Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manuale d'uso

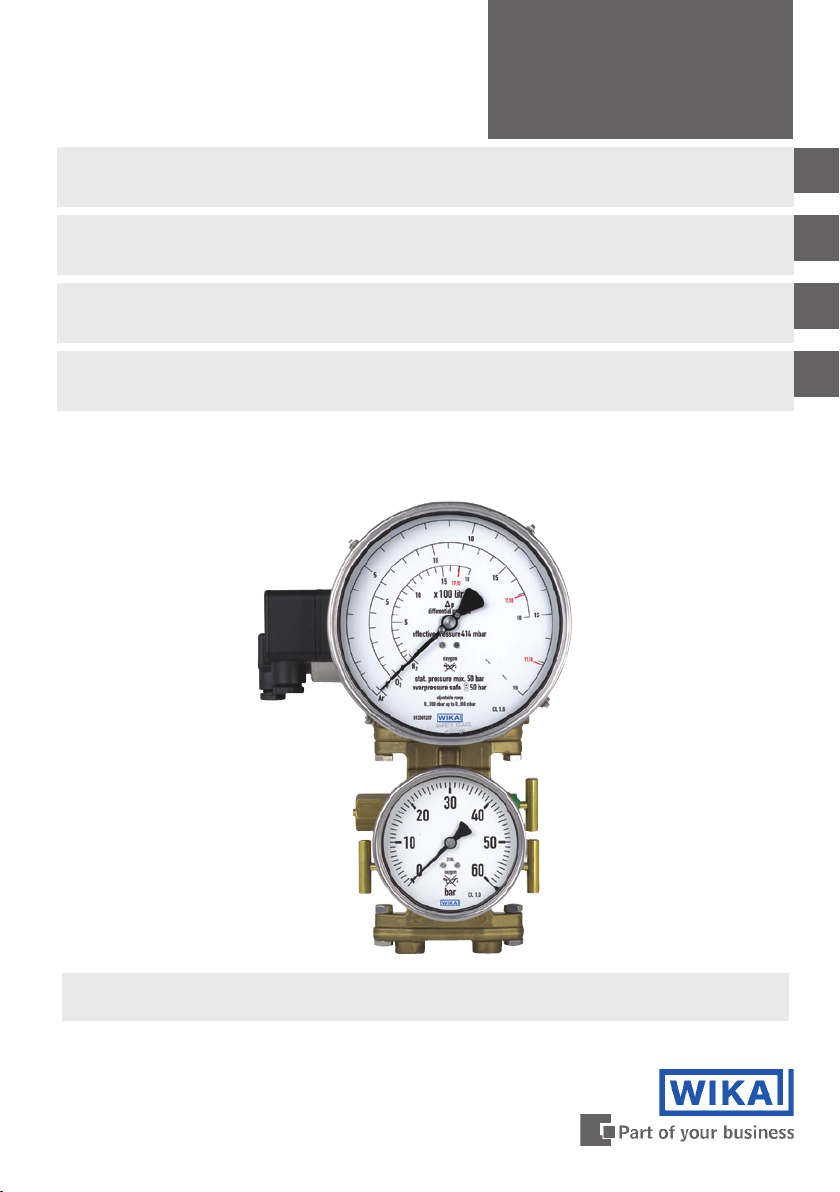

Dierential pressure gauge

Models 712.15.160, 732.15.160

Dierenzdruckmessgerät

Typen 712.15.160, 732.15.160

Manomètre pour pression diérentielle

Types 712.15.160, 732.15.160

Manometro dierenziale

Modelli 712.15.160, 732.15.160

GB

D

F

I

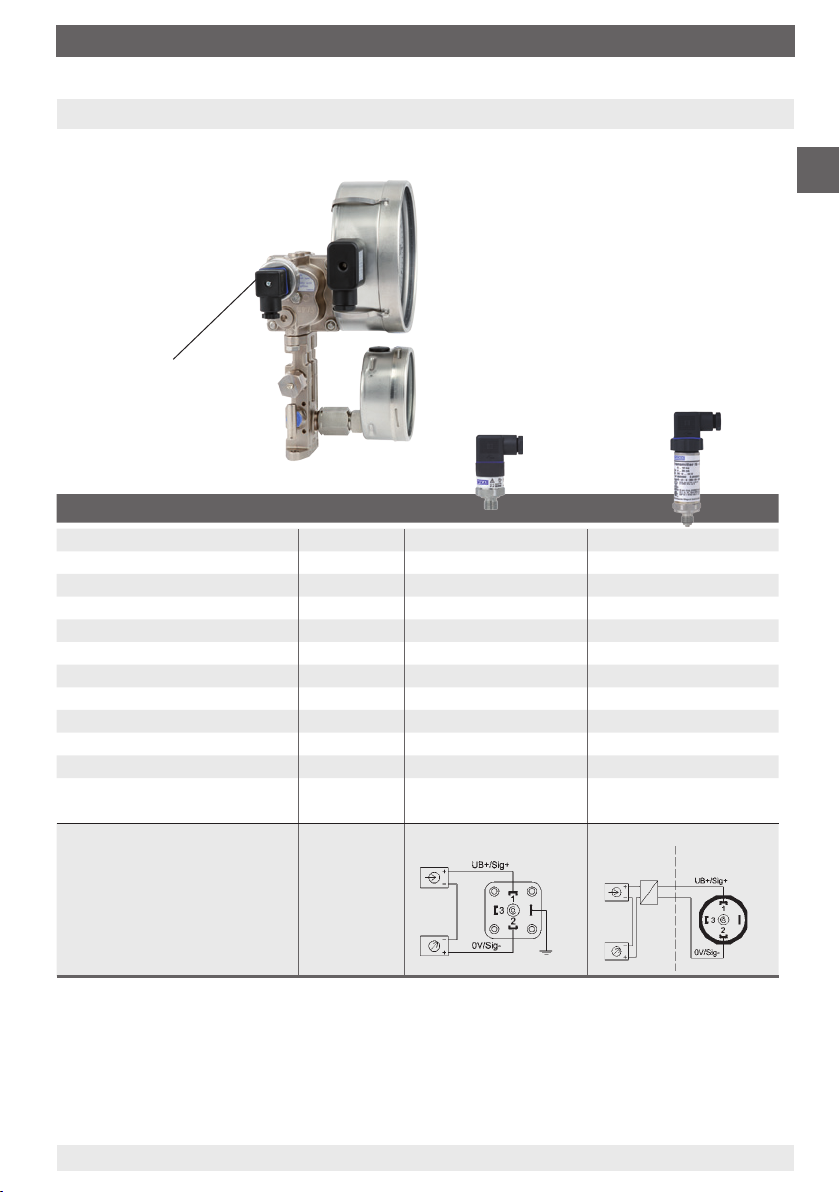

Cryo Gauge

Model 712.15.160 with optional transmitters for dierential

pressure and working pressure

Page 2

Operating instructions for dierential pressure gauges

GB

Models 712.15.160, 732.15.160 Page 3-19

Betriebsanleitung für Dierenzdruckmessgeräte

D

Typen 712.15.160, 732.15.160 Seite 21-37

Mode d’emploi pour manomètres pour pression diérentielle

F

Types 712.15.160, 732.15.160 Page 39-52

Manuale d‘uso per manometri dierenziali

I

Modelli 712.15.160, 732.15.160 Pagine 53-66

© 2010 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

Prima di iniziare ad utilizzare lo strumento, leggere il manuale d‘uso!

Conservare per future consultazioni!

2

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

11265191.07 12/2012 GB/D/F/I

Page 3

Contents

Contents

1. Safety 4

2. General information 4

3. Installation 4

4. Dierential pressure gauge 6

5. Valve manifold with working pressure gauge (optional) 8

6. Application note 9

7. Adapter for process connection (optional) 9

8. Transmitter for level measurement (optional) 9

9. Transmitter for working pressure indication (optional) 13

10. Switch contacts (optional) 14

11. Maintenance 16

GB

12. Disposal 16

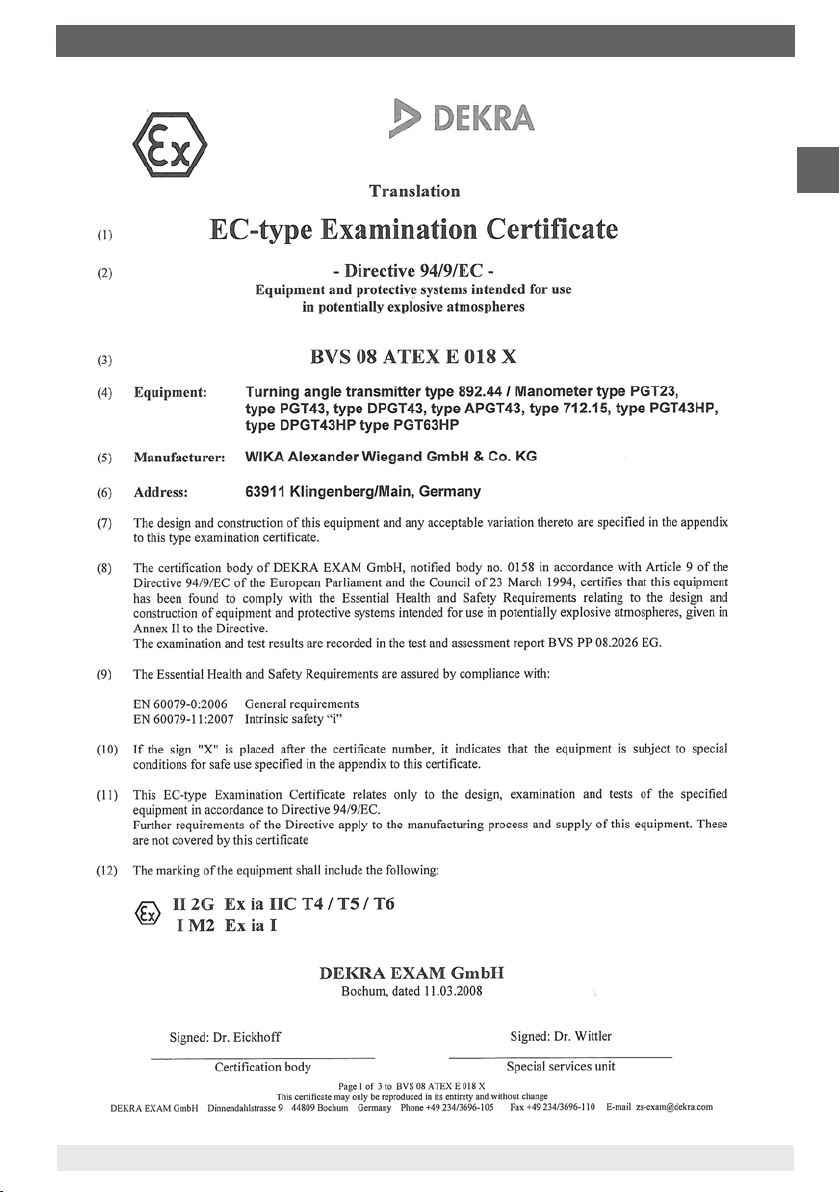

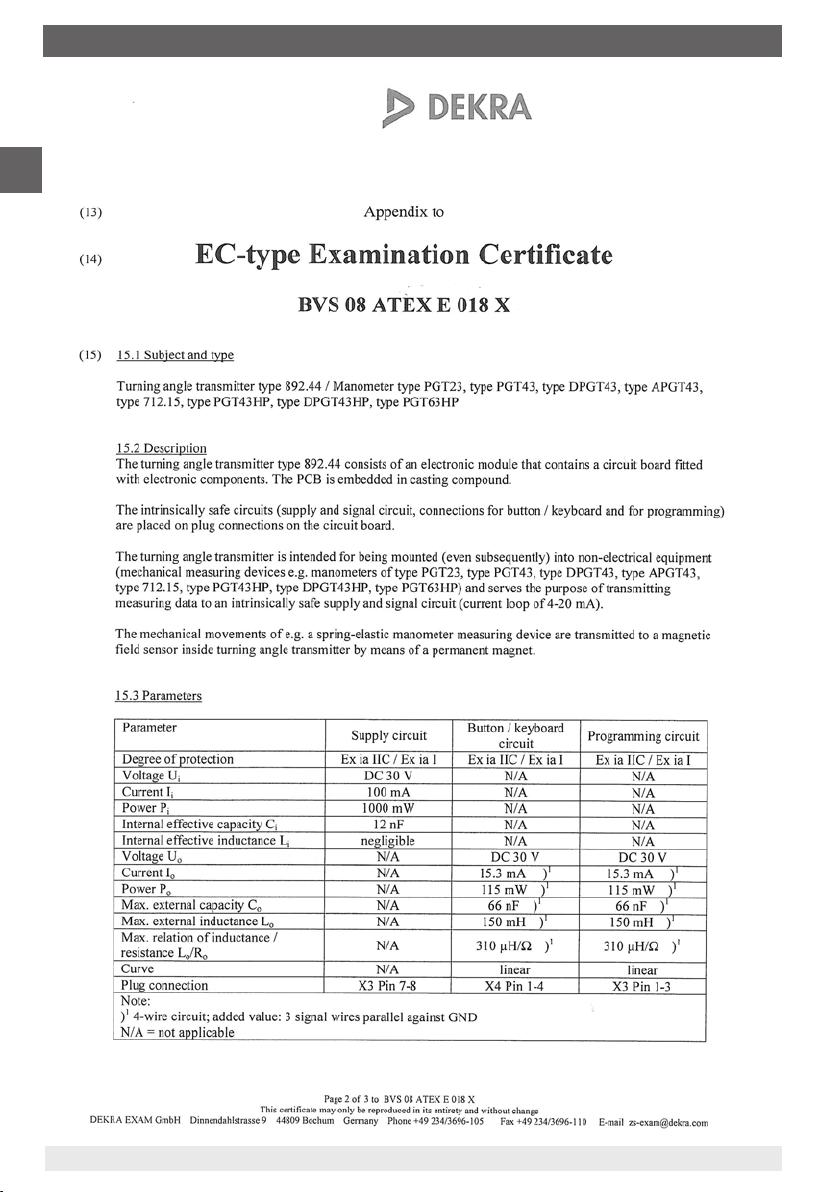

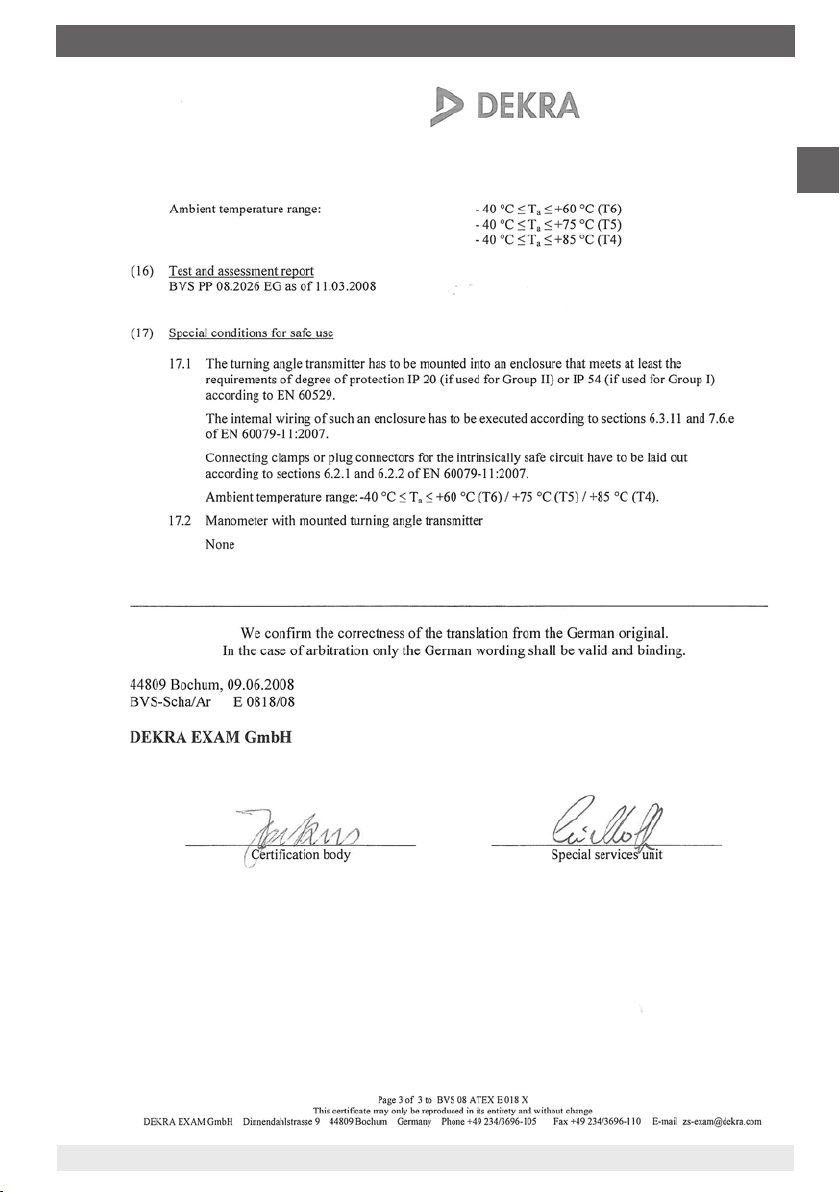

Enclosure 1: EC-type examination certicate (Ex approval)

for turning angle transmitter type 892.44 17

Information

This symbol provides you with information, notes and

tips.

Warning!

This symbol warns you against actions that can cause

injury to people or damage to the instrument.

11265191.07 12/2012 GB/D/F/I

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

3

Page 4

1. Safety ... 3. Installation

1. Safety

GB

WARNING!

Before installation, commissioning and operation, ensure that the

appropriate dierential pressure gauge has been selected in terms of

measuring range, design and specic measuring conditions.

Only work on the gauge with the voltage disconnected.

Non-observance can result in serious injury and/or damage to equipment.

Only appropriately qualied skilled personnel should work on these

instruments.

2. General information

These operating instructions are based upon the following:

EN 837-2: Selection and installation recommendations for pressure gauges

Data sheet PM 07.30: Dierential pressure gauges models 712.15.160, 732.15.160

Data sheet PM 02.01, PM 02.02, PM 02.04: Bourdon tube pressure gauges

3. Installation

The installation of the dierential pressure gauge should be carried out in accordance with the

installation recommendations for pressure gauges per EN 837-2 /7.

Prior to the installation of the pressure gauge, the pipes should be thoroughly cleaned

The pressure gauge should be installed and operated such as to avoid exposure to

vibration.

Mounting by means of - rigid tailpipe and/or

- 4 M8 threaded mounting holes incorporated in the body

The pressure gauges should be protected against contamination and high temperature

uctuations

The maximum permissible media/ambient temperature must not be exceeded

Fitting of the pressure connections as per the j and i symbols

j

higher pressure ⇒ bottom pressure (p

i

lower pressure ⇒ working pressure/overriding pressure (p

p

= pFL + pD

B

(with p

4

= hydrostatic pressure of liquid = r • g • h)

FL

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

),

B

)

D

11265191.07 12/2012 GB/D/F/I

Page 5

3. Installation

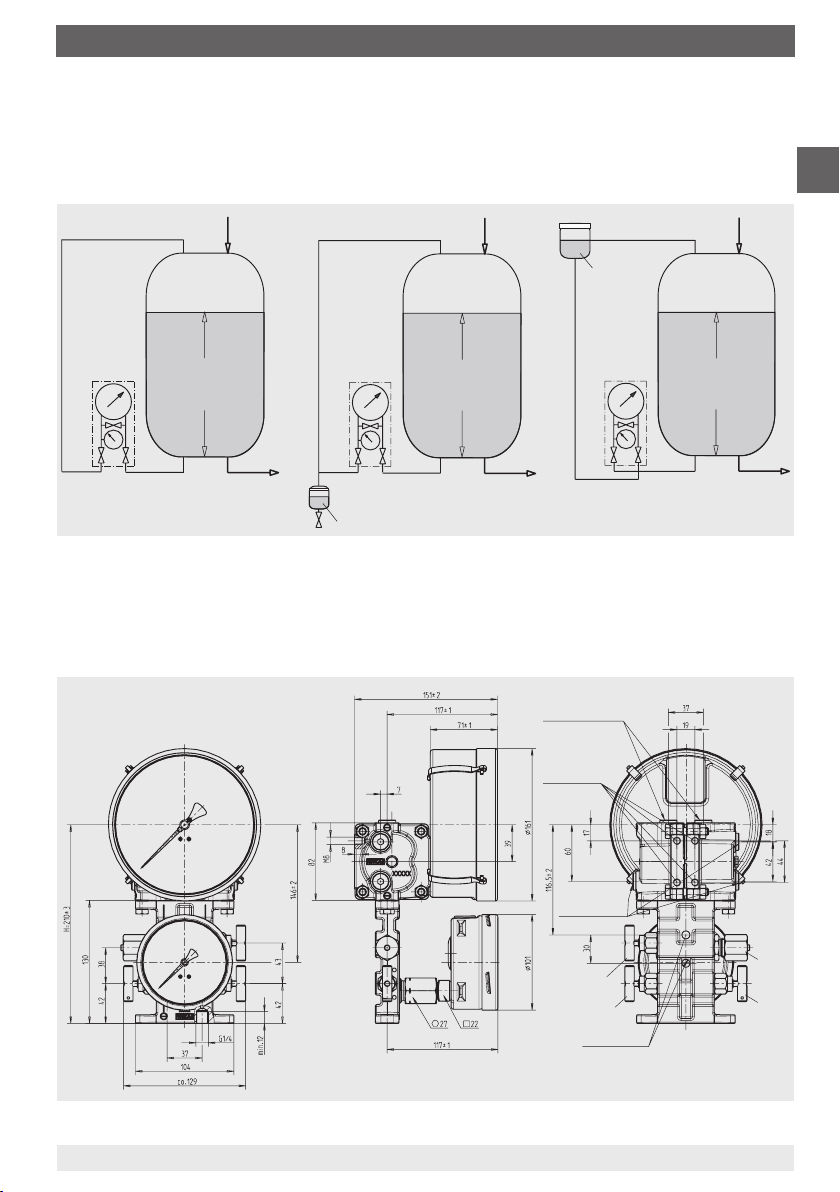

Types of installation for level measurement

Standard in cryogenic equipment 2 examples with condensate formation

(liquid gases)

Fillin g hole

p

D

Dp Dp Dp

p

D

p

B

p

D

Drain pipe Drain pipe

p

B

i ji j

Condensate

Fillin g

hole

p

D

Condensate

⇔

Constant

level

vessel

i j

Wall mounting

Installation/fastening to the 4 mounting holes M8 / 2 xing holes Ø 8.5

Pressur e connection s G 1/4

p

D

hhh

Fillin g

hole

Drain pipe

GB

M8

mountin g holes

Pressur e connections G 1/4

Pressur e

equalis ing valve

Isolati ng valve

j

Ø 8.5 xing h oles

11265191.07 12/2012 GB/D/F/I

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

Test

connect ion

Isolati ng

valve

i

5

11236396.02a

Page 6

3. Installation / 4. Dierential pressure gauge

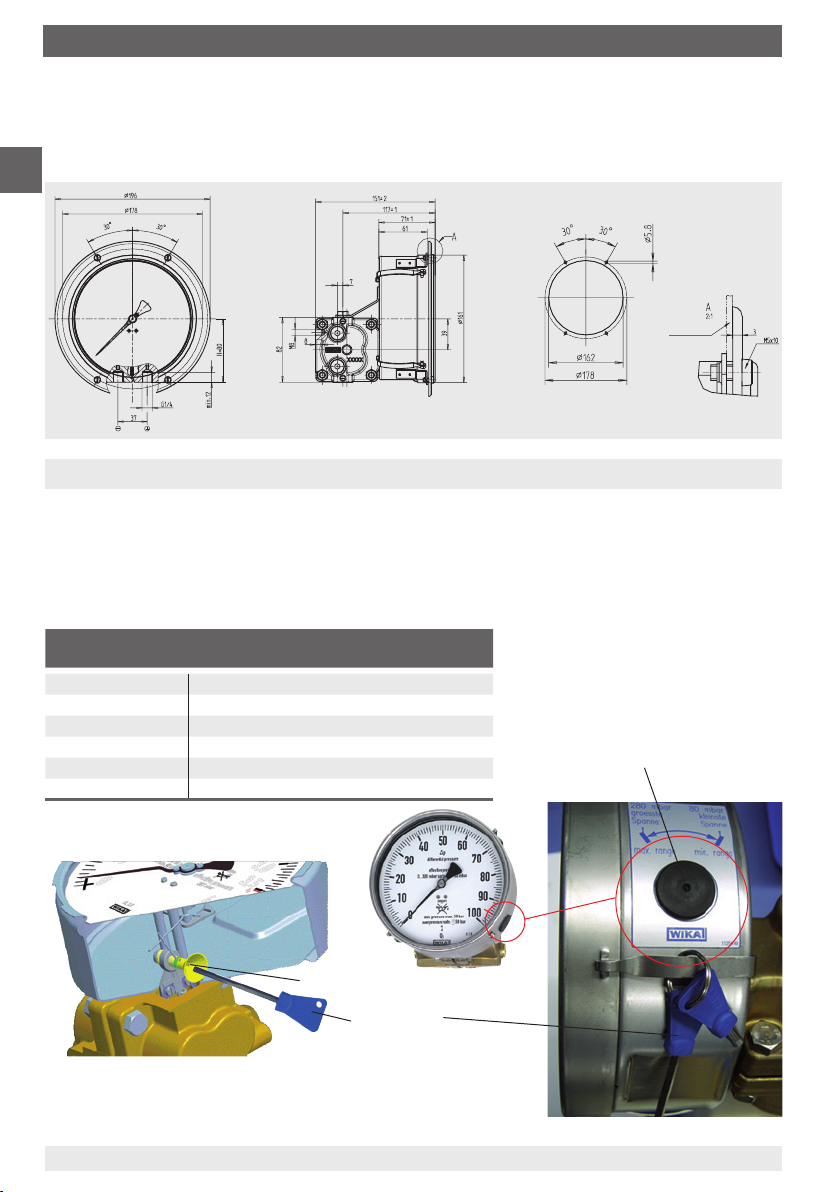

Option

Panel mounting

GB

Panel cu t-out

Panel

4. Dierential pressure gauge

The measuring range of the dierential pressure gauge can, depending on the particular

measurement system used, be adjusted within the limits given in the previous specications

table). Ideally, this adjustment should be made on a test bench, though it can also be carried

out at the measuring point using a hand test pump.

Measuring range limits

Measuring cell Adjustable measuring ranges

from to

140 mbar 0 ... 40 mbar - 0 ... 140 mbar

280 mbar 0 ... 80 mbar - 0 ... 280 mbar

560 mbar 0 ... 160 mbar - 0 ... 560 mbar

1130 mbar 0 ... 320 mbar - 0 ... 1130 mbar

2300 mbar 0 ... 650 mbar - 0 ... 2300 mbar

4000 mbar 0 ... 1150 mbar - 0 ... 4000 mbar

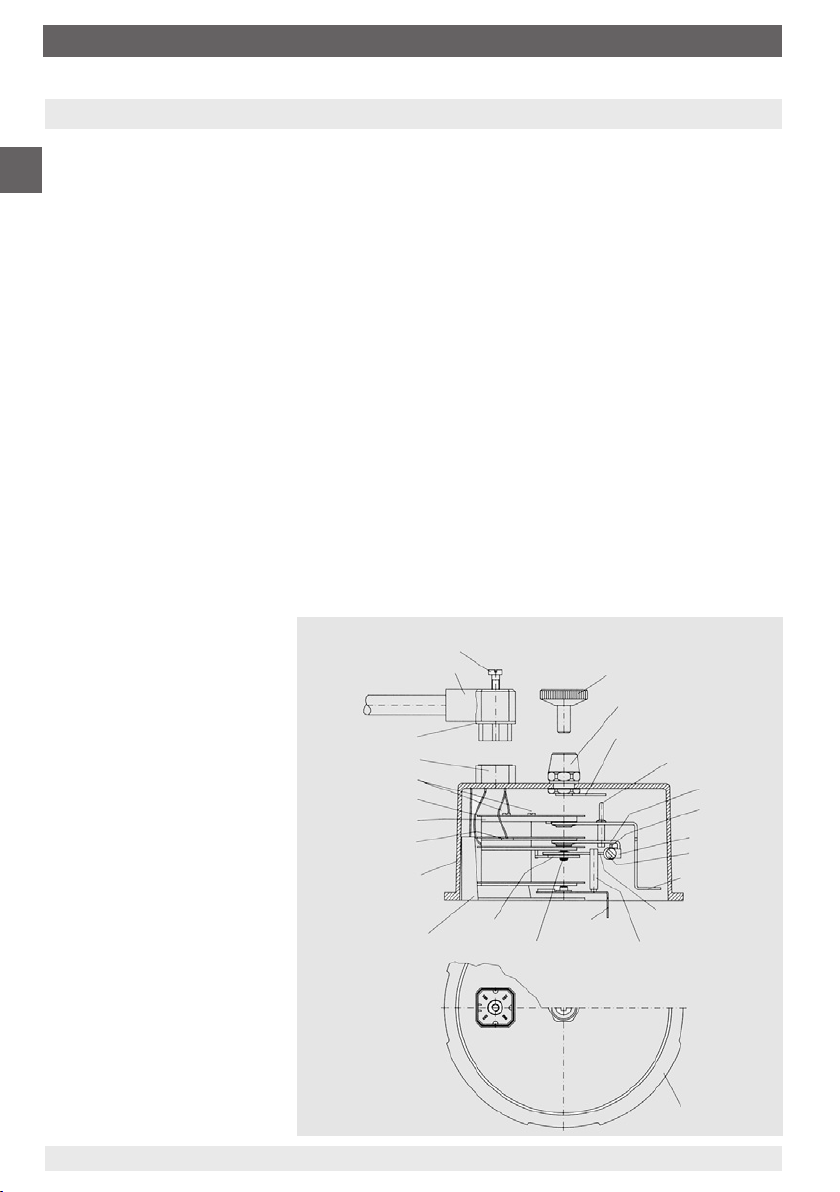

Cover cap for adjustable

measuring span

11248832.02

Adjustable measuring span

Turn clockwise: reduce measuring range

Turn anticlockwise: expand measuring range

6

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

Adjustable measuring span

Allen key

(included in delivery)

11265191.07 12/2012 GB/D/F/I

Page 7

4. Dierential pressure gauge

1. The span adjustment, situated at the ‚4 o‘clock‘ point on the instrument case, is accessible

through the case by removing the cover cap.

2. Charge the instrument to the desired nominal pressure.

3. To set the pointer to the span value, using an allen key (size 3 mm) inserted into the funnel,

turn it either clockwise (reduce the measuring range) or anticlockwise (expand the measuring range). The gauge will then be fully adjusted to the required measuring range.

4. If the gauge is equipped with a transmitter Model 89x.44, then this procedure will also

adjust the output signal to the new measuring range.

5. After completing the adjustment the equipment should be resealed with the cover cap.

Interchangeable scales (optional)

1. Loosen the clamp clip on the case of the

dierential pressure gauge and remove the

cover ring complete with the lens.

2. Loosen and remove the knurled screw.

3. Remove all three scales, place the desired

scale on top and put them back in place.

4. Reinsert the knurled screw and tighten it.

Mount the cover ring and lens and fasten

the clamp clips again.

Additional pressure connections

Legend

Clamp clip

Cover ring

Knurled s crew

Scales

G 1/4 pressure conne ctions

GB

Three additional G ¼ female threads are

available on the minus measurement chamber

(the right measuring cell ange when viewed

from the back) e.g. for connecting a pressure

switch, safety valve or A-10 Cryo or IS-20

transmitters

Two G ¼ female threads are available on

the plus measurement chamber (the left cell

ange when viewed from the back) e.g. for

recalibration

Mounting holes M8

G 1/4 pressure conne ctions

11265191.07 12/2012 GB/D/F/I

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

11224380.02BA

7

Page 8

5. Valve manifold with working pressure gauge (optional)

5. Valve manifold with working pressure gauge (optional)

The compact optional anged valve manifold for an NG 100 working pressure gauge allows

the central measurement of level and working pressure in a single device.

GB

To isolate line pressures without inter-

rupting the process, enabling gauge

removal/examination and protecting the

gauge against overpressure of n-times

rated pressure which may occur during

plant pressure testing.

11236396.01BA

To protect the gauge against pressure

surges/pressure spikes, and thus against

unspecied operating conditions

For gauge shut-downs, if no measure-

Working

pressure gauge

NS 100

Test connect ion

M20 x 1.5

Isolati ng valve

i

Pressure equalising

valve

Isolati ng valve

j

c) Connect the pressure standard and test pump using the additional G ¼ female port in

the plus chamber of the measuring system

d) Remove the test connection screw from the minus side valve manifold

e) The plus side can then be pressurised

f) After adjustment:

- Close the air bleed screw

- Disconnect the pressure standard and test pump and close the connection

- Open the integrated pressure equalising valve

- Slowly open rst the plus and then the minus shut-o valve

- Close the pressure equalising valve

Test connection M20 x 1.5 for checking the working pressure gauge

The pressure equalising valve allows a zero point control during operation (with open valve).

While the media is owing from the higher pressure side to the other side, the dierential

pressure at the pressure gauge drops to zero (the dierential pressure display must be at

zero, i.e. within the zero tolerance range which shows that the gauge is

A zero adjustment can be made using the standard integra-

ted, adjustable pointer (remove snap t bezel incl. window and

sealing ring beforehand). Twisting the slotted screw on the

adjustable pointer you can adjust the zero point.

After completing the zero adjustment, the snap t bezel,

incl. window and ‚o‘-ring seal, must be correctly re-tted

and the pressure equalising valve must then be closed again.

Subsequently the zero point of versions with integrated

transmitter (see page 9) should be checked.

8

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

ments are required for long operating

periods, i.e. if only occasional measurements are necessary (to increase service

life of those dierential and working pressure gauges with a high frequency of pressure

uctuations).

Recalibration of dierential pressure

gauges (tank volume display)

a) Open pressure equalising valve

b) Close the plus and minus shut-o valves,

and then close the pressure equalising

valve again

working correctly).

Slotted

screw

11265191.07 12/2012 GB/D/F/I

Page 9

6. Application note ... 8. Transmitter for level measurement

6. Application note

For dangerous media such as, for example, oxygen, acetylene,

combustible or acidic media, as well as for pressure vessels,

the general directives, and also the prevailing directives/guidelines

must also be adhered to.

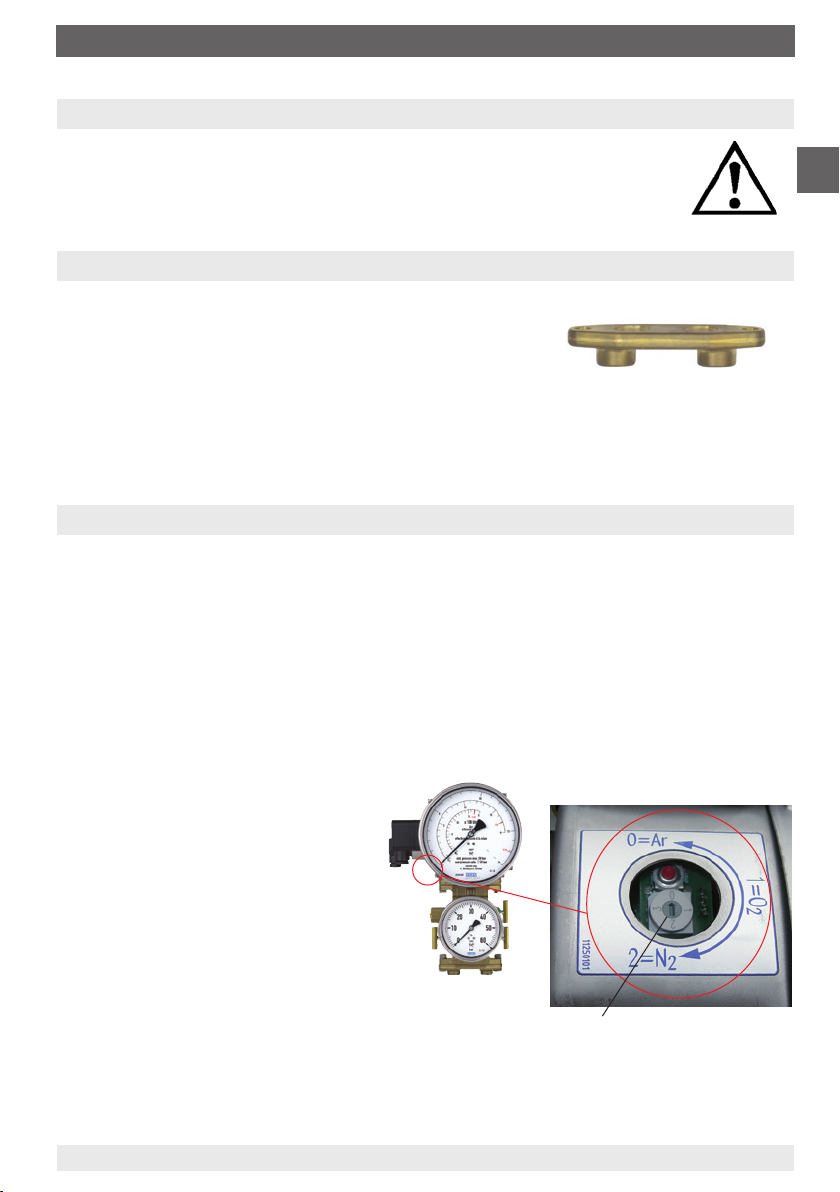

7. Adapter for process connection (optional)

The adapters can be ange-connected either directly to

the dierential pressure gauge or to the valve manifold.

5 dierent process connections are available:

2 x G 1/4, female, connection distance 31 mm or 54 mm

2 x 1/4 NPT, female, connection distance 31 mm, 37 mm or 54 mm

With a single order, all parts necessary for tting to the dierential pressure gauge or to the

valve manifold are included in the scope of supply:

2 x hexagon screw M8 x 16, 2 x hexagon screw M8 x 28, 2 x nut M8 and 2 x O-Ring seal

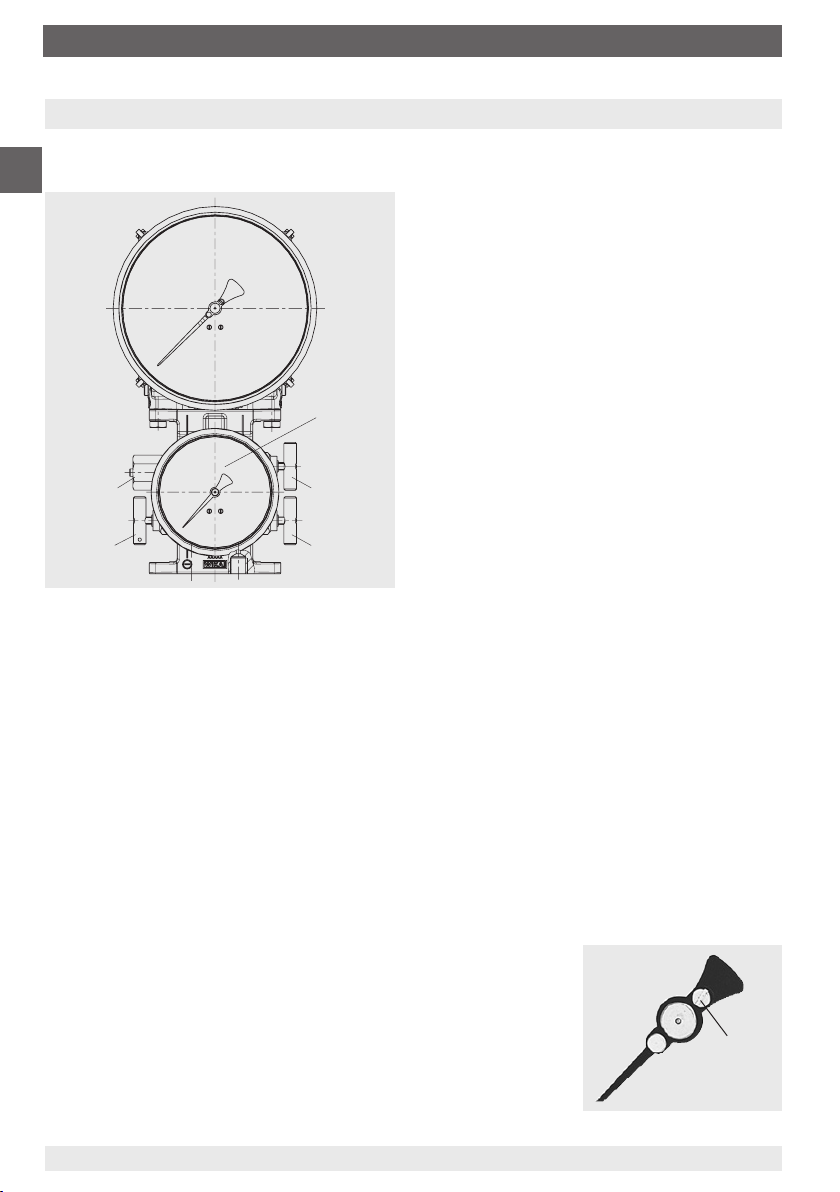

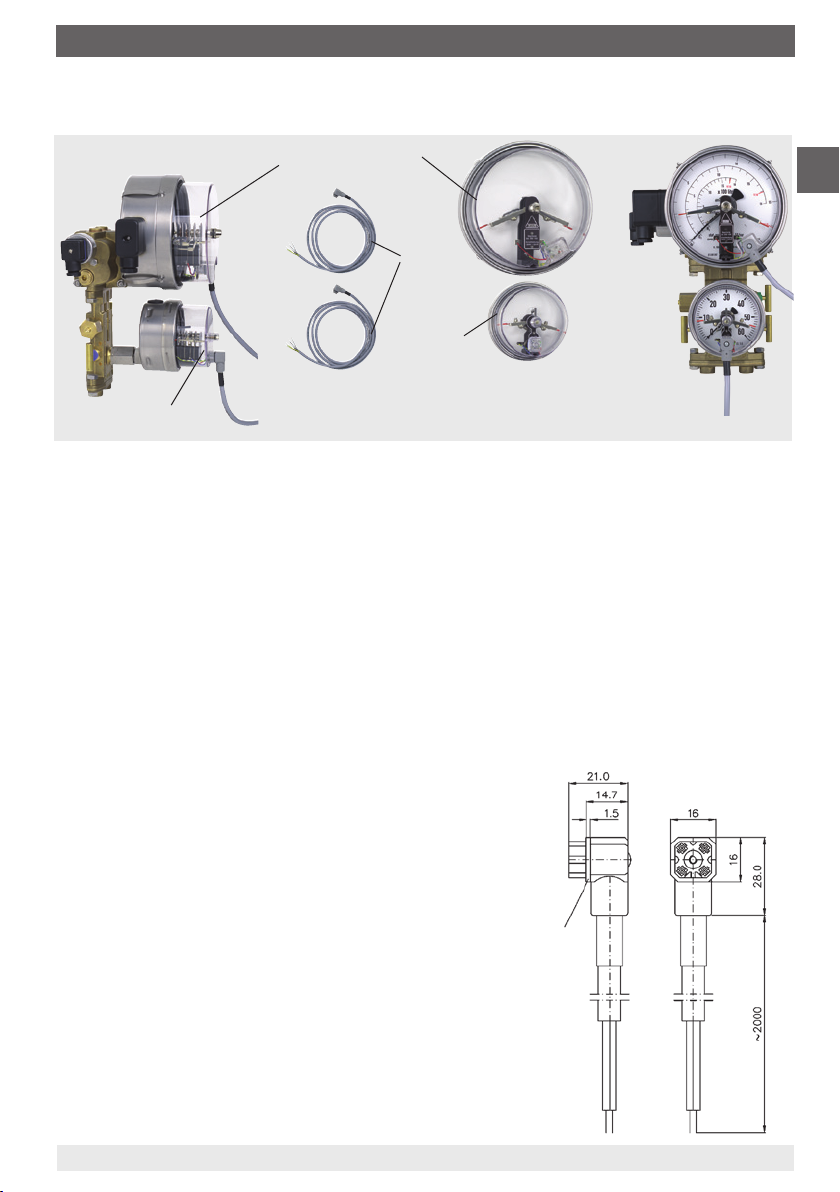

8. Transmitter for level measurement (optional)

Standard version model 891.44

Ex version model 892.44

WIKA dierential pressure gauges with an integrated Model 89x.44 transmitter combines all

the advantages of an on-site mechanical display with the demands modern industry makes

for electrical signal transmission for the acquisition of measured values.

GB

The transmitter is integrated into the housing of the level display. The measurement span

(electrical output signal) is set automatically by the mechanical display, i.e. the scale over a

swept angle of 270 degrees corresponds to 4 …20 mA (see section 4. Dierential pressure

gauge).

With multiple scales or interchangeable

dials (optional) the output signal of

4 ... 20 mA corresponding to each,

can be stored in a microprocessor.

The output signal can be changed over

to the desired uid type by rotating the

optional BCD switch (accessible through

a cover cap on the left side of the case)

using a screwdriver.

Electrical zero point (with option BCD switch)

BCD switc h (scale select ion switch) and

zero poi nt button (cover ca p removed)

If a zero point compensation is required (e.g. after mechanical zero point correction), press

the zero point button for approx. 1 sec. within 30 sec. with the voltage disconnected

and with the pressure compensation valve open.

plug)

11265191.07 12/2012 GB/D/F/I

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

(remove

9

Page 10

8. Transmitter for level measurement

Electrical zero point (without option BCD switch)

If the mechanical zero point is changed by means of the

GB

adjustable pointer, the electrical zero point must be reset to

the mechanical zero point.

First depressurise the pressure gauge.

Loosen the complete cable hood on the right-hand side of

the pressure gauge by completely unscrewing the screw

on the top of the cable hood cover

screwdriver (0.6 x 3.5 mm).

using an appropriate

Extract the screw. Remove the cable hood

socket insert

separate the pressure gauge from the power supply.

Remove the cable hood cover

and push the socket insert

entire cable hood

Use a short stranded wire with bare points at both ends

(max. permissible resistance 30 Ω) to bridge contacts 5 and

6 on the socket insert.

Reassemble the plug in reverse order. Place the plug, with

the attached piece of stranded wire, onto the pin insert

and thus reestablish the power supply.

Within a max. 30 seconds the new zero point will be stored

within the electronics. During this period, the current in the

loop will increase to 9.5 mA.

The new zero point also remains stored in the case of a

power failure.

Loosen the plug again in the same sequence as described above and remove the piece of stranded wire. After

reassembling the plug, the electrical output signal will once

more correspond to the indication of the mechanical pointer.

Ensure the seals

securely reinstalled to maintain the

protection class.

from the cable socket base and thus

from the cable hood

out downwards through the

.

with the

,

are properly and

Screw

Cable hood cover

Cable hood

Socket insert

Cable socket base

Seals

10

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

11265191.07 12/2012 GB/D/F/I

Page 11

8. Transmitter for level measurement

Specications Models 891.44 and 892.44 (Ex Version)

Power supply UB

for Non-Ex version DC

for Ex version see the section ‚Ex protection‘!

Permissible residual ripple

% of span/10 V

Supply voltage eect % ss

Output signal 4 … 20 mA, 2-wire system

Permissible max. load R

A for Non-Ex versions, Model 891.44:

Eect of load % of span

Output signal adjustment

Zero point, electrical A

djustment of zero point through brief bridging of terminals 5 and 6,

or using the „scale selection switch“ option, selectable via button

Scale selection 4 scales selectable via BCD switch

Linearity % of span

Permissible

ambient temperatures °C -40 … +80, -40 … +60 with oxygen

Compensated temp. range °C -40 … +80

Temperature coecients in

compensated temp. range

Mean TK of zero

Mean TK of span

% of span/10 K

% of span/10 K

Ex protection according to EC-Type Examination Certicate

Ex certication EEx II 2G EEx ia IIC T6

Conformity specications

Power supply U

Short circuit rating I

Rating P

Internal capacitance C

Internal inductance L

i DC 14 … 30 V

i mA max. 100

i W max. 1

i nF 12

i mH negligible

Medium temperature °C -40 … +80, -40 … +60 with oxygen

Ambient temperature °C -40 … +60 (T6)

CE-Conformity interference emission and immunity per EN 61326

Wiring L-connector (screw terminals up to 2.5 mm²)

Wiring protection protected against reverse polarity and overvoltage

Ingress protection IP 65 per EN 60529 / IEC 529

Wiring details,

2-wire

Earth , connected

to case 2)

B ≤ 30 V

12 V < U

≤ 0.1

≤ 10

A ≤ (UB - 12 V) / 0.02 A with RA in Ω and UB in Volt

R

for Ex versions, Model 892.44:

A ≤ (UB - 14 V) / 0.02 A with RA in Ω and UB in Volt

R

≤ 0.1

≤ 1.0 (limit point calibration)

≤ 0.3

≤ 0.3

BSV 08 ATEX E 018 X for Model 892.44

Terminals 3 , 4, 5 and 6: only for inte rnal

B+/Sig+

U

0V/Sig-

applic ation

2) This connection must not be used

for equipotential bonding. The

instrument must be incorporated in

the equipotential bonding via the

process connection.

GB

1)

1) Only poss ible within 30 s econds of conn ecting the sup ply voltage

11265191.07 12/2012 GB/D/F/I

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

11

Page 12

8. Transmitter for level measurement

Trouble shooting

Defect Possible reason Remedy

GB

No signal output

Steady signal Pressure entry blocked Check tailpipes and pressure entry

despite pressure bore, if necessary clean it carefully

variation Open press. compensation valve Close pressure compensation valve

Steady and too high Electronic defect through Return pressure gauge to

signal despite of incorrect supply voltage manufacturer for repair

pressure variation or stray voltage spikes

Full span reading too low Supply voltage too low Adjust supply voltage

Zero signal too low Wrong zero compensation Readjust zero point

Zero signal too high Wrong zero compensation Readjust zero point

Failure of power supply Check power supply and wiring

Wiring interrupted (or broken) replace defective components

Transmitter incorrectly wired Check wiring;

if necessary rectify it

No pressure Check tailpipes

Open press. compensation valve

Electronic defect e.g. through Return pressure gauge to

incorrect supply voltage manufacturer for repair

or stray voltage spikes

Electronic defect e.g. through Return pressure gauge to

incorrect supply voltage manufacturer for repair

or stray voltage spikes

Ferngeber defekt nach Return pressure gauge to

mechanischer Überbelastung manufacturer for repair

Load impedance too high Consider permissible max. load

Wrong scale selected Check position of scale selection

Transmitter over-pressured Return pressure gauge to

Close pressure compensation valve

switch

manufacturer for repair

12

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

11265191.07 12/2012 GB/D/F/I

Page 13

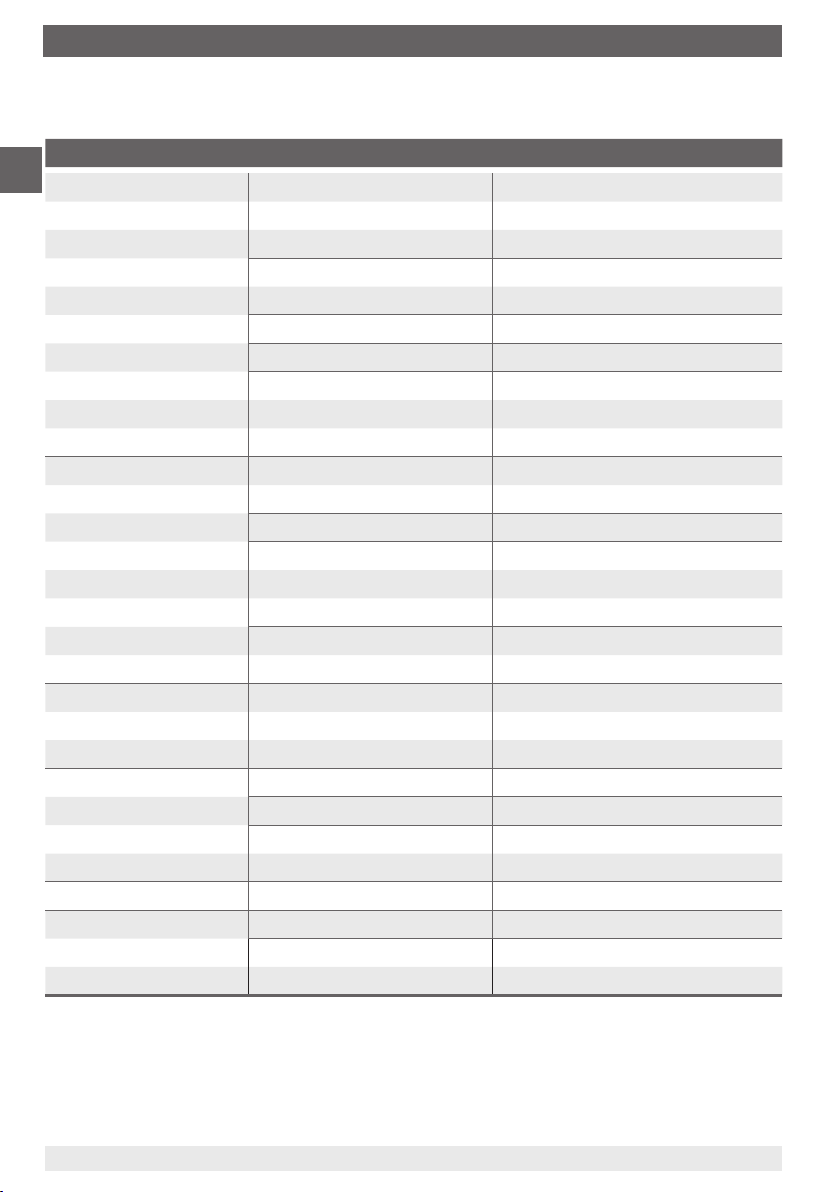

9. Transmitter for working pressure indication

9. Transmitter for working pressure indication (optional)

Standard version model A-10

or Ex version model IS-20

The transmitters for the working pressure

are screwed in sideways, on the left side of

the minus measurement chamber and can,

if necessary, be retrotted on-site.

Pressure connection for Transmitter: G 1/4

(male)

Transmitter for working

pressure indication

Specications A-10 IS-20

Data sheet PE 81.60 PE 81.50

Design standard intrinsically safe

Pressure ranges bar 0 ... 6 to 0 ... 60 0 ... 6 to 0 ... 60

Outputs mA 4 ... 20 4 ... 20 (line transformer)

Medium temperature °C -30 ... +100 -20 ... +80

Ambient temperature °C -30 ... +100 -20 ... +80

Wetted parts stainless steel stainless steel

Power supply U

Maximum load R

Accuracy

BFSL % of span ≤ 0.5 ≤ 0.25

Compensated temperature

range

Wiring details,

2-wire

B DC 8 V < UB ≤ 30 V 10 V < UB ≤ 30 V

A Ohm RA ≤ (UB - 8 V) / 0.02 A RA ≤ (UB - 10 V) / 0.02 A

°C 0 ... +80 °C 0 ... +80 °C

Non hazardous

area

Hazardous

(classied) area

GB

The corresponding operating instructions are included in the delivery

of each dierential pressure gauge with integrated transmitter for

working pressure indication.

11265191.07 12/2012 GB/D/F/I

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

13

Page 14

10. Switch contacts

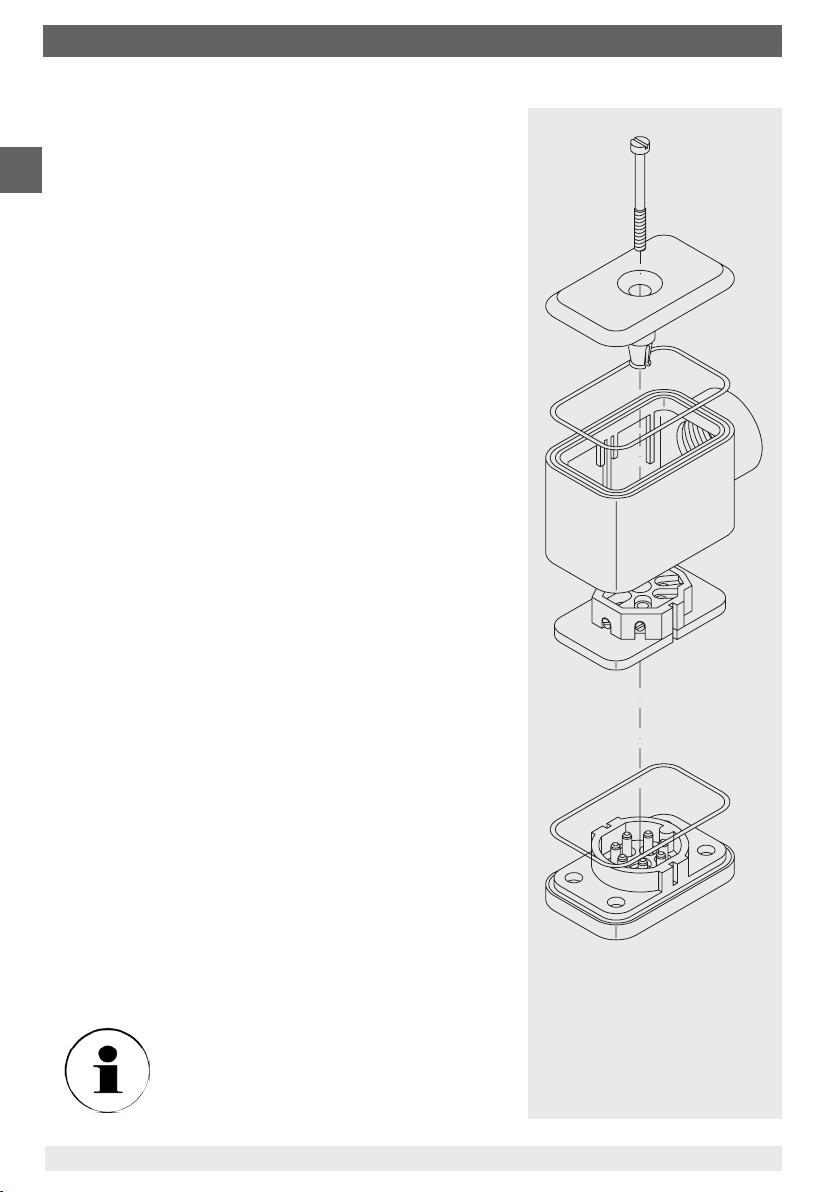

10. Switch contacts (optional)

These switch contacts are tted into the case of a pressure gauge and intended to make or

GB

break an electric control circuit triggered by the position of the instrument‘s pointer.

Versions

Single and double magnetic snap-action contacts or single and double inductive alarm

sensors. Please refer to data sheet AC 08.01 for technical data.

The modular switch contact is a self-contained unit, which can be built onto the pressure

gauge within a few minutes.

The switch contacts provide IP65 ingress protection even for oil-lled gauges. The connection to the instrument pointer is made by means of a special fork so that a carrying pin at

the pointer itself is not necessary. By means of this simple mounting, the instrument can be

converted into a contact measuring instrument quickly and inexpensively.

The switch contacts mainly comprise:

the pre-wired switch contact, which is provided with a special foot and a fork coupling

a transparent hood (polycarbonate) with dovetail lead into which the alarm contact is

pushed and which is fastened by means of a recessed head screw

a 4-pin plug socket, injection-moulded or welded to the transparent cover

an adjustable lock, mounted in the middle of the transparent cover.

The set pointers of the built-in

switch contact are adjusted, to

the value at which the contact

should switch, from the outside

via the adjustable lock using a

separate or a rigidly mounted

key.

The switch contacts are

designed to allow the instrument pointer to move beyond

the adjusted set pointer after

contact actuation takes place,

with the contact remaining

actuated.

The design therefore guarantees a stable switching condition, which corresponds to

the position of the instrument

pointer, even if the power fails.

14

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

Plug with cable

Plug seal

Plug socket

Type plate screws

Type plate

Front plate

Connection

Transparent hood

Special foot

with dovetail lead

Plug screw

Spiral spring

Coupling fork

Ruby bearing

Spanner

Adjustable lock

Metal ag

Adjustable pin

Carrying arm

Contact pin

Magnet carrying

plate

Screw-in magnet

Desired value

indicator, red

Contact arm with

plate spring

Carrying pin of coupling fork

Bayonet rim

11265191.07 12/2012 GB/D/F/I

Page 15

10. Switch contacts

Mounting of switch contacts

Legend

Self-contained unit with switch contact for level measurement

First the snap t style bezel with sealing ring, and the gauge window, must be removed. Prior

to attaching the transparent hood to the measuring instrument, the contacts must be adjusted

in accordance with their operating range.

Using the magnetic snap-action contact, the magnetic retention force must be adapted to the

instrument-specic conditions by adjusting (twisting) the screw-in magnet. The magnet must

then be protected against unintentional adjustment by using an appropriate locking varnish.

The small plate spring at the exible contact arm must be angled accordingly.

The fully-adjusted unit must now be tted to the gauge, together with the snap-t bezel, and

aligned to the extent that the fork coupling guiding the exible contact arms grips over the

gauge pointer without touching the dial. Should this occur, the carrying fork must be shortened using a suitable cutting tool.

The contacts are best adjusted when they are factory-tted.

By snapping the bezel onto the case, the whole contact unit will be xed to the pressure

gauge.

Connector plug

As counterpart to the connector base welded

onto the transparent hood

Material: PA 6 - GF 30

Colour: grey

Connection: stripped and tinned wires

Ingress protection: IP 65 per EN 60529 / IEC 529

For magnetic snap-action contacts:

Connector plug 3 poles + l (250 V max.)

with 2 m cable 4 x 1.0 mm

For inductive alarm sensors:

Low voltage execution without protective earth conductor

Connector plug 4 poles (50 V max.)

with 2 m cable 4 x 0.75 mm

Extent of delivery: 1 plug with cable,

1 central screw M3 x 20 and 1 gasket

11265191.07 12/2012 GB/D/F/I

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

Self-contained unit with switch contact for working pressure

Connector plug

Gasket

2

2

GB

15

Page 16

10. Switch contacts ... 12. Disposal

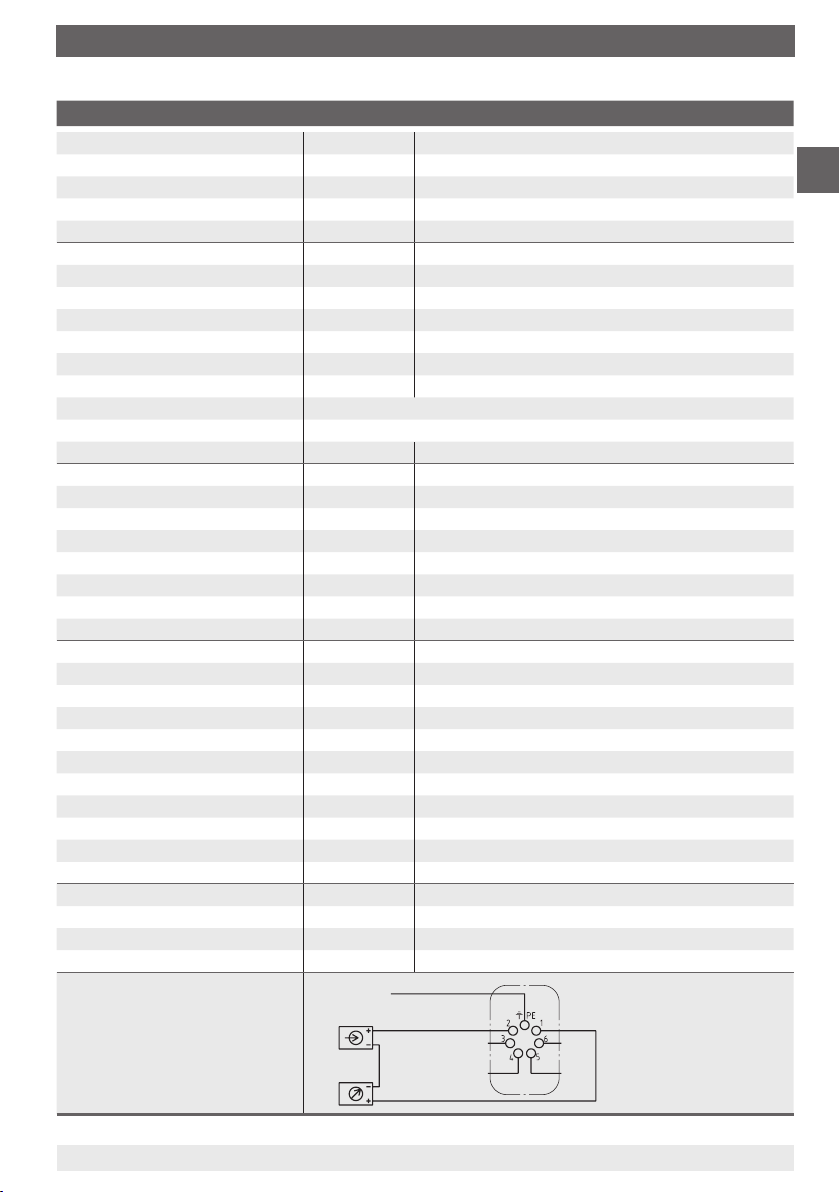

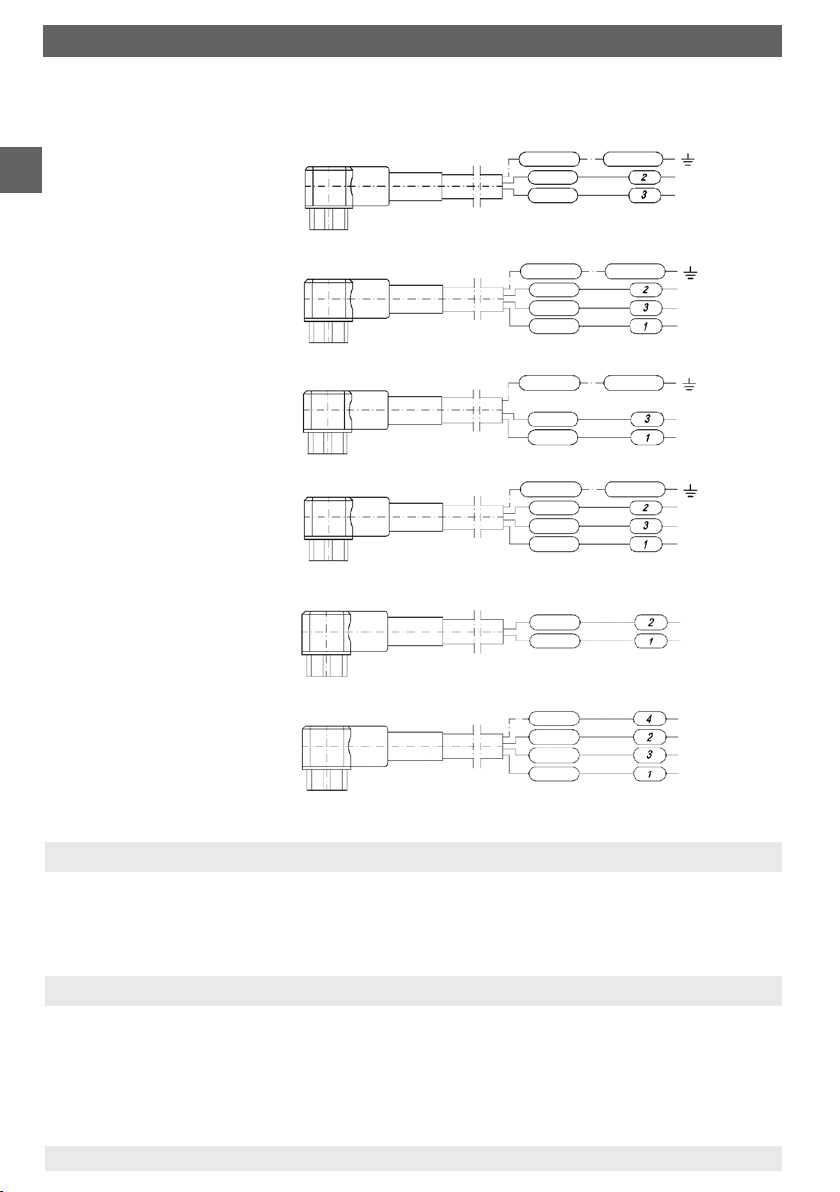

Terminal conguration

Magnetic snap-action

GB

contacts:

Single contact,

NS 100

Double contact,

NS 100

Single contact,

NS 160

Double contact,

NS 160

Inductive alarm sensors:

Single contact,

NS 100 and 160

Double contact,

NS 100 and 160

green/ yellow

blue

brown

green/ yellow

blue

brown

black

green/ yellow

brown

black

green/ yellow

blue

brown

black

yellow

white

violet

yellow

black

white

green/ yellow

1st contac t

common

green/ yellow

1st contac t

common

2nd cont act

green/ yellow

common

2nd cont act

green/ yellow

1st contac t

common

2nd cont act

1st contac t +

1st contac t -

1st contac t +

1st contac t 2nd cont act 2nd cont act +

11. Maintenance

WIKA dierential pressure gauges require no maintenance or servicing and will give very long

service when handled and operated properly.

12. Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally compatible

way and in accordance with the country-specic waste disposal regulations.

16

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

11265191.07 12/2012 GB/D/F/I

Page 17

Enclosure 1

GB

11265191.07 12/2012 GB/D/F/I

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

17

Page 18

Enclosure 1

GB

18

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

11265191.07 12/2012 GB/D/F/I

Page 19

Enclosure 1

GB

11265191.07 12/2012 GB/D/F/I

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

19

Page 20

GB

20

WIKA operating instructions dierential pressure gauge models 712.15.160, 732.15.160

11265191.07 12/2012 GB/D/F/I

Page 21

Inhalt

Inhalt

1. Sicherheit 22

2. Allgemeines 22

3. Montage 22

4. Dierenzdruckanzeige 24

5. Ventilblock mit Betriebsdruckanzeige (Option) 26

6. Applikationshinweis 27

7. Adapter für Prozessanschluss (Option) 27

8. Transmitter für Füllstandanzeige (Option) 27

9. Transmitter für Betriebsdruckanzeige (Option) 31

10. Schaltkontakte (Option) 32

11. Wartung 34

12. Entsorgung 34

Anlage 1: EG-Baumusterprüfbescheinigung

(Ex-Zulassung) für Drehwinkelgeber Typ 892.44 35

D

Information

Dieses Zeichen gibt Ihnen Informationen, Hinweise

oder Tipps.

Warnung!

Dieses Symbol warnt Sie vor Handlungen, die Schäden

an Personen oder am Gerät verursachen können.

11265191.07 12/2012 GB/D/F/I

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

21

Page 22

1. Sicherheit ... 3. Montage

1. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige

Dierenzdruckmessgerät hinsichtlich Messbereich, Ausführung und spezi-

D

2. Allgemeines

Vorliegende Betriebsanleitung baut auf folgende Informationen auf:

EN 837-2: Auswahl- und Einbauempfehlungen für Druckmessgeräte

Datenblatt PM 07.30: Dierenzdruckmessgeräte Typen 712.15.160, 732.15.160

Datenblatt PM 02.01, PM 02.02, PM 02.04: Druckmessgeräte mit Rohrfeder

schen Messbedingungen ausgewählt wurde.

Alle Arbeiten dürfen nur im spannungslosen Zustand erfolgen.

Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

Nur entsprechend qualiziertes Fachersonal darf an diesen Geräten

arbeiten.

3. Montage

Die Montage des Dierenzdruckmessgerätes erfolgt in Anlehnung an die Einbauempfehlungen für Druckmessgeräte nach EN 837-2 /7.

Messleitungen vor der Gerätemontage gründlich durch Abklopfen und Ausblasen

oder Durchspülen reinigen

Messgeräte sollen erschütterungsfrei montiert und betrieben werden

Befestigung über: - starre Messleitungen und/oder

- 4 Montagebohrungen M8 im Messansch

Messgeräte sollen vor Verschmutzung und starken Temperaturschwankungen

geschützt sein

Maximal zulässige Messsto-/Umgebungstemperatur darf nicht überschritten werden

Montage des Druckanschlusses nach angebrachten Symbolen j und

j

hoher Druck ⇒ Bodendruck (p

i

niedriger Druck ⇒ Betriebsdruck/Überlagerungsdruck (p

p

= pFL + pD

B

(wobei p

22

= hydrostatischer Druck der Flüssigkeit = r • g • h)

FL

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

)

B

)

D

i

11265191.07 12/2012 GB/D/F/I

Page 23

3. Montage

Montagearten zur Füllstandsmessung

Standard bei Tiefkälteanlagen 2 Beispiele mit Kondensatanfall

(verüssigte Gase)

Kondensat

⇔

Niveau-

p

D

p

D

gefäß

ZufuhrZufuhrZufuhr

D

p

D

Dp Dp Dp

p

D

p

B

p

D

Entnahme Entnahme

p

B

i ji j

i j

hhh

Entnahme

Kondensat

Montage an Wand

Anbringung/Befestigung an den 4 Montagebohrungen M8 / 2 Befestigungsbohrungen Ø 8,5

Drucka nschlüsse G 1/4

Montage bohrung en M8

ruckan schlüsse

D

G 1/4

11236396.02a

Drucka usgleich sventil

Absperr ventil

j

11265191.07 12/2012 GB/D/F/I

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

Befesti gungsbohrung en Ø 8,5

Prüfanschlu ss

Absperrventil

i

23

Page 24

3. Montage / 4. Dierenzdruckanzeige

Option

Schalttafeleinbau

Schalttafelausschnit t

D

Schalt tafel

4. Dierenzdruckanzeige

Die Messspanne des Dierenzdruckmessgerätes kann je nach Messzelle auf die in der Tabelle angegebenen Messbereichsgrenzen eingestellt werden. Die Einstellung sollte zweckmäßig

auf dem Prüfstand erfolgen, kann jedoch auch direkt an der Messstelle mittels Handprüfpumpe vorgenommen werden.

Messbereichsgrenzen

Messzelle Einstellbare Messbereiche

von bis

140 mbar 0 ... 40 mbar - 0 ... 140 mbar

280 mbar 0 ... 80 mbar - 0 ... 280 mbar

560 mbar 0 ... 160 mbar - 0 ... 560 mbar

1130 mbar 0 ... 320 mbar - 0 ... 1130 mbar

2300 mbar 0 ... 650 mbar - 0 ... 2300 mbar

4000 mbar 0 ... 1150 mbar - 0 ... 4000 mbar

Verschlusskappe

zur Spanneverstellung

11248832.02

Spanneverstellung

Rechtsdrehen: kleinerer Messbereich

Linksdrehen: größerer Messbereich

24

Spanneverstellung

Inbus-Schraubendreher

(im Lieferumfang enthalten)

11265191.07 12/2012 GB/D/F/I

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

Page 25

4. Dierenzdruckanzeige

1. Die Spanneverstellung ist am Gehäuseumfang bei 4 Uhr durch Abnehmen der

Verschlusskappe zugänglich.

2. Das Gerät mit dem gewünschten Nenndruck beaufschlagen.

3. Mittels Inbus-Schraubendreher (SW 3 mm) in die Trichterführung eintauchen und durch

Rechts- (kleinerer Messbereich) oder Linksdrehen (größerer Messbereich) den Zeiger auf

Endwert verstellen. Danach ist das Messgerät bereits auf den gewünschten Messbereich

eingestellt.

4. Ist das Messgerät mit einem Ferngeber Typ 89x.44 ausgerüstet (siehe Seite 23), so ist

mit dieser Prozedur auch das Ausgangssignal auf den neuen Messbereich eingestellt.

5. Nach Beendigung der Einstellung ist das Gerät wieder mit der Verschlusskappe zu

verschließen.

D

Wechselbare Skalen (Option)

1. Spannbügel am Gehäuse des Dierenzdruck-Messgerätes lösen und Überring

mit Sichtscheibe entfernen

2. Rändelschraube lösen und ganz herausnehmen

3. Alle drei Skalen entnehmen, gewünschte

Skale oben auf legen und wieder einlegen

4. Rändelschraube aufsetzen

und festziehen,

Überring mit Sichtscheibe montieren und

die Spannbügel wieder einschnappen

Zusätzliche Druckanschlüsse

Drei zusätzliche G ¼ Innengewinde an Minus-

messstokammer (rechter Messzellenansch

bei Ansicht des Gerätes von hinten) z. B. zum

Anschluss eines Druckschalters, Sicherheitsventiles oder Messumformers Typ A-10 Cryo

bzw. IS-20

Zwei G ¼ Innengewinde an Plusmesssto-

kammer (linker Messzellenansch bei

Ansicht des Gerätes von hinten) z. B.

zur Rekalibrierung

Legende

Spannbügel

Überring

Rändelschraube

Skalen

Montagebohrungen M8

Druckansch lüsse G 1/4

11224380.02BA

Druckansch lüsse G 1/4

11265191.07 12/2012 GB/D/F/I

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

25

Page 26

5. Ventilblock mit Betriebsdruckanzeige (Option)

5. Ventilblock mit Betriebsdruckanzeige (Option)

Der optional ananschbare kompakte Ventilblock mit Betriebsdruck-Messgerät NG 100

ermöglicht die zentrale Messung von Füllstand und Betriebsdruck in einem Gerät.

Absperrung der Messleitungsdrücke ohne

Störung des Betriebsablaufes

D

BetriebsdruckMessgerät

NG 100

Prüf

anschlu ss

M20 x 1,5

Absperr ventil

i

Druckausgleichsventil

Absperr ventil

j

c) Über zusätzliches G ¼ Innengewinde in der Pluskammer des Messsystems wird

Drucknormal und Druckerzeuger angeschlossen

d) Im Ventilblock auf der Minusseite Prüfanschluss-Schraube entfernen

e) Plusseite kann jetzt mit Druck beaufschlagt werden

f) Nach erfolgter Justage:

- Prüfanschlussschraube wieder schließen

- Drucknormal und Druckerzeuger wieder entfernen und Anschluss verschließen

- Druckausgleichsventil önen

- zuerst Plus-, dann Minusabsperrhahn langsam önen

- Druckausgleichsventil wieder schließen

Prüfanschluss M20 x 1,5 für die Überprüfung des Betriebsdruck-Messgerätes

Mit dem Druckausgleichsventil wird eine Nullpunktkontrolle im laufenden Betriebsprozess

(bei geönetem Ventil) ermöglicht.

Der Messsto strömt von der Seite höheren Druckes nach der Gegenseite, Dierenz-druck

am Messgerät fällt auf Null (Dierenzdruckanzeige muss auf Null, d.h. in den Bereich des

Nullpunkt-Toleranzbandes gehen, Gerätefunktion ist damit in Ordnung).

Bei Abweichung kann eine Nullpunktkorrektur über den

standardmäßig eingebauten Verstellzeiger erfolgen (vorher die

Spannbügel lösen und Sichtscheibe und Dichtung entfernen).

Die Nullpunkt-Verstellung wird durch Verdrehen der Schlitzschraube am Verstellzeiger erreicht. Nach erfolgter Nullpunktkorrektur Schnappring incl. Sichtscheibe und Dichtung

wieder befestigen und Druckausgleichsventil schließen.

Anschließend ist bei Ausführungen mit integriertem Transmitter

auch dessen Nullpunkt zu kontrollieren (siehe Seite 27).

26

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

- zur Gerätedemontage/-prüfung

- zum Schutz des Gerätes gegen unzulässige Überdruckbelastung bei n-facher

Prüfdruckbelastung von Anlagen

11236396.01BA

Schutz des Gerätes gegen Druckstöße/

-schläge und damit undenierten

Betriebsverhältnissen

Gerätestilllegung, wenn über längere Be-

triebszeiten keine Messung erforderlich,

d.h. nur sporadische Messungen (zur

Erhöhung der Lebensdauer von Dierenzund Betriebsdruck-Messgeräten mit hoher

Frequenz der Druckwechsel)

Rekalibrierung des Dierenzdruckmess-

gerätes (Tankinhaltsanzeige)

a) Druckausgleichsventil önen

b) Plus- und Minusabsperrhahn schließen

und anschl. Druckausgleichsventil wieder

schließen

Schlitzschraube

11265191.07 12/2012 GB/D/F/I

Page 27

6. Applikationshinweis ... 8. Transmitter für Füllstandanzeige

6. Applikationshinweis

Bei gefährlichen Messstoen, wie z. B. Sauersto, Acetylen, brennbaren

oder giftigen Stoen, sowie bei Druckbehältern etc., sind über die allgemeinen Regeln hinaus die bestehenden Vorschriften/Richtlinien zu beachten.

7. Adapter für Prozessanschluss (Option)

Die Adapter können entweder direkt an das Dierenzdruckmessgerät oder an den Ventilblock angeanscht werden.

5 verschiedene Prozessanschlüsse stehen zur Auswahl:

2 x G 1/4, Innengewinde, Achsabstand 31 mm oder 54 mm

2 x 1/4 NPT, Innengewinde, Achsabstand 31 mm, 37 mm oder 54 mm

Bei Einzelbestellung sind alle für die Montage am Dierenzdruckmessgerät oder am Ventilblock erforderlichen Teile im Lieferumfang enthalten:

2 x Sechskantschrauben M8 x 16, 2 x Sechskantschrauben M8 x 28, 2 x Mutter M8 und

2 x O-Ring Dichtung

8. Transmitter für Füllstandanzeige (Option)

Standardausführung Typ 891.44

Ex-Ausführung Typ 892.44

WIKA Dierenzdruckmessgeräte mit integriertem Transmitter Typ 89x.44 verbinden alle

Vorteile einer mechanischen Anzeige vor Ort mit den Forderungen nach einer elektrischen

Signalübertragung für eine moderne Messwerterfassung in der Industrie.

Der Transmitter ist im Gehäuse der Füllstandanzeige integriert. Die Messspanne (elektrisches Ausgangssignal) wird automatisch mit der mechanischen Anzeige eingestellt, d.h. die

Skale über 270 Winkelgrade entspricht 4 … 20 mA (siehe Punkt 4. Dierenzdruckanzeige).

Bei Mehrfachskalen oder wechselbaren

Steckskalen (Option) kann das darauf

abgestimmte Ausgangssignal von

4 ... 20 mA in einem Mikroprozessor

abgelegt werden.

D

Durch Verdrehen des optionalen BCDSchalters (erreichbar durch Abnehmen einer

Verschlusskappe links seitlich am Gehäuse)

mittels Schraubendreher lässt sich das Ausgangssignal auf die gewünschte Gasart umstellen.

Elektrischer Nullpunkt (mit Option BCD-Schalter)

BCD-S chalter (Skale nauswahlsch alter) und

Nullpu nkt-Ta ster (Verschlu sskappe ent fernt)

Sollte ein Nullpunktabgleich notwendig werden (z. B. nach erfolgter mechanischer

Nullpunktkorrektur), so ist im spannungslosen Zustand (Stecker abziehen) und bei geönetem

Druckausgleichsventil innerhalb von 30 Sek. der Nullpunkt-Taster für ca. 1 Sek. zu drücken.

11265191.07 12/2012 GB/D/F/I

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

27

Page 28

8. Transmitter für Füllstandanzeige

Elektrischer Nullpunkt (ohne Option BCD-Schalter)

Wird der mechanische Nullpunkt über den Verstellzeiger

verändert, sollte der elektrische Nullpunkt wieder dem

mechanischen angepasst werden.

Bringen Sie hierzu das Manometer zuerst in den drucklosen

D

Zustand.

Lösen Sie die ganze Kabelhaube an der rechten Manometerseite, in dem Sie mit einem Schlitzschraubendreher (0,6 x 3,5 mm) die Schraube

Kabelhaubendeckels

die Schraube heraus. Ziehen Sie die Kabelhaube

Buchseneinsatz

trennen somit das Manometer von der Spannungsversorgung.

vollständig lösen. Nehmen Sie

vom Kabeldosenunterteil ab und

an der Oberseite des

samt

Entfernen Sie den Kabelhaubendeckel

haube

und drücken Sie den Buchseneinsatz ganz

durch die Kabelhaube

Überbrücken Sie die Kontakte 5 und 6 an dem Buchseneinsatz mit einem kurzen, an beiden Enden abisolierten Stück

Litze (max. zulässiger Widerstand 30 Ω).

Montieren Sie den Stecker wieder in umgekehrter Reihenfolge. Stecken Sie den Stecker mit montiertem Stück

Litzendraht auf den Stifteinsatz

Versorgungsspannung wieder her.

Innerhalb von max. 30 Sekunden wird der neue Nullpunkt in

der Elektronik gespeichert. Während dieser Zeit steigt der

Strom in der Schleife auf 9,5 mA.

Der neue Nullpunkt bleibt auch bei Spannungsausfall auf

Dauer gespeichert.

Lösen Sie wieder den Stecker in der oben beschriebenen

Reihenfolge und entfernen das Stück Litzendraht. Nach

erneutem Montieren des Steckers ist das elektrische

Ausgangssignal wieder deckungsgleich mit der Anzeige

des mechanischen Zeigers.

Damit die Schutzart erhalten bleibt,

unbedingt die Dichtungen

montieren.

nach unten heraus.

von der Kabel-

und stellen Sie somit die

wieder

Schraube

Kabelhaubendeckel

Kabelhaube

Buchseneinsatz

Kabeldosenunterteil

Dichtungen

28

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

11265191.07 12/2012 GB/D/F/I

Page 29

8. Transmitter für Füllstandanzeige

Technische Daten Typen 891.44 und 892.44 (Ex-Ausführung)

Hilfsenergie UB

für Nicht-Ex-Ausführungen DC

für Ex-Ausführungen siehe im Abschnitt Ex-Schutz!

Einuss der Hilfsenergie % v. EW/10 V

Zulässige Restwelligkeit % ss

Ausgangssignal 4 … 20 mA, Zweileiter

Zulässige max. Bürde R

A für Nicht-Ex-Ausführungen, Typ 891.44:

Bürdeneinuss % vom EW

Einstellbarkeit

Nullpunkt, elektrisch Nullung durch kurzzeitiges Überbrücken der Klemmen 5 und 6

oder bei Option "Skalenauswahlschalter" einstellbar über Taster

Skalenauswahl 4 Skalen über BCD-Schalter einstellbar

Kennlinienabweichung % d. Spanne

Zulässige

Umgebungstemperaturen °C -40 … +80, -40 … +60 bei Sauersto

Kompensierter Temp.-bereich °C -40 … +80

Temperaturkoezienten im

kompensierten Temp.-bereich

Mittlerer TK Nullpunkt

Mittlerer TK Spanne

% d. Spanne/10 K

% d. Spanne/10 K

Ex-Schutz nach EG-Baumusterprüfbescheinigung

Zündschutzart EEx II 2G EEx ia IIC T6

Sicherheitstechn. Höchstwerte

Hilfsenergie U

Kurzschlussstrom I

Leistung P

innere Kapazität C

innere Induktivität L

i DC 14 … 30 V

i mA max. 100

i W max. 1

i nF 12

i mH vernachlässigbar

Messstotemperatur °C -40 … +80, -40 … +60 bei Sauersto

Umgebungstemperatur °C -40 … +60 (T6)

CE-Kennzeichen Störemission und Störfestigkeit nach EN 61326

Elektrischer Anschluss Winkelsteckverbinder

Elektrische Schutzarten Verpolungs- und Überspannungsschutz

Schutzart IP 65 nach EN 60529 / IEC 529

Belegung der Anschluss-

klemmen, 2-Leiter

1) Nur innerhalb von 3 0 Sekunden nach Anlegen der Vers orgungsspa nnung möglic h

11265191.07 12/2012 GB/D/F/I

Erde, verb unden

mit Gehä use 2)

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

B ≤ 30 V

12 V < U

≤ 0,1

≤ 10

A ≤ (UB - 12 V) / 0,02 A mit RA in Ω und UB in Volt

R

für Ex-Ausführungen, Typ 892.44:

A ≤ (UB - 14 V) / 0,02 A mit RA in Ω und UB in Volt

R

≤ 0,1

≤ 1,0 (Grenzpunkteinstellung)

≤ 0,3

≤ 0,3

BSV 08 ATEX E 018 X für Typ 892.44

(Schraubklemmen bis 2,5 mm²)

Klemme n 3, 4, 5 und 6: nur für inte rnen

B+/Sig+

U

0V/Sig-

Verbrauc h

2) Dieser Anschluss darf nicht für

den Potentialausgleich verwendet

werden. Das Gerät muss über

den Prozessanschluss in den

Potentialausgleich einbezogen

werden.

D

1)

29

Page 30

8. Transmitter für Füllstandanzeige

Maßnahmen bei Störungen

Störung Mögliche Ursache Maßnahme

Kein Ausgangssignal keine Versorgungsspannung Spannungsversorgung und Leitungen

Leitungsbruch überprüfen; ggf. defekte Teile

D

Ferngeber falsch Anschlüsse überprüfen;

angeschlossen Anschlüsse ggf. korrigieren

kein Eingangsdruck Druckzuführung überprüfen

Druckausgleichsventil oen Druckausgleichsventil schließen

Elektronik defekt z. B. durch zu Messgerät zur Instandsetzung

hohe Versorgungsspannung an Hersteller

oder durch Fremdspannung

Gleichbleibendes Eingangskanal verstopft Eingangskanal bzw. Drosselschraube

Ausgangssignal reinigen

bei Druckänderung Druckausgleichsventil oen Druckausgleichsventil schließen

Elektronik defekt z. B. durch zu Messgerät zur Instandsetzung

hohe Versorgungsspannung an Hersteller

oder durch Fremdspannung

Ferngeber defekt nach Messgerät zur Instandsetzung

mechanischer Überbelastung an Hersteller

Zu hohes, bei Druckän- Elektronik defekt durch zu Messgerät zur Instandsetzung

derung gleichbleibendes hohe Versorgungsspannung an Hersteller

Ausgangssignal oder durch Fremdspannung

Signalspanne zu klein Versorgungsspannung zu niedrig Versorgungsspannung korrigieren

Bürde zu hoch max. zulässige Bürde beachten

falsche Skala gewählt Stellung des Skalenauswahlschalters

Nullpunktsignal zu klein fehlerhafter Nullpunktabgleich Nullpunkt neu einstellen

Nullpunktsignal zu groß fehlerhafter Nullpunktabgleich Nullpunkt neu einstellen

mechanische Überlastung Ferngeber neu justieren, ggf. Mess-

austauschen

überprüfen

gerät zur Instandsetzung an Hersteller

30

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

11265191.07 12/2012 GB/D/F/I

Page 31

9. Transmitter für Betriebsdruckanzeige

9. Transmitter für Betriebsdruckanzeige (Option)

Standardausführung Typ A-10

oder Ex-Ausführung Typ IS-20

Die Transmitter für den Betriebsdruck

werden links, seitlich in die MinusMessstokammer eingeschraubt und

können bei Bedarf auch vor Ort angebaut

werden.

Druckanschluss des Transmitters:

Außengewinde G 1/4

Transmitter für

Betriebsdruckanzeige

Technische Daten A-10 IS-20

Datenblatt PE 81.60 PE 81.50

Bauform standard eigensicher

Messbereiche bar 0 ... 6 bis 0 ... 60 0 ... 6 bis 0 ... 60

Ausgänge mA 4 ... 20 4 ... 20 (Speisetrenner)

Messstotemperatur °C -30 ... +100 -20 ... +80

Umgebungstemperatur °C -30 ... +100 -20 ... +80

Messstoberührte Teile CrNi-Stahl CrNi-Stahl

Hilfsenergie U

Zulässige max. Bürde R

Genauigkeit

Toleranzbandeinstellung, BFSL % d. Spanne ≤ 0,5 ≤ 0,25

Kompensierter Temperaturbereich

Belegung der Anschluss-

klemmen, 2-Leiter

B DC 8 V < UB ≤ 30 V 10 V < UB ≤ 30 V

A Ohm RA ≤ (UB - 8 V) / 0,02 A RA ≤ (UB - 10 V) / 0,02 A

°C 0 ... +80 °C 0 ... +80 °C

Nicht Ex-Bereich

Ex-Bereich

D

Bei jedem Dierenzdruckmessgerät mit angebautem Transmitter

für Betriebsdruckanzeige wird bei Auslieferung die entsprechende

Betriebsanleitung beigelegt.

11265191.07 12/2012 GB/D/F/I

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

31

Page 32

10. Schaltkontakte

10. Schaltkontakte (Option)

Elektrische Schaltkontakte für Füllstandsanzeiger und/oder Betriebsdruck önen Stromkreise

in Abhänigigkeit von der Zeigerstellung der anzeigenden Messgeräte.

Ausführungen

1- und 2-fach Magnetspringkontakte oder 1- und 2-fach Induktiv-Kontakte

Technische Daten gemäß Datenblatt AC 08.01

D

Beim Schaltkontakt im Baukastensystem handelt es sich um eine Aufbaueinheit, die in

wenigen Minuten auf das Druckmessgerät aufgebaut werden kann.

Die Schaltkontakte sind in Schutzart IP 65 ausgeführt.

Die Ankopplung an den lstwertzeiger erfolgt über eine Spezialgabel, so dass am Zeiger selbst

kein Mitnehmerstift benötigt wird. Durch diese einfache Montage kann äußerst schnell und

preiswert in ein Kontakt-Messgerät umgebaut werden.

Die Schaltkontakte bestehen im wesentlichen aus:

dem bereits verdrahteten Schaltkontakt, der mit einem Spezialfuß und einer Gabel-

kupplung ausgerüstet ist,

einer Klarsichthaube (Material Polycarbonat) mit Schwalbenschwanzführung, in die der

Grenzsignalgeber mit dem Spezialfuß eingeschoben und mittels einer Kreuzschlitz-

schraube befestigt ist,

einem der Klarsichthaube angespritzten bzw. verschweißten Steckerunterteil (4-polig),

einem in der Mitte der Klarsichthaube montierten Verstellschloss.

Durch das Verstellschloss

mit separatem oder fest

montiertem Schlüssel werden

die Sollwertzeiger des eingebauten Schaltkontaktes von

außen auf den Wert eingestellt,

bei dem der Schaltvorgang

erfolgen soll.

Die Schaltkontakte sind so

konstruiert, dass der Istwertzeiger nach erfolgter Kontaktgabe über den eingestellten

Sollwertzeiger hinaus weiterlaufen kann; die einmal erfolgte

Kontaktgabe bleibt jedoch

erhalten.

Die Konstruktion garantiert

daher auch bei Stromausfall

einen stabilen, der Stellung des

Istwertzeigers entsprechenden

Schaltzustand.

32

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

Anschlussstecker

mit Kabel

Steckerdichtung

Steckerunterteil

Typenschildschrauben

Typenschild

Frontplatte

Anschluss

Klarsichthaube

Spezialfuß mit

Schwalbenschwanzführung

Steckerschraube

Spiralfeder

Kupplungsgabel

Rubin-Lagersteine

Verstellschlüssel

Verstellschloss

Schlossfahne

Verstellstift

Trägerarm

Mitnehmerstift der Kupplungsgabel

Kontaktstift

Magnethalteblech

Einschraubmagnet

roter Sollwertzeiger

Kontaktarm mit

Blattfeder

Bajonettrand

11265191.07 12/2012 GB/D/F/I

Page 33

10. Schaltkontakte

Montage der Schaltkontakte

Legende

Aufbaueinheit mit Schaltkontakt für Füllstandsanzeige

Zuerst ist der Schnappring mit Dichtung und Sichtscheibe des Messgerätes zu entfernen.

Vor dem Aufsetzen der Klarsichthaube auf das Messgerät sind die Kontakte entsprechend

dem Anwendungsbereich einzustellen.

Beim Magnetspringkontakt ist die magnetische Haltekraft durch Einstellen (Verdrehen) des

Einschraubmagneten den gerätespezischen Gegebenheiten anzupassen und anschließend

mit einem geeigneten Sicherungslack gegen unbeabsichtigtes Verstellen zu sichern.

Die kleine Blattfeder am beweglichen Kontaktarm ist entsprechend abzuwinkeln.

Die fertig justierte Einheit wird nun mit dem Schnappring so auf das Messgerät aufgesetzt

und ausgerichtet, dass die Gabelkupplung, die die beweglichen Kontaktarme führt,

über den Istwertzeiger des Messgerätes greift, ohne das darunterliegende Zierblatt

zu berühren. Sollte dieses doch der Fall sein, so ist die Mitnehmergabel mit einem entsprechenden Schneidwerkzeug nach Bedarf zu kürzen.

Bei werkseitigem Anbau sind die Kontakte optimal justiert.

Durch das Anschnappen des Ringes an das Gehäuse wird die gesamte Kontakteinheit mit

dem Messgerät befestigt.

Anschlussstecker

Als Gegenstück zu dem auf der Klarsichthaube

verschweißten Steckerunterteil

Material: Isolierteile PA 6 - GF 30

Gehäusefarbe: grau

Anschlussart: Leitungsenden abisoliert und verzinnt

Schutzart: IP 65 nach EN 60529 / IEC 529

Für Magnetspringkontakte:

Anschlussstecker 3-polig + l (bis 250 V)

mit 2 m Kabel 4 x 1,0 mm

Für Induktiv-Kontakte:

Niederspannungsausführung ohne Schutzleiter

Anschlussstecker 4-polig (bis 50 V)

mit 2 m Kabel 4 x 0.75 mm

Lieferumfang: 1 Anschlussstecker am Anschlusskabel

angespritzt, 1 Zentralschraube M3 x 20 und 1 Dichtung

11265191.07 12/2012 GB/D/F/I

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

Aufbaueinheit mit Schaltkontakt für Betriebsdruckanzeige

Anschlussstecker

Dichtung

2

2

D

33

Page 34

10. Schaltkontakte ... 12. Entsorgung

Anschlussbelegung

Magnetspringkontakte:

Einfachkontakt,

NG 100

D

Zweifachkontakt,

NG 100

Einfachkontakt,

NG 160

Zweifachkontakt,

NG 160

Induktiv-Kontakte:

Einfachkontakt,

NG 100 und 160

Zweifachkontakt,

NG 100 und 160

grün/g elb

blau

braun

grün/g elb grün/g elb

blau

braun

schwar z

grün/g elb grün /gelb

braun

schwar z

grün/g elb grün/g elb

blau

braun

schwar z

gelb

weiß

violet t

gelb

schwar z

weiß

grün/g elb

1. Kontakt

Gemein samer

1. Kontakt

Gemein samer

2. Kontak t

Gemein samer

2. Kontak t

1. Kontakt

Gemein samer

2. Kontak t

1. Kontakt +

1. Kontakt -

1. Kontakt +

1. Kontakt -

2. Kontak t -

2. Kontak t +

11. Wartung

WIKA-Dierenzdruckmessgeräte sind wartungsfrei und zeichnen sich bei sachgemäßer

Behandlung/Bedienung durch hohe Lebensdauer aus.

12. Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezischen

Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

34

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

11265191.07 12/2012 GB/D/F/I

Page 35

Anlage 1

D

11265191.07 12/2012 GB/D/F/I

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

35

Page 36

Anlage 1

D

36

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

11265191.07 12/2012 GB/D/F/I

Page 37

Anlage 1

D

11265191.07 12/2012 GB/D/F/I

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

37

Page 38

D

38

WIKA Betriebsanleitung Dierenzdruckmessgerät Typen 712.15.160, 732.15.160

11265191.07 12/2012 GB/D/F/I

Page 39

Sommaire

Sommaire

1. Sécurité 40

2. Généralités 40

3. Installation 40

4. Manomètre pour pression diérentielle 42

5. Manifold avec indication de la pression de travail (option) 44

6. Conseils d‘utilisation 45

7. Adaptateurs pour raccordement process (option) 45

8. Transmetteur pour indication du niveau (option) 45

9. Transmetteur pour indication de la pression de travail (option) 49

10. Commutateurs (option) 50

11. Entretien 52

12. Mise au rebut 52

Attestation d‘examen CE (homologation Ex) pour

capteur rotatif des types 892.44 anglais

allemand

Informations

Ce signe vous donne des informations, des remarques

ou des conseils.

17-19

35-37

F

Avertissement !

Ce symbole vous avertit d'actions qui sont susceptibles

d'entraîner des dommages physiques ou matériels.

11265191.07 12/2012 GB/D/F/I

WIKA mode d‘emploi manomètre pour pression diérentielle types 712.15.160, 732.15.160

39

Page 40

1. Sécurité ... 3. Installation

1. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement, s‘assurer que

l‘appareil a été choisi de façon adéquate, en ce qui concerne la plage de

mesure, la version et les conditions de mesure spéciques.

Toutes les interventions doivent être eectuées hors tension.

F

Un non respect de cette consigne peut entraîner des blessures corporelles

graves et/ou des dégâts matériels.

Seul le personnel habilité et qualié est autorisé à manipuler les

instruments.

2. Généralités

Le présent mode d‘emploi repose sur les informations suivantes:

EN 837-2: Recommandations pour le choix et l‘installation de manomètres

Fiche technique PM 07.30: Manomètre pour pression diérentielle types 712.15.160,

732.15.1605

Fiche technique PM 02.01, PM 02.02, PM 02.04: Manomètre à tube manométrique

3. Installation

Le montage du manomètre pour pression diérentielle s‘eectue conformément aux recommandations de montage pour manomètres suivant EN 837-2/7.

Avant de monter l‘appareil, bien nettoyer les raccords de l‘appareil de mesure.

Lors du montage ou de l‘utilisation, éviter toute exposition des appareils aux

vibrations et chocs.

Fixation des appareils: - Conduites rigides et/ou

- 4 trous de montage M8 dans le corps de l‘appareil

Protéger les appareils de la saleté et des fortes variations de température

Les températures max. admissibles pour le uide et la température ambiante ne doivent

pas être dépassées.

Montage du raccord de pression conformément aux symboles apposés j et

j

haute pression ⇒ Pression de contact (p

i

basse pression ⇒ Pression de service / Pression de recouvrement (p

p

= pFL + pD

B

(p

= Pression hydrostatique du liquide = r • g • h)

FL

40

WIKA mode d'emploi manomètre pour pression diérentielle types 712.15.160, 732.15.160

),

B

i

)

D

11265191.07 12/2012 GB/D/F/I

Page 41

3. Installation

Types de montage pour mesure de niveau

Standard avec installations cryogéniques 2 exemples avec formation de condensat

(Gaz liquides)

Condensat

⇔

Bac à

p

D

p

D

niveau

p

D

ArrivéeArrivéeArrivée

F

Dp Dp Dp

p

D

p

B

p

D

Prise Pr ise

p

B

i ji j

Condensat

Montage mural

Pose/xation sur les 2 trous de montage M8 / 2 trous de montage Ø 8,5

Raccord s de pression G 1/4

Trous de monta ge

M8

Raccord s de

pressio n G 1/4

i j

hhh

Prise

11236396.02a

Vanne

d’équilib rage

de la press ion

Vanne d’arrêt

j

Trous de monta ge

Ø 8,5

11265191.07 12/2012 GB/D/F/I

WIKA mode d‘emploi manomètre pour pression diérentielle types 712.15.160, 732.15.160

Raccord

test

Vanne

d’arrêt

i

41

Page 42

3. Installation / 4. Manomètre pour pression diérentielle

Option

Encastrement

Découpe du panneau

F

4. Manomètre pour pression diérentielle

L‘étendue de mesure du manomètre pour pression diérentielle peut en fonction de la cellule

de mesure être réglée selon les limites indiquées dans le tableau suivant. Idéalement, le

réglage doit être eectué sur un banc de test mais il peut également être fait au point de

mesure à l‘aide d‘une pompe manuelle.

Limites de l‘étendue de mesure

Celulle de mesure Etendues de mesure possibles

de à

140 mbar 0 ... 40 mbar - 0 ... 140 mbar

280 mbar 0 ... 80 mbar - 0 ... 280 mbar

560 mbar 0 ... 160 mbar - 0 ... 560 mbar

1130 mbar 0 ... 320 mbar - 0 ... 1130 mbar

2300 mbar 0 ... 650 mbar - 0 ... 2300 mbar

4000 mbar 0 ... 1150 mbar - 0 ... 4000 mbar

Capuchon pour le

réglage de l‘étendue

Panneau

11248832.02

Réglage de l‘étendue

Vers la droite: étendue de mesure plus faible

vers la gauche: étendue de mesure plus grande

42

WIKA mode d'emploi manomètre pour pression diérentielle types 712.15.160, 732.15.160

Réglage de l‘étendue

Six pans creux

(compris dans la livraison)

11265191.07 12/2012 GB/D/F/I

Page 43

4. Manomètre pour pression diérentielle

1. Le réglage de l‘étendue est accessible sur le pourtour du boîtier (au niveau de 4 heures)

en enlevant le capuchon.

2. Régler la pression nominale souhaitée sur l‘appareil.

3. Introduire un tournevis pour vis à six pans creux (3 mm) dans l‘ouverture (entonnoir) et

régler l‘aiguille sur la valeur nale en tournant vers la droite (étendue de mesure plus

faible) ou vers la gauche (étendue de mesure plus grande). Après celà le manomètre est

alors déjà réglé sur l‘étendue de mesure souhaitée.

4. Si l‘appareil de mesure est équipé d‘un transmetteur de type 89x.44 (voir page 37), le

signal de sortie est réglé également sur la nouvelle étendue de mesure grâce à cette

procédure.

5. A la n du réglage, refermer l‘appareil avec le capuchon.

Graduations amovibles (option)

1. Desserrer la bride de xation sur le boîtier

du manomètre pour pression diérentielle

et enlever la lunette avec son voyant

2. Desserrer la vis moletée et l’enlever

entièrement

3. Enlever les trois graduations, placer la

graduation souhaitée sur le dessus et

remettre en place

4. Poser la vis moletée et la serrer à fond, remonter la lunette

avec son voyant et remettre les clips de xation

Légende

Bride de serrage

Anneau supérieur

Vis moleté e

Graduations

Raccords de pre ssion G 1/4

Raccords de pression supplémentaires

Trois taraudages supplémentaires G ¼ sur la

chambre de mesure Moins (bride droite de la

cellule de mesure, si l‘on regarde l‘appareil de

derrière), par ex. pour le raccordement d‘un

pressostat, d‘une soupape de sûreté ou d‘un

transmetteur de pression de type A-10 Cryo ou

IS-20

F

11224380.02BA

Deux taraudages G ¼ sur la chambre de

mesure Plus (bride gauche de la cellule de

mesure si l‘on regarde l‘appareil de derrière)

par ex. pour le réétalonnage

11265191.07 12/2012 GB/D/F/I

WIKA mode d‘emploi manomètre pour pression diérentielle types 712.15.160, 732.15.160

Trous de mont age M8

Raccords de pre ssion G 1/4

43

Page 44

5. Manifold avec indication de la pression de travail (option)

5. Manifold avec indication de la pression de travail (option)

En option, le manifold compact couplé avec un instrument de mesure de pression de travail

diamètre 100 mm rend possible la mesure centralisée de niveau et de pression de travail

dans un seul appareil.

Pour isoler les conduites de la pression

sans interrompre le fonctionnement du process

- en cas de démontage/contrôle de l‘appareil

- pour la protection de l‘appareil contre les

surpressions non admissibles, en cas de solli-

F

Manomètre de

travail

63 mm

Raccord t est

M20 x 1,5

Vanne d’arrêt

i

Vanne

d’équilibrage

de la pression

Vanne d’arrêt

j

a) Ouvrir la vanne d‘équilibrage de la pression intégrée dans le système de mesure

b)

Fermer les robinet plus et moins et refermer ensuite la vanne d‘équilibrage de la pression

c) Connecter la pression normale et raccorder le générateur de pression au moyen du

raccord taraudé G ¼ femelle dans la chambre plus du système de mesure

d) Retirer la vis du raccord test dans le bloc vannes sur le côté moins

e) Le côté plus peut à présent être mis sous pression

f) Une fois l‘ajustement eectué: - Refermer la vis de vidange - Déconnecter à

nouveau la pression normale et la génération de pression puis refermer le raccord

- Ouvrir la vanne d‘équilibrage de pression intégrée

- Ouvrir lentement tout d‘abord le robinet plus, puis le robinet moins

- Refermer la vanne d‘équilibrage de pression

Raccord test M20 x 1,5 pour le contrôle de l‘instrument de mesure de la pression de

travail

La vanne d’équilibrage de pression (quand elle est ouverte) rend possible un contrôle du

point zéro en cours de fonctionnement du process.

L

e uide s‘écoule du côté où la pression est la plus élevée vers le côté opposé. La pression

diérentielle tombe à zéro (Si l‘achage de la pression diérentielle tombe à zéro, c‘est-àdire dans la plage de tolérance du point zéro, l‘appareil fonctionne alors correctement).

Une correction du point zéro peut être eectuée en réglant

l‘aiguille de réglage intégrée (auparavant retirer la lunette avec

clips de xation, ainsi que le voyant et le joint). La correction du

point zéro s‘eectue en tournant la vis à fente sur l‘aiguille de

réglage. Une fois la correction du point zéro eectuée, remonter

la lunette avec clips de xation (attention à la mise en place du

voyant et du joint) et fermer la vanne d‘équilibrage de la pression.

Pour les versions munies d’un transmetteur intégré, le point zéro

doit être ensuite contrôlé (voir page 45).

44

WIKA mode d'emploi manomètre pour pression diérentielle types 712.15.160, 732.15.160

citation multipliée des installations lors d‘essais

11236396.01BA

de pression.

Pour la protection de l‘appareil contre les

coups de bélier et, en conséquence, contre des

conditions d‘exploitation non dénies.

En cas de mise hors service de l‘appareil

dans le cas où des mesures ne sont pas nécessaires pendant un laps de temps relativement

long, c‘est-à-dire en cas de mesures sporadiques seulement (an d‘augmenter la durée de

vie des appareils pour pression diérentielle et

de service avec fréquence élevée de changements de pression).

En cas de réétalonnage du manomètre

pour pression diérentielle (achage du contenu du réservoir)

Vis à fente

11265191.07 12/2012 GB/D/F/I

Page 45

6. Conseils d‘utilisation ... 8. Transmetteur pour indication du niveau

6. Conseils d‘utilisation

Les milieux de mesure dangereux, comme l‘oxygène, l‘acétylène, les

substances inammables et toxiques, ainsi que les réservoirs sous pression

etc, .. sont assujettis à des règles générales d‘utilisation. En dehors de

ces règles, il est également indispensable de respecter les prescriptions

et directives en vigueur.

7. Adaptateurs pour raccordement process (option)

Les adaptateurs peuvent être bridés directement sur le

manomètre pour pression diérentielle ou sur le manifold.

5 raccords process diérents sont disponibles:

2 x G 1/4, taraudage, entraxe 31 mm ou 54 mm

2 x 1/4 NPT, taraudage, entraxe 31 mm, 37 mm ou 54 mm

En cas de commande individuelle,toutes les pièces requises pour le montage sur le manomètre pour pression diérentielle ou sur le manifold sont contenues dans le volume de livraison :

2 x vis à tête hexagonale M8 x 16, 2 x vis à tête hexagonale M8 x 28,

2 x écrous M8 et 2 x joints toriques

8. Transmetteur pour indication du niveau (option)

Version standard type 891.44

Version Ex type 892.44

Les manomètres pour pression diérentielle WIKA avec transmetteur intégré de type 89x.44

allie tous les avantages d‘un achage mécanique sur place et l‘exigence d‘une transmission

électrique du signal permettant une saisie moderne des valeurs de mesure dans l‘industrie.

Le transmetteur est intégré dans le boîtier de l’indicateur de niveau. L’étendue de mesure

(signal de sortie électrique) est réglé automatiquement avec l’achage mécanique, ce qui

signie que la graduation sur 270 degrés correspond à 4 … 20 mA (voir chapitre 4. Manomètre pour pression diérentielle).

F

Pour les graduations multiples ou

graduations enchables amovibles

(option), le signal de sortie de 4 ... 20 mA

peut être enregistré dans un microprocesseur.

Le signal de sortie peut être adapté au

type de gaz souhaité avec un tournevis en

tournant le commutateur BCD optionnel

(accessible en enlevant un capuchon situé

sur le côté gauche du boîtier).

Zéro électrique (avec option commutateur BCD)

Si un ajustage du point zéro est nécessaire,

Commutateur BC D (s électeur de gr aduations)

et bouto n point zéro (capuc hon enlevé))

(par ex. après une correction mécanique du point zéro), appuyer sur le bouton-poussoir du

point zéro pendant env. 1 sec. en l‘espace de 30 sec. avec l‘appareil hors tension

connecteur)

11265191.07 12/2012 GB/D/F/I

WIKA mode d‘emploi manomètre pour pression diérentielle types 712.15.160, 732.15.160

et avec la vanne d‘équlibrage de la pression ouverte.

(retirer le

45

Page 46

8. Transmetteur pour indication du niveau

Zéro électrique (sans option commutateur BCD)

Si le zéro mécanique est modié au moyen de l‘indicateur

de réglage, le zéro électrique doit être réadapté au zéro

mécanique.

A cet eet, ramenez d‘abord le manomètre en pression

atmosphérique.

Dégagez l‘ensemble du capot de jonction sur le côté droit

F

du manomètre en dévissant complètement la vis

le dessus du couvercle du capot de jonction

tournevis droit (0,6 x 3,5 mm).

sur

avec un

Sortez la vis. Retirez le capot de jonction

femelle

ainsi le manomètre de l‘alimentation en tension.

Retirez le couvercle du capot de jonction

jonction

travers du capot de jonction

Pontez les contacts 5 et 6 sur l‘insert femelle avec un court

morceau de tresse isolée aux deux bouts (résistance

maximale admissible 30 Ω).

Remontez le connecteur dans l‘ordre inverse. Raccordez

le connecteur avec un morceau monté de l de tresse sur

l‘insert mâle et rétablissez ainsi la tension d‘alimentation.

En 30 secondes au maximum, le nouveau zéro est enregistré dans l‘électronique. Pendant ce laps de temps, le courant

monte dans la boucle à 9,5 mA.

Le nouveau zéro reste enregistré durablement, même en

cas de panne de tension.

Dégagez de nouveau le connecteur dans l‘ordre désigné

ci-dessus et supprimez le morceau de l tressé. Après

avoir de nouveau monté le connecteur, le signal de sortie

électrique est de nouveau identique à l‘achage de

l‘indicateur mécanique.

An que le type de protection reste le

même, il faut impérativement remonter

les joints

du support de la boîte de jonction et séparez

et faites sortir l‘insert femelle entièrement au

vers le bas.

.

avec l‘insert

du capot de

Vis

Couvercle du capot

de jonction

Capot de jonction

Sortir l‘insert femelle

Boîte de jonction

Joints

46

WIKA mode d'emploi manomètre pour pression diérentielle types 712.15.160, 732.15.160

11265191.07 12/2012 GB/D/F/I

Page 47

8. Transmetteur pour indication du niveau

Données techniques Types 891.44 et 892.44 (modèle Ex)

Alimentation UB

pour modèle non Ex DC

pour modèle Ex voir au paragraphe Protection Ex !

Inuence de l‘énergie auxil.

% du gain/10 V

Ondulation résiduelle admiss. % ss

Signal de sortie 4 … 20 mA, 2-ls

Résist. charge max autorisée RA pour modèle non Ex, Type 891.44:

Inuence d. l.

résistance charge % du gain

Réglage du signal de sortie

Point neutre, électr.

Remise à zéro en

„commutateur de sélection d‘échelle“ réglable par bouton-poussoir

Sélection de l‘échelle 4 graduations réglables via commutateur BCD

Linéarité % du gain

Température

Températ. ambiante admiss. °C -40 … +80, -40 … +60 pour oxygène

Plage de temp. compensée °C -40 … +80

Coe. thermique sur

plage compensée

TK moyen du point neutre

TK moyen du gain

% du gain/10 K

% du gain/10 K

Protection Ex selon certicat de conformité

Homologation EEx II 2G EEx ia IIC T6

Valeurs maximales de sécurité

Alimentation U

Courant de court-circuit I

Puissance P

Capacité interne C

Inductance interne L

i DC 14 … 30 V

i mA max. 100

i W max. 1

i nF 12

i mH négligeable

Température du uide °C -40 … +80, -40 … +60 pour oxygène

Température ambiante °C -40 … +60 (T6)

Conformité-CE E

mission de perturbations et résistance aux perturbations selon EN 61326

Branchement électrique Prise câblée (Bornes à vis jusqu‘à 2,5 mm²)

Protection électrique La protection court-circuits et fausse polarité

Degré de protection IP 65 suivant EN 60529 / IEC 529

Branchement éléctrique,

2-ls

Terre, relié e au

boîtie r 2)

B ≤ 30 V

12 V < U

≤ 0,1

≤ 10

A ≤ (UB - 12 V) / 0,02 A avec RA en Ω et UB en Volt

R

pour modèle Ex, Type 892.44:

A ≤ (UB - 14 V) / 0,02 A avec RA en Ω et UB en Volt

R

≤ 0,1

pontant temporairement les bornes 5 et 6 ou pour l‘option

≤ 1,0 (réglage du point de coupure)

≤ 0,3

≤ 0,3

BSV 08 ATEX E 018 X pour Type 892.44

Bornes 3 , 4, 5 et 6: uniquemen t pour

B+/Sig+

U

l‘util isation inter ne

2) Ce raccord ne doit pas être utilisé

pour une liaison équipotentielle.

L‘instrument doit être intégré dans la

liaison équipotentielle via le raccord

process.

F

1)

11265191.07 12/2012 GB/D/F/I

WIKA mode d‘emploi manomètre pour pression diérentielle types 712.15.160, 732.15.160

47

Page 48

8. Transmetteur pour indication du niveau

Mesures à prendre en cas de pannes

Panne Cause possible Mesure à prendre

Aucun signal de sortie Aucune tension d‘alimentation Contrôler l‘alimentat. en courant et les

Rupture de ls ls; le cas échéant changer les

pièces défectueuses

Transducteur mal branché Contrôler les branchements; le cas

F

Aucune pression d‘entrée Contrôler l‘arrivée de pression

Vanne d’équil. pression ouverte Fermer vanne d’équil. pression

Electronique défectueuse, conséquence

d‘une tension d‘alimentation trop élevée

ou d‘une tension d‘origine étrangère

Signal de sortie Canal d‘entrée bouché Nettoyer le canal d‘entrée et/ou

constant malgré une la vis d‘étranglement

variation de pression Vanne d’équil. pression ouverte Fermer vanne d’équil. pression

Electronique défectueuse, conséquence

d‘une tension d‘alimentation trop élevée

ou d‘une tension d‘origine étrangère

Transducteur défectueux à la Envoyer le transducteur au fabricant

suite d‘une surpression pour réparation

Signal de sortie trop