Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

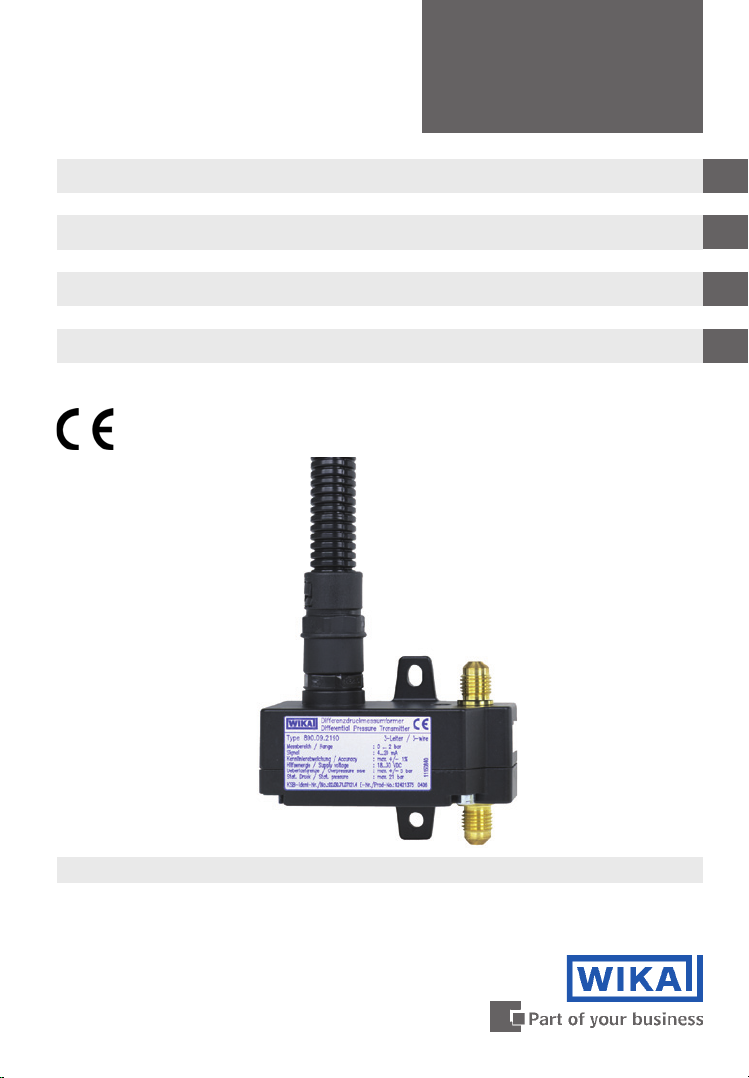

Dierential pressure transmitter model 890.09.2190

Dierenzdruck-Messumformer Typ 890.09.2190

Transmetteur de pression diérentielle type 890.09.2190

Transmisor de presión diferencial modelo 890.09.2190

GB

D

F

E

Model 890.09.2190

Page 2

GB

Operating instructions model 890.09.2190 Page 3-11

D

Betriebsanleitung Typ 890.09.2190 Seite 13-21

F

Mode d‘emploi type 890.09.2190 Page 23-31

E

anual de instrucciones modelo

M

© WIKA Alexander Wiegand SE & Co. KG 2010

Prior to starting any work, read the operating instructions!

Keep for later use!

890.09.2190 Página 33-41

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

11171545.02 08/2010 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 7

4. Design and function 8

5. Transport, packaging and storage 9

6. Commissioning, operation 9

7. Maintenance 11

8. Dismounting, return and disposal 11

GB

11171545.02 08/2010 GB/D/F/E

WIKA operating instructions dierential pressure transmitter model 890.09.2190 3

Page 4

1. General information

1. General information

The transmitter described in the operating instructions has been designed and

GB

manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria

during production. Our management systems are certied to ISO 9001 and ISO

14001.

These operating instructions contain important information on handling the

transmitter. Working safely requires that all safety instructions and work instructions are observed.

Observe the relevant local accident prevention regulations and general safety

regulations for the transmitter's range of use.

The operating instructions are part of the instrument and must be kept in the

immediate vicinity of the transmitter and readily accessible to skilled personnel

at any time.

Skilled personnel must have carefully read and understood the operating

instructions, prior to beginning any work.

The manufacturer's liability is void in the case of any damage caused by using

the product contrary to its intended use, non-compliance with these operating

instructions, assignment of insuciently qualied skilled personnel or unauthorised modications to the transmitter.

The general terms and conditions, contained in the sales documentation, shall

apply.

Subject to technical modications.

Further information:

- Internet address:: www.wika.de / www.wika.com

- Relevant data sheet: PE 81.78

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in

serious injury or death, if not avoided.

Information

… points out useful tips, recommendations and information for

ecient and trouble-free operation.

4

WIKA operating instructions dierential pressure transmitter model 890.09.2190

11171545.02 08/2010 GB/D/F/E

Page 5

2. Safety

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the

appropriate transmitter has been selected in terms of measuring

range, design and specic measuring conditions.

The compatibility with the medium of the materials subjected to

pressure must be checked!

In order to guarantee the measuring accuracy and long-term

stability specied, the corresponding load limits must be

observed.

Only work on the transmitter with the voltage disconnected.

Non-observance can result in serious injury and/or damage to

equipment.

Further important safety instructions can be found in the individual chapters of these operating instructions.

2.1 Intended use

The model 890.09.2190 transmitter is used for dierential pressure measurement,

e.g. between ow and return in heating systems, lter plants, in technical building

equipment, drinking and service water treatment, pump monitoring and control in

pressure boosting and re extinguishing systems.

GB

The transmitter has been designed and built solely for the intended use described

here and may only be used accordingly.

The manufacturer shall not be liable for claims of any type based on operation

contrary to the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage

to equipment.

The activities described in these operating instructions

may only be carried out by skilled personnel who have the

qualications described below.

11171545.02 08/2010 GB/D/F/E

WIKA operating instructions dierential pressure transmitter model 890.09.2190 5

Page 6

2. Safety

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical

training, knowledge of measurement and control technology and on their experience and knowledge of country-specic regulations, current standards and direc-

GB

tives, are capable of carrying out the work described and independently recognising potential hazards.

2.3 Special hazards

WARNING!

Residual media in dismounted pressure gauges may result in a

risk to people, the environment and the system. Take sucient

precautionary measures.

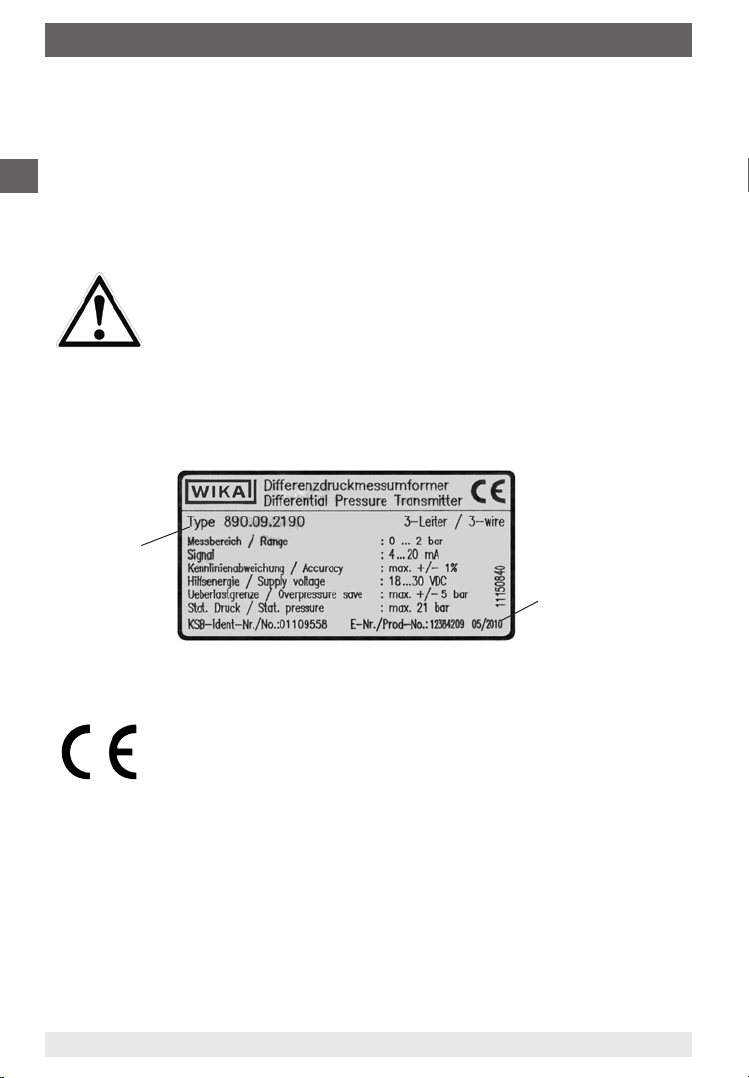

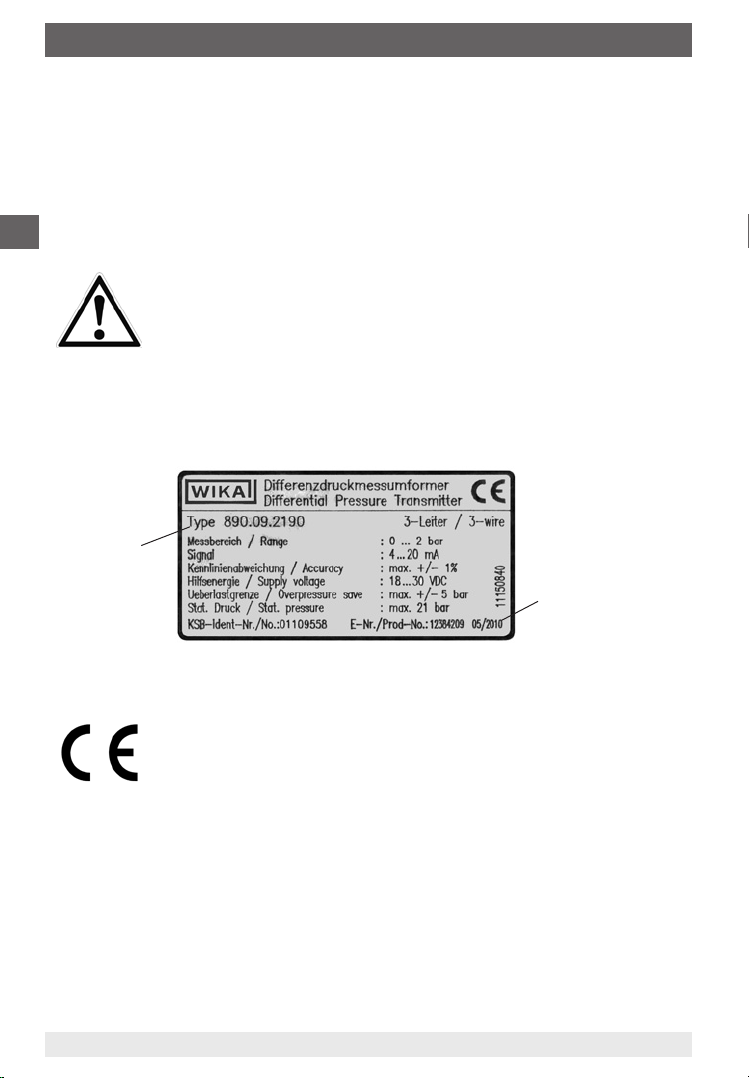

2.4 Labelling / safety marks

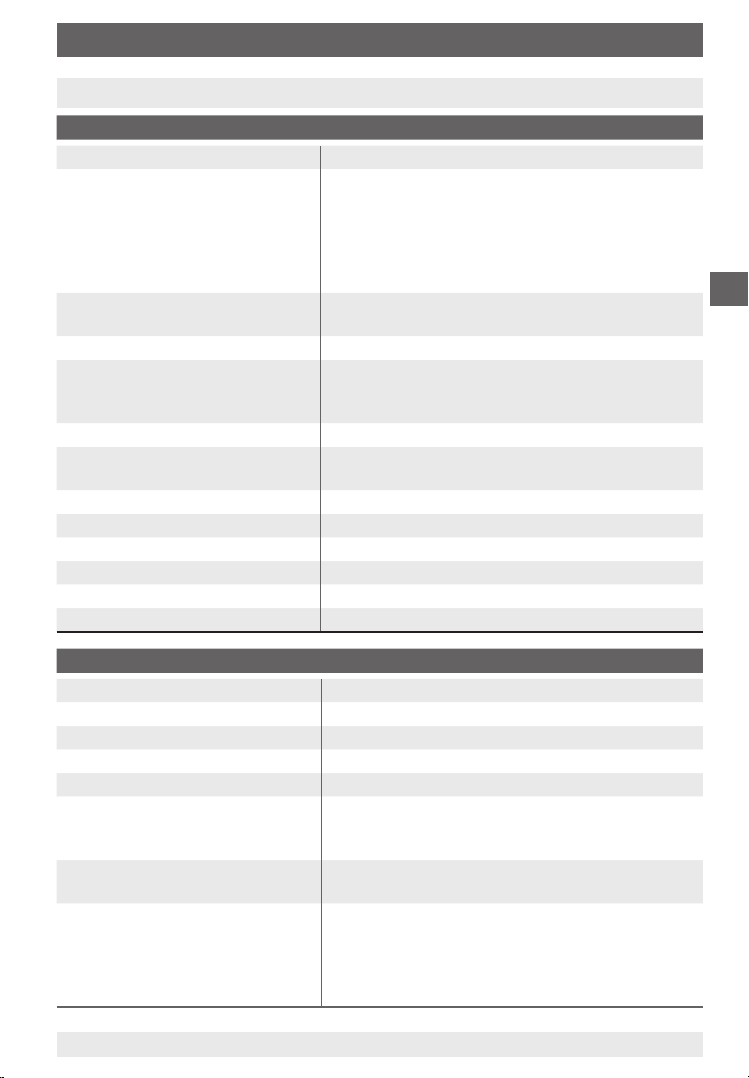

Product label

Model

Year of manufacture

Explanation of symbols

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European

directives.

6

WIKA operating instructions dierential pressure transmitter model 890.09.2190

11171545.02 08/2010 GB/D/F/E

Page 7

3. Specications

3. Specications

General

Process connection 2 x 7/16 UNF male thread

Materials

Pressure connections

Sealings

Media chamber

Sensor element

Dierential pressure measuring

ranges

Max. working pressure (stat.) 21 bar

Overpressure safe either side

max.

Measurement time constant T

Accuracy (error band) ± 2 % of span (linearity, hysteresis, temperature

Linearity, hysteresis ± 1 % of span

Temperature coecient 0.2 % of span / 10 K

Zero oset ± 0.1 mA

Permissible ambient temperature -10 °C ... 50 °C

Permissible medium temperature -10 °C … 80 °C

Ingress protection IP 55 per EN 60529 / IEC 529

Cu alloy - wetted

FPM/FKM - wetted

Zinc diecast - wetted

Ceramic Al

2O3 - wetted

0 ... 1 bar, 0 ... 2 bar, 0 ... 4 bar, 0 ... 6 bar or

0 ... 10 bar

2.5 x end value of measuring range, max. 21 bar

Pressure spikes are to be reduced through

constructive measures (e.g. capillaries)

mess = 10 ms (sensor + electronics)

error 10 ... 70 °C)

GB

Electrical data

Nominal voltage DC 24 V

Permissible supply voltage DC 18 … 30 V

Electrical connection 3-wire

Output signal 4 ... 20 mA

Max. load 500 Ohm

Current supply

at output max.

at current limitation

approx. 32 mA normal (typical)

approx. 36 mA (at overpressure)

Wiring protection Short-circuit-proof, after eliminating the fault the

operability is recovered

Electrical connection

3-wire numbered cable

Connection with snap-in M8

connector (3-pin)

11171545.02 08/2010 GB/D/F/E

WIKA operating instructions dierential pressure transmitter model 890.09.2190 7

0.34 mm², 0.8 m to 2.5 m long

replaceable at the instrument, outer cable end

with single wires for clamping

Page 8

3. Specications / 4. Design and function

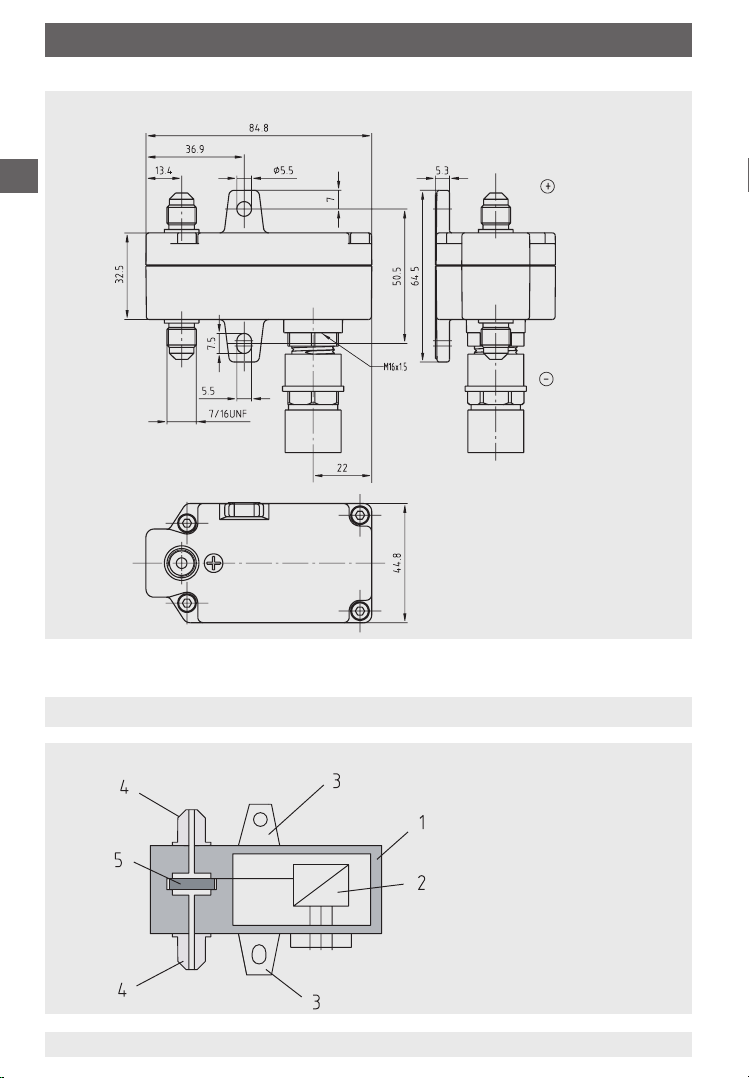

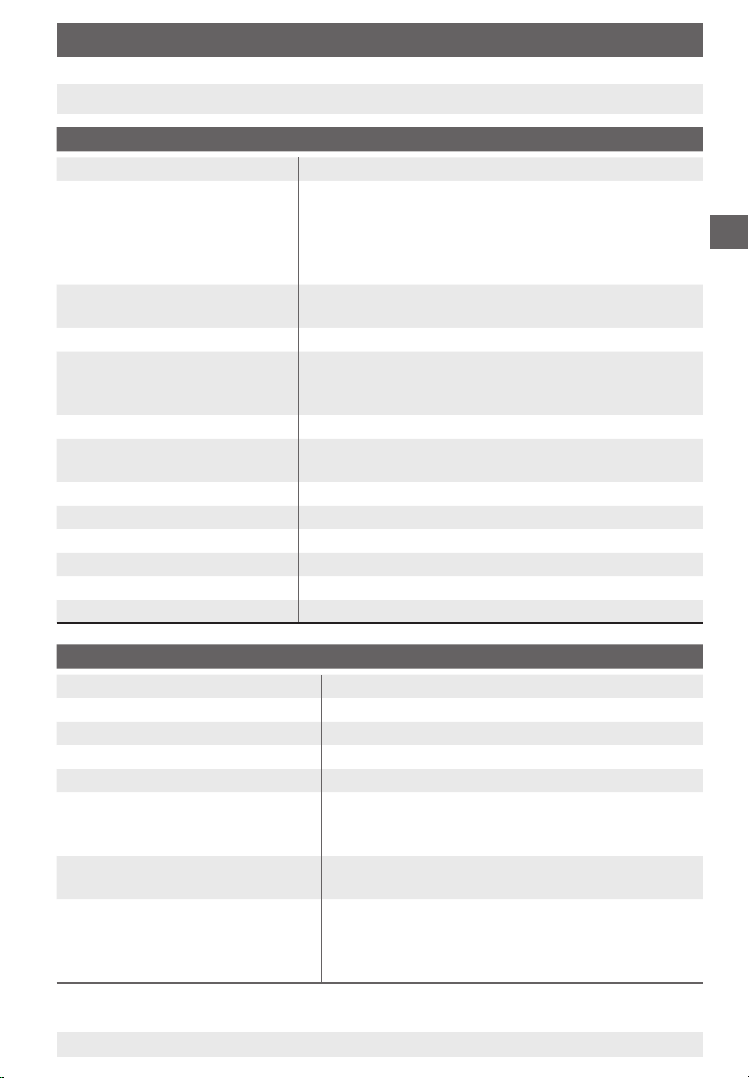

Dimensions in mm

GB

2150258.03PD890-09-2190a

For further specications, see WIKA data sheet PE 81.78 and the order documentation.

4. Design and function

Illustration of the principle

1 Case

2 Electronics

3 Mounting lug

4 Pressure connection

5 Sensor

8

WIKA operating instructions dierential pressure transmitter model 890.09.2190

11171545.02 08/2010 GB/D/F/E

Page 9

4. Design and function ... 6. Commissioning, operation

Design and operating principle

The dierential pressure transmitter has a ceramic dierential pressure sensor

with thick lm technology, which works according to the principle of a Wheatstone bridge. The dierential pressure deects the ceramic diaphragm, thereby

changing the strain gauge signal, which is amplied to a standard current output

signal by the integrated electronics. The sensor is mounted between the two case

halves and sealed by O-rings. The sensor signal is transmitted, free of interfe-

rence, to the printed circuit board via ex cables. The transmitter is electrically

connected by means of a 3-wire cable which is led to the room for service

connections through a protective tube. The instrument has 2 lugs for mounting.

The dierential pressure transmitter is both factory calibrated and temperature

compensated.

Scope of delivery

Cross-check scope of delivery with delivery note.

5. Transport, packaging and storage

5.1 Transport

Check transmitter for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g.

change in installation site, sending for repair).

GB

5.3 Storage

Permissible conditions at the place of storage:

Storage temperature: -20 ... +50 °C

6. Commissioning, operation

Mechanical connection

The transmitter is designed for mounting on at mounting plates. For screwing it to

the mounting plate, the instrument has a mounting bore

Ø 5.5 mm and an elongated hole with a width of 5.5 mm.

The IP 55 ingress protection (front panel) is only guaranteed when the supplied

cable gland, with internal sealing element, and corrugated hose are used. To

ensure this, the M8 connection cable is pre-assembled with the associated corrugated hose / cable gland combination, and then mounted into the built-in M8

11171545.02 08/2010 GB/D/F/E

WIKA operating instructions dierential pressure transmitter model 890.09.2190 9

Page 10

6. Commissioning, operation

connector on the instrument.

By applying slight pressure the cable snaps into the connector. Screw the cable

gland to the case. Then the internal sealing of the cable gland is press-tted to the

cable.

GB

When mounting the instrument, ensure that the air lter will not become clogged

by dust or liquid.

Opening the case is not allowed, as this will lead to permanent instrument

damage.

Process connection

When connecting the instrument, the lines must be free of pressure.

The instrument must be protected from pressure spikes by taking appropriate

measures

Only for operation with suitable media

Observe maximum pressure

Observe the permissible overpressure

The pressure connections are marked with ⊕ and ⊖ symbols on the instrument.

For dierential pressure measurements, the higher pressure should be connected

to the ⊕ side and the lower pressure to the ⊖ side of the instrument.

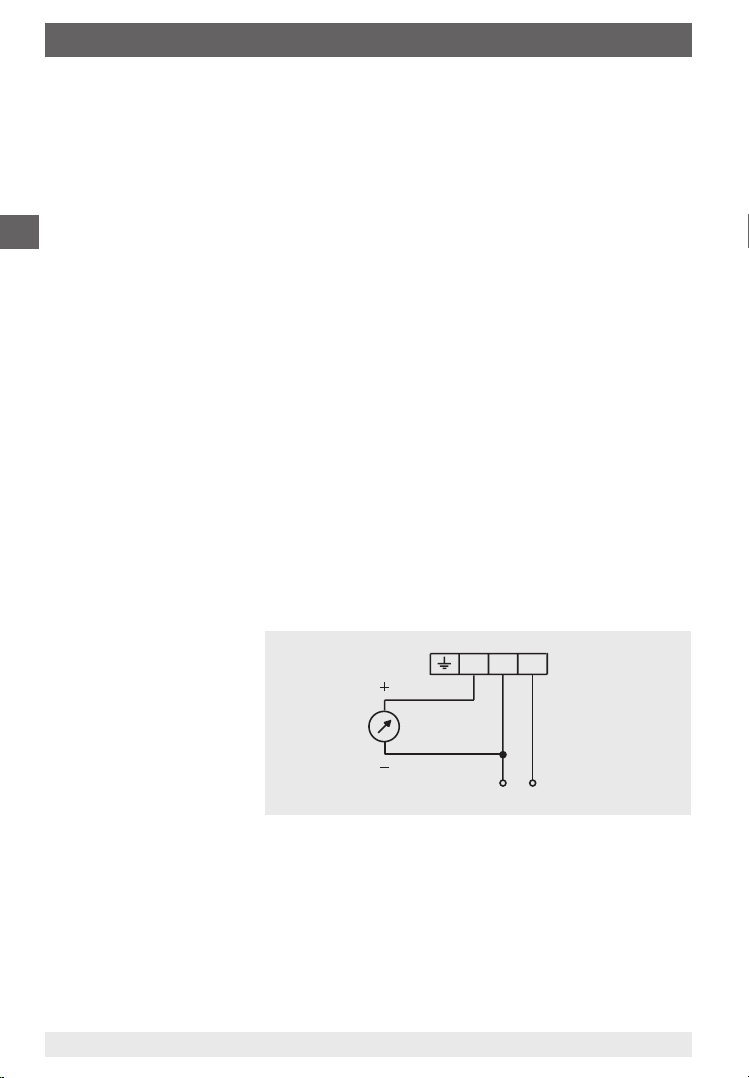

Electrical connection

The electrical connection of the instrument must be carried out in accordance

with both the applicable codes and standards (VDE regulations) and the local

power supply company's regulations

Before connecting the instrument the plant must be electrically isolated

Safety fuses should be series-connected and sized appropriately for the power

rating

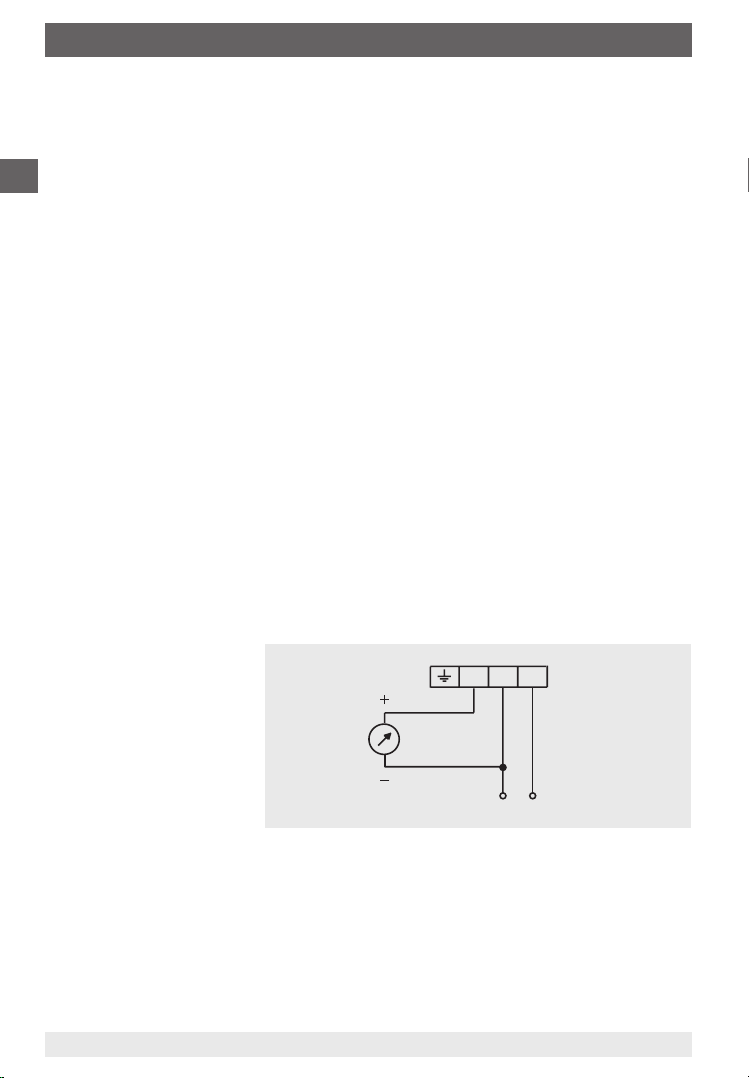

The instrument has a

3-wire connection and its

electrical connection is

detailed in the illustration.

4 ... 20 mA

1

1 ... black

-2 +3

DC 24 V

2 ... blue

3 ... brown

Commissioning

Before commissioning, the instrument and all electrical wiring must be properly

installed. All connection lines must be run so that no mechanical forces will act

on the instrument.

The pressure measuring lines should be constructed so that a sucient gradient

exists, so that, for example, no air pockets can occur when measuring liquids

nor water pockets when measuring gases. If the gradient required cannot be

achieved, water or air separators must be tted at the appropriate points.

10

WIKA operating instructions dierential pressure transmitter model 890.09.2190

11171545.02 08/2010 GB/D/F/E

Page 11

6. Commissioning, operation ... 8. Dismounting, return ...

The pressure measuring lines must be as short as possible and should be

arranged without sharp radii in order to avoid any disruptive time lags.

Before commissioning the instrument, check the mechanical connections to

ensure they are leak-tight.

7. Maintenance

The instruments are maintenance-free.

In order to ensure safe and reliable operation and a long service life for the

instrument, we recommend carrying out the following tests at regular intervals:

- Measurement signal test

- Leak-tightness checks at the pressure connection lines

- Electrical connection checks (clamp connection of the cables)

The testing intervals are to be adapted to the specic operating and ambient

conditions. In applications where various instrument components interact,

the operating instructions of all the other instruments involved must also be

observed.

Repairs are only to be carried out by the manufacturer or appropriately trained

skilled personnel.

8. Dismounting, return and disposal

GB

WARNING!

Residual media in dismounted instruments can result in a risk to

persons, the environment and equipment. Take sucient precautionary measures.

9.1 Dismounting

Only disconnect the pressure gauge once the system has been depressurised!

9.2 Return

All defective or faulty instruments must be sent directly to our repair department.

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal

regulations.

11171545.02 08/2010 GB/D/F/E

WIKA operating instructions dierential pressure transmitter model 890.09.2190 11

Page 12

GB

12

WIKA operating instructions dierential pressure transmitter model 890.09.2190

11171545.02 08/2010 GB/D/F/E

Page 13

Inhalt

Inhalt

1. Allgemeines 14

2. Sicherheit 15

3. Technische Daten 17

4. Aufbau und Funktion 18

5. Transport, Verpackung und Lagerung 19

6. Inbetriebnahme, Betrieb 19

7. Wartung 21

8. Demontage, Rücksendung und Entsorgung 21

D

11171545.02 08/2010 GB/D/F/E

13WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.2190

Page 14

1. Allgemeines

1. Allgemeines

Der in der Betriebsanleitung beschriebene Messumformer wird nach den

neuesten Erkenntnissen konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts-

und Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und

ISO 14001 zertiziert.

D

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem

Messumformer. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller

angegebenen Sicherheitshinweise und Handlungsanweisungen.

Die für den Einsatzbereich des Messumformers geltenden örtlichen Unfallver-

hütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe

des Messumformers für das Fachpersonal jederzeit zugänglich aufbewahrt

werden.

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten

sorgfältig durchgelesen und verstanden haben.

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige

Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend

qualizierten Fachpersonals sowie eigenmächtiger Veränderung am Messumformer.

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

Technische Änderungen vorbehalten.

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: PE 81.78

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die

zum Tod oder zu schweren Verletzungen führen kann, wenn sie

nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen

für einen ezienten und störungsfreien Betrieb hervor.

WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.219014

11171545.02 08/2010 GB/D/F/E

Page 15

2. Sicherheit

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass der

richtige Messumformer hinsichtlich Messbereich, Ausführung und

spezischen Messbedingungen ausgewählt wurde.

Verträglichkeit der druckbelasteten Werkstoe mit dem Messsto

prüfen!

Die Belastungsgrenzen sind einzuhalten, um die Messgenauigkeit und die Lebensdauer zu gewährleisten.

Alle Arbeiten dürfen nur im spannungslosen Zustand erfolgen.

Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den

einzelnen Kapiteln dieser Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Der Messumformer Typ 890.09.2190 dient zur Dierenzdruckmessung

z. B. zwischen Vor- und Rücklauf in Heizungsanlagen, Filteranlagen, in der

Technischen Gebäudeausrüstung, Trink- und Brauchwasseraufbereitung,

Pumpenüberwachung und -steuerung in Druckerhöhungs- und Feuerlöschanlagen.

D

Der Messumformer ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung

sind ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und

Sachschäden führen.

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur

durch Fachpersonal nachfolgend beschriebener Qualikation

durchführen lassen.

11171545.02 08/2010 GB/D/F/E

15WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.2190

Page 16

2. Sicherheit

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse

der Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der

landesspezischen Vorschriften, geltenden Normen und Richtlinien in der Lage,

die beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig zu

erkennen.

D

2.3 Besondere Gefahren

WARNUNG!

Messstoreste in ausgebauten Druckmessgeräten können zur

Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

2.4 Beschilderung / Sicherheitskennzeichnungen

Typenschild

Typ

Herstellungsjahr

Symbolerklärung

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den

zutreenden europäischen Richtlinien.

WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.219016

11171545.02 08/2010 GB/D/F/E

Page 17

3. Technische Daten

3. Technische Daten

Allgemein

Prozessanschluss 2 x 7/16 UNF Außengewinde

Werkstoe

Druckanschlüsse

Dichtungen

Messstokammer

Sensorelement

Dierenzdruckmessbereiche 0 ... 1 bar, 0 ... 2 bar, 0 ... 4 bar, 0 ... 6 bar oder

Max. Betriebsdruck (stat.) 21 bar

Überdruckbelastbar ein-, beid-

u. wechselseitig max.

Messzeitkonstante T

Genauigkeit (Fehlerband) ± 2 % d. Spanne (Linearität, Hysterese, Temperatur-

Linearität, Hysterese ± 1 % d. Spanne

Temperaturkoezient 0,2 % d. Spanne / 10 K

Nullpunkt-Oset ± 0,1 mA

Zul. Umgebungstemperatur -10 °C ... 50 °C

Zul. Medientemperatur -10 °C … 80 °C

Schutzart IP 55 nach EN 60529 / IEC 529

Cu-Legierung - messstoberührt

FPM/FKM - messstoberührt

Zinkdruckguss - messstoberührt

Keramik Al

2O3 - messstoberührt

0 ... 10 bar

2,5 x Messbereichsendwert, max. 21 bar

Druckspitzen sind durch konstruktive Maßnahmen

zu mindern (z. B. Kapillare)

mess = 10 ms (Sensor + Elektronik)

fehler 10 ... 70 °C)

D

Elektrische Daten

Nennspannung DC 24 V

Zulässige Versorgungsspannung DC 18 … 30 V

Elektrischer Anschluss 3-Leiter

Ausgangssignal 4 ... 20 mA

Max. Bürde 500 Ohm

Stromaufnahme

bei Ausgang max.

bei Strombegrenzung

ca. 32 mA normal (typisch)

ca. 36 mA (bei Überdruck)

Elektrische Schutzart kurzschlussfest, nach Aufheben des Fehlers ist

die Funktionsfähigkeit wiederhergestellt

Elektrischer Anschluss

3-adriges Nummernkabel

Anschluss mit Raststecker

M8 (3-polig)

11171545.02 08/2010 GB/D/F/E

0,34 mm², 0,8 m bis 2,5 m lang

am Gerät austauschbar, äußeres Kabelende mit

Einzeladern zum Klemmen

17WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.2190

Page 18

3. Technische Daten / 4. Aufbau und Funktion

Abmessungen in mm

D

2150258.03PD890-09-2190a

Weitere technische Daten siehe WIKA Datenblatt PE 81.78 und Bestellunterlagen.

4. Aufbau und Funktion

Prinzipdarstellung

1 Gehäuse

2 Elektronik

3 Montagelasche

4 Druckanschluss

5 Sensor

WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.219018

11171545.02 08/2010 GB/D/F/E

Page 19

4. Aufbau und Funktion ... 6. Inbetriebnahme, Betrieb

Aufbau und Wirkungsweise

Der Dierenzdruck-Messumformer besitzt einen keramischen Dierenzdrucksensor in Dickschichttechnik, der nach dem Prinzip einer Wheatston´schen Brücke

arbeitet. Der Dierenzdruck verformt die Keramikmembran und verändert dabei

das DMS-Brückensignal, das von der integrierten Elektronik auf ein normiertes

Stromausgangssignal verstärkt wird. Der Sensor ist zwischen den beiden

Gehäusehälften montiert und mit O-Ringen gedichtet. Das Sensorsignal wird

über exible Leitungen rückwirkungsfrei auf die Platine geführt. Der elektrische

Anschluss des Messumformers erfolgt über ein dreiadriges Kabel, das durch

einen Schutzschlauch zum Anschlussraum geführt wird. Das Gerät besitzt 2

Laschen als Befestigungsmöglichkeit. Der Dierenzdruck-Messumformer wird

werksseitig kalibriert und temperaturkompensiert.

Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

5. Transport, Verpackung und Lagerung

5.1 Transport

Messumformer auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen

optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

D

5.3 Lagerung

Zulässige Bedingungen am Lagerort

Lagertemperatur: -20 ... +50 °C

6. Inbetriebnahme, Betrieb

Mechanischer Anschluss

Der Messumformer ist für den Aufbau auf ebenen Montageplatten vorgesehen.

Zum Verschrauben mit der Montageplatte besitzt das Gerät eine Montagebohrung

Ø 5,5 mm und ein Langloch mit der Breite 5,5 mm.

Die Gehäuseschutzart IP 55 ist nur gewährleistet, wenn die vorgesehene Kabelverschraubung mit innenliegender Dichtung und dem vorgesehenen Wellrohr

verwendet wird. Dazu wird das Anschlusskabel M8 mit der zugehörigen Wellrohr

/ Kabelverschraubung-Kombination vormontiert und das Anschlusskabel M8 an

11171545.02 08/2010 GB/D/F/E

19WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.2190

Page 20

6. Inbetriebnahme, Betrieb

den Einbaustecker M8 im Gerät gesteckt.

Durch leichten Druck rastet das Kabel am Stecker ein. Die Kabelverschraubung

mit dem Gehäuse verschrauben. Anschließend wird die innenliegende Dichtung

der Kabelverschraubung mit dem Kabel verpresst.

Bei der Montage beachten, dass der Belüftungslter nicht durch Staub oder

Flüssigkeit verschlossen wird.

D

Das Önen des Gehäuses ist nicht zulässig, da dadurch das Gerät nachhaltig

beschädigt wird.

Prozessanschluss

Beim Anschließen des Gerätes müssen die Leitungen drucklos sein

Das Gerät ist durch geeignete Maßnahmen vor Druckstößen zu sichern

Nur für den Betrieb geeigneter Medien

Maximaldruck beachten

Zulässigen Überlastdruck beachten

Die Druckanschlüsse sind mit ⊕ und ⊖ Symbolen am Gerät gekennzeichnet.

Bei Dierenzdruckmessungen wird der höhere Druck an der ⊕-Seite und der

niedrigere Druck an der ⊖-Seite des Gerätes angeschlossen.

Elektrischer Anschluss

Der elektrische Anschluss des Gerätes ist gemäß den relevanten Vorschriften

des VDE sowie den Vorschriften des örtlichen EVU durchzuführen

Vor Anschluss des Gerätes ist die Anlage elektrisch freizuschalten

Verbrauchsangepasste Sicherungselemente sind vorzuschalten

Das Gerät besitzt einen

3-Leiteranschluss und

wird gemäß Abbildung

elektrisch angeschlossen.

4 ... 20 mA

1

1 ... schwarz

-2 +3

DC 24 V

2 ... blau

3 ... braun

Inbetriebnahme

Vorraussetzung für die Inbetriebnahme ist die ordnungsgemäße Installation

des Gerätes sowie aller elektrischen Schaltleitungen. Alle Anschlussleitungen

müssen dabei so verlegt werden, dass keine mechanische Kräfte auf das

Gerät einwirken.

Die Druckmessleitungen sind so mit Gefälle zu verlegen, dass z. B. bei Flüssig-

keitsmessungen keine Luftsäcke und bei Gasmessungen keine Wassersäcke

auftreten können. Wenn das notwendige Gefälle nicht erreicht wird, so sind an

geeigneten Stellen Wasser- bzw. Luftabscheider einzubauen.

WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.219020

11171545.02 08/2010 GB/D/F/E

Page 21

6. Inbetriebnahme, Betrieb ... 8. Demontage, Rücksendung ...

Die Druckmessleitungen sind möglichst kurz zu halten und ohne scharfe

Krümmungen zu verlegen, um das Auftreten störender Verzugzeiten zu

vermeiden.

Vor Inbetriebnahme die Dichtheit der mechanischen Anschlüsse prüfen.

7. Wartung

Die Geräte sind wartungsfrei.

Um einen zuverlässigen Betrieb und eine lange Lebensdauer des Gerätes

sicherzustellen, empfehlen wir eine regelmäßige Prüfung des Gerätes wie:

- Überprüfung des Messsignals

- Dichtheitskontrollen der Druckanschlussleitungen

- Kontrolle der elektrischen Anschlüsse (Klemmverbindung der Kabel)

Die Prüfzyklen sind den Betriebs- und Umgebungsbedingungen anzupassen.

Beim Zusammenwirken verschiedener Gerätekomponenten sind auch die

Bedienungsanleitungen aller anderen Geräte zu beachten.

Reparaturen sind ausschließlich vom Hersteller oder entsprechend

qualiziertem Fachpersonal durchzuführen.

8. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste in ausgebauten Geräten können zur Gefährdung

von Personen, Umwelt und Einrichtung führen. Ausreichende

Vorsichtsmaßnahmen ergreifen.

9.1 Demontage

Druckmessgerät nur im drucklosen Zustand demontieren!

9.2 Rücksendung

Alle defekten oder mit Mängeln behafteten Geräte sind direkt an unsere Reparaturabteilung zu senden.

D

9.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den

landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften

umweltgerecht entsorgen.

11171545.02 08/2010 GB/D/F/E

21WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.2190

Page 22

WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.219022DWIKA mode d'emploi transmetteur de pression diérentielle type 890.09.2190 23

11171545.02 08/2010 GB/D/F/E

Page 23

Sommaire

Sommaire

1. Généralités 14

2. Sécurité 15

3. Caractéristiques techniques 17

4. Conception et fonction 18

5. Transport, emballage et stockage 19

6. Mise en service, exploitation 19

7. Entretien 21

8. Démontage, retour et mise au rebut 21

F

11171545.02 08/2010 GB/D/F/E

Page 24

1. Généralités

1. Généralités

Le transmetteur décrit dans le présent mode d'emploi est conçu et fabriqué

selon les dernières technologies en vigueur et tous les composants sont

soumis à des critères de qualité et d'environnement stricts durant la fabrication.

Nos systèmes de gestion sont certiés selon ISO 9001 et ISO 14001.

Ce mode d'emploi donne des indications importantes concernant l'utilisation

du transmetteur. Il est possible de travailler en toute sécurité avec ce produit en

respectant toutes les consignes de sécurité et d'utilisation indiquées.

F

Respecter les prescriptions locales de prévention contre les accidents et les

prescriptions générales de sécurité en vigueur pour le domaine d'application

du transmetteur.

Le mode d'emploi fait partie du transmetteur et doit être conservé à proximité

immédiate du transmetteur et accessible à tout moment au personnel qualié.

Le personnel qualié doit, avant de commencer toute opération, avoir lu

soigneusement et compris le mode d’emploi.

La responsabilité du fabricant n'est pas engagée en cas de dommages provo-

qués par une utilisation non conforme à l'usage prévu, de non respect de ce

mode d'emploi, d'utilisation de personnel trop peu qualié de même qu'en cas

de modications du transmetteur eectuées du propre chef de l'utilisateur.

Les conditions générales de vente mentionnées dans les documents de vente

s'appliquent.

Sous réserve de modications techniques.

Pour obtenir d'autres informations:

- Consulter notre site internet : www.wika.de / www.wika.com

- Fiche technique correspondante : PE 81.78

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles

de provoquer la mort ou des blessures graves si elle n'est pas

évitée.

Information

… met en exergue les conseils et recommandations utiles de

même que les informations permettant d'assurer un fonctionne-

ment ecace et normal.

WIKA mode d'emploi transmetteur de pression diérentielle type 890.09.219024

11171545.02 08/2010 GB/D/F/E

Page 25

2. Sécurité

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement,

s'assurer que le transmetteur a été choisi de façon adéquate, en

ce qui concerne l'étendue de mesure, la version et les conditions

de mesure spéciques.

Vérier si les matériaux soumis à la pression sont compatibles

avec le uide de mesure !

Les limites de surpression admissible sont à respecter an

d'assurer la précision et la durée de vie.

Toutes les interventions doivent être eectuées hors tension.

Un non respect de cette consigne peut entraîner des blessures

corporelles graves et/ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les sections

individuelles du présent mode d'emploi.

2.1 Utilisation conforme à l'emploi prévu

Le transmetteur type 890.09.2190 sert à la mesure de la pression diérentielle

par exemple entre le départ et le retour dans les installations de chauage, les

installations de ltration, l'équipement technique des bâtiments, les installations

de traitement d'eau potable et non potable, pour la surveillance des pompes et la

commande des installations de surpressions et d'extinction d'incendie.

Le transmetteur est conçu et construit exclusivement pour une utilisation conforme

à l'usage prévu décrit ici et ne doit être utilisé qu'en conséquence.

Aucune réclamation ne peut être recevable en cas d‘utilisation non conforme à

l‘usage prévu.

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants

dommages corporels et matériels.

Les opérations décrites dans ce mode d‘emploi ne doivent

être eectuées que par un personnel ayant la qualication

décrite ci-après.

F

11171545.02 08/2010 GB/D/F/E

WIKA mode d'emploi transmetteur de pression diérentielle type 890.09.2190 25

Page 26

2. Sécurité

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses connaissances dans le domaine de la technique de mesure et de régulation et de ses

expériences de même que de sa connaissance des prescriptions nationales des

normes et directives en vigueur, en mesure d'eectuer les travaux décrits et de

reconnaître automatiquement les dangers potentiels.

2.3 Dangers particuliers

F

AVERTISSEMENT !

Les restes de uides se trouvant dans des instruments

démontés peuvent mettre en danger les personnes, l‘environnement ainsi que l‘installation. Prendre des mesures de sécurité

susantes.

2.4 Etiquetage / Marquages de sécurité

Plaque signalétique

Type

Explication des symboles

CE, Communauté Européenne

Les appareils avec ce marquage sont conformes aux directives

européennes pertinentes.

Année de fabrication

WIKA mode d'emploi transmetteur de pression diérentielle type 890.09.219026

11171545.02 08/2010 GB/D/F/E

Page 27

3. Caractéristiques techniques

3. Caractéristiques techniques

1. Généralités

Raccord process Filetage mâle 2 x 7/16 UNF

Matériaux

Raccords de pression

Joints

Chambre de mesure

Élément de mesure

Etendues de mesure de la

pression diérentielle

Pression de service maximale (stat.)

Surpression maximale admissible

d'un côté, des deux côtés et de

chaque côté

Constante de temps de mesure Tmess = 10 ms (capteur + système électronique)

Précision (plage d'erreur) ± 2 % de l'échelle (linéarité, hystérésis, erreur de

Linéarité, hystérésis ± 1 % de l'échelle

Coecient de température 0,2 % de l'échelle / 10 K

Oset du point zéro ± 0,1 mA

Température ambiante adm. -10 °C ... 50 °C

Température admissible du uide

Indice de protection IP 55 selon EN 60529 / IEC 529

Alliage Cu - en contact avec le uide

FPM/FKM - en contact avec le uide

Fonte de zinc coulée sous pression- en contact

avec le uide

Céramique Al

2O3 - en contact avec le uide

0 ... 1 bar, 0 ... 2 bar, 0 ... 4 bar, 0 ... 6 bar ou

0 ... 10 bar

21 bar

2,5 x n d'échelle, max. 21 bar

Les pics de pression doivent être réduits àl’aide de

dispositifs adéquats (par exemple des capillaires)

température 10 ... 70 °C)

-10 °C … 80 °C

F

Caractéristiques électriques

Tension nominale DC 24 V

Tension d'alimentation admissible DC 18 … 30 V

Branchement électrique 3 ls

Signal de sortie 4 ... 20 mA

Charge maximale 500 ohms

Courant d'entrée

à la sortie max.

en cas de limitation du courant

env. 32 mA normal (typique)

env. 36 mA (en cas de surpression)

Protection électrique résistant aux courts-circuits, après l'élimination du

défaut, la fonctionalité est rétablie.

Branchement électrique

Câble 3 ls

Connexion avec connecteur

enchable M8 (3 pôles)

11171545.02 08/2010 GB/D/F/E

WIKA mode d'emploi transmetteur de pression diérentielle type 890.09.2190 27

0,34 mm², 0,8 m jusqu'à 2,5 m de long

peut être remplacé sur l'appareil, extrémité

extérieure de câble avec conducteurs individuels

pour le raccordement

Page 28

3. Caractéristiques techniques / 4. Conception et fonction

Dimensions en mm

F

2150258.03PD890-09-2190a

Pour les autres caractéristiques techniques, voir Fiche technique WIKA PE 81.78

et documents de commande.

4. Conception et fonction

Représentation de principe

1 Boîtier

2 Système électronique

3 Pattes de xation

4 Raccord de pression

5 Capteur

WIKA mode d'emploi transmetteur de pression diérentielle type 890.09.219028

11171545.02 08/2010 GB/D/F/E

Page 29

4. Conception et fonction ... 6. Mise en service, exploitation

Structure et mode de fonctionnement

Le transmetteur de pression diérentielle est équipé d'un capteur de pression

diérentiel en céramique utilisant la technique de la couche épaisse qui

fonctionne selon le principe d'un pont de Wheatstone. La pression diérentielle

déforme la membrane en céramique et modie également le signal du pont

DMS qui est amplié par le système électronique intégré pour devenir un signal

de sortie de courant normalisé. Le capteur est monté entre les deux moitiés du

boîtier et étanché par des joints toriques. Le signal du capteur est transmis au

moyen de câbles souples sans rétroactions à la carte. Le branchement électrique

du transmetteur est eectué à l'aide du câble 3 ls qui est acheminé vers le lieu

de raccordement par une gaine de protection. L'appareil est équipé de deux

pattes de xation. Le transmetteur de pression diérentielle est calibré à l'usine et

compensé en température.

Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe sur le transmetteur des dégâts liés au transport. Communiquer

immédiatement les dégâts constatés.

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l‘emballage, celui-ci ore, lors d‘un transport, une protection optimale

(par ex. changement de lieu d‘utilisation, renvoi pour réparation).

F

5.3 Stockage

Conditions admissibles sur le lieu de stockage

Température de stockage: -20 ... +50 °C

6. Mise en service, exploitation

Raccordement mécanique

Le transmetteur est prévu pour le montage sur des plaques de montage plates.

L'appareil est doté d'un trou de montage permettant de le visser avec la plaque de

montage Ø 5,5 mm et un trou oblong avec une largeur de 5,5 mm.

L'indice de protection IP 55 du boîtier n'est garanti que si le presse-étoupe prévu

est utilisé avec le joint intérieur et le tube ondulé prévu. Pour cela, le câble de

raccordement M8 est prémonté avec la combinaison correspondante tube ondulé

/ presse-étoupe et le câble de raccordement M8 est raccordé au connecteur M8

de l'appareil.

11171545.02 08/2010 GB/D/F/E

WIKA mode d'emploi transmetteur de pression diérentielle type 890.09.2190 29

Page 30

6. Mise en service, exploitation

Le câble s'enclenche dans le connecteur en appuyant légèrement. Visser le

presse-étoupe avec le boîtier. Le joint intérieur du presse-étoupe est ensuite

pressé avec le câble.

Lors du montage, veillez à ce que le ltre d’aération ne soit pas bouché par de la

poussière ou du liquide.

L’ouverture du boîtier n’est pas autorisée puisque cela endommage de manière

durable l’appareil.

Raccord process

F

Lors du raccordement de l’appareil, les conduites doivent être hors pression.

L’appareil doit être protégé par des mesures appropriées contre les pics de

pression.

Seulement pour l'utilisation des produits adaptés

Respecter la pression maximale

Respecter la pression de surcharge admissible

Les raccords de pression sont matérialisés par des symboles ⊕ et ⊖ sur l'appareil. En cas de mesure de pression diérentielle, le raccord pour la pression la plus

élevée est raccordé sur le côté ⊕ et celui pour la pression la plus faible sur le côté

⊖ de l'appareil.

Branchement électrique

Le raccordement électrique de l'appareil doit être eectué conformément aux

prescriptions pertinentes VDE et aux prescriptions des entreprises d'électricité

locales (EVU).

Avant le raccordement de l'appareil, déconnecter l'alimentation électrique de

l'installation

Insérer les fusibles adaptés à l'application

L'appareil est équipé

d'un bornier à 3 bornes

et le branchement

électrique doit être

eectué conformément à

l'illustration.

Mise en Service

4 ... 20 mA

1

1 ... noir

-2 +3

DC 24 V

2 ... bleu

3 ... brun

Une condition pour la mise en service est l'installation correcte de l'appareil

et de toutes les lignes de connexion électriques. Tous les câbles de raccorde-

ment doivent être posés de sorte qu'aucune force mécanique ne s'exerce sur

l'appareil.

Les conduites de mesure de la pression sont posées avec une pente de

manière à éviter par exemple, en cas de mesure de liquides, la formation de

WIKA mode d'emploi transmetteur de pression diérentielle type 890.09.219030

11171545.02 08/2010 GB/D/F/E

Page 31

6. Mise en service, exploitation ... 8. Démontage, retour ...

bulles d’air et en cas de mesure de gaz la formation de bulles d’eau. Si la

pente nécessaire n’est pas obtenue, il faut monter aux endroits appropriés des

séparateurs d’eau ou d’air.

Utiliser des conduites de mesure de la pression les plus courtes possibles et

sans courbures trop importantes an d'éviter des retards perturbateurs.

Avant la mis en service, vérier l'étanchéité des connexions mécaniques.

7. Entretien

Les instruments ne requièrent aucun entretien.

An de garantir un fonctionnement sûr et une longue durée de vie de l'appareil,

nous recommandons un contrôle de l'appareil à des intervalles réguliers :

- Contrôle du signal de mesure

- Contrôles d'étanchéité des conduites de pression

- Contrôle des connexions électriques (borne des câbles)

Adapter les cycles de contrôle aux conditions de fonctionnement et ambiantes.

Respecter également les modes d'emploi de tous les autres appareils en cas

d'interaction de diérents composants des appareils.

Toute réparation doit être exclusivement conée au fabricant ou au personnel

qualié correspondant..

8. Démontage, retour et mise au rebut

AVERTISSEMENT !

Les restes de uides se trouvant dans des appareils démontés

peuvent mettre en danger les personnes, l'environnement ainsi

que l'installation. Prendre des mesures de sécurité susantes.

9.1 Démontage

Démonter le manomètre uniquement qu‘en état exempt de pression !

9.2 Retour

Envoyer directement tous les appareils défectueux à notre département de

réparations.

F

9.3 Mise au rebut

Une mise au rebut inadéquate peut entraîner des dangers pour l‘environnement.

Éliminer les composants des appareils et les matériaux d'emballage

conformément aux prescriptions nationales pour le traitement et l'élimination des

déchets et aux lois de protection de l'environnement en vigueur.

11171545.02 08/2010 GB/D/F/E

WIKA mode d'emploi transmetteur de pression diérentielle type 890.09.2190 31

Page 32

F

WIKA mode d'emploi transmetteur de pression diérentielle type 890.09.219032

11171545.02 08/2010 GB/D/F/E

Page 33

Contenido

Contenido

1. Información general 14

2. Seguridad 15

3. Datos técnicos 17

4. Diseño y función 18

5. Transporte, embalaje y almacenamiento 19

6. Puesta en servicio, funcionamiento 19

7. Mantenimiento 21

8. Desmontaje, devolución y eliminación 21

E

11171545.02 08/2010 GB/D/F/E

WIKA manual de Instrucciones transmisor de presión diferencial modelo 890.09.2190

33

Page 34

1. Información general

1. Información general

El transmisor descrito en el manual de instrucciones está construido y fabrica-

do según los conocimientos actuales. Todos los componentes están sujetos a

criterios rígidos de calidad y medio ambiente durante la producción. Nuestros

sistemas de gestión están certicados según ISO 9001 y ISO 14001.

Este manual de instrucciones proporciona indicaciones importantes acerca del

manejo del transmisor. Para que el trabajo con este instrumento sea seguro

es imprescindible cumplir con todas las instrucciones de seguridad y manejo

indicadas.

Cumplir siempre las normativas sobre la prevención de accidentes y las

E

normas de seguridad en vigor en el lugar de utilización del transmisor.

El manual de instrucciones es una parte integrante del transmisor y debe

guardarse en la proximidad del mismo para que el personal especializado

pueda consultarlo en cualquier momento.

El personal especializado debe haber leído y entendido el manual de instruc-

ciones antes de comenzar cualquier trabajo.

El fabricante queda exento de cualquier responsabilidad en caso de daños

causados por un uso no conforme a la nalidad prevista, la inobservancia del

presente manual de instrucciones, un manejo por personal insucientemente

cualicado así como una modicación no autorizada del transmisor.

Se aplican las condiciones generales de venta incluidas en la documentación

de venta.

Modicaciones técnicas reservadas.

Para obtener más informaciones consultar:

- Página web: www.wika.de / www.wika.com

- Hoja técnica correspondiente: PE 81.78

Explicación de símbolos

¡ADVERTENCIA!

... indica una situación probablemente peligrosa que pueda

causar la muerte o lesiones graves si no se evita.

Información

... marca consejos y recomendaciones útiles así como informa-

ciones para una utilización ecaz y libre de fallos.

WIKA manual de Instrucciones transmisor de presión diferencial modelo 890.09.2190

34

11171545.02 08/2010 GB/D/F/E

Page 35

2. Seguridad

2. Seguridad

¡ADVERTENCIA!

Antes del montaje, la puesta servicio y el funcionamiento asegurarse de que se haya seleccionado el transmisor adecuado con

respecto a rango de medida, versión y condiciones de medición

especícas.

¡Asegúrese de que los productos bajo presión sean aptos para el

material de medición!

Para garantizar la precisión de medición y la durabilidad del

instrumento, se deberán respetar los límites de carga.

Todos los trabajos que se ejecuten en los instrumentos han de

hacerse sin someter el instrumento a presión.

Riesgo de lesiones graves y/o daños materiales en caso de

inobservancia.

Los distintos capítulos de este manual de instrucciones contienen otras importantes indicaciones de seguridad.

2.1 Uso conforme a lo previsto

El transmisor modelo 890.09.2190 mide la presión diferencial, por ejemplo entre

la ida y el retorno en sistemas de calefacción, en instalaciones de ltración, en

el equipamiento técnico de edicios, en el tratamiento de agua potable y aguas

residuales, en la monitorización y control de bombas en sistemas de aumento de

presión y en sistemas de extinción de incendios.

E

El transmisor ha sido diseñado y construido únicamente para la nalidad aquí

descrita y debe utilizarse en conformidad a la misma.

No se admite ninguna reclamación debido a un manejo no adecuado.

2.2 Cualicación del personal

¡ADVERTENCIA!

¡Riesgo de lesiones debido a una insuciente cualicación!

Un manejo no adecuado puede causar considerables daños

personales y materiales.

Las actividades descritas en este manual de instrucciones

deben realizarse únicamente por personal especializado con

la consiguiente cualicación.

11171545.02 08/2010 GB/D/F/E

WIKA manual de Instrucciones transmisor de presión diferencial modelo 890.09.2190

35

Page 36

2. Seguridad

Personal especializado

Debido a su formación profesional, a sus conocimientos de la técnica de regulación y medición así como a su experiencia y su conocimiento de las normativas,

normas y directivas vigentes en el país de utilización el personal especializado es

capaz de ejecutar los trabajos descritos y reconocer posibles peligros por sí solo.

2.3 Riesgos especícos

¡ADVERTENCIA!

Restos de medios en manómetros desmontados pueden crear

riesgos para personas, medio ambiente e instalación. Tomar

E

2.4 Rótulos / Marcajes de seguridad

Placa indicadora

Modelo

adecuadas medidas de precaución.

Año de fabricación

Explicación de símbolos

CE, Communauté Européenne

Los instrumentos con este marcaje cumplen las directivas

europeas aplicables.

WIKA manual de Instrucciones transmisor de presión diferencial modelo 890.09.2190

36

11171545.02 08/2010 GB/D/F/E

Page 37

3. Datos técnicos

3. Datos técnicos

Información general

Conexión a proceso 2 x 7/16 UNF rosca exterior

Materias primas

Conexiones a presión

Juntas

Cámara de medición

Sensor

Rangos de medida de la presión

diferencial

Presión de trabajo máx. (estática) 21 bar

Máx. carga por sobrepresión -

unilateral, bilateral, alterna

Constante de tiempo de medición T

Precisión (margen de error) ± 2 % del span (linealidad, histéresis, error de

Linealidad, histéresis ± 1 % del span

Coeciente de temperatura 0,2 % del span / 10 K

Oset del punto cero ± 0,1 mA

Temperatura ambiental admisible -10 °C a 50 °C

Temperatura admisible del medio -10 °C … 80 °C

Tipo de protección IP 55 según EN 60529 / IEC 529

Aleación de cobre - en contacto con el medio

FPM/FKM - en contacto con el medio

Zinc fundido a presión - en contacto con el medio

Cerámica Al

2O3 - en contacto con el medio

0 ... 1 bar, 0 ... 2 bar, 0 ... 4 bar, 0 ... 6 bar o

0 ... 10 bar

2,5 x del valor límite del rango de medida, máx.

21 bar

Reducir picos de presión mediante una construcción adecuada (p. ej. tubos capilares)

med = 10 ms (sensor + sistema electrónico)

temperatura 10 ... 70 °C)

E

Datos eléctricos

Tensión nominal DC 24 V

Tensión de alimentación admisible

DC 18 … 30 V

Conexión eléctrica 3 hilos

Señal de salida 4 ... 20 mA

Carga máxima 500 ohmios

Consumo de corriente

en salida máx.

con limitación eléctrica

aprox. 32 mA normal (típico)

aprox. 36 mA (con sobrepresión)

Proteccion eléctrica resistente a cortocircuitos; se vuelve a establecer

la funcionalidad después de eliminar el fallo

Conexión eléctrica

Cable de 3 conductores

0,34 mm², 0,8 m a 2,5 m de longitud

identicado por números

Conexión con conector M8

(3-pin)

11171545.02 08/2010 GB/D/F/E

WIKA manual de Instrucciones transmisor de presión diferencial modelo 890.09.2190

puede intercambiase en el instrumento; extremo

de cable exterior con conductores individuales

para conectar

37

Page 38

3. Datos técnicos / 4. Diseño y función

Dimensiones en mm

E

2150258.03PD890-09-2190a

Para más datos técnicos consúlte hoja técnica de WIKA PE 81.78 y la documentación de pedido.

4. Diseño y función

Ilustración del principio

1 Caja

2 Sistema electrónico

3 Aleta de montaje

4 Toma de presión

5 Sensor

WIKA manual de Instrucciones transmisor de presión diferencial modelo 890.09.2190

38

11171545.02 08/2010 GB/D/F/E

Page 39

4. Diseño y función ... 6. Puesta en servicio y funcionamiento

Diseño y modo de funcionamiento

El transmisor de presión diferencial tiene un sensor cerámico de película gruesa

para la medición de la presión diferencial y funciona según el principio del puente

de Wheatstone. La presión diferencial deforma la membrana cerámica variando

así la señal de la galga extensiométrica; el sistema electrónico integrado convierte

esta señal en una señal de salida de corriente estandarizada. El sensor está

ubicado entre las dos partes de la caja y obturado mediante juntas tóricas. La

señal del sensor se transmite sin efecto retroactivo a través de líneas exibles a la

pletina. La conexión eléctrica del transmisor se realiza mediante un cable de tres

conductores que pasa a través de un tubo protector a la cámara de conexión. El

instrumento tiene 2 aletas para su jación. La calibración y la compensación de

temperatura del transmisor diferencial se realiza desde fábrica.

Volumen de suministro

Comprobar mediante el albarán si se han entregado todas las piezas.

5. Transporte, embalaje y almacenamiento

5.1 Transporte

Comprobar si el transmisor presenta eventuales daños causados en el transporte.

Noticar daños obvios de forma inmediata.

5.2 Embalaje

No quitar el embalaje hasta justo antes del montaje.

Guardar el embalaje porque es la protección ideal durante el transporte (por

ejemplo si el lugar de instalación cambia o si se envía el instrumento para

posibles reparaciones).

E

5.3 Almacenamiento

Condiciones admisibles en el lugar de almacenamiento

Temperatura de almacenamiento: -20 ... +50 °C

6. Puesta en servicio, funcionamiento

La conexión mecánica

El transmisor está diseñado para ser montado en placas de montaje planas. El

instrumento tiene una perforación para atornillarlo a la placa de montaje

de un diámetro de 5,5 mm y un ojal con un ancho de 5,5 mm.

El tipo de protección IP 55 de la caja está únicamente asegurado si se utiliza el

prensaestopas con obturación integrada y el tubo corrugado previstos. Por eso

se premonta el cable de conexión M8 con la combinación de tubo corrugado y

prensaestopas correspondiente, y se conecta el cable de conexión M8 al enchufe

11171545.02 08/2010 GB/D/F/E

WIKA manual de Instrucciones transmisor de presión diferencial modelo 890.09.2190

39

Page 40

6. Puesta en servicio, funcionamiento

de montaje M8 del instrumento.

Aplicar una ligera presión para enganchar el cable en el enchufe. Enroscar el

prensaestopas en el instrumento. Después apretar el cable en la obturación

integrada del prensaestopas.

Prestar atención durante el montaje para prevenir la obstrucción del ltro de ventilación con polvo o líquido.

No se permite abrir la caja porque esto daña la caja de forma irreparable.

Conexión a proceso

Los conductos deben estar sin presión para conectar el instrumento

Proteger el instrumento de golpes de ariete tomando medidas adecuadas

Sólo para el funcionamiento con medios adecuados

E

Respetar la presión máxima

Tener en cuenta la presión de sobrecarga

Marcar las tomas de presión en el instrumento con los símbolos ⊕ y ⊖. En

mediciones de presión diferencial se conecta la presión mayor al lado marcado

con ⊕ y la inferior al lado marcado con ⊖.

Conexión eléctrica

Realizar la conexión eléctrica del instrumento según las disposiciones relevan-

tes de VDE (asociación alemana para tecnologías eléctrica, electrónica y de la

información) y las prescripciones de su suministrador local de energía eléctrica

Antes de conectar el instrumento desconectar la alimentación eléctrica al sistema

Intercalar fusibles adaptados a la aplicación

El instrumento tiene un

terminal de 3 conductores;

la conexión eléctrica se

realiza como representado

en la ilustración.

4 ... 20 mA

1

1 ... negro

-2 +3

DC 24 V

2 ... azul

3 ... marrón

Puesta en servicio

Una condición para la puesta en servicio es la instalación correcta del instru-

mento y de todas las líneas de conmutación eléctricas. Colocar todas las

líneas de conexión de modo que no se aplique ninguna fuerza mecánica al

instrumento.

Colocar las líneas de medición de la presión en pendiente de modo que no se

formen bolsas de aire en mediciones de líquidos y bolsas de agua en medicio-

nes de gas. Si no se alcanza el pendiente necesario, montar separadores de

agua o aire en posiciones adecuadas.

WIKA manual de Instrucciones transmisor de presión diferencial modelo 890.09.2190

40

11171545.02 08/2010 GB/D/F/E

Page 41

6. Puesta en servicio ... 8. Desmontaje, devolución ...

Utilizar conductos de medición de la presión tan cortas como posible y

colocarlas de forma recta para evitar retrasos perturbadores.

Antes de poner en servicio el instrumento comprobar que las conexiones

metálicas estén herméticas.

7. Mantenimiento

Los instrumentos no requieren mantenimiento.

Para garantizar un funcionamiento able y una larga vida útil del instrumento

recomendamos pruebas periódicas como sigue:

- Controlar la señal de medición

- Comprobar la estanqueidad de los conductos de presión

- Revisión de las conexiones eléctricas (bornes de los cables)

Adaptar los ciclos de prueba a las condiciones de servicio y ambiente.

Tener en cuenta también los manuales de instrucciones de todos los demás

instrumentos si interaccionan varios componentes.

Todas las reparaciones solamente las debe efectuar el fabricante o personal

especializado e instruido.

8. Desmontaje, devolución y eliminación

¡ADVERTENCIA!

Restos de medios en instrumentos desmontados pueden crear

riesgos para personas, medio ambiente e instalación. Tomar

adecuadas medidas de precaución.

E

9.1 Desmontaje

¡Desmontar el manómetro sólo si no está sometido a presión!

9.2 Devolución

Devolver todos los instrumentos defectuosos o con fallos directamente a nuestro

departamento de reparaciones.

9.3 Eliminación de residuos

Una eliminación incorrecta puede provocar peligros para el medio ambiente.

Eliminar los componentes de los instrumentos y los materiales de embalaje

conforme a los reglamentos relativos al tratamiento de residuos y eliminación

vigentes en el país de utilización.

11171545.02 08/2010 GB/D/F/E

WIKA manual de Instrucciones transmisor de presión diferencial modelo 890.09.2190

41

Page 42

WIKA Global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand GmbH & Co. KG

1230 Vienna

Tel. (+43) 1 86916-31

Fax: (+43) 1 86916-34

E-Mail: info@wika.at

www.wika.at

Benelux

WIKA Benelux

6101 WX Echt

Tel. (+31) 475 535-500

Fax: (+31) 475 535-446

E-Mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

Bul. „Al. Stamboliiski“ 205

1309 Soa

Tel. (+359) 2 82138-10

Fax: (+359) 2 82138-13

E-Mail: t.antonov@wika.bg

Croatia

WIKA Croatia d.o.o.

Hrastovicka 19

10250 Zagreb-Lucko

Tel. (+385) 1 6531034

Fax: (+385) 1 6531357

E-Mail: info@wika.hr

www.wika.hr

Finland

WIKA Finland Oy

00210 Helsinki

Tel. (+358) 9-682 49 20

Fax: (+358) 9-682 49 270

E-Mail: info@wika.

www.wika.

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Tel. (+33) 1 343084-84

Fax: (+33) 1 343084-94

E-Mail: info@wika.fr

www.wika.fr

Germany

WIKA Alexander Wiegand

SE & Co. KG

63911 Klingenberg

Tel. (+49) 9372 132-0

Fax: (+49) 9372 132-406

E-Mail: info@wika.de

www.wika.de

Italy

WIKA Italia Srl & C. sas

20020 Arese (Milano)

Tel. (+39) 02 9386-11

Fax: (+39) 02 9386-174

E-Mail: info@wika.it

www.wika.it

Poland

WIKA Polska S.A.

87-800 Wloclawek

Tel. (+48) 542 3011-00

Fax: (+48) 542 3011-01

E-Mail: info@wikapolska.pl

www.wikapolska.pl

Romania

WIKA Instruments Romania S.R.L.

Bucuresti, Sector 5

Calea Rahovei Nr. 266-268

Corp 61, Etaj 1

Tel. (+40) 21 4048327

Fax: (+40) 21 4563137

E-Mail: m.anghel@wika.ro

Russia

ZAO WIKA MERA

127015 Moscow

Tel. (+7) 495-648 01 80

Fax: (+7) 495-648 01 81

E-Mail: info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

Sime Solaje 15

11060 Belgrade

Tel. (+381) 11 2763722

Fax: (+381) 11 753674

E-Mail: info@wika.co.yu

www.wika.co.yu

Spain

Instrumentos WIKA, S.A.

C/Josep Carner, 11-17

08205 Sabadell (Barcelona)

Tel. (+34) 902 902577

Fax: (+34) 933 938666

E-Mail: info@wika.es

www.wika.es

Switzerland

Manometer AG

6285 Hitzkirch

Tel. (+41) 41 91972-72

Fax: (+41) 41 91972-73

E-Mail: info@manometer.ch

www.manometer.ch

Turkey

WIKA Instruments Istanbul

Basinc ve Sicaklik Ölcme Cihazlari

Ith. Ihr. ve Tic. Ltd. Sti.

Bayraktar Bulvari No. 21

34775 Yukari Dudullu - Istanbul

Tel. (+90) 216 41590-66

Fax: (+90) 216 41590-97

E-Mail: info@wika.com.tr

www.wika.com.tr

Ukraine

WIKA Pribor GmbH

83016 Donetsk

Tel. (+38) 062 34534-16

Fax: (+38) 062 34534-17

E-Mail: info@wika.ua

www.wika.ua

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill RH13LG

Tel. (+44) 1737 644-008

Fax: (+44) 1737 644-403

E-Mail: info@wika.co.uk

www.wika.co.uk

North America

Canada

WIKA Instruments Ltd.

Head Oce

Edmonton, Alberta, T6N 1C8

Tel. (+1) 780 46370-35

Fax: (+1) 780 46200-17

E-Mail: info@wika.ca

www.wika.ca

Mexico

Instrumentos WIKA Mexico S.A.

de C.V.

01210 Mexico D.F.

Tel. (+52) 55 55466329

E-Mail: ventas@wika.com

www.wika.com.mx

USA

WIKA Instrument Corporation

Lawrenceville, GA 30043

Tel. (+1) 770 5138200

Fax: (+1) 770 3385118

E-Mail: info@wika.com

www.wika.com

WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.219042

11171545.02 08/2010 GB/D/F/E

Page 43

WIKA Global

WIKA Instrument Corporation

Electrical Temperature Division

950 Hall Court

Deer Park, TX 77536

Tel. (+1) 713 47500-22

Fax (+1) 713 47500-11

E-Mail: info@wikaetemp.com

www.wika.com

Mensor Corporation

201 Barnes Drive

San Marcos, TX 78666

Tel. (+1) 512 3964200-15

Fax (+1) 512 3961820

E-Mail: sales@mensor.com

www.mensor.com

South America

Argentina

WIKA Argentina S.A.

Buenos Aires

Tel. (+54) 11 47301800

Fax: (+54) 11 47610050

E-Mail: info@wika.com.ar

www.wika.com.ar

Brazil

WIKA do Brasil Ind. e Com. Ltda.

CEP 18560-000 Iperó - SP

Tel. (+55) 15 34599700

Fax: (+55) 15 32661650

E-Mail: marketing@wika.com.br

www.wika.com.br

Asia

China

WIKA International Trading

(Shanghai) Co., Ltd.

200001 Shanghai

Tel. (+86) 21 538525-72

Fax: (+86) 21 538525-75

E-Mail: info@wika.com.cn

www. wika.com.cn

India

WIKA Instruments India Pvt. Ltd.

Village Kesnand, Wagholi

Pune - 412 207

Tel. (+91) 20 66293-200

Fax: (+91) 20 66293-325

E-Mail: sales@wika.co.in

www.wika.co.in

Japan

WIKA Japan K. K.

Tokyo 105-0023

Tel. (+81) 3 543966-73

Fax: (+81) 3 543966-74

E-Mail: t-shimane@wika.co.jp

Kazakhstan

TOO WIKA Kazakhstan

050050 Almaty

Tel. (+7) 32 72330848

Fax: (+7) 32 72789905

E-Mail: info@wika.kz

www.wika.kz

Korea

WIKA Korea Ltd.

#569-21 Gasan-dong

Seoul 153-771 Korea

Tel. (+82) 2 869 05 05

Fax (+82) 2 869 05 25

E-Mail: info@wika.co.kr

www.wika.co.kr

Malaysia

WIKA Instrumentation (M) Sdn.

Bhd.

47100 Puchong, Selangor

Tel. (+60) 3 80 63 10 80

Fax: (+60) 3 80 63 10 70

E-Mail: info@wika.com.my

www.wika.com.my

Singapore

WIKA Instrumentation Pte. Ltd.

569625 Singapore

Tel. (+65) 68 44 55 06

Fax: (+65) 68 44 55 07

E-Mail: info@wika.com.sg

www.wika.com.sg

Taiwan

WIKA Instrumentation Taiwan Ltd.

Pinjen, Taoyuan

Tel. (+886) 3 420 6052

Fax: (+886) 3 490 0080

E-Mail: info@wika.com.tw

www.wika.com.tw

Africa / Middle East

Egypt

WIKA Near East Ltd.

El-Serag City Towers

-Tower#2 - Oce#67-

Nasr City Cairo

Tel. (+20) 2 22733140

Fax: (+20) 2 22703815

E-Mail: wika.repcairo@wika.de

www.wika.com.eg

Namibia

WIKA Instruments Namibia (Pty)

Ltd.

P.O. Box 31263

Pionierspark

Windhoek

Tel. (+26) 4 6123 8811

Fax (+26) 4 6123 3403

E-Mail: info@wika.com.na

www.wika.com.na

South Africa

WIKA Instruments (Pty.) Ltd.

Gardenview,

Johannesburg 2047

Tel. (+27) 11 62100-00

Fax: (+27) 11 62100-59

E-Mail: sales@wika.co.za

www.wika.co.za

United Arab Emirates

WIKA Middle East FZE

Jebel Ali, Dubai

Tel. (+971) 4 8839-090

Fax: (+971) 4 8839-198

E-Mail: wikame@emirates.net.ae

Australia

Australia

WIKA Australia Pty. Ltd.

Rydalmere, NSW 2116

Tel. (+61) 2 88455222

Fax: (+61) 2 96844767

E-Mail: sales@wika.com.au

www.wika.com.au

New Zealand

Process Instruments Limited

Unit 7 / 49 Sainsbury Road

St Lukes - Auckland 1025

Tel. (+64) 9 8479020

Fax: (+64) 9 8465964

E-Mail: info@wika.co.nz

www.wika.co.nz

11171545.02 08/2010 GB/D/F/E

WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.2190

43

Page 44

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. (+49) 9372/132-0

Fax (+49) 9372/132-406

E-Mail info@wika.de

www.wika.de

44

WIKA Betriebsanleitung Dierenzdruck-Messumformer Typ 890.09.2190

11171545.02 08/2010 GB/D/F/E

Loading...

Loading...