Whirlpool GBD307PD, GBD277PD, RBD245PD, RBD275PD, RBD276PD User Manual

...

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

ELECTRIC

BUILT-IN

DOUBLE OVEN

KR-30

JOB AID

Part No. 8178007

FORWARD

This Job Aid, “Whirlpool Electric Built-In Double Oven,” (Part No. 8178007), provides the technician

with information on the installation and service of the Whirlpool Electric Built-In Double Oven. It is

to be used as a training Job Aid and Service Manual. For specific information on the model being

serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with the Whirlpool Electric

Built-In Double Oven.

The Wiring Diagrams and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the Whirlpool Electric Built-In Double Oven.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the Electric Built-In Double Oven to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repair made

on our products by anyone other than Authorized Factory Service Technicians.

Copyright 2001, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

Table of Contents

Page

SPECIFICATIONS .................................................................................................................. 1-1

INSTALLATION HIGHLIGHTS................................................................................................ 2-1

Electrical Supply Requirements ......................................................................................... 2-1

Removing & Reinstalling The Oven Door .......................................................................... 2-3

PRODUCT OPERATION ........................................................................................................ 3-1

Air Flow .............................................................................................................................. 3-1

The Oven Shutdown Thermal Fuse & Control Panel Thermal Fuse ................................. 3-2

The Oven Door Latch Assembly ........................................................................................ 3-3

How The Self-Clean Cycle Works ..................................................................................... 3-4

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The Thermal Fuse, The Oven Control/Display Boards,

And The Touch Panel Assembly .................................................................................... 4-2

Removing The Power Supply Wiring Terminal Block

And The Upper & Lower Blower Motors ......................................................................... 4-4

Removing The Upper & Lower Oven Door Latch Assembly.............................................. 4-6

Removing An Oven Light & An Oven Temperature Sensor .............................................. 4-8

Removing A Broil Element ................................................................................................. 4-9

Removing A Bake Element .............................................................................................. 4-10

Removing An Oven Shutdown Thermal Fuse ................................................................. 4-11

Removing The Convection Fan Motor Assembly ............................................................ 4-12

Removing The Oven Door Glass, Hinges, & Handle ....................................................... 4-14

Removing The Oven Door Gasket................................................................................... 4-16

COMPONENT TESTING ........................................................................................................ 5-1

Blower Motors .................................................................................................................... 5-1

Oven Temperature Sensor ................................................................................................ 5-1

Convection Fan Motor ....................................................................................................... 5-2

Oven Shutdown Thermal Fuse .......................................................................................... 5-2

Broil Element ..................................................................................................................... 5-3

Bake Element .................................................................................................................... 5-3

Oven Door Latch Assembly ............................................................................................... 5-4

Control Panel Thermal Fuse .............................................................................................. 5-4

DIAGNOSIS & TROUBLESHOOTING.................................................................................... 6-1

Diagnostics ........................................................................................................................ 6-1

Fahrenheit To Celsius Conversion .................................................................................... 6-1

Programming The Cavity Size ........................................................................................... 6-1

Electrostatic Discharge Sensitive Electronics .................................................................... 6-1

Failure/Error Display Codes—Tech Sheets 4451887C & 4451888A ................................ 6-2

Failure/Error Display Codes—Tech Sheet 4452022A ....................................................... 6-3

Relay Logic Chart—Tech Sheets 4451887C & 4451888A ................................................ 6-4

Relay Logic Chart—Tech Sheet 4452022A ....................................................................... 6-4

Control Panel Test Locations—Tech Sheets 4451887C & 4451888A .............................. 6-5

Control Panel Test Locations—Tech Sheet 4452022A ..................................................... 6-6

- iii -

Page

WIRING DIAGRAMS & STRIP CIRCUITS .............................................................................. 7-1

Schematic Diagram 1 (Tech Sheet 4451887C) ................................................................. 7-1

Strip Circuits ...................................................................................................................... 7-2

Schematic Diagram 2 (Tech Sheet 4451888A) ................................................................. 7-4

Strip Circuits ...................................................................................................................... 7-5

Schematic Diagram 3 (Tech Sheet 4452022A) ................................................................. 7-7

Strip Circuits ...................................................................................................................... 7-8

Tech Sheet / Model Number Usage Charts ..................................................................... 7-10

TECH TIPS ............................................................................................................................. 8-1

- iv -

WHIRLPOOL MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER G B D 2 7 7 P D S 0

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

PRODUCT GROUP

G = WHIRLPOOL GOLD

R = ELECTRIC

S = GAS

PRODUCT IDENTIFICATION

B = BUILT-IN

M = BUILT-IN MICROWAVE COMBO

S = BUILT-IN HIGH-SPEED COMBO

CONFIGURATION

S = SINGLE

D = DOUBLE

C = COMBO

OVEN SIZE

24 = 24˝

27 = 27˝

30 = 30˝

FEATURE VARIATIONS

0 = STANDARD

2 = CONTINUOUS CLEAN

3 = EASY CLEAN

5 = S/C SINGLE & S/C STD DOUBLE & MWC-S/C COMBO

6 = S/C-S/C DOUBLE & CRISP S/C COMBO

7 = CONVECTION SINGLE, S/C-CONV. DOUBLE & CRISP

CONV. COMBO

8 = CONV.-CONV. DOUBLE & CONV.-CONV. COMBO

9 = MULTIMODE

DOOR TYPE

B = SOLID BLACK GLASS

P = PANORAMIC WINDOW GLASS

YEAR OF INTRODUCTION

D = 1995, G = 1998, H = 1999, J = 2000, K = 2001

COLOR CODE

B = BLACK, Z = ALMOND, Q = WHITE, S = STAINLESS, T = BISCUIT

ENGINEERING CHANGE (0, 1, 2, ETC.)

SERIAL NUMBER

SERIAL NUMBER X K 4 1 01002

MANUFACTURING SITE

X = OXFORD

YEAR OF PRODUCTION

K = 2000, L = 2001, M = 2002

WEEK OF PRODUCTION

41st WEEK

PRODUCT SEQUENCE NUMBER

- v -

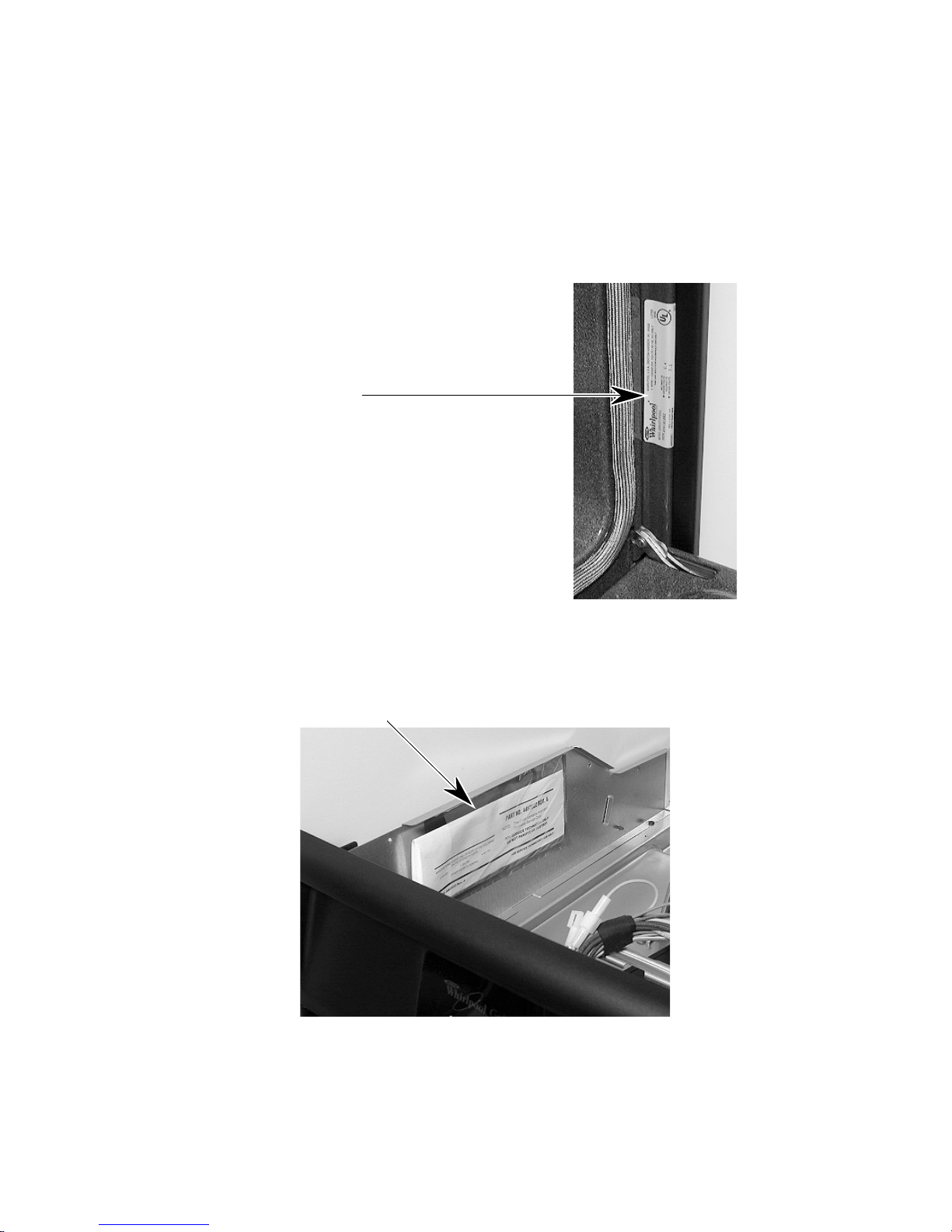

MODEL & SERIAL NUMBER LABEL

AND TECH SHEET LOCATIONS

The Model/Serial Number label and Tech Sheet locations are shown below.

Model & Serial Number Location

Upper Oven

Tech Sheet Location

(Below Top Front Cover)

- vi -

IMPORTANT SAFETY INFORMATION

Your safety and the safety of others is very important.

Important safety messages have been provided in this Job Aid. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will be preceded by the safety alert symbol and the word

“WARNING.”

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell

you what can happen if the instructions are not followed.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage or weaken the electronic control assembly. The new control assembly may appear to work well after repair is finished,

but failure may occur at a later date due to ESD stress.

• Use an anti-static wrist strap. Connect the wrist strap to the green ground connection

point, or to an unpainted metal surface in the appliance.

- OR -

Touch your finger repeatedly to a green ground connection point, or to an unpainted

metal surface in the appliance.

• Before removing the part from its package, touch the anti-static bag to a green ground

connection point, or to an unpainted metal surface in the appliance.

• Avoid touching electronic parts, or terminal contacts. Handle the electronic control

assembly by the edges only.

• When repackaging the failed electronic control assembly in an anti-static bag, observe

the previous instructions.

- vii -

— NOTES —

- viii -

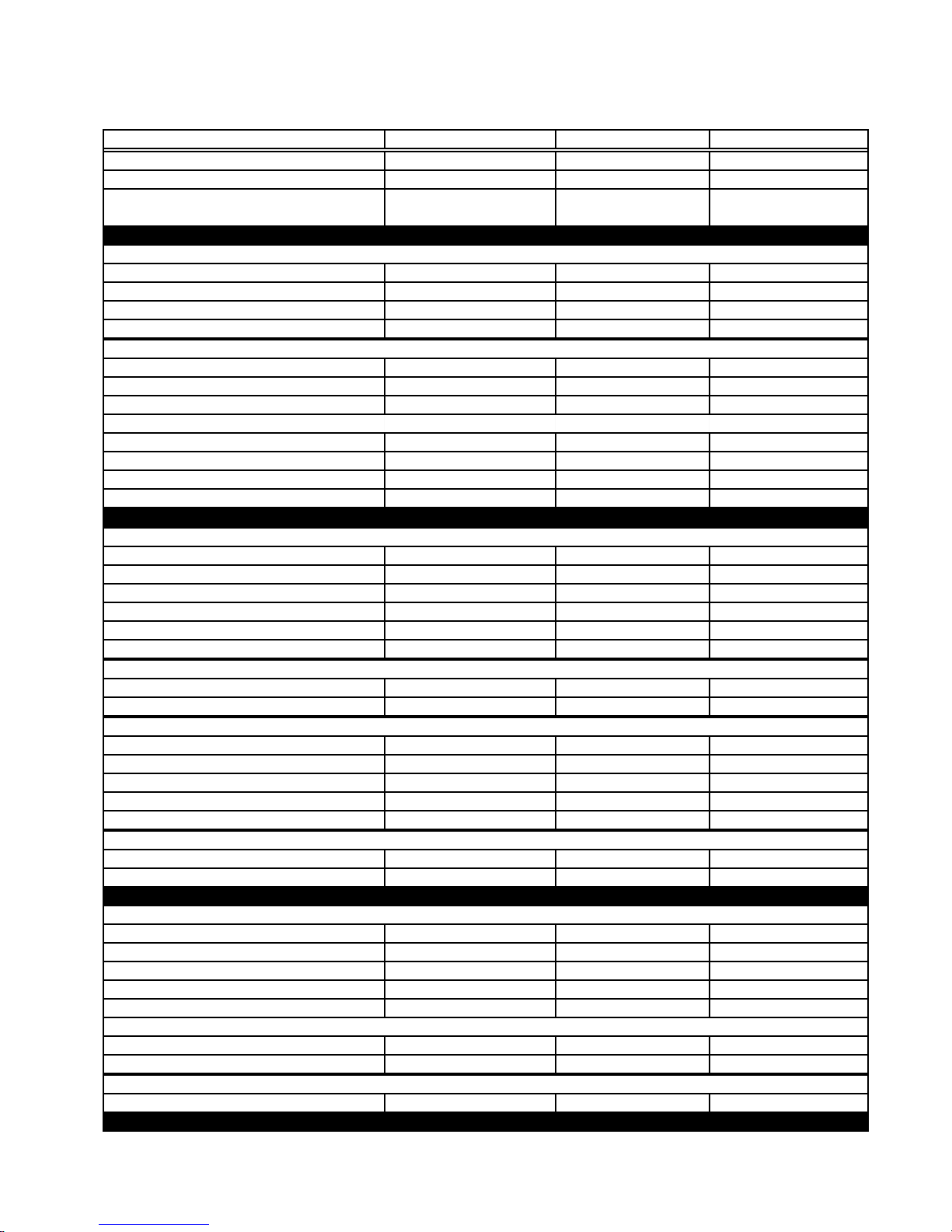

SPECIFICATIONS

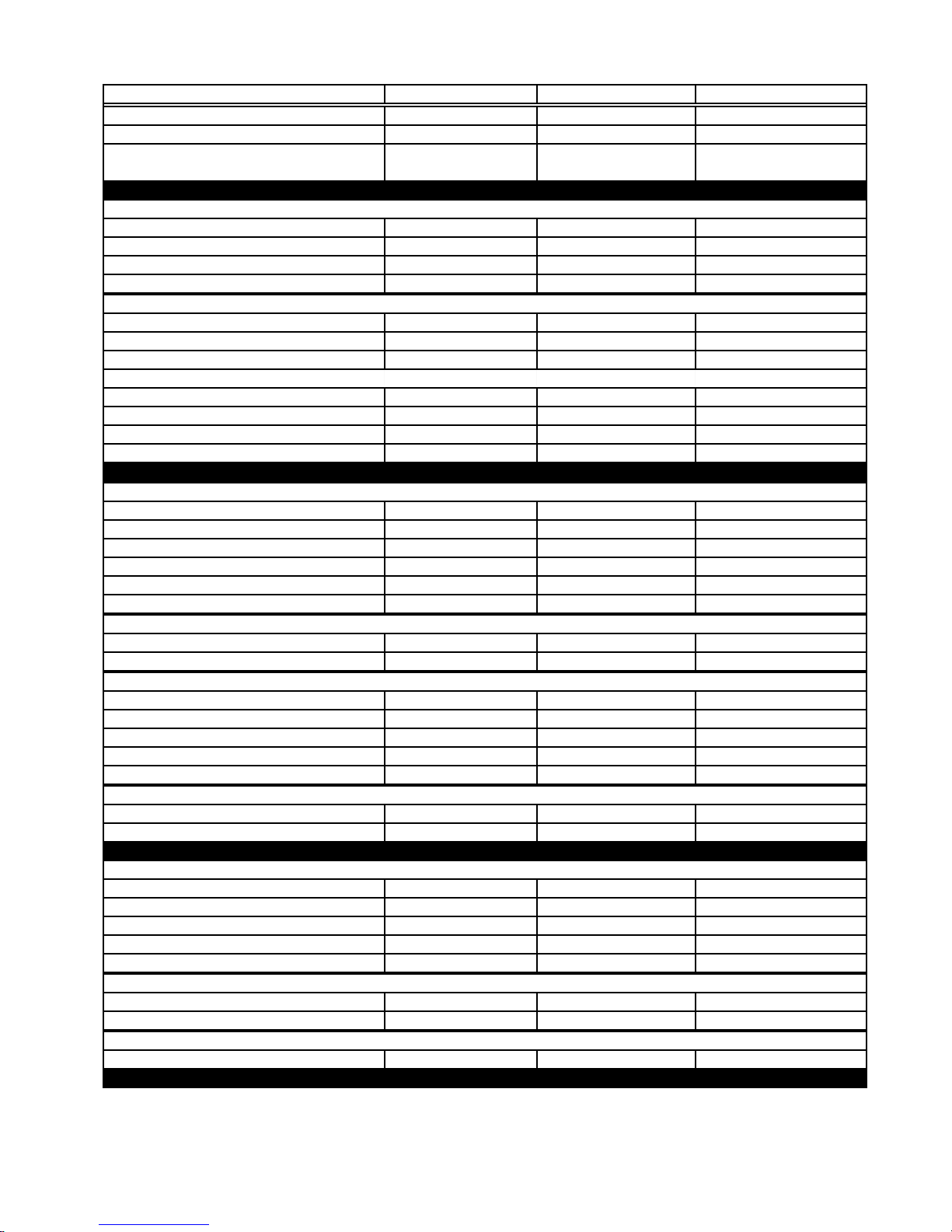

Model Number

Model Description

Size-Configuration 30 " 27 " 2 4"

Color Available Biscuit, Stainless Stainless

Dimensions/Specifications

Exterior Dimensions

Overall Height (in) 51 1/8" 51 1/8" 51 1/8"

Overall Width (in) 29 3/4" 26 3/4" 23 3/4"

Overall Depth Inc Hrdwr/Hndl (in) 25 1/8" 25 1/8" 25 1/8"

Depth W/O Handle (in)

Cutout Dimensions

Cutout Height (in) (Measure Or Min/Max) 49 3/4" 49 3/4" 49 3/4"

Cutout Width (in) (Measure Or Min/Max) 28 1/2" 25 1/2" 22 1/2"

Cutout Depth (in) (Measure Or Min/Max) 23 1/4" 23 1/4" 23 1/4"

Total Connected Load (In KW)

240 Volts 7.2 7.2 9.7

208 Volts 5.4 5. 4 7.3

Circuit Amps 4 0 4 0 4 0

Oven Control Type

Interior

Main/Single Oven

Main Cleaning System Self Cleaning Self Cleaning Self Cleaning

Main Self Clean Latch Yes Yes Yes

Main Oven Liner Finish Porcelain Porcelain Porcelain

Main Oven Height (in) 16 " 16" 16"

Main Oven Width (in) 2 5 " 2 2 " 19"

Main Oven Depth (in)

Electric Element Output

Bake (W@240/208V) 2000 W/ 1500 W 2000 W/ 1500 W 2000 W/ 1500 W

Broil (W@240/208V)

Lower/Secondary Oven

Lower/Secondary Cleaning System Self Cleaning Self Cleaning Standard

Lower/Secondary Auto Self Clean Latch Yes Yes No

Lower/Secondary Oven Height (in) 16" 16 " 16"

Lower/Secondary Oven Width (in) 2 5" 2 2 " 19"

Lower/Secondary Oven Depth (in)

Lower/Secondary Electric Element Output

Lower/Secondary Bake (w@240/208v) 2000 W/ 1500 W 2000 W/ 1500 W 2000 W/ 1500 W

Lower/Secondary Broil (w@240/208v) 3000 W/ 2250 W 3000 W/ 2250 W 3000 W/ 2250 W

Miscellaneous

Product Literature

Cookbook Part/Comment 4449237 4449237 N/A

Installation Instructions Part/Comment 4450411 4450410 4448969

Service Manual Part/Comment 8178007 8178007 8178007

Tech Sheet Part/Comment 4451887 4451887 4451887

Use & Care Guide Oven Part/Comment 4450569 4450569 4448976

Other

Agency Approvals UL UL UL, CSA

Residential Use Only

Warranty

Full (Months) 12 12 12

GBD307PD GBD277PD RBD245PD

Double Built-In Oven Double Built-In Oven Double Built-In Oven

Biscuit, White-On-White,

Black

23 7/8" 23 7/8" 23 7/8"

Electronic Electronic Electronic

18 1/2" 18 1/2" 18 1/2"

3000 W/ 2250 W 3000 W/ 2250 W 3000 W/ 2250 W

18 1/2" 18 1/2" 18 1/2"

Yes Yes Yes

1-1

Model Number

Model Description

Size-Configuration 27 " 27 " 27 "

Dimensions/Specifications

Exterior Dimensions

Overall Height (in) 51 1/8" 51 1/8" 51 1/8"

Overall Width (in) 26 3/4" 26 3/4" 26 3/4"

Overall Depth Inc Hrdwr/Hndl (in) 25 1/8" 25 1/8" 25 1/8"

Depth W/O Handle (in)

Cutout Dimensions

Cutout Height (in) (Measure Or Min/Max) 49 3/4" 49 3/4" 49 3/4"

Cutout Width (in) (Measure Or Min/Max) 25 1/2" 25 1/2" 25 1/2"

Cutout Depth (in) (Measure Or Min/Max) 23 1/4" 23 1/4" 23 1/4"

Total Connected Load (In KW)

240 Volts 9.7 9.7 9.7

208 Volts 7.3 7.3 7.3

Circuit Amps 4 0 4 0 4 0

Oven Control Type

Interior

Main/Single Oven

Main Cleaning System Self Cleaning Self Cleaning Self Cleaning

Main Self Clean Latch Yes Yes Yes

Main Oven Liner Finish Porcelain Porcelain Porcelain

Main Oven Height (in) 16 " 16" 16"

Main Oven Width (in) 2 2 " 2 2" 2 2 "

Main Oven Depth (in)

Electric Element Output

Bake (W@240/208V) 2000 W/ 1500 W 2000 W/ 1500 W 2000 W/ 1500 W

Broil (W@240/208V)

Lower/Secondary Oven

Lower/Secondary Cleaning System Standard Self Cleaning Self Cleaning

Lower/Secondary Auto Self Clean Latch No Yes Yes

Lower/Secondary Oven Height (in) 16" 16" 16"

Lower/Secondary Oven Width (in) 19" 19" 22 "

Lower/Secondary Oven Depth (in)

Lower/Secondary Electric Element Output

Lower/Secondary Bake (w@240/208v) 2000 W/ 1500 W 2000 W/ 1500 W 2000 W/ 1500 W

Lower/Secondary Broil (w@240/208v) 3000 W/ 2250 W 3000 W/ 2250 W 3000 W/ 2250 W

Miscellaneous

Product Literature

Cookbook Part/Comment N / A N / A N/ A

Installation Instructions Part/Comment 4448970 4448970 4448969

Service Manual Part/Comment 8178007 8178007 8178007

Tech Sheet Part/Comment 4451887 4451887 4451887

Use & Care Guide Oven Part/Comment

Other

Agency Approvals UL, CSA UL, CSA UL, CSA

Residential Use Only

Warranty

Full (Months) 12 12 12

RBD275PD RBD276PD RBD277PD

Double Built-In Oven Double Built-In Oven Double Built-In Oven

Biscuit, White-On-

White, Black

23 7/8" 23 7/8" 23 7/8"

Electronic Electronic Electronic

18 1/2" 18 1/2" 18 1/2"

3000 W/ 2250 W 3000 W/ 2250 W 3000 W/ 2250 W

18 1/2" 18 1/2" 18 1/2"

4448976 4448976 4448976

Yes Yes Yes

Black, White-On -White Color Available Black, White-On -White

1-2

Model Number

Model Description

Size-Configuration 30 " 30 " 30 "

Color Available

Dimensions/Specifications

Exterior Dimensions

Overall Height (in) 51 1/8" 51 1/8" 51 1/8"

Overall Width (in) 29 3/4" 29 3/4" 29 3/4"

Overall Depth Inc Hrdwr/Hndl (in) 25 1/8" 25 1/8" 25 1/8"

Depth W/O Handle (in)

Cutout Dimensions

Cutout Height (in) (Measure Or Min/Max) 49 3/4" 49 3/4" 49 3/4"

Cutout Width (in) (Measure Or Min/Max) 28 1/2" 28 1/2" 28 1/2"

Cutout Depth (in) (Measure Or Min/Max) 23 1/4" 23 1/4" 23 1/4"

Total Connected Load (In KW)

240 Volts 9.7 9.7 9.7

208 Volts 7.3 7.3 7.3

Circuit Amps 4 0 4 0 4 0

Oven Control Type

Interior

Main/Single Oven

Main Cleaning System Self Cleaning Self Cleaning Self Cleaning

Main Self Clean Latch Yes Yes Yes

Main Oven Liner Finish Porcelain Porcelain Porcelain

Main Oven Height (in) 16 " 16" 16"

Main Oven Width (in) 2 5 " 2 5 " 2 5 "

Main Oven Depth (in)

Electric Element Output

Bake (W@240/208V) 2000 W/ 1500 W 2000 W/ 1500 W 2000 W/ 1500 W

Broil (W@240/208V)

Lower/Secondary Oven

Lower/Secondary Cleaning System Standard Standard Self Cleaning

Lower/Secondary Auto Self Clean Latch No No Yes

Lower/Secondary Oven Height (in) 16" 1 6" 16"

Lower/Secondary Oven Width (in) 25 " 2 5 " 2 5 "

Lower/Secondary Oven Depth (in)

Lower/Secondary Electric Element Output

Lower/Secondary Bake (w@240/208v) 2000 W/ 1500 W 2000 W/ 1500 W 2000 W/ 1500 W

Lower/Secondary Broil (w@240/208v) 3000 W/ 2250 W 3000 W/ 2250 W 3000 W/ 2250 W

Miscellaneous

Product Literature

Cookbook Part/Comment 4449066 4449066 4449066

Installation Instructions Part/Comment 4448975 4448975 4448975

Service Manual Part/Comment 8178007 8178007 8178007

Tech Sheet Part/Comment 4451887 4451887 4451887

Use & Care Guide Oven Part/Comment

Other

Agency Approvals UL, CSA UL, CSA UL, CSA

Residential Use Only

Warranty

Full (Months) 12 12 12

RBD305PD RBD306PD RBD307PD

Double Built-In Oven Double Built-In Oven Double Built-In Oven

Biscuit, White-On-

White, Black

23 7/8" 23 7/8" 23 7/8"

Electronic Electronic Electronic

18 1/2" 18 1/2" 18 1/2"

3000 W/ 2250 W 3000 W/ 2250 W 3000 W/ 2250 W

18 1/2" 18 1/2" 18 1/2"

4448976 4448976 4448976

Yes Yes Yes

Black, Almond-On-

Almond, White-On-White

Black, Almond-On-Almond,

White-On-White

1-3

— NOTES —

1-4

INSTALLATION HIGHLIGHTS

ELECTRICAL SUPPLY REQUIREMENTS

• The oven must be connected with copper

WARNING

Electrical Shock Hazard

• An electrical ground is required on this

appliance.

• Do not use an extension cord with this

appliance.

• If a cold water pipe is interrupted by plastic, nonmetallic gaskets, or other insulating materials, do not use for grounding.

• Do not ground to a gas pipe.

• Do not use a fuse in the neutral or grounding circuit. It could result in an electrical

shock.

• Check with a qualified electrician if you are

in doubt as to whether the appliance is

properly grounded.

Failure to follow these instructions could

result in death or serious injury.

GENERAL

If codes permit, and a separate grounding wire

is used, it is recommended that a qualified electrician determine that the grounding path and

wire gauge are in accordance with local codes.

The following information applies to the builtin electric wall oven wiring:

• The oven must be connected to the proper

electrical voltage and frequency as specified

on the model/serial rating plate (located on

the upper oven frame).

wire only.

• Wire sizes and connections must conform to

the requirements of the National Electrical

Code, ANSI/NFPA 70—latest edition*, and

all local codes and ordinances. Wire sizes

and connections must conform with the rating of the appliance. Copies of the standards

listed above may be obtained from:

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

• The oven should be connected directly to a

time delay fuse or circuit breaker through

flexible, armored, or nonmetallic sheathed,

copper cable. The flexible, armored cable

that extends from the appliance should be

connected directly to the junction box.

• Fuse both sides of the line.

• Locate the junction box to allow as much

slack as possible between the junction box

and the appliance so that the appliance can

be moved if servicing is ever necessary. Do

not cut the conduit.

• A U.L.-listed conduit connector must be provided at the junction box.

• Wiring diagrams are located in Section 7 of

this Job Aid.

• A Tech Sheet is located below the top access cover on all models.

• Models rated from 7.3 to 9.6 kW at 240-volts,

(5.5 to 7.2 kW at 208-volts), require a separate 40-ampere circuit. Models rated at 7.2

kW and below at 240-volts, (5.4 kW and

below at 208-volts), require a separate 30ampere circuit.

2-1

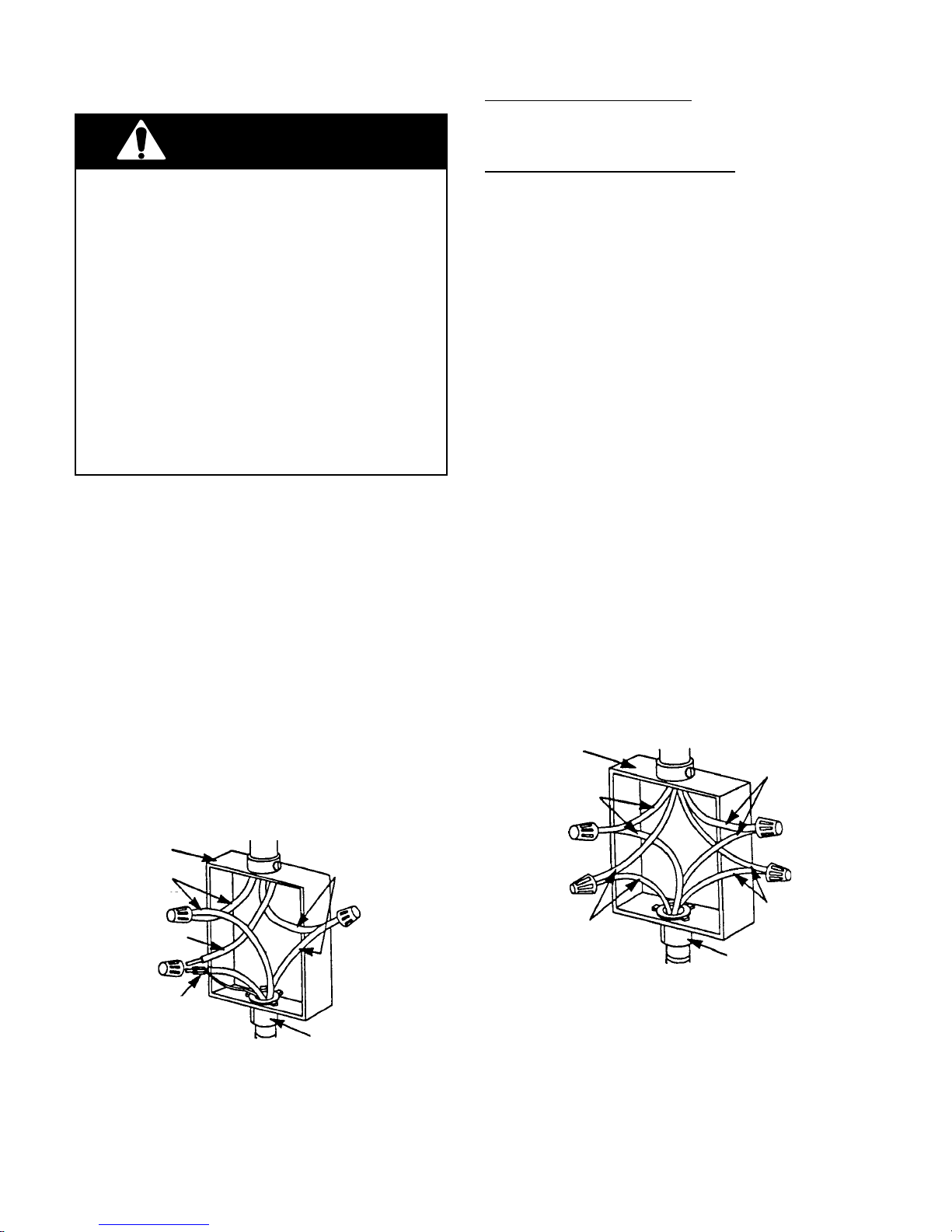

ELECTRICAL WIRING

WARNING

Electrical Shock Hazard

• An electrical ground is required on this

appliance.

• Do not connect to the electrical supply

until the appliance is permanently

grounded.

• Turn off power to the junction box before

making the electrical connections.

• Connect the appliance to a grounded,

metallic, permanent wiring system.

Failure to follow these instructions could

result in death or serious injury.

1. Insert the end of the flexible conduit through

the cabinet opening to the junction box

inlet.

2. Disconnect the power going to the junction box.

3. Open the junction box cover and connect

the flexible conduit to the U.L.-listed conduit connector.

4. Connect the ends of the black wires together with twist-on connectors (see the

illustration below).

5. Connect the ends of the red wires together

with twist-on connectors.

cable from

power supply

junction box

red wires

black wires

If local codes DO permit connecting the cabinet-grounding conductor to a neutral junction

box wire, perform steps 6 and 7.

If local codes DO NOT permit connecting the

cabinet-grounding conductor to a neutral junction box wire, or if you are connecting the

appliance to a 4-wire electrical system, perform steps 8 through 11.

6. Connect the factory-crimped bare and

white electrical wires coming from the

appliance conduit cable to the white (neutral) wire inside the junction box (see the

illustration below).

7. Replace the junction box cover.

8. Separate the factory-crimped bare and

white electrical wires coming from the

appliance conduit cable.

9. Connect the white appliance wire to the

white (neutral) wire inside the junction

box.

10. Connect the bare grounding wire from the

appliance to a grounded wire inside the

junction box. IMPORTANT: Do not con-

nect the bare grounding wire to the

white (neutral) wire in the junction box.

11. Replace the junction box cover.

cable from

power supply

junction box

white wires

red wires

white wire

white & bare

grounding

appliance wires

factory crimped cable from

oven

Crimped Grounding Conductors

To White (Neutral) Wire

U.L.-listed

connector

conduit

2-2

bare

grounding

appliance wires

cable from

oven

Separate Grounding Conductors

To White (Neutral) & Bare Wires

U.L.-listed

conduit

connector

black wires

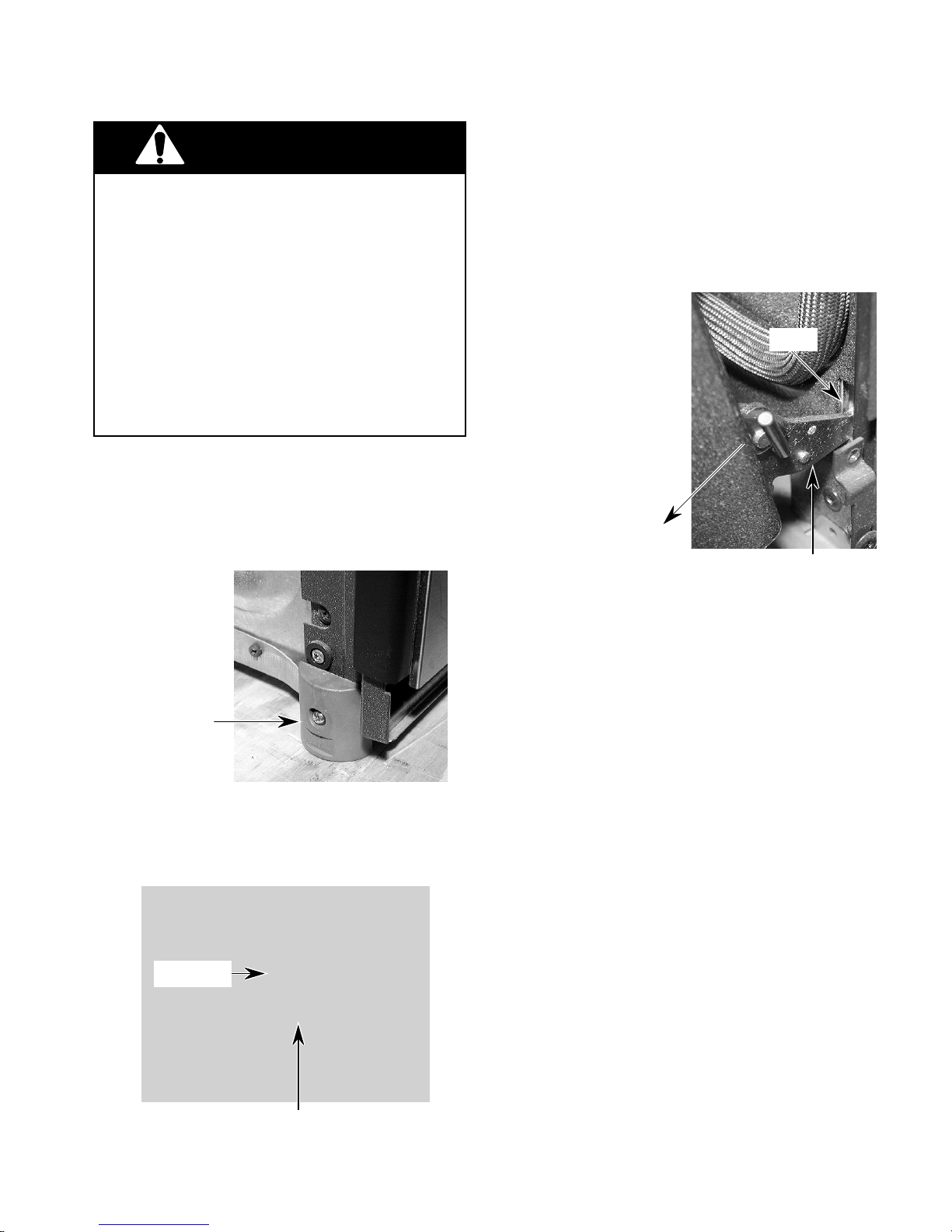

REMOVING & REINSTALLING THE OVEN DOOR

WARNING

Personal Injury Hazard

• Use both hands to remove oven doors.

• Do not use the handle or any portion of the

front frame or trim for lifting.

• Because of the weight and size of the

oven, two or more people are required to

move and safely install it.

Failure to properly grasp the oven doors or to

lift the oven properly could result in personal

injury or damage to the product.

CAUTION: Do not remove the shipping base

or the shipping feet at the front lower corners of the oven. The shipping feet will

protect the lower oven trim until the oven is

inserted into the cabinet cutout.

2. Close the oven door as far as the two pins

will allow.

3. Grasp the sides of the door and lift the door

until it stops, then pull the hinge hangers

out of the slots.

Slot

Hinge Hanger

Shipping Foot

To remove the oven door:

1. Install a pin in the hole of each oven door

hinge hanger.

Door Pin

To reinstall the oven door:

1. Grasp the sides of the door and tilt it back

at a slight angle, then insert the hinge

hangers into the hinge slots as far as they

will go.

2. Rotate the top of the door towards the

oven so the hinge hangers fit onto the

support pins.

3. Close the oven door as far as the pins will

allow, and make sure that the hinge hangers are fully seated on the support pins. If

they are not seated properly, the door will

not close tightly and may be off-center. To

seat the hinge hangers, open the door

slightly, and push in on the bottom until the

hangers are fully seated.

4. Open the oven door to its fully open position and remove the two hinge hanger

pins.

5. Close the oven door completely and check

it for proper operation and alignment.

Door Pin Into Hinge Hanger Hole

2-3

— NOTES —

2-4

PRODUCT OPERATION

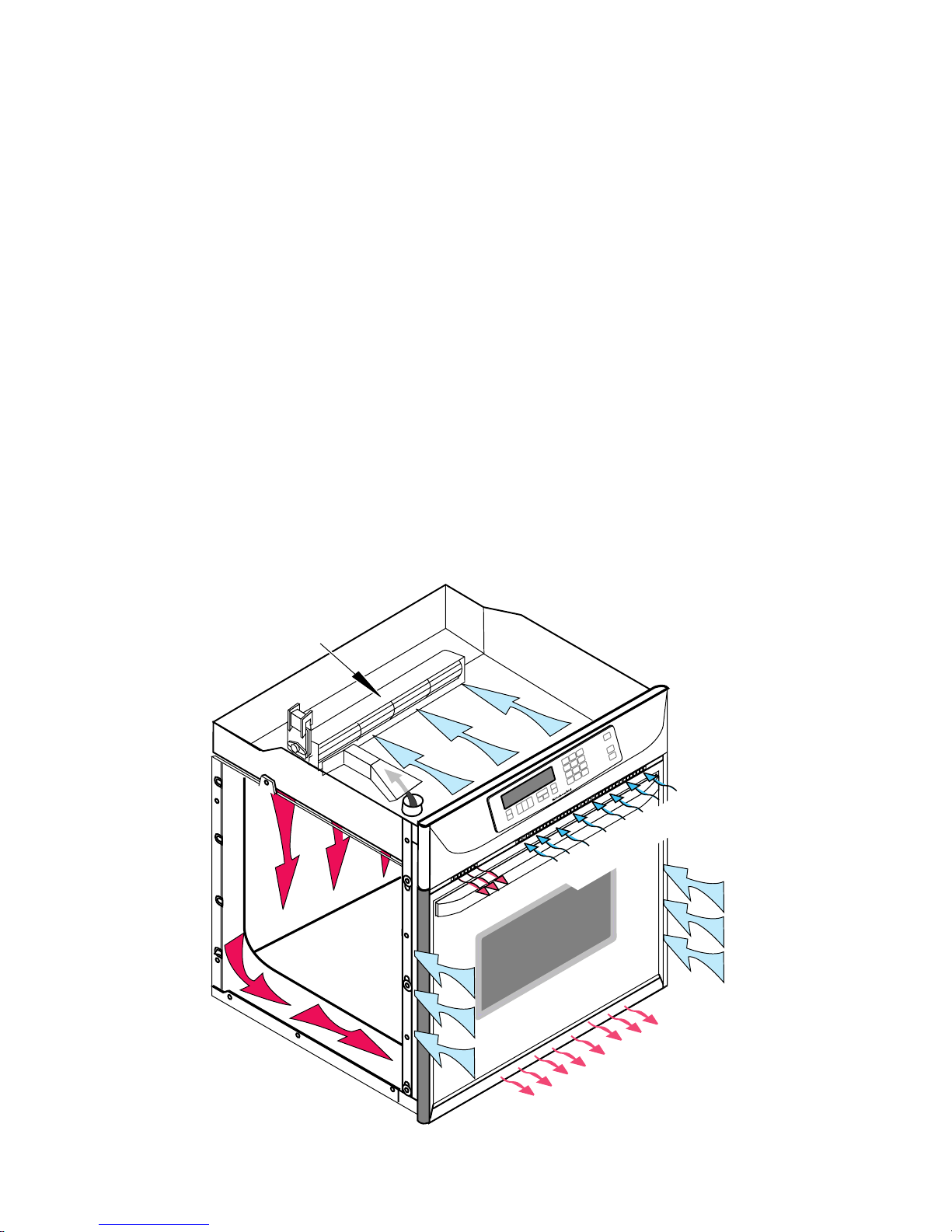

AIR FLOW

Intake air is drawn into the oven at two locations: through the control panel vent, (over the

latch assembly and the inner chassis top), and

through the side mounting rails (over the oven

sides and around the back). Air also enters the

oven at the back through the openings on the

upper section of the rear cover. At this point,

the air from the sides and the top mix. The air

is then pulled through the blower, down the

back of the unit between the outer and inner

rear covers, and out the front of the unit via the

bottom vent trim.

Air from the blower is forced over the cavity

vent. The pressure differential causes air to be

drawn from the cavity, where the air exits

through a small opening on the left side of the

control panel vent.

Air passes through the oven door by a combination of natural and forced convection. Air

enters the door through the bottom slots, and

passes between the outer glass, and the angled

inner glass. This air exits through the top slots

in the door via natural convection. Air also

enters the bottom of the door, and is drawn

between the two pieces of inner door glass,

where it exits through the top slots in the upper

part of the door. This air is then drawn into the

blower, and is forced down the back of the unit

between the inner and outer chassis covers,

and finally out the bottom vent.

The purpose of the convection fan is to circulate hot air inside the oven cavity, not to evacuate the air. Thus, the air flow for the convection

models and the non-convection models, is the

same.

BLOWER

INTAKE AIR

EXHAUST AIR

INTAKE AIR

OVEN

EXHAUST AIR

3-1

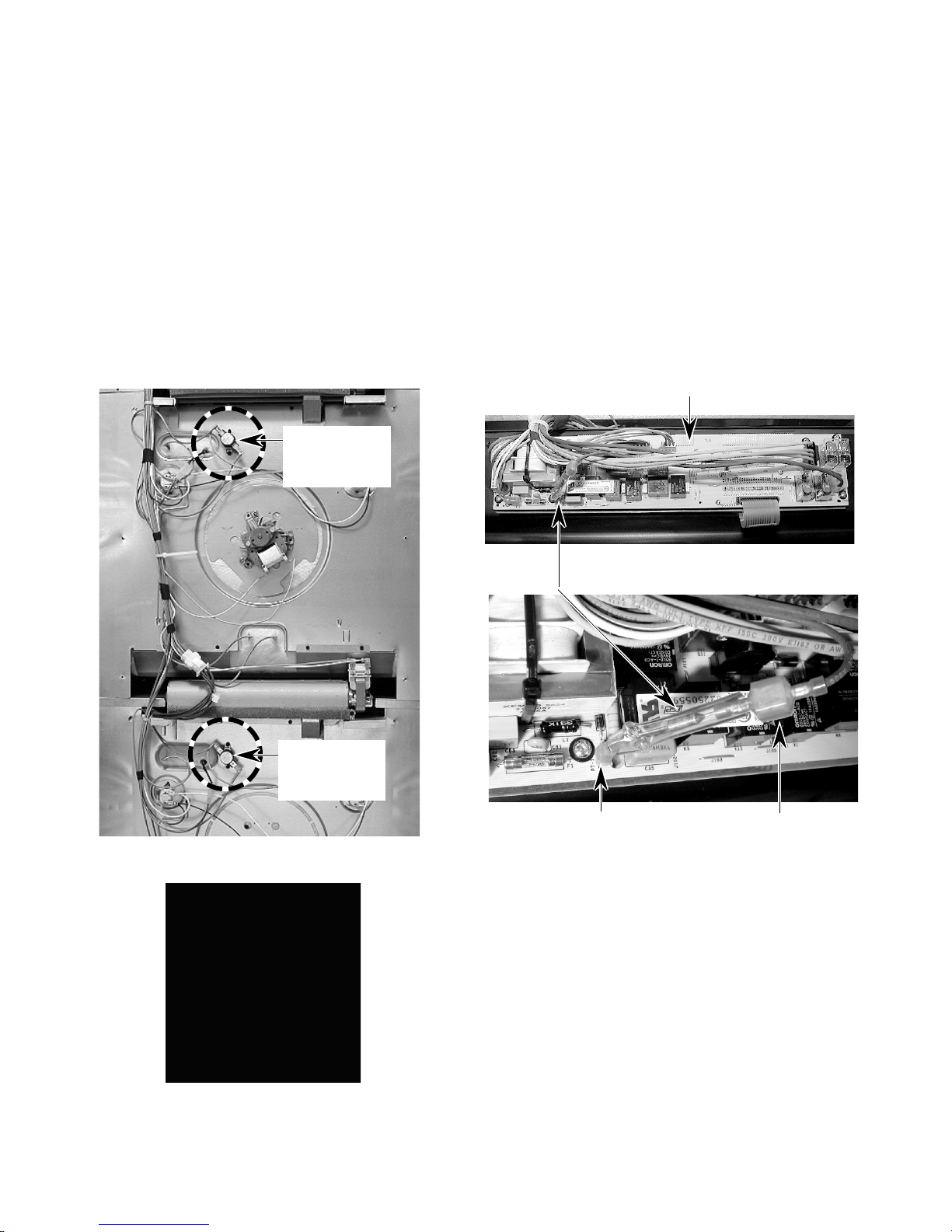

THE OVEN SHUTDOWN THERMAL FUSE

& CONTROL PANEL THERMAL FUSE

There are two thermal fuses on the oven. The

thermal fuses operate as follows:

• Upper & Lower Oven Shutdown Ther-

mal Fuse — These thermal fuses are

located on the rear of the oven at the indicated locations. Each oven shutdown

thermal fuse opens L2 to the oven if the

temperature at the rear panel exceeds

160˚C/320˚F. The two fuses are onetime, non-resettable safety devices.

Upper Oven

Shutdown

Thermal Fuse

• Control Panel Thermal Fuse — Protects the control panel area if the temperature exceeds 101˚C/214˚F. If the

fuse opens, it shuts down the entire unit

(no clock, etc.). One end of the thermal

fuse is connected to the control panel

at lug P7-1, and the other end is connected to the main wire harness. The

thermal fuse is a one-time, nonresettable fuse.

Control Panel

Thermal Fuse

Lower Oven

Shutdown

Thermal Fuse

BACK OF OVEN

Oven Shutdown Thermal Fuse

3-2

Connector P7-1

Connector To Wire

Harness

Loading...

Loading...