Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Gas actuated thermometer per ATEX, models 73, 74

Gasdruck-Thermometer nach ATEX, Typen 73, 74

Thermomètre à dilatation de gaz selon ATEX, types 73, 74

Termómetro de dilatación de gas según ATEX, modelos 73, 74

CE Ex

II 2 GD c TX

Model F73.100

Model R74.100

GB

D

F

E

Page 2

Operating instructions models 73, 74 (ATEX)

GB

Page 3 - 18

Betriebsanleitung Typen 73, 74 (ATEX)

D

Mode d'emploi types 73, 74 (ATEX)

F

Manual de instrucciones modelos 73, 74 (ATEX)

E

© 2010 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

Seite 19 - 34

Page 35 - 50

Página 51 - 66

11591367.02 05/2012 GB/D/F/E

2

WIKA operating instructions models 73, 74 (ATEX)

Page 3

Contents

Contents

1. General information 4

2. Safety 6

3. Specications 10

4. Design and function 10

5. Transport, packaging and storage 11

6. Commissioning, operation 12

7. Maintenance and cleaning 15

8. Dismounting, return and disposal 16

Appendix 1: EC declaration of conformity 18

Declarations of conformity can be found online at www.wika.com.

GB

11591367.02 05/2012 GB/D/F/E

WIKA operating instructions models 73, 74 (ATEX) 3

Page 4

1. General information

1. General information

■

The gas actuated thermometers described in these operating

GB

instructions have been designed and manufactured using state-ofthe-art technology. All components are subject to stringent quality

and environmental criteria during production. Our management

systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on

handling the instrument. Working safely requires that all safety

instructions and work instructions are observed.

■

Observe the local accident prevention regulations and general

safety regulations in eect for the instrument's range of use.

■

The operating instructions are part of the instrument and must

be kept in the immediate vicinity of the instrument and readily

accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the

operating instructions, prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage

caused by using the product contrary to its intended use,

non-compliance with these operating instructions, assignment

of insuciently qualied skilled personnel or unauthorised

modications to the instrument.

■

The general terms and conditions, contained in the sales

documentation, shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: TM 73.01, TM 74.01

4 WIKA operating instructions models 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 5

1. General information

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can

result in serious injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation, which can

result in light injuries or damage to equipment or the

environment, if not avoided.

Information

… points out useful tips, recommendations and

information for ecient and trouble-free operation.

WARNING!

... indicates a potentially dangerous situation in the

hazardous area, which can result in serious injury or

death, if not avoided.

WARNING!

... indicates a potentially dangerous situation which can

result in burns caused by hot surfaces or liquids if not

avoided.

GB

11591367.02 05/2012 GB/D/F/E

WIKA operating instructions models 73, 74 (ATEX) 5

Page 6

2. Safety

2. Safety

WARNING!

GB

2.1 Intended use

These gas actuated thermometers are used for measuring

temperature in hazardous areas of industrial applications.

The instrument has been designed and built solely for the intended

use described here, and may only be used accordingly.

The technical specications contained in these operating instructions

must be observed. Improper handling or operation of the instrument

outside of its technical specications requires the instrument to be

taken out of service immediately and inspected by an authorised

WIKA service engineer.

Before installation, commissioning and operation, ensure

that the appropriate gas actuated thermometer has been

selected in terms of measuring range, design and specic

measuring conditions. The compatibility of the wetted

parts of the process connection (thermowell, thermowell

stem) with the medium must be tested.

Non-observance can result in serious injury and/or

damage to the equipment.

Further important safety instructions can be found in the

individual chapters of these operating instructions.

The manufacturer shall not be liable for claims of any type based on

operation contrary to the intended use.

6 WIKA operating instructions models 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 7

2. Safety

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and

damage to equipment.

■

The activities described in these operating instructions

may only be carried out by skilled personnel who have

the qualications described below.

■

Keep unqualied personnel away from hazardous

areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on

their technical training, knowledge of measurement and control

technology and on their experience and knowledge of countryspecic regulations, current standards and directives, are capable

of carrying out the work described and of independently recognising

potential hazards.

2.3 Additional safety instructions for instruments per ATEX

WARNING!

Non-observance of these instructions and their contents

may result in the loss of explosion protection.

WARNING!

It is imperative that the application conditions and safety

requirements are followed.

Temperature measuring instruments must be earthed via

the process connection!

GB

Gas actuated thermometers contain no internal heat source,

and, when correctly installed and operated, cause no increase in

temperature!

11591367.02 05/2012 GB/D/F/E

WIKA operating instructions models 73, 74 (ATEX) 7

Page 8

2. Safety

A heat return ow from the process, which exceeds the ignition

temperature of the surrounding hazardous area, is not permitted and

must be prevented through appropriate thermal insulation!

GB

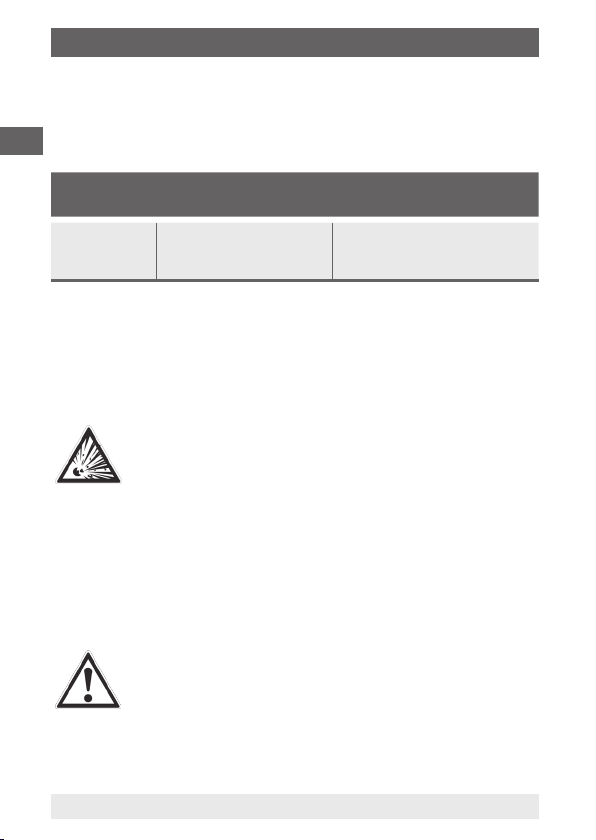

The following surface temperatures must not be exceeded:

Potentially explosive atmosphere

Gas, air, vapour, mist Dust, air

Permissible

surface

temperature

1) If dust should settle on the instrument (up to a max. 5 mm layer thickness), a safety margin

of 75 K must be maintained between the minimum ignition temperature of the dust layer

and the surface temperature! For thicker dust layers a greater safety margin should be

incorporated!

2.4 Special hazards

≤ 80 % of the ignition

temperature in °C

≤ 2/3 of the minimum

ignition temperature in °C

WARNING!

Observe the information given in the applicable type

examination certicate and the relevant countryspecic regulations for installation and use in potentially

explosive atmospheres (e.g. IEC 60079-14, NEC, CEC).

Non-observance can result in serious injury and/or

damage to the equipment.

For additional important safety instructions for instruments

with ATEX approval see chapter 2.3 "Additional safety

instructions for instruments per ATEX".

1)

WARNING!

Residual media in dismounted instruments can result in

a risk to persons, the environment and equipment. Take

sucient precautionary measures.

8 WIKA operating instructions models 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 9

2. Safety

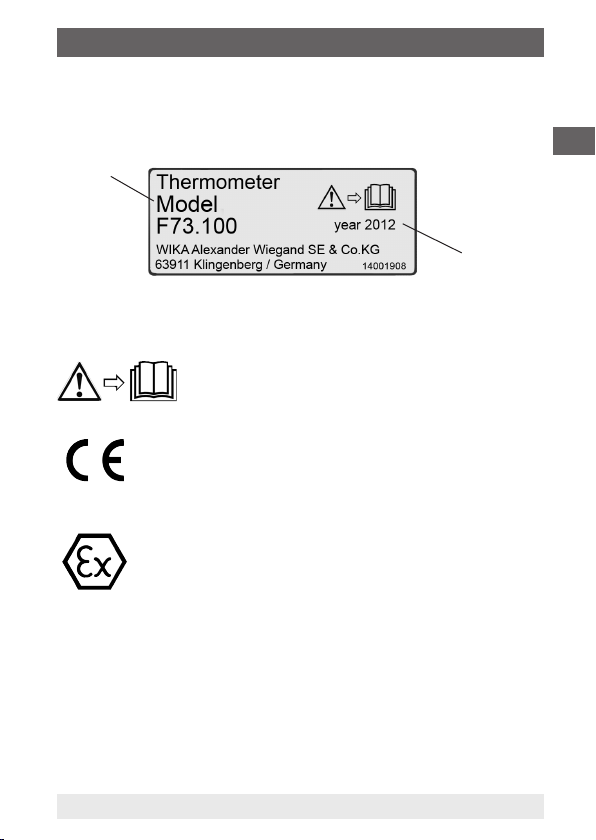

2.5 Labelling, safety marks

Product label

Model

Explanation of symbols

Before mounting and commissioning the instrument,

ensure you read the operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant

European directives.

ATEX European Explosion Protection Directive

(Atmosphère = AT, explosible = EX)

Instruments bearing this mark comply with the

requirements of the European Directive 94/9/EC (ATEX)

on explosion protection.

GB

Year of manufacture

11591367.02 05/2012 GB/D/F/E

WIKA operating instructions models 73, 74 (ATEX) 9

Page 10

3. Specications / 4. Design and function

3. Specications

Specications

GB

Measuring element Gas-pressure inert gas lling

Nominal size 100, 160, 144 x 144 100

Instrument version

■

Model A7x

■

Model R7x

■

Model S73

■

Model F73

Permissible ambient

temperature

Working pressure

■

Continuous load (1 year)

■

short term (max. 24 h)

Case, ring

Stem, process connection

Ingress protection

per EN 60529/ IEC 529

Model 73 Model 74

Back mount (axial)

Lower mount (radial)

Back mount, adjustable

stem and dial

Instruments with capillaries

0 ... 40 °C

Measuring range (EN 13190)

Scale range (EN 13190)

Stainless steel 1.4301

Stainless steel 1.4571

IP 65

IP 66 (liquid-lled)

Stainless steel 1.4435

IP 65

(option: IP 66)

For further specications see WIKA data sheets TM 73.01 or

TM 74.01 and order documentation.

4. Design and function

4.1 Description

The gas actuated thermometer consists of a stem, capillary and

Bourdon tube in the casing. These parts are combined to form a

single unit. The entire measuring system is lled with an inert gas

under pressure.

A change in temperature will cause a change in internal pressure

in the stem. The pressure deforms the measuring spring and the

deection is transferred to the pointer via a dial movement.

10 WIKA operating instructions models 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 11

4. Design, function / 5. Transport, packaging ...

Fluctuations in ambient temperature aecting the casing can be

neglected, as a bimetal compensation element is tted between the

dial movement and the measuring spring.

Scale ranges with accuracy class 1 per EN 13190

between -200 ... +700 °C

4.2 Scope of delivery

Cross-check scope of delivery with delivery note.

5. Transport, packaging and storage

5.1 Transport

Check instrument for any damage that may have been caused by

transport. Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during

transport (e.g. change in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

Storage temperature: -20 ... +60 °C

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

GB

11591367.02 05/2012 GB/D/F/E

WIKA operating instructions models 73, 74 (ATEX) 11

Page 12

5. Transport, ... / 6. Commissioning, operation

Store the instrument in its original packaging in a location that fulls

the conditions listed above. If the original packaging is not available,

pack and store the thermometer as described below:

1. Wrap the thermometer in an antistatic plastic lm.

GB

2. Place the thermometer, along with shock-absorbent material, in the

packaging.

3. If stored for a prolonged period of time (more than 30 days), place a

bag containing a desiccant inside the packaging.

WARNING!

Before storing the instrument (following operation), remove

any residual media. This is of particular importance if

the medium is hazardous to health, e.g. caustic, toxic,

carcinogenic, radioactive, etc.

The use of liquid damping is always recommended for

temperatures near the dew point (±1 °C around 0 °C).

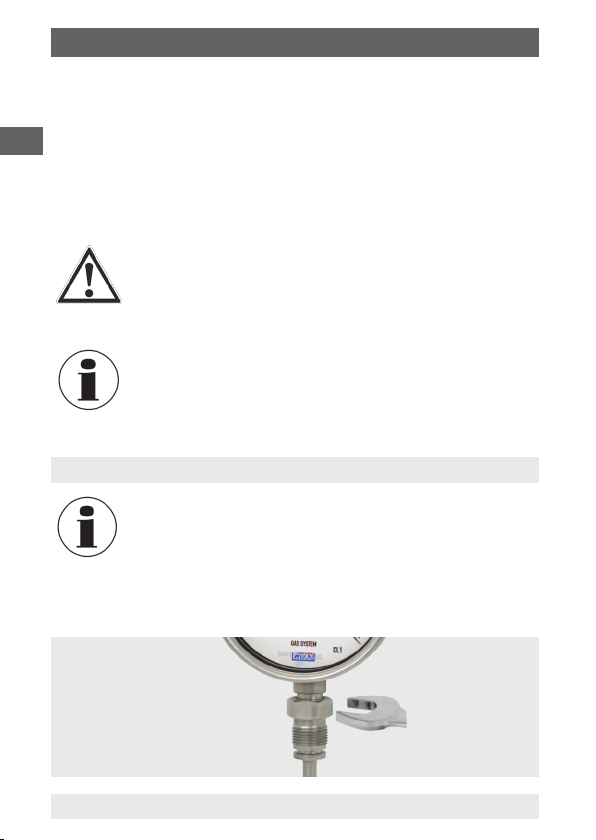

6. Commissioning, operation

The gas actuated thermometer must be earthed via the

process connection!

When screwing the instruments in, the force required to do this must

not be applied through the casing, but only through the spanner ats

provided for this purpose and using a suitable tool.

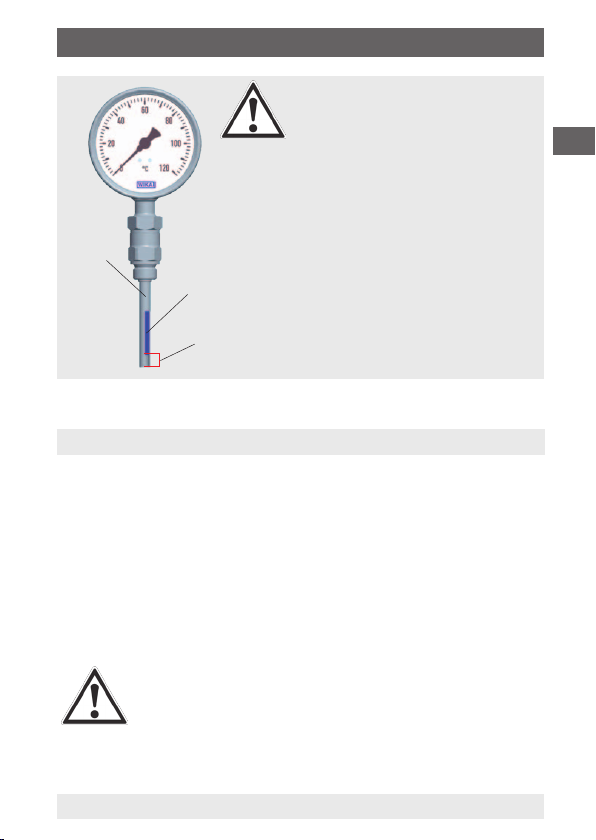

Installation with

open-ended spanner

12 WIKA operating instructions models 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 13

6. Commissioning, operation

■

If possible, the entire length of the stem should be exposed to the

temperature being measured. However, at least the length of the

active part that corresponds to the length of the gas expansion

vessel (active length).

■

In pipelines or other measuring points, the temperature probe must

be angled as far towards the ow as possible.

■

Errors in thermal conduction occur if the area where the

temperature is to be measured is so small, that the mass of the

temperature probe acts as thermal capacity. Errors in thermal

conduction may also occur if the immersion depth is insucient, if

the mounting ttings are connected to a good thermal conductor

(metal plate or similar) and there is a considerable dierence

in temperature between the measuring and mounting element

temperatures.

■

Mount the indicator case free from vibration. If necessary, it is

possible to isolate the instrument from the mounting point by

installing a exible connection line between the measuring point

and the thermometer and mounting the instrument on a suitable

bracket.

If this is not possible, the following limit values must not be exceeded:

GB

Dry gauges: Frequency range < 150 Hz

Acceleration < 0.7 g (7 m/s

Liquid-lled gauges: Frequency range < 150 Hz

Acceleration < 2 g (20 m/s

2

)

2

)

After mounting, set the compensating valve (if

available) from CLOSE to OPEN.

11591367.02 05/2012 GB/D/F/E

WIKA operating instructions models 73, 74 (ATEX) 13

Page 14

6. Commissioning, operation

The liquid lling must be checked on a regular basis.

The liquid level must not drop below 75 % of the gauge diameter.

Heavy shocks, oscillations and vibrations lead to imprecise values,

increased wear in the transmission mechanism, and fractures on

GB

welded or soldered joints.

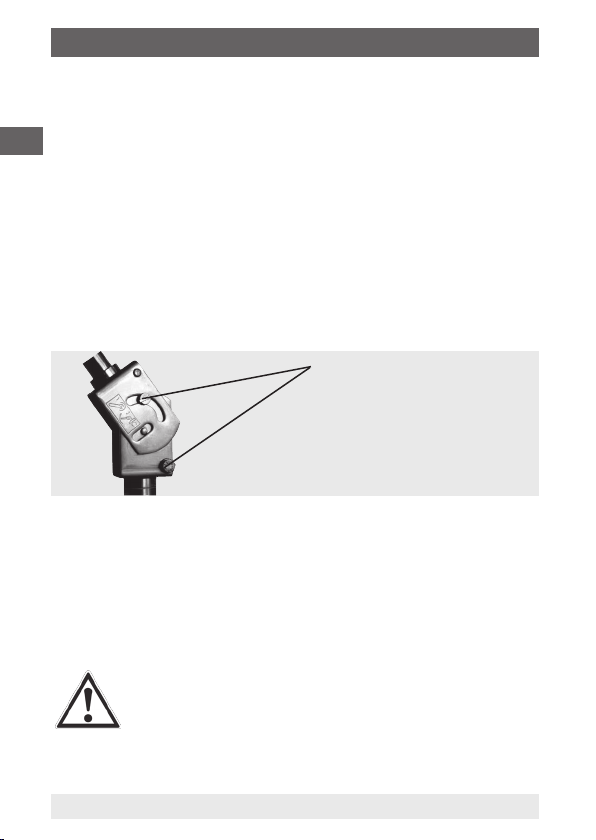

When mounting a gas actuated thermometer that can be rotated

and swivelled, the specic instructions must be followed. In order to

set the indicator to the desired position, the following steps must be

taken:

1. The lock nut or union nut must be loosened at the process

connection.

2. The hexagon bolts and slotted screws at the swivel joint must be

loosened.

loosening

Make sure to loosen the

screws on the opposite side

as well!

3. Position the indicator as required, tighten the hexagon bolts and

slotted screws, and nally tighten the lock nut or union nut rmly.

When using thermowells, they must be lled with a thermal contact

medium in order to reduce the heat transfer resistance between the

outer wall of the sensor and the inner wall of the thermowell. The

working temperature of the thermal compound is -40 ... +200 °C.

WARNING!

Do not ll hot thermowells. There is a risk of the oil

spraying out!

14 WIKA operating instructions models 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 15

6. Commissioning, operation / 7. Maintenance

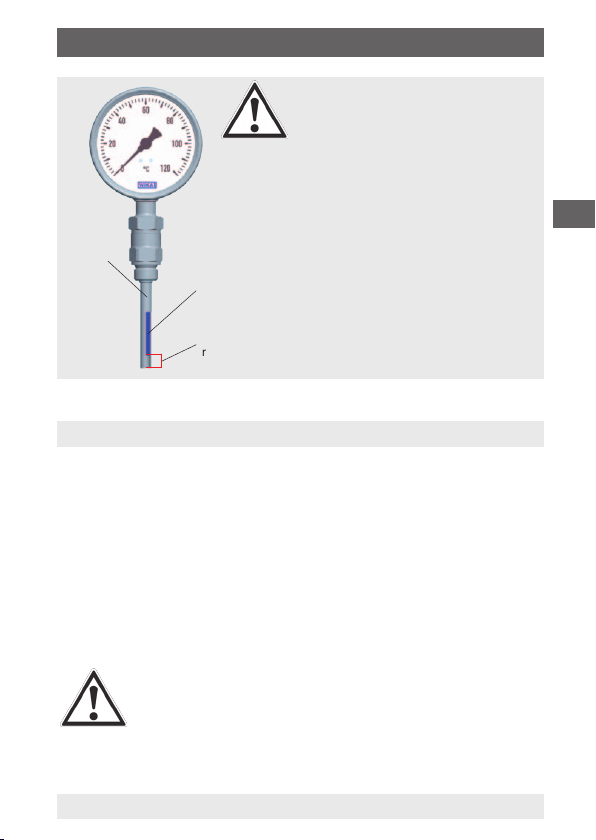

CAUTION!

When using thermowells, please

ensure that the stem does not

touch the bottom of the thermowell

since, due to the dierent

expansion coecients of the

materials, the stem may become

buckled at the bottom of the

Thermowell

Stem

Required safety

clearance

thermowell.

(Formula for the calculation of

the insertion length l1 see the

respective thermowell data sheet)

7. Maintenance and cleaning

7.1 Maintenance

These gas actuated thermometers are maintenance-free!

The indicator should be checked once or twice every year. For this

the instrument must be disconnected from the process and checked

using a temperature calibrator.

Repairs must only be carried out by the manufacturer.

...

GB

7.2 Cleaning

CAUTION!

■

Clean the thermometer with a moist cloth.

■

Wash or clean the thermometer before returning it, in

order to protect personnel and the environment from

exposure to residual media.

11591367.02 05/2012 GB/D/F/E

WIKA operating instructions models 73, 74 (ATEX) 15

Page 16

7. Maintenance, cleaning / 8. Dismounting, ...

■

Residual media in dismounted instruments can result in

a risk to persons, the environment and equipment. Take

sucient precautionary measures.

GB

For information on returning the instrument see chapter

8.2 "Returns".

8. Dismounting, return and disposal

WARNING!

Residual media in dismounted instruments can result in

a risk to persons, the environment and equipment. Take

sucient precautionary measures.

8.1 Dismounting

WARNING!

Risk of burns!

Let the instrument cool down suciently before

dismounting it! During dismounting there is a risk of

dangerously hot pressure media escaping.

8.2 Returns

WARNING!

Absolutely observe when shipping the instrument:

All instruments delivered to WIKA must be free from any

kind of hazardous substances (acids, leachate, solutions,

etc.).

When returning the instrument, use the original packaging or a

suitable transport package.

16 WIKA operating instructions models 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 17

8. Dismounting, return and disposal

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with shock-absorbent material, in the

packaging. Place shock-absorbent material evenly on all sides of

the shipping box.

3. If possible, place a bag containing a desiccant inside the

packaging.

4. Label the shipment as carriage of a highly sensitive measuring

instrument.

Enclose the completed returns form with the instrument.

The return form is available in the 'Service' section on

www.wika.com.

8.3 Disposal

Incorrect disposal may endanger the environment.

Dispose of instrument components and packaging materials in an

environmentally compatible way and in accordance with the countryspecic waste disposal regulations.

GB

11591367.02 05/2012 GB/D/F/E

WIKA operating instructions models 73, 74 (ATEX) 17

Page 18

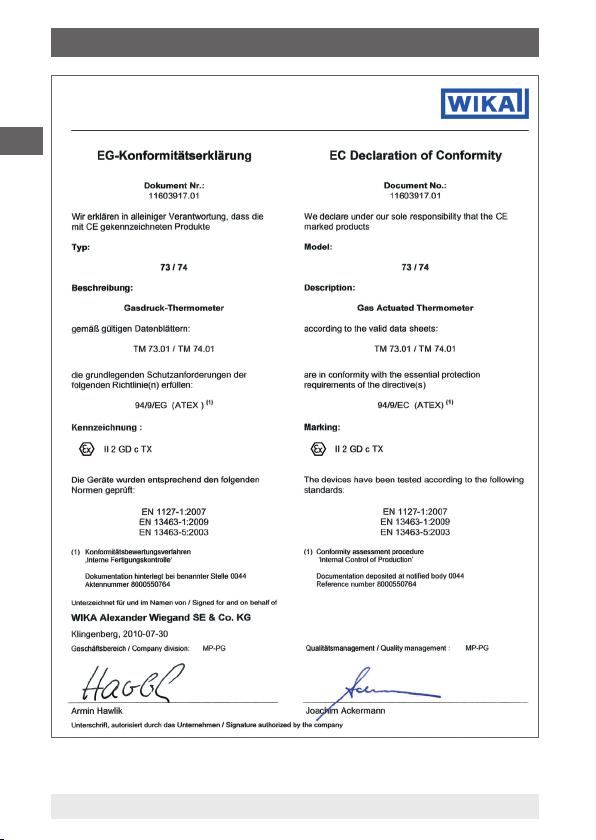

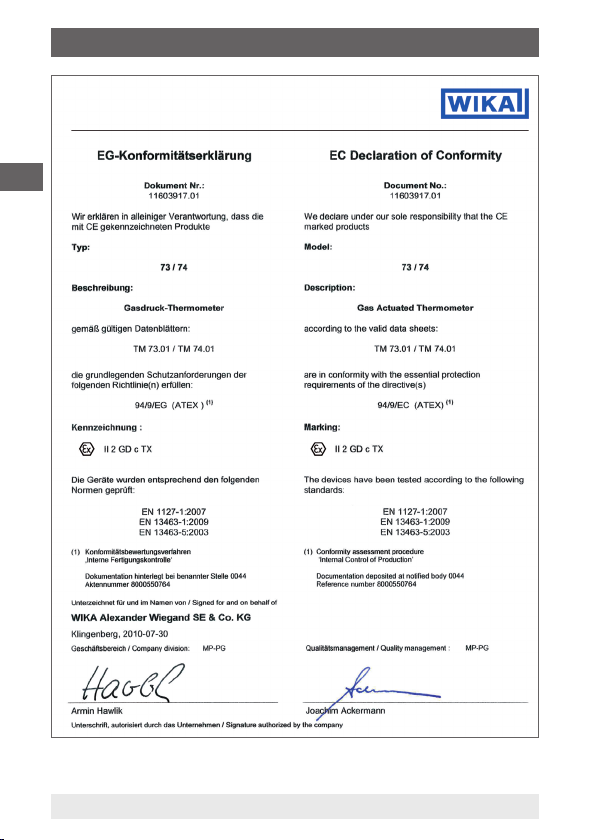

Appendix 1: EC declaration of conformity

GB

18 WIKA operating instructions models 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 19

Inhalt

Inhalt

1. Allgemeines 20

2. Sicherheit 22

3. Technische Daten 26

4. Aufbau und Funktion 26

5. Transport, Verpackung und Lagerung 27

6. Inbetriebnahme, Betrieb 28

7. Wartung und Reinigung 31

8. Demontage, Rücksendung und Entsorgung 32

Anlage 1: EG-Konformitätserklärung 34

Konformitätserklärungen nden Sie online unter www.wika.de.

D

11591367.02 05/2012 GB/D/F/E

WIKA Betriebsanleitung Typen 73, 74 (ATEX)

19

Page 20

1. Allgemeines

1. Allgemeines

■

Die in der Betriebsanleitung beschriebenen Gasdruck-Thermometer werden nach den neuesten Erkenntnissen konstruiert und

gefertigt. Alle Komponenten unterliegen während der Fertigung

strengen Qualitäts- und Umweltkriterien. Unsere Management-

D

systeme sind nach ISO 9001 und ISO 14001 zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit

dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung

aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen

einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des Gerätes für das Fachpersonal jederzeit zugänglich

aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller

Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten Fachpersonals sowie

eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: TM 73.01, TM 74.01

20 WIKA Betriebsanleitung Typen 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 21

1. Allgemeines

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin,

die zum Tod oder zu schweren Verletzungen führen kann,

wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation

hin, die zu geringfügigen oder leichten Verletzungen bzw.

Sach- und Umweltschäden führen kann, wenn sie nicht

gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie

Informationen für einen ezienten und störungsfreien

Betrieb hervor.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation

im explosionsgefährdeten Bereich hin, die zum Tod oder

zu schweren Verletzungen führen kann, wenn sie nicht

gemieden wird.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation

hin, die durch heiße Oberächen oder Flüssigkeiten zu

Verbrennungen führen kann, wenn sie nicht gemieden

wird.

D

11591367.02 05/2012 GB/D/F/E

WIKA Betriebsanleitung Typen 73, 74 (ATEX)

21

Page 22

2. Sicherheit

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen,

dass das richtige Gasdruck-Thermometer hinsichtlich

D

2.1 Bestimmungsgemäße Verwendung

Die Gasdruck-Thermometer dienen zum Messen von Temperatur bei

industriellen Anwendungen in explosionsgefährdeten Bereichen.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und

darf nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind

einzuhalten. Eine unsachgemäße Handhabung oder ein Betreiben

des Gerätes außerhalb der technischen Spezikationen macht die

sofortige Stilllegung und Überprüfung durch einen autorisierten

WIKA-Servicemitarbeiter erforderlich.

Messbereich, Ausführung und spezischen Messbedingungen ausgewählt wurde. Die Verträglichkeit der

messstoberührten Bauteile des Prozessanschlusses

(Schutzrohr, Tauchrohr etc.) muss mit dem Messsto

geprüft werden.

Bei Nichtbeachten können schwere Körperverletzungen

und/oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den

einzelnen Kapiteln dieser Betriebsanleitung.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer

Verwendung sind ausgeschlossen.

.

22 WIKA Betriebsanleitung Typen 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 23

2. Sicherheit

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personenund Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen

Tätigkeiten nur durch Fachpersonal nachfolgend

beschriebener Qualikation durchführen lassen.

■

Unqualiziertes Personal von den Gefahrenbereichen

fernhalten.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner

Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen

sowie Kenntnis der landesspezischen Vorschriften, geltenden

Normen und Richtlinien in der Lage, die beschriebenen Arbeiten

auszuführen und mögliche Gefahren selbstständig zu erkennen.

2.3 Zusätzliche Sicherheitshinweise für Geräte nach ATEX

WARNUNG!

Die Nichtbeachtung dieser Inhalte und Anweisungen kann

zum Verlust des Explosionsschutzes führen.

WARNUNG!

Einsatzbedingungen und sicherheitstechnische Daten

unbedingt beachten.

Temperaturmessgeräte über den Prozessanschluss

erden!

D

Gasdruck-Thermometer beinhalten keine eigene Wärmequelle und

verursachen bei bestimmungsgemäßen Einbau und Betrieb keine

Temperaturerhöhung!

11591367.02 05/2012 GB/D/F/E

WIKA Betriebsanleitung Typen 73, 74 (ATEX)

23

Page 24

2. Sicherheit

Ein Wärmerückuss aus dem Prozess, welcher die Zündtemperatur

der umgebenden explosionsfähigen Atmosphäre überschreitet ist

nicht zulässig und muss durch geeignete Wärmeisolierung verhindert

werden!

Folgende Oberächentemperaturen nicht überschreiten:

D

Explosionsfähige Atmosphäre

Gas, Luft, Dampf, Nebel Staub, Luft

Zulässige

Oberächentemperatur

1) Bei Staubablagerungen auf dem Gerät (bis max. 5 mm Schichtdicke) ist ein Sicherheitsabstand von 75 K zwischen der Mindestzündtemperatur der Staubschicht und der

Oberächentemperatur einzuhalten! Bei dickeren Staubschichten sind größere Sicherheitsabstände zu berücksichtigen!

2.4 Besondere Gefahren

≤ 80 % der Zündtemperatur

in °C

≤ 2/3 der Mindestzündtemperatur

1)

in °C

WARNUNG!

Die Angaben der geltenden Baumusterprüfbescheinigung

sowie die jeweiligen landesspezischen Vorschriften

zur Installation und Einsatz in explosionsgefährdeten

Bereichen (z. B. IEC 60079-14, NEC, CEC) einhalten. Bei

Nichtbeachten können schwere Körperverletzungen und/

oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise für Geräte mit ATEXZulassung siehe Kapitel 2.3 „Zusätzliche Sicherheitshinweise für Geräte nach ATEX“.

WARNUNG!

Messstoreste im ausgebauten Gerät können zur Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

24 WIKA Betriebsanleitung Typen 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 25

2. Sicherheit

2.5 Beschilderung, Sicherheitskennzeichnungen

Typenschild

Typ

Symbolerklärung

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit

den zutreenden europäischen Richtlinien.

ATEX Europäische Explosionsschutz-Richtlinie

(Atmosphère = AT, explosible = EX)

Geräte mit dieser Kennzeichnung stimmen überein mit

den Anforderungen der europäischen Richtlinie 94/9/EG

(ATEX) zum Explosionsschutz.

D

Herstellungsjahr

Vor Montage und Inbetriebnahme des Gerätes

unbedingt die Betriebsanleitung lesen!

11591367.02 05/2012 GB/D/F/E

WIKA Betriebsanleitung Typen 73, 74 (ATEX)

25

Page 26

3. Technische Daten / 4. Aufbau und Funktion

3. Technische Daten

Technische Daten

Messelement Gasdruck-Inertgasfüllung

Nenngröße 100, 160, 144 x 144 100

D

Geräteausführung

■

Typ A7x

■

Typ R7x

■

Typ S73

■

Typ F73

Zulässige Umgebungstemperatur

Verwendungsbereich

■

Dauerbelastung (1 Jahr)

■

kurzzeitig (max. 24 h)

Gehäuse, Ring

Tauchschaft, Prozessanschluss

Schutzart

nach EN 60529/ IEC 529

Typ 73 Typ 74

Anschlusslage rückseitig (axial)

Anschlusslage unten (radial)

Anschlusslage rückseitig,

dreh- und schwenkbar

Geräte mit Fernleitung

0 ... 40 °C

Messbereich (EN 13190)

Anzeigebereich (EN 13190)

CrNi-Stahl 1.4301

CrNi-Stahl 1.4571 CrNi-Stahl 1.4435

IP 65

IP 66 (üssigkeitsgefüllt)

IP 65

(Option: IP 66)

Weitere technische Daten siehe WIKA-Datenblatt TM 73.01 oder

TM 74.01 und Bestellunterlagen.

4. Aufbau und Funktion

4.1 Beschreibung

Das Gasdruck-Thermometer besteht aus Tauchschaft, Kapillarleitung

und Rohrfeder im Gehäuse. Diese Teile sind zu einer Einheit

verbunden. Das komplette Messsystem ist unter Druck mit einem

inerten Gas gefüllt.

Eine Temperaturänderung bewirkt im Tauchschaft eine Veränderung

des Innendruckes. Der Druck verformt die Messfeder, deren

Auslenkung über ein Zeigerwerk auf den Zeiger übertragen wird.

26 WIKA Betriebsanleitung Typen 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 27

4. Aufbau und Funktion / 5. Transport, ...

Schwankungen der Umgebungstemperatur auf das Gehäuse können

vernachlässigt werden, da zwischen dem Zeigerwerk und der

Messfeder ein Bimetallelement zur Kompensation eingebaut ist.

Anzeigebereiche bei Genauigkeitsklasse 1 nach EN 13190

zwischen -200 ... +700 °C

4.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

5. Transport, Verpackung und Lagerung

5.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport

einen optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

Lagertemperatur: -20 ... +60 °C

D

Folgende Einüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

11591367.02 05/2012 GB/D/F/E

WIKA Betriebsanleitung Typen 73, 74 (ATEX)

27

Page 28

5. Transport, ... / 6. Inbetriebnahme, Betrieb

Das Gerät in der Originalverpackung an einem Ort, der die oben gelisteten Bedingungen erfüllt, lagern. Wenn die Originalverpackung nicht

vorhanden ist, dann das Thermometer wie folgt verpacken und lagern:

1. Das Thermometer in eine antistatische Plastikfolie einhüllen.

2. Das Thermometer mit dem Dämmmaterial in der Verpackung

platzieren.

D

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit

Trocknungsmittel der Verpackung beilegen.

WARNUNG!

Vor der Einlagerung des Gerätes (nach Betrieb) alle

anhaftenden Messstoreste entfernen. Dies ist besonders

wichtig, wenn der Messsto gesundheitsgefährdend ist,

wie z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

Empfohlen wird bei Temperaturen um den Taupunkt (±1 °C

um 0 °C) immer die Verwendung einer Flüssigkeitsdämpfung.

6. Inbetriebnahme, Betrieb

Das Gasdruck-Thermometer über den Prozessanschluss

erden!

Beim Einschrauben der Geräte darf die dazu erforderliche Kraft nicht

über das Gehäuse aufgebracht werden, sondern mit geeignetem

Werkzeug nur über die dafür vorgesehenen Schlüsselächen.

Montage mit

Gabelschlüssel

28 WIKA Betriebsanleitung Typen 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 29

6. Inbetriebnahme, Betrieb

■

Der Tauchschaft soll möglichst mit seiner ganzen Länge der zu

messenden Temperatur ausgesetzt sein. Mindestens aber die

Länge des aktiven Teils, welche der Länge des Gasausdehnungsgefäßes entspricht (aktive Länge).

■

Der Temperaturfühler muss in Rohrleitungen oder sonstigen

Messstellen der Strömungsrichtung möglichst schräg entgegengerichtet stehen.

■

Wärmeableitfehler entstehen, wenn der Messraum, dessen

Temperatur angezeigt werden soll, sehr klein ist, so dass sich die

Masse des Temperaturfühlers als Wärmekapazität bemerkbar

macht. Wärmeableitfehler können auch bei nicht genügender

Einbautiefe entstehen, wenn die Befestigungsarmatur an einem

guten Wärmeleiter (Metallplatten oder dergleichen) befestigt ist

und ein erheblicher Temperaturunterschied zwischen der Messund der Befestigungselement-Temperatur besteht.

■

Das Anzeigegehäuse muss erschütterungsfrei montiert werden.

Gegebenenfalls kann z. B. durch eine exible Verbindungsleitung

von der Messstelle zum Thermometer und die Befestigung über

eine Messgerätehalterung eine Entkopplung vom Einbauort

erreicht werden.

Falls dies nicht möglich ist, dürfen folgende Grenzwerte nicht

überschritten werden:

D

Ungefüllte Geräte: Frequenzbereich < 150 Hz

Beschleunigung < 0,7 g (7 m/s

Flüssigkeitsgefüllte Geräte: Frequenzbereich < 150 Hz

Beschleunigung < 2 g (20 m/s

Belüftungsventil (falls vorhanden) nach der

Montage von CLOSE auf OPEN stellen.

11591367.02 05/2012 GB/D/F/E

WIKA Betriebsanleitung Typen 73, 74 (ATEX)

2

)

2

)

29

Page 30

6. Inbetriebnahme, Betrieb

Die Flüssigkeitsfüllung ist regelmäßig zu überprüfen.

Der Flüssigkeitsspiegel darf nicht unter 75 % des Gerätedurchmessers

fallen.

Starke Erschütterungen, Schwingungen und Vibrationen führen zu

Anzeigeunsicherheiten, erhöhtem Verschleiß im Übersetzungswerk

bzw. Bruch an den Schweiß- oder Lötstellen.

D

Bei der Montage eines dreh- und schwenkbaren Gasdruck-Thermometers sind besondere Vorschriften zu beachten. Um die Anzeige

in die gewünschte Position zu bringen, müssen folgende Schritte

eingehalten werden:

1. Die Konter- oder Überwurfmutter muss am Prozessanschluss

gelöst sein.

2. Sechskant- und Schlitzschrauben müssen am Schwenkgelenk

gelöst sein.

lösen

Unbedingt auch die auf der

gegenüberliegenden Seite

liegenden Schrauben lösen!

3. Anzeige positionieren, Sechskant- und Schlitzschrauben anziehen

und schließlich die Konter- oder Überwurfmutter fest anziehen.

Bei Verwendung von Schutzrohren ist möglichst durch Einfüllen eines

Wärmekontaktmittels der Wärmeübertragungswiderstand zwischen

Fühleraußenwand und Schutzrohrinnenwand zu reduzieren. Die

Arbeitstemperatur der Wärmeleitpaste beträgt -40 ... +200 °C.

WARNUNG!

Nicht in heiße Schutzrohre einfüllen. Gefahr durch herausspritzendes Öl!

30 WIKA Betriebsanleitung Typen 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 31

6. Inbetriebnahme, Betrieb / 7. Wartung ...

VORSICHT!

Bei der Verwendung von Schutzrohren beachten, dass der

Tauchschaft nicht den Boden des

Schutzrohres berührt, da durch die

unterschiedlichen Ausdehnungskoezienten der Materialen sich

der Tauchschaft am Boden des

Schutzrohr

Tauchschaft

Benötigter

Sicherheitsabstand

Schutzrohres verbiegen könnte.

(Formeln zur Berechnung der

Einbaulänge l1 siehe entsprechendes Schutzrohr-Datenblatt)

7. Wartung und Reinigung

7.1 Wartung

Diese Gasdruck-Thermometer sind wartungsfrei!

Eine Überprüfung der Anzeige sollte etwa 1- bis 2-mal pro Jahr

erfolgen. Dazu ist das Gerät vom Prozess zu trennen und mit einem

Temperaturkalibrator zu kontrollieren.

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

D

7.2 Reinigung

VORSICHT!

■

Das Thermometer mit einem feuchten Tuch reinigen.

■

Ausgebautes Thermometer vor der Rücksendung

spülen bzw. säubern, um Personen und Umwelt vor

Gefährdung durch anhaftende Messstoreste zu

11591367.02 05/2012 GB/D/F/E

WIKA Betriebsanleitung Typen 73, 74 (ATEX)

schützen.

31

Page 32

7. Wartung und Reinigung / 8. Demontage, ...

■

Messstoreste im ausgebauten Gerät können zur

Gefährdung von Personen, Umwelt und Einrichtung

führen. Ausreichende Vorsichtsmaßnahmen ergreifen.

Hinweise zur Rücksendung des Gerätes siehe Kapitel 8.2

D

„Rücksendung“.

8. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste im ausgebauten Gerät können zur Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

8.1 Demontage

WARNUNG!

Verbrennungsgefahr!

Vor dem Ausbau das Gerät ausreichend abkühlen lassen!

Beim Ausbau besteht Gefahr durch austretende, gefährlich heiße Messstoe.

8.2 Rücksendung

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoen (Säuren, Laugen, Lösungen, etc.) sein.

Zur Rücksendung des Gerätes die Originalverpackung oder eine

geeignete Transportverpackung verwenden.

32 WIKA Betriebsanleitung Typen 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 33

8. Demontage, Rücksendung, Entsorgung

Um Schäden zu vermeiden:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

3. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung

beifügen.

4. Sendung als Transport eines hochempndlichen Messgerätes

kennzeichnen.

Dem Gerät das Rücksendeformular ausgefüllt beifügen.

Das Rücksendeformular bendet sich in der Rubrik

'Service' unter www.wika.de.

8.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den

landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften

umweltgerecht entsorgen.

D

11591367.02 05/2012 GB/D/F/E

WIKA Betriebsanleitung Typen 73, 74 (ATEX)

33

Page 34

Anlage 1: EG-Konformitätserklärung

D

34 WIKA Betriebsanleitung Typen 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 35

Sommaire

Sommaire

1. Généralités 36

2. Sécurité 38

3. Caractéristiques techniques 42

4. Conception et fonction 42

5. Transport, emballage et stockage 43

6. Mise en service, exploitation 44

7. Entretien et nettoyage 47

8. Démontage, retour et mise au rebut 48

Annexe 1 : Déclaration de conformité CE 50

Déclarations de conformité se trouve sur www.wika.fr.

F

11591367.02 05/2012 GB/D/F/E

WIKA mode d'emploi types 73, 74 (ATEX)

35

Page 36

1. Généralités

1. Généralités

■

Le thermomètre à dilatation de gaz décrit dans le mode d'emploi

est conçu et fabriqué selon les dernières technologies en vigueur.

Tous les composants sont soumis à des critères de qualité et

d'environnement stricts durant la fabrication. Nos systèmes de

gestion sont certiés selon ISO 9001 et ISO 14001.

F

■

Ce mode d'emploi donne des indications importantes concernant

l'utilisation de l'instrument. Il est possible de travailler en toute

sécurité avec ce produit en respectant toutes les consignes de

sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les

accidents et les prescriptions générales de sécurité en vigueur

pour le domaine d'application de l'instrument.

■

Le mode d'emploi fait partie de l'instrument et doit être conservé à

proximité immédiate de l'instrument et accessible à tout moment

pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération,

avoir lu soigneusement et compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de

dommages provoqués par une utilisation non conforme à l'usage

prévu, de non respect de ce mode d'emploi, d'utilisation de

personnel peu qualié de même qu'en cas de modications de

l'instrument eectuées par l'utilisateur.

■

Les conditions générales de vente mentionnées dans les

documents de vente s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir dautres informations :

- Consulter notre site internet :

- Fiche technique correspondante : TM 73.01, TM 74.01

www.wika.fr

36 WIKA mode d'emploi types 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 37

1. Généralités

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques

susceptibles de provoquer la mort ou des blessures

graves si elle n'est pas évitée.

ATTENTION !

… indique une situation potentiellement dangereuse et

susceptible de provoquer de légères blessures ou des

dommages matériels et pour l'environnement si elle n'est

pas évitée.

Information

… met en exergue les conseils et recommandations utiles

de même que les informations permettant d'assurer un

fonctionnement ecace et normal.

AVERTISSEMENT !

… indique une situation en zone explosive présentant

des risques susceptibles de provoquer la mort ou des

blessures graves si elle n'est pas évitée.

AVERTISSEMENT !

… indique une situation présentant des risques

susceptibles de provoquer des brûlures dues à des

surfaces ou liquides chauds si elle n'est pas évitée.

11591367.02 05/2012 GB/D/F/E

WIKA mode d'emploi types 73, 74 (ATEX)

F

37

Page 38

2. Sécurité

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement,

s'assurer que le thermomètre à dilatation de gaz a été

choisi de façon adéquate, en ce qui concerne la plage

de mesure, la version et les conditions de mesure

F

2.1 Utilisation conforme à l'emploi prévu

Ces thermomètre à dilatation de gaz sont utilisés pour la mesure

de la température dans les zones dangereuses des applications

industrielles.

L'instrument est conçu et construit exclusivement pour une utilisation

conforme à l'usage prévu décrit ici et ne doit être utilisé qu'en

conséquence.

Les spécications techniques mentionnées dans ce mode d'emploi

doivent être respectées. En cas d'utilisation inadéquate ou de

fonctionnement de l'instrument en dehors des spécications

techniques, un arrêt et contrôle doivent être immédiatement eectués

par un collaborateur autorisé du service de WIKA.

spéciques. Vérier si les composants du raccord process

en contact avec le uide (doigt de gant, tube plongeur)

sont compatibles avec le uide de mesure.

Un non-respect de cette consigne peut entraîner des

blessures corporelles graves et/ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les

sections individuelles du présent mode d'emploi.

Aucune réclamation ne peut être recevable en cas d'utilisation non

conforme à l'usage prévu.

38 WIKA mode d'emploi types 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 39

2. Sécurité

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants

dommages corporels et matériels.

■

Les opérations décrites dans ce mode d'emploi ne

doivent être eectuées que par un personnel ayant la

qualication décrite ci-après.

■

Tenir le personnel non qualié à lécart des zones

dangereuses.

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de

ses connaissances dans le domaine de la technique de mesure et de

régulation et de ses expériences de même que de sa connaissance

des prescriptions nationales des normes et directives en vigueur,

en mesure d'eectuer les travaux décrits et de reconnaître

automatiquement les dangers potentiels.

2.3 Consignes de sécurité complémentaires pour les

instruments selon ATEX

AVERTISSEMENT !

Le non respect de ces instructions et de leurs contenus

peut entraîner une perte de la protection contre les

explosions.

AVERTISSEMENT !

Les consignes de sécurité et les conditions d'application

doivent impérativement être respectées.

Les thermomètres doivent être mis à la terre à l'aide du

branchement de process !

F

Puisque les thermomètres à dilatation de gaz ne disposent pas d'une

source de chaleur interne, les instruments montés ne peuvent pas

causer une augmentation de température !

11591367.02 05/2012 GB/D/F/E

WIKA mode d'emploi types 73, 74 (ATEX)

39

Page 40

2. Sécurité

Un retour de la chaleur du processus dépassant la température

d'inammation de l'environnement présentant des risques d'explosion

n'est pas permis et doit être évité par l'intermédiaire d'une isolation

thermique appropriée !

Les températures de surface suivantes ne doivent pas être

dépassées :

F

Température

de surface

admissible

1) Lorsqu'il y a risque de formation d'une couche de poussière au-dessus de l'instrument

(jusqu'à une épaisseur de max. 5 mm), une diérence de température de 75 K entre la

température d'inammation de la couche de poussière et la température de surface doit

être observée ! Pour les couches de poussière plus épaisses, respecter une diérence

plus élevée !

2.4 Dangers particuliers

Atmosphère présentant un risque d'explosion

Gaz, air, vapeur, brouillard Poussière, air

≤ 80 % de la température

d'inammation en °C

≤ 2/3 de la température

minimum d'inammation

1)

en °C

AVERTISSEMENT !

Respecter les indications de l'attestation d'examen de

type valable de même que les prescriptions nationales

respectives concernant l'installation et l'utilisation en

zone explosive (par exemple CEI 60079-14, NEC, CEC).

Un non-respect de cette consigne peut entraîner des

blessures corporelles graves et/ou des dégâts matériels.

Autres consignes de sécurité importantes pour les

instruments avec homologation ATEX, voir chapitre

2.3 "Consignes de sécurité complémentaires pour les

instruments selon ATEX".

AVERTISSEMENT !

Les restes de uides se trouvant dans des instruments

démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation. Prendre des

mesures de sécurité susantes.

40 WIKA mode d'emploi types 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 41

2. Sécurité

2.5 Etiquetage, marquages de sécurité

Plaque signalétique

Type

Explication des symboles

Avant de monter et mettre l'instrument en service,

lire impérativement le mode d‘emploi !

CE, Communauté Européenne

Les instruments avec ce marquage sont conformes aux

directives européennes pertinentes.

ATEX Directive européenne sur les instruments

destinés à être utilisés en atmosphère explosible

(Atmosphère = AT, explosible = EX)

Les instruments avec ce marquage sont conformes aux

exigences de la directive européenne 94/9/CE (ATEX) sur

la protection contre les explosions.

F

Année de fabrication

11591367.02 05/2012 GB/D/F/E

WIKA mode d'emploi types 73, 74 (ATEX)

41

Page 42

3. Caractéristiques techniques / 4. Concep

3. Caractéristiques techniques

tion ...

Caractéristiques

Type 73 Type 74

techniques

Elément de mesure Rempli de gaz inerte, système à dilatation

Diamètre 100, 160, 144 x 144 100

Version de l'instrument

F

■

Type A7x

■

Type R7x

■

Type S73

■

Type F73

Température ambiante

admissible

Pression de service

■

Fonctionnement continu (1 an)

■

temporaire (max. 24 h)

Boîtier, anneau

Tube plongeur, raccord process

Indice de protection

selon EN 60529/ IEC 529

Situation de branchement en arrière (axial)

Situation de branchement en bas (radial)

Situation de branchement

en arrière, orientable et

cadran inclinable

Instruments avec capillaire

0 ... 40 °C

Etendue de mesure (EN 13190)

Echelle de mesure (EN 13190)

Acier inox 1.4301

Acier inox 1.4571

IP 65

IP 66 (rempli de liquide)

Acier inox 1.4435

IP 65

(option: IP 66)

Pour les autres caractéristiques techniques, voir che technique

WIKA TM 73.01 ou TM 74.01 et les documents de commande.

4. Conception et fonction

4.1 Description

Le thermomètre à dilatation de gaz est composé d'un tube plongeur,

d'un capillaire et d'un tube de Bourdon dans le boîtier. Ces pièces

sont groupées pour former un tout. Le système de mesure complet

est rempli sous pression avec du gaz inerte.

La modication de la température entraîne une modication de la

pression intérieure dans le tube plongeur. La pression déforme le

ressort de mesure dont la déformation est transmise à l'aiguille via

42 WIKA mode d'emploi types 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 43

4. Conception et fonction / 5. Transport, ...

un mouvement. Des uctuations de la température ambiante sur

le boîtier sont négligeables étant donné qu'entre le mouvement

et le ressort de mesure, il existe un élément à bimétal assurant la

compensation.

Plages d'achage pour la classe de précision 1 selon EN 13190

entre -200 ... +700 °C

4.2 Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur l'instrument liés au transport.

Communiquer immédiatement les dégâts constatés.

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une

protection optimale (par ex. changement de lieu d'utilisation, renvoi

pour réparation).

5.3 Stockage

Conditions admissibles sur le lieu de stockage :

Température de stockage : -20 ... +60 °C

F

Eviter les inuences suivantes :

■

Lumière solaire directe ou proximité d'objets chauds

■

Vibrations mécaniques, chocs mécaniques (mouvements

brusques en le posant)

■

Suie, vapeur, poussière et gaz corrosifs

11591367.02 05/2012 GB/D/F/E

WIKA mode d'emploi types 73, 74 (ATEX)

43

Page 44

5. Transport, emballage ... / 6. Mise en ...

Conserver l'instrument dans l'emballage original dans un endroit qui

satisfait aux conditions susmentionnées. Si l'emballage original n'est

pas disponible, emballer et stocker le thermomètre comme suit :

1. Emballer le thermomètre dans une feuille de plastique antistatique.

2. Placer le thermomètre avec le matériau isolant dans l'emballage.

3. En cas d'entreposage long (plus de 30 jours), mettre également un

sachet absorbeur d'humidité dans l'emballage.

F

AVERTISSEMENT !

Enlever tous les restes de uides adhérents avant

l'entreposage de l'instrument (après le fonctionnement).

Ceci est particulièrement important lorsque le uide

représente un danger pour la santé, comme p. ex.

des substances corrosives, toxiques, carcinogènes,

radioactives etc.

Lorsque le thermomètre est utilisé dans une plage de

températures près du point de rosée (±1 °C, près de

0 °C), l'utilisation d'un amortissement par liquide est

recommandée

.

6. Mise en service, exploitation

Le thermomètre à dilatation de gaz doit être mis à la terre

par le raccord process !

Lors du vissage des instruments, le couple de serrage ne doit pas

être appliqué sur le boîtier mais seulement sur les surfaces prévues

et ce avec un outil approprié.

Montage avec

clé à fourche

44 WIKA mode d'emploi types 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 45

6. Mise en service, exploitation

■

Le tube plongeur doit être soumis sur toute sa longueur à la

température à mesurer. Au moins cependant sur la longueur de la

partie active correspondant à la longueur du vase d'expansion de

gaz (longueur active).

■

Le capteur de température doit être placé dans les conduites ou

autres points de mesure le plus possible en biais dans le sens

opposé à la direction d'écoulement du uide.

■

Des erreurs de de transfert thermique se produisent si la chambre

de mesure dont la température doit être achée est très petite,

si bien que la masse du capteur de température représente une

capacité thermique. Des erreurs de transfert thermique peuvent

aussi apparaître si la profondeur de montage est insusante, si

le support de montage est xé sur un bon conducteur thermique

(plaques métalliques ou similaires) et s'il existe une diérence

considérable entre la température de l'élément de mesure et celle

de l'élément de xation.

■

Le boîtier l'achage doit être installé à un endroit exempt de

vibrations. Le cas échéant, il est possible d'isoler l'instrument du

lieu d'installation en utilisant par exemple une liaison exible entre

le point de mesure et le thermomètre et en xant ce dernier à l'aide

d'un support d'instrument mural.

Lorsque cela n'est pas possible, veiller à ce que les valeurs limites

suivantes ne soient pas dépassées :

Instruments secs : Plage de fréquence < 150 Hz

Accélération < 0,7 g (7 m/s

Instruments remplis de liquide : Plage de fréquence < 150 Hz

Accélération < 2 g (20 m/s

2

)

2

)

F

Après montage, passer le levier de mise à

l'atmosphère (si disponible) de la position

CLOSE sur OPEN.

11591367.02 05/2012 GB/D/F/E

WIKA mode d'emploi types 73, 74 (ATEX)

45

Page 46

6. Mise en service, exploitation

Le liquide de remplissage doit être contrôlé régulièrement.

Le niveau de remplissage de liquide ne doit pas descendre en-dessous

de 75 % du diamètre de l'instrument.

De fortes secousses, des oscillations et/ou des vibrations provoquent

des erreurs d'achage, augmentent l'usure du mouvement ou

peuvent occasionner des ruptures aux soudures et brasages.

F

Lors du montage d'un thermomètre à dilatation de gaz à cadran

pivotant et orientable, des prescriptions particulières doivent être

observées. Pour placer l'achage dans la position requise, il convient

de respecter les points suivants :

1. Le contre-écrou ou l'écrou-raccord doit être desserré sur le raccord

process.

2. Les boulons et vis doivent être desserrées sur l'articulation

pivotante.

desserrer

Desserrer impérativement

également les vis situées sur

le côté opposé !

3. Positionner l'achage, serrer les boulons et les vis. Pour nir, serrer

le contre-écrou ou l'écrou-raccord à fond.

En cas d'utilisation de doigts de gants, il convient de réduire au

maximum la résistance de transmission de la chaleur entre la paroi

extérieure du capteur et la paroi intérieure du doigt de gant en

ajoutant un agent de contact thermique. La température de service de

la pâte thermique est de -40 ... +200 °C.

AVERTISSEMENT !

Ne pas verser dans des doigts de gant chauds ! Risque

de projection d'huile !

46 WIKA mode d'emploi types 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 47

6. Mise en service ... / 7. Entretien et ...

ATTENTION !

Lors de l'utilisation des doigts

de gants, veiller à ce que le tube

plongeur ne touche pas le fond

du doigt de gant, en raison des

diérents coecients d'extension

des matériaux, il y a risque de

déformation du tube plongeur sur

Doigt de

gant

Tube plongeur

le fond du doigt de gant.

(Formules pour le calcul de la

longueur d'insertion l1 voir la

che technique du doigt de gant

correspondant)

Ecart de sécurité

requis

7. Entretien et nettoyage

7.1 Entretien

Ces thermomètre à dilatation de gaz ne nécessitent pas d'entretien !

Un contrôle de l'achage et des fonctions de commande est

recommandé 1 à 2 fois/an. Pour le contrôle de l'achage et des

fonctions de commande, il faut isoler l'instrument du process et le

contrôler avec un calibrateur de température.

Les réparations ne doivent être eectuées que par le fabricant.

F

7.2 Nettoyage

ATTENTION !

■

Nettoyer le thermomètre avec un chion humide.

■

Laver ou nettoyer le thermomètre démonté avant de

le retourner an de protéger les collaborateurs et

l'environnement contre le danger lié aux restes de

11591367.02 05/2012 GB/D/F/E

WIKA mode d'emploi types 73, 74 (ATEX)

uides adhérents.

47

Page 48

7. Entretien et nettoyage / 8. Démontage, ...

■

Les restes de uides se trouvant dans des instruments

démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation. Prendre des

mesures de sécurité susantes.

Indications concernant le retour de l'instrument, voir

chapitre 8.2 "Retour".

F

8. Démontage, retour et mise au rebut

AVERTISSEMENT !

Les restes de uides se trouvant dans des instruments

démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation. Prendre des

mesures de sécurité susantes.

8.1 Demontage

AVERTISSEMENT !

Danger de brûlure !

Avant le démontage du thermomètre, laisser refroidir

susamment l'instrument ! Danger de brûlure lié à la

sortie de uides dangereux chauds.

8.2 Retour

AVERTISSEMENT !

En cas d'envoi de l'instrument, il faut respecter

impérativement ceci : Tous les instruments envoyés

à WIKA doivent être exempts de tout substance

dangereuse (acides, lixiviat, solutions, etc.).

Pour retourner l'instrument, utiliser l'emballage original ou un

emballage adapté pour le transport.

48 WIKA mode d'emploi types 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 49

8. Démontage, retour et mise au rebut

Pour éviter des dommages :

1. Emballer l'instrument dans une feuille de plastique antistatique.

2. Placer l'instrument avec le matériau isolant dans l'emballage. Isoler

de manière uniforme tous les côtés de l'emballage.

3. Mettre si possible un sachet absorbeur d'humidité dans

l'emballage.

4. Indiquer lors de l'envoi qu'il s'agit d'un instrument de mesure très

sensible à transporter.

Joindre le formulaire de retour rempli à l'instrument.

Le formulaire de retour est disponible sous le titre

'Services' à www.wika.fr.

8.3 Mise au rebut

Une mise au rebut inadéquate peut entraîner des dangers pour

l'environnement.

Éliminer les composants des instruments et les matériaux

d'emballage conformément aux prescriptions nationales pour le

traitement et l'élimination des déchets et aux lois de protection de

l'environnement en vigueur.

F

11591367.02 05/2012 GB/D/F/E

WIKA mode d'emploi types 73, 74 (ATEX)

49

Page 50

Annexe 1 : Déclaration de conformité CE

F

50 WIKA mode d'emploi types 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 51

Contenido

Contenido

1. Información general 52

2. Seguridad 54

3. Datos técnicos 58

4. Diseño y función 58

5. Transporte, embalaje y almacenamiento 59

6. Puesta en servicio, funcionamiento 60

7. Mantenimiento y limpieza 63

8. Desmontaje, devolución y eliminación 64

Anexo 1: Declaración de conformidad CE 66

Declaraciones de conformidad puede encontrar en www.wika.es.

E

11591367.02 05/2012 GB/D/F/E

WIKA manual de instrucciones modelos 73, 74 (ATEX)

51

Page 52

1. Información general

1. Información general

■

Los termómetros de dilatación de gas descritos en el manual

de instrucciones están construidos y fabricados según los

conocimientos actuales. Todos los componentes están sujetos

a criterios rígidos de calidad y medio ambiente en el proceso de

la producción. Nuestros sistemas de gestión están certicados

según ISO 9001 e ISO 14001.

■

Este manual de instrucciones proporciona indicaciones

E

importantes acerca del manejo del instrumento. Para un trabajo

seguro, es imprescindible cumplir con todas las instrucciones de

seguridad y manejo indicadas.

■

Cumplir siempre las normativas sobre la prevención de accidentes

y las normas de seguridad en vigor en el lugar de utilización del

instrumento.

■

El manual de instrucciones es una parte integrante del instrumento

y debe guardarse en la proximidad del mismo para que el personal

especializado pueda consultarlo en cualquier momento.

■

El personal especializado debe haber leído y entendido el manual

de instrucciones antes de comenzar cualquier trabajo.

■

El fabricante queda exento de cualquier responsabilidad en caso

de daños causados por un uso no conforme a la nalidad prevista,

la inobservancia del presente manual de instrucciones, un

manejo por personal insucientemente cualicado, así como una

modicación no autorizada del instrumento.

■

Se aplican las condiciones generales de venta incluidas en la

documentación de venta.

■

Modicaciones técnicas reservadas.

■

Para obtener más informaciones consultar:

- Página web: www.wika.es

- Hoja técnica correspondiente: TM 73.01, TM 74.01

52 WIKA manual de instrucciones modelos 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 53

1. Información general

Explicación de símbolos

¡ADVERTENCIA!

... indica una situación probablemente peligrosa que

pueda causar la muerte o lesiones graves si no se evita.

¡CUIDADO!

... indica una situación probablemente peligrosa que

pueda causar lesiones leves o medianas o daños materiales y medioambientales si no se evita.

Información

... marca consejos y recomendaciones útiles así como

informaciones para una utilización ecaz y libre de fallos.

¡ADVERTENCIA!

... indica una situación probablemente peligrosa en una

atmósfera potencialmente explosiva que puede causar la

muerte o lesiones graves si no se evita.

¡ADVERTENCIA!

... indica una situación probablemente peligrosa que

pueda causar quemaduras debido a supercies o líquidos

calientes, si no se evita.

E

11591367.02 05/2012 GB/D/F/E

WIKA manual de instrucciones modelos 73, 74 (ATEX)

53

Page 54

2. Seguridad

2. Seguridad

¡ADVERTENCIA!

Antes de proceder con el montaje, la puesta en

servicio y el funcionamiento, asegurarse de que se

haya seleccionado el termómetro de dilatación de gas

adecuado en relación con rango de medida, versión y

condiciones de medición especícas. Hay que controlar si

los componentes en contacto con el uido de la conexión

E

2.1 Uso conforme a lo previsto

Esos termómetros de dilatación de gas sirven para medir

la temperatura en aplicaciones industriales en atmósferas

potencialmente explosivas.

El instrumento ha sido diseñado y construido únicamente para la

nalidad aquí descrita y debe utilizarse en conformidad a la misma.

Cumplir las especicaciones técnicas de este manual de

instrucciones. Un manejo no apropiado o una utilización del

instrumento no conforme a las especicaciones técnicas requiere la

inmediata puesta fuera de servicio y la comprobación por parte de un

técnico autorizado por WIKA.

a proceso (vaina, bulbo, etc.) son compatibles con el

uido.

Riesgo de lesiones graves y/o daños materiales en caso

de inobservancia.

Los distintos capítulos de este manual de instrucciones

contienen otras importantes indicaciones de seguridad.

No se admite ninguna reclamación debido a un manejo no adecuado.

54 WIKA manual de instrucciones modelos 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 55

2. Seguridad

2.2 Cualicación del personal

¡ADVERTENCIA!

¡Riesgo de lesiones debido a una insuciente

cualicación!

Un manejo no adecuado puede causar considerables

daños personales y materiales.

■

Las actividades descritas en este manual de

instrucciones deben realizarse únicamente por personal

especializado con la consiguiente cualicación.

■

Mantener alejado a personal no cualicado de las zonas

peligrosas.

Personal especializado

Debido a su formación profesional, a sus conocimientos de la

técnica de regulación y medición así como a su experiencia y su

conocimiento de las normativas, normas y directivas vigentes en el

país de utilización el personal especializado es capaz de ejecutar los

trabajos descritos y reconocer posibles peligros por sí solo.

2.3 Instrucciones de seguridad adicionales para instrumentos

según ATEX

¡ADVERTENCIA!

La inobservancia del contenido y de las instrucciones

puede originar la pérdida de la protección contra

explosiones.

¡ADVERTENCIA!

Es imprescindible observar las condiciones de uso y los

datos de seguridad.

¡Poner a tierra los instrumentos de medición a través de la

conexión al proceso!

E

Los termómetros de dilatación de gas no tienen fuente de calor

propia y no causan un aumento de temperatura si están instalados y

utilizados según la nalidad prevista!

11591367.02 05/2012 GB/D/F/E

WIKA manual de instrucciones modelos 73, 74 (ATEX)

55

Page 56

2. Seguridad

No está permitido un reujo térmico proveniente del proceso que

supere la temperatura de encendido de la atmósfera potencialmente

explosiva y debe ser impedido mediante un aislamiento térmico

adecuado!

No sobrepasar las temperaturas superciales siguientes:

Atmósfera potencialmente explosiva

Gas, aire, vapor, niebla Polvo, aire

E

Temperatura

supercial

≤ 80 % de la temperatura

de encendido en °C

permitida

1) Si hay depósitos de polvo en el instrumento (espesor de 5 mm como máximo) hay que

mantener una distancia de seguridad de 75 K entre la temperatura mínima de encendido

de la capa de polvo y la temperatura supercial! Si las capas de polvo son más espesas,

hay que mantener distancias de seguridad mayores!

2.4 Riesgos especícos

¡ADVERTENCIA!

Cumplir las indicaciones del certicado de tipo así como

las normativas vigentes en el país de utilización acerca

de la instalación y el uso en atmósferas potencialmente

explosivas (p. ej. IEC 60079-14, NEC, CEC). Riesgo

de lesiones graves y/o daños materiales en caso de

inobservancia.

Consultar el capítulo 2.3 "Instrucciones de seguridad

adicionales para instrumentos según ATEX" para

más instrucciones de seguridad importantes para

instrumentos con certicación ATEX.

≤ 2/3 de la temperatura

de encendido mínima

1)

en °C

¡ADVERTENCIA!

Restos de medios en instrumentos desmontados

pueden causar riesgos para personas, medio ambiente e

instalación. Tomar adecuadas medidas de precaución.

56 WIKA manual de instrucciones modelos 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 57

2. Seguridad

2.5 Rótulos, marcados de seguridad

Placa indicadora de modelo

Modelo

Explicación de símbolos

¡Es absolutamente necesario leer el manual de

instrucciones antes del montaje y la puesta en

servicio del instrumento!

CE, Communauté Européenne

Los instrumentos con este marcaje cumplen las directivas

europeas aplicables.

Directiva europea ATEX para garantizar la seguridad

frente a las explosiones

(Atmosphère = AT, explosible = EX)

Los instrumentos con este marcaje están conformes a

las exigencias de la directiva europea 94/9/CE (ATEX)

relativa a la prevención de explosiones.

11591367.02 05/2012 GB/D/F/E

WIKA manual de instrucciones modelos 73, 74 (ATEX)

Año de fabricación

E

57

Page 58

3. Datos técnicos / 4. Diseño y función

3. Datos técnicos

Datos técnicos

Elemento de medición Relleno de gas inerte a presión

Diámetro nominal 100, 160, 144 x 144 100

Construcción del aparato

■

Modelo A7x

■

Modelo R7x

■

Modelo S73

E

■

Modelo F73

Temperatura ambiente

admisible

Rango de servicio

■

Carga a largo plazo (1 año)

■

a corto plazo (máx. 24 h)

Caja, anillo

Bulbo, conexión a proceso

Protección

según EN 60529 / IEC 529

Modelo 73 Modelo 74

Conexión dorsal (axial)

Conexión inferior (radial)

Conexión dorsal,

giratoria y orientable

Instrumentos con capilar

0 ... 40 °C

Rango de medida (EN 13190)

Rango de indicación (EN 13190)

Acero inoxidable 1.4301

Acero inoxidable 1.4571

IP 65

IP 66 (lleno de líquido)

Acero inoxidable 1.4435

IP 65

(opción: IP 66)

Para más datos técnicos véase las hojas técnicas TM 73.01 o

TM 74.01 y la documentación de pedido.

4. Diseño y función

4.1 Descripción

El termómetro de gas está compuesto de bulbo, línea capilar y tubo

exible en la caja. Estos componentes forman una unidad. El sistema

de medida completo está rellenado a presión con gas inerte.

Si cambia la temperatura, cambia también la presión interior del

bulbo. La presión deforma el muelle de medición, cuyo movimiento se

transmite al indicador a través de un mecanismo de indicación.

58 WIKA manual de instrucciones modelos 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 59

4. Diseño, función / 5. Transporte, embalaje ...

Las variaciones de la temperatura ambiente son despreciables

porque hay un elemento bimetálico entre el mecanismo de indicación

y el muelle que sirve de compensador.

Rangos de indicación en la clase de precisión 1 según EN 13190

entre -200 ... +700 °C

4.2 Volumen de suministro

Comprobar mediante el albarán si se ha entregado la totalidad de las

piezas.

5. Transporte, embalaje y almacenamiento

5.1 Transporte

Comprobar si el instrumento presenta eventuales daños causados en

el transporte.

Noticar de inmediato cualquier daño evidente.

5.2 Embalaje

No quitar el embalaje hasta justo antes del montaje.

Guardar el embalaje porque es la protección ideal durante el transporte (por ejemplo si el lugar de instalación cambia o si se envía el

instrumento para posibles reparaciones).

5.3 Almacenamiento

Condiciones admisibles en el lugar de almacenamiento:

Temperatura de almacenamiento: -20 ... +60 °C

E

Evitar lo siguiente:

■

Luz solar directa o proximidad a objetos calientes

■

Vibración mecánica, impacto mecánico (apoyarlo de golpe)

■

Hollín, vapor, polvo y gases corrosivos

11591367.02 05/2012 GB/D/F/E

WIKA manual de instrucciones modelos 73, 74 (ATEX)

59

Page 60

5. Transporte, ... / 6. Puesta en servicio, ...

Almacenar el instrumento en su embalaje original en un lugar que

cumple las condiciones arriba mencionadas. Si no se dispone del

embalaje original, empaquetar y almacenar el termómetro como sigue:

1. Envolver el termómetro en un lm de plástico antiestático.

2. Colocar el termómetro junto con el material aislante en el embalaje.

3. Para un almacenamiento prolongado (más de 30 días) colocar una

bolsa con un desecante en el embalaje.

E

¡ADVERTENCIA!

Antes de almacenar el instrumento (después del

funcionamiento), eliminar todos los restos de medios

adherentes. Esto es especialmente importante cuando el

medio es nocivo para la salud, como p. ej. cáustico, tóxico,

cancerígeno, radioactivo, etc.

Con temperaturas alrededor del punto de condensación

(±1 °C alrededor de 0 °C) se recomienda siempre el relleno

de líquido.

6. Puesta en servicio, funcionamiento

¡Poner a tierra el termómetro de dilatación de gas través

de la conexión al proceso!

Para atornillar el aparato, se debe utilizar la fuerza mediante el uso

de herramientas adecuadas sobre las supercies planas de ajuste

-previstas para este n-.

Montaje mediante

llave de boca

60 WIKA manual de instrucciones modelos 73, 74 (ATEX)

11591367.02 05/2012 GB/D/F/E

Page 61

6. Puesta en servicio, funcionamiento

■

Para conseguir óptimos resultados el bulbo debe exponerse en

toda su longitud a la temperatura a medir. La longitud mínima y

necesaria es la longitud de la parte activa que corresponde a la

longitud del vaso de expansión de gas (longitud activa).

■

Posicionar el sensor de temperatura en tuberías u otros puntos de

medición con la máxima inclinación contra el sentido del ujo.

■

Errores en la disipación del calor surgen cuando la temperatura

del espacio de medición que se desea indicar es muy baja,

de modo que la masa del sensor de temperatura aplica como

capacidad térmica. Tales errores también pueden surgir debido

a una insuciente profundidad de montaje, si el dispositivo de

jación está sujeto a un efectivo conductor de calor (placas de

metal o semejantes) y si existe una diferencia considerable de

temperatura entre el elemento de medición y el elemento de

jación.

■

La caja del indicador debe montarse de modo libre de vibraciones.

Si es necesario, el desacoplamiento del lugar de instalación puede

conseguirse por ejemplo mediante una línea de conexión exible

del punto de medición al termómetro y mediante jación por medio

de un soporte para el manómetro.

Si esto no es posible, no se debe sobrepasar en ningun caso los

siguientes valores límites:

E

Instrumentos sin relleno: Rango de frecuencias < 150 Hz

Aceleración < 0,7 g (7 m/s

Instrumentos llenados de líquido: Rango de frecuencias < 150 Hz

Aceleración < 2 g (20 m/s

Tras el montaje se debe posicionar la válvula

de ventilación (si existe) de CLOSE a OPEN.

11591367.02 05/2012 GB/D/F/E

WIKA manual de instrucciones modelos 73, 74 (ATEX)

2)

2

)

61

Page 62

6. Puesta en servicio, funcionamiento

Comprobar el llenado de líquido a intervalos regulares.

El nivel de líquido no debe caer debajo del 75 % del diámetro del

instrumento.

Fuertes sacudidas, oscilaciones y vibraciones provocan

imprecisiones de indicación, aumentan el desgaste en el mecanismo