Page 1

Pressure transmitter

For general industrial applications

Model A-10

for further approvals

see page 9

Applications

■

Machine building

■

Shipbuilding

■

Measurement and control technology

■

Hydraulics and pneumatics

■

Pumps and compressors

Electronic

pressure measurement

WIKA data sheet PE 81.60

Special features

■

Measuring ranges from 0 ... 20in WC to 0 ... 15,000 psi

(0 ... 0.05 to 0 ... 1,000 bar)

■

Non-linearity 0.25 % or 0.5 %

■

Output 4 ... 20 mA, DC 0 ... 10 V, DC 0 ... 5 V and others

■

Electrical connection: Angular connector form A and C,

circular connector M12 x 1, cable outlet 6 ft

■

Process connection G ¼ A DIN 3852-E, ¼ NPT

and others

Description

The model A-10 pressure transmitter for general industrial

applications is not only notable for its compact design, but it

also oers excellent quality at an extremely competitive price.

The user can choose between a non-linearity of 0.25 %

and 0.5 %. A free test protocol provides information on the

measuring points recorded during manufacture.

Pressure transmitter, model A-10

The model A-10 is set up for worldwide use through the

international cULus and EAC certication. The various

pressure units and process connections required for

particular operating conditions are available at short notice.

WIKA data sheet PE 81.60

Data sheets showing similar products:

High-quality pressure transmitter for general industrial applications; model S-20; see data sheet PE 81.61

∙ 10/2017

Page 1 of 12

Page 2

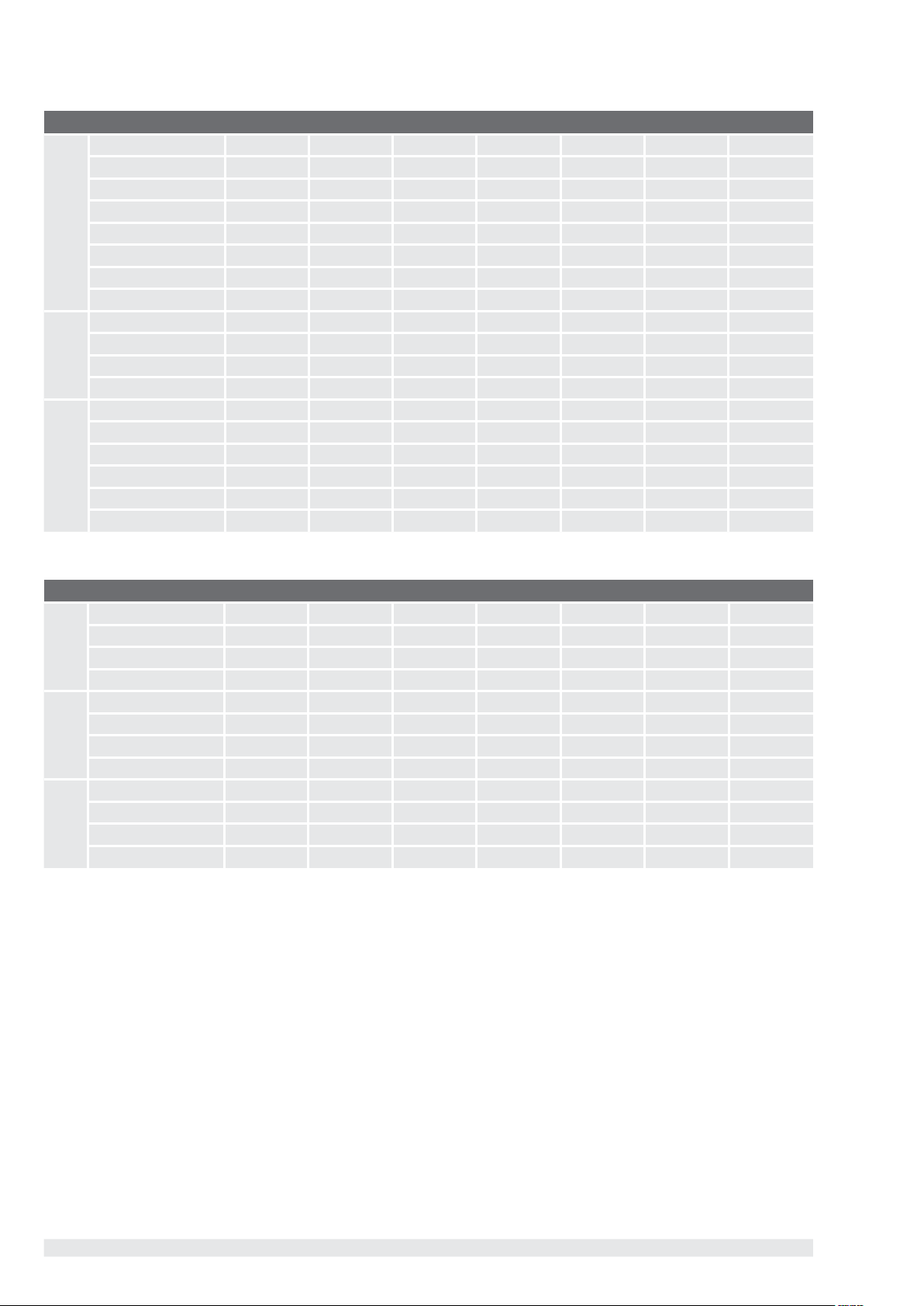

Measuring ranges

Gauge pressure

bar Measuring range 0 ... 0.05 0 ... 0.1 0 ... 0.16 0 ... 0.25 0 ... 0.4 0 ... 0.6 0 ... 1

Overload safety 0.2 0.2 1 1 1 3 3

Measuring range 0 ... 1.6 0 ... 2.5 0 ... 4 0 ... 6 0 ... 10

1)

Overload safety 3.2 5 8 12 20 32 50

Measuring range 0 ... 40 0 ... 60 0 ... 100 0 ... 160 0 ... 250 0 ... 400 0 ... 600

Overload safety 80 120 200 320 500 800 1,200

Measuring range 0 ... 1,000

Overload safety 1,500

inWC Measuring range 0 ... 20 0 ... 40 0 ... 60 0 ... 80 0 ... 100 0 ... 120 0 ... 150

Overload safety 84 84 400 400 400 400 400

Measuring range 0 ... 200 0 ... 250 0 ... 400

Overload safety 400 1,200 1,200

psi Measuring range 0 ... 1 0 ... 5 0 ... 15 0 ... 25 0 ... 30 0 ... 50 0 ... 100

Overload safety 3 14.5 45 60 60 100 200

Measuring range 0 ... 160

1)

0 ... 200

1)

0 ... 300

1)

0 ... 500 0 ... 1,000 0 ... 1,500 0 ... 2,000

Overload safety 290 400 600 1,000 1,740 2,900 4,000

Measuring range 0 ... 3,000 0 ... 5,000 0 ... 15,000

Overload safety 6,000 10,000 21,756

1 ) If the medium water is measured, a higher overload safety is recommended.

0 ... 16

1)

0 ... 25

1)

Absolute pressure

bar Measuring range 0 ... 0.1 0 ... 0.16 0 ... 0.25 0 ... 0.4 0 ... 0.6 0 ... 1 0 ... 1.6

Overload safety 1 1 1 1 3 3 3.2

Measuring range 0 ... 2.5 0 ... 4 0 ... 6 0 ... 10 0 ... 16 0 ... 25

Overload safety 5 8 12 20 32 50

inWC Measuring range 0 ... 40 0 ... 60 0 ... 80 0 ... 100 0 ... 120 0 ... 150 0 ... 200

Overload safety 400 400 400 400 400 400 400

Measuring range 0 ... 250 0 ... 400

Overload safety 1,200 1,200

psi Measuring range 0 ... 5 0 ... 15 0 ... 25 0 ... 30 0 ... 50 0 ... 100 0 ... 150

Overload safety 14.5 45 60 60 100 200 290

Measuring range 0 ... 200 0 ... 300

Overload safety 400 600

Page 2 of 12 WIKA data sheet PE 81.60 ∙ 10/2017

Page 3

Vacuum and +/- measuring range

bar Measuring range -0.025 ... +0.025 -0.05 ... 0 -0.05 ... +0.05 -0.05 ... +0.15 -0.05 ... +0.2

Overload safety ±0.2 ±0.2 ±0.2 1 1

Measuring range -0.05 ... +0.25 -0.1 ... 0 -0.1 ... +0.1 -0.15 ... +0.15 -0.16 ... 0

Overload safety 1 ±0.2 1 1 1

Measuring range -0.2 ... +0.2 -0.25 ... 0 -0.25 ... +0.25 -0.3 ... +0.3 -0.4 ... 0

Overload safety 1 1 1 3 1

Measuring range -0.5 ... +0.5 -0.6 ... 0 -1 ... 0 -1 ... +0.6 -1 ... +1.5

Overload safety 3 3 3 3.2 5

Measuring range -1 ... +3 -1 ... +5 -1 ... +9

1)

-1 ... +15

Overload safety 8 12 20 32 50

inWC Measuring range -10 ... +10 -20 ... 0 -20 ... +20 -40 ... 0 -40 ... +40

Overload safety ±80 ±80 ±80 ±80 ±80

Measuring range -50 ... +50 -60 ... 0 -75 ... +75 -80 ... 0 -100 ... 0

Overload safety 400 400 400 400 400

Measuring range -100 ... +100 -120 ... 0 -125 ... +125 -150 ... 0 -200 ... +200

Overload safety 400 400 1,200 400 1,200

Measuring range -250 ... 0

Overload safety 1,200

psi Measuring range -1 ... 0 -30 inHg ... 0 -30 inHg ... +15 -30 inHg ... +30 -30 inHg ... +60

Overload safety ±3 45 60 60 150

Measuring range -30 inHg ... +100

-30 inHg ... +160 1)-30

inHg

... +200 1)-30

Overload safety 250 350 450 600

inHg

1)

... +300

1)

-1 ... +24

1)

1 ) If the medium water is measured, a higher overload safety is recommended.

The given measuring ranges are also available in mbar, kg/cm2, MPa and kPa.

Other measuring ranges available on request.

3-fold overload safety available on request.

Vacuum tightness

Yes (for restrictions see overload safety)

WIKA data sheet PE 81.60 ∙ 10/2017 Page 3 of 12

Page 4

Output signals

Output signals

Current (2-wire) 4 ... 20 mA

Voltage (3-wire) DC 0 ... 10 V

DC 0 ... 5 V

DC 1 ... 5 V

DC 0.5 ... 4.5 V

Ratiometric (3-wire) DC 0.5 ... 4.5 V

Other output signals on request

Load in Ω

Current (2-wire): ≤ (power supply - 8 V) / 0.02 A

Voltage (3-wire): > maximum output signal / 1 mA

Ratiometric (3-wire): > 10k

Voltage supply

Output signal Power supply

Standard Option

4 ... 20 mA DC 8 ... 30 V DC 8 ... 35 V

DC 0 ... 10 V DC 14 ... 30 V DC 14 ... 35 V

DC 0 ... 5 V

DC 1 ... 5 V DC 8 ... 30 V DC 8 ... 35 V

DC 0.5 ... 4.5 V DC 8 ... 30 V DC 8 ... 35 V

DC 0.5 ... 4.5 V ratiometric DC 5 V ± 10 % -

3)

DC 8 ... 30 V DC 8 ... 35 V

1) 2)

1) Not possible with non-linearity 0.25 % BFSL

2) Only possible for temperatures up to 80 °C (176 °F)

3) Not possible with measuring ranges ≤ 0.1 bar (or equivalent)

The power supply for the pressure transmitter must be made via an energy-limited electrical circuit in accordance with section

9.3 of UL/EN/IEC 61010-1, or an LPS per UL/EN/IEC 60950-1, or class 2 in accordance with UL1310/UL1585 (NEC or CEC).

The power supply must be suitable for operation above 2,000 m should the pressure transmitter be used at this altitude.

Total current consumption

Current (2-wire): Signal current, max. 25 mA

Voltage (3-wire): 8 mA

Ratiometric (3-wire): 8 mA

Page 4 of 12 WIKA data sheet PE 81.60 ∙ 10/2017

Page 5

Accuracy specications

Optionally the model A-10 is available with an improved non-linearity. Depending on the selected non-linearity the following

values result:

Standard Option

Non-linearity per BFSL (IEC 61298-2)

■

Measuring range ≤ 0.1 bar ≤ ±0.5 % of span -

■

Measuring range > 0.1 bar ≤ ±0.5 % of span ≤ ±0.25 % of span

Measuring deviation of the zero signal

■

4 ... 20 mA ≤ ±0.3 % of span ≤ ±0.2 % of span

■

DC 0 ... 10 V ≤ ±0.5 % of span ≤ ±0.4 % of span

■

DC 0 ... 5 V

■

DC 1 ... 5 V ≤ ±0.3 % of span ≤ ±0.2 % of span

■

DC 0.5 ... 4.5 V ≤ ±0.3 % of span ≤ ±0.2 % of span

■

DC 0.5 ... 4.5 V ratiometric ≤ ±0.3 % of span ≤ ±0.2 % of span

4)

Accuracy at room temperature

■

Measuring range ≥ 0.6 bar ≤ ±1 % of span ≤ ±0.5 % of span

■

Measuring range ≥ 0.4 bar ≤ ±1.2 % of span ≤ ±0.7 % of span

■

Measuring range ≥ 0.25 bar ≤ ±1.3 % of span ≤ ±0.8 % of span

■

Measuring range ≥ 0.16 bar ≤ ±1.5 % of span ≤ ±1 % of span

■

Measuring range ≥ 0.1 bar ≤ ±1.8 % of span -

■

Measuring range ≥ 0.05 bar ≤ ±2.4 % of span -

In case of occasional faults due to electrostatic discharges, a temporary measuring error of up to ±2.5 % can occur.

1) Not possible with output signal DC 0 ... 5 V

2) Measuring ranges ≤ 0.1 bar (or equivalent) only possible with ≤ ±0.5 % of span.

3) Outside reference conditions the temperature hysteresis has to be added for measuring ranges < 0.6 bar.

4) Not possible with measuring range ≤ 0.1 bar (or equivalent)

5) Including non-linearity, hysteresis, zero oset and end value deviation (corresponds to measured error per IEC 61298-2), calibrated in vertical mounting position with process connection

facing downwards

2) 3)

≤ ±0.6 % of span -

5)

1)

Non-repeatability (per IEC 61298-2)

Measuring range ≤ 0.1 bar: ≤ 0.2 % of span

Measuring range > 0.1 bar: ≤ 0.1 % of span

Signal noise

≤ ±0.3 % of span

(≤ ±0.2 % of span on request)

Temperature error at 0 ... 80 °C (32 ... 176 °F)

Typical: ≤ ±1 % of span

Maximum: ≤ ±2.5 % of span

Maximum ≤ ±1.5 % of span on request

Long-term drift (per IEC 61298-2)

Measuring ranges ≤ 0.1 bar: ≤ ±0.5 % of span

1)

Measuring ranges ≤ 0.4 bar: ≤ ±0.2 % of span

Measuring ranges > 0.4 bar: ≤ ±0.1 % of span

1) Outside reference conditions the temperature hysteresis has to be added for measuring ranges ≤ 0.1 bar.

Temperature hysteresis -30 ... +100°C (-22 ... +212 °F) for measuring ranges < 0.6 bar

Measuring range Gauge pressure Absolute pressure

≥ 0.40 bar ≤ ±0.2 % of span ≤ ±0.2 % of span

≥ 0.25 bar ≤ ±0.3 % of span ≤ ±0.3 % of span

≥ 0.16 bar ≤ ±0.5 % of span ≤ ±0.5 % of span

≥ 0.10 bar ≤ ±0.7 % of span ≤ ±0.8 % of span

≥ 0.05 bar ≤ ±1.4 % of span -

WIKA data sheet PE 81.60 ∙ 10/2017 Page 5 of 12

Page 6

Time response

Reference conditions (per IEC 61298-1)

Measuring

Settling time Switch-on time

range

≥ 0.4 bar < 4 ms

≥ 0.05 bar < 1 min < 1 min

1) 1 ms on request

1)

< 15 ms

Operating conditions

Ingress protection (per IEC 60529)

see table “Specications”

Vibration resistance

10 g (IEC 60068-2-6, under resonance)

20 g available on request

1) With GL approval and measuring range 0 ... 0.6 bar only feasible with an accuracy of 1 %

2) With GL approval only feasible for measuring range > 0 ... 1 bar

3) From -30 °C (-22 °F)

2) 3)

Shock resistance

500 g (IEC 60068-2-27, mechanical)

100 g at -40 °C (-40 °F)

Service life

Measuring range > 0.1 bar: 100 million load cycles

Measuring range ≤ 0.1 bar: 10 million load cycles

1)

Temperature

15 ... 25 °C (59 ... 77 °F)

Atmospheric pressure

860 ... 1,060 mbar (12.5 ... 15.4 psi)

Humidity

45 ... 75 % relative

Power supply

DC 24 V

Mounting position

as required

Permissible temperature ranges

Standard Option

Voltage

signal

Ambient 0 ... +80 °C

(32 ... 176 °F)

Medium 0 ... +80 °C

(32 ... 176 °F)

Storage -40 ... +70 °C

Restrictions and derating of the ambient temperature depend on the medium temperature.

Depending on the choice of sealing on the process connection, there may be limitations in

the permissible temperature range (for limitations see “Process connections, sealings”).

1) With cULus approval the minimum ambient and medium temperature is -30 °C (-22 °F)

2) Only with power supply DC 8 ... 30 V

3) Only with housed installation site that is protected from condensation

(-40 ... +158 °F)

-30 ... +100 °C

(-22 ... +212 °F)

-30 ... +100 °C

(-22 ... +212 °F)

-40 ... +70 °C

(-40 ... +158 °F)

Current

1) 2)

signal

-40 ... +100 °C

(-40 ... +212 °F)

-40 ... +100 °C

(-40 ... +212 °F)

-40 ... +70 °C

(-40 ... +158 °F)

3)

3)

Page 6 of 12 WIKA data sheet PE 81.60 ∙ 10/2017

Page 7

Process connections

Standard Thread size

EN 837 G ⅛ B

DIN 3852-E

3) 4)

ANSI/ASME B1.20.1 ⅛ NPT

DIN 16288 M20 x 1.5

ISO 7 R ¼

KS PT ¼

SAE J514 E

3) 4)

1)

G ¼ B

G ¼ female

G ¼ female, with ange connection

G ⅜ B

G ½ B

G ¼ A

G ½ A

M14 x 1.5

1)

¼ NPT

¼ NPT female

½ NPT

R ⅜

R ½

PT ½

PT ⅜

7/16-20 UNF O-ring BOSS

Sealings

For the process connections of the following standards the

listed sealing materials are available.

Standard Standard Option

EN 837 Copper Stainless steel

DIN 3852-E NBR FKM

2)

DIN 16288 Copper Stainless steel

SAE J514 E NBR FKM

The sealings listed under “Standard” are included in the

delivery.

1) Maximum measuring range 400 bar

2) Maximum measuring range 100 bar

3) Maximum overload safety 600 bar

4) Maximum permissible temperature -20 ... +100 °C (-4 ... +212 °F)

Pressure port

Pressure port Possible process

connections

Standard 3.5 mm All

Option 1 0.6 mm All male threads

Option 2 0.3 mm All male threads

Option 3 6.0 mm G ¼ A and ¼ NPT

Optionally a T-restrictor is possible for the following process

connections:

■

G ¼ B

■

G ⅜ B

■

G ½ B

■

M20 x 1.5

WIKA data sheet PE 81.60 ∙ 10/2017 Page 7 of 12

Page 8

Electrical connections

Designation Ingress

protection

3)

Wire crosssection

Cable diameter Cable material

Angular connector DIN 175301-803 A

■

with mating connector IP65 up to a max. 1.5 mm² 6 ... 8 mm -

■

with moulded cable IP65 3 x 0.75 mm² 6 mm PUR

Angular connector DIN 175301-803 C

■

with mating connector IP65 up to a max. 0.75 mm² 4.5 ... 6 mm -

■

with moulded cable IP65 4 x 0.5 mm² 6.2 mm PUR

Circular connector M12 x 1 (4-pin)

■

without mating connector IP67 - - -

■

straight with moulded cable IP67 3 x 0.34 mm² 4.3 mm PUR

■

angled with moulded cable IP67 3 x 0.34 mm² 4.3 mm PUR

Cable outlet

■

unshielded

■

OEM version, unshielded

1) Not feasible with GL approval

2) up to a max. 90 °C (194 °F)

3) The stated ingress protection (per IEC 60529) only applies when plugged in using mating connectors that have the appropriate ingress protection.

1)

2)

IP67 3 x 0.34 mm² 4 mm PUR

IP67 3 x 0.14 mm² 2.85 mm TPU

Mating connectors (with and without cable) are also separately available as accessories.

Cable lengths of 6 ft or 15 ft (2 m or 5 m) are available.

Short-circuit resistance

S+ vs. 0V

Reverse polarity protection

U

vs. 0V

B

no reverse polarity protection with ratiometric output signal

Insulation voltage

DC 500 V

Connection diagrams

All connectors with moulded cable have the same colour assignment as the unshielded cable outlet.

Angular connector DIN 175301-803 A

2-wire 3-wire

U

1 1

B

0V 2 2

S+ - 3

Angular connector DIN 175301-803 C

2-wire 3-wire

U

1 1

B

0V 2 2

S+ - 3

Cable outlet, unshielded

2-wire 3-wire

U

brown brown

B

0V blue blue

S+ - black

Cable outlet, OEM version, unshielded

2-wire 3-wire

U

brown brown

B

0V blue blue

S+ - black

Circular connector M12 x 1 (4-pin)

2-wire 3-wire

U

1 1

B

Legend

U

Positive power supply terminal

B

0V Negative power supply terminal

S

Analogue output

+

0V 3 3

S+ - 4

Page 8 of 12 WIKA data sheet PE 81.60 ∙ 10/2017

Page 9

Materials

Wetted parts

< 10 bar (150 psi): Stainless steel 316L

≥ 10 bar (150 psi): Stainless steel 316L and PH steel

≤ 0 ... 25 bar abs. (400 psia): Stainless steel 316L

Non-wetted parts

■

Stainless steel 316L

■

HNBR

■

PA

For sealing materials see “Process connections”

For cable materials see “Electrical connections”

Pressure transmission medium

< 0 ... 10 bar (150 psi): Synthetic oil

≤ 0 ... 25 bar abs. (400 psia): Synthetic oil

≥ 0 ... 10 bar (150 psi): Dry measuring cell

Approvals

Logo Description Country

EU declaration of conformity

■

EMC directive

■

Pressure equipment directive

■

RoHS directive

1)

UL

Safety (e.g. electr. safety, overpressure, ...)

EAC

■

Electromagnetic compatibility

GOST

Metrology, measurement technology

KazInMetr

Metrology, measurement technology

MTSCHS

Permission for commissioning

BelGIM

Metrology, measurement technology

UkrSEPRO

Metrology, measurement technology

Uzstandard

Metrology, measurement technology

DNV GL

Ships, shipbuilding (e.g. oshore)

CRN

Safety (e.g. electr. safety, overpressure, ...)

1) not for measuring ranges < 0.6 bar and not for medium temperature -40 ...+100 °C (-40 ... +212 °F)

1)

European Community

USA and Canada

Eurasian Economic Community

Russia

Kazakhstan

Kazakhstan

Belarus

Ukraine

Uzbekistan

Germany

Canada

Manufacturer‘s information and certications

Logo Description

- MTTF: > 100 years

- China RoHS conformity

Approvals and certicates, see website

WIKA data sheet PE 81.60 ∙ 10/2017 Page 9 of 12

Page 10

Dimensions in mm

Pressure transmitter

with angular connector form A with angular connector form C

with angular connector form A and

ange connection

Weight: approx. 80 g Weight: approx. 80 g

Weight: approx. 350 g

with M12 x 1 circular connector with standard cable outlet, unshielded with cable outlet OEM version,

unshielded

Weight: approx. 80 g Weight: approx. 80 g Weight: approx. 80 g

Page 10 of 12 WIKA data sheet PE 81.60 ∙ 10/2017

Page 11

Process connections

G L1

G ¼ A DIN 3852-E 14

G ½ A DIN 3852-E 17

M14 x 1.5 14

Female thread Female thread

G L1 L2 L3 D1

G ¼ EN 837

20 13 10 Ø 25

G L1

G ¼ B EN 837 13

G ⅜ B EN 837 16

G ½ B EN 837 20

M20 x 1.5 20

G L1 L2 D1

¼ NPT 20 14 Ø 25

G L1

7/16-20 UNF BOSS 12.85

G L1

G ⅛ B EN 837 10

G L1

⅛ NPT 10

¼ NPT 13

½ NPT 19

R ¼ 13

R ⅜ 15

R ½ 19

PT ¼ 13

PT ⅜ 15

PT ½ 19

G ¼ female, with ange connection

For dimensions see drawing

For information on tapped holes and welding sockets, see Technical information IN 00.14 at www.wika.com

WIKA data sheet PE 81.60 ∙ 10/2017 Page 11 of 12

Page 12

Accessories and spare parts

Mating connector

Sealing for mating

connector

Sealing for process connection

Mating connector

Designation Order number

without cable with 2 m cable with 5 m cable

Angular connector DIN 175301-803 C 1439081

Angular connector DIN 175301-803 A

■

with cable gland, metric 11427567 11225793 11250186

■

with cable gland, conduit 11022485 - -

Circular connector M12 x 1, 4-pin

■

straight 2421262 11250780 11250259

■

angled 2421270 11250798 11250232

1) Connector not permissible for A-10 with GL approval

1)

11225823 11250194

Sealings for mating connectors

Designation Order number

Blue (WIKA) Brown (neutral)

Angular connector DIN 175301-803 A 1576240 11437902

Angular connector DIN 175301-803 C 11169479 11437881

Sealings for process connection

Designation Order number

Cu Stainless steel NBR FKM

G ¼ EN 837 11250810 11250844 - -

M14 x 1.5 - - 1537857 1576534

G ½ EN 837 11250861 11251042 - -

M20 x 1.5 11250861 11251042 - -

G ⅛ EN 837 11251051 - - -

G ¼ DIN 3852-E - - 1537857 1576534

G ½ DIN 3852-E - - 1039067 1039075

Only use the accessories and spare parts listed, otherwise it could lead to the loss of the approval.

Ordering information

Model / Measuring range / Output signal / Power supply / Non-linearity / Temperature range / Process connection / Sealing /

Electrical connection

© 2011 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modications to the specications and materials.

Page 12 of 12 WIKA data sheet PE 81.60 ∙ 10/2017

WIKA Instrument Corporation

1000 Wiegand Boulevard

Lawrenceville, GA 30043

1-888-WIKA-USA /770-513-8200 (in GA)

Fax 770-338-5118

info@wika.com www.wika.com

10/2017 EN

Loading...

Loading...