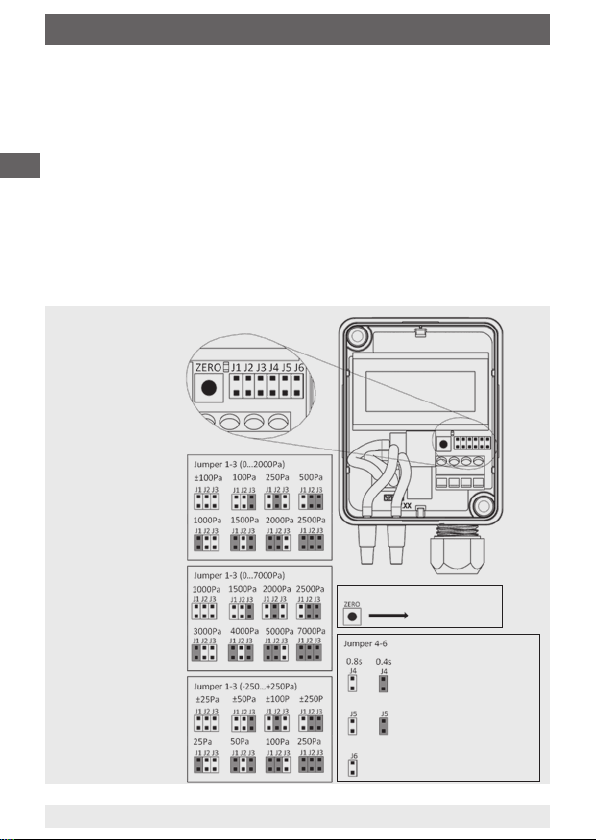

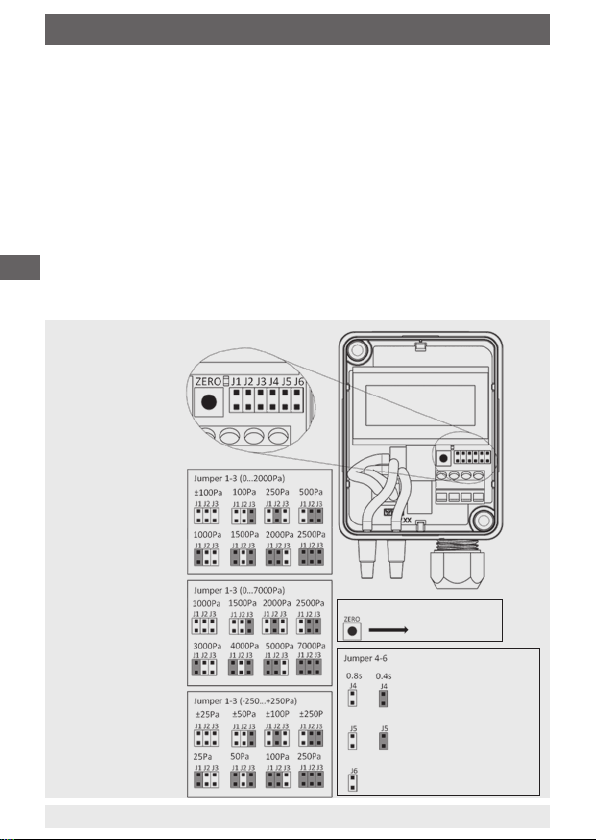

Measuring ranges

■

Variant 1: 0 ... 2,500 Pa standard

(-100 ... +100/0 ... 100/250/500/1,000/1,500/2,000 Pa adjustable via

jumper)

■

Variant 2: 0 ... 7,000 Pa standard

(0 ... 1,000/1,500/2,000/2,500/3,000/4,000/5,000 Pa adjustable via

jumper)

■

Variant 3: -250 ... +250 Pa (-25 ... +25/-50 ... +50/

-100... +100/0 ... 25/50/100/250 Pa adjustable via jumper)

Pressure limitation

Maximum pressure: 25 kPa

Burst pressure: 50 kPa

Permissible temperature

Ambient: -20 … +70 °C

Operation: -5 … +50 °C

Permissible ambient humidity

0 … 95 % rH, non-condensing

4.2 Scope of delivery

Cross-check scope of delivery with the delivery note.

8

WIKA operating instructions air2guide model A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 9

5. Transport, packaging ... / 6. Commissioning, operation

5. Transport, packaging and storage

5.1 Transport

Check the dierential pressure transmitter for any damage that may

have been caused during transportation. Obvious damage must be

reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

Storage temperature: -20 ... +70 °C

Protect the instruments from moisture and dust.

6. Commissioning, operation

Installation and mechanical connection

■

Protect measuring instruments from contamination, high temperature

changes and vibrations

■

In order to avoid any additional heating, the instruments must not be

exposed to direct solar irradiation while in operation.

■

The dierential pressure transmitter must be screw-tted on a

suitable vertical surface. The instrument has to be mounted horizontally using the enclosed mounting screws.

GB

40202780.02 05/2012 GB/D/F/E/I

WIKA operating instructions air2guide model A2G-50

9

Page 10

6. Commissioning, operation

Electrical connection

The instruments are designed to operate with safety extra-low voltage

(SELV). When wiring up the instruments, the technical specications for

those instruments should be followed. As a rule, the transmitter should

GB

be operated in the middle of the measuring range, since deviations can

occur at the range limits. The ambient temperature of the transmitter

electronics should be kept constant.

The dierential pressure transmitters must be operated at a constant

operating voltage (±0.2 V). Current/voltage spikes from switching the

power supply on or o must be prevented by the customer.

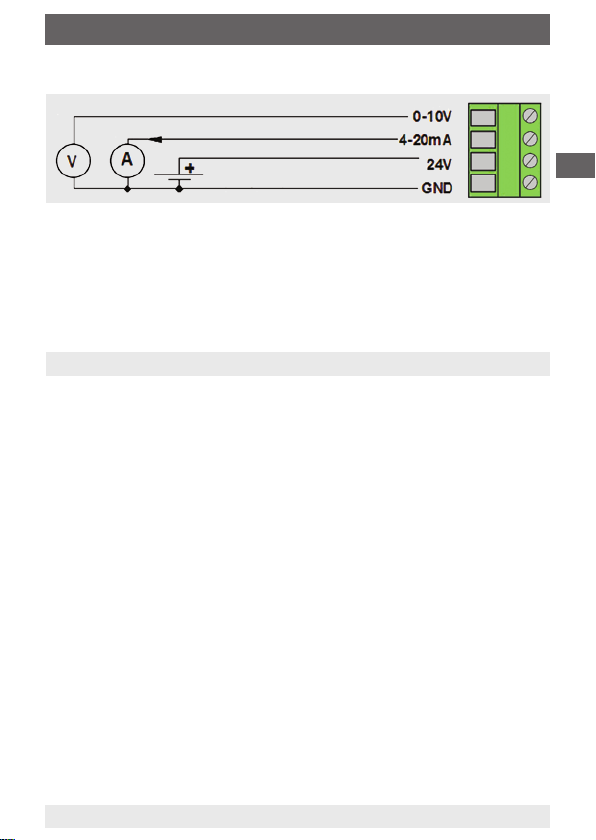

Connection diagram

Zeroing: Press the button

Select unit

Not in use

10

WIKA operating instructions air2guide model A2G-50

LED: Turns ON

Zeroing

Set response time

Note: Measuring unit

can be changed pressing

the ZERO button when

jumper 5 is placed.

Please remove jumper

after setting

40202780.02 05/2012 GB/D/F/E/I

Page 11

6. Commissioning, operation / 7. Zero point adjustment

Connection diagram

Output signal 0 ... 10 V

Output signal 4 ... 20 mA

Supply voltage

AC 24 V / DC 24 V

Commissioning

A prerequisite for the commissioning is a proper installation of all

electrical supply, control and measuring lines and of the pressure

connection lines. Before commissioning, the leak tightness of the

pressure connection lines must be checked.

7. Zero point adjustment

7.1 Standard

■

Attention! The power supply must be connected one hour before

calibrating the zero point. Remove both hoses from the pressure

connections ⊕ and ⊖.

■

Press the zero key until the red LED switches on.

■

Wait until the LED switches o again and install the hoses to the

pressure connections again.

■

In normal operation, we recommend that a zero point calibration is

carried out every 12 months.

7.2 Automatic zero adjustment (option)

The automatic zero adjustment makes the instrument maintenancefree. The element adjusts the zero point from time to time and thus

prevents a zero point drift of the piezo-resistive sensor element.

During the zero adjustment the display and output value remains

at the last measured value. The automatic zero adjustment takes

4 seconds and is repeated every 10 minutes.

40202780.02 05/2012 GB/D/F/E/I

WIKA operating instructions air2guide model A2G-50

GB

11

Page 12

8. Options and accessories ... 10. Disposal

8. Options and accessories

Standard accessories

■

2 mounting screws

GB

Options

■

LC display for measured value display

■

Automatic zero adjustment

■

2 duct connectors

■

2 m PVC hose with 4 mm inner diameter

9. Maintenance and cleaning

The dierential pressure transmitter is maintenance-free and oers long

service life provided it is handled and operated properly.

Clean the instruments with a moist cloth (soap water).

Repairs must only be carried out by the manufacturer or appropriately

qualied skilled personnel.

10. Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an

environmentally compatible way and in accordance with the country-

specic waste disposal regulations.

12

WIKA operating instructions air2guide model A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 13

Inhalt

Inhalt

1. Allgemeines 14

2. Sicherheit 15

3. Technische Daten 16

Aufbau und Funktion

4.

5. Transport, Verpackung und Lagerung 19

6. Inbetriebnahme, Betrieb 19

7. Nullpunkteinstellung 21

8. Optionen und Zubehör 22

9. Wartung und Reinigung 22

10. Entsorgung 22

18

D

40202780.02 05/2012 GB/D/F/E/I

WIKA Betriebsanleitung air2guide Typ A2G-50

13

Page 14

1. Allgemeines

1. Allgemeines

■

Der in der Betriebsanleitung beschriebene Dierenzdrucktransmitter

wird nach nach dem aktuellen Stand der Technik konstruiert und

gefertigt. Alle Komponenten unterliegen während der Fertigung

strengen Qualitäts- und Umweltkriterien. Unsere Managementsy-

steme sind nach ISO 9001 und ISO 14001 zertiziert.

D

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit

dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung

aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen

einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des Gerätes für das Fachpersonal jederzeit zugänglich

aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller

Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsanleitung,

Einsatz ungenügend qualizierten Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

www.air2guide.com

- zugehöriges Datenblatt: SP 69.03

14

WIKA Betriebsanleitung air2guide Typ A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 15

1. Allgemeines / 2. Sicherheit

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin,

die zum Tod oder zu schweren Verletzungen führen kann,

wenn sie nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Infor-

mationen für einen ezienten und störungsfreien Betrieb

hervor.

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen,

dass der richtige Dierenzdrucktransmitter hinsichtlich

Messbereich, Ausführung und spezischen Messbedin-

gungen ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen

und/oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den

einzelnen Kapiteln dieser Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Dieser Dierenzdrucktransmitter dient zur:

■

Überwachung des Dierenzdruckes von Luft und anderen nicht

brennbaren und nicht aggressiven Gasen

■

Überwachung von Luftltern, Gebläsen in Lüftungskanälen

■

Regelung von Luft- und Brandschutzklappen und zur Überdrucküberwachung von Reinräumen und Labors

D

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur

dementsprechend verwendet werden.

40202780.02 05/2012 GB/D/F/E/I

WIKA Betriebsanleitung air2guide Typ A2G-50

15

Page 16

2. Sicherheit / 3. Technische Daten

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer

Verwendung sind ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

D

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner

Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen

sowie Kenntnis der landesspezischen Vorschriften, geltenden Normen

und Richtlinien in der Lage, die beschriebenen Arbeiten auszuführen

und mögliche Gefahren selbstständig zu erkennen.

Symbolerklärung

3. Technische Daten

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personenund Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen

Tätigkeiten nur durch Fachpersonal nachfolgend

beschriebener Qualikation durchführen lassen.

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den

zutreenden europäischen Richtlinien.

Prozessanschluss

Anschlussstutzen (ABS), für Schläuche mit Innendurchmesser 4 oder

6 mm

Messelement

Piezo-Messzelle

Gehäuse

Kunststo (ABS)

16

WIKA Betriebsanleitung air2guide Typ A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 17

3. Technische Daten

Elektrischer Anschluss

Kabelverschraubung M16, Schraubklemmen max. 1,5 mm

Ausgangssignal

4 ... 20 mA oder 0 … 10 V, 3-Leiter

Versorgungsspannung

AC 24 V oder DC 24 V ±10 %

Leistung < 1 W (1,5 W mit 20 mA) 3-Leiter-Typen

Langzeitstabilität

0 ... 2.500 Pa ±8 Pa pro Jahr

0 ... 7.000 Pa ±24 Pa pro Jahr

-250 ... +250 Pa ±3 Pa pro Jahr

±1 Pa mit automatischer Nullpunktkorrektur (Option)

Abmessungen in mm

Schutzart

IP 54 nach EN 60529 / lEC 529

2

D

Gewicht

150 g

Weitere technische Daten siehe WIKA-Datenblatt SP 69.03 und

Bestellunterlagen.

40202780.02 05/2012 GB/D/F/E/I

WIKA Betriebsanleitung air2guide Typ A2G-50

17

Page 18

4. Aufbau und Funktion

4. Aufbau und Funktion

4.1 Beschreibung

Ausführung

CE-Konformität:

2004/108/EG Elektromagnetische Verträglichkeit

D

2002/95/EG RoHS (Beschränkung der Verwendung bestimmter

gefährlicher Stoe in Elektro- und Elektronikgeräten)

Genauigkeit

±1,5 %

(bei Messbereich -250 ... +250 Pa: ±3 %)

Messbereiche

■

Variante 1: 0 ... 2.500 Pa Standard

(-100 ... +100/0 ... 100/250/500/1.000/1.500/2.000 Pa über Jumper

einstellbar)

■

Variante 2: 0 ... 7.000 Pa Standard

(0 ... 1.000/1.500/2.000/2.500/3.000/4.000/5.000 Pa über Jumper

einstellbar)

■

Variante 3: -250 ... +250 Pa (-25 ... +25/-50 ... +50/

-100... +100/0 ... 25/50/100/250 Pa über Jumper einstellbar)

Druckbelastbarkeit

Maximaler Druck: 25 kPa

Berstdruck: 50 kPa

Zulässige Temperatur

Umgebung: -20 … +70 °C

Betrieb: -5 … +50 °C

Zulässige Umgebungsfeuchte

0 … 95 % rF, nicht kondensierend

4.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

18

WIKA Betriebsanleitung air2guide Typ A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 19

5. Transport, Verpackung ... / 6. Inbetriebnahme, Betrieb

5. Transport, Verpackung und Lagerung

5.1 Transport

Dierenzdrucktransmitter auf eventuell vorhandene Transportschäden

untersuchen. Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport

einen optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort

Lagertemperatur: -20 … +70 °C

Geräte vor Feuchtigkeit und Staub schützen.

6. Inbetriebnahme, Betrieb

Installation und mechanischer Anschluss

■

Messgeräte vor Verschmutzung und starken Temperaturschwankungen und Vibrationen schützen

■

Um zusätzliche Aufheizungen zu vermeiden, dürfen die Geräte im

Betrieb keiner direkten Sonneneinstrahlung ausgesetzt sein.

■

Der Dierenzdrucktransmitter muss auf einer geeigneten vertikalen

Fläche aufgeschraubt werden. Das Gerät ist waagrecht mit den

beiliegenden Befestigungsschrauben zu befestigen.

D

40202780.02 05/2012 GB/D/F/E/I

WIKA Betriebsanleitung air2guide Typ A2G-50

19

Page 20

6. Inbetriebnahme, Betrieb

Elektrischer Anschluss

Die Geräte sind für den Betrieb an Schutzkleinspannung (SELV)

ausgelegt. Beim elektrischen Anschluss der Geräte gelten die

technischen Daten der Geräte. Der Dierenzdrucktransmitter sollte

in der Regel in der Messbereichsmitte betrieben werden, da an den

Messbereichsendpunkten erhöhte Abweichungen auftreten können.

Die Umgebungstemperatur der Messumformerelektronik sollte konstant

D

gehalten werden.

Die Dierenzdrucktransmitter müssen bei einer konstanten Betriebsspannung (±0,2 V) betrieben werden. Strom-/Spannungsspitzen beim

Ein-/Ausschalten der Versorgungsspannung müssen bauseitig vermieden werden.

Anschlussplan

Nullung: Taste drücken

Einheit wählen

Nicht genutzt

20

WIKA Betriebsanleitung air2guide Typ A2G-50

LED: Geht AN

Nullung

Einstellen der Ansprechzeit

Hinweis: Wenn Jumper

5 gesetzt ist, kann die

Messeinheit durch

Drücken der ZERO-Taste

geändert werden.

Bitte nach dem Einstellen

Jumper entfernen

40202780.02 05/2012 GB/D/F/E/I

Page 21

6. Inbetriebnahme, Betrieb / 7. Nullpunkteinstellung

Anschlussschema

Ausgangssignal 0 ... 10 V

Ausgangssignal 4 ... 20 mA

Hilfsenergie

AC 24 V / DC 24 V

Inbetriebnahme

Voraussetzung für die Inbetriebnahme ist die ordnungsgemäße

Installation aller elektrischen Versorgungs-, Schalt- und Messleitungen

und der Druckanschlussleitungen. Vor Inbetriebnahme ist die Dichtigkeit

der Druckanschlussleitungen zu prüfen.

7. Nullpunkteinstellung

7.1 Standard

■

Achtung! Die Spannungsversorgung muss eine Stunde vor der

Nullpunktkalibrierung angeschlossen sein. Beide Schläuche von

den Druckanschlüssen ⊕ und ⊖ lösen.

■

Null-Taste drücken bis sich die rote LED einschaltet.

■

Warten bis sich die LED wieder ausschaltet und anschließend die

Schläuche wieder an die Druckanschlüsse installieren.

■

Bei normalem Betrieb ist es empfehlenswert, die Nullpunktkalibrierung alle 12 Monate vorzunehmen.

D

7.2 Automatische Nullpunktkorrektur (Option)

Die automatische Nullpunktkorrektur macht das Gerät wartungsfrei.

Das Element korrigiert von Zeit zu Zeit den Nullpunkt und verhindert

somit einen Nullpunktdrift des piezoresistiven Sensorelements.

Während der Nullpunktkorrektur bleibt der Anzeige- und Ausgangswert

beim letzten gemessenen Wert stehen. Die automatische Nullpunktkorrektur dauert 4 Sekunden und wird alle 10 Minuten wiederholt.

40202780.02 05/2012 GB/D/F/E/I

WIKA Betriebsanleitung air2guide Typ A2G-50

21

Page 22

8. Optionen und Zubehör ... 10. Entsorgung

8. Optionen und Zubehör

Standardzubehör

■

2 Befestigungsschrauben

Optionen

■

LC-Display zur Messwertanzeige

D

■

Automatische Nullpunktkorrektur

■

2 Kanalanschlussnippel

■

2 m PVC-Schlauch Innendurchmesser 4 mm

9. Wartung und Reinigung

Der Dierenzdrucktransmitter ist wartungsfrei und zeichnet sich

bei sachgemäßer Behandlung und Bedienung durch eine hohe

Lebensdauer aus.

Reinigen der Geräte mit einem (in Seifenlauge) angefeuchteten Tuch.

Reparaturen sind ausschließlich vom Hersteller oder entsprechend

qualiziertem Fachpersonal durchzuführen.

10. Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den

landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften

umweltgerecht entsorgen.

22

WIKA Betriebsanleitung air2guide Typ A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 23

Sommaire

Sommaire

1. Généralités 24

2. Sécurité 25

3. Spécications 26

Conception et fonction

4.

5. Transport, emballage et stockage 29

6. Mise en service, exploitation 29

7. Réglage du point zéro 31

8. Options et accessoires 32

9. Entretien et nettoyage 32

10. Mise au rebut 32

28

F

40202780.02 05/2012 GB/D/F/E/I

Mode d´emploi WIKA air2guide type A2G-50

23

Page 24

1. Généralités

1. Généralités

■

Le transmetteur de pression diérentielle décrit dans le mode

d'emploi est conçu et fabriqué selon les dernières technologies en

vigueur. Tous les composants sont soumis à des critères de qualité

et d'environnement stricts durant la fabrication. Nos systèmes de

gestion sont certiés selon ISO 9001 et ISO 14001.

■

Ce mode d’emploi donne des indications importantes concernant

F

l’utilisation de l’instrument. Il est possible de travailler en toute

sécurité avec ce produit en respectant toutes les consignes de

sécurité et d’utilisation.

■

Respecter les prescriptions locales de prévention contre les

accidents et les prescriptions générales de sécurité en vigueur pour

le domaine d‘application de l’instrument.

■

Le mode d’emploi fait partie du produit et doit être conservé à

proximité immédiate de l’instrument et être accessible à tout moment

pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération,

avoir lu soigneusement et compris le mode d’emploi.

■

La responsabilité du fabricant n’est pas engagée en cas de

dommages provoqués par une utilisation non conforme à l’usage

prévu, de non respect de ce mode d’emploi, d’utilisation de

personnel peu qualié de même qu’en cas de modications de

l’instrument eectuées par l’utilisateur.

■

Les conditions générales de vente mentionnées dans les documents

de vente s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site internet : www.wika.fr

www.air2guide.com

- Fiche technique correspondante : SP 69.03

24

Mode d´emploi WIKA air2guide type A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 25

1. Généralités / 2. Sécurité

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer la mort ou des blessures graves si elle

n'est pas évitée.

Information

… met en exergue les conseils et recommandations utiles

de même que les informations permettant d'assurer un

fonctionnement ecace et normal.

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement,

s'assurer que le transmetteur de pression diérentielle

a été choisi de façon adéquate, en ce qui concerne la

plage de mesure, la version et les conditions de mesure

spéciques.

Un non-respect de cette consigne peut entraîner des

blessures corporelles graves et/ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les

sections individuelles du présent mode d'emploi.

2.1 Utilisation conforme à l'usage prévu

Ce transmetteur de pression diérentiel est utilisé pour :

■

La surveillance de la pression diérentielle de l'air et d'autres gaz

non inammables et non agressifs

■

Surveillance de ltres à air, de soueries dans des canaux de

ventilation

■

La surveillance de registres d'air et de clapets coupe-feu et pour

la surveillance de la surpression dans des pièces propres et des

laboratoires

L’instrument est conçu et construit exclusivement pour une utilisation

conforme à l’usage prévu décrit ici et ne doit être utilisé qu’en

conséquence.

40202780.02 05/2012 GB/D/F/E/I

Mode d´emploi WIKA air2guide type A2G-50

F

25

Page 26

2. Sécurité / 3. Spécications

Aucune réclamation ne peut être recevable en cas d'utilisation non

conforme à l'usage prévu.

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insufsante!

F

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de

ses connaissances dans le domaine de la technique de mesure et de

régulation et de ses expériences de même que de sa connaissance des

prescriptions nationales des normes et directives en vigueur, en mesure

d'eectuer les travaux décrits et de reconnaître automatiquement les

dangers potentiels.

Explication des symboles

3. Spécications

Une utilisation non conforme peut entraîner d'importants

dommages corporels et matériels.

■

Les opérations décrites dans ce mode d'emploi ne

doivent être eectuées que par un personnel ayant la

qualication décrite ci-après.

CE, Communauté Européenne

Les instruments avec ce marquage sont conformes aux

directives européennes pertinentes.

Raccord process

Embout de raccordement (ABS), pour tuyaux souples de diamètre

intérieur 4 ou 6 mm

Elément de mesure

Cellule de mesure piézo-électrique

Boîtier

Plastique (ABS)

26

Mode d´emploi WIKA air2guide type A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 27

3. Spécications

Raccordement électrique

Presse-étoupe M16, Bornes à vis, max. 1,5 mm²

Signal de sortie

4 ... 20 mA ou 0 … 10 V, 3 ls

Tension d'alimentation

24 VAC ou 24 VDC ±10 %

Puissance < 1 W (1,5 W avec 20 mA) types à 3 ls

Stabilité à long terme

0 ... 2.500 Pa ±8 Pa par an

0 ... 7.000 Pa ±24 Pa par an

-250 ... +250 Pa ±3 Pa par an

±1 Pa avec réglage automatique du point zéro (option)

Dimensions en mm

F

Indice de protection

IP 54 selon EN 60529 / lEC 529

Pour de plus amples spécications, voir la che technique WIKA

SP 69.03 et la documentation de commande.

40202780.02 05/2012 GB/D/F/E/I

Mode d´emploi WIKA air2guide type A2G-50

Poids

150 g

27

Page 28

4. Conception et fonction

4. Conception et fonction

4.1 Description

Design

Conformité CE:

2004/108/CE Compatibilité électromagnétique (CEM)

2002/95/CE RoHS (restriction de l'utilisation de certaines substances

dangereuses dans les équipements électriques et électroniques)

F

Précision

±1,5 %

(avec étendue de mesure -250 ... +250 Pa: ±3 %)

Etendues de mesure

■

Exécution 1: 0 ... 2.500 Pa standard

(-100 ... +100/0 ... 100/250/500/1.000/1.500/2.000 Pa ajustable par

cavalier)

■

Exécution 2: 0 ... 7.000 Pa standard

(0 ... 1.000/1.500/2.000/2.500/3.000/4.000/5.000 Pa ajustable par

cavalier)

■

Exécution 3: -250 ... +250 Pa (-25 ... +25/-50 ... +50/

-100... +100/0 ... 25/50/100/250 Pa ajustable par cavalier)

Plages d' utilisation

Pression maximale : 25 kPa

Pression d'éclatement: 50 kPa

Température admissible

Ambiante: -20 … +70 °C

Température de service : -5 … +50 °C

Humidité ambiante admissible

0 ... 95 % d'HR, sans condensation

4.2 Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

28

Mode d´emploi WIKA air2guide type A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 29

5. Transport ... / 6. Mise en service, fonctionnement

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur le transmetteur de pression diérentielle liés au transport. Communiquer immédiatement les dégâts

constatés.

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection

optimale (par ex. changement de lieu d'utilisation, renvoi pour réparation).

5.3 Stockage

Conditions admissibles sur le lieu de stockage :

Température de stockage : -20 ... +70 °C

Protégez les instruments contre l’humidité et la poussière.

6. Mise en service, exploitation

Installation et branchement mécanique

■

Protégez les instruments de mesure contre la contamination, les

variations de température élevées et les vibrations

■

An d'éviter tout échauement supplémentaire, les instruments ne

doivent pas être exposés directement aux rayons du soleil pendant

le fonctionnement.

F

■

Le transmetteur de pression diérentielle doit être vissé sur

une surface verticale adaptée. L'instrument doit être monté

horizontalement à l'aide des vis de montage fournies.

40202780.02 05/2012 GB/D/F/E/I

Mode d´emploi WIKA air2guide type A2G-50

29

Page 30

6. Mise en service, exploitation

Raccordement électrique

Les instruments sont conçus pour travailler avec une tension extrabasse de sécurité (SELV). Lorsque l'on câble les instruments, il faut

respecter les spécications techniques de ces instruments. En règle

générale, le transmetteur doit être utilisé au milieu de la plage de

mesure, car des déviations peuvent se produire aux limites de l'étendue.

Il faut maintenir constante la température ambiante de l'électronique du

transmetteur.

F

Les transmetteurs de pression diérentielle doivent fonctionner à une

tension constante (±0,2 V). Des pics de courant/tension provenant de

l'allumage et de l'extinction de l'alimentation doivent être évités par le

client.

Schéma de raccordement

Mise à zéro : Appuyer sur le bouton

Sélectionner l’unité

Hors

fonctionnement

30

Mode d´emploi WIKA air2guide type A2G-50

LED: Allumée

Mise à zéro

Congurer le temps de réponse

Note: L’unité de mesure

peut être changée en

appuyant sur le bouton

ZERO quand le cavalier

5 est en place.

Merci d’enlever le

cavalier après réglage

40202780.02 05/2012 GB/D/F/E/I

Page 31

6. Mise en service, exploitation / 7. Réglage du point zéro

Schéma de raccordement

Signal sortie 0 ... 10 V

Signal de sortie 4 ... 20 mA

Tension d'alimentation

CA 24 V / CC 24 V

Mise en service

Une condition préalable à la mise en service est une installation

correcte de toute l'alimentation électrique, des lignes de contrôle et

de mesure et des lignes de raccordement de pression. Avant la mise

en service, il faut contrôler l'étanchéité des lignes de raccordement de

pression.

7. Réglage du point zéro

7.1 Standard

■

Attention ! L'alimentation électrique doit être connectée une heure

avant la calibration du point zéro. Enlevez les deux tuyaux des

raccordements de pression ⊕ et ⊖.

■

Presser la touche zéro jusqu'à ce que la LED rouge s'allume.

■

Attendre jusqu'à ce que la LED s'éteigne et installer à nouveau les

tuyaux sur les raccordements de pression.

■

En fonctionnement normal, nous recommandons de calibrer le point

zéro tous les 12 mois.

7.2 Réglage automatique du point zéro (option)

Le réglage automatique du point zéro fait que l'instrument ne nécessite pas d'entretien. L'élément règle le point zéro de temps en temps et

empêche ainsi une dérive du point zéro de l'élément capteur piézorésistant.

Pendant le réglage du point zéro, la valeur de sortie et d'achage

demeure à la dernière valeur mesurée. Le réglage automatique du

point zéro prend 4 secondes et est répété toutes les 10 minutes.

40202780.02 05/2012 GB/D/F/E/I

Mode d´emploi WIKA air2guide type A2G-50

F

31

Page 32

8. Options et accessoires ... 10. Mise au rebut

8. Options et accessoires

Accessoires standard

■

2 vis de montage

Options

■

Achage LC pour achage de valeur mesurée

■

Réglage automatique du point zéro

F

■

2 connecteurs de conduit

■

2 m de tube PVC de diamètre intérieur de 4 mm

9. Entretien et nettoyage

Le transmetteur de pression diérentielle ne nécessite aucun entretien

et ore une longue durée de vie à condition qu'il soit manipulé et

actionné correctement.

Nettoyez les instruments avec un chion humide (eau savonneuse).

Toute réparation doit être exclusivement conée au fabricant ou au

personnel qualié correspondant.

10. Mise au rebut

Une mise au rebut inadéquate peut entraîner des dangers pour

l'environnement.

Eliminer les composants des instruments et les matériaux d'emballage

conformément aux prescriptions nationales pour le traitement et

l'élimination des déchets et aux lois de protection de l'environnement en

vigueur.

32

Mode d´emploi WIKA air2guide type A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 33

Contenido

Contenido

1. Información general 14

2. Seguridad 15

3. Datos técnicos 16

Diseño y función

4.

5. Transporte, embalaje y almacenamiento 19

6. Puesta en servicio, funcionamiento 19

7. Ajuste del punto cero 21

8. Opciones y accesorios 22

9. Mantenimiento y limpieza 22

10. Eliminación de residuos 22

40202780.02 05/2012 GB/D/F/E/I

WIKA manual de instrucciones air2guide modelo A2G-50

18

E

33

Page 34

1. Información general

1. Información general

■

El transmisor de presión diferencial descrito en el manual de

instrucciones está construido y fabricado según el estado actual de

la técnica. Todos los componentes están sujetos a rigurosos criterios de calidad y medio ambiente en el proceso de la producción.

Nuestros sistemas de gestión están certicados según ISO 9001 e

ISO 14001.

■

Este manual de instrucciones proporciona indicaciones importantes

acerca del manejo del instrumento. Para que el trabajo con este

E

instrumento sea seguro es imprescindible cumplir con todas las

instrucciones de seguridad y manejo indicadas.

■

Cumplir siempre las normativas sobre la prevención de accidentes

y las normas de seguridad en vigor en el lugar de utilización del

instrumento.

■

El manual de instrucciones es una parte integrante del instrumento

y debe guardarse en la proximidad del mismo para que el personal

especializado pueda consultarlo en cualquier momento.

■

El personal especializado debe haber leído y entendido el manual

de instrucciones antes de comenzar cualquier trabajo.

■

El fabricante queda exento de cualquier responsabilidad en caso de

daños causados por un uso no conforme a la nalidad prevista, la

inobservancia del presente manual de instrucciones, un manejo por

personal insucientemente cualicado así como una modicación no

autorizada del instrumento.

■

Se aplican las condiciones generales de venta incluidas en la

documentación de venta.

■

Modicaciones técnicas reservadas.

■

Para obtener más informaciones consultar:

- Página web: www.wika.es

www.air2guide.com

- Hoja técnica correspondiente: SP 69.03

34

WIKA manual de instrucciones air2guide modelo A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 35

1. Información general / 2. Seguridad

Explicación de símbolos

¡ADVERTENCIA!

… indica una situación probablemente peligrosa que

pueda causar la muerte o lesiones graves si no se evita.

Información

... destaca consejos y recomendaciones útiles así como

informaciones para una utilización ecaz y libre de fallos.

2. Seguridad

¡ADVERTENCIA!

Antes del montaje, la puesta servicio y el funcionamiento

asegurarse de que se haya seleccionado el transmisor

de presión diferencial adecuado con respecto a rango de

medida, versión y condiciones de medición especícas.

El no respetar las instrucciones puede generar lesiones

graves y/o daños materiales.

Los distintos capítulos de este manual de instrucciones

contienen otras importantes indicaciones de seguridad.

2.1 Uso conforme a lo previsto

Esto transmisor de presión diferencial se utiliza para:

■

La supervisión de la presión diferencial de aire y otros gases no

combustibles y no agresivos

■

Supervisión de ltros de aire, ventiladores en canales de ventilación

■

Regulación de válvulas de ventilación y cortafuegos y para la

supervisión de sobrepresiones en salas limpias y laboratorios

E

El instrumento ha sido diseñado y construido únicamente para la

nalidad aquí descrita y debe utilizarse en conformidad a la misma.

40202780.02 05/2012 GB/D/F/E/I

WIKA manual de instrucciones air2guide modelo A2G-50

35

Page 36

2. Seguridad / 3. Datos técnicos

No se admite ninguna reclamación debido a un manejo no adecuado.

2.2 Cualicación del personal

¡ADVERTENCIA!

¡Riesgo de lesiones debido a una insuciente

cualicación!

Un manejo no adecuado puede causar considerables

daños personales y materiales.

■

Las actividades descritas en este manual de

E

Personal especializado

Debido a su formación profesional, a sus conocimientos de la técnica

de regulación y medición así como a su experiencia y su conocimiento

de las normativas, normas y directivas vigentes en el país de utilización

el personal especializado es capaz de ejecutar los trabajos descritos y

reconocer posibles peligros por sí solo.

Explicación de símbolos

3. Datos técnicos

Conexión a proceso

Racor de conexión (ABS), para mangueras con diámetro interior de 4 o

6 mm

instrucciones deben realizarse únicamente por

personal especializado con la consiguiente

cualicación.

CE, Communauté Européenne

Los instrumentos con este marcaje cumplen las directivas

europeas aplicables.

Elemento de medición

Sensor piezoresistivo

Caja

Plástico (ABS)

36

WIKA manual de instrucciones air2guide modelo A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 37

3. Datos técnicos

Conexión eléctrica

Racor de cable M16, Bornes max. 1,5 mm

2

Señal de salida

4 ... 20 mA ó 0 … 10 V, 3 hilos

Tensión de alimentación

AC 24 V ó DC 24 V ±10 %

Potencia < 1 W (1,5 W con 20 mA) modelos de 3 hilos

Estabilidad a largo plazo

0 ... 2.500 Pa ±8 Pa por año

0 ... 7.000 Pa ±24 Pa por año

-250 ... +250 Pa ±3 Pa por año

±1 Pa con ajuste automático del punto cero (opción)

Dimensiones en mm

E

Peso

150 g

Tipo de protección

IP 54 según EN 60529 / IEC 529

Para más datos técnicos véase la hoja técnica de WIKA SP 69.03 y la

documentación de pedido.

40202780.02 05/2012 GB/D/F/E/I

WIKA manual de instrucciones air2guide modelo A2G-50

37

Page 38

4. Diseño y función

4. Diseño y función

4.1 Descripción

Modelo

Conformidad CE:

Compatibilidad electromagnética según 2004/108/CE

2002/95/CE RoHS (Restricción al uso de determinadas sustancias

peligrosas en aparatos eléctricos y electrónicos)

Precisión

E

±1,5 %

(con rango de medida -250 ... +250 Pa: ±3 %)

Rangos de medida

■

Variante 1: 0 ... 2.500 Pa estándar

(-100 ... +100/0 ... 100/250/500/1.000/1.500/2.000 Pa ajustable

mediante jumper)

■

Variante 2: 0 ... 7.000 Pa estándar

(0 ... 1.000/1.500/2.000/2.500/3.000/4.000/5.000 Pa ajustable

mediante jumper)

■

Variante 3: -250 ... +250 Pa (-25 ... +25/-50 ... +50/

-100... +100/0 ... 25/50/100/250 Pa ajustable mediante jumper)

Presión admisible

Presión máxima: 25 kPa

Presión de estallido: 50 kPa

Temperatura admisible

Ambiente: -20 … +70 °C

Servicio: -5 … +50 °C

Humedad ambiente admisible

0 ... 95 % rF, sin condensación

4.2 Volumen de suministro

Comparar mediante el albarán si se han entregado todas las piezas.

38

WIKA manual de instrucciones air2guide modelo A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 39

5. Transporte ... / 6. Puesta en servicio, funcionamiento

5. Transporte, embalaje y almacenamiento

5.1 Transporte

Comprobar si el transmisor de presión diferencial presenta eventuales

daños causados en el transporte. Noticar de inmediato cualquier daño

evidente.

5.2 Embalaje

No quitar el embalaje hasta justo antes del montaje.

Guardar el embalaje ya que es la protección ideal para el transporte

(por ejemplo un cambio del lugar de instalación o un envío del instrumento para posibles reparaciones).

5.3 Almacenamiento

Condiciones admisibles en el lugar de almacenamiento

Temperatura de almacenamiento: -20 ... +70 °C

Proteger los instrumentos de medición de humedad y polvo.

6. Puesta en servicio, funcionamiento

Instalación y conexión mecánica

■

Proteger los dispositivos de medición contra la obturación, las

grandes oscilaciones de temperatura y las vibraciones.

■

No exponer los instrumentos a la radiación solar directa durante el

funcionamiento para evitar un calentamiento adicional.

E

■

El transmisor de presión diferencial debe atornillarse a una super-

cie vertical adecuada. Fijar horizontalmente el aparato con los

tornillos de sujeción suministrados.

40202780.02 05/2012 GB/D/F/E/I

WIKA manual de instrucciones air2guide modelo A2G-50

39

Page 40

6. Puesta en servicio, funcionamiento

Conexión eléctrica

Los aparatos son previstos para la utilización con baja tensión de

protección (SELV). Para la conexión eléctrica de los aparatos se

aplican los datos técnicos de los aparatos. Utilizar el transmisor de

presión diferencial en el centro de la zona de medición porque en

las extremidades pueden manifestarse diferencias elevadas. La

temperatura ambiental de la electrónica de convertidores de medición

debe mantenerse constante.

Los transmisores de presión diferencial deben utilizarse con una

E

tensión de trabajo (±0,2 V) constante. Hay que evitar picos de corriente/

tensión al conectar/desconectar la tensión de alimentación.

Esquema de conexión

Punto cero: pulsar botón

Seleccionar la unidad

No aplicado

40

WIKA manual de instrucciones air2guide modelo A2G-50

LED: ACTIVAR

Cero

Ajustar el tiempo de respuesta

Comentario:

Conguración del Jumper

5 permite el cambio de

la unidad de medida

mediante tecla CERO.

Por favor eliminar

jumper tras ajustar

40202780.02 05/2012 GB/D/F/E/I

Page 41

6. Puesta en servicio ... / 7. Ajuste del punto cero

Esquema de conexión

Señal de salida 0 ... 10 V

Señal de salida 4 ... 20 mA

Alimentación auxiliar

AC 24 V / DC 24 V

Puesta en servicio

Para la puesta en servicio es imprescindible instalar correctamente

todas las líneas de alimentación, conmutación, medición y presión.

Antes de la puesta en servicio hay que comprobar si las líneas de

presión están herméticamente cerradas.

7. Ajuste del punto cero

7.1 Estándar

■

¡Atención! La alimentación de corriente debe estar conectada una

hora antes de calibrar el punto cero. Desconectar los dos tubos de

las tomas de presión ⊕ y ⊖.

■

Pulsar la tecla cero hasta que se ilumine el LED rojo.

■

Esperar que se apague el LED y volver a conectar los tubos a las

tomas de presión.

■

Durante el funcionamiento normal se recomienda calibrar el punto

cero cada 12 meses.

E

7.2 Ajuste automático del punto cero (opción)

El instrumento no necesita mantenimiento gracias a la corrección

automática del punto cero. El elemento corrige el punto cero de vez en

cuando e impide una desviación del punto cero del elemento piezorresistivo de la sonda.

Durante la corrección del punto cero, el valor de indicación y salida se

para en el valor medido por último. La corrección automática del punto

cero dura 4 segundos y se repite cada 10 minutos.

40202780.02 05/2012 GB/D/F/E/I

WIKA manual de instrucciones air2guide modelo A2G-50

41

Page 42

8. Opciones y accesorios ... 10. Eliminación de residuos

8. Opciones y accesorios

Accesorios estándar

■

2 tornillos para la jación

Opciones

■

Pantalla LCD para la indicación del valor de medición

■

Ajuste automático del punto cero

■

2 boquillas de conexión de canal

■

Manguera de PVC de 2 m con un diámetro interior de 4 mm

E

9. Mantenimiento y limpieza

El transmisor de presión diferencial no necesita mantenimiento y se

distingue por su prolongada vida útil si se maneja y opera de forma

apropiada.

Limpiar los instrumentos con un trapo húmedo (mojado en lejía de

jabón).

Todas las reparaciones solamente las debe efectuar el fabricante o

personal especializado e instruido.

10. Eliminación de residuos

Una eliminación incorrecta puede provocar peligros para el medio

ambiente.

Eliminar los componentes de los instrumentos y los materiales de

embalaje conforme a los reglamentos relativos al tratamiento de

residuos y eliminación vigentes en el país de utilización.

42

WIKA manual de instrucciones air2guide modelo A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 43

Contenuti

Contenuti

1. Informazioni generali 44

2. Norme di sicurezza 45

3. Speciche tecniche 46

Esecuzione e funzioni

4.

5. Trasporto, imballaggio e stoccaggio 49

6. Messa in servizio, funzionamento 49

7. Regolazione dello zero 51

8. Opzioni e accessori 52

9. Manutenzione e pulizia 52

10. Smaltimento 52

48

I

40202780.02 05/2012 GB/D/F/E/I

WIKA manuale d‘uso air2guide, modello A2G-50

43

Page 44

1. Informazioni generali

1. Informazioni generali

■

Il trasmettitore di pressione dierenziale descritto in questo manuale

d‘uso è stato progettato e costruito secondo lo stato dell‘arte della

tecnica. Tutti i componenti sono soggetti a stringenti controlli di

qualità ed ambientali durante la produzione. I nostri sistemi di qualità

sono certicati ISO 9001 e ISO 14001.

■

Questo manuale contiene importanti informazioni sull’uso dello

strumento. Lavorare in sicurezza implica il rispetto delle istruzioni di

sicurezza e di funzionamento.

I

■

Osservare le normative locali in tema di prevenzione incidenti e le

regole di sicurezza generali per il campo d’impiego dello strumento.

■

Il manuale d’uso è parte dello strumento e deve essere conservato

nelle immediate vicinanze dello stesso e facilmente accessibile in

ogni momento al personale qualicato.

■

Il manuale d’uso deve essere letto con attenzione e compreso dal

personale qualicato prima dell’inizio di qualsiasi attività.

■

Il costruttore declina ogni responsabilità per qualsiasi danno causato

da un utilizzo scorretto del prodotto, dal non rispetto delle istruzioni riportate in questo manuale, da un impiego di personale non

adeguatamente qualicato oppure da modiche non autorizzate allo

strumento.

■

Si applicano le nostre condizioni generali di vendita, allegate alla

conferma d’ordine.

■

Soggetto a modiche tecniche.

■

Ulteriori informazioni:

- Indirizzo Internet: www.wika.it

www.air2guide.com

- Scheda tecnica prodotto: SP 69.03

44

WIKA manuale d‘uso air2guide, modello A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 45

1. Informazioni generali / 2. Norme di sicurezza

Legenda dei simboli

ATTENZIONE!

... indica una situazione di potenziale pericolo che, se non

evitata, può causare ferite gravi o morte.

Informazione

... fornisce suggerimenti utili e raccomandazioni per

l'utilizzo eciente e senza problemi dello strumento.

2. Norme di sicurezza

ATTENZIONE!

Prima dell‘installazione, messa in servizio e funzionamento, assicurarsi che sia stato selezionato il trasmettitore

di pressione dierenziale adatto per quanto riguarda il

campo di misura, l'esecuzione e le condizioni speciche

della misura.

La non osservanza può condurre a ferite gravi o danni alle

apparecchiature.

Altre importanti norme di sicurezza sono riportate nei

singoli capitoli di questo manuale d‘uso.

2.1 Destinazione d’uso

Questo tramsettitore di pressione dierenziale viene usato per:

■

Monitoraggio della pressione dierenziale per aria e gas non inam-

mabili o aggressivi

■

Monitoraggio ltri, ventilatori in condotti di ventilazione

■

Regolazione di serrande aria e serrande tagliafuoco e monitoraggio

della sovrapressione in camere bianche e laboratori

Lo strumento è stato progettato e costruito esclusivamente per la sua

destinazione d’uso e può essere impiegato solo per questa.

40202780.02 05/2012 GB/D/F/E/I

WIKA manuale d‘uso air2guide, modello A2G-50

I

45

Page 46

2. Norme di sicurezza / 3. Speciche tecniche

Il costruttore non è responsabile per reclami di qualsiasi natura in caso

di utilizzo dello strumento al di fuori del suo impiego consentito.

2.2 Qualicazione del personale

ATTENZIONE!

Rischio di infortuni in caso di personale non qualicato!

L‘uso improprio può condurre a gravi infortuni o danni alle

apparecchiature.

■

Le attività riportate in questo manuale d‘uso possono

I

Personale qualicato

Per personale qualicato si intende personale che, sulla base delle

proprie conoscenze tecniche di strumentazione e controllo e delle

normative nazionali e sulla base della propria esperienza, è in grado

di portare a termine il lavoro e riconoscere autonomamente potenziali

pericoli.

Legenda dei simboli

3. Speciche tecniche

essere eettuate solo da personale in possesso delle

qualiche riportate di seguito.

CE, Communauté Européenne

Gli strumenti riportanti questo marchio sono in accordo con

le relative Direttive Europee.

Attacco al processo

Attacchi per tubi (plastica ABS), per tubi con Ø interno da 4 o 6 mm

Elemento di misura

Sensore piezoresistivo

Cassa

Plastica (ABS)

46

WIKA manuale d‘uso air2guide, modello A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 47

3. Speciche tecniche

Connessione elettrica

Pressacavo M16, morsetti a vite max. 1,5 mm

2

Segnale di uscita

4 ... 20 mA o 0 … 10 V, 3 li

Tensione di alimentazione

AC 24 V o DC 24 V ±10 %

Potenza < 1 W (1,5 W con 20 mA) modelli a 3 li

Stabilità a lungo termine

0 ... 2.500 Pa ±8 Pa per anno

0 ... 7.000 Pa ±24 Pa per anno

-250 ... +250 Pa ±3 Pa per anno

±1 Pa regolazione automatica dello zero (opzione)

Dimensioni in mm

I

Peso

150 g

Grado di protezione

IP 54 conforme a EN 60529 / lEC 529

Per ulteriori informazioni tecniche, fare riferimento alla Scheda tecnica

WIKA SP 69.03 ed ai documenti d'ordine.

40202780.02 05/2012 GB/D/F/E/I

WIKA manuale d‘uso air2guide, modello A2G-50

47

Page 48

4. Esecuzione e funzioni

4. Esecuzione e funzioni

4.1 Descrizione

Esecuzione

Conformità CE:

2004/108/CE compatibilità elettromagnetica (EMC)

2002/95/CE RoHS (restrizioni sull'uso di determinate sostanze pericolose

nella costruzione di vari tipi di apparecchiature elettriche ed elettroniche)

Precisione

±1,5 %

(con campo di misura -250 ... +250 Pa: ±3 %)

I

Campi di misura

■

Variante 1: 0 ... 2.500 Pa standard

(-100 ... +100/0 ... 100/250/500/1.000/1.500/2.000 Pa regolabile

tramite jumper)

■

Variante 2: 0 ... 7.000 Pa standard

(0 ... 1.000/1.500/2.000/2.500/3.000/4.000/5.000 Pa regolabile

tramite jumper)

■

Variante 3: -250 ... +250 Pa (-25 ... +25/-50 ... +50/

-100... +100/0 ... 25/50/100/250 Pa regolabile tramite jumper)

Pressione di lavoro

Massima pressione: 25 kPa

Pressione di scoppio: 50 kPa

Temperature consentite

Ambiente: -20 … +70 °C

Funzionamento: -5 … +50 °C

Umidità ambiente consentita

0 ... 95 % rH, non condensante

4.2 Scopo di fornitura

Controllare lo scopo della fornitura con il documento di consegna /

trasporto.

48

WIKA manuale d‘uso air2guide, modello A2G-50

40202780.02 05/2012 GB/D/F/E/I

Page 49

5. Trasporto, imballaggio ... / 6. Messa in servizio ...

5. Trasporto, imballaggio e stoccaggio

5.1 Trasporto

Controllare che il trasmettitore di pressione dierenziale non sia

stato danneggiato durante il trasporto. Danni evidenti devono essere

segnalati tempestivamente.

5.2 Imballaggio

Rimuovere l‘imballo solo appena prima dell‘installazione.

Conservare l‘imballo per proteggere lo strumento in caso di successivi

trasporti (es. variazione del sito di installazione, invio in riparazione).

5.3 Stoccaggio

Condizioni consentite per lo stoccaggio

Temperatura di stoccaggio: -20 ... +70 °C

Proteggere gli strumenti dall’umidità e dalla polvere.

6. Messa in servizio, funzionamento

Installazione e attacco meccanico

■

Proteggere gli strumenti di misura da contaminazioni, forti escursioni

termiche e vibrazioni.

■

Al ne di evitare ogni riscaldamento aggiuntivo, gli strumenti non

devono essere esposti alla radiazione diretta del sole durante il

funzionamento.

I

■

Il trasmettitore di pressione dierenziale deve essere installato su

una idonea supercie verticale. Lo strumento deve essere montato

orizzontalmente usando le viti di montaggio in dotazione.

40202780.02 05/2012 GB/D/F/E/I

WIKA manuale d‘uso air2guide, modello A2G-50

49

Page 50

6. Messa in servizio, funzionamento

Connessione elettrica

Gli strumenti sono progettati per funzionare con bassissima tensione

di sicurezza (SELV - Safety Extra Low Voltage). Per il collegamento

elettrico si devono osservare le speciche tecniche di questi strumenti.

Di regola, il trasmettitore dovrebbe essere usato al centro del campo

di misura perché ai limiti del campo si possono vericare degli errori.

La temperatura ambiente all'elettronica del trasmettitore deve essere

costante.

Il trasmettitore di pressione dierenziale deve essere utilizzato con una

tensione operativa costante (±0,2 V). Il cliente è tenuto a evitare che si

verichino picchi di corrente/tensione risultanti dall'accensione/dallo

I

spegnimento.

Schema di collegamento

Azzeramento: Premere il tasto

Selezione unità

50

WIKA manuale d‘uso air2guide, modello A2G-50

LED: si ACCENDE

Azzeramento

Impostazione del tempo di risposta

Nota: L’unità di misura

può essere cambiata

premendo il tasto ZERO

dopo aver posizionato il

ponticello 5.

Non in uso

Rimuovere il ponticello

dopo l’impostazione

40202780.02 05/2012 GB/D/F/E/I

Page 51

6. Messa in servizio ... / 7. Regolazione dello zero

Schema di collegamento

Segnale di uscita 0 ... 10 V

Segnale di uscita 4 ... 20 mA

Tensione di alimentazione

AC 24 V / DC 24 V

Messa in funzione

Un prerequisito per la messa in funzione dello strumento è che tutte

le linee di alimentazione, di controllo e di misura e la connessione al

processo siano realizzate correttamente. Prima della messa in funzione,

è necessario controllare la tenuta della connessione al processo.

7. Regolazione dello zero

7.1 Standard

■

Attenzione! L'alimentazione elettrica deve essere collegata un ora

prima di calibrare il punto zero. Scollegare entrambi i tubi dalle

connessioni al processo ⊕ e ⊖.

■

Premere il pulsante punto zero no a quando il LED rosso non si

illumina.

■

Attendere che si spenga il LED e ricollegare i tubi alle connessioni al

processo.

■

Nel funzionamento normale raccomandiamo di calibrare il punto zero

ogni 12 mesi.

I

7.2 Regolazione automatica dello zero (opzione)

Lo strumento non necessita manutenzione grazie alla regolazione

automatica dello zero. Lo strumento eettua frequentemente la

regolazione di zero e previene quindi la deriva di zero del sensore

piezoresistivo.

Durante la regolazione dello zero, i valori di indicazione ed uscita si

fermano all' ultimo valore misurato. La regolazione automatica dello

zero dura 4 secondi e si ripete ogni 10 minuti.

40202780.02 05/2012 GB/D/F/E/I

WIKA manuale d‘uso air2guide, modello A2G-50

51

Page 52

8. Opzioni e accessori ... 10. Smaltimento

8. Opzioni e accessori

Accessori standard

■

2 viti di ssaggio

Opzioni

■

Display LCD per l'indicazione del valore misurato

■

Regolazione automatica dello zero

■

2 adattatori per condotti

■

Tubo essibile in PVC da 2 m con diametro interno 4 mm

9. Manutenzione e pulizia

Il trasmettitore di pressione dierenziale non richiede manutenzione e si

I

distingue per la sua lunga durata se viene utilizzato in modo corretto.

Pulire gli apparecchi con un panno umido (con acqua e sapone).

Le riparazioni devono essere eettuate solo dal costruttore o da

personale adeguatamente qualicato.

10. Smaltimento

Lo smaltimento inappropriato può provocare rischi per l‘ambiente.

Lo smaltimento dei componenti dello strumento e dei materiali di

imballaggio deve essere eettuato in modo compatibile ed in accordo

alle normative nazionali.

WIKA subsidiaries worldwide can be found online at www.wika.com.

WIKA-Niederlassungen weltweit nden Sie online unter www.wika.de.

La liste des liales WIKA dans le monde se trouve sur www.wika.fr.

Sucursales WIKA en todo el mundo puede encontrar en www.wika.es.

Per liali WIKA nel mondo, visitate il nostro sito www.wika.it.

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel (+49) 93 72/132-0

Fax (+49) 93 72/132-406

E-Mail info@wika.de

www.wika.de

52

WIKA manuale d‘uso air2guide, modello A2G-50

40202780.02 05/2012 GB/D/F/E/I

Loading...

Loading...