Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Combined bimetal thermometer, model 54

Kombi-Bimetall-Thermometer, Typ 54

Thermomètre bimétallique combiné, type 54

Termómetro bimetálico combinado, modelo 54

Twin-Temp

Twin-Temp, model 54

GB

D

F

E

Page 2

GB

Operating instructions model 54

Page 3 - 16

D

Betriebsanleitung Typ 54

Mode d'emploi type 54

F

E

Manual de instrucciones modelo 54

© 2011 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions model 54, Twin-Temp

Seite 17 - 30

Page 31 - 44

Página 45 - 58

14004105.01 05/2011 GB/D/F/E

Page 3

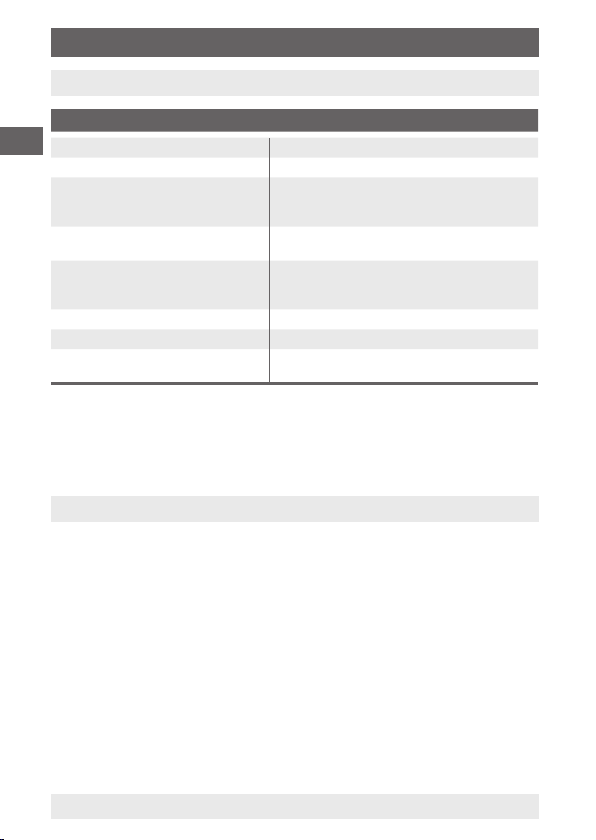

Contents

Contents

1. General information 4

2. Safety 6

3. Specications 8

4. Design and function 8

5. Transport, packaging and storage 9

6. Commissioning, operation 10

7. Maintenance and cleaning 11

8. Faults 12

9. Dismounting, return and disposal 13

10. Accessories 15

GB

14004105.01 05/2011 GB/D/F/E

WIKA operating instructions model 54, Twin-Temp 3

Page 4

1. General information

1. General information

■

The combined bimetal thermometer described in these operating

GB

instructions has been designed and manufactured using state-ofthe-art technology. All components are subject to stringent quality

and environmental criteria during production. Our management

systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on

handling the combined bimetal thermometer. Working safely requires

that all safety instructions and work instructions are observed.

■

Observe the local accident prevention regulations and

general safety regulations, in eect for the combined bimetal

thermometer‘s range of use.

■

The operating instructions are part of the product and must be kept

in the immediate vicinity of the combined bimetal thermometer and

readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the

operating instructions prior to beginning any work.

■

The manufacturer‘s liability is void in the case of any damage

caused by using the product contrary to its intended use,

non-compliance with these operating instructions, assignment

of insuciently qualied skilled personnel or unauthorised

modications to the combined bimetal thermometer.

■

The general terms and conditions contained in the sales

documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: TV 15.01

4 WIKA operating instructions model 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 5

1. General information

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can

result in serious injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can

result in light injuries or damage to equipment or the

environment, if not avoided.

Information

… points out useful tips, recommendations and information for ecient and trouble-free operation.

WARNING!

... indicates a potentially dangerous situation that can

result in burns caused by hot surfaces or liquids if not

avoided.

GB

14004105.01 05/2011 GB/D/F/E

WIKA operating instructions model 54, Twin-Temp 5

Page 6

2. Safety

2. Safety

GB

2.1 Intended use

The combined bimetal thermometer is mainly used in the process

industry to monitor process temperatures.

The combined bimetal thermometer has been designed and built

solely for the intended use described here, and may only be used

accordingly.

The technical specications contained in these operating instructions

must be observed. Improper handling or operation of the combined

bimetal thermometer outside of its technical specications requires

the instrument to be taken out of service immediately and inspected

by an authorised WIKA service engineer.

The manufacturer shall not be liable for claims of any type based on

operation contrary to the intended use.

WARNING!

Before installation, commissioning and operation, ensure

that the appropriate bimetal thermometer has been

selected in terms of measuring range, design and specic

measuring conditions. The compatibility of the wetted

parts of the process connection (thermowell, thermowell

stem) with the medium must be tested.

Non-observance can result in serious injury and/or

damage to the equipment.

Further important safety instructions can be found in the

individual chapters of these operating instructions.

6 WIKA operating instructions model 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 7

2. Safety

2.2 Personnel qualication

WARNING!

Risk of injury if qualication is insucient!

Improper handling can result in considerable injury and

damage to equipment.

■

The activities described in these operating instructions

may only be carried out by skilled personnel who have

the qualications described below.

■

Keep unqualied personnel away from hazardous

areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on

their technical training, knowledge of measurement and control

technology and on their experience and knowledge of countryspecic regulations, current standards and directives, are capable

of carrying out the work described and of independently recognising

potential hazards.

2.3 Special hazards

WARNING!

Residual media in dismounted instruments can result in

a risk to persons, the environment and equipment. Take

sucient precautionary measures.

WARNING!

For lled instruments, make sure that the medium

temperature is lower than 250 °C.

Reason: The sheath also contains a lling liquid; at a

temperature > 250 °C, this liquid may become cloudy or

change colour or, in some cases, may ignite.

GB

14004105.01 05/2011 GB/D/F/E

WIKA operating instructions model 54, Twin-Temp 7

Page 8

3. Specications / 4. Design and function

3. Specications

Specications

GB

Measuring element Bimetal helix and Pt100

Nominal size 63, 80, 100, 160

Instrument version

■

Model A5x

■

Model R5x

Permissible ambient

temperature

Working pressure

■

Continuous load (1 year)

■

short term (max. 24 h)

Case, ring

Stem, process connection

Ingress protection

Model 54, Twin-Temp

Rear mount (axial)

Lower mount (radial)

at the housing max. +60 °C (other versions

on request)

Measuring range (DIN EN 13190)

Scale range (DIN EN 13190)

Stainless steel 1.4301

Stainless steel 1.4571

IP 65 per EN 60529 / IEC 529

IP 66, liquid-lled

For further specications see WIKA data sheet TV 15.01 and the

order documentation.

4. Design and function

4.1 Description

This series of thermometers is designed for installation in pipes,

vessels, plant and machinery.

The „Twin-Temp“ combined bimetal thermometer oers two

measuring systems in one instrument.

A bimetal thermometer enables the visualisation of measured values

on site without power supply, while, in addition, the integrated Pt100

resistance sensor provides an electrical signal for further processing.

This design is particularly recommended for safety-critical applications and in case of limited space where the process can be opened

only at one place.

8 WIKA operating instructions model 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 9

5. Transport, packaging and storage

4.2 Scope of delivery

Cross-check scope of delivery with the delivery note.

5. Transport, packaging and storage

5.1 Transport

Check the instrument for any damage that may have been caused

during transportation.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

Storage temperature: -20 ... +60 °C

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Potentially explosive environments, ammable atmospheres

Store the instrument in its original packaging in a location that fulls

the conditions listed above. If the original packaging is not available,

pack and store the thermometer as described below:

1. Wrap the thermometer in an antistatic plastic lm.

2. Place the thermometer, along with shock-absorbent material, in the

packaging.

3. If stored for a prolonged period of time (more than 30 days), place a

bag containing a desiccant inside the packaging.

GB

14004105.01 05/2011 GB/D/F/E

WIKA operating instructions model 54, Twin-Temp 9

Page 10

6. Commissioning, operation

WARNING!

Before storing the instrument (following operation),

remove any residual media. This is of particular impor-

GB

tance if the medium is hazardous to health, e.g. caustic,

toxic, carcinogenic, radioactive, etc.

The use of liquid damping is always recommended for

temperatures near the dew point (±1 °C around 0 °C).

6. Commissioning, operation

When screwing the instrument in, the force required to do this must

not be applied through the casing, but only through the spanner ats

provided for this purpose and using a suitable tool.

Installation with

spanner

When using thermowells, they must be lled with a thermal contact

medium in order to reduce the heat transfer resistance between the

outer wall of the sensor and the inner wall of the thermowell. The

working temperature of the thermal compound is -40 ... +200 °C.

WARNING!

Do not ll hot thermowells. There is a risk of the oil

spraying out!

10 WIKA operating instructions model 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 11

6. Commissioning, ... / 7. Maintenance and ...

CAUTION!

When using thermowells, please

ensure that the stem does not

touch the bottom of the thermowell

since, due to the dierent

expansion coecients of the

materials, the stem may become

Thermowell

Stem

buckled at the bottom of the

thermowell.

(Formula for the calculation of the

stem length l1 see the respective

thermowell‘s data sheet)

Required safety

clearance

7. Maintenance and cleaning

7.1 Maintenance

The combined bimetal thermometer is maintenance-free!

The indicator should be checked once or twice every year. To do this

the instrument must be disconnected from the process and checked

using a temperature calibrator.

Repairs must only be carried out by the manufacturer.

GB

7.2 Cleaning

CAUTION!

■

Clean the thermometer with a moist cloth.

■

Wash or clean the disconnected thermometer before

returning it in order to protect personnel and the

environment from exposure to residual media.

14004105.01 05/2011 GB/D/F/E

WIKA operating instructions model 54, Twin-Temp 11

Page 12

7. Maintenance and cleaning / 8. Faults

■

Residual media in dismounted instruments can result

in a risk to persons, the environment and equipment.

Take sucient precautionary measures.

GB

For information on returning the instrument see chapter

9.2 "Returns".

8. Faults

Faults Causes Measures

No signal/ line

breakage

Erroneous measured

values

Erroneous measured

values (too low)

Erroneous measured

values and response

times too long

Measurement signal

"comes and goes"

Corrosion

Mechanical load too high

or overtemperature

Sensor drift caused by

overtemperature

Sensor drift caused by

chemical attack

Entry of moisture into

cable or measuring insert

Wrong mounting geometry, for example mounting

depth too deep or heat

dissipation too high

Deposits on the sensor or

thermowell

Cable break in connecting

cable or loose contact

caused by mechanical

overload

Composition of the medium

not as expected or modied

or wrong thermowell

material selected

Replace probe or measuring

insert with a suitable design

Replace probe or measuring

insert with a suitable design

Use a design with

thermowell

Replace probe or measuring

insert with a suitable design

Temperature-sensitive area

of the sensor must be inside

the medium, and surfaces

must be isolated

Remove deposits

Replace probe

Analyse medium and then

select a more-suitable

material or replace

thermowell regularly

12 WIKA operating instructions model 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 13

8. Faults / 9. Dismounting, return, disposal

Signal interference

Stray currents caused

by electric elds or earth

loops

Earth circuits Eliminate potentials, use

Use screened connecting

cables, increase in the

distance to motors and

power lines

galvanically isolated transmitter supply isolators or

transmitters

CAUTION!

If faults cannot be eliminated by means of the measures

listed above, the instrument must be shut down immediately, and it must be ensured that pressure and/or signal

are no longer present, and it must be prevented from being

inadvertently put back into service.

In this case, contact the manufacturer.

If a return is needed, follow the instructions see chapter 9.2

"Return".

9. Dismounting, return and disposal

WARNING!

Residual media in dismounted instruments can result in

a risk to persons, the environment and equipment. Take

sucient precautionary measures.

9.1 Dismounting

WARNING!

Risk of burns!

Let the instrument cool down suciently before

dismounting! During dismounting there is a risk of

dangerously hot pressure media escaping.

GB

14004105.01 05/2011 GB/D/F/E

WIKA operating instructions model 54, Twin-Temp 13

Page 14

9. Dismounting, return and disposal

9.2 Return

WARNING!

GB

When returning the instrument, use the original packaging or a

suitable transport package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with shock-absorbent material, in the

packaging. Place shock-absorbent material evenly on all sides of

the shipping box.

3. If possible, place a bag containing a desiccant inside the

packaging.

4. Label the shipment as carriage of a highly sensitive measuring

instrument.

Enclose the completed return form with the instrument.

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an

environmentally compatible way and in accordance with the countryspecic waste disposal regulations.

Absolutely observe the following when shipping

the instrument: All instruments delivered to WIKA must

be free from any kind of hazardous substances (acids,

leachate, solutions, etc.).

The returns form is available on the internet:

www.wika.de / Service / Return

14 WIKA operating instructions model 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 15

10. Accessories

10. Accessories

Description Order number

ODU Mini Snap, size 0, mating connectors 11015217

ODU Mini Snap, size 0, with 1.5 m PTFE cable 14005534

ODU Mini Snap, size 0, with 3.0 m PTFE cable 14005545

Example

Assembly instruction

Half shells

Case

Solder insert

Crimp insert

EMI ring

Back nut

Collet

Seal ring (optional)

1. Slide back nut, collet and EMI

ring over the cable

GB

2. Strip cable and wire

3. Pre-tinning of strands

recommended

14004105.01 05/2011 GB/D/F/E

WIKA operating instructions model 54, Twin-Temp 15

Page 16

10. Accessories

GB

Half shells

Internal guides

Solder iron

1

4. Solder each wire to the

corresponding contact

5. Bend cable shield outwards,

assemble half shells

6. Slide the EMI ring and collet

against the half shells so that the

shield is clamped between EMI

ring and half shells

7. Put the assembled cable into the

plug-housing, considering the

internal guides.

If needed, secure thread (A) with

locking glue

8. Screw back nut on the plug, hold

against at (1) and fasten with an

open-ended spanner.

Tightening torque: 0.6 Nm

16 WIKA operating instructions model 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 17

Inhalt

Inhalt

1. Allgemeines 18

2. Sicherheit 20

3. Technische Daten 22

4. Aufbau und Funktion 22

5. Transport, Verpackung und Lagerung 23

6. Inbetriebnahme, Betrieb 24

7. Wartung und Reinigung 25

8. Störungen 26

9. Demontage, Rücksendung und Entsorgung 27

10. Zubehör 29

D

14004105.01 05/2011 GB/D/F/E

WIKA Betriebsanleitung Typ 54, Twin-Temp

17

Page 18

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Kombi-BimetallThermometer wird nach den neuesten Erkenntnissen konstruiert

und gefertigt. Alle Komponenten unterliegen während der

D

Fertigung strengen Qualitäts- und Umweltkriterien. Unsere

Managementsysteme sind nach ISO 9001 und ISO 14001

zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit

dem Kombi-Bimetall-Thermometer. Voraussetzung für sicheres

Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise

und Handlungsanweisungen.

■

Die für den Einsatzbereich des Kombi-Bimetall-Thermometers

geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen

Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in

unmittelbarer Nähe des Kombi-Bimetall-Thermometers für das

Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller

Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch

bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten Fachpersonals sowie

eigenmächtiger Veränderung am Kombi-Bimetall-Thermometer.

■

Es gelten die allgemeinen Geschäftsbedingungen in den

Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: TV 15.01

18 WIKA Betriebsanleitung Typ 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 19

1. Allgemeines

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin,

die zum Tod oder zu schweren Verletzungen führen kann,

wenn sie nicht gemieden wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation

hin, die zu geringfügigen oder leichten Verletzungen bzw.

Sach- und Umweltschäden führen kann, wenn sie nicht

gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen ezienten und störungsfreien Betrieb

hervor.

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation

hin, die durch heiße Oberächen oder Flüssigkeiten zu

Verbrennungen führen kann, wenn sie nicht gemieden

wird.

D

14004105.01 05/2011 GB/D/F/E

WIKA Betriebsanleitung Typ 54, Twin-Temp

19

Page 20

2. Sicherheit

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen,

D

2.1 Bestimmungsgemäße Verwendung

Das Kombi-Bimetall-Thermometer wird hauptsächlich in der

Prozessindustrie eingesetzt, um die Temperatur des Prozesses zu

überwachen.

Das Kombi-Bimetall-Thermometer ist ausschließlich für den hier

beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert

und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind

einzuhalten. Eine unsachgemäße Handhabung oder ein Betreiben

des Kombi-Bimetall-Thermometers außerhalb der technischen

Spezikationen macht die sofortige Stilllegung und Überprüfung

durch einen autorisierten WIKA-Servicemitarbeiter erforderlich.

dass das richtige Bimetall-Thermometer hinsichtlich

Messbereich, Ausführung und spezischen Messbedingungen ausgewählt wurde. Die Verträglichkeit der

messstoberührten Bauteile des Prozessanschlusses

(Schutzrohr, Tauchrohr etc.) muss mit dem Messsto

geprüft werden.

Bei Nichtbeachten können schwere Körperverletzungen

und/oder Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den

einzelnen Kapiteln dieser Betriebsanleitung.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer

Verwendung sind ausgeschlossen.

20 WIKA Betriebsanleitung Typ 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 21

2. Sicherheit

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personenund Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen

Tätigkeiten nur durch Fachpersonal nachfolgend

beschriebener Qualikation durchführen lassen.

■

Unqualiziertes Personal von den Gefahrenbereichen

fernhalten.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner

Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen

sowie Kenntnis der landesspezischen Vorschriften, geltenden

Normen und Richtlinien in der Lage, die beschriebenen Arbeiten

auszuführen und mögliche Gefahren selbstständig zu erkennen.

2.3 Besondere Gefahren

WARNUNG!

Messstoreste in ausgebauten Geräten können zur

Gefährdung von Personen, Umwelt und Einrichtung

führen. Ausreichende Vorsichtsmaßnahmen ergreifen.

WARNUNG!

Bei gefüllten Geräten ist darauf zu achten, dass die

Mediumstemperatur unter 250 °C liegt.

Grund: Im Tauchschaft bendet sich auch die

Füllüssigkeit, diese kann sich bei einer Temperatur

>250 °C vertrüben bzw. verfärben und gegebenenfalls

zum Brand führen.

D

14004105.01 05/2011 GB/D/F/E

WIKA Betriebsanleitung Typ 54, Twin-Temp

21

Page 22

3. Technische Daten / 4. Aufbau und Funktion

3. Technische Daten

Technische Daten

Messelement Bimetallwendel und Pt100

Nenngröße 63, 80, 100, 160

D

Geräteausführung

■

Typ A5x

■

Typ R5x

Zulässige

Umgebungstemperatur

Verwendungsbereich

■

Dauerbelastung (1 Jahr)

■

kurzzeitig (max. 24 h)

Gehäuse, Ring

Tauchschaft, Prozessanschluss

Schutzart

Typ 54, Twin-Temp

Anschlusslage rückseitig (axial)

Anschlusslage unten (radial)

am Gehäuse +60 °C max. (andere auf

Anfrage)

Messbereich (DIN EN 13190)

Anzeigebereich (DIN EN 13190)

CrNi-Stahl 1.4301

CrNi-Stahl 1.4571

IP 65 nach EN 60529 / IEC 529

IP 66, üssigkeitsgefüllt

Weitere technische Daten siehe WIKA Datenblatt TV 15.01 und

Bestellunterlagen.

4. Aufbau und Funktion

4.1 Beschreibung

Thermometer dieser Typenreihe sind vorgesehen zum Einbau in

Rohrleitungen, Behälter, Anlagen und Maschinen.

Das Kombi-Bimetall-Thermometer "Twin-Temp" vereint zwei

Messsysteme in einem Gerät.

Ein Bimetall-Thermometer ermöglicht die Visualisierung des

Messwertes vor Ort ohne Hilfsenergie, der integrierte Pt100

Messwiderstand liefert zusätzlich ein elektrisches Signal zur Weiterverarbeitung. Dies empehlt sich besonders bei sicherheitskritischen

Applikationen und bei beschränktem Bauraum, wenn nur eine

Prozessönung verwendet werden kann.

22 WIKA Betriebsanleitung Typ 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 23

4. Aufbau und Funktion / 5. Transport, ...

4.2 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

5. Transport, Verpackung und Lagerung

5.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport

einen optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

Lagertemperatur: -20 ... +60 °C

Folgende Einüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

Das Gerät in der Originalverpackung an einem Ort, der die oben

gelisteten Bedingungen erfüllt, lagern. Wenn die Originalverpackung

nicht vorhanden ist, dann das Thermometer wie folgt verpacken und

lagern:

1. Das Thermometer in eine antistatische Plastikfolie einhüllen.

2. Das Thermometer mit dem Dämmmaterial in der Verpackung

platzieren.

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der Verpackung beilegen.

14004105.01 05/2011 GB/D/F/E

WIKA Betriebsanleitung Typ 54, Twin-Temp

D

23

Page 24

5. Transport, ... / 6. Inbetriebnahme, Betrieb

WARNUNG!

Vor der Einlagerung des Gerätes (nach Betrieb) alle

anhaftenden Messstoreste entfernen. Dies ist besonders

wichtig, wenn der Messsto gesundheitsgefährdend ist,

wie z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

D

Empfohlen wird bei Temperaturen um den Taupunkt (±1 °C

um 0 °C) immer die Verwendung einer Flüssigkeitsdämpfung.

6. Inbetriebnahme, Betrieb

Beim Einschrauben des Gerätes darf die dazu erforderliche Kraft

nicht über das Gehäuse aufgebracht werden, sondern mit geeignetem

Werkzeug nur über die dafür vorgesehenen Schlüsselächen.

Montage mit

Gabelschlüssel

Bei Verwendung von Schutzrohren ist möglichst durch Einfüllen eines

Wärmekontaktmittels der Wärmeübertragungswiderstand zwischen

Fühleraußenwand und Schutzrohrinnenwand zu reduzieren. Die

Arbeitstemperatur der Wärmeleitpaste beträgt -40 ... +200 °C.

WARNUNG!

Nicht in heiße Schutzrohre einfüllen. Gefahr durch herausspritzendes Öl!

24 WIKA Betriebsanleitung Typ 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 25

6. Inbetriebnahme, Betrieb / 7. Wartung ...

VORSICHT!

Bei der Verwendung von Schutzrohren beachten, dass der

Tauchschaft nicht den Boden des

Schutzrohres berührt, da durch die

unterschiedlichen Ausdehnungskoezienten der Materialen sich

der Tauchschaft am Boden des

Schutzrohr

Schutzrohres verbiegen könnte.

(Formeln zur Berechnung der

Tauchschaft

Tauchschaftlänge l1 siehe entsprechendes Schutzrohr-Datenblatt)

Benötigter

Sicherheitsabstand

7. Wartung und Reinigung

7.1 Wartung

Das Kombi-Bimetall-Thermometer ist wartungsfrei!

Eine Überprüfung der Anzeige sollte etwa 1 bis 2 mal pro Jahr

erfolgen. Dazu ist das Gerät vom Prozess zu trennen und mit einem

Temperaturkalibrator zu kontrollieren.

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

D

7.2 Reinigung

VORSICHT!

■

Das Thermometer mit einem feuchten Tuch reinigen.

■

Ausgebautes Thermometer vor der Rücksendung

spülen bzw. säubern, um Personen und Umwelt vor

Gefährdung durch anhaftende Messstoreste zu

14004105.01 05/2011 GB/D/F/E

WIKA Betriebsanleitung Typ 54, Twin-Temp

schützen.

25

Page 26

7. Wartung und Reinigung / 8. Störungen

■

Messstoreste in ausgebauten Geräten können zur

Gefährdung von Personen, Umwelt und Einrichtung

führen. Ausreichende Vorsichtsmaßnahmen ergreifen.

Hinweise zur Rücksendung des Gerätes siehe Kapitel

D

9.2 „Rücksendung“.

8. Störungen

Störungen Ursachen Maßnahmen

Kein Signal/

Leitungsbruch

Fehlerhafte

Messwerte

Fehlerhafte

Messwerte (zu

gering)

Fehlerhafte

Messwerte und zu

lange Ansprechzeiten

Messsignal

„kommt und geht“

Korrosion

26 WIKA Betriebsanleitung Typ 54, Twin-Temp

zu hohe mechanische

Belastung oder

Übertemperatur

Sensordrift durch

Übertemperatur

Sensordrift durch

chemischen Angri

Feuchtigkeitseintritt an

Kabel oder Messeinsatz

Falsche Einbaugeometrie,

z. B. zu geringe

Einbautiefe oder zu hohe

Wärmeableitung

Ablagerungen auf dem

Sensor oder Schutzrohr

Leitungsbruch im

Anschlusskabel

oder Wackelkontakt

durch mechanische

Überbelastung

Zusammensetzung

des Mediums nicht wie

angenommen oder

geändert oder falsches

Schutzrohrmaterial gewählt

Fühler oder Messeinsatz durch

eine geeignete Ausführung

ersetzen

Fühler oder Messeinsatz durch

eine geeignete Ausführung

ersetzen

Ausführung mit Schutzrohr

verwenden

Fühler oder Messeinsatz durch

eine geeignete Ausführung

ersetzen

Temperaturempndlicher

Bereich des Sensors muss

innerhalb des Mediums liegen,

Oberächenmessungen

müssen isoliert sein

Ablagerungen entfernen

Fühler ersetzen

Medium analysieren und

danach besser geeignetes

Material wählen oder

Schutzrohr regelmäßig

erneuern

14004105.01 05/2011 GB/D/F/E

Page 27

8. Störungen / 9. Demontage, Rücksendung ...

Signal gestört

Einstreuung durch

elektrische Felder oder

Erdschleifen

Erdschleifen Potentialen beseitigen, galva-

Geschirmte Anschlussleitungen verwenden, Abstand zu

Motoren und leistungsführenden Leitungen erhöhen

nisch getrennte Speisetrenner

oder Transmitter verwenden

VORSICHT!

Können Störungen mit Hilfe der oben aufgeführten

Maßnahmen nicht beseitigt werden, ist das Gerät unverzüglich außer Betrieb zu setzen, sicherzustellen, dass kein

Druck bzw. Signal mehr anliegt und gegen versehentliche

Inbetriebnahme zu schützen.

In diesem Falle Kontakt mit dem Hersteller aufnehmen.

Bei notwendiger Rücksendung die Hinweise siehe Kapitel

9.2 „Rücksendung“ beachten.

9. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste in ausgebauten Geräten können zur

Gefährdung von Personen, Umwelt und Einrichtung

führen. Ausreichende Vorsichtsmaßnahmen ergreifen.

9.1 Demontage

WARNUNG!

Verbrennungsgefahr!

Vor dem Ausbau das Gerät ausreichend abkühlen lassen!

Beim Ausbau besteht Gefahr durch austretende, gefährlich heiße Messstoe.

D

14004105.01 05/2011 GB/D/F/E

WIKA Betriebsanleitung Typ 54, Twin-Temp

27

Page 28

9. Demontage, Rücksendung und Entsorgung

9.2 Rücksendung

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahr-

D

Zur Rücksendung des Gerätes die Originalverpackung oder eine

geeignete Transportverpackung verwenden.

Um Schäden zu vermeiden:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

3. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung

beifügen.

4. Sendung als Transport eines hochempndlichen Messgerätes

kennzeichnen.

Dem Gerät das Rücksendeformular ausgefüllt beifügen.

9.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den

landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften

umweltgerecht entsorgen.

stoen (Säuren, Laugen, Lösungen, etc.) sein.

Das Rücksendeformular steht im Internet zur Verfügung:

www.wika.de / Service / Rücksendung

28 WIKA Betriebsanleitung Typ 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 29

10. Zubehör

10. Zubehör

Bezeichnung Bestellnummer

ODU Mini Snap, Größe 0, Gegenstecker 11015217

ODU Mini Snap, Größe 0, mit 1,5 m PTFE-Kabel 14005534

ODU Mini Snap, Größe 0, mit 3,0 m PTFE-Kabel 14005545

Beispiel

Montageanleitung

D

Halbschalen

Gehäuse

Löteinsatz

14004105.01 05/2011 GB/D/F/E

WIKA Betriebsanleitung Typ 54, Twin-Temp

Crimpeinsatz

Spannmutter

Spannzange

Schirmring Stützscheibe (optional)

1. Spannmutter, Spannzange

und Schirmring über das Kabel

schieben

2. Kabel und Leiter abisolieren

3. Vorzugsweise Adern verzinnen

29

Page 30

10. Zubehör

Lötkolben

4. Litze nach Nummerierung in

Kontakte löten

D

5. Schirm aufspreizen, Halbschalen

im Einsatz einhängen

Halbschalen

6. Schirmring und Spannzange

gegen die Halbschalen schieben,

so dass der Schirm zwischen

Schirmring und Halbschalen

eingeklemmt wird

Führungen

1

7. Das montierte Kabel unter

Beachtung der Führungen in das

Steckergehäuse schieben.

Gewinde (A) ggf. mit Sicherungskleber benetzen

8. Spannmutter auf den montierten

Stecker schrauben, an Fläche

(1) gegenhalten und mit einem

Gabelschlüssel anziehen.

Anzugsdrehmoment: 0,6 Nm

30 WIKA Betriebsanleitung Typ 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 31

Sommaire

Sommaire

1. Généralités 32

2. Sécurité 34

3. Spécications 36

4. Conception et fonction 36

5. Transport, emballage et stockage 37

6. Mise en service, exploitation 38

7. Entretien et nettoyage 39

8. Dysfonctionnements 40

9. Démontage, retour et mise au rebut 41

10. Accessoires 43

F

14004105.01 05/2011 GB/D/F/E

WIKA mode d'emploi type 54, Twin-Temp

31

Page 32

1. Généralités

1. Généralités

■

Le thermomètre bimétallique combiné décrit dans le mode

d'emploi est conçu et fabriqué selon les dernières technologies en

vigueur. Tous les composants sont soumis à des critères de qualité

et d'environnement stricts durant la fabrication. Nos systèmes de

gestion sont certiés selon ISO 9001 et ISO 14001.

F

■

Ce mode d'emploi donne des indications importantes concernant

l'utilisation du thermomètre bimétallique combiné. Il est possible de

travailler en toute sécurité avec ce produit en respectant toutes les

consignes de sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les

accidents et les prescriptions générales de sécurité en vigueur

pour le domaine d'application du thermomètre bimétallique

combiné.

■

Le mode d'emploi fait partie du produit et doit être conservé à

proximité immédiate du thermomètre bimétallique combiné d'air et

accessible à tout moment pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération,

avoir lu soigneusement et compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de

dommages provoqués par une utilisation non conforme à l'usage

prévu, de non respect de ce mode d'emploi, d'utilisation de

personnel peu qualié de même qu'en cas de modications du

thermomètre bimétallique combiné.

■

Les conditions générales de vente mentionnées dans les

documents de vente s‘appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site internet : www.wika.fr

- Fiche technique correspondante : TV 15.01

32 WIKA mode d'emploi type 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 33

1. Généralités

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques

susceptibles de provoquer la mort ou des blessures

graves si elle n'est pas évitée.

ATTENTION !

… indique une situation potentiellement dangereuse et

susceptible de provoquer de légères blessures ou des

dommages matériels et pour l'environnement si elle n'est

pas évitée.

Information

… met en exergue les conseils et recommandations utiles

de même que les informations permettant d'assurer un

fonctionnement ecace et normal.

AVERTISSEMENT !

… indique une situation présentant des risques

susceptibles de provoquer des brûlures dues à des

surfaces ou liquides chauds si elle n'est pas évitée.

14004105.01 05/2011 GB/D/F/E

WIKA mode d'emploi type 54, Twin-Temp

F

33

Page 34

2. Sécurité

2. Sécurité

AVERTISSEMENT!

Avant le montage, la mise en service et le fonctionnement,

s'assurer que le thermomètre bimétallique a été choisi de

façon adéquate, en ce qui concerne la plage de mesure,

F

2.1 Utilisation conforme à l'usage prévu

Le thermomètre bimétallique combiné est principalement utilisé dans

l'industrie du process pour surveiller la température du process.

Le thermomètre bimétallique combiné est conçu et construit

exclusivement pour une utilisation conforme à l'usage prévu décrit ici

et ne doit être utilisé qu'en conséquence.

Les spécications techniques mentionnées dans ce mode d'emploi

doivent être respectées. En cas d'utilisation inadéquate ou de

fonctionnement du thermomètre bimétallique combiné en dehors

des spécications techniques, un arrêt et contrôle doivent être

immédiatement eectués par un collaborateur autorisé du service de

WIKA.

la version et les conditions de mesure spéciques. Vérier

si les composants du raccord process en contact avec

le uide (doigt de gant, tube plongeur) sont compatibles

avec le uide de mesure.

Un non-respect de cette consigne peut entraîner des

blessures corporelles graves et/ou des dégâts matériels.

Vous trouverez d'autres consignes de sécurité dans les

sections individuelles du présent mode d'emploi.

Aucune réclamation ne peut être recevable en cas d'utilisation non

conforme à l'usage prévu.

34 WIKA mode d'emploi type 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 35

2. Sécurité

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication

insusante!

Une utilisation non conforme peut entraîner d'importants

dommages corporels et matériels.

■

Les opérations décrites dans ce mode d'emploi ne

doivent être eectuées que par un personnel ayant la

qualication décrite ci-après.

■

Tenir le personnel non qualié à lécart des zones

dangereuses.

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de

ses connaissances dans le domaine de la technique de mesure et de

régulation et de ses expériences de même que de sa connaissance

des prescriptions nationales des normes et directives en vigueur,

en mesure d'eectuer les travaux décrits et de reconnaître

automatiquement les dangers potentiels.

2.3 Dangers particuliers

AVERTISSEMENT !

Les restes de uides se trouvant dans les instruments

démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation. Prendre des

mesures de sécurité susantes.

F

AVERTISSEMENT !

Pour les instruments remplis de liquide, veiller à ce que la

température du uide de mesure ne dépasse pas 250 °C.

Raison: Le liquide se trouvant dans le tube plongeur peut

se troubler ou changer de couleur ou même s‘enammer

si la température dépasse 250 °C.

14004105.01 05/2011 GB/D/F/E

WIKA mode d'emploi type 54, Twin-Temp

35

Page 36

3. Spécications / 4. Conception et fonction

3. Spécications

Spécications

Elément de mesure Hélice bimétallique et Pt100

Diamètre 63, 80, 100, 160

Version de l'appareil

■

Type A5x

F

■

Type R5x

Température ambiante

admissible

Pression de service

■

Fonctionnement continu (1 an)

■

Temporaire (max. 24 h)

Boîtier, anneau

Tube plongeur, raccord process

Indice de protection

Type 54, Twin-Temp

Départ capillaire (axial)

Départ capillaire vertical

sur le boîtier max. +60 °C (autres versions

sur demande)

Etendue de mesure (DIN EN 13190)

Echelle de mesure (DIN EN 13190)

Acier inox 1.4301

Acier inox 1.4571

IP 65 selon EN 60529 / IEC 529

IP 66, rempli de liquide

Pour de plus amples spécications, voir la che technique WIKA

TV 15.01 et la documentation de commande.

4. Conception et fonction

4.1 Description

Les thermomètres bimétalliques de cette série sont conçus pour

l'installation dans des tuyauteries, réservoirs, systèmes ou machines.

Le thermomètre bimétallique combiné "Twin-Temp" ore deux

systèmes de mesure en un seul instrument.

Un thermomètre bimétallique permet de visualiser les valeurs mesurées

sur place sans alimentation, tandis que le capteur de résistance

Pt100 intégré fournit en outre un signal électrique pour la suite du

traitement. Cette conception est particulièrement recommandée pour

les applications de sécurité critiques et en cas d'espace limité où le

processus peut être ouvert seulement à un endroit.

36 WIKA mode d'emploi type 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 37

4. Conception et fonction / 5. Transport, ...

4.2 Détail de la livraison

Comparer le détail de la livraison avec le bordereau de livraison.

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur l'instrument liés au transport.

Communiquer immédiatement les dégâts constatés.

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une

protection optimale (par ex. changement de lieu d'utilisation, renvoi

pour réparation).

5.3 Stockage

Conditions admissibles sur le lieu de stockage :

Température de stockage : -20 ... +60 °C

Eviter les inuences suivantes :

■

Lumière solaire directe ou proximité d'objets chauds

■

Vibrations mécaniques, chocs mécaniques (mouvements

brusques en le posant)

■

Suie, vapeur, poussière et gaz corrosifs

■

Environnement présentant des risques d'explosion, atmosphères

inammables

F

Conserver l'instrument dans l'emballage original dans un endroit qui

satisfait aux conditions susmentionnées. Si l'emballage original n'est

pas disponible, emballer et stocker le thermomètre comme suit :

1. Emballer le thermomètre dans une feuille de plastique antistatique.

2. Placer le thermomètre avec le matériau isolant dans l'emballage.

3. En cas de stockage long (plus de 30 jours), mettre également un

sachet absorbeur d'humidité dans l'emballage.

14004105.01 05/2011 GB/D/F/E

WIKA mode d'emploi type 54, Twin-Temp

37

Page 38

5. Transport, emballage .. / 6. Mise en service ...

AVERTISSEMENT !

Enlever tous les restes de uides adhérents avant

l'entreposage de l'instrument (après le fonctionnement).

Ceci est particulièrement important lorsque le uide

représente un danger pour la santé, comme p. ex.

des substances corrosives, toxiques, carcinogènes,

F

radioactives etc.

Lorsque le thermomètre est utilisé dans une plage de

températures près du point de rosée (±1 °C, près de

0 °C), l'utilisation d'un amortissement par liquide est

recommandée.

6. Mise en service, exploitation

Lors du vissage de l'instrument, le couple de serrage ne doit pas être

appliqué sur le boîtier mais seulement sur les surfaces prévues et ce

avec un outil approprié.

Montage avec

clé à fourche

En cas d'utilisation de doigts de gants, il convient de réduire au

maximum la résistance de transmission de la chaleur entre la paroi

extérieure du capteur et la paroi intérieure du doigt de gant en

ajoutant un agent de contact thermique. La température de service de

la pâte thermique est de -40 ... +200 °C.

AVERTISSEMENT !

Ne pas verser dans des doigts de gant chauds ! Risque

de projection d'huile !

38 WIKA mode d'emploi type 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 39

6. Mise en service, exploitation / 7. Entretien ...

ATTENTION !

Lors de l'utilisation des doigts

de gants, veiller à ce que le tube

plongeur ne touche pas le fond

du doigt de gant, en raison des

diérents coecients d'extension

des matériaux, il y a risque de

déformation du tube plongeur sur le

Gaine

fond du doigt de gant.

(Formules pour le calcul de la

Plongeur

longueur du doigt de gant l

voir la

1

che technique du doigt de gant

Ecart de

sécurité requis

correspondant)

7. Entretien et nettoyage

7.1 Entretien

Le thermomètre bimétallique combiné ne requiert aucun entretien !

Un contrôle de l'achage et des fonctions de commande est

recommandé 1 à 2 fois/an. Pour le contrôle de l'achage et des

fonctions de commande, il faut isoler l'instrument du process et le

contrôler avec un calibrateur de température.

Les réparations ne doivent être eectuées que par le fabricant.

F

14004105.01 05/2011 GB/D/F/E

WIKA mode d'emploi type 54, Twin-Temp

39

Page 40

7. Entretien, nettoyage / 8. Dysfonctionnements

7.2 Nettoyage

ATTENTION !

■

Nettoyer le thermomètre avec un chion humide.

■

Laver ou nettoyer le thermomètre déconnecté avant

de le retourner an de protéger les collaborateurs et

l'environnement contre le danger lié aux restes de

F

uides adhérents.

■

Les restes de uides se trouvant dans les instruments

démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation. Prendre des

mesures de sécurité susantes.

Indications concernant le retour de l'instrument, voir

chapitre 9.2 "Retour".

8. Dysfonctionnements

Dysfonctionne-

Raisons Mesures

ments

Aucun signal/rupture

de ligne

Valeurs mesurées

erronées

Valeurs mesurées

erronées (trop

basses)

Valeurs mesurées

erronées et temps de

réponse trop longs

40 WIKA mode d'emploi type 54, Twin-Temp

Charge mécanique trop

élevée ou température

excessive

Dérive du capteur causée

par une température

excessive

Dérive du capteur causée

par une attaque chimique

Pénétration d'humidité

dans le câble ou l'élément

de mesure

Géométrie de montage

incorrecte, par exemple

profondeur de montage

trop profonde ou dissipation thermique trop élevée

Dépôts sur le capteur ou le

doigt de gant

Remplacer le capteur ou

l'élément de mesure avec

une conception adaptée

Remplacer le capteur ou

l'élément de mesure avec

une conception adaptée

Utiliser une version avec

doigt de gant

Remplacer le capteur ou

l'élément de mesure avec

une conception adaptée

La zone thermosensible

du capteur doit se trouver

dans le uide et les surfaces

doivent être isolées.

Eliminer les dépôts

14004105.01 05/2011 GB/D/F/E

Page 41

8. Dysfonctionnements / 9. Démontage, ...

Signal de mesure

"va-et-vient"

Corrosion

Interférence du signal

Rupture de câble dans le

câble de raccordement ou

contact lâche causé par

une surcharge mécanique

La composition du uide

n'est pas celle exigée ou

est modiée ou un matériau

de doigt de gant incorrect

est sélectionné

Courants vagabonds

provoqués par des

champs électriques ou

des boucles de terre

Circuits de terre Eliminer des potentiels,

Remplacer le capteur

Analyser le uide et

sélectionner ensuite un

matériau mieux adapté ou

remplacer régulièrement le

doigt de gant

Utiliser des câbles de

raccordement blindés,

augmenter la distance par

rapport aux moteurs et

lignes de puissance

utilisation de séparateurs

d'alimentation ou de

transmetteurs séparés

galvaniquement

ATTENTION !

Si des dysfonctionnements ne peuvent pas être éliminés

à l'aide des mesures indiquées ci-dessus, l'instrument

doit être immédiatement mis hors service, il faut s'assurer

qu'aucune pression et/ou qu'aucun signal n'est plus

disponible et le protéger contre toute remise en service

involontaire. Contacter dans ce cas le fabricant.

S'il est nécessaire de retourner l'instrument au fabricant,

respecter les indications mentionnées au chapitre

9.2 "Retour".

9. Démontage, retour et mise au rebut

F

AVERTISSEMENT !

Les restes de uides se trouvant dans les instruments

démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation. Prendre des

14004105.01 05/2011 GB/D/F/E

WIKA mode d'emploi type 54, Twin-Temp

mesures de sécurité susantes.

41

Page 42

9. Démontage, retour et mise au rebut

9.1 Démontage

AVERTISSEMENT !

Danger de brûlure !

Avant le démontage, laisser refroidir susamment

l'instrument ! Danger de brûlure lié à la sortie de uides

dangereux chauds.

F

9.2 Retour

AVERTISSEMENT !

Il faut absolument observer les consignes suivantes

lors de l'expédition de l'instrument : Tous les

instruments envoyés à WIKA doivent être exempts de toute

substance dangereuse (acides, lixiviats, solutions, etc.).

Pour retourner l'instrument, utiliser l'emballage original ou un

emballage adapté pour le transport.

Pour éviter des dommages :

1. Emballer l'instrument dans une feuille de plastique antistatique.

2. Placer l'instrument avec le matériau isolant dans l'emballage. Isoler

de manière uniforme tous les côtés de l'emballage de transport.

3. Mettre si possible un sachet absorbeur d'humidité dans

l'emballage.

4. Indiquer lors de l'envoi qu'il s'agit d'un instrument de mesure très

sensible à transporter.

Joindre le formulaire de retour rempli à l'instrument.

Le formulaire de retour est disponible sur internet :

www.wika.fr / Services / Retour

9.3 Mise au rebut

Une mise au rebut inadéquate peut entraîner des dangers pour

l‘environnement.

Eliminer les composants des instruments et les matériaux

d‘emballage conformément aux prescriptions nationales pour le

traitement et l‘élimination des déchets et aux lois de protection de

l‘environnement en vigueur.

42 WIKA mode d'emploi type 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 43

10. Accessoires

10. Accessoires

Description N° de commande

ODU Mini Snap, taille 0, connecteurs homologues 11015217

ODU Mini Snap, taille 0, avec câble en PTFE de 1,5 m 14005534

ODU Mini Snap, taille 0, avec câble en PTFE de 3,0 m 14005545

Exemple

Instructions de montage

F

Demi-coquilles

Boîtier

Élément à souder

14004105.01 05/2011 GB/D/F/E

WIKA mode d'emploi type 54, Twin-Temp

Élément à sertir

Écrou de blocage

Pince

Bague EMI

Bague d'étanchéité

(option)

1. Glisser l'écrou de blocage, la

pince et la bague EMI sur le câble

2. Dénuder le câble et le l

3. Pré-étamage recommandé des

conducteurs

43

Page 44

10. Accessoires

Fer à souder

F

4. Souder chaque l au contact

correspondant

5. Plier le blindage de câble vers

l'extérieur, monter les demi-

Demi-coquilles

coquilles

6. Faire glisser la bague EMI et la

pince contre les demi-coquilles,

de manière à ce que le blindage

soit serré entre la bague EMI et

les demi-coquilles

Guides internes

7. Placer le câble assemblé dans

le boîtier connecteur en tenant

compte des guides internes.

Si nécessaire, sécuriser le let

(A) avec une colle de xation

1

8. Visser l'écrou de blocage sur le

connecteur, maintenir contre le

plat (1) et xer avec une clé plate.

Couple de serrage : 0,6 Nm

44 WIKA mode d'emploi type 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 45

Contenido

Contenido

1. Información general 46

2. Seguridad 48

3. Datos técnicos 50

4. Diseño y función 50

5. Transporte, embalaje y almacenamiento 51

6. Puesta en servicio, funcionamiento 52

7. Mantenimiento y limpieza 53

8. Fallos 54

9. Desmontaje, devolución y eliminación 55

10. Accesorios 57

E

14004105.01 05/2011 GB/D/F/E

WIKA manual de instrucciones modelo 54, Twin-Temp

45

Page 46

1. Información general

1. Información general

■

El termómetro bimetálico combinado descrito en el manual de

instrucciones está construido y fabricado según los conocimientos

actuales. Todos los componentes están sujetos a criterios rígidos

de calidad y medio ambiente en el proceso de la producción.

Nuestros sistemas de gestión están certicados según ISO 9001

e ISO 14001.

■

Este manual de instrucciones proporciona indicaciones

E

importantes acerca del manejo del termómetro bimetálico

combinado. Para que el trabajo con este instrumento sea

seguro es imprescindible cumplir con todas las instrucciones de

seguridad y manejo indicadas.

■

Cumplir siempre las normativas sobre la prevención de accidentes

y las normas de seguridad en vigor en el lugar de utilización del

termómetro bimetálico combinado.

■

El manual de instrucciones es una parte integrante del instrumento

y debe guardarse en la proximidad del termómetro bimetálico

combinado para que el personal especializado pueda consultarlo

en cualquier momento.

■

El personal especializado debe haber leído y entendido el manual

de instrucciones antes de comenzar cualquier trabajo.

■

El fabricante queda exento de cualquier responsabilidad en caso

de daños causados por un uso no conforme a la nalidad prevista,

la inobservancia del presente manual de instrucciones, un

manejo por personal insucientemente cualicado así como una

modicación no autorizada del termómetro bimetálico combinado.

■

Se aplican las condiciones generales de venta incluidas en la

documentación de venta.

■

Modicaciones técnicas reservadas.

■

Para obtener más informaciones consultar:

- Página web: www.wika.es

- Hoja técnica correspondiente: TV 15.01

46 WIKA manual de instrucciones modelo 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 47

1. Información general

Explicación de símbolos

¡ADVERTENCIA!

... indica una situación probablemente peligrosa que

pueda causar la muerte o lesiones graves si no se evita.

¡CUIDADO!

... indica una situación probablemente peligrosa que

pueda causar lesiones leves o medianas o daños

materiales y medioambientales si no se evita.

Información

... destaca consejos y recomendaciones útiles así como

informaciones para una utilización ecaz y libre de fallos.

¡ADVERTENCIA!

... indica una situación probablemente peligrosa que

pueda causar quemaduras debido a supercies o líquidos

calientes, si no se evita.

E

14004105.01 05/2011 GB/D/F/E

WIKA manual de instrucciones modelo 54, Twin-Temp

47

Page 48

2. Seguridad

2. Seguridad

¡ADVERTENCIA!

Antes de proceder con el montaje, la puesta en

servicio y el funcionamiento asegurarse de que se haya

seleccionado el termómetro bimetálico adecuado en

relación con rango de medida, versión y condiciones

de medición especícas. Hay que controlar si los

E

2.1 Uso conforme a lo previsto

El termómetro bimetálico combinado se utiliza principalmente en la

industria de procesos para supervisar la temperatura del proceso.

El termómetro bimetálico combinado ha sido diseñado y construido

únicamente para la nalidad aquí descrita y debe utilizarse en

conformidad a la misma.

Cumplir las especicaciones técnicas de este manual de

instrucciones. Un manejo no apropiado o una utilización del

termómetro bimetálico combinado no conforme a las especicaciones

técnicas requiere la inmediata puesta fuera de servicio y la

comprobación por parte de un técnico autorizado por WIKA.

componentes en contacto con el uido de la conexión a

proceso (vaina, bulbo, etc.) son compatibles con el uido.

El no respetar las instrucciones puede generar lesiones

graves y/o daños materiales.

Los distintos capítulos de este manual de instrucciones

contienen otras importantes indicaciones de seguridad.

No se admite ninguna reclamación debido a un manejo inadecuado.

48 WIKA manual de instrucciones modelo 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 49

2. Seguridad

2.2 Cualicación del personal

¡ADVERTENCIA!

¡Riesgo de lesiones debido a una insuciente

cualicación!

Un manejo no adecuado puede causar considerables

daños personales y materiales.

■

Las actividades descritas en este manual de

instrucciones deben realizarse únicamente por

personal especializado con la consiguiente

cualicación.

■

Mantener alejado a personal no cualicado de las

zonas peligrosas.

Personal especializado

Debido a su formación profesional, a sus conocimientos de la

técnica de regulación y medición así como a su experiencia y su

conocimiento de las normativas, normas y directivas vigentes en el

país de utilización el personal especializado es capaz de ejecutar los

trabajos descritos y reconocer posibles peligros por sí solo.

2.3 Riesgos especícos

¡ADVERTENCIA!

Restos de medios en instrumentos desmontados

pueden causar riesgos para personas, medio ambiente e

instalación. Tomar adecuadas medidas de precaución.

¡ADVERTENCIA!

Hay que asegurarse que los instrumentos llenados

no deben ser expuestos a una temperatura del medio

superior a 250 °C.

Causa: En el bulbo se encuentra el líquido de relleno

que puede enturbiarse o cambiar de color y con una

temperatura > de 250 °C puede provocar eventualmente

un incendio.

14004105.01 05/2011 GB/D/F/E

WIKA manual de instrucciones modelo 54, Twin-Temp

E

49

Page 50

3. Datos técnicos / 4. Diseño, función

3. Datos técnicos

Datos técnicos

Elemento de medición Espiral bimetálica y Pt100

Diámetro nominal 63, 80, 100, 160

Construcción del aparato

■

Modelo A5x

■

Modelo R5x

Temperatura ambiente

E

admisible

Rango de servicio

■

Carga a largo plazo (1 año)

■

A corto plazo (máx. 24 h)

Caja, anillo

Bulbo, conexión a proceso

Tipo de protección

Modelo 54, Twin-Temp

Conexión dorsal (axial)

Conexión inferior (radial)

en la caja +60 °C máx. (otras a petición)

Rango de medida (DIN EN 13190)

Rango de indicación (DIN EN 13190)

Acero inoxidable 1.4301

Acero inoxidable 1.4571

IP 65 según EN 60529 / IEC 529

IP 66, lleno de líquido

Para más datos técnicos véase la hoja técnica de WIKA TV 15.01 y la

documentación de pedido.

4. Diseño y función

4.1 Descripción

Los termómetros de esta serie son adecuados para el uso en tubería,

depósitos, instalaciones y máquinas.

El termómetro bimetálico combinado "Twin-Temp" reúne dos sistemas

de medición en un instrumento.

Un termómetro bimetálico permite visualizar el valor de medida in situ

sin alimentación auxiliar y la resistencia Pt100 incorporada entrega

una señal eléctrica para que sea procesada. Eso es recomendable

sobre todo para aplicaciones de seguridad crítica y si puede utilizarse

sólo una conexión proceso debido a un espacio reducido.

50 WIKA manual de instrucciones modelo 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 51

4. Diseño, función / 5. Transporte, embalaje ...

4.2 Volumen de suministro

Comparar mediante el albarán si se han entregado todas las piezas.

5. Transporte, embalaje y almacenamiento

5.1 Transporte

Comprobar si el instrumento presenta eventuales daños causados en

el transporte.

Noticar de inmediato cualquier daño evidente.

5.2 Embalaje

No quitar el embalaje hasta justo antes del montaje.

Guardar el embalaje ya que es la protección ideal para el transporte

(por ejemplo un cambio del lugar de instalación o un envío del

instrumento para posibles reparaciones).

5.3 Almacenamiento

Condiciones admisibles en el lugar de almacenamiento:

Temperatura de almacenamiento: -20 ... +60 °C

Evitar lo siguiente:

■

Luz solar directa o proximidad a objetos calientes

■

Vibración mecánica, impacto mecánico (colocación brusca)

■

Hollín, vapor, polvo y gases corrosivos

■

Entorno potencialmente explosivo, atmósferas inamables

Almacenar el instrumento en su embalaje original en un lugar que

cumple las condiciones arriba mencionadas. Si no se dispone del

embalaje original, empaquetar y almacenar el termómetro como sigue:

1. Envolver el termómetro en un lm de plástico antiestático.

2. Colocar el termómetro junto con el material aislante en el embalaje.

3. Para un almacenamiento prolongado (más de 30 días) colocar una

bolsa con un desecante en el embalaje.

E

14004105.01 05/2011 GB/D/F/E

WIKA manual de instrucciones modelo 54, Twin-Temp

51

Page 52

5. Transporte, embalaje ... / 6. Puesta en ...

¡ADVERTENCIA!

Antes de almacenar el instrumento (después del

funcionamiento), eliminar todos los restos de medios

adherentes. Esto es especialmente importante cuando el

medio es nocivo para la salud, como p. ej. cáustico, tóxico,

cancerígeno, radioactivo, etc.

Con temperaturas alrededor del punto de condensación

E

(±1 °C alrededor de 0 °C) se recomienda siempre el relleno

de líquido.

6. Puesta en servicio, funcionamiento

Para atornillar el instrumento, la fuerza necesaria debe aplicarse,

mediante el uso de herramientas adecuadas, sólo sobre las supercies

planas de ajuste previstas para este n, y no a través de la caja.

Montaje mediante

llave de boca

Si se utilizan vainas, reducir la resistencia de transferencia de calor

entre la pared exterior del sensor y la pared interior de la vaina llenando la vaina con un agente de contacto. La temperatura de trabajo de

la pasta térmica está entre -40 ... +200 °C.

¡ADVERTENCIA!

No llenar en vainas calientes. ¡Peligro causado por un

escape de aceite!

52 WIKA manual de instrucciones modelo 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 53

6. Puesta en servicio, ... / 7. Mantenimiento ...

¡CUIDADO!

Si se utilizan vainas, hay que

asegurarse de que el bulbo no

tenga contacto con el fondo de

la vaina porque los diferentes

coecientes de dilatación de

los materiales pueden causar la

deformación del bulbo en el fondo

Vaina

Bulbo

de la vaina.

(Para las fórmulas para calcular

las longitudes del bulbo l

,

1

véase la cha técnica de la vaina

Distancia de

seguridad necesaria

correspondiente)

7. Mantenimiento y limpieza

7.1 Mantenimiento

¡El termómetro bimetálico combinado no requiere mantenimiento!

Controlar el instrumento y la función de conmutación una o dos veces

al año. Para eso, separar el instrumento del proceso y controlarlo con

un dispositivo de calibración de temperatura.

Todas las reparaciones las debe efectuar únicamente el fabricante.

E

7.2 Limpieza

¡CUIDADO!

■

Limpiar el termómetro con un trapo húmedo.

■

Lavar o limpiar el termómetro desmontado antes de

devolverlo para proteger a los empleados y el medio

ambiente de los peligros causados por restos de

14004105.01 05/2011 GB/D/F/E

WIKA manual de instrucciones modelo 54, Twin-Temp

medios.

53

Page 54

7. Mantenimiento y limpieza / 8. Fallos

■

Restos de medios en instrumentos desmontados

pueden causar riesgos para personas, medio

ambiente e instalación. Tomar adecuadas medidas de

precaución.

Véase el capítulo 9.2 "Devolución" para obtener más

información acerca de la devolución del instrumento.

E

8. Fallos

Fallos Causas Medidas

Sin señal/rotura de

cable

Valores de

medición erróneos

Valores de

medición erróneos

(demasiado bajos)

Valores de

medición erróneos

y tiempos de

activación

demasiado largos

La señal de

medición "aparece

y desaparece"

Corrosión

54 WIKA manual de instrucciones modelo 54, Twin-Temp

Carga mecánica excesiva o

sobretemperatura

Desviación por

sobretemperatura

Desviación por ataque

químico

Humedad en el cable o en la

unidad extraíble

Geometría de montaje

equivocada, p. ej. profundidad

de montaje demasiado

reducida o disipación de calor

demasiado elevada

Depósitos en el sensor o la

vaina

Rotura en el cable de

conexión o contacto

intermitente por sobrecarga

mecánica

La composición del medio no

coincide con la composición

supuesta o se ha modicado o

se ha seleccionado el material

de vaina no correcto

Sustituir el sensor o la

unidad extraíble por una

versión adecuada

Sustituir el sensor o la

unidad extraíble por una

versión adecuada

Utilizar una versión con

vaina

Sustituir el sensor o la

unidad extraíble por una

versión adecuada

La zona del sensor

sensible a la temperatura

debe situarse in el interior

del medio y las supercies

deben estar aisladas

Eliminar los residuos

Sustituir el sensor

Analizar el medio,

seleccionar un material

más apto o sustituir

periódicamente la vaina

14004105.01 05/2011 GB/D/F/E

Page 55

8. Fallos / 9. Desmontaje, devolución y ...

Señal perturbada

Interferencia por campos

eléctricos o bucles de tierra

Bucles de tierra Eliminar los potenciales,

Utilizar líneas de conexión

blindadas, aumentar la

distancia a motores y

líneas bajo corriente

utilizar seccionadores

de alimentación o

transmisores aislados

galvánicamente

¡CUIDADO!

Si no es posible eliminar los fallos mediante las medidas

arriba mencionadas, poner inmediatamente el instrumento

fuera de servicio; asegurarse de que ya no esté sometido

a ninguna presión o señal y proteger el instrumento contra

una puesta en servicio accidental o erronea.

En este caso ponerse en contacto con el fabricante.

En caso de una devolución del instrumento, respetar las

indicaciones en el capítulo 9.2 "Devolución".

9. Desmontaje, devolución y eliminación

¡ADVERTENCIA!

Restos de medios en instrumentos desmontados

pueden causar riesgos para personas, medio ambiente e

instalación. Tomar adecuadas medidas de precaución.

9.1 Desmontaje

¡ADVERTENCIA!

¡Riesgo de quemaduras!

¡Dejar enfriar el instrumento lo suciente antes de

desmontarlo! Peligro debido a medios muy calientes que

se escapan durante el desmontaje.

E

14004105.01 05/2011 GB/D/F/E

WIKA manual de instrucciones modelo 54, Twin-Temp

55

Page 56

9. Desmontaje, devolución y eliminación

9.2 Devolución

¡ADVERTENCIA!

Es imprescindible observar lo siguiente para el envío

del instrumento: Todos los instrumentos enviados a

WIKA deben estar libres de sustancias peligrosas (ácidos,

lejías, soluciones, etc.).

Utilizar el embalaje original o un embalaje adecuado para la

devolución del instrumento.

E

Para evitar daños:

1. Envolver el instrumento en un lm de plástico antiestático.

2. Colocar el instrumento junto con el material aislante en el embalaje.

Aislar uniformemente todos los lados del embalaje de transporte.

3. Si es posible, adjuntar una bolsa con secante.

4. Aplicar un marcaje que indique que se trata de un envío de un

instrumento de medición altamente sensible.

Rellenar el formulario de devolución y adjuntarlo al instrumento.

El formulario de devolución está disponible en internet:

www.wika.es / Servicio / Devoluciónes

9.3 Eliminación de residuos

Una eliminación incorrecta puede provocar peligros para el medio

ambiente.

Eliminar los componentes de los instrumentos y los materiales de

embalaje conforme a los reglamentos relativos al tratamiento de

residuos y eliminación vigentes en el país de utilización.

56 WIKA manual de instrucciones modelo 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 57

10. Accesorios

10. Accesorios

Denominación N° de pedido

ODU Mini Snap, tamaño 0, contraconector 11015217

ODU Mini Snap, tamaño 0, con 1,5 m de cable de PTFE 14005534

ODU Mini Snap, tamaño 0, con 3,0 m de cable de PTFE 14005545

Ejemplo

Instrucciones de montaje

Semicasquillos

Caja

Inserto para

soldar

Anillo de blindaje

1. Desplazar por el cable tuerca

de sujeción, pinza de sujeción y

anillo de blindaje

2. Desguarnecer cable y

conductores

3. Preferentemente estañar los

14004105.01 05/2011 GB/D/F/E

WIKA manual de instrucciones modelo 54, Twin-Temp

conductores

E

Inserto para engarce

Tuerca de sujeción

Pinza de sujeción

Disco de apoyo (opcional)

57

Page 58

10. Accesorios

Cautín

4. Soldar los cordones conductores

a los contactos, según la

numeración

5. Expandir el blindaje, enganchar

E

Semicasquillos

el semicasquillo en el inserto

6. Empujar el anillo de blindaje y

la pinza de sujeción contra los

semicasquillos, de tal forma que

el blindaje quede apresado entre

aquél y éstos.

Guías

7. Introducir el cable montado en la

caja de conectores teniendo en

cuenta las guías.

En caso necesario, untar la rosca

(A) con pegamento de seguridad

1

8. Atornillar la tuerca de sujeción en

el conector montado, aguantar

en la supercie (1) y apretar con

una llave de boca.

Par de apriete: 0,6 Nm

58 WIKA manual de instrucciones modelo 54, Twin-Temp

14004105.01 05/2011 GB/D/F/E

Page 59

WIKA global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand

GmbH & Co. KG

1230 Vienna

Tel. (+43) 1 86916-31

Fax: (+43) 1 86916-34

E-Mail: info@wika.at

www.wika.at

Benelux

WIKA Benelux

6101 WX Echt

Tel. (+31) 475 535-500

Fax: (+31) 475 535-446

E-Mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

Bul. "Al. Stamboliiski" 205

1309 Soa

Tel. (+359) 2 82138-10

Fax: (+359) 2 82138-13

E-Mail: t.antonov@wika.bg

Croatia

WIKA Croatia d.o.o.

Hrastovicka 19

10250 Zagreb-Lucko

Tel. (+385) 1 6531034

Fax: (+385) 1 6531357

E-Mail: info@wika.hr

www.wika.hr

Finland

WIKA Finland Oy

00210 Helsinki

Tel. (+358) 9-682 49 20

Fax: (+358) 9-682 49 270

E-Mail: info@wika.

www.wika.

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Tel. (+33) 1 343084-84

Fax: (+33) 1 343084-94

E-Mail: info@wika.fr

www.wika.fr

Germany

WIKA Alexander Wiegand

SE & Co. KG

63911 Klingenberg

Tel. (+49) 9372 132-0

Fax: (+49) 9372 132-406

E-Mail: info@wika.de

www.wika.de

Italy

WIKA Italia Srl & C. sas

20020 Arese (Milano)

Tel. (+39) 02 9386-11

Fax: (+39) 02 9386-174

E-Mail: info@wika.it

www.wika.it

Poland

WIKA Polska S.A.

87-800 Wloclawek

Tel. (+48) 542 3011-00

Fax: (+48) 542 3011-01

E-Mail: info@wikapolska.pl

www.wikapolska.pl

Romania

WIKA Instruments Romania

S.R.L.

Bucuresti, Sector 5

Calea Rahovei Nr. 266-268

Corp 61, Etaj 1

Tel. (+40) 21 4048327

Fax: (+40) 21 4563137

E-Mail: m.anghel@wika.ro

Russia

ZAO WIKA MERA

127015 Moscow

Tel. (+7) 495-648 01 80

Fax: (+7) 495-648 01 81

E-Mail: info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

Sime Solaje 15

11060 Belgrade

Tel. (+381) 11 2763722

Fax: (+381) 11 753674

E-Mail: info@wika.co.yu

www.wika.co.yu

Spain

Instrumentos WIKA, S.A.

C/Josep Carner, 11-17

08205 Sabadell (Barcelona)

Tel. (+34) 902 902577

Fax: (+34) 933 938666

E-Mail: info@wika.es

www.wika.es

Switzerland

Manometer AG

6285 Hitzkirch

Tel. (+41) 41 91972-72

Fax: (+41) 41 91972-73

E-Mail: info@manometer.ch

www.manometer.ch

Turkey

WIKA Instruments Istanbul

Basinc ve Sicaklik Ölcme

Cihazlari

Ith. Ihr. ve Tic. Ltd. Sti.

Bayraktar Bulvari No. 21

34775 Yukari Dudullu Istanbul

Tel. (+90) 216 41590-66

Fax: (+90) 216 41590-97

E-Mail: info@wika.com.tr

www.wika.com.tr

14004105.01 05/2011 GB/D/F/E