White Rodgers 3046-5 Installation Instructions

Type 3046

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

Automatic pilots are required on gas-fired heating equipment to prevent the flow of gas to the main burner if the

pilot flame is not burning or is insufficient to properly ignite

the main burner.

This pilot has automatic reset (automatic recycling) needing merely relighting or possibly only the resumption of

proper gas pressure to put back in operation.

If in doubt about whether your wiring is millivolt, line, or low

voltage, have it inspected by a qualified heating and air

conditioning contractor, electrician, or someone familiar

with basic electricity and wiring.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical

codes and ordinances.

This control is a precision instrument, and should be

handled carefully. Rough handling or distorting components could cause the control to malfunction.

WARNING

!

Do not use on circuits exceeding specified voltage. Higher voltage will damage control and could

cause shock or fire hazard.

Automatic Pilots

INSTALLATION INSTRUCTIONS

DESCRIPTION

These automatic pilots may be used with natural, manufactured, or mixed gases, and with LP gases where

means are provided for obtaining a 100% shutoff system.

The pilot burner should be equipped with the recommended size orifice fitting.

The metal box containing the switch may be conveniently

mounted in any position. The cover is easily removed,

making the switch terminals readily accessible.

PRECAUTIONS

CAUTION

!

To prevent electrical shock and/or equipment

damage, disconnect electric power to system at

main fuse or circuit breaker box until installation

is complete.

Shut off main gas to heating system until installation is complete.

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper

and dangerous operation.

Following installation or replacement, follow appliance manufacturer’s recommended installation and/or service instructions to insure proper

operation.

These Pilots can be used with either A, B, or E series pilot

burners.

Pilot Burners are available in 14 port arrangements,

Bunsen and “Non-linting”, and with a wide choice of

mounting facilities.

Contact Action is SPST snap-action, close-on-rise.

ATTENTION!

This product contains mercury. There will not be any exposure to mercury under normal conditions of use. This product may

replace a unit which contains mercury. Do not open mercury cells. If a cell becomes damaged, do not touch any spilled

mercury. Wearing nonabsorbent gloves, take up the spilled mercury with sand or other absorbent material and place into a

container which can be sealed. If a cell becomes damaged, the unit should be discarded. Mercury must not be discarded in

household trash. When this unit or the unit it is replacing is to be discarded, place in a suitable container and return to us .

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123-5398

(314) 577-1300, FAX (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, FAX (905) 475-4625

Printed in U.S.A.

SPECIFICATIONS

Orifice fittings offer three different styles of connections

each available for the most used gases.

Timing: Contacts close approximately 60 seconds after

the pilot is ignited. Contacts open approximately 40

seconds after the flame is extinguished.

PART NO. 37-0613G

Replaces 37-0613F

9651

INSTALLATION

CAUTION

!

To avoid personal injury and/or property damage,

shut off gas and electric to heating system until

installation is complete.

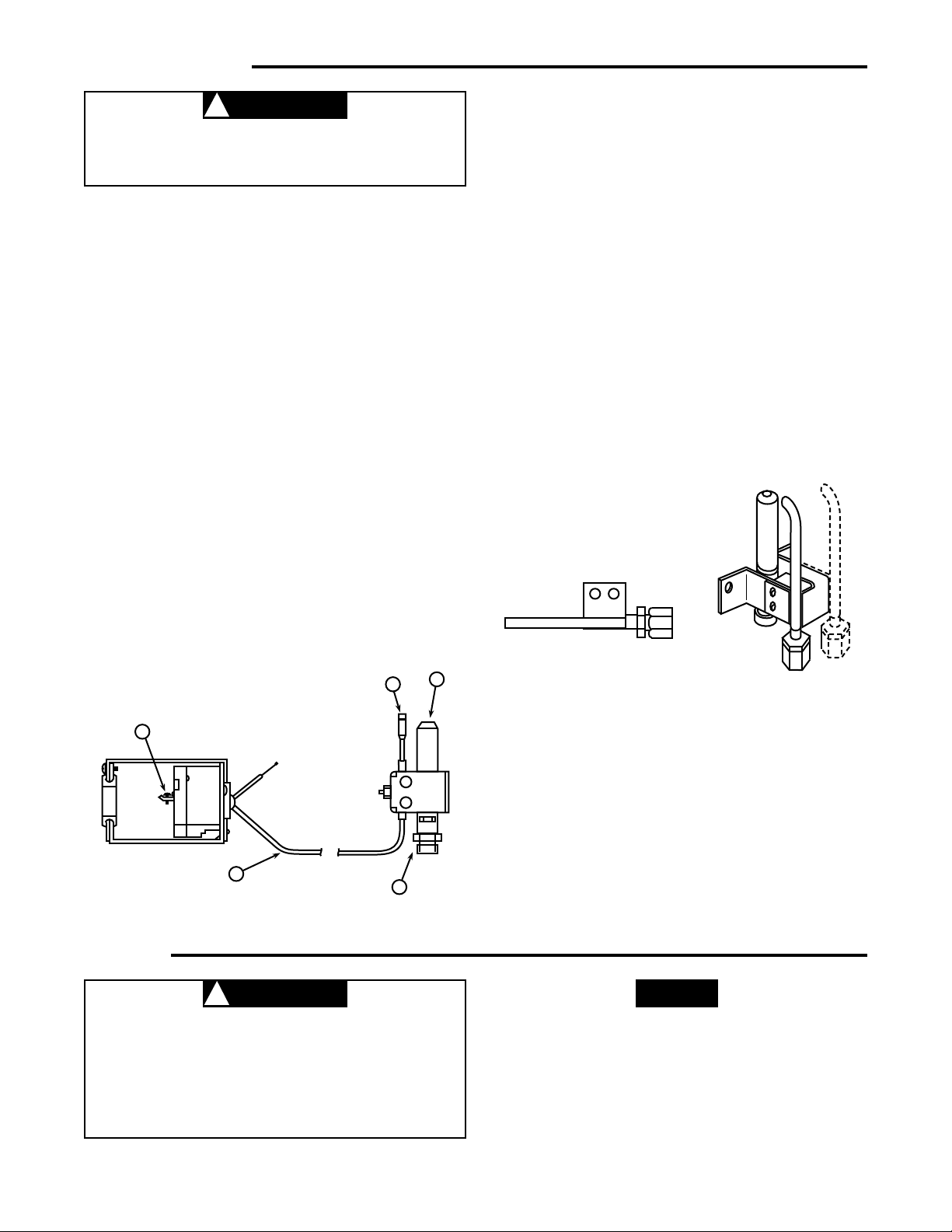

Uncoil the capillary carefully, making certain that it is not

bent sharply at any place. Be particularly careful with that

part of the capillary connected to the diaphragm.

The thermal element of the automatic pilot may be attached to the pilot burner either before of after the pilot

burner is mounted to the main burner. To attach the

thermal element to the pilot burner: remove nut and

lockwasher, slip thermal element into bracket of pilot

burner so that screw on element extends through the hole

in bracket. Then fasten with nut and lockwasher.

The orifice fitting should then be screwed into the pilot

burner and the tubing connected to the orifice fitting.

The proper location of an automatic pilot, with respect to

the main burner, should be determined by the manufacturer of the burner according to the requirements of the

American Gas Association and the local gas utility.

1. The operating temperatures, as taken by thermocouples attached to the surface of the automatic pilot

and pilot burner at the points shown below, must not

exceed the following:

2. The automatic pilot must be mounted near enough to

the main gas burner so it is easily ignited by the pilot

ignition flame even when the pilot flame is reduced to

the point where it is just sufficient to keep the pilot

switch contacts closed.

3. Proper functioning of the automatic pilot requires that

the flame from the main gas burner not touch any part

of the automatic pilot.

4. The pilot burner must be positioned so as to receive

incoming secondary air and not the products of combustion.

5. Unless protected from strong drafts of secondary air,

which tend to carry the flame away from the bulb, the

automatic pilot may not be supplied with sufficient

heat for proper operation.

6. It is recommended that on installations burning manufactured gas, an approved filter of sufficient capacity

be connected into the pilot gas line to prevent formation of gum at the orifice.

Bleed Burners are available

for vertical or horizontal pilots.

1. Tip of pilot burner, 1200 ° F.

2. Tip of thermal element, 1400 ° F.

3. Orifice fitting, 475 ° F.

4. Capilllary 500 ° F.

5. Terminal screw on pilot, 175 ° F.

5

4

2

3

WIRING

CAUTION

!

To prevent electrical shock and/or equipment

damage, disconnect electric power to system at

main fuse or circuit breaker box until installation

is complete.

All wiring should be installed in accordance with

local and national electrical codes and ordinances.

1

7. Bleed tubes are available for attaching to the bracket

of the pilot burner. This tube is for burning the bleed

gas from the diaphragm gas valve and from the

pressure regulator and should be connected accordingly.

Horizontal

Vertical

NOTE

These typical wiring diagrams show only the terminal

identification and wiring hook up. Always refer to wiring

instructions provided by equipment manufacturer for system hookup operation.

2

Loading...

Loading...