Page 1

Air Filter Compartment

Model Number

ACM/ACB

With Media Filter

ACM1000

ACM1400

ACM1600

ACM2000

No Media Filter

ACB1000

ACB1400

ACB1600

ACB2000

OWNER’S MANUAL

• Installation

• Operation

• Technical Repair Guide

• Repair and Upgrade Parts

Please read and familiarize yourself with the contents of this manual before

installing, operating or performing maintenance on the unit.

White-Rodgers is a division

of Emerson Electric Co.

www.white-rodgers.com

Printed In U.S.A.

PART NO. 37-6383A

Replaces 846-2032-B

0206

Page 2

INTRODUCTION

The White-Rodgers Air Cleaner Compartment comes complete with a 5” media furnace air filter. This filter must be

changed every three months to maintain efficiency of the filter

and furnace system. For maximum efficiency, the compartment can be upgraded to a White-Rodgers Electronic Air

Cleaner.

Please read instructions before installing and using the Air

Filter Compartment.

! CAUTION

▲

The fiber filter used in this cabinet for air cleaning

must be replaced every 90 days. Your heating and

cooling efficiency will decrease due to insufficient

air flow when filter becomes dirty.

! WARNING

▲

Do not attempt installation of this unit unless you

are familiar with the necessary tools, equipment,

and potential hazards.

Installation should be performed only by a qualified

service provider.

Failure to do so could result in reduced performance

of the unit, serious personal injury or death.

GUARANTEE

White-Rodgers will not assume any responsibility for

component failures due to incorrect installation procedures.

RULES FOR SAFE INSTALLATION

AND OPERATION

1. Read the Owners Manual and the Rules for Safe

Operation carefully. Failure to follow these rules and

instructions could cause a malfunction of filter or

unsatisfactory service.

! WARNING

▲

Installation of this unit must comply with local

electric codes or other applicable codes.

Review and understand local codes prior to

installation.

! WARNING

▲

Before installing or servicing, always

shut off electricity. This will prevent

any electrical shocks.

2. Follow a regular service and maintenance schedule

for efficient operation.

TABLE OF CONTENTS

Rules for Safe Installation and Operation ............2

How the Air Filter Works ......................................3

Construction of the Air Filter Compartment .........3

Preinstallation.......................................................4

Installation ............................................................ 6

Maintenance.........................................................7

Repair and Upgrade Parts ................................... 7

DID YOU GET THE RIGHT SIZE

AIR FILTER COMPARTMENT

Model ACB & ACM1000 are designed for heating or

cooling blowers delivering 600 to 1200 cubic feet of air per

minute (cfm.)

Model ACB & ACM1400 are designed for heating or

cooling blowers delivering 1000 to 1600 cfm.

Model ACB & ACM1600 are designed for heating or

cooling blowers delivering 1200 to 1800 cfm.

Model ACB & ACM2000 are designed for heating or

cooling blowers delivering 1600 to 2200 cfm.

Before installing the filter, make sure you have selected

the proper size unit for your heating and cooling system

requirements. See specifications on page 4.

BASIC TOOLS REQUIRED

Tin Snip

Screwdriver

Rule or Tape Measure

Drill

2

Page 3

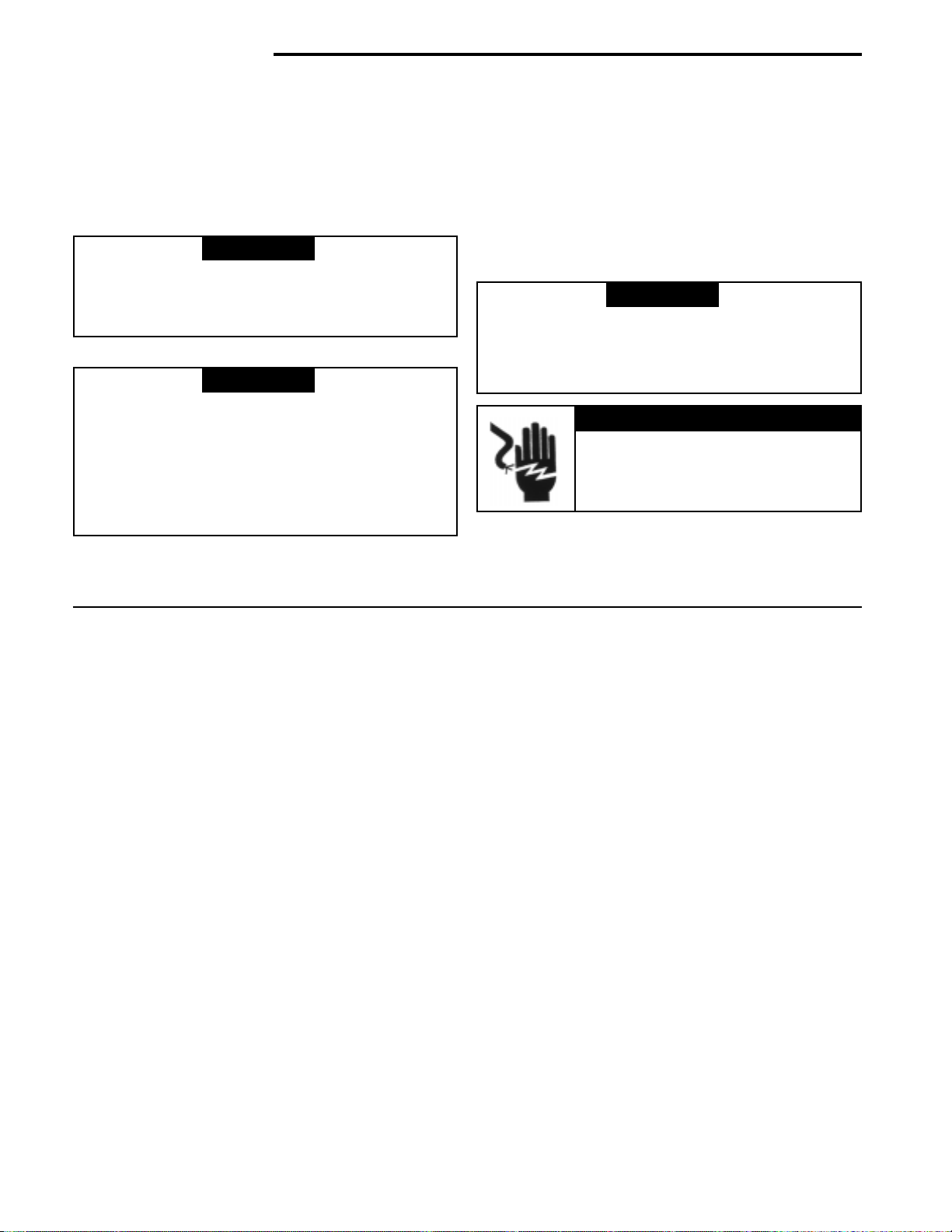

HOW THE AIR FILTER WORKS

5" FILTER

Dirty air flows through your return air ducts and enters the

compartment where particles (hair, lint, etc.) are removed

by the filter. See figure 1.

Filtered air re-enters to the supply duct system of your

building.

DIRTY AIR IN

CONSTRUCTION OF THE AIR FILTER COMPARTMENT

Not only is your air filter compartment easy to install, it is

also easy to maintain. Its basic components, and their

functions, are as follows: (See Figure 2)

Air Filter Compartment- mounts to existing duct work and

houses the filters or optional electronic air cleaner

cells.

NOTE: To upgrade your air filter compartment

with a high efficiency Electronic Air Cleaner, use

the ACR (Air Cleaner Retrofit) Kit for your model.

See page 7 for details.

5” Filter - collects dust, dirt and other particles.

AIR FILTER COMPARTMENT

FILTERED AIR OUT

Figure 1

5" FILTER

DOOR

Figure 2

3

Page 4

PREINSTALLATION

LOCATING THE AIR FILTER

Your air filter must be mounted in the return air duct of a

central forced-air system, on the air entering side of your

furnace. (See Figure 3 for example.)

Select a location that meets the following:

1. The face of the filter will be at a right angle to the air

stream.

2. Allow 25” of clearance in front of the air filter compartment door to permit removal of filters.

See figure 4 for complete compartment dimensions.

3. The air filter is not to be placed in the discharge of

either the heating or cooling unit.

4. IMPORTANT: If atomizing spray type humidifier is

used, it must be installed downstream from the air

filter.

If furnace opening cannot be enlarged to required size, a

transition sheet metal section must be used. Transition

must be planned for each job. Reduction should not be

more than 4 inches per linear foot, approximately 20

angular degrees (Figure 3).

AIR FLOW

FURNACE

OPENING

FURNACE

NOT TO EXCEED 20

AIR CLEANER

TRANSITION SECTION (IF NEEDED)

Figure 3

6 7/8

THIS CABINET

CAN ACCEPT

ELECTRONIC

AIR CLEANER

OPTION

(SEE PAGE 7)

AIR FLOW

AIR CLEANER

OPENING

DUCTWORK

D

C

B

A

E

Model No. A B C D E

ACB/ACM1000 20-1/4 12-5/8 13-9/16 16-7/16 19-1/16

ACB/ACM1400 26-1/4 23-5/8 13-9/16 16-7/16 19-1/16

ACB/ACM1600 20-1/4 12-5/8 17-3/4 20-5/8 23-3/8

ACB/ACM2000 26-1/4 23-5/8 17-3/4 20-5/8 23-3/8

Figure 4

4

Page 5

TYPICAL MOUNTING POSITIONS

AIR FLOW

Figure 5

BASEMENT FURNACE

(LOWBOY) (Figure 5)

Filter is mounted horizontally in return plenum, just

above furnace.

AIR FLOW

Figure 6

COUNTERFLOW

FURNACE (Figure 6)

Filter is mounted horizontally

in return duct or plenum, just

above furnace.

AIR FLOW

Figure 7

HIGHBOY FURNACE

(Figure 7)

Side installation. Filter is

mounted vertically, where

return air enters side inlet

of furnace.

HIGHBOY FURNACE

(Figure 8)

Installation beneath furnace.

Filter mounts horizontally,

where return air enters from

below. Raise furnace and install beneath base.

AIR FLOW

AIR FLOW

HORIZONTAL FURNACE

(Figure 10)

Figure 10

Filter is mounted vertically in

the return duct near furnace.

LESS THAN

7 INCHES

FIGURE 9

OFFSET

AT LEAST

9 INCHES

OFFSET INSTALLATION

(Figure 9)

Typical use of duct offset to match air filter opening.

If duct connection to furnace allows less than nine

inches for mounting the air filter, shorten the lateral

trunk, or attach an offset fitting to the elbow.

5

Page 6

INSTALLATION

REMOVE OLD FILTER AND DISCARD

(Figure 11)

NOTE: This filter may be mounted in the furnace compartment.

CLEAN BLOWER COMPARTMENT

NOTE: The air filter cannot remove dirt from blower and

ducts.

INSTALLATION

The following is a typical installation of the air filter on a

“Highboy” furnace (Figure 7).

1. Place the air filter compartment on the floor. Stand it

upright with the door facing you (Figure 2). If a

horizontal installation is being planned, lay the compartment on its side, this will help you to visualize the

relative location of all parts.

2. Unscrew the knob, remove the door (by grasping top

and pulling door away from compartment) and set it

aside. Remove 5” filter. Set in a safe location until the

compartment is installed.

3. Set the compartment next to the furnace (if possible)

to match the opening in the compartment.

If the furnace opening cannot be enlarged, a transition fitting should be used. (Figure 3).

The compartment can be attached directly (Figure

12), or a starting collar can first be fitted to the furnace

inlet. A butt or slip joint can be used.

Securely attach the compartment to furnace inlet,

using at least two of the mounting holes on each side

of the compartment.

4. Using butt joint, attach duct work (normally an elbow)

to the upstream side of air filter compartment. (Note

the use of the sheet metal turning vanes inside the

elbow to improve air distribution.) (Figure 13)

NOTE: An optional method of attaching duct work to the

air filter cabinet is to modify the compartment (Figure 14)

by bending the tabs outward at a 90° angle and attaching

duct work to tabs.

Air Flow

Figure 11

Turning

Vanes

Figure 13

Transition Fittings

If the air duct does not fit the compartment opening, a

transition fitting should be used. Gradual transitions are

preferred for greatest efficiency. Not more than four

inches per linear foot (approximately 20° angle) should be

allowed (Figure 3).

5. Connect the vertical duct section to the elbow. Wedge

a wood block between floor and elbow for support

(Figure 15).

6. Seal all joints in the return air system downstream

from the air filter with duct tape to prevent dust from

entering the air stream. Tape is usually applied on the

outside of ducts, but may also be applied on the

inside, or both.

(Bend tabs outward at 90˚ angle)

7. With the air filter compartment installed, re-install 5”

6

Optional method

Figure 14

filter and door. (Figure 2)

Page 7

Vertical

Section

Wood Block

FLOOR

CONDUIT

Tape All

Joints

DUCT

Figure 15

MAINTENANCE

! CAUTION

▲

The fiber filter used in this compartment for air

cleaning must be replaced every 90 days. Your

heating and cooling efficiency will decrease due

to insufficient air flow when filter becomes dirty.

For maximum efficiency, your air filter should be inspected once a month and changed if dirt loading is

heavy. When changing is required, the following procedure should be used:

REPAIR and UPGRADE PARTS

1

2

3

1

AIR CLEANER

Figure 16

1. Remove door from air filter compartment by unscrewing the knob.

2. Remove 5” filter and throw away.

3. Replace 5” filter by sliding it into the compartment.

(Note direction of air flow.)

4. Replace door.

PARTS LIST FOR

AIR FILTER COMPARTMENT

When ordering repair parts, always give the following

information as shown in this list.

1. The PART NUMBER

2. The PART DESCRIPTION

3. The MODEL NUMBER of the Air Filter Compart-

ment

UPGRADE!

ELECTRONIC AIR CLEANER KIT

Always order by “PART NUMBER” . . .

Not by “ITEM NUMBER”

Part Number

Item

No. Description 1000 1400 1600 2000

1 Compartment & Door ACB1000 ACB1400 ACB1600 ACB2000

2 Filters 5” FR1000 FR1400 FR1600 FR2000

3 Screw, Fastener F870-0026 F870-0026 F870-0026 F870-0026

Description 1000 1400 1600 2000

Electronic Air Cleaner Retrofit Kit ACR1000 ACR1400 ACR1600 ACR2000

7

Page 8

NOTICE TO CONSUMERS

White-Rodgers

Electronic Air Cleaner

Dear Consumer;

White-Rodgers would like to thank you for purchasing a White-Rodgers Electronic Air

Cleaner or product containing a White-Rodgers Electronic Air Cleaner. Although WhiteRodgers does not extend a warranty directly to consumers, White-Rodgers does extend a

warranty to Wholesalers and Original Equipment Manufacturers who use White-Rodgers

Products. To obtain more information about how your Wholesaler or Original Equipment

Manufacturer’s warranty may benefit you, please contact your Wholesaler or Original

Equipment Manufacturer.

Sincerely,

White-Rodgers

The Emerson logo is a

trademark and service mark

of Emerson Electric Co.

Loading...

Loading...