Page 1

Model WHES48

How to install, operate

and maintain your

E-Z Touch Demand

Controlled Water Softener

Do not return water softener to store

If you have any questions or concerns when

installing, operating or maintaining your water

softener, call our toll free number:

1-866-986-3223

Monday- Friday, 8 AM - 7 PM EST or visit

www.ecodynewatertreatment.com

When you call, please be prepared to provide

the model, date code and serial number of your

product, found on the rating decal, typically

located on the rim below the salt lid hinges.

System tested and certified by NSF International

against NSF/ANSI Standard 44

for hardness reduction and efficiency.

System tested and certified by the Water Quality

Association against CSA B483.1.

Manufactured and warranted by

Ecodyne Water Systems

1890 Woodlane Drive

Woodbury, MN 55125

Installation and Operation Manual

Printed on recycled paper

7310359 (Rev K 9/9/11)

Product No. W10270201

Page 2

TABLE OF CONTENTS

Page

Specifications & Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Water Softener Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Inspect Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Water Conditioning Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Water Softener Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Programming Your E-Z Touch Water Softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-17

Retrieving Information from the Water Softener Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Customizing Features / Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-22

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-29

WATER SOFTENER WARRANTY - MODEL WHES48

Warrantor: Ecodyne Water Systems, 1890 Woodlane Drive, Woodbury, MN 55125

Warrantor guarantees, to the original owner, that:

For the lifetime of the original owner, the salt storage tank and mineral tank will not rust, corrode, leak, burst, or in any

other manner, fail to perform their proper functions; and that

For the lifetime of the original owner, the ion exchange resin will not fail to perform its proper function; and that

For a period of three (3) years after installation, the electronic control board will be free of defects in materials and

workmanship and will perform its normal functions; and that

For a period of two (2) years after installation, all other parts will be free from defects in materials and workmanship

and will perform their normal functions; and that

For a period of two (2) years after installation, labor to repair or replace any part deemed to be defective in materials

or workmanship, will be provided at no additional cost.

If, during such respective period, a part proves to be defective, Warrantor will ship a replacement part, directly to your home,

without charge. After the second year, labor necessary to maintain this product is not covered by the product warranty.

If you have questions regarding a warranted product, need assistance with installation or troubleshooting, wish to order a

part or report a warranty issue, we are just a phone call away. SIMPLY DIAL 1-866-986-3223, Monday - Friday, 8 am - 7

pm EST, for assistance.

General Provisions

The above warranties are effective provided the water softener is operated at water pressures not exceeding 125 psi, and

at water temperatures not exceeding 120°F; provided further that the water softener is not subject to abuse, misuse, alteration, neglect, freezing, accident or negligence; and provided further that the water softener is not damaged as the result of

any unusual force of nature such as, but not limited to, flood, hurricane, tornado or earthquake.

Warrantor is excused if failure to perform its warranty obligations is the result of strikes, government regulation, materials

shortages, or other circumstances beyond its control.

*THERE ARE NO WARRANTIES ON THE WATER SOFTENER BEYOND THOSE SPECIFICALLY DESCRIBED ABOVE.

ALL IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR OF FITNESS FOR

A PARTICULAR PURPOSE, ARE DISCLAIMED TO THE EXTENT THEY MIGHT EXTEND BEYOND THE ABOVE PERIODS. THE SOLE OBLIGATION OF WARRANTOR UNDER THESE WARRANTIES IS TO REPLACE OR REPAIR THE

COMPONENT OR PART WHICH PROVES TO BE DEFECTIVE WITHIN THE SPECIFIED TIME PERIOD, AND WARRANTOR IS NOT LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES. NO WARRANTOR DEALER, AGENT,

REPRESENTATIVE, OR OTHER PERSON IS AUTHORIZED TO EXTEND OR EXPAND THE WARRANTIES EXPRESSLY DESCRIBED ABOVE.

Some states do not allow limitations on how long an implied warranty lasts or exclusions or limitations of incidental or consequential damage, so the limitations and exclusions in this warranty may not apply to you. This warranty gives you specific legal rights, and you may have other rights which vary from state to state. This warranty applies to consumer-owned

installations only.

® Registered trademark/TM Trademark of Whirlpool, USA.

Manufactured under license by Ecodyne Water Systems, Woodbury, Minnesota.

© 2009 Whirlpool Corporation. All rights reserved.

2

Page 3

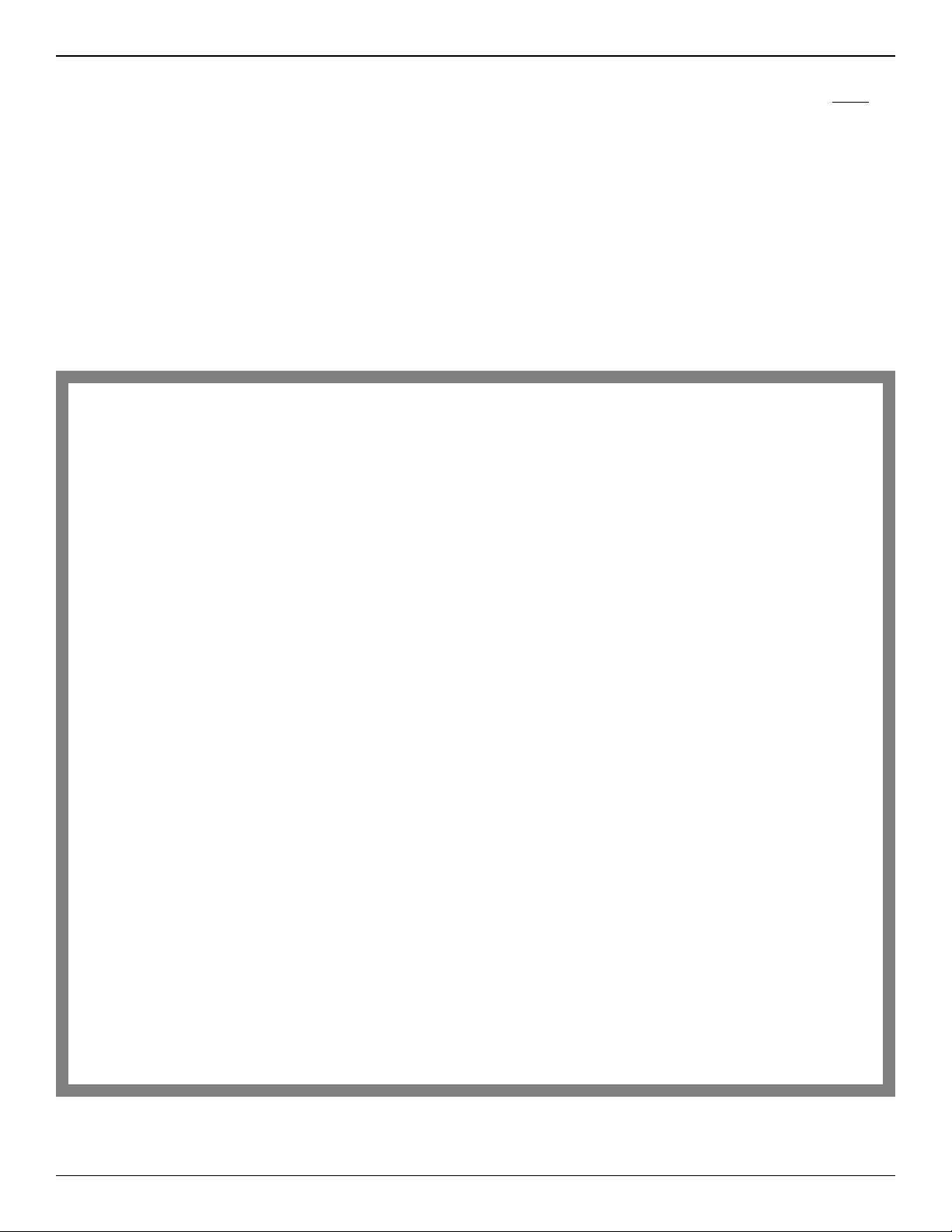

Specifications & Dimensions

Model WHES48

Model Code EZ 48

14,300 @ 2.8 lbs.

Rated Softening Capacity (Grains @ Salt Dose)

Rated Efficiency (Grains/Pound of Salt @ Minimum Salt Dose) 5,107 @ 2.8 lbs.

Water Used During Regeneration @ Minimum Salt Dose 3.0 gal. / 1,000 grains

Total Water Used Per Regeneration @ Maximum Salt Dose 44.2 gallons

Rated Service Flow Rate 11.9 gpm

Amount of High Capacity Ion Exchange Resin 1.33 cu. ft.

Pressure Drop at Rated Service Flow 15 psig

Water Supply Max. Hardness 160 gpg

Water Supply Max. Clear Water Iron 12 ppm*

Water Pressure Limits (minimum / maximum) 20 - 125 psi**

Water Temperature Limits (minimum / maximum) 40 - 120 °F

Minimum Water Supply Flow Rate 3 gpm

Maximum Drain Flow Rate 2.0 gpm

Salt Storage Capacity 200 lbs.

*Capacity to reduce clear water iron is substantiated by WQA test data. State of Wisconsin

requires additional treatment if water supply contains clear water iron exceeding 5 ppm.

**Canada working pressure limits: 1.4 - 7.0 kg/cm

These systems conform to NSF/ANSI 44 for the specific performance claims as verified

and substantiated by test data.

The efficiency rating is only valid at the stated salt dose. These softeners were efficiency

rated according to NSF/ANSI Standard 44.

Variable Salt Dose: The salt dose is selected by the electronic controls at regeneration

time based on the amount needed.

2

.

37,900 @ 10.5 lbs.

48,000 @ 18.1 lbs.

19”

IN

3-3/4”

OUT

IN – OUT

41-1/2”

18”

47-7/8”

39-1/2”

FIG. 1

Questions? Call Toll Free 1-866-986-3223 Monday- Friday, 8 AM - 7 PM EST

or visit www.ecodynewatertreatment.com

When you call, please be prepared to provide the model, date code and serial number,

found on the rating decal, typically located on the rim below the salt lid hinges.

3

Page 4

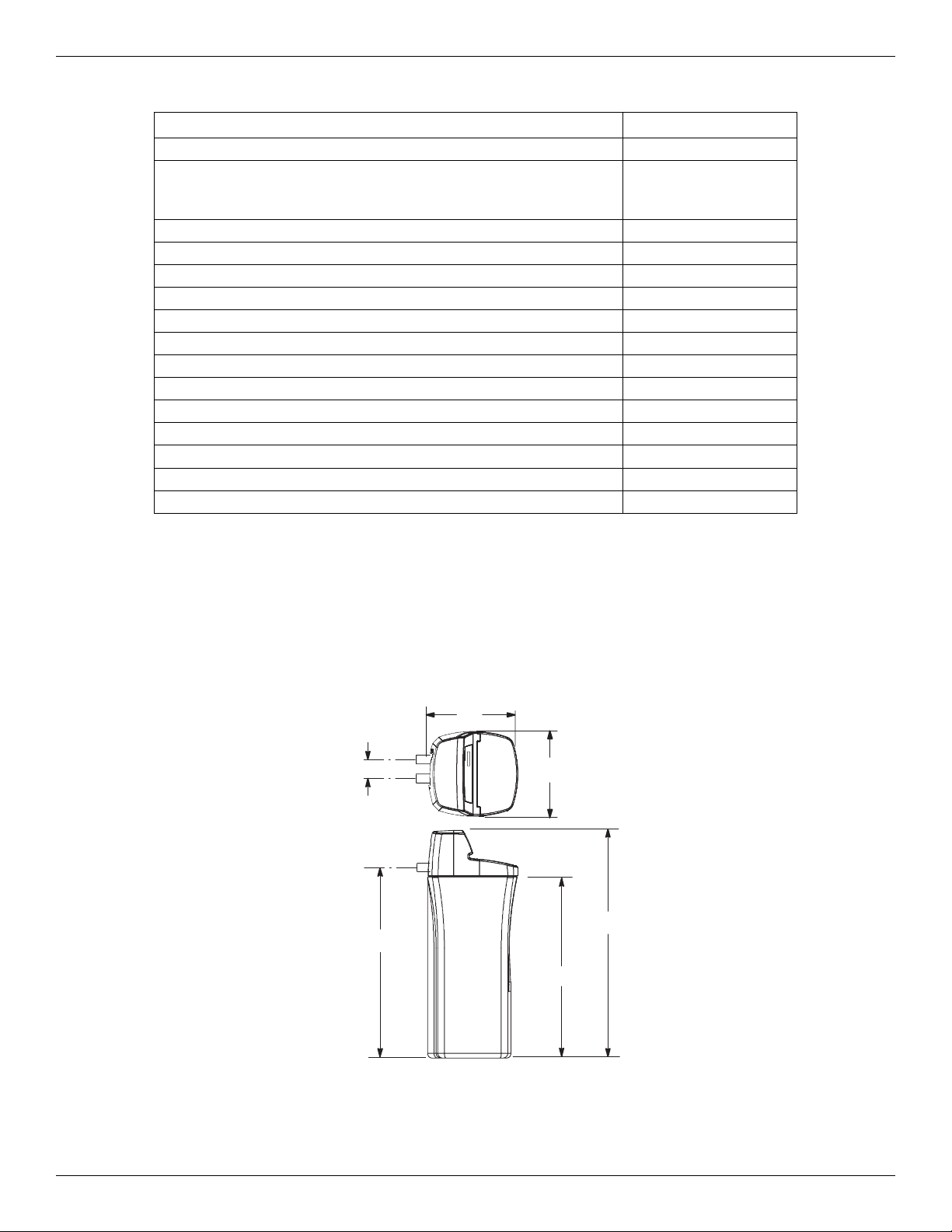

Water Softener Safety

Your safety and the safety of others are very important.

We have provided many safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING”

These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell

you what can happen if the instructions are not followed.

In the state of Massachusetts: The Commonwealth of Massachusetts plumbing code 248-CMR shall

be adhered to. A licensed plumber shall be used for this installation.

In the state of California: You must turn the Salt Efficiency Feature setting to ON. This may initiate

more frequent recharges. However, it will operate at 4,000 grains per pound of salt or higher. To turn

on the Salt Efficiency Feature, follow the instructions in the “Salt Efficiency” section of this manual.

Before You Start

= The water softener requires a minimum water flow of 3 gallons per minute at the inlet. Maximum allowable inlet

water pressure is 125 psi. If daytime pressure is over 80 psi, nighttime pressure may exceed the maximum. Use

a pressure reducing valve if necessary (Adding a pressure reducing valve may reduce the flow). If your home is

equipped with a back flow preventer, an expansion tank must be installed in accordance with local codes and

laws.

= The water softener works on 24 volt, 60 Hz electrical power only, supplied by a direct plug-in transformer (includ-

ed). Be sure to use the included transformer and plug it into a nominal 120V, 60 cycle household outlet that is in

a dry location only, grounded and properly protected by an overcurrent device such as a circuit breaker or fuse. If

transformer is replaced, use only UL, CUL or CSA approved Class 2 transformer with the following specifications:

§ Input: 120 VAC, 60 Hz, 13.5 W § Output Voltage: 24 VAC § Output Current: 400 mA

= Do not use this system to treat water that is microbiologically unsafe or of unknown quality without adequate dis-

infection upstream or downstream of the system.

European Directive 2002/96/EC requires all electrical and electronic equipment to be disposed of according to Waste Electrical and Electronic Equipment (WEEE) requirements. This directive or similar laws are

in place nationally and can vary from region to region. Please refer to your state and local laws for proper

disposal of this equipment.

Do not return the water softener to store.

If you have any questions, or there are missing parts or damage, please call Toll Free 1-866-986-3223,

Monday - Friday, 8 am - 7 pm EST, or visit www.ecodynewatertreatment.com

When you call, please be prepared to provide the model, date code and serial number, found on the rating

decal, typically located on the rim below the salt lid hinges.

4

Page 5

Inspect Shipment

The parts required to assemble and install the water

softener are included with the unit. Thoroughly check

the water softener for possible shipping damage and

parts loss. Also inspect and note any damage to the

shipping carton.

Packing List

Ground Clamp

Kit

Hose Clamps

Bypass Valve Clips

Adaptor Elbow

Grommet O-rings

Remove and discard (or recycle) all packing materials.

To avoid loss of small parts, we suggest you keep the

small parts in the parts bag until you are ready to use

them.

20 ft. Drain Hose

Installation

Adaptors

Water Hardness

Test Strip

FIG. 2

Water Conditioning Information

IRON

Iron in water can cause stains on clothing and plumbing fixtures. It can negatively affect the taste of food,

drinking water, and other beverages. Iron in water is

measured in parts per million (ppm). The total* ppm of

iron, and type or types*, is determined by chemical

analysis. Four different types of iron in water are:

= Ferrous (clear water) iron

= Ferric (red water) iron

= Bacterial and organically bound iron

= Colloidal and inorganically bound iron (ferrous or

ferric)

Ferrous (clear water) iron is soluble and dissolves in

water. This water softener will reduce moderate

amounts of this type of iron (see specifications).**

Ferrous (clear water) iron is usually detected by taking

a sample of water in a clear bottle or glass.

Immediately after taking, the sample is clear. As the

water sample stands, it gradually clouds and turns

slightly yellow or brown as air oxidizes the iron. This

usually occurs in 15 to 30 minutes.

When using the softener to reduce Ferrous (clear

water) iron, add 5 grains to the hardness setting for

every 1 ppm of Ferrous (clear water) iron. See "Set

Water Hardness Number" section.

Ferric (red water), and bacterial and organically bound

irons are insoluble. This water softener will not

remove ferric or bacterial iron. This iron is visible

immediately when drawn from a faucet because it has

oxidized before reaching the home. It appears as

small cloudy yellow, orange, or reddish suspended

particles. After the water stands for a period of time,

the particles settle to the bottom of the container.

Generally these irons are removed from water by filtration. Chlorination is also recommended for bacterial

iron.

Colloidal and inorganically bound iron is of ferric or ferrous form that will not filter or exchange out of water.

This water softener will not remove colloidal iron. In

some instances, treatment may improve colloidal iron

water. Colloidal iron water usually has a yellow

appearance when drawn. After standing for several

hours, the color persists and the iron does not settle,

but remains suspended in the water.

SEDIMENT

Sediment is fine, foreign material particles suspended

in water. This water softener will not remove sediment. This material is most often clay or silt. Extreme

amounts of sediment may give the water a cloudy

appearance. A sediment filter installed upstream of the

water softener normally corrects this situation.

* Water may contain one or more of the four types of

iron and any combination of these. Total iron is the

sum of the contents.

** Capacity to reduce clear water iron is substantiated

by WQA test data.

5

Page 6

Installation Requirements

LOCATION REQUIREMENTS

Consider all of the following when selecting an installation location for the water softener.

= Do not locate the water softener where freezing

temperatures occur. Do not attempt to treat water

over 120ºF. Freezing temperatures or hot water

damage voids the warranty.

= To condition all water in the home, install the water

softener close to the water supply inlet, and

upstream of all other plumbing connections, except

outside water pipes. Outside faucets should remain

on hard water to avoid wasting conditioned water

and salt.

= A nearby drain is needed to carry away regenera-

tion discharge (drain) water. Use a floor drain,

laundry tub, sump, standpipe, or other options

(check your local codes). See "Air Gap

Requirements" and "Valve Drain Requirements"

sections.

= The water softener works on 24 volt, 60 Hz electri-

cal power only, supplied by a direct plug-in transformer (included). Provide an electrical outlet within

10 feet, in accordance with NEC and local codes.

= Always install the water softener between the water

inlet and water heater. Any other installed water

conditioning equipment should be installed between

the water inlet and water softener (See Figure 4

below).

= Avoid installing in direct sunlight. Excessive sun

heat may cause distortion or other damage to nonmetallic parts.

PLUMBING CODES

All plumbing must be completed in accordance with

national, state and local plumbing codes.

In the state of Massachusetts: The Commonwealth

of Massachusetts plumbing code 248-CMR shall

be adhered to. A licensed plumber shall be used

for this installation.

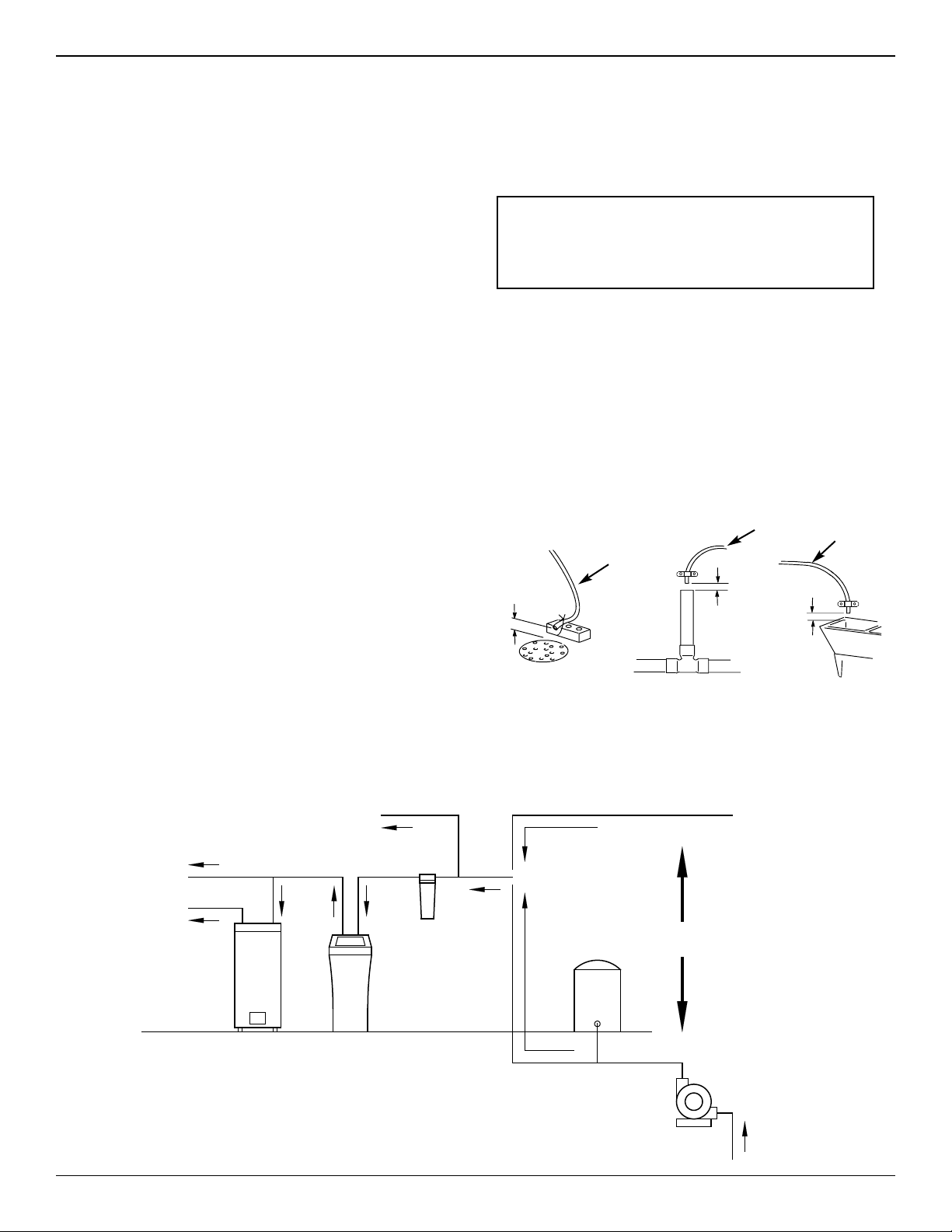

AIR GAP REQUIREMENTS

A drain is needed for regeneration water (See Figure

3). A floor drain, close to the water softener, is

preferred. A laundry tub, standpipe, etc. are other

drain options. Secure valve drain hose in place.

Leave an air gap of 1-1/2” between the end of the

hose and the drain. This gap is needed to prevent

backflow of sewer water into the water softener. Do

not put the end of the drain hose into the drain.

1-1/2”

air gap

FLOOR DRAIN

Drain

Hose

1-1/2”

air gap

Drain

Hose

1-1/2”

air gap

LAUNDRY TUBSTANDPIPE

Drain

Hose

FIG. 3

THE PROPER ORDER TO INSTALL WATER TREATMENT EQUIPMENT

Cold Water

to House

Hot Water

to House

Untreated Water to

Outside Faucets

Water

Heater

Water

Softener

Optional

Sediment

Filter

City Water Supply

Pressure

Tank

Well Water Supply

OR

Well

Pump

FIG. 4

6

Page 7

Installation RequirementsInstallation Requirements

VALVE DRAIN REQUIREMENTS

Using the flexible drain hose (included), measure and

cut to the length needed. Flexible drain hose is not

allowed in all localities (check your plumbing codes). If

local codes do not allow use of a flexible drain hose, a

rigid valve drain run must be used. Purchase a compression fitting (1/4 NPT x 1/2 in. minimum tube) and

1/2" tubing from your local hardware store. Plumb a

rigid drain as needed (See Figure 6).

NOTE: Avoid drain hose runs longer than 30 feet.

Avoid elevating the hose more than 8 feet

above the floor. Make the valve drain line as

short and direct as possible.

1/4” NPT

Thread

Clip

Cut barbs from drain fit-

ting (pull clip to remove

1/4 NPT

Threads

Barbs

fitting from valve)

Barbs for 3/8”

I.D. Tubing

Hose Clamp

Drain Hose

FIG. 5

Compression Fitting.

1/4 NPT x 1/2” O.D.

Tube (not included)

1/2” Outside Dia.

Copper Tube

(not included)

FIG. 6

INLET / OUTLET PLUMBING OPTIONS

Always install either a single bypass valve (provided),

as shown in Figure 7, or, if desired, parts for a 3 valve

bypass system (not included) can be purchased and

assembled, as shown in Figure 8. Bypass valves

allow you to turn off water to the softener for maintenance if needed, but still have water in house pipes.

Pipe fittings must be 3/4” minimum.

Use:

= Copper pipe

= Threaded pipe

= PEX (Crosslinked Polyethylene) pipe

= CPVC plastic pipe

= Other pipe approved for use with potable water

IMPORTANT: Do not solder with plumbing attached to

installation adaptors and single bypass

valve. Soldering heat will damage the

adaptors and valve.

Outlet

Valve

SINGLE BYPASS VALVE

Pull out for “Service”

(Soft water)

Push in for

“Bypass”

3 VALVE BYPASS

Bypass

Valve

From Water

Softener

To Water

Softener

FIG. 7

Inlet

Valve

FIG. 8

7

Page 8

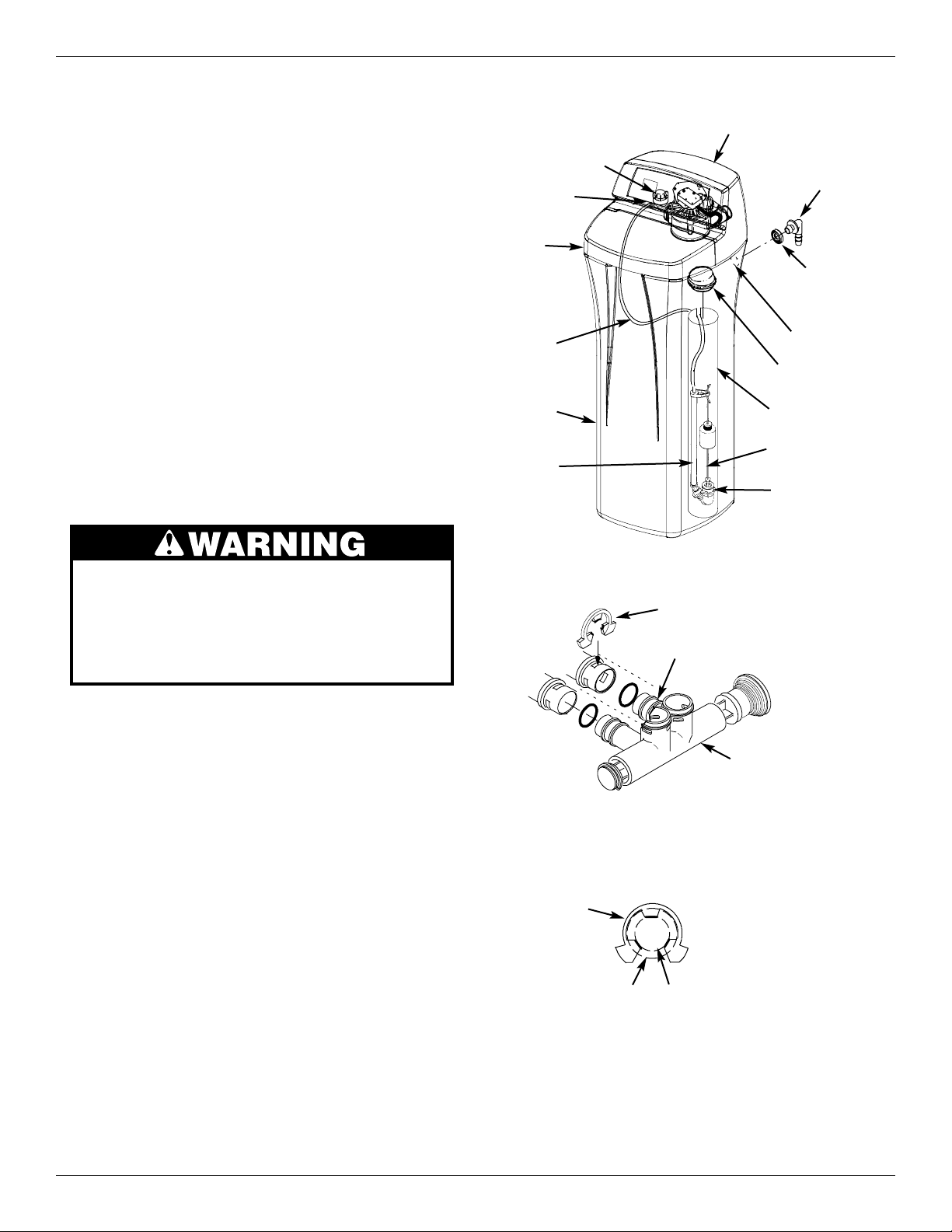

Installation Instructions

TYPICAL INSTALLATION

To Outside

Faucets

Water Softener

Plug-in

Transformer

To

Controller

Valve Drain

Elbow

Valve Drain

Hose*

*Do not connect

the water softener

valve drain tubing

to the salt storage

tank overflow

hose.

Hard Water

Valve

Main Water Pipe

Floor Drain

Conditioned

Water

Ground

Clamp

Overflow

Drain Elbow

Salt Storage

Tank Overflow

Hose*

Secure Valve Drain Hose

in place over Floor Drain

1-1/2”

air gap

Inlet

Lubricated

O-ring

Ground

Ground

Clamp

Clamp

Pipe

Clips

Outlet

O-ring

Single Bypass Valve

NOTE: See “Air Gap Requirements” section.

NOTE: Water Softener shown with Salt Hole

Cover and Top Cover removed

1” NPT Sweat

Adaptor (not

included)

1” NPT

Threaded

Adaptor

Clip

FIG. 9

8

Page 9

Installation Instructions

TURN OFF WATER SUPPLY

1. Close the main water supply valve, located near the

well pump or water meter.

2. Open all faucets to drain all water from house pipes.

NOTE: Be sure not to drain water from the water

heater, as damage to the water heater elements could result.

INSTALL THE BRINE TANK OVERFLOW

ELBOW

Install the brine tank overflow grommet and elbow in

the 13/16” diameter hole in the back of the salt storage

tank sidewall.

NOTE: The brine tank overflow elbow accepts either

1/2” or 3/8” I.D. hose.

MOVE THE WATER SOFTENER INTO PLACE

Ferrule

Salt

Hole

Cover

Brine

Tubing

Salt

Storage

Tank

Stand

Tube

Nozzle

Venturi

Assembly

Nut -

Top Cover

Brine Tank

Overflow

Elbow

Brine Tank

Overflow

Grommet

13/16” Hole

Brinewell

Cover

Brinewell

Float Stem

Brine

Valve

FIG. 10

Excessive Weight Hazard

Use two or more people to move and install

water softener.

Failure to do so can result in back or other

injury.

1. Move the water softener into the desired location.

Set it on a solid, level surface.

IMPORTANT: Do not place shims directly under the

salt storage tank to level the softener.

The weight of the tank, when full of

water and salt, may cause the tank to

fracture at the shim.

2. Visually check and remove any debris from the

water softener valve inlet and outlet ports.

3. Make sure the turbine assembly spins freely in the

"out" port of the valve.

4. If not already done, put a light coating of silicone

grease on the single bypass valve o-rings.

5. Push the single bypass valve into the softener valve

as far as it will go. Snap the two large holding clips

into place, from the top down as shown in Figures

11 & 12.

IMPORTANT: Be sure the clips snap firmly into place

so the single bypass valve will not pull

out.

Clip

Channel

Single Bypass Valve

FIG. 11

CORRECT ASSEMBLY

Clip

Outside diameter

of water softener

valve inlet & outlet

NOTE: Be sure all 3 tabs of the clip go through the matching

holes on the water softener valve inlet or outlet, and

fully into the channel on the single bypass valve.

Make sure that the tabs are fully seated.

Outside diameter

of clip channel on

single bypass valve

FIG. 12

9

Page 10

Installation Instructions

COMPLETE INLET AND OUTLET PLUMBING

Measure, cut, and loosely assemble pipe and fittings

from the main water pipe to the inlet and outlet ports of

the water softener valve. Be sure to keep fittings fully

together, and pipes squared and straight.

Be sure hard water supply pipe goes to the water softener valve inlet side.

NOTE: Inlet and outlet are marked on the water softener

valve. Trace the water flow direction to be sure

hard water is to inlet.

IMPORTANT: Be sure to fit, align and support all plumb-

ing to prevent putting stress on the water

softener valve inlet and outlet. Stress

from misaligned or unsupported plumbing

may cause damage to the valve.

Complete the inlet and outlet plumbing for the type of

pipe you will be using. Secure ground clamp to metal

pipes (See Fig. 13).

INSTALL VALVE DRAIN HOSE

Electrical Shock Hazard

Install metal ground clamp to metal house

water supply pipe before beginning installation.

Securely tighten connection in center of metal

ground clamp.

Failure to do so can result in death or

electrical shock.

Ground

Clamp

Ground

Clamp

1. Measure, cut to needed length and connect the 3/8"

drain line (provided) to the water softener valve drain

fitting. Use a hose clamp to hold the hose in place.

NOTE: Avoid drain hose runs longer than 30 feet. Avoid

elevating the hose more than 8 feet above the

floor. Make the valve drain line as short and

direct as possible.

IMPORTANT: If codes require a rigid drain line see

“Valve Drain requirements" section.

2. Route the drain hose or copper tubing to the floor

drain. Secure drain hose. This will prevent “whipping'' during regenerations. See “Air Gap

Requirements" section.

INSTALL SALT STORAGE TANK OVERFLOW

HOSE

1. Measure, cut to needed length and connect the 3/8"

drain line (provided) to the salt storage tank overflow elbow and secure in place with a hose clamp.

2 Route the hose to the floor drain, or other suitable

drain point no higher than the drain fitting on the salt

storage tank (This is a gravity drain). If the tank

overfills with water, the excess water flows to the

drain point. Cut the drain line to the desired length

and route it neatly out of the way.

IMPORTANT: For proper operation of the water soften-

er, do not connect the water softener

valve drain tubing to the salt storage

tank overflow hose.

FIG. 13

10

Page 11

Installation Instructions

TEST FOR LEAKS

To prevent air pressure in the water softener and

plumbing system, complete the following steps in

order:

1. Fully open two or more softened cold water faucets

close to the water softener, located downstream

from the water softener.

2. Place the bypass valve (single or 3 valve) into the

"bypass" position. See Figures 7 & 8 on Page 7.

3. Slowly open the main water supply valve. Run

water until there is a steady flow from the opened

faucets, with no air bubbles.

4. Place bypass valve(s) in "service" or soft water posi-

tion as follows:

= Single bypass valve: Slowly move the valve stem

toward "service," pausing several times to allow

the water softener to fill with water.

= 3 valve bypass: Fully close the bypass valve and

open the outlet valve. Slowly open the inlet

valve, pausing several times to allow the water

softener to fill with water.

5. After about three minutes, open a hot water faucet

until there is a steady flow and there are no air bubbles, then close this faucet.

6. Close all cold water faucets and check for leaks at

the plumbing connections that you made.

7. Check for leaks around clips at softener’s inlet and

outlet. If a leak occurs at a clip, depressurize the

plumbing (turn off the water supply and open

faucets) before removing clip. When removing clips

at the softener’s inlet or outlet, push the single

bypass valve body toward the softener (See Figure

14). Improper removal may damage clips. Do not

reinstall damaged clips.

ADD WATER AND SALT TO THE SALT

STOR AGE TANK

Excessive Weight Hazard

Use two or more people to move and lift salt

bags.

Failure to do so can result in back or other

injury.

1. Using a container, add about three gallons of clean

water into the salt storage tank.

2. Add salt to the storage tank. Use nugget, pellet or

coarse solar salts with less than 1% impurities.

PLUG IN THE WATER SOFTENER

During installation, the water softener wiring may be

moved or jostled from place. Be sure all leadwire connectors are secure on the back of the electronic board

and be sure all wiring is away from the valve gear and

motor area, which rotates during regenerations.

1. Plug the water softener into an electrical outlet that

is not controlled by a switch.

NOTE: The water heater is filled with hard water and,

as hot water is used, it will refill with conditioned water. In a few days, the hot water will

be fully conditioned. To have fully conditioned

hot water immediately, wait until the initial

recharge is over. Then, drain the water heater

(following instructions for water heater) until

water runs cold.

SANITIZE THE WATER SOFTENER /

SANITIZE AFTER SERVICE

If removing

clips...

...depressurize the

plumbing, then push

Bypass Valve body

toward softener

FIG. 14

1. Open salt hole cover, remove the brinewell cover

and pour about 3 oz. (6 tablespoons) of household

bleach into the softener brinewell. Replace the

brinewell cover.

2 Make sure the bypass valve(s) is in the “service”

(open) position.

3 Start a recharge (regeneration). See “Recharge Now”

on Page 15.

4. After the recharge has completed, fully open a cold

water faucet, downstream from the softener, and

allow 75 gallons of water to pass through the system. This should take at least 10 minutes. Close

the faucet.

11

Page 12

Water Softener Setup

TOUCH SCREEN

Controls for programming the water softener are displayed on a touch screen, located on the softener’s

front panel (See Figure 17). On-screen “buttons”

appear as rectangular outlines with rounded corners

and change with each display (See Figures below).

Button presses are acknowledged with a “beep.”

NOTE: Before cleaning the touch screen to remove

fingerprints, unplug the transformer. The controller’s memory items (including clock time,

water hardness, etc.) are retained during brief

power interruptions. Use a microfiber towel or

household cleaner safe for plastics on the

touch screen.

SETUP PROCEDURE

When the softener is plugged in for the first time, a

beep sounds and the display briefly shows “E-Z

Touch”, followed by the model number and software

version.

Next, a series of three setup screens prompts you to

enter basic operating information:

Touch

Screen

FIG. 17

FIG. 18

FIG. 15

1. LANGUAGE: If the desired language is not

checked (See Figure 15), press the button next to

the desired language, then press the NEXT button.

FIG. 16

2. CURRENT TIME: Press the DOWN () or UP ()

buttons to set the current time (See Figure 16).

Hold the button down to rapidly advance. Be sure

AM or PM is correct. When the current time is

shown, press the NEXT button.

3. WATER HARDNESS: Press the UP (

() buttons to set the value of your water’s hardness (See Figure 18), then press the NEXT button.

NOTE: Do not increase the hardness setting to com-

pensate for iron in your water. The electronic

control will compensate automatically after

you set the iron level, as described on Page

17.

) or DOWN

FIG. 19

4. If, at this point, you want to go back and make

changes, press the button next to NO, then press

the NEXT button to repeat the three setup screens.

5. If no changes are desired, make sure the button

next to YES is checked and press the NEXT button. The softener begins normal operation,

described on the next page.

Questions? Call Toll Free 1-866-986-3223 Monday- Friday, 8 AM - 7 PM EST

or visit www.ecodynewatertreatment.com

When you call, please be prepared to provide the model, date code and serial number,

found on the rating decal, typically located on the rim below the salt lid hinges.

12

Page 13

Programming Your E-Z Touch Water Softener

SOFTENER STATUS SCREEN

During normal operation, the softener’s display shows

a screen like the one in Figure 20, below. The display automatically returns to this screen from other

screens after 4 minutes of inactivity.

Indicates

water flow

through the

softener

Indicates salt

level in the salt

storage tank

During normal operation, there are four active buttons

on the softener’s status screen. They access subsidiary screens used to control softener operations, as

shown below:

FIG. 20

¤ Salt Level Button (See Page 13)

¤ Recharge Button (See Page 15)

=Recharge Now (See Page 15)

=Set Recharge Time (See Page 15)

=Schedule Recharge (See Page 16)

¤ Info (Information) Button (See Page 18)

=Water Flow (See Page 18)

=Average Daily Use (See Page 18)

=Water Used Today (See Page 18)

=Capacity Remaining (See Page 18)

=Days In Use (See Page 18)

=Total Recharges (See Page 18)

¤ Setup Button (See Page 16)

=Set Time (See Page 16)

=Set Hardness (See Page 17)

=Set Recharge Time (See Page 15)

=Set Iron Level (See Page 17)

=Advanced Setup

=Additional Features

=Set Clean Feature (See Page 19)

=Set Clean Time (See Page 19)

=Set Salt Efficiency (See Page 20)

=Set Salt Type (See Page 20)

=Set Units (See Page 21)

=Volume Units (See Page 21)

=Time Format (See Page 21)

=Hardness Units (See Page 21)

=Set Contrast (See Page 14)

=Restore Factory Settings (See Page 22)

=Set Language (See Page 14)

SALT LEVEL BUTTON

For the “Low salt” indicator to work, whenever you

add salt to the softener, you must reset the salt level

indicator on the display to match the new level of salt

in the tank. A decal on the brinewell shows numbers

up to 8, corresponding to the numbers on the display.

Each press of the SALT LEVEL button (See Figure

20) makes the level indicated on the display go up by

one. A “Low salt” message will flash on the display

(See Figure 21) whenever the level is 2 or below.

Low salt

level is

indicated

FIG. 21

TANK LIGHT

Touching the screen anywhere will turn on the light in

the softener’s brine tank. The light will turn off again

automatically after 4 minutes.

FLASHING BACKLIGHT

The softener’s display is backlit to make it easy to

read. The contrast may be adjusted, as described on

Page 14. The backlight will flash on and off when

one or more of the following conditions occurs:

=Salt needs to be added

=Time has been lost, perhaps after a long power

loss (The Set Time screen will be displayed

instead of the status screen)

=Error condition (Service is required)

The flashing will stop after any key is pressed.

However, it will start again at Midnight if the underlying condition (e.g. low salt level) has not been

addressed.

ALERTS & REMINDERS

Normally, the current time is the only thing displayed

along the top right portion of the screen. A flashing

message, like the one shown in Figure 21, will be displayed instead if one of the following conditions

occurs:

=Low salt indicates that salt needs to be added

(See Page 23) and the salt level indicator reset

(See “Salt Level Button”, above). This message

appears whenever the salt level is 2 or below.

=Error (Service is required)

13

Page 14

Programming Your E-Z Touch Water Softener

SET LANGUAGE

When the softener’s electronic control is first powered

up, the setup procedure prompts you to set the language (See Page 12). To change the language:

1. Press the SETUP button on the softener status

screen (See Figure 22).

FIG. 22

2. Press the LEFT () button to display the screen

shown in Figure 23.

FIG. 23

SET CONTRAST

The contrast of the softener’s display screen may be

adjusted to optimize its readability. Depending on the

ambient lighting conditions, you may want to increase

or decrease the contrast from the medium level that is

the default when the electronic control is first powered

up. To change the contrast:

1. Press the SETUP button on the softener status

screen (See Figure 22).

2. Press the LEFT (

screen shown in Figure 25.

) button twice to display the

FIG. 25

3. Press the ADVANCED SETUP button. The display

will change to the following screen.

FIG. 24

3. Press the LANGUAGE button and the display will

change to show the Select Language screen (See

Figure 24).

4. Press the button next to the desired language.

When the desired language is checked, press the

OK button.

5. To return to the softener status screen, press the

RETURN (

TO SET THE SOFTENER TO ENGLISH

IF ANOTHER LANGUAGE IS DISPLAYED:

If the softener status screen is not showing, press

the RETURN (

tus screen, press the PRGM button. Press the

LEFT (

LANGUE button. Press the button next to

ENGLISH, then press the OK button. Press the

RETURN (

) button.

) button a few times. On the sta-

) button, then press the large IDIOMA or

) button to return to the status screen.

FIG. 26

4. Press the LEFT () button twice to display the

screen shown in Figure 27.

FIG. 27

FIG. 28

5. Press the SET CONTRAST button and the display

will change to show the Set contrast screen (See

Figure 28).

6. Press the UP (

or decrease the contrast. When the preferred contrast is reached, press the RETURN (

7. To return to the softener status screen, press the

RETURN () button twice.

) or DOWN () buttons to increase

) button.

14

Page 15

Programming Your E-Z Touch Water Softener

RECHARGE BUTTON

The long button at the bottom of the softener status

screen (See Figure 29) will show recharge status,

including whether a recharge is scheduled (See

Figure 41). During a recharge cycle, a countdown

clock is displayed in the button (See Figure 32).

RECHARGE NOW

To manually initiate an immediate recharge:

1. Press the RECHARGE button at the bottom of the

softener status screen (See Figure 29).

FIG. 29

2. The display will change to show the following

screen.

SET RECHARGE TIME

When the softener’s electronic control is first powered

up, the default time for starting an automatic recharge

is 2:00 a.m. This is a good time in most households

because water is not being used.

To change the recharge time:

1. Press the RECHARGE button on the softener sta-

tus screen (See Figure 33).

FIG. 33

2. The display will change to show the following

screen.

FIG. 30

3. Press the RECHARGE NOW button. The recharge

begins and display will change to show a recharge

status screen, like the one in Figure 31.

FIG. 31

4. To return to the softener status screen, press the

RETURN (

) button.

FIG. 32

FIG. 34

3. Press the RIGHT () button. The display will

change to show the following screen.

FIG. 35

FIG. 36

4. Press the SET RECHARGE TIME button and the

display will change to show the Set recharge time

screen (See Figure 36).

5. Press the UP (

recharge time in 1 hour increments. Hold the button down to rapidly advance. Be sure AM or PM is

correct (unless softener is set for a 24-hour clock).

When the desired recharge start time is shown,

press the RETURN (

back to the softener status screen.

) or DOWN () buttons to set the

) button. The display will go

15

Page 16

Programming Your E-Z Touch Water Softener

SCHEDULE A RECHARGE

To schedule a recharge for the next preprogrammed

recharge time (2:00 a.m., or as set on Page 15):

1. Press the RECHARGE button at the bottom of the

softener status screen (See Figure 37).

FIG. 37

2. The display will change to show the following

screen.

FIG. 38

3. Press the LEFT (

to show the following screen.

) button. The display will change

SETUP BUTTON

The SETUP button on the softener status screen is

used to set items of basic operating information:

=Set current time

=Set water’s hardness

=Set recharge time

=Set water’s iron level

=Advanced setup (Accesses more items that can

be set. These are described starting on Page 19)

=Set language

SET TIME

When the softener’s electronic control is first powered

up, the setup procedure prompts you to set the current time (See Page 12). To change the time at a

later date, such as after a long power loss:

1. Press the SETUP button on the softener status

screen (See Figure 42).

FIG. 39

4. Press the SCHEDULE RECHARGE button. The

display will change to show the screen in Figure 40.

FIG. 40

5. Press the button next to ON, then press the

RETURN (

the screen shown in Figure 39.

6. To return to the softener status screen, press the

RETURN () button.

) button. The display will go back to

FIG. 41

FIG. 42

2. Press the SET TIME button (See Figure 43) and

the display will change to show the Set time

screen (See Figure 44).

FIG. 43

FIG. 44

3. Press the DOWN () or UP () buttons to set the

current time. Hold the button down to rapidly

advance. Be sure AM or PM is correct (unless softener is set for a 24-hour clock). When the current

time is shown, press the RETURN (

4. To return to the softener status screen, press the

RETURN (

) button.

) button.

16

Page 17

Programming Your E-Z Touch Water Softener

SET HARDNESS

When the softener’s electronic control is first powered

up, the setup procedure prompts you to enter your

water’s hardness (See Page 12). To change it:

1. Press the SETUP button on the softener status

screen (See Figure 45).

FIG. 45

2. Press the RIGHT () button to display the screen

shown in Figure 46.

FIG. 46

SET IRON LEVEL

The softener’s electronic control can adjust cycle

times to compensate for ferrous (clear water) iron in

the water. When the softener’s electronic control is

first powered up, the iron level is set at 0.

NOTE: The iron level will always be displayed in ppm

(parts per million), regardless of whether the

Hardness units setting is grains or ppm. The

conversion factor is 3 grains per ppm of clear

water iron.

To enter your water’s iron level:

1. Press the SETUP button on the softener status

screen (See Figure 45).

2. Press the RIGHT (

the screen shown in Figure 48.

) button three times to display

FIG. 48

FIG. 47

3. Press the SET HARDNESS button and the display

will change to show the Set hardness screen (See

Figure 47).

4. Press the UP (

value for your water’s hardness. Hold the button

down to rapidly advance. When the correct hard-

ness is shown, press the RETURN () button.

NOTE: Do not increase the hardness setting to com-

pensate for iron in your water. The electronic

control will compensate automatically after

you set the iron level, as described under “Set

Iron Level” on this page.

5. To return to the softener status screen, press the

RETURN (

) or DOWN () buttons to set the

) button.

SET RECHARGE TIME

Refer to Page 15 for instructions on setting the start

time for automatic recharges.

FIG. 49

3. Press the SET IRON LEVEL button and the display

will change to show the Set iron level screen (See

Figure 49).

4. Press the UP (

value for iron in your water. Hold the button down

to rapidly advance. When the correct iron level is

shown, press the RETURN (

5. To return to the softener status screen, press the

RETURN (

) or DOWN () buttons to set the

) button.

) button.

17

Page 18

Retrieving Information from the

Water Softener Management System

INFO (INFORMATION) BUTTON

The INFO button on the softener status screen is

used to look up the following information about the

softener and its operations:

=Current water flow

=Average daily water use

=Water used today

=Capacity remaining

=Days in use

=Total recharges

To display one of these screens:

1. Press the INFO button at the center of the softener

status screen (See Figure 50).

FIG. 51

FIG. 52

FIG. 50

2. Press the RIGHT () or LEFT () buttons to scroll

through the six information screens (Figures 51-56).

3. To return to the softener status screen, press the

RETURN () button.

FIG. 53

FIG. 54

FIG. 55

FIG. 56

18

Page 19

Customizing Features / Options

SET CLEAN FEATURE

The Clean Feature with Sediment Guard technology

is beneficial on water supplies containing ferrous

(clear water) iron. The default setting is OFF. When

set to ON, an additional backwash and fast rinse

cycle will occur first, preceding the normal regeneration sequence. This provides extra cleaning of the

resin bed before it is regenerated with the salt brine.

To conserve water set this feature OFF if your water

supply does not contain iron or sediments.

To set this feature:

1. Press the SETUP button on the softener status

screen.

2. Press the LEFT (

screen shown in Figure 57.

) button twice to display the

FIG. 57

3. Press the ADVANCED SETUP button. The display

will change to the following screen.

6. Press the button next to ON to enable this feature

(or OFF to disable it) and then press the RETURN

(

) button.

7. To return to the softener status screen, press the

RETURN () button three times.

SET CLEAN TIME

The length of the Clean Feature with Sediment Guard

technology can be adjusted, from 1 to 30 minutes.

The default value for this feature is 7 minutes.

To change the clean time:

1. Press the SETUP button on the softener status

screen.

2. Press the LEFT (

screen shown in Figure 57.

3. Press the ADVANCED SETUP button to display the

screen shown in Figure 58.

4. Press the ADDITIONAL FEATURES button to dis-

play the screen shown in Figure 59.

5. Press the RIGHT (

shown in Figure 61.

) button twice to display the

) button to display the screen

FIG. 58

4. Press the ADDITIONAL FEATURES button to dis-

play the screen shown in Figure 59.

FIG. 59

FIG. 60

5. Press the SET CLEAN FEATURE button and the

display will change to show the Set clean feature

screen (See Figure 60).

continued

FIG. 61

FIG. 62

6. Press the SET CLEAN TIME button and the dis-

play will change to show the Set clean time

screen (See Figure 62).

7. Press the UP (

clean time in 1 minute increments. Hold the button

down to rapidly advance. When the desired clean

time is shown, press the RETURN (

8. To return to the softener status screen, press the

RETURN (

) or DOWN () buttons to set the

) button three times.

) button.

19

Page 20

Customizing Features / Options

SET SALT EFFICIENCY

When this feature is ON, the water softener will operate at salt efficiencies of 4000 grains of hardness per

pound of salt or higher (May recharge more often

using smaller salt dosage and less water). The softener is shipped with this feature set OFF, which utilizes the maximum rated capacity while most often

achieving maximum salt efficiencies. When installing

this unit in the State of California, you MUST turn this

feature ON.

To set this feature:

1. Press the SETUP button on the softener status

screen.

2. Press the LEFT (

screen shown in Figure 63.

) button twice to display the

FIG. 63

3. Press the ADVANCED SETUP button. The display

will change to the following screen.

7. Press the button next to ON to enable this feature

(or OFF to disable it) and then press the RETURN

(

) button.

8. To return to the softener status screen, press the

RETURN (

) button three times.

SET SALT TYPE

Use this feature to program the electronic control with

which type of salt you will use. The default is Sodium

Chloride (NaCl). Selecting Potassium Chloride (KCl)

increases fill and brine rinse times.

To set this feature:

1. Press the SETUP button on the softener status

screen.

2. Press the LEFT (

screen shown in Figure 63.

3. Press the ADVANCED SETUP button to display the

screen shown in Figure 64.

4. Press the RIGHT (

shown in Figure 67.

) button twice to display the

) button to display the screen

FIG. 64

4. Press the ADDITIONAL FEATURES button.

5. Press the LEFT (

shown in Figure 65.

) button to display the screen

FIG. 65

FIG. 66

6. Press the SET SALT EFFICIENCY button and the

display will change to show the Set salt efficiency

screen (See Figure 66).

FIG. 67

FIG. 68

5. Press the SET SALT TYPE button and the display

will change to show the Set salt type screen (See

Figure 68).

6. Press the button next to the type of salt you will

use. When the correct salt type is checked, press

the RETURN (

7. To return to the softener status screen, press the

RETURN (

) button.

) button twice.

20

Page 21

Customizing Features / Options

SET UNITS

The softener can be set to display values such as volume and water hardness in either English or Metric

units. In addition the clock may be set to display time

in either 12-hour (AM/PM) or 24-hour format.

VOLUME UNITS

To select between gallons and liters as volume units:

1. Press the SETUP button on the softener status

screen.

2. Press the LEFT (

screen shown in Figure 69.

) button twice to display the

FIG. 69

3. Press the ADVANCED SETUP button. The display

will change to the following screen.

FIG. 70

TIME FORMAT

To select between 12-hour (AM/PM) and 24-hour time

format:

1-5. Go to the Volume units screen by following

Steps 1-5 in “Volume Units” in the previous column.

6. Press the RIGHT (

format screen (See Figure 73).

) button to display the Time

FIG. 73

7. Press the button next to the desired time format

and then press the RETURN (

8. To return to the softener status screen, press the

RETURN () button twice.

) button.

4. Press the RIGHT () button twice to display the

screen shown in Figure 71.

FIG. 71

5. Press the SET UNITS button and the display will

change to show the Volume units screen (See

Figure 72).

FIG. 72

6. Press the button next to the desired volume units

and then press the RETURN (

7. To return to the softener status screen, press the

RETURN () button twice.

) button.

HARDNESS UNITS

To select between grains and ppm (parts per million)

as water hardness units:

1-5. Go to the Volume units screen by following

Steps 1-5 in “Volume Units” in the previous column.

6. Press the LEFT (

Hardness units screen (See Figure 74).

) button to display the

FIG. 74

7. Press the button next to the desired hardness units

and then press the RETURN (

8. To return to the softener status screen, press the

RETURN () button twice.

) button.

21

Page 22

Customizing Features / Options

POWER OUTAGE MEMORY

If electrical power to the water softener is lost, “memory'' built into the electronic control circuitry will keep

all settings for up to six hours. While the power is

out, the display is blank and the water softener will

not regenerate. When electrical power is restored,

the following will occur.

You have to reset the current time only if the display’s

backlight is flashing and the Set time screen is displayed instead of the softener’s status screen.

Even if the clock is incorrect after a long power outage, the softener operates as it should to keep your

water soft. However, regenerations may occur at the

wrong time of day until you reset the clock to the correct time of day.

NOTE: If the water softener was regenerating when

power was lost, it will now finish the cycle.

RESTORE FACTORY SETTINGS

This feature resets the softener’s electronic controller

to its initial startup condition. All settings, such as language, current time and water hardness, are cleared

and returned to their default values. The user must

then follow the setup procedure (See Page 12) before

the softener will be ready to run again.

1. Press the SETUP button on the softener status

screen.

2. Press the LEFT (

screen shown in Figure 75.

) button twice to display the

FIG. 75

3. Press the ADVANCED SETUP button. The display

will change to the following screen.

FIG. 76

4. Press the LEFT () button to display the screen

shown in Figure 77.

FIG. 77

FIG. 78

5. Press the RESTORE FACTORY SETTINGS button

and the display will change to show the Restore

factory settings screen (See Figure 78).

6. Press the button next to YES and then press the

RETURN (

7. Follow the setup procedure on Page 12.

) button.

22

Page 23

Routine Maintenance

ADDING SALT

Lift the salt hole cover and check the salt storage level

frequently. If the water softener uses all the salt before

you refill it, you will experience hard water. Until you

have established a refilling routine, check the salt

every two or three weeks. Always add if less than 1/4

full. Be sure the brinewell cover is on.

NOTE: If using potassium chloride (KCl), do not fill

above level 4 on the brinewell decal.

NOTE: In humid areas, it is best to keep the salt stor-

age level lower, and to refill more often to avoid

salt “bridging”.

Recommended Salt: Nugget, pellet or coarse solar

salts with less than 1% impurities.

Salt Not Recommended: Rock salt, high in impurities,

block, granulated, table, ice melting, ice cream making

salts, etc.

BREAKING A SALT BRIDGE

Sometimes, a hard crust or salt “bridge” forms in the

brine tank. It is usually caused by high humidity or the

wrong kind of salt. When the salt “bridges,” an empty

space forms between the water and the salt. Then,

salt will not dissolve in the water to make brine.

Without brine, the resin bed is not recharged and hard

water will result.

If the storage tank is full of salt, it is difficult to tell if

you have a salt bridge. A bridge may be underneath

loose salt. Take a broom handle, or like tool, and hold

it next to the water softener. Measure the distance

from the floor to the rim of the water softener. Then,

gently push the broom handle straight down into the

salt. If a hard object is felt before the pencil mark is

even with the top, it is most likely a salt bridge. Gently

push into the bridge in several places to break it. Do

not use any sharp or pointed objects as you may

puncture the brine tank. Do not try to break the salt

bridge by pounding on the outside of the salt tank.

You may damage the tank.

Push Tool into

Salt Bridge to

Break

1” - 2”

Salt

Pencil

Mark

Broom

Handle

Salt

Bridge

Water

Level

FIG. 79

CLEANING THE NOZZLE & VENTURI

A clean nozzle & venturi (See Figure 80) is a necessity

for the water softener to work properly. This small

component creates the suction to move brine from the

brine tank, into the resin tank. If it should become

plugged with sand, silt, dirt, etc., the water softener will

not work, and hard water will result.

Cap

O-ring Seal

Screen Support

Screen

Nozzle & Venturi Disc

Gasket

*Flow Plug (HVDC)

Housing

*Install with lettered

side up, concave

side down.

IMPORTANT: Be sure small hole in the gasket is centered directly over the small hole in the nozzle & venturi housing. Be sure the numbers are facing up

Ferrule

Nut

*Flow Plug

Cone Screen

FIG. 80

To get access to the nozzle & venturi, remove the

water softener’s top cover. Put the bypass valve(s)

into the bypass position. Be sure the water softener is

in soft water (service) cycle (no water pressure at nozzle & venturi). Then, holding the nozzle & venturi

housing with one hand, un screw the cap. Do not lose

the o-ring seal. Lift out the screen support and screen.

Then, remove the nozzle & venturi disc, gasket and

flow plug(s). Wash the parts in warm, soapy water

and rinse in fresh water. Be sure to clean both the top

and bottom of the nozzle & venturi disc. If needed,

use a small brush to remove iron or dirt. Do not

scratch, misshape, etc., surfaces of the nozzle & venturi.

Gently replace all parts in the correct order. Lubricate

the o-ring seal with silicone grease and locate in place.

Install and tighten the cap by hand, while supporting

the housing. Overtightening may break the cap or

housing. Put the bypass valve(s) into service (soft

water) position.

Recharge the softener to reduce water level in the

tank. This will also assure that the softener is completely recharged and ready to provide softened water

again. Check the water level in the tank by looking

down the brinewell. If the water level does not drop

after a recharge, the problem has not been resolved.

Call 1-866-986-3223, Monday - Friday, 8 am to 7 pm,

EST.

23

Page 24

E-Z Touch

Troubleshooting

AUTOMATIC ELECTRONIC DIAGNOSTICS

This water softener has a self-diagnostic function for

the electrical system (except input power and/or water

meter). The water softener monitors electronic components and circuits for correct operation. If a malfunction occurs, an error code appears in the display.

FIG. 82

A service person should be contacted to perform the

diagnostics, see below, to further isolate the problem.

Procedure for removing error code from display:

1. Unplug transformer from electrical outlet.

2. Correct problem.

3. Plug in transformer.

4. Wait 6 minutes. The error code will return if

the problem was not corrected.

OTHER INITIAL DIAGNOSTICS

NOTE: Be sure water is in contact with the salt, and

not separated by a salt bridge (See "Breaking

A Salt Bridge" section).

Other information which may be beneficial in diagnosing problems may be found in the Total recharges

and Days in use information screens. This information is retained by the computer from the first time

electrical power is applied to the electronic controller.

On the softener’s status screen, press the INFO but-

ton, then the LEFT (

screens (See Page 12).

) button to display these

CHECKING THE MODEL CODE

1. Unplug the softener’s transformer and plug it back

in, watching the touch screen display.

2. After the “E-Z Touch” screen displays briefly, a

screen that looks like Figure 86 will be shown for a

few seconds. Take note of the number next to the

word “Model:”.

CHECKING THE TURBINE

Use the following procedure to check the turbine that

measures water flow through the softener.

1. Press the INFO button on the softener’s status

screen to display the Water flow screen (See

Figure 83).

2. Open a nearby soft water faucet. There should be

a non-zero reading in the display with the faucet

open.

3. When water is flowing, the Water used today

screen (See Fig. 84) can be used to check the turbine reading against volume of water exiting the

softener. Beginning when this screen is displayed,

a beep sounds with each gallon (or liter, as set).

FIG. 83

FIG. 85

FIG. 86

3. The correct code for Model WHES48 is “EZ 48.”

This code identifies the softener model. If an incorrect model code is displayed, the softener will operate on incorrect configuration data.

FIG. 84

24

Page 25

Troubleshooting

MANUAL ADVANCE REGENERATION

CHECK

This check verifies proper operation of the valve

motor, brine tank fill, brine draw, regeneration flow

rates, and other controller functions. Always make

the initial checks first.

Use the following procedure to advance the water

softener through the regeneration cycles to check

operation. In the following steps you will use the

ADVANCE VALVE button to move the valve into each

cycle and check correct switch operation (See

Figures 87 & 88).

Switch is open

(Cam not rotating)

FIG. 87

Switch is closed

(Cam rotating)

FIG. 88

NOTE: The following procedure shows the normal

recharge cycle. If the Clean feature is set to

ON, there will be an extra backwash and fast

rinse before the normal regeneration

sequence.

1. Press the RECHARGE button on the softener’s

status screen.

2. Press the RECHARGE NOW button to initiate a

recharge. The softener’s valve advances from the

service to fill position.

3. Remove the brinewell cover and, using a flashlight,

observe fill water entering the tank.

If water does not enter the tank, look for an

obstructed nozzle, venturi, fill flow plug, brine tubing, or brine valve riser pipe.

4. After observing fill, press the ADVANCE VALVE

button to move the softener’s valve into the brine

position. A slow flow of water to the drain will

begin. Verify brine draw from the brine tank by

shining a flashlight into the brinewell and observing

a noticeable drop in the liquid level. This may take

15 to 20 minutes.

NOTE: Be sure water is in contact with the salt, and

not separated by a salt bridge (See "Breaking

A Salt Bridge" section).

If the water softener does not draw brine, check for

(most likely to least likely):

= Dirty or plugged nozzle and venturi, see

"Cleaning the Nozzle and Venturi" section.

= Nozzle and venturi not seated on the gasket, or

gasket deformed

= Valve seals leaking.

= Restriction in valve drain, causing a back-pres-

sure (bends, kinks, elevated too high, etc.). See

"Install Valve Drain Hose" section.

= Obstruction in brine valve or brine tubing.

NOTE: If water system pressure is low, an elevated

drain hose may cause back pressure, stopping brine draw.

5. Press the ADVANCE VALVE button to move the

softener’s valve into the backwash position. Look

for a fast flow of water from the drain hose. Check

that the drain can adequately handle the flow and

volume.

An obstructed flow indicates a plugged top distributor, backwash flow plug, or drain hose.

6. Press the ADVANCE VALVE button to move the

softener’s valve into the fast rinse position. Again

look for a fast drain flow. Allow the softener to

rinse for a few minutes to flush out any brine that

may remain in the resin tank from the brining cycle

test.

7. To return the softener’s valve to the service posi-

tion, press the ADVANCE VALVE button.

Need help troubleshooting? Call Toll Free 1-866-986-3223

or visit www.ecodynewatertreatment.com

When you call, please be prepared to provide the model, date code and serial number,

found on the rating decal, typically located on the rim below the salt lid hinges.

25

Monday- Friday, 8 AM - 7 PM EST

Page 26

8

7

6

5

Softener Exploded View

Softener Exploded View

26

Valve Assembly

See Pages 28 - 29

for parts

1

2

3

4

5

9

122

42

43

6

7

8

27

28

29

30

31

32

34

10

12

11

13

14

15

25

24

23

22

21

20

19

18

17

16

33

35

36

37

38

39

40

41

26

Page 27

Softener Parts List

Key

No.

Part No. Description

1 7170296 O-Ring, 2-7/8” x 3-1/4”

2 7170254 O-Ring, 13/16” x 1-1/16”

3 7077870 Top Distributor

4 7170270 O-Ring, 2-3/4” x 3”

5 7105047 Repl. Bottom Distributor

6 7265025 Filter Screen

7 7176292 Clamp Section (2 req.)

8 7088033 Retainer Clip (2 req.)

9 7247996 Repl. Resin Tank, 10” x 40”

10 0502272 Resin, 1 cu. ft.

11 7221746 Brine Tube

12 7113016 Tubing Assembly

13 7131365 Screen

14 7142942 Clip

15 7308881 Brine Valve Body

16 7116713 Clip

17 0516924 Bottom Seal Retainer

18 0516211 Seal

19 7170288 O-Ring, 15/16” x 1-3/16”

20 7308904 Guide Cap

21 7220627 Float, Rod & Stem

22 0516947 Float Seal

23 7097202 Float (incl. Key No. 22)

24 0513860 Float Stop

25 7168647 Ceramic Weight

7310202 Repl. Brine Valve Assembly

¢

Key

No.

Part No. Description

26 7275907 Transformer

27 7305443

28 7305477

7330668 Faceplate Decal

¢

29 7305207 Salt Hole Cover (order decal below)

7296571 Instruction Decal

¢

30 7296416 Vapor Barrier

31 7305299 Rim

32 7218696 Repl. Light Assembly

33 7082150 Nut

34 7219888 Brinewell Cover

35 7137824 Brinewell

36 9003500 Grommet

37 1103200 Hose Adaptor

38 0900431 Hose Clamp

39 7262792 Screw

40 7003847 O-Ring

41 7305451 Repl. Brine Tank

42 7248706 Grounding Kit

43 7214383

7310359 Owner’s Manual

¢

¢ Not illustrated.

Repl. Electronic Control Board

(PWA)

Top Cover & Faceplate Assembly,

(order decal below)

Bypass Valve (includes 2 ea. of

Key Nos. 120 & 122)

To order repair parts call toll free 1-866-986-3223, Monday - Friday, 8 am - 7 pm EST.

Manufactured and warranted by

Ecodyne Water Systems

1890 Woodlane Drive

Woodbury, MN 55125

Questions? Call Toll Free 1-866-986-3223

Monday- Friday, 8 AM - 7 PM EST

or visit www.ecodynewatertreatment.com

When you call, please be prepared to provide the model, date code and serial number,

found on the rating decal, typically located on the rim below the salt lid hinges.

27

Page 28

Valve Exploded View

100

101

139

138

137

136

135

143

142

144

141

seal

cross-section

140

wear-strip

view

125

102

103

104

105

106

107

108109110

111

121

112

113

114

120

115

134

133

132

131

130

129

127

128

126

28

119

116

117

118

122

123

124

Page 29

Valve Parts List

Key

No.

100 7224087 Screw, #8-32 x 1” (2 req.)

101 7286039 Motor (incl. 2 ea. of Key No. 100)

102 7231393 Motor Plate

103 0900857 Screw, #6-20 x 3/8” (3 req.)

104 7171250 Bearing

105 7283489 Cam & Gear

106 7169180 Clip, Drain

107 0900431 Hose Clamp

108 7271270 Drain Hose Adaptor

109 7170288 O-Ring, 15/16” x 1-3/16”

110 0501228 Flow Plug, 2.0 gpm

111 7170327 O-Ring, 5/8” x 13/16”

112 7173024 O-Ring, 1-1/8” x 1-1/2”

113 7174313 Bearing, Wave Washer

114 7185500 Rotor & Disc

115 7173032 O-Ring, 4-1/2” x 4-7/8”

116 7185495 Rotor Seal

117 7172989 Seal

118 7171187 Plug, Drain Seal

119 7129889 Spring

120 7089306 Clip (4 req.)

121 7271204 1” NPT Threaded Adaptor (2 req.)

122 7311127 O-Ring, 1-1/16” x 1-5/16” (4 req.)

123 7094898 Turbine Support

124 7101548 Turbine

Part No. Description

Key

No.

125 7309811 Wire Harness, Sensor

126 7081201 Retainer, Nozzle & Venturi

127 7195482 Seal, Nozzle & Venturi

128 7171145 Valve Body

129 7170319 O-Ring, 1/4” x 3/8” (2 req.)

130 7081104 Housing, Nozzle & Venturi

131 1202600 Nut - Ferrule

132 7095030 Cone Screen

133 1148800 Flow Plug, .3 gpm

134

135 7084607 Flow Plug, .15 gpm

136 7146043 Screen

137 7167659 Screen Support

138 7170262 O-Ring, 1-1/8” x 1-3/8”

139 7199729 Cap

140 7175199 Wave Washer

141 7171161 Valve Cover

142 7172997 Screw, #10 x 2-5/8”” (8 req.)

143 7305150 Switch

144 7140738 Screw, #4-24 x 3/4” (2 req.)

Part No. Description

7114533 Nozzle & Venturi Gasket Kit

7204362 Gasket Only

7253808

¢

7185487

¢

3479901 Adaptor Kit, 1” to 1-1/4”

¢

Nozzle & Venturi Assembly (incl.

Key Nos. 130 & 132 - 139)

Seal Kit (incl. Key Nos. 111, 112,

115, 116, 117 & 127)

¢ Not illustrated.

To order repair parts call toll free 1-866-986-3223, Monday - Friday, 8 am - 7 pm EST.

Manufactured and warranted by

Ecodyne Water Systems

1890 Woodlane Drive

Woodbury, MN 55125

Questions? Call Toll Free 1-866-986-3223

Monday- Friday, 8 AM - 7 PM EST

or visit www.ecodynewatertreatment.com

When you call, please be prepared to provide the model, date code and serial number,

found on the rating decal, typically located on the rim below the salt lid hinges.

29

Loading...

Loading...