Page 1

Operating Instructions

Betriebsanleitung

Mode d’emploi

Differential Pressure Transmitter DELTA-trans

Model 891.34.2189

Differenzdruck-Messumformer DELTA-trans

Typ 891.34.2189

Transmetteur de pression différentielle DELTA-trans

Type 891.34.2189

W

GB

D

F

DELTA-trans Model 891.34.2189 with integrated 3½-digit LCD-display

(optional) and compression fitting with ferrule (optional)

Page 2

Operating Instructions Differential Pressure Transmitter

GB

DELTA-trans Model 891.34.2189 Page 3 - 15

Betriebsanleitung Differenzdruck-Messumformer

D

DELTA-trans Typ 891.34.2189 Seite 17 - 29

Mode d‘emploi Transmetteur de pression différentielle

F

DELTA-trans Type 891.34.2189 Page 31 - 43

2279453 08/2009 GB/D/F

Page 3

Contents

Contents

1. Safety instructions 4

2. Operating principle 4

3. Installation instructions 5

4. Installation and commissioning 6

5. Measuring arrangements 7

6. Wiring details 7

7. Version with LCD-display (optional extra) 8

8. Technical data 9

9. Service and maintenance 11

10. Special instructions for integrated pressure equalising valve

or 4-way valve manifold

11. Storage 14

12. Troubleshooting 14

13. Maintenance and servicing 15

GB

12

14. Repairs 15

15. Disposal 15

Warning!

This symbol warns you against actions that can cause

injury to people or damage to the instrument.

2279453 08/2009 GB/D/F

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans 3

Page 4

1. Safety instructions / 2. Operating principle

1. Safety instructions

GB

The appropriate national safety regulations (i.e. VDE 0100 /

EN 60 079-14 / EN 837-2) must be observed when installing,

commissioning and operating these instruments.

Do not work on the gauge while it is powered

Serious injuries and/or damage can occur should the appropriate regulations

not be observed

Only appropriately qualified personnel should work on these instruments

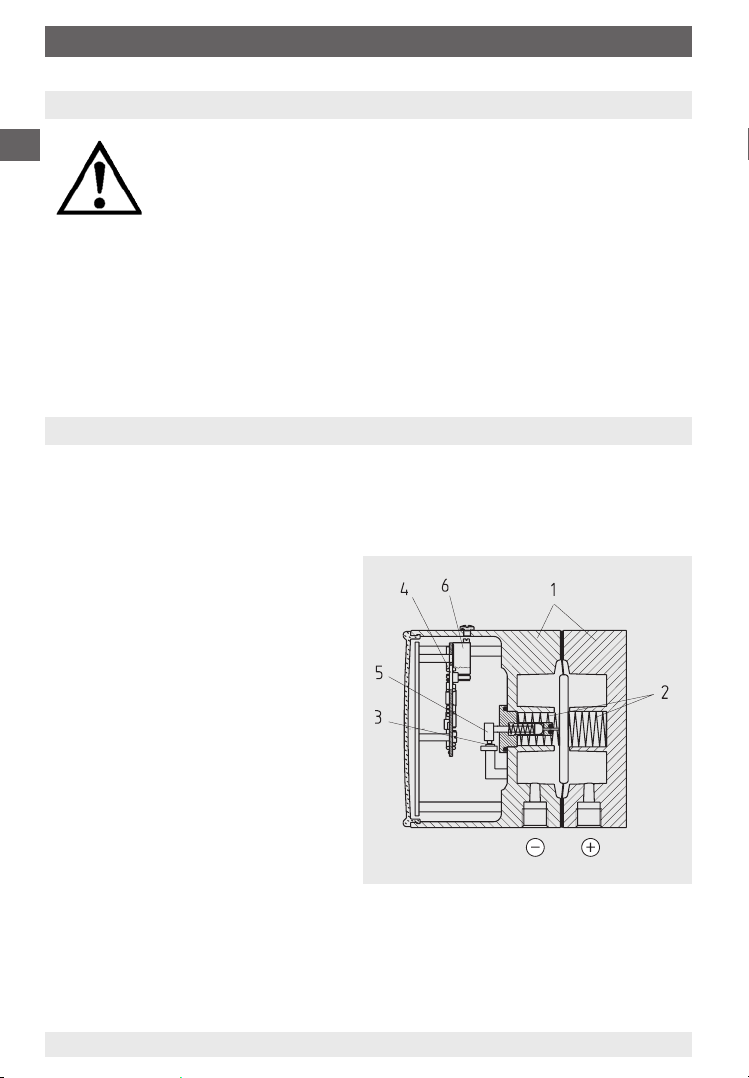

2. Operating principle

The differential pressure transmitter consists mainly of a mechanical measuring system (1) with an elastic pressure element (2), a Hall-effect sensor (3) with

signal processing board (4) and a case with the connections for the electronics.

A magnet (5), rigidly coupled to the

pressure element, influences the

electromagnetic field of the HALLeffect sensor. The resulting signal is

amplified to a standard output signal

via the signal processing board.

2155079.01

For recalibration, zero and span

can be adjusted by means of easily

accessible potentiometers (6).

Pressure entries are identified by the

symbols; j high pressure and i low

pressure

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans4

2279453 08/2009 GB/D/F

Page 5

3. Installation instructions

3. Installation instructions

Installation arrangement

The pressure transmitter should be installed and operated without exposure

to vibration. It is common practise to install the pressure transmitter fitted to

an isolating device to enable replacement while the system is pressurised

and to isolate the transmitter when reading is not required.

Test connector

Local safety codes such as those for pressure or steam vessels may specify

isolating devices to enable on-site testing of the pressure transmitter.

Mounting provisions

If the pressure system or tailpipe is not rigid enough to accept the weight of

the transmitter, or capable of withstanding any vibrations present, the transmitter should be wall-mounted using a suitable bracket.

Effects of temperature

The operating temperature of the pressure transmitter, resulting from the

effects of the pressure medium, ambient temperatures and possible radiated

heat, must not exceed the temperature range the pressure transmitter is

intended for. Suitably shaped tailpipes or syphons with water filling may be

used to separate the pressure transmitter and its isolating device from hot

pressure media.

Overload protection for pressure elements

Should the measuring media be subject to rapid pressure fluctuations or

there is a possibility of pressure surges, these must not be allowed to act

directly on the pressure element. The effect of any pressure surges must

be restricted, for example, by fitting integral restrictor screws (to reduce the

bore in the pressure connection) or by using adjustable snubber devices.

GB

Pressure test connection

The pressure test connection, with a sufficiently large bore (≥ 6 mm diameter), should be arranged, as far as possible, over a shut-off device, in a

position where the accuracy of reading will not be affected by the flow of the

media being measured. The piping between the pressure test connection

and the pressure transmitter should have an inner diameter large enough to

avoid blockages or delays in pressure transmission. It should also not have

any sharp bends. It is recommended that it is laid with a continuous incline

of approx. 1:15.

2279453 08/2009 GB/D/F

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans 5

Page 6

Installation instructions / 4. Installation and commissioning

Piping

The piping should be arranged and fitted so that it can withstand the

GB

stresses caused by expansion, vibration and the influence of heat. When

the media is gaseous, a water drain point should be provided at the lowest

point. For liquid pressure media, an air bleed should be provided at the

highest point.

4. Installation and commissioning

Correct sealing of pressure connections should be achieved by means of

suitable sealing rings, sealing washers or WIKA profile seals.

If the pressure transmitter is positioned lower than the pressure test connection, the tailpipe should be thoroughly cleaned prior to fitting the transmitter.

Once the pressure and electrical connections have been made, the transmitters

are ready for immediate use.

No attempt should be made to remove a pressurised transmitter. If the transmitter cannot be otherwise isolated, the pressure system must be fully vented.

Any residual pressure medium contained in the pressure element may be

hazardous or toxic. This should be taken into account when handling and

storing pressure gauges which have been removed.

2279453 08/2009 GB/D/F

6

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans

Page 7

5. Measuring arrangements / 6. Wiring details

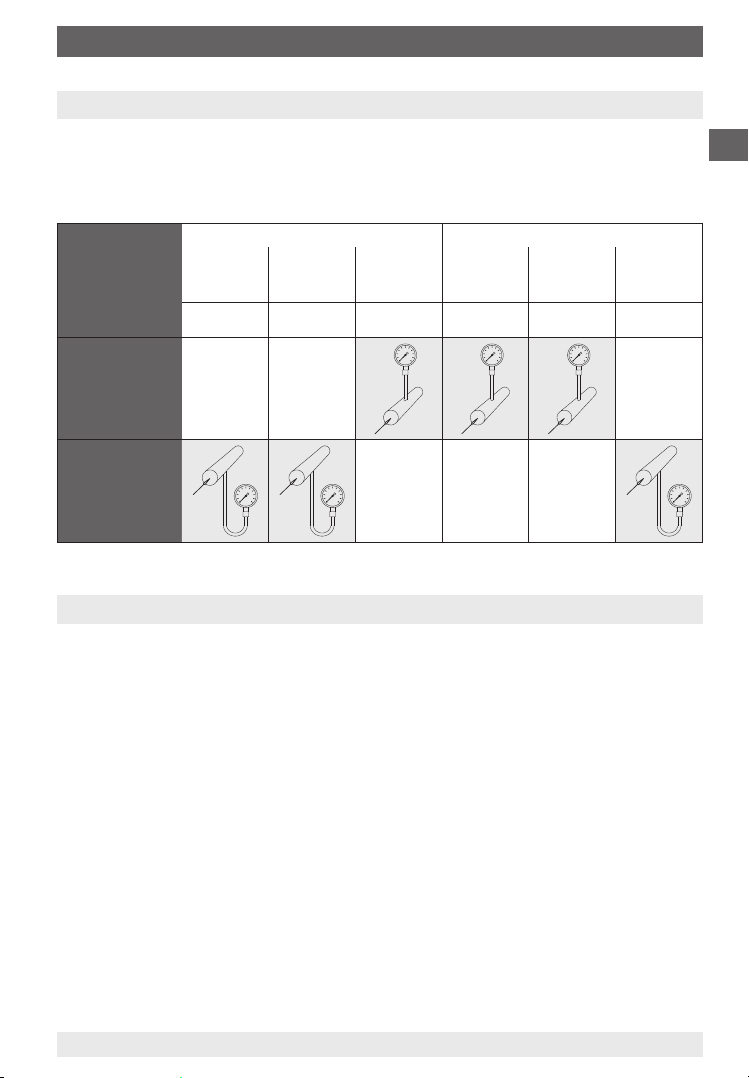

5. Measuring arrangements

Proven measuring arrangements for various types of media.

The recommended arrangements for particular applications are shown below.

Liquid media Gaseous media

Contents of

tailpipe

Typically

Pressure

instrument

higher than

tapping point

Pressure

instrument

lower than

tapping point

Liquid Liquid with

vapour

Condensate Boiling liquid Liquefied gas Dry air Moist air,

Vapour

only

Gas only Wet gas Liquid gas

Flue gas

condensate

Steam

6. Wiring details

Electrical connection of this pressure transmitter is made by cable and connector. Precise wiring diagrams can be seen in the following drawings.

In addition to the wiring details, output signal and required power supply are

given on the rating plate.

GB

Description of terminal designations used:

UB+ Plus terminal for supply voltage

0 V Minus terminal for supply voltage

S+ Plus terminal for output signal

S- Minus terminal for output signal

Test Test terminal

The instruments must be included within the plant’s equipotential bonding

2279453 08/2009 GB/D/F

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans 7

Page 8

6. Wiring details / 7. Version with LCD-display (optional extra)

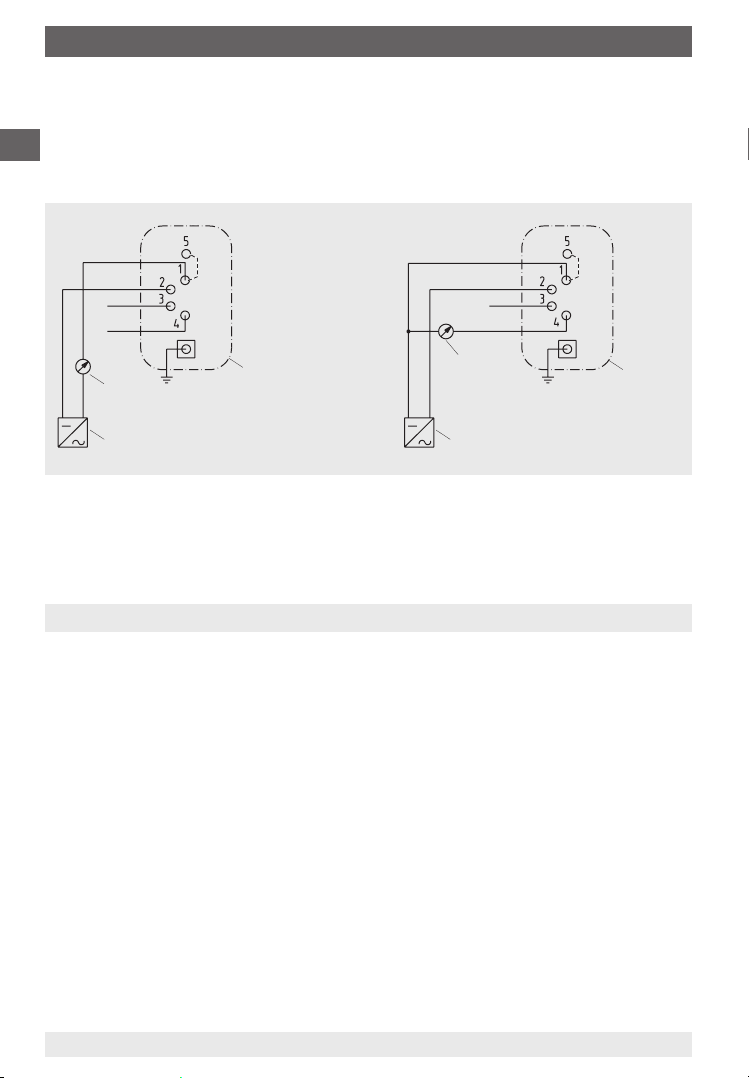

Terminal assignment

Terminals 1 and 5 are bridged internally within the connector, so that two terminals are available for the 0 V / S - connection.

GB

4 ... 20 mA 2-wire system 0 ... 20 mA 3-wire system

0 V / S-

UB+ / S+

Test -

Test +

mA

Evaluation

(display/recorder)

Power supply

Connector

housing

0 V / S-

UB+

Test +

S+ / Test-

mA

Evaluation

(display/recorder)

Power suppy

Connector

housing

The transmitter can operate using a non-stabilised supply voltage within the

given limits, so long as the voltage available to the transmitter does not fall

below 10 V, or below 14 V for the LCD-display version.

7. Version with LCD-display (optional)

On integrated LCD-displays, for local pressure read-out, the output signal is 2wire 4 ... 20 mA. For the required power supply for the integrated LCD display,

please refer to Chapter 8, Technical Data.

Limitation on zero point and span adjustment:

If an LCD display is integrated, it must be noted that the zero point and span

adjustment is only to be used for resetting the measuring range. Changes to

the measuring range, made using the zero and span adjustment will not be

shown on the display.

1416 324.03

2279453 08/2009 GB/D/F

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans8

Page 9

8. Technical data

8. Technical data

Technical data DELTA-trans, Model 891.34.2189

Differential measuring range bar 0 ... 0.16 to 0 ... 25

Working pressure (stat.) max. bar 25

Overload value either side max.

Pressure connections exposed

Pressure media chamber

Press. element comp. spring stainless steel 1.4310 or FD SiCr EN 10 270-2

Press. element separ. diaphr. FPM/FKM fabric back stay (optional NBR)

Links stainless steel 1.4305, FPM/FKM (optional NBR)

Sealing rings FPM/FKM (optional NBR)

Press. equalising valve

(optional)

4-way valve manifold

(optional)

Power supply U

Permissible residual ripple ≤ 0.1 % of span/10 V

Supply voltage effect % ss ≤ 10

Output signal and permissible

max. load R

Effect of load % of span ≤ 0.1

Response time s approx. 1 (optional approx. 50 ms)

Output signal adjustment

Zero point, electrical % of span ± 15

Span, electrical % of span ± 30

Linearity % of span 2.5 (limit point calibration)

(including hysteresis) optional 1.6 (limit point calibration)

Permissible

Medium temperature °C +80 maximum

Ambient temperature °C -10 … +60 (optional LCD-display 0 … 50)

Compensated temp. range °C -10 … +60 (optional LCD-display 0 … 50)

Temperature coefficient in

compensated temp. range

Average TK on zero point ≤ 0.4 % of span/10 K

Average TK on span ≤ 0.4 % of span/10 K

LCD-display (optional)

Voltage load DC V 3.5

Display 3 ½-digit, height 12.7

Ambient temperature °C 0 … 50

Storage temperature °C -10 … +80

Wiring Terminal box (screw terminals up tu 2.5 mm²)

Wiring protection Protected against reverse polarity and overvoltage

EMC (electro-magnetic

compatibility)

Ingress protection IP 54 (optional IP 65) according EN 60 529 / IEC 529

Weight kg approx. 1.3

B

A

bar 25

to medium

exposed to medium

DC V

2 x G ¼ female, bottom, in-line, centre distance 26 mm (optional: other

pressure connections male or female or compression fitting with ferrule for

pipe Ø 6, 8 or 10 mm respectively)

GD-AlSi 12 (Cu) 3.2982, black painted (optional GD-AlSi 12 (Cu) HARD-COAT

surface protection or stainless steel)

stainless steel and FPM/FKM

Cu-alloy or stainless steel, 1x Press. equalising valve, 2 x gauge valve,

1 x valve for purging or air bleeding

10 < UB ≤ 30 (optional LCD-display 14 < UB ≤ 30)

4 … 20 mA, 2-wire system RA ≤ (UB - 10 V) / 0.02 A with RA in Ohm and UB in Volt

0 … 20 mA, 3-wire system RA ≤ (UB - 10 V) / 0.02 A with RA in Ohm and UB in Volt

Interference emission per EN 50 081 - 1 (March 93) and EN 50 081 - 2 (March 94),

Interference immunity per EN 50 082 - 2 (March 95)

GB

2279453 08/2009 GB/D/F

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans 9

Page 10

8. Technical data

Approval German Lloyd (optional)

GB

Additional or deviating technical data

Pressure ranges bar 0 ... 0.25 to 0 ... 10

Output signal 4 ... 20 mA, 2-wire or 0 ... 20 mA, 3-wire current limit I < 32 mA

Permissible ambient

temperature

EMC (electro-magnetic

compatibility)

ESD kV ± 8 contact discharge IEC 1000-4-2

Electromagnetic fields V/m 10 80 % AM, 1 kHz, 0.01 ... 1000 MHz IEC 1000-4-3

Burst kV ± 2 coupling clamp IEC 1000-4-4

Conducted HF-disturbance V 3 80 % AM, 1 kHz, 0.01 ... 100 MHz IEC 1000-4-6

Surge kV ± 0.5 symmetrically IEC 1000-4-5

Conducted NF-disturbance Veff 3 0.05 ... 10 kHz IEC 945

Vibration test Fc

2 ... 25 Hz, +/- 1.6 mm % < 2.5 error IEC 68-2-6

25 ... 100 Hz, 4 g % < 2.5 error

°C -10 … +70

Interference emission per EN 50 081-1 (March 93) and

EN 50 081-2 (March 94),

interference immunity per EN 50 082-2 (March 95)

kV ± 1 asymmetrically, R i = 42 Ohm

kV ± 1 symmetrically

kV ± 2 asymmetrically, R i = 42 Ohm, with surge

protection only e.g. model MM-DS/xNFE(L), firm Dehn & Söhne or equivalent

10

2279453 08/2009 GB/D/F

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans

Page 11

9. Service and maintenance

9. Service and maintenance

Always open isolating devices gently, as abrupt opening may generate sudden

pressure surges that may damage the transmitter.

The pressure transmitters require no maintenance or servicing and will give very

long service when handled and operated correctly. It may well be necessary

to check and readjust the zero point periodically. This depends on the working

conditions.

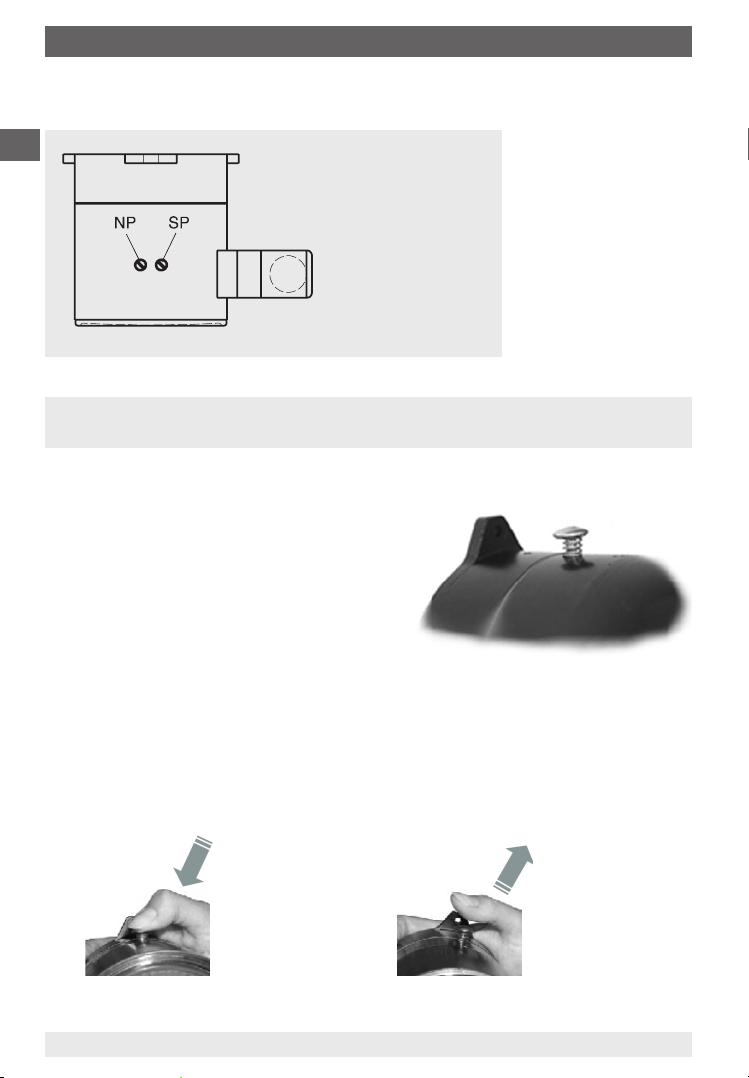

To check zero point

In general, the zero point should be checked and adjusted with the instrument in the unpressurised state.

With differential pressure transmitters the zero point should be checked and

adjusted by opening the pressure equalising valve while under a static load.

The plug screw (NP), found on the top of the case, must be unscrewed to

correct the zero point of the pressure transmitter. The zero point potentiometer

can then be readjusted using a small screwdriver:

turning anticlockwise ⇒ reduces the output signal

turning clockwise ⇒ increases the output signal

To check measuring span

Checking and adjusting the measuring span is a little more complex and has

to be carried out when the pressure transmitter is under pressure, up to the

upper limit of the effective range.

A sufficiently-accurate pressure standard is necessary as a reference.

Only when it is necessary to correct the measuring span should the plug

screw (SP) in the top of the case be unscrewed, and the measuring span

potentiometer can then be readjusted using a small screwdriver:

GB

turning anticlockwise ⇒ reduces the output signal

turning clockwise ⇒ increases the output signal

Once this has been done, the zero point must be checked again and, if necessary, the zero point must be readjusted. This procedure should be repeated

until the zero point and span are calibrated.

2279453 08/2009 GB/D/F

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans 11

Page 12

9. Service and maintenance / 10. Special instructions ...

Position of potentiometers in the electronics case

GB

SP potentiometer for span

NP potentiometer for zero point

2158991.01

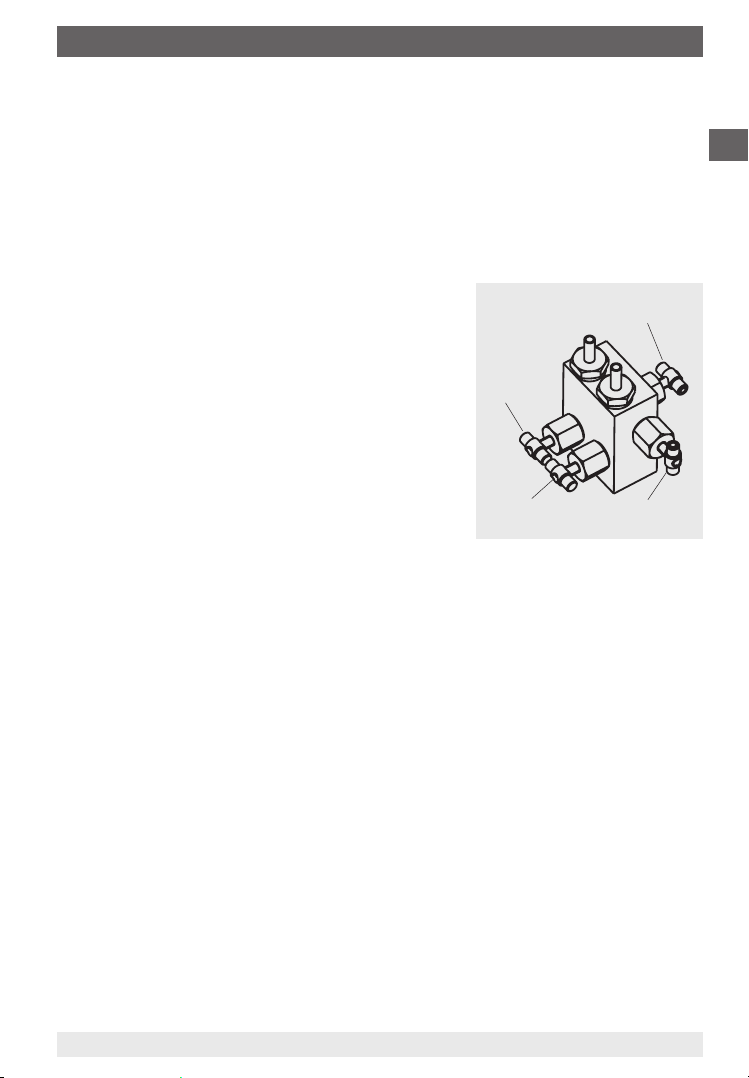

10. Special instructions for integrated pressure equalising valve or

4-way valve manifold

10.1 Integrated pressure equalising valve

For zero point control on working

processes. Offset errors can be adjusted

using the zero point potentiometer (see

Chapter 9. Service and Maintenance)

Principle of operation

When the button is pressed, the

separation between the measuring chambers is released. The pressure

is thus equalised in both chambers, and the differential pressure is zero.

Releasing the button separates the chambers again and the current differential pressure is measured.

12

valve

actuate

Differential pressure drops to zero

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans

release

Measuring differential

pressure again

2279453 08/2009 GB/D/F

Page 13

10. Special instructions for integrated pressure equalising valve ...

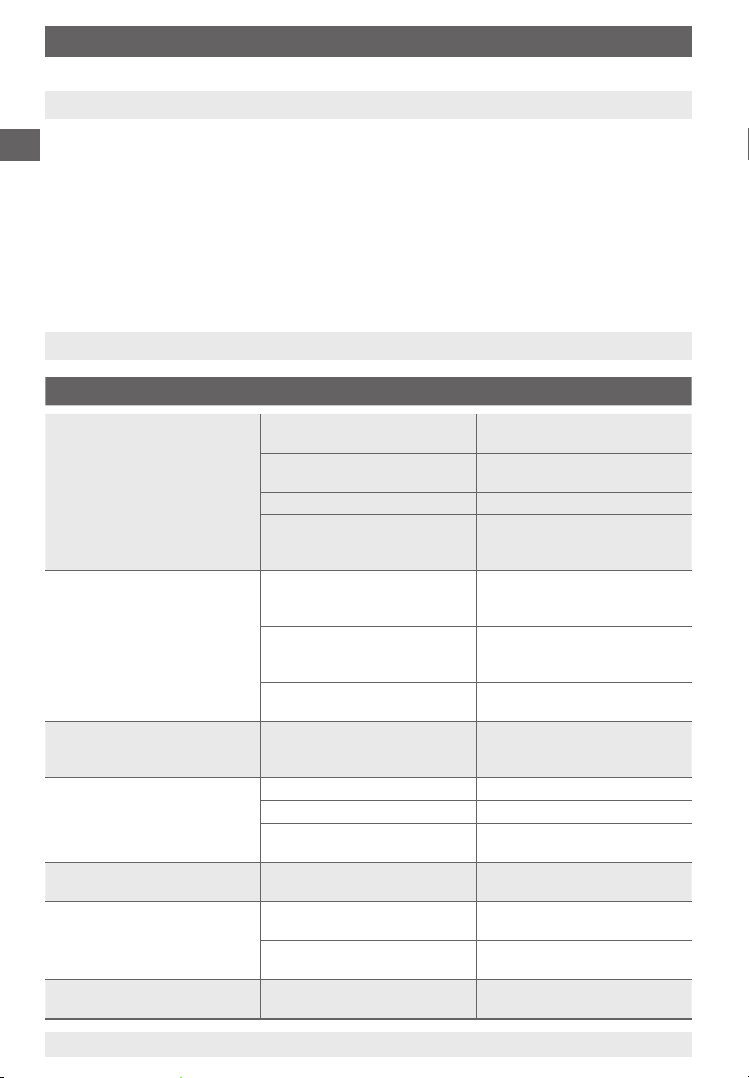

10.2 Four-way valve manifold

Functions

Shut off j- and i-process line for removing the transmitter from working

processes

Pressure equalisation for zero point control on working processes

Process line air bleeding

10.2.1 Handling instructions

Sequence of operations to start measuring

1. Open pressure equalising valve (middle

valve)

2. Open shut-off valve for the minus media

Gauge valve,

high pressure

j-

side

Pressure equalising valve

chamber (i) left valve

3. Open shut-off valve for the plus media

chamber (j) right valve

4. Close pressure equalising valve

Sequence of operations at the end of the

Gauge valve, low

pressure i-side

Valve for purging

or bleeding air

measuring operation (also for partial shutdown of the system)

1. Open pressure equalising valve

2. Close shut-off valve for the minus media chamber (i)

3. Close shut-off valve for the plus media chamber (j)

Sequence of operations to remove the transmitter during working processes

1. Open pressure equalising valve

2. Close shut-off valve for the minus media chamber (i)

3. Close shut-off valve for the plus media chamber (j)

4. Open valve for purging or air bleeding

GB

2279453 08/2009 GB/D/F

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans 13

Page 14

11. Storage / 12. Troubleshooting

11. Storage

GB

Before installation, in order to prevent damage to the transmitters, the following

points should be observed:

The pressure transmitter should remain in its original packing until installation.

After taking out the transmitter (e.g. for tests), reuse the original packaging

material.

The storage temperature should not be less than -20 °C or more than +60 °C.

Transmitters should be protected against dust and humidity.

12. Troubleshooting

Defect Possible reason Remedy

No signal output Failure of power supply or wiring

Steady signal, despite pressure

changes

Steady and excessively high

signal, despite pressure

changes

Full span reading too low Supply voltage too low Adjust supply voltage

Zero signal too low Zero adjustment made incor-

Zero signal too high Zero adjustment made incor-

Non-linear signal output despite

correct zero adjustment

14

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans

interrupted

Transmitter miswired Check wiring; if necessary

No pressure Check tailpipes

Electronic defect through incor-

rect supply voltage or external

voltage

Pressure entry blocked Check tailpipes and pressure

Electronic defect through incorrect supply voltage or external

voltage

Transmitter failure through

overpressurisation

Electronic defect through incorrect supply voltage or external

voltage

Load impedance too high Consider permissible max. load

Span adjustment made incor-

rectly

rectly

rectly

Transmitter over-pressurised Return transmitter to manufac-

Transmitter over-pressurised Return transmitter to manufac-

Check power supply and wiring;

replace defective components

rectify it

Return transmitter to manufacturer for repair

entry bore, if necessary clean it

carefully

Return transmitter to manufacturer for repair

Return transmitter to manufacturer for repair

Return transmitter to manufacturer for repair

Re-calibrate transmitter

Re-calibrate transmitter

Re-calibrate transmitter

turer for repair

turer for repair

2279453 08/2009 GB/D/F

Page 15

13. Maintenance and servicing/cleaning ... 15. Disposal

13. Maintenance and servicing/cleaning

The instruments require no maintenance or servicing and will give very long

service when handled and operated properly.

The indicator and switching function should be checked once or twice every

12 months. The instrument must be disconnected from the process before

being checked using pressure testing equipment.

The instruments should be cleaned with a damp cloth, moistened with soap

solution. Ensure that all the parts are dry before the power is switched on again.

Any residual pressure medium contained in the pressure element may be

hazardous or toxic. This should be taken into account when handling and

storing pressure gauges which have been removed.

14. Repairs

Repairs are only to be carried out by the manufacturer or appropriately trained

personnel.

For further details see the Data Sheet for the respective basic gauge PV 17.18.

15. Disposal

Dispose of instrument components and packaging materials in accordance

with the respective waste treatment and disposal regulations of the region or

country to which the instrument is supplied.

GB

2279453 08/2009 GB/D/F

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans 15

Page 16

GB

16

2279453 08/2009 GB/D/F

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans

Page 17

Inhalt

Inhalt

1. Sicherheitshinweise 18

2. Funktionsprinzip 18

3. Montagehinweise 19

4. Montage und Inbetriebnahme 20

5 Messanordnung 21

6. Elektrischer Anschluss 21

7. Ausführung mit LCD-Anzeige (Option) 22

8. Technische Daten 23

9. Bedienung und Wartung 25

10. Besonderheiten bei integriertem Druckausgleichsventi oder

Vierfach-Ventilblock

11. Lagerung 28

12. Maßnahmen bei Störungen 28

13. Wartung und Reinigung 29

D

26

14. Reparaturen 29

15. Entsorgung 29

Warnung!

Dieses Symbol warnt Sie vor Handlungen, die Schäden an

Personen oder am Gerät verursachen können.

2279453 08/2009 GB/D/F

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans 17

Page 18

1. Sicherheitshinweise / 2. Funktionsprinzip

1. Sicherheitshinweise

Beachten Sie unbedingt bei Montage, Inbetriebnahme und

Betrieb dieser Geräte die entsprechenden nationalen Sicher

heitsvorschriften (z. B. VDE 0100 / EN 60 079-14 / EN 837-2).

D

Alle Arbeiten dürfen nur im spannungslosen Zustand erfolgen

Bei Nichtbeachten der entsprechenden Vorschriften können schwere Körper-

verletzungen und / oder Sachschäden auftreten

Nur entsprechend qualifiziertes Personal darf an diesen Geräten arbeiten

2. Funktionsprinzip

Der Differenzdruck-Messumformer besteht im Wesentlichen aus den Funktionsgruppen mechanisches Messsystem (1) mit federelastischem Messglied

(2), magnetfeldabhängiger Sensor (3) mit Signalverarbeitungsplatine (4) und

Gehäuse mit den Anschlussteilen für die Elektronik.

Ein mit dem Messglied fest gekoppelter Magnet (5) beeinflusst das

elektromagnetische Feld des HALLSensors.

Das dabei entstehende Signal wird

durch die Signalverarbeitungsplatine

in ein normiertes Stromausgangssignal verstärkt.

2155079.01

Zur Nachkalibrierung können

Nullpunkt und Spanne über leicht

zugängliche Potentiometer (6) eingestellt werden.

Montage nach angebrachten

Symbolen, j hoher Druck und i

niedriger Druck

18

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans

2279453 08/2009 GB/D/F

Page 19

3. Montagehinweise

3. Montagehinweise

Montageanordnung

Der Druckmessumformer muss erschütterungsfrei befestigt und betrieben

werden. Es empfiehlt sich, zwischen Druckentnahmestelle und Druckmessumformer eine Absperrvorrichtung zwischenzuschalten, die einen

Austausch des Messgerätes und eine Nullpunktkontrolle bei laufender

Anlage ermöglicht.

Prüfanschluss

Bei bestimmten Anwendungsfällen (z. B. Dampfkessel) müssen die Absperrarmaturen einen Prüfanschluss besitzen, damit der Druckmessumformer

ohne Ausbau überprüft werden kann.

Messgerätebefestigung

Ist die Leitung zum Druckmessumformer für eine erschütterungsfreie Anbringung nicht stabil genug, so ist die Befestigung über die Befestigungslaschen

zur Wandmontage vorzunehmen.

Temperaturbelastung

Die Anbringung des Druckmessumformers ist so auszuführen, dass die

zulässigen Betriebstemperaturen (Umgebung, Messstoff), auch unter

Berücksichtigung des Einflusses von Konvektion und Wärmestrahlung,

weder unter noch überschritten werden. Druckmessumformer und gegebenenfalls angebaute Absperrarmaturen sind z. B. durch ausreichend lange

Messleitungen zu schützen. Der Temperatureinfluss auf die Messgenauigkeit

ist zu beachten.

D

Schutz der Messglieder vor Überlastung

Unterliegt der Messstoff schnellen Druckänderungen oder ist mit Druckstößen zu rechnen, so dürfen diese nicht direkt auf das Messglied einwirken.

Die Druckstöße müssen in ihrer Wirkung gedämpft werden, z. B. durch

Einbau einer Drosselstrecke (Verringerung des Querschnittes im Druckkanal)

oder durch Vorschaltung einer einstellbaren Drosselvorrichtung.

Druckentnahmestutzen

Der Druckentnahmestutzen soll mit einer genügend großen Bohrung (≥ 6 mm)

möglichst über ein Absperrorgan so angeordnet werden, dass die Druckentnahme nicht durch eine Strömung des Messstoffes verfälscht wird. Die Messleitung zwischen Druckentnahmestutzen und Druckmessumformer soll zur

Vermeidung von Verstopfung und Verzögerungen bei der Druckübertragung

einen genügend großen Innendurchmesser besitzen und ohne scharfe

Krümmung sein. Ihre Verlegung mit einer stetigen Neigung von ca. 1:15 ist zu

empfehlen.

2279453 08/2009 GB/D/F

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans 19

Page 20

3. Montagehinweise / 4. Montage und Inbetriebnahme

Messleitung

Die Messleitung ist so auszuführen und zu montieren, dass sie die auftretenden Belastungen durch Dehnung, Schwingung und Wärmeeinwirkung

aufnehmen kann. Bei Gasen als Messstoff ist an der tiefsten Stelle eine

Entwässerung, bei flüssigen Messstoffen an der höchsten Stelle eine Entlüftung vorzusehen.

D

4. Montage und Inbetriebnahme

Zur Abdichtung der Anschlüsse sind Flachdichtungen, Dichtlinsen oder WIKAProfildichtungen einzusetzen.

Ist der Druckmessumformer tiefer als der Druckentnahmestutzen angeordnet,

dann muss die Messleitung vor dem Anschließen gut durchgespült werden, um

Fremdkörper zu beseitigen.

Nach Herstellen der Druckverbindung und der elektrischen Anschlüsse sind die

Druckmessumformer sofort betriebsbereit.

Vor dem Ausbau des Druckmessumformers ist das Messglied drucklos zu

machen. Gegebenenfalls muss die Messleitung entspannt werden.

Messstoffreste in ausgebauten Druckmessumformern können zur Gefährdung

von Menschen, Umwelt und Einrichtung führen. Ausreichende Vorsichtsmaßnahmen sind zu ergreifen.

2279453 08/2009 GB/D/F

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans20

Page 21

5. Messanordnungen / 6. Elektrischer Anschluss

5. Messanordnungen

Bewährte Messanordnungen für verschiedene Messstoffarten.

Die zur Anwendung besonders empfohlenen Anordnungen sind nachfolgend

dargestellt.

flüssige Messstoffe gasförmige Messstoffe

Füllung der

Messleitung

Beispiele

Druckmessgerät

oberhalb des

Entnahmestutzens

Druckmessgerät

unterhalb des

Entnahmestutzens

flüssig zum Teil

Kondensat siedende

ausgasend

Flüssigkeiten

vollständig

verdampft

„Flüssiggase“ trockene Luft feuchte Luft,

gasförmig z. T. kon-

densiert

(feucht)

Rauchgase

vollständig

kondensiert

Wasserdampf

6. Elektrischer Anschluss

D

Der elektrische Anschluss der Druckmessumformer wird über Kabeldose und

Kabel hergestellt.

Die genauen Anschlussbelegungen können den nachfolgenden Zeichnungen

entnommen werden. Zusätzlich sind Anschlussbelegung, Ausgangssignal und

erforderliche Hilfsenergie auf dem Typenschild vermerkt.

Bedeutung der verwendeten Klemmenbezeichnungen:

UB+ Plusklemme der Versorgungsspannung

0 V Minusklemme der Versorgungsspannung

S+ Plusklemme des Ausgangssignals

S- Minusklemme des Ausgangssignals

Test Prüfklemmen

Die Geräte sind in den Potenzialausgleich der Anlage mit einzubeziehen.

2279453 08/2009 GB/D/F

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans 21

Page 22

6. Elektrischer Anschluss / 7. Ausführung mit LCD-Anzeige

Belegung der Anschlussklemmen

Die Klemmen 1 und 5 sind in der Kabeldose intern gebrückt. Dadurch stehen

für den Anschluss von 0 V / S- zwei Klemmen zur Verfügung.

4 … 20 mA Zweileitersystem 0 … 20 mA Dreileitersystem

D

0 V / S-

UB+ / S+

Test -

Test +

mA

Auswertung

(Anzeige, Schreiber)

Hilfsenergie

Kabeldose

0 V / S-

UB+

S+ / Test-

mA

Auswertung

(Anzeige,

Schreiber)

Hilfsenergie

Test +

Kabeldose

Als Hilfsenergie genügt eine unstabilisierte Gleichspannung im Bereich der

angegebenen Grenzen. Es ist darauf zu achten, dass die angelegte Versorgungsspannung um den Betrag höher ist als die maximal erforderliche

Spannung, die an den externen Anzeige- und Auswertegeräten abfällt, d. h.

dass die am Druckmessumformer anliegende Spannung nicht unter 10 V, bei

Ausführung mit LCD-Anzeige nicht unter 14 V abfällt.

7. Ausführung mit LCD-Anzeige (Option)

Bei werksseitig integrierten LCD-Anzeigen zur direkten Druckablesung ist

das Ausgangssignal 4 ... 20 mA / Zweileiter. Die erforderliche Hilfsenergie bei

eingebauter LCD-Anzeige entnehmen Sie bitte den technischen Daten unter

Punkt 8.

1416 324.03

Einschränkung bei Nullpunkt- bzw. Spanneverstellung:

Bei eingebauter LCD-Anzeige ist zubeachten, dass die Nullpunkt- und Spanneverstellmöglichkeit nur zur Nachjustage auf den Messbereich genutzt werden

sollte.

Die Anzeige berücksichtigt keine vom Anwender mittels der Nullpunkt- und

Spanneverstellung vorgenommene Messbereichsveränderung.

22

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans

2279453 08/2009 GB/D/F

Page 23

8. Technische Daten

8. Technische Daten

Technische Daten DELTA-trans, Typ 891.34.2189

Differenzdruckmessbereich bar 0 ... 0,16 bis 0 ... 25

max. Betriebsdruck (stat.) bar 25

überdruckbelastbar ein-, beid-

u. wechselseitig max.

Druckanschlüsse

Messstoffkammer

Messglied Druckfeder CrNi-Stahl 1.4310 oder FD SiCr EN 10 270-2

Messglied Trennmembran FPM/FKM gewebeverstärkt (Option: NBR)

Übertragungsteile CrNi-Stahl 1.4305, FPM/FKM (Option: NBR)

Dichtungen FPM/FKM (Option: NBR)

Druckausgleichsventil (Option) CrNi-Stahl, Dichtung FPM/FKM

4-fach Ventilblock (Option) 1x Druckausgleichsventil, 2x Absperrventil, 1x Spül- und Entlüftungsven-

Hilfsenergie U

Einfluss der Hilfsenergie ≤ 0,1 % d. Spanne/10 V

zulässige Restwelligkeit % ss ≤ 10

Ausgangssignal und

zulässige max. Bürde R

Bürdeneinfluss % d. Spanne ≤ 0,1

Einstellzeit s ca. 1 (ca. 0,05 Option)

Einstellbarkeit

Kennlinienabweichung

(einschließlich Hysterese)

zulässige

Kompensierter Temp.-bereich °C -10 … +60 (bei Option LCD-Anzeige 0 … 50)

Temperaturkoeffizienten im

kom-pensierten Temperaturbereich

LCD Anzeige (Option)

Elektrischer Anschluss Kabeldose (Schraubklemmen bis 2,5 mm²)

Elektrische Schutzarten Verpolungs- und Überspannungsschutz

EMV (elektromagnetische

Verträglichkeit)

Schutzart IP54 (Option: IP65) nach EN 60 529 / IEC 529

Masse kg ca. 1,3

2279453 08/2009 GB/D/F

B

Nullpunkt, elektrisch % d. Spanne ± 15

Spanne, elektrisch % d. Spanne ± 30

Messstofftemperatur °C max. + 80

Umgebungstemperatur °C -10 … +60 (bei Option LCD-Anzeige 0 … 50)

mittlerer TK des Nullpunktes ≤ 0,4 % d. Spanne/10 K

mittlerer TK der Spanne ≤ 0,4 % d. Spanne/10 K

Spannungslast DC V 3,5

Anzeige 3½-stellig, 12,7 mm hoch

Betriebstemperatur °C 0 … 50

Lagertemperatur °C -10 … +80

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans 23

bar

messstoffberührt

DC V 10 < UB ≤ 30 (bei Option LCD-Anzeige 14 < UB ≤ 30)

A

% d. Spanne 2,5 (Grenzpunkteinstellung)

25

2 x G ¼ lnnengewinde, unten, hintereinander, Achsabstand 26 mm

(Option: andere Druckanschlüsse für Innen- und Außengewinde bzw.

Schneid- oder Klemmringverschraubungen für Rohrdurchmesser 6, 8

und 10 mm

GD-AlSi 12 (Cu) 3.2982, schwarz lackiert

(Option GD-AlSi 12 (Cu) HART-COAT-Oberflächenschutz oder CrNi-Stahl)

messstoffberührt

til Kupferlegierung oder CrNi-Stahl

4 … 20 mA, Zweileiter RA ≤ (UB - 10 V) / 0,02 A mit RA in Ohm und UB in Volt

0 … 20 mA, Dreileiter RA ≤ (UB - 10 V) / 0,02 A mit RA in Ohm und UB in Volt

Option: 1,6 (Grenzpunkteinstellung)

Störemission nach EN 50 081 - 1 (März 93) und EN 50 081 - 2 (März 94),

Störfestigkeit nach EN 50 082 - 2 (März 95)

D

Page 24

8. Technische Daten

Zulassung Germanischer Lloyd (Option)

D

Ergänzende/abweichende technische Daten

Messbereiche bar 0 ... 0,25 bis 0 ... 10

Ausgangssignal 4 ... 20 mA, Zweileiter oder 0 ... 20 mA, Dreileiter

zulässige

Umgebungstemperatur °C -10 … +70

EMV

(elektromagnetische

Verträglichkeit)

ESD kV ± 8 Kontaktentladung IEC 1000-4-2

elektromagnetische Felder V/m 10 80 % AM, 1 kHz, 0,01 ... 1000 MHz IEC 1000-4-3

Burst kV ± 2 Koppelzange IEC 1000-4-4

leitungsgebundene

HF- Störungen

Surge kV ± 0,5 symmetrisch IEC 1000-4-5

leitungsgebundene NFStörungen

Vibration Prüfung Fc

2 ... 25 Hz, +/- 1,6 mm % < 2,5 Fehler IEC 68-2-6

25 ... 100 Hz, 4 g % < 2,5 Fehler

Strombegrenzung I < 32 mA

Störemission nach EN 50 081-1 (März 93) und

Störfestigkeit nach EN 50 082-2 (März 95)

V 3 80 % AM, 1 kHz, 0,01 ... 100 MHz IEC 1000-4-6

kV ± 1 asymmetrisch, R i = 42 Ohm

kV ± 1 symmetrisch

kV ± 2 asymmetrisch, R i = 42 Ohm, nur mit

V

eff

Überspannungsbegrenzer z. B. MMDS/x-NFE(L), Firma Dehn & Söhne, oder

gleichwertig

3 0,05 ... 10 kHz IEC 945

EN 50 081-2 (März 94),

2279453 08/2009 GB/D/F

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans24

Page 25

9. Bedienung und Wartung

9. Bedienung und Wartung

Absperreinrichtungen dürfen zur Vermeidung von Druckstößen nur langsam

geöffnet werden.

Die Druckmessumformer sind wartungsfrei und zeichnen sich bei sachgemäßer

Behandlung und Bedienung durch eine hohe Lebensdauer aus. Durch mechanische Belastung je nach Einsatzbedingungen kann es notwendig werden, dass

der Nullpunkt und die Messspanne überprüft und nachjustiert werden müssen:

Nullpunktprüfung

Im Allgemeinen erfolgt die Überprüfung und Einstellung des Nullpunktes im

drucklosen Zustand. Bei Differenzdruck-Messumformern sollte die Überprüfung und Einstellung des Nullpunktes durch Öffnen des Druckausgleichsventiles unter statischer Last erfolgen.

Für die Nullpunktkorrektur des Druckmessumformers ist die Verschlussschraube (NP) auf der Gehäuseoberseite herauszudrehen und mit einem kleinen

Schraubendreher lässt sich daraufhin an einem Potentiometer der Nullpunkt

nachjustieren:

linksdrehen ⇒ Ausgangssignal wird kleiner

rechtsdrehen ⇒ Ausgangssignal wird größer

Spannenüberprüfung

Die Überprüfung und Justage der Messspanne ist aufwendiger und darf nur

erfolgen, wenn der Druckmessumformer bis zum Messbereichsendwert mit

Druck beaufschlagt ist. Hierzu ist ein ausreichend genaues Drucknormal als

Referenz erforderlich. Nur wenn eine Korrektur der Messspanne notwendig

ist, sollte die Verschlussschraube (SP) auf der Gehäuseoberseite gelöst

werden und mit einem kleinen Schraubendreher an dem Potentiometer die

Messspanne nachjustiert werden:

D

linksdrehen ⇒ Ausgangssignal wird kleiner

rechtsdrehen ⇒ Ausgangssignal wird größer

Anschließend muss auch die Nullpunktüberprüfung wiederholt werden und

gegebenenfalls auch der Nullpunkt nachgeregelt werden. Dieser Vorgang ist so

lange zu wiederholen, bis Nullpunkt und Spanne kalibriert sind.

2279453 08/2009 GB/D/F

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans 25

Page 26

9. Bedienung und Wartung / 10. Besonderheiten ...

Lage der Potentiometer am Elektronikgehäuse

SP Potentiometer für Spanne

NP Potentiometer für Nullpunkt

D

2158991.01

10. Besonderheiten bei integriertem Druckausgleichsventil oder

Vierfach-Ventilblock

10.1 Integriertes Druckausgleichsventil

Zur Nullpunktkontrolle während des

laufenden Prozesses.

Nullpunktabweichungen können mittels

Potentiometer für Nullpunkt (siehe Punkt

9. Bedienung und Wartung) korrigiert

werden.

Funktionsprinzip

Durch Betätigen des Druckknopfes wird die Trennung der Messstoffkammern aufgehoben. In beiden Kammern liegt nun der gleiche Druck an, d. h.

der Differenzdruck ist Null. Nach dem Loslassen des Druckausgleichsventils

werden die Messstoffkammern wieder getrennt und der aktuelle Differenzdruck wird wieder gemessen.

26

Ventil

betätigt

Differenzdruck

gleich Null

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans

Losgelassen

Differenzdruck

wird wieder gemessen

2279453 08/2009 GB/D/F

Page 27

10. Besonderheiten bei integriertem Druckausgleichsventil ...

10.2 Vierfach-Ventilblock

Funktionen

Absperrung der j- und i-Prozessleitung zur Demontage des Messge-

rätes bei laufenden Prozess

Druckausgleich zur Nullpunktkontrolle bei laufenden Prozess

Entlüftung der Messleitungen

10.2.1 Angaben zum Handling

Arbeitsgangfolge zum Messanfang

1. Druckausgleichsventil (mittlere Ventilspindel)

öffnen

2. Absperrventil der Minus-Messstoffkammer

(i, rechtes Ventil) öffnen

3. Absperrventil der Plus-Messstoffkammer

(j, linkes Ventil) öffnen

4. Druckausgleichsventil schließen

Arbeitsgangfolge zu Messende

(auch zeitweise Stilllegung)

1. Druckausgleichsventil öffnen

2. Absperrventil der Minus-Messstoffkammer

(i) schließen

3. Absperrventil der Plus-Messstoffkammer

(j) schließen

Absperrventil

j-Seite

Absperrventil

i-Seite

Druckausgleichsventil

Entlüftungsventil

D

Arbeitsgangfolge zur Demontage des Messgerätes bei laufenden Prozess

1. Druckausgleichsventil öffnen

2. Absperrventil der Minus-Messstoffkammer (i) schließen

3. Absperrventil der Plus-Messstoffkammer (j) schließen

4. Entlüftungsventil öffnen

2279453 08/2009 GB/D/F

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans 27

Page 28

11. Lagerung / 12. Maßnahmen bei Störungen

11. Lagerung

Für die Lagerung der Druckmessumformer bis zur Montage sind, um Schäden

zu vermeiden, folgende Punkte zu beachten:

D

Druckmessumformer in der Originalverpackung belassen.

Nach einer eventuellen Entnahme der Messgeräte (z. B. für Prüfungen) ist die

Originalverpackung wieder zu verwenden.

Lagertemperaturbereich -20 °C ... +60 °C

Messgeräte vor Feuchtigkeit und Staub schützen.

12. Maßnahmen bei Störungen

Störung mögliche Ursache Maßnahme

Kein Ausgangssignal keine Versorgungsspannung

gleichbleibendes Ausgangssignal bei Druckänderung

zu hohes, bei Druckänderung

gleichbleibendes Ausgangssignal

Signalspanne zu klein Versorgungsspannung zu

Nullpunktsignal zu klein Nullpunkt-Potentiometer

Nullpunktsignal zu groß Nullpunkt-Potentiometer

Signalkennlinie unlinear nach

Nullpunktkorrektur

oder Leitungsbruch

Messumformer falsch

angeschlossen

kein Eingansdruck Druckzuführung überprüfen

Elektronik defekt durch zu hohe

Versorgungsspannung oder

durch Fremdspannung

Eingangskanal verstopft Eingangskanal bzw. Drossel-

Elektronik defekt durch zu hohe

Versorgungsspannung oder

durch Fremdspannung

Messumformer defekt nach

mechanischer Überbelastung

Elektronik defekt durch zu hohe

Versorgungsspannung oder

durch Fremdspannung

niedrig

Bürde zu hoch max. zulässige Bürde beachten

Spannen-Potentiometer verstellt Messumformer neu justieren

verstellt

verstellt

mechanische Überlastung Messumformer zur Instandset-

mechanische Überlastung Messumformer zur Instandset-

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans28

Spannungsversorgung und

Leitungen überprüfen. ggf.

defekte Teile austauschen

Anschlüsse überprüfen;

Anschlüsse ggf. korrigieren

Messumformer zur Instandsetzung an Hersteller zurück

schraube reinigen

Messumformer zur Instandset-

zung an Hersteller zurück

Messumformer zur Instandsetzung an Hersteller zurück

Messumformer zur Instandsetzung an Hersteller zurück

Versorgungsspannung korrigieren

Messumformer neu justieren

Messumformer neu justieren

zung an Hersteller

zung an Hersteller

2279453 08/2009 GB/D/F

Page 29

13. Wartung und Reinigung ... 15. Entsorgung

13. Wartung und Reinigung

Die Geräte sind wartungsfrei und zeichnen sich bei sachgemäßer Behandlung

und Bedienung durch eine hohe Lebensdauer aus.

Eine Überprüfung der Anzeige und der Schaltfunktion sollte etwa 1 bis 2 mal

pro Jahr erfolgen. Dazu ist das Gerät vom Prozess zu trennen und mit einer

Druckprüfvorrichtung zu kontrollieren.

Reinigen der Geräte mit einem (in Seifenlauge) angefeuchteten Tuch.

Vor Wiedereinschalten des Stromes ist sicherzustellen, dass alle Teile

abgetrocknet sind.

Messstoffreste in ausgebauten Druckmessgeräten können zu Gefährdung von

Menschen, Umwelt und Einrichtungen führen. Ausreichende Vorsichtsmaßnahmen sind zu ergreifen.

14. Reparaturen

Reparaturen sind ausschließlich vom Hersteller oder entsprechend geschultem

Personal durchzuführen.

Weitere technische Daten bitte dem Datenblatt PV 17.18 entnehmen.

15. Entsorgung

D

Entsorgen Sie Gerätekomponenten und Verpackungsmaterialien entsprechend

den einschlägigen landesspezifischen Abfallbehandlungs- und Entsorgungsvorschriften des Anliefergebietes.

2279453 08/2009 GB/D/F

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans 29

Page 30

D

2279453 08/2009 GB/D/F

WIKA Betriebsanleitung Differenzdruck-Messumformer DELTA-trans30

Page 31

Sommaire

Sommaire

1. Consignes de sécurité 32

2. Principe de fonctionnement 32

3. Instructions de montage 33

4. Installation et mise en service 34

5 Installation sur le point de mesure 35

6. Branchement électrique 35

7. Exécution avec afficheur LCD (option) 36

8. Caractéristiques techniques 37

9. Exploitation et entretien 39

10. Particularités avec robinet d'équilibrage de pression ou

manifold 4 voies

11. Stockage 42

12. Mesures à prendre en cas de pannes 42

13. Entretien / Nettoyage 43

14. Réparations 43

15. Mise au rebus 43

40

F

Attention!

Ce symbôle vous prévient contre les actions qui peuvent

causer des blessures aux utilisateurs ou endommager les

instruments.

2279453 08/2009 GB/D/F

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans 31

Page 32

1. Consignes de sécurité / 2. Principe de fonctionnement

1. Consignes de sécurité

Les prescriptions de sécurité nationales en vigueur (par

exemple VDE 0100 / EN 60 079-14 / EN 837-2) doivent absolument être respectées lors du montage, de la mise en service et

de l‘utilisation des instruments ici présentés.

Toutes les interventions doivent être effectuées hors tension

F

Le non-respect des instructions correspondantes est susceptible d‘entraîner

des risques de blessure et/ou des dégâts matériels

Seul le personnel habilité et qualifié est autorisé à manipuler les instruments

2. Principe de fonctionnement

Le transmetteur de pression différentielle est essentiellement constitué d'un

système de mesure mécanique (1) avec élément de mesure élastique (2), un

capteur à effet Hall (3) associé à une carte de traitement du signal (4) et un

boîtier de raccordement électrique.

Un aimant (5) couplé à l'élément de

mesure influe sur le champ électromagnétique du capteur à effect Hall.

Le signal en résultant est amplifié par

la carte de traitement de signal pour

devenir signal de sortie normalisé.

2155079.01

Pour le réétalonnage, le zéro et l'étendue de mesure peuvent être réglés au

moyen de potentiomètres facilement

accessibles (6).

Identification des raccords:

j pression et i pression

32

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans

2279453 08/2009 GB/D/F

Page 33

3. Instructions de montage

3. Instructions de montage

Disposition

Le transmetteur de pression doit être fixé exempt de vibrations mécaniques

et sa position doit permettre une lecture facile. Il est utile de monter entre le

transmetteur de pression et la prise de pression un robinet d'isolement, ce

qui permet, en cas de nécessité et avec l'installation en service, de remplacer le transmetteur de pression ou d'en contrôler le zéro.

Prise de contrôle

Dans certains cas d'application (par exemple dans le cas de chaudières de

vapeur) les organes de fermeture doivent être pourvus d'une prise de contrôle afin de pouvoir contrôler le transmetteur de pression sans démontage.

Fixation des instruments de mesure

Si la tuyauterie recevant le transmetteur de pression n'est pas assez stable

pour garantir une pose sans vibration, la fixation de l'appareil doit être effectuée au moyen des pattes de fixation murale.

Amortissement du système de mesure

S'il est impossible, au moyen d'installations appropriées, d'éviter les vibrations, il faut alors utiliser des appareils à amortissement par remplissage de

liquide.

F

Contraintes thermiques

La position du transmetteur de pression est à choisir en fonction de la

température de service qui ne doit pas être dépassée, en tenant compte

également de l'influence de la conduction et du rayonnement thermique.

Pour ce faire on utilisera des tuyaux-raccord suffisamment longs ou des

syphons placés avant le robinet et le transmetteur de pression. Prendre en

considération l'influence de la température sur la précision de la mesure.

Protection des organes moteur contre les surcharges

Si le milieu de mesure est soumis à des fluctuations rapides de pression ou

s'il faut s'attendre à des coups de bélier, il faut veiller à ce que ces phénomènes n‘exercent aucun impact sur l‘organe moteur de l’appareil. Les effets

des coups de bélier doivent être amortis, par exemple par la mise en place

d‘une vis frein (diminution de la section du canal sous pression) ou par l‘installation en amont de l‘appareil d‘un dispositif d‘amortissement réglable.

2279453 08/2009 GB/D/F

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans 33

Page 34

3. Instructions de montage / 4. Installation et mise en service

Raccord de la prise de pression

Le raccord de la prise de pression doit être pourvu d'un orifice suffisam-

ment grand ( 6 mm), si possible posséder un robinet d'isolement et être

installé de façon à ce que le débit du fluide ne perturbe pas la mesure. La

tuyauterie entre le raccord de mesure et le transmetteur de pression doit

avoir un diamètre suffisant afin d'en éviter son bouchage ou de provoquer

des retards dans la transmission de la pression. On évitera également des

courbures trop importantes. Il est recommandé d'installer la tuyauterie avec

F

un rapport d'inclinaison de 1:15.

Tuyauterie

La tuyauterie est à concevoir et à installer de telle façon qu'elle supporte les

contraintes dues á des dilatations, vibrations et influences thermiques. Pour

la mesure de gaz, il faut prévoir une purge de condensat au point le plus bas

de l'installation, et pour la mesure de liquides il faut une purge d'air au point

le plus èlevé.

4. Installation et mise en service

Pour l'étanchéité des raccords, il faut utiliser des joints plats, des lentilles

d'étanchéité ou des joints profilés WIKA.

En cas d'installation du transmetteur de pression au-dessous du point de

mesure, il faut nettoyer soigneusement la tuyauterie afin d'éviter que des particules pénètrent à l'intérieur de l'appareil.

Après réalisation du raccord de pression et des branchements électriques, les

transmetteurs sont prêts à fonctionner.

La pression sur le transmetteur de pression doit être à zéro avant de le démonter. Si nécessaire vider la tuyauterie.

Les résidus de fluide se trouvant à l'intérieur des transmetteurs de pression

démontés peuvent présenter des dangers pour les personnes, l'environnement

et les installations. Il faut prendre toutes les précautions nécessaires pour en

assurer la sécurité.

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans34

2279453 08/2009 GB/D/F

Page 35

5. Installation sur le point de mesure / 6. Branchement électrique

5. Installation sur le point de mesure

Dispositions éprouvées pour les différents types de matériaux.

Les différentes dispositions recommandées pour application sont représentées

ci-après.

fluides liquides fluides gazeux

Remplissage

de la conduite

de mesure

Exemples

Manomètre

au-dessus

du point de

mesure

Manomètre

au-dessous

du point de

mesure

liquides en partie

condensat liquides en

gazeux

ébullition

complètement

évaporés

„gaz liquides“ air sec air humide,

fluide

gazeux

en partie

condensés

(humides)

gaz de

combustion

entièrement

condensé

vapeur d‘eau

6. Branchement électrique

F

Le raccordement électrique des transmetteurs de pression s'effectue à l'aide

d‘un boîtier de raccordement et d’un câble. La disposition exacte des connections est donnée sur les dessins présentés ci-après. En outre, la disposition

des connections, le signal de sortie et l'alimentation auxiliaire nécessaires sont

notés sur la plaque de signalisation de l'appareil.

Signification des différents symboles de borne utilisés:

UB+ Borne positive de la tension d'alimentation

0 V Borne négative de la tension d'alimentation

S+ Borne positive du signal de sortie

S- Borne négative du signal de sortie

Test Bornes de contrôle

Les appareils doivent être intégrés dans la compensation de potentiel du

site.

2279453 08/2009 GB/D/F

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans 35

Page 36

6. Branchement électrique / 7. Exécution avec afficheur LCD (option)

Détail des connections

Les bornes 1 et 5 sont shuntées à l'intérieur du boîtier de raccordement pour

fournir 2 bornes pour la connexion 0 V / S.

4 … 20 mA 2-fils 0 … 20 mA 3-fils

F

0 V / S-

UB+ / S+

Test -

Test +

mA

Appareil récepteur

(ex: indicateur)

Alimentation

Boîtier de

raccord

0 V / S-

UB+

Test +

S+ / Test-

mA

Appareil

récepteur

(ex: indicateur)

Alimentation

En tant qu'alimentation auxiliaire, une tension continue non-stabilisée dans

les limites indiquées est suffisante. Il est indispensable de veiller à ce que la

tension d'alimentation appliquée présente une valeur supérieure à la tension

maximale requise au droit des appareils d'affichage et d'évaluation externes,

c'est-à-dire que la tension appliquée au droit du transmetteur de pression

ne doit pas être inférieure à 10 V; dans le cas des modèles avec afficheur à

cristaux liquides (LCD), elle ne doit pas être inférieure à 14 V.

7. Exécution avec afficheur LCD (option)

Avec l’afficheur LCD intégré pour indication locale de la pression, le signal de

sortie est de 4 … 20 mA / deux fils. L‘énergie auxiliaire nécessaire à l’afficheur

LCD intégré est indiquée au tableau des caractéristiques techniques, point 8.

Boîtier de

raccord

1416 324.03

Conditions limitatives pour le réglage du point zéro et de l'écart:

Si l‘appareil est équipé d‘un afficheur LCD intégré, il faut tenir compte du fait

que la possibilité de réglage du point zéro et de l‘écart ne doit être utilisée que

pour l‘ajustement sur l‘étendue de mesure. L‘affichage ignore toute modification de l‘étendue de mesure que l‘utilisateur effectuerait par réglage du point

zéro et de l‘écart.

36

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans

2279453 08/2009 GB/D/F

Page 37

8. Caractéristiques techniques

8. Caractéristiques techniques

Caractéristiques techniques DELTA-trans, Type 891.34.2189

Etendue de mesure bar 0 ... 0,16 à 0 ... 25

Pression de service maxi

(pression statique)

Surcharge admissible bar 25 (de chaque côte)

Raccords en contact

Chambre de mesure

Ressort acier inox 1.4310 (304H) ou FD SiCr EN 10 270-2

Membrane FPM/FKM renforcé par textile (option: NBR)

Pièces de liaison acier inox 1.4305 (303), FPM/FKM (option: NBR)

Joints d'étanchéité FPM/FKM (option: NBR)

Robinet d'équil. de pression acier inox ou FPM/FKM

Manifold 4 voies en option: 1 x rob. équil. pres., 2 x rob. mano., 1 x purge/mise à l'air

Alimentation U

Influence d'alimentation ≤ 0,1

Ondulation résiduelle admis. % ss ≤ 10

Signal de sortie et résis- 4 … 20 mA, 2 fils RA ≤ (UB - 10 V) / 0,02 A avec RA en Ohm et UB en Volt

tance de charge R

Déviation due à la charge % d'échelle ≤ 0,1

Temps du réponse s environ 1 (option: environ 0,05)

Réglage du signal de sortie:

Précision % d'échelle 2,5 (méthode des points extrêmes)

(incluant l'hystérésis) option: 1,6 (méthode des points extrêmes)

Températures autorisées:

Coefficient de température sur

plage compensée:

≤ 0,4

≤ 0,4

Afficheur LCD (option)

Câblage Boîtier presse-étoupe (section des vis jusqu'à 2,5 mm²)

Protection électrique Protégé contre l'inversion de polarité et la surtension

CEM Emission de perturbation selon EN 50 081-1 (Mars 93) et EN 50 081-2

Degré de protection IP 54 (IP 65 en option) (selon EN 60529 / IEC 529)

Poids kg env. 1,3 kgs

B

A

point zéro % d'échelle ± 15

gain % d'échelle ± 30

fluide °C +80 maximum

ambiante °C -10 … +60 (option afficheur LCD 0 ... 50)

plage de tem. Compensée °C -10 … +60 (option afficheur LCD 0 ... 50)

TK coef. de temp. moy. du

pt. zéro

TK coef. de temp. moy. du

gain

chute de tension DC V 3,5

afficheur 3½ digits, hauteur 12,7 mm

température ambiante °C 0 … 50

température de stockage °C -10 … +80

2279453 08/2009 GB/D/F

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans 37

bar 25

avec le

fluide

DC V 10 < UB ≤ 30 (option afficheur LCD 14 < UB ≤ 30)

2 x G ¼ femelle, en bas, espacement axial 26 mm

(en option: autres raccords filetées mâle ou femelle, raccords pour

tuyaux souples ou rigides Ø 6, 8 ou 10 mm)

alliage d'aluminium peint en noir (en option: alliage d'aluminium avec

revêtement HART-COAT, inox)

en contact avec le fluide

% d'échelle/10 V

0 … 20 mA, 3 fils RA ≤ (UB - 10 V) / 0,02 A avec RA en Ohm et UB en Volt

% d'échelle/10 V

% d'échelle/10 V

(Mars 94), Immunité aux perturbations EN 50 082-2 (Mars 95)

F

Page 38

8. Données techniques

Homologation GL (option)

Données techniques supplémentaires/differentes

Etendue de mesure bar 0 ... 0,25 à 0 ... 10

F

Signal de sortie 4 ... 20 mA, 2 fils ou 0 ... 20 mA, 3 fils

Températures autorisées

ambiante

CEM

Déchargé electro-statique kV ± 8 Décharge aux contacts IEC 1000-4-2

Champ électromagnétique V/m 10 80 % AM, 1 kHz, 0,01 ... 1000 MHz IEC 1000-4-3

Transitoires rapides kV ± 2 Couplage direct IEC 1000-4-4

HF V 3 80 % AM, 1 kHz, 0,01 ... 100 MHz IEC 1000-4-6

Onde hybride kV ± 0,5 symétrique IEC 1000-4-5

leitungsgebundene NFStörungen

Vibration test Fc

2 ... 25 Hz, +/- 1,6 mm % < 2,5 Erreur IEC 68-2-6

25 ... 100 Hz, 4 g % < 2,5 Erreur

Limitation du courant I < 32 mA

°C -10 … +70

Emission de perturbation selon

Immunité aux

perturbations

kV ± 1 asymétrique, R i = 42 Ohm

kV ± 1 symétrique

kV ± 2 asymétrique, R i = 42 Ohm,

V

eff

seulement avec limitateur de tension

par exemple MM-DS/x-NFE(L),

Dehn & Söhne ou identique

3 0,05 ... 10 kHz IEC 945

EN 50 081-1 (Mars 93) et

EN 50 081-2 (Mars 94),

EN 50 082-2 (Mars 95)

38

2279453 08/2009 GB/D/F

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans

Page 39

9. Exploitation et entretien

9. Exploitation et entretien Homologation GL (option)

Les dispositifs d'ouverture/fermeture ne doivent être ouverts que lentement

pour éviter les coups de bélier.

Les transmetteurs de pression ne nécessitent aucun entretien et sont caractérisés par une grande longévité, sous réserve d'une manipulation et exploitation

correctes.

Contrôle du point zéro

En règle générale, le contrôle et le réglage du point zéro s'effectuent l'appareil hors pression. Dans le cas des transmetteurs de pression différentielle, le

contrôle et le réglage du point zéro doivent s'effectuer en ouvrant la soupape

de compensation de pression sous charge statique.

Pour la correction du point zéro du transmetteur, il faut dévisser la vis de fermeture (NP) qui se trouve sur le dessus du boîtier. Ensuite, le point zéro peut être

réajusté sur un potentiomètre, au moyen d'un petit tournevis:

En tournant vers la gauche ⇒ Signal de sortie diminue

En tournant vers la droite ⇒ Signal de sortie augmente

Contrôle de la plage de mesure

Le contrôle et l'ajustage de la plage de mesure est une opération complexe

qui ne doit être effectuée que si le transmetteur de pression est soumis à

une pression atteignant la valeur maximale de l'étendue de mesure. Dans ce

contexte, une normale de pression suffisamment exacte est nécessaire en

tant que référence.

Dans le cas où une correction de la plage de mesure s'avère nécessaire, il

faut dévisser la vis de fermeture (SP) qui se trouve sur la partie supérieure

du boîtier et réajuster la plage de mesure sur le potentiomètre avec un petit

tournevis:

F

En tournant vers la gauche ⇒ Signal de sortie diminue

En tournant vers la droite ⇒ Signal de sortie augmente

Enuite, il faut également réitérer le contrôle du point zéro et, le cas échéant, le

réajuster. Cette opération est à répéter jusqu'à ce que le point zéro et l'étendue

de mesure soient réétalonnés.

2279453 08/2009 GB/D/F

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans 39

Page 40

9. Exploitation et entretien / 10. Particularités ...

Position du potentiomètre sur le boîtier électronique

SP Potentiomètre pour gain

NP Potentiomètre pour point zéro

F

2158991.01

10. Particularités avec robinet d'équilibrage de pression ou manifold 4 voies

10.1 Robinet d'équilibrage de pression intégré

Pour le contrôle du point zéro en

fonctionnement. Les écarts du point

zéro peuvent être corrigés au moyen du

potentiomètre pour point zéro (voir point

8: Exploitation et entretien)

Principe de fonctionnement

En appuyant sur le bouton-poussoir,

on ouvre la séparation entre les

chambres du système de mesure. Il y a alors égalisation de la pression

dans chacune des deux chambres, c'est-à-dire que la pression différentielle

est alors égale à zéro. En relâchant la soupape d'équilibre de pression, on

rétablit la séparation entre les chambres et la pression différentielle peut

alors être à nouveau mesurée.

40

Activation de

la soupape

Pression

différentielle = zéro

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans

Relâchement

de la soupape

La pression différentielle est à nouveau

mesurée

2279453 08/2009 GB/D/F

Page 41

10. Particularités avec robinet d'équilibrage de pression ...

10.2 Manifold 4 voies

Fonctions

Isolement de la conduite du circuit pour démontage de l'appareil de

mesure en cours de fonctionnement

Egalisation de la pression pour contrôle du point zéro en cours de fonction-

nement

Purge de l'air des conduites de mesure

10.2.1 Informations pour la manipulation de l'appareil

Séquence des opérations avant démarrage

des mesures

1. Ouvrir robinet d'équilibrage de pression

(tige de soupape médiane)

2. Ouvrir robinet à pointeau de la chambre

moins du système de mesure (soupape

Robinet à

pointeau

(côté j)

droite, côté moins i)

3. Ouvrir robinet à pointeau de la chambre

plus du système de mesure (soupape

gauche, côté plus j)

4. Fermer robinet d'équilibre de pression

Séquence des opérations avant la fin des

Robinet à pointeau (côté i)

mesures (également en cas de mise hors

service temporaire)

1. Ouvrir robinet d'équilibrage de pression

2. Fermer robinet à pointeau de la chambre moins du système de mesure (i)

3. Fermer robinet à pointeau de la chambre plus du système de mesure (j)

Robinet d'équilibrage de pression

soupape de

vidange d'air

F

Séquence des opérations avant démontage de l'appareil de mesure en

cours de fonctionnement

1. Ouvrir robinet d'équilibrage de pression

2. Fermer robinet à pointeau de la chambre moins du système de mesure (i)

3. Fermer robinet à pointeau de la chambre plus du système de mesure (j)

4. Ouvrir la soupape de purge d'air

2279453 08/2009 GB/D/F

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans 41

Page 42

11. Stockage / 12. Mesures à prendre en cas de pannes

11. Stockage

Pour stocker les transmetteurs de pression en attendant leur montage, il est

nécessaire - afin d'éviter des dégats - de respecter les points suivants:

Laisser les transmetteurs de pression dans leur emballage d'origine.

Après avoir prélevé un transmetteur de pression (par exemple pour un

contrôle) le réemballer dans son emballage d'origine.

F

Température de stockage -20 °C ... +60 °C

Protéger les appareils de l'humidité et de la poussière.

12. Mesures à prendre en cas de pannes

Panne Cause possible Mesure à prendre

Aucun signal de sortie Aucune tension d'alimentation Rupture

Signal de sortie constant

sous modification de

pression

Signal de sortie trop élevé

et constant sous modification de pression

Plage de signalisation trop

faible

Point zéro trop faible Déréglage du potentiomètre du point

Point zéro trop élevé Déréglage du potentiomètre du point

Courbe caractéristique de

signalisation non-linéaire

après correction du point

zéro

42

de cable

Transmetteur mal branché Contrôler les branchements; le cas

Aucune pression d'entrée Contrôler l'arrivée de pression

Electronique défectueuse, conséquence

d'une tension d'alimentation trop élevée ou

d'une tention d'origine étrangère

Canal d'entrée bouché Nettoyer le canal d'entrée et/ou la vis

Electronique défectueuse, conséquence

d'une tension d'alimentation trop élevée ou

d'une tention d'origine étrangère

Transmetteur défectueux à la suite d'une

surcharge mécanique

Electronique défectueuse, conséquence

d'une tension d'alimentation trop élevée ou

d'une tention d'origine étrangère

Tension d'alimentation trop faible Corriger la tension d'alimentation

Charge ohmique trop élevée Respecter la charge ohmique max. admise

Déréglage du potent. de la plage de

mesure

neutre

neutre

Surcharge mécanique Envoyer le transmetteur au fabricant pour

Surcharge mécanique Envoyer le transmetteur au fabricant pour

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans

Contrôler l'alimentat. en courant et les

cables; le cas échéant changer les pièces

défectueuses

échéant, corriger les branchements

Envoyer le transmetteur au fabricant pour

réparation

d'étranglement

Envoyer le transmetteur au fabricant pour

réparation

Envoyer le transmetteur au fabricant pour

réparation

Envoyer le transmetteur au fabricant pour

réparation

Réajuster le transmetteur

Réajuster le transmetteur

Réajuster le transmetteur

réparation

réparation

2279453 08/2009 GB/D/F

Page 43

13. Entretien / Nettoyage ... 15. Mise au rebus

13. Entretien / Nettoyage

S‘ils sont manipulés et utilisés correctement, les instruments ne requièrent

aucune maintenance et se distinguent par une longue durée de vie.

Un contrôle de l‘affichage et des fonctions de commande est recommandé 1

à 2 fois/an. Pour le contrôle de l‘afficheur et des fonctions de commande, il

faut isoler l‘appareil du process de mesure et le contrôler avec un dispositif de

contrôle de pression.

L‘appareil se nettoie à l‘aide d‘un chiffon humidifié (avec du savon).

Avant de rebrancher l‘instrument, s‘assurer que toutes les pièces soient

complètement sèches.

Des restes de fluide se trouvant dans les manomètres démontés peuvent provoquer une mise en danger de personnes, de l‘environnement et de

l‘équipement. Des précautions adéquates sont à prendre.

14. Réparations

Toute réparation doit être exclusivement confiée au fabricant à du personnel

qualifié correspondant.

Pour autres données, se reporter à la fiche technique de l‘instrument PV 17.18)

F

15. Mise au rebus

Mettez les composants des appareils et les emballages au rebus en respectant

les prescriptions nationales pour le traitement et la mise au rebus des régions

ou pays de livraison.

2279453 08/2009 GB/D/F

WIKA Mode d‘emploi Transmetteur de pression différentielle DELTA-trans 43

Page 44

Technical alteration rights reserved.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. (+49) 9372/132-0

Fax (+49) 9372/132-406

E-Mail info@wika.de

www.wika.de

44

2279453.02 08/2009 GB/D/F

Loading...

Loading...