Page 1

Operating Instructions

Betriebsanleitung

Mode d'emploi

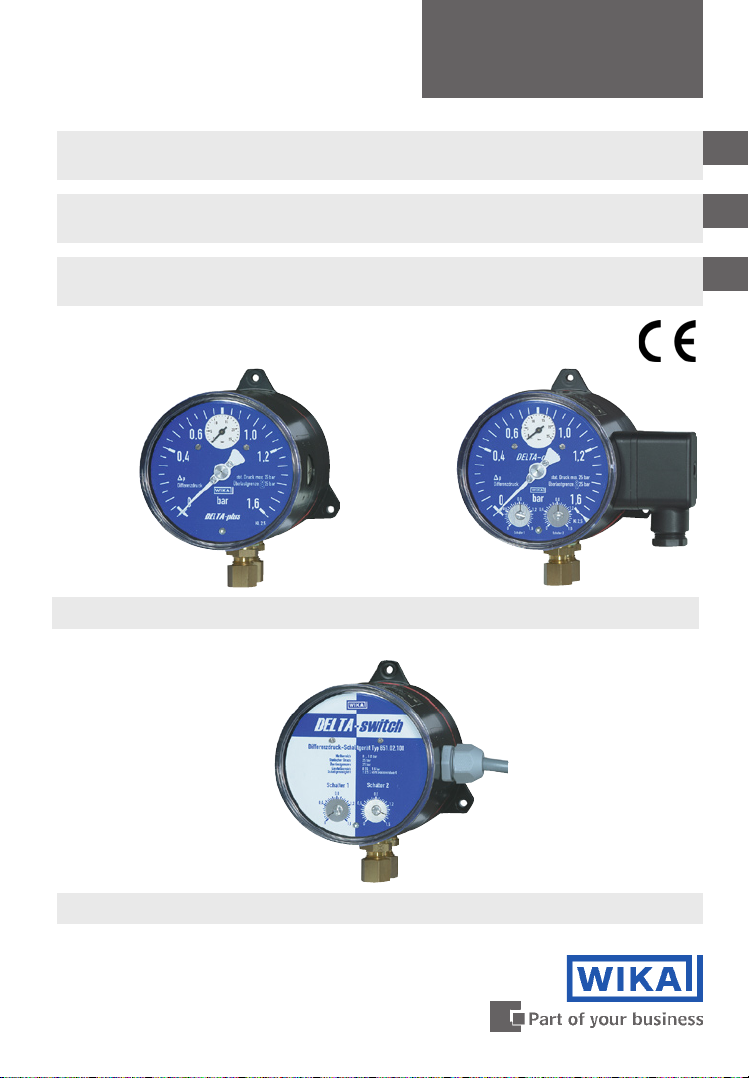

Differential pressure gauges

Model 702.01.100, 702.02.100 and 851.02.100

Differenzdruckmessgeräte

Typ 702.01.100, 702.02.100 und 851.02.100

Manomètres pour pression différentielle

Type 702.01.100, 702.02.100 et 851.02.100

su st

Model 702.01.100 Model 702.02.100

sv

GB

D

F

Model 851.02.100

Page 2

Operating instructions

GB

Model 702.01.100, 702.02.100 and 851.02.100 Page 1 - 10

Betriebsanleitung

D

Typ 702.01.100, 702.02.100 und 851.02.100 Seite 11 - 18

Mode d’emploi

F

Type 702.01.100, 702.02.100 et 851.02.100 Page 19 - 26

2080276 07/2009 GB/D/F

2

WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch

Page 3

Contents

Contents

1. Safety instructions 4

2. General 4

3. Operating principle 4

4. Installation instructions 5

5. Measuring assembly 6

6. Comissioning 6

7. Options and accessories 8

8. Storage 10

9. Maintenance and servicing / cleaning 10

10. Repairs 10

11. Disposal 10

GB

2308215 07/2009 GB/D/F

WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch

3

Page 4

1. Safety instructions ... 3. Operating principle

1. Safety instructions

The appropriate national safety regulations (i.e. VDE 0100 /

EN 60 079-14 / EN 837-2) must be observed when installing,

!

GB

Caution

Do not work on gauge while under voltage (applies to Model 702.02/03.100

and 851.02.100)

Serious injuries and/or damage can occur should the appropriate regulations

not be observed

Only appropriately qualified personnel should work on these instruments

commissioning and operating these instruments.

2. General

These operating instructions are based on the following information:

EN 837-2: Selection and installation recommendations for pressure gauges

Data sheet PM 07.15: Differential pressure gauge with integrated working

pressure gauge

Data sheet PV 27.16: Differential pressure gauge with integrated working

pressure gauge and micro switch

Model 702.02.100

Data sheet PV 27.17: Differential pressure switch

Model 851.02.100

su Model 702.01.100

sv

T

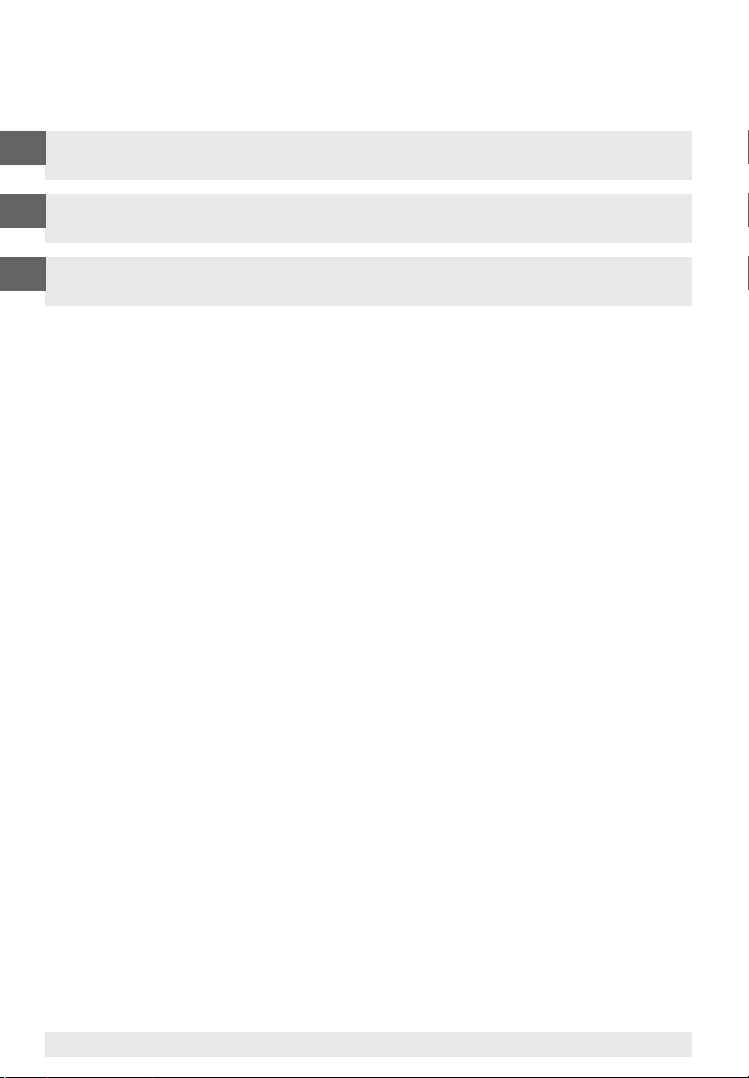

3. Operating principle

The j and i measuring medium chambers

are separated by an elastic diaphragm.

The differential pressure causes an

axial movement (measured travel) in the

diaphragm against the measuring range

spring. The measured travel is proportional

to the differential pressure and is transmitted, „pressure sealed“ and with minimal

friction, via a connecting rod; for:

su to the movement

st to the movement

and in addition to the plungers

on the microswitches

sv to the plungers

on the microswitches

4

WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch

Illustration for example st

2122740.01

2308215 07/2009 GB/D/F

Page 5

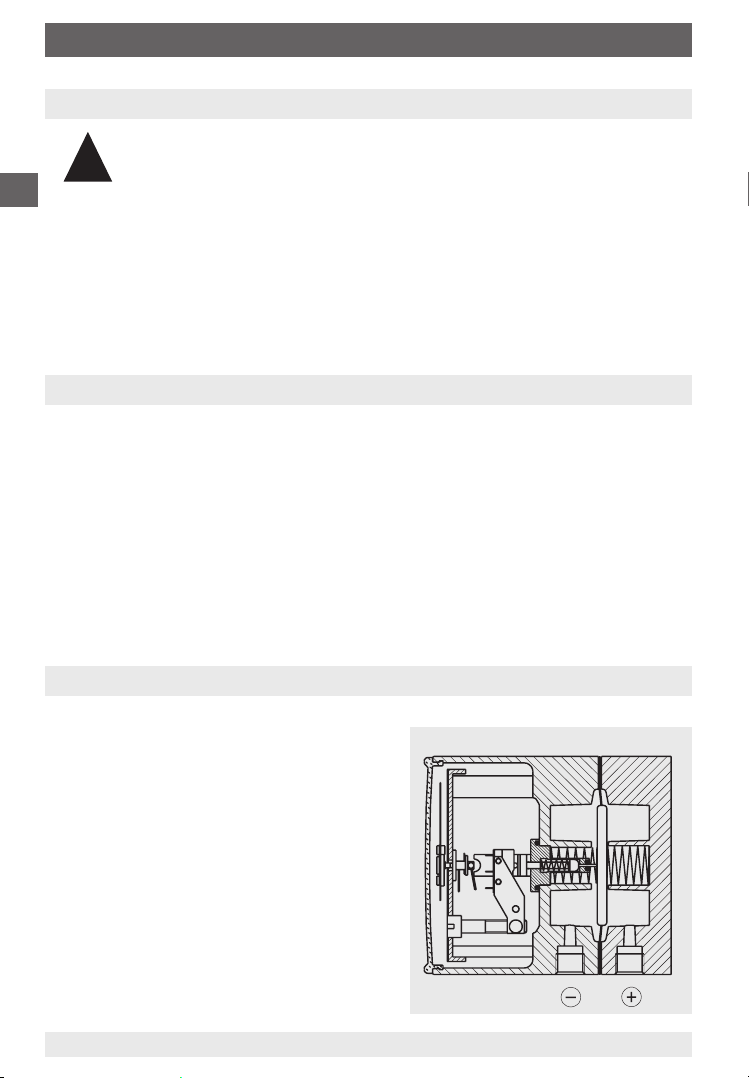

4. Installation instructions

4. Installation instructions

Installation of the differential pressure gauge should follow the installation

recommendations for pressure gauges according to EN 837-2 /7.

The maximum permissible medium / ambient temperature must not be

exceeded

Prior to the installation of the pressure gauge, the pipes should be

thoroughly cleaned by tapping, blowing or rinsing

The pressure gauges must be protected against contamination and high

temperature fluctuations!

The pressure gauges should be installed and operated such as to avoid

exposure to vibration. If the line to the pressure gauge is not robust enough

to prevent vibration it should be secured by means of brackets for wall

mounting.

Wall mounting

Installation using the three integral, cast mounting brackets

GB

2308215 07/2009 GB/D/F

WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch

2123541.01

5

Page 6

5. Measuring assembly / 6. Commissioning

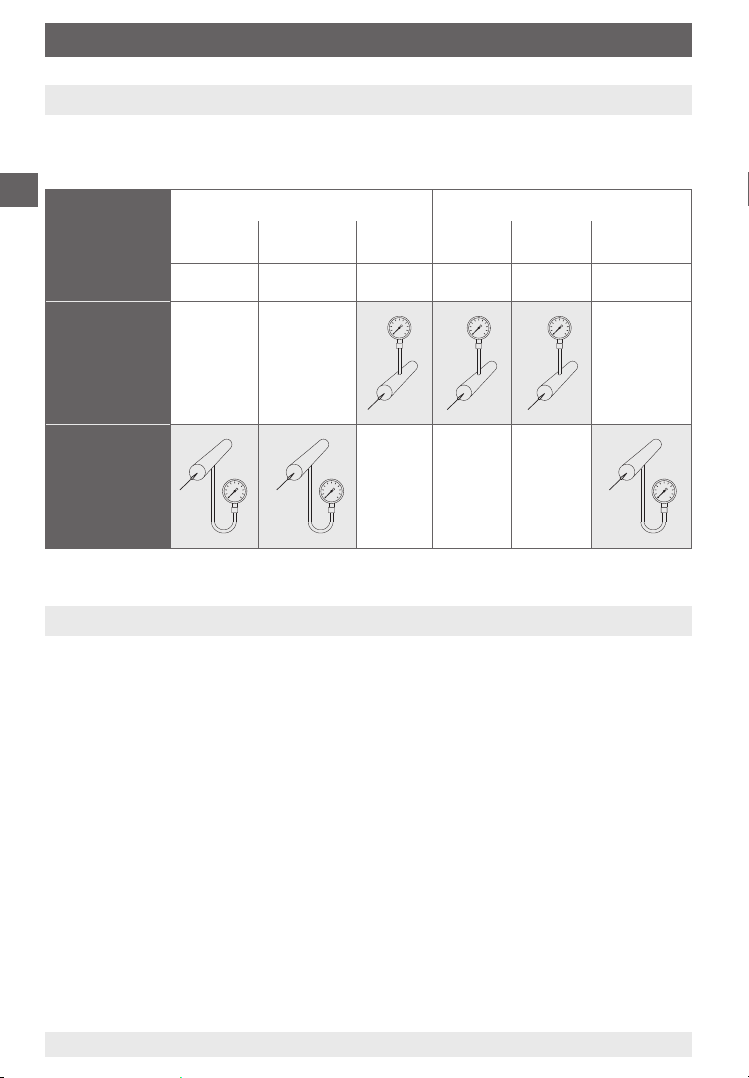

5. Measuring assembly

Proven measuring assemblies for various types of media. Recommended setup for pressure measurement instruments are shown below.

GB

Contents of

tail pipe

Typically

Pressure

instrument

higher than

tapping point

Pressure

instrument

lower than

tapping point

Liquid Liquid with

Condensate Boiling liquid LPG Dry air

Liquid media Gaseous media

vapour

Vapour

only

Gas only Wet gas Liquid gas

Most air

Flue gas

condensate

Steam

6. Commissioning

6.1 Mounting of the pressure connection

Pressure entries identified j and i j high pressure

i low pressure

6.2 Wiring details

(applies to Model 702.02.100 and 851.02.100)

The electrical connections should be made by qualified electricians

Connection details and switch functions are given on the instrument rating

plate. Connection terminals (1 ... 6) and the ground terminal are appropriately

marked.

The mains connection lines to be provided must be suitable for maximum

instrument power consumption and comply with IEC 227 or IEC 245

The instruments must be included in the equipotential bonding of the plant

6

WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch

2308215 07/2009 GB/D/F

Page 7

6. Commissioning

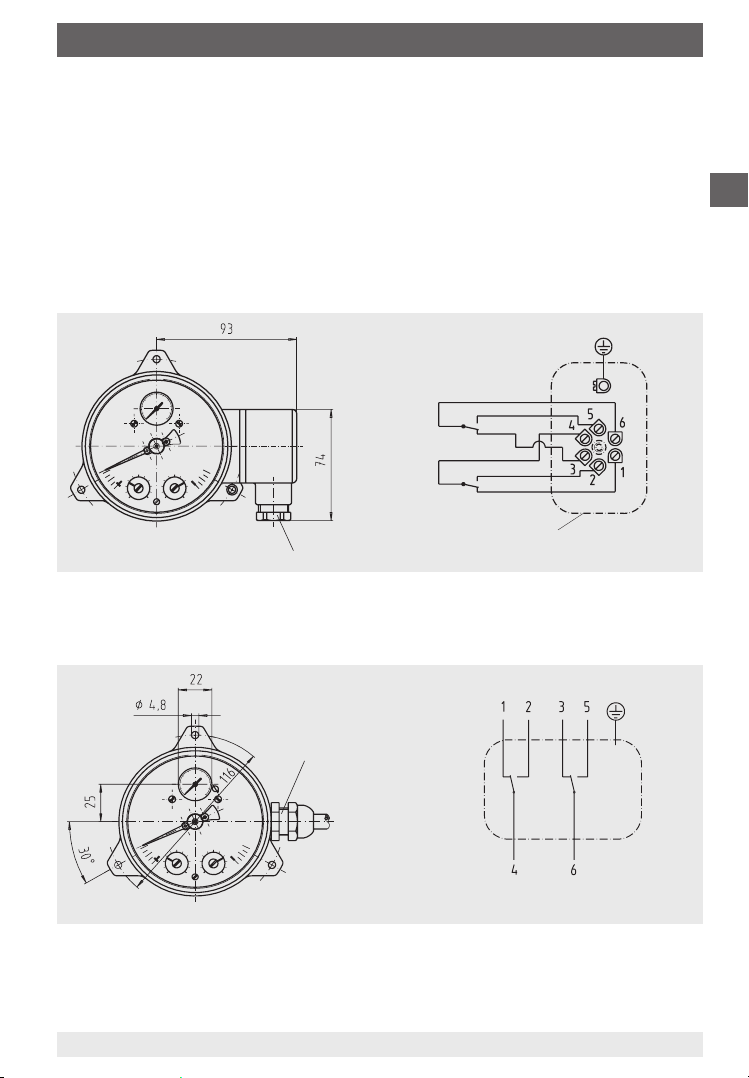

st and sv:

Power ratings (see data sheet)

Precise wiring schemes can be seen in the following drawings.

In addition to the wiring details and required power supply are given on the type

plate.

Electrical connection is by means

of terminal box or L-plug per DIN 43 651

2157306.0X

850.33 2nd contact

850.3 1st contact

Terminal box

M20 x 1,5

or electrical connection is by means

of cable gland and cable

Cable gland

M20 x 1.5

with 1 m cable

GB

2162679.01

2162679.0X

850.3

1st contact

2123568.0X

2308215 07/2009 GB/D/F

WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch

850.33

2nd contact

7

Page 8

6. Commissioning / 7. Options and accessories

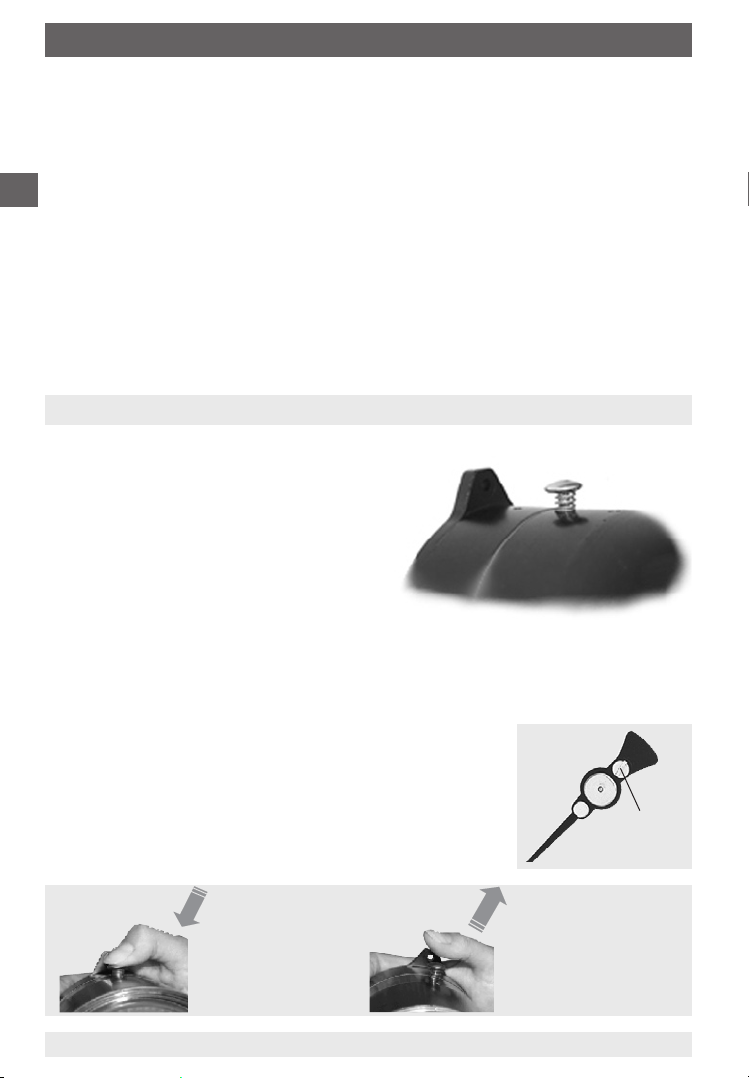

6.3 Setting the switch point / checking the zero point

The switch points are set at the factory when the desired values are given. The

adjustment of the switch point is made by setpoint screws accessible from the

front. The assistant scales enable a relatively accurate adjustment of the switch

points over 270

GB

p° and indicate the setpoint that is momentarily adjusted.

For contact re-adjustment the snap-fit window is to be lifted off using a screw

driver at the recess in the circumference. The desired switch point can be set

by turning the contact adjustment screws with a screw driver.

If a more accurate switch point adjustment is desired, a test variable should be

used.

Afterwards press the window back into the case.

To check zero point see below

7. Options and accessories

7.1 Integrated pressure equalising valve

The zero point check during the working

process is enabled by pushing the valve

button. The measuring medium flows from

the higher pressure side to the opposite

side and the differential pressure drops to

zero.

st and sv:

When the valve button is pushed, the differential pressure pointer must move

into the range of the zero point tolerance bar. As a consequence the function

of the instrument is in order. In the case of possible deviations beyond the

tolerance bar a zero point correction can be made via a standard integrated

adjustment pointer. For that purpose the snap-fit window

is to be lifted off using a screw driver at the impression/

recess in the circumference. The zero point is corrected

by turning the slotted screw at the adjustment pointer.

Afterwards the window is to be snap-fitted to the case

again. The differential pressure is indicated again, as soon

as the valve button is released.

Slotted

screw

Valve button

pushed

Differential pressure

is zero

8

WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch

Released

Differential pressure

is measured again

2308215 07/2009 GB/D/F

Page 9

7. Options and accessories

7.2 Four-way valve manifold

Shut off j- and i process line for disassembling and testing of

measuring instrument without interrupting the process that is running.

Protect the instrument against inadmissible

overpressure loading, such as, for example, in

the case of pressure tests and undefined

operating conditions (also temporary shut down).

Pressure equalising for zero point check during

normal operation as well as equalisation of the

pressures at high pressure and low pressure

side during start-up and operation (with opened

pressure equalising valve).

Process line air bleeding for liquid measuring

media and purging the process line for removing

impurities.

7.2.1 Handling instructions

Work sequence to start measuring

1. Open pressure equalising valve (middle valve)

2. Open shut-off valve of the negative-pressure media chamber (

valve) and the positive-pressure media chamber (

3. Close pressure equalising valve

Gauge valve,

high pressure

side j

Gauge valve,

low pressure

side i

j left valve)

Pressure

equalising valve

Valve for

purging or

air bleeding

i right

GB

Operating sequence for air bleeding/purging of piping

1. start: Open shut-off valve of the negative-pressure (

pressure (

j) media chamber

i) and positive-

Open pressure equalising valve and valve for purging or air bleeding

2. end: Close pressure equalising valve and valve for purging or air bleeding

Procedure at the end of the measuring operation

(also for partial system shut-down)

1. Open pressure equalising valve

2. Close shut-off valve of the negative-pressure (

(

j) media chamber

i) and positive-pressure

Task list for removing the transmitter during normal operation

1. Open pressure equalising valve

2. Close shut-off valve of the negative-pressure (

(

j) media chamber

3.

2308215 07/2009 GB/D/F

Open valve for purging or air bleeding

WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch

i) and positive-pressure

9

Page 10

7. Options and accessories ... 11. Disposal

7.3 Front flange for panel mounting

GB

Panel cut-out

Panel

2123649.0Y

8. Storage

Before installation, in order to prevent damage from the pressure gauges, follow

the subsequent points:

The pressure gauge should remain in its original packing until installation

After taking out the pressure gauge (e.g. for tests) reuse the original

packaging material

Storage temperature should not exceed -20 °C ... +60 °C

Pressure gauges should be protected against dust and humidity

9. Maintenance and servicing / cleaning

These WIKA differential pressure gauges will give very long service when

handled and operated properly. Control and safety devices are to be checked

for their efficiency (see also VDI 3033 Table1).

The instruments should be cleaned with a damp cloth, moistened with soap

solution. The residual pressure medium in dismounted pressure gauges may be

hazardous or toxic. This should be considered when handling and storing the

removed pressure gauges.

10. Repairs

Repairs should only be carried out by the manufacturer or appropriately trained

personnel. For further technical details see WIKA data sheet PM 07.15,

PV 27.16 or PV 27.17.

11. Disposal

Dispose of instrument components and packaging materials in accordance

with the respective waste treatment and disposal regulations of the region or

country to which the instrument is supplied.

10

WIKA Operating instructions DELTA-plus, DELTA-comb and DELTA-switch

2308215 07/2009 GB/D/F

Page 11

Inhalt

Inhalt

1. Sicherheitshinweise 12

2. Allgemeines 12

3. Funktionsprinzip 12

4. Montagehinweise 13

5. Messanordnungen 14

6. Inbetriebnahme 14

7. Optionen und Zubehör 16

8. Lagerung 18

9. Wartung / Reinigung 18

10. Reparaturen 18

11. Entsorgung 18

D

2308215 07/2009 GB/D/F

WIKA Betriebsanleitung DELTA-plus, DELTA-comb und DELTA-switch

11

Page 12

1. Sicherheitshinweise ... 3. Funktionsprinzip

1. Sicherheitshinweise

Beachten Sie unbedingt bei Montage, Inbetriebnahme und Betrieb

dieser Geräte die entsprechenden nationalen Sicherheitsvorschriften

!

Vorsicht

Alle Arbeiten dürfen nur im spannungslosen Zustand erfolgen (betrifft Typen

D

702.02/03.100 und 851.02.100)

Bei Nichtbeachten der entsprechenden Vorschriften können schwere Körper-

verletzungen und/oder Sachschäden auftreten

Nur entsprechend qualifiziertes Personal darf an diesen Geräten arbeiten

(z. B. VDE 0100 / EN 60 079-14 / EN 837-2).

2. Allgemeines

Vorliegende Betriebsanleitung baut auf folgenden Informationen auf:

EN 837-2: Auswahl- und Einbauempfehlungen für Druckmessgeräte

Datenblatt PM 07.15: Differenzdruckmessgerät mit integrierter Betriebs-

druckanzeige

Datenblatt PV 27.16: Differenzdruckmessgerät mit integrierter Betriebs-

druckanzeige und Mikroschalter

Typ 702.02.100

Datenblatt PV 27.17: Differenzdruck-Schaltgerät

su Typ 702.01.100

T

sv Typ 851.02.100

3. Funktionsprinzip

Die j- und i- Messstoffkammern sind durch eine elastische Membrane

getrennt. Der Differenzdruck bewirkt eine

axiale Auslenkung (Messweg) der Membrane gegen die Messbereichsfeder. Der

dem Differenzdruck proportionale Messweg

wird über eine Schubstange druckdicht und

reibungsarm übertragen; bei:

su auf ein Zeigerwerk

st auf ein Zeigerwerk

und zusätzlich an die Stößel der

Mikroschalter

sv an die Stößel der

Mikroschalter

12

WIKA Betriebsanleitung DELTA-plus, DELTA-comb und DELTA-switch

Darstellung am Beispiel st

2122740.01

2308215 07/2009 GB/D/F

Page 13

4. Montagehinweise

4. Montagehinweise

Die Montage des Differenzdruckmessgerätes erfolgt in Anlehnung an die

Einbauempfehlung für Druckmessgeräte nach EN 837-2 /7.

Die maximal zulässige Messstoff-/Umgebungstemperatur darf nicht über-

schritten werden

Messleitungen vor der Gerätemontage gründlich durch Abklopfen und

Ausblasen oder Durchspülen reinigen

Messgeräte vor Verschmutzung und starken Temperaturschwankungen

schützen!

Messgeräte sollen erschütterungsfrei montiert und betrieben werden.

Ist die Leitung zum Druckmessgerät für eine erschütterungsfreie Anbringung

nicht stabil genug, so ist die Befestigung über die Befestigungslaschen zur

Wandmontage vorzunehmen.

Wandmontage

Befestigung über drei angegossene Befestigungslaschen

D

2308215 07/2009 GB/D/F

WIKA Betriebsanleitung DELTA-plus, DELTA-comb und DELTA-switch

2123541.01

13

Page 14

5. Messanordnungen / 6. Inbetriebnahme

5. Messanordnungen

Bewährte Messanordnungen für verschiedene Messstoffarten. Die zur Anwendung besonders empfohlenen Anordnungen sind nachfolgend dargestellt.

Füllung der

D

Messleitung

Beispiele

flüssige Messstoffe gasförmige Messstoffe

flüssig zum Teil

ausgasend

Kondensat siedende

Flüssigkeiten

vollständig

verdampft

„Flüssiggase“

gasförmig zum Teil

trockene

Luft

Druckmessgerät oberhalb des

Entnahmestutzens

Druckmessgerät unterhalb des

Entnahmestutzens

6. Inbetriebnahme

6.1 Montage der Druckanschlüsse

Nach angebrachten Symbolen j und i j hoher Druck

i niedriger Druck

6.2 Elektrischer Anschluss

(betrifft Typen 702.02.100 und 851.02.100)

kondensiert

(feucht)

feuchte Luft

Rauchgase

vollständig

kondensiert

Wasserdampf

Der elektrische Anschluss darf nur durch qualifiziertes Personal erfolgen

Die Belegung der Anschlüsse und die Schaltfunktionen sind auf dem Typen-

schild am Gerät angegeben und die Anschlußklemmen (1 ... 6) sowie die

Erdungsklemme sind entsprechend gekennzeichnet.

Die vorgesehenen Netzanschlussleitungen müssen für die größte Stromauf-

nahme des Gerätes bemessen sein und IEC 227 oder IEC 245 entsprechen

Die Geräte sind in den Potenzialausgleich der Anlage mit einzubeziehen

14

WIKA Betriebsanleitung DELTA-plus, DELTA-comb und DELTA-switch

2308215 07/2009 GB/D/F

Page 15

6. Inbetriebnahme

st und sv:

Leistungsdaten (siehe Datenblatt)

Die genauen Anschlussbelegungen können dem nachfolgenden Anschlussschema entnommen werden. Zusätzlich sind Anschlussbelegung und erforderliche Hilfsenergie auf dem Typenschild am Gehäuseumfang vermerkt.

Elektrischer Anschluss über

Kabeldose oder Winkelstecker nach DIN 43 651

D

M20 x 1,5

oder elektrischer Anschluss über

Kabelverschraubung und Kabel

Kabelverschraubung

M20 x 1,5

mit 1 m Kabel

2157306.0X

2123568.0X

850.33 2. Kontakt

850.3 1. Kontakt

Kabelanschlussdose

850.3

1. Kontakt

850.33

2. Kontakt

2162679.01

2162679.0X

2308215 07/2009 GB/D/F

WIKA Betriebsanleitung DELTA-plus, DELTA-comb und DELTA-switch

15

Page 16

6. Inbetriebnahme / 7. Optionen und Zubehör

6.3 Schaltpunkteinstellung / Nullpunktüberprüfung

Bei Angabe der Sollwerte werden werkseitig die Schaltpunkte eingestellt.

Die Schaltpunktverstellung erfolgt über frontseitig zugängliche Einstellschrauben. Eine Hilfsskala über 270

p° ermöglicht eine relativ genaue Schalt-

punktjustierung und zeigt den momentan eingestellten Sollwert.

Zur Kontaktverstellung Schnappscheibe mittels Schraubendreher an der am

Umfang angebrachten Einprägung/Aussparung abheben. Durch Drehen der

D

Kontakt-Einstellschrauben mittels Schraubendreher kann gewünschter Schaltpunkt eingestellt werden.

Wird eine noch genauere Schaltpunkteinstellung gewünscht, sollte ein Prüfnormal zur Justage verwendet werden.

Anschließend die Sichtscheibe wieder in das Gehäuse eindrücken.

Nullpunktprüfung siehe unten

7. Optionen und Zubehör

7.1 Integriertes Druckausgleichsventil

Durch Betätigen des Druckknopfes wird

eine Nullpunktkontrolle im laufenden

Betriebsprozess ermöglicht. Der Messstoff

strömt von der Seite höheren Druckes

nach der Gegenseite und der Differenzdruck am Messgerät fällt auf Null.

st und sv:

Durch Betätigen des Druckknopfes muss die Differenzdruckanzeige auf Null,

d.h. in den Bereich des Nullpunkt-Toleranzbalkens gehen. Die Gerätefunktion ist damit in Ordnung. Bei möglichen Abweichungen, die außerhalb des

Toleranzbalkens liegen, kann eine Nullpunktkorrektur über den standardmäßig eingebauten Verstellzeiger erfolgen. Dazu ist die

Schnappscheibe mittels Schraubendreher an der am

Umfang angebrachten Einprägung/Aussparung abzuheben. Die Nullpunkt-Verstellung wird durch ein Verdrehen

der Schlitzschraube am Verstellzeiger erreicht. Anschließend ist die Schnappscheibe wieder auf dem Gehäuse

aufzubringen. Der Differenzdruck wird wieder angezeigt,

Schlitzschraube

sobald der Druckkopf freigeben wird.

16

Ventil betätigt

Differenzdruck

gleich Null

WIKA Betriebsanleitung DELTA-plus, DELTA-comb und DELTA-switch

Losgelassen

Differenzdruck wird

wieder gemessen

2308215 07/2009 GB/D/F

Page 17

7. Optionen und Zubehör

7.2 Vierfach-Ventilblock

Absperrung der j- und i- Prozessleitung zur Demontage oder Prüfung

des Messgerätes ohne Störung des laufenden Betriebsprozesses.

Schutz des Gerätes gegen unzulässige

Überdruckbelastung, wie z. B. bei Druckprüfungen und undefinierten Betriebsverhältnissen

(auch zeitweiliger Stilllegung).

Absperrventil

Druckausgleich zur Nullpunktkontrolle bei

j-Seite

laufenden Prozess sowie Vermeidung einseitiger

Überdruckbelastung während der Anfahr- bzw.

Betriebsphase (bei geöffnetem Druckausgleichsventil).

Entlüftung der Messleitungen bei flüssigen

Messstoffen und Spülung der Messleitungen um

Verunreinigungen zu entfernen.

7.2.1 Angaben zum Handling

Arbeitsgangfolge zum Messanfang

1. Druckausgleichsventil (mittlere Ventilspindel) öffnen

2. Absperrventil der Minus-Messstoffkammer (

Plus-Messstoffkammer (

j, linkes Ventil) öffnen

i, rechtes Ventil) und der

3. Druckausgleichsventil schließen

Absperrventil

i-Seite

Druckausgleichsventil

Entlüftungsventil

D

Arbeitsgangfolge zum Spülen/Entlüften der Messleitungen

1. Anfang: Absperrventil der i- und j- Messstoffkammer öffnen

Druckausgleichsventil und Entlüftungsventil öffnen

2. Ende: Druckausgleichsventil und Entlüftungsventil schließen

Arbeitsgangfolge zu Messende (auch zeitweise Stilllegung)

1. Druckausgleichsventil öffnen

2. Absperrventil der

i- und j- Messstoffkammer schließen

Arbeitsgangfolge zur Demontage des Messgerätes bei laufenden Prozess

1. Druckausgleichsventil öffnen

2. Absperrventil der

3.

Entlüftungsventil öffnen

2308215 07/2009 GB/D/F

WIKA Betriebsanleitung DELTA-plus, DELTA-comb und DELTA-switch

i- und j- Messstoffkammer schließen

17

Page 18

7. Optionen und Zubehör ... 11. Entsorgung

7.3 Befestigungsrand für Schalttafelmontage

2123649.0Y

D

Ausschnitt

Schalttafel

8. Lagerung

Für die Lagerung der Druckmessgeräte bis zur Montage sind, um Schäden zu

vermeiden, folgende Punkte zu beachten:

Druckmessgeräte in der Originalverpackung belassen

Nach einer eventuellen Entnahme der Messgeräte (z. B. für Prüfungen) ist die

Originalverpackung wieder zu verwenden

Lagertemperaturbereich -20 °C ... +60 °C

Messgeräte vor Feuchtigkeit und Staub schützen

9. Wartung / Reinigung

Diese WIKA-Differenzdruckmessgeräte zeichnen sich bei sachgemäßer

Behandlung und Bedienung durch eine hohe Lebensdauer aus. Regel- und

Sicherheitseinrichtungen sind auf ihre Wirksamkeit zu überprüfen (siehe auch

VDI 3033 Tafel1).

Reinigen der Geräte mit einem (in Seifenlauge) angefeuchteten Tuch.

Messstoffreste in ausgebauten Druckmessgeräten können zur Gefährdung von

Menschen, Umwelt und Einrichtungen führen. Ausreichende Vorsichtsmaßnahmen sind zu ergreifen.

10. Reparaturen

Reparaturen sind ausschließlich vom Hersteller oder entsprechend geschultem

Personal durchzuführen. Weitere technische Daten bitte dem WIKA Datenblatt

PM 07.15, PV 27.16 oder PV 27.17 entnehmen.

11. Entsorgung

Entsorgen Sie Gerätekomponenten und Verpackungsmaterialien entsprechend

den einschlägigen landesspezifischen Abfallbehandlungs- und Entsorgungsvorschriften des Anliefergebietes.

18

WIKA Betriebsanleitung DELTA-plus, DELTA-comb und DELTA-switch

2308215 07/2009 GB/D/F

Page 19

Sommaire

Sommaire

1. Consignes de sécurité 20

2. Généralités 20

3. Principe de fonctionnement 20

4. Instructions de montage 21

5. Dispositions de montage 22

6. Mise en service 22

7. Options / accessoires 24

8. Stockage 26

9. Entretien / nettoyage 26

10. Réparations 26

11. Mise au rebus 26

F

2308215 07/2009 GB/D/F

Mode d'emploi WIKA DELTA-plus, DELTA-comb et DELTA-switch

19

Page 20

1. Consignes de sécurité ... 3. Principe de fonctionnement

1. Consignes de sécurité

Les prescriptions de sécurité nationales en vigueur (par exemple

VDE 0100 / EN 60 079-14 / EN 837-2) doivent absolument être

!

Vorsicht

Toutes les interventions doivent être effectuées hors tension (concerne les

types 702.02/03.100 et 851.02.100)

F

Le non-respect des instructions correspondantes est susceptible d‘entraîner

des risques de blessure et/ou des dégâts matériels

Seul le personnel habilité et qualifié est autorisé à manipuler les instruments

respectées lors du montage, de la mise en service et de l‘utilisation

des instruments ici présentés.

2. Généralités

Le présent mode d‘emploi repose sur les informations suivantes:

EN 837-2: Recommandations pour le choix et l‘installation de manomètres

Fiche technique PM 07.15 : Manomètre pour pression différentielle avec

indication de la pression de travail su Type 702.01.100

Fiche technique PV 27.16 : Manomètre pour pression différentielle avec

indication de la pression de travail et microcontact T Type 702.02.100

Fiche technique PV 27.17 : Pressostat différentiel sv Type 851.02.100

3. Principe de fonctionnement

Les chambres de mesure j- et i- sont séparées par une membrane élastique.

La différence de pression provoque

un déplacement axial de la membrane

(chemin de mesure) contre le ressort

de l‘étendue de mesure. Le déplacement proportionnel à la différence de

pression est transmis avec un frottement minimal par une biellette étanche

en fonction du type d‘appareil :

su à un mouvement

st à un mouvement et en

plus au poussoir du microcontact

sv

20

au poussoir du microcontact

Mode d'emploi WIKA DELTA-plus, DELTA-comb et DELTA-switch

Exemple de présentation d'un st

2122740.01

2308215 07/2009 GB/D/F

Page 21

4. Instructions de montage

4. Instructions de montage

Le montage de l‘appareil de mesure de pression différentielle s‘effectue en

référence à la recommandation pour l‘installation des appareils de mesure de

pression selon EN 837-2/7.

Les températures maximales autorisées pour le fluide et l‘environnement ne

doivent pas être dépassées

Avant le montage de l‘appareil, nettoyer à fond la tuyauterie en tapant

dessus ou en soufflant à l‘air comprimé ou en les rinçant

Protéger les appareils de mesure de la pollution et des variations de

température élevées!

Les appareils de mesure doivent être installés et utilisés de façon à ne pas

être soumis à des vibrations. Un découplage du lieu de montage avec

vibrations peut être obtenu, par exemple par l‘installation de l‘appareil de

mesure sur une paroi rigide avec pose d‘une conduite flexible entre l‘appareil

de mesure et le point de mesure.

Montage sur parol

Fixation à l‘aide de trois oeillets intégrés

F

2308215 07/2009 GB/D/F

Mode d'emploi WIKA DELTA-plus, DELTA-comb et DELTA-switch

2123541.01

21

Page 22

5. Dispositions de montage / 6. Mise en service

5. Dispositions de montage

Dispositions de montage éprouvées pour différents fluides. Les dispositions

particulièrement recommandables sont décrites ci-après.

Remplissage de la

conduite de

mesure

F

Exemples

liquides en partie

condensat liquides en

fluides liquides fluides gazeux

dégazés

ébullition

complètement

évaporés

„gaz liquides“ air sec

gazeux en partie

condensés

(humides)

air humide

gaz de fumées

Manomètre

au-dessus

du point de

mesure

Manomètre

en-dessous

du point de

mesure

6. Mise en service

complètement

condensés

vapeur d‘eau

6.1 Montage des raccords process

Selon les symboles indiqués j et i j pression élevée

i pression basse

6.2 Branchement électrique

(concerne les types 702.02.100 et 851.02.100)

Le branchement électrique ne peut être effectué que par du personnel

qualifié

La position des branchements et les fonctions de commutation sont

indiquées sur la plaquette signalétique de l‘appareil, les bornes de branchement (1 ... 6) ainsi que la borne de terre sont marquées en conséquence.

Les conducteurs secteurs prévus doivent être adaptés à la puissance

consommée la plus élevée du courant de l‘appareil et correspondre à

IEC 227 ou IEC 245

Les appareils doivent être intégrés dans la compensation de potentiel du site

22

Mode d'emploi WIKA DELTA-plus, DELTA-comb et DELTA-switch

2308215 07/2009 GB/D/F

Page 23

6. Mise en service

st und sv:

Caractéristiques (voir fiche technique)

Les affectations exactes peuvent être prélevées sur le schéma de branchement

ci-après. En plus, l‘affectation de branchement et l‘alimentation nécessaire sont

indiquées sur la plaque signalétique du boîtier.

Branchement électrique

Branchement par boîte de jonction ou fiche coudée selon DIN 43 651

ou branchement électrique

Branchement par presse-étoupe et câble

2157306.0X

850.33 2ème contact

850.3 1er contact

M20 x 1,5

Câble avec presse-étoupe

M20 x 1,5 avec

câble longueur 1 m

Boîte de jonction

850.3

1er contact

850.33

2ème contact

F

2162679.01

2162679.0X

2123568.0X

2308215 07/2009 GB/D/F

Mode d'emploi WIKA DELTA-plus, DELTA-comb et DELTA-switch

23

Page 24

6. Mise en service / 7. Options / accessoires

6.3 Réglage des points de commutation / Contrôle du point zéro

Les réglages des points de commutation s‘effectuent par des vis de réglage

depuis la face avant. L‘échelle d‘assistance de 270

p° permet un réglage du

point de commutation relativement exact et indique la valeur de consigne

réglée actuellement.

Afin de déplacer le contact, il faut tout d‘abord ouvrir le voyant en le soulevant par les rainures se trouvant sur sa périphérie. La valeur de point de seuil

requise est obtenue en tournant la vis de réglage.

F

Si on souhaite un réglage du point de commutation encore plus précis, il faut

utiliser un étalon de contrôle pour le réglage.

Ensuite remonter le voyant en le clipsant sur le boîtier.

Contrôle du point zéro voir ci-après

7. Options / accessoires

7.1 Valve de compensation de pression intégrée

En appuyant sur le poussoir on permet un

contrôle du zéro en cours de fonctionnement du process.

Le fluide passe du côté haute pression au

côté opposé et la différence de pression

passe à zéro.

st et sv:

Quand on appuye sur le poussoir l‘affichage de la pression différentielle doit

passer à zéro, c‘est à dire doit se trouver dans la barre de tolérance du zéro.

La fonction de l‘appareil est alors correcte. En cas d‘une dérive hors de la barre

de tolérance du zéro, une correction du zéro peut être faite par l‘aiguille micrométrique réglable montée de série.

Pour ce faire, il faut tout d‘abord ouvrir le voyant en

le soulevant à l‘aide d‘un tournevis par les rainures se

trouvant sur sa périphérie. Le réglage du zéro se fait en

tournant la vis se trouvant sur l‘aiguille réglable. Ensuite

remonter le voyant en le clipsant sur le boîtier. La pression

Vis à fente

différentielle sera de nouveau affichée dès qu‘on relâche

le bouton.

24

Vanne

manœuvrée

Pression différentielle

égale à zéro

Mode d'emploi WIKA DELTA-plus, DELTA-comb et DELTA-switch

relâchée

Pression différentielle

est de nouveau mesurée

2308215 07/2009 GB/D/F

Page 25

7. Options / accessoires

7.2 Manifold 4 voies

Fermeture des conduites de processus j et i pour le démontage ou le

contrôle de l‘appareil de mesure sans perturber le process en cours.

Protection de l‘appareil contre les surpres-

sions, comme par exemple lors de contrôles de

pression et des conditions de fonctionnement

indéfinies (également lors de la mise hors service

temporaire).

Equilibrage de la pression pour le contrôle du

Robinet

d‘isolement

côté j

zéro en cours de process ainsi que pour éviter

une surpression unilatérale pendant le démarrage ou le service de l‘installation (avec vanne

d‘équilibre de pression ouverte).

Ventilation des conducteurs de mesure de

fluides liquides et rinçage des conducteurs afin

d‘éliminer des impuretés.

Robinet

d‘isolement

côté i

7.2.1 Indications de l‘utilisation

Déroulement des opérations en début de mesure

1. Ouvrir la vanne d‘équilibrage de pression (vanne du milieu)

2. Ouvrir le robinet d‘isolement du côté négatif de la chambre de mesure

(

i, robinet de droite), ensuite ouvrir le robinet d‘isolement du côté positif

de la chambre de mesure (

j, robinet de gauche)

3. Fermer la vanne d‘équilibrage de pression

Vanne d‘équilibre

de pression

Vanne de

purge

F

Déroulement des opérations pour le rinçage / la ventilation des conduites

de mesure

1. Début: Ouvrir les robinets

i et j de la chambre de mesure

Ouvrir la vanne d‘équilibrage de pression et la vanne de purge

2. Fin: Fermer la vanne d‘équilibrage de pression et la vanne de purge

Déroulement des opérations en fin de mesure (également lors de la mise

hors service temporaire)

1. Ouvrir la vanne d‘équilibrage de pression

2. Fermer les robinets

Déroulement des opérations pour le démontage de l‘appareil de mesure en

i et j de la chambre de mesure

cours de fonctionnement du process

1. Ouvrir la vanne d‘équilibrage de pression

2. Fermer les robinets

3.

Ouvrir la vanne de purge

2308215 07/2009 GB/D/F

Mode d'emploi WIKA DELTA-plus, DELTA-comb et DELTA-switch

i et j de la chambre de mesure

25

Page 26

7. Options / accessoires ... 11. Mise au rebus

7.3 Collerette avant pour le montage sur panneau

2123649.0Y

F

Découpure

Panneau

8. Stockage

Pour stocker les transmetteurs de pression en attendant leur montage, il est

nécessaire - afin d‘éviter des dégats - de respecter les points suivants:

Laisser les transmetteurs de pression dans leur emballage d‘origine.

Après avoir prélevé un transmetteur de pression (par exemple pour un

contrôle) le réemballer dans son emballage d‘origine.

Température de stockage -20 °C ... +60 °C

Protéger les appareils de l‘humidité et de la poussière.

9. Entretien / Nettoyage

S‘ils sont manipulés et utilisés correctement, les manomètres pour pression

différentielle WIKA se distinguent par une longue durée de vie. Control and

safety devices are to be checked for their efficiency (see also VDI 3033 Table1).

L‘appareil se nettoie à l‘aide d‘un chiffon humidifié (avec du savon).

Des restes de fluide se trouvant dans les manomètres démontés peuvent

provoquer une mise en danger de personnes, de l‘environnement et de l‘équi-

pement. Des précautions adéquates sont à prendre.

10. Réparations

Toute réparation doit être exclusivement confiée au fabricant ou à du personnel

qualifié correspondant. Pour autres données, se reporter à la fiche technique

de l‘instrument correspondant (PM 07.15, PV 27.16 ou PV 27.17)

11. Mise au rebus

Mettez les composants des appareils et les emballages au rebus en respectant

les prescriptions nationales pour le traitement et la mise au rebus des régions

ou pays de livraison.

26

Mode d'emploi WIKA DELTA-plus, DELTA-comb et DELTA-switch

2308215 07/2009 GB/D/F

Page 27

WIKA Global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand GmbH & Co. KG

1230 Vienna

Phone: (+43) 1-86 91 631

E-mail: info@wika.at

www.wika.at

Benelux

WIKA Benelux

6101 WX Echt

Phone: (+31) 475-535 500

E-mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

1309 Sofia

Phone: (+359) 2 82138-10

E-mail: t.antonov@wika.bg

Croatia

WIKA Croatia d.o.o.

Hrastovička 19

10250 Zagreb-Lučko

Phone: (+385) 1 6531034

E-mail: info@wika.hr

Finland

WIKA Finland Oy

00210 Helsinki

Phone: (+358) 9-682 49 20

E-mail: info@wika.fi

www.wika.fi

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Phone: (+33) 1-34 30 84 84

E-mail: info@wika.fr

www.wika.fr

Germany

WIKA Alexander Wiegand

SE & Co. KG

63911 Klingenberg

Phone: (+49) 93 72-13 20

Fax: (+49) 93 72-13 24 06

E-mail: info@wika.de

www.wika.de

2308215 07/2009 GB/D/F

Italy

WIKA Italiana SRL

20020 Arese (Milano)

Phone: (+39) 02-93 86 11

Fax: (+39) 02-93 86 174

E-mail: info@wika.it

www.wika.it

Poland

WIKA Polska S.A.

87-800 Wloclawek

Phone: (+48) 542 30 11 00

E-mail: info@wikapolska.pl

www.wikapolska.pl

Romania

WIKA Instruments Romania S.R.L.

Bucuresti, Sector 5

Calea Rahovei Nr. 266-268

Phone: (+40) 21 4563138

E-mail: m.anghel@wika.ro

Russia

ZAO „WIKA Mera“

127015 Moscow

Phone: (+7) 495-648 01 80

E-mail: info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

11060 Belgrade

Phone: (+381) 11 27 63 722

E-mail: info@wika.co.yu

www.wika.co.yu

Spain

Instrumentos WIKA, S.A.

08205 Sabadell (Barcelona)

Phone: (+34) 902 902 577

E-mail: info@wika.es

www.wika.es

Switzerland

Manometer AG

6285 Hitzkirch

Phone: (+41) 41-919 72 72

E-mail: info@manometer.ch

www.manometer.ch

Turkey

WIKA Alexander Wiegand

GmbH & Co. KG, Türkiye

Maltepe - Istanbul

Phone: (+90) 216/305 46 24

E-mail: info@wika.com.tr

www.wika.com.tr

Ukraine

WIKA Pribor GmbH

83016 Donetsk

Phone: (+38) 062 345 34 16

E-mail: info@wika.ua

www.wika.ua

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill RH13LG

Phone: (+44) (0) 1737 644 008

E-mail: info@wika.co.uk

www.wika.co.uk

North America

Canada

WIKA Instruments Ltd.

Head Office

Edmonton, Alberta, T6N 1C8

Fax: (+1) 780-462 00 17

E-mail: info@wika.ca

www.wika.ca

Mexico

Instrumentos WIKA Mexico S.A.

de C.V.,

01210 Mexico D.F.

Phone: (+52) 555 020 53 00

E-mail: ventas@wika.com

www.wika.com.mx

USA

WIKA Instrument Corp.

Lawrenceville, GA 30043

Phone: (+1) 770-513 82 00

E-mail: info@wika.com

www.wika.com

South America

Argentina

WIKA Argentina S.A.

Buenos Aires

Phone: (+54) 11-4730 18 00

E-mail: info@wika.com.ar

www.wika.com.ar

Brazil

WIKA do Brasil Ind. e Com.

Ltda.

CEP 18560-000 Iperó - SP

Phone: (+55) 15-3459 97 00

E-mail: marketing@wika.com.br

www.wika.com.br

WIKA Betriebsanleitung DELTA-plus, DELTA-comb und DELTA-switch

Page 28

WIKA Global

Africa / Middle East

Egypt

WIKA Alexander Wiegand

GmbH & Co. KG, El-Serag

Nasr City, Cairo

Phone: (+20) 2 2287 6219

Fax: (+20) 2 2273 3140

E-mail: ahmed.azab@wika.de

South Africa

WIKA Instruments (Pty.) Ltd.

Johannesburg 2047

Phone: (+27) 11-621 00 00

E-mail: sales@wika.co.za

www.wika.co.za

United Arab Emirates

WIKA Middle East FZE

Jebel Ali, Dubai

Phone: (+971) 4-883 90 90

E-mail: wikame@emirates.net.ae

Asia

China

WIKA International Trading

(Shanghai) Co., Ltd.

200001 Shanghai

Phone: (+86) 21-53 85 25 72

E-mail: info@wika.com.cn

India

WIKA Instruments India Pvt.

Village Kesnand, Wagholi

Pune - 412 207

Phone: (+91) 20-66 29 32 00

E-mail: sales@wika.co.in

www.wika.co.in

Japan

WIKA Japan K. K.

Tokyo 105-0023

Phone: (+81) 3-54 39 66 73

Fax: (+81) 3-54 39 66 74

E-mail: t-shimane@wika.co.jp

Kazakhstan

TOO WIKA Kazakhstan

050050 Almaty

Phone: (+7) 32 72 33 08 48

Fax: (+7) 32 72 78 99 05

E-mail: info@wika.kz

Korea

WIKA Korea Ltd.

Seoul 153-023

Phone: (+82) 2 - 8 69 05 05

Fax: (+82) 2 - 8 69 05 25

E-mail: info@wika.co.kr

Malaysia

WIKA Instrumentation (M) Sdn.

Bhd.

47100 Puchong, Selangor

Phone: (+03) 80 63 10 80

Fax: (+03) 80 63 10 70

E-mail: info@wika.com.my

www.wika.com.my

Singapore

WIKA Instrumentation Pte. Ltd.

569625 Singapore

Phone: (+65) 68 44 55 06

E-mail: info@wika.com.sg

www.wika.com.sg

Taiwan

WIKA Instrumentation Taiwan

Ltd.

Pinjen, Taoyuan

Phone: (+886) 3 420 6052

E-mail: info@wika.com.tw

www.wika.com.tw

Australia

Australia

WIKA Australia Pty. Ltd.

Rydalmere, NSW 2116

Phone: (+61) 2-88 45 52 22

E-mail: sales@wika.com.au

www.wika.com.au

New Zealand

Process Instruments Limited

Unit 7 / 49 Sainsbury Road

St Lukes - Auckland 1025

Phone: (+64) 9 - 847 90 20

E-mail: info@wika.co.nz

www.wika.co.nz

Technical alteration rights reserved.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. (+49) 9372/132-0

Fax (+49) 9372/132-406

E-Mail info@wika.de

www.wika.de

28

2308215.03 07/2009 GB/D/F

Loading...

Loading...