Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Dierential pressure gauge with magnetic piston model 700.01

and with magnetic piston and separation diaphragm model 700.02

Dierenzdruckmessgerät mit Magnetkolben Typ 700.01 und mit

Magnetkolben und Trennmembrane Typ 700.02

Manomètre pour pression diérentielle avec piston magnétique

type 700.01 et avec piston magnétique et membrane de séparation

type 700.02

Manómetro diferencial con pistón magnético modelo 700.01 y con

pistón magnético y membrana de separación modelo 700.02

GB

D

F

E

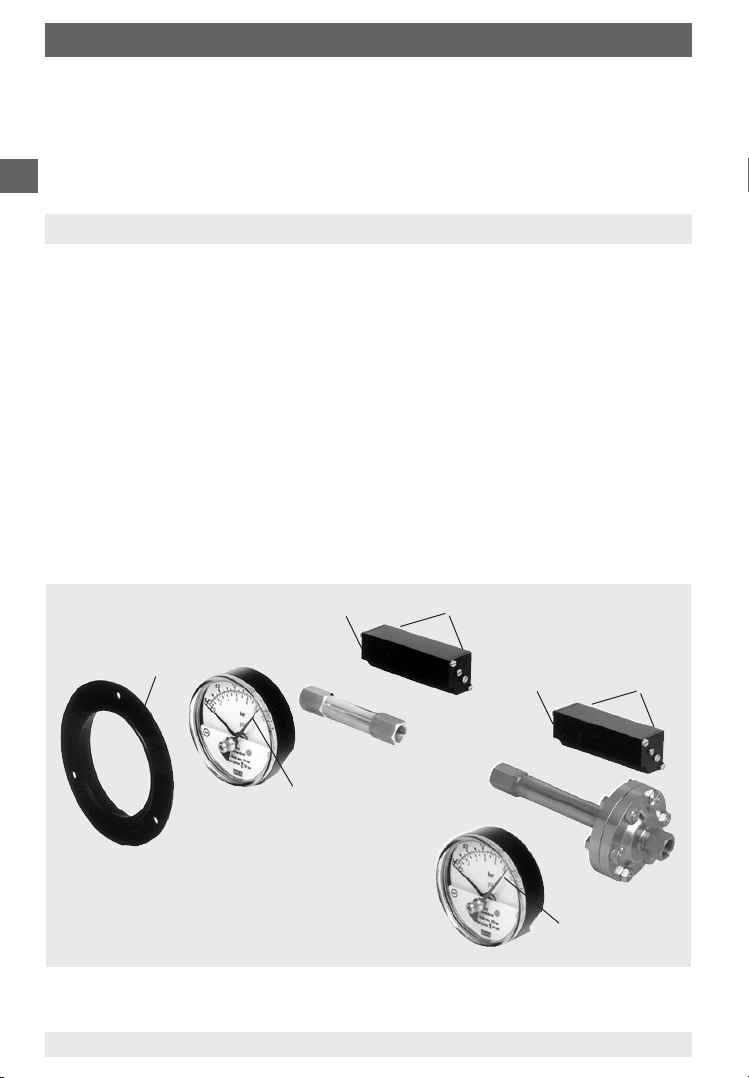

Model 700.01.080 Model 700.02.080

Page 2

Operating instructions model 700.01 and 700.02 Page 3-12

GB

Betriebsanleitung Typ 700.01 und 700.02 Seite 13-22

D

Mode d'emploi type 700.01 et 700.02 Page 23-32

F

Manual de instrucciones modelo 700.01 y 700.02 Página 33-42

E

© 2011 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta posterior!

2

WIKA operating instructions dierential pressure gauge with piston

2103869.04 12/2012 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 7

4. Design and function 7

5. Options and accessories 8

6. Transport, packaging and storage 9

7. Commissioning, operation 9

8. Maintenance and cleaning 12

9. Dismounting and disposal 12

GB

2103869.04 12/2012 GB/D/F/E

WIKA operating instructions dierential pressure gauge with piston 3

Page 4

1. General information

1. General information

The dierential pressure gauge described in the operating instructions has been

designed and manufactured using state-of-the-art technology.

GB

All components are subject to stringent quality and environmental criteria during

production. Our management systems are certied to ISO 9001 and ISO 14001.

These operating instructions contain important information on handling the

dierential pressure gauge. Working safely requires that all safety instructions

and work instructions are observed.

Observe the relevant local accident prevention regulations and general safety

regulations for the dierential pressure gauge's range of use.

The operating instructions are part of the product and must be kept in the

immediate vicinity of the pressure gauge and readily accessible to skilled

personnel at any time.

Skilled personnel must have carefully read and understood the operating

instructions prior to beginning any work.

The manufacturer's liability is void in the case of any damage caused by

using the product contrary to its intended use, non-compliance with these

operating instructions, assignment of insuciently qualied skilled personnel or

unauthorised modications to the dierential pressure gauge.

The general terms and conditions contained in the sales documentation shall

apply.

Subject to technical modications.

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: PM 07.14

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in

serious injury or death, if not avoided.

Information

… points out useful tips, recommendations and information for

ecient and trouble-free operation.

4

WIKA operating instructions dierential pressure gauge with piston

2103869.04 12/2012 GB/D/F/E

Page 5

2. Safety

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that

the appropriate pressure gauge has been selected in terms of

measuring range, design and specic measuring conditions.

Observe the selection and installation recommendations for

pressure gauges in accordance with EN 837-2.

Check the compatibility with the medium of the materials

subjected to pressure!

In order to guarantee the measuring accuracy and long-term

stability specied, the corresponding load limits must be

observed.

Non-observance can result in serious injury and/or damage to

the equipment.

Further important safety instructions can be found in the

individual chapters of these operating instructions.

2.1 Intended use

These dierential pressure gauges are used for monitoring dierential pressures

in industrial applications.

GB

The dierential pressure gauge has been designed and built solely for the

intended use described here and may only be used accordingly.

The manufacturer shall not be liable for claims of any type based on operation

contrary to the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage

to equipment.

■

The activities described in these operating instructions

may only be carried out by skilled personnel who have the

qualications described below.

2103869.04 12/2012 GB/D/F/E

WIKA operating instructions dierential pressure gauge with piston 5

Page 6

2. Safety

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical

training, knowledge of measurement and control technology and on their

experience and knowledge of country-specic regulations, current standards

GB

and directives, are capable of carrying out the work described and independently

recognising potential hazards.

2.3 Special hazards

WARNING!

Residual media in dismounted pressure gauges can result in a

risk to people, the environment and the system. Take sucient

precautionary measures.

2.5 Labelling / safety marks

Product label (with option reed contact)

Model 700.02.080 Cont 851.3

MAX. LASTDATEN / CONTACT RATING

Pmax AC/DC 3 W

Umax AC/DC 30 V

Imax AC/DC 0.2 A

E-Nr./Prod-No: 1234567 12/2010

UL-Nr: E103299

CSA-Nr: LR57810

⊖ left

⊕ right

1234567

Explanation of symbols

Before mounting and commissioning the pressure gauge, ensure

you read the operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European

directives.

6

WIKA operating instructions dierential pressure gauge with piston

Date of manufacture

2103869.04 12/2012 GB/D/F/E

Page 7

3. Specications / 4. Design and function

3. Specications

Specications Model 700.01 Model 700.02

Nominal size 80

Accuracy class ± 3 % of full scale value with

increasing dierential pressure

Scale ranges 0 … 400 mbar to 0 … 10 bar 0 … 160 mbar to 0 … 2.5 bar

Max. working

pressure

(static pressure)

Overpressure safety either side to maximum working pressure

Ingress protection lP 54 (EN 60529 / lEC 529)

Measuring chamber

with pressure

connection (wetted)

optionally 100, 250 or 400 bar 100 bar

(exception for model 700.02, scale ranges 0 ... 160 mbar and

0 ... 250 mbar: Overpressure safety up to 50 bar)

Stainless steel 1.4571, 2 x G ¼ female, on the right and left side,

in-line (EN 837-1 /7.3)

± 5 % of full scale value with

increasing dierential pressure

(scale ranges 0 ... 160 mbar and

0 ... 250 mbar: 50 bar)

For further specications see WIKA data sheet PM 07.14 and the order

documentation.

4. Design and function

Description

Pressures p

by the magnetic piston under pressure(or magnetic piston and separating

diaphragm for model 700.02).

and p2 are given in the ⊕ and ⊖ measuring chambers, separated

1

GB

The dierence in pressure causes an axial movement (deection) of the piston

supported by the compression spring.

The deection resulting from this is taken up by a ring magnet found on the

instrument pointer and appropriately displayed. This design combines the

advantages of complete separation of the measuring system and the indication

while eliminating any leakage to the exterior.

For model 700.01 the volume ow from the ⊕ measuring chamber to the ⊖

measuring chamber is minimised by the constructive design and will not interfere

with standard processes.

These instruments are mainly intended for gas/air supply and preparation applications where no magnetic particles are involved.

2103869.04 12/2012 GB/D/F/E

WIKA operating instructions dierential pressure gauge with piston 7

Page 8

5. Options and accessories

In processes with oating particles model 700.02 should be used.

Scope of delivery

Cross-check the scope of delivery with the delivery note.

GB

5. Options and accessories

5.1 Mounting ange (only for model 700.01, see left illustration)

May be retrotted on site as required.

Alignment of the front bezel (A) by means of the stamped cams to the grooves

found on the case circumference. Push front bezel on the case until it snaps into

position.

5.2 Minimum or maximum drag pointer (see illustrations)

The drag pointer (B) serves to monitor and control the miniumum or maximum

occurring dierential pressure.

5.3 Reed contact model 851.3 and 851.3.3 (see illustrations)

May be retrotted and adjusted on site as required.

Fastening is by means of two screws (D) integrated in the reed case (C) on the

display case with the pertinent female thread.

C

D

A

C

D

B

B

8

WIKA operating instructions dierential pressure gauge with piston

2103869.04 12/2012 GB/D/F/E

Page 9

6. Transport, packaging and storage / 7. Commissioning ...

6. Transport, packaging and storage

5.1 Transport

Check pressure gauge for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

6.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g.

change in installation site, sending for repair).

6.3 Storage

Permissible conditions at the place of storage:

Storage temperature: -20 ... +70 °C (optional: -40 … +70 °C)

7. Commissioning, operation

Mechanical connection

The installation of the dierential pressure gauge is made following the installation

recommendations for pressure gauges in accordance with EN 837-2 /7.

Mounting of the process connection according to axed symbols ⊕ and ⊖

⊕ high pressure, ⊖ low pressure

GB

■

Hold against the connection pieces in the case of installation by means of

17 mm screw spanner (installation without holding against the connection

pieces may cause thet measuring system to get loose).

■

The maximum permissible medium/ambient temperature must not be

exceeded

■

Prior to the installation of the pressure gauge, clean the measuring lines

thoroughly by tapping and blowing or rinsing

■

Mount and operate the measuring instruments free from vibration

■

Protect measuring instruments from contamination and high temperature

changes

To avoid foreign matter in the measuring system and the resulting damage to the

system, the pressure gauge must be mounted above the connector. For measuring

media containing suspended particles model 700.02 should be used.

2103869.04 12/2012 GB/D/F/E

WIKA operating instructions dierential pressure gauge with piston 9

Page 10

7. Commissioning, operation

If the line to the gauge is not rigid enough for a vibration-free installation, the gauge

should be mounted by means of appropriate fastening elements for wall mounting,

or, if necessary, with a capillary.

GB

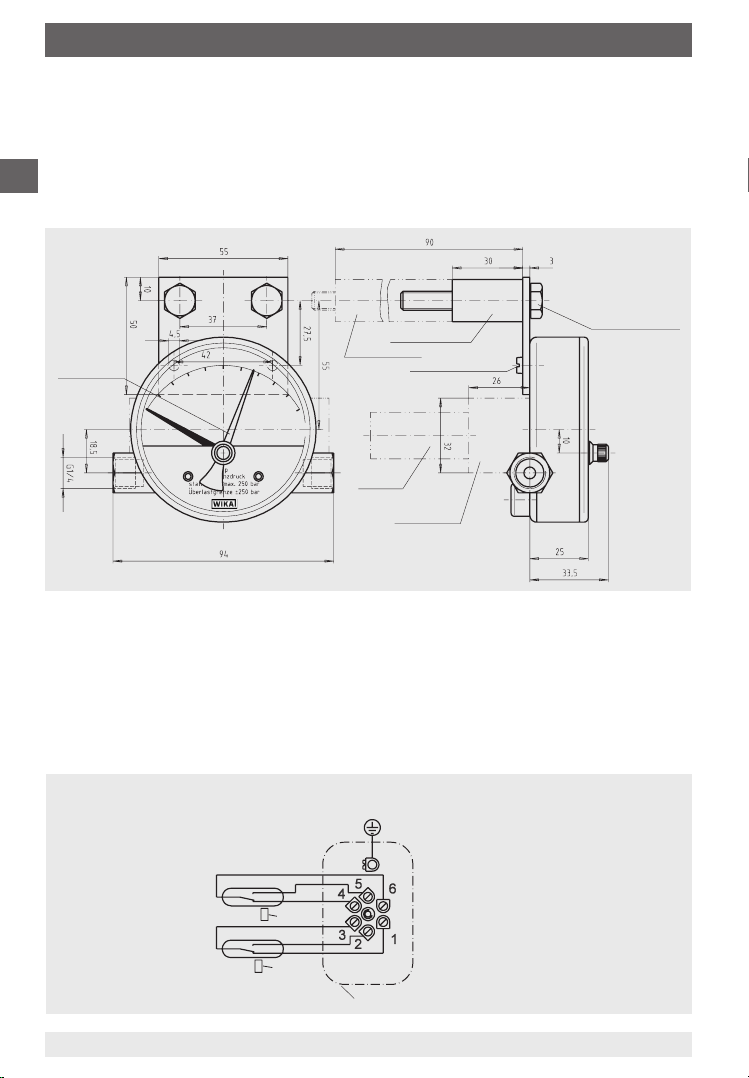

Wall mounting (see drawing)

Installation / fastening by means of mounting brackets

Hexagon bolt

M8 x 50 (M8 x 100)

Drag pointer

Electrical connection

without reed contact

with reed contact

Slotted screw M4 x 10

Plug

Reed case

(for instruments with electrical accessories)

Electrical connection of the pressure gauge is by means of terminal box and

cable. Precise wiring schemes can be seen in the following connection diagram.

In addition both the pin assignment and the required power supply are stated on

the product label of the reed case.

Electrical connection diagram

Reed contact model 851.3 and 851.3.3

(change-over contact)

The instruments do not

provide for incorporated

851.3. 3

2nd contact

overcurrent protectors. If

overcurrent protectors are

requested, these have to

10

851. 3

1nd contact

Terminal box

WIKA operating instructions dierential pressure gauge with piston

be provided for externally.

1581007.02

2103869.04 12/2012 GB/D/F/E

Page 11

7. Commissioning, operation

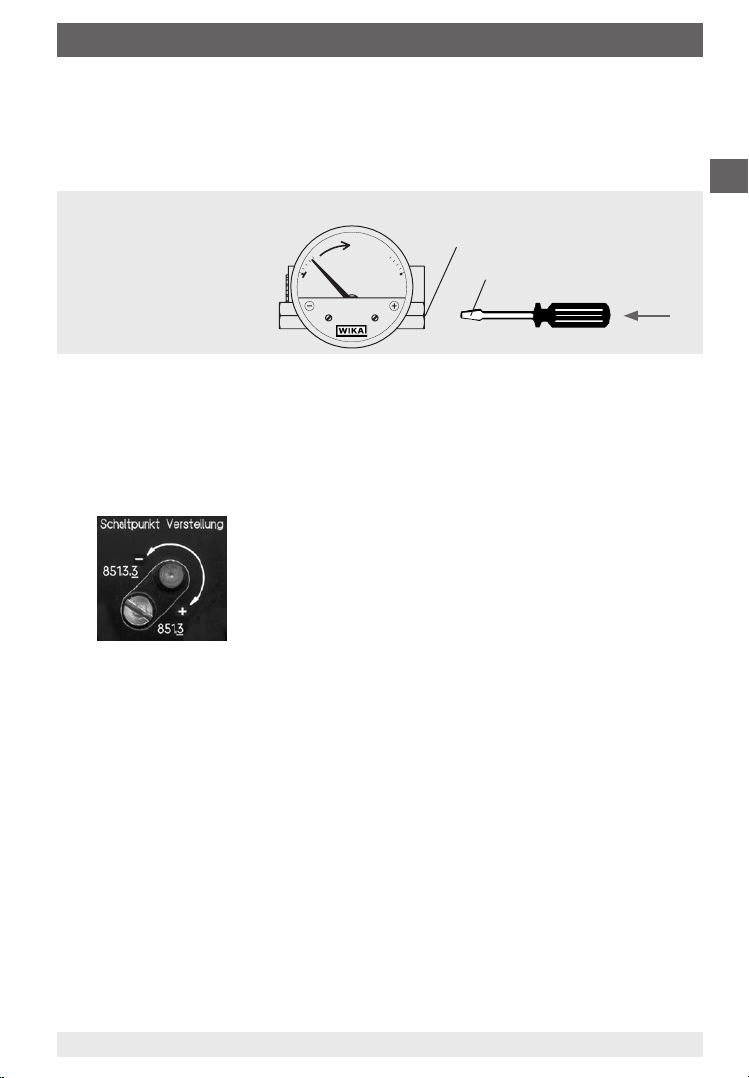

Switch point adjustment

Preference should be given to setting the switch point before installing the

measuring instrument. The necessary test path is generated manually (e.g. by

means of an antimagnetic screwdriver).

Manual test path generation

Plus media chamber

antimagnetic

The switch point can also be set in a pressurised condition after installation. The

switch points are set at the factory when the set points are given.

The switch point is adjusted by turning the contact adjustment screws on the

outside of the reed case.

Anticlockwise rotation:

Switch point can be moved in the direction of the

start of the measuring range

Clockwise rotation:

Switch point can be moved in the direction of the

end of the measuring range

GB

Zero point check

In general, the zero point should only be checked and adjusted at zero pressure.

The system fastening lug on the back of the case can be easily slackened o for

zero point correction of the pressure gauge. Now the zero point can be readjusted

by moving the measuring system to the right or left. After this has been done the

measuring system is to be secured again with the mounting screw (recommended

tightening torque of the mounting screw 1.3 Nm).

2103869.04 12/2012 GB/D/F/E

WIKA operating instructions dierential pressure gauge with piston 11

Page 12

8. Maintenance and cleaning / 9. Dismounting and disposal

8. Maintenance and cleaning

8.1 Maintenance

The instruments are maintenance-free.

GB

The dierential pressure gauges with piston oer long service life provided they

are handled and operated properly.

Checks should be carried out on a regular basis to ensure the measuring

accuracy of the pressure gauge.

Repairs must only be carried out by the manufacturer or appropriately qualied

skilled personnel.

8.2 Cleaning

CAUTION!

■

Clean the pressure gauge with a moist cloth.

■

Wash or clean the dismounted pressure gauge before returning it, in order to protect persons and the environment from

exposure to residual media.

9. Dismounting and disposal

WARNING!

Residual media in dismounted pressure gauges can result in a

risk to persons, the environment and equipment. Take sucient

precautionary measures.

9.1 Dismounting

Only disconnect the pressure gauge once the system has been depressurised!

9.2 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an

environmentally compatible way and in accordance with the country-specic

waste disposal regulations.

12

WIKA operating instructions dierential pressure gauge with piston

2103869.04 12/2012 GB/D/F/E

Page 13

Inhalt

Inhalt

1. Allgemeines 14

2. Sicherheit 15

3. Technische Daten 17

4. Aufbau und Funktion 17

5. Optionen und Zubehör 18

6. Transport, Verpackung und Lagerung 19

7. Inbetriebnahme, Betrieb 19

8. Wartung und Reinigung 22

9. Demontage und Entsorgung 22

D

2103869.04 12/2012 GB/D/F/E

13WIKA Betriebsanleitung Kolben-Dierenzdruckmessgerät

Page 14

1. Allgemeines

1. Allgemeines

Das in der Betriebsanleitung beschriebene Dierenzdruckmessgerät wird nach

den neuesten Erkenntnissen konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitätsund Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und

ISO 14001 zertiziert.

D

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem

Dierenzdruckmessgerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung

aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

Die für den Einsatzbereich des Dierenzdruckmessgerätes geltenden örtlichen

Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen

einhalten.

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe

des Druckmessgerätes für das Fachpersonal jederzeit zugänglich aufbewahrt

werden.

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige

Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend

qualizierten Fachpersonals sowie eigenmächtiger Veränderung am

Dierenzdruckmessgerät.

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

Technische Änderungen vorbehalten.

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: PM 07.14

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die

zum Tod oder zu schweren Verletzungen führen kann, wenn sie

nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen

für einen ezienten und störungsfreien Betrieb hervor.

WIKA Betriebsanleitung Kolben-Dierenzdruckmessgerät14

2103869.04 12/2012 GB/D/F/E

Page 15

2. Sicherheit

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass

das richtige Druckmessgerät hinsichtlich Messbereich, Ausführung und spezischen Messbedingungen ausgewählt wurde.

Auswahl- und Einbauempfehlungen für Druckmessgeräte nach

EN 837-2 beachten.

Verträglichkeit der druckbelasteten Werkstoe mit dem

Messsto prüfen!

Die Belastungsgrenzen sind einzuhalten, um die Messgenauigkeit und die Lebensdauer zu gewährleisten.

Bei Nichtbeachten können schwere Körperverletzungen und/

oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den

einzelnen Kapiteln dieser Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Diese Dierenzdruckmessgeräte dienen zur Überwachung von Dierenzdrücken

bei industriellen Anwendungen.

Das Dierenzdruckmessgerät ist ausschließlich für den hier beschriebenen

bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf

nur dementsprechend verwendet werden.

D

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung

sind ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und

Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur

durch Fachpersonal nachfolgend beschriebener Qualikation

durchführen lassen.

2103869.04 12/2012 GB/D/F/E

15WIKA Betriebsanleitung Kolben-Dierenzdruckmessgerät

Page 16

2. Sicherheit

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse

der Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der

landesspezischen Vorschriften, geltenden Normen und Richtlinien in der Lage,

die beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig

zu erkennen.

D

2.3 Besondere Gefahren

WARNUNG!

Messstoreste in ausgebauten Druckmessgeräten können zur

Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

2.5 Beschilderung / Sicherheitskennzeichnungen

Typenschild (bei Option Reed-Kontakt)

Model 700.02.080 Cont 851.3

MAX. LASTDATEN / CONTACT RATING

Pmax AC/DC 3 W

Umax AC/DC 30 V

Imax AC/DC 0,2 A

E-Nr./Prod-No: 1234567 12/2010

UL-Nr: E103299

CSA-Nr: LR57810

⊖ left

⊕ right

1234567

Symbolerklärung

Vor Montage und Inbetriebnahme des Druckmessgerätes

unbedingt die Betriebsanleitung lesen!

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den

zutreenden europäischen Richtlinien.

Herstellungsdatum

2103869.04 12/2012 GB/D/F/E

WIKA Betriebsanleitung Kolben-Dierenzdruckmessgerät16

Page 17

3. Technische Daten / 4. Aufbau und Funktion

3. Technische Daten

Technische Daten Typ 700.01 Typ 700.02

Nenngröße 80

Anzeigegenauigkeit ± 3 % vom Skalenendwert bei

ansteigendem Dierenzdruck

Anzeigebereiche 0 … 400 mbar bis 0 … 10 bar 0 … 160 mbar bis 0 … 2,5 bar

Max. Betriebsdruck

(statischer Druck)

Überlastbarkeit ein-, beid- und wechselseitig bis zum maximalen Betriebsdruck

Schutzart lP 54 (EN 60529 / lEC 529)

Messkammer mit

Druckanschluss

(messstoberührt)

wahlweise 100, 250 oder

400 bar

(Ausnahme bei Typ 700.02, Anzeigebereiche 0 ... 160 mbar und

0 ... 250 mbar: Überlastbarkeit bis 50 bar)

CrNi-Stahl 1.4571, 2 x G ¼ Innengewinde, rechts und links

seitlich, gegenüberliegend (EN 837-1 /7.3)

± 5 % vom Skalenendwert bei

ansteigendem Dierenzdruck

100 bar

(Anzeigebereiche 0 ... 160 mbar

und 0 ... 250 mbar: 50 bar)

Weitere technische Daten siehe WIKA Datenblatt PM 07.14 und

Bestellunterlagen.

4. Aufbau und Funktion

Beschreibung

In den ⊕- und ⊖- Messstokammern herrschen die Drücke p

durch den druckbeaufschlagten Magnetkolben (bzw. Magnetkolben und

Trennmembrane bei Typ 700.02).

und p2, getrennt

1

D

Die Druckdierenz verursacht eine axiale Bewegung (Messweg) des Kolbens,

der sich gegen die Messbereichsfeder abstützt.

Der sich daraus ergebende Messweg wird von einem auf dem Instrumentenzeiger bendlichen Ringmagneten abgegrien und zur Anzeige gebracht. Dieser

konstruktive Aufbau verbindet den Vorteil einer vollständigen Trennung von

Messsystem und Anzeige und verhindert jegliche Leckage nach außen.

Der Volumenstrom von der ⊕- zur ⊖- Messstokammer bei Typ 700.01 ist

aufgrund des konstruktiven Aufbaus minimal und in Regelanwendungen nicht

störend.

Bewährte Anwendungen/Einsatzgebiete sind Gas- und Luftversorgung und deren

Aufbereitung, in denen keine magnetischen Partikel enthalten sind.

2103869.04 12/2012 GB/D/F/E

17WIKA Betriebsanleitung Kolben-Dierenzdruckmessgerät

Page 18

5. Optionen und Zubehör

Benden sich Schwebekörper im Prozess sollte der Typ 700.02 eingesetzt

werden.

Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

D

5. Optionen und Zubehör

5.1 Befestigungsrand (nur bei Typ 700.01, siehe Darstellung links)

Nach Bedarf vor Ort nachrüstbar.

Ausrichten des Frontringes (A) über eingeprägte Nocken zu am Gehäuseumfang

bendlichen Nuten. Frontring auf Gehäuse bis zum Einschnappen aufschieben.

5.2 Minimum- bzw. Maximum-Schleppzeiger (siehe Darstellungen)

Schleppzeiger (B) dient zur Überwachung und Kontrolle des minimalen bzw.

maximalen aufgetretenen Dierenzdruckes.

5.3 Reed-Kontakt Typ 851.3 und 851.3.3 (siehe Darstellungen)

Nach Bedarf vor Ort nachrüst- und einstellbar.

Befestigung erfolgt über zwei im Reedgehäuse (C) integrierte Schrauben (D) am

Anzeigegehäuse mit dem dazugehörigen Innengewinde.

C

D

A

C

D

B

B

WIKA Betriebsanleitung Kolben-Dierenzdruckmessgerät18

2103869.04 12/2012 GB/D/F/E

Page 19

6. Transport, Verpackung und Lagerung / 7. Inbetriebnahme ...

6. Transport, Verpackung und Lagerung

5.1 Transport

Druckmessgerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

6.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen

optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

6.3 Lagerung

Zulässige Bedingungen am Lagerort

Lagertemperatur: -20 ... +70 °C (optional: -40 … +70 °C)

7. Inbetriebnahme, Betrieb

Mechanischer Anschluss

Die Montage des Dierenzdruckmessgerätes erfolgt in Anlehnung an die Einbauempfehlungen für Druckmessgeräte nach EN 837-2 /7.

Montage des Prozessanschlusses nach angebrachten Symbolen ⊕ und ⊖

⊕ hoher Druck, ⊖ niedriger Druck

D

■

Bei Montage mittels Schraubenschlüssel SW 17 an den Anschlussstücken

gegenhalten (Einschrauben ohne gegenhalten kann zur Lockerung des

Messsystems führen).

■

Maximale zulässige Messsto-/Umgebungstemperatur darf nicht überschritten

werden

■

Messleitungen vor der Gerätemontage gründlich durch Abklopfen und

Ausblasen oder Durchspülen reinigen

■

Messgeräte sollen erschütterungsfrei montiert und betrieben werden

■

Messgeräte sollen vor Verschmutzung und starken Temperaturschwankungen

geschützt sein

Um Fremdkörper im Messsystem und somit eine Beschädigung desselben zu

vermeiden, ist das Druckmessgerät oberhalb des Entnahmestutzens anzubringen.

Für schwebekörperhaltige Messstoe ist der Typ 700.02 vorzusehen.

2103869.04 12/2012 GB/D/F/E

19WIKA Betriebsanleitung Kolben-Dierenzdruckmessgerät

Page 20

7. Inbetriebnahme, Betrieb

Ist die Leitung zum Druckmessgerät für eine erschütterungsfreie Anbringung nicht

stabil genug, so ist die Befestigung über entsprechende Befestigungselemente für

Wandmontage oder ggf. über eine Kapillare vorzunehmen.

Montage an Wand (siehe Zeichnung)

Anbringung/Befestigung mittels Messgerätehalter

D

Sechskantschraube

M8 x 50 (M8 x 100)

Schleppzeiger

Elektrischer Anschluss

ohne Reedkontakt

mit Reedkontakt

Schlitzschraube M4 x 10

Stecker

Reedgehäuse

(bei Geräten mit elektrischen Zusatzeinrichtungen)

Der elektrische Anschluss des Druckmessgerätes wird über Kabeldose und Kabel

hergestellt. Die genauen Anschlussbelegungen können dem nachfolgenden

Anschlussschema entnommen werden. Zusätzlich sind Anschlussbelegung und

erforderliche Hilfsenergie auf dem Typenschild des Reedgehäuses vermerkt.

Elektrisches Anschlussschema

Reed-Kontakt Typ 851.3 und 851.3.3

(Wechsler)

In den Geräten sind

keine Überstrom-Schutz-

851.3. 3

2. Kontakt

einrichtungen eingebaut.

Falls Schutzeinrichtungen

gefordert werden, sind

851. 3

1. Kontakt

Kabeldose

WIKA Betriebsanleitung Kolben-Dierenzdruckmessgerät20

diese extern vorzusehen.

1581007.02

2103869.04 12/2012 GB/D/F/E

Page 21

7. Inbetriebnahme, Betrieb

Schaltpunkteinstellung

Vorzugsweise erfolgt die Schaltpunkteinstellung vor dem Einbau des

Messgerätes. Der erforderliche Prüfweg wird manuell (z. B. mit Hilfe eines

nicht magnetischen Schraubendrehers) erzeugt.

Manuelle Prüfwegerzeugung

Plusmessstokammer

antimagnetisch

Die Schaltpunkteinstellung kann auch im druckbeaufschlagten Zustand nach

Einbau erfolgen. Bei Angabe der Sollwerte werden werkseitig die Schaltpunkte

eingestellt.

Die Verstellung des Schaltpunktes erfolgt durch Drehen der Kontakt-Einstellschrauben an der Reed-Gehäuseaußenseite.

Drehrichtung links:

Schaltpunkt lässt sich in Richtung

Messbereichsanfang verschieben

Drehrichtung rechts:

Schaltpunkt lässt sich in Richtung

Messbereichs

ende verschieben

D

Nullpunktprüfung

Im Allgemeinen erfolgt die Überprüfung und Einstellung des Nullpunktes im

drucklosen Zustand. Für die Nullpunktkorrektur des Druckmessgerätes ist

die Systembefestigungslasche an der Gehäuserückseite leicht zu lösen. Der

Nullpunkt lässt sich nun durch Verschieben des Messsystems nach rechts

oder links nachjustieren. Anschließend ist das Messsystem wieder mit der

Befestigungsschraube (empfohlenes Anzugsmoment der Befestigungsschraube

1,3 Nm) zu xieren.

2103869.04 12/2012 GB/D/F/E

21WIKA Betriebsanleitung Kolben-Dierenzdruckmessgerät

Page 22

8. Wartung und Reinigung / 9. Demontage und Entsorgung

8. Wartung und Reinigung

8.1 Wartung

Die Geräte sind wartungsfrei.

Bei sachgemäßer Behandlung und Bedienung zeichnen sich die Kolben-Die-

renzdruckmessgeräte durch eine hohe Lebensdauer aus.

D

Die Messgenauigkeit des Druckmessgerätes sollte durch regelmäßige Prüfungen

sichergestellt werden.

Reparaturen sind ausschließlich vom Hersteller oder entsprechend qualiziertem

Fachpersonal durchzuführen.

8.2 Reinigung

VORSICHT!

■

Das Druckmessgerät mit einem feuchten Tuch reinigen.

■

Ausgebautes Druckmessgerät vor der Rücksendung spülen

bzw. säubern, um Personen und Umwelt vor Gefährdung durch

anhaftende Messstoreste zu schützen.

9. Demontage und Entsorgung

WARNUNG!

Messstoreste in ausgebauten Druckmessgeräten können

zur Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

9.1 Demontage

Druckmessgerät nur im drucklosen Zustand demontieren!

9.2 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht

entsorgen.

WIKA Betriebsanleitung Kolben-Dierenzdruckmessgerät22

2103869.04 12/2012 GB/D/F/E

Page 23

Sommaire

Sommaire

1. Généralités 24

2. Sécurité 25

3. Caractéristiques techniques 27

4. Conception et fonction 27

5. Options et accessoires 28

6. Transport, emballage et stockage 29

7. Mise en service, exploitation 29

8. Entretien et nettoyage 32

9. Démontage et mise au rebut 32

F

2103869.04 12/2012 GB/D/F/E

WIKA mode d'emploi manomètre pour pression diérentielle avec piston 23

Page 24

1. Généralités

1. Généralités

Le manomètre de pression diérentielle décrit dans le mode d'emploi est conçu

et fabriqué selon les dernières technologies en vigueur. Tous les composants

sont soumis à des critères de qualité et d'environnement stricts durant la

fabrication. Nos systèmes de gestion sont certiés selon ISO 9001 et ISO 14001.

Ce mode d'emploi donne des indications importantes concernant l'utilisation du

manomètre de pression diérentielle. Il est possible de travailler en toute sécurité

avec ce produit en respectant toutes les consignes de sécurité et d'utilisation.

F

Respecter les prescriptions locales de prévention contre les accidents et les

prescriptions générales de sécurité en vigueur pour le domaine d‘application du

manomètre de pression diérentielle.

Le mode d'emploi fait partie de l'appareil et doit être conservé à proximité

immédiate du manomètre et accessible à tout moment pour le personnel qualié.

Le personnel qualié doit, avant de commencer toute opération, avoir lu

soigneusement et compris le mode d'emploi.

La responsabilité du fabricant n'est pas engagée en cas de dommages

provoqués par une utilisation non conforme à l'usage prévu, de non respect de

ce mode d'emploi, d'utilisation de personnel peu qualié de même qu'en cas de

modications du manomètre de pression diérentielle eectuées par l'utilisateur.

Les conditions générales de vente mentionnées dans les documents de vente

s'appliquent.

Sous réserve de modications techniques.

Pour obtenir d'autres informations :

- Consulter notre site internet : www.wika.fr

- Fiche technique correspondante : PM 07.14

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles

de provoquer la mort ou des blessures graves si elle n'est pas

évitée.

Information

… met en exergue les conseils et recommandations utiles de

même que les informations permettant d'assurer un fonctionnement ecace et normal.

WIKA mode d'emploi manomètre pour pression diérentielle avec piston24

2103869.04 12/2012 GB/D/F/E

Page 25

2. Sécurité

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement,

s'assurer que le manomètre a été choisi de façon adéquate, en

ce qui concerne la plage de mesure, la version et les conditions

de mesure spéciques.

Respecter les recommandations de sélection et d'installation

pour les manomètres conformément à la norme EN 837-2.

Vérier si les matériaux soumis à la pression sont compatibles

avec le uide de mesure !

Les limites de surpression admissible sont à respecter an

d'assurer la précision et la durée de vie.

Un non-respect de cette consigne peut entraîner des blessures

corporelles graves et/ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les sections

individuelles du présent mode d'emploi.

2.1 Utilisation conforme à l'emploi prévu

Les manomètres diérentiels sont utilisés pour visualiser les pressions diérentielles dans des applications industrielles.

F

Le manomètre de pression diérentielle est conçu et construit exclusivement

pour une utilisation conforme à l'usage prévu décrit ici et ne doit être utilisé qu'en

conséquence.

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à

l'usage prévu.

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants

dommages corporels et matériels.

■

Les opérations décrites dans ce mode d'emploi ne doivent

être eectuées que par un personnel ayant la qualication

décrite ci-après.

2103869.04 12/2012 GB/D/F/E

WIKA mode d'emploi manomètre pour pression diérentielle avec piston 25

Page 26

2. Sécurité

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses connaissances dans le domaine de la technique de mesure et de régulation et de ses

expériences de même que de sa connaissance des prescriptions nationales des

normes et directives en vigueur, en mesure d'eectuer les travaux décrits et de

reconnaître automatiquement les dangers potentiels.

2.3 Dangers particuliers

F

AVERTISSEMENT !

Les substances résiduelles dans les manomètres démontés

peuvent occasionner un risque pour les personnes,

l'environnement et l'équipement. Prendre des mesures de

sécurité susantes.

2.5 Etiquetage / Marquages de sécurité

Plaque signalétique (avec l'option contact reed)

Model 700.02.080 Cont 851.3

MAX. LASTDATEN / CONTACT RATING

Pmax AC/DC 3 W

Umax AC/DC 30 V

Imax AC/DC 0.2 A

E-Nr./Prod-No: 1234567 12/2010

Explication des symboles

Avant de monter et mettre le manomètre en service, lire impérativement le mode d'emploi !

CE, Communauté Européenne

Les appareils avec ce marquage sont conformes aux directives

européennes pertinentes.

UL-Nr: E103299

CSA-Nr: LR57810

⊖ left

⊕ right

1234567

Date de fabrication

WIKA mode d'emploi manomètre pour pression diérentielle avec piston26

2103869.04 12/2012 GB/D/F/E

Page 27

3. Caractéristiques techniques / 4. Conception et fonction

3. Caractéristiques techniques

Caractéristiques

techniques

Diamètre 80

Classe de précision ± 3 % de la valeur de pleine

Echelles de mesure 0 … 400 mbar à 0 … 10 bar 0 … 160 mbar à 0 … 2,5 bar

Pression de service

max.

(pression statique)

Sécurité contre la

surpression

Indice de protection lP 54 (EN 60529 / lEC 529)

Chambre de mesure

avec raccord de

pression (en contact)

Type 700.01 Type 700.02

± 5 % de la valeur de pleine

échelle avec augmentation de

la pression diérentielle

en option, 100, 250 ou 400 bar 100 bar (échelles de mesure

de chaque côté de la pression de service maximale (exception pour le type 700.02, échelles de mesure 0 ... 160 mbar et

0 ... 250 mbar : sécurité contre la surpression jusqu'à 50 bar)

Acier inoxydable 1.4571, 2 x letage G ¼ femelle, côtés droit et

gauche, en ligne (EN 837-1 /7.3)

échelle avec augmentation de

la pression diérentielle

0 ... 160 mbar et 0 ... 250 mbar:

50 bar)

Pour de plus amples spécications, voir la che technique WIKA PM 07.14 et la

documentation de commande.

4. Conception et fonction

Description

Dans les chambres de mesure de uide ⊕ et ⊖ il y a les pressions p

séparées par le piston magnétique sous charge (ou piston magnétique et

membrane de séparation pour le type 700.02).

et p2,

1

F

La diérence de pression provoque un déplacement axial (chemin de mesure) du

piston s‘appuyant contre le ressort de l‘étendue de mesure.

Le chemin de mesure en résultant est prélevé par un aimant torique se trouvant

sur l‘aiguille de l‘instrument et est ainsi aché. Ce montage associe l‘avantage

d‘une séparation intégrale entre le système de mesure et l‘achage et empêche

toute fuite à l‘extérieur.

Le débit du volume de la chambre de mesure ⊕ à la chambre⊖ est, pour le type

700.01 en raison de sa construction minime et non gênant en utilisation normale.

Des utilisations/domaines d‘applications éprouvées sont les alimentations en gaz

et en air ne contenant aucune particule magnétique.

2103869.04 12/2012 GB/D/F/E

WIKA mode d'emploi manomètre pour pression diérentielle avec piston 27

Page 28

5. Options et accessoires

Il faut utiliser le type 700.02 si des matières en suspension se trouvent dans le

processus.

Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

5. Options et accessoires

5.1 Bride de montage (uniquement pour le type 700.01, voir illustration de

F

gauche)

Peut être réajustée sur site le cas échéant.

Aligner les ergots empreints de la collerette (A) aux rainures sur la circonférence

du boîtier. Enfoncer la collerette jusqu‘à l‘encliquetage.

5.2 Aiguille suiveuse minimum ou maximum (voir illustrations)

L'aiguille suiveuse (B) permet une visualisation et un contrôle de la pression

diérentielle minimale ou maximale présente.

5.3 Contact reed type 851.3 et 851.3.3 (voir illustrations)

Peuvent être réajustés sur site le cas échéant.

À l'aide de deux vis (D) intégrées dans le boîtier du reed (C), la xation s'eectue

sur le boîtier d'achage via les taraudages correspondants.

C

D

A

C

D

B

B

WIKA mode d'emploi manomètre pour pression diérentielle avec piston28

2103869.04 12/2012 GB/D/F/E

Page 29

6. Transport, emballage et stockage / 7. Mise en service ...

6. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur le manomètre liés au transport. Communiquer

immédiatement les dégâts constatés.

6.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection optimale

(par ex. changement de lieu d'utilisation, renvoi pour réparation).

6.3 Stockage

Conditions admissibles sur le lieu de stockage :

Température de stockage : -20 ... +70 °C (en option : -40 … +70 °C)

7. Mise en service, exploitation

Raccordement mécanique

L'installation du manomètre de pression diérentielle s'eectue d'après les

recommandations d'installation pour les manomètres conformément à la norme

EN 837-2 /7.

Monter le raccordement process conformément aux symboles apposés ⊕ et ⊖

⊕ haute pression, ⊖ basse pression

F

■

Lors du montage maintenir les raccords sur l‘appareil au moyen d‘une

clé à fourche de 17 (un vissage sans cette précaution peut conduire à un

desserrement du système de mesure).

■

La température admissible pour le uide/l‘ambiance ne doit pas être dépassée

■

Avant d'installer le manomètre, nettoyer les conduites de mesure en tapant et

en souant ou en rinçant

■

Monter et utiliser les instruments de mesure de manière à ce qu'ils ne soient

pas soumis à des vibrations

■

Protégez les instruments de mesure contre la contamination et les variations

de température élevées

An d'éviter toute pénétration de corps étrangers dans le système de mesure

et tout dommage qui peut en résulter pour le système, monter le manomètre

au-dessus du raccord. Pour la mesure de uide contenant des particules en

suspension, utiliser le type 700.02.

2103869.04 12/2012 GB/D/F/E

WIKA mode d'emploi manomètre pour pression diérentielle avec piston 29

Page 30

7. Mise en service, exploitation

Au cas où le tuyau raccordant le manomètre ne serait pas susamment stable

pour une xation exempte de vibrations, il faut eectuer la xation à l‘aide

d‘éléments pour installation sur paroi ou, le cas échéant, par l‘intermédiaire d‘un

tube capillaire.

Montage sur paroi (voir dessin)

Installation / xation à l'aide d'étriers

F

sans contact de reed

avec contact de reed

Aiguille suiveuse

Vis à tête fendue M4 x 10

Connecteur

Boîtier de reed

Boulon hexagonal

M8 x 50 (M8 x 100)

1581007,02

Raccords électriques (pour des instruments avec accessoires électrique)

Le raccord électrique du manomètre est eectué par une boîte de jonction et des

câbles. Le groupement exact des raccords est montré dans le schéma de branchement suivant. En outre, le groupement des raccords et l’énergie auxiliaire sont

marqués sur la plaque signalétique du boîtier de reed.

Schéma de raccordement électrique

Contact reed type 851.3 et 851.3.3

(contact inverseur)

Aucun dispositif de

protection de surtension

851,3. 3

2ème contact

n‘est installé dans les

instruments. Au cas où

des dispositifs de protec-

851. 3

1er contact

Boîte de jonction

WIKA mode d'emploi manomètre pour pression diérentielle avec piston30

tion sont exigés, ceux-ci

sont à prévoir à l‘extérieur.

2103869.04 12/2012 GB/D/F/E

Page 31

7. Mise en service, exploitation

Réglage du point de commutation

De préférence, le réglage du point de commutation doit se faire avant le montage

de l‘instrument. Le contrôle du déplacement se fait manuellement (par exemple à

l‘aide d‘un tournevis non magnétique).

Réalisation du contrôle de déplacement manuel

Chambre du uide positive

antimagnétique

Le réglage du point de commutation peut aussi être fait sous pression, après le

montage. Sous indication des valeurs de consigne, les points de commutation

sont réglés en usine.

Le réglage se fait en tournant les vis de réglage de commutation du contact à

l‘extérieur du boîtier de reed.

Rotation antihoraire :

Le point de commutation peut être déplacé en

direction du début de l‘étendue de mesure

Rotation horaire :

Le point de commutation se déplace en direction

de la n de l‘étendue de mesure

F

Contrôle du zéro

En général, le contrôle et le réglage du zéro se font sans pression. Pour corriger

le zéro, il faut légèrement dévisser l’éclisse de xation du système à l’arrière du

boîtier. Maintenant le zéro peut être corrigé en déplaçant le système de mesure à

gauche ou à droite. Ensuite le système de mesure doit être xé de nouveau avec la

vis de xation (couple de serrage recommandé de la vis de xation 1,3 Nm).

2103869.04 12/2012 GB/D/F/E

WIKA mode d'emploi manomètre pour pression diérentielle avec piston 31

Page 32

8. Entretien et nettoyage / Démontage et mise au rebut

8. Entretien et nettoyage

8.1 Entretien

Les instruments ne requièrent aucun entretien.

S‘ils sont manipulés et utilisés correctement, les instruments ne requièrent

aucune maintenance et se distinguent par une longue durée de vie.

Procéder aux contrôles à intervalles réguliers de manière à garantir la précision

de mesure du manomètre.

F

Les réparations doivent être eectuées exclusivement par le fabricant ou par un

personnel qualié.

8.2 Nettoyage

ATTENTION !

■

Nettoyer le manomètre avec un chion humide.

■

Laver ou nettoyer le manomètre démonté avant de le retourner

an de protéger les collaborateurs et l‘environnement contre le

danger lié aux restes de uides adhérents.

9. Démontage et mise au rebut

AVERTISSEMENT !

Les restes de uides se trouvant dans des manomètres démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation. Prendre des mesures de

sécurité susantes.

9.1 Démontage

Déconnecter le manomètre uniquement une fois que le système a été mis hors

pression.

9.2 Mise au rebut

Une mise au rebut inadéquate peut entraîner des dangers pour l'environnement.

Éliminer les composants des appareils et les matériaux d'emballage

conformément aux prescriptions nationales pour le traitement et l'élimination des

déchets et aux lois de protection de l'environnement en vigueur.

WIKA mode d'emploi manomètre pour pression diérentielle avec piston32

2103869.04 12/2012 GB/D/F/E

Page 33

Contenido

Contenido

1. Información general 34

2. Seguridad 35

3. Datos técnicos 37

4. Diseño y función 37

5. Opciones y accesorios 38

6. Transporte, embalaje y almacenamiento 39

7. Puesta en servicio, funcionamiento 39

8. Mantenimiento y limpieza 42

9. Desmontaje y eliminación 42

E

2103869.04 12/2012 GB/D/F/E

WIKA manual de instrucciones manómetro diferencial con pistón 33

Page 34

1. Información general

1. Información general

El manómetro diferencial descrito en el manual de instrucciones está construido

y fabricado según los conocimientos actuales. Todos los componentes están

sujetos a criterios rígidos de calidad y medio ambiente durante la producción.

Nuestros sistemas de gestión están certicados según ISO 9001 e ISO 14001.

Este manual de instrucciones proporciona indicaciones importantes acerca del

manejo del manómetro diferencial. Para un trabajo seguro es imprescindible

cumplir con todas las instrucciones de seguridad y manejo indicadas.

Cumplir normativas sobre la prevención de accidentes y las normas de seguridad

en vigor en el lugar de utilización del manómetro diferencial.

El manual de instrucciones es una parte integrante del manómetro y debe

guardarse en la proximidad del mismo para que el personal especializado pueda

E

consultarlo en cualquier momento.

El personal especializado debe haber leído y entendido el manual de

instrucciones antes de comenzar cualquier trabajo.

El fabricante queda exento de cualquier responsabilidad en caso de daños

causados por un uso no conforme a la nalidad prevista, la inobservancia del

presente manual de instrucciones, un manejo por personal insucientemente

cualicado así como una modicación no autorizada del manómetro diferencial.

Se aplican las condiciones generales de venta incluidas en la documentación de

venta.

Modicaciones técnicas reservadas.

Para obtener más informaciones consultar:

- Página web: www.wika.es

- Hoja técnica correspondiente: PM 07.14

Explicación de símbolos

¡ADVERTENCIA!

… indica una situación probablemente peligrosa que pueda

causar la muerte o lesiones graves si no se evita.

Información

... marca consejos y recomendaciones útiles así como

informaciones para una utilización ecaz y libre de fallos.

WIKA manual de instrucciones manómetro diferencial con pistón34

2103869.04 12/2012 GB/D/F/E

Page 35

2. Seguridad

2. Seguridad

¡ADVERTENCIA!

Antes del montaje, la puesta en servicio y el funcionamiento

asegurarse de que se haya seleccionado el manómetro

adecuado con respecto a rango de medida, versión y

condiciones de medición especícas.

Observar las recomendaciones relativas a la selección y al

montaje para manómetros según EN 837-2.

¡Asegúrese de que los productos bajo presión sean aptos para

el material de medición!

Para garantizar la precisión de medición y la durabilidad del

instrumento, se deberán respetar los límites de carga.

El no respetar las instrucciones puede generar lesiones graves

y/o daños materiales.

Los capítulos de este manual de instrucciones contienen otras

importantes indicaciones de seguridad.

2.1 Uso conforme a lo previsto

Los manómetros diferenciales sirven para monitorizar las presiones diferenciales

en aplicaciones industriales.

E

El manómetro diferencial ha sido diseñado y construido únicamente para la

nalidad aquí descrita y debe utilizarse en conformidad a la misma.

No se admite ninguna reclamación debido a una utilización no conforme a lo

previsto.

2.2 Cualicación del personal

¡ADVERTENCIA!

¡Riesgo de lesiones debido a una insuciente

cualicación!

Un manejo no adecuado puede causar considerables daños

personales y materiales.

■

Las actividades descritas en este manual de instrucciones

deben realizarse únicamente por personal especializado con

la consiguiente cualicación.

2103869.04 12/2012 GB/D/F/E

WIKA manual de instrucciones manómetro diferencial con pistón 35

Page 36

2. Seguridad

Personal especializado

Debido a su formación profesional, a sus conocimientos de la técnica de regulación y medición así como a su experiencia y su conocimiento de las normativas,

normas y directivas vigentes en el país de utilización el personal especializado es

capaz de ejecutar los trabajos descritos y reconocer posibles peligros por sí solo.

2.3 Riesgos especícos

¡ADVERTENCIA!

Restos de medios en manómetros desmontados pueden crear

riesgos para personas, medio ambiente e instalación. Tomar

adecuadas medidas de precaución.

2.5 Rótulos / Marcados de seguridad

E

Placa indicadora (con opción contacto Reed)

Model 700.02.080 Cont 851.3

MAX. LASTDATEN / CONTACT RATING

Pmax AC/DC 3 W

Umax AC/DC 30 V

Imax AC/DC 0,2 A

E-Nr./Prod-No: 1234567 12/2010

UL-Nr: E103299

CSA-Nr: LR57810

⊖ left

⊕ right

1234567

Explicación de símbolos

¡Es absolutamente necesario leer el manual de instrucciones

antes del montaje y la puesta en servicio del manómetro!

CE, Communauté Européenne

Los instrumentos con este marcaje cumplen las directivas

europeas aplicables.

WIKA manual de instrucciones manómetro diferencial con pistón36

Fecha de fabricación

2103869.04 12/2012 GB/D/F/E

Page 37

3. Datos técnicos / 4. Diseño y función

3. Datos técnicos

Datos técnicos Modelo 700.01 Modelo 700.02

Diámetro nominal 80

Precisión de

indicación

Rangos de indicación 0 … 400 mbar a 0 … 10 bar 0 … 160 mbar a 0 … 2,5 bar

Presión de trabajo

máx.

(presión estática)

Protección contra la

sobrepresión

Tipo de protección lP 54 (EN 60529 / lEC 529)

Cámara de medición

con conexión (en

contacto con el medio)

± 3 % del valor de escala con

presión diferencial subiendo

seleccionable 100, 250 ó

400 bar

un lado dos lados y alternantes hasta la presión de servicio máx.

(excepto modelo 700.02, rango de indicación 0 ... 160 mbar y

0 ... 250 mbar: resistencia contra sobrecarga hasta 50 bar)

Acero CrNi 1.4571, 2 x G ¼ rosca hembra, derecha e izquierda

lateral, en lado opuesto (EN 837-1 /7.3)

± 5 % del calor de escala con

presión diferencial subiendo

100 bar (Rangos de indicación

0 ... 160 mbar y 0 ... 250 mbar:

50 bar)

Para más datos técnicos véase la hoja técnica de WIKA PM 07.14 y la

documentación de pedido.

4. Diseño y función

E

Descripción

Las cámaras de medio de medida ⊕ y ⊖ tienen las presiones p

y p2, separa-

1

dos por el pistón magnético, sometido a presión o pistón y membrana en el

modelo 700.02.

Diferencia de presión, provocada por un movimiento axial (trayecto de medida)

del pistón apoyado al muelle del rango de medida.

El imán circular en la aguja toma el trayecto de medida resultante y lo visualiza.

Ese diseño combina las ventajas de la separación total del sistema de medición

y de la indicación e impide el escape hacia fuera.

El caudal que se produce desde la cámara ⊕ hacia ⊖ es mímimo en el modelo

700.01 debido a su forma constructiva y no perturba las aplicaciones habituales.

Los campos de aplicación típicos son la alimentación de gas y aire y la preparación de los mismos sin partículas magnéticas.

2103869.04 12/2012 GB/D/F/E

WIKA manual de instrucciones manómetro diferencial con pistón 37

Page 38

5. Opciones y accesorios

Utilizar el modelo 700.02 si hay partículas en suspensión en el proceso.

Volumen de suministro

Comprobar mediante el albarán si se ha entregado la totalidad de las piezas.

5. Opciones y accesorios

5.1 Borde (sólo con modelo 700.01, véase la ilustración a la izquierda)

Puede reequiparse in situ.

Alinear el anillo frontal (A) insertando los salientes en las ranuras de la caja.

Empujar el anillo frontal hasta que enganche en la caja.

5.2 Indicador de seguimiento para MÍN y MÁX (véase las ilustraciones)

E

El indicador de seguimiento (B) sirve para monitorizar y controlar la presión

diferencial mínima y máxima.

5.3 Contacto Reed modelos 851.3 y 851.3.3 (véase las ilustraciones)

Puede reequiparse y ajustarse in situ.

Los contactos se jan a través de dos tornillos (D) integrados en la caja Reed (C)

a la caja del indicador con las roscas hembra correspondientes.

C

D

A

C

D

B

B

WIKA manual de instrucciones manómetro diferencial con pistón38

2103869.04 12/2012 GB/D/F/E

Page 39

6. Transporte, embalaje y almacenamiento / 7. Puesta en servicio ...

6. Transporte, embalaje y almacenamiento

5.1 Transporte

Comprobar si el manómetro presenta eventuales daños causados en el

transporte. Noticar daños obvios de forma inmediata.

6.2 Embalaje

No quitar el embalaje hasta justo antes del montaje.

Guardar el embalaje porque es la protección ideal durante el transporte (por

ejemplo si el lugar de instalación cambia o si se envía el instrumento para

posibles reparaciones).

6.3 Almacenamiento

Condiciones admisibles en el lugar de almacenamiento

Temperatura de almacenamiento: -20 ... +70 °C (opcional: -40 … +70 °C)

7. Puesta en servicio, funcionamiento

La conexión mecánica

El manómetro diferencial se instala según las recomendaciones relativas al

montaje para manómetros según EN 837-2 /7.

Montaje de la conexión a proceso según símbolos indicados, ⊕ y ⊖

⊕ presión alta, ⊖ presión baja

E

■

Para el montaje utilizar una llave (ancho de llave 17) para retener los

conectores (si se atornillan sin mantener los conectores puede ser que se

suelte el sistema de medición).

■

No debe excederse la temperatura de la sustancia a medir/ambiente máx.

admisible

■

Antes de montar el instrumento, sacudir o limpiar con aire comprimido o agua

las líneas de medición

■

Los dispositivos de medición deben montarse y operarse de modo libre de

vibraciones.

■

Proteger los dispositivos de medición contra la obturación, las grandes

oscilaciones de temperatura y las vibraciones

El manómetro debe montarse por encima del racor de toma para evitar que

cuerpos ajenos entren en el sistema de medición y dañen el instrumento. Para los

medios con partículas en suspensión se debe utilizar el modelo 700.02.

2103869.04 12/2012 GB/D/F/E

WIKA manual de instrucciones manómetro diferencial con pistón 39

Page 40

7. Puesta en servicio, funcionamiento

Si el soporte conductor hacia el manómetro no es sucientemente estable para

proteger contra sacudidas, hay que jar el manómetro mediante elementos de

jación adecuados para el montaje en la pared, si fuera necesario, a través de un

capilar.

Montaje en la pared (véase el dibujo)

Montaje/jación mediante soporte de instrumento

Sin contacto Reed

Con contacto Reed

Aguja de arrastre

E

Tornillo de cabeza ranurada

M4 x 10

Clavija

Caja Reed

Tornillo de cabeza

hexagonal

M8 x 50 (M8 x 100)

1581007.02

Conexión eléctrica

(para instrumentos con dispositivos eléctricos adicionales)

La conexión eléctrica del manómetro se realiza a través de una caja de cables y

un cable. Los detalles del conexionado pueden verse en el esquema de conexión

siguiente. Los detalles del conexionado y la alimentación auxiliar necesaria se

encuentran también en la placa indicadora de la caja Reed.

Esquema de conexión eléctrica

Contacto Reed modelo 851.3 y 851.3.3

(inversor)

Los instrumentos no

incluyen dispositivos de

851.3. 3

2o contacto

seguridad contra sobrecorriente. Si se necesitan

dispositivos de seguridad

WIKA manual de instrucciones manómetro diferencial con pistón40

851. 3

1º contacto

Caja de cables

hay que utilizar dispositivos exteriores.

2103869.04 12/2012 GB/D/F/E

Page 41

7. Puesta en servicio, funcionamiento

Ajuste del punto de interrupción

El punto de interrupción se ajusta preferentemente antes de instalar el dispositivo

de medición. El trayecto de prueba necesario se genera manualmente (p. ej. con

un destornillador antimagnético).

Generación manual del trayecto de prueba

Cámara de sustancia a medir positiva

Antimagnético

El punto de interrupción puede ajustarse también después del montaje en estado

a presión. Los puntos de interrupción pueden ajustarse en fábrica si se indican

los valores nominales.

El punto de interrupción puede cambiarse girando los tornillos de ajuste del

contacto en el exterior de la caja Reed.

Rotación hacia la izquierda:

El punto de interrupción se desplaza en dirección

del inicio del rango de medida

Rotación hacia la derecha:

El punto de interrupción se desplaza en dirección

del

nal del rango de medida

Control del punto cero

El control y ajuste del punto cero deberá efectuarse sin someter el instrumento

a presión. Para ajustar el punto cero del manómetro hay que soltar la oreja de

jación del sistema en el lado posterior de la caja. El punto cero puede ajustarse

deplazando el sistema de medición hacia la derecha o la izquierda. Fijar otra vez

el sistema de medición con el tornillo de jación (par de apriete recomendado del

tornillo de jación 1,3 Nm).

E

2103869.04 12/2012 GB/D/F/E

WIKA manual de instrucciones manómetro diferencial con pistón 41

Page 42

8. Mantenimiento y limpieza / 9. Desmontaje y eliminación

8. Mantenimiento y limpieza

8.1 Mantenimiento

Los instrumentos no requieren mantenimiento.

Los manómetros diferenciales con pistón no necesitan mantenimiento y

se distinguen por su prolongada vida útil si se manejan y operan de forma

apropiada.

Mediante comprobaciones periódicas se debe asegurar la precisión de medición

de los manómetros.

Todas las reparaciones solamente las debe efectuar el fabricante o personal

especializado e instruido.

8.2 Limpieza

E

¡CUIDADO!

■

Limpiar el manómetro con un trapo húmedo.

■

Lavar o limpiar el manómetro desmontado antes de devolverlo

para proteger a los empleados y el medio ambiente de los

peligros causados por restos de medios.

9. Desmontaje y eliminación

¡ADVERTENCIA!

Restos de medios en manómetros desmontados pueden crear

riesgos para personas, medio ambiente e instalación. Tomar

adecuadas medidas de precaución.

9.1 Desmontaje

¡Desmontar el manómetro sólo si no está sometido a presión!

9.2 Eliminación de residuos

Una eliminación incorrecta puede provocar peligros para el medio ambiente.

Eliminar los componentes de los instrumentos y los materiales de embalaje

conforme a los reglamentos relativos al tratamiento de residuos y eliminación

vigentes en el país de utilización.

WIKA manual de instrucciones manómetro diferencial con pistón42

2103869.04 12/2012 GB/D/F/E

Page 43

WIKA global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand GmbH & Co. KG

1230 Vienna

Tel. (+43) 1 86916-31

Fax: (+43) 1 86916-34

E-mail: info@wika.at

www.wika.at

Belarus

WIKA Belarus

Ul. Zaharova 50B

Oce 3H

220088 Minsk

Tel. (+375) 17-294 57 11

Fax: (+375) 17-294 57 11

E-mail: info@wika.by

www.wika.by

Benelux

WIKA Benelux

6101 WX Echt

Tel. (+31) 475 535-500

Fax: (+31) 475 535-446

E-mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

Bul. „Al. Stamboliiski“ 205

1309 Soa

Tel. (+359) 2 82138-10

Fax: (+359) 2 82138-13

E-mail: info@wika.bg

www.wika.bg

Croatia

WIKA Croatia d.o.o.

Hrastovicka 19

10250 Zagreb-Lucko

Tel. (+385) 1 6531034

Fax: (+385) 1 6531357

E-mail: info@wika.hr

www.wika.hr

Finland

WIKA Finland Oy

00210 Helsinki

Tel. (+358) 9-682 49 20

Fax: (+358) 9-682 49 270

E-mail: info@wika.

www.wika.

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Tel. (+33) 1 343084-84

Fax: (+33) 1 343084-94

E-mail: info@wika.fr

www.wika.fr

Germany

WIKA Alexander Wiegand

SE & Co. KG

63911 Klingenberg

Tel. (+49) 9372 132-0

Fax: (+49) 9372 132-406

E-mail: info@wika.de

www.wika.de

2103869.04 12/2012 GB/D/F/E

Italy

WIKA Italia Srl & C. Sas

20020 Arese (Milano)

Tel. (+39) 02 9386-11

Fax: (+39) 02 9386-174

E-mail: info@wika.it

www.wika.it

Poland

WIKA Polska spółka z ograniczoną

odpowiedzialnością sp. k.

ul. Legska 29/35

87-800 Wloclawek

Tel. (+48) 542 3011-00

Fax: (+48) 542 3011-01

E-mail: info@wikapolska.pl

www.wikapolska.pl

Romania

WIKA Instruments Romania S.R.L.

Bucuresti, Sector 5

Calea Rahovei Nr. 266-268

Corp 61, Etaj 1

Tel. (+40) 21 4048327

Fax: (+40) 21 4563137

E-mail: m.anghel@wika.ro

www.wika.ro

Russia

ZAO WIKA MERA

127015 Moscow

Tel. (+7) 495-648 01 80

Fax: (+7) 495-648 01 81

E-mail: info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

Sime Solaje 15

11060 Belgrade

Tel. (+381) 11 2763722

Fax: (+381) 11 753674

E-mail: info@wika.rs

www.wika.rs

Spain

Instrumentos WIKA, S.A.

C/Josep Carner, 11-17

08205 Sabadell (Barcelona)

Tel. (+34) 933 938630

Fax: (+34) 933 938666

E-mail: info@wika.es

www.wika.es

Switzerland

MANOMETER AG

6285 Hitzkirch

Tel. (+41) 41 91972-72

Fax: (+41) 41 91972-73

E-mail: info@manometer.ch

www.manometer.ch

Turkey

WIKA Instruments Istanbul

Basinc ve Sicaklik Ölcme Cihazlari

Bayraktar Bulvari No. 17

34775 Şerifali-Yukarı Dudullu - Istanbul

Tel. (+90) 216 41590-66

Fax: (+90) 216 41590-97

E-mail: info@wika.com.tr

www.wika.com.tr

Ukraine

TOV WIKA Prylad

M. Raskovoy Str. 11, A

PO 200

02660 Kyiv

Tel. (+38) 044 496-8380

Fax: (+38) 044 496-8380

E-mail: info@wika.ua

www.wika.ua

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill RH13LG

Tel. (+44) 1737 644-008

Fax: (+44) 1737 644-403

E-mail: info@wika.co.uk

www.wika.co.uk

North America

Canada

WIKA Instruments Ltd.

Head Oce

Edmonton, Alberta, T6N 1C8

Tel. (+1) 780 46370-35

Fax: (+1) 780 46200-17

E-mail: info@wika.ca

www.wika.ca

Mexico

Instrumentos WIKA Mexico

S.A. de C.V.

06600 Mexico D.F.

Tel. (+52) 55 50205300

Fax: (+52) 55 50205300

E-mail: ventas@wika.com

www.wika.com.mx

USA

WIKA Instrument Corporation

Lawrenceville, GA 30043

Tel. (+1) 770 5138200

Fax: (+1) 770 3385118

E-mail: info@wika.com

www.wika.com

WIKA Instrument Corporation

Houston Facility

950 Hall Court

Deer Park, TX 77536

Tel. (+1) 713-475 0022

Fax: (+1) 713-475 0011

E-mail: info@wikahouston.com

www.wika.com

Mensor Corporation

201 Barnes Drive

San Marcos, TX 78666

Tel. (+1) 512 3964200-15

Fax: (+1) 512 3961820

E-mail: sales@mensor.com

www.mensor.com

43WIKA operating instructions dierential pressure gauge with piston

Page 44

WIKA global

South America

Argentina

WIKA Argentina S.A.

Buenos Aires

Tel. (+54) 11 47301800

Fax: (+54) 11 47610050

E-mail: info@wika.com.ar

www.wika.com.ar

Brazil

WIKA do Brasil Ind. e Com. Ltda.

CEP 18560-000 Iperó - SP

Tel. (+55) 15 34599700

Fax: (+55) 15 32661650

E-mail: vendas@wika.de

www.wika.com.br

Chile

WIKA Chile S.p.A.

Coronel Pereira 72

Ocina 101

Las Condes

Santiago de Chile

Tel. (+56) 2 3651719

E-mail: info@wika.cl

www.wika.cl

Asia

China

WIKA International Trading (Shanghai)

Co., Ltd.

A2615, NO.100, Zunyi Road

Changning District

Shanghai 200051

Tel. (+86) 21 538525-72

Fax: (+86) 21 538525-75

E-mail: info@wika.cn

www. wika.com.cn

WIKA Instrumentation (Suzhou)

Co., Ltd.

81, Ta Yuan Road,

SND, Suzhou 215011

Tel. (+86) 512 68788000

Fax: (+86) 512 68780300

E-mail: info@wika.cn

www. wika.com.cn

India

WIKA Instruments India Pvt. Ltd.

Village Kesnand, Wagholi

Pune - 412 207

Tel. (+91) 20 66293-200

Fax: (+91) 20 66293-325

E-mail: sales@wika.co.in

www.wika.co.in

Japan

WIKA Japan K. K.

Tokyo 105-0023

Tel. (+81) 3 543966-73

Fax: (+81) 3 543966-74

E-mail: info@wika.co.jp

www.wika.co.jp

Kazakhstan

TOO WIKA Kazakhstan

050050 Almaty

Tel. (+7) 727 2330848

Fax: (+7) 727 2789905

E-mail: info@wika.kz

www.wika.kz

Korea

WIKA Korea Ltd.

#569-21 Gasan-dong

Seoul 153-771 Korea

Tel. (+82) 2 869 05 05

Fax: (+82) 2 869 05 25

E-mail: info@wika.co.kr

www.wika.co.kr

Malaysia

WIKA Instrumentation (M) Sdn. Bhd.

47100 Puchong, Selangor

Tel. (+60) 3 80 63 10 80

Fax: (+60) 3 80 63 10 70

E-mail: info@wika.com.my

www.wika.com.my

Singapore

WIKA Instrumentation Pte. Ltd.

569625 Singapore

Tel. (+65) 68 44 55 06

Fax: (+65) 68 44 55 07

E-mail: info@wika.com.sg

www.wika.com.sg

Taiwan

WIKA Instrumentation Taiwan Ltd.

Pinjen, Taoyuan

Tel. (+886) 3 420 6052

Fax: (+886) 3 490 0080

E-mail: info@wika.com.tw

www.wika.com.tw

Thailand

WIKA Instrumentation Corporation

(Thailand) Co., Ltd.

850/7 Ladkrabang Road, Ladkrabang

Bangkok 10520

Tel. (+66) 2 326 6876-80

Fax: (+66) 2 326 6874

E-mail: info@wika.co.th

www.wika.co.th

Further WIKA subsidiaries worldwide can be found online at www.wika.com.

Weitere WIKA-Niederlassungen weltweit nden Sie online unter www.wika.de.

La liste des autres liales WIKA dans le monde se trouve sur www.wika.fr.

Otras sucursales WIKA en todo el mundo puede encontrar en www.wika.es.

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. (+49) 9372/132-0

Fax (+49) 9372/132-406

E-Mail info@wika.de

www.wika.de

44

2103869.04 12/2012 GB/D/F/E

Loading...

Loading...