Whirlpool WGD8500SR, WED8500SR, WGD8300SW Use & Care Manual

ELECTRONIC

GAS & ELECTRIC

DRYERS

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

L-79

JOB AID

Part No. 8178559

MODELS: WED8300SW, WED8500SR

WGD8300SW, WGD8500SR

FORWARD

This Whirlpool Job Aid, “Duet Sport™ Electronic Gas & Electric Dryers” (Part No. 8178559),

provides the technician with information on the installation, operation, and service of the Duet

Sport™ Electronic Gas & Electric Dryers. For specific information on the model being serviced,

refer to the “Use and Care Guide,” or “Tech Sheet” provided with the dryer.

The Wiring Diagrams used in this Job Aid are typical and should be used for training purposes

only. Always use the Wiring Diagram supplied with the product when servicing the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide information that will enable the service technician to properly diagnose malfunctions and repair the Duet Sport™ Electronic Gas & Electric Dryers.

The objectives of this Job Aid are to:

Understand and follow proper safety precautions.

•

Successfully troubleshoot and diagnose malfunctions.

•

Successfully perform necessary repairs.

•

Successfully return the dryer to its proper operational status.

•

WHIRLPOOL CORPORATION assumes no responsibility for any repairs

made on our products by anyone other than Authorized Service Technicians.

Copyright © 2006, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

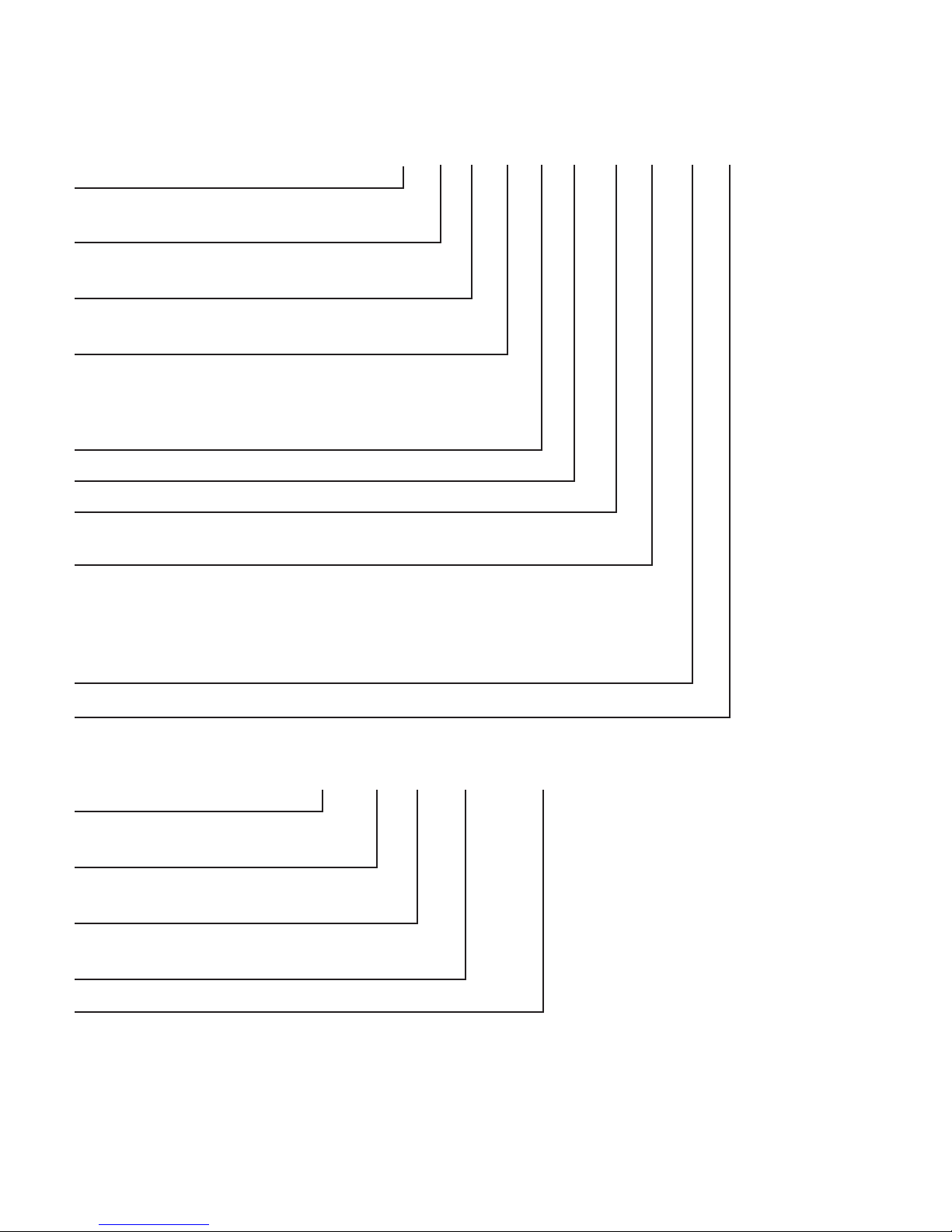

TABLE OF CONTENTS

Page

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Dryer Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Model & Serial Number Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Model & Serial Number Label And Tech Sheet Locations . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3

INSTALLATION INFORMATION

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

PRODUCT OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Dryer Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Dryer Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

COMPONENT ACCESS

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Removing The Console And The Console Electronics Assembly . . . . . . . . . . . . . . . . . . .

Removing The Machine Control Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing The Door Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing The Moisture Sensor

Removing The Drum Light Socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing The Front Panel

Removing The Thermal Fuse & Exhaust Thermistor

Removing The Belt & Drum, And Rollers

Removing The Drive Motor And Belt Switch

Removing The Ignitor, Flame Sensor, High-Limit Thermostat,

And Thermal Cutoff (Gas Models Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing The Gas Burner Assembly Coils

Removing The Heater, High-Limit Thermostat, And Thermal Cutoff

(Electric Models Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Removing The Dryer Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

4-2

4-4

4-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4-18

COMPONENT TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Moisture Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Door Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Thermal Fuse

Exhaust Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Flame Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

High-Limit Thermostat & Thermal Cutoff (Gas Dryers Only) . . . . . . . . . . . . . . . . . . . . . . .

Burner Ignitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Gas Burner Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Thermal Cutoff (Electric Dryers Only)

Heater (Electric Dryers Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-4

5-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

- iii -

Page

DIAGNOSTICS & TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Diagnostic Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Diagnostic Tests

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Display Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Troubleshooting Guide

Troubleshooting Tests

Removing The Toe Panel

Accessing & Removing The Electronic Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing The Back Panel

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Electric Dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Gas Dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

- iv -

GENERAL

DANGER

DRYER SAFETY

Your safety and the safety of others is very important.

We have provided many important safety messages in this Job Aid and on the appliance.

Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and

others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the

chance of injury, and tell you what can happen if the instructions are not followed.

1-1

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER W E D 8 3 00 S W 0

BRAND

W = Whirlpool

FUEL

E = Electric G = Gas

PRODUCT

D = Dryer

SERIES

5 = Whirlpool Leap 6 = Oasis

7 = 24

9 = Duet Front Load

PRICE POINT LEVELS (1 - 9)

TRADE PARTNER ID (00 = BRANDED)

YEAR OF INTRODUCTION

S = 2006, T = 2007

COLOR CODE

T = Biscuit

Q = White

W = White With Metallic Accent

R = White With Metallic (Sport Only)

ENGINEERING CHANGE (NUMERIC)

˝ Front Load 8 = Mid Line Front Load

SERIAL NUMBER

SERIAL NUMBER M T 09 62410

DIVISION RESPONSIBILITY

M = Marion, OH

YEAR OF PRODUCTION

T = 2006

WEEK OF PRODUCTION

09 = 9th Week

PRODUCT SEQUENCE NUMBER

1-2

MODEL & SERIAL NUMBER LABEL

AND TECH SHEET LOCATIONS

The Model & Serial Number Label and Tech Sheet locations are shown below.

Model & Serial

Number Label

(Behind Lower Access Panel)

Tech Sheet

1-3

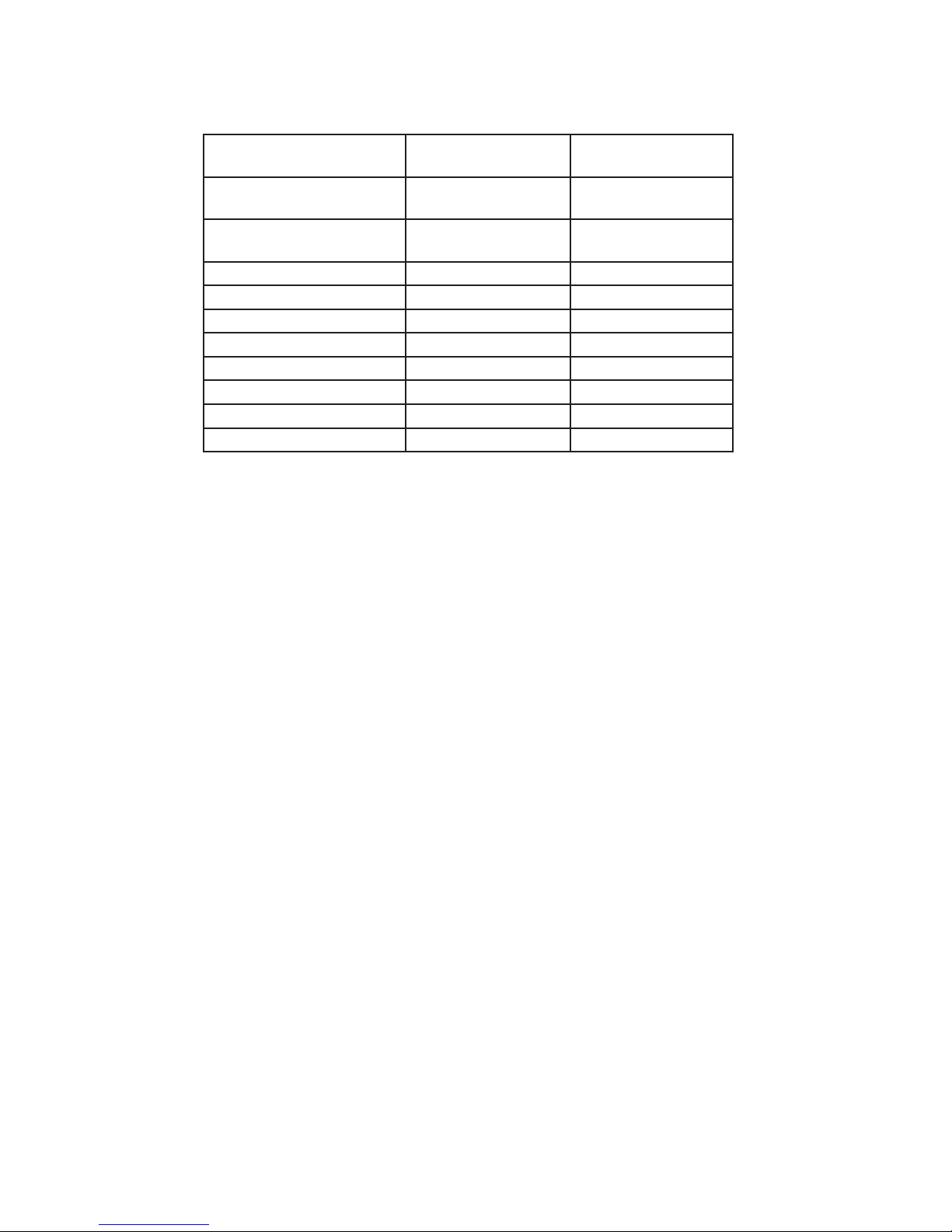

SPECIFICATIONS

Model Number WED8300SW

WGD8300SW

Model Description Matching Dryer For

Front Load Washer

Color White with Gray

Accents

Capacity (Cu.Ft. IEC) 6.7 6.7

Venting

Reversible Door Yes Yes

Lint Screen Location Front Front

Height 36.0" 36.0"

Install Depth: Min - Max 28.90" - 32.90" 28.90" - 32.90"

Width

Product Weight (approx)

4 way 4 way

27" 27"

122 lbs. 122 lbs.

WED8500SR

WGD8500SR

Matching Dryer For

Front Load Washer

White with Sterling

Bright Accents

1-4

INSTALLATION INFORMATION

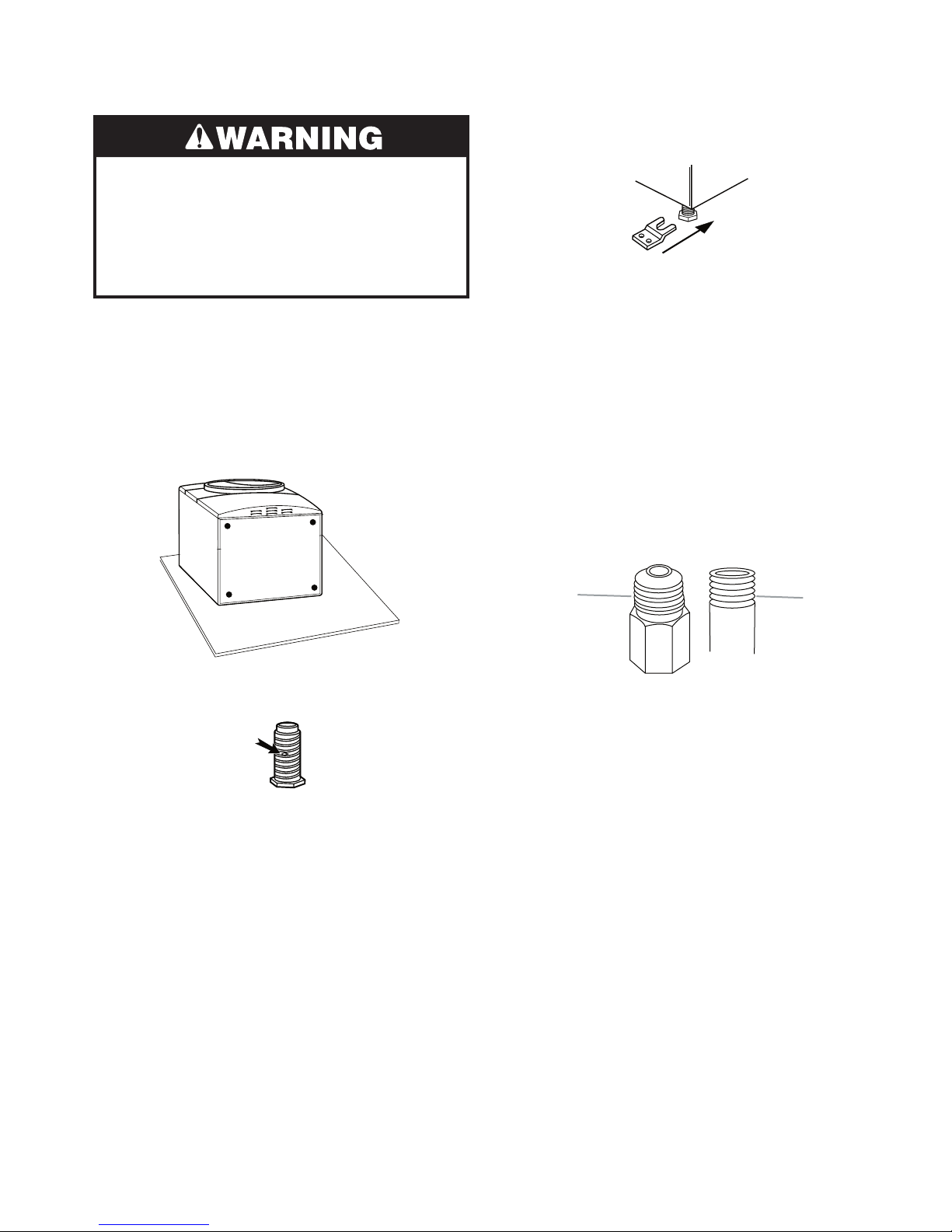

4 Leveling legs

34.15"

(86.74 cm)

INSTALLATION INSTRUCTIONS

TOOLS AND PARTS

Gather the required tools and parts before

starting installation. Read and follow the safe

ty instructions provided with any tools listed

here.

Electric Models

Flat-blade screwdriver

•

#2 Phillips screwdriver

•

Adjustable wrench that opens to 1˝ (2.5 cm)

•

or hex-head socket wrench (for adjusting

dryer feet)

Wire stripper (direct wire installations)

•

Level

•

Vent clamps

•

Caulking gun and compound (for installing

•

new exhaust vent)

Tin snips (new vent installations)

•

1/4˝ nut driver or socket wrench

•

(recommended)

Tape measure

•

Parts Supplied

Remove parts packages from dryer drum.

Check that all parts are included.

Parts package•

NOTE: Do not use leveling legs if installing

the dryer on a pedestal.

Parts needed

Check local codes and with gas supplier.

Check existing gas supply, electrical supply

and venting. Read “Electrical Requirements,”

“Gas Supply Requirements” and “Venting Requirements” before purchasing parts.

For close-clearance installations between

•

28.65˝ (72.77 cm) and 34.15˝ (86.74 cm),

see “Plan Vent System” section for venting

requirements.

Gas Models

8˝ or 10˝ pipe wrench

•

8˝ or 10˝ adjustable wrench (for gas

•

connections)

Flat-blade screwdriver

•

Adjustable wrench that opens to 1˝

•

(2.5 cm) or hex-head socket wrench (for

adjusting dryer feet)

1/4˝ nut driver or socket wrench

•

(recommended)

Level

•

Vent clamps

•

Knife

•

Pipe-joint compound resistant to LP gas

•

Caulking gun and compound (for installing

•

new exhaust vent)

Pliers

•

Tape measure

•

Mobile home installations require special

parts (listed following) that may be ordered by

calling the dealer from whom you purchased

your dryer. For further information, please refer to the “Assistance or Service” section of

the “Use & Care Guide.”

Mobile Home Installation Kit. Ask for Part

•

Number 346764.

Metal exhaust system hardware.

•

2-1

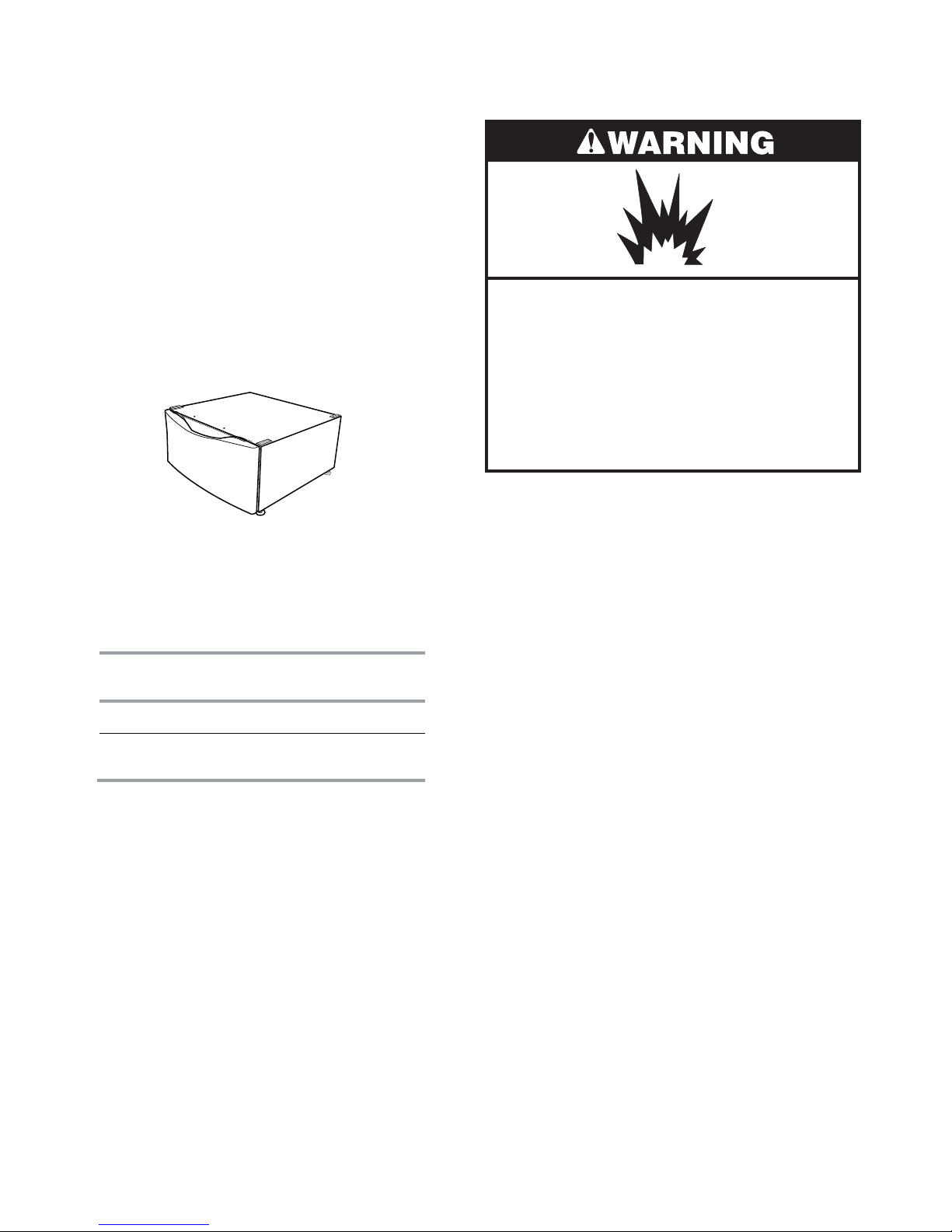

OPTIONS

Optional pedestal (15.5˝ [39.4 cm] model shown)

Pedestal

Height

Color Part Number

10" (25.4 cm

) White WHP1000SQ

15

.5" (39.4 cm) with

shelf and bin dividers

White WHP1500SQ

Pedestal

Are you placing the dryer on a pedestal?

You have the option of purchasing pedestals

of different heights separately for this dryer.

You may select a 10˝ (25.4 cm) pedestal or a

15.5˝ (39.4 cm) pedestal with a shelf and bin

dividers. These pedestals will add to the total

height of the unit for a total height of approxi

mately 46˝ (116.8 cm) or 51.5˝ (130.8 cm).

LOCATION REQUIREMENTS

-

Explosion Hazard

For a garage installation, you will need to

place the dryer at least 18

˝ (46 cm) above

the floor.

To order, call the dealer from whom you purchased your dryer or refer to the “Assistance or

Service” section of the “Use & Care Guide.”

Keep flammable materials and vapors,

such as gasoline, away from dryer.

Place dryer at least 18 inches (46 cm)

above the floor for a garage installation.

Failure to do so can result in death,

explosion, or fire.

You will need

A location that allows for proper exhaust in-

•

stallation. See “Venting Requirements.”

•

Electric Models Only: A separate 30-amp

circuit.

If you are using a power cord, a grounded

•

electrical outlet located within 2 ft (61 cm)

of either side of the dryer. See “Electrical

Requirements.”

A sturdy floor to support the total dryer

•

weight of 127 lbs (57.6 kg). The combined

weight of a companion appliance should

also be considered.

Drying Rack

To order a drying rack, call the dealer from

whom you purchased the dryer or refer to the

“Assistance or Service” section of the “Use &

Care Guide.” Ask for Part Number 8563738.

Stack Kit

Are you planning to stack your DUET SPORT™

washer and dryer? To do so, you will need to

purchase a Stack Kit.

To order, call the dealer from whom you purchased your dryer or refer to the “Assistance

or Service” section of the “Use & Care Guide.”

Ask for Part Number 8572546.

A level floor with a maximum slope of

•

1˝(2.5 cm) under entire dryer. (If slope is

greater than 1

Dryer Feet Kit, Part No.

˝ [2.5 cm], install Extended

279810.) Clothes

may not tumble properly and automatic

sensor cycles may not operate correctly if

dryer is not level.

For a garage installation, you will need to

•

place the dryer at least 18

˝ (46 cm) above

the floor. If using a pedestal, you will need

18˝ (46 cm) to the bottom of the dryer.

Do not operate your dryer at temperatures

below 45

°F (7°C). At lower temperatures, the

dryer might not shut off at the end of an auto

matic cycle. Drying times can be extended.

2-2

-

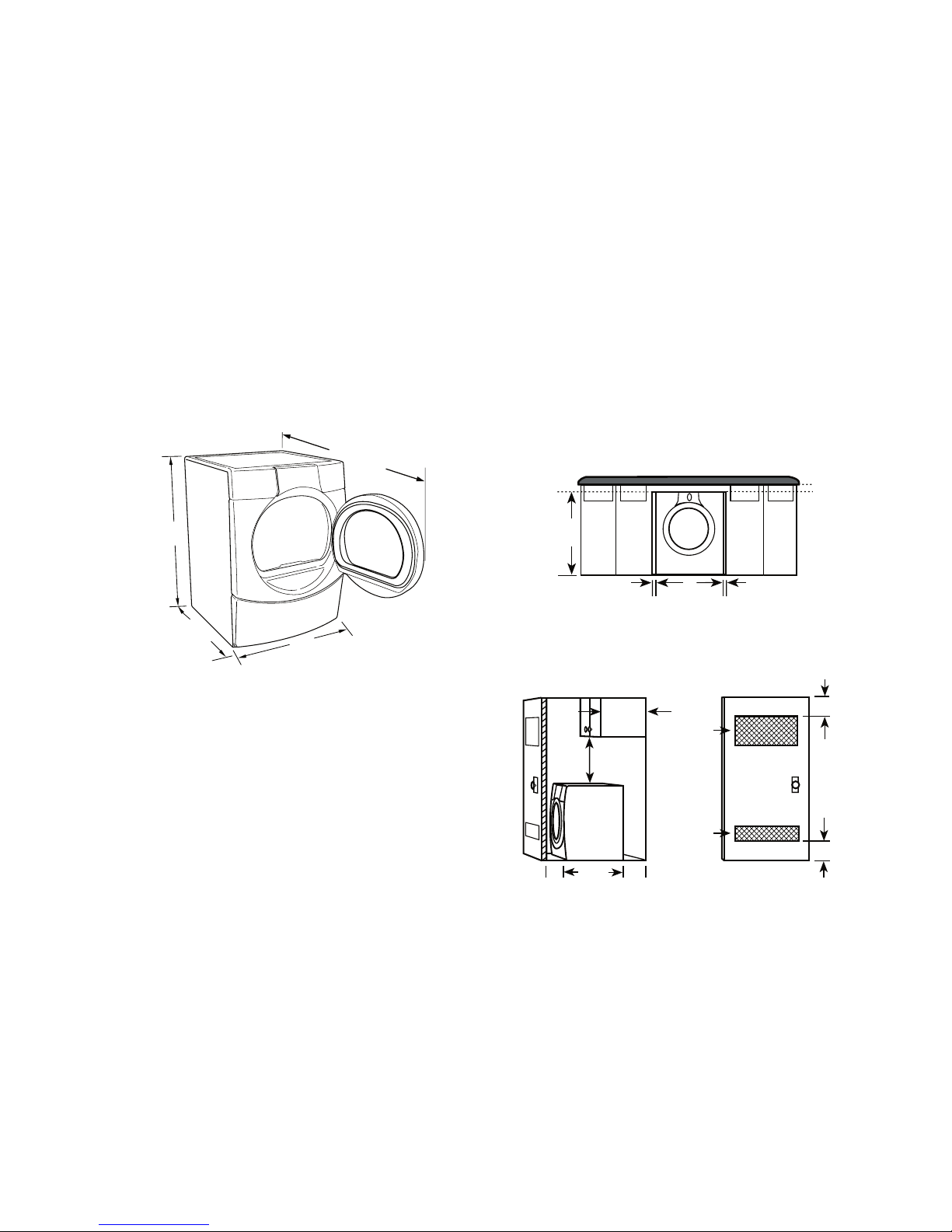

36"

(91.4 cm)

50½"

(128.27 cm)

27"

(68.6 cm)

*28.65"

(72.77 cm)

The dryer must not be installed or stored in an

2"*

(5 cm

)

36" mi

n

(91.4 cm)

1"

*

(2.5 cm

)

1"

*

(2.5 cm

)

27"

(68.6 cm)

A. Side view - closet or confined area

B. Closet door

with vents

A

B

14" max.*

(35.6 cm)

15" min.

*

(38.1 cm)

1"*

(2.5 cm)

5"**

(12.7 cm)

28.65"

(72.77 cm)

48 in.

2

*

(310 cm2)

24 in.

2

*

(155 cm2)

3"*

(7.6 cm)

3"*

(7.6 cm)

area where it will be exposed to water and/or

weather.

Check code requirements. Some codes limit,

or do not permit, installation of the dryer in

garages, closets, mobile homes, or sleeping

quarters. Contact your local building inspec

tor.

NOTE: No other fuel-burning appliance can

be installed in the same closet as a dryer.

Installation Clearances

The location must be large enough to allow

the dryer door to open fully.

Dryer Dimensions

Additional spacing should be considered

•

for ease of installation and servicing.

Additional clearances might be required for

•

wall, door and floor moldings.

Additional spacing should be considered

•

on all sides of the dryer to reduce noise

-

transfer.

For closet installation, with a door, mini

•

mum ventilation openings in the top and

bottom of the door are required. Louvered

doors with equivalent ventilation openings

are acceptable.

Companion appliance spacing should also

•

be considered.

Custom undercounter installation - Dryer

only

-

* Most installations require a minimum 5˝

(12.7 cm) clearance behind the dryer for

the exhaust vent with elbow. See “Venting

Requirements.”

Installation spacing for recessed area or

closet installation

The following spacing dimensions are recommended for this dryer. This dryer has been

tested for spacing of 0

˝ (0 cm) clearance on

the sides and rear. Recommended spacing

should be considered for the following rea

sons:

* Required Spacing

Closet installation - Dryer only

-

* Required spacing

** For side or bottom venting, 0˝ (0 cm) spacing is allowed.

2-3

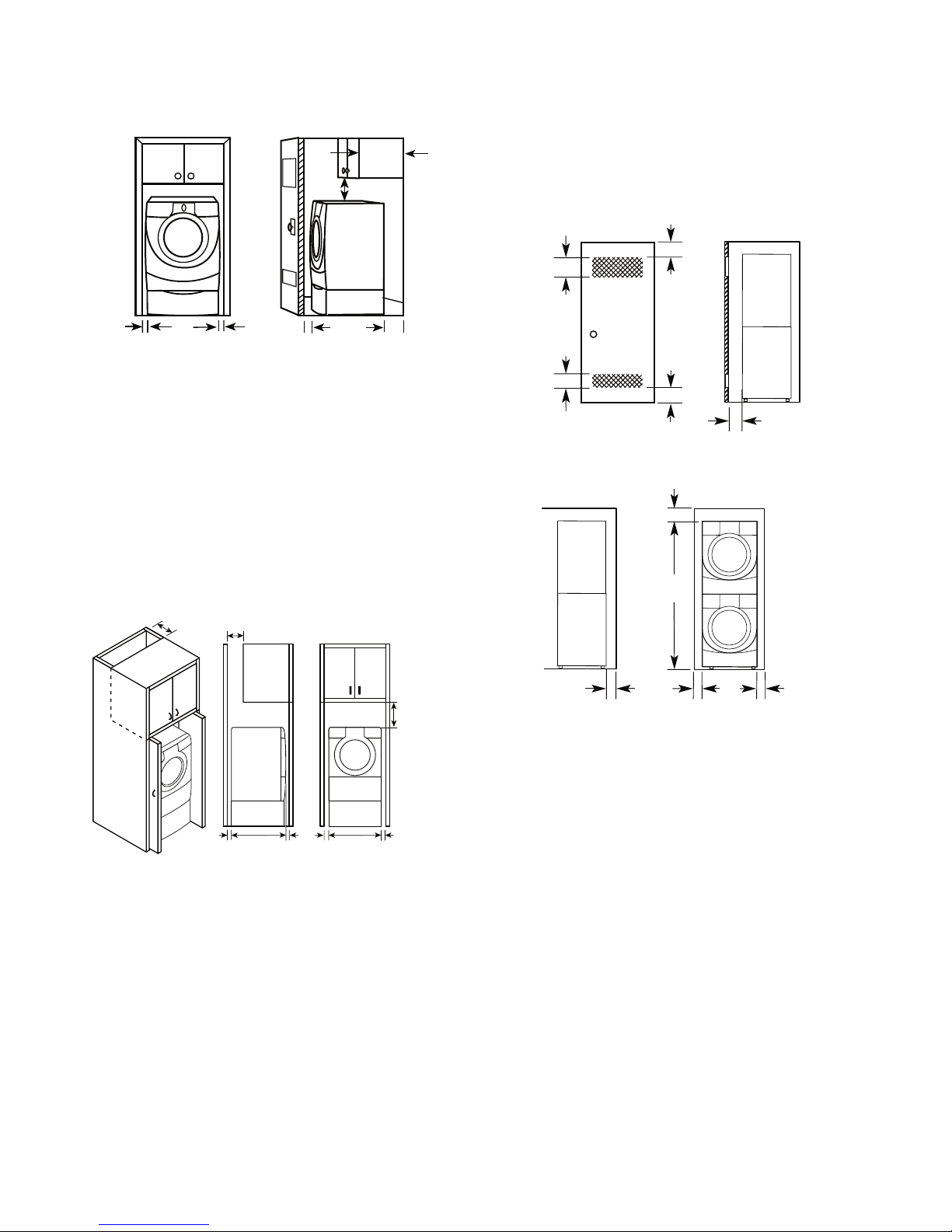

Recessed or closet installation - Dryer on

A. Recessed area

B. Side

view - closet or confined area

A

B

1"

(2.5 cm)

1"

(2.5 cm)

27"

(68.6 cm)

1"

(2.5 cm)

5

"**

(12.7 cm)

28.65"

(72.77 cm)

15" min.

*

(38.1 cm)

14" max.

*

(35.6 cm

)

7"* (17.8 cm)

9"*

(22.9 cm)

7"* (17.8 cm)

5"**

(

12.7 cm)

28.65"

(72.77 cm)

27"

(68.6 cm)

1"

(2.5 cm)

(2.5 cm)

1"

(2.5 cm)

1"

48 in.2 *

(310 cm2)

3"*

(7.6 cm)

3"*

(7.6 cm)

1"*

(2.5 cm)

24 in.

2

*

(155 cm2)

6"* (15.2 cm)

72"

(182.9 cm)

27"

(68.6 cm)

5"*

(12.7 cm)

1"

(2.5 cm)

1"

(2.5 cm)

pedestal

* Required spacing

** For side or bottom venting, 0˝ (0 cm) spacing is allowed.

Installation spacing for cabinet installation

The dimensions shown are for the recom-

•

mended spacing.

For cabinet installation, with a door, mini

•

mum ventilation openings in the top of the

cabinet are required.

Recommended installation spacing for

recessed or closet installation with

stacked washer and dryer

The dimensions shown are for the recommended spacing

* Required spacing

-

* Required spacing

** For side or bottom venting, 0˝ (0 cm) spacing is allowed.

* Required spacing

Mobile home - additional installation requirements

This dryer is suitable for mobile home instal

lations. The installation must conform to the

Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280 (formerly

the Federal Standard for Mobile Home Con

struction and Safety, Title 24, HUD Part 280).

Mobile home installations require:

•

Metal exhaust system hardware, which is

available for purchase from your dealer.

Special provisions must be made in mo-

•

bile homes to introduce outside air into the

dryer. The opening (such as a nearby win

dow) should be at least twice as large as

the dryer exhaust opening.

2-4

-

-

-

ELECTRICAL REQUIREMENTS

Electric Models Only

It is your responsibility

To contact a qualified electrical installer.

•

To be sure that the electrical connection

•

is adequate and in conformance with the

National Electrical Code, ANSI/NFPA 70latest edition and all local codes and ordinances.

The National Electric Code requires a

4-wire supply connection for homes built

after 1996, dryer circuits involved in re

modeling after 1996, and all mobile home

installations.

A copy of the above code standards can be

obtained from: National Fire Protection As

sociation, One Batterymarch Park, Quincy,

MA 02269.

To supply the required 3 or 4 wire, single

•

phase, 120/240 volt, 60-Hz., AC-only electrical supply (or 3 or 4 wire, 120/208 volt

electrical supply, if specified on the serial/

rating plate) on a separate 30-amp circuit,

fused on both sides of the line. A time-de

lay fuse or circuit breaker is recommended.

Connect to an individual branch circuit. Do

not have a fuse in the neutral or grounding

circuit.

Do not use an extension cord.

•

If codes permit and a separate ground wire

•

is used, it is recommended that a qualified

electrician determine that the ground path

is adequate.

Electrical Connection

To properly install your dryer, you must determine the type of electrical connection you will

be using and follow the instructions provided

for it here.

•

If local codes do not permit the connection

of a neutral ground wire to the neutral wire,

see “Optional 3-wire connection” section.

This dryer is manufactured ready to install

•

with a 3-wire electrical supply connection.

The neutral ground wire is permanently

connected to the neutral conductor (white

wire) within the dryer. If the dryer is installed

with a 4-wire electrical supply connection,

the neutral ground wire must be removed

from the external ground conductor screw

(green screw), and secured under the neu

-

-

-

tral terminal (center or white wire) of the

terminal block. When the neutral ground

wire is secured under the neutral terminal

(center or white wire) of the terminal block,

the dryer cabinet is isolated from the neu

tral conductor.

•

A 4-wire power supply connection must be

used when the appliance is installed in a lo

cation where grounding through the neutral

conductor is prohibited. Grounding through

the neutral is prohibited for (1) new branchcircuit installations,(2) mobile homes, (3)

recreational vehicles, and (4) areas where

local codes prohibit grounding through the

neutral conductors.

If using a power supply cord:

Use a UL listed power supply cord kit marked

for use with clothes dryers. The kit should

contain:

A UL listed 30-amp power supply cord, rat-

•

ed 120/240-volt minimum. The cord should

be type SRD or SRDT and be at least 4 ft

(1.22 m) long. The wires that connect to the

dryer must end in ring terminals or spade

terminals with upturned ends.

A UL listed strain relief.

•

-

-

-

2-5

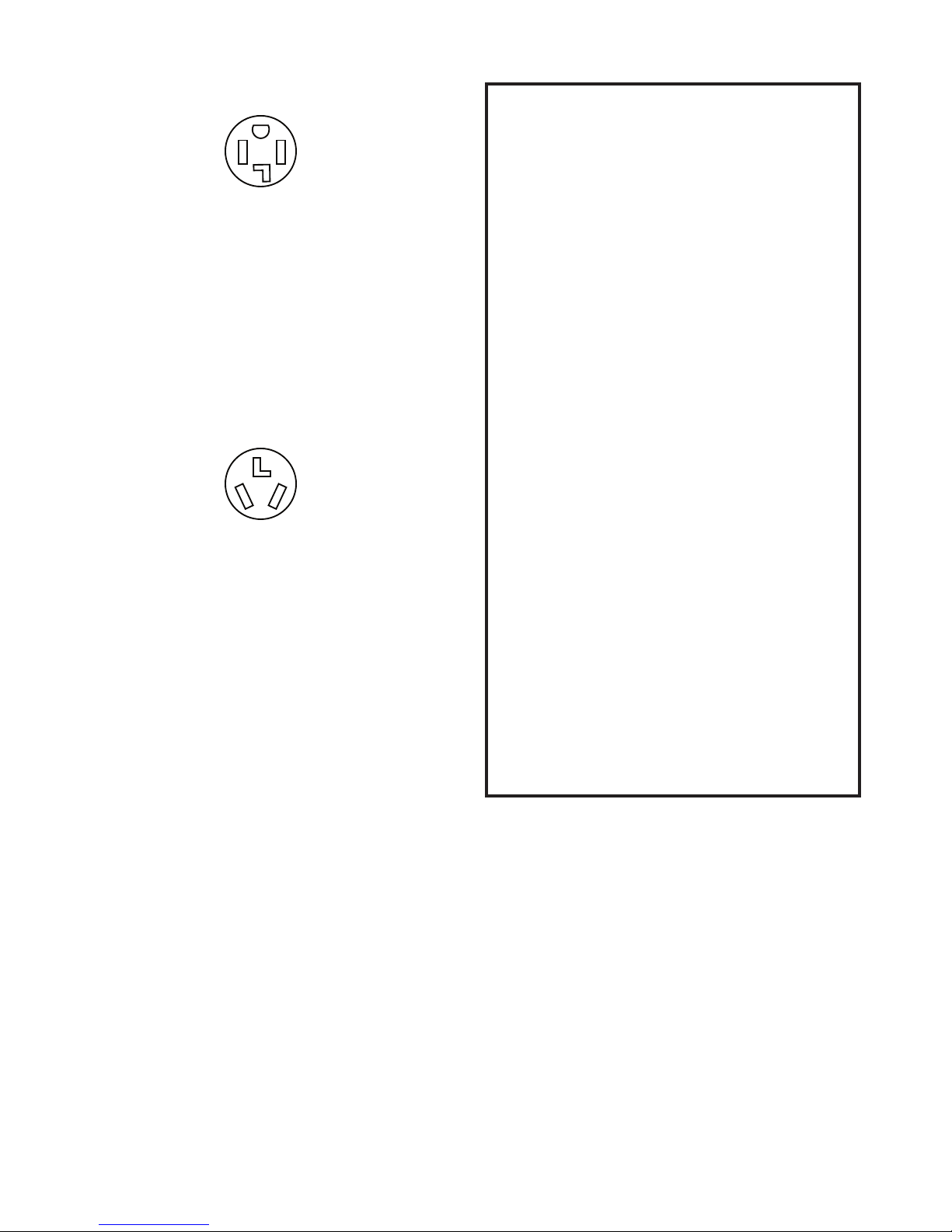

4-wire receptacle (14-30R)

3-wire receptacle (10-30R)

If your outlet looks like this:

Then choose a 4-wire power supply cord with

ring or spade terminals and UL listed strain

relief. The 4-wire power supply cord, at least

4 ft (1.22 m) long, must have 4, 10-gauge copper wires and match a 4-wire receptacle of

NEMA Type 14-30R. The ground wire (ground

conductor) may be either green or bare. The

neutral conductor must be identified by a

white cover.

If your outlet looks like this:

Then choose a 3-wire power supply cord with

ring or spade terminals and UL listed strain

relief. The 3-wire power supply cord, at least

4 ft (1.22 m) long, must have 3, 10-gauge

copper wires and match a 3-wire receptacle

of NEMA Type 10-30R.

If connecting by direct wire:

Power supply cable must match power supply

(4-wire or 3-wire) and be:

Flexible armored cable or nonmetallic

•

sheathed copper cable (with ground wire),

protected with flexible metallic conduit. All

current-carrying wires must be insulated.

GROUNDING INSTRUCTIONS

For a grounded, cord-connected dryer:

•

This dryer must be grounded. In the event

of malfunction or breakdown, grounding

will reduce the risk of electric shock by

providing a path of least resistance for

electric current. This dryer uses a cord

having an equipment-grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that

is properly installed and grounded in accordance with all local codes and ordinances.

For a permanently connected dryer:

•

This dryer must be connected to a grounded metal, permanent wiring system, or an

equipment-grounding conductor must be

run with the circuit conductors and connected to the equipment-grounding terminal or lead on the dryer.

WARNING:

Improper connection of the

equipment-grounding conductor can result

in a risk of electric shock. Check with a

qualified electrician or service representative or personnel if you are in doubt as to

whether the dryer is properly grounded.

Do not modify the plug on the power supply cord: if it will not fit the outlet, have a

proper outlet installed by a qualified electrician.

10-gauge solid copper wire (do not use

•

aluminum).

At least 5 ft (1.52 m) long.

•

2-6

ELECTRICAL CONNECTION

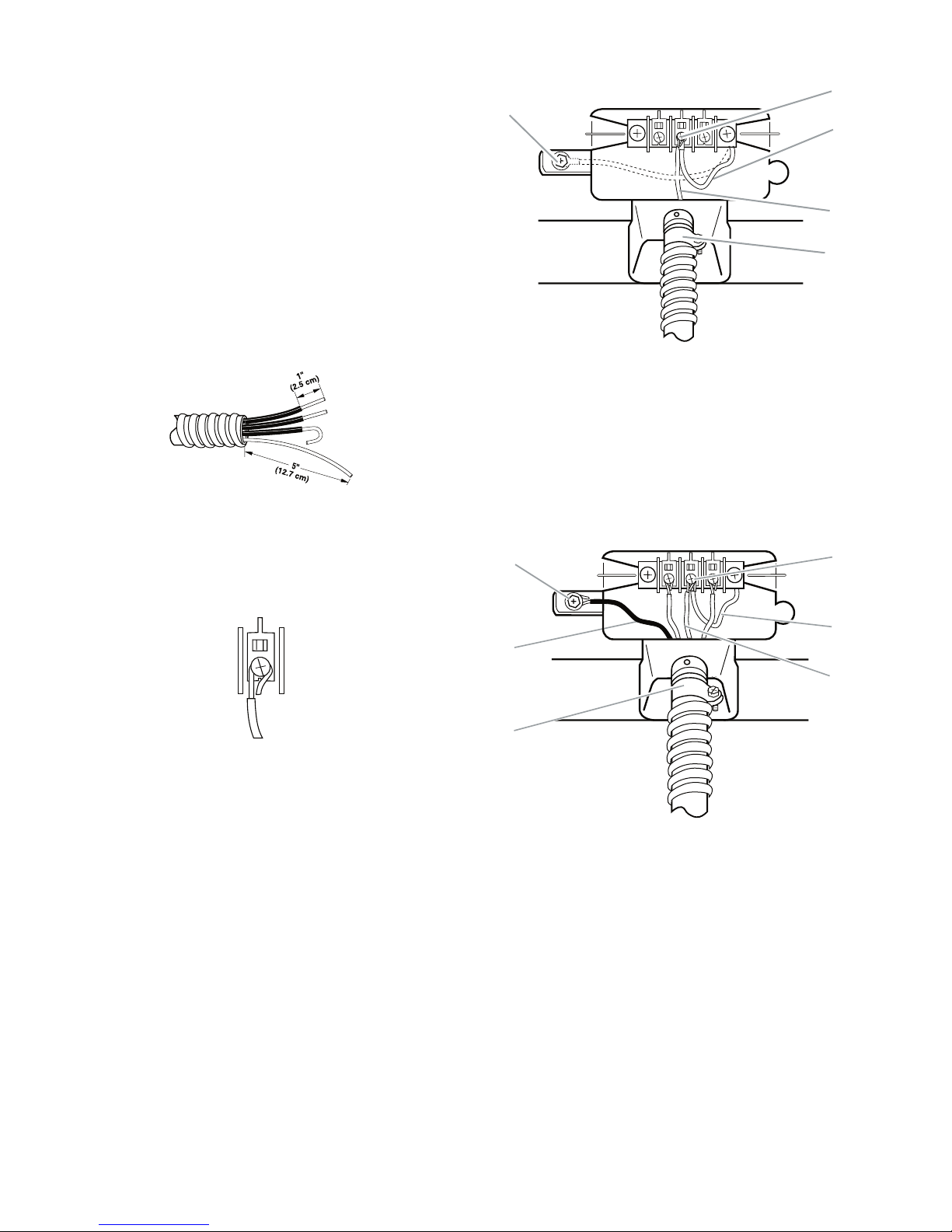

A. Neutral ground wire

B. External ground conductor screw

C. Center, silve

r-colored terminal block screw

D. Terminal block cover and hold-down scre

w

A

B

C

D

A. Strain relief tab pointing up

B. Hole below terminal block opening

C. Clamp section

D. Strain relief tab pointing down

A

B

C

D

Electric Models Only

POWER SUPPLY CORD

DIRECT WIRE

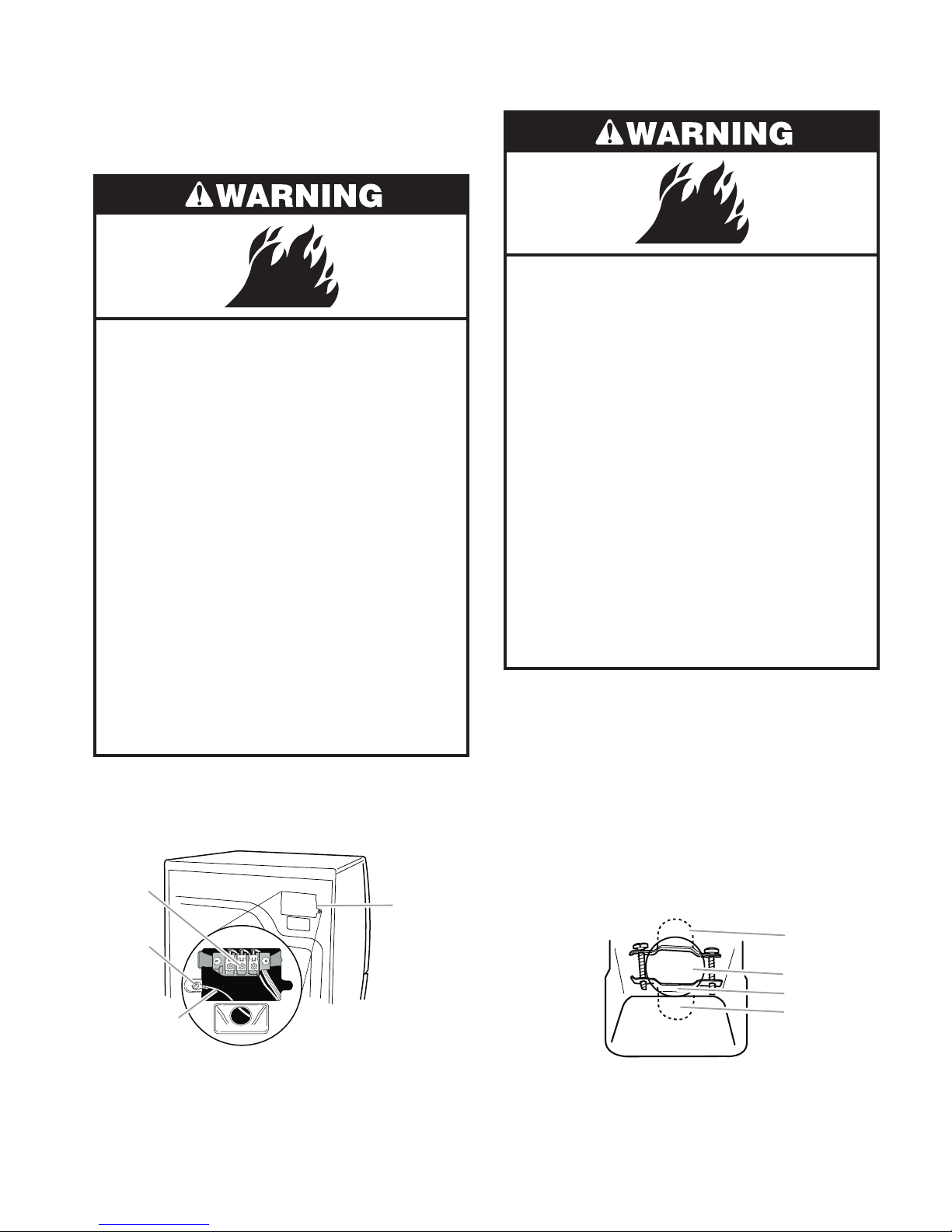

Fire Hazard

Use 10 gauge solid copper wire.

Fire Hazard

Use a new UL listed 30 amp power

supply cord.

Use a UL listed strain relief.

Disconnect power before making

electrical connections.

Connect neutral wire (white or center

wire) to center terminal (silver).

Ground wire (green or bare wire)

must be connected to green ground

connector.

Connect remaining 2 supply wires to

remaining 2 terminals (gold).

Securely tighten all electrical

connections.

Failure to do so can result in death, fire,

or electrical shock.

1. Disconnect power.

2. Remove the hold-down screw and terminal block cover.

Use a UL listed strain relief.

Disconnect power before making

electrical connections.

Connect neutral wire (white or center

wire) to center terminal (silver).

Ground wire (green or bare wire)

must be connected to green ground

connector.

Connect remaining 2 supply wires to

remaining 2 terminals (gold).

Securely tighten all electrical

connections.

Failure to do so can result in death, fire,

or electrical shock.

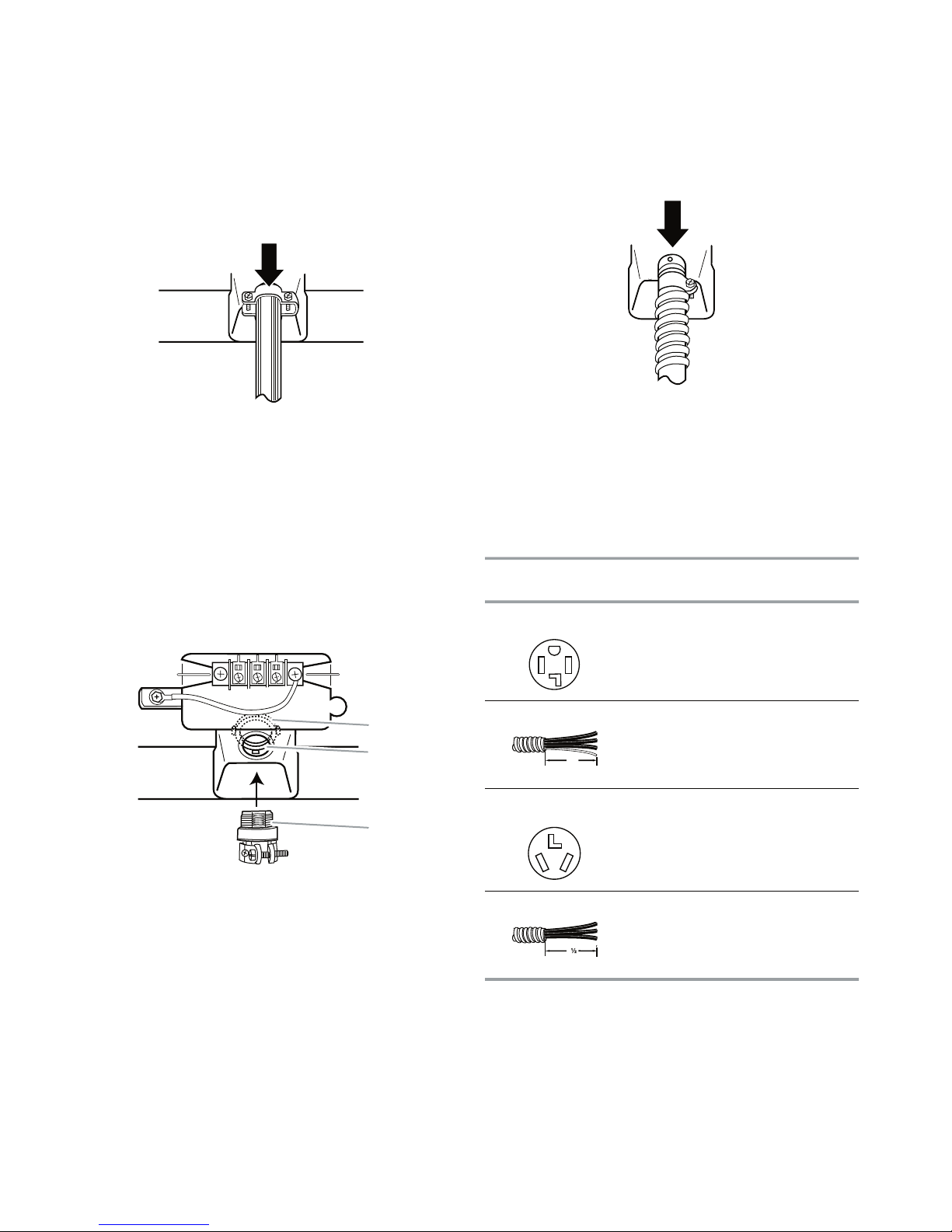

Style 1: Power supply cord strain relief

Remove the screws from a 3/4˝ (1.9 cm)

•

UL listed strain relief (UL marking on strain

relief). Put the tabs of the two clamp sec

tions into the hole below the terminal block

opening so that one tab is pointing up

and the other is pointing down, and hold

in place. Tighten strain relief screws just

enough to hold the two clamp sections to

gether.

-

-

3. Install strain relief.

2-7

Put power supply cord through the strain

A. Removable conduit connector

B. Hole

below terminal block opening

C. Strain relief thread

s

A

B

C

If your home has: And you will be

connecting to

:

Go to Sectio

n

4-wire receptacle

(NEMA Type 14-30R

)

A UL listed,

120/240-volt

minimum,

30-amp, dryer

power supply

cord

*

4-wire connection

:

Power supply cord

4-wire direct A fused

disc

onnect or

circuit breaker

box*

4-wire connection

:

Direct Wire

3-wire receptacle

(NEMA type 10-30R

)

A UL listed,

120/240-volt

minimum,

30-amp, dryer

power supply

cord

*

3-wire connection

:

Power supply cord

3-wire direct A fused

disc

onnect or

circuit breaker

box*

3-wire connection

:

Direct Wire

5"

(12.7 cm)

3

"

(8.9 cm)

•

relief. Be sure that the wire insulation on

the power supply cord is inside the strain

relief. The strain relief should have a tight

fit with the dryer cabinet and be in a hori

zontal position. Do not further tighten strain

relief screws at this point.

Style 2: Direct wire strain relief

Unscrew the removable conduit connector

•

and any screws from a 3/4

˝ (1.9 cm) UL

listed strain relief (UL marking on strain re

lief). Put the threaded section of the strain

relief through the hole below the terminal

block opening. Reaching inside the terminal block opening, screw the removable

conduit connector onto the strain relief

threads.

Put direct wire cable through the strain re-

•

lief. The strain relief should have a tight fit

with the dryer cabinet and be in a horizontal

position. Tighten strain relief screw against

-

the direct wire cable.

4. Now complete installation following in-

structions for your type of electrical con

nection:

4-wire (recommended)

-

3-wire (if 4-wire is not available)

Electrical Connection Options

-

* If local codes do not permit the connection

of a cabinet-ground conductor to the neu

tral wire, go to “Optional 3-wire connection”

-

section.

2-8

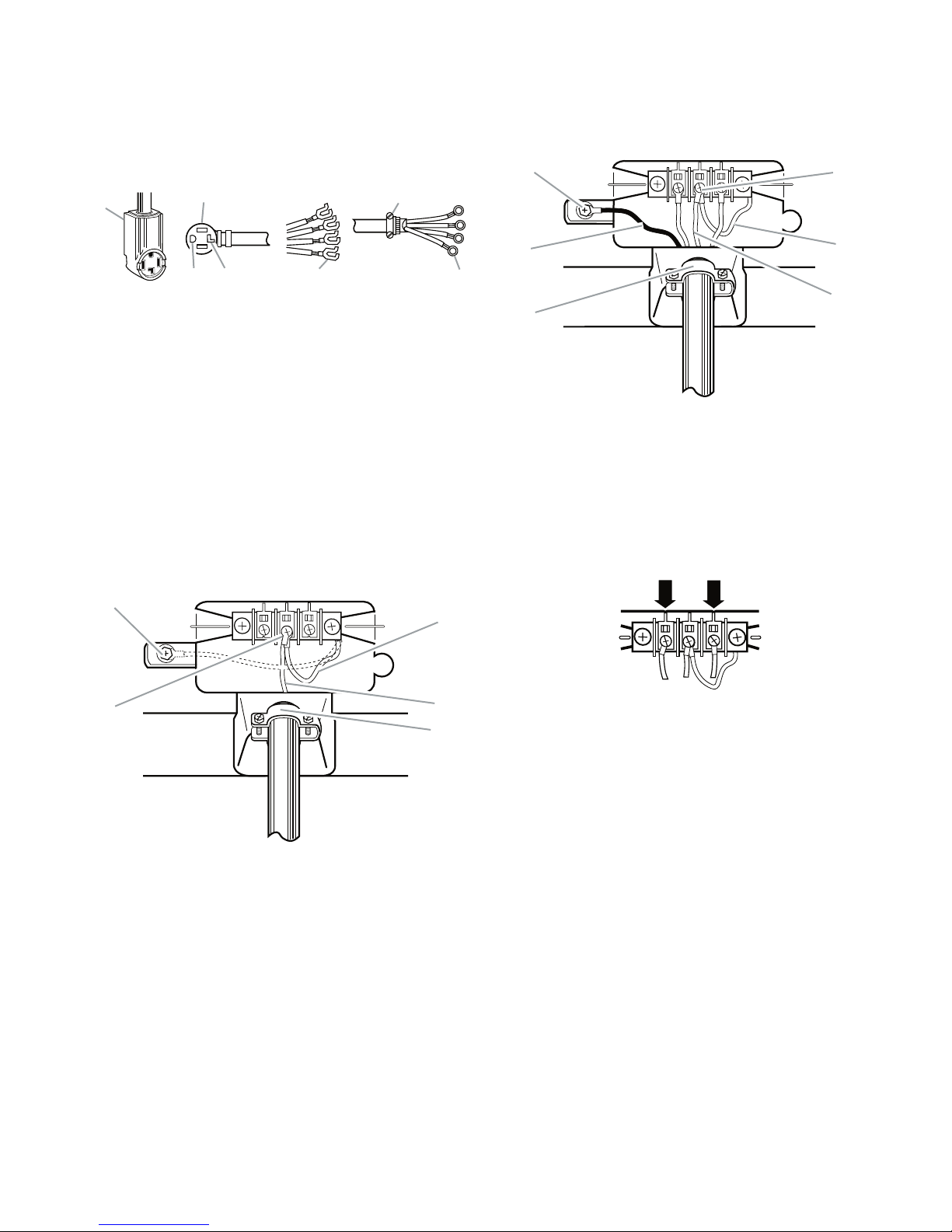

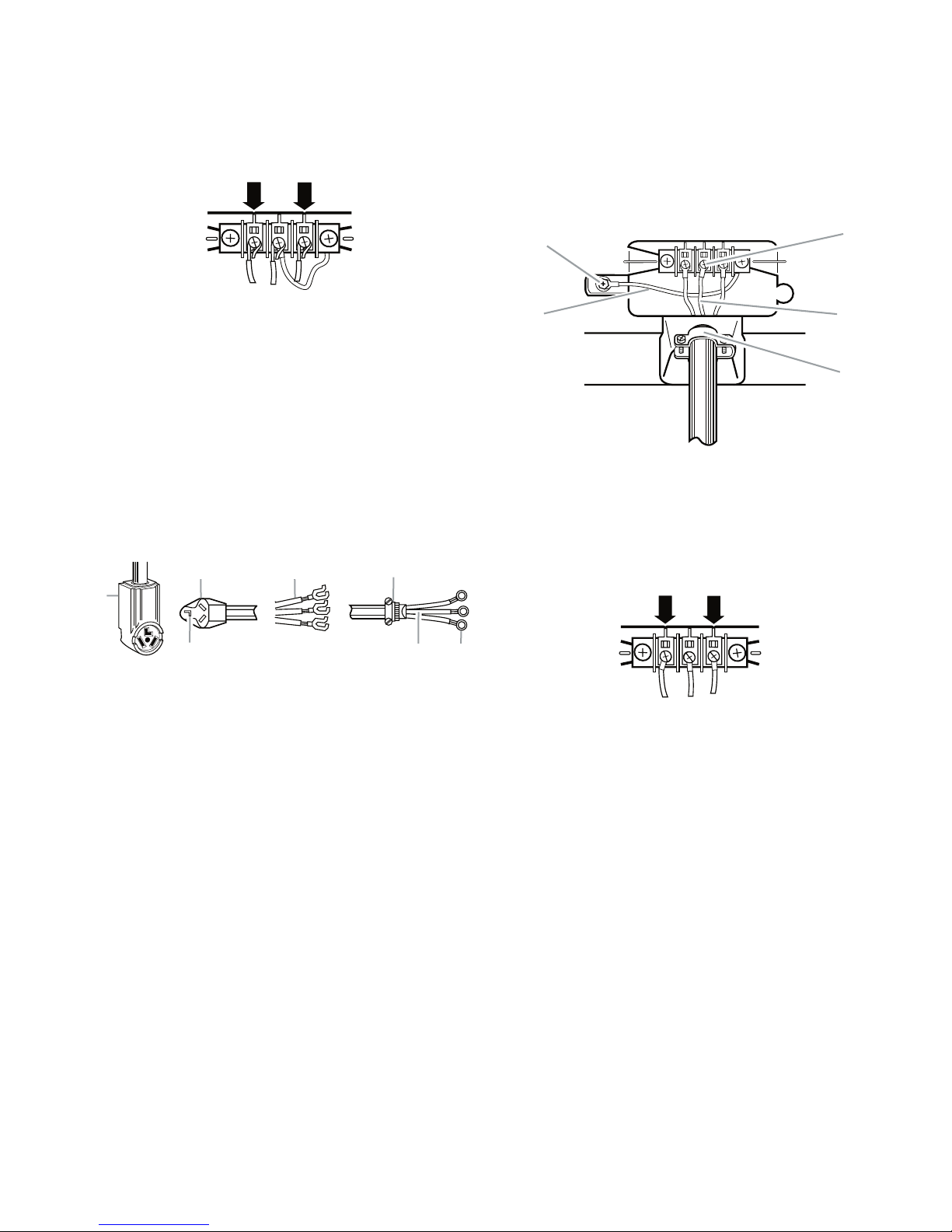

4-wire connection: Power supply cord

A. 4-wire receptacle (NEMA type 14-30R)

B. 4-prong plug

C. Ground prong

D. Neutral pron

g

E. Spade terminals with upturned ends

F. ¾" (1.9 cm) UL listed strain relie

f

G. Ring terminals

A

B F

E

G

D

C

A. External ground conductor screw - Dotted line shows

position

of NEUTRAL ground wire before being moved to

center

silver-colored terminal block screw

B. Center silver-colored terminal block screw

C. Neutral ground wire

D. Neutral wire (white or center wire)

E.

¾" (1.9 cm) UL listed strain relief

A

C

B

D

E

A. External ground conductor screw

B. Ground

wire (green or bare) of power supply cord

C.

³⁄

4

" (1.9 cm) UL listed strain relief

D. Center silver-colored terminal block scre

w

E. Neutral ground wire

F. Neutral wire (white or

center wire)

A

B

C

D

E

F

IMPORTANT: A 4-wire connection is required

for mobile homes and where local codes do

not permit the use of 3-wire connections.

1. Remove center silver-colored terminal

block screw.

2. Remove neutral ground wire from external

ground conductor screw. Connect neutral

ground wire and the neutral wire (white or

center wire) of power supply cord under

center, silver-colored terminal block screw.

Tighten screw.

3. Connect ground wire (green or bare) of

power supply cord to external ground con

ductor screw. Tighten screw.

4. Connect the other wires to outer terminal

block screws. Tighten screws.

-

5. Tighten strain relief screws.

6. Insert tab of terminal block cover into slot

of dryer rear panel. Secure cover with

hold-down screw.

7. You have completed your electrical con

nection. Now go to “Venting Require

-

-

ments.”

2-9

4-wire connection: Direct wire

A. External ground conductor screw - Dotted line shows

position of NEUTRAL ground wire before being moved

to center silver-colored terminal block scre

w

B. Center silver-colored terminal

block screw

C. Neutral ground wire

D. Neutral wire (white or

center wire)

E. ¾"

(1.9 cm) UL listed strain relief

A

C

B

D

E

A. External ground conductor screw

B. Ground wire (green or

bare) of power supply cable

C.

¾" (1.9 cm) UL listed strain relief

D. Center silver-colored terminal block scre

w

E. Neutral ground wire

F. Neutral wire (white or center

wire)

A

B

C

D

E

F

IMPORTANT: A 4-wire connection is required

for mobile homes and where local codes do

not permit the use of 3-wire connections.

Direct wire cable must have 5 ft (1.52 m) of

extra length so dryer can be moved if need

ed.

Strip 5˝ (12.7 cm) of outer covering from

end of cable, leaving bare ground wire at 5˝

(12.7 cm). Cut 1-1/2

ing wires. Strip insulation back 1

˝ (3.8 cm) from 3 remain-

˝(2.5 cm).

Shape ends of wires into a hook shape.

When connecting to the terminal block, place

the hooked end of the wire under the screw of

the terminal block (hook facing right), squeeze

hooked end together and tighten screw, as

shown.

-

3. Connect ground wire (green or bare) of direct wire cable to external ground conduc

tor screw. Tighten screw.

-

1. Remove center silver-colored terminal

block screw (see top right illustration).

2. Remove neutral ground wire from external ground conductor screw. Connect

neutral ground wire and place the hooked

end (hook facing right) of the neutral wire

(white or center wire) of direct wire cable

under the center screw of the terminal

block. Squeeze hooked ends together.

Tighten screw. (See top right illustration.)

2-10

4. Place the hooked ends of the other direct

A. 3-wire receptacle (NEMA type 10-30R)

B. 3-wire plug

C. Neutral pron

g

D. Spade terminals with up turned ends

E.

³⁄

4

" (1.9 cm) UL listed strain relief

F. Ring terminals

G. Neutral (white or center wire

)

A

B

D

C

E

F

G

A. External ground conductor screw

B. Neutral ground

wire

C. Center silver-colored terminal block scre

w

D. Neutral wire (white or

center wire)

E.

³⁄

4

" (1.9 cm) UL listed strain relief

A

B

C

D

E

wire cable wires under the outer terminal

block screws (hooks facing right). Squeeze

hooked ends together. Tighten screws.

5. Tighten strain relief screw.

6. Insert tab of terminal block cover into slot

of dryer rear panel. Secure cover with

hold-down screw.

7. You have completed your electrical connection. Now go to “Venting Require

ments.”

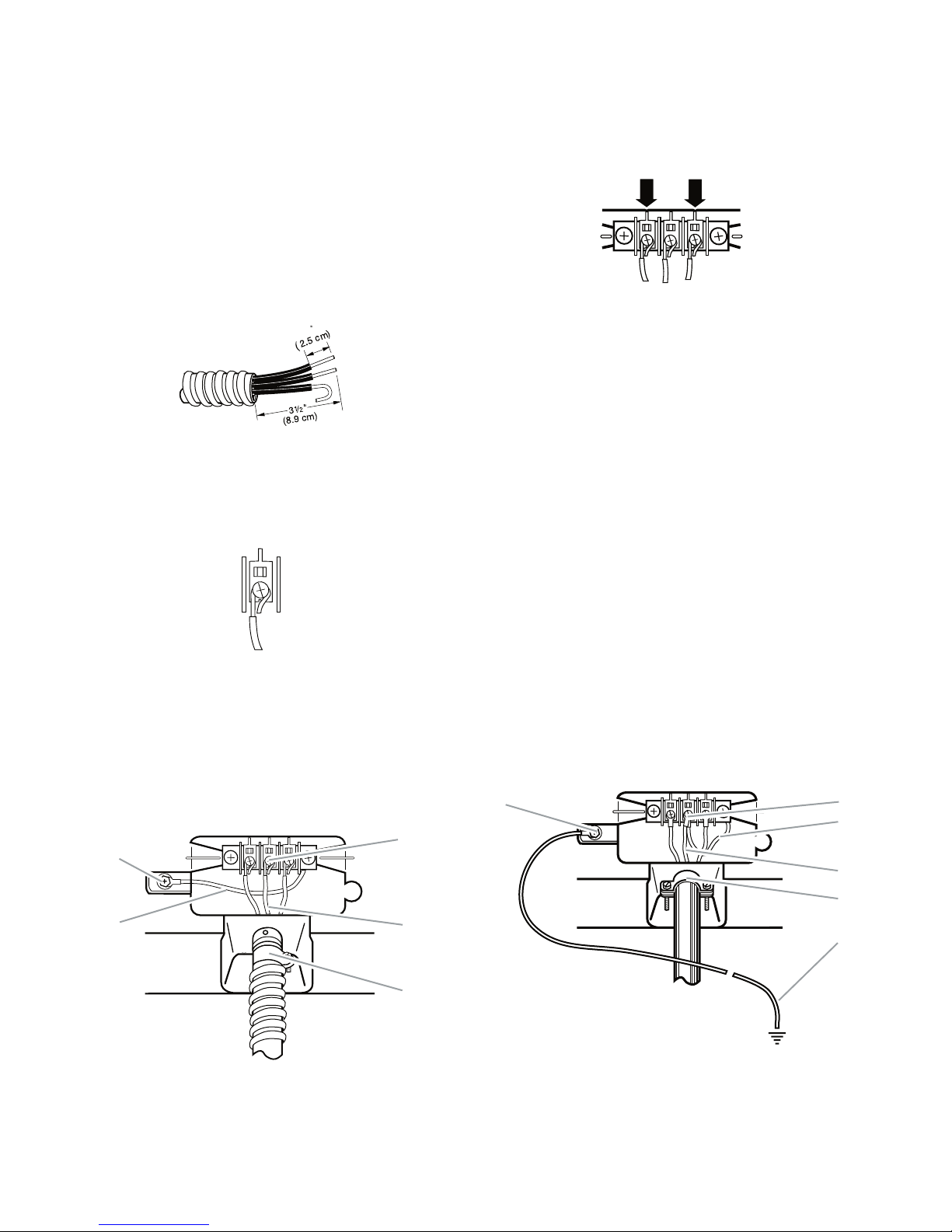

3-wire connection: Power supply cord

Use where local codes permit connecting

cabinet-ground conductor to neutral wire.

1. Loosen or remove center silver-colored

terminal block screw.

2. Connect neutral wire (white or center wire)

of power supply cord to the center, silvercolored terminal screw of the terminal

block. Tighten screw.

-

3. Connect the other wires to outer terminal

block screws. Tighten screws.

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot

of dryer rear panel. Secure cover with

hold-down screw.

6. You have completed your electrical con

nection. Now go to “Venting Require

-

-

ments.”

2-11

3-wire connection: Direct wire

1

A. External ground conductor screw

B. Neutral ground wire

C. Center silver-colored terminal block scre

w

D. Neutral wire (white or center wire

)

E.

³⁄

4

" (1.9 cm) UL listed strain relief

A

B

D

C

E

A. External ground conductor screw

B. Center silver-colored terminal block scre

w

C. Neutral ground wire

D. Neutral wire (white or center wire

)

E.

³⁄

4

" (1.9 cm) UL listed strain relief

F. Grounding path determined

by a qualified electrician

A

B

C

D

F

E

Use where local codes permit connecting

cabinet-ground conductor to neutral wire.

Direct wire cable must have 5 ft (1.52 m) of extra length so dryer can be moved if needed.

3. Place the hooked ends of the other direct

wire cable wires under the outer terminal

block screws (hooks facing right). Squeeze

hooked ends together. Tighten screws.

Strip 3-1/2

˝ (8.9 cm) of outer covering from

end of cable. Strip insulation back 1˝ (2.5 cm).

If using 3-wire cable with ground wire, cut bare

wire even with outer covering. Shape ends of

wires into a hook shape.

When connecting to the terminal block, place

the hooked end of the wire under the screw of

the terminal block (hook facing right), squeeze

hooked end together and tighten screw, as

shown.

1. Loosen or remove center silver-colored

terminal block screw.

2. Place the hooked end of the neutral wire

(white or center wire) of direct wire cable

under the center screw of terminal block

(hook facing right). Squeeze hooked end

together. Tighten screw.

4. Tighten strain relief screw.

5. Insert tab of terminal block cover into slot

of dryer rear panel. Secure cover with

hold-down screw.

6. You have completed your electrical connec

tion. Now go to “Venting Requirements.”

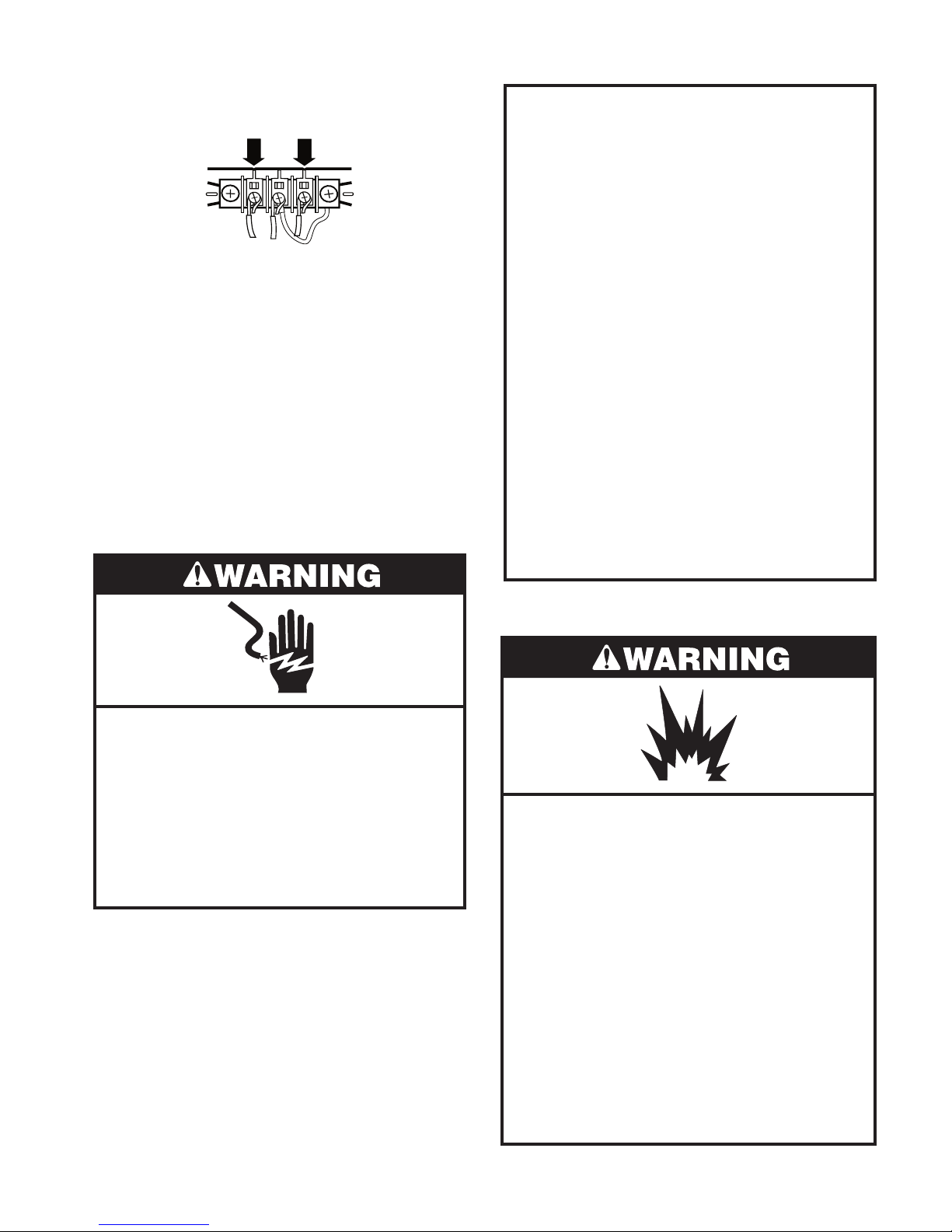

Optional 3-wire connection

Use for direct wire or power supply cord

where local codes do not permit connect

ing cabinet-ground conductor to neutral

wire.

1. Remove center silver-colored terminal

block screw.

2. Remove neutral ground wire from external

ground conductor screw. Connect neutral

ground wire and the neutral wire (white or

center wire) of power supply cord/cable

under center, silver-colored terminal block

screw. Tighten screw.

-

-

2-12

3. Connect the other wires to outer terminal

block screws. Tighten screws.

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot

of dryer rear panel. Secure cover with

hold-down screw.

6. Connect a separate copper ground wire

from the external ground conductor screw

to an adequate ground.

7. You have completed your electrical connection. Now go to “Venting Requirements.”

ELECTRICAL REQUIREMENTS

Gas Models Only

GROUNDING INSTRUCTIONS

• For a grounded, cord-connected dryer:

This dryer must be grounded. In the event

of malfunction or breakdown, grounding will

reduce the risk of electric shock by provid

ing a path of least resistance for electric

current.This dryer is equipped with a cord

having an equipment-grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that

is properly installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the

equipment-grounding conductor can re

sult in a risk of electric shock. Check with a

qualified electrician or service representa

tive or personnel if you are in doubt as to

whether the dryer is properly grounded. Do

not modify the plug provided with the dryer:

if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

-

-

-

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

120 Volt, 60 Hz., AC only, 15- or 20-amp

•

fused electrical supply is required. A timedelay fuse or circuit breaker is recommend

ed. It is also recommended that a separate

circuit serving only this dryer be provided.

GAS SUPPLY REQUIREMENTS

Explosion Hazard

Use a new CSA International approved

gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified

person make sure gas pressure does

-

not exceed 13˝ (33 cm) water column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death,

explosion, or fire.

2-13

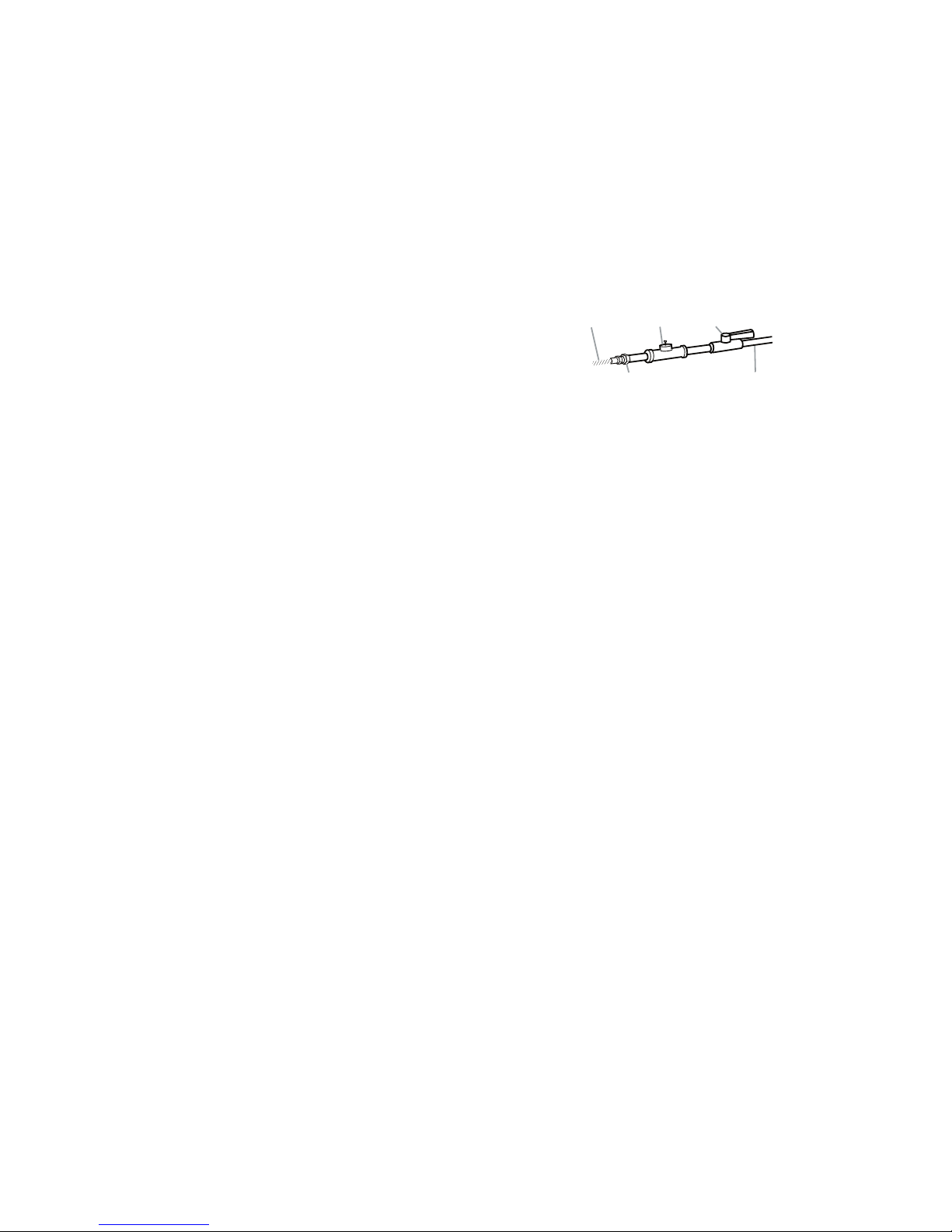

Gas Type

A. ³⁄8

³⁄8

1

⁄8

" flexible gas connector

B. " pipe to flare adapter fittin

g

C. " NPT minimum plugged tappin

g

D.

½" NPT gas supply line

E. Gas shutoff valv

e

A

B

E

D

C

Natural gas:

This dryer is equipped for use with Natural

gas. It is design-certified by CSA International

for LP (propane or butane) gases with appro

priate conversion.

This dryer must have the correct burner for

the type of gas in your home. Burner informa

tion is located on the rating plate in the door

well of your dryer. If this information does not

agree with the type of gas available, contact

your dealer or call the phone numbers refer

enced in the “Assistance or Service” section

of the “Use & Care Guide.”

LP gas conversion:

Conversion must be made by a qualified

technician.

No attempt shall be made to convert the appliance from the gas specified on the model/

serial rating plate for use with a different gas

without consulting the gas company.

Gas supply line

1/2˝ IPS pipe is recommended.

•

3/8˝ approved tubing is acceptable for

•

lengths under 20 ft (6.1 m) if local codes

and gas supplier permit.

Must include 1/8˝ NPT minimum plugged

•

tapping accessible for test gauge connec

tion, immediately upstream of the gas con

nection to the dryer (see illustration in the

right column).

Must include a shutoff valve:

•

In the U.S.A.:

An individual manual shutoff valve must be

installed within six (6) feet (1.8 m) of the

dryer in accordance with the National Fuel

Gas Code, ANSI Z223.1.

In Canada:

An individual manual shutoff valve must be

installed in accordance with the B149.1,

Natural Gas and Propane Installation

-

Code. It is recommended that an individual

manual shutoff valve be installed within six

(6) feet (1.8 m) of the dryer.

-

The location should be easy to reach for

opening and closing.

-

Gas supply connection requirements

For close clearances, a 3/8˝ to 3/8˝ elbow

•

is recommended to avoid kinking of the

gas line.

Use only pipe-joint compound. Do not use

•

TEFLON

†®

tape.

There are many methods by which your gas

dryer can be connected to the gas supply.

Listed here are some guidelines for two differ

ent methods of connection.

Option 1 (Recommended method)

-

-

Flexible stainless steel gas connector:

If local codes permit, use a new flexible

•

stainless steel gas connector (Design Cer

tified by CSA International) to connect the

dryer to the rigid gas supply line. Use an

elbow and a 3/8˝flare x 3/8˝ NPT adapter

fitting between the stainless steel gas con

nector and the dryer gas pipe, as needed

to avoid kinking.

†®

TEFLON is a registered trademark of E.I. Du Pont

De Nemours and Company.

-

-

-

2-14

Option 2 (Alternate method)

A. ½" NPT gas supply line

B.

³⁄

8

" NPT dryer pipe

A

B

*6¼"

(15.9 cm)

1½"

(3.8 cm)

Dryer gas pipe

Approved aluminum or copper tubing:

Lengths under 20 ft (6.1 m) can use 3/8˝

•

approved tubing (if codes and gas supplier

permit).

If you are using Natural gas, do not use

•

copper tubing.

3/8˝ flare x 3/8˝ NPT adapter fitting be-

•

tween dryer pipe and 3/8

˝ approved tub-

ing.

Lengths over 20 ft (6.1 m) should use larger

•

tubing and a different size adapter fitting.

•

If the dryer has been converted to use LP

gas, 3/8

˝ LP compatible copper tubing can

be used. If the total length of the supply

line is more than 20 ft (6.1 m), use larger

tubing.

NOTE: Pipe-joint compounds that resist

the action of LP gas must be used. Do not

use TEFLON

†®

TEFLON is a registered trademark of E.I. Du Pont

De Nemours and Company.

®†

tape.

The gas pipe that comes out through the

•

rear of your dryer has a 3/8

˝ male pipe

thread.

*NOTE: If the dryer is mounted on a pedestal,

the gas pipe height must be an additional 10

(25.4 cm) or 15.5

˝ (39.4 cm) from the floor,

˝

depending on the pedestal model. For a ga

rage installation, the gas pipe height must be

an additional 18˝ (46 cm) from the floor.

VENTING REQUIREMENTS

-

Burner input requirements

Elevations up to 10,000 ft (3,048 m):

The design of this dryer is certified by

•

CSA International for use at altitudes up

to 10,000 ft (3,048 m) above sea level at

the Btu rating indicated on the model/serial

number plate. Burner input adjustments

are not required when the dryer is oper

ated up to this elevation.

Elevations above 10,000 ft (3,048 m):

When installed above 10,000 ft (3,048 m)

•

a 4% reduction of the burner Btu rating

shown on the model/serial number plate is

required for each 1,000 ft (305 m) increase

in elevation.

Gas supply pressure testing

The dryer must be disconnected from the

•

gas supply piping system during pressure

testing at pressures greater than 1/2 psi.

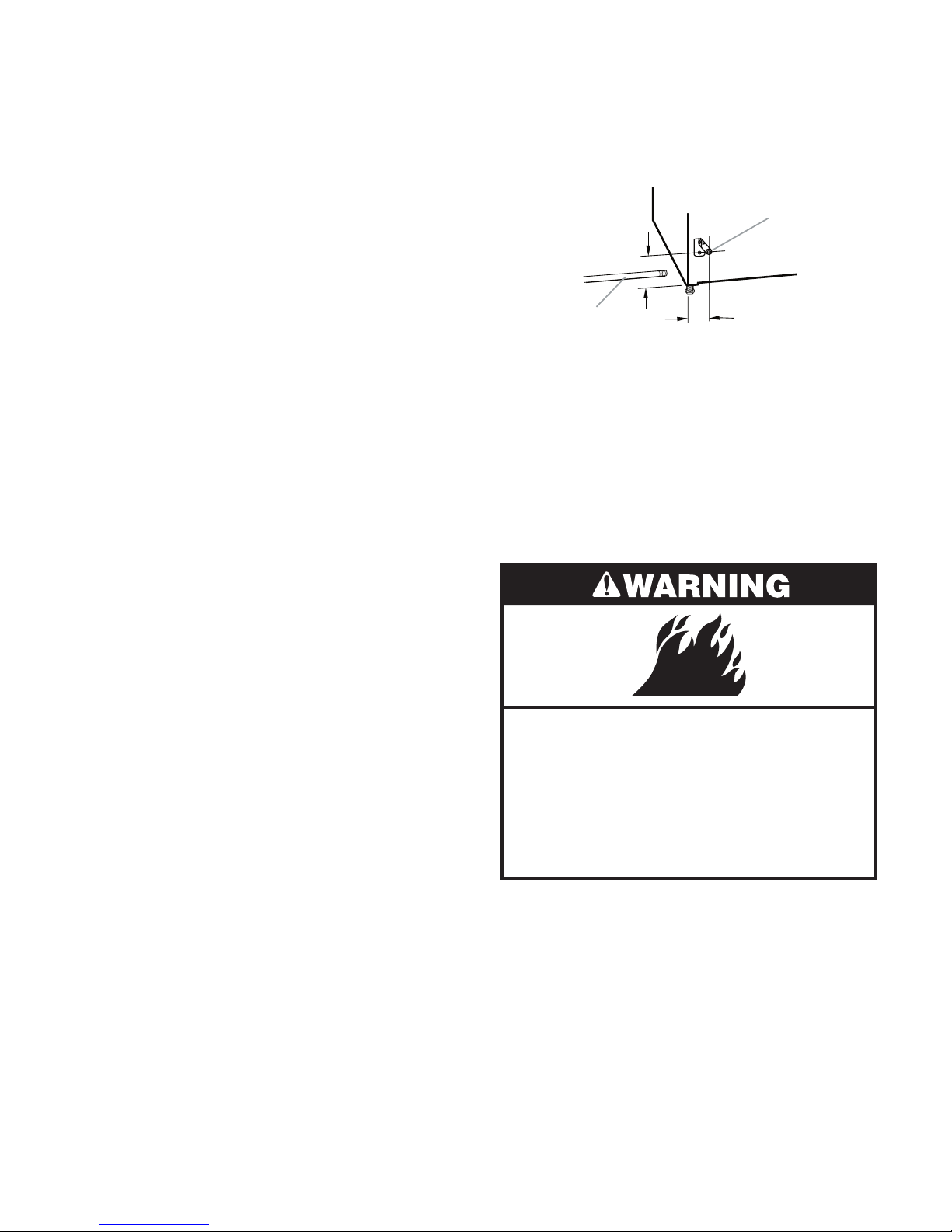

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

-

Do not use a metal foil vent.

Failure to follow these instructions can

result in death or fire.

WARNING: To reduce the risk of fire, this dry-

er MUST BE EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes

and ordinances.

The dryer exhaust must not be connected into

any gas vent, chimney, wall, ceiling, or a con

cealed space of a building.

-

2-15

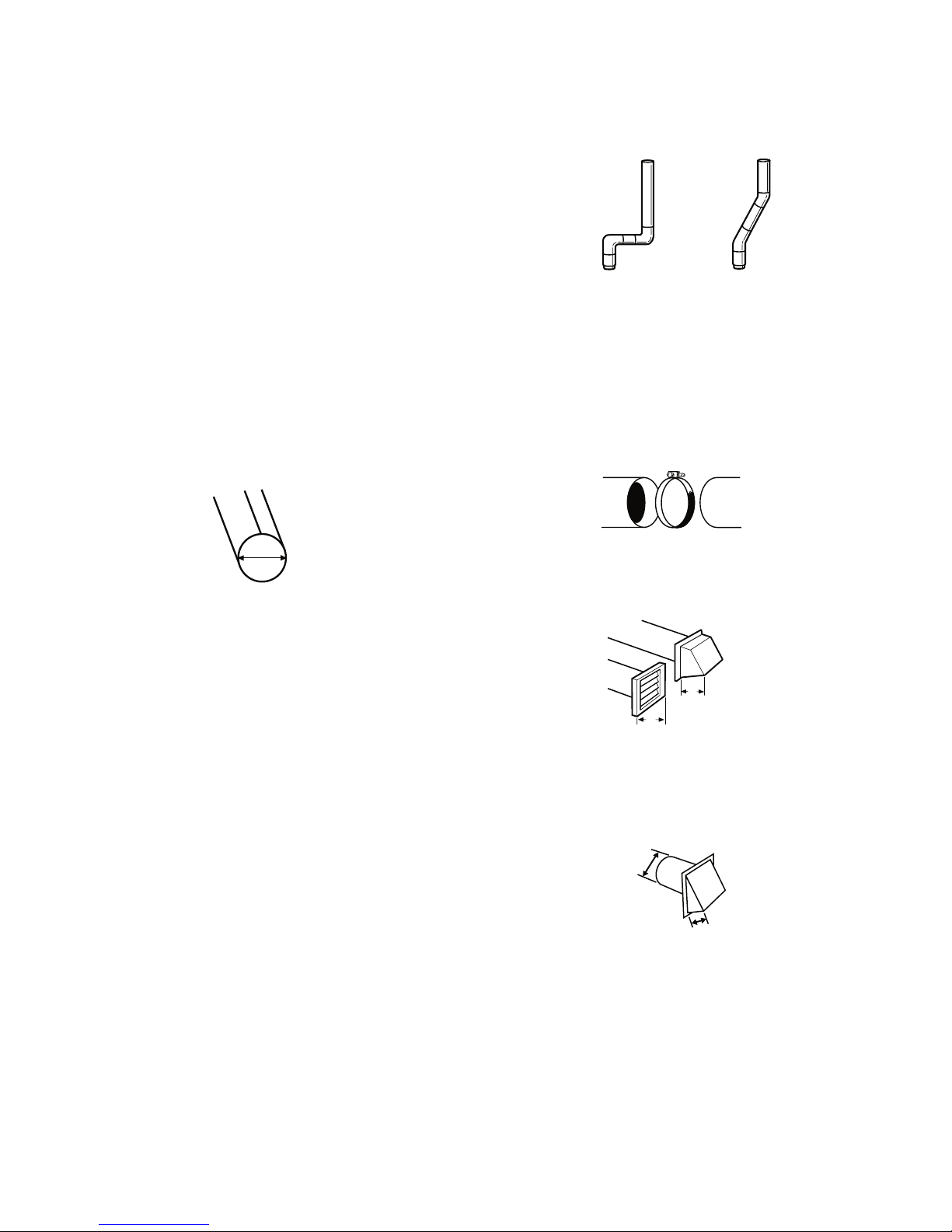

If using an existing vent system

4" (10.2 cm) heavy metal exhaust vent

4"

10.2 cm

Good Better

Clamp

A. Louvered hood style

B. Box hood styl

e

4"

(10.2 cm)

4"

(10.2 cm)

B

A

4"

(10.2 cm)

2½"

(6.4 cm)

Clean lint from the entire length of the sys-

•

tem and make sure exhaust hood is not

plugged with lint.

Replace any plastic or metal foil vent with

•

rigid or flexible heavy metal vent.

Review Vent system chart. Modify existing

•

vent system if necessary to achieve the

best drying performance.

Elbows

45° elbows provide better airflow than 90° elbows

If this is a new vent system

Vent Material

Use a heavy metal vent. Do not use plastic

•

or metal foil vent.

4˝ (10.2 cm) heavy metal exhaust vent

•

and clamps must be used. DURASAFE

venting products are recommended.

™

DURASAFE

vent products can be purchased from your dealer or by calling

Whirlpool Parts and Accessories.

Rigid metal vent

For best drying performance, rigid metal

•

vents are recommended.

Clamps

Use clamps to seal all joints.

•

Exhaust vent must not be connected or se-

•

cured with screws or other fastening devic

-

es that extend into the interior of the duct.

™

Do not use duct tape.

Exhaust

Recommended hood styles are shown here.

Rigid metal vent is recommended to pre-

•

vent crushing and kinking.

Flexible metal vent

Flexible metal vents are acceptable only if

•

accessible for cleaning.

Flexible metal vent must be fully extended

•

and supported when the dryer is in its final

position.

Remove excess flexible metal vent to avoid

•

sagging and kinking that may result in re

duced airflow and poor performance.

Do not install flexible metal vent in enclosed

•

walls, ceilings or floors.

The angled hood style (shown here) is ac

ceptable.

An exhaust hood should cap the vent to

•

prevent rodents and insects from entering

-

the home.

Exhaust hood must be at least 12˝ (30.5 cm)

•

from the ground or any object that may be

in the path of the exhaust (such as flowers,

rocks or bushes, snow line, etc.).

2-16

-

A. Dryer

B. Elbo

w

C. Wall

D. Exhaust hood

E. Clamps

F. Rigid metal or flexible metal ven

t

G. Vent length necessary to connect elbows

H. Exhaust outle

t

H

G

F

E

D

C

A

B

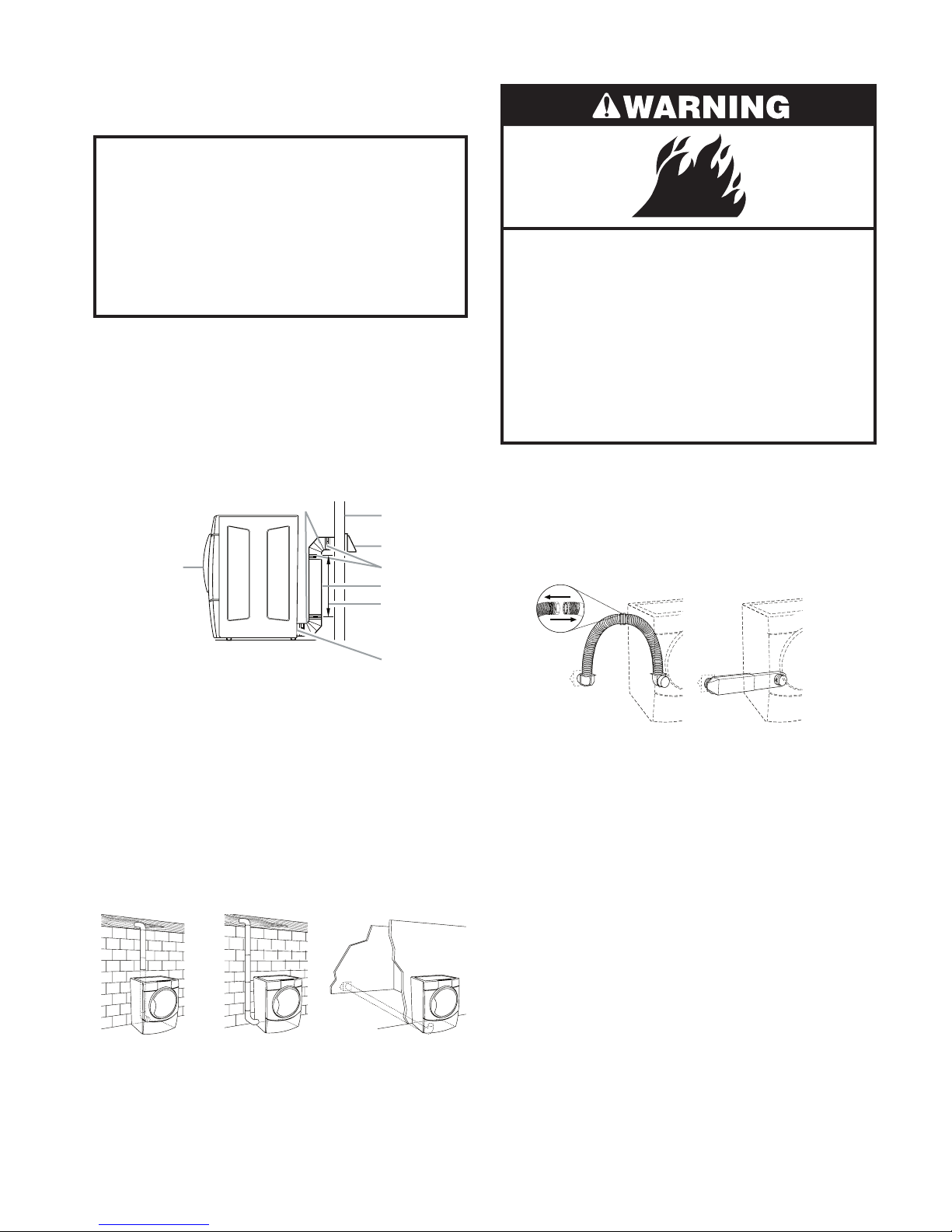

A. Standard rear offset exhaust installation

B. Left or right side exhaust installation

C. Bottom exhaust installation (not an option

with pedestal installations)

A

B

C

Do not use an exhaust hood with a mag-

A. Over-The-Top installation (also available with one

offset elbow)

B. Periscope installatio

n

A B

•

netic latch.

Improper venting can cause moisture

and lint to collect indoors, which may

result in:

Moisture damage to woodwork, furni-

•

ture, paint, wallpaper, carpets, etc.

Housecleaning problems and health

•

problems.

PLAN VENT SYSTEM

Choose your exhaust installation type

Recommended exhaust installations

Typical installations vent the dryer from the

rear of the dryer. Other installations are pos

sible.

Fire Hazard

Cover unused exhaust holes with the

following kit:

279818 (white)

Contact your local dealer.

Failure to follow these instructions can

result in death, fire, electrical shock, or

serious injury.

-

Alternate installations for close clearances

Venting systems come in many varieties. Se

lect the type best for your installation. Two

close-clearance installations are shown. Re

fer to the manufacturer’s instructions.

-

-

Optional exhaust installations

This dryer can be converted to exhaust out

the right side, left side, or through the bottom.

Contact your local dealer to have the dryer

converted.

2-17

Number of

90º turns

or elbows

Type of

vent

Box or

louvered

hood

s

Angled

hood

s

0 Rigid meta

l

Flexible meta

l

64 ft (20 m)

36 ft (11 m)

58 ft (17.7 m)

28 ft (8.5 m)

1 Rigid meta

l

Flexible meta

l

54

ft (16.5 m)

31 ft (9.4 m)

48 ft (14.6 m)

23 ft (7

m)

2 Rigid meta

l

Flexible meta

l

44 ft (13.4 m)

27 ft (8.2 m)

38 ft (11.6 m)

19 ft (5.8 m)

3 Rigid meta

l

Flexible meta

l

35 ft (10.7 m)

25 ft (7.6 m)

29 ft (8.8 m)

17 ft (5.2 m)

4 Rigid meta

l

Flexible meta

l

27 ft (8.2 m)

23 ft (7 m)

21 ft (6.4 m)

15 ft (4.6 m)

NOTE: The following kits for close clearance

alternate installations are available for pur

chase.

Over-the-top Installation:

•

Part Number

Periscope Installation (For use with dryer

•

4396028

vent to wall vent mismatch):

Part Number

4396037 - 0˝ (0 cm) to 18˝

(45.72 cm) mismatch

Part Number 4396011 - 18˝ (45.72 cm) to

29˝ (73.66 cm) mismatch

Part Number 4396014 - 29˝ (73.66 cm) to

50˝ (127 cm) mismatch

Special provisions for mobile home

installations

The exhaust vent must be securely fastened to

a noncombustible portion of the mobile home

structure and must not terminate beneath the

mobile home. Terminate the exhaust vent outside.

NOTE: Do not use vent runs longer than

-

those specified in the Vent system chart.

Exhaust systems longer than those speci

fied will:

Shorten the life of the dryer.

•

Reduce performance, resulting in longer

•

drying times and increased energy us

age.

The Vent system chart provides venting re

quirements that will help to achieve the best

drying performance.

Vent System Chart

NOTE: Side and bottom exhaust installations

have a 90

° turn inside the dryer. To determine

maximum exhaust length, add one 90

the chart.

-

-

-

° turn to

Determine vent path

Select the route that will provide the

•

straightest and most direct path outdoors.

Plan the installation to use the fewest num-

•

ber of elbows and turns.

When using elbows or making turns, allow

•

as much room as possible.

Bend vent gradually to avoid kinking.

•

Use the fewest 90° turns possible.

•

Determine vent length and elbows needed

for best drying performance

Use the following Vent system chart to

•

determine type of vent material and hood

combinations acceptable to use.

INSTALL VENT SYSTEM

1. Install exhaust hood. Use caulking compound to seal exterior wall opening around

exhaust hood.

2. Connect vent to exhaust hood. Vent must

fit inside exhaust hood. Secure vent to ex

haust hood with 4˝ (10.2 cm) clamp.

3. Run vent to dryer location. Use the straightest path possible. See “Determine vent

path.” Avoid 90º turns. Use clamps to seal

all joints. Do not use duct tape, screws or

other fastening devices that extend into

the interior of the vent to secure vent.

2-18

-

INSTALL LEVELING LEGS

A. Flared male fitting

B. Non-flared male fitting

A

B

Excessive Weight Hazard

Use two or more people to move and

install dryer.

Failure to do so can result in back or

other injury.

1. To protect the floor, use a large flat piece

of cardboard from the dryer carton. Place

cardboard under the entire back edge of

the dryer.

2. Firmly grasp the body of the dryer. Gently

lay the dryer on the cardboard. See illus

tration.

For mobile home use

Gas dryers must be securely fastened to the

floor at the time of installation.

Mobile home installations require a Mobile

Home Installation Kit. For more information,

please reference the service numbers in the

“Assistance or Service” section of the “Use &

Care Guide.”

MAKE GAS CONNECTION

1. Remove the red cap from the gas pipe.

-

2. Using a wrench to tighten, connect the gas

supply to the dryer. Use pipe-joint com

pound on the threads of all nonflared male

fittings. If flexible metal tubing is used, be

sure there are no kinks.

-

3. Examine the leveling legs. Find the diamond marking.

NOTE: For LP gas connections, you must use

pipe-joint compound resistant to the action of

®†

tape.

4. Screw the legs into the leg holes by hand.

Use a wrench to finish turning the legs un

til the diamond marking is no longer vis

LP gas. Do not use TEFLON

†®

TEFLON is a registered trademark of E.I. Du Pont

De Nemours and Company.

-

-

ible.

5. Place a carton corner post from dryer

packaging under each of the 2 dryer back

corners. Stand the dryer up. Slide the dry

er on the corner posts until it is close to its

final location. Leave enough room to con

nect the exhaust vent.

2-19

A. Closed valve

B. Open valv

e

A

B

³⁄

8

" flexible gas connector

B.

A.

³⁄

8

" dryer pipe

C.

³⁄

8

" to

³⁄

8

" pipe elbow

D.

³⁄

8

" pipe-to-flare adapter fitting

A

B

C

D

A combination of pipe fittings must be used

to connect the dryer to the existing gas line.

Shown is a recommended connection. Your

connection may be different, according to the

supply line type, size and location.

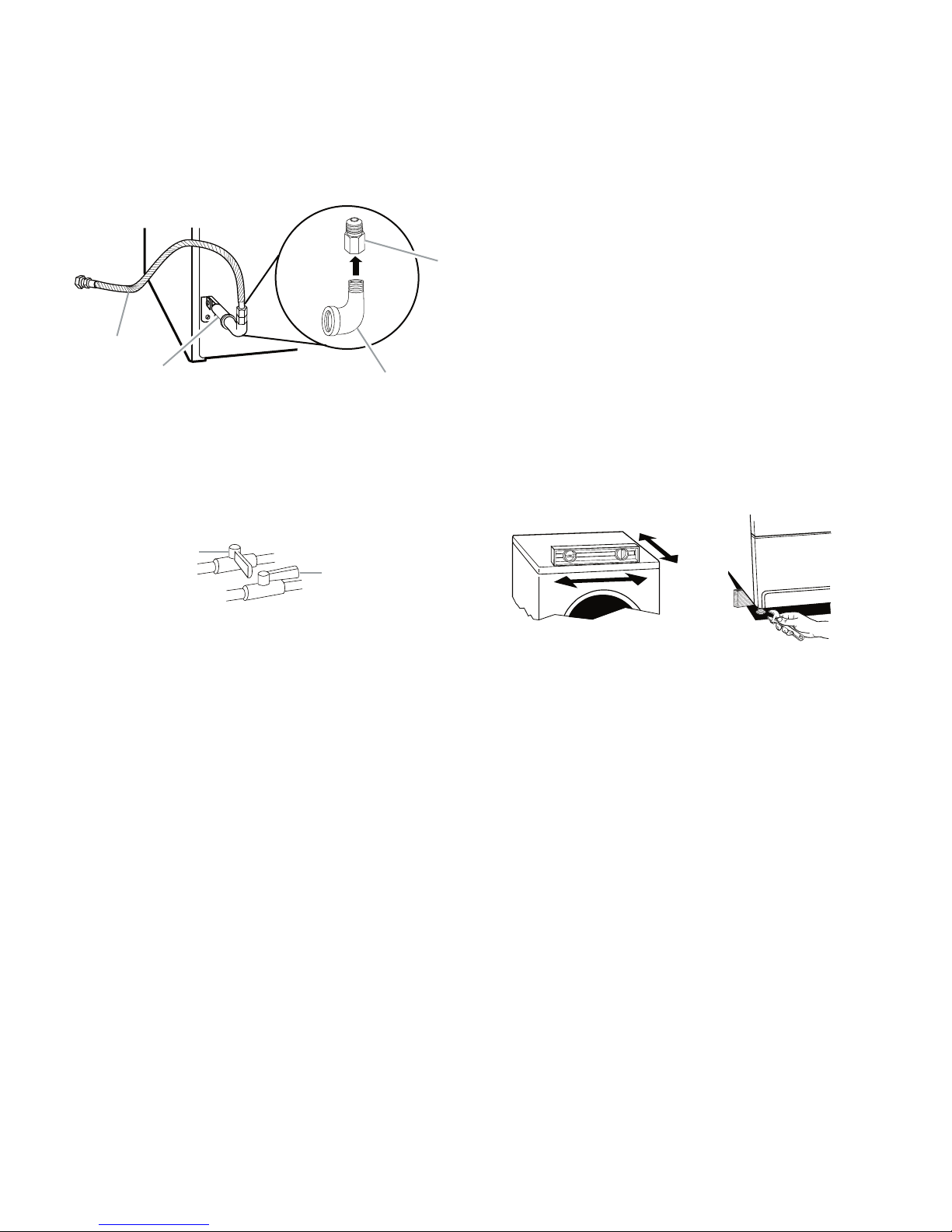

CONNECT VENT

1. Using a 4˝ (10.2 cm) clamp, connect vent

to exhaust outlet in dryer. If connecting to

existing vent, make sure the vent is clean.

The dryer vent must fit over the dryer exhaust outlet and inside the exhaust hood.

Make sure the vent is secured to exhaust

hood with a 4˝ (10.2 cm) clamp.

2. Move dryer into its final position. Do not

crush or kink vent.

3. (On gas models) Check that there are no

kinks in the flexible gas line.

4. Once exhaust vent connection is made,

remove corner posts and cardboard.

LEVEL DRYER

3. Open the shutoff valve in the supply line.

The valve is open when the handle is par

allel to the gas pipe.

4. Test all connections by brushing on an ap

proved noncorrosive leak-detection solu

tion. Bubbles will show a leak. Correct any

leak found.

Check the levelness of the dryer. Check levelness first side to side, then front to back.

-

If the dryer is not level, prop up the dryer using

a wood block. Use a wrench to adjust the legs

up or down and check again for levelness.

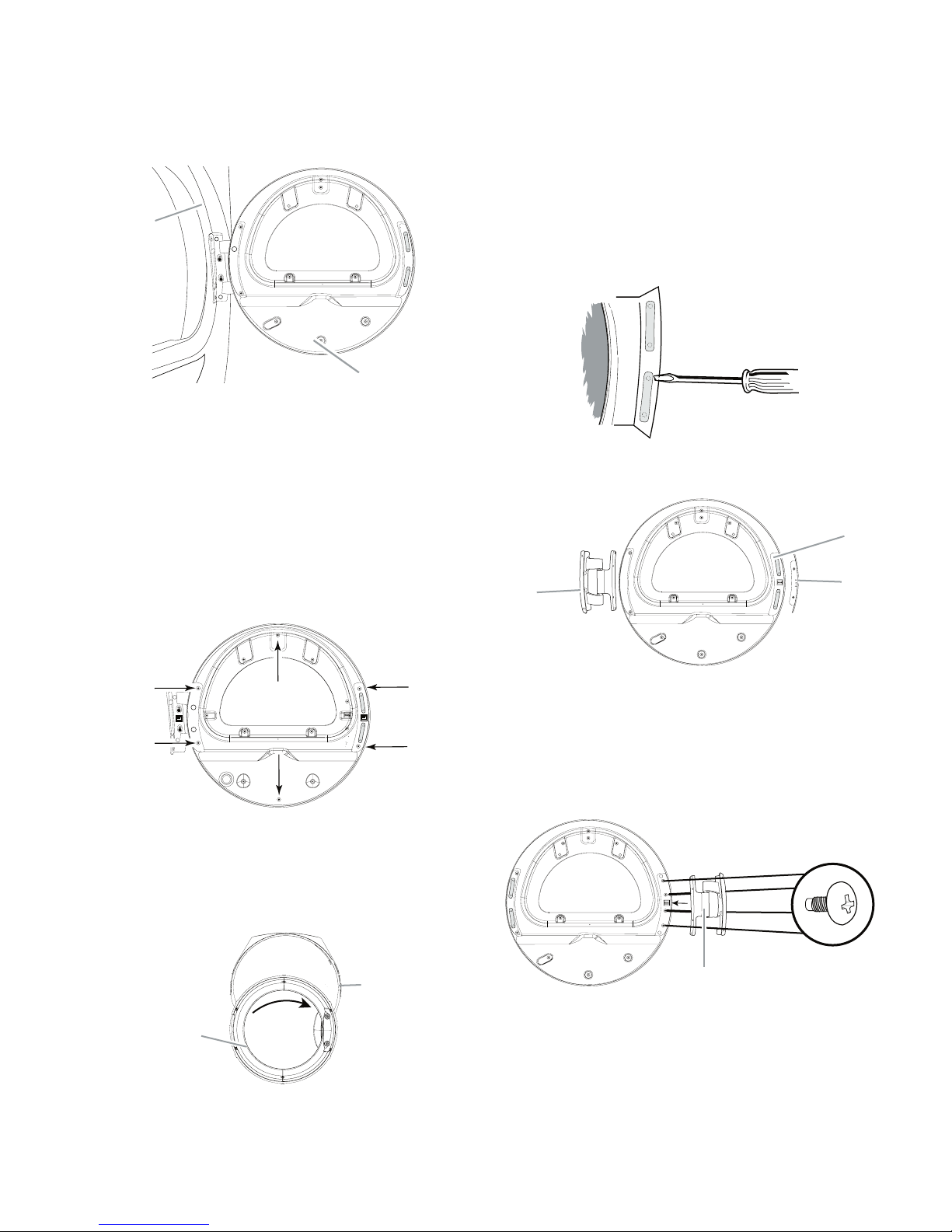

REVERSE DOOR SWING

You can change your door swing from a rightside opening to a left-side opening, if de

sired.

1. Place a towel or soft cloth on top of the

dryer or work space to protect the sur

face.

-

-

2-20

A. Dryer front panel

B. Door assembly

A

B

A. Inner ring

B. Outer rin

g

A

B

Remove the door assembly

A. Door hinge

B. Plug strips

C. Hinge cove

r

A

C

B

A. Door hinge

A

1. Remove the 4 screws that hold the door

hinge on the front panel of the dryer.

2. Lay the door assembly on a flat, protected

surface with the inside (inner door assem

bly) facing up.

3. Remove the 6 Phillips head screws to release the outer door assembly from the

inner door assembly, as indicated below.

See illustration. It is important that you remove only the 6 indicated screws.

6. Turn inner ring 180° and lock tabs into

place.

Reverse hinge

1. Use a small flat-blade screwdriver to remove 2 plug strips from the inner door.

Slide the head of the screwdriver under

the plugs, being certain not to scratch the

inner door surface. Lift up.

-

2. Remove hinge cover.

4. Lift the inner door assembly off the outer

door assembly.

5. Disengage locking tabs by rotating inner

ring clockwise. See illustration.

3. Remove the 4 screws that attach to the in

ner door hinge and move the hinge to the

other side. Reinstall the 4 screws.

2-21

Loading...

Loading...