Page 1

1F56W-444

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

This low voltage thermostat is designed to provide convenient control of the heating/cooling system. To provide

greater room comfort, the sensitive spiral bimetal is combined with an adjustable heating anticipator and a fixed

cooling anticipator to provide maximum comfort.

Low Voltage Heating/Cooling Thermostat

INSTALLATION INSTRUCTIONS

DESCRIPTION

If in doubt about whether your wiring is millivolt, line, or low

voltage, have it inspected by a qualified heating and air

conditioning contractor, electrician, or someone familiar

with basic electricity and wiring.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical

codes and ordinances.

CONTENTS

Description......................................................... 1

Precautions........................................................ 1

Specifications..................................................... 2

Installation.......................................................... 2

Select Thermostat Location

Route Wires to Location

Attach Subbase to Wall

Special System Configurations

Electric Heat Furnaces (Single Trans-

former Systems Only)

Two-Transformer Systems

Heat Pump Applications

Special Application Terminals

Attach Thermostat to Subbase

Operation & Maintenance .................................. 5

Adjusting Heat Anticipator

Calibrating Thermostat

PRECAUTIONS

This control is a precision instrument, and should be

handled carefully. Rough handling or distorting components could cause the control to malfunction.

CAUTION

!

To prevent electrical shock and/or equipment

damage, disconnect electric power to system at

main fuse or circuit breaker box until installation

is complete.

Do not short out terminals on gas valve or primary control to test. Short or incorrect wiring will

burn out heat anticipator and could cause personal injury and/or property damage.

WARNING

!

Do not use on circuits exceeding 30 volts. Higher

voltage will damage control and could cause

shock or fire hazard.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS ROAD

ST. LOUIS, MISSOURI 63123-5398

Printed in U.S.A.

PART NO. 37-5026B

Replaces 37-5026A

9622

Page 2

SPECIFICATIONS

ELECTRICAL DATA

Switch Rating: 24 VAC (30 VAC max.)

Heating - 0.15 to 1.2 Amps

Cooling - 0 to 1.5 Amps

Switch Action: SPST - Sealed mercury switch

Anticipator Rating:

Heating - Adjustable from 0.15 to 1.2 Amps

Cooling - Fixed 24 VAC

THERMAL DATA

Temperature Range: 50°F to 90°F (10°C to 32°C)

Differential: 1°F

INSTALLATION

SELECT THERMOSTAT LOCATION

Proper location insures that the thermostat will provide a

comfortable home temperature. Observe the following

general rules when selecting a location:

1. Locate thermostat about 5 ft. above the floor.

2. Install thermostat on a partitioning wall, not on an

outside wall.

3. Never expose thermostat to direct light from lamps,

sun, fireplaces or any temperature radiating equipment.

4. Avoid locations close to windows, adjoining outside

walls, or doors that lead outside.

5. Avoid locations close to air registers or in the direct

path of air from them.

6. Make sure there are no pipes or duct work in that part

of the wall chosen for the thermostat location.

7. Never locate thermostat in a room that is warmer or

cooler than the rest of the home, such as the kitchen.

8. Avoid locations with poor air circulation, such as

behind doors or in alcoves.

9. The living or dining room is normally a good location,

provided there is no cooking range or refrigerator on

opposite side of wall.

APPLICATIONS

The 1F56W-444 is designed for use with

• Standard heating and cooling systems

• Electric heating and cooling systems

• Single stage heat pump systems

• Two-transformer systems

• Electronic air cleaners

• Humidifiers

• Zone dampers

This thermostat CANNOT BE USED with:

• Millivolt systems

• Multi-stage applications

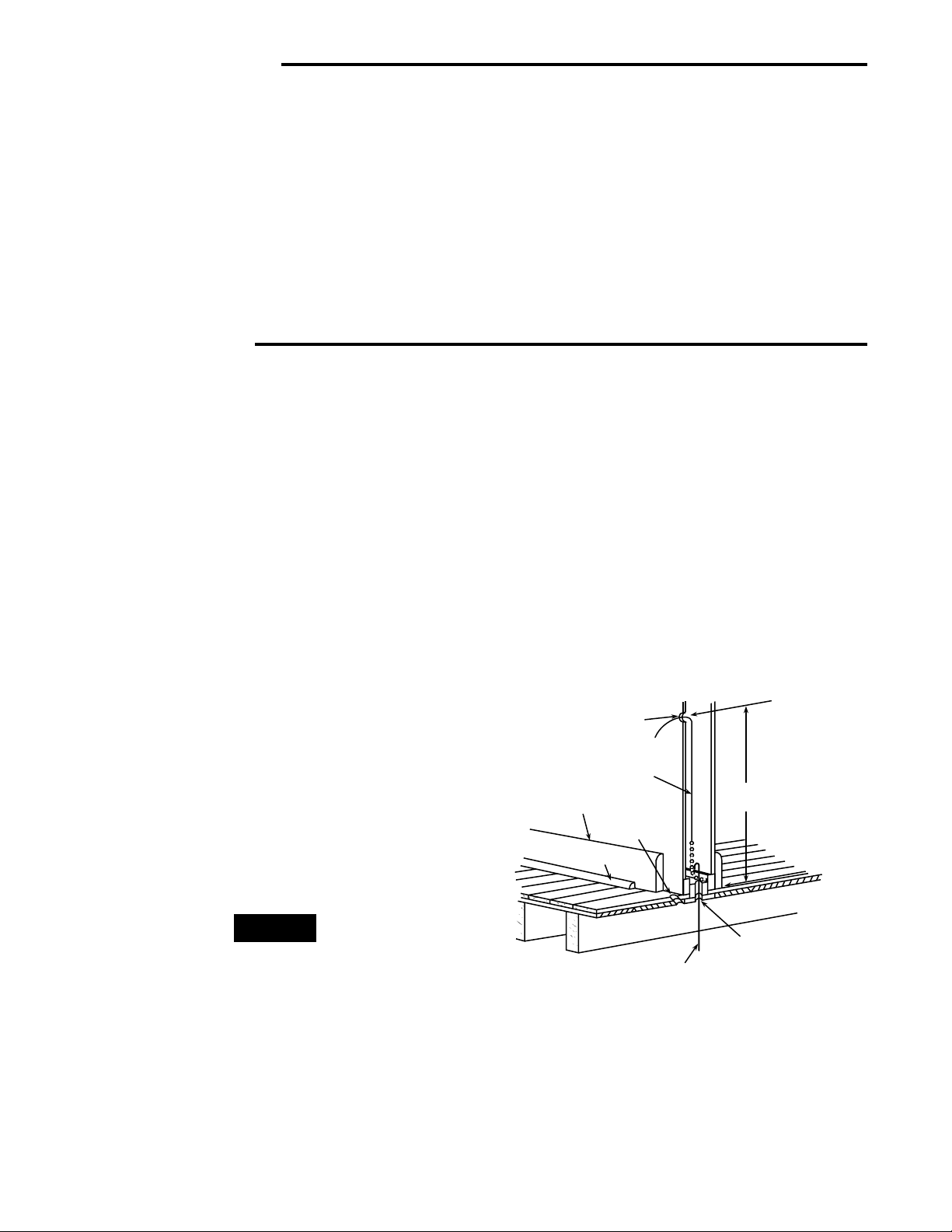

3. Probe for obstructions in partition before drilling 1⁄2”

hole in wall at selected location. Take up quarter

round and drill a small guide hole for sighting (see

fig. 1). From basement, drill 3⁄4” hole in partition floor

next to guide hole. In houses without basements, drill

1

⁄2” hole through ceiling and into partition from above

(see fig. 1).

4. Through this hole drop a light chain, or 6” chain

attached to a strong cord. Snag cord in basement with

hooked wire. In houses without basements, drop cord

through hole in ceiling and down partitioning; snag

cord at the thermostat location.

5. Attach thermostat wires to cord and pull thermostat

wires through hole in wall so that 6” of wire protrudes.

1

⁄2” hole for

thermostat wire

Stout cord with 6”

chain attached

Baseboard

strip moulding

Quarter round

removed

1

⁄4” guide hole

for sighting

Approximately

5 feet from floor

ROUTE WIRES TO LOCATION

NOTE

All wiring must conform with local and national electrical

codes and ordinances.

1. If an old thermostat being replaced is in a satisfactory

location, and the wiring appears to be in good condition, use existing wiring. If in doubt, re-wire.

2. If a new location is chosen or if this is a new installation, thermostat wiring must first be run to the location

selected.

3

⁄4” hole in floor of partition

Hooked wire for snagging chain

Figure 1. Routing thermostat wires

2

Page 3

ATTACH SUBBASE TO WALL

Heat Pump Applications

CAUTION

!

To prevent electrical shock and/or equipment

damage, disconnect electric power to system at

main fuse or circuit breaker box until installation

is complete.

1. Disconnect electrical power at main fuse or circuit

breaker.

2. Pull wires through opening near center of subbase

and connect wires beneath terminal screws (see figs.

2 through 6 for typical wiring for each application. Also

refer to subsections below for special system configurations).

3. Push excess wiring into wall and plug hole with fireresistant material (such as fiberglass insulation) to

prevent drafts from affecting thermostat operation.

4. Position subbase over hole in wall and mark mounting

hole locations on wall.

5. Drill mounting holes.

6. Fasten subbase loosely to wall, as shown, using two

mounting screws. Place a level against bottom of

subbase, adjust until level, and then tighten mounting

screws to secure subbase. If holes in wall are too

large and do not allow you to tighten subbase snugly,

use plastic expansion plugs to secure subbase.

SPECIAL SYSTEM CONFIGURATIONS

Electric Heat Furnaces (Single Transformer Systems

Only)

The subbase as shipped may not operate the fan correctly. If both the heating and cooling system must operate the fan relay, remove the yellow factory-installed

jumper wire from the Y terminal and connect it to the A

terminal. The fan should now cycle when the thermostat

calls for either heat or cool.

This subbase WILL NOT provide multi-stage heating or

cooling operation. For single-stage heat pump applications, install a short jumper wire across terminals W and

Y. If the old thermostat has a terminal that is continuously

energized, disconnect the wire from the old thermostat's

terminal and connect it either to the: 1) B terminal, if the

reversing valve is energized on a call for heat; or to the 2)

O terminal, if the reversing valve is energized on a call for

cool. If the system heats on a call for cool, or vice versa,

this wire has been connected to the wrong terminal.

NOTE

RH and RC must be jumpered for single transformer heat

pump systems.

Special Application Terminals

The B and O terminals can provide switching for special

functions other than heat pump operation. When the

system switch is in the HEAT position, the B terminal is

energized. When the system switch is in the COOL

position, the O terminal is energized.

ATTACH THERMOSTAT TO SUBBASE

1. Remove cover from thermostat base by gripping the

base in one hand. Use the other hand to pull gently at

the top or bottom of the cover.

2. Carefully remove the shipping protective packing

from the switch.

3. Attach thermostat base to subbase, being sure that all

captive screws are tightened snugly, since they serve

as electrical connections between thermostat and

subbase (see fig. 7).

4. Snap cover on thermostat and set switches and

temperature lever to desired set point (see OPERA-

TION section).

5. Turn on power to the system.

Two-Transformer Systems

CAUTION

!

If two transformers are used, they MUST be in

phase. Failure to do so may result in personal

injury and/or property damage.

NOTE

Wire color DOES NOT indicate polarity. Polarity is obtained from an oscilloscope or voltmeter.

AUTO ON

O

Mounting screw KEEP THIS AREA

CLEAR OF WIRES

Figure 2. Thermostat subbase

3

FAN

COOL HEAT

GRC

ARH

SYSTEM

OFF

Y

W

Hole

in wall

B

Mounting screw

Page 4

CAUTION

!

Take care when securing and routing wires so

they do not short to adjacent terminals or rear of

thermostat. Personal injury and/or property damage may occur.

Adjustable Heating

Anticipator

Fan

Switch

ON

AUTO

G

Moveable

Yellow Jumper

RC O

Factory-installed Jumper

Figure 3. Typical wiring diagram (see figs. 4, 5, and 6 for typical system/thermostat wiring)

COOL

OFF

System

Switch

HEAT

NOTE

These typical wiring diagrams show only the terminal

identification and wiring hookup. Always refer to wiring

instructions, provided by equipment manufacturer, for

system hookup operation.

Fixed Cooling

Anticipator

THERMOSTAT

Captive

Screws

System

Switch

RH

* Terminal "A" is not for field wiring. See

SPECIAL SYSTEM CONFIGURATIONS

section for proper use of terminal "A".

COOL

OFF

HEAT

W

Y

A* B

SUBBASE

SYSTEM

KEEP THIS

AREA CLEAR

OF WIRES!

Factory-installed

Red Jumper Wire

Factory-installed

Yellow Jumper Wire

Hot

120 VAC

Neutral

TRANSFORMER

RH W B O Y G RC A

Heat

Relay

24 VAC

Terminal energized

* * *

in cooling

GRC

O

RH

Factory-Installed Jumper

A

Compressor

** *

Terminal energized

in heating

Relay

B

THERMOSTAT

W

Y

Fan

Relay

WIRING

SYSTEM

Figure 4. Typical wiring for single transformer heating/cooling system

KEEP THIS

AREA CLEAR

OF WIRES!

Factory-installed

Yellow Jumper Wire

NOTE: Remove factoryinstalled jumper between

RC and RH terminals for

this application.

O

RH

GRC

B

THERMOSTAT

W

A

Y

WIRING

TRANSFORMER

Hot

120 VAC

Neutral

RH W B O Y GA

Heat

Relay

24 VAC

Terminal energized

* * *

in cooling

** *

Terminal energized

in heating

Compressor

Relay

Fan

Relay

RC

24 VAC

TRANSFORMER

Hot

120 VAC

Neutral

SYSTEM

Figure 5. Typical wiring for two-transformer heating/cooling system

4

Page 5

KEEP THIS

AREA CLEAR

OF WIRES!

Factory-installed

Red Jumper Wire

Factory-installed

Yellow Jumper Wire

TRANSFORMER

Hot

120 VAC

Neutral

Factory-Installed Jumper

Fan

Relay

RH

RC

24 VAC

Terminal energized

* * *

in cooling

GRC

Y

Compressor

Relay

B

W

O

RH

* * *

A

Field-Installed Jumper

W BO YG A

Terminal energized

in heating

THERMOSTAT

WIRING

Field-installed

Jumper Wire

SYSTEM

Figure 6. Typical wiring for single transformer, single stage heat pump system

FAN

AUTO ON

SYSTEM

COOL HEAT

OFF

60

70

50

80

90

90

80

70

60

50

Subbase

This thermostat is easy to operate. Fig. 8

shows how the heating/cooling system

and fan operate when the switches are in

various positions. Use the system switch

to select either heating or cooling, or to

turn the heating/cooling system off. Use

the fan switch to control fan operation.

When the fan switch is in the AUTO

position, the fan will cycle with the heating

or cooling system (the fan will not run if

the system switch is in the OFF position

and the fan switch is in the AUTO position). When the fan switch is in the ON

position, the fan will run continuously,

regardless of system switch position (even

if the system switch is set to OFF, the fan

will run if the fan switch is in the ON

position).

Cover

Thermostat

Figure 7. Attach thermostat to subbase

Shows switch position

FAN

AUTO ON

SYSTEM

COOL OFF HEAT

No heating; no cooling; no fan

No heating; no cooling; fan runs continuously

Cooling system cycles from thermostat; fan runs

continuously

Cooling system and fan cycle from thermostat

Heating system cycles from thermostat; fan cycles

from fan control on furnace

Heating system cycles from thermostat; fan runs

continuously

Figure 8. Subbase switching and thermostat/system operation

OPERATION &

MAINTENANCE

OPERATION

5

Page 6

ADJUSTING HEAT ANTICIPATOR

CAUTION

!

The adjustable heat anticipator WILL BURN OUT

if 25 VAC is applied directly to the thermostat by

shorting out the primary control during testing.

This may cause personal injury and/or property

damage.

This thermostat is equipped with an adjustable heat

anticipator and was preset at the factory to provide

satisfactory operation of the heating system under normal

conditions. If additional adjustments are necessary, they

may be made as follows (see fig. 9):

1. Remove thermostat cover.

2. If heat cycle is too long, set heat anticipator to a

slightly lower dial setting (1⁄2 division).

3. If heat cycle is too short, set heat anticipator to a

slightly higher dial setting (1⁄2 division).

4. Replace thermostat cover.

CALIBRATING THERMOSTAT

This thermostat has been carefully adjusted at the factory

and should not require recalibration.

Due to environmental conditions, during normal operation

there may be a few degrees of difference between the

indicator setting of the thermostat and actual room temperature. If the disagreement is appreciable, however,

first make sure that the thermostat is properly located and

leveled. Then, if recalibration still seems necessary, proceed as follows:

3. Remove thermostat cover. Slip 7⁄32” wrench onto hex

nut beneath bimetal. While holding temperature adjustment lever stationary, turn hex nut clockwise until

mercury shifts to the right end of the tube (see fig. 10).

4. Move temperature adjustment lever to lowest setting.

5. Replace thermostat cover. Wait 10 minutes for bimetal temperature to stabilize. Do not stand near the

thermostat during this period, as your breath and

body heat will affect bimetal temperature.

6. Move temperature adjustment lever to correspond to

actual room temperature. Then remove thermostat

cover.

7. Slip 7⁄32” wrench onto hex nut. While holding temperature adjustment lever stationary, turn hex nut counterclockwise until mercury just barely shifts to the left

end of the tube (see fig. 10).

8. Replace thermostat cover and set temperature adjustment lever to desired temperature. Turn on electrical power to system.

.25

.3

.4

E

R

G

N

C

O

Y

L

.5

.6

.8

1.

Arrow points to the

matched current rating

of the primary control

Figure 9. Anticipator adjustment

.2

C

L

E

S

.18

.15

Move this lever to

adjust heat

anticipator

CAUTION

!

To prevent electrical shock and/or equipment

damage, disconnect electrical power to the system until recalibration is complete.

1. The anticipator’s heat may adversely affect thermostat recalibration. To prevent this, disconnect electrical power to the thermostat at the furnace, main fuse,

or breaker box.

2. Move temperature adjustment lever to a setting about

5° above room temperature.

If you need further information about this product, write to us at:

WHITE-RODGERS DIVISION

Emerson Electric Co.

9797 Reavis Road

St. Louis, MO 63123-5398

Attn: Technical Service Department

Temperature

adjustment

Bimetal

7

⁄

32

”

Calibration

wrench

lever

Figure 10. Calibrating thermostat

Loading...

Loading...