Page 1

HIGH ALTITUDE / NATURAL GAS

TO PROPANE CONVERSION KIT

20491502 INSTALLATION INSTRUCTIONS

FOR ALTITUDES 4,500 - 7,000 FT. ONLY

Table of Contents

HIGH ALTITUDE KIT/PROPANE CONVERSION KIT SAFETY ................ 1

INSTALLATION REQUIREMENTS .............................................................2

Tools and Parts.........................................................................................2

Natural Gas Requirements .......................................................................2

LP Gas Requirements............................................................................... 3

INSTALLATION INSTRUCTIONS ...............................................................3

Convert Furnace - High Altitude Natural Gas Conversion....................... 3

Convert Furnace - High Altitude LP Gas Conversion .............................. 4

Make Gas Connections ............................................................................ 6

Check the Furnace Input Rate ................................................................. 7

Adjust the Furnace Input Rate.................................................................. 7

Complete Installation................................................................................ 7

HIGH ALTITUDE KIT/PROPANE CONVERSION KIT SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or

“WARNING.” These words mean:

You can be killed or seriously injured if you don't

immediately follow instructions.

can be killed or seriously injured if you don't

You

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can

This conversion kit shall be installed by a qualified service agency in accordance with the manufacturer’s instructions and

all applicable codes and requirements of the authority having jurisdiction. If the information in these instructions is not

followed exactly, a fire, explosion, or production of carbon monoxide may result, causing property damage, personal

injury, or loss of life. The qualified service agency is responsible for the proper installation of this kit. The installation is not

proper and complete until the operation of the converted appliance is checked as specified in the manufacturer’s

instructions supplied with the kit.

happen if the instructions are not followed.

WARNING

Model WPG

20563001

Page 2

Caution:

The gas supply shall be shut off prior to disconnecting the electrical power, before proceeding with the conversion.

ADDITIONAL SAFETY INFORMATION

In the State of Massachusetts, the following installation instructions apply:

■

Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or

licensed by the State of Massachusetts.

■

If using a ball valve, it shall be a T-handle type.

■

A flexible gas connector, when used, must not exceed 3 feet.

INSTALLATION REQUIREMENTS

These instructions are intended as a general guide only and do

not supersede any national or local codes in any way. Compliance

with all local, state or national codes pertaining to this type of

equipment should be determined prior to installation.

Read this entire instruction manual as well as instructions

supplied with separate equipment before starting the installation.

This kit contains parts and instructions for converting natural gas

furnaces for use at altitudes from 4,500 to 7,000 ft. and also parts

and instructions for converting furnaces from natural gas to

propane at altitudes from 4,500 to 7,000 ft. In these instructions,

LP is an abbreviation for propane.

IMPORTANT:

■ For altitudes 7,000 to 10,000 ft above sea level, see Table F.4

in Appendix F of the National Fuel Gas Code (ANSI Z223.1/

NFPA 54, latest edition) for the correct orifice sizes.

■ The furnace is not recommended for installations above

10,000 ft.

■ It is recommended that the conversion be completed prior to

making final gas connections.

Tools and Parts

Check that you have everything necessary for correct installation.

Proper installation is your responsibility.

Assemble the required tools before starting installation. Read and

follow the instructions provided with any tools listed here.

Tools Needed:

■ Flat-blade and Phillips

screwdrivers

■ ³⁄₁₆ in. Allen wrench

■ ⁵⁄₁₆ in. nut driver

■ ¹⁄₄ in. nut driver

■ ⁷⁄₁₆ in. open-end wrench

■ Pipe wrench

■ Adjustable wrench

■ Thread sealant

■ Noncorrosive leak

detection solution

■ Test g aug e wi th ¹⁄₈ in. NPT

connection (for measuring

gas supply pressure)

Parts Supplied:

High Altitude Conversion for Natural Gas:

■ Pressure switch

High Altitude Conversion for Propane:

■ Pressure switch

■ #8 x 1 in. spoiler

screws (5)

■ Conversion plate label

■ #55 size orifice (5)

■ Gas conversion manifold

label

■ Conversion kit for gas

control valve

Parts Needed:

■ For high altitude conversion for natural gas, read “LP Gas

Requirements” and check local codes and ordinances before

purchasing parts.

■ For high altitude conversion to propane, read “Natural Gas

Requirements” before purchasing parts.

Natural Gas Requirements

■ The minimum Natural Gas pressure required at the furnace is

4.5 in. W.C.

■ The maximum Natural Gas pressure allowed at the furnace is

10 in. W.C.

■ An orifice change is required. See “Natural Gas Orifice

Requirements” chart.

Natural Gas Orifice Requirements

Altitude (ft) 4,500-6,000 6,000-7,000

Orifice size 44 45

2

Page 3

LP Gas Requirements

2

4

5

6

3

The furnace has a regulator in the gas control valve. A regulator is

also required on the propane tank. Another regulator is required at

the house or unit.

■ The minimum LP Gas pressure required at the furnace

is 11 in. W.C.

■ The maximum LP Gas pressure allowed at the furnace

is 13 in. W.C.

■ An orifice change is required. Use the #55 orifices provided in

the kit for propane conversion.

INSTALLATION

INSTRUCTIONS

Convert Furnace - High Altitude

Natural Gas Conversion

3. Remove the burner access door.

4. Remove the pressure tube and wires from the pressure

switch.

1

3

Explosion Hazard

Furnace must be installed and serviced by a

qualified person.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel.

Read and follow all instructions provided for

installation, adjustment, service, alteration, or

maintenance.

Failure to follow these instructions can result in death,

explosion, fire, or carbon monoxide poisoning.

WARNING

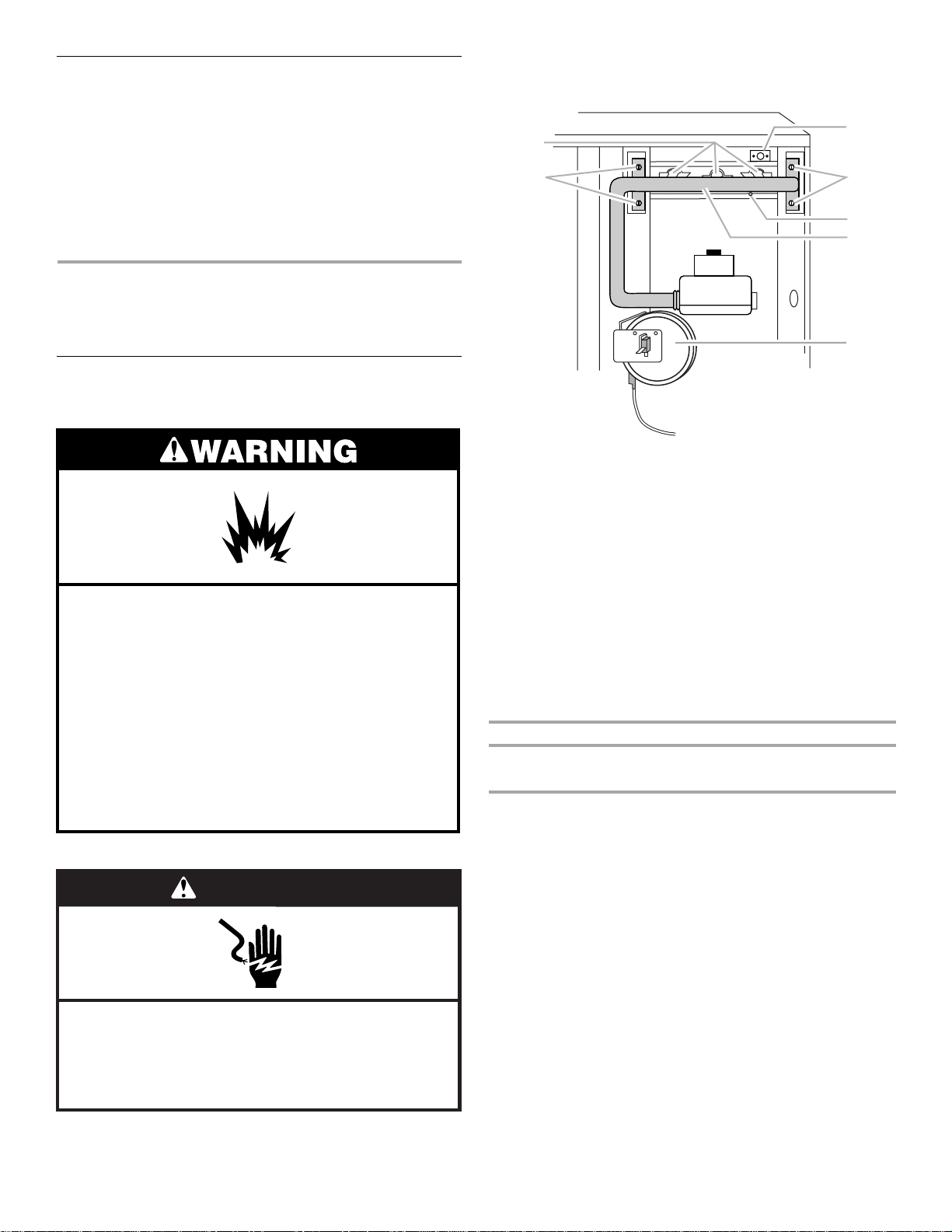

1. Orifice locations

2. Rollout switch location

3. Mounting screws

5. Replace the pressure switch with the pressure switch

provided in the kit.

6. Connect the pressure tube and wires to the new pressure

switch.

7. Disconnect all wires from gas control valve.

8. Disconnect the rollout switch and flame sensor wires.

9. Remove the manifold pipe from the burner assembly by

removing the 4 mounting screws.

10. Slide the manifold pipe (with gas control valve) forward and

out of the control compartment.

11. Remove the orifices from the manifold. Thread in the new

Natural Gas orifices of the correct size. See “Natural Gas

Orifice Requirements” chart.

Natural Gas Orifice Requirements

Altitude (ft) 4,500-6,000 6,000-7,000

Orifice size 44 45

NOTE: Make sure that the orifices are straight and positioned

at a 90º angle to the manifold.

12. Reinstall the manifold pipe to the burner assembly.

13. Reconnect all wires on the gas control valve.

14. Reconnect rollout switch and flame sensor wires.

15. Replace the burner access door.

16. Dispose of all remaining parts.

17. Go to “Make Gas Connections.”

4. Flame sensor location

5. Manifold

6. Pressure switch

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Turn off gas supply at manual gas shutoff valve.

2. Disconnect power.

3

Page 4

Convert Furnace - High Altitude

2

4

5

6

3

5

4

LP Gas Conversion

Explosion Hazard

Furnace must be installed and serviced by a

qualified person.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel.

Read and follow all instructions provided for

installation, adjustment, service, alteration, or

maintenance.

Failure to follow these instructions can result in death,

explosion, fire, or carbon monoxide poisoning.

WARNING

6. Remove the manifold pipe from the burner assembly by

removing the 4 mounting screws.

1

3

1. Orifice locations

2. Rollout switch location

3. Mounting screws

4. Flame sensor location

5. Manifold

6. Pressure switch

7. Slide the manifold pipe (with gas control valve) forward and

out of the control compartment.

8. Remove the regulator adjustment cap with “O” ring, pressure

regulator adjusting screw, and spring from the gas control

valve. See “Gas Control Valve.”

Gas Control Valve

OFF

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Turn off gas supply at manual gas shutoff valve.

2. Disconnect power.

3. Remove the burner access door.

4. Disconnect all wires from gas control valve.

5. Disconnect the rollout switch and flame sensor wires.

1

2

3

1. Gas control knob

2. Gas outlet

3. Outlet pressure tap

4. Gas inlet

5. Inlet pressure tap

ON

6. Regulator adjustment cap

7. “O” ring

8. Pressure regulator adjusting screw

9. Spring

IN

PSI

6

6

7

8

9

4

Page 5

9. Convert the Gas Control Valve for LP Gas.

4

3

4

2

4

5

6

3

■ Open the plastic bag included in this kit.

■ Locate the new spring (different color) and install.

■ Locate the new pressure regulator adjusting screw and

thread in such a way that the top of the regulator adjusting

screw is flush with the surface of the gas control valve.

■ Turn regulator adjusting screw clockwise 11 full turns.

■ Install new “O” ring into new regulator adjustment cap

(BLACK).

■ Install the new regulator adjustment cap (BLACK).

■ Affix the gas control valve conversion label included in the

plastic bag to the top of the gas control valve.

10. Remove the orifices from the manifold. Thread in the new

#55 LP Gas orifices located in the kit.

NOTE: Make sure that the orifices are straight and positioned

at a 90º angle to the manifold.

11. Remove the #10 screws that secure the burner assembly to

the flue panel.

12. Remove burner assembly from vestibule compartment. Be

careful to support burner opening inlet plate.

Manifold and Burner Assembly

13. Remove two (2) screws securing top air shield to burner

assembly. Move top air shield to allow access to spoiler

screws holes. See “Manifold and Burner Assembly.”

14. Install spoiler screws into each burner. Thread screw down

until the head of the screw just touches the surface of the

burner. Make sure not to overtighten. See “Orifice and Spoiler

Screw Location.”

15. Reinstall the top air shield.

16. Reinstall burner assembly with burner opening inlet plate.

Burner opening inlet plate must rest against flue panel.

17. Reinstall the manifold pipe to the burner assembly.

IMPORTANT: Ensure that the burner igniter is aligned properly

with the burner. The burner igniter tube should be aligned

vertically as shown.

1

2

1

2

1

2

3

1. Top shield

2. Burner opening inlet plate

3. Manifold

Orifice and Spoiler Screw Location

1

2

4. Spoiler screw

5. Burner

1. Burner igniter tube

2. Burner throat

18. Affix the gas conversion manifold label “This control has been

converted for use with propane gas” to the manifold in a

visible location.

19. Reconnect all wires on the gas control valve.

20. Reconnect rollout switch and flame sensor wires.

5

1

3

1. Manifold

2. Orifice

3. Spoiler screw

4. Burner

1. Orifice locations

2. Rollout switch location

3. Mounting screws

4. Flame sensor location

5. Manifold

6. Pressure switch

21. Fill in the required information on the conversion plate label

(day-month-year of conversion, and the name and address of

the organization making this conversion).

22. Attach conversion plate label to the exterior panel adjacent to

the unit rating plate.

23. Replace the burner access door.

24. Dispose of all remaining parts.

25. Go to “Make Gas Connections.”

5

Page 6

Make Gas Connections

4

5

5

2

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result

in serious injury, death or property damage.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically

for the detection of leaks to check all connections. A fire

or explosion may result causing property damage,

personal injury or loss of life.

1. Install the field gas supply for either side or bottom gas pipe

entry as shown.

2. Provide a sediment trap on the outside of the furnace section

in accordance with any local codes.

3. Install a manual gas shutoff valve in the gas line, outside the

unit in accordance with any local codes.

4. Install a test gauge connection with a ¹⁄₈ in. NPT plugged

tapping immediately upstream of the manual gas shutoff valve

as shown.

5. Connect the gas pipe to the furnace controls providing a

ground joint union as close to the controls as possible to

facilitate removal of controls and manifold.

Pipe-joint compounds suitable for use with natural and LP gas

must be used. Do not use Teflon

®

tape.

1

2

3

4

1. Ground joint union

2. Gas control valve

3. Control drawer

4. Bottom entry

¹⁄₈

in. NPT plugged tapping

5.

6. Manual gas shutoff valve

7. Sediment trap

Check Inlet Pressure

1. Turn off the gas supply at the manual gas shutoff valve.

1

6

7

Side Gas Pipe Entry

Side entry is the primary method of routing the gas supply to

the unit. Use the factory provided grommet to seal the

opening around the gas pipe preventing rain and moisture

from entering the unit.

1

2

6" Min.

3

1. Manual gas shutoff valve

¹⁄₈

in. NPT plugged tapping

2.

3. Sediment trap

4. Ground joint union

5. Grommet

Bottom Gas Pipe Entry

When bottom entry of gas pipe is used, the side entry hole must

first be completely covered by a field-provided plug. Route the

pipe up through the bottom entry hole and immediately into an

elbow to route pipe along the base of the unit. Use another elbow

to route gas pipe up through holes provided in control drawer

mount. One more elbow will route the pipe to the union and gas

control valve.

1. Closed valve

2. Open valve

2. Remove the inlet pressure tap plug on the gas control valve.

3. Install a ¹⁄₈ in. NPT hose connector and connect the pressure

gauge tube.

Gas Control Valve

OFF

1

NPT Outlet

2

1. Gas control knob

¹⁄₈

in. NPT outlet pressure tap

2.

4. Turn on the gas supply at the manual gas shutoff valve.

5. Turn on the electrical power to the furnace.

6. To light the main burners, set the room thermostat to a point

above room temperature.

NOTE: This furnace is equipped with an ignition device, which

automatically lights the burner. This furnace cannot be lighted

manually. Do not try to light the burner by hand.

ON

¹⁄₈

in. NPT inlet pressure tap

3.

4. Regulator adjustment cap

NPT Inlet

IN

PSI

3

4

®Teflon is a registered trademark of E.I. Dupont de Nemours and Company.

6

Page 7

7. Check minimum inlet gas supply pressure.

■ Turn on all other gas appliances.

■ Observe the pressure rating on the pressure gauge. The

minimum inlet gas supply pressure is 4.5 in. W.C. for

natural gas and 11 in. W.C. for propane gas.

8. Check maximum inlet gas supply pressure.

■ Turn off all other gas appliances.

■ Observe the pressure reading on the pressure gauge. The

maximum inlet gas supply pressure is 10 in. W.C. for

natural gas and 13 in. W.C. for propane gas.

IMPORTANT: If the inlet gas supply pressure is not within the

minimum and maximum range as shown on the rating plate,

contact your gas supplier.

9. Turn off the electrical power to the furnace.

10. Turn off the gas supply at the manual gas shutoff valve.

11. Remove the pressure gauge tube and the ¹⁄₈ in. hose

connector.

12. Replace the inlet pressure tap plug on the gas control valve.

13. Turn on the gas supply at the manual gas shutoff valve.

14. Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leak found.

■ At test pressures greater than ¹⁄₂ psig (3.5 kPa), the

furnace and the manual gas shutoff valve must be

disconnected from the gas supply piping system.

■ At test pressures less than or equal to ¹⁄₂ psig (3.5 kPa), the

furnace must be isolated from the gas supply piping

system by closing the manual gas shutoff valve.

Check the Furnace Input Rate

(if required)

BTU ratings shown on the furnace rating plate are for elevations

up to 2,000 ft.

IMPORTANT:

■ The furnace input rate must not exceed the input rating on the

furnace rating plate.

■ For elevations above 2,000 ft, the ratings should be reduced

at the rate of 4% for each 1,000 ft above sea level.

■ This furnace is equipped for rated input at manifold pressure

of 3.5 in. W.C. for natural gas.

■ This furnace is equipped for rated input at manifold pressure

of 10.0 in. W.C. for propane gas.

■ The actual heating value of your propane gas can be obtained

from your local gas supplier.

5. Move the gas control knob to the ON position.

NOTE: This furnace is equipped with an ignition device which

automatically lights the burner. This furnace cannot be lighted

manually. Do not try to light the burner by hand.

6. Turn on the electrical power to the furnace.

7. To light the main burners, set the room thermostat to a point

above room temperature .

8. Observe the pressure reading on the pressure gauge. If

necessary, adjust the manifold pressure to 3.5 in. W.C. for

natural gas and 10.0 in. W.C. for propane gas.

9. If necessary, remove the regulator adjusting cap on the gas

control valve and turn the regulator adjusting screw clockwise

to increase pressure and input, or counterclockwise to

decrease pressure and input.

IMPORTANT: If the manifold pressure cannot be adjusted to

the correct value, contact your gas supplier.

10. Move the gas control knob to the OFF position.

11. Disconnect the pressure gauge from the ¹⁄₈ in. NPT outlet

pressure tap.

12. Replace outlet pressure tap plug and the regulator adjusting

cap on the gas valve.

13. Move the gas control knob to the ON position.

14. Replace the burner access door.

15. Set the room thermostat to the desired temperature necessary

to achieve optimum temperature rise.

Complete Installation

IMPORTANT: Do not use this furnace if any part has been under

water. Immediately call a qualified person to inspect the furnace

and to replace any part of the control system and gas control

which has been under water.

1. Check to be sure you have all of your tools.

2. Dispose of all packaging materials.

3. Check the furnace in its final location. Be sure the vent is not

blocked.

Measure Temperature Rise

1. After 20 minutes of heating operation, measure the furnace

temperature rise. Take air temperature readings in both the

return air ducts and the heated air ducts.

2. If furnace doesn’t maintain temperature rise within the range

shown on the furnace rating plate, adjust the blower speed.

Adjust Blower Speed

Adjust the Furnace Input Rate

For installations above 2,000 ft, the furnace input rate is to be

reduced per the requirements of the National Fuel Gas Code

(ANSI Z223.1/NFPA 54, latest edition), at the rate of 4% for each

1,000 ft above sea level.

1. Remove the burner access door.

2. Move the gas control knob to the OFF position. Use only your

hand to move the gas control knob; tools are not required.

3. Remove the outlet pressure tap plug on the gas valve and

connect pressure gauge to the ¹⁄₈ in. NPT outlet pressure tap.

4. Be sure the gas control knob has been in the OFF position for

at least 5 minutes before starting the unit.

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

NOTE: See the “Wiring Connection Diagram” while performing

the following procedure.

7

Page 8

Blower Speed Tap Change

1

Red

Blue

White

Red

Blue

LOW

MED

HIGH

COM

UNUSED

HEAT

COOL

Violet

To Select Different Speeds for COOL and HEAT

At the Blower Motor Connector

1. Disconnect power.

2. Remove blower access panel.

3. Place blue wire on the HIGH, MED or LOW motor speed tap,

as desired for COOLING.

4. Place red wire on any of the other motor speed taps for

HEATING.

At the Unit Control Board

1. Remove and discard the violet jumper wire from the COOL

terminal to the HEAT terminal.

2

3

2. Place blue wire on the COOL terminal.

3. Place red wire on the HEAT terminal.

4. Replace blower access panel.

5. Reconnect power.

Factory Setting Heat/Cool Speeds

Unit Heat Cool

1. Blower motor connector

2. Control board

3. Jumper wire

Select the Same Speed for COOL and HEAT

At the Blower Motor Connector

1. Disconnect power.

2. Remove blower access panel.

3. Place blue wire on the HIGH, MED or LOW motor speed tap,

as desired.

4. Place red wire on any of the other motor speed taps.

5. Reconnect power.

At the Furnace Control Board

1. Place red wire on the UNUSED terminal.

2. Place blue wire (with piggyback terminal) on the COOL

terminal.

3. Place the factory supplied violet jumper wire from the COOL

terminal to the HEAT terminal.

WPG124, 130, 136, 148, 230, 236 MED MED

WPG248A125 MED MED

WPG142, 160, 242 MED HIGH

WPG260A125 MED HIGH

WPG224 LOW MED

WPG248A100 MED LOW

Shut Down the Furnace

1. Set the room thermostat to the lowest setting.

2. Disconnect power.

3. Remove burner access door.

4. Shut off the gas by moving the gas control knob to the OFF

position.

5. Replace the burner access door.

See your Furnace Installation Instructions for troubleshooting

information.

20563001

© 2003. All rights reserved.

Printed in U.S.A.

10/03

Loading...

Loading...