Whirlpool KEHS01PMT2 Parts Diagram

TECH SHEET – DO NOT DISCARD PAGE 1

WARNING

Electrical Shock Hazard

Disconnect power before

servicing.

Replace all parts and panels

before operating.

Failure to do so can result in

death or electrical shock.

DIAGNOSTIC GUIDE

Before servicing, check the following:

Make sure there is power at the wall outlet.

■

Has a household fuse blown or circuit breaker

■

tripped? Time delay fuse?

Is dryer vent properly installed and clear of lint

■

or obstructions?

All tests/checks should be made with a VOM

■

(volt-ohm-milliammeter) or DVM

(digital-voltmeter) having a sensitivity of

20,000 ohms per volt DC or greater.

Check all connections before replacing

■

components. Look for broken or loose wires,

failed terminals, or wires not pressed into

connectors far enough.

■ A potential cause of a control not functioning

is corrosion on connections. Observe

connections and check for continuity with an

ohmmeter.

■ Connectors: Look at top of connector. Check

for broken or loose wires. Check for wires not

pressed into connector far enough to engage

metal barbs.

■

Resistance checks must be made with dryer

unplugged or power disconnected.

DIAGNOSTIC TESTS

These tests allow factory or service personnel to test

and verify all inputs to the machine control

electronics. You may want to do a quick and overall

checkup of the dryer with these tests before going

to specific troubleshooting tests.

ACTIVATING THE DIAGNOSTIC TEST

MODE

1. Be sure the dryer is in standby mode (plugged in

and all indicators off).

2. Press the following button sequence:

+ (more time), – (less time), + (more time),

– (less time), all within 5 seconds.

3. All indicators on the console are illuminated with

88 showing in the Estimated Time Remaining

(two-digit) display, if this test mode has been

entered successfully.

IMPORTANT

Electrostatic Discharge (ESD) Sensitive Electronics

ESD problems are present everywhere. ESD may damage or weaken the electronic

control assembly. The new control assembly may appear to work well after repair is

fin is hed, but failure may occur at a later date due to ESD stress.

Use an anti-static wrist strap. Connect wrist strap to green gr ou nd connecti on

■

point or unpainted metal in the appliance

Touch your finger repeatedly to a green ground connecti on point or u npainted

metal in the appliance.

Before removing the part from its package, touch the anti-static bag to a green

■

ground con nection point or unpainted metal in the appliance.

Avoid touching electronic parts or terminal contacts; handle electronic control

■

assembly by edges only.

When repackaging failed electronic control assembly in anti-static bag, observe

■

above instructions.

If unsuccessful entry into diagnostic

mode, actions can be taken for

specific indications:

Indication 1: None of the indicators

or display turns on.

Action:

Select any manual cycle.

If indicators come on, then try to

➔

change the dryer time by pressing the

+ and – buttons. If either button fails to

change the time, something is faulty

with one of those buttons, and it is not

possible to enter the diagnostic mode.

Remove the console electronics and

housing. See Accessing & Removing

the Electronic Assemblies, page 7.

➔

If no indicators come on after pressing

the Manual cycle buttons, go to

TEST #1, page 3.

Indication 2: E1 or E2 flashes from

the display.

Action:

Proceed to TEST #3a, page 4.

Indication 3: E3 flashes from the

display.

Action:

Check that the correct machine

control electronics and console

electronics and housing are installed. Do

so by removing these components to view

the part numbers and compare them to

the part numbers in the Service Parts List

-OR-

for this unit. See Accessing & Removing

the Electronic Assemblies, page 7.

Replace components if necessary.

Diagnostic: Console switches and

indicators

Pressing each button or turning the cycle

selector to each cycle should cause a beep

tone and control one or more LEDs as shown

in figure 1, page 3. Pressing the Hold To Start

button will also control the motor and heater,

while the two-digit display will indicate a

software project i.d. number.

Diagnostic: Moisture Sensor

Locate two metal strips on the face of the lint

screen housing. Bridge these strips with a

wet cloth or a finger.

➔

If a beep is heard and a software

revision number is displayed on the

console, the sensor is OK.

➔

If not, or if a beep tone is heard before

bridging the moisture strips, go to

TEST#4,step2,page5.

Diagnostic: Door Switch

Opening the door should cause a beep tone

and a number and letter to be indicated in the

two-digit display. Closing the door firmly

should cause a beep tone and the display to

go blank or indicate

88.

DISPLAY FAULT/ERROR CODES

The error codes below would be indicated when attempting to start a drying cycle, or after

activating the diagnostic test mode.

DISPLAY DESCRIPTION EXPLANATION AND RECOMMENDED PROCEDURE

PF flashes to indicate that a power failure occurred while the dryer

PF

E1

POWER FAILURE

THERMISTOR OPEN

was running. Press HOLD TO START to continue the cycle, or press

OFF/Pause to clear the display.

E1 flashes if the thermistor is open. See TEST #3a, page 4.

THERMISTOR SHORTED

E2

E3

USER INTERFACE OR

SOFTWARE MISMATCH

E2 flashes if the thermistor has shorted. See TEST #3a, page 4.

E3 flashes when there is a keyswitch or software mismatch. This

error code will ONLY appear when in the diagnostic test mode.

See TEST #5, page 6.

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. 8563816 REV. B

PAGE 2 TECH SHEET – DO NOT DISCARD

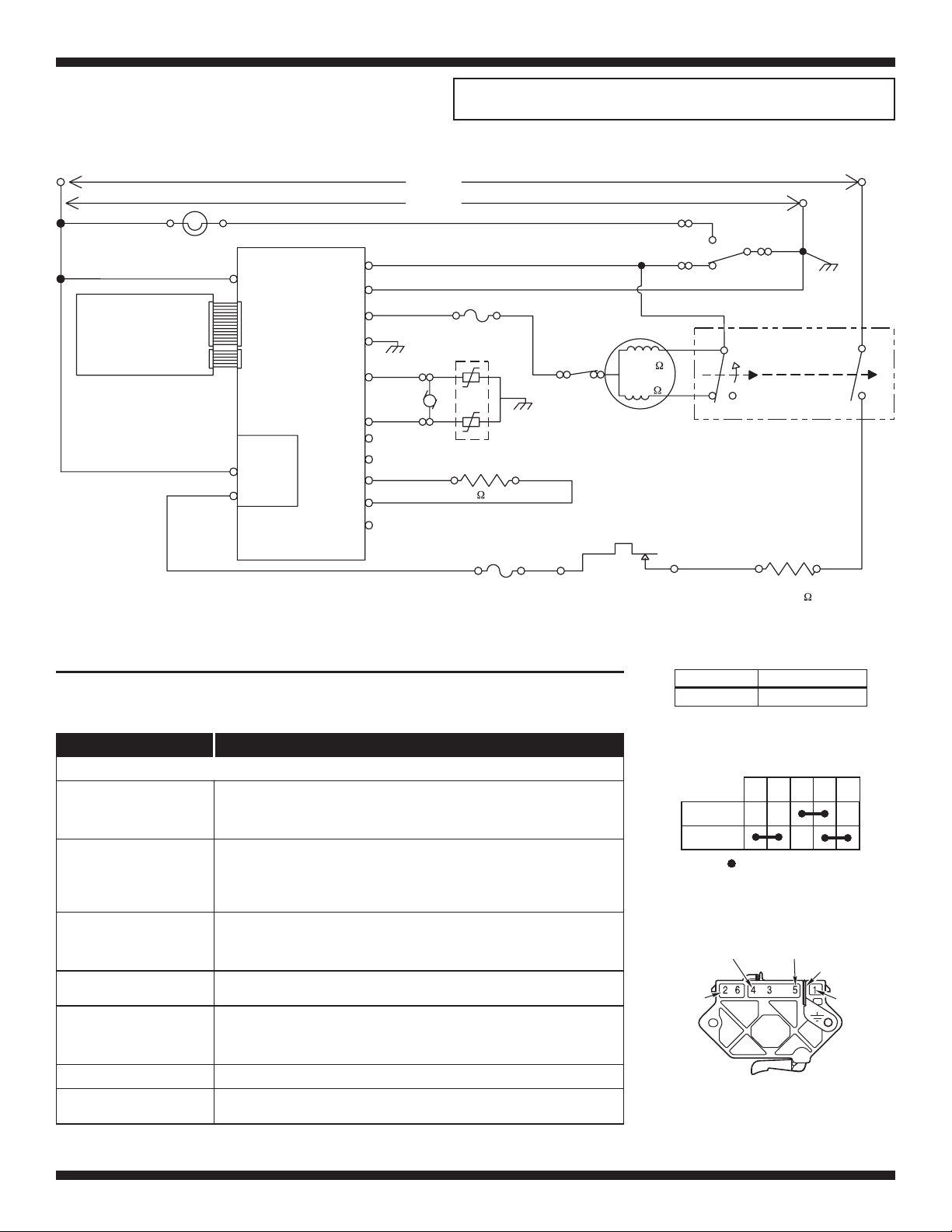

ELECTRIC DRYER WIRING DIAGRAM

L1 LINE – BK

BK

DRUM LAMP

BK

USER INTERFACE

(ACTIVE OVERLAY or

ALTERNATE TECHNOLOGY)

(0.250 TERMINAL)

(0.250 TERMINAL)

P1-5

N.O.

COM

DL

L1

P3

P4

HEATER

RELAY

HEATER +V

HEATER RTN

ELECTRONIC

CONTROL

BR

DOOR

NEUTRAL

MOTOR

PT-1

MOIST.

MOIST RTN

MODEL

MODEL RTN

TEMP.

TEMP RTN

N.C.

P1-3

P1-2 NEUTRAL

P1-4

P1-1

P2-1

P2-2

P2-3

P2-4

P2-5

P2-6

P2-7

240 VOLTS

120 VOLTS

LBU

G-Y

Y- R

SENSOR

BK

R-W

BK

IMPORTANT: Electrostatic (static electricity) discharge may cause damage

to electronic control assemblies. See page 1 for details.

R – LINE L2

W

LBU

THERMAL FUSE

196° F (91° C)

SENSOR

MOVS

THERMISTOR

10k ± 3%

R

THERMAL CUT-OFF

(TCO) 352° F (178° C)

G-Y

BK

W

4M

BELT

SWITCH

HIGH LIMIT

THERMOSTAT

295° F (146° C)

– NEUTRAL

BU

MAIN

2.4– 3.6

START

2.4– 3.8

DRIVE MOTOR

1/3 H.P.

NC

BU

DOOR

SWITCH

W

5M

CENTRIFUGAL SWITCH

3M

6M

R-W

W

HEATER

–11.8

7.8

NEUTRAL

TERMINAL

LINKED TO

CABINET

W

2M

1M

R

TROUBLESHOOTING GUIDE

Some tests will require accessing components. See figure 13, page 7 for component locations.

PROBLEM POSSIBLE CAUSE / TEST

NOTE: Possible Cause/Tests MUST be performed in the sequence shown for each problem.

WON’T POWER UP.

(No response when Control

On button is pressed.)

WON’T START CYCLE

WHEN HOLD TO START

BUTTON IS PRESSED.

WON’T SHUT OFF WHEN

EXPECTED.

CONTROL WON’T ACCEPT

SELECTIONS.

WON’T HEAT.

HEATS IN AIR CYCLE.

SHUTS OFF BEFORE

CLOTHES ARE DRY.

1. Supply Connections. See TEST #1, page 3.

2. Check harness connections.

3. Console electronics and housing. See TEST #5, page 6.

1. If number display flashes, check to be sure the door is completely shut,

and press and hold down HOLD TO START for about 1 second.

2. See TEST #2, page 3.

3. See TEST #6, page 6.

1. Check OFF/Pause button. See TEST #5, page 6.

2. Console electronics and housing. See TEST #5, page 6.

3. Moisture Sensor. See TEST #4, page 5.

Console electronics and housing. See TEST #5, page 6.

1. Heater. See TEST #3, page 4.

2. Check harness connections.

3. Check installation.

Thermistor. See TEST #3a, page 4.

Moisture Sensor. See TEST #4, page 5.

Drum Size: Drum Speed:

7.0 cubic feet

51.5 ± 3 RPM CW

Contacts

Function

1M 2M 3M 5M 6M

Start

Run

=

Contacts closed

Centrifugal Switch (Motor)

Blue White

Red

Green-

Yellow

Red

Pluggable Drive

Motor Switch

PART NO. 8563816 REV. B FOR SERVICE TECHNICIAN’S USE ONLY

TECH SHEET – DO NOT DISCARD PAGE 3

Controls Status LEDs,

and turns on dryer

Start button

controls these

LEDs

Control On

button controls

this LED

Cycle selector

controls LED

where pointing

Figure 1. Console Diagnostics

TROUBLESHOOTING TESTS

NOTE: These checks are done with the dryer

unplugged or disconnected from power.

TEST #1 Supply Connections

This test assumes that proper voltage is present

at the outlet, and visual inspection indicates that

the power cord is securely fastened to the

terminal block.

1. Unplug dryer or disconnect power.

2. Remove the cover plate from the top right

corner of the back of the dryer. See figure 2.

Remove

Screw

Terminal

Block Cover

Figure 2. Remove the cover plate.

3. With an ohmmeter, check for continuity

between the neutral (N) terminal of the plug

and the center contact on the terminal block.

See figure 3.

Power Cord

Plug

N

COM

Figure 3. Plug-to-terminal connections.

➔

If there is no continuity, replace the power

cord and test the dryer.

➔

If there is continuity, go to step 4.

4. In a similar way, check which terminal of the

plug is connected to the left-most contact on

the terminal block and make a note of it. This

Terminal Block

L1

This button controls

the left digit

This button controls

the right digit

will be L1 (black wire) in the wiring diagram.

See figure 3.

When this is found, go to step 5.

➔

If neither of the plug terminals have

➔

continuity with the left-most contact of the

terminal block, replace the power cord

and test the dryer.

5. Access the machine control electronics

without disconnecting any wiring to the

control board. See Accessing & Removing

the Electronic Assemblies, page 7.

6. With an ohmmeter, check for continuity

between the L1 terminal of the plug (found in

step 4) and P1-5 (black wire) on the

machine control board.

➔

If there is continuity, go to step 7.

➔

If there is no continuity, check that wires

to the terminal block are mechanically

secure. If so, replace the main wire

harness and test the dryer.

7. Check for continuity between the neutral (N)

terminal of the plug and P1-2 (white wire) at

the control board.

➔

If there is continuity, go to step 8.

➔

If there is no continuity and the

mechanical connections of the wire are

secure, replace the main wire harness.

8. If the dryer still does not operate, replace the

machine control electronics.

TEST #2 Motor Circuit

This test will check the wiring to the motor and

the motor itself. The following items are part of

this system:

–

Harness/connection

–

Thermal fuse

–

Belt/belt switch

–

Drive Motor

1. Unplug dryer or disconnect power.

2. Access the machine control electronics. See

Accessing & Removing the Electronic

Assemblies, page 7. Measure the resistance

across P1-3 and P1-4.

➔

If resistance across P1-3 and P1-4 is in

the range of 1 to 6 ohms, replace the

machine control electronics.

–

Door switch

–

Machine control

electronics. See ESD

information, page 1.

Each button controls

all LEDs above button

Otherwise, go to step 3.

➔

Turns off all LEDs

and exits

diagnostic mode

3. Check the wiring and components in the

path between these measurement points by

referring to the wiring diagram on page 2.

4. Check the thermal fuse. See TEST #3b,

page 5.

5. Check the belt switch and drive motor.

Access the belt switch and drive motor by

removing the back panel. See Removing the

Back Panel, page 8. Slowly remove the drum

belt from the spring-loaded belt switch

pulley, gently letting the belt switch pulley

down. See figure 4.

Belt Switch Pulley

Drum

Belt

Figure 4. Slowly remove drum belt.

6. Remove the white connector from the drive

motor switch. See figure 5.

Drive Motor

Switch

White Connector

Figure 5. Remove white connector.

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. 8563816 REV. B

Loading...

Loading...