Page 1

FOR SERVICE TECHNICIAN’S USE ONLY

Voltage Measurement Safety Information

When performing live voltage measurements, you must do the following:

Verify the controls are in the off position so that the appliance does not start when energized.

Allow enough space to perform the voltage measurements without obstructions.

Keep other people a safe distance away from the appliance to prevent potential injury.

Always use the proper testing equipment.

After voltage measurements, always disconnect power before servicing.

IMPORTANT: Electrostatic Discharge (ESD) Sensitive Electronics

ESD problems are present everywhere. Most people begin to feel an ESD discharge at

approximately 3000V. It takes as little as 10V to destroy, damage, or weaken the main control

assembly. The new main control assembly may appear to work well after repair is finished,

but a malfunction may occur at a later date due to ESD stress.

Use an anti-static wrist strap. Connect wrist strap to green ground connection point or

unpainted metal in the appliance

-OR Touch your finger repeatedly to a green ground connection point or unpainted metal

in the appliance.

Before removing the part from its package, touch the anti-static bag to a green ground

connection point or unpainted metal in the appliance.

Avoid touching electronic parts or terminal contacts; handle electronic control assembly

by edges only.

When repackaging main control assembly in anti-static bag, observe above instructions.

This service data sheet is intended for use by persons having electrical, electronic, and

mechanical experience and knowledge at a level generally considered acceptable in the

appliance repair trade. Any attempt to repair a major appliance may result in personal injury

and property damage. The manufacturer or seller cannot be responsible, nor assume any

liability for injury or damage of any kind arising from the use of this data sheet.

Contents

IMPORTANT SAFETY NOTICE — “For Technicians only”

Diagnostic Guide ......................................... 2

Activating the Service Diagnostic

Test Modes (Washer) .................................. 2

Diagnostic Test Modes (Washer) ............. 3–5

Customer Viewable Fault Codes (Washer) ....5

Fault/Error Codes (Washer) ..................... 6, 7

Automatic Test Mode (Washer) .................... 8

Manual Test Mode (Washer) ........................ 9

PART NO. W11082888C

Washer Troubleshooting Guide ............ 10, 11

Washer Troubleshooting Tests ............. 12–18

Washer Main Control Connectors & Pinouts ..12

Dryer Troubleshooting Guide ..................... 19

Dryer Troubleshooting Tests ................ 20–24

Component Locations &

Washer Specifications ............................... 25

Wiring and Timer Diagrams ................. 26–28

PAGE 1

Page 2

FOR SERVICE TECHNICIAN’S USE ONLY

DIAGNOSTIC GUIDE

Before servicing, check the following:

Make sure there is power at the wall outlet.

Has a household fuse blown or circuit breaker

tripped? Was a regular fuse used? Inform

customer that a time-delay fuse is required.

Is dryer vent properly installed and clear

of lint or obstructions?

Are both hot and cold water faucets open

and water supply hoses unobstructed?

Make sure drain hose is not sealed into

drain pipe, and that there is an air gap for

ventilation. Ensure drain height is between

39" (991 mm) and 8' (2.4 m) above the floor.

All tests/checks should be made with a

VOM (volt-ohm-milliammeter) or DVM

(digital-voltmeter) having a sensitivity of

20,000 Ω per volt DC or greater.

Resistance checks must be made with washer/

dryer unplugged or power disconnected.

IMPORTANT: Avoid using large

diameter probes when checking harness

connectors as the probes may damage

the connectors upon insertion.

Check all harnesses and connections before

replacing components. Look for connectors

not fully seated, broken or loose wires and

terminals, or wires not pressed into connectors

far enough to engage metal barbs.

A potential cause of a control not

functioning is corrosion or contamination on

connections. Use an ohmmeter to check for

continuity across suspected connections.

ACTIVATING THE SERVICE

DIAGNOSTIC TEST MODES (WASHER)

1. Be sure the washer/dryer is in standby

mode (plugged in with all indicators off).

NOTE: After initial power is applied, wait 10

seconds before activating Service Diagnostic

Test Modes.

2. Perform the following sequence of

movement using the cycle selector knob.

NOTE: AFTER RESET, sequence “a” through

“e” must be completed within 6 seconds.

RESET - Rotate cycle selector knob

L

counterclockwise one or more clicks

to clear sequence.

a. Rotate cycle selector knob clockwise

R

one click and wait ½ second.

b. Rotate cycle selector knob clockwise

R

one click and wait ½ second.

c. Rotate cycle selector knob clockwise

R

one click and wait ½ second.

d. Rotate cycle selector knob

L

counterclockwise one click and

wait ½ second.

e. Rotate cycle selector knob

R

clockwise one click.

DIAGNOSTIC LED – MAIN CONTROL (WASHER)

A troubleshooting tool has been implemented

onto the main control board—a diagnostic LED.

LED ON – The Control is detecting correct incoming

line voltage and the processor is functioning.

LED OFF – Control malfunction. Perform TEST #1:

Main Control, page 12, to verify main control

functionality.

LED Location

Figure 1

SERVICE DIAGNOSTIC TEST MODES (WASHER)

These tests allow factory or service personnel

to test and verify all inputs to the main control

board. You may want to do a quick and overall

checkup of the washer with these tests before

going to specific troubleshooting tests.

PAGE 2

Successful activation of Diagnostic Test

Modes will be indicated by all status

LEDs (except for Lid Lock) flashing

ON and OFF in half-second intervals.

NOTE: LED names may vary between

makes and models.

Legend: = ON = OFF

0.5 Seconds ON

Sense Wash Rinse Drain Done

Fill Spin

0.5 Seconds OFF

Figure 2 - Status LEDs flashing ON and OFF

If the status LEDs do not display as

described above, the sequence may

not have been completed within 6

seconds. Repeat step 2 to ensure this

was not the cause. If still unsuccessful,

see Unsuccessful Entry, page 3.

DO NOT REMOVE OR DESTROY

Page 3

FOR SERVICE TECHNICIAN’S USE ONLY

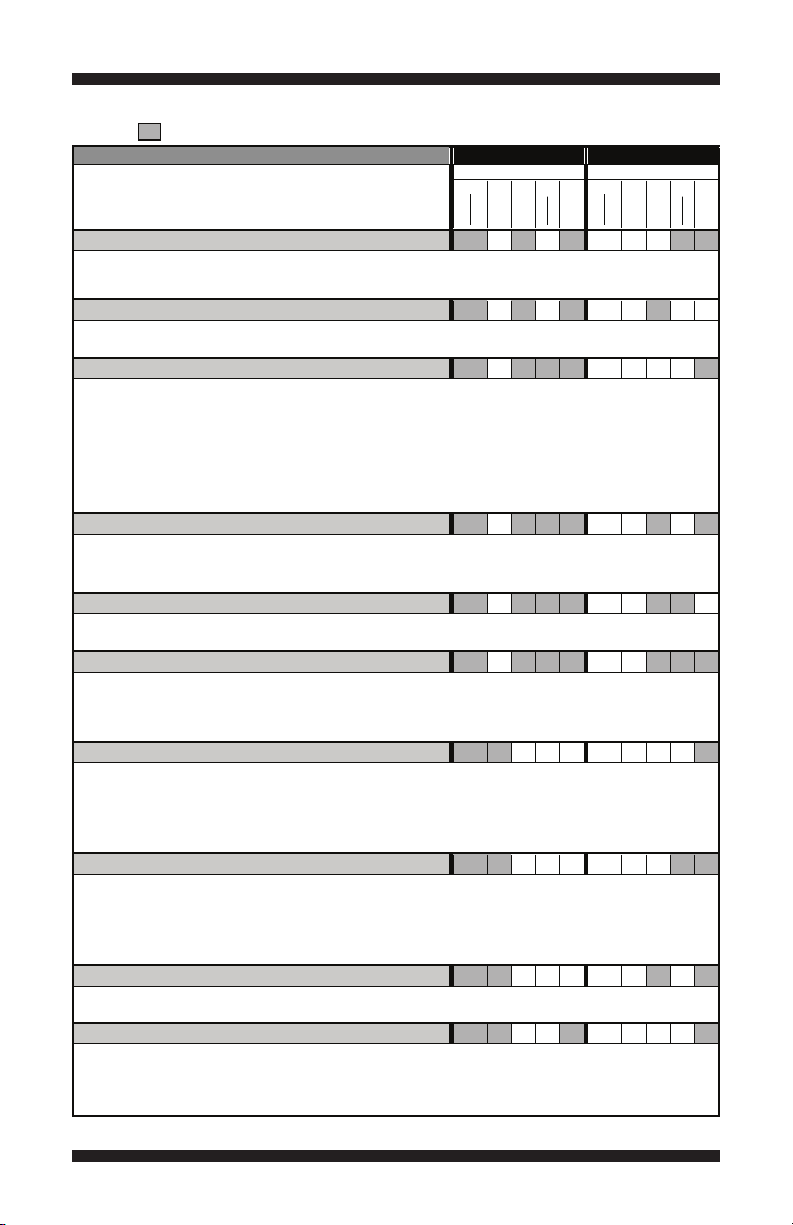

DIAGNOSTIC TEST MODES

20

41

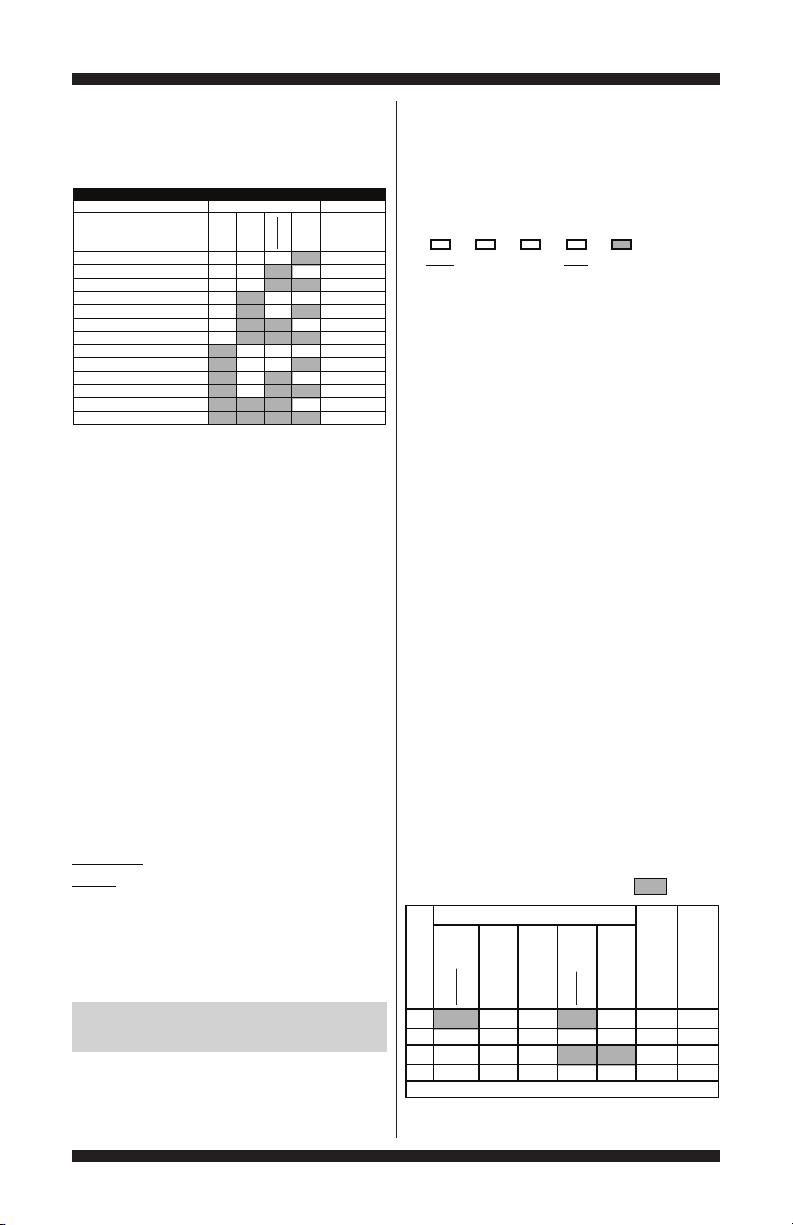

3. There are several accessible Diagnostic

Test Modes shown in the chart below. To

select the desired Mode of Operation, turn

the cycle selector knob until the status LEDs

match the mode desired to enter.

MODE

(Status LED names may vary

between makes and models)

Fault Code Display Mode

Automatic Test Mode

Manual Test Mode

Calibration Mode

Sales Demo Mode

UI Test Mode

SW Version Display Mode

Factory Diagnostics Mode

Tachometer Ve rification

Dry Factory Diagnostics

Factory Cal Test Cycle

AATCC Cycle

NVH Cycle

STATUS LEDs

WASH

RINSE

DRAIN

SPIN

DISPLAY

(Only on models

with a display)

DONE

01

02

03

04

05

06

07

08

09

10

11

14

15

4. Press the START button to enter desired

mode of operation.

Refer to the following pages for detailed

information on each mode of operation:

FAULT CODE DISPLAY MODE: Page 3

AUTOMATIC TEST MODE: Page 4

MANUAL TEST MODE: Page 4

CALIBRATION MODE: Page 4

SALES DEMO: NOT FOR SERVICE USE*

UI TEST MODE: Page 4

SW VERSION DISPLAY MODE: Page 5

FACTORY DIAGNOSTICS: NOT FOR SERVICE USE.*

If accessed, washer must be recalibrated (see

Calibration Mode)

TACHOMETER VERIFICATION MODE: Page 5

DRY FACTORY DIAGNOSTICS: NOT FOR SERVICE

USE*

FACTORY CAL TEST CYCLE: NOT FOR SERVICE USE*

AATCC CYCLE: NOT FOR SERVICE USE*

NVH CYCLE: NOT FOR SERVICE USE*

*Press and hold START for 3 seconds to exit.

Unsuccessful Entry

If entry into diagnostic test mode is unsuccessful,

refer to the following indication and action:

Indication: None of the LEDs turn on.

Action: Press START button to enter setting mode.

If indicators come on, repeat steps

1 through 4 of Activating the Service

Diagnostic Modes. NOTE: Rotating the

dial too fast or too slow will affect entry.

If no indicators come on after pressing the

START button, go to TEST #1, page 12.

EXITING THE SERVICE

DIAGNOSTIC TEST MODES

Press and hold the START button for 3 seconds

at any time to exit diagnostic test modes.

Washer will exit diagnostic test modes after 5

minutes of inactivity or unplugging the power cord.

FAULT CODE DISPLAY MODE (Pgs 6–7)

To access fault/error codes, perform steps 1

and 2 of Activating the Service Diagnostic Test

Modes. Turn the cycle selector knob until the

status LEDs correspond as follows:

“Done” LED On

Sense Wash Rinse Drain Done

Fill Spin

Press the START button to enter Fault Code

Display Mode. The status LEDs flash on and off.

1. To view last four fault codes:

Turn cycle selector knob clockwise

to view fault codes in the order of most

recent to oldest. (Refer to Fault/Error

Code charts on pages 6 & 7.)

NOTE: A fault/error code will be removed

from memory if it does not reoccur after

10 consecutive wash cycles.

2. To clear fault codes:

Turn cycle selector knob until the status LEDs

flash ON and OFF (see figure 2, page 2).

Press and hold the START button

for 3 seconds to clear all fault codes

and exit Fault Code Display Mode.

Fault/Error Code Display Method

Fault/error codes are displayed by alternating the

state of the Status LEDs in one second intervals.

All fault/error codes have an F# and an E#. The

F# indicates the suspect System/Category and

the E# indicates the suspect Component system.

If the Sense/Fill LED is ON, the Fault Number

is represented; if OFF, the Error Number is

represented (see example below). The remaining

LEDs (Wash, Rinse, Drain/Spin, and Done)

represent the fault and error code in binary. (See

Fault/Error Code Charts on pages 6 & 7 for more

information.) = ON.

STATUS LEDs

Frame Number

SENSE

FILL

WASH

RINSE

SPIN

DONE

Fault / Error Code

1F 8421F2

DRAIN

3E 8421E3

Repeat…

LED names may vary between makes and models.

Frame Timing (sec.)

0.5

.5

0.5

.0

DO NOT REMOVE OR DESTROY

PAGE 3

Page 4

FOR SERVICE TECHNICIAN’S USE ONLY

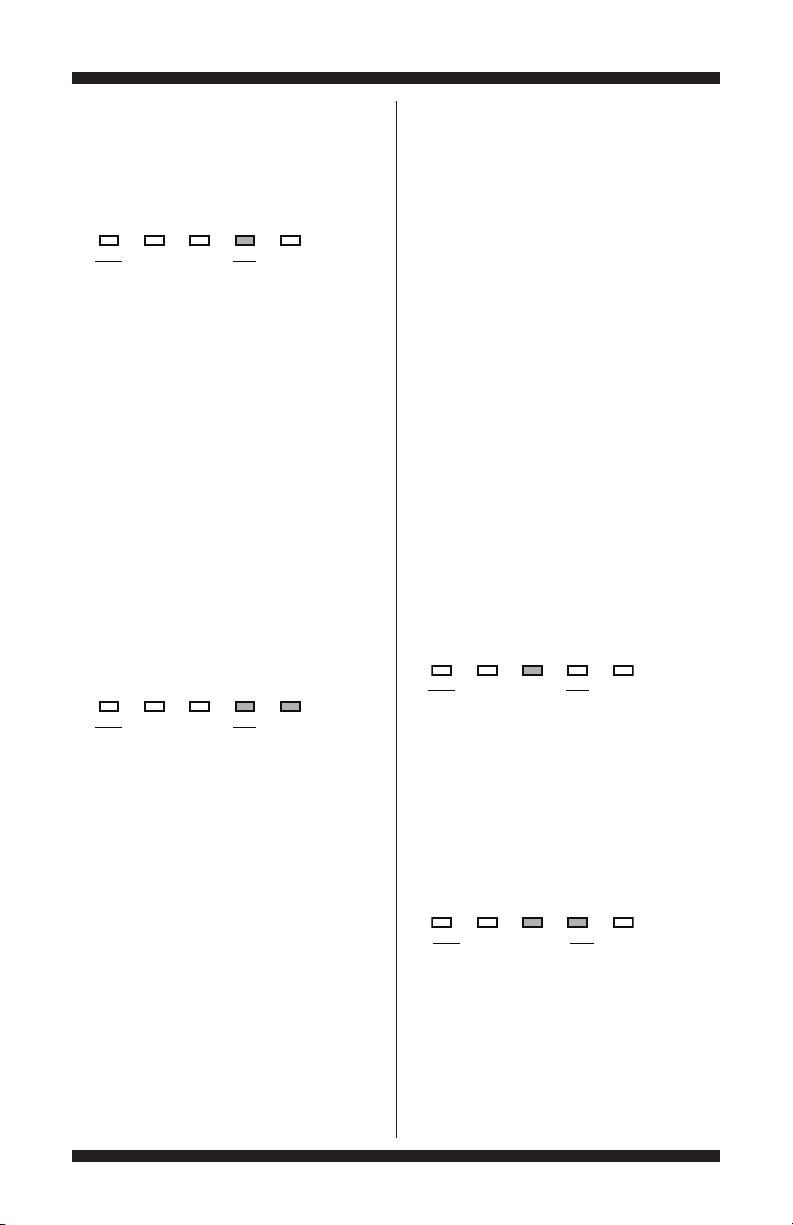

AUTOMATIC TEST MODE (Page 8)

To access Automatic Test Mode, perform steps

1 and 2 of Activating the Service Diagnostic

Test Modes. Turn the cycle selector knob until

the status LEDs correspond as follows:

“Drain/Spin” LED On

Sense Wash Rinse Drain Done

Fill Spin

NOTE: Status LED names may vary between

makes and models.

Press the START button to begin the automatic

test. See page 8 for order of automatic test.

Upon entering the automatic test mode, the

washer will perform an automatic test with

water cycles to check major washer functions.

Pressing the START button will manually

advance to the next step.

Press and hold the START button for 3 seconds

at any time to exit Automatic Test mode.

IMPORTANT: Lid must be closed with lid lock

enabled to perform test.

MANUAL TEST MODE (Page 9)

To access Manual Test Mode, perform steps

1 and 2 of Activating the Service Diagnostic

Test Modes. Turn the cycle selector knob

until the status LEDs correspond as follows:

“Drain/Spin” & “Done” LEDs On

Sense Wash Rinse Drain Done

Fill Spin

Press the START button to enter Manual Test

Mode. See page 9 for manual test mode.

Upon entering the manual test mode,

the washer will have all outputs OFF.

The cycle selector knob is used to select

the output to be tested.

The Start button will activate/deactivate

the selected output.

When the selected output is activated, the

corresponding status LEDs flash ON & OFF.

Press and hold the START button for 3

seconds at any time to exit Manual test mode.

IMPORTANT: As a safety feature, the lid

must be closed with lid lock enabled to

activate either Agitate or Spin Test.

NOTE: Multiple outputs may be activated

simultaneously.

NOTE: Outputs left on will time-out after 5 minutes.

CALIBRATION MODE

NOTE: Calibration only applies to models

that do not have level selection.

IMPORTANT: Calibration must be performed

when any of the following components have

been replaced: Main Control, Basket, Drive

Assembly, Suspension, Motor, and Capacitor.

Not performing calibration will result in poor

wash performance.

Do NOT interrupt calibration, disturb washer,

or remove power; otherwise, calibration

must be repeated.

Lid must be down to perform test.

Basket must be empty to perform test

(no water or clothes).

Calibration cycle runs for approximately

2–4 minutes.* Cycle completes when lid

unlocks and washer enters standby mode.

*If Calibration Mode is run on a washer

with a porcelain basket, the time necessary

to complete the calibration may be longer.

NOTE: Before beginning calibration, check

the drive system to verify that the cam on the

splutch is moving freely and not binding.

To access Calibration Mode, perform steps

1 and 2 of Activating the Service Diagnostic

Test Modes. Turn the cycle selector knob

until the status LEDs correspond as follows:

“Rinse” LED On

Sense Wash Rinse Drain Done

Fill Spin

NOTE: Status LED names may vary between

makes and models.

Press the START button to begin washer

calibration. All status LEDs will turn on.

UI TEST MODE

To access UI (User Interface) Test Mode, perform

steps 1 and 2 of Activating the Service Diagnostic

Test Modes. Turn the cycle selector knob until the

status LEDs correspond as follows:

“Rinse” & “Drain/Spin” LEDs On

(1)Sense (2)Wash (3)Rinse (4)Drain (5)Done

(1) Fill (4)Spin

NOTE: Status LED names may vary between

makes and models. Use LED # identifications.

Press the START button to begin the UI test.

Upon entering the UI test mode, all status

LEDs will be turned ON.

Pressing the Start button will turn on and

off all status LEDs, or toggle the state of

each status LED independently. (Example:

if 2 are on, and 3 are off, then 2 will be

turned off and 3 turned on.)

PAGE 4

DO NOT REMOVE OR DESTROY

Page 5

FOR SERVICE TECHNICIAN’S USE ONLY

When rotating the cycle selector knob, each

click “indent” toggles the “Done” (5) LED.

Turning the rotary switches will toggle

the following status LEDs on and off.

• Rotary Switch #1 – toggles (1)

Sense/Fill LED

• Rotary Switch #2 – toggles (2) Wash LED

• Rotary Switch #3 – toggles (3) Rinse LED

• Rotary Switch #4 – toggles (4)

Drain/Spin LED

NOTE: The number and location of rotary

switches varies between makes and models.

Switches are read from left to right, the leftmost switch being #1.

Press and hold the START button for

3 seconds at any time to exit UI test mode.

Washer will exit UI test mode after

5 minutes of inactivity or unplugging

the power cord.

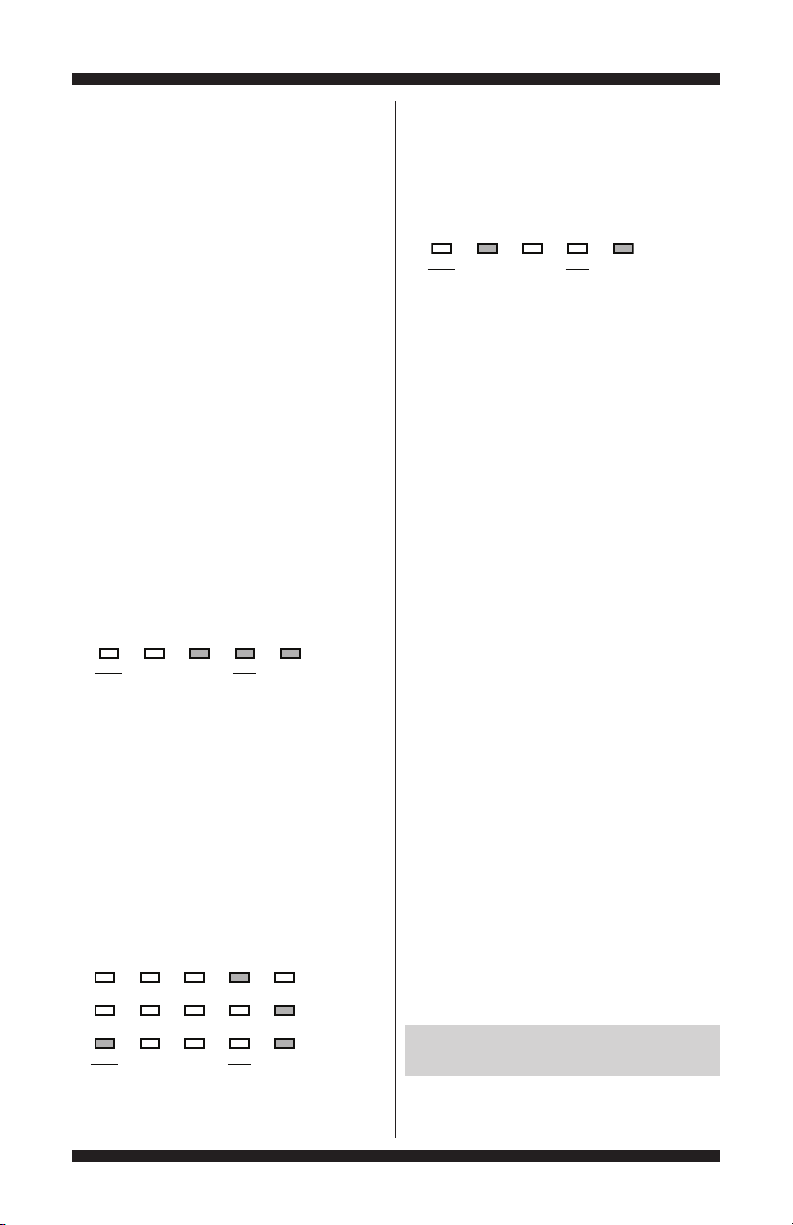

SOFTWARE VERSION DISPLAY MODE

To access Software Version Display Mode,

perform steps 1 and 2 of Activating the Service

Diagnostic Test Modes. Turn the cycle selector

knob until the status LEDs correspond as follows:

“Rinse,” “Drain/Spin,” and “Done” LEDs On

Sense Wash Rinse Drain Done

Fill Spin

NOTE: Status LED names may vary between

makes and models.

Press the START button to begin software

display mode.

Upon entering the software version display

mode, the Major, Minor, and Test version

numbers for the software are displayed by

alternating the state of the Status LEDs in

one second intervals; the process repeats

following a pause.

For example, if the s/w version is 02.01.17,

the following sequence would be displayed:

16 8 4 2 1

02

Sense Wash Rinse Drain Done

Fill Spin

Press and hold the START button for

3 seconds at any time to exit software

version display mode.

01

17

TACHOMETER VERIFICATION MODE

To access Tachometer Verification Mode,

perform steps 1 and 2 of Activating the Service

Diagnostic Modes. Turn the cycle selector knob

until the status LEDs correspond as follows:

“Wash” and “Done” LEDs On

Sense Wash Rinse Drain Done

Fill Spin

NOTE: Status LED names may vary between

makes and models.

Press the START button to begin tachometer

verification mode.

Tachometer verification uses the status

LEDs to represent the tachometer

frequency (basket RPM).

For example, slowly turn the basket

by hand; as the basket turns, the DONE,

DRAIN/SPIN, RINSE, and WASH status

LEDs will illuminate one at a time in a

visually repeating cycle. The LED timing is

derived from the tachometer signal itself.

Press and hold the START button for

3 seconds at any time to exit tachometer

verification mode.

CUSTOMER VIEWABLE FAULT CODES

(WASHER)

There are three fault codes that may be visible

to the customer indicated by the following

Status LEDs:

WASH LED ON (Long Fill Fault) – Refer to

“No Fill, Long Fill” on page 7 for information.

DRAIN/SPIN LED ON (Long Drain Fault) –

Refer to “Long Drain” on page 7 for

information.

LID LOCK LED FLASHING CONTINUOUSLY

(Lid Lock Fault) – Run TEST #3: Drive

System on page 13. According to the result,

refer to “Basket Speed Fault,” “Shifter Fault,”

“Motor Fault,” or “Motor Unable to Reach

Target RPM” on page 7. Finally, refer to “Lid

Lock Fault” on page 6.

FOR SERVICE FAULT AND ERROR CODES,

CONTINUE TO PAGES 6 AND 7

DO NOT REMOVE OR DESTROY

PAGE 5

Page 6

FOR SERVICE TECHNICIAN’S USE ONLY

21

22

21

41

41

42

8421

FE

FE

FE

FE

FE

FE

FE

FE

FE

FE

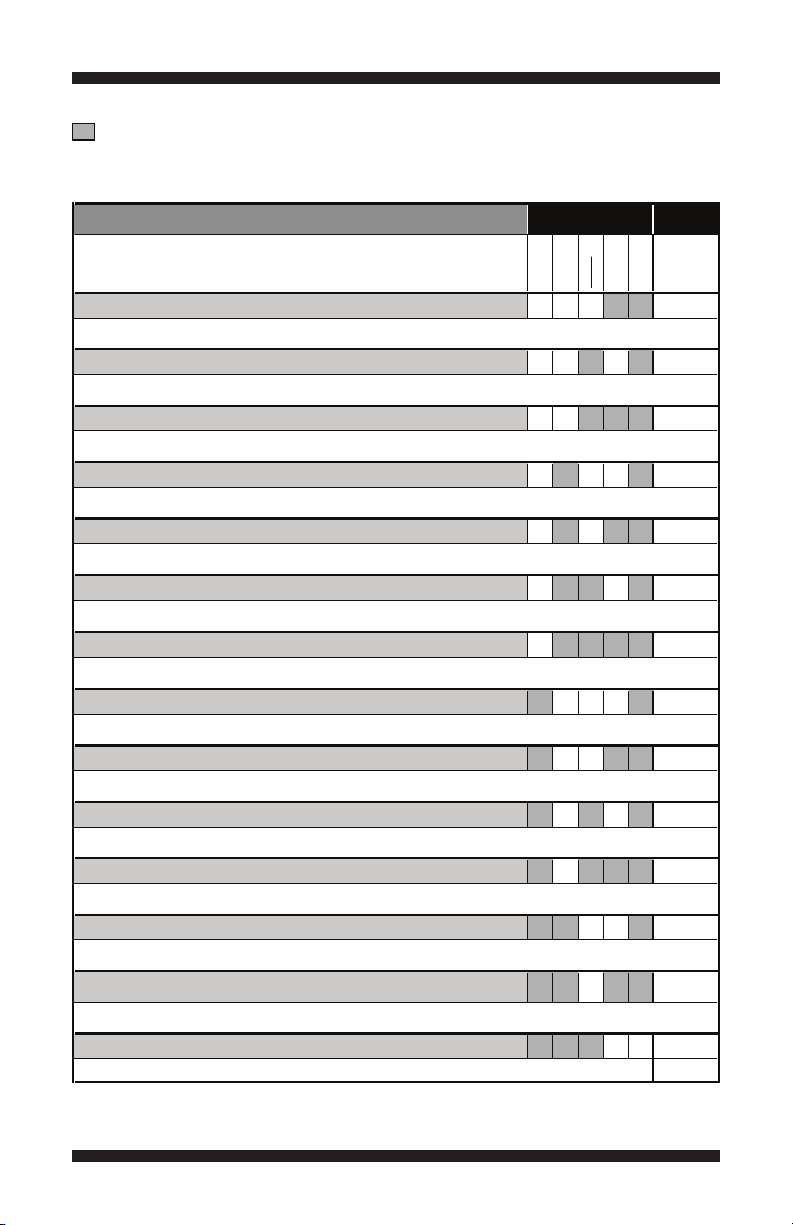

FAULT/ERROR CODES (WASHER) — See page 3 to access Fault Code Display Mode.

= ON

FAULT/ERROR CODE – DESCRIPTION

Status LEDs

Explanation & Recommended Procedure

(Status LED names may vary between makes and models)

SENSE

FILL*

WASH

RINSE

F0E0 – NO FAULT

On

DRAIN

8421 Off

F0E2 – OVERSUDS CONDITION DETECTED

Fault is displayed when suds prevent the basket from spinning up to speed or the pressure sensor detects rising

suds level. The main control will flush water in attempt to clear suds. If the water flush is unable to correct the

problem, this may indicate:

• Not using HE detergent.

• Excessive detergent usage.

• Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

• Mechanical friction on drive mechanism or basket (clothing between basket and tub).

F0E4 – HIGH WATER TEMPERATURE – RINSE CYCLE

Fault is displayed when washer detects water temperature 105°F (40°C) or higher during rinse cycle.

• Hot water getting in. Make sure inlet hoses are connected correctly.

F0E5 – OFF BALANCE LOAD DETECTED

Fault is displayed when an off balance condition is detected.

• Check for weak suspension. Basket should not bounce up and down more than once when pushed.

• Clothing should be distributed evenly when loading.

F1E1 – MAIN CONTROL FAULT

Indicates a main control fault.

• See TEST #1: Main Control, page 12.

F1E2 – MOTOR CONTROL FAULT

Indicates a fault of the motor control section of the main control.

• See TEST #3b: Drive System – Motor, page 14.

F2E1 – STUCK KEY

One or more keys on the User Interface were actuated for 15 consecutive seconds.

• Fault occurs during Diagnostic Test Mode if a stuck key is detected.

• See TEST #4: Console and Indicators, page 16.

F2E3 – SWITCH MISMATCH

The switches do not match the console or are not operating correctly.

• Fault occurs during Diagnostic Test Mode if a switch mismatch is detected.

• See TEST #4: Console and Indicators, page 16.

F3E1 – PRESSURE SYSTEM FAULT

Fault is displayed when the Main Control detects an out of range pressure signal.

• Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

• See TEST #5: Water Level, page 16.

F5E1 – LID SWITCH FAULT

Fault is displayed if lid is in locked state, but lid switch is open; control not sensing the strike in the lid lock.

• User presses Start with lid open.

• The main control cannot detect the lid switch opening and closing properly.

• Strike not assembled correctly on the lid.

• Lid lock bezel not installed correctly (must be square to embossing and flush to top).

• See TEST #7: Lid Lock, page 18.

F5E2 – LID LOCK FAULT

Fault is displayed if lid lock has not moved into locked position or motor cannot be powered.

• Lid is not closed completely due to interference.

• Check for lock interference with lock striker.

• Wash media buildup (detergent, lint, etc.) is preventing the lock mechanism from sliding.

• Main control detects open lid switch when attempting to lock.

• Main control cannot determine if lid lock is in a locked state.

• See TEST #7: Lid Lock, page 18.

* If the Sense/Fill LED is ON, the fault code is represented; if OFF, the error code is represented.

ERROR NUMBERFAULT NUMBER

Status LEDs

DONE

SENSE

SPIN

FILL*

1

1

1

1

1

WASH

RINSE

DRAIN

2

4

2

DONE

SPIN

1

1

PAGE 6

DO NOT REMOVE OR DESTROY

Page 7

FOR SERVICE TECHNICIAN’S USE ONLY

F2

41

41

81

82

84

81

44

FE

FE

FE

FE

FE

FAULT/ERROR CODES (WASHER) (cont.) — See page 3 to access Fault Code Display

Mode. = ON

FAULT/ERROR CODE – DESCRIPTION

Status LEDs

Explanation & Recommended Procedure

(Status LED names may vary between makes and models)

WASH

RINSE

SENSE

FILL*

F5E3 – LID UNLOCK FAULT

Fault is displayed if lid lock has not moved into unlocked position or motor cannot be powered.

• Check for lock interference with lock striker.

• Main control cannot determine if lid lock is in an unlocked state.

• See TEST #7: Lid Lock, page 18.

F5E4 – LID NOT OPENED BETWEEN CYCLES

Fault is displayed if the following conditions occur:

• User presses Start after several consecutive washer cycles without opening lid.

• See TEST #7: Lid Lock, page 18.

4

F7E1 – BASKET SPEED FAULT

Fault is displayed when the main control cannot determine speed of basket, or speed changes too quickly.

• See TEST #3: Drive System, page 13.

• Calibration—run Calibration Mode, page 4.

• Locked rotor—check that basket, impeller, and motor can rotate freely.

• Check harness connections from main control to motor and shifter.

• See TEST #3a: Drive System–Shifter, page 13.

• Control not sensing the basket move in spin—run Tachometer Verification Mode, page 5.

• Bad motor capacitor, motor or capacitor connector disconnected, or broken wires to motor or capacitor.

• Belt is off or pulley is loose—check drive belt. Verify that belt is fully installed on both pulleys. Also, check that the pulleys

are fastened securely to the motor shaft and agitator shaft.

• See TEST #3b: Drive System–Motor, page 14.

• For more details, see document W10606242.

F7E5 – SHIFTER FAULT

Fault is displayed when the main control cannot determine position of shifter.

• See TEST #3: Drive System, page 13.

• Check harness connections from main control to motor and shifter.

• Observe shifter operation.

• See TEST #3a: Drive System–Shifter, page 13.

F7E6 – MOTOR FAULT

Indicates an open clockwise or counterclockwise circuit of the motor.

• See TEST #3: Drive System, page 13.

• See TEST #3b: Drive System–Motor, page 14.

F

F7E7 – MOTOR UNABLE TO REACH TARGET RPM

Fault is displayed when basket speed sensor detects that target RPM was not reached.

• See TEST #3: Drive System, page 13.

• Mechanical friction on drive mechanism or basket (clothing between basket and tub).

• Weak motor or run capacitor, or no connection to run capacitor.

• Load off balance. Clothing should be distributed evenly when loading.

• See TEST #3b: Drive System–Motor, page 14.

F8E1 – NO FILL, LONG FILL

Fault is displayed when the water level does not change for a period of time OR water is present but main control does not

detect the water level changing.

• Is water supply connected and turned on?

• Low water pressure; fill times longer than six minutes. Are hose screens plugged?

• Check for proper drain hose installation. Is water siphoning out of the drain hose?

• Drain hose must not be more than 4.5" (114 mm) into the drain pipe.

• Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

• See TEST #2: Valves, page 13.

F8E3 – OVERFLOW CONDITION

Fault is displayed when main control senses water level that exceeds the washer’s capacity.

• May signify problem with inlet water valves.

• Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

• Onboard pressure transducer fault.

• Check for proper drain hose installation. Is water siphoning out of the drain hose? Drain hose must not be more than

4.5" (114 mm) into the drain pipe. Make sure drain hose is not seated into drain pipe, and that there is an air gap for

ventilation. Ensure drain height is between 39" (991 mm) and 8' (2.4 m) above the floor.

• See TEST #2: Valves, page 13 and TEST #5: Water Level, page 16.

F8E5 – HOT, COLD REVERSED

Fault is displayed when the hot and cold inlet hoses are reversed.

• Make sure inlet hoses are connected correctly.

• See TEST #2: Valves, page 13.

F9E1 – LONG DRAIN

Fault is displayed when the water level does not change after the drain pump is on for 10 minutes.

• Is the drain hose or the drain pump clogged? Check tub sump under impeller for obstructions.

• Is the drain hose height greater than 8' (2.4 m)?

• Too much detergent.

• Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

• Is the pump running? If not, see TEST #6: Drain Pump, page 17.

* If the Sense/Fill LED is ON, the fault code is represented; if OFF, the error code is represented.

F E

F E

F E

DONE

DRAIN

SPIN

1

21

21

1

ERROR NUMBERFAULT NUMBER

Status LEDs

SENSE

FILL*

E482148

E

WASH

RINSE

DRAIN

SPIN

4

421

4421

2

2

DONE

1

1

1

1

DO NOT REMOVE OR DESTROY

PAGE 7

Page 8

FOR SERVICE TECHNICIAN’S USE ONLY

AUTOMATIC TEST MODE (WASHER) — See page 4 to access Automatic Test Mode.

= ON

Press the START button to begin the Automatic Test.

IMPORTANT: Lid must be closed and locked to perform Automatic Test.

FUNCTION

STATUS LEDs

Est. TIME

Recommended Procedure

(Status LED names may vary between makes and models)

LID WILL LOCK

Motor must be at “0” RPM. If lid does not lock, go to Manual Test: Lid Lock, page 9.

COLD VALVE WILL ACTUATE

If water is not present, go to Manual Test: Cold Valve, page 9.

HOT VALVE WILL ACTUATE

If water is not present, go to Manual Test: Hot Valve, page 9.

RESERVED FOR FUTURE DEVELOPMENT

Washer will pause for 5 seconds.

RESERVED FOR FUTURE DEVELOPMENT

Hot water valve will actuate for the specified time period.

RESERVED FOR FUTURE DEVELOPMENT

Cold water valve will actuate for the specified time period.

HOT & COLD VALVE WILL ACTUATE

Hot & cold water valves will actuate for the specified time period.

SHIFTER MOVES TO AGITATION POSITION

If motor does not agitate, go to Manual Test: Gentle or Heavy Agitation, page 9.

MOTOR AGITATES

If motor does not agitate, go to Manual Test: Gentle or Heavy Agitation, page 9.

DRAIN PUMP WILL ACTUATE

If water is not draining, go to Manual Test: Drain, page 9.

WASH

RINSE

DRAIN

SPIN

2

21

4

4 1

42

421

8

8 1

8 2

1

DONE

On

On

On

On

On

On

On

On

On

On

In Seconds

LID LOCK

1

5

5

5

5

5

45

~5–15

10

~30–40

SHIFTER MOVES TO SPIN POSITION

If basket is not turning, go to Manual Test: Low or High Spin, page 9.

MOTOR SPINS

If basket is not turning, go to Manual Test: Low or High Spin, page 9.

LID REMAINS LOCKED UNTIL WASHER SENSES A STOPPED

BASKET

Basket must stop spinning (0 RPM) before test continues to next phase. Time for basket to stop spinning may vary

from 30 seconds up to 2 minutes.

LID WILL UNLOCK AND CYCLE COMPLETES

If lid does not unlock, go to Manual Test: Lid Lock, page 9.

PAGE 8

8 2 1

84

84 1

842

DO NOT REMOVE OR DESTROY

On

On

On

~5–15

10

~30–45

1

~3 min

Page 9

FOR SERVICE TECHNICIAN’S USE ONLY

MANUAL TEST MODE (WASHER) — See page 4 to access Manual Test Mode.

= ON

Pressing the START button will activate/deactivate each output. When the output is activated, the

corresponding Status LEDs will flash. IMPORTANT: Lid must be closed and locked to perform SPIN

& AGITATE tests.

OUTPUT

Output Details

NOTE: Outputs will time-out after 5 minutes.

LID LOCK

Lock and unlock the lid. NOTES: When lock is enabled, the “Lid Lock” LED will turn ON. Will only lock when lid is closed.

Will only unlock when basket RPM is 0. If lid is not closed, washer will flash status LEDs on and off.

• If lid does not lock or unlock, go to TEST #7: Lid Lock, page 18.

COLD VALV E

Turns ON and turns OFF cold water valve.

• If valve does not turn on, go to TEST #2: Valves, page 13.

HOT VALV E

Turns ON and turns OFF hot water valve.

• If valve does not turn on, go to TEST #2: Valves, page 13.

RESERVED FOR FUTURE DEVELOPMENT

If selected, status LEDs will flash on and off.

STATUS LEDs

WASH

RINSE

DRAIN

SPIN

2

2

DONE

1

1

LID LOCK

RESERVED FOR FUTURE DEVELOPMENT

If selected, status LEDs will flash on and off.

RESERVED FOR FUTURE DEVELOPMENT

If selected, status LEDs will flash on and off.

RESERVED FOR FUTURE DEVELOPMENT

If selected, status LEDs will flash on and off.

DRAIN

Turns ON and turns OFF the drain pump.

• If pump does not turn on, go to TEST #6: Drain Pump, page 17.

RESERVED FOR FUTURE DEVELOPMENT

If selected, status LEDs will flash on and off.

LOW SPIN – To perform test, lid must be closed and locked.

Spins basket from 0 to 500 RPM. NOTE: Allow up to 15 seconds for shifter to reposition.

IMPORTANT: To activate Low Spin, RPM must read “0” and lid must be closed with lid lock enabled.

If lid is not closed, status LEDs will flash on and off. IMPORTANT: Water in tub must be drained before test.

• If motor does not spin, go to TEST #3a & 3b: Drive System (Shifter & Motor), pages 13 & 14.

HIGH SPIN – To perform test, lid must be closed and locked.

Spins basket from 0 to maximum RPM. NOTE: Allow up to 15 seconds for shifter to reposition.

IMPORTANT: To activate High Spin, RPM must read “0” and lid must be closed with lid lock enabled.

If lid is not closed, status LEDs will flash on and off. IMPORTANT: Water in tub must be drained before test.

• If motor does not spin, go to TEST #3a & 3b: Drive System (Shifter & Motor), pages 13 & 14.

GENTLE AGITATION – To perform test, lid must be closed and locked.

Shifts from idle motor to gentle CW/CCW agitation. NOTE: Allow up to 15 seconds for shifter to reposition.

IMPORTANT: To activate Gentle Agitation, RPM must read “0” and lid must be closed with lid lock enabled. If lid is not

closed, status LEDs will flash on and off.

• If motor does not agitate, go to TEST #3a & 3b: Drive System (Shifter & Motor), pages 13 & 14.

HEAVY AGITATION – To perform test, lid must be closed and locked.

Shifts from idle motor to heavy CW/CCW agitation. NOTE: Allow up to 15 seconds for shifter to reposition.

IMPORTANT: To activate Heavy Agitation, RPM must read “0” and lid must be closed with lid lock enabled. If lid is not

closed, status LEDs will flash on and off.

• If motor does not agitate, go to TEST #3a & 3b: Drive System (Shifter & Motor), pages 13 & 14.

4

1

4

2

4

2 1

4

8

8 On

8 On

8 2 1

8 4

1

2

On

On

DO NOT REMOVE OR DESTROY

PAGE 9

Page 10

FOR SERVICE TECHNICIAN’S USE ONLY

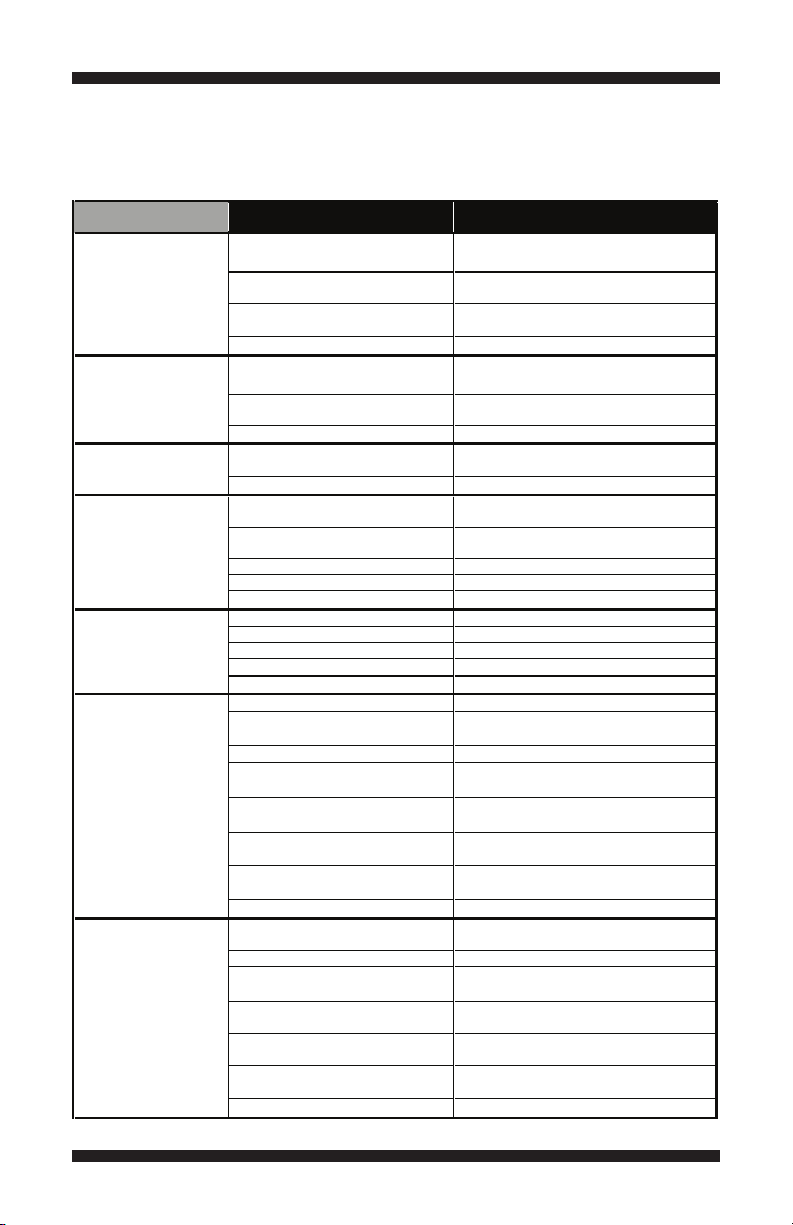

WASHER TROUBLESHOOTING GUIDE

NOTE: Always check for error codes first (pgs. 6–7).

Some tests will require accessing components. See Figures 7 & 8, page 19, for component locations.

For detailed troubleshooting procedures, refer to “Troubleshooting Tests” beginning on page 12.

PROBLEM POSSIBLE CAUSE

WON’T POWER UP

•No operation

• No Status LEDs

WON’T START CYCLE

No response when

Start button is pressed.

UI WON’T ACCEPT

SELECTIONS

WON’T FILL

OVERFILLS

WON’T AGITATE

WON’T SPIN

No power to washer.

Connection problem between AC

power cord and power harness.

Main control not properly installed

in console.

Main control problem.

Lid not closed.

User Interface problem.

Main control problem.

User Interface problem.

Main control problem.

No water supplied to washer.

Plugged filter/screen.

Drain hose installation.

Valve problem.

Main control problem.

Pressure hose.

Valve problem.

Washer requires calibration.

Onboard pressure transducer.

Main control problem.

Water covering impeller?

Is lid open during the cycle?

Drive belt.

Harness connections.

Shifter problem.

Motor problem.

Tachometer problem. No tub movement or tub speed out of normal

Main control problem.

Is lid lock showing open during

the cycle?

Drive belt.

Harness connections.

Shifter problem.

Motor problem.

Tachometer problem. No tub movement or tub speed out of normal

Main control problem.

Check power at outlet, check circuit

breakers, fuses, or junction box connections.

Check the AC plug, power harness, and

main control for continuity.

See TEST #4: Console and Indicators,

page 16.

See TEST #1: Main Control, page 12.

Check for interference with lid. Lid must

be closed for cycle to start.

See TEST #4: Console and Indicators,

page 16.

See TEST #1: Main Control, page 12.

See TEST #4: Console and Indicators,

page 16.

See TEST #1: Main Control, page 12.

1. Check water connections to washer.

2. Verify hot and cold water supply is on.

Check for plugged filter or screen in the

water valve or hoses.

Check for proper drain hose installation.

See TEST #2: Valves, page 13.

See TEST #1: Main Control, page 12.

See TEST #5: Water Level, page 16.

See TEST #2: Valves, page 13.

Perform washer calibration on page 4.

See TEST #5: Water Level, page 16.

See TEST #1: Main Control, page 12.

See TEST #5: Water Level, page 16.

Check for interference with lid. Lid must

be closed.

Verify that drive belt is not damaged.

Check harness connections between main

control and drive system.

See TEST #3a: Drive System – Shifter,

page 13.

See TEST #3b: Drive System – Motor,

page 14.

range (obstruction/belt/motor).

See TEST #1: Main Control, page 12.

See TEST #7: Lid Lock, page 18.

Verify that drive belt is not damaged.

Check harness connections between main

control and drive system.

See TEST #3a: Drive System – Shifter,

page 13.

See TEST #3b: Drive System – Motor,

page 14.

range (obstruction/belt/motor).

See TEST #1: Main Control, page 12.

CHECKS & TESTS

PAGE 10

DO NOT REMOVE OR DESTROY

Page 11

FOR SERVICE TECHNICIAN’S USE ONLY

WASHER TROUBLESHOOTING GUIDE (continued)

Some tests will require accessing components. See Figures 7 & 8, page 19, for component locations.

For detailed troubleshooting procedures, refer to “Troubleshooting Tests” beginning on page 12.

PROBLEM POSSIBLE CAUSE

INCORRECT WATER

TEMPERATURE

WON’T DRAIN

CYCLE TIME LONGER

THAN EXPECTED

POOR WASH

PERFORMANCE

Please reference

Use & Care Guide

Water hose installation.

Valve problem. See TEST #2: Valves, page 13.

Main control problem.

Drain hose installation.

Standpipe position. Ensure drain height is between 39" (991 mm)

Plugged drain hose.

Obstructions to drain pump.

Harness connections.

Drain pump.

Main control problem.

Oversuds. 1. Verify use of HE detergent.

Off balance. 1. Load is off balance.

Drain hose installation. Check for proper drain hose installation. Make

Standpipe position. Ensure drain height is between 39" (991 mm)

Draining slowly. Check for pump or drain hose obstructions.

Water pressure drop. Results in longer fill time.

Friction or drag on drive. Check motor and bearings; check for

Weak suspension. Basket should not bounce up and down

Oversuds.

Load is tangling.

Incorrect water level.

Clothes wet after cycle is complete

(not water saturated, but very damp).

Load not rinsed.

Not cleaning clothes.

Fabric damage.

Wrong option or cycle selection.

Make sure inlet hoses are connected

properly.

See TEST #1: Main Control, page 12.

Check for proper drain hose installation. Make

sure it is not inserted more than 4.5" (114 mm).

Make sure drain hose is not sealed into drain

pipe, and that there is an air gap for ventilation.

and 8' (2.4 m) above the floor.

Check drain hose for obstructions.

Check tub sump under agitator plate &

basket for obstructions.

Check harness connections between main

control and drain pump.

See TEST #6: Drain Pump, page 17.

See TEST #1: Main Control, page 12.

2. Excessive detergent usage.

2. Balance ring water leak.

sure it is not inserted more than 4.5" (114 mm).

Make sure drain hose is not sealed into drain

pipe, and that there is an air gap for ventilation.

and 8' (2.4 m) above the floor.

clothes between tub and basket.

more than once when pushed.

1. Verify use of HE detergent.

2. Excessive detergent usage.

1. Washer not loaded properly.

2. Perform washer calibration on page 4.

1. Perform washer calibration on page 4.

2. See TEST #2: Valves, page 13.

3. See TEST #5: Water Level, page 16.

1. Overloaded washer.

2. Oversuds (see above).

3. Items caught in tub sump.

4. Weak suspension.

5. Shifter not moving into position

6. Cold/Rinse water >105°F.

7. See TEST #6: Drain Pump, page 17.

1. Check proper water supply.

2. Not using HE detergent.

3. Washer not loaded properly.

4. Shifter not moving into position

5. See TEST #2: Valves, page 13.

1. Washer not loaded properly.

2. Not using HE detergent.

3. Not using correct cycle.

4. Shifter not moving into position

1. Washer overloaded.

2. Bleach added incorrectly.

3. Sharp items in tub.

Refer customer to Use & Care Guide.

CHECKS & TESTS

(see TEST #3a).

(see TEST #3a).

(see TEST #3a).

DO NOT REMOVE OR DESTROY

PAGE 11

Page 12

FOR SERVICE TECHNICIAN’S USE ONLY

WASHER TROUBLESHOOTING TESTS

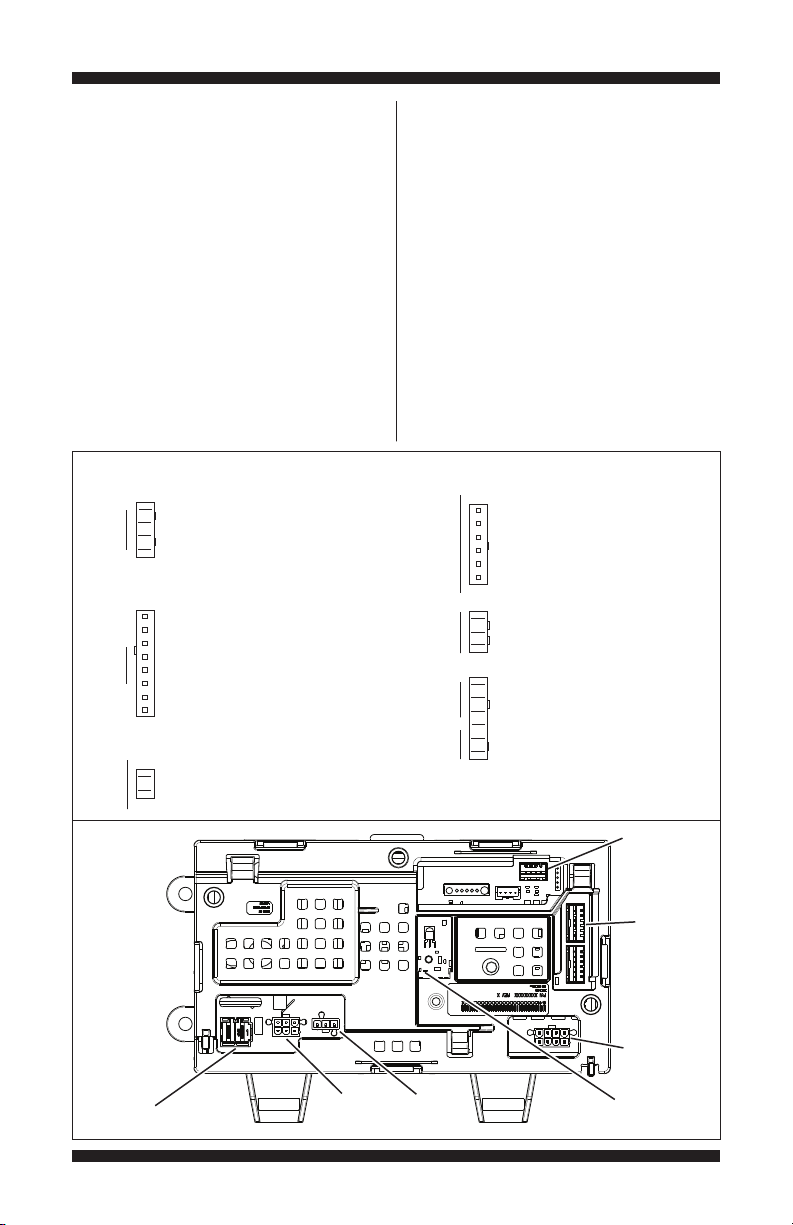

TEST #1: Main Control

This test checks for incoming and outgoing supplies

to and from the main control. This test assumes

that proper voltage is present at the outlet.

1. Unplug washer/dryer or disconnect power.

2. Remove console to access main control.

3. Verify that ALL connectors are inserted

all the way into the main control.

4. Plug in washer/dryer or reconnect power.

5. With a voltmeter set to AC, connect black

probe to J5-2 (Neutral) and red probe to J5-1 (L1).

If 120VAC is present, go to step 6.

If 120VAC is not present, check the AC

power cord and power harness for continuity

(See Figure 9).

6. Is the “Diagnostic LED” ON or OFF?

(See Figure 3 below for LED location.)

ON: (+5VDC present) continue to step 7.

OFF: (+5VDC missing) proceed to step 8.

7. With a voltmeter set to DC, connect black

probe to J12-4 (Circuit Gnd) and red probe to

J12-1 (+12VDC).

If +12VDC is present, main control

supplies are good.

If +12VDC is not present, go to step 8.

8. Check if shifter assembly is affecting the

main control DC supplies.

a. Unplug washer/dryer or disconnect power.

b. Remove connector J12 from main control.

c. Plug in washer/dryer or reconnect power.

d. Repeat steps 6 and 7. Perform the +12VDC

check inside header J12 on the board – do not

short pins together.

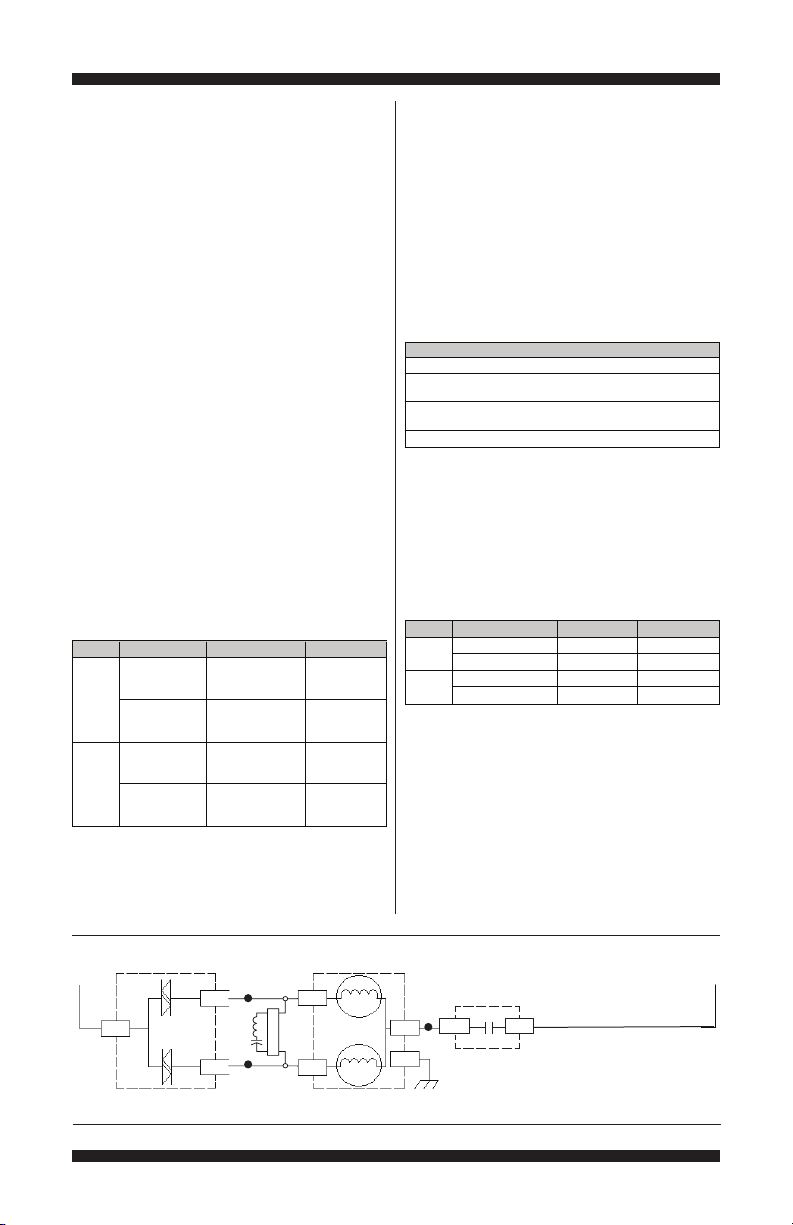

Main Control Board Connectors & Pinouts (Figure 3)

J12

J12-4 GRY –5VDC (CIRCUIT GND)

J12-3 BLU SHIFTER POSITION INPUT

J12-2 PNK RPM INPUT

SHIFTERVALVES

J12-1 BLK +12VDC

J9

J9-8 OPEN

J9-7 OPEN

J9-6 OPEN

J9-5 BLU COLD VALVE (N)

J9-4 W COMMON (L1)

J9-3 OPEN

J9-2 OPEN

J9-1 RED HOT VALVE (N)

J5

J5-2 BLK NEUTRAL

J5-1 BLK L1

POWER

HARNESS

J3

ROTARY ENCODERS

J6

LID LOCK

J2

DRAIN MOTOR

J3-6 BLK ROW 2

J3-5 BLK ROW 3

J3-4 BLK COLUMN 0

J3-3 RED COLUMN 1

J3-2 RED COLUMN 2

J3-1 RED COLUMN 3

J6-3 RED LOCK SWITCH

J6-2 WHT L1

J6-1 BLU LID SWITCH/LOCK SOLENOID

J2-6 RED MOTOR CW WINDING (N)

J2-5 ORN MOTOR CCW WINDING (N)

J2-4 BK/W MOTOR (L1 COMMON)

J2-3 LT BLU DRAIN PUMP MOTOR (N)

J2-2 BK/W L1 COMMON

J2-1 BRN SHIFTER MOTOR (N)

= represents

pin 1

J5 Power Harness

PAGE 12

J12 Shifter

J3 Rotary

Encoders

J2 Drain/

Motor

J6 Lid

Lock

J9 Valves

Diagnostic LED

DO NOT REMOVE OR DESTROY

Page 13

FOR SERVICE TECHNICIAN’S USE ONLY

tuoniPevlaV

J9, 5 & 4evlaV dloC

Component

Shifter Motor

J2 Connector Pinout

J2, 1 & 2

If one or more DC voltages are still missing,

go to step 9.

If the DC voltages return, check for short in

harness between main control and shifter assy.

If harness and connections are good,

replace shifter assembly.

9. Main Control has malfunctioned.

a. Unplug washer/dryer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer/dryer or reconnect power.

Calibrate washer and perform Automatic Test

to verify repair.

TEST #2: Valves

This test checks the electrical connections

to the valves, and the valves themselves.

1. Check the relays and electrical connections

to the valves by performing the Cold and Hot

Valve tests under Manual Test Mode on page 9.

Each test activates and deactivates the selected

valve. The following steps assume one (or

more) valve(s) did not turn on.

2. For the valve(s) in question check the

individual solenoid valves:

a. Unplug washer/dryer or disconnect power.

b. Remove console to access main control.

c. Remove connector J9 from main control.

Refer to main control diagram on page 12.

d. Check harness connection to solenoid valves.

3. Check resistance of the valve coils across

the following J9 connector pinouts:

J9, 1 & 4evlaV toH

Resistance should be 890–1.3k Ω.

If resistance readings are tens of ohms

outside of range, check lower washer

harness connector according to diagram.

If still outside of range, replace the

valve assembly.

If resistance readings are within range,

replace main control and calibrate washer.

Perform Automatic Test to verify repair.

TEST #3: Drive System

1. Activate Service Diagnostic Test Mode,

retrieve any fault/error codes, and clear them.

If the displayed error codes are F7-E1, F7-E5,

or motor speed codes, there is likely a motor,

capacitor, or shifter related issue.

2. Once the error codes are cleared, enter

Manual Test Mode and run the Heavy Agitation

test; if the motor runs after 15–20 seconds,

there is not a problem with the motor, capacitor,

control, or wiring harness connections

(although the black wire from the shifter to the

control should still be checked).

NOTE: The speed wheel in the transmission

only turns during the spin cycle.

3. While in Manual Test Mode, try to get the

washer to spin; if the motor hums briefly and

then shuts down (with the lid lock indicator

blinking), go to Fault Code Display Mode and

look for shifter or basket speed errors, which

verify an issue with the shifter/sensor assembly

(optical sensor is not reading the motor speed).

TEST #3a: Drive System – Shifter

This test checks connections, shifter motor,

switch, and optical sensor.

NOTE: Refer to Figure 4, “Shifter Assembly Strip

Circuit” on page 14 for tests and measurements.

IMPORTANT: Drain water from tub before

accessing bottom of washer.

Functional Check:

1. Check the shifter and electrical connections

by performing both the Spin AND Agitate test

under Manual Test Mode on page 9. The following

steps assume that this step was unsuccessful.

2. Unplug washer/dryer or disconnect power.

3. Check to see if basket will turn freely.

If basket turns freely, go to step 4.

If basket does not turn freely, determine what

is causing the mechanical friction or lockup.

4. Remove console to access main control.

5. Visually check that the J12 and J2 connectors

are inserted all the way into the main control.

If visual checks pass, go to step 6.

If connectors are not inserted properly,

reconnect J12 and J2 and repeat step 1.

Shifter Motor:

NOTE: Before starting the electrical check,

verify that the cam on the splutch is moving

freely and not binding.

6. Remove connector J2 from main control.

With an ohmmeter, verify resistance of the shifter

motor across the following J2 connector pinouts:

Resistance should be 2k to 3.5k Ω.

If values are correct, reconnect J2 and

proceed to step 7.

If values are open or out of range, check

lower washer harness connector according

to diagram. If the values are still open or out

of range, go to step 13.

7. Plug in washer/dryer or reconnect power.

8. With a voltmeter set to AC, connect the

black probe to J2-2 (L1) and red probe to

J2-1 (N). Activate shifter motor by switching

between Spin and Agitate modes. Energize

outputs using Manual Test Mode on page 9.

IMPORTANT: Lid must be closed with Lid Lock

enabled to run the SPIN and AGITATE tests.

NOTE: It will take 4–15 seconds for the shifter

to change states.

DO NOT REMOVE OR DESTROY

PAGE 13

Page 14

If 120VAC is present, go to step 9.

Shifter to Main Control & Drain Pum

p

Shifter connector Pin 6 to lower harness connector Pin 5 to main control J2-1

If 120VAC is not present, go to step 17.

Shifter Switch:

9. With a voltmeter set to DC, connect the

black probe to J12-4 (Circuit Gnd) and red

probe to J12-3 (Shifter Switch). In manual test

mode, switch between Spin and Agitate modes.

Voltage should toggle between 0 and +5VDC.

SPIN = +5 VDC

AGITATE = 0 VDC

If voltage corresponds to setting, go to step 10.

If voltage does not switch, check lower

harness connector according to diagram.

If voltage still does not switch, go to step 12.

Optical Sensor:

10. With a voltmeter set to DC, connect the

black probe to J12-4 (Circuit Gnd) and red

probe to J12-1 (+12VDC).

If +12VDC is present, go to step 11.

If +12VDC is not present, check lower

harness connector according to diagram.

If +12VDC is still not present, go to step 17.

11. Activate Tachometer Verification Mode

from the Service Diagnostic Test Modes

(see page 5). Slowly turn the basket by hand.

The four status LEDs should illuminate one

at a time to represent basket RPM.

If the tachometer is not verified, go to step 12.

If the tachometer is verified, go to step 17.

12. Unplug washer/dryer or disconnect power.

13. Tilt washer/dryer back to access the

bottom of the washer and the drive motor area.

14. Visually check the electrical connections

to the shifter.

If visual check passes, go to step 15.

If connections are loose, reconnect the

electrical connections and repeat step 1.

15. With an ohmmeter, check the harness for

continuity between the shifter and main control

using the pinouts in the following chart.

If there is continuity, go to step 16.

If there is no continuity, replace the lower

or upper washer harness and repeat step 1.

N

Main Control

J5-2

Shifter Motor

TRIAC

Circuit Ground

+12VDC

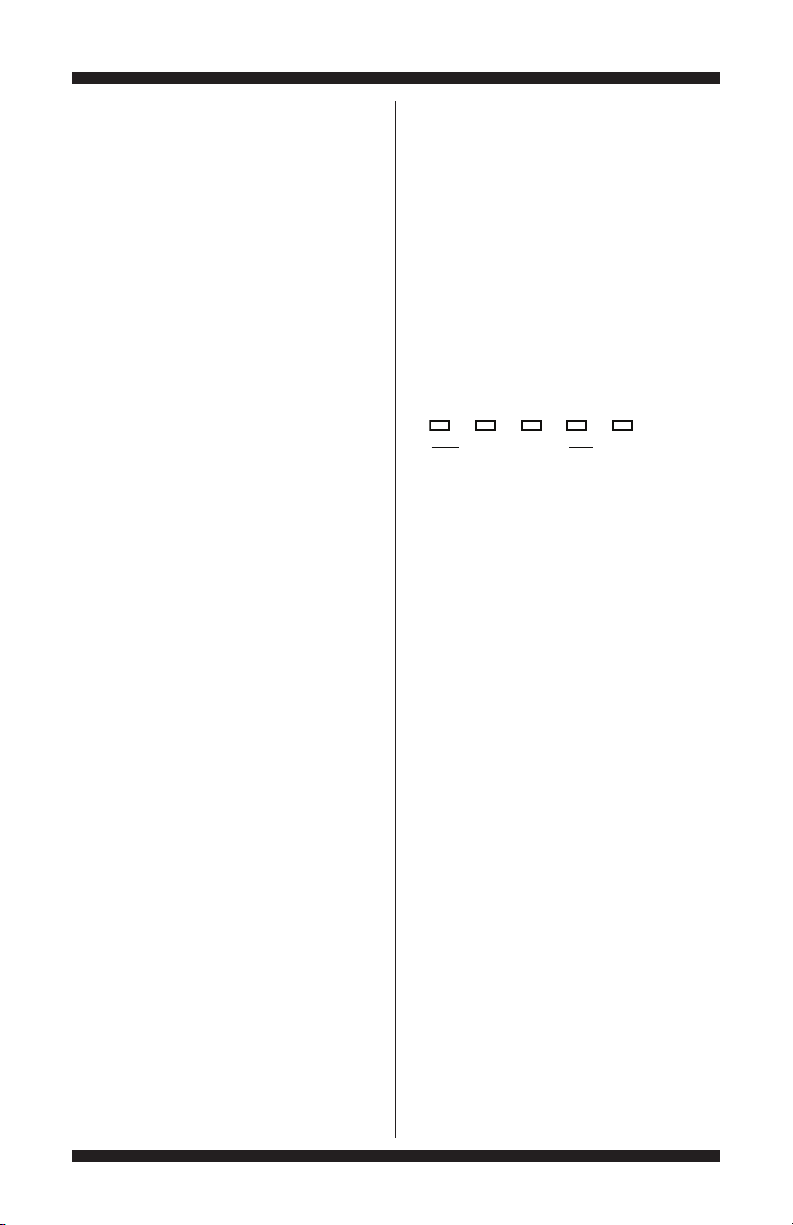

Figure 4 - Shifter Assembly Strip Circuit (Shifter Switch: Open = SPIN, Closed = AGITATE)

FOR SERVICE TECHNICIAN’S USE ONLY

Shifter connector Pin 1 to lower harness connector Pin 2 to main control J12-2

Shifter connector Pin 2 to lower harness connector Pin 4 to main control J12-1

Shifter connector Pin 3 to lower harness connector Pin 6 to main control J2-2

Shifter connector Pin 4 to lower harness connector Pin 1 to main control J12-3

Shifter connector Pin 5 to lower harness connector Pin 3 to main control J12-4

16. Replace the shifter assembly.

a. Unplug washer/dryer or disconnect power.

b. Replace shifter assembly.

c. Reassemble all parts and panels.

d. Plug in washer/dryer or reconnect power.

Calibrate washer and perform Automatic Test

to verify repair.

17. If the preceding steps did not correct the

problem, replace the main control.

a. Unplug washer/dryer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer/dryer or reconnect power.

Calibrate washer and perform Automatic Test

to verify repair.

TEST #3b: Drive System – Motor

This test checks the motor, motor windings,

wiring, and start capacitor.

NOTE: Refer to Figure 5, “PSC Motor Strip

Circuit” on page 15 for tests and measurements.

IMPORTANT: Drain water from tub before

accessing bottom of washer.

1. Check the motor and electrical connections

by performing the Gentle or Heavy Agitation test

under Manual Test Mode on page 9. Verify that

the basket is spinning in a clockwise direction

while performing Low or High Spin test under

Manual Test Mode on page 9. The following

steps assume that this step was unsuccessful.

2. Unplug washer/dryer or disconnect power.

3. Check to see if basket will turn freely.

If basket turns freely, go to step 4.

If basket does not turn freely, determine what

is causing the mechanical friction or lockup.

4. Remove console to access main control.

5. Visually check that the J12 and J2 connectors

are inserted all the way into the main control.

Shifter Assy

J2-1

J12-4

J12-1

Motor Resistance 2k to 3.5k ohms

Pin 5

Pin 6

120VAC

Motor

Pin 5

Pin 2

Shifter Switch

Optical

Sensor

Pin 3

Pin 4

Pin 3

Pin 1

Pin 6

Pin 1

Pin 2

Main Control

J2-2

J12-3Pin 4

J12-2

Shifter Position

Input

RPM Input

L1

J5-1

PAGE 14

DO NOT REMOVE OR DESTROY

Page 15

FOR SERVICE TECHNICIAN’S USE ONLY

Motor Winding J2 Pinout

Size

Resistance

Motor Harness Check

Motor Winding Motor Pinout

Size

Resistance

If visual checks pass, go to step 6.

If connectors are not inserted properly,

reconnect J12 and J2 and repeat step 1.

6. Plug in washer/dryer or reconnect power.

Run the Gentle Agitation test under Manual Test

Mode on page 9.

7. With a voltmeter set to AC, connect black

probe to J2-4 (L1) and red probe to J2-6 (CW

Winding).

If 120VAC is cycling ON during CW rotation,

go to step 8.

If 120VAC is not present, go to Test #1:

Main Control, page 12.

8. With a voltmeter set to AC, connect black probe

to J2-4 (L1), red probe to J2-5 (CCW Winding).

If 120VAC is cycling ON during CCW

rotation, go to step 9.

If 120VAC is not present, go to Test #1:

Main Control, page 12.

9. Unplug washer/dryer or disconnect power.

10. Remove connector J2 from main control.

With an ohmmeter, check resistance of motor

windings across the following J2 connector

pinouts:

NOTE: If the console has a cycle selector knob

and 4 rotary switches, the motor size is 1/3 HP.

CW Winding J2, 4 & 6

1/4 HP

CCW Winding J2, 4 & 5

CW Winding J2, 4 & 6

1/3 HP

CCW Winding J2, 4 & 5

Lower harness

connector, 8 & 9

Lower harness

connector, 8 & 10

Lower harness

connector, 8 & 9

Lower harness

connector, 8 & 10

5 to 9.5 Ω

5 to 9.5 Ω

3.5 to 6 Ω

3.5 to 6 Ω

If values are open or out of range, go to step 11.

If values are correct, go to step 15.

11. Tilt washer/dryer back to access drive

system.

12. Visually check the mounting bracket and

electrical connections to the motor and shifter.

Verify that the wires between the motor and the

harness are connected this way: Black-white/

White, Orange/Yellow, and Red/Red.

If visual check passes, go to step 13.

If connections are loose, reconnect the

electrical connections, reassemble motor

cover, and repeat step 1.

13. With an ohmmeter, check the harness

for continuity between the main control, motor,

and run capacitor using the following test points.

Motor connector Pin 1 to chassis ground

Motor connector Pin 3 to lower harness connector Pin 10 to main control J2-5

Motor connector Pin 3 to run capacitor Pin 3

Motor connector Pin 4 to lower harness connector Pin 9 to main control J2-6

Motor connector Pin 4 to run capacitor Pin 1

Motor connector Pin 2 to lower harness connector Pin 8 to main control J2-4

If there is continuity, go to step 14.

If there is no continuity, replace the lower

or upper washer harness (depending on

where the issue was) and repeat step 1.

14. With an ohmmeter, check resistance of motor

windings at the following motor connections.

NOTE: If the console has a cycle selector knob

and 4 rotary switches, the motor size is 1/3 HP.

1/4 HP

1/3 HP

CW Winding Pins 4 & 2

CCW Winding Pins 3 & 2

CW Winding Pins 4 & 2

CCW Winding Pins 3 & 2

5 to 9.5 Ω

5 to 9.5 Ω

3.5 to 6 Ω

3.5 to 6 Ω

If values are open or out of range, replace

motor.

If values are correct, go to step 15.

15. Test Motor Run Capacitor. NOTE: A faulty

capacitor may cause the motor to “hum,” not

start, or turn slowly.

a. Discharge the capacitor by touching the leads

of a 20,000 Ω resistor to the two terminals.

b. Disconnect the wires from the capacitor

terminals.

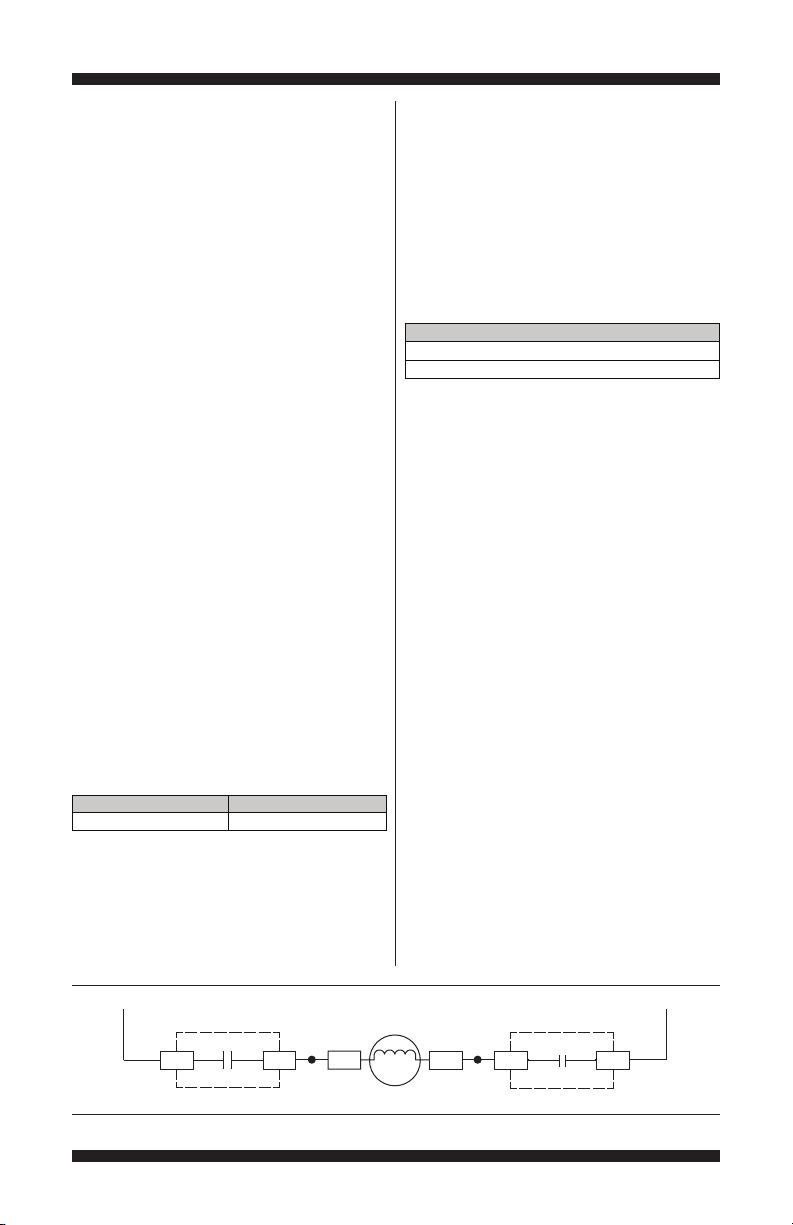

N

DO NOT REMOVE OR DESTROY

Main Control

Pin 9

J2-6

CW TRIAC

J5-2

CCW TRIAC

* 1/3 HP Motor – Each Winding 3.5 to 6 ohms/ * 1/4 HP Motor – Each Winding 5 to 9.5 ohms

Run

Cap/

Inductor

J2-5

Pin 10

Figure 5 - PSC Motor Strip Circuit (shown in On position)

PSC Motor

Pin 2

Pin 1

Main Control

Pin 8

J2-4

K4

Main Relay

J5-1

Pin 4

1

CW Winding*

CCW Winding*

3

Pin 3

L1

PAGE 15

Page 16

FOR SERVICE TECHNICIAN’S USE ONLY

c. With an ohmmeter, measure across the

terminals and note reading.

If a steady increase in resistance is noted,

continue to step 16.

If the capacitor is either shorted or open,

replace capacitor, calibrate, and repeat step 1.

16. If the preceding steps did not correct the

motor problem, replace the main control.

a. Unplug washer/dryer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer/dryer or reconnect power.

Calibrate washer and perform Automatic Test

to verify repair.

TEST #4: Console and Indicators

Console and Indicators Check:

This test is performed when any of the

following situations occurs during “UI Test

Mode” on page 4.

3None of the LEDs light up

3One or more Status LEDs are flashing

3Turning rotary switch does not toggle LED

None of the LEDs light up:

1. Unplug washer/dryer or disconnect power.

2. Access the main control and visually check

that ALL connectors are inserted all the way

into their respective headers.

3. Visually check that the main control

assembly is properly inserted in the console.

4. If both visual checks pass, follow procedure

under TEST #1, “Main Control” on page 12 to

verify supply voltages.

5. To verify repair, activate the Service

Diagnostic Mode, and then perform UI Test

Mode on page 4.

One or more Status LEDs are flashing:

If one or more of the status LEDs are flashing

(on and off in 0.5 second intervals), refer to

the following notes to identify the switch(es)

in question. Reference the wiring diagram

on page 26 when performing the following

procedures.

a. Verify the switch connector is inserted

all the way into the main control.

b. Check the harness between the switch and

main control for continuity. Check for shorts.

c. Replace the switch.

NOTE 1: The number and location of rotary

switches varies between makes and models.

NOTE 2: Regardless of location, switches are

read from left to right, the left-most switch being

#1.

NOTE 3: Each rotary switch and the cycle

selector knob is represented by the following

status LEDs:

• Rotary Switch #1 – toggles (1) Sense/Fill LED

• Rotary Switch #2 – toggles (2) Wash LED

• Rotary Switch #3 – toggles (3) Rinse LED

• Rotary Switch #4 – toggles (4) Drain/Spin LED

• Cycle Select Knob – toggles (5) Done LED

NOTE 4: Status LED names may vary between

makes and models. Use LED # identification.

(1)Sense (2)Wash (3)Rinse (4)Drain (5)Done

(1) Fill (4)Spin

Turning rotary switch does not toggle LED:

Perform the procedures under “One or more

Status LEDs are flashing.”

TEST #5: Water Level

This test checks the water level sensing

components. The washer has an on-board

pressure transducer. NOTE: Usually, if the

pressure transducer malfunctions, the washer

will generate a long fill, or long drain error.

1. Check the functionality of the pressure

transducer by running a small load cycle.

The valves should turn off automatically

after sensing the correct water level in the

tub. The following steps assume that this

step was unsuccessful.

2. Drain the tub until all water has been removed.

3. Unplug washer/dryer or disconnect power.

4. Remove console to access controls.

5. Check hose connection between the

pressure transducer and the pressure dome

attached to the tub. Make sure barbed

connector between hoses is correctly

assembled.

6. Check to ensure hose is routed correctly in

the dryer and the lower washer cabinet and not

pinched or crimped by the back panel.

PAGE 16

DO NOT REMOVE OR DESTROY

Page 17

FOR SERVICE TECHNICIAN’S USE ONLY

Component

Drain Pum

p

J2, 2 & 3

J2 Connector Pinout

Main Control to Drain Pum

p

Drain pump Pin 2 to lower harness connector Pin 6 to main control J2-2

7. Verify there is no water, suds, or debris in

the hose or dome. Disconnect hose from main

control and blow into hose to clear water, suds,

or debris.

8. Check hose for leaks. Replace if needed.

9. Replace the main control and calibrate

washer. Perform Automatic Test to verify repair.

TEST #6: Drain Pump

Perform the following checks if washer does

not drain.

NOTE: Refer to Figure 6, “Drain Pump Strip

Circuit” for tests and measurements.

IMPORTANT: Drain water from tub before

accessing bottom of washer.

1. Check for obstructions in the usual areas.

Clean and then perform step 2.

2. Check the drain pump and electrical

connections by performing the Drain Test under

Manual Test Mode on page 9. The following

steps assume that this step was unsuccessful.

3. Unplug washer/dryer or disconnect power.

4. Remove console to access main control.

5. Visually check that the J2 connector is

inserted all the way into the main control.

If visual check passes, go to step 6.

If connector is not inserted properly,

reconnect J2 and repeat step 2.

6. Remove connector J2 from main control.

With an ohmmeter, verify resistance values

shown below across the following J2

connector pinouts:

Resistance should be 14–25 Ω.

If values are open or out of range,

check lower harness connector, pin 7 & 6.

If values are still open or out of range, go

to step 7.

If values are correct, go to step 11.

7. Tilt washer/dryer back to access drain

pump. Verify pump is free from obstructions.

8. Visually check the electrical connections

at the drain pump.

If visual check passes, go to step 9.

If connections are loose, reconnect the

electrical connections and repeat step 2.

9. With an ohmmeter, check harness for

continuity between the drain pump and main

control. See chart below.

Drain pump Pin 1 to lower harness connector Pin 7 to main control J2-3

If there is continuity, go to step 10.

If there is no continuity, replace the lower

or upper washer harness (depending on

where the issue was) and repeat step 2.

10. With an ohmmeter, measure the resistance

across the two pump terminals. Resistance

should be 14–25 Ω.

If values are open or out of range, replace

the pump motor.

If the resistance at the pump motor is

correct, go to step 11.

11. If there is a stuck pump, check for a

blown board. If the board has a blown R69

surge resistor, check for stuck or shorted

pump motor; if OK, check all other loads

with input to the board.

12. If the preceding steps did not correct the

drain problem, replace the main control.

a. Unplug washer/dryer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer/dryer or reconnect power.

Calibrate washer and perform Automatic Test

to verify repair.

N L1

DO NOT REMOVE OR DESTROY

Main Control Main Control

K2

Drain Pump Motor Relay

J2-3J5-2 J2-2Pin 1 Pin 2 J5-1

Figure 6 - Drain Pump Strip Circuit

Drain Pump Motor

Pin 7

Motor Resistance 14 to 25 ohms

120VAC

Motor

Pin 6

K4

Main Relay

PAGE 17

Page 18

FOR SERVICE TECHNICIAN’S USE ONLY

TEST #7: Lid Lock

Perform the following checks if the washer

does not lock (or unlock).

1. Perform the Lid Lock test under Manual

Test Mode on page 9. The following steps

assume that this step was unsuccessful.

2. Check lid lock mechanism for obstruction

or binding. Repair as necessary.

3. Unplug washer/dryer or disconnect power.

4. Remove console to access main control.

5. Visually check that the J6 connector is

inserted all the way into the main control.

If visual check passes, go to step 6.

If connector is not inserted properly,

reconnect J6 and repeat step 1.

6. Remove connector J6 from main control.

With an ohmmeter, verify lid lock resistance

values shown below across the following J6

connector pinouts:

Component

Lock Switch

Solenoid

Lid Switch

LID LOCK RESISTANCE

Resistance

Lid Closed =

85 to 155 ohms

Locked = 0 ohms

Unlocked = Open Circuit

Lid Open = Open Circuit

Contacts

Measured

J6-2

J6-1

J6-3

J6-2Lock Switch

J6-1J6-2

Lid Lock

Connection

Pin 2 & 3

Pin 1 & 2

Pin 2 & 3

If resistance values are good, go to step 7.

If switch measurements do not match the

values shown in the table for unlocked (or

locked) condition, verify the connection

with the upper washer harness according

to the chart. If the connection is OK, a

problem exists in the lid lock. Replace

the lid lock mechanism.

7. If the preceding steps did not correct the

lock problem, replace the main control.

a. Unplug washer/dryer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer/dryer or reconnect power.

Calibrate washer and perform Automatic Test

to verify repair.

PAGE 18

DO NOT REMOVE OR DESTROY

Page 19

FOR SERVICE TECHNICIAN’S USE ONLY

DRYER TROUBLESHOOTING GUIDE

Problem Possible Cause Checks & Tests

Won’t Power Up No power to dryer. Check power at outlet, check circuit breakers, fuses,

• No operation or junction box connections.

• No button response

AC plug and dryer.

Won’t Start Cycle Door not fully closed or striking Be sure the door is completely closed, then press and

No response when the door latch. hold the START button.

Start button is pressed

Drive belt/belt switch problem. See Test #2: Motor Circuit, page 22.

Thermal fuse/motor problem. See Test #2: Motor Circuit, page 22.

Won’t Shut Off Poor airflow. Check lint screen and exhaust vent. Clean if necessary.

When Expected

(long vent models only).

Heat system problem. See Test #3: Heat System, page 22.

Drum Won’t Spin Drive belt/belt switch problem. See Test #2: Motor Circuit, page 22.

Thermal fuse problem. See Test #3a: Thermal Fuse, page 23.

Door switch problem. See Test #5: Door Switch, page 24.

Motor problem. See Test #2: Motor Circuit, page 22.

Won’t Heat Check installation. Verify proper dryer installation.

Heat system malfunction. See Test #3: Heat System, page 22.

Inline thermal fuse problem. See Test #3d: Inline Thermal Fuse, page 23.

Heats In Air Cycle Heater coil shorted. See Test #3: Heat System, page 22.

Heater relay shorted. See Test #3: Heat System, page 22.

Heater system problem. See Test #3: Heat System, page 22.

Shuts Off Before Lint screen full. Clean if necessary. Refer customer to Use and Care Guide.

Clothes Are Dry

Moisture sensor problem. See Test #4: Moisture Sensor, page 23

(long vent models only).

Connection problem between See Test #1: Supply Connections, page 20.

Door switch problem. See Test #5: Door Switch, page 24.

Moisture sensor problem. See Test #4: Moisture Sensor, page 23

Exhaust vent clogged. Clean if necessary. Refer customer to Use and Care Guide.

DO NOT REMOVE OR DESTROY

PAGE 19

Page 20

FOR SERVICE TECHNICIAN’S USE ONLY

DRYER TROUBLESHOOTING TESTS

IMPORTANT: The following procedures

may require the use of needle probes

to measure voltage. Failure to use needle

probes will damage the connectors.

TEST #1: Supply Connections

This test assumes that proper voltage is

present at the outlet, and for U.S. electric dryer

installations, a visual inspection indicates that

the power cord is securely fastened to the

terminal block, and for U.S. and Canadian

gas dryer installations, that the power cord

is securely fastened to the wire harness

connection.

ELECTRIC DRYER (U.S. Installations):

1. Unplug dryer or disconnect power.

2. Remove the cover plate from the lower

center portion of the back of the dryer.

3. With an ohmmeter, check for continuity

between the neutral (N) terminal of the plug

and the center contact on the terminal block.

If there is no continuity, replace the power

cord and test the dryer.

If there is continuity, go to step 4.

4. In a similar way, check which terminal of

the plug is connected to the left-most contact

on the terminal block and make a note of

it. This will be L1 (black wire) in the wiring

diagram.

When this is found, go to step 5.

If neither of the plug terminals have

continuity with the left-most contact of the

terminal block, replace the power cord and

retest dryer.

5. Access the machine electronics without

disconnecting any wiring to the timer.

6. With an ohmmeter, check for continuity

between the L1 terminal of the plug (found

in step 4) and pin C on the timer.

If there is continuity, go to step 7.

If there is no continuity, check that wires to

the terminal block are mechanically secure.

If so, replace the main wire harness and

test the dryer.

7. Check for continuity between the neutral

(N) terminal of the plug and the door switch.

If there is continuity, go to step 8.

If there is no continuity, and the mechanical

connections of the wire are secure, replace

the main wire harness.

8. Visually check that ALL connectors are

fully inserted into the timer and the Start

switch.

9. Reassemble all parts and panels.

10. Plug in dryer or reconnect power.

ELECTRIC DRYER

(Canadian Installations):

1. Unplug dryer or disconnect power.

2. Remove the cover plate from the lower

center portion of the back of the dryer.

3. Access the machine electronics without

disconnecting any wiring to the timer.

4. With an ohmmeter, check the continuity

from the L1 plug terminal of the power cord

to pin C on the timer and from the N plug

terminal of the power cord to the door switch.

If continuity exists for both connections,

go to step 6.

If an open circuit is found, check the integrity

of the connections of the power cord to the

harness in the dryer and the integrity of the

power cord itself.

5. If it is necessary to replace the power

cord, remove the retaining clip that secures

the cord to the back panel. Disconnect the

cord from the main harness and the ground

wire from the rear panel, then pull out the

power cord.

6. Visually check that ALL connectors are

fully inserted into the timer and the Start

switch.

7. Reassemble all parts and panels.

8. Plug in dryer or reconnect power.

PAGE 20

DO NOT REMOVE OR DESTROY

Page 21

FOR SERVICE TECHNICIAN’S USE ONLY

Light blue wire in back at pin 4

GAS DRYER

(U.S. and Canadian Installations):

1. Unplug dryer or disconnect power.

2. Remove the cover plate from the lower

center portion of the back of the dryer.

3. Check that the power cord is firmly

connected to the dryer’s wire harness.

4. Access the machine electronics without

disconnecting any wiring to the timer.

5. With an ohmmeter, check for continuity

between the neutral (N) terminal of the plug

and the door switch.

If there is continuity, go to step 6.

If there is no continuity or if there is an open

circuit, replace the power cord. Otherwise,

go to step 6.

6. In a similar way, check for continuity

between the L1 terminal of the plug and pin C

on the timer.

If there is continuity, go to step 7.

If there is no continuity or if there is an open

circuit, replace the power cord. Otherwise,

replace the main harness.

7. Visually check that ALL connectors are

fully inserted into the timer and the Start

switch.

8. Reassemble all parts and panels.

9. Plug in dryer or reconnect power.

TEST #2: Motor Circuit

This test will check the wiring to the motor

and the motor itself.

1. Unplug dryer or disconnect power.

2. Check for loose, worn, or damaged drum

belt—repair as necessary.

3. Door Switch problems can be uncovered

by following procedure under TEST #5: Door

Switch, page 24.

4. Check the wiring and components in the

motor circuit by referring to the appropriate

wiring diagram on pages 27–28.

Check the thermal fuse. See TEST #3a:

Thermal Fuse, page 23.

Continue with step 5 to test the remaining

components in the motor circuit.

5. Check the drive motor and belt switch.

Slowly remove the drum belt.

6. Remove the white connector from the drive

motor switch.

7. Remove the bare copper wire terminal from

pin 5 of black drive motor switch.

8. Using the appropriate wiring diagram on

pages 27–28, check for the resistance values

of the motor’s Main and Start winding coils

as shown in the following table.

NOTE: Main and Start winding coils must be

checked at the motor.

Winding

START 2.4–3.8

Resistance

in ohms

MAIN 2.4–3.6

Contact Points

of Measurement

and bare copper wire terminal

removed from pin 5 of black

drive motor switch

Light blue wire in back at pin 4

and bare copper wire terminal

on pin 3 of black drive

motor switch

If the resistance at the motor is correct,

there is an open circuit between the motor

and the timer. Check for a belt switch

problem (see step 9) and check and repair