Page 1

TKirlpool

CORPORATION

ECKMF-28

HOW TO INSTALL

YOUR AUTOMATIC

ICE MAKER

USE THESE INSTRUCTIONS ONLY FOR

28 INCH TOP FREEZER REFRIGERATORS

Part No 939024 A

Page 2

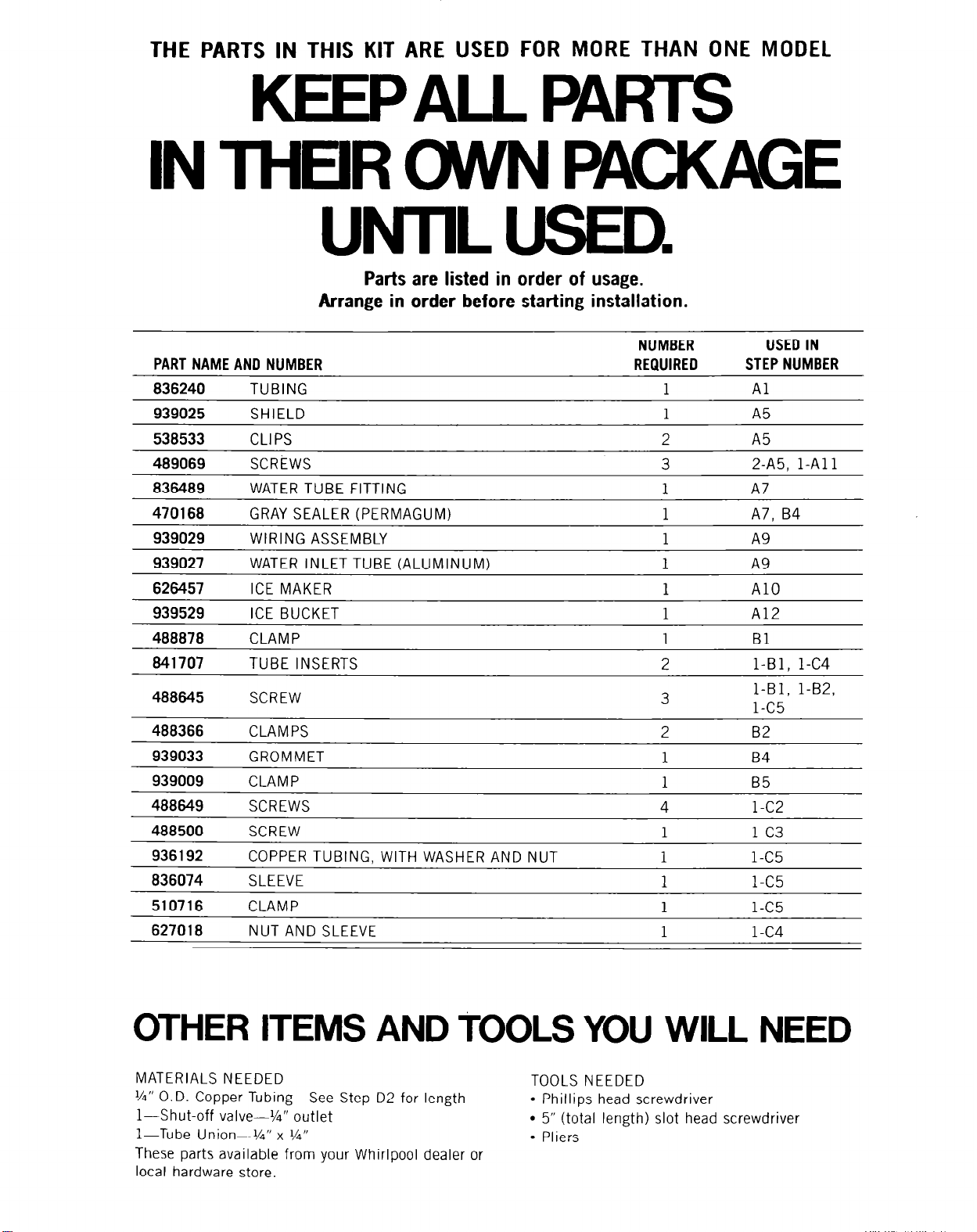

THE PARTS IN THIS KIT ARE USED FOR MORE THAN ONE MODEL

KEEPALL PARTS

IN THEIR WVN PACKAGE

UNTIL USED.

Parts are listed in order of usage.

Arrange in order before starting installation.

NUMBER

PART NAME AND NUMBER

TUBING

939025 SHIELD

538533

489069 SCREWS

836489 WATER TUBE FITTING

470168 GRAY SEALER (PERMAGUM)

939029 WIRING ASSEMBLY

939027 WATER INLET TUBE (ALUMINUM)

626457 ICE MAKER

939529 ICE BUCKET

488878 CLAMP

841707 TUBE INSERTS

488645

488366 CLAMPS

939033 GROMMET 1

939009

488649

488500

936192

836074 SLEEVE 1

510716

6270 1 B

CLIPS

CLAMP

SCREWS

SCREW

COPPER TUBING, WITH WASHER AND NUT

CLAMP

NUT AND SLEEVE

REQUIRED

4

1 l-C5

2

3

2

2

1

1

1

1

1

1

1

1

1

USED IN

STEP NUMBER

Al

A5

A5

2-A5, l-Al 1

A7. B4

A9

A10

Al2

Bl

l-Bl. l-C4

1-Bl, l-B2,

1-c!i

82

B4

B5

l-C2

l-C5

l-C4

OTHER ITEMS AND TOOLS YOU WILL NEED

MATERIALS NEEDED

‘/4” O.D. Copper Tubing-See Step D2 for length

l-Shut-off valve--‘/a” outlet

l-Tube Union--‘/a” x %”

These parts available from your Whirlpool dealer or

local hardware store.

TOOLS NEEDED

l

Phillips head screwdriver

l

5” (total length) slot head screwdriver

l

Pliers

Page 3

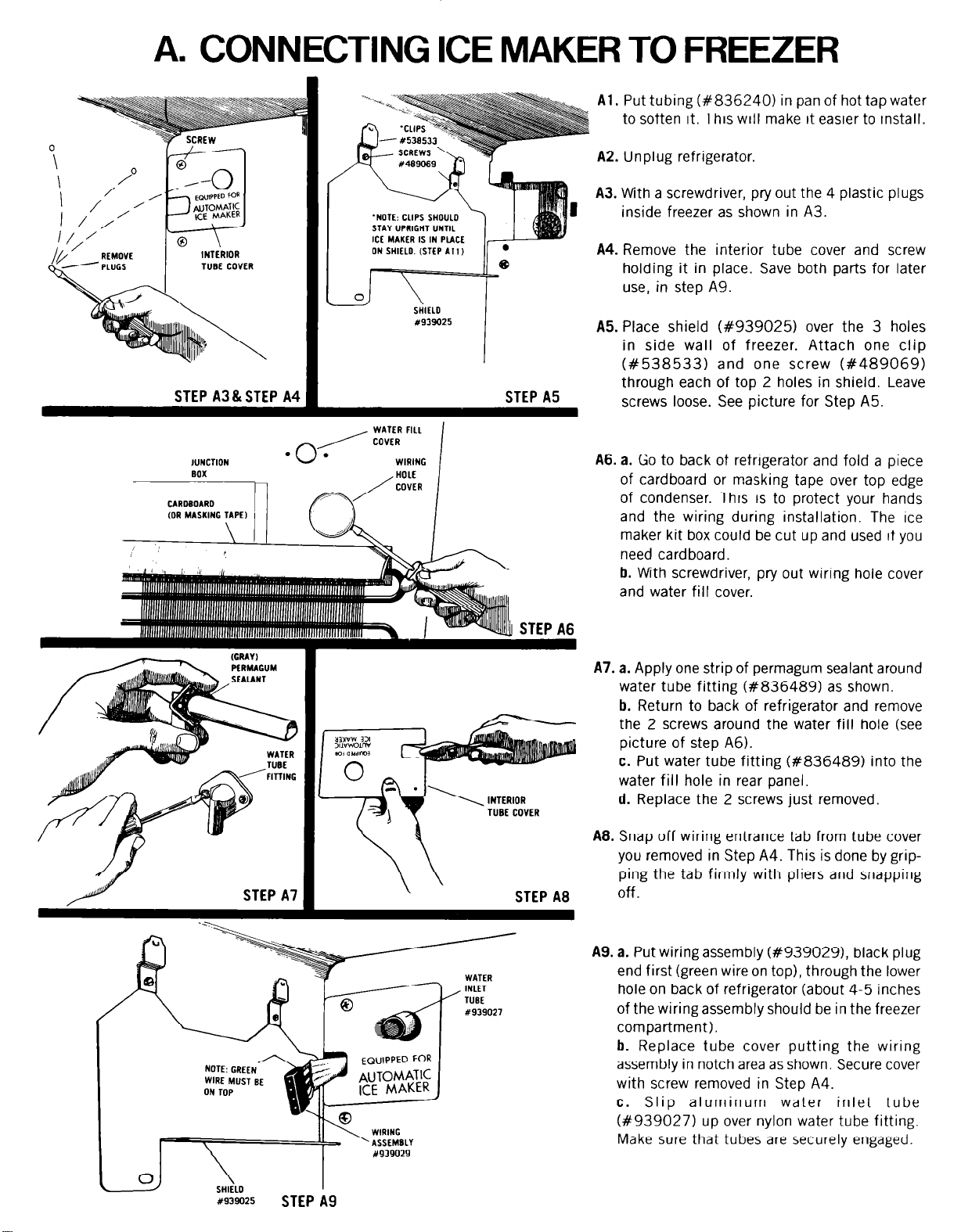

A. CONNECTING ICE MAKER TO FREEZER

Al. Put tubing (#836240) in pan of hot tap water

to soften it. This will make it easier to install.

A2. Unplug refrigerator.

A3. With a screwdriver, pry out the 4 plastic plugs

inside freezer as shown in A3.

A4. Remove the interior tube cover and screw

holding it in place. Save both parts for later

use, in step A9.

A5. Place shield (#939025) over the 3 holes

in side wall of freezer. Attach one clip

(#538533) and one screw (#489069)

through each of top 2 holes in shield. Leave

screws loose. See picture for Step A5.

A6. a. Go to back of refrigerator and fold a piece

of cardboard or masking tape over top edge

of condenser. This is to protect your hands

and the wiring during installation. The Ice

maker kit box could be cut up and used if you

need cardboard.

b. With screwdriver, pry out wiring hole cover

and water fill cover.

STEP A3&STEP A4 1

‘NOTE: CLIPS SHOULD

STAY UPRIGHT UNTIL

ICE MAKER IS IN PLACE

ON SHIELD. (STEP Al 1)

STEP A5

I

NOTE: CREEL’

WIRE MUST BE

ON TOP

EQy’TPED FoR I

AUlOMATIC

ICE MAKER

A7. a. Apply one strip of permagum sealant around

water tube fitting (#836489) as shown.

b. Return to back of refrigerator and remove

the 2 screws around the water fill hole (see

picture of step A6).

c. Put water tube fitting (#836489) into the

water fill hole in rear panel.

d. Replace the 2 screws just removed.

TUBE COVER

A8. Snap off wiring entrance tab from tube cover

you removed in Step A4. This is done by gripping the tab firmly with pliers and snapping

off.

A9. a. Put wiring assembly (#939029), black plug

end first (green wire on top), through the lower

hole on back of refrigerator (about 4-5 inches

of the wiring assembly should be in the freezer

compartment).

b. Replace tube cover putting the wiring

assembly in notch area as shown. Secure cover

I

with screw removed in Step A4.

c. Slip aluminum water inlet tube

(#939027) up over nylon water tube fitting.

Make sure that tubes are securely engaged.

ly939025

STEP A9

Page 4

STEP A10

NOTE. GREEN

WIRE MUST BE

ROTATE CLIPS

TIGHTEN SCREWS

AlO. Connect Ice Maker to wiring assembly. Place

the ice maker on the side of the freezer so:

1. Wiring lays between shield and Ice Maker.

2. Plug is flat against the shield.

3. Wiring is above the bracket on the back of

Ice Maker.

WARNING-DO NOT PINCH WIRES BETWEEN

BRACKET AND SIDE OF FREEZER.

Al 1. Put screw (#489069) through bottom bracket

and into freezer wall, then turn the 2 top clips

down (Step A5). Tighten all 3 screws.

A12. Place ice bucket under Ice Maker.

\

SCREW

Y‘w9069

\

BRACKET

B. INSTALLING WATER LINE AND WIRING

ON BACKOF CABINET

Bl. Place clamp (#488878) over spout of water

tube fitting. Put tube insert (#841707) in one

end of tubing that has been soaking in hot

water. Put tube insert and end of tubing into

spout. Tighten clamp with screw (#488645).

CLAMP Y4a8816

(WITH SCREW Y4.38645)

STEPAll -STEPA

B2. Slide 2 clamps (#488366) over tubing.

Remove the screw from cabinet and attach

upper clamp to cabinet with this screw. Use

screw (#488645) from kit to attach lower

clamp to cabinet. Hold wires away from screw

when tightening.

CLAMPS

-48

(FEEDS UNDER

WIRING ASSEMBLY

Page 5

83. Remove the metal junction box and save the

2 mounting screws.

a. Bend back ears of 3 wire plug on ice maker

wiring assembly.

b. With the green wire up, snap the plug into

hole in side of junction box.

c. Connect the 3 wire plug into mating part

in junction box. Remount metal junction box.

WARNING-DO NOT PINCH WIRES BETWEEN

JUNCTION BOX AND CABINET.

84. Place split grommet (#939033) around wiring

assembly and push into cabinet hole. Seal

space between wiring and grommet with permagum sealant.

WHITE AND TAN

WIRES

B5. Route white and tan wires behind con-

denser to unit compartment. Remove screw

from cabinet. Place clamp (#939009) around

both wires and attach to cabinet with the screw

just removed. Hold wires away from screw

when tightening.

Page 6

C. INSTALLING WATER VALVE

ON LOWER BACKOF CABINET LEG.

Cl. Plug wiring assembly into water valve so that

the two parts fit together tightly.

C2. Fasten water valve to cabinet leg with 1 screw

(#488649).

w

Ii49

STEP Cl

C3. Attach valve ground wire to cabinet with ground

screw (#488500).

,U6?6074

C4. Slide retaining nut (#627018) over tubing.

Push tube insert (#841707) into end of

tubing. Push end of tubing into water valve.

Tighten the retaining nut, but do not

overtighten.

C5. Attach copper tubing and hose connector

(#936192) to water valve. Be sure that rubber

washer is in place and tighten hose connector.

Attach copper tubing to refrigeratorwith sleeve

(#836074), clamp (#510716), and screw

(#488645).

C6. Remove cardboard or tape (installed in step

A61 from top of condenser.

WASHER

-/STEP C5

TUBING

Page 7

D. CONNECTING ICE MAKER

TO WATER SUPPLY

You will need enough %-inch O.D. copper

tubing to connect refrigerator to water source

and two 6” or 8” adjustable or open end wrenches.

TYPICAL WAYS TO CONNECT TO WATER SUPPLY

Through floor to

basement cold

water pipe.

Through wall to

utility room cold

water pipe.

\

c

I

‘c-

e ’

Under sink to

cold water pipe.

In crawl space

under home.

CAUTION:

Ice Maker tubing should not be

installed where temperature may fall below freezing.

Page 8

Dl. Find a %-inch to l-inch vertical COLD water pipe

near the refrigerator. (Horizontal pipe will work

but extra precaubons must be taken.)

SHUTOFF

D2. Measure from inlet on rear of refrigerator to

water pipe. Add 7 feet to allow for moving refrigerator for cleaning. This is the length of X-

inch O.D. copper tubing you will need for the

job (length from inlet tube to water pipe PLUS

7 feet). Be sure both ends of copper tubing are

cut square.

D3. Turn OFF main water supply. Turn ON nearest

faucet long enough to clear line of water.

04. Using a grounded drill, drill a %-inch hole in

the vertical cold water pipe you have selected.

Some water almost always remains in pipes. If

it enters the drill, it can cause lethal shock. BE

SURE YOUR DRILL IS GROUNDED.

Fasten a separate ground wire from drill to a

good ground that complies to local electrical

codes. (If in doubt, consult a licensed electrician.) UNLESS PROPER GROUNDING IS FOLLOWED, YOU ARE NOT PROTECTED AGAINST

SEVERE OR LETHAL SHOCK.

If you must use a horizontal pipe, take extra

precautions:

Drill on the top or side of the pipe, not bottom.

This helps keep water away from the drill. Also,

it keeps normal sediment from collecting in the

valve.

D5. Fasten shutoff valve to cold water pipe with pipe

clamp. Be sure inlet end is solidly in the %6-inch

drilled hole in the water pipe and that washer is

under the pipe clamp. Tighten packing nut.

Tighten the pipe clamp screws carefully and

evenly so washer makes a watertight connection.

Do not overtighten or you may crush copper

tubing, especially if soft copper tubing is used.

Now you are ready to connect the copper tubing.

PIPE CLAMP

\

WASHER

INLET END

OUTLET END

07. Assemble compression nuts on tubing as shown

in diagram. Insert ends of tubing into connector

and tighten compression nuts. Be sure ends of

tubing are squarely in connector as far as they

will go. Do not overtighten.

%” TUBE TO SHUTOFF VALVE

kNUT-

CONNECTOR

SLEEVE

NUT

INLET TUBE TO REFRIGERATOR

SLEEVE ~

UNION

08. Turn shutoff valve on. TIGHTEN ANY CONNEC-

TIONS OR NUTS THAT LEAK.

D9. REPLACE LOWER BACK COVER PREVIOUSLY

REMOVED.

010.

Copper tubing may now be fastened to baseboard.

Dll.

The Ice Maker is equipped with a built-in water

strainer located on the inlet side of the water

valve. If local water conditions require periodic

cleaning or a well is your source of water supply,

a second water strainer should be installed In

the X-inch water line.

012. Water Pressure Limitations: Not below (15 P.S.I.)

or above (125 P.S.I.). If a problem occurs call

your Utility Company.

RTICAL

D WATER

PIPE

D6. Slip compression nut and compression sleeve

on copper tubing as shown in diagram. Insert

end of tubing into outlet end squarely as far as

it will go. Screw compression nut to outlet end

with adjustable wrench. Do not overtighten. Turn

ON main water supply and fl’ush out tubing until

water is clear. Turn OFF shutoff valve on the

water pipe. You are now ready to connect other

end of %-inch copper tubing to inlet tube or

water valve on back of refrigerator.

D13. PLUG IN YOUR REFRIGERATOR.

When you have your first batch of ice you may

throw away extra parts.

IMPORTANT:

It may take up to 24 hours for your Ice

Maker to begin producing ice crescents.

To enjoy your Ice Maker most

PLEASE READ CAREFULLY THE ICE

MAKER SECTION OF YOUR USE AND

CARE GUIDE.

Loading...

Loading...