Specifications and Main Features

- Number of threads: 3 or 4 Threads

- Number of needles: 1 or 2 Needles.

- Needles: Standard HAx1 #11–#14.

- Overlock width: W-bracket between two needles

- Width of the Standard Cutter: Usually standard cutting is 5.5 mm which is between 5.2 to 7 mm.

- Maximum stitch length: 5 mm, minimum is 1 mm.

- Sewing ratio: the differential feed ratio is set to one to two.

- s/m speed: Maximum Speed is 1500 RPM.

- Machine measurements:

- Width: 300 mm

- Depth: 230 mm which max out to 340 mm

- Height: 290 mm which can reach to 350 mm or 555 mm.

- Weight: the weight is roughly around 8.7 kilograms.

Frequently Asked Questions

Q: What kind of sewing and stitches can this sewing machine do?

A: The most appropriate sewing machine for making overlock stitches and for rolling edge stitches.

Q: Why is it difficult for me to adjust the stitches in an appropriate length on this machine?

A: A Length dial is typically the best way to adjust stitch length as it has a range of 1 to 5 millimeters.

Q: What will you recommend to me if my needle happened to break?

A: Remove the fabric, see if the needle is bent, blunt, put improperly, or if the fabric was being pulled or sewn. In case of any of these conditions do replace the needle.

Q: What is the maximum sewing speed of the machine?

A: The maximum sewing speed is pegged at 1500 RPM.

Q: How can I replace the lower cutter?

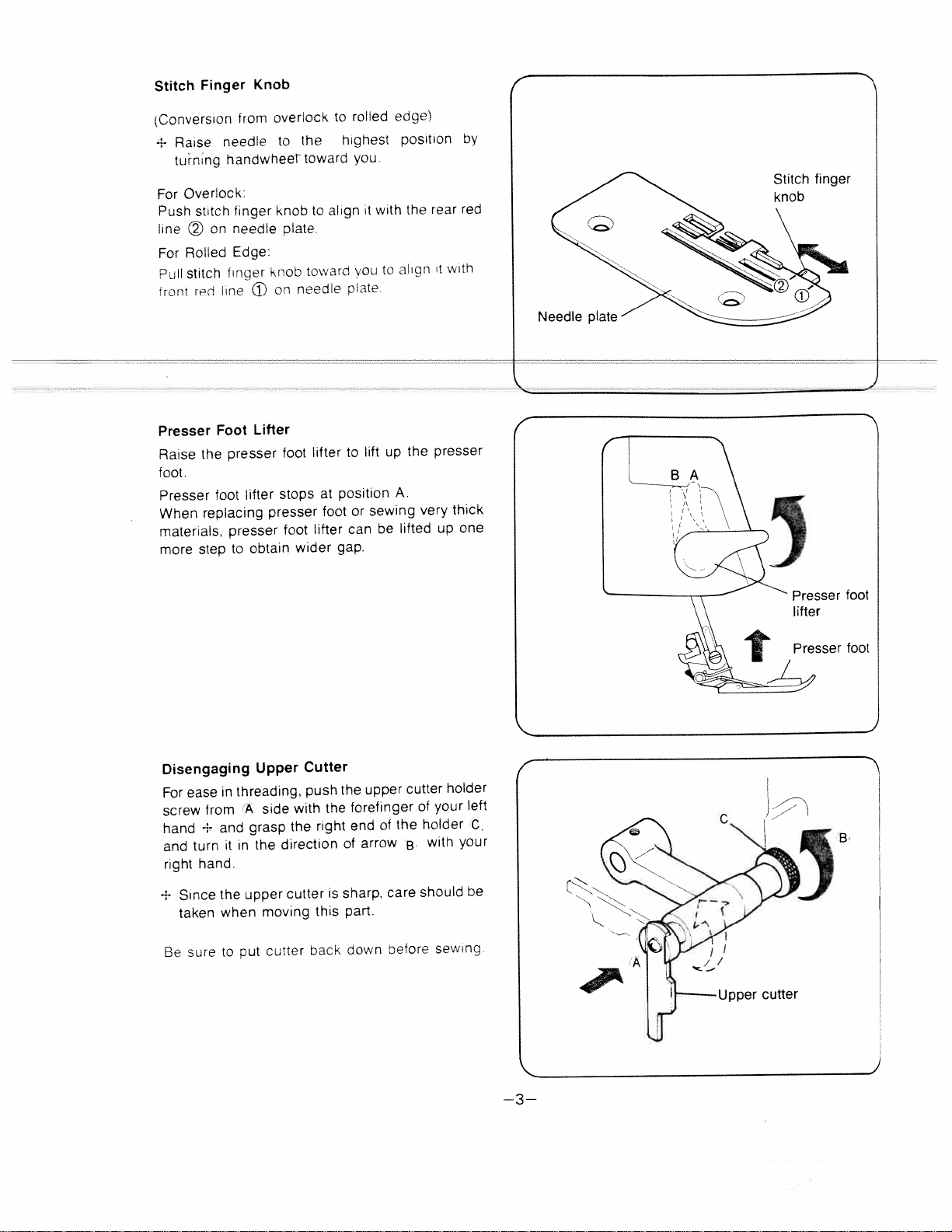

A: There is a certain order which one needs to follow to replace the lower cutter, Unplug the machine, remove the front cover, disengage the upper cutter, tighten the clamp screw of the lower cutter and remove the lower cutter then insert a new one.

Q: Which needles does this machine require?

A: For this machine you need to have the HAx1 needles, size #11 to #14 (SCHMETZ 130/705H) as it is efficient with such size needles.

Q: Will I be able to change the differential feed ratio?

A: Of course, the differential feed ratio can be altered between 1:07 to 2 according to the different fabrics and to avoid the material to pucker.

User Manual

Loading...

Loading...