Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

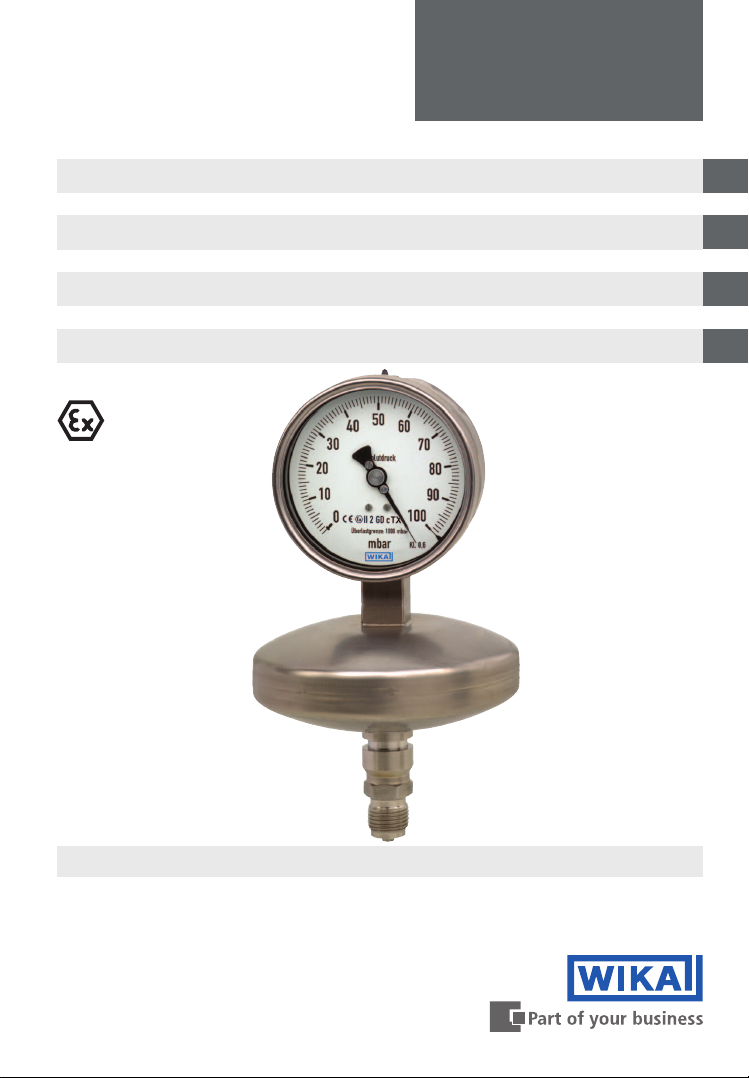

Pressure gauge model 5 per directive 94/9/EC (ATEX)

Druckmessgerät Typ 5 nach Richtlinie 94/9/EG (ATEX)

Manomètre type 5 selon directive 94/9/EG (ATEX)

Manómetro modelo 5 según la directiva 94/9/CE (ATEX)

II 2 GD c TX

GB

D

F

E

Model 532.51.100 per ATEX

Page 2

Operating instructions model 5 per ATEX Page 3-13

GB

Betriebsanleitung Typ 5 nach ATEX Seite 15-25

D

Mode d’emploi type 5 selon ATEX Page 27-37

F

Manual de instrucciones modelo 5 según ATEX Página 39-49

E

© 2013 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions pressure gauge model 5 per ATEX

11554810.02 11/2013 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 8

4. Design and function 8

5. Transport, packaging and storage 9

6. Commissioning, operation 10

7. Maintenance and cleaning 12

GB

8.

Dismounting, return and disposal

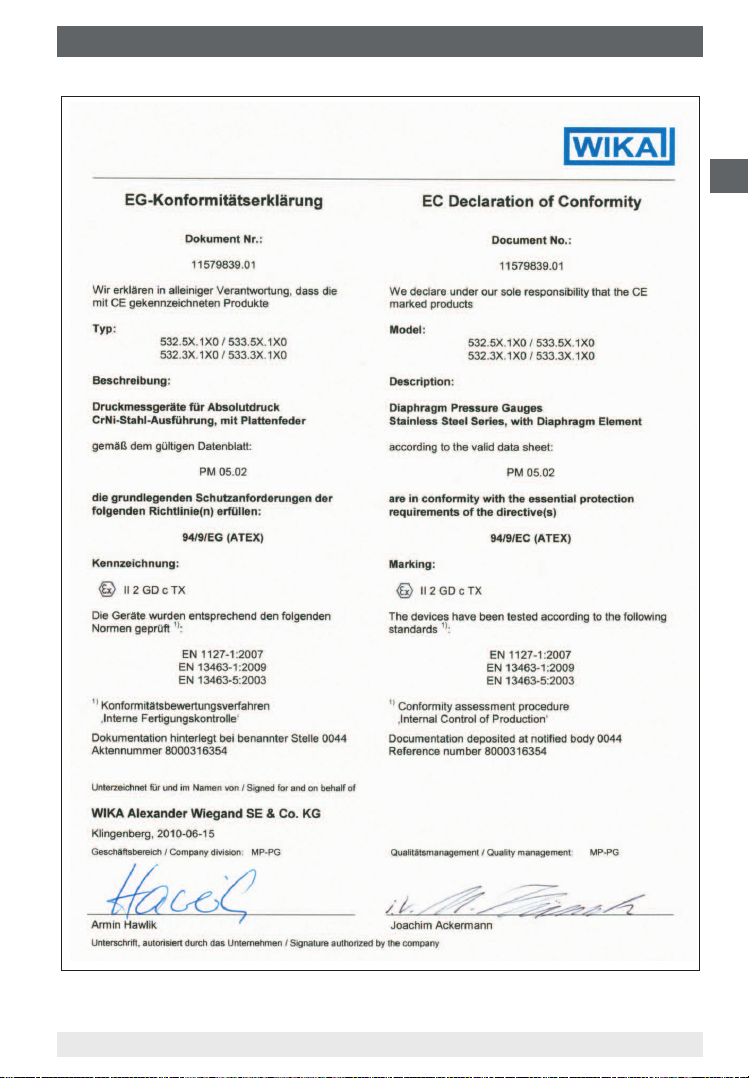

Appendix 1: EC declaration of conformity 13

11554810.02 11/2013 GB/D/F/E

WIKA operating instructions pressure gauge model 5 per ATEX

12

3

Page 4

1. General information

1. General information

■

The absolute pressure gauge described in the operating instructions has been

GB

designed and manufactured using state-of-the-art technology. All components

are subject to stringent quality and environmental criteria during production.

Our management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the

instrument. Working safely requires that all safety instructions and work

instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the

immediate vicinity of the instrument and readily accessible to skilled personnel

at any time.

■

Skilled personnel must have carefully read and understood the operating

instructions prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by

using the product contrary to its intended use, non-compliance with these

operating instructions, assignment of insuciently qualied skilled personnel

or unauthorised modications to the instrument.

■

The general terms and conditions contained in the sales documentation shall

apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: PM 05.02

Explanation of symbols

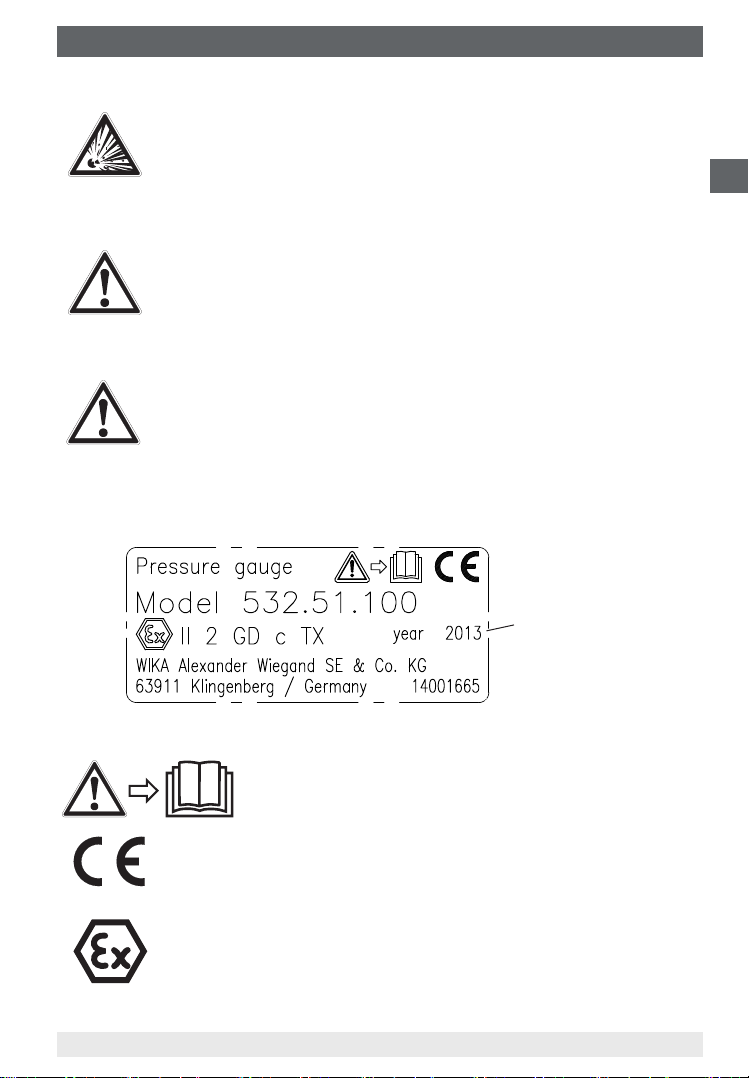

WARNING!

... indicates a potentially dangerous situation that can result in

serious injury or death, if not avoided.

Information

... points out useful tips, recommendations and information for

ecient and trouble-free operation.

4

WIKA operating instructions pressure gauge model 5 per ATEX

11554810.02 11/2013 GB/D/F/E

Page 5

1. General information / 2. Safety

WARNING!

... indicates a potentially dangerous situation in the hazardous

area that can result in serious injury or death, if not avoided.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that

the appropriate absolute pressure gauge has been selected in

terms of design and specic measuring conditions.

Check the compatibility with the medium of the materials

subjected to pressure!

In order to guarantee the measuring accuracy and long-term

stability specied, the corresponding load limits must be

observed.

Further important safety instructions can be found in the

individual chapters of these operating instructions.

2.1 Intended use

This absolute pressure gauge is particularly used for the monitoring of

vacuum pumps, the control of vacuum packing machines, the monitoring of

condensation pressures and the determination of vapour pressure in liquids.

GB

Instruments per directive 94/9/EC (ATEX) are used in hazardous areas of

industrial applications.

The instrument has been designed and built solely for the intended use described

here, and may only be used accordingly.

The manufacturer shall not be liable for claims of any type based on operation

contrary to the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage

to equipment.

■

The activities described in these operating instructions

may only be carried out by skilled personnel who have the

qualications described below.

11554810.02 11/2013 GB/D/F/E

WIKA operating instructions pressure gauge model 5 per ATEX

5

Page 6

2. Safety

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical

training, knowledge of measurement and control technology and on their

experience and knowledge of country-specic regulations, current standards

GB

and directives, are capable of carrying out the work described and independently

recognising potential hazards.

2.3 Safety instructions for pressure gauges per ATEX

WARNING!

Non-observance of these instructions and their contents may

result in the loss of explosion protection.

WARNING!

It is imperative that the application conditions and safety

requirements of the EC-type examination certicate are followed.

Pressure gauges must be grounded via the process connection!

Specications

Permissible temperatures

Ambient: -20 … +60 °C

with option silicone oil lling: -40 ... +60 °C

Medium: The permissible medium temperature does not only depend on

the instrument design, but also on the ignition temperature of the

surrounding gases, vapours or dust. Both aspects have to be taken into

account.

For permissible maximum medium temperatures see table 1.

Attention!

With gaseous substances, the temperature may increase as a result

of compression warming. In these cases it may be necessary to throttle the rate of

change of pressure or reduce the permissible medium temperature.

Table 1: Permissible medium temperature

Temperature class of the ambient

explosive atmosphere (ignition

temperature)

T 6 (85 °C < T ≤ 100 °C) +70 °C

T 5 (100 °C < T ≤ 135 °C) +85 °C

T 4 (135 °C < T ≤ 200 °C) +100 °C or +120 °C

T 3 (200 °C < T ≤ 300 °C) +100 °C or +185 °C

T 2 (300 °C < T ≤ 450 °C) +100 °C or +200 °C

T 1 (T > 450 °C) +100 °C or +200 °C

1) The higher values apply only to special versions with higher permissible medium temperatures.

6

WIKA operating instructions pressure gauge model 5 per ATEX

Maximum permissible medium

temperature (in the measuring

system)

1)

1)

1)

1)

11554810.02 11/2013 GB/D/F/E

Page 7

2. Safety

2.4 Special hazards

WARNING!

Observe the information given in the applicable type examination

certicate and the relevant country-specic regulations for

installation and use in hazardous areas (e.g. IEC 60079-14, NEC,

CEC). Non-observance can result in serious injury and/or damage

to the equipment.

WARNING!

For hazardous media such as oxygen, acetylene, ammable or

toxic gases or liquids, and refrigeration plants, compressors, etc.,

in addition to all standard regulations, the appropriate existing

codes or regulations must also be followed.

WARNING!

Residual media in dismounted measuring instruments can result in

a risk to persons, the environment and equipment.

Take sucient precautionary measures.

2.5 Labelling / safety marks

Product label

GB

Explanation of symbols

Before mounting and commissioning the pressure

gauge, ensure you read the operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European

directives.

ATEX European Explosion Protection Directive

(Atmosphère = AT, explosible = EX)

Instruments bearing this mark comply with the requirements of

the European directive 94/9/EC (ATEX) on explosion protection.

11554810.02 11/2013 GB/D/F/E

WIKA operating instructions pressure gauge model 5 per ATEX

Date of

manufacture

7

Page 8

3. Specications / 4. Design and function

3. Specications

Pressure limitation

Steady: Full scale value

GB

Fluctuating: 0.9 x full scale value

Overpressure safety

Minimum 1 bar absolute pressure (atmospheric pressure),

in addition 10 x full scale value, max. 25 bar absolute pressure

Wetted parts

Process connection and measuring chamber: Stainless steel

Pressure element

≤ 0.25 bar: Stainless steel 1.4571

> 0.25 bar: NiCr-alloy (Inconel)

Case, bayonet ring

Stainless steel

(models 532.3x, 533.32, 533.33, 533.34 with blow-out back)

Temperature eect

When the temperature of the measuring system deviates from the reference

temperature (+20 °C):

max. ±0.8 %/10 K of full scale value

IP ingress protection

IP 54 per EN 60529 / IEC 529

(with liquid lling IP 65)

For further specications see WIKA data sheet PM 05.02 and the order

documentation.

4. Design and function

Description

■

Nominal size 100 and 160 mm

■

The instruments measure the pressure by means of resilient diaphragm

measuring elements. The reference point is absolute pressure “zero”.

■

The measuring characteristics are in accordance with the EN 837-3 standard.

8

WIKA operating instructions pressure gauge model 5 per ATEX

11554810.02 11/2013 GB/D/F/E

Page 9

4. Design and function / 5. Transport, packaging and storage

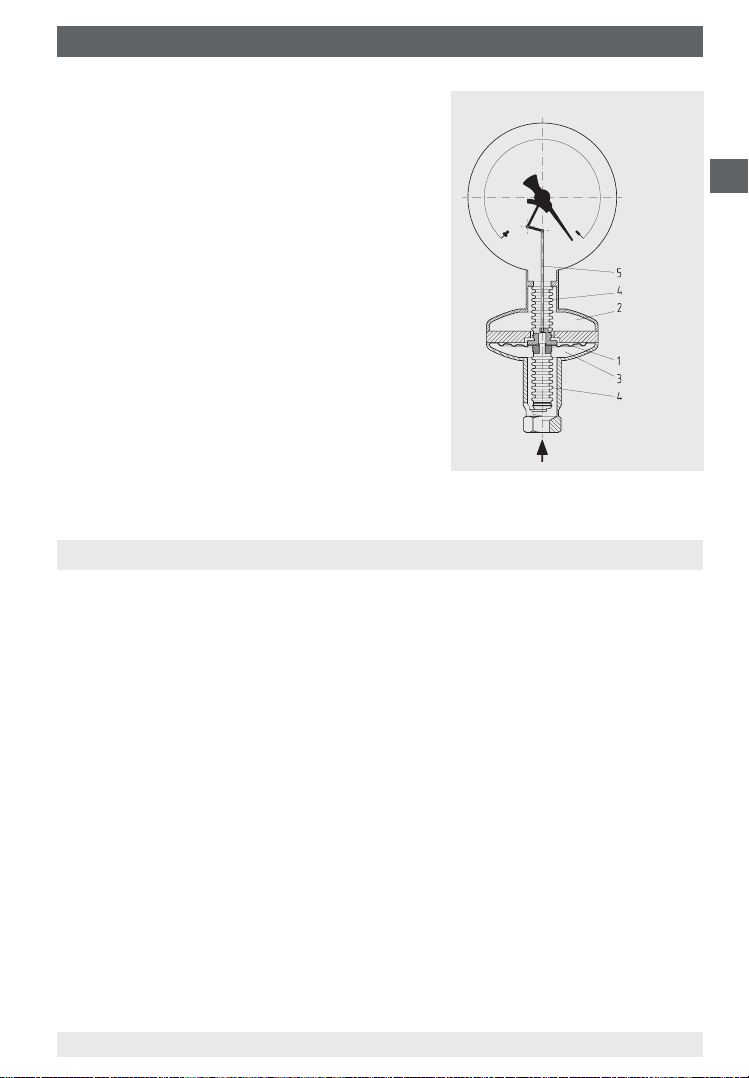

■

The diaphragm (1) separates the media

chamber (3) and the reference pressure

chamber (2) with absolute pressure zero

Illustration of the principle

■

Pressure dierential between media chamber

(3) and reference pressure chamber (2) will

deect the diaphragm (1)

■

In case of an overpressure overload the

pressure element will be protected by a

contoured metal bolster

■

The deection is transferred from the

(evacuated)

pressure chambers through bellows or

corrugated tubes (4), transmitted to the

movement via the link (5) and indicated.

Scope of delivery

Cross-check scope of delivery with delivery

note.

5. Transport, packaging and storage

5.1 Transport

Check the absolute pressure gauge for any damage that may have been caused

by transport. Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g.

change in installation site, sending for repair).

GB

289752.01

5.3 Storage

Permissible conditions at the place of storage

Storage temperature: -20 ... +60 °C

In order to prevent damage, the following points should be noted for the

storage of the pressure gauges:

■

Leave the pressure gauges in their original packaging

■

Following any possible removal of the measuring instruments, e.g. for testing,

the instrument should again be stored in its original packaging.

11554810.02 11/2013 GB/D/F/E

WIKA operating instructions pressure gauge model 5 per ATEX

9

Page 10

5. Transport, packaging ... / 6. Commissioning, operation

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

GB

Soot, vapour, dust, humidity and corrosive gases

■

Potentially explosive environments, ammable atmosphere

WARNING!

Before storing the instrument, any residual media must be

removed. This is of particular importance if the medium is

hazardous to health, e.g. caustic, toxic, carcinogenic, radioactive,

etc.

6. Commissioning, operation

6.1 Mechanical connection

■

In accordance with the general technical regulations for pressure gauges (e.g.

EN 837-2 “Selection and installation recommendations for pressure gauges”).

■

When screwing gauges in, the force required for this must not be applied

through the case, but rather through the spanner ats (using a suitable tool)

provided for this purpose on the square shaft of standard connections.

Installation with openended spanner

■

Prior to the installation of the pressure gauge, clean the measuring lines

thoroughly by tapping and blowing or rinsing

■

The pressure gauge must be mounted free from vibration and should be

aligned so that it is easy to read. It is recommended that an isolation device is

interposed between the pressure tapping point and the pressure gauge, which

will enable the replacement of the pressure gauge while the plant is running.

The instruments should be protected against coarse dirt and wide uctuations

in ambient temperature.

10

WIKA operating instructions pressure gauge model 5 per ATEX

11554810.02 11/2013 GB/D/F/E

Page 11

6. Commissioning, operation

Installation

Nominal position per EN 837-3 / 9.6.6 gure 7: 90° ( ⊥ )

Process connection lower mount (LM)

In order to ensure that with models 53x.31 ... 53x.34 pressure can be safely

and reliably vented through the case back, a distance of at least 25 mm must

be left free behind the case!

In order to avoid any additional heating, the instruments must not be exposed to

direct solar irradiation while in operation!

With lled versions the vent valve at the top of the case must be opened before

commissioning!

Permissible ambient and operating temperatures

When mounting the pressure gauge it must be ensured that, taking into

consideration the inuence of convection and heat radiation, no deviation above

or below the permissible ambient and medium temperatures can occur. The

inuence of temperature on the indication accuracy must be observed.

Permissible vibration load at the installation site

■

The instruments should always be installed in locations free from vibration.

■

If necessary, it is possible to isolate the instrument from the mounting point

by installing a exible connection line between the measuring point and the

pressure gauge and mounting the instrument on a suitable bracket.

GB

If this is not possible, the following limit values must not be exceeded:

Dry gauges: Frequency range < 150 Hz

(models 532.5x or 532.3x) Acceleration < 0.7 g (7 m/s

2

)

Liquid-lled gauges: Frequency range < 150 Hz

(models 533.5x or 533.3x) Acceleration < 4 g (40 m/s

2

)

The liquid lling must be checked on a regular basis.

The liquid level must not drop below 75 % of the gauge diameter.

Commissioning

During the commissioning process pressure surges must be avoided at all costs.

Open the shut-o valves slowly.

11554810.02 11/2013 GB/D/F/E

WIKA operating instructions pressure gauge model 5 per ATEX

11

Page 12

7. Maintenance and cleaning / 8. Dismounting, return and ...

7. Maintenance and cleaning

7.1 Maintenance

■

The instruments are maintenance-free.

GB

■

The indicator should be checked once or twice every year. For this the

instrument must be disconnected from the process to check with a pressure

testing device.

■

Repairs must only be carried out by the manufacturer or appropriately qualied

skilled personnel.

7.2 Cleaning

CAUTION!

■ Clean the pressure gauge with a moist cloth.

■ Wash or clean the dismounted instrument before returning it,

in order to protect persons and the environment from exposure

to residual media.

8. Dismounting, return and disposal

WARNING!

Residual media in dismounted measuring instruments can result

in a risk to persons, the environment and equipment.

Take sucient precautionary measures.

8.1 Dismounting

Only disconnect the measuring instrument once the system has been

depressurised and the power disconnected!

If necessary, the measuring line must have strain relief.

8.2 Return

Wash or clean the dismounted measuring instrument before returning it, in order

to protect personnel and the environment from exposure to residual media.

8.3 Disposal

Incorrect disposal can put the environment at risk. Dispose of instrument

components and packaging materials in an environmentally compatible way and

in accordance with the country-specic waste disposal regulations.

12

WIKA operating instructions pressure gauge model 5 per ATEX

11554810.02 11/2013 GB/D/F/E

Page 13

Appendix 1: EC declaration of conformity

GB

11554810.02 11/2013 GB/D/F/E

WIKA operating instructions pressure gauge model 5 per ATEX

13

Page 14

GB

14

11554810.02 11/2013 GB/D/F/E

WIKA operating instructions pressure gauge model 5 per ATEX

Page 15

Inhalt

Inhalt

1. Allgemeines 16

2. Sicherheit 17

3. Technische Daten 20

4. Aufbau und Funktion 20

5. Transport, Verpackung und Lagerung 21

6. Inbetriebnahme, Betrieb 22

7. Wartung und Reinigung 24

D

8.

Demontage, Rücksendung und Entsorgung

Anlage 1: EG-Konformitätserklärung 25

11554810.02 11/2013 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ 5 nach ATEX 15

24

Page 16

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Absolutdruckmessgerät wird nach

dem aktuellen Stand der Technik konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts-

und Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und

ISO 14001 zertiziert.

D

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät.

Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen

Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe

des Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige

Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend

qualizierten Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: PM 05.02

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die

zum Tod oder zu schweren Verletzungen führen kann, wenn sie

nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen

für einen ezienten und störungsfreien Betrieb hervor.

WIKA Betriebsanleitung Druckmessgerät Typ 5 nach ATEX16

11554810.02 11/2013 GB/D/F/E

Page 17

1. Allgemeines / 2. Sicherheit

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation im explosionsgefährdeten Bereich hin, die zum Tod oder zu schweren

Verletzungen führen kann, wenn sie nicht gemieden wird.

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass

das richtige Absolutdruckmessgerät hinsichtlich Ausführung und

spezischen Messbedingungen ausgewählt wurde.

Verträglichkeit der druckbelasteten Werkstoe mit dem Messsto prüfen!

Die Belastungsgrenzen sind einzuhalten, um die Messgenauigkeit und die Lebensdauer zu gewährleisten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen Kapiteln dieser Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Dieses Absolutdruckmessgerät wird vorzugsweise zur Überwachung von

Vakuumpumpen, zur Kontrolle an Vakuum-Verpackungsmaschinen, zur Überwachung von Kondensationsdrücken sowie zur Dampfdruckbestimmung von

Flüssigkeiten eingesetzt.

D

Geräte nach Richtlinie 94/9/EG (ATEX) dienen zur Druckmessung bei industriellen

Anwendungen in explosionsgefährdeten Bereichen.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen

Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend

verwendet werden.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung

sind ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und

Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur

durch Fachpersonal nachfolgend beschriebener Qualikation

durchführen lassen.

11554810.02 11/2013 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ 5 nach ATEX 17

Page 18

2. Sicherheit

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse

der Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der

landesspezischen Vorschriften, geltenden Normen und Richtlinien in der Lage,

die beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig zu

erkennen.

D

2.3 Sicherheitshinweise für Druckmessgeräte nach ATEX

WARNUNG!

Die Nichtbeachtung dieser Inhalte und Anweisungen kann zum

Verlust des Explosionsschutzes führen.

WARNUNG!

Einsatzbedingungen und sicherheitstechnische Daten der

EG Baumusterprüfbescheinigung unbedingt beachten.

Druckmessgeräte über den Prozessanschluss erden!

Technische Daten

Zulässige Temperaturen

Umgebung: -20 … +60 °C

bei Option Silikonölfüllung: -40 ... +60 °C

Messsto: Die zulässige Messstotemperatur hängt außer von der Gerätebauart

auch von der Zündtemperatur der umgebenden Gase, Dämpfe bzw.

Stäube ab. Beide Aspekte sind zu berücksichtigen.

Maximal zulässige Grenzwerte siehe Tabelle 1.

Achtung!

Bei gasförmigen Stoen kann sich die Temperatur durch Kompressions-

wärme erhöhen. In solchen Fällen muss ggf. die Druckänderungsgeschwindigkeit

gedrosselt bzw. die zulässige Messstotemperatur reduziert werden.

Tabelle 1: Zulässige Messstotemperatur

Temperaturklasse der umgebenden

zündfähigen Atmosphäre

Zulässige maximale Messstotemperatur (im Messsystem)

(Zündtemperatur)

T 6 (85 °C < T ≤ 100 °C) +70 °C

T 5 (100 °C < T ≤ 135 °C) +85 °C

T 4 (135 °C < T ≤ 200 °C) +100 °C bzw. +120 °C

T 3 (200 °C < T ≤ 300 °C) +100 °C bzw. +185 °C

T 2 (300 °C < T ≤ 450 °C) +100 °C bzw. +200 °C

T 1 (T > 450 °C) +100 °C bzw. +200 °C

1) Die höheren Werte gelten nur für Sonderausführungen mit höheren zulässigen Messstotemperaturen.

WIKA Betriebsanleitung Druckmessgerät Typ 5 nach ATEX18

1)

1)

1)

1)

11554810.02 11/2013 GB/D/F/E

Page 19

2. Sicherheit

2.4 Besondere Gefahren

WARNUNG!

Die Angaben der geltenden Baumusterprüfbescheinigung sowie

die jeweiligen landesspezischen Vorschriften zur Installation und

Einsatz in explosionsgefährdeten Bereichen (z. B. IEC 60079-14,

NEC, CEC) einhalten. Bei Nichtbeachten können schwere

Körperverletzungen und/oder Sachschäden auftreten.

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen,

brennbaren oder giftigen Stoen, sowie bei Kälteanlagen,

Kompressoren etc. müssen über die gesamten allgemeinen

Regeln hinaus die jeweils bestehenden einschlägigen Vorschriften

beachtet werden.

WARNUNG!

Messstoreste in ausgebauten Messgeräten können zur

Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

2.5 Beschilderung / Sicherheitskennzeichnungen

Typenschild

D

Herstellungsdatum

Symbolerklärung

Vor Montage und Inbetriebnahme des Druckmessgerätes unbedingt die Betriebsanleitung lesen!

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den

zutreenden europäischen Richtlinien.

ATEX Europäische Explosionsschutz-Richtlinie

(Atmosphère = AT, explosible = EX)

Geräte mit dieser Kennzeichnung stimmen überein mit den

Anforderungen der europäischen Richtlinie 94/9/EG (ATEX) zum

Explosionsschutz.

11554810.02 11/2013 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ 5 nach ATEX 19

Page 20

3. Technische Daten / 4. Aufbau und Funktion

3. Technische Daten

Druckbelastbarkeit

Ruhebelastung: Skalenendwert

Wechselbelastung: 0,9 x Skalenendwert

Überlastbarkeit

D

mindestens 1 bar Absolutdruck (Atmosphärendruck), darüber hinaus

10 x Skalenendwert, max. 25 bar Absolutdruck

Messstoberührte Teile

Prozessanschluss und Messkammer: CrNi-Stahl

Messglied

≤ 0,25 bar: CrNi-Stahl 1.4571

> 0,25 bar: NiCr-Legierung (Inconel)

Gehäuse, Bajonettring

CrNi-Stahl

(Typen 532.3x, 533.32, 533.33, 533.34 mit ausblasbarer Rückwand)

Temperatureinuss

Bei Abweichung von der Referenztemperatur (+20 °C) am Messsystem:

max. ±0,8 %/10 K vom jeweiligen Skalenendwert

IP-Schutzart

IP 54 nach EN 60529 / IEC 529

(mit Flüssigkeitsfüllung IP 65)

Weitere technische Daten siehe WIKA Datenblatt PM 05.02 und Bestellunterlagen.

4. Aufbau und Funktion

Beschreibung

■

Nenngröße 100 und 160 mm

■

Die Geräte erfassen den zu messenden Druck mit elastischen PlattenfederMessgliedern. Der Bezugspunkt ist Absolutdruck „Null“.

■

Die messtechnischen Eigenschaften entsprechen der Norm EN 837-3.

WIKA Betriebsanleitung Druckmessgerät Typ 5 nach ATEX20

11554810.02 11/2013 GB/D/F/E

Page 21

4. Aufbau und Funktion / 5. Transport, Verpackung und Lagerung

■

Plattenfeder (1) trennt Messstoraum (3) und

Prinzipdarstellung

Referenzdruckraum (2) mit Absolutdruck Null

■

Druckdierenz zwischen Messstoraum (3)

und Referenzdruckraum (2) bewirkt Durchbiegung (Messweg) der Plattenfeder (1)

■

Messglied wird bei Überdruckbelastung

durch Stütz-Anlageäche geschützt

■

Messweg wird über Bälge bzw. Wellrohre

(evakuiert)

(4) aus Druckkammern herausgeführt, über

Schubstange (5) auf Zeigerwerk übertragen

und angezeigt.

Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

5. Transport, Verpackung und Lagerung

5.1 Transport

Absolutdruckmessgerät auf eventuell vorhandene Transportschäden

untersuchen. Oensichtliche Schäden unverzüglich mitteilen.

289752.01

D

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen

optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort

Lagertemperatur: -20 ... +60 °C

Um Schäden zu vermeiden, sind für die Lagerung der Druckmessgeräte

folgende Punkte zu beachten:

■

Druckmessgeräte in der Originalverpackung belassen

■

Nach einer eventuellen Entnahme der Messgeräte für z. B. Prüfungen, sollte

das Gerät wieder in der Originalverpackung eingelagert werden.

11554810.02 11/2013 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ 5 nach ATEX 21

Page 22

5. Transport, Verpackung ... / 6. Inbetriebnahme, Betrieb

Vermeiden Sie folgende Einüsse:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub, Feuchtigkeit und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphäre

D

WARNUNG!

Vor der Einlagerung des Gerätes müssen alle ggf. anhaftenden

Messstoreste entfernt werden. Dies ist besonders wichtig, wenn

das Medium gesundheitsgefährdend ist, wie z. B. ätzend, giftig,

krebserregend, radioaktiv, usw.

6. Inbetriebnahme, Betrieb

6.1 Mechanischer Anschluss

■

Entsprechend den allgemeinen technischen Regeln für Druckmessgeräte

(z. B. EN 837-2 „Auswahl- und Einbauempfehlungen für Druckmessgeräte“).

■

Beim Einschrauben der Geräte darf die zum Abdichten erforderliche Kraft

nicht über das Gehäuse aufgebracht werden, sondern mit geeignetem

Werkzeug nur über die dafür vorgesehenen Schlüsselächen am Vierkant des

Anschlusszapfens.

Montage mit Gabelschlüssel

■

Messleitungen vor der Gerätemontage gründlich durch Abklopfen und

Ausblasen oder Durchspülen reinigen

■

Das Druckmessgerät muss erschütterungsfrei befestigt werden und soll gut

ablesbar angeordnet sein. Es empehlt sich, zwischen Druckentnahmestelle

und Druckmessgerät eine Absperrvorrichtung zwischenzuschalten, die einen

Austausch des Messgerätes bei laufender Anlage ermöglicht. Die Geräte sind

vor grober Verschmutzung und starken Schwankungen der Umgebungstemperatur zu schützen.

WIKA Betriebsanleitung Druckmessgerät Typ 5 nach ATEX22

11554810.02 11/2013 GB/D/F/E

Page 23

6. Inbetriebnahme, Betrieb

Installation

Nennlage nach EN 837-3 / 9.6.6 Bild 7: 90° ( ⊥ )

Prozessanschluss unten

Damit bei den Typen 53x.31 ... 53x.34 im Fehlerfall die sichere Druckent-

lastung durch die Rückwand erfolgen kann, müssen hinter dem Gehäuse

mindestens 25 mm frei bleiben!

Um zusätzliche Aufheizung zu vermeiden, dürfen die Geräte im Betrieb keiner

direkten Sonneneinstrahlung ausgesetzt werden!

Bei gefüllten Ausführungen muss vor Inbetriebnahme das Entlüftungsventil an der

Oberseite des Gehäuses geönet werden!

Zulässige Umgebungs- und Betriebstemperaturen

Die Anbringung des Druckmessgerätes ist so auszuführen, dass die zulässigen

Umgebungs- und Messstotemperaturgrenzen, auch unter Berücksichtigung des

Einusses von Konvektion und Wärmestrahlung, weder unter- noch überschritten

werden. Der Temperatureinuss auf die Anzeigegenauigkeit ist zu beachten.

Zulässige Schwingungsbelastung am Einbauort

■

Die Geräte sollten grundsätzlich nur an Stellen ohne Schwingungsbelastung

eingebaut werden.

■

Gegebenenfalls kann z. B. durch eine exible Verbindungsleitung von

der Messstelle zum Druckmessgerät und die Befestigung über eine

Messgerätehalterung eine Entkopplung vom Einbauort erreicht werden.

D

Falls dies nicht möglich ist, dürfen folgende Grenzwerte nicht überschritten werden:

Ungefüllte Geräte: Frequenzbereich < 150 Hz

(Typen 532.5x bzw. 532.3x) Beschleunigung < 0,7 g (7 m/s

2

)

Flüssigkeitsgefüllte Geräte: Frequenzbereich < 150 Hz

(Typen 533.5x bzw. 533.3x) Beschleunigung < 4 g (40 m/s

2

)

Die Flüssigkeitsfüllung ist regelmäßig zu überprüfen.

Der Flüssigkeitsspiegel darf nicht unter 75 % des Gerätedurchmessers fallen.

Inbetriebnahme

Bei Inbetriebnahme Druckstöße unbedingt vermeiden, Absperrventile langsam

önen.

11554810.02 11/2013 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ 5 nach ATEX 23

Page 24

7. Wartung und Reinigung / 8. Demontage, Rücksendung und ...

7. Wartung und Reinigung

7.1 Wartung

■

Die Geräte sind wartungsfrei.

■

Eine Überprüfung der Anzeige sollte etwa 1 bis 2 mal pro Jahr erfolgen.

Dazu ist das Gerät vom Prozess zu trennen und mit einer Druckprüfvorrichtung

D

zu kontrollieren.

■

Reparaturen sind ausschließlich vom Hersteller oder entsprechend qualiziertem Fachpersonal durchzuführen.

7.2 Reinigung

VORSICHT!

■ Das Druckmessgerät mit einem feuchten Tuch reinigen.

■ Ausgebautes Gerät vor der Rücksendung spülen bzw.

säubern, um Personen und Umwelt vor Gefährdung durch

anhaftende Messstoreste zu schützen.

8. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste in ausgebauten Messgeräten können zur

Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

8.1 Demontage

Messgerät nur im drucklosen und spannungsfreiem Zustand demontieren!

Gegebenenfalls muss die Messleitung entspannt werden.

8.2 Rücksendung

Ausgebautes Messgerät vor der Rücksendung spülen bzw. säubern, um

Mitarbeiter und Umwelt vor Gefährdung durch anhaftende Messstoreste zu

schützen.

8.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den

landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften

umweltgerecht entsorgen.

WIKA Betriebsanleitung Druckmessgerät Typ 5 nach ATEX24

11554810.02 11/2013 GB/D/F/E

Page 25

Anlage 1: EG-Konformitätserklärung

D

11554810.02 11/2013 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ 5 nach ATEX 25

Page 26

D

11554810.02 11/2013 GB/D/F/E

WIKA Betriebsanleitung Druckmessgerät Typ 5 nach ATEX26

Page 27

Sommaire

Sommaire

1. Généralités 28

2. Sécurité 29

3. Spécications 32

4. Conception et fonction 32

5. Transport, emballage et stockage 33

6. Mise en service, exploitation 34

7. Entretien et nettoyage 36

8.

Démontage, retour et mise au rebut

Annexe 1 : Déclaration de conformité CE 37

36

F

11554810.02 11/2013 GB/D/F/E

WIKA mode d‘emploi manomètre type 5 selon ATEX 27

Page 28

1. Généralités

1. Généralités

■

Le manomètre pour pression absolue décrit dans le mode d'emploi est conçu

et fabriqué selon les dernières technologies en vigueur. Tous les composants

sont soumis à des critères de qualité et d'environnement stricts durant

la fabrication. Nos systèmes de gestion sont certiés selon ISO 9001 et

ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant l'utilisation

de l'instrument. Il est possible de travailler en toute sécurité avec ce produit en

F

respectant toutes les consignes de sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents et les

prescriptions générales de sécurité en vigueur pour le domaine d'application

de l'instrument.

■

Le mode d'emploi fait partie de l'instrument et doit être conservé à proximité

immédiate de l'instrument et accessible à tout moment pour le personnel

qualié.

■

Le personnel qualié doit, avant de commencer toute opération, avoir lu

soigneusement et compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de dommages

provoqués par une utilisation non conforme à l'usage prévu, de non respect de

ce mode d'emploi, d'utilisation de personnel peu qualié de même qu'en cas

de modications de l'instrument eectuées par l'utilisateur.

■

Les conditions générales de vente mentionnées dans les documents de vente

s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site internet : www.wika.fr

- Fiche technique correspondante : PM 05.02

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles

de provoquer la mort ou des blessures graves si elle n'est pas

évitée.

Information

… met en exergue les conseils et recommandations utiles

de même que les informations permettant d'assurer un

fonctionnement ecace et normal.

11554810.02 11/2013 GB/D/F/E

WIKA mode d‘emploi manomètre type 5 selon ATEX28

Page 29

1. Généralités / 2. Sécurité

AVERTISSEMENT !

… indique une situation en zone explosive présentant des

risques susceptibles de provoquer la mort ou des blessures

graves si elle n'est pas évitée.

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement,

s'assurer que le manomètre pour pression absolue a été choisi

de façon adéquate, en ce qui concerne la plage de mesure, la

version et les conditions de mesure spéciques.

Vérier si les matériaux soumis à la pression sont compatibles

avec le uide de mesure !

Les limites de surpression admissible sont à respecter an

d'assurer la précision et la durée de vie.

Vous trouverez d'autres consignes de sécurité dans les sections

individuelles du présent mode d'emploi.

2.1 Utilisation conforme à l'usage prévu

Ce manomètre pour pression absolue est utilisé particulièrement pour la

surveillance de pompes à vide, de machines d'emballage, détermination de la

pression de condensation et de la pression de vapeur de liquides.

F

Les instruments selon la directive 94/9/CE (ATEX) sont utilisés dans les zones

dangereuses d'applications industrielles.

L'instrument est conçu et construit exclusivement pour une utilisation conforme à

l'usage prévu décrit ici et ne doit être utilisé qu'en conséquence.

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à

l'usage prévu.

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants

dommages corporels et matériels.

■

Les opérations décrites dans ce mode d'emploi ne doivent

être eectuées que par un personnel ayant la qualication

décrite ci-après.

11554810.02 11/2013 GB/D/F/E

WIKA mode d‘emploi manomètre type 5 selon ATEX 29

Page 30

2. Sécurité

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses

connaissances dans le domaine de la technique de mesure et de régulation et de

ses expériences de même que de sa connaissance des prescriptions nationales,

des normes et directives en vigueur, en mesure d'eectuer les travaux décrits et

de reconnaître automatiquement les dangers potentiels.

2.3 Instructions de sécurité pour les manomètres selon ATEX

AVERTISSEMENT !

F

Spécications

Températures admissibles

Ambiante : -20 … +60 °C

avec option remplissage à l'huile de silicone : -40 ... +60 °C

Fluide : la température admissible du uide ne dépend pas seulement de la

Voir le tableau 1 pour les températures de uide maximales admissibles.

Le non respect de ces instructions et de leurs contenus peut

entraîner une perte de la protection contre les explosions.

AVERTISSEMENT !

Les consignes de sécurité de l'attestation d'examen de type et les

conditions d'application doivent impérativement être respectées.

Les manomètres doivent être mis à la terre à l'aide du branchement de process !

fabrication de l'instrument, mais également de la température d'allumage

des gaz, vapeurs ou poussières environnants. Ces deux aspects doivent

être pris en compte.

Attention !

suite d'un réchauement de compression.

Avec les substances gazeuses, la température pourrait augmenter à la

Dans ces cas-là, il peut s'avérer néces-

saire d'accélérer le taux de changement de pression ou de réduire la température

du uide admissible.

Tableau 1 : température du uide admissible

Classe de température de

l'atmosphère explosive ambiante

(température d'allumage)

T 6 (85 °C < T ≤ 100 °C) +70 °C

T 5 (100 °C < T ≤ 135 °C) +85 °C

T 4 (135 °C < T ≤ 200 °C) +100 °C or +120 °C

T 3 (200 °C < T ≤ 300 °C) +100 °C or +185 °C

T 2 (300 °C < T ≤ 450 °C) +100 °C or +200 °C

T 1 (T > 450 °C) +100 °C or +200 °C

Les valeurs supérieures s'appliquent uniquement aux versions spéciales avec des températures du uide permises plus élevées.

Température du uide admissible

maximale (dans le système de

mesure)

1)

1)

1)

1)

WIKA mode d‘emploi manomètre type 5 selon ATEX30

11554810.02 11/2013 GB/D/F/E

Page 31

2. Sécurité

2.4 Dangers particuliers

AVERTISSEMENT !

Respecter les indications de l'attestation d'examen de type valable

de même que les prescriptions nationales respectives concernant

le montage et l'utilisation en zone explosive (par exemple

CEI 60079-14, NEC, CEC). Un non respect de cette consigne

peut entraîner des blessures corporelles graves et/ou des dégâts

matériels.

AVERTISSEMENT !

Dans le cas de uides de mesure dangereux comme notamment

l'oxygène, l'acétylène, les substances combustibles ou toxiques,

ainsi que dans le cas d'installations de réfrigération, de

compresseurs etc., les directives appropriées existantes doivent

être observées en plus de l'ensemble des règles générales.

AVERTISSEMENT !

Les restes de uides se trouvant dans des instruments de

mesure démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation.

Prendre des mesures de sécurité susantes.

2.5 Etiquetage / Marquages de sécurité

Plaque signalétique

F

Date de

fabrication

Explication des symboles

Lire impérativement le mode d'emploi avant le montage et la mise en service de l'indicateur de pression

portable !

CE, Communauté Européenne

Les instruments avec ce marquage sont conformes aux directives

européennes pertinentes.

ATEX Directive européenne sur les instruments destinés à

être utilisés en atmosphère explosible

(Atmosphère = AT, explosible = EX)

Les instruments avec ce marquage sont conformes aux

exigences de la directive européenne 94/9/CE (ATEX) sur la

11554810.02 11/2013 GB/D/F/E

WIKA mode d‘emploi manomètre type 5 selon ATEX 31

protection contre les explosions.

Page 32

3. Spécications / 4. Conception et fonction

3. Spécications

Plages d' utilisation

Charge statique : Fin d'échelle

Charge dynamique : 0,9 x de n d'échelle

Surpression admissible

Minimum 1 bar de pression absolue (pression atmosphérique), en plus 10 x la

valeur de pleine échelle, maximum 25 bar de pression absolue

F

Parties en contact avec le uide

Raccord process et chambre de mesure: Acier inox

Elément de mesure

≤ 0,25 bar: Acier inox 1.4571

> 0,25 bar: Alliage NiCr (Inconel)

Boîtier, lunette baïonnette

Acier inox

(types 532.3x, 533.32, 533.33, 533.34 avec paroi arrière éjectable)

Eet de la température

Au cas où la température du système de mesure dévie de la température de

référence (+20 °C) : max. ±0,8 %/10 K de la valeur pleine échelle

IP indice de protection

IP 54 selon EN 60529 / IEC 529

(avec remplissage de liquide IP 65)

Pour de plus amples spécications, voir la che technique WIKA PM 05.02 et la

documentation de commande.

4. Conception et fonction

Description

■

Diamètre 100 et 160 mm

■

Les instruments mesurent la pression par le biais d'éléments de mesure à

membrane à déformation élastique. Le point de référence est la pression

absolue “zéro”.

■

Les caractéristiques techniques de mesure correspondent aux normes

EN 837-3.

WIKA mode d‘emploi manomètre type 5 selon ATEX32

11554810.02 11/2013 GB/D/F/E

Page 33

4. Conception et fonction / 5. Transport, emballage et stockage

■

La membrane (1) sépare la chambre de

mesure (3) et la chambre de pression de

Illustration du principe

de fonctionnement

référence (2) avec une pression absolue de

zéro

■

Le diérentiel de pression entre la chambre

de mesure (3) et la chambre de pression de

référence (2) va déformer la membrane (1)

■

En cas de surpression, l'élément de pression

sera protégé par un plateau en métal prolé

■

La déformation de la membrane est

(évacué)

transmise depuis les chambres de pression

par des souets ou des tubes forgés (4),

puis transmise au mouvement par l'élément

de liaison (5) et indiquée.

Détail de la livraison

Comparer le détail de la livraison avec le

bordereau de livraison.

5. Transport, emballage et stockage

5.1 Transport

Vérier s'il existe des dégâts sur le manomètre pour pression absolue liés au

transport. Communiquer immédiatement les dégâts constatés.

289752,01

F

5.2 Emballage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection optimale

(par ex. changement de lieu d'utilisation, renvoi pour réparation).

5.3 Stockage

Conditions admissibles sur le lieu de stockage

Température de stockage : -20 ... +60 °C

An d'éviter des dommages, il faut respecter les points suivants concernant le stockage des manomètres :

■

Laisser les manomètres dans leur emballage d'origine

■

Suite à tout déplacement éventuel des instruments de mesure, par exemple

pour des essais, l'instrument doit à nouveau être stocké dans son emballage

d'origine.

11554810.02 11/2013 GB/D/F/E

WIKA mode d‘emploi manomètre type 5 selon ATEX 33

Page 34

5. Transport, emballage ... / 6. Mise en service, exploitation

Eviter les inuences suivantes :

■

Lumière solaire directe ou proximité d'objets chauds

■

Vibrations mécaniques, chocs mécaniques (mouvements brusques en le

posant)

■

Suie, vapeur, poussière, humidité et gaz corrosifs

■

Environnements présentant des risques d'explosion, atmosphères inammables

AVERTISSEMENT !

Enlever tous les restes de uides adhérents avant l'entreposage

F

de l'instrument. Ceci est particulièrement important lorsque le

uide représente un danger pour la santé, comme p. ex. des

substances corrosives, toxiques, cancérogènes, radioactives etc.

6. Mise en service, exploitation

6.1 Raccordement mécanique

■

Conformément aux règles techniques générales pour les manomètres (par ex.

EN 837-2 “Recommandations sur le choix et l'installation des manomètres”).

■

Lors du vissage des appareils, la force nécessaire ne doit pas être appliquée

sur le boîtier mais seulement sur les surfaces prévues par un outil approprié

sur le carré du raccord.

Montage avec clé à

fourche

■

Avant d'installer le manomètre, nettoyer les conduites de mesure en tapant et

en souant ou en rinçant

■

Le manomètre doit être monté sans entraîner de vibrations et doit être aligné

de façon qu'il puisse être bien lu. Il est recommandé qu'un dispositif d'isolation

soit interposé entre le point de mesure de la pression et le manomètre, ce qui

permet le remplacement du manomètre lors du fonctionnement de l'installation.

Les instruments doivent être protégés contre un encrassement important et

contre les uctuations de la température ambiante.

WIKA mode d‘emploi manomètre type 5 selon ATEX34

11554810.02 11/2013 GB/D/F/E

Page 35

6. Mise en service, exploitation

Installation

Position de base selon EN 837-3 / 9.6.6 image 7: 90° ( ⊥ )

Raccord process vertical (LM)

Pour que, avec types 52x.31 ... 53x.34, une surpression puisse s'évacuer

en toute sécurité par l'arrière du boîtier en cas d'incident sur un manomètre,

une distance minimum de 25 mm doit rester libre à l'arrière du boîtier de

l'appareil !

An d'éviter tout échauement supplémentaire, les instruments ne doivent pas

être exposés directement aux rayons du soleil pendant le fonctionnement !

Pour les appareils remplis la soupape d'aération au sommet du boîtier doit être

ouverte avant la mise en service!

Températures ambiantes et d'exploitation admissibles

Lors du montage du manomètre, la température ne doit pas être inférieure ou

supérieure à la température ambiante et d'exploitation admissible, même si la

convection et la dissipation de la chaleur sont prises en compte. L'inuence de la

température sur la précision de l'indication doit être observée.

Contrainte de vibration admissible sur le point de montage

■

L'instrument ne doit être installé que dans des endroits exempts de vibrations.

■

Le cas échéant, il est possible d'isoler l'appareil du lieu d'installation en utilisant

par exemple une liaison exible entre le point de mesure et le manomètre et en

xant ce dernier à l'aide d'un support d'appareil mural.

F

Lorsque cela n'est pas possible, veiller à ce que les valeurs limites suivantes ne

soient pas dépassées:

Instruments secs : Plage de fréquence < 150 Hz

(types 532.5x ou 532.3x) Accélération < 0,7 g (7 m/s

2

)

Instruments remplis de liquide : Plage de fréquence < 150 Hz

(types 533.5x ou 533.3x) Accélération < 4 g (40 m/s

2

)

Le liquide de remplissage doit être contrôlé régulièrement.

Le niveau de remplissage de liquide ne doit pas descendre en-dessous de 75 %

du diamètre de l'instrument.

Mise en service

Lors de la mise en service il faut absolument éviter les coups de bélier. Ouvrir

lentement les robinets d'isolement.

11554810.02 11/2013 GB/D/F/E

WIKA mode d‘emploi manomètre type 5 selon ATEX 35

Page 36

7. Entretien et nettoyage / 8. Démontage, retour et ...

7. Entretien et nettoyage

7.1 Entretien

■

Les instruments ne requièrent aucun entretien.

■

Un contrôle de l'achage et des fonctions de commande est recommandé 1

à 2 fois/an. Pour contrôler l'achage et la fonction de commutation, l'appareil

doit être isolé du processus de mesure et contrôlé à l'aide d'un dispositif de

contrôle de la pression.

■

F

Les réparations doivent être eectuées exclusivement par le fabricant ou par

un personnel qualié.

7.2 Nettoyage

ATTENTION !

■ Nettoyer le manomètre avec un chion humide.

■ Laver ou nettoyer l'instrument démonté avant de le renvoyer,

an de protéger les personnes et l‘environnement contre le

danger lié aux restes de uides adhérents.

8. Démontage, retour et mise au rebut

AVERTISSEMENT !

Les restes de uides se trouvant dans des instruments de

mesure démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation.

Prendre des mesures de sécurité susantes.

8.1 Démontage

Déconnecter l'instrument de mesure seulement une fois que le système a été mis

hors pression et que l'alimentation a été coupée !

Si nécessaire, la conduite de mesure doit avoir un dispositif de détente.

8.2 Retour

Lavez ou nettoyez l'instrument de mesure démonté avant de le renvoyer pour

protéger le personnel et l'environnement contre l'exposition à des substances

résiduelles.

8.3 Mise au rebut

Une mise au rebut inadéquate peut entraîner des dangers pour l'environnement.

Eliminer les composants des instruments et les matériaux d'emballage

conformément aux prescriptions nationales pour le traitement et l'élimination

des déchets et aux lois de protection de l'environnement en vigueur.

WIKA mode d‘emploi manomètre type 5 selon ATEX36

11554810.02 11/2013 GB/D/F/E

Page 37

Annexe 1 : Déclaration de conformité CE

F

11554810.02 11/2013 GB/D/F/E

WIKA mode d‘emploi manomètre type 5 selon ATEX 37

Page 38

F

11554810.02 11/2013 GB/D/F/E

WIKA mode d‘emploi manomètre type 5 selon ATEX38

Page 39

Contenido

Contenido

1. Información general 40

2. Seguridad 41

3. Datos técnicos 44

4. Diseño y función 44

5. Transporte, embalaje y almacenamiento 45

6. Puesta en servicio, funcionamiento 46

7. Mantenimiento y limpieza 48

E

8.

Desmontaje, devolución y eliminación de residuos

Anexo 1: Declaración de conformidad CE 49

11554810.02 11/2013 GB/D/F/E

48

39WIKA manual de instrucciones para manómetro modelo 5 según ATEX

Page 40

1. Información general

1. Información general

■

El manómetro absoluto descrito en el manual de instrucciones está construido

y fabricado según el estado actual de la técnica. Todos los componentes

están sujetos a rigurosos criterios de calidad y medio ambiente durante la

producción. Nuestros sistemas de gestión están certicados según ISO 9001

e ISO 14001.

■

Este manual de instrucciones proporciona indicaciones importantes acerca del

manejo del instrumento. Para que el trabajo con este instrumento sea seguro

es imprescindible cumplir con todas las instrucciones de seguridad y manejo

indicadas.

■

Cumplir siempre las normativas sobre la prevención de accidentes y las

E

normas de seguridad en vigor en el lugar de utilización del instrumento.

■

El manual de instrucciones es una parte integrante del instrumento y debe

guardarse en la proximidad del mismo para que el personal especializado

pueda consultarlo en cualquier momento.

■

El personal especializado debe haber leído y entendido el manual de

instrucciones antes de comenzar cualquier trabajo.

■

El fabricante queda exento de cualquier responsabilidad en caso de daños

causados por un uso no conforme a la nalidad prevista, la inobservancia del

presente manual de instrucciones, un manejo por personal insucientemente

cualicado así como una modicación no autorizada del instrumento.

■

Se aplican las condiciones generales de venta incluidas en la documentación

de venta.

■

Modicaciones técnicas reservadas.

■

Para obtener más informaciones consultar:

- Página web: www.wika.es

- Hoja técnica correspondiente: PM 05.02

Explicación de símbolos

¡ADVERTENCIA!

… indica una situación probablemente peligrosa que puede

causar la muerte o lesiones graves si no se la evita.

Información

... marca consejos y recomendaciones útiles así como

informaciones para una utilización ecaz y libre de fallos.

40 WIKA manual de instrucciones para manómetro modelo 5 según ATEX

11554810.02 11/2013 GB/D/F/E

Page 41

1. Información general / 2. Seguridad

¡ADVERTENCIA!

... indica una situación probablemente peligrosa en una

atmósfera potencialmente explosiva que puede causar la

muerte o lesiones graves si no se evita.

2. Seguridad

¡ADVERTENCIA!

Antes del montaje, la puesta en servicio y el funcionamiento

asegurarse de que se haya seleccionado el manómetro

absoluto adecuado con respecto a versión y condiciones de

medición especícas.

¡Asegúrese de que los productos bajo presión sean aptos para

el material de medición!

Para garantizar la precisión de medición y la durabilidad del

instrumento, se deberán respetar los límites de carga.

Los distintos capítulos de este manual de instrucciones

contienen otras importantes indicaciones de seguridad.

2.1 Uso conforme a lo previsto

Este manómetro absoluto se utiliza sobre todo para la monitorización de

bombas de vacío, para el control en máquinas envasadoras al vacío, para la

monitorización de presiones de condensación, así como para la determinación

de la presión de vapor de líquidos.

E

Instrumentos según directiva 94/9/CE (ATEX) sirven para medir la presión en

aplicaciones industriales en atmósferas potencialmente explosivas.

El instrumento ha sido diseñado y construido únicamente para la nalidad aquí

descrita y debe utilizarse en conformidad a la misma.

No se admite ninguna reclamación debido a una utilización no conforme a lo

previsto.

2.2 Cualicación del personal

¡ADVERTENCIA!

¡Riesgo de lesiones debido a una insuciente cualicación!

Un manejo no adecuado puede causar considerables daños

personales y materiales.

■

Las actividades descritas en este manual de instrucciones

deben realizarse únicamente por personal especializado con

la consiguiente cualicación.

11554810.02 11/2013 GB/D/F/E

41WIKA manual de instrucciones para manómetro modelo 5 según ATEX

Page 42

2. Seguridad

Personal especializado

Debido a su formación profesional, a sus conocimientos de la técnica de

regulación y medición así como a su experiencia y su conocimiento de las

normativas, normas y directivas vigentes en el país de utilización el personal

especializado es capaz de ejecutar los trabajos descritos y reconocer posibles

peligros por sí solo.

2.3 Instrucciones de seguridad para manómetros según ATEX

¡ADVERTENCIA!

La inobservancia del contenido y de las instrucciones puede

originar la pérdida de la protección contra explosiones.

E

¡ADVERTENCIA!

Es imprescindible observar las condiciones de uso y los datos de

seguridad del certicado CE de tipo.

¡Poner a tierra los manómetros a través de la conexión al proceso!

Datos técnicos

Temperaturas admisibles

Ambiente: -20 … +60 °C

con opción relleno de aceite silicona: -40 ... +60 °C

Medio: La temperatura del medio admisible depende del tipo de construcción del

instrumento y de la temperatura de inamación de los gases, vapores o

polvos en el ambiente.

Es preciso considerar los dos valores.

Para los valores límite máx. admisibles, véase la tabla 1.

¡Atención!

La temperatura puede aumentar con medios gaseosos a causa del

calor de compresión. En estos casos, hay que disminuir la velocidad de cambio de

presión o reducir la temperatura admisible del medio si fuera necesario.

Tabla 1: Temperatura admisible del medio

Clase de temperatura de la

atmósfera ambiente inamable

(temperatura de inamación)

T 6 (85 °C < T ≤ 100 °C) +70 °C

T 5 (100 °C < T ≤ 135 °C) +85 °C

T 4 (135 °C < T ≤ 200 °C) +100 °C bzw. +120 °C

T 3 (200 °C < T ≤ 300 °C) +100 °C bzw. +185 °C

T 2 (300 °C < T ≤ 450 °C) +100 °C bzw. +200 °C

T 1 (T > 450 °C) +100 °C bzw. +200 °C

1) Los valores superiores son válidos únicamente para versiones especiales con temperaturas admisibles superiores.

42 WIKA manual de instrucciones para manómetro modelo 5 según ATEX

Temperatura máx. admisible

del medio (en el sistema de

medición)

1)

1)

1)

1)

11554810.02 11/2013 GB/D/F/E

Page 43

2. Seguridad

2.4 Riesgos especícos

¡ADVERTENCIA!

Cumplir las indicaciones del certicado de tipo así como las

normativas vigentes en el país de utilización acerca de la

instalación y el uso en atmósferas potencialmente explosivas

(p. ej. IEC 60079-14, NEC, CEC). Riesgo de lesiones graves y/o

daños materiales en caso de inobservancia.

¡ADVERTENCIA!

En los casos de sustancias de medición peligrosas (por ej.:

oxígeno, acetileno, sustancias inamables o tóxicas), así como

en instalaciones de refrigeración, compresores, etc., deberán

respetarse tanto las normas generales, como las especicaciones

referentes a cada una de estas sustancias.

¡ADVERTENCIA!

Medios residuales en instrumentos de medición desmontados

pueden causar riesgos para personas, medio ambiente e

instalación.

Tomar las medidas de precaución adecuadas.

2.5 Rótulos / Marcados de seguridad

Placa indicadora de modelo

E

Explicación de símbolos

CE, Communauté Européenne

Los instrumentos con este marcaje cumplen las directivas

europeas aplicables.

ATEX Directiva europea para garantizar la seguridad frente

a las explosiones

(Atmosphère = AT, explosible = EX)

Los instrumentos con este marcaje están conformes a las

exigencias de la directiva europea 94/9/CE (ATEX) relativa a la

11554810.02 11/2013 GB/D/F/E

prevención de explosiones.

Fecha de

fabricación

¡Es absolutamente necesario leer el manual de

instrucciones antes del montaje y la puesta en

servicio del manómetro!

43WIKA manual de instrucciones para manómetro modelo 5 según ATEX

Page 44

3. Datos técnicos / 4. Diseño y función

3. Datos técnicos

Carga de presión máxima

Carga estática: Valor nal de escala

Carga dinámica: 0,9 x valor nal de escala

Protección contra la sobrepresión

por lo menos 1 bar de presión absoluta (presión atmosférica), además 10 veces

el valor nal de escala, pero máx. 25 bar de presión absoluta

Piezas en contacto con el medio

Conexión a proceso y cámara de medición: acero inoxidable

E

Elemento sensible

≤ 0,25 bar: Acero inoxidable 1.4571

> 0,25 bar: Aleación de acero inoxidable (Inconel)

Caja, aro bayoneta

Acero inoxidable

(modelos 532.3x, 533.32, 533.33, 533.34 con disco de seguridad)

Inuencia de temperatura

En caso de desviación de la temperatura de referencia en el sistema de medición

(+20 °C): max. ±0,8 %/10 K del respectivo valor nal de escala

Tipo de protección IP

IP 54 según EN 60529 / IEC 529

(con líquido de llenado IP 65)

Para más datos técnicos véase la hoja técnica de WIKA PM 05.02 y la

documentación de pedido.

4. Diseño y función

Descripción

■

Diámetro nominal 100 y 160 mm

■

Los instrumentos captan la presión a medir mediante membranas elásticas.

El punto de referencia es la presión absoluta “cero”.

■

Las características técnicas de medición corresponden a la norma EN 837-3.

44 WIKA manual de instrucciones para manómetro modelo 5 según ATEX

11554810.02 11/2013 GB/D/F/E

Page 45

4. Diseño y función / 5. Transporte, embalaje y almacenamiento

■

La membrana (1) separa la cámara del

Esquema de funcionamiento

medio (3) y la cámara de presión referencial

(2) con presión absoluta cero

■

La diferencia de presión entre la cámara del

medio (3) y la cámara de presión referencial

(2) produce una desviación (trayecto de

medición) de la membrana (1)

■

El elemento sensible es protegido por la

supercie de soporte de carga en caso de

(evacuado)

sobrecarga de presión

■

La desviación se transmite mediante fuelles

o tubos corrugados (4) desde la cámara

de presión y a través de una biela (5) al

mecanismo indicador, donde es visualizada.

Volumen de suministro

Comparar mediante el albarán si se han entregado todas las piezas.

5. Transporte, embalaje y almacenamiento

5.1 Transporte

Comprobar si el manómetro absoluto presenta eventuales daños causados en el

transporte. Noticar daños obvios de forma inmediata.

289752.01

E

5.2 Embalaje

No quitar el embalaje hasta justo antes del montaje.

Guardar el embalaje ya que es la protección ideal durante el transporte (por

ejemplo si el lugar de instalación cambia o si se envía el instrumento para

posibles reparaciones).

5.3 Almacenamiento

Condiciones admisibles en el lugar de almacenamiento

Temperatura de almacenamiento: -20 ... +60 °C

Para evitar daños, deben observarse los siguientes aspectos para el almacenamiento de los manómetros:

■

Dejar los manómetros en su embalaje original

■

Tras retirarlos, por ejemplo para comprobaciones, los instrumentos deberán

almacenarse nuevamente en su embalaje original.

11554810.02 11/2013 GB/D/F/E

45WIKA manual de instrucciones para manómetro modelo 5 según ATEX

Page 46

5. Transporte, embalaje ... / 6. Puesta en servicio, funcionamiento

Evitar lo siguiente:

■

Luz solar directa o proximidad a objetos calientes

■

Vibración mecánica, impacto mecánico (colocación brusca)

■

Hollín, vapor, polvo, humedad y gases corrosivos

■

Entorno potencialmente explosivo, atmósfera inamable

¡ADVERTENCIA!

Antes de almacenar el instrumento, eliminar todos los restos de

medios adheridos. Esto es especialmente importante cuando

el medio es nocivo para la salud, como p. ej. cáustico, tóxico,

cancerígeno, radioactivo, etc.

E

6. Puesta en servicio, funcionamiento

6.1 La conexión mecánica

■

Conforme a las reglas técnicas generales para manómetros (por ejemplo

EN 837-2 “Recomendaciones relativas a la selección y montaje de

manómetros”).

■

Para atornillar el instrumento, se debe utilizar la fuerza mediante el uso de

herramientas adecuadas sobre las supercies planas de ajuste -previstas

para este n-. Nunca sobre la caja.

Montaje mediante

llave de boca

■

Antes de montar el instrumento, sacudir o limpiar con aire comprimido o agua

las líneas de medición

■

El manómetro debe montarse libre de vibraciones y orientado para una fácil

lectura. Se recomienda interponer una válvula de cierre entre la toma de

presión y el manómetro para sustituir el instrumento durante el proceso de la

instalación. Los instrumentos deben protegerse contra contaminación y fuertes

oscilaciones de la temperatura ambiente.

46 WIKA manual de instrucciones para manómetro modelo 5 según ATEX

11554810.02 11/2013 GB/D/F/E

Page 47

6. Puesta en servicio, funcionamiento

Instalación

Posición nominal según EN 837-3 / 9.6.6 ilustr 7: 90° ( ⊥ )

Conexión a proceso inferior

¡Asegúrese de que haya un espacio de mín. 25 mm detrás de la caja de los

modelos 53x.31 ... 53x.34 para garantizar el alivio seguro de presión a través

de la pared trasera en caso de fallo!

¡No exponer los instrumentos a la radiación solar directa durante el

funcionamiento para evitar un calentamiento adicional!

¡En versiones con relleno hay que abrir la válvula de ventilación en el lado

superior de la caja!

Las temperaturas ambiente y de funcionamiento permitidas

Se debe efectuar la instalación del manómetro de tal forma, que no se excedan

los límites de la temperatura ambiente ni la del material de medición, incluyendo

la inuencia de convección y la radiación térmica. Debe tenerse en cuenta la

inuencia de la temperatura en la precisión de indicación.

Oscilación admisible en el lugar de instalación

■

Instalar los instrumentos sólo en lugares sin oscilaciones.

■

El desacoplamiento del lugar de instalación puede conseguirse por ejemplo

mediante una línea de conexión exible del punto de medición al manómetro

y mediante jación por medio de un soporte para el manómetro.

E

Si esto no es posible, no se debe sobrepasar en ningun caso los siguientes valores

límites:

Instrumentos sin relleno: Gama de frecuencias < 150 Hz

(modelos 532.5x o 532.3x) Aceleración < 0,7 g (7 m/s

2

)

Instrumentos llenados de líquido: Gama de frecuencias < 150 Hz

(modelos 533.5x o 533.3x) Aceleración < 4 g (40 m/s

2

)

Comprobar periodicamente el llenado de líquido

El nivel de líquido no debe caer por debajo del 75 % del diámetro del instrumento.

Puesta en servicio

Evitar golpes de ariete en todo caso durante la puesta en servicio, abrir

lentamente las válvulas de cierre.

11554810.02 11/2013 GB/D/F/E

47WIKA manual de instrucciones para manómetro modelo 5 según ATEX

Page 48

7. Mantenimiento y limpieza / 8. Desmontaje, devolución y ...

7. Mantenimiento y limpieza

7.1 Mantenimiento

■

Los instrumentos no requieren mantenimiento.

■

Controlar el instrumento y la función de conmutación una o dos veces al año.

Para eso, separar el instrumento del proceso y controlarlo con un dispositivo

de control de presión.

■

Todas las reparaciones solamente las debe efectuar el fabricante o personal

especializado e instruido.

7.2 Limpieza

E

¡CUIDADO!

■ Limpiar el manómetro con un trapo húmedo.

■ Una vez desmontado el instrumento se debe enjuagar y

limpiar antes de devolverlo para proteger a las personas y el

medio ambiente contra residuos del medio de medición.

8. Desmontaje, devolución y eliminación

¡ADVERTENCIA!

Medios residuales en instrumentos de medición desmontados

pueden causar riesgos para personas, medio ambiente e

instalación.

Tomar las medidas de precaución adecuadas.

8.1 Desmontaje

¡Desmontar el instrumento de medición sólo si no está sometido a tensión!

En caso necesario hay que destensar la línea de medición.

8.2 Devolución

Una vez desmontado el instrumento de medición se debe enjuagar y limpiar

el instrumento antes de devolverlo para proteger a los empleados y el medio

ambiente contra medios residuales de medición.

8.3 Eliminación de residuos

Una eliminación incorrecta puede provocar peligros para el medio ambiente.

Eliminar los componentes de los instrumentos y los materiales de embalaje

conforme a los reglamentos relativos al tratamiento de residuos y eliminación

vigentes en el país de utilización.

48 WIKA manual de instrucciones para manómetro modelo 5 según ATEX

11554810.02 11/2013 GB/D/F/E

Page 49

Anexo 1: Declaración de conformidad CE

E

11554810.02 11/2013 GB/D/F/E

49WIKA manual de instrucciones para manómetro modelo 5 según ATEX

Page 50

WIKA global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand GmbH & Co. KG

Perfektastr. 83

1230 Vienna

Tel. +43 1 8691631

Fax: +43 1 8691634

info@wika.at

www.wika.at

Belarus

WIKA Belrus

Ul. Zaharova 50B, Oce 3H

220088 Minsk

Tel. +375 17 2945711

Fax: +375 17 2945711

info@wika.by

www.wika.by

Benelux

WIKA Benelux

Industrial estate De Berk

Newtonweg 12

6101 WX Echt

Tel. +31 475 535500

Fax: +31 475 535446

info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

Akad.Ivan Geshov Blvd. 2E

Business Center Serdika

1330 Soa

Tel. +359 2 82138-10

Fax: +359 2 82138-13

info@wika.bg

www.wika.bg

Croatia

WIKA Croatia d.o.o.

Hrastovicka 19

10250 Zagreb-Lucko

Tel. +385 1 6531-034

Fax: +385 1 6531-357

info@wika.hr

www.wika.hr

Finland

WIKA Finland Oy

Melkonkatu 24

00210 Helsinki

Tel. +358 9 682492-0

Fax: +358 9 682492-70

info@wika.

www.wika.

France

WIKA Instruments s.a.r.l.

Parc d‘Aaires des Bellevues

8 rue Rosa Luxembourg

95610 Eragny-sur-Oise

Tel. +33 1 343084-84

Fax: +33 1 343084-94

info@wika.fr

www.wika.fr

Germany

WIKA Alexander Wiegand SE &

Co. KG

Alexander-Wiegand-Str. 30

63911 Klingenberg

Tel. +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

www.wika.de

Italy

WIKA Italia S.r.l. & C. S.a.s.

Via G. Marconi 8

20020 Arese (Milano)

Tel. +39 02 93861-1

Fax: +39 02 93861-74

info@wika.it

www.wika.it

Poland

WIKA Polska S.A.

Ul. Legska 29/35

87-800 Wloclawek

Tel. +48 54 230110-0

Fax: +48 54 230110-1

info@wikapolska.pl

www.wikapolska.pl

Romania

WIKA Instruments Romania

S.R.L.

050897 Bucuresti

Calea Rahovei Nr. 266-268

Corp 61, Etaj 1

Tel. +40 21 4048327

Fax: +40 21 4563137

m.anghel@wika.ro

www.wika.ro

Russia

ZAO WIKA MERA

Wjatskaya Str. 27, Building 17

Oce 205/206

127015 Moscow

Tel. +7 495-648018-0

Fax: +7 495-648018-1

info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

Sime Solaje 15

11060 Beograd

Tel. +381 11 2763722

Fax: +381 11 753674

info@wika.rs

www.wika.rs

Spain

Instrumentos WIKA S.A.U.

C/Josep Carner, 11-17

08205 Sabadell Barcelona

Tel. +34 933 9386-30

Fax: +34 933 9386-66

info@wika.es

www.wika.es

Switzerland

MANOMETER AG

Industriestrasse 11

6285 Hitzkirch

Tel. +41 41 91972-72

Fax: +41 41 91972-73

info@manometer.ch

www.manometer.ch

Turkey

WIKA Instruments Istanbul

Basinc ve Sicaklik Ölcme

Cihazlari

Ith. Ihr. ve Tic. Ltd. Sti.

Bayraktar Bulvari No. 17

34775 Yukari Dudullu - Istanbul

Tel. +90 216 41590-66

Fax: +90 216 41590-97

info@wika.com.tr

www.wika.com.tr

Ukraine

TOV WIKA Prylad

M. Raskovoy Str. 11, A

PO 200

02660 Kyiv

Tel. +38 044 4968380

Fax: +38 044 4968380

info@wika.ua

www.wika.ua

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill RH13LG

Tel. +44 1737 644-008

Fax: +44 1737 644-403

info@wika.co.uk

www.wika.co.uk

50 WIKA operating instructions pressure gauge model 5 per ATEX

11554810.02 11/2013 GB/D/F/E

Page 51

WIKA global

North America

Canada

WIKA Instruments Ltd.

Head Oce, 3103 Parsons Road

Edmonton, Alberta, T6N 1C8

Tel. +1 780 4637035

Fax: +1 780 4620017

info@wika.ca

www.wika.ca

Mexico

Instrumentos WIKA Mexico

S.A. de C.V.

Viena 20 Ofna 301

Col. Juarez, Del. Cuauthemoc

06600 Mexico D.F.

Tel. +52 55 50205300

Fax: +52 55 50205300

ventas@wika.com

www.wika.com.mx

USA

WIKA Instrument, LP

1000 Wiegand Boulevard

Lawrenceville, GA 30043

Tel. +1 770 5138200

Fax: +1 770 3385118

info@wika.com

www.wika.com

WIKA Process Solutions, LP.

950 Hall Court

Deer Park, TX 77536

Tel. +1 713 47500-22

Fax: +1 713 47500-11

info@wikahouston.com

www.wika.com

Mensor Corporation

201 Barnes Drive

San Marcos, TX 78666

Tel. +1 512 396-4200

Fax: +1 512 396-1820

sales@mensor.com

www.mensor.com

Latin America

Argentina

WIKA Argentina S.A.

Gral. Lavalle 3568

(B1603AUH) Villa Martelli

Buenos Aires

Tel. +54 11 47301800

Fax: +54 11 47610050

info@wika.com.ar

www.wika.com.ar

11554810.02 11/2013 GB/D/F/E

Brazil

WIKA do Brasil Ind. e Com. Ltda.

Av. Ursula Wiegand, 03

CEP 18560-000 Iperó - SP

Tel. +55 15 34599700

Fax: +55 15 32661650

vendas@wika.de

www.wika.com.br

Chile

WIKA Chile S.p.A.

Av. Coronel Pereira 72,

Las Condes - Santiago de Chile

Tel. +56 2 365-1719

info@wika.cl

www.wika.cl

Colombia

Instrumentos WIKA Colombia

S.A.S.

Dorado Plaza,

Avenida Calle 26 No. 85D – 55

Local 126 y 126 A

Bogotá – Colombia