Page 1

ENGLISH

21

3

Instructions for use Page 3

1

Page 2

2

Page 3

Contents

Before Using The Washing Machine

Accessories/Supplied Parts

Installation

Precautions and General Recommendations

Description Of The Washing Machine

Door

Child Safety

Before The First Wash Cycle

Preparing The Wash

Detergent And Additives

Removing The Filter

Draining Residual Water

Care And Maintenance

Troubleshooting Guide

After-Sales Service

Transport/Handling

Electrical connection

3

Page 4

Before Using The Washing Machine

1. Remove the packaging

and check

•

After unpacking, make sure

that the washing machine is

undamaged. If in doubt, do

not use the washing machine.

Contact After-Sales Service or

your local retailer

•

Check that the accessories

and supplied parts are all

present

•

Keep the packing material

(plastic bags, polystyrene

parts, etc.) out of reach of

children, as they are

potentially dangerous

2. Remove the transport

bolts

•

The washing machine is fitted

with a transport bolts to

avoid any possible damage to

the interior during transport.

Before using the washing

machine, it is imperative that

the transport bolts are

removed

3. Install the washing

machine

•

Remove the protective foil

from the control panel

•

Move the appliance without

lifting it by the worktop

•

Install the appliance on a

solid and level floor surface,

preferably in a corner of the

room

•

Make sure that all four feet

are resting firmly on the floor

and check that the appliance

is perfectly level (use a spirit

level)

4. Water inlet

•

Connect the water supply

inlet hose in accordance with

regulations of your local

water company

•

Water inlet: Cold water only

•

Tap: 3/4 threaded

•

Water

pressure

(flow

pressure):

hose

connection

100-1000 kPa

(1-10 bar)

5. Drain hose

•

Connect the drain hose to the

siphon or hook it over the

edge of a sink by means of the

“U” bend supplied

•

If the washing machine is

connected to a built-in

pumping out system, ensure

that the latter is equipped

with a vent to avoid

simultaneous loading and

draining of water (siphoning

effect)

6. Electrical connections

•

Electrical connections must be

carried out by a qualified

technician in compliance with

the manufacturer's

instructions and local safety

regulations

•

Data concerning voltage,

consumption and fuses are

located on the inside of the

appliance door

•

The appliance must be

connected to the mains

exclusively by means of a

socket with an earth

connection in accordance with

established regulations. The

washing machine must be

earthed by law. The

manufacturer declines all

liability for damage to

property or injury to persons or

animals due to noncompliance with the directions

given above

•

Do not use extension leads or

multi sockets

•

Before any maintenance on

the washing machine

disconnect it from the mains

supply

•

Access to the mains plug or to

disconnection from mains

supply via a double-pole switch

must be ensured at all times

following the installation

•

Do not operate the washing

machine if it has been

damaged during transport.

Inform the After-Sales Service

•

Mains cable replacement is

only to be carried out by

After-Sales Service

•

The washing machine must

only be used in the household

for the prescribed uses

Minimum housing

dimensions:

Width: 600 mm

Height: 825 mm

Depth: 600 mm

4

Page 5

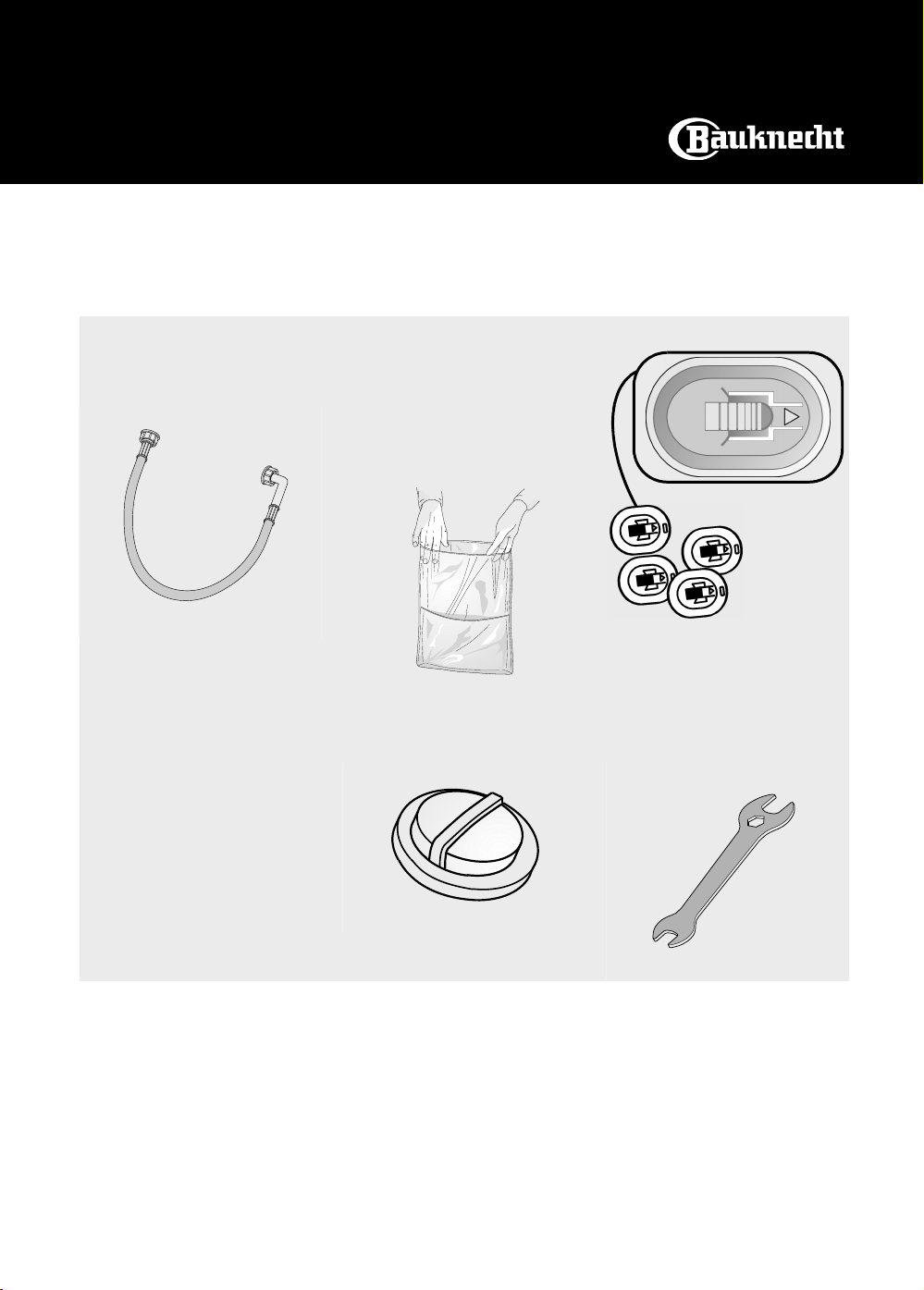

Accessories/Supplied Parts

Fastened on the rear of

the appliance:

Water inlet hose

Plastic bag containing:

Instructions for use

Quick reference guide with

programme summary

(Information and tips for

daily use)

Mesh filter for inlet hose

(if not premounted)

Four plastic caps

Spanner

5

Page 6

Installation

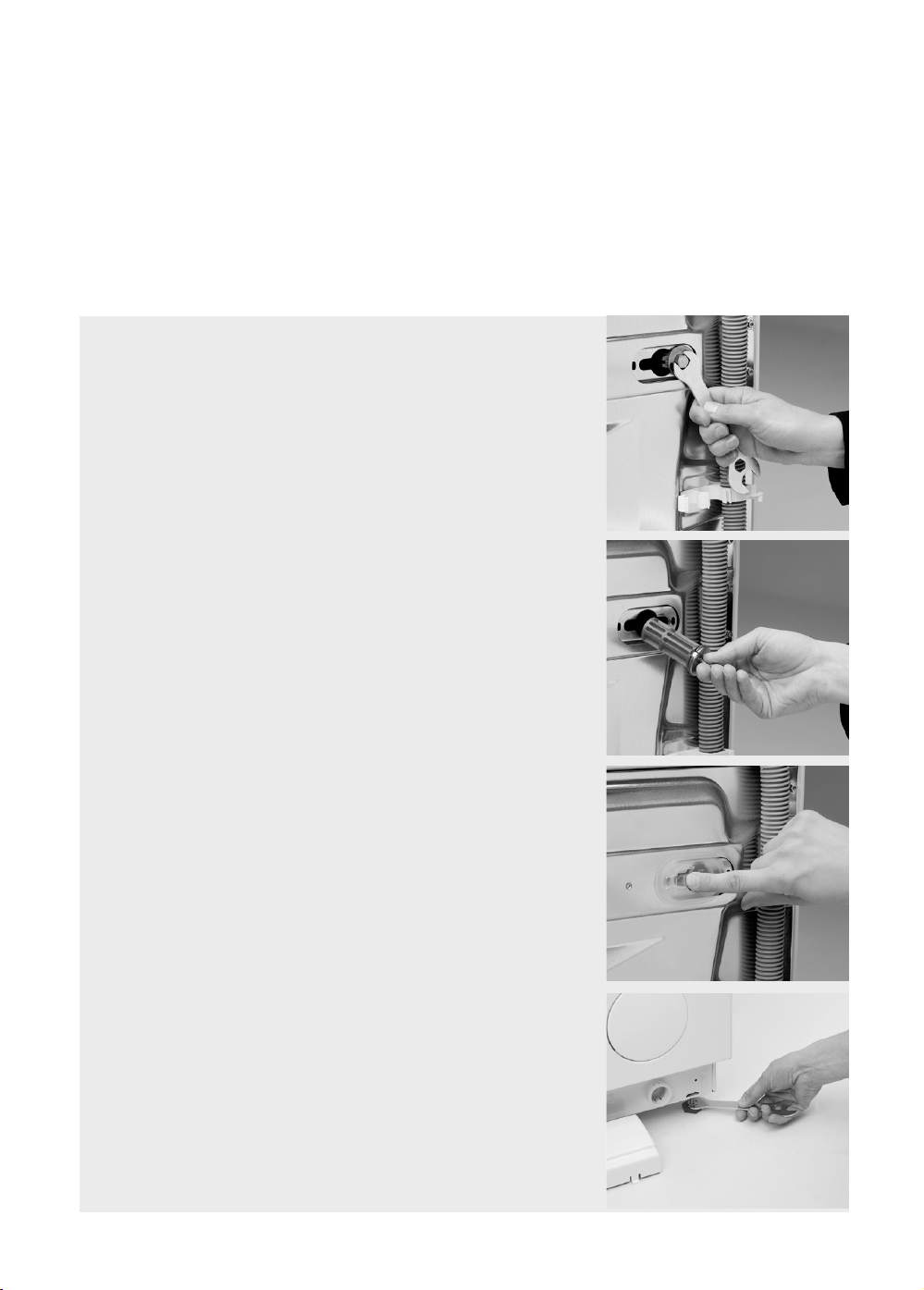

Remove the transport bolts

1.

Slacken the four bolts with

the spanner supplied.

2.

Remove by hand.

3.

Grip the bolt and remove it

through the large aperture.

4.

Seal the resulting holes

using the plastic caps

supplied; insert the covers in

the wide part of the hole

and slide them toward the

narrow part until they click

into place.

5.

Retain transit bolts.

Secure the washing

machine before

transporting it:

1.

Pry off the plastic covers

with a screwdriver, slide

them in the opposite

direction of the arrow and

remove.

2.

Refit the transit bolts in

reverse order.

Adjusting the feet

Small unevennesses in the floor

can be compensated for by

screwing the four appliance feet

up or down (never use pieces of

wood, cardboard or similar

material):

1.

Loosen the locknut using the

wrench provided.

2.

Adjust the height of the foot

by hand.

3.

Tighten the locknut

anticlockwise towards the

washing machine.

If the appliance is to be installed

on a wooden floor, place it on a

sheet of plywood at least

60x60 cm in size and 3 cm thick.

Secure the plywood sheet to the

floor.

6

Page 7

Worktop for built-under

models

The appliance

installed beneath a continuous

worktop.

The appliance

built under using the

intermediate cover panel of the

UBS base set. This can be

obtained from specialist dealers

or After-Sales Service.

must only

may only

be

be

1.

Pull out the power plug.

2.

Remove the worktop fixing

screws on the rear of the

appliance.

3.

Slide the worktop fully

backwards, lift it up and

remove it.

Install the base set following

the relevant instructions.

4.

Refit the fixing screws and

tighten them.

5.

Connect the appliance to the

electricity.

Connect the water inlet

hose

For models with straight

hose:

1.

Insert the mesh filter

(already premounted on the

hose end or included in the

accessories) into the

threaded tap coupling.

2.

Carefully screw the water inlet

hose connection onto the tap

by hand.

3.

Make sure there are no kinks

in the drain hose.

4.

Turn the tap on fully and

check that the joints at the

washing machine and the tap

are watertight.

Connect the water drain

hose

1.

Connect the drain hose to

the siphon or hook it over

the edge of a sink by means

of the “U” bend supplied.

2.

Make sure there are no kinks

in the drain hose.

3.

Secure the hose so that it

cannot fall down while the

appliance is running.

If the hose is too short, replace

it with a suitable length of

pressure resistant hose (1000

kPa min, EN 50084 approved

type).

Check the hose regularly for

brittleness and cracks and

replace if necessary.

The washing machine can be

connected without a nonreturn valve.

For models with Water

Stop hose:

1.

Screw the threaded

connection with the mesh

filter onto the tap.

2.

Turn the tap on fully and

check that the tap joint is

watertight.

Small hand basins are not

suitable.

To make an extension, use a

hose of the same type. Secure

the connections with clips.

Max. Overall drain hose length:

2.50 m

Maximum drain height: 1.25 m

If the flexible hose is too short,

replace it with a 3 m Water Stop

hose (available from After-Sales

Service or from your dealer).

This replacement is only to

carried out by a trained

electrician.

The appliance

connected to the mixing tap of

an un-pressurized water

heater.

Depending on the design, the

inlet hose and the plastic

enclosure at the tap connection

contain electrical components.

Do not cut the hose and do

not immerse the plastic

enclosure in water.

Isolate the appliance from the

mains immediately if the hose is

damaged.

must not

be

Depending on the

model, the drain hose

can be:

A.

installed in the upper part of

the washing machine. In this

case the hose can be undone

from both fastenings.

B.

Installed in the lower part of

the washing machine.

Important:

In this case never undo the

hose from the right-hand

fastening, otherwise the

appliance could overflow

when operating.

7

Page 8

Precautions and General Recommendations

1.Packaging

•

The packaging is 100%

recyclable and is marked with

the recycling symbol.

Adhere to current local

regulations when disposing of

packaging material

2.Disposing of packaging

and old washing

machines

•

The washing machine is built

from reusable materials. It

must be disposed of in

compliance with current local

waste disposal regulations

•

Before scrapping, remove all

detergent residues and cut off

the power cable so that the

washing machine is made

unusable

3.General

recommendations

•

Do not leave the washing

machine connected when not

in use

•

Turn off the tap

•

Before any cleaning and

maintenance switch off the

machine or disconnect it from

the mains

•

Clean the outside of the

washing machine with a damp

cloth. Do not use abrasive

detergents

•

Never open the door forcibly

or use it as a step

•

Children must not be allowed

to play with the washing

machine or to climb into the

drum (see also the following

page chapter “Child Safety”)

•

If necessary, the power cable

may be replaced with an

identical one obtained from

our After-Sales Service. The

power cable must only be

replaced by a qualified

technician

4.EC Declaration of

Conformity

This appliance complies with

the EC Directives:

-

73/23/EEC Low Voltage

Directive

-

89/336/EEC EMC Directive

-

93/68/EEC CE Marking

Directive

8

Page 9

Description Of The Washing Machine

1.

Worktop

2.

Control panel

3.

Detergent dispenser

4.

After-Service sticker

(inside door)

5.

Door

6.

Child safety (inside door)

7.

Filter (inside compartment

door)

8.

Plinth

9.

Adjustable feet.

3

8

9

Door

1.

Pull the handle to open the

double glass door. Close the

door with light force, it will

lock home audibly.

2.

To open the single glass door

hold the door handle, press

the inside handle and pull the

door up. Close the door with

light force, it will lock home

audibly.

1

1

2

4

5

6

7

2

Child Safety

To secure the appliance against

improper use turn the plastic

screw on the interior of the

door. To do this, use the thick

rounded corner of the coloured

insert from the detergent

dispenser or a coin:

•

Slot vertical: the door will

not lock

•

Slot horizontal: the door can

be locked again

9

Page 10

Before The First Wash Cycle

To remove any residual water

used in testing by the

manufacturer, we recommend

that you carry out a short wash

cycle without laundry.

1.

Turn on the tap.

2.

Close the door.

Preparing The Wash

1. Sort the laundry according

to...

• Type of fabric / care label

symbol

Cottons, mixed fibres, easy

care/synthetics, wool,

handwashed items

• Colours

Separate coloured and white

items. Wash new coloured

articles separately

• Size

Laundry items of different

sizes distribute themselves

better in the drum and

optimise the washing and

spinning action

• Delicates

Wash small items (e.g. nylon

stockings, belts etc.) and items

with hooks (e.g. bras) in a

washbag or pillow case with a

zip fastener. Always remove

curtain glides or wash curtains

with the glides inside a cotton

bag

2. Empty all pockets

Coins, safety pins etc. can

damage the laundry, drum

and tub.

3. Closures

Close zips and hooks and

eyes; Tie loose belts or straps

together.

3.

Pour a little detergent

(about 30 ml) into the

detergent compartment

.

4.

Select and start a short

programme (see quick

reference guide).

Stain removal

•

Blood, milk, eggs etc. are

generally removed by the

automatic enzyme phase of

the programme

•

To remove red wine, coffee,

tea, grass and fruit stains etc.

add a stain remover to the

detergent dispenser

chamber

•

Pre-treat heavily-soiled areas

with stain remover if

necessary

Dyeing

•

Only use dyes that are suitable

for washing machines

•

Follow the manufacturer's

instructions.

•

Plastic and rubber parts of the

washing machine can be

stained by dyes

Loading the laundry

1.

Open the door.

2.

Unfold the laundry and place

it loosely in the drum.

Observe the load sizes given

in the Quick Reference Guide.

Note:

overloading the

machine will result in

unsatisfactory washing results

and creased laundry.

3.

Close the door.

10

Page 11

Detergent And Additives

The choice of detergent

depends on:

•

type of fabric (cottons, easy

care/synthetics, delicate items,

wool).

Note: Use only specific

detergents for washing wool

•

colour

•

the wash temperature

•

degree and type of soiling

Remarks:

Whitish residues on dark fabrics

are caused by insoluble

compounds used in modern

phosphate-free powder

detergents. If this occurs, shake

or brush out the fabric or use

liquid detergents.

Use only detergents and

additives specifically produced

for domestic washing machines.

When using descaling agents,

dyes or bleaches for the prewash, make sure that they are

suitable for use in domestic

washing machines. Descaler

could contain components which

can attack parts of your washing

machine

Do not use any solvents (e.g.

turpentine, benzine). Do not

wash fabrics in the machine

which have been treated with

solvents or flammable liquids.

Dosage

Follow the dosage

recommendations on the

detergent pack. They depend on:

•

degree and type of soiling

•

size of wash

full load follow the detergent

manufacturer's instructions;

half load: 3/4 the amount used

for a full load;

Minimum load (about 1 kg):

1/2 the amount used for a full

load

•

water hardness in your area

(request information from the

water company). Soft water

requires less detergent than

hard water (refer to water

hardness table)

Notes:

Too much detergent can result in

excess foam formation.

The cleaning effect deteriorates.

If the washing machine detects

too much foam, it may prevent

spinning.

Insufficient detergent may result

in grey laundry in time and also

calcifies the heating system,

drum and hoses.

A

Water Hardness Chart

Water hardness CHARACTERISTICS GERMAN

1

2

3

4

You can set the water hardness level of your household supply (1 to 4) by means of the coloured “pointer”

(A) in the detergent dispenser. To do this, move the slider on the bottom of the dispenser to the desired

position.

soft

medium

hard

very hard

°dH

0-7

7-14

14-21

over 21

FRENCH

°fH

0-12

12-25

25-37

over 37

ENGLISH

°eH

0-9

9-17

17-26

over 26

11

Page 12

Filling the detergents and additives

1.

Pull out the detergent dispenser to its full extent.

2.

Fill the detergent:

•

Programme with pre and main wash

•

Main wash programme without prewash

When using liquid detergent, remove the coloured

insert from the detergent container and fit it in the

chamber.

The graduate scale on the insert makes dosing easier

•

Fabric softener (no more than to the “MAX” mark)

•

Stain remover

•

Water softener (water hardness 4)

•

Starch (dissolved in water)

3.

Slide the drawer in until it clicks shut.

Chamber

Notes:

•

Keep detergents and additives in a safe, dry place out of the reach of children

•

You can use liquid detergent in the “Prewash” phase for programmes with this option.

In this case put only powder detergents in the compartment for the main wash

•

When using concentrated fabric softeners, add water in the detergent dispenser up to “MAX” level

mark

•

To prevent dispensing problems when using highly concentrated powder and liquid detergents, use

the special detergent ball or bag supplied with the detergent and place it inside the drum

12

Page 13

Removing The Filter

We recommend that you check

and clean the filter regularly, at

least two or three times a year.

Especially:

•

When the appliance does

not drain or spin properly

•

If the pump is blocked by a

foreign body (e.g. buttons,

coins or safety pins)

IMPORTANT: make sure

the water has had time to

cool before draining the

appliance.

1.

Switch off the appliance and

unplug it.

2.

Open the filter cover. Open

the filter cover with the help

of the coloured insert from

the detergent container.

3.

Place a container beneath it.

4.

Open the filter but do not

withdraw it completely.

Slowly turn the handle

anticlockwise until the

water drains out.

5.

Wait until all the water has

drained off.

6.

Now unscrew the filter

completely and remove it.

7.

Clean the filter and the

filter chamber.

8.

Check that the pump rotor

moves freely.

9.

Insert the filter with the

guide pin upwards and

screw it in clockwise to the

stop (handle horizontal).

10.

Pour about 1 litre of water

into the detergent drawer

to reactivate the Eco

system. Check that the

foreign body trap is seated

properly and tightly in

place.

11.

Fold the cover up and lock

it.

12.

Reinsert the plug in the

socket.

13.

Select a programme and

start it.

Draining Residual Water

Before emptying the

residual water, switch the

appliance off and unplug it

from the mains socket.

Open the cover to the

foreign body trap. Open the

filter cover with the help of

the coloured insert from the

detergent container. Place a

container beneath it.

1.

Open the filter but do not

withdraw it completely.

Slowly turn the handle

anticlockwise until the water

drains out.

2.

Wait until all the water has

drained off.

3.

Now unscrew the filter

completely and remove it.

4.

5.

6.

Before using the washing

machine again:

1.

2.

Tilt the appliance forwards

carefully to allow the water

to flow out.

Insert the filter with the

guide pin upwards and

screw it in clockwise to the

stop (handle horizontal).

Fold the cover up and lock it.

Pour approx. 1 litre of water

into the detergent drawer to

reactivate the Eco system.

Reinsert the plug in the

socket.

13

Page 14

Care And Maintenance

Appliance exterior and

control panel

•

Can be washed down with a

soft, damp cloth

•

A little neutral cleaner (not

abrasive) can be used

•

Dry with a soft cloth

Detergent dispenser

Mesh Filters in the

Water Connection

Check and clean regularly.

For washing machines with a

straight inlet hose

1.

Turn off the tap and

unscrew the water inlet hose

from the tap.

2.

Clean the internal mesh

filter and screw the water

inlet hose back onto the tap.

3.

Now unscrew the inlet hose

on the rear of the washing

machine.

4.

Pull off the mesh filter from

the washing machine

connection with universal

pliers and clean it.

5.

Refit the mesh filter and

screw the inlet hose on

again.

6.

Turn on the tap and ensure

that the connections are

completely water-tight.

Door seal

•

Clean with a damp cloth when

necessary

•

Check the seal folds for foreign

bodies periodically

1.

Press the release lever in the

prewash compartment

downward and remove the

drawer.

2.

Remove the inserts (the

siphon from the softener

compartment and the

coloured insert for liquid

detergent).

3.

Wash all the parts under

running water.

4.

Replace the parts and refit

the detergent dispenser.

Insert the detergent

dispenser in the washing

machine.

For washing machines with

Water Stop hose

1.

Turn off the tap and

unscrew the Water Stop

hose from the tap.

2.

Clean the internal mesh

filter and screw the water

inlet hose back onto the tap.

3.

Turn on the tap and ensure

that the connection is

completely water-tight.

Filter

•

We recommend that you check

and clean the filter regularly,

at least two or three times a

year see “Removing The

Filter”)

14

Page 15

Troubleshooting Guide

(Valid for all models except “LCD Intelligent Dialogue

WAL....”)

•

Depending on the model, your

washing machine is equipped

with various automatic safety

functions. This enables faults to

be detected in good time and the

safety system can react

appropriately. These faults are

frequently so minor that they can

be removed within a few

minutes.

The appliance will not start,

no lamp lights up.

Check whether:

•

the mains plug is inserted into

the socket

•

the wall socket is functioning

correctly (use a table lamp or

similar) to tes

the washing machine will

not start...

to model)...

(varies according

and the “Start/

Pause” light flashes

Check whether:

•

the appliance door is properly

closed (child safety)

•

the “Start/Pause” button has

been pressed

...and the “Start/Pause” light

goes on

display a dash appears here)

Check whether:

•

(for models with a digital

.

a programme has been

selected

...and the “On/Off” lamp

goes on.

Check whether:

•

the appliance door is properly

closed (child safety)

the tap is turned on (see also

“Fault in the water supply/

safety hose”)

•

a programme has been

selected

The washing machine stops

during the programme

(varies depending on model)

Check whether:

•

the “Rinse Hold” light flashes,

or the “Rinse Hold” button has

been pressed; terminate this

special option by pressing the

button

•

another programme has been

selected and the “Start/Pause”

button is flashing. Reselect the

desired programme and press

the “Start/Pause” button

•

the door has been opened and

the “Start/Pause” light is

flashing. Close the door and

press the “Start/Pause” button

again

•

the “On/Off” button has been

pressed and the light is on

•

the washing machine safety

system has been activated (see

“Fault Indicators” table)

.

Detergent and additive

product residues in

dispenser at end of wash.

Check whether:

•

the siphon is correctly installed

and clean (see “Care And

Maintenance”)

•

sufficient water is entering.

The mesh filters in the water

connection could be blocked

(see “Care And Maintenance”)

•

when using powder detergent

beforehand the coloured

insert for dosing liquid

detergent has been removed

from the dispenser

The washing machine

vibrates during the spin

cycle.

Check whether:

•

the washing machine is level

and standing firmly on all four

feet

•

the transport bolts have been

removed. Before using the

washing machine, it is

imperative that the transport

bolts are removed

Final spin results are poor.

The washing machine has an

unbalance detection and

correction system. If individual

heavy items are loaded (e.g. a

bathmat or bathrobe), this

system may reduce the spin

speed automatically or even

interrupt the spin completely if it

detects too great an imbalance

even after several spin starts, in

order to protect the washing

machine.

•

If the laundry is still too wet at

the end of the cycle, add

smaller articles of laundry and

repeat the spin cycle

•

Excessive foam formation may

prevent spinning. Observe

correct detergent dosages

•

Check whether spin speed “0”

was selected

15

Page 16

Fault display table

Luminous display

“Water tap” flash “H” and “F”“Fault in water supply”

-flash“P” and “F”“Draining fault”

-flashfrom “F4” to “F16”“Fault in an electrical component”

“Water Stop” flash “A” and “F”“Water Stop fault”

Spin

speed

lights

Digital display

(if fitted)

Fault description

Fault in the water supply

a.

The appliance has no or

insufficient water supply.

For models with a fault display,

“Tap Off”

the

display lights up

and the spin speed indication

LED flashes. If a digital display is

fitted, “H

” and “F” are also

displayed alternately.

For models with no fault display,

the washing machine stops in the

appropriate programme step.

Switch the appliance off and pull

out the mains plug.

Check whether:

•

the water tap is fully turned

on, and the water supply

pressure is sufficient

•

the water inlet hose is kinked

•

the water connection mesh

filters are blocked (see “Care

And Maintenance”/”Mesh

Filters in the Water

Connection”)

•

the water supply hose is

frozen up

•

the washing machine has a

safety hose and the safety

valve is open (red indicator in

the safety valve inspection

window); In this case replace it

with a new safety hose

Reconnect the appliance to the

electrical socket.

For models with a fault display,

reselect the desired programme

and start it.

For models without a fault

display continue the programme

by pressing the “On/Off” button

again.

If the fault occurs again, please

contact After-Sales Service (see

“After-Sales Service”).

Draining fault

b.

Waste water not pumped out.

For models with a fault display,

the spin speed indication LEDs

flash. If a digital display is fitted,

“P

” and “F” are also displayed

alternately.

For models with no fault display,

the washing machine stops in the

appropriate programme step.

Switch the appliance off and pull

out the mains plug.

Check whether:

•

the drain hose is kinked

•

the pump or the filter is

blocked (see “Removing The

Filter”)

IMPORTANT:

before

draining, make sure that the

water has cooled down.

•

The water in the drain hose is

frozen up

Reconnect the appliance to the

electrical socket.

For models with fault display,

select and start the “Drain/

Cancel” programme.

To rinse the laundry, we then

recommend a short programme

without the addition of

detergent.

For models without a fault

display continue the programme

by pressing the

“On/Off” button again.

If the fault occurs again, please

contact After-Sales Service (see

“After-Sales Service”).

Fault in an electrical

c.

component

The appliance stops in the middle

of a programme.

For models with a fault display,

the spin speed indicator LEDs

flash. If a digital display is fitted,

“F4

” to “F16” are also displayed.

Switch the washing machine off.

First of all select and start the

“Drain/Cancel” programme.

Then select and start the desired

programme again.

For models with no fault display,

the washing machine stops in the

appropriate programme step.

First switch the washing machine

off and on again to continue

with the programme.

If the fault persists, please

contact After-Sales Service (see

“After-Sales Service”).

“Water Stop” fault

d.

(if

fitted)

The “Water Stop” fault may have

been triggered by:

1.

excess foaming

2.

a leak in the washing machine.

In this case the pump is switched

on automatically in order to

pump the water out.

For models with a fault display,

the “Water Stop” indicator lights

up and the spin speed indicator

LEDs flash. If a digital display is

fitted, “A

” and “F” are also

displayed alternately.

For models with no fault display,

the washing machine stops in the

appropriate programme step.

Switch the appliance off, pull out

the mains plug and turn the

water tap off.

Tilt the appliance forwards

carefully to allow the collected

water to flow out from the

bottom of the appliance.

16

Page 17

Then:

1.

Plug in the appliance.

2.

Turn the water tap on (if

water immediately flows into

the appliance again, without

the appliance being started,

there is a fault. Turn off the

tap and notify After-Sales

Service).

3.

For models with fault display,

select and start the desired

programme again.

For models with no fault

display, continue the

programme by pressing the

“On/Off” button again.

If the fault occurs again, please

contact After-Sales Service (see

“After-Sales Service”).

“Water Stop” fault when

the programme selector

switch is in the “”

position.

The pump is switched on

automatically in order to pump

the water out.

For models with fault display the

washing machine will also detect

a Water Stop fault (leak) if the

programme selector is in the

“” position. In this case the

digital display (if one exists)

alternately shows “A

For models with no fault display,

the “Water Stop” fault is

detected when the appliance is

switched on again.

Pull the mains plug out and

ensure that the water tap is

turned off.

” and “F”.

Tilt the appliance forwards

carefully to allow the collected

water to flow out.

Then:

1.

Plug in the appliance.

2.

Turn the water tap on (if

water immediately flows into

the appliance again, without

the appliance being started,

there is a fault. Turn off the

tap and notify After-Sales

Service).

17

Page 18

Troubleshooting Guide

(valid for all “LCD Intelligent Dialogue WAL.....” models)

•

Depending on the model, your

washing machine is equipped

with various automatic safety

functions. This enables faults to

be detected in good time and the

safety system can react

appropriately.

These faults are frequently so

minor that they can be removed

within a few minutes.

The appliance will not start,

no display is visible.

Check whether:

•

the mains plug is inserted into

the socket

•

the wall socket is functioning

correctly (use a table lamp or

similar) to test

•

the “On/Off” button has been

pressed and the washing

machine is switched on

The washing machine will

not start and the “Start”

light is flashing.

The notice “Door Open!”

appears in the display:

•

close the door (child safety)

The washing machine stops

shortly after the

programme start.

The message “No Water Supply!”

appears on the display.

Switch the washing machine off,

pull out the mains plug and

check whether:

•

the tap is fully turned on

•

the water supply pressure is

sufficient

•

the water inlet hose is kinked

•

the mesh filters are blocked

(see “Care And Maintenance”/

”Mesh Filters in the Water

Connection”)

•

the water in the inlet hose is

frozen

the washing machine has a

safety hose and the safety

valve is open (red indicator in

the safety valve inspection

window); In this case replace it

with a new safety hose

Reconnect the appliance to the

electrical socket. Switch the

washing machine on and restart

the desired programme (do not

add any more detergent).

The washing machine stops

during the programme and

the “Start” light flashes.

Check whether:

•

“Rinse Hold Selected

in the display

•

the door has been opened.

Close the door

Press the “Start” button to

continue with the programme

” appears

Detergent and additive

product residues in

dispenser at end of wash.

Check whether:

•

the siphon is correctly installed

and clean (see “Care And

Maintenance”)

•

sufficient water is entering.

The mesh filters could be

clogged (see Care And

Maintenance/Mesh Filters in

the Water Connection)

•

when using powder detergent

beforehand the coloured

insert for dosing liquid

detergent has been removed

from the dispenser

The washing machine

vibrates during the spin

cycle.

Check whether:

•

the washing machine is level

and standing firmly on all four

feet

•

the transport bolts have been

removed. Before using the

machine, it is imperative that

the transport bolts are

removed

Final spin results are poor:

Check whether the notice “Load

Imbalance!” or “Excessive

Foam!” appears on the display.

The washing machine has an

unbalance detection and

correction system. If individual

heavy items are loaded (e.g. a

bathmat or bathrobe), this

system may reduce the spin

speed automatically or even

interrupt the spin completely if it

detects too great an imbalance

even after several spin starts, in

order to protect the washing

machine

•

if the laundry is still too wet at

the end of the cycle, add

smaller articles of laundry and

repeat the spin cycle

•

excessive foam formation may

prevent spinning. Observe

correct detergent dosages

Check whether:

•

spin speed “0” has been

selected

18

Page 19

The water is not pumped

out of the washing

machine.

The notice “FP” appears in the

display.

Switch the appliance off and pull

out the mains plug.

Check whether:

•

the drain hose is kinked

•

the pump or the filter is

blocked (see “Removing The

Filter”)

IMPORTANT:

ensure that the water has

cooled down.

•

the water in the drain hose is

frozen up

Reconnect the appliance to the

electrical socket.

Switch the washing machine on

again, select a programme and

start the appliance. To rinse the

laundry, we recommend a short

programme without the

addition of detergent.

If the fault occurs again, please

contact After-Sales Service (see

“After-Sales Service”).

Before emptying

There is a fault in an

electrical component.

A notice from “F4” to “F16”

appears in the display.

•

press the “Reset

start the programme again

with the “Start/Pause” button

•

if the fault occurs again, please

contact After-Sales Service (see

“After-Sales Service”)

” button and

There is a fault in the

“Water Stop”.

The message “Excessive Foam!”

or “FA

” appears on the display

and the pump operates.

The “Water Stop” fault may have

been triggered by:

1.

excess foaming;

2.

a leak in the washing

machine.

In this case the pump is switched

on automatically in order to

pump the water out.

Switch the appliance off, pull out

the mains plug and turn the

water tap off. Tilt the appliance

forwards carefully to allow the

collected water to drain out of

the appliance base.

Then:

1.

Reinsert the mains plug in the

socket.

2.

Turn the water tap on (if

water immediately flows into

the appliance again, without

the appliance being started,

there is a fault. Turn the tap

off and notify After-Sales

Service, see “After-Sales

Service”).

3.

Switch the washing machine

on again, select the desired

programme and start the

appliance.

If the fault occurs again, please

contact After-Sales Service (see

“After-Sales Service”).

19

Page 20

After-Sales Service

Before contacting AfterSales Service:

1.

Try to remedy the problem

yourself (see

“Troubleshooting Guide”).

2.

Restart the programme to

check whether the problem

has solved itself.

3.

If the washing machine

continues to function

incorrectly, call After-Sales

Service.

Transport/Handling

Never lift the appliance by

the worktop when

transporting.

1.

Pull out the power plug.

2.

Turn off the tap.

3.

Remove the water supply

and drain hose.

Specify:

•

The nature of the problem

•

The washing machine model

•

The service code (number after

the word SERVICE)

4.

Drain residual water from

the appliance and hoses (see

“Removing The Filter”/

”Draining Residual Water”).

5.

Fit the transit bolts

(obligatory).

The After-Sales Service

sticker is on the inside of

the door.

•

Your full address

•

Your telephone number and

area code.

After-Sales Service numbers

and addresses can be found in

the guarantee booklet or

contact the dealer

20

Page 21

Electrical connection

1) For Great Britain only

Warning - this appliance

must be earthed

Fuse replacement

If the mains lead of this

appliance is fitted with a

BS 1363A 13amp fused plug,

to change a fuse in this type

of plug use an A.S.T.A.

approved fuse to BS 1362

type and proceed as follows:

1.

Remove the fuse cover (A)

and fuse (B).

2.

Fit replacement 13A fuse into

fuse cover.

3.

Refit both into plug.

Important:

The fuse cover must be

refitted when changing a

fuse and if the fuse cover is

lost the plug must not be

used until a correct

replacement is fitted.

Correct replacement are

identified by the colour

insert or the colour

embossed in words on the

base of the plug.

Replacement fuse covers are

available from your local

electrical store.

2) For the Republic of

Ireland only

The information given in

respect of Great Britain will

frequently apply, but a third

type of plug and socket is also

used, the 2-pin, side earth type.

3) Socket outlet / plug

(valid for both

countries)

If the fitted plug is not suitable

for your socket outlet, Please

contact Whirlpool Service for

further instruction. Please do

not attempt to change plug

yourself. This procedure needs

to be carried out by a qualified

Whirlpool technician in

compliance with the

manufactures instructions and

current standard safety

regulations.

21

Loading...

Loading...