Whirlpool WA 4740, WA 1402, WA 4520, WA 4330, WA 4730 INSTRUCTION FOR USE

...

QUICK REFERENCE GUIDE GB

BEFORE USING THE APPLIANCE FOR THE FIRST TIME:

• FOLLOW THE “INSTALLATION INSTRUCTIONS

• REMOVE THE TRANSIT BOLTS BEFORE USING THE APPLIANCE.

• First wash cycle without laundry:

Turn on the tap.

1.

Close the appliance door.

2.

Pour a small amount of detergent (about 30 ml) into the detergent dispenser .

3.

Select a short program (see programme chart).

4.

Press the

5.

This initial cycle serves to eliminate any water remaining after your appliance was tested at

the factory.

NORMAL DAILY USE:

Turn on the tap.

1.

Sort the wash according to fabric type and colour and load the appliance.

2.

Close the door.

3.

Put in detergent and any additives required into the dispenser.

4.

Select the programme, the temperature and any special options required.

5.

Press the

6.

“On/Off”

“On/Off”

button.

button.

”.

19

GB CONTENTS

INSTALLATION INSTRUCTIONS

APPLIANCE AND ACCESSORIES

CHILD SAFETY

PROTECTING THE ENVIRONMENT

SAFETY INSTRUCTIONS

TRANSPORT / HANDLING

PREPARING THE WASH

DETERGENT AND ADDITIVES

DYEING AND BLEACHING

PROGRAMME SELECTION / PROGRAMME START

PAGE

PAGE

PAGE

PAGE

PAGE

PAGE

PAGE

PAGE

PAGE

PAGE

21

25

25

26

26

26

27

28

29

29

DOOR LOCK / PROGRAMME END

CHANGING / INTERRUPTING /

CLEARING PROGRAMME

REMOVING THE FILTER

DRAINING RESIDUAL WATER

CARE AND MAINTENANCE

TROUBLESHOOTING GUIDE

AFTER-SALES SERVICE

20

PAGE

PAGE

PAGE

PAGE

PAGE

PAGE

PAGE

30

30

31

32

32

33

34

INSTALLATION INSTRUCTIONS

Never move the appliance by carrying it at the

worktop.

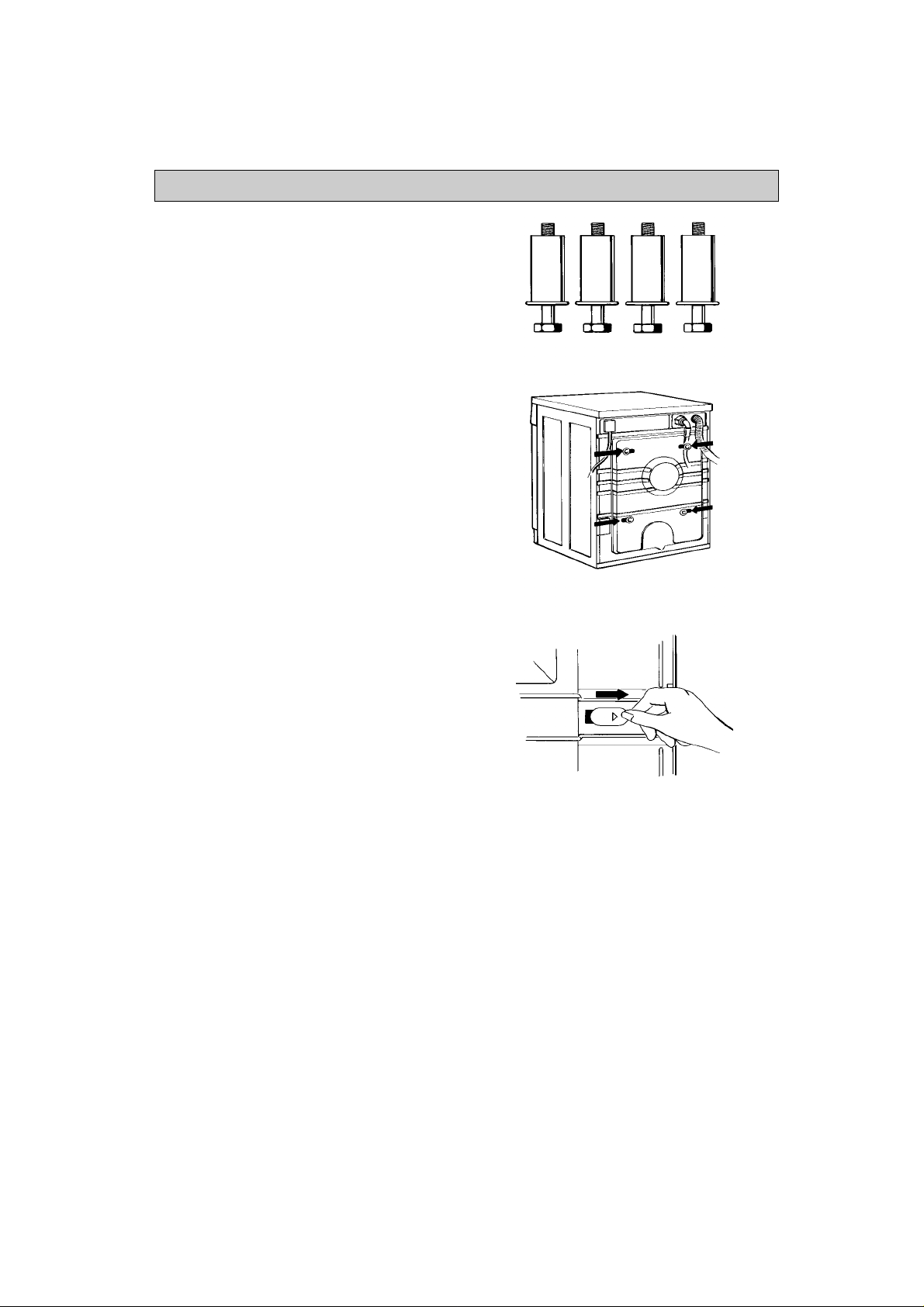

TRANSIT BOLTS

The appliance is fitted with transit bolts to prevent

internal damage during transport.

Before using the machine you must remove

the transit bolts (Fig. 1).

1. Slacken the four bolts with the wren ch

supplied (Fig. 2).

2. Unscrew the bolts by hand.

3. Holding the bolt head, pull each bolt through

the wide part of the holes.

4. Close the holes with the plastic covers supplied;

insert the covers in the wide part of the hole and

slide them toward the narrow part until they click

into place (Fig. 3).

5. Keep the transit bolts for future us e.

Important

Whenever the appliance is transported, the transit

bolts must be refitted.

Pry up the plastic covers with a screwdrive r, slide

them in the opposite direction to the arrow and

remove. Insert the transit bolts, performing the

steps for removal in reverse order.

Fig. 1

Fig. 2

Fig. 3

21

INSTALLATION INSTRUCTIONS

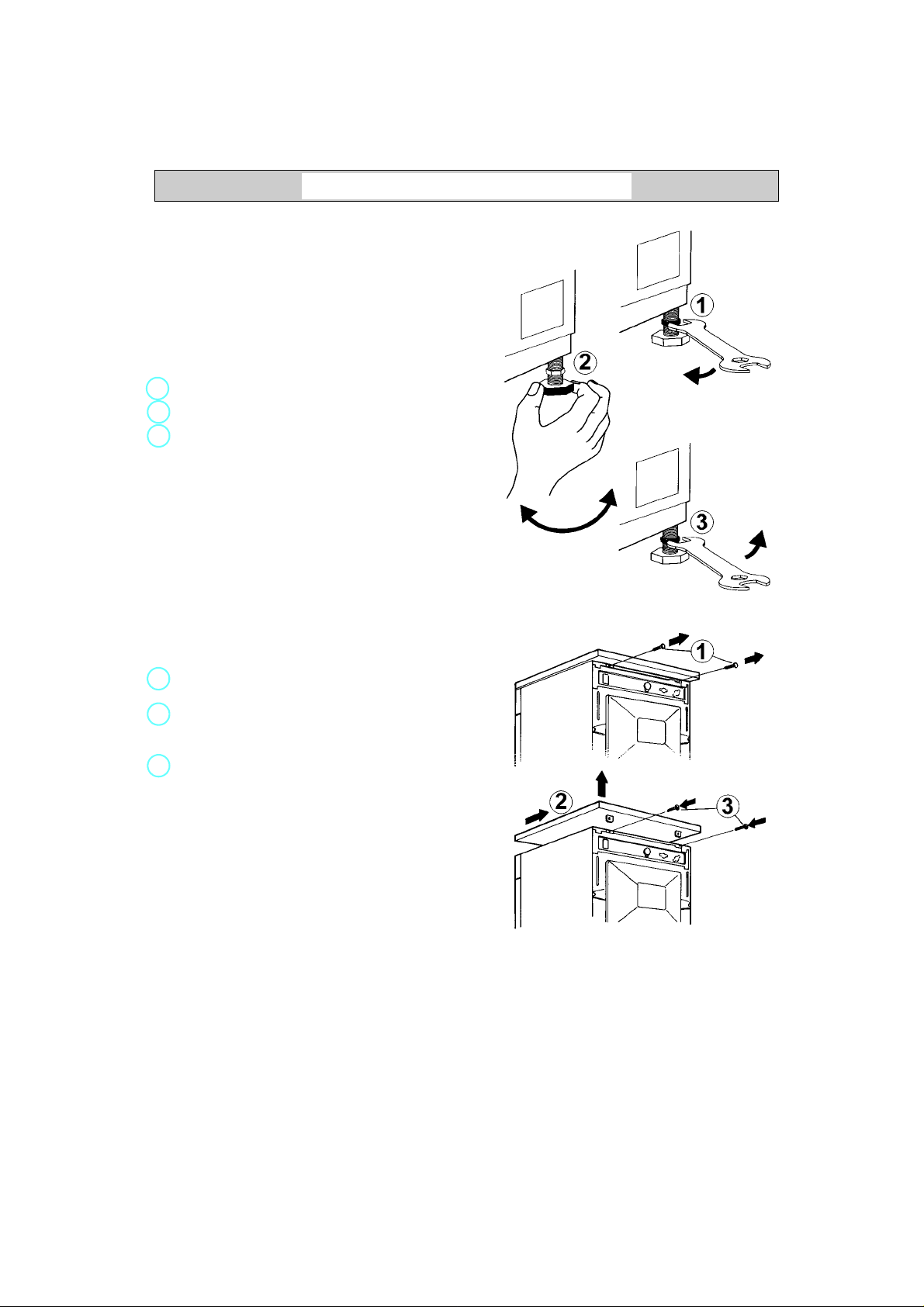

INSTALLATION

•

Install the appliance on a so lid and level floor

surface, preferably in a corner of the room.

•

Make sure that all four feet are stable and resting on

the floor and then check that the appliance is

perfectly level (use a spirit level).

•

If the floor is uneven, adjust the levelling feet as

required (do not insert pieces of wood etc. under the

feet):

1.

Slacken the locknut using the w re nc h s up pli ed .

2.

Adjust the height of the foot, turning it by hand.

3.

Tighten the locknut by turning it anti-clockwi se

towards the appliance casing.

•

If the appliance is to be installed on a wooden floor,

distribute the weight by placing it on a 60 x 60 cm

sheet of plywood at least 3 cm in thickness.

Secure the plywood sheet to the fl oo r.

WORKTOP / COVER PANEL

The appliance must only be installed beneath a

continuous fitted kitchen worktop.

If the appliance will be built under it is mandatory

to use the cover panel UBS. This can be obtained

from specialist shops or from After-Sales Service.

•

Unplug the appliance.

1.

Unscrew the worktop fixing screws from the rear of

the appliance.

2.

Slide the worktop fully backward and lift it upwards

to remove. Install the cover panel following th e

relative instructions.

3.

Refit the fixing screws and t igh te n th em .

BUILD-UNDER OPENING DIMENSIONS

Width 600 mm

Height 825 mm

Depth 600 mm

WARNING:

Only plug the appliance into th e mai ns p owe r so cke t

after you have fitted the cover panel or the appliance

worktop.

22

INSTALLATION INSTRUCTIONS

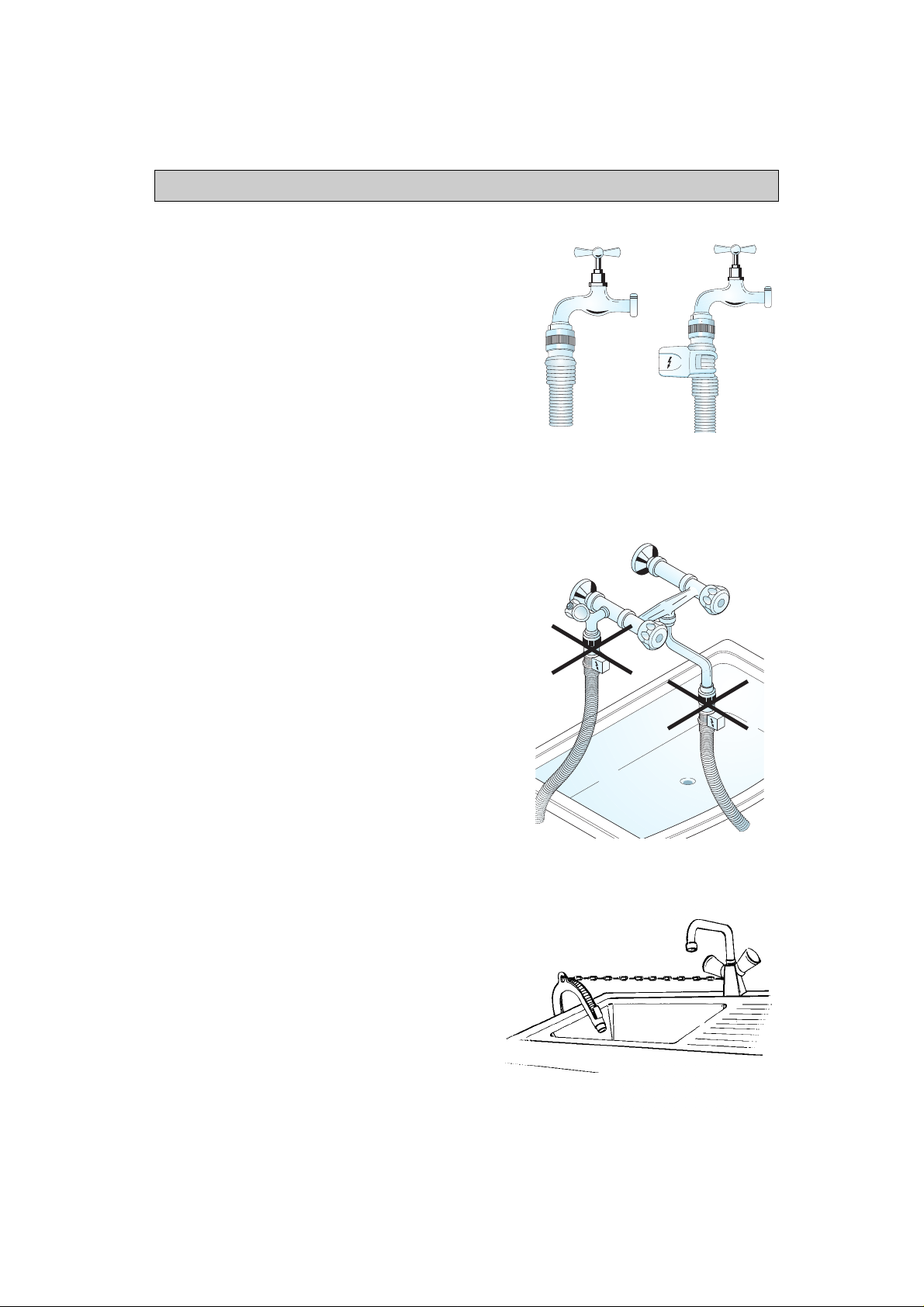

WATER SUPPLY

•

Water supply: cold water only

•

Tap: 3/4” threaded hose connection

•

Pressure: 100-1000 kPa (1-10 bar).

WATER INLET HOSE

1.

The dirt strainer (already premounted on the hose

end or included in the accessories) must be

inserted into the threaded tap coupling.

2.

Carefully screw the hose connect i o n ont o th e ta p

preferably by hand. Make sure there are no kinks in

the hose.

3.

Check water-tightness of tap and appliance

connections by turning the tap completely on.

•

If the hose is too short, repla ce it w i th a s uit ab le

length of pressure resistant ho se (10 00 kPa min,

EN 50084 approved type).

•

Periodically check the hose for brit tl en ess a nd

cracks and replace if necessary.

•

The appliance can be connected without an antibackpressure valve.

•

Install the appliance in accordance wit h regulations

of your local water company.

WATER STOP (depends on model)

•

Screw the threaded connector with the filter in serted

onto the tap. Open the water tap fully and chec k the

water-tightness of the connect io n p oi nt .

•

The appliance must not be connected to the mixing

tap of a non-pressurized water heater.

•

The inlet hose and the plastic enclosure at the tap

connection contain electrical co mp on en ts.

N.B. Do not cut the hose and do not immerse

the plastic enclosure in water.

•

If the flexible hose is damaged, un plug th e

appliance from the mains immediately.

•

If the hose is too short, repla ce it w i th a 3 m Wa te r

Stop hose (available from After-Sales Service or

from your dealer). This operation must be carried

out exclusively by a licensed electrician.

DRAINING

•

Connecting the water drain hose.

Connect the drain hose to the siphon or hook it

over the edge of a sink by means of the “U” bend

(see figure).

The drain hose should not be hooked onto small

washbasins.

Max. drain height: 1.25 m

If you need to add an extension, use a flexible

hose of the same type and secure t he un io n wit h

screw-on hose clips.

Max. drain hose length: 2.50 m

Important:

Make sure there are no kinks in the hose. Secure

the hose so that it cannot f al l dow n w hil e th e

appliance is running.

Straight hose Water Stop hose

23

Loading...

Loading...