Page 1

Operating Instructions

Betriebsanleitung

Mode d’emploi

Instrucciones de servicio

Diaphragm Seal Measuring Systems

Druckmittler-Messsysteme

Système de Mesure avec Séparateur

Sistema de Medición con Separador

GB

D

F

E

Examples/Beispiele/Exemples/Ejemplos

Page 2

GB

Operating Instructions for Diaphragm Seals Page 3 - 6

D

Betriebsanleitung für Druckmittler Seite 7 - 10

F

Mode d’emploi pour Séparateurs Page 11 - 14

E

Modo de empleo para Separador Página 15 - 18

9045830 10/2006

Page 3

Diaphragm Seal Measuring Systems

Contents

Contents

1. Safety instructions 4

2. Product description 4

3. General installation instructions 4

4. Commissioning 5

5. Admissible ambient and working temperatures 5

6. Installation instructions for diaphragm seal

measuring systems with capillary extension 5

7. Maintenance instructions 6

GB

Note according to Pressure Equipment Directive 97/23/EC

Please find Declarations of Conformity and Declarations by the

Manufacturer for download on our website www.wika.de under

Service / PED Documents

9045830 10/2006

WIKA Operating Instructions Diaphragm Seals

3

Page 4

Diaphragm Seal Measuring Systems

GB

!

(corrosion) for the specific measuring conditions of the respective application is selected.

In order to guarantee the accuracy and long-term stability specified, the corresponding load

limits are to be observed. Specifications: see data sheet under www.wika.de

■ Only qualified persons authorised by the plant manager are permitted to install, maintain

and service the pressure gauges

■ Dangerous pressure media such as Oxygen, Acetylene, flammable gases or liquids, toxic

gases or liquids as well as for refrigeration plants or compressors requires attention above

the standard regulations. Here the specific safety codes or regulations must be considered

■ Serious injuries and/or damage can occur should the appropriate regulations not

be observed

■ Instruments should be protected against coarse dirt and wide fluctuations in ambient

temperature

■ If the operating instructions are not observed and complied with, approvals (e.g. ATEX)

can become invalid

1. Safety instructions

■ The user must ensure that the appropriate pressure gauge with regard

to scale range and performance and the appropriate wetted material

2. Product description

A diaphragm seal measuring system comprises the following components: Diaphragm seal,

transmission line (i.e. capillary extension) and measuring instrument, all of which must not be

separated. The measuring system uses hydraulics to transmit pressure. Apart from the capillary

extension the diaphragm with a thickness of only approx. 0.1 mm, is the most sensitive

component.

The smallest of leaks in the transmission system will lead to loss of filling liquid and as a result

to inaccurate measurements or failure of the measuring system. To avoid leaks and measuring

errors, please observe the following general instructions for handling, installation and

maintenance as well as the operating manual of the measuring instruments which are

combined with the diaphragm seal.

3. General installation instructions

■ To protect the measuring system from mechanical damage leave it in the factory packing

until installation.

■ When removing the measuring system from the factory packing and during installation treat

the system with particular care to prevent damage and mechanical deformation of the diaphragm

■ Never undo the sealed filling screw on either the diaphragm seal or the measuring istrument

■ Do not damage the diaphragm. Scratches on the diaphragm(caused by sharp objects, for

example) are the main causes of corrosion.

■ For sealing choose appropriate seals.

■ For flange fitting use a seal with adequate large inner diameter and center it. Contact with

the diaphragm leads to deviations in measurement.

■ When using soft or PTFE seals, observe the instructions of the seal manufacturer, especially

with regards to tightening torque and setting cycles.

■ For installation use appropriate fixing position, screws and screw nut according to fitting

and flange standard.

4

WIKA Operating Instructions Diaphragm Seals

9045830 10/2006

Page 5

Diaphragm Seal Measuring Systems

4. Commissioning

In order to avoid pressure peaks, a shut-off valve, if available, is to be opened slowly.

5. Admissible ambient and working temperatures

When installing the pressure gauge it has to be ensured that, taking the influence of convection

and heat radiation into consideration, no upper or lower deviation from the permissible ambient

and medium temperatures can occur. The influence of temperature on the class accuracy is to

be observed. When selecting the diaphragm seals, the pressure and temperature stability of

the fittings and flange components has to be observed by choosing suitable materials and

pressure ratings. The pressure rating marked on the diaphragm seal is valid for ambient

temperatures. For higher temperatures the max. working pressure should be taken from the

industrial standard marked on the diaphragm seal.

Use of diaphragm seals with pressure measuring instruments in hazardous areas:

■ When using diaphragm seals with pressure transmitters in hazardous areas, the permissible

ambient temperature limits for the pressure measuring instrument must not be exceeded.

Hot surfaces at the part cooling element (capillary or cooling tower) might also be a

possible ignition source. Appropriate measures have to be taken.

■ When mounting diaphragm seals with flame proof throttle, the permissible ambient

temperature is determined by the mounted pressure measuring instrument. In an explosive

atmosphere the temperature around the flame proof throttle must not exceed +60 °C.

See also supplement to operating instructions for diaphragm seals with built-in flame proof

throttle.

6. Installation instructions for diaphragm seal measuring systems with

capillary extension

■ Do not carry the measuring system at the capillary

■ To protect the capillary extension from mechanical stress, do not lift or carry the diaphragm

seal measuring system by the capillary extensions

■ Do not kink capillary extensions; this will increase the risk of a leak or the setting time of the

measuring system

■ Make sure that the system is not overstressed because of the risk of kinking and fracture

especially where the capillary extension and diaphragm seal and capillary extension and

measuring instrument ar joined

■ When laying the capillary extensions, do not bend under a radius of 150 mm

■ Fit capillary extension so that it is not subject to vibration

■ Permissible differences in height

When installing the pressure gauge above the measuring point, the maximum difference in

height must not exceed 7 m in the case of diaphragm seal measuring systems with silicon,

-glycerine or paraffine oil filling (measurement H1).

If halocarbon oil is used as filling liquid, the maximum difference in height (H1) is 4 m

(see examples 1 and 2).

If a negative pressure can occur while measuring, the permissible difference in height must be

reduced correspondingly.

9045830 10/2006

GB

5WIKA Operating Instructions Diaphragm Seals

Page 6

Diaphragm Seal Measuring Systems

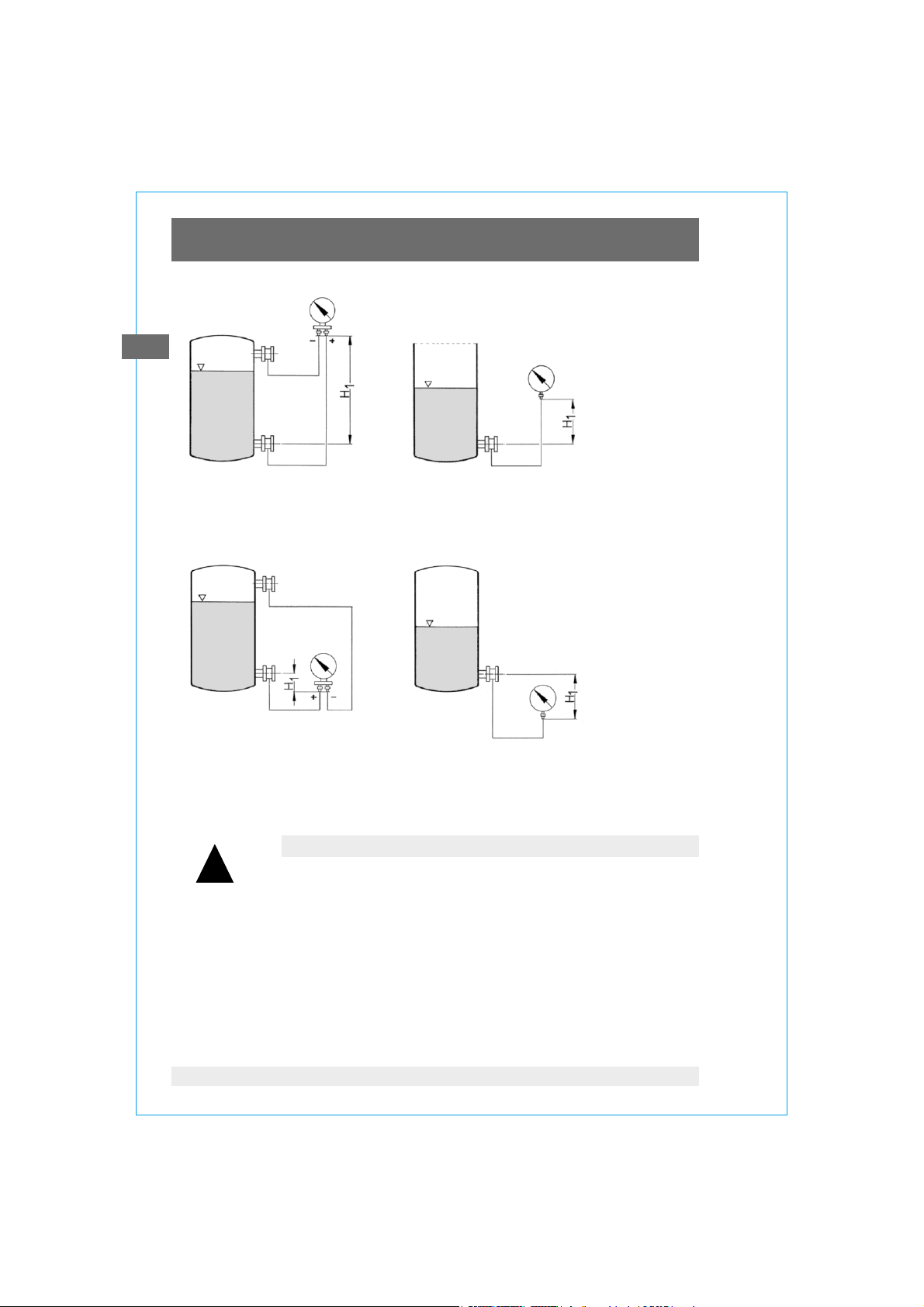

Example 1 Example 2

D

Height (H1) max. 7 m or 4 m, respectively

When doing absolute pressure measurements (vacuum), the measuring instrument has to be

fitted at least on the same level as the diaphragm seal or below (see examples 3 and 4).

Example 3 Example 4

Vacuum

Vacuum:fit the measuring instrument below the

measuring point or on the same level in height (H1).

■ To keep the influence of temperature low in case of diaphragm seal measuring systems with

differential pressure measuring instruments, fit or install plus and minus sides symmetric

with regards to ambient influences and ambient temperatures in particular.

Vacuum

7. Maintenance instructions

!

to guarantee the measuring accuracy of the pressure gauge. The tests or recalibrations have to

be carried out by qualified persons with the appropriate equipment.

For dismounting the measuring system must be in an unpressurised condition. Remainder of

the pressure medium contained in the pressure element may be hazardous or toxic. This

should be considered when handling and storing the removed pressure gauge.

In case of polluted, viscous or crystallizing pressure media, it may be necessary to clean the

diaphragm from time to time. Only remove deposits from the diaphragm with a soft brush and a

suitable solvent. Do not use aggressive cleaning agents.

Caution: do not damage the diaphragm with sharp edged tools.

Under normal circumstances the diaphragm seal measuring system

requires no maintenance. Tests should be carried out on a regular basis

6

WIKA Operating Instructions Diaphragm Seals

9045830 10/2006

Page 7

Druckmittler-Messsysteme

Inhalt

Inhalt

1. Sicherheitshinweise 8

2. Produktbeschreibung 8

3. Allgemeine Montagehinweise 8

4. Inbetriebnahme 9

5. Zulässige Umgebungs- und Betriebstemperaturen 9

6. Montagehinweise bei Druckmittler-Messsystemen

mit Kapillarleitung 9

7. Wartungshinweise 10

D

Hinweis gemäß Druckgeräterichtlinie 97/23/EG

Konformitäts- und Herstellererklärungen finden Sie im Internet

unter www.wika.de in der Rubrik Service / DGRL (PED) Dokumente

9045830 10/2006

WIKA Betriebsanleitung Druckmittler

7

Page 8

Druckmittler-Messsysteme

1. Sicherheitshinweise

!

D

aufgrund der spezifischen Messbedingungen der geeignete messstoffberührte Werkstoff (Korrosion) ausgewählt wurde. Die Belastungsgrenzen sind einzuhalten, um die Messgenauigkeit und

die Lebensdauer zu gewährleisten. Technische Daten: siehe Datenblatt unter www.wika.de

■ Druckmessgeräte nur durch ausgebildetes und vom Anlagenbetreiber autorisiertem

Fachpersonal montieren und warten lassen.

■ Bei gefährlichen Messstoffen wie z.B. Sauerstoff, Acetylen, brennbaren oder giftigen

Stoffen, sowie bei Kälteanlagen, Kompressoren etc. müssen über die gesamten allgemeinen

Regeln hinaus die jeweils bestehenden einschlägigen Vorschriften beachtet werden.

■ Bei Nichtbeachten der entsprechenden Vorschriften können schwere Körperverletzungen

und/oder Sachschäden auftreten.

■ Die Geräte sind vor grober Verschmutzung und starken Schwankungen der Umgebungs-

temperatur zu schützen.

■ Bei Nichtbeachtung und -Einhaltung der Betriebsanleitung können Zulassungen (z.B. ATEX)

ungültig werden.

2. Produktbeschreibung

Ein Druckmittlermesssystem besteht aus den Komponenten Druckmittler, Übertragungsleitung

(z.B. Kapillarleitung) und Messgerät, die auf keinen Fall getrennt werden dürfen. Das Messsystem arbeitet zur Druckübertragung auf hydraulischer Basis. Im Druckmittler-Messsystem ist

neben der Kapillarleitung insbesondere die Druckmittler-Membrane, deren Materialstärke nur

~0,1 mm beträgt, das empfindlichste Bauteil. Geringste Undichtheiten im Übertragungssystem

führen zu Verlust von Übertragungsflüssigkeit und daraus folgend zu Messungenauigkeiten

oder Ausfall des Messsystems. Um Undichtheiten und Messfehler zu vermeiden, beachten Sie

bitte neben den Sicherheitshinweisen die nachfolgenden allgemeinen Behandlungs-, Montageund Wartungshinweise sowie die Betriebsanleitung der mit dem Druckmittler kombinierten

Messgeräte.

3. Allgemeine Montagehinweise

■ Messsystem zum Schutz vor mechanischen Beschädigungen bis zur Montage in der

Werksverpackung lassen

■ Bei der Entnahme aus der Werksverpackung und bei der Montage Beschädigungen und

mechanische Verformungen der Membrane durch besondere Vorsicht verhindern

■ Versiegelte Füllschrauben am Druckmittler bzw. am Messgerät niemals lösen

■ Die Druckmittler-Membrane nicht beschädigen; Kratzer auf der Druckmittler-Membrane

(z.B. von scharfkantigen Gegenständen) sind Hauptangriffstellen für Korrosion

■ Zur Abdichtung sind geeignete Dichtungen auszuwählen

■ Zum Anflanschen Dichtung mit genügend großen Innendurchmesser verwenden und die

Dichtung zentrisch einlegen; Membranberührungen führen zu Messabweichungen

■ Bei Einsatz von Weichstoff- bzw. PTFE-Dichtungen Vorschriften des Dichtungsherstellers

insbesondere hinsichtlich Anzugsmoment und Setzzyklen beachten

■ Zur Montage müssen entsprechend der Fittings- und Flanschnormen geeignete

Befestigungsteile, wie Schrauben und Muttern, verwendet werden

8

■ Beachten Sie unbedingt vor Montage, Inbetriebnahme und Betrieb, dass

das richtige Druckmessgerät hinsichtlich Anzeigebereich, Ausführung und

WIKA Betriebsanleitung Druckmittler

9045830 10/2006

Page 9

Druckmittler-Messsysteme

4. Inbetriebnahme

Zur Vermeidung von Druckstößen ist ein eventuell vorhandenes Absperrventil langsam zu

öffnen.

5. Zulässige Umgebungs- u. Betriebstemperaturen

Die Anbringung des Druckmessgerätes ist so auszuführen, dass die zulässigen Umgebungsund Messstofftemperaturgrenzen, auch unter Berücksichtigung des Einflusses von Konvektion

und Wärmestrahlung, weder unter- noch überschritten werden. Der Temperatureinfluss auf die

Anzeigegenauigkeit ist zu beachten. Bei der Auswahl der Druckmittler muss die Druck-Temperatur-Festigkeit der Fittings- und Flanschbauteile durch die Wahl des Werkstoffes und der

Druckstufe beachtet werden. Die auf dem Druckmittler angegebene Druckstufe gilt für Umgebungstemperaturen. Bei höheren Temperaturen ist der max. zulässige Druck aus der auf dem

Druckmittler angegebenen Norm zu entnehmen.

Einsatz von Druckmittlern mit Druckmessgeräten für explosionsgefährdete Bereiche:

■ Bei Verwendung von Druckmittler mit Druckmessumformern für explosionsgefährdete

Bereiche dürfen die zulässigen Grenzen der Umgebungstemperaturen für den Messumformer nicht überschritten werden. Auch heiße Oberflächen an der Kühlstrecke (Kapillare

oder Kühlelement) können eine mögliche Zündquelle darstellen. Entsprechende Maßnahmen sind zu ergreifen.

■ Bei Anbau von Druckmittlern mit Flammensperre wird die zulässige Umgebungstemperatur

vom angebauten Druckmessgerät bestimmt. Bei anstehender explosionsfähiger Atmosphäre, darf die Temperatur um die Flammensperre +60 °C nicht überschreiten. Siehe hierfür die

ergänzende Betriebsanleitung für Druckmittler mit eingebauter Flammensperre.

D

6. Montagehinweise bei Druckmittler-Messsystemen mit Kapillarleitung

■ Messanordnung nicht an Kapillarleitung tragen

■ Kapillarleitungen nicht knicken; Leckagegefahr bzw. Gefahr der wesentlichen Erhöhung der

Einstellzeit des Messsystems

■ Wegen Knick- bzw. Bruchgefahr insbesondere an den Verbindungsstellen Kapillarleitung-

Druckmittler und Kapillarleitung-Messgerät auf mechanische Überlastung achten

■ Beim Verlegen der Kapillare Radius nicht unter 150 mm biegen

■ Kapillarleitung schwingungsfrei befestigen

■ Zulässige Höhenunterschiede

Bei Montage des Druckmessgerätes oberhalb der Messstelle darf ein maximaler Höhenunterschied bei Druckmittler-Messsystemen mit Silikon-, Glyzerin- oder Paraffinölfüllung

von H1 max. 7 m nicht überschritten werden

Wird Halocarbonöl als Füllflüssigkeit eingesetzt, ist dieser maximale Höhenunterschied nur

H1 max. 4 m (Siehe Beispiel 1 und 2)

Kann bei der Messung negativer Überdruck auftreten, muss der zulässige Höhenunterschied

entsprechend verringert werden.

9045830 10/2006

WIKA Betriebsanleitung Druckmittler

9

Page 10

Druckmittler-Messsysteme

Beispiel 1 Beispiel 2

D

H1 bis max. 7 m bzw. 4 m

Bei Absolutdruckmessungen (Vakuum) ist das Messgerät mindestens auf gleicher Höhe mit

dem Druckmittler oder unterhalb zu montieren (siehe Beispiel 3 und 4).

Beispiel 3 Beispiel 4

Vakuum

Vakuum: Bei H1 unterhalb der Messstelle

oder auf gleicher Höhe montieren

■ Um bei Druckmittler-Messsystemen mit Differenzdruckmessgerät die Temperatureinflüsse

gering zu halten, Aufbau bzw. Montage möglichst so ausführen, dass Plus- und Minusseite

bezüglich der Umgebungseinflüsse, insbesondere der Umgebungstemperaturen, symmetrisch sind.

Vakuum

7. Wartungshinweise

!

gen sichergestellt werden. Die Prüfung oder eine neue Kalibrierung müssen von geschultem

Personal mit geeigneter Ausrüstung vorgenommen werden. Messanordnung nur im drucklosen

Zustand demontieren. Messstoffreste in ausgebauten Druckmessgeräten können zur Gefährdung von Menschen, Umwelt und Einrichtung führen. Ausreichende Vorsichtsmaßnahmen sind

zu ergreifen.

Bei verunreinigten, viskosen oder kristallisierenden Messstoffen kann es notwendig werden, die

Membrane von Zeit zu Zeit zu reinigen. Ablagerungen von der Membrane nur mit weichem Pinsel/Bürste und geeignetem Lösungsmittel entfernen. Keine das Material angreifende Reinigungsmittel verwenden. Vorsicht, nicht mit scharfkantigen Werkzeugen die Membrane beschädigen.

Normalerweise bedarf das Druckmittler-Messsystem keiner Wartung. Die

Messgenauigkeit des Druckmessgerätes sollte durch regelmäßige Prüfun-

10

WIKA Betriebsanleitung Druckmittler

9045830 10/2006

Page 11

Système de Mesure avec Séparateur

Sommaire

Sommaire

1. Conseils de sécurité 12

2. Description du produit 12

3. Recommandations 12

4. Mise en service 13

5. Températures ambiantes et de service autorisées 13

6. Recommandations de montage pour des séparateurs

avec capillaire 13

7. Instructions d’entretien 14

Remarque selon la directive 97/23/EC pour appareils sous

pression

F

Vous trouverez les certificats de conformité et du fabricant

sur notre site internet www.wika.de sous la rubrique Service /

PED Documents

9045830 10/2006

WIKA Mode d'emploi pour Système de Mesure avec Séparateur

11

Page 12

Système de Mesure avec Séparateur

1. Conseils de sécurité

!

mesure adéquat quant à l'étendue de mesure et au modèle. Les limites de surpression

admissible sont à respecter afin d'assurer la précision et la durée de vie.

F

Caractéristiques techniques: voir fiches techniques sous www.wika.fr

■ Seul le personnel habilité et qualifié est autorisé à manipuler les instruments.

■ Pour les fluides dangereux comme par exemple l'oxygène, l'acétylène les matiéres

combustibles ou nocives ainsi que pour les systèmes frigorifiques et les compresseurs il

faut en plus des règles techniques courantes tenir compté des prescriptions spécifiques à

ces applications.

■ Le non-respect des instructions correspondantes est susceptible d'entraîner des risques de

blessures et/ou des dégâts matériels.

■ Les instruments doivent être protégés contre un encrassement important et contre les

fluctuations de la température ambiante.

■ Le non-respect de l'instruction de service peuvent avoir pour conséquence la perte de

l'homologation (par ex. ATEX).

2. Description du produit

Un système de mesure avec séparateur se compose du séparateur, du canal de transmission

(par exemple capillaire) et de l'instrument de mesure, qui ne doivent pas être séparés.

Le principe de transmission de la mesure de pression est hydraulique. A part le capillaire, la

membrane du séparateur est la partie la plus fragile: L’épaisseur de la membrane n’est que de

0,1 mm environ.

La plus petite fuite dans le système de transmission entraîne une perte de liquide ayant pour

conséquence une imprécision de mesure voir une absence de mesure. Pour éviter les fuites et

erreurs de mesure, veuillez respecter les instructions générales suivantes du mode d'emploi

pour le montage el'entretien ainsi que le mode d'emploi des instruments de mesure associés

au séparateur.

3. Recommandations

■ Laisser l’instrument de mesure dans son emballage d’origine jusqu’au montage afin de le

protéger d’éventuelles détériorations.

■ Prendre toutes les précautions lors du déballage et du montage pour éviter la déformation

mécanique de la membrane.

■ Ne jamais enlever les vis de remplissage plombées sur le séparateur ou

l’instrument de mesure.

■ Ne pas détériorer la membrane du séparateur (des rayures éventuelles pouvant être à

l’origine d’une corrosion).

■ Choisir des joints appropriées pour l'étanchéité.

■ Lors d’un montage avec brides, il est nécessaire d’utiliser un joint d’étanchéité parfaitement

centré et de diamètre intérieur suffisamment grand pour éviter tout contact avec la

membrane (à l'origine d'erreurs de mesure).

■ En cas d’utilisation de joint souple telle que PTFE, respecter les recommandations du

fabricant en ce qui concerne le couple de serrage ainsi que le fluage.

■ En rapport avec les normes de raccordement il faut une position de fixation adéquate ainsi

que des vis et des écroux appropriés.

12 WIKA Mode d'emploi pour Système de Mesure avec Séparateur

■ Veuillez absolument prendre en considération avant le montage,

la mise en service et l'utilisation, que vous avez choisi l'instrument de

9045830 10/2006

Page 13

Système de Mesure avec Séparateur

4. Mise en service

S'il y a une vanne, il faut l'ouvrir lentement afin d'éviter les coups de bélier.

5. Températures ambiantes et de service autorisées

Le montage du manomètre est à réaliser de façon que la température de service autorisée

(ambiante et fluide à mesurer), même sous l'influence de la chaleur de convection et de

radiation, ne doit pas être ni dépassée ni rester en dessous. Il faut prendre en considération

l'influence de la température par rapport à la précision de l'affichage. Lors du choix du

séparateur, il faut prendre en considération la résistance mécanique à la pression et à la

température, des raccords et composants de la bride en choisissant la matière et le palier de

pression. La pression nominale (PN) indiquée sur le séparateur est valable pour des

températures ambiantes. Pour des températures plus élevées se reporter au tableau pression

température de la norme mentionnée sur le séparateur.

Utilisation de séparateurs avec manomètres dans des zones sous danger d'explosion:

■ Lors de l'utilisation de séparateurs avec manomètres pour les zones sous danger d'explosion,

les limites autorisées des températures ambiantes ne doivent pas être dépassées. Les

surfaces brûlantes sur la ligne de refroidissement (capillaire ou dissipateur thermique) peuvent

également présenter une source d'explosion. Des mesures adéquates doivent être prises.

■ Lors de l'adjonction de séparateurs avec blocage de retour de flame, les températures

ambiantes autorisées sont déterminées par le manomètre ajouté. Dans une atmosphère

explosive la température autour du anti-retour de flamme ne doit pas dépasser +60 °C.

Pour ceci voir l'instruction de service supplémen taire pour les séparateurs avec anti-retour

de flamme intégré.

F

6. Recommandations de montage pour des séparateurs avec capillaire

■ Ne jamais transporter le système de mesure par le capillaire.

■ Ne pas couder le capillaire, ce qui pourrait entraîner un risque de fuite ou une augmentation

considérable du temps de réponse.

■ Pour éviter les contraintes mécaniques, faire attention aux endroits sensibles tels que les

connections entre le séparateur et le capillaire et entre le capillaire et l'instrument de

mesure. Ne pas plier les capillaires.

■ Lors de la pose ne pas descendre en-dessous d’un rayon de courbure de 150 mm.

■ Fixer le capillaire de façon à ce qu’il ne soit pas sujet à vibrations.

■ Différences de hauteur tolérées:

Pour un montage de l'instrument de mesure en amont du point de mesure, la différence de

hauteur (H1) ne doit pas dépasser 7 m dans le cas d’un séparateur-système de mesure

rempli avec silicone, glycérine ou huile paraffine.

Lors d’un remplissage avec fluide halocarbone, la différence de hauteur maximum (H1) est

seulement de 4 m (voir exemples 1 et 2).

Lors de la mesure, il peut se produire surpression négative; la différence de hauteur admissible

devra être diminuée en conséquence.

9045830 10/2006

13WIKA Mode d'emploi pour Système de Mesure avec Séparateur

Page 14

Système de Mesure avec Séparateur

Exemple 1 Exemple 2

F

H1 =respectivement jusqu'à max. 7 m et 4 m

Lors de mesure en pression absolue (vide), l’appareil de mesure doit être monté au moins à la

même hauteur que le séparateur, ou bien au-dessous. (voir exemples 3 et 4).

Exemple 3 Exemple 4

Vide

Vide: instrument de mesure monté en dessous

du point de mesure ou à la même hauteur (H1).

■ Pour limiter au maximum l'influence de la température avec des ensembles de mesure de

pression différentielle avec séparateur, le montage doit être effectué si possible

symétriquement du coté positif et du coté négatif pour tenir compte des influences de

l'environnement et particulièrement de la température ambiante.

Vide

7. Instructions d’entretien

!

doit être assurée par des contrôles réguliers. Le contrôle ou un ré-étalonnage doivent être

effectués par du personnel qualifié et avec un équipement adéquat. Démonter l'équipement de

mesure uniquement hors pression. Les résidus de fluide se trouvant à l’intérieur des

instruments de mesure démontés peuvent présenter des dangers pour les personnes,

l’environnement et les installations.

Il faut prendre toutes les précautions nécessaires pour en assurerla sécurité lors du démontage

et de la manutention. Lors de la mise en oeuvre de fluides visqueux ou cristallisant, nettoyer la

membrane de temps en temps.

Enlever les dépôts éventuels sur la membrane uniquement avec un pinceau ou brosse doux et

un nettoyant approprié. Attention de ne pas abîmer la membrane avec un outil tranchant.

14 WIKA Mode d'emploi pour Système de Mesure avec Séparateur

Normalement le système de mesure avec séparateur ne nécessite

pas besoin d'entretien. La précision de mesure de l'instrument de mesure

9045830 10/2006

Page 15

Sistema de medición con separador

Contenido

Contenido

1. Instrucciones de seguridad 16

2. Descripción del producto 16

3. Instrucciones generales de instalación 16

4. Puesta en marcha 17

5. Temperaturas de ambiente permisibles 17

6. Recomendaciones para el montaje de

separadores con capilar 17

7. Instrucciones de mantenimiento 18

Indicación según directiva del manómetro 97/23/EG

Declaración de conformidad y del fabricante se encuentra en el

Internet dirección www.wika.de en la rubrica servicio / DGRL (PED)

documentos

E

9045830 10/2006

15WIKA Modo de empleo para separador

Page 16

Sistema de medición con separadores

1. Instrucciones de seguridad

!

contacto con el medio (corrosión) para las condiciones de medida especificas de la aplicación

respectiva. Para garantizar la precisión y la estabilidad a largo plazo, deben ser observados los

límites correspondientes de carga. Datos técnicos: ver hoja técnica vía Internet dirección

www.wika.de

E

■ Sólo a las personas autorizadas por el director de la planta les están permitidas instalar

mantener y prestar servicio a los manómetros.

■ Con medios peligrosos como por ejemplo oxígeno, acetileno, medios inflamables o tóxicos,

así como con instalaciones de refrigeración, compresores etc. se deben observar las reglas

generales así como las correspondientes regulaciones.

■ Pueden producirse daños graves en el cuerpo y/o daños materiales si no se respetan las

normas apropiadas.

■ Se tiene que proteger los aparatos contra la suciedad y las fluctuaciones fuertes de la

temperatura del ambiente.

■ Si no se respetan las instrucciones de servicio, puede provocar la pérdida de las

homologaciones (p.ejemplo ATEX).

2. Descripción del producto

Un sistema de medición con separador se compone de los siguientes componentes,

separador, conducto de transmisión (por ejemplo capilar) y del instrumento de medición, los

cuales no deben estar separados. El principio de transmisión de la medida es hidraúlica.

Aparte del capilar, la membrana del separador, con un espesor de aproximadamente solo -0,1

mm, es el componente más sensible. La más pequeña de las fugas en el sistema de

transmisión conducirá a una pérdida de líquido de relleno y dando como resultado mediciones

inadecuadas o fallos del sistema de medición. Para evitar fugas y errores de medición,

observar por favor el siguiente modo de empleo para la instalación, utilzación y mantenimiento.

3. Instrucciones generales de instalación

■ Para proteger el sistema de medición de deterioro mecánico, dejarlo en el embalaje de

fábrica hasta su instalación

■ Cuando se saque el sistema de medición del embalaje de fábrica y durante la instalación se

debe tratar el sistema con particular cuidado, para prevenir deterioramiento y deformación

mecánica de la membrana

■ Nunca se debe aflojar el tornillo del orificio de llenado sellado ni en el separador ni en el

instrumento de medición

■ No dañar la superficie del sello separador; Arañazos en la superficie del separador

(causados por objetos afilados, por ejemplo) son las causas principales de corrosión

■ Para la estanqueidad se tiene que elegir juntas adecuados

■ En caso de montaje con bridas, es necesario la utilización de una junta de estanqueidad

perfectamente centrada y de un diámetro interior suficientemente grande para evitar

cualquier contacto con la membrana

■ Cuando se utilicen materiales blandos de junta como PTFE, respectar las recomendaciones

del fabricante en lo que concierne al par de apriete y los ciclos de asentamiento

■ Para su instalación se tienen que utilizar las normas de fijación, así como los tornillos y

tuercas apropiados

16 WIKA Modo de empleo para separador

■ El usario debe asegurarse que selecciona el manómetro apropiado en

relación a rango escala y así como el uso y el material de partes en

9045830 10/2006

Page 17

Sistema de medición con separadores

4. Puesta en marcha

Para evitar impulsos de presión eventualmente tiene que abrir lentamente una válvula de

cierre.

5. Temperaturas del ambiente permisibles

Tiene que efectuarse la instalación del manómetro asegurando que el límite de la temperatura

del ambiente y del medio ni baje por debajo ni exceda, también en vista de la influencia de

convección y radiación calorífica. Tiene que observarse la influencia de la temperatura en la

precisión de la indicación. Con la elección de separadores la estabilidad de la temperatura y la

presión de los componentes de fijación y brida tiene que ser observada mediante la elección

de materiales y el grado de presión. El grado de presión que está indicado en el separador es

válido para las temperaturas del ambiente. Con temperaturas más altas la presión máxima

permisible se debe obtener de la norma indicada del separador.

Uso de separadores con aparatos de medición para zonas peligrosas:

■ Con el uso de separadores con manómetros para zonas peligrosas los límites permisibles

de las temperaturas del ambiente para el transmisor no pueden ser excedidos. También

superficies calientes en la torre de refrigeración (capilar o elemento de refrigeración) pueden

representar una fuente de ignición posible. Tiene que cumplir las medidas

correspondientes.

■ Con la instalación de separadores con una válvula antillama la temperatura del ambiente

permisible está determinado del manómetro que está instalado. En una atmósfera

explosiva, la temperatura no puede exceder +60 ºC alrededor de la válvula antillama. Ver el

modo de empleo suplementario para manómetros con una válvula antillama integrado.

E

6. Recomendaciones para el montaje de separadores con capilar

■ No transportar nunca el sistema de medición por los capilares

■ No doblar el capilar, lo cúal podría provocar un riesgo de fuga o aumentar

considerablemente el tiempo de respuesta del sistema de medición

■ Para evitar cargas mecánicas, tener especial atención, de no retorcer y fracturar, los puntos

donde esta conectado el capilar con el separador así como el capilar con el instrumento.

No doblar los capilares.

■ El radio de curvatura del capilar no debe en ningún caso serinferior a 150 mm

■ Colocar el capilar de forma que este totalmente exento de vibraciones

■ Diferencias permitidas en altura:

Para un montaje del aparato de medida por encima del punto de medición, la máxima

diferencia en altura no debe exceder de 7 m en el caso de sistemas de medición con

separadores llenados con silicona, glicerina o aceite parafina.

Si se utiliza para el llenado fluido de halocarbono, la diferencia de altura máxima (H1) es

solamente de 4 m (ver ejemplos 1 y 2)

En caso de que se produzca una presión negativa mientras se está midiendo, la diferencia de

altura permitida debe ser reducida correspondientemente.

9045830 10/2006

17WIKA Modo de empleo para separador

Page 18

Sistema de medición con separadores

Ejemplo 1 Ejemplo 2

E

H1 hasta un máx. de 7 m, o 4 m respectivamente.

En caso de medida de presión absoluta (vacío), el aparato de medición debe estar montado

como mínino a la misma altura que el separador, o bien más bajo (ver ejemplo 3 y 4).

Ejemplo 3 Ejemplo 4

Vacío

Vacío: Para H1 montar debajo del punto

de medida o en el mismo nivel.

■ Para que la influencia de la temperatura sea baja en el caso de montaje de sistemas de

medición de presión diferencial con separadores, el montaje se debe efectuar lo más cerca

posible de la cota positiva y de la cota negativa, en simetría para prevenir las influencias

del ambiente y en particular las temperaturas ambientales.

Vacío

7. Instrucciones generales de mantenimiento

!

controles regulares. El control o una nueva calibración tienen que ser efectuados por personal

con un equipo apropiado. Desmontar dispositivo de medida solamente en un estado sin

presión. Restos del medio en un manómetro desmontado pueden provocar al peligro de

personas, medio ambiente y instalaciones. Se deben tomer medidas preventivas.

En el caso de medios sucios, viscosos o cristalizantes puede ser necesario limpiar la

membrana regularmente. Quitar sólo las deposiciones en la membrana con un cepillo suave y

un disolvente adecuado. No utilizar agentes de limpieza agresivos.

Precaución: No dañar la membrana con herramientas de cantos afilados.

Normalmente los sistemas de medición con separadores no necesitan

mantenimiento. La precisión del manómetro debe ser asegurada mediante

18 WIKA Modo de empleo para separador

9045830 10/2006

Page 19

WIKA Global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand

GmbH & Co. KG

1230 Wien

Phone: (+43) 1-86 91 631

Fax: (+43) 1-86 91 634

E-mail: info@wika.at

www.wika.at

Benelux

WIKA Benelux

6101 WX ECHT

Phone: (+31) 475-535 500

Fax: (+31) 475-535 446

E-mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

1309 Sofia

Phone: (+359) 2 82138-10

Fax: (+359) 2 82138-13

E-mail: t.antonov@wika.bg

Finland

WIKA Finland Oy

00210 Helsinki

Phone: (+358) 9-682 49 20

Fax: (+358) 9-682 49 270

E-mail: info@wika.fi

www.wika.fi

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Phone: (+33) 1-34 30 84 84

Fax: (+33) 1-34 30 84 94

E-mail: info@wika.fr

www.wika.fr

Germany

WIKA

Alexander Wiegand

GmbH & Co. KG

63911 Klingenberg

Phone: (+49) 93 72-13 20

Fax: (+49) 93 72-13 24 06

E-mail: info@wika.de

www.wika.de

Italy

WIKA Italiana SRL

20020 Arese (Milano)

Phone: (+39) 02-93 86 11

Fax: (+39) 02-93 86 174

E-mail: info@wika.it

www.wika.it

Poland

Kujawska Fabryka Manometrow

-KFM S.A.

87-800 Wloclawek

Phone: (+48) 542 30 11 00

Fax: (+48) 542 30 11 01

E-mail: info@manometry.com.pl

www.manometry.com.pl

Romania

WIKA Instruments S.R.L.

Bucuresti, Sector 5

Phone: (+40) 21-456 31 38

Fax: (+40) 21-456 31 37

E-mail: m.anghel@wika.ro

Russia

ZAO „WIKA MERA“

127015 Moscow

Phone: (+7) 495-786 21 25

Fax: (+7) 495-786 21 23

E-mail: info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

11060 Belgrad

Phone: (+381) 11 27 63 722

Fax: (+381) 11 75 36 74

E-mail: info@wika.co.yu

www.wika.co.yu

Spain

Instrumentos WIKA, S.A.

08280 Sabadell (Barcelona)

Phone: (+34) 90-290 25 77

Fax: (+34) 93-393 86 66

E-mail: info@wika.es

www.wika.es

Switzerland

MANOMETER AG

6285 Hitzkirch

Phone: (+41) 41-919 72 72

Fax: (+41) 41-919 72 73

E-mail: info@manometer.ch

www.manometer.ch

Ukraine

WIKA Pribor GmbH

83016 Donetsk

Phone: (+38) 062 345 34 16

Fax: (+38) 062 345 34 16

E-mail: info@wika.donetsk.ua

www.wika.donetsk.ua

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill RH13LG

Phone: (+44) 17 37 64 40 08

Fax: (+44) 17 37 64 44 03

E-mail: info@wika.co.uk

www.wika.co.uk

North America

Canada

WIKA Instruments Ltd.

Head Office

Edmonton, Alberta, T6N 1C8

Phone: (+1) 780-463 70 35

Fax: (+1) 780-462 00 17

E-mail: info@wika.ca

www.wika.ca

Mexico

Instrumentos WIKA Mexico S.A.

de C.V.

01219 Mexico D.F.

Phone: (+52) 555 020 53 00

Fax: (+52) 555 020 53 01

E-Mail ventas@wika.com.mx

www.wika.com.mx

USA

WIKA Instrument Corporation

Lawrenceville, GA 30043

Phone: (+1) 770-513 82 00

Fax: (+1) 770-338 51 18

E-mail: info@wika.com

www.wika.com

South America

Argentina

WIKA Argentina S.A.

Buenos Aires

Phone: (+54-11) 4730 18 00

Fax: (+54-11) 4761 00 50

E-mail: info@wika.com.ar

www.wika.com.ar

Brazil

WIKA do Brasil Ind. e Com. Ltda.

CEP 18560-000 Iperó - SP

Phone: (+55) 15-3266 16 55

Fax: (+55) 15-3266 16 50

E-mail: marketing@wika.com.br

www.wika.com.br

Africa/Middle East

Egypt

WIKA Alexander Wiegand GmbH &

Co. KG

Branch Office Tehran

Nasr City, Cairo

Phone: (+20) 2 - 273 31 40

Fax: (+20) 2 - 273 31 40

E-mail: ahmed.azab@wika.de

9045830 10/2006

19WIKA Betriebsanleitung Druckmittler

Page 20

WIKA Global

Iran

WIKA Instrumentation Pars (KFZ)

Ltd.

Anahita Tower, Tehran

Phone: (+98-21) 8878 3514-17

Fax: (+98-21) 8887 8593

E-mail: info@wika.ir

www.wika.ir

South Africa

WIKA Instruments (Pty.) Ltd.

Gardenview, Johannesburg 2047

Phone: (+27) 11-621 00 00

Fax: (+27) 11-621 00 59

E-mail: sales@wika.co.za

www.wika.co.za

United Arab Emirates

WIKA Middle East FZE

Jebel Ali, Dubai

Phone: (+971) 4 - 883 90 90

Fax: (+971) 4 - 883 91 98

E-mail: wikame@emirates.net.ae

Asia

China

WIKA International Trading

(Shanghai) Co., Ltd.

200001 Shanghai

Phone: (+86) 21 - 53 85 25 73

Fax: (+86) 21 - 53 85 25 75

E-mail: wikash@online.sh.cn

www.wika.com.cn

India

WIKA Instruments India Pvt. Ltd.

Village Kesnand, Wagholi

Pune - 412 207

Phone: (+91) 20 - 27 05 29 01

Fax: (+91) 20 - 27 05 19 25

E-mail: sales@wika.co.in

www.wika.co.in

Japan

WIKA Japan K. K.

Tokyo 105-0023

Phone: (+81) 3-54 39 66 73

Fax: (+81) 3-54 39 66 74

E-mail: t-shimane@wika.co.jp

Kazakhstan

TOO WIKA Kazakhstan

050050 Almaty

Phone: (+7) 32 72 33 08 48

Fax: (+7) 32 72 78 99 05

E-mail:

wika-kazakhstan@nursat.kz

Korea

WIKA Korea Ltd.

Seoul 153-023

Phone: (+82) 2 - 8 69 05 05

Fax: (+82) 2 - 8 69 05 25

E-mail: info@wika.co.kr

Malaysia

WIKA Instrumentation (M) Sdn.

Bhd.

Selangor Darul Ehsan

Phone: (+60) 3 - 56 36 88 58

Fax: (+60) 3 - 56 36 90 72

E-mail: info@wika.com.my

www.wika.com.my

Singapore

WIKA Instrumentation Pte. Ltd.

569625 Singapore

Phone: (+65) 68 44 55 06

Fax: (+65) 68 44 55 07

E-mail: info@wika.com.sg

www.wika.com.sg

Taiwan

WIKA Instrumentation Taiwan Ltd.

Pinjen, Taoyuan

Phone: (+886) 034 20 60 52

Fax: (+886) 034 90 00 80

E-mail: info@wika.com.tw

www.wika.com.tw

Australia

Australia

WIKA Australia Pty. Ltd.

Rydalmere, NSW 2116

Phone: (+61) 2 - 88 45 52 22

Fax: (+61) 2 - 96 84 47 67

E-mail: sales@wika.com.au

www.wika.com.au

Technical alteration rights reserved.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

Nos reservamos cualquier modificación.

20

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Phone (+49) 93 72/132-0

Fax (+49) 93 72/132-406

E-Mail info@wika.de

www.wika.de

9045830 10/2006

WIKA Betriebsanleitung Druckmittler

Loading...

Loading...