Whirlpool WHES Installation Instructions Manual

Installation Instructions

WHES Series

Demand Controlled

Water Softener

For a detailed owner’s manual,

including specifications,

programming and parts list, go to:

www.whirlpoolwatersofteners.com

or call 1-866-986-3223

Do not return water softener to store

If you have any questions or concerns when

installing, operating or maintaining your water

softener, call our toll free number:

1-866-986-3223

Monday- Friday, 8 AM - 7 PM EST or visit

www.whirlpoolwatersofteners.com

When you call, please be prepared to provide

the model and serial number of your product,

found on the rating decal, typically located on

the rim below the salt lid hinges.

Systems tested and certified by NSF International

against NSF/ANSI Standard 44

for hardness reduction and efficiency,

and certified to NSF/ANSI Standard 372.

Systems tested and certified by the Water Quality

Association against CSA B483.1.

English

Manufactured and warranted by

Ecodyne Water Systems

1890 Woodlane Drive

Woodbury, MN 55125

1

7345485 (Rev. A 9/30/14)

Water Softener Safety

Your safety and the safety of others are very important.

We have provided many safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING”

These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell

you what can happen if the instructions are not followed.

Before You Start

= The water softener requires a minimum water flow

English

= Do not use this system to treat water that is micro-

LOCATION REQUIREMENTS

Consider all of the following when selecting an installation location for the water softener.

= Do not locate the water softener where freezing

= To condition all water in the home, install the water

= A nearby drain is needed to carry away regenera-

of 3 gallons per minute at the inlet. Maximum

allowable inlet water pressure is 125 psi. If daytime

pressure is over 80 psi, nighttime pressure may

exceed the maximum. Use a pressure reducing

valve if necessary (Adding a pressure reducing

valve may reduce the flow). If your home is

equipped with a back flow preventer, an expansion

tank must be installed in accordance with local

codes and laws.

biologically unsafe or of unknown quality without

adequate disinfection upstream or downstream of

the system.

temperatures occur. Do not attempt to treat water

over 120ºF. Freezing temperatures or hot water

damage voids the warranty.

softener close to the water supply inlet, and

upstream of all other plumbing connections, except

outside water pipes. Outside faucets should remain

on hard water to avoid wasting conditioned water

and salt.

tion discharge (drain) water. Use a floor drain,

laundry tub, sump, standpipe, or other options

(check your local codes). See "Air Gap

Requirements" and "Valve Drain Requirements"

sections.

= The water softener works on 28V DC electrical

power, supplied by a direct plug-in power supply

(included). Be sure to use the included power supply and plug it into a nominal 120V, 60 Hz household outlet that is in a dry location only, grounded

and properly protected by an overcurrent device

such as a circuit breaker or fuse.

= Always install the water softener between the water

inlet and water heater. Any other installed water

conditioning equipment should be installed between

the water inlet and water softener (See Figure 6).

= Avoid installing in direct sunlight. Excessive sun

heat may cause distortion or other damage to nonmetallic parts.

PLUMBING CODES

All plumbing must be completed in accordance with

national, state and local plumbing codes.

In the state of Massachusetts: The Commonwealth

of Massachusetts plumbing code 248-CMR shall

be adhered to. A licensed plumber shall be used

for this installation.

2

Before You Start

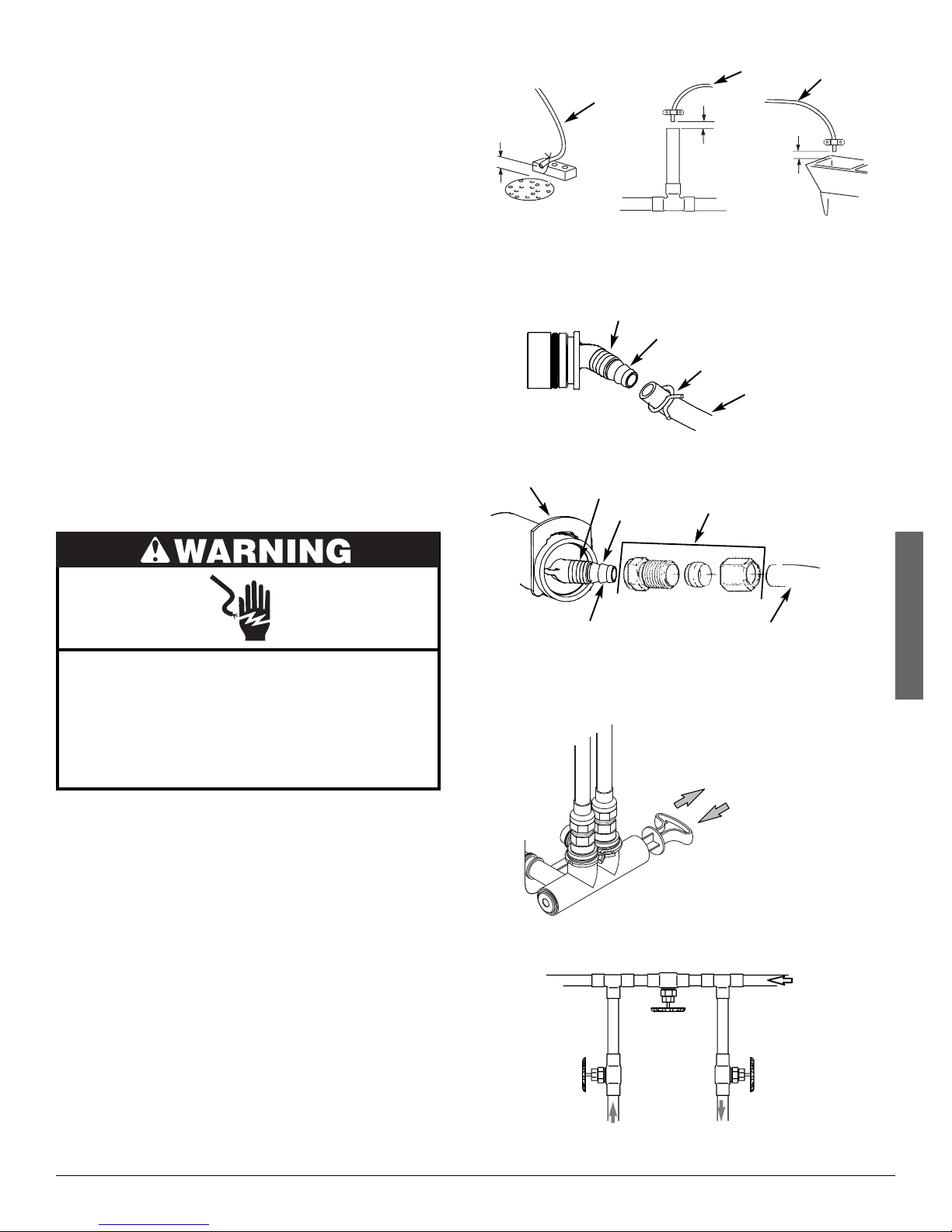

AIR GAP REQUIREMENTS

A drain is needed for regeneration water (See Figure

1). A floor drain, close to the water softener, is

preferred. A laundry tub, standpipe, etc. are other

drain options. Secure valve drain hose in place.

Leave an air gap of 1-1/2” between the end of the

hose and the drain. This gap is needed to prevent

backflow of sewer water into the water softener. Do

not put the end of the drain hose into the drain.

VALVE DRAIN REQUIREMENTS

Using the flexible drain hose (included), measure and

cut to the length needed. Flexible drain hose is not

allowed in all localities (check your plumbing codes). If

local codes do not allow use of a flexible drain hose, a

rigid valve drain run must be used. Purchase a compression fitting (1/4 NPT x 1/2 in. minimum tube) and

1/2" tubing from your local hardware store. Plumb a

rigid drain as needed (See Figure 3).

NOTE: Make the valve drain line as short and direct

as possible.

1-1/2”

air gap

FLOOR DRAIN

Clip

1/4 NPT

Threads

Drain

Hose

1/4” NPT

Thread

Barbs

1-1/2”

air gap

Barbs for 3/8”

I.D. Tubing

Hose Clamp

Compression Fitting.

1/4 NPT x 1/2” O.D.

Tube (not included)

Drain

Hose

1-1/2”

air gap

LAUNDRY TUBSTANDPIPE

Drain Hose

Drain

Hose

FIG. 1

FIG. 2

Electrical Shock Hazard

Prior to installation on metallic plumbing,

securely install two grounding clamps and a

#4 copper wire per installation instructions.

Failure to follow these instructions can result

in death or electrical shock.

INLET / OUTLET PLUMBING OPTIONS

Always install either a single bypass valve (provided),

as shown in Figure 4, or, if desired, parts for a 3 valve

bypass system (not included) can be purchased and

assembled, as shown in Figure 5. Bypass valves

allow you to turn off water to the softener for maintenance if needed, but still have water in house pipes.

Pipe fittings must be 3/4” minimum.

Use:

= Copper pipe

= Threaded pipe

= PEX (Crosslinked Polyethylene) pipe

= CPVC plastic pipe

= Other pipe approved for use with potable water

IMPORTANT: Do not solder with plumbing attached to

installation adaptors and single bypass

valve. Soldering heat will damage the

adaptors and valve.

Cut barbs from drain fitting (pull clip to remove

fitting from valve)

SINGLE BYPASS VALVE

3 VALVE BYPASS

Outlet

Valve

From Water

Softener

1/2” Outside Dia.

Copper Tube

(not included)

Bypass

Valve

To Water

Softener

English

FIG. 3

Pull out for “Service”

(Soft water)

Push in for

“Bypass”

FIG. 4

Inlet

Valve

FIG. 5

3

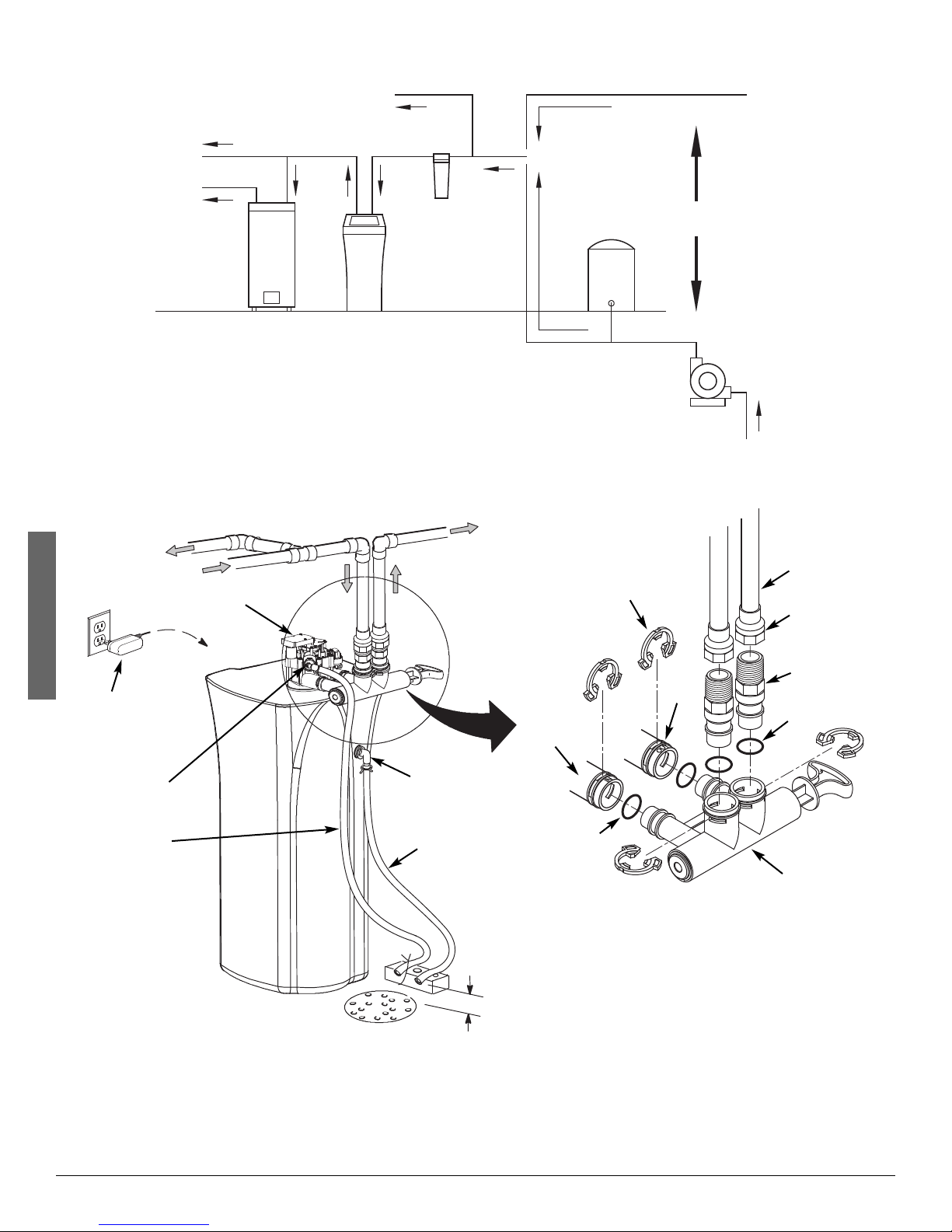

THE PROPER ORDER TO INSTALL WATER TREATMENT EQUIPMENT

To Outside

English

Plug-in

Power

Supply

Cold Water

to House

Hot Water

to House

Faucets

Water Softener

Controller

To

Untreated Water to

Water

Heater

Hard Water

Valve

Outside Faucets

Water

Softener

Main Water Pipe

Optional

Pressure

Sediment

Filter

TYPICAL INSTALLATION

Conditioned

Water

Inlet

City Water Supply

Tank

OR

Well Water Supply

Well

Pump

Clips

Outlet

FIG. 6

Pipe

1” NPT Sweat

Adaptor (not

included)

1” NPT

Threaded

Adaptor

O-ring

Valve Drain

Elbow

Valve Drain

Hose*

*Do not connect the

water softener valve drain

tubing to the salt storage

tank overflow hose.

Questions? Call Toll Free 1-866-986-3223 Monday- Friday, 8 AM - 7 PM EST

or visit www.whirlpoolwatersofteners.com

When you call, please be prepared to provide the model and serial number,

found on the rating decal, typically located on the rim below the salt lid hinges.

Floor Drain

Overflow

Drain Elbow

Salt Storage

Tank Overflow

Hose*

Secure Valve Drain Hose

in place over Floor Drain

4

1-1/2”

air gap

Lubricated

O-ring

Single

Bypass Valve

NOTE: See “Air Gap Requirements” section.

NOTE: Water Softener shown with Salt Lid and

Top Cover removed

FIG. 7

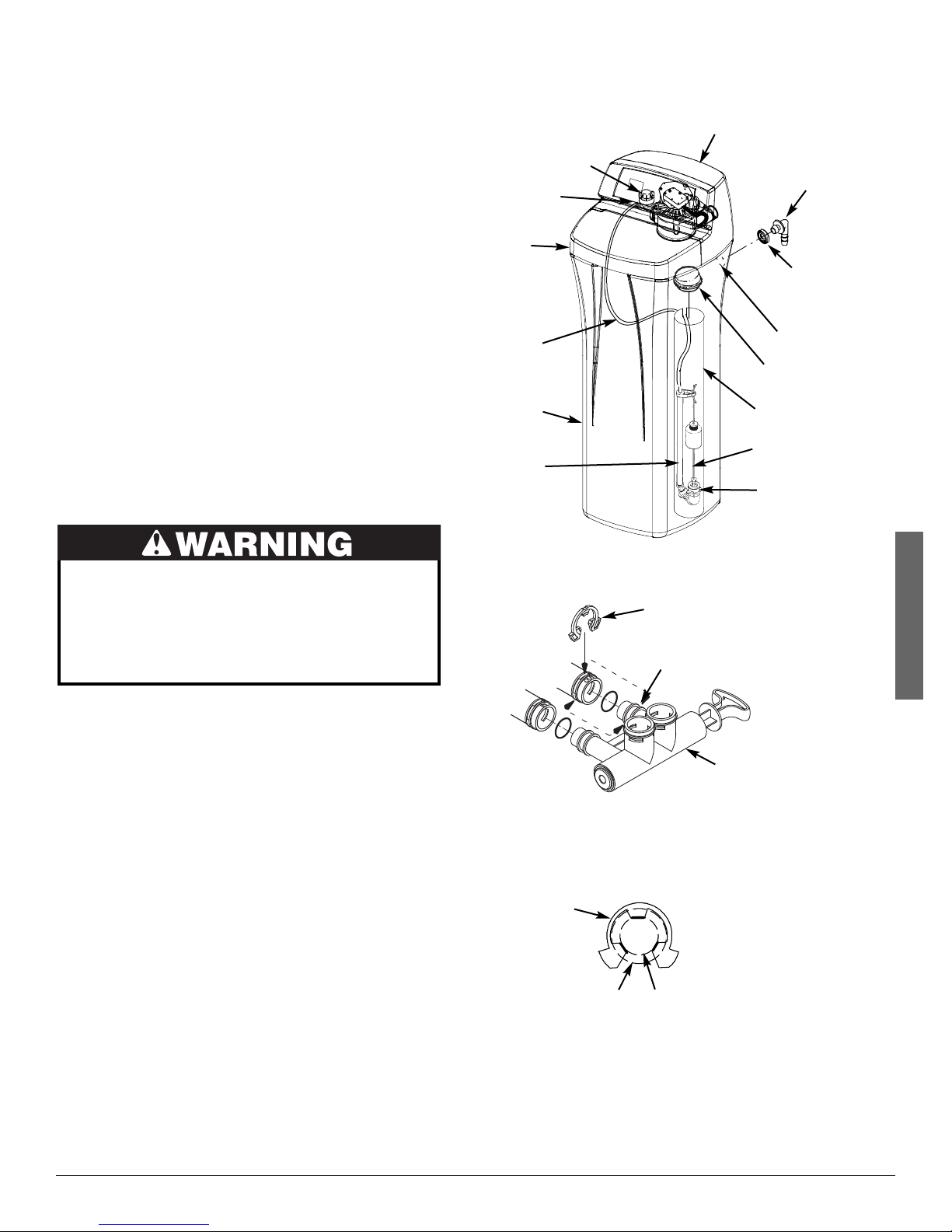

Installation Instructions

TURN OFF WATER SUPPLY

1. Close the main water supply valve, located near the

well pump or water meter.

2. Open all faucets to drain all water from house pipes.

NOTE: Be sure not to drain water from the water

heater, as damage to the water heater elements could result.

INSTALL THE BRINE TANK OVERFLOW

ELBOW

Install the brine tank overflow grommet and elbow in

the 13/16” diameter hole in the back of the salt storage

tank sidewall.

NOTE: The brine tank overflow elbow accepts either

1/2” or 3/8” I.D. hose.

MOVE THE WATER SOFTENER INTO PLACE

Ferrule

Salt

Lid

Brine

Tubing

Salt

Storage

Tank

Stand

Tube

Nozzle

Venturi

Assembly

Nut -

Top Cover

Brine Tank

Overflow

Elbow

Brine Tank

Overflow

Grommet

13/16” Hole

Brinewell

Cover

Brinewell

Float Stem

Brine

Valve

FIG. 8

Excessive Weight Hazard

Use two or more people to move and install

water softener.

Failure to do so can result in back or other

injury.

1. Move the water softener into the desired location.

Set it on a solid, level surface.

IMPORTANT: Do not place shims directly under the

salt storage tank to level the softener.

The weight of the tank, when full of

water and salt, may cause the tank to

fracture at the shim.

2. Visually check and remove any debris from the

water softener valve inlet and outlet ports.

3. Make sure the turbine assembly spins freely in the

"out" port of the valve.

4. If not already done, put a light coating of silicone

grease on the single bypass valve o-rings.

5. Push the single bypass valve into the softener valve

as far as it will go. Snap the two large holding clips

into place, from the top down as shown in Figures 9

& 10.

IMPORTANT: Be sure the clips snap firmly into place

so the single bypass valve will not pull

out.

Clip

Channel

Single Bypass Valve

FIG. 9

CORRECT ASSEMBLY

Clip

Outside diameter

of water softener

valve inlet & outlet

NOTE: Be sure all 3 tabs of the clip go through the matching

holes on the water softener valve inlet or outlet, and

fully into the channel on the single bypass valve.

Make sure that the tabs are fully seated.

Outside diameter

of clip channel on

single bypass valve

FIG. 10

English

5

GROUNDING INFORMATION

(for Installations on Metal Pipe)

The house main incoming water pipe is often used to

ground electrical outlets in the home. Grounding protects you from electrical shock. Installing the water

softener with a plastic bypass valve will break this

ground. Before beginning installation, purchase and

securely install two grounding clamps and a #4 copper

wire across the location where the softener will be,

English

tightly clamping it at both ends, as shown in Figure 11.

NOTE: Check local plumbing and electrical codes

Installation Instructions

Electrical Shock Hazard

Prior to installation on metallic plumbing,

securely install two grounding clamps and a

#4 copper wire per installation instructions.

Failure to follow these instructions can result

in death or electrical shock.

for proper installation of the ground wire.

The installation must conform to them. In

Massachusetts, plumbing codes of

Massachusetts shall be conformed to.

Consult with your licensed plumber.

Complete the inlet and outlet plumbing for the type of

pipe you will be using.

INSTALL VALVE DRAIN HOSE

1. Measure, cut to needed length and connect the 3/8"

drain line (provided) to the water softener valve

drain fitting. Use a hose clamp to hold the hose in

place.

NOTE: Make the valve drain line as short and direct

as possible.

IMPORTANT: If codes require a rigid drain line see

“Valve Drain requirements" section.

2. Route the drain hose or copper tubing to the floor

drain. Secure drain hose. This will prevent “whipping'' during regenerations. See “Air Gap

Requirements" section.

INSTALL SALT STORAGE TANK OVERFLOW

HOSE

1. Measure, cut to needed length and connect the 3/8"

drain line (provided) to the salt storage tank overflow elbow and secure in place with a hose clamp.

2 Route the hose to the floor drain, or other suitable

drain point no higher than the drain fitting on the salt

storage tank (This is a gravity drain). If the tank

overfills with water, the excess water flows to the

drain point. Cut the drain line to the desired length

and route it neatly out of the way.

IMPORTANT: For proper operation of the water soften-

er, do not connect the water softener

valve drain tubing to the salt storage

tank overflow hose.

Ground Wire

(not included)

Clamp

(2 - not included)

FIG. 11

COMPLETE INLET AND OUTLET PLUMBING

Measure, cut, and loosely assemble pipe and fittings

from the main water pipe to the inlet and outlet ports of

the water softener valve. Be sure to keep fittings fully

together, and pipes squared and straight.

Be sure hard water supply pipe goes to the water softener valve inlet side.

NOTE: Inlet and outlet are marked on the water softener

valve. Trace the water flow direction to be sure

hard water is to inlet.

IMPORTANT: Be sure to fit, align and support all plumb-

ing to prevent putting stress on the water

softener valve inlet and outlet. Stress

from misaligned or unsupported plumbing

may cause damage to the valve.

TEST FOR LEAKS

To prevent air pressure in the water softener and

plumbing system, complete the following steps in

order:

1. Fully open two or more softened cold water faucets

close to the water softener, located downstream

from the water softener.

2. Place the bypass valve (single or 3 valve) into the

"bypass" position. See Figures 4 & 5.

3. Slowly open the main water supply valve. Run

water until there is a steady flow from the opened

faucets, with no air bubbles.

4. Place bypass valve(s) in "service" or soft water posi-

tion as follows:

= Single bypass valve: Slowly move the valve stem

toward "service," pausing several times to allow

the water softener to fill with water.

= 3 valve bypass: Fully close the bypass valve and

open the outlet valve. Slowly open the inlet

valve, pausing several times to allow the water

softener to fill with water.

5. After about three minutes, open a hot water faucet

until there is a steady flow and there are no air bubbles, then close this faucet.

6. Close all cold water faucets and check for leaks at

the plumbing connections that you made.

6

Installation Instructions

ADD WATER AND SALT TO THE SALT

STORAGE TANK

Excessive Weight Hazard

Use two or more people to move and lift salt

bags.

Failure to do so can result in back or other

injury.

1. Using a container, add about three gallons of clean

water into the salt storage tank.

2. Add salt to the storage tank. Use nugget, pellet or

coarse solar salts with less than 1% impurities.

PLUG IN THE POWER SUPPLY

During installation, the water softener wiring may be

moved or jostled from place. Be sure all leadwire connectors are secure on the back of the electronic board

and be sure all wiring is away from the valve gear and

motor area, which rotates during regenerations.

1. Plug the power supply into an electrical outlet that is

not controlled by a switch.

NOTE: The water heater is filled with hard water and,

as hot water is used, it will refill with conditioned water. In a few days, the hot water will

be fully conditioned. To have fully conditioned

hot water immediately, wait until the initial

recharge is over. Then, drain the water heater

(following instructions for water heater) until

water runs cold.

PROGRAMMING THE SOFTENER

Lift the salt lid and follow the instructions on the decal

to program the following into the electronic controller:

= Current time of day

= Hardness of your water supply

= Time of day when automatic recharges will begin

= Type of salt you will be using (only on select models)

NOTE: You can find complete instructions for program-

ming the softener and customizing features of

the electronic controller in the owner’s manual.

Go to www.whirlpoolwatersofteners.com

or call 1-866-986-3223.

SANITIZE THE WATER SOFTENER /

SANITIZE AFTER SERVICE

1. Open salt lid, remove the brinewell cover and pour

about 3 oz. (6 tablespoons) of household bleach

into the softener brinewell. Replace the brinewell

cover.

2 Make sure the bypass valve(s) is in the “service”

(open) position.

3 Start a recharge (regeneration) by pressing and hold-

ing for 3 seconds the RECHARGE button on the faceplate.

4. After the recharge has completed, fully open a cold

water faucet, downstream from the softener, and

allow 50 gallons of water to pass through the system. This should take at least 20 minutes. Close

the faucet.

ADDING SALT

Lift the salt lid and check the salt storage level frequently. If the water softener uses all the salt before

you refill it, you will experience hard water. Until you

have established a refilling routine, check the salt

every two or three weeks. Always add if less than 1/4

full. Be sure the brinewell cover is on.

NOTE: If using potassium chloride (KCl), do not fill

above level 4 on the brinewell scale.

NOTE: In humid areas, it is best to keep the salt stor-

age level lower, and to refill more often to avoid

salt “bridging”.

Recommended Salt: Nugget, pellet or coarse solar

salts with less than 1% impurities.

Salt Not Recommended: Rock salt, high in impurities,

block, granulated, table, ice melting, ice cream making

salts, etc.

English

In the state of California: You must turn the Salt

Efficiency Feature setting to ON. This may initiate

more frequent recharges. However, it will operate

at 4,000 grains per pound of salt or higher. To turn

on the Salt Efficiency Feature, follow the instructions in the “Salt Efficiency” section of the owner’s

manual.

TANK LIGHT (Only on select models)

The water softener is equipped with a tank light for

viewing the salt level in the brine tank. Push the tank

light button on the electronic control once, and the tank

light will turn on. Pushing the tank light button again

will turn the light off. The tank light will automatically

turn off after a period of four minutes if the tank light

button is not used to turn it off.

7

EXTEND YOUR WARRANTY:

Use Whirlpool

®

WHE-WSC Water Softener Cleanser

The factory warranty for your water softener is shown below. The one year full warranty period on parts and labor

can be extended to two years from the date of purchase if you use Whirlpool

on your system. Use one bottle of Whirlpool

from the date of purchase of the water softener. Retain proof of purchase of Whirlpool

Cleanser to validate any warranty claim during the second year. Use of any water softener additive other than

Whirlpool

English

®

®

WHE-WSC Water Softener Cleanser, as directed, every four months

®

WHE-WSC will not provide extended warranty coverage.

WHE-WSC Water Softener Cleanser

®

WHE-WSC Water Softener

WATER SOFTENER WARRANTY

Warrantor: Ecodyne Water Systems, 1890 Woodlane Drive, Woodbury, MN 55125

Warrantor guarantees, to the original owner, that:

One Year Full Warranty:

● For a period of one (1) year from the date of purchase, all parts will be free from defects in materials and workmanship and will perform their normal functions.

● For a period of one (1) year from the date of purchase, labor to repair or replace any part deemed to be defective

in materials or workmanship, will be provided at no additional cost.

Limited Warranties:

● For a period of ten (10) years from the date of purchase, the salt storage tank and fiberglass mineral tank will not

rust, corrode, leak, burst, or in any other manner, fail to perform its proper functions.

● For a period of three (3) years from the date of purchase, the electronic control board will be free of defects in

materials and workmanship and will perform its normal functions.

If, during such respective period, a part proves to be defective, Warrantor will ship a replacement part, directly to your

home, without charge. After the first year, labor necessary to maintain this product is not covered by the product warranty.

If you have questions regarding a warranted product, need assistance with installation or troubleshooting, wish to

order a part or report a warranty issue, we are just a phone call away. SIMPLY DIAL 1-866-986-3223, Monday Friday, 8 am - 7 pm EST, for assistance.

General Provisions

The above warranties are effective provided the water softener is operated at water pressures not exceeding 125 psi,

and at water temperatures not exceeding 120°F; provided further that the water softener is not subject to abuse, misuse, alteration, neglect, freezing, accident or negligence; and provided further that the water softener is not damaged

as the result of any unusual force of nature such as, but not limited to, flood, hurricane, tornado or earthquake.

Warrantor is excused if failure to perform its warranty obligations is the result of strikes, government regulation, materials shortages, or other circumstances beyond its control.

*THERE ARE NO WARRANTIES ON THE WATER SOFTENER BEYOND THOSE SPECIFICALLY DESCRIBED

ABOVE. ALL IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR OF

FITNESS FOR A PARTICULAR PURPOSE, ARE DISCLAIMED TO THE EXTENT THEY MIGHT EXTEND BEYOND

THE ABOVE PERIODS. THE SOLE OBLIGATION OF WARRANTOR UNDER THESE WARRANTIES IS TO

REPLACE OR REPAIR THE COMPONENT OR PART WHICH PROVES TO BE DEFECTIVE WITHIN THE SPECIFIED TIME PERIOD, AND WARRANTOR IS NOT LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES.

NO WARRANTOR DEALER, AGENT, REPRESENTATIVE, OR OTHER PERSON IS AUTHORIZED TO EXTEND OR

EXPAND THE WARRANTIES EXPRESSLY DESCRIBED ABOVE.

Some states do not allow limitations on how long an implied warranty lasts or exclusions or limitations of incidental or

consequential damage, so the limitations and exclusions in this warranty may not apply to you. This warranty gives

you specific legal rights, and you may have other rights which vary from state to state. This warranty applies to consumer-owned installations only.

Manufactured under license by Ecodyne Water Systems, Woodbury, Minnesota.

For a detailed owner’s manual, including specifications, programming and parts list, go to:

www.whirlpoolwatersofteners.com or call 1-866-986-3223

® /TM © 2014 Whirlpool. All rights reserved.

8

Loading...

Loading...