VENTLESS KITCHEN RANGE HOOD

FOR 120 V. OPERATION

READ AND SAVE THESE INSTRUCTIONS

Before you begin, read the following instructions completely

and carefully. If followed, they will simplify the installation

job.

IMPORTANT: OBSERVE ALL GOVERNING CODES

AND ORDINANCES

VENTLESS

INSTALLATION

KITCHEN

RANGE HOOD

MODEL

RH2600XL-1

SERIES

I

SAVE THESE INSTRUCTIONS FOR THE LOCAL

ELECTRICAL INSPECTOR’S USE

Your range hood has been designed to filter out smoke,

odors and grease which rise from the cooking surface.

Before you begin the installation be sure that all parts and

accessories are removed from carton. For best results and

ease in the rnstallation of this range hood, read the

instructions sheet to become familiar with the step by step

installation.

TOOLS AND MATERIALS REQUIRED

Drill, electric or ratchet drive, with 1’55” wood bit (to drill an

access hole in the cabinet or kitchen wall for the electric

power line.)

One common head screwdriver (to secure hood mounting

screws to the cabinet and hood sheet metal parts).

Plrers (for opening knockouts)

I

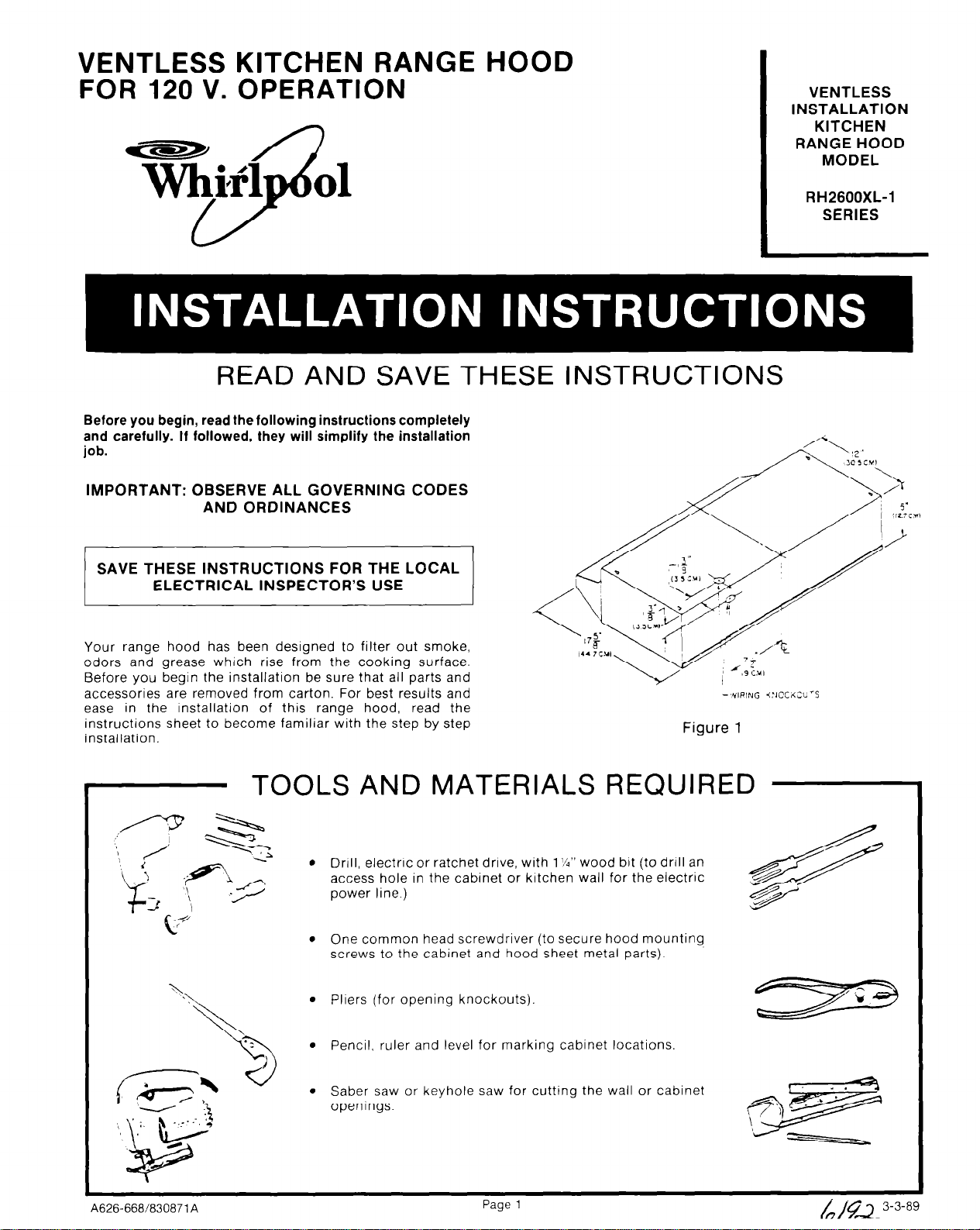

Figure 1

A626-66EW330871 A

Pencil, ruler and level for marking cabinet locations

Saber saw or keyhole saw for cutting the wall or cabinet

openings.

Page 1

TO INSTALL RANGE HOOD

For most efficient operation, top of hood should be

approximately 66 (167.6 CM) inches from floor.

1. Mark locations for electrical wiring from dimensions

grven in Figure 1.

2 Cut hole to accomodate electrical wiring. Be sure to

minimize openings through outside walls or the ceiling.

These will have to be sealed later.

3. Run wire through wall or cabinets according to

National Electrical Code and applrcable local codes. DO

NOT turn power on until installation is complete.

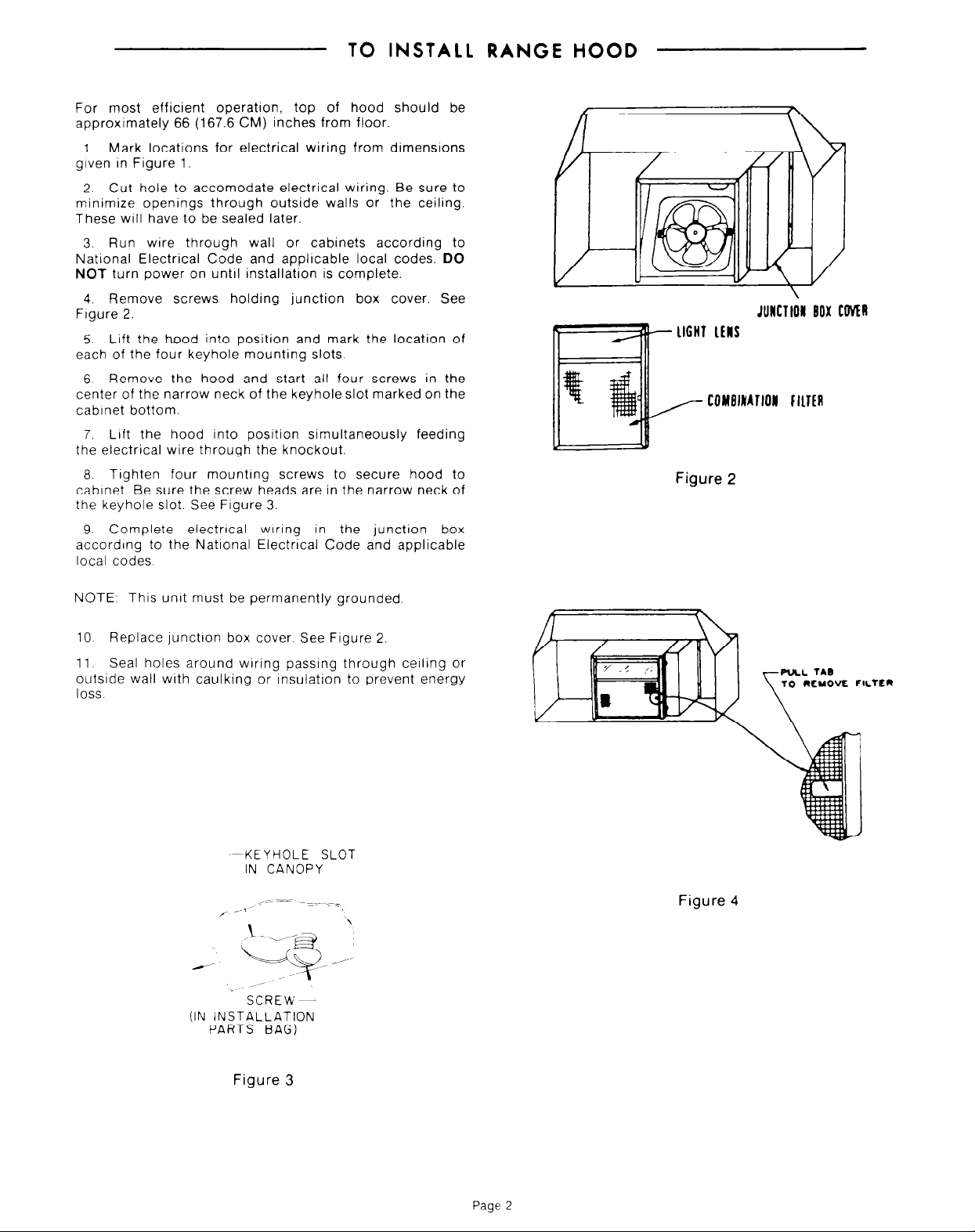

4. Remove screws holding junction box cover. See

Frgure 2.

5. Lrft the hood into position and mark the location of

each of the four keyhole mounting slots.

6 Remove the hood and start all four screws in the

center of the narrow neck of the keyhole slot marked on the

cabinet bottom.

7. Lift the hood into position srmultaneously feeding

the electrical wire through the knockout.

8. Tighten four mounting screws to secure hood to

cabrnet Be sure the screw heads are in the narrow neck of

the keyhole slot. See Figure 3.

9 Complete electrrcal wiring In the junction box

according to the National Electrical Code and applicable

local codes.

Figure 2

NOTE, Thus unit must be permanently grounded

10 Replace junction box cover. See Figure 2.

11 Seal holes around wiring passing through ceiling or

outside wall with caulking or lnsulatron to prevent energy

loss.

KEYHOLE SLOT

IN CANOPY

SCREW --

(IN INSTALLATION

PARTS BAG)

Figure 4

Figure 3

Page 2

OPERATION AND CARE OF UNIT

COMBINATION FILTER:

This filter should be inspected periodically and when it

becomes saturated should be replaced. There are no effec-

tive means of reactivating this filter.

LIGHTS:

Do not use bulb larger than 60 watts in light socket.

CARE OF EXTERIOR SURFACES:

Your range hood is a beautifully finished addition to your

kitchen and requires only the care you give your range to

preserve its lasting beauty. Clean with a mild detergent to

preserve finish DO NOT use abrasive cleaners.

CARE OF FAN MOTOR:

Fan motor has life time sealed bearings that never need

oiling under normal usage. A few drops on each bearing after

three years of heavy usage will prolong the motor life. Clean

motor with a damp cloth and grease cutting detergent when

a heavy coating of grease has accumulated.

For most effectrve removal of smoke and odors; turn on fan at

beginning of cookrng operation and allow to run until smoke

and odors are removed from room.

IMPORTANT SAFEGUARDS FOR

ELECTRICAL APPLIANCES

When using electrical appliances, basic safety precautions

should always be followed including the following:

1. Read and follow all instructions

2. Close supervrsron is necessary when any appliance is

used by or near children.

3. To avoid providing fuel for a grease pan fire, clean lint

and grease from all hood surfaces-interior and exterior, Be

sure to replace air filter every three months.

4. Do not saturate electrical connections, switches, and

motor in water during cleaning. Remember, WATER AND

ELECTRICITY DO NOT MIX!

5. If any electrical malfunction becomes evident during

use, disconnect power to hood at your home fuse or breaker

box.

6. To prevent the risk of fire, electric shock, or injury, be

sure to disconnect power before cleaning or servicing.

WARNING:

not use this fan with any solid-state speed control device.

To reduce the risk of fire or electric shock. do

If

you need service or assistance, we suggest you follow these four steps:

1. Before calling

Performance problems often result from Itttle lhings you can find

and fix yourself wrthout tools of any krnd.

If nothing operates:

l

Have you checked the

If

you need assistance...

0

2

Call the Whirlpool COOL

number. Dial free from:

Continental U.S. (800) 253-1301

Michigan. (800) 632-2243

Alaska& Hawaii.. (800)253-1121

and talk with one of our trained Consultants. The Consultant can

Instruct you In how to obtain satisfactory operation from your

appliance or, If service IS necessary recommend a qualified service

company In your area.

for

assistance...

marn

fuse or circuit breaker box?

-LINE@

service assistance telephone

l

If you need service...

Whrrlpool has a natronwade network of franchised

TECH-CARE” Service

Companies. TECH-CARE

service technlclans are

to fulfill the product warranty

and orovlde after-warranty

service anywhere in the United States. To locate TECH-CARE

service in your area, call our COOL-LINE servrce assistance

telephone number (see Step 2) or look in your telephone drrectory

Yellow Pages under,

APPLIANCES-HOSEHOLD ELECTRICALAPPLIANCES-

MAJOR-SERVICE h REPAIR MAJOR--REPAIRING 6 PARTS

WHIRLPOOL APPLIANCES

FRANCHISED TECH-CARE SERVICE FRANCHISED TECH-CARE SERVICE

SERVICE COMPANIES SERVICE COMPANIES

XYZ SERVICE CO XYZ SERVICE CO

123Maple 999-9999 OR 123MapIe 999-9999

WASHING MACHINES, DRYERS

WHIRLPOOL APPLIANCES

FRANCHISED TECH-CARE SERVICE

SERVICE COMPANIES

XYZ SERVICE CO

123 Maple

l If

you

4

Call our COOL-LINE service assrstance telepone number (see

Step 2) and talk with one of our Consultants, or If you prefer, write to

Mr. Robert Stanley, Dlvrsion Vice President

WhIrlpool Corporation

AdministratIve Center

2000 US-33

Benton Harbor, Ml 49022

If you must call or write, please provide model number, senal

number, date of purchase, and a complete description of the

problem. Thus information

your

request for assistance.

have

North

OR

WHIRLPOOL APPLIANCES

A IRONERS-SERVICING

999-9999

a problem...

IS

needed In order to better respond to

Page 3

Loading...

Loading...