Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Expansion thermometer with/without micro switch, model 70

Tensionsthermometer mit/ohne Mikroschalter, Typ 70

Thermomètres à expansion avec/sans microrupteur, type 70

Termómetro de tensión con/sin microswitch, modelo 70

GB

D

F

E

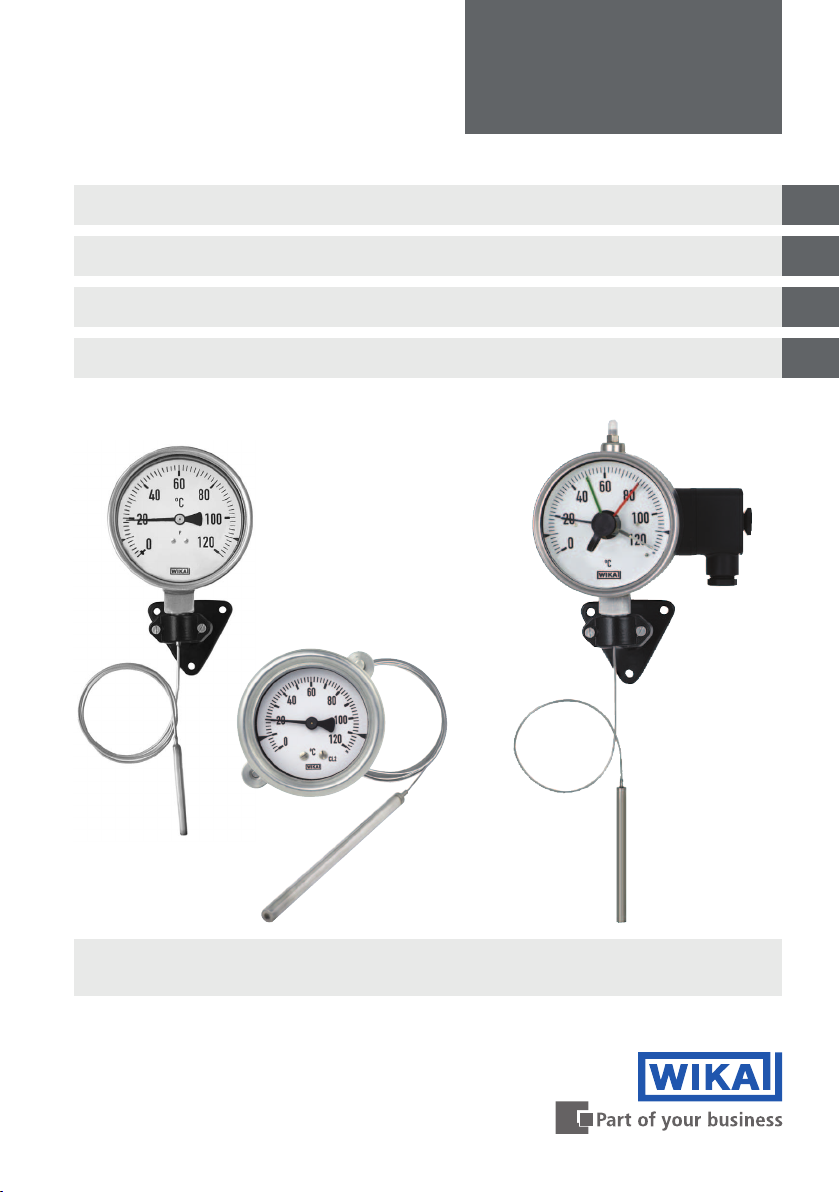

Expansion thermometer

without micro switch, model 70

Expansion thermometer

with micro switch, model 70

Page 2

Operating instructions model 70 Page 3 - 16

GB

Betriebsanleitung Typ 70 Seite 17 - 30

D

Mode d'emploi type 70 Page 31 - 44

F

Manual de instrucciones modelo 70 Página 45 - 57

E

© 2012 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions expansion thermometer, model 70

11472988.02 04/2013 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 8

4. Design and function 8

5. Transport, packaging and storage 9

6. Commissioning, operation 10

7. Indicator check 12

8. Zero adjustment 12

9. Maintenance and cleaning 13

10. Faults 14

GB

11. Dismounting, return and disposal 14

11472988.02 04/2013 GB/D/F/E

WIKA operating instructions expansion thermometer, model 70

3

Page 4

1. General information

1. General information

The expansion thermometers described in the operating instructions are manufactured

GB

using state-of-the-art technology. All components are subject to stringent quality and

environmental criteria during production. Our management systems are certied to

ISO 9001 and ISO 14001.

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument‘s range of use.

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

The manufacturer‘s liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions,

assignment of insuciently qualied skilled personnel or unauthorised modications to

the instrument.

The general terms and conditions contained in the sales documentation shall apply.

Subject to technical modications.

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: TM 81.01, TV 28.01

- Application consultant:

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury or

death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or

damage to equipment or the environment, if not avoided.

4

Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-mail: info@wika.de

WIKA operating instructions expansion thermometer, model 70

11472988.02 04/2013 GB/D/F/E

Page 5

1. General information / 2. Safety

Information

... points out useful tips, recommendations and information for ecient and

trouble-free operation.

DANGER!

... identies hazards caused by electric power. Should the safety instructions

not be observed, there is a risk of serious or fatal injury.

WARNING!

... indicates a potentially dangerous situation that can result in burns, caused

by hot surfaces or liquids, if not avoided.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate

thermometer has been selected in terms of measuring range, design and

specic measuring conditions.

Non-observance can result in serious injury and/or damage to the equipment.

GB

Further important safety instructions can be found in the individual chapters of

these operating instructions.

2.1 Intended use

The model 70 expansion thermometers are general-purpose temperature measurement

instruments/temperature controllers (with micro switch) for gaseous, liquid and highlyviscous process media.

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The technical specications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specications

requires the instrument to be taken out of service immediately and inspected by an

authorised WIKA service engineer.

11472988.02 04/2013 GB/D/F/E

WIKA operating instructions expansion thermometer, model 70

5

Page 6

2. Safety

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

GB

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to equipment.

The activities described in these operating instructions may only be carried

out by skilled personnel who have the qualications described below.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and

knowledge of country-specic regulations, current standards and directives, are capable

of carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

2.3 Special hazards

WARNING!

For hazardous media such as oxygen, acetylene, ammable or toxic gases or

liquids, and refrigeration plants, compressors, etc., in addition to all standard

regulations, the appropriate existing codes or regulations must also be

followed.

WARNING!

To ensure safe working on the instrument, the operating company must ensure

that suitable rst-aid equipment is available and aid is provided whenever

required.

that the operating personnel are regularly instructed in all topics regarding

work safety, rst aid and environmental protection and know the operating

instructions and, in particular, the safety instructions contained therein.

6

11472988.02 04/2013 GB/D/F/E

WIKA operating instructions expansion thermometer, model 70

Page 7

2. Safety

DANGER!

Danger of death caused by electric current

Upon contact with live parts, there is a direct danger of death.

The instrument may only be installed and mounted by skilled personnel.

Operation using a defective power supply unit (e.g. short circuit from the

mains voltage to the output voltage) can result in life-threatening voltages at

the instrument!

WARNING!

Residual media at the dismounted instrument can result in a risk to persons,

the environment and the equipment.

Take sucient precautionary measures.

Do not use this instrument in safety or emergency stop devices. Incorrect use

of the instrument can result in injury.

Should a failure occur, aggressive media with extremely high temperature and

under high pressure or vacuum may be present at the instrument.

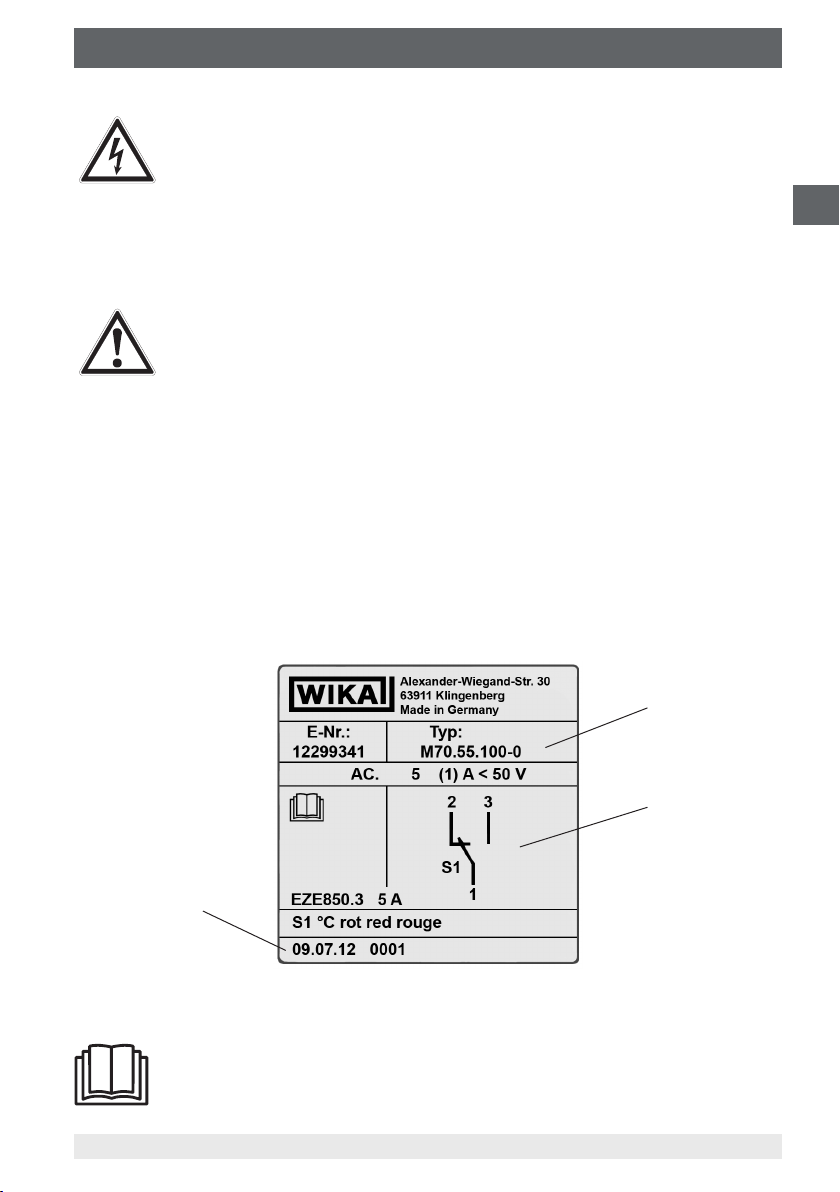

2.4 Labelling, safety marking

Product label

GB

Date of manufacture

Explanation of symbols

Before mounting and commissioning the instrument, ensure you read the

operating instructions!

11472988.02 04/2013 GB/D/F/E

WIKA operating instructions expansion thermometer, model 70

Model

Switch points

7

Page 8

3. Specications / 4. Design and function

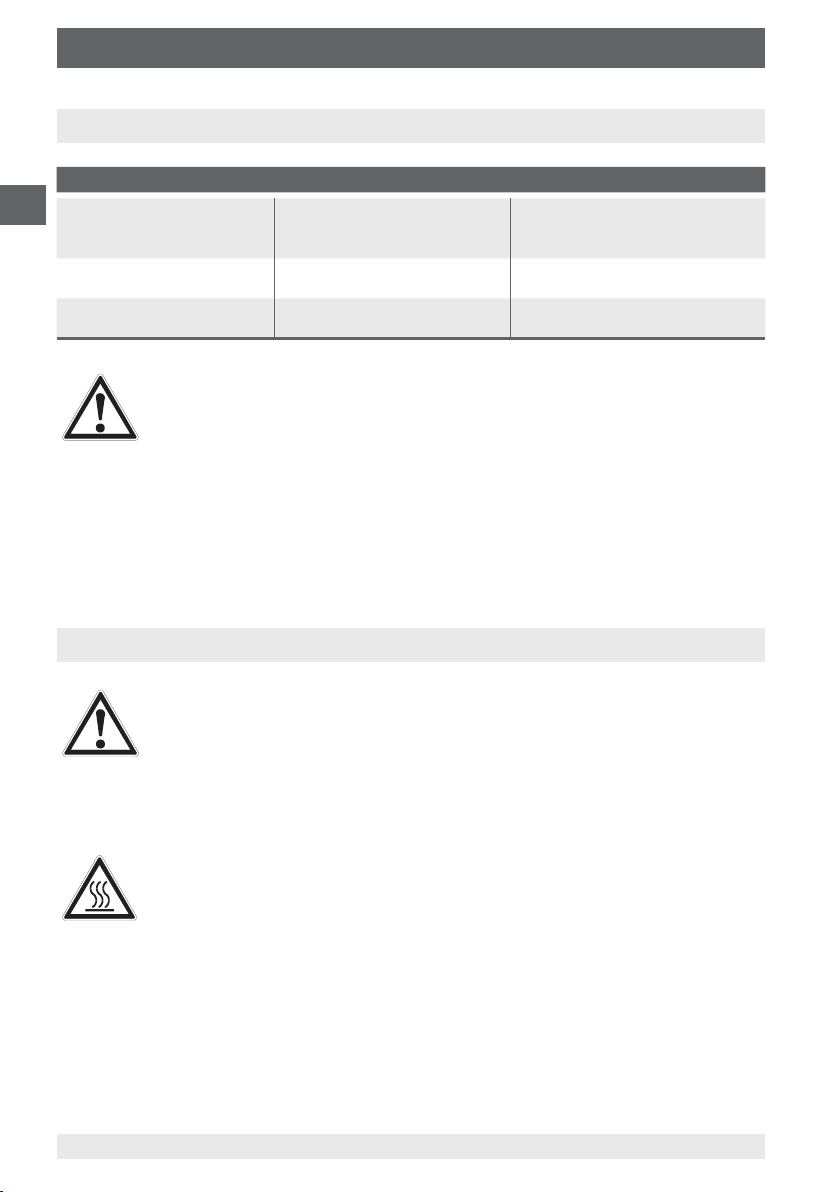

3. Specications

Specications with micro switch without micro switch

GB

Nominal size in mm 100 63, 100, 160

Measuring principle Bourdon tube system

Filling medium Xylol, silicone oil or syltherm Xylol or silicone oil

Capillary entry lower mount or back mount

Case Stainless steel

Indication accuracy Class 2

Scale range -100 ... +400 °C

Measuring line Ø 2 mm, stainless steel 1.4571

Length of the measuring line Max. 10 m

Contact max. 2 micro switches (adjustable/xed)

Load data

Setting range from 10 % to 90 % of the full scale value

Standard switch dierential < 2 % of measuring range

Electrical connection via cable terminal box

Ingress protection

per EN 60529 / IEC 529

5 A, AC 48 V

The instruments do not provide for incorporated overcurrent

protectors. In order to prevent the contacts from welding through

overload, suitable protection systems must be implemented by

the operator.

Fixed, factory set to customer specication

IP 44 IP 65

For further specications, see WIKA data sheet TV 28.01 or TM 81.01 and the order

documentation.

4. Design and function

4.1 Description

The liquid-lled, closed measuring system consists of a temperature sensor, a capillary

and a Bourdon tube. The volume change as a consequence of the heat applied to the

temperature sensor, and thus the pressure change in the closed system, is transmitted

through the capillary to the Bourdon tube and then indicated on the dial by the angular

deection of the pointer shaft.

Temperature measuring instruments with micro switch (temperature controllers)

The switching disc (cam disc) connected to the pointer shaft actuates the switching

operation on the micro switch when the switch point is reached.

8

WIKA operating instructions expansion thermometer, model 70

11472988.02 04/2013 GB/D/F/E

Page 9

4. Design, function / 5. Transport, packaging, storage

In addition to the standard version with 1 or 2 adjustable contacts, further combinations

are available, such as:

1 or 2 xed micro switches

1 xed and 1 adjustable micro switch

The switch points of the xed micro switches are marked on the product label.

4.2 Scope of delivery

Cross-check scope of delivery with delivery note.

5. Transport, packaging and storage

5.1 Transport

Check the instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

installation site, sending for repair).

GB

5.3 Storage

Permissible conditions at the place of storage:

Storage temperature: -20 ... +60 °C (DIN EN 13190)

Humidity: 35 ... 85 % relative humidity (no condensation)

Avoid exposure to the following factors:

Direct sunlight or proximity to hot objects

Mechanical vibration, mechanical shock (putting it down hard)

Soot, vapour, dust and corrosive gases

Potentially explosive environments, ammable atmospheres

Store the instrument in its original packaging in a location that fulls the conditions

listed above. If the original packaging is not available, pack and store the instrument as

described below:

1. Place the instrument along with shock-absorbent material in the packaging.

2. If stored for a prolonged period of time (more than 30 days), place a bag containing a

desiccant inside the packaging.

11472988.02 04/2013 GB/D/F/E

WIKA operating instructions expansion thermometer, model 70

9

Page 10

5. Transport, packaging ... / 6. Commissioning, operation

WARNING!

Before storing the instrument (following operation), remove any residual

media. This is of particular importance if the medium is hazardous to health,

GB

6. Commissioning, operation

Please observe the following general requirements when mounting and operating the

instrument:

The scale range of the temperature control instrument should be selected so that the

maximum temperature present at the sensor does not exceed the scale range. Once

the switch point is exceeded, you should also be careful of any temperature rise that

occurs.

In operation, the instrument should not be exposed to any strong vibrations or shock

loadings.

Avoid soiling and strong uctuations of the ambient temperature.

Cutting the measuring line leads to the destruction of the instrument and, thus, to a

shut-down of the electrical output signal.

e.g. caustic, toxic, carcinogenic, radioactive, etc.

Electrical connection

The terminal connections are given on the product label which is located

around the edge of the housing.

6.1 Installation conditions

Before mounting the sensor, check whether the sensor material used (specied in the

delivery note) is chemically resistant/neutral to the medium being measured. This also

applies to thermowells.

Make sure that the suitable accessories required for fastening the case of the instrument

into the panel are available.

The accessories are either tted or located in a bag fastened to the thermometer.

If possible, the entire length of the stem should be exposed to the temperature being

measured. However, at least the length of the active part that corresponds to the length

of the expansion vessel (active length).

In pipelines or other measuring points, the temperature sensor must be positioned as

far towards the ow as possible.

When using thermowells, it must be ensured that the stem does not touch the bottom of

the thermowell.

10

WIKA operating instructions expansion thermometer, model 70

11472988.02 04/2013 GB/D/F/E

Page 11

6. Commissioning, operation

Protect capillaries against bending. The smallest bending radius of the capillary should

not be less than 6 mm. Any bending or discontinuities of the capillary may result in the

failure of the instrument.

If the sensor is installed in a location which is exposed to shock and vibration, it is

essential that the capillary is coiled in several loops between the last attachment point

and the sensor, and free from tension. Any excess length must also be coiled, since

cutting would render the instrument unserviceable.

The welding or soldering of the capillary, as well as all permanent xing of the capillary,

should be avoided, since this can seriously damage the capillary and can impair the

operation of the instrument.

The dial casing must be mounted free from vibration. If necessary, it is possible to

isolate the installation from the mounting point, e.g. by installing a exible connection

line between the measuring point and the thermometer and mounting the instrument on

a suitable bracket.

If this is not possible, the following limit values must not be exceeded:

Frequency range < 150 Hz

Acceleration < 0.5 g (5 m/s

The liquid lling must be checked on a regular basis.

The liquid level must not drop below 75 % of the gauge diameter.

Heavy shocks, oscillations and vibrations lead to imprecise values, increased wear in the

transmission mechanism, and fractures on welded or soldered joints.

2

)

GB

In thermometers with built-in micro switches, the contacts can chatter as a result of

vibrations, which can lead to an increase in contact wear and a displacement in the

desired contact point.

6.2 Ambient conditions

Unless the ingress protection of the thermometer‘s housing is specically identied

in the order conrmation, the instruments must be protected from humid air and other

aggressive atmospheres.

To ensure the best measuring accuracy possible, the ambient temperature on the

indicator case should be between 0 ... 40 °C. Higher or lower ambient temperatures can

cause indication errors.

11472988.02 04/2013 GB/D/F/E

WIKA operating instructions expansion thermometer, model 70

11

Page 12

7. Indicator check / 8. Zero adjustment

7. Indicator check

Indicator checks should only be carried out in comparison with a more accurate

instrument or, if possible, with a calibrated instrument. The temperature during the check

GB

must remain constant.

Fluctuating temperatures can lead to reading errors caused by the dierent response

times of the sensors.

With thermometers without thermowells, with a full and correct insertion length, a

minimum waiting time of 5 minutes must be maintained for temperature equalisation.

Temperature checks using thermometers with sensors assembled with thermowells can,

in many cases, only result in a reference temperature at the instrument under test, due to

permanent heat dissipation caused by the thermowell. In temperature applications tted

with static checking thermometers (e.g. pipeline systems), permanent osets in reference

temperatures can also be caused by the measuring path. Ambient temperatures around

the indicator case which dier substantially from room temperature can lead to steady

indication errors with constant ambient temperatures and to varying indication errors with

uctuating ambient temperatures.

Permanent indication errors caused by the ageing of the measuring system can be

ignored, as they only account for a fraction of the indication accuracy.

8. Zero adjustment

WARNING!

Any interference with or modication to the instrument will invalidate the

warranty!

A zero adjustment may only be carried out by the manufacturer or in adequately equipped

workshops by qualied persons.

The electrical connection must only be made by qualied skilled personnel.

Connection of the switch via terminal box

Conductor cross-section max. 1.5 mm

The terminal assignment is stated on the connection label of the thermometer

12

WIKA operating instructions expansion thermometer, model 70

2

11472988.02 04/2013 GB/D/F/E

Page 13

8. Zero adjustment / 9. Maintenance and cleaning

Adjusting the set pointer (with micro switch)

The adjustment of the set point is achieved using the adjustment key in the window.

The set pointers for the micro switches are freely adjustable over the full scale range. For

reasons of switching accuracy and the service life of the mechanical measuring systems,

the switch points should be between 10 % and 90 % of the measuring range.

The switch points with a xed setting to customer requirements cannot be altered

subsequently.

As a result of surface oxidation on the contact surfaces, especially with intrinsically-safe

switching (small voltages and low currents), aws that can lead to contact erosion can

arise as a result of the developed isolation resistance and with higher contact loads.

9. Maintenance and cleaning

9.1 Maintenance

These expansion thermometers are maintenance-free.

The indicator and switching function should be checked once or twice every year. To

do this, the instrument must be disconnected from the process and checked using a

temperature calibrator.

Repairs must exclusively be carried out by the manufacturer or by appropriately qualied

personnel.

9.2 Cleaning

GB

CAUTION!

Prior to cleaning, disconnect the instrument from the mains.

Clean the instrument with a moist cloth (soap water).

Electrical connections must not come into contact with moisture.

Ensure that all parts are dry before the power is switched on again.

Wash or clean the dismounted instrument before returning it, in order to

protect persons and the environment from exposure to residual media.

Residual media at the dismounted instrument can result in a risk to

persons, the environment and the equipment. Take sucient precautionary

measures.

For information on returning the instrument see chapter 11.2 "Return".

11472988.02 04/2013 GB/D/F/E

WIKA operating instructions expansion thermometer, model 70

13

Page 14

10. Faults / 11. Dismounting, return and disposal

10. Faults

Faults Causes Measures

GB

The pointer drops below the

start of the scale range.

Instrument switches at the

wrong temperature

Instrument does not switch Defect in switch setting/ micro

CAUTION!

If faults cannot be eliminated by means of the measures listed above, take the

instrument out of service immediately, ensure that no pressure/temperature

or signal are still present and secure the instrument from being put back into

operation inadvertently.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter

11.2 "Return".

Damaged capillary Carefully dismount the instrument,

pack it (tightly sealed) and return it

Switch point is set incorrectly. Check the switch point

switch

to the manufacturer for repair.

Return the instrument to the

manufacturer for repair

11. Dismounting, return and disposal

WARNING!

Residual media at the dismounted instrument can result in a risk to persons,

the environment and the equipment.

Take sucient precautionary measures.

11.1 Dismounting

WARNING!

Risk of burns!

Let the instrument cool down suciently before dismounting!

During dismounting there is a risk of dangerously hot pressure media

escaping.

Only disconnect the expansion thermometer once the system has been depressurised!

14

WIKA operating instructions expansion thermometer, model 70

11472988.02 04/2013 GB/D/F/E

Page 15

11. Dismounting, return and disposal

11.2 Return

WARNING!

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous

substances (acids, bases, solutions, etc.).

When returning the instrument, use the original packaging or a suitable transport package.

To avoid damage:

1. Place the instrument along with shock-absorbent material in the packaging.

Place shock-absorbent material evenly on all sides of the transport packaging.

2. If possible, place a bag containing a desiccant inside the packaging.

3. Label the shipment as carriage of a highly sensitive measuring instrument.

Information on returns can be found under the heading "Service" on our local

website.

11.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal regulations.

GB

11472988.02 04/2013 GB/D/F/E

WIKA operating instructions expansion thermometer, model 70

15

Page 16

GB

16

11472988.02 04/2013 GB/D/F/E

WIKA operating instructions expansion thermometer, model 70

Page 17

Inhalt

Inhalt

1. Allgemeines 18

2. Sicherheit 19

3. Technische Daten 22

4. Aufbau und Funktion 22

5. Transport, Verpackung und Lagerung 23

6. Inbetriebnahme, Betrieb 24

7. Anzeigekontrolle 26

8. Anzeigekorrektur 26

9. Wartung und Reinigung 27

10. Störungen 28

11. Demontage, Rücksendung und Entsorgung 28

D

11472988.02 04/2013 GB/D/F/E

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

17

Page 18

1. Allgemeines

1. Allgemeines

Die in der Betriebsanleitung beschriebenen Tensionsthermometer werden nach dem

aktuellen Stand der Technik gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und Umwelt-

kriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001 zertiziert.

D

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraus-

setzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise

und Handlungsanweisungen.

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschrif-

ten und allgemeinen Sicherheitsbestimmungen einhalten.

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwen-

dung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten

Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

Technische Änderungen vorbehalten.

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: TM 81.01, TV 28.01

- Anwendungsberater:

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder

zu schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen kann,

wenn sie nicht gemieden wird.

18

Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.de

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

11472988.02 04/2013 GB/D/F/E

Page 19

1. Allgemeines / 2. Sicherheit

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen ezienten und störungsfreien Betrieb hervor.

GEFAHR!

… kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung

der Sicherheitshinweise besteht die Gefahr schwerer oder tödlicher Verletzungen.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die durch heiße

Oberächen oder Flüssigkeiten zu Verbrennungen führen kann, wenn sie nicht

gemieden wird.

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richti-

ge Thermometer hinsichtlich Messbereich, Ausführung und spezischen

Messbedingungen ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen Kapiteln

dieser Betriebsanleitung.

D

2.1 Bestimmungsgemäße Verwendung

Die Tensionsthermometer Typ 70 sind universell einsetzbare Temperaturmessgeräte/

Temperaturregler (mit Mikroschalter) für gasförmige, üssige und hochviskose Messstoe.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen

Spezikationen macht die sofortige Stilllegung und Überprüfung durch einen autorisierten

WIKA-Servicemitarbeiter erforderlich.

11472988.02 04/2013 GB/D/F/E

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

19

Page 20

2. Sicherheit

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

D

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden

führen.

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualikation durchführen lassen.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der Mess-

und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen

Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen Arbeiten

auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

2.3 Besondere Gefahren

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen, brennbaren oder

giftigen Stoen, sowie bei Kälteanlagen, Kompressoren etc. müssen über die

gesamten allgemeinen Regeln hinaus die einschlägigen Vorschriften beachtet

werden.

WARNUNG!

Für ein sicheres Arbeiten am Gerät muss der Betreiber sicherstellen,

dass eine entsprechende Erste-Hilfe-Ausrüstung vorhanden ist und bei

Bedarf jederzeit Hilfe zur Stelle ist.

dass das Bedienpersonal regelmäßig in allen zutreenden Fragen von

Arbeitssicherheit, Erste-Hilfe und Umweltschutz unterwiesen wird, sowie

die Betriebsanleitung und insbesondere die darin enthaltenen Sicherheitshinweise kennt.

20

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

11472988.02 04/2013 GB/D/F/E

Page 21

2. Sicherheit

GEFAHR!

Lebensgefahr durch elektrischen Strom

Bei Berührung mit spannungsführenden Teilen besteht unmittelbare Lebensgefahr.

Einbau und Montage des Gerätes dürfen nur durch Fachpersonal erfolgen.

Bei Betrieb mit einem defekten Netzgerät (z. B. Kurzschluss von Netzspan-

nung zur Ausgangsspannung) können am Gerät lebensgefährliche

Spannungen auftreten!

WARNUNG!

Messstoreste am ausgebauten Gerät können zur Gefährdung von Personen,

Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

Dieses Gerät nicht in Sicherheits- oder in Not-Aus-Einrichtungen benutzen.

Fehlerhafte Anwendungen des Gerätes können zu Verletzungen führen.

Am Gerät können im Fehlerfall aggressive Medien mit extremer Temperatur

und unter hohem Druck oder Vakuum anliegen.

2.4 Beschilderung, Sicherheitskennzeichnungen

D

Typenschild

Herstellungsdatum

Symbolerklärung

Vor Montage und Inbetriebnahme des Gerätes unbedingt die Betriebsanleitung lesen!

11472988.02 04/2013 GB/D/F/E

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

Typ

Schaltpunkte

21

Page 22

3. Technische Daten / 4. Aufbau und Funktion

3. Technische Daten

Technische Daten Mit Mikroschalter Ohne Mikroschalter

Nenngröße in mm 100 63, 100, 160

Messprinzip Bourdonfedersystem

D

Füllmedium Xylol, Siliconöl oder Syltherm Xylol oder Siliconöl

Fernleitungsabgang Unten oder rückseitig

Gehäuse CrNi-Stahl

Anzeigegenauigkeit Klasse 2

Anzeigebereich -100 ... +400 °C

Messleitung Ø 2 mm, CrNi-Stahl 1.4571

Messleitungslänge Max. 10 m

Kontakt max. 2 Mikroschalter (einstellbar/fest)

Lastdaten

Einstellbereich von 10 % bis 90 % des Skalenendwertes

Standardschaltdierenz < 2 % vom Messbereich

Elektrischer Anschluss über Kabelanschlussdose

Schutzart nach EN 60529 / IEC 529 IP 44 IP 65

5 A, AC 48 V

In den Geräten sind keine Überstrom-Schutzeinrichtungen

eingebaut. Um ein Verschweißen der Schalter durch

Überlast zu verhindern sind geeignete Schutzeinrichtungen vom Anwender vorzusehen.

Fest eingestellt, werkseitig nach Kundenvorgabe

Weitere technische Daten siehe WIKA-Datenblatt TV 28.01 oder TM 81.01 und Bestellunterlagen.

4. Aufbau und Funktion

4.1 Beschreibung

Das üssigkeitsgefüllte, geschlossene Messsystem besteht aus einem Temperaturfühler, einer Messleitung und einer Bourdonfeder. Die durch die Wärmebeaufschlagung am

Temperaturfühler erzeugte Volumenänderung und somit auch die Druckänderung im

geschlossenen System wird durch die Messleitung zur Bourdonfeder übertragen und über

den Winkelausschlag der Zeigerwelle auf dem Zierblatt zur Anzeige gebracht.

Temperaturmessgeräte mit Mikroschalter (Temperaturregler)

Die mit der Zeigerwelle verbundene Schaltscheibe (Kurvenscheibe) löst bei Erreichen des

Schaltpunktes den Schaltvorgang am Mikroschalter aus.

22

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

11472988.02 04/2013 GB/D/F/E

Page 23

4. Aufbau und Funktion / 5. Transport, Verpackung ...

Neben der Standardversion mit 1 oder 2 verstellbaren Kontakten gibt es weitere

Kombinationen wie:

1 oder 2 fest eingestellte Mikroschalter

1 fest und 1 variabel eingestellter Mikroschalter

Die Schaltpunkte der fest eingestellten Mikroschalter sind auf dem Typenschild vermerkt.

4.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

5. Transport, Verpackung und Lagerung

5.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

Lagertemperatur: -20 ... +60 °C (DIN EN 13190)

Feuchtigkeit: 35 ... 85 % relative Feuchte (keine Betauung)

Folgende Einüsse vermeiden:

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

Ruß, Dampf, Staub und korrosive Gase

Explosionsgefährdete Umgebung, entzündliche Atmosphären

D

Das Gerät in der Originalverpackung an einem Ort lagern, der die oben gelisteten Bedingungen erfüllt. Wenn die Originalverpackung nicht vorhanden ist, dann das Gerät wie folgt

verpacken und lagern:

1. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

2. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der

Verpackung beilegen.

11472988.02 04/2013 GB/D/F/E

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

23

Page 24

5. Transport, Verpackung ... / 6. Inbetriebnahme, Betrieb

WARNUNG!

Vor der Einlagerung des Gerätes (nach Betrieb) alle anhaftenden Messstoreste entfernen. Dies ist besonders wichtig, wenn der Messsto gesundheits-

gefährdend ist, wie z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

D

6. Inbetriebnahme, Betrieb

Für die Montage und den Betrieb der Geräte folgende, grundsätzliche Anforderungen

beachten:

Der Anzeigebereich des Temperatrurregelgerätes sollte so gewählt werden, dass die

maximal am Fühler anliegende Temperatur den Anzeigebereich nicht überschreitet.

Dabei auch nach Überschreiten des Schaltpunktes auftretende Nachheizvorgänge

beachten.

In Betrieb sollte das Gerät keinen starken Schwingungen und Stoßbelastungen ausge-

setzt sein.

Verschmutzungen und hohe Umgebungstemperaturschwankungen vermeiden.

Ein Durchtrennen der Messleitung führt zur Zerstörung des Gerätes und zur Abschal-

tung.

Elektrischer Anschluss

Die Klemmenbelegung ist auf dem Typenschild am Gehäuseumfang

angegeben.

6.1 Einbaubedingungen

Vor der Montage des Fühlers ist zu prüfen, ob der verwendete Fühlerwerksto (aus dem

Lieferschein ersichtlich) gegenüber dem Messmedium chemisch beständig/neutral ist.

Dies gilt auch für Schutzrohre.

Darauf achten, dass das notwendige Zubehör (je nach Gehäusebefestigungsart) für

Tafeleinbaubefestigung vorhanden ist.

Das Zubehör ist eingebaut oder bendet sich in einem am Thermometer befestigten

Beutel.

Der Tauchschaft soll möglichst mit seiner ganzen Länge der zu messenden Temperatur

ausgesetzt sein. Mindestens aber die Länge des aktiven Teils, welche der Länge der

Ausdehnungsgefäßes entspricht (aktive Länge).

Der Temperaturfühler muss in Rohrleitungen oder sonstigen Messstellen der

Strömungsrichtung möglichst schräg entgegengerichtet stehen.

24

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

11472988.02 04/2013 GB/D/F/E

Page 25

6. Inbetriebnahme, Betrieb

Bei der Verwendung von Schutzrohren ist zu beachten, dass der Tauchschaft nicht den

Boden des Schutzrohres berühren darf.

Fernleitungen sind vor Knickungen zu schützen. Der kleinste Biegeradius der Fernlei-

tung sollte 6 mm nicht unterschreiten. Knickung oder Unterbrechung der Fernleitung

führen zum Ausfall des Gerätes.

Ist der Fühler an einer erschütterten oder vibrierenden Stelle eingebaut, so ist die

Fernleitung unbedingt zwischen dem letzten Befestigungspunkt und dem Fühler in

mehreren Schlaufen freischwingend zu verlegen. Überlängen sind ebenfalls als Schlaufen zu verlegen, da das Abschneiden das Gerät

unbrauchbar macht.

Das Anschweißen oder Löten der Fernleitung, sowie alle unlösbaren Befestigungen

der Fernleitung sind zu vermeiden, da hierbei die Fernleitung stark beschädigt und die

Funktion des Gerätes beeinträchtigt werden kann.

Das Anzeigegehäuse muss erschütterungsfrei montiert werden.

Gegebenenfalls kann z. B. durch eine exible Verbindungsleitung von der Messstelle

zum Thermometer und die Befestigung über eine Messgerätehalterung eine Entkopplung vom Einbauort erreicht werden.

Falls dies nicht möglich ist, dürfen folgende Grenzwerte nicht überschritten werden:

Frequenzbereich < 150 Hz

Beschleunigung < 0,5 g (5 m/s

2

)

D

Die Flüssigkeitsfüllung ist regelmäßig zu überprüfen.

Der Flüssigkeitsspiegel darf nicht unter 75 % des Gerätedurchmessers fallen.

Starke Erschütterungen, Schwingungen und Vibrationen führen zu Anzeigeunsicherheiten,

erhöhtem Verschleiß im Übersetzungswerk bzw. Bruch an den Schweiß- oder Lötstellen.

Thermometer mit eingebautem Mikroschalter können infolge von Erschütterungen

atternd schalten, wodurch erhöhter Kontaktverschleiß und eine Verstellung des

gewünschten Kontaktpunktes auftreten kann.

6.2 Umgebungsbedingungen

Thermometer, deren Gehäuseschutzart nicht besonders in der Auftragsbestätigung

gekennzeichnet ist, sind vor feuchter Luft und sonstiger aggressiver Atmosphäre zu

schützen.

Die Umgebungstemperatur am Anzeigegehäuse sollte sich innerhalb von 0 ... 40 °C

bewegen, um die größte Messgenauigkeit zu gewährleisten. Höhere bzw. niedrigere

Umgebungstemperaturen können zu Anzeigefehlern führen.

11472988.02 04/2013 GB/D/F/E

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

25

Page 26

7. Anzeigekontrolle / 8. Anzeigekorrektur

7. Anzeigekontrolle

Die Anzeigekontrolle sollte nur im Vergleich zu einem genaueren oder möglichst kalibrierten Gerät erfolgen. Die Kontrolltemperatur muss konstant sein.

Bei veränderlichen Temperaturen entstehen Ablesefehler, die ihre Ursache in unterschiedlichen Ansprechzeiten der Fühler haben.

D

Bei Thermometern ohne Schutzrohr muss bei voller ordnungsgemäßer Eintauchlänge

eine Mindestwartezeit von 5 Minuten zum Temperaturausgleich eingehalten werden.

Temperaturkontrollen, bei denen die Fühler in Schutzrohren eingebaut sind, können in

vielen Fällen nur eine Bezugstemperatur am Prüing ergeben, da durch das Schutzrohr bleibende Wärmeableitungen entstehen. In Temperaturfeldern, die mit stationären

Kontrollthermometern ausgerüstet sind (z. B. Rohrleitungssystemen) können ebenfalls

Bezugstemperaturen mit bleibender Abweichung entstehen, deren Ursache in der

Messstrecke liegt. Sehr stark von der Raumtemperatur abweichende Umgebungstemperaturen am Anzeigegehäuse können bei konstanten Umgebungstemperaturen zu bleibenden, bei veränderlichen Umgebungstemperaturen zu wechselnden Anzeigefehlern führen.

Bleibende Anzeigefehler durch Nachalterung des Messsystems sind vernachlässigbar, da

sie nur einen Bruchteil der Anzeigegenauigkeit betragen.

8. Anzeigekorrektur

WARNUNG!

Bei Eingrien jeglicher Art in das Gerät erlischt der Garantieanspruch!

Eine Anzeigekorrektur kann nur beim Hersteller bzw. in entsprechend eingerichteten

Werkstätten durch qualiziertes Personal erfolgen.

Der elektrische Anschluss darf nur durch qualiziertes Personal erfolgen.

Anschluss der Schalter über Kabelanschlussdose

Leitungsquerschnitt max. 1,5 mm

Klemmenbelegung auf Anschlussschild am Thermometer

Einstellen der Sollwertzeiger (mit Mikroschalter)

Das Einstellen der Sollwerte erfolgt über das Verstellschloss in der Sichtscheibe.

26

2

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

11472988.02 04/2013 GB/D/F/E

Page 27

8. Anzeigekorrektur / 9. Wartung und Reinigung

Die Sollwertzeiger der Mikroschalter sind im gesamten Skalenbereich frei einstellbar. Aus

Gründen der Schaltgenauigkeit und der Lebensdauer der mechanischen Messsysteme

sollen die Schaltpunkte zwischen 10 % und 90 % der Messspanne liegen.

Die auf Kundenwunsch fest eingestellten Schaltpunkte sind nachträglich nicht mehr

veränderbar.

Infolge von Oberächenoxidation an den Kontaktächen können sich Störungen ergeben,

die besonders bei eigensicheren Schaltungen (kleine Spannungen und geringe Ströme)

infolge des entstehenden lsolationswiderstandes und bei höheren Kontaktbelastungen zu

Kontaktbrand führen können.

9. Wartung und Reinigung

9.1 Wartung

Diese Tensionsthermometer sind wartungsfrei.

Eine Überprüfung der Anzeige und der Schaltfunktion sollte etwa 1 bis 2 mal pro Jahr

erfolgen. Dazu ist das Gerät vom Prozess zu trennen und mit einem Temperaturkalibrator

zu kontrollieren.

D

Reparaturen sind ausschließlich vom Hersteller oder entsprechend qualiziertem Personal durchzuführen.

9.2 Reinigung

VORSICHT!

Vor der Reinigung das Gerät ordnungsgemäß vom Netz trennen.

Das Gerät mit einem feuchten Tuch (Seifenlauge) reinigen.

Elektrische Anschlüsse nicht mit Feuchtigkeit in Berührung bringen.

Vor Wiedereinschalten des Stromes sicherzustellen, dass alle Teile

abgetrocknet sind.

Ausgebautes Gerät vor der Rücksendung spülen bzw. säubern, um Perso-

nen und Umwelt vor Gefährdung durch anhaftende Messstoreste zu

schützen.

Messstoreste am ausgebauten Gerät können zur Gefährdung von Perso-

nen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

Hinweise zur Rücksendung des Gerätes siehe Kapitel 11.2 „Rücksendung“.

11472988.02 04/2013 GB/D/F/E

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

27

Page 28

10. Störungen / 11. Demontage, Rücksendung ...

10. Störungen

Störungen Ursachen Maßnahmen

Zeiger fällt unter den Anfang

des Anzeigebereichs

D

Gerät schaltet bei falscher

Temperatur

Gerät schaltet nicht Defekt am Schaltaufbau/

VORSICHT!

Können Störungen mit Hilfe der oben aufgeführten Maßnahmen nicht beseitigt

werden, ist das Gerät unverzüglich außer Betrieb zu setzen, sicherzustellen,

dass kein Druck/Temperatur bzw. Signal mehr anliegt und gegen versehentliche Inbetriebnahme zu schützen.

In diesem Falle Kontakt mit dem Hersteller aufnehmen.

Bei notwendiger Rücksendung die Hinweise unter Kapitel 11.2 „Rücksendung“

beachten.

Beschädigte Kapillarleitung Messgerät vorsichtig ausbauen,

dicht verpacken und zur Instandhal-

Schaltpunkt nicht richtig

eingestellt

Mikroschalter

tung an Hersteller zurück.

Schaltpunkt überprüfen

Messgerät zur Instandhaltung an

Hersteller zurück

11. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste am ausgebauten Gerät können zur Gefährdung von Personen,

Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

11.1 Demontage

WARNUNG!

Verbrennungsgefahr!

Vor dem Ausbau das Gerät ausreichend abkühlen lassen!

Beim Ausbau besteht Gefahr durch austretende, gefährlich heiße Messstoe.

Tensionsthermometer nur im drucklosen Zustand demontieren!

28

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

11472988.02 04/2013 GB/D/F/E

Page 29

11. Demontage, Rücksendung und Entsorgung

11.2 Rücksendung

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoen (Säuren,

Laugen, Lösungen, etc.) sein.

Zur Rücksendung des Gerätes die Originalverpackung oder eine geeignete Transportverpackung verwenden.

Um Schäden zu vermeiden:

1. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

2. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung beifügen.

3. Sendung als Transport eines hochempndlichen Messgerätes kennzeichnen.

Hinweise zur Rücksendung benden sich in der Rubrik „Service“ auf unserer

lokalen Internetseite.

11.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezischen

Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

D

11472988.02 04/2013 GB/D/F/E

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

29

Page 30

D

30

11472988.02 04/2013 GB/D/F/E

WIKA Betriebsanleitung Tensionsthermometer, Typ 70

Page 31

Sommaire

Sommaire

1. Généralités 32

2. Sécurité 33

3. Spécications 36

4. Conception et fonction 36

5. Transport, emballage et stockage 37

6. Mise en service, exploitation 38

7. Contrôles de mesure 40

8. Réglage du zéro 40

9. Entretien et nettoyage 41

10. Dysfonctionnements 42

11. Démontage, retour et mise au rebut 42

F

11472988.02 04/2013 GB/D/F/E

WIKA mode d'emploi thermomètres à expansion, type 70

31

Page 32

1. Généralités

1. Généralités

Les thermomètres à expansion décrits dans le mode d'emploi sont conçus et fabriqués

selon les dernières technologies en vigueur. Tous les composants sont soumis à des

critères de qualité et d'environnement stricts durant la fabrication. Nos systèmes de

gestion sont certiés selon ISO 9001 et ISO 14001.

Ce mode d'emploi donne des indications importantes concernant l'utilisation de

l'instrument. Il est possible de travailler en toute sécurité avec ce produit en respectant

F

toutes les consignes de sécurité et d'utilisation.

Respecter les prescriptions locales de prévention contre les accidents et les

prescriptions générales de sécurité en vigueur pour le domaine d'application de

l'instrument.

Le mode d'emploi fait partie de l'instrument et doit être conservé à proximité immédiate

de l'instrument et accessible à tout moment pour le personnel qualié.

Le personnel qualié doit, avant de commencer toute opération, avoir lu

soigneusement et compris le mode d'emploi.

La responsabilité du fabricant n'est pas engagée en cas de dommages provoqués par

une utilisation non conforme à l'usage prévu, de non respect de ce mode d'emploi,

d'utilisation de personnel peu qualié de même qu'en cas de modications de

l'instrument eectuées par l'utilisateur.

Les conditions générales de vente mentionnées dans les documents de vente

s'appliquent.

Sous réserve de modications techniques.

Pour obtenir d'autres informations :

- Consulter notre site Internet : www.wika.fr

- Fiche technique correspondante : TM 81.01, TV 28.01

- Conseiller applications :

Tel. : (+49) 9372/132-0

Fax : (+49) 9372/132-406

E-Mail : info@wika.fr

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer la

mort ou des blessures graves si elle n'est pas évitée.

ATTENTION !

… indique une situation potentiellement dangereuse et susceptible de

provoquer de légères blessures ou des dommages matériels et pour

l'environnement si elle n'est pas évitée.

32

11472988.02 04/2013 GB/D/F/E

WIKA mode d'emploi thermomètres à expansion, type 70

Page 33

1. Généralités / 2. Sécurité

Information

... met en exergue les conseils et recommandations utiles de même que les

informations permettant d'assurer un fonctionnement ecace et normal.

DANGER !

... indique les dangers liés au courant électrique. Danger de blessures graves

ou mortelles en cas de non respect des consignes de sécurité.

AVERTISSEMENT !

... indique une situation présentant des risques susceptibles de provoquer des

brûlures dues à des surfaces ou liquides chauds si elle n'est pas évitée.

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement, s'assurer que le

thermomètre a été choisi de façon adéquate, en ce qui concerne l'étendue de

mesure, la version et les conditions de mesure spéciques.

Un non respect de cette consigne peut entraîner des blessures corporelles

graves et/ou des dégâts matériels.

F

Vous trouverez d'autres consignes de sécurité dans les sections individuelles

du présent mode d'emploi.

2.1 Utilisation conforme à l'usage prévu

Les thermomètres à expansion type 70 sont des instruments de mesure de température/

régulateurs de température universels (avec microrupteur) pour des uides de processus

gazeux, liquides et hautement visqueux.

L'instrument est conçu et construit exclusivement pour une utilisation conforme à l'usage

prévu décrit ici et ne doit être utilisé qu'en conséquence.

Les spécications techniques mentionnées dans ce mode d'emploi doivent être

respectées. En cas d'utilisation inadéquate ou de fonctionnement de l'instrument en

dehors des spécications techniques, un arrêt et contrôle doivent être immédiatement

eectués par un collaborateur autorisé du service de WIKA.

11472988.02 04/2013 GB/D/F/E

WIKA mode d'emploi thermomètres à expansion, type 70

33

Page 34

2. Sécurité

Si l'instrument est transporté d'un environnement froid dans un environnement chaud,

la formation de condensation peut provoquer un dysfonctionnement fonctionnel de

l'instrument. Il est nécessaire d'attendre que la température de l'instrument se soit adaptée

à la température ambiante avant une nouvelle mise en service.

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à l'usage prévu.

2.2 Qualication du personnel

F

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses connaissances

dans le domaine de la technique de mesure et de régulation et de ses expériences de

même que de sa connaissance des prescriptions nationales, des normes et directives en

vigueur, en mesure d'eectuer les travaux décrits et de reconnaître automatiquement les

dangers potentiels.

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants dommages corporels

et matériels.

Les opérations décrites dans ce mode d'emploi ne doivent être eectuées

que par un personnel ayant la qualication décrite ci-après.

Les conditions d'utilisation spéciales exigent également une connaissance adéquate par

exemple des liquides agressifs.

2.3 Dangers particuliers

AVERTISSEMENT !

Dans le cas de uides de mesure dangereux comme notamment l'oxygène,

l'acétylène, les substances combustibles ou toxiques, ainsi que dans le

cas d'installations de réfrigération, de compresseurs etc., les directives

appropriées existantes doivent être observées en plus de l'ensemble des

règles générales.

AVERTISSEMENT !

An de travailler en toute sécurité sur l'instrument, la société exploitante doit

s'assurer

qu'un équipement de premier secours adapté est disponible et que les premiers

soins peuvent être dispensés sur place à tout moment en cas de besoin.

que le personnel de service reçoit à intervalles réguliers des instructions

relatives à toutes les questions pertinentes concernant la sécurité du travail, les

premiers secours et la protection de l'environnement et qu'il connaît le mode

d'emploi et particulièrement les consignes de sécurité contenues dans celui-ci.

34

WIKA mode d'emploi thermomètres à expansion, type 70

11472988.02 04/2013 GB/D/F/E

Page 35

2. Sécurité

DANGER !

Danger de mort lié au courant électrique

Danger de mort en cas de contact avec les pièces sous tension.

Le montage de l'instrument électrique ne doit être eectué que par un

électricien qualié.

En cas d'utilisation avec un instrument d'alimentation défectueux (par

exemple court-circuit entre la tension du secteur et la tension de sortie), des

tensions présentant un danger de mort peuvent apparaître sur l'instrument !

AVERTISSEMENT !

Les restes de uides se trouvant dans des instruments démontés peuvent

mettre en danger les personnes, l'environnement ainsi que le montage.

Prendre des mesures de sécurité susantes.

Ne pas utiliser cet instrument dans des dispositifs de sécurité ou d'arrêt

d'urgence. Une utilisation incorrecte de l'instrument peut occasionner des

blessures.

En cas d'erreur, des uides agressifs peuvent être présents à une température

extrême et sous une pression élevée ou sous vide au niveau de l'instrument.

2.4 Etiquetage, marquages de sécurité

F

Plaque signalétique

Date de fabrication

Explication des symboles

Lire impérativement le mode d'emploi avant le montage et la mise en service

de l'instrument !

11472988.02 04/2013 GB/D/F/E

WIKA mode d'emploi thermomètres à expansion, type 70

Type

Points de seuils

35

Page 36

3. Spécications / 4. Conception et fonction

3. Spécications

Spécications avec microrupteur sans microrupteur

Diamètre en mm 100 63, 100, 160

Principe de mesure Système à tube de Bourdon

Remplissage uide Xylol, huile de silicone ou Syltherm Xylol ou huile silicone

Départ du capillaire Raccord vertical ou arrière

Boîtier Acier inox

F

Précision de mesure Classe 2

Echelle de mesure -100 ... +400 °C

Conduite de mesure Ø 2 mm, acier inox 1.4571

Longueur de la conduite de mesure

Contact 2 microrupteurs max. (réglables/xes)

Données de charge

Plage de réglage de 10 % à 90 % de la valeur pleine échelle

Diérentiel de contact standard < 2 % de l'étendue de mesure

Raccordement électrique par un boîtier de raccordement

Indice de protection

selon EN 60529/CEI 529

Max. 10 m

5 A, 48 VAC

Aucun dispositif de protection de surtension n'est installé

dans les instruments. An de protéger les contacts d'un

soudage par surcharge, des systèmes de protection adaptés

doivent être mis en œuvre par l'opérateur.

Fixes, dénis en usine selon les spécications du client

IP 44 IP 65

Pour de plus amples spécications, voir la che technique WIKA TV 28.01 ou TM 81.01 et

la documentation de commande.

4. Conception et fonction

4.1 Description

Le système de mesure fermé rempli de liquide consiste en un capteur de température,

un capillaire et un tube de Bourdon. Le changement de volume résultant de la chaleur

appliquée au capteur de température, et donc le changement de pression dans le

système fermé, sont transmis à travers le capillaire au tube de Bourdon et ensuite

indiqués sur le cadran par une déformation angulaire sur la tige de l‘aiguille.

Instruments de mesure de température avec microrupteur (régulateurs de

température)

Le disque de commutation (baïonnette) connecté à la tige de l‘aiguille déclenche

l‘opération de commutation sur le microrupteur lorsque le point de commutation est atteint.

36

WIKA mode d'emploi thermomètres à expansion, type 70

11472988.02 04/2013 GB/D/F/E

Page 37

4. Conception et fonction / 5. Transport, emballage ...

En plus de la version standard à 1 ou 2 contacts réglables, d'autres combinaisons sont

disponibles, par exemple :

1 ou 2 microrupteurs

1 microrupteur xe et 1 microrupteur réglable

Les points de commutation des microrupteurs xes sont indiqués sur la plaque

signalétique du produit.

4.2 Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur l'instrument liés au transport.

Communiquer immédiatement les dégâts constatés.

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection optimale (par ex.

changement de lieu d'utilisation, renvoi pour réparation).

5.3 Stockage

Conditions admissibles sur le lieu de stockage :

Température de stockage : -20 ... +60 °C (DIN EN 13190)

Humidité: 35 ... 85 % d'humidité relative (sans condensation)

Eviter les inuences suivantes :

Lumière solaire directe ou proximité d'objets chauds

Vibrations mécaniques, chocs mécaniques (mouvements brusques en le posant)

Suie, vapeur, poussière et gaz corrosifs

Environnement présentant des risques d'explosion, atmosphères inammables

F

Conserver l'instrument dans l'emballage original dans un endroit qui satisfait aux

conditions susmentionnées. Si l'emballage original n'est pas disponible, emballer et

stocker l'instrument comme suit :

1. Placer l'instrument avec le matériau isolant dans l'emballage.

2. En cas d'entreposage long (plus de 30 jours), mettre également un sachet absorbeur

d'humidité dans l'emballage.

11472988.02 04/2013 GB/D/F/E

WIKA mode d'emploi thermomètres à expansion, type 70

37

Page 38

5. Transport ... / 6. Mise en service, fonctionnement

AVERTISSEMENT !

Enlever tous les restes de uides adhérents avant l'entreposage de

l'instrument (après le fonctionnement). Ceci est particulièrement important

lorsque le uide représente un danger pour la santé, comme p. ex. des

substances corrosives, toxiques, cancérogènes, radioactives etc.

F

6. Mise en service, fonctionnement

Veillez à respecter les exigences générales suivantes lors du montage et de l'utilisation de

l'instrument :

L'échelle de mesure de l'instrument de régulation de la température doit être

sélectionnée de telle sorte que la température maximale présente au niveau du

capteur ne dépasse pas l'échelle de mesure. Une fois que le point de commutation est

dépassé, faire attention aux augmentations de température.

En fonctionnement, l'instrument ne doit pas être exposé à de fortes vibrations ou à des

charges par à-coups.

Eviter les salissures et les fortes uctuations de la température ambiante.

Couper la ligne de mesure aboutit à la destruction de l'instrument et ainsi à une

extinction du signal de sortie électrique.

Raccordement électrique

Les connexions terminales sont indiquées sur la plaque signalétique du

produit située sur le bord du boîtier.

6.1 Installation conditions

Avant l'installation du capteur, vérier si le matériau de capteur utilisé (spécié dans

les instructions de livraison) est chimiquement résistant ou neutre au uide que l'on va

mesurer. Ceci s'applique aussi aux doigts de gant.

Assurez-vous que les accessoires adéquats requis pour le blocage du boîtier de

l'instrument dans le panneau sont disponibles.

Les accessoires sont soit installés soit posés dans un sac attaché au thermomètre.

La tige doit être soumise sur toute sa longueur à la température à mesurer. Au moins

cependant sur la longueur de la partie active correspondant à la longueur de la cuve de

gaz (longueur active).

Le capteur de température doit être placé dans les conduites ou d'autres points de

mesure le plus possible dans le sens opposé à la direction d'écoulement du uide.

Lorsque vous utilisez des doigts de gant, s'assurer que la tige ne touche pas le fond du

doigt de gant.

38

WIKA mode d'emploi thermomètres à expansion, type 70

11472988.02 04/2013 GB/D/F/E

Page 39

6. Mise en service, fonctionnement

Protéger les capillaires contre toute torsion. Le rayon de courbure le plus faible du

capillaire ne doit pas être inférieur à 6 mm. Tout rayon ou discontinuité du capillaire peut

provoquer une panne de l'instrument.

Si le capteur est installé dans un endroit qui est exposé aux chocs et aux vibrations, il

est essentiel que le capillaire soit mis en spirale sur plusieurs boucles entre le dernier

point d'attache et le capteur, et libre de tension. Toute longueur excessive doit être mise

en spirale, car couper rendrait l'instrument inutilisable.

Eviter de souder, de braser ou de bloquer de manière permanente le capillaire, car

ceci pourrait sérieusement endommager le capillaire et entraver le fonctionnement de

l'instrument.

Le boîtier du cadran doit être monté de manière à ce qu'il soit exempt de toute

vibration. Le cas échéant, il est possible d'isoler l'instrument du lieu d'installation en

utilisant par exemple un câble de connexion exible entre le point de mesure et le

thermomètre et en xant ce dernier à l'aide d'un support d'instrument mural.

Lorsque cela n'est pas possible, veiller à ce que les valeurs limites suivantes ne soient

pas dépassées :

Plage de fréquence < 150 Hz

Accélération < 0,5 g (5 m/s

Le liquide de remplissage doit être contrôlé régulièrement.

Le niveau de remplissage de liquide ne doit pas descendre en-dessous de 75 % du

diamètre de l'instrument.

Les fortes secousses, les oscillations et les vibrations provoquent des erreurs d'achage,

augmentent l'usure du mécanisme de transmission et peuvent occasionner des ruptures

au niveau des soudures et brasages.

2

)

F

Dans les thermomètres avec microrupteurs intégrés, les contacts peuvent s'entrechoquer

en raison des vibrations, ce qui peut provoquer une augmentation de l'usure des contacts

et un déplacement du point de contact souhaité.

6.2 Conditions ambiantes

À moins que l'indice de protection du boîtier du thermomètre soit spécialement précisé

dans la conrmation de la commande, les instruments doivent être protégés de l'air

humide et d'autres atmosphères agressives.

Pour assurer la précision de mesure la meilleure possible, la température ambiante

sur le boîtier de l'aiguille doit se trouver entre 0 ... 40 °C. Des températures ambiantes

supérieures ou inférieures peuvent provoquer des erreurs d'indication.

11472988.02 04/2013 GB/D/F/E

WIKA mode d'emploi thermomètres à expansion, type 70

39

Page 40

7. Contrôles de mesure / 8. Réglage du zéro

7. Contrôles de mesure

Les contrôles de mesure ne doivent être eectués qu'en comparaison avec un instrument

plus précis ou, si possible, avec un instrument étalonné. La température doit demeurer

constante pendant le contrôle.

Des températures uctuantes peuvent conduire à des erreurs de lecture provoquées par

des temps de réponse diérents des capteurs.

F

Avec les thermomètres sans doigts de gant et avec une longueur utile complète et

correcte, un temps d'attente minimal de 5 minutes doit être conservé pour le lissage de la

température.

Les contrôles de température utilisant des thermomètres avec des capteurs assemblés

avec des doigts de gant peuvent, dans bien des cas, avoir pour résultat une température

de référence sur l'instrument en train d'être testé, à cause de la dissipation permanente

de chaleur causée par le doigt de gant. Dans les applications de température équipées

de thermomètres de contrôles statiques (par exemple des systèmes d'oléoducs), des

osets permanents dans les températures de référence peuvent être aussi causés par le

chemin de mesure. Des températures ambiantes régnant autour du boîtier qui dièrent

substantiellement de la température de la pièce peuvent conduire à des erreurs régulières

de mesure avec des températures ambiantes constantes et à des erreurs de mesures

variables avec des températures ambiantes uctuantes.

Des erreurs de mesure permanentes causées par le vieillissement du système de mesure

peuvent être ignorées, car elles ne comptent que pour une fraction de la précision de

mesure.

8. Réglage du zéro

AVERTISSEMENT !

Toute interférence avec l'instrument ou modication sur l'instrument annule

tout droit de garantie !

Un réglage du zéro peut être eectué uniquement par le fabricant ou dans des ateliers

équipés spécialement et par des personnes qualiées.

Les travaux de raccordement électrique ne doivent être eectués que par des

personnels qualiés.

Raccordement du contact via le boîtier de raccordement

Section du conducteur max. 1,5 mm

Le raccordement des bornes est indiqué sur l'étiquette de raccordement du

thermomètre

40

2

WIKA mode d'emploi thermomètres à expansion, type 70

11472988.02 04/2013 GB/D/F/E

Page 41

8. Réglage du zéro / 9. Entretien et nettoyage

Ajustement de l'aiguille de réglage (avec microrupteur)

On ajuste l'indicateur de la valeur de consigne au moyen de la clé de réglage située dans

le voyant.

Les aiguilles de réglage pour les microrupteurs sont librement réglables sur toute l'échelle

de mesure. Pour des raisons de précision et de sécurité de commutation, et an de

ne pas porter préjudice à la durée de vie des systèmes de mesure mécaniques, il est

recommandé de xer les points de commutation entre 10 % et 90 % de l'étendue de

mesure.

Les points de commutation avec un réglage xe selon les spécications du client ne

peuvent pas être modiés ultérieurement.

En raison de l'oxydation de surface sur les contacts, en particulier avec la commutation

à sécurité intrinsèque (tensions et courants faibles), des défauts pouvant provoquer une

érosion des contacts peuvent survenir en raison de la résistance d'isolation développée et

avec des pouvoirs de coupure supérieurs.

9. Entretien et nettoyage

F

9.1 Entretien

Ces thermomètres à expansion ne nécessitent pas d'entretien.

Un contrôle de l'achage et de la fonction de commutation est recommandé 1 à 2 fois/an.

Pour le contrôle de l'achage et des fonctions de commande, il faut isoler l'instrument du

process et le contrôler avec un calibrateur de température.

Les réparations doivent être eectuées exclusivement par le fabricant ou par un personnel

qualié.

9.2 Nettoyage

ATTENTION !

Avant le nettoyage, débrancher l'instrument du secteur.

Nettoyer l'instrument avec un chion humide (l'eau savonneuse).

Eviter tout contact des raccords électriques avec l'humidité.

Assurez-vous que toutes les pièces sont bien sèches avant de remettre le

courant.

Laver ou nettoyer l'instrument démonté avant de le renvoyer, an de

protéger les personnes et l'environnement contre le danger lié aux restes

11472988.02 04/2013 GB/D/F/E

WIKA mode d'emploi thermomètres à expansion, type 70

de uides adhérents.

41

Page 42

9. Entretien ... 11. Démontage, retour et mise au rebut

Les restes de uides se trouvant dans des instruments démontés peuvent

mettre en danger les personnes, l'environnement ainsi que le montage.

Prendre des mesures de sécurité susantes.

Pour des indications concernant le retour de l'instrument, voir chapitre

11.2 "Retour".

F

10. Dysfonctionnements

Dysfonctionnements Raisons Mesures

L'aiguille chute en-dessous

de la valeur inférieure de

l'échelle de mesure.

Contacts de l'instrument à la

mauvaise température

L'instrument ne commute pas Défaut de réglage du contact/

ATTENTION !

Si des dysfonctionnements ne peuvent pas être éliminés à l'aide des mesures

indiquées ci-dessus, mettre immédiatement l'instrument hors service et

s'assurer de l'absence de pression, de température et de signal. Puis,

sécuriser l'instrument an d'empêcher toute remise en service involontaire.

Contacter dans ce cas le fabricant.

S'il est nécessaire de retourner l'instrument au fabricant, respecter les

indications mentionnées au chapitre 11.2 "Retour".

Capillaire endommagé Démonter l'instrument avec

précaution, l'emballer (fermé

hermétiquement) et l'envoyer au

Le point de commutation est

réglé de manière incorrecte.

microrupteur

fabricant pour réparation.

Contrôler le point de commutation

Envoyer l'instrument au fabricant

pour réparation

11. Démontage, retour et mise au rebut

AVERTISSEMENT !

Les restes de uides se trouvant dans des instruments démontés peuvent

mettre en danger les personnes, l'environnement ainsi que le montage.

Prendre des mesures de sécurité susantes.

42

WIKA mode d'emploi thermomètres à expansion, type 70

11472988.02 04/2013 GB/D/F/E

Page 43

11. Démontage, retour et mise au rebut

11.1 Démontage

AVERTISSEMENT !

Danger de brûlure !

Avant le démontage, laisser refroidir susamment l'instrument !

Danger de brûlure lié à la sortie de uides dangereux chauds.

Déconnecter le thermomètre à dilatation de liquide uniquement une fois que le système a

été mis hors pression.

11.2 Retour

AVERTISSEMENT !

En cas d'envoi de l'instrument, il faut respecter impérativement ceci :

Tous les instruments envoyés à WIKA doivent être exempts de toute

substance dangereuse (acides, solutions alcalines, solutions, etc.).

Pour retourner l'instrument, utiliser l'emballage original ou un emballage adapté pour le

transport.

Pour éviter des dommages :

1. Placer l'instrument avec le matériau isolant dans l'emballage.

Isoler de manière uniforme tous les côtés de l'emballage de transport.

2. Mettre si possible un sachet absorbeur d'humidité dans l'emballage.

3. Indiquer lors de l'envoi qu'il s'agit d'un instrument de mesure très sensible à transporter.

F

Des informations relatives à la procédure de retour sont disponibles sur notre

site Internet à la rubrique "Services".

11.3 Mise au rebut

Une mise au rebut inadéquate peut entraîner des dangers pour l'environnement.

Eliminer les composants des instruments et les matériaux d'emballage conformément

aux prescriptions nationales pour le traitement et l'élimination des déchets et aux lois de

protection de l'environnement en vigueur.

11472988.02 04/2013 GB/D/F/E

WIKA mode d'emploi thermomètres à expansion, type 70

43

Page 44

F

44

11472988.02 04/2013 GB/D/F/E

WIKA mode d'emploi thermomètres à expansion, type 70

Page 45

Contenido

Contenido

1. Información general 46

2. Seguridad 47

3. Datos técnicos 50

4. Diseño y función 50

5. Transporte, embalaje y almacenamiento 51

6. Puesta en servicio, funcionamiento 52

7. Control del indicador 54

8. Corrección del indicador 54

9. Mantenimiento y limpieza 55

10. Errores 56

11. Desmontaje, devolución y eliminación de residuos 56

E

11472988.02 04/2013 GB/D/F/E

WIKA manual de instrucciones termómetro de tensión, modelo 70

45

Page 46

1. Información general

1. Información general

Los termómetros de tensión descritos en el manual de instrucciones están fabricados

según el estado actual de la técnica. Todos los componentes están sujetos a rigurosos

criterios de calidad y medio ambiente durante la producción. Nuestros sistemas de

gestión están certicados según ISO 9001 e ISO 14001.

Este manual de instrucciones proporciona indicaciones importantes acerca del manejo

del instrumento. Para que el trabajo con este instrumento sea seguro es imprescindible

cumplir con todas las instrucciones de seguridad y manejo indicadas.

E

Cumplir siempre las normativas sobre la prevención de accidentes y las normas de

seguridad en vigor en el lugar de utilización del instrumento.

El manual de instrucciones es una parte integrante del instrumento y debe guardarse

en la proximidad del mismo para que el personal especializado pueda consultarlo en

cualquier momento.

El personal especializado debe haber leído y entendido el manual de instrucciones

antes de comenzar cualquier trabajo.

El fabricante queda exento de cualquier responsabilidad en caso de daños causados

por un uso no conforme a la nalidad prevista, la inobservancia del presente manual

de instrucciones, un manejo por personal insucientemente cualicado así como una

modicación no autorizada del instrumento.

Se aplican las condiciones generales de venta incluidas en la documentación de venta.

Modicaciones técnicas reservadas.

Para obtener más informaciones consultar:

- Página web: www.wika.es

- Hoja técnica correspondiente: TM 81.01, TV 28.01

- Servicio técnico:

Explicación de símbolos

¡ADVERTENCIA!

… indica una situación probablemente peligrosa que puede causar la muerte

o lesiones graves si no se la evita.

¡CUIDADO!

... indica una situación probablemente peligrosa que puede causar lesiones

leves o medianas, o daños materiales y medioambientales, si no se la evita.

46

Tel.: (+49) 9372/132-0

Fax: (+49) 9372/132-406

E-Mail: info@wika.es

WIKA manual de instrucciones termómetro de tensión, modelo 70

11472988.02 04/2013 GB/D/F/E

Page 47

1. Información general / 2. Seguridad

Información

... marca consejos y recomendaciones útiles así como informaciones para una

utilización ecaz y libre de fallos.

¡PELIGRO!

... indica riesgos causados por corriente eléctrica. Existe riesgo de lesiones

graves o mortales si no se observan estas indicaciones de seguridad.

¡ADVERTENCIA!

... indica una situación probablemente peligrosa que pueda causar

quemaduras debido a supercies o líquidos calientes si no se evita.

2. Seguridad

¡ADVERTENCIA!

Antes de proceder con el montaje, la puesta en servicio y el funcionamiento

asegurarse de que se haya seleccionado el termómetro adecuado en relación

con rango de medida, versión y condiciones de medición especícas.

Riesgo de lesiones graves y/o daños materiales en caso de inobservancia.

Los distintos capítulos de este manual de instrucciones contienen otras

importantes indicaciones de seguridad.

2.1 Uso conforme a lo previsto

Los termómetros de tensión modelo 70 son instrumentos de medición de la temperatura/

reguladores de temperatura (con microinterruptor) universales para medios gaseosos,

líquidos y altamente viscosos.

El instrumento ha sido diseñado y construido únicamente para la nalidad aquí descrita y

debe utilizarse en conformidad a la misma.

E

Cumplir las especicaciones técnicas de este manual de instrucciones. Un manejo no

apropiado o una utilización del instrumento no conforme a las especicaciones técnicas

requiere la inmediata puesta fuera de servicio y la comprobación por parte de un técnico

autorizado por WIKA.

11472988.02 04/2013 GB/D/F/E

WIKA manual de instrucciones termómetro de tensión, modelo 70

47