WHIRLPOOL AWSE 7100 Installation Instructions

DWG NO.

DWG REV

DESCRIPTION

DRAWING NUMBER

SHEET

A RELEASE NEW DRAWING

Chens8

663165

2011-8-09

NOTE: Rohs conformity.

W10416137 A

THIS DRAWING IS THE PROPERTY OF WHIRLPOOL CORP. IT CONTAINS CONFIDENTIAL

INFORMATION BELONGING TO AND/OR ENTRUSTED TO WHIRLPOOL. IT IS DISCLOSED IN

CONFIDENCE AND SHALL NOT BE HELD, REPRODUCED, DISCLOSED OR USED EXCEPT IN A

MANNER AND FOR A PURPOSE EXPRESSLY PERMITTED BY WHIRLPOOL IN WRITING.

VENDORS SHALL NOT REVISE ANY PHYSICAL, DIMENSIONAL, OR PERFORMANCE

CHARACTERISTICS UNLESS AUTHORIZED IN WRITING BY WHIRLPOOL ENGINEERING GROUP.

WHIRLPOOL TEST SPECIFICATIONS, IF ANY, ARE NOT INTENDED TO ASSUME ANY

RESPONSIBILITY FOR SUBSEQUENT PROBLEMS WITH OR CAUSED BY THE PART, COMPONENT,

OR ASSEMBLY PROVIDED BY THE SUPPLIER, AND DO NOT RELIEVE THE SUPPLIER OF ITS

OBLIGATIONS INCLUDING, BUT NOT LIMITED TO, THE NEED TO PERFORM ITS OWN TESTING,

INSPECTION AND ONGOING QUALITY CONTROL, AND ASSURING FITNESS FOR USE. ANY

WHIRLPOOL RECOMMENDED TEST AND ITS OUTCOME DO NOT IN ANYWAY LIMIT OR CHANGE

THE WARRANTY CONTAINED IN WHIRLPOOL'S PURCHASE ORDER OR SUPPLY AGREEMENT.

BY

= CONTROL CHARACTERISTIC

Summer Chen

install instruction

W10416137

Released

DATE

2011-8-09

1 OF 1

Whirlpool Corporation

Benton Harbor, MI

USA

REV DESCRIPTION OF CHANGE BY E.N. DATE.

In some European factories the letter "W" of the part code

mentioned herein will be automatically replaced by the

number "4000" (e.g. "W12345678" becomes "400012345678")

Released

F

,CONTROL PANEL.

In some European factories the letter "W" of the part code

mentioned herein will be automatically replaced by the

number "4000" (e.g. "W12345678" becomes "400012345678")

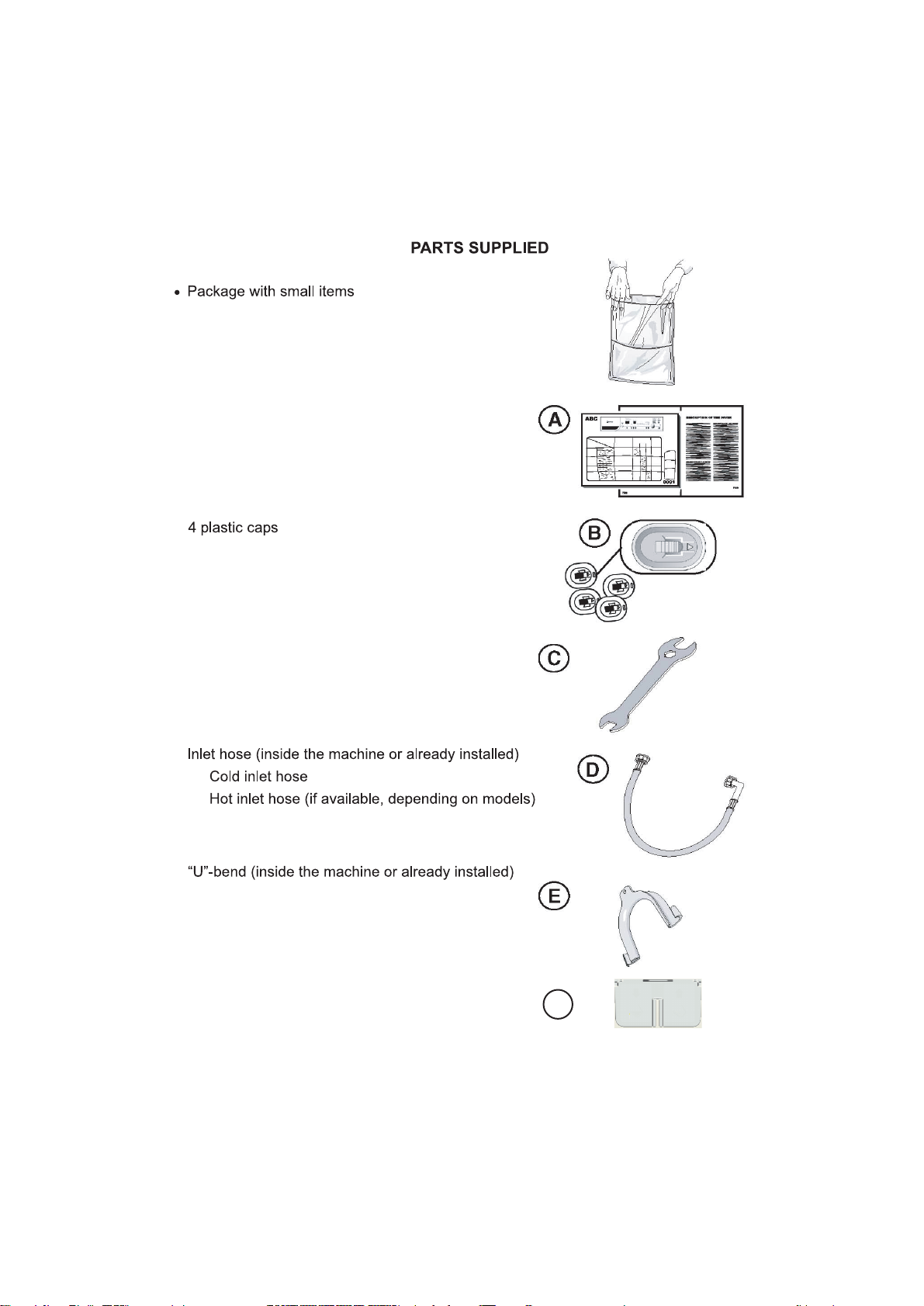

Instruction for use, installation guide, warranty card

(depends on model) (A)

(B)

Wrench(depends on model) (C)

(D)

Released

(E)

Separator (installation should refer to IFU and only

applicable for specific model) (F)

F

In some European factories the letter "W" of the part code

mentioned herein will be automatically replaced by the

number "4000" (e.g. "W12345678" becomes "400012345678")

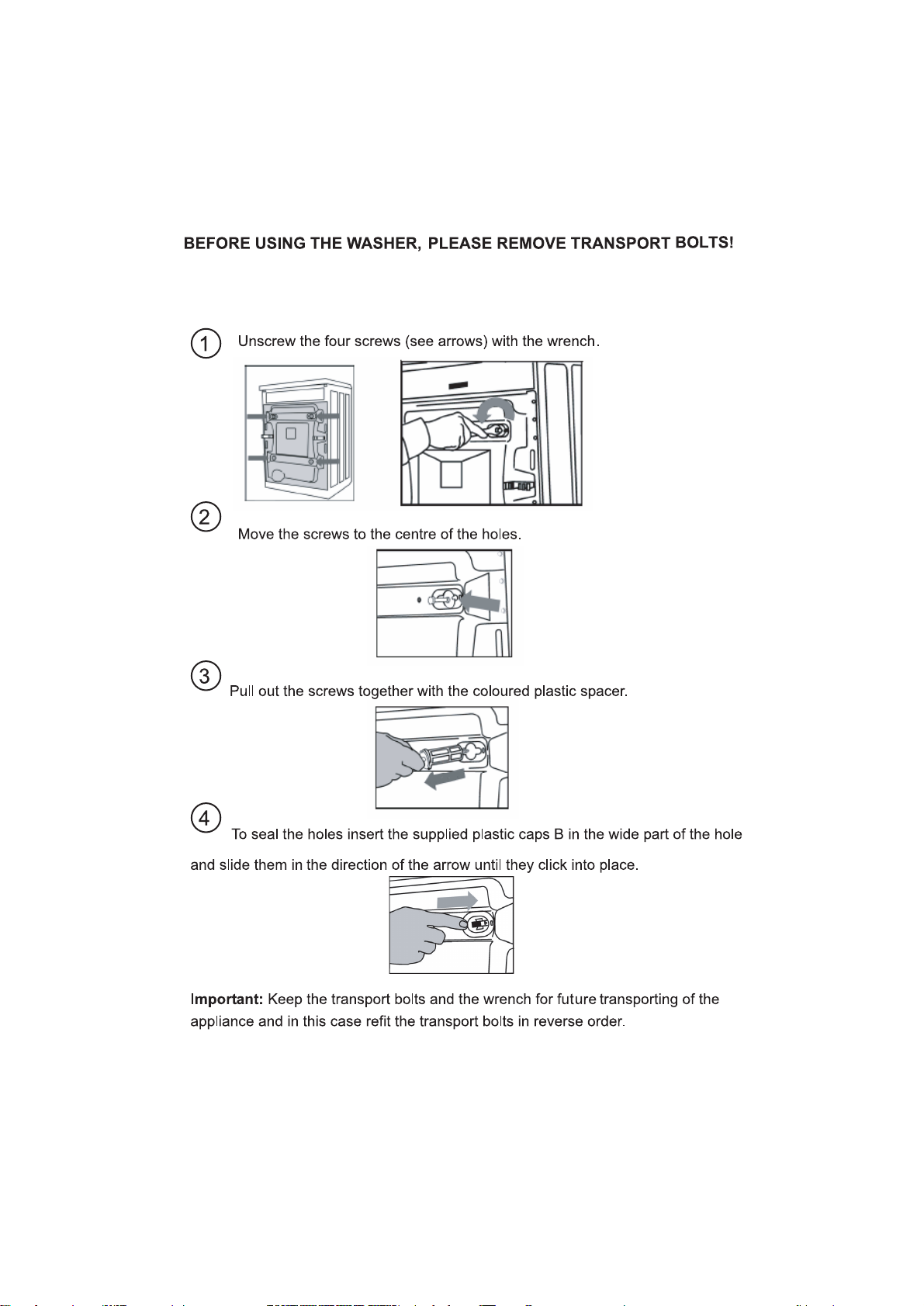

Important: Transport bolts which are not removed can cause damage to the

appliance.the weight of the wash machine is excess 55kg,so need

two adults to move it

Released

Notes:

Do not operate the appliance without the protective covers installed!

In some European factories the letter "W" of the part code

mentioned herein will be automatically replaced by the

number "4000" (e.g. "W12345678" becomes "400012345678")

by

Released

In some European factories the letter "W" of the part code

mentioned herein will be automatically replaced by the

number "4000" (e.g. "W12345678" becomes "400012345678")

for models having Dual Inlets.

If the flexible hose is too short, replace it with a 3 m Water Stop hose (available for sale

from After-Sales Service or from your dealer). This replacement is only to be carried

out by a trained electrician. Depending on the model, the inlet hose and the plastic

enclosure at the tap connection contain electrical components. Do not cut the hose

and do not immerse the plastic enclosure in water. Isolate the appliance from the

mains immediately if the hose is damaged.

Released

In some European factories the letter "W" of the part code

mentioned herein will be automatically replaced by the

number "4000" (e.g. "W12345678" becomes "400012345678")

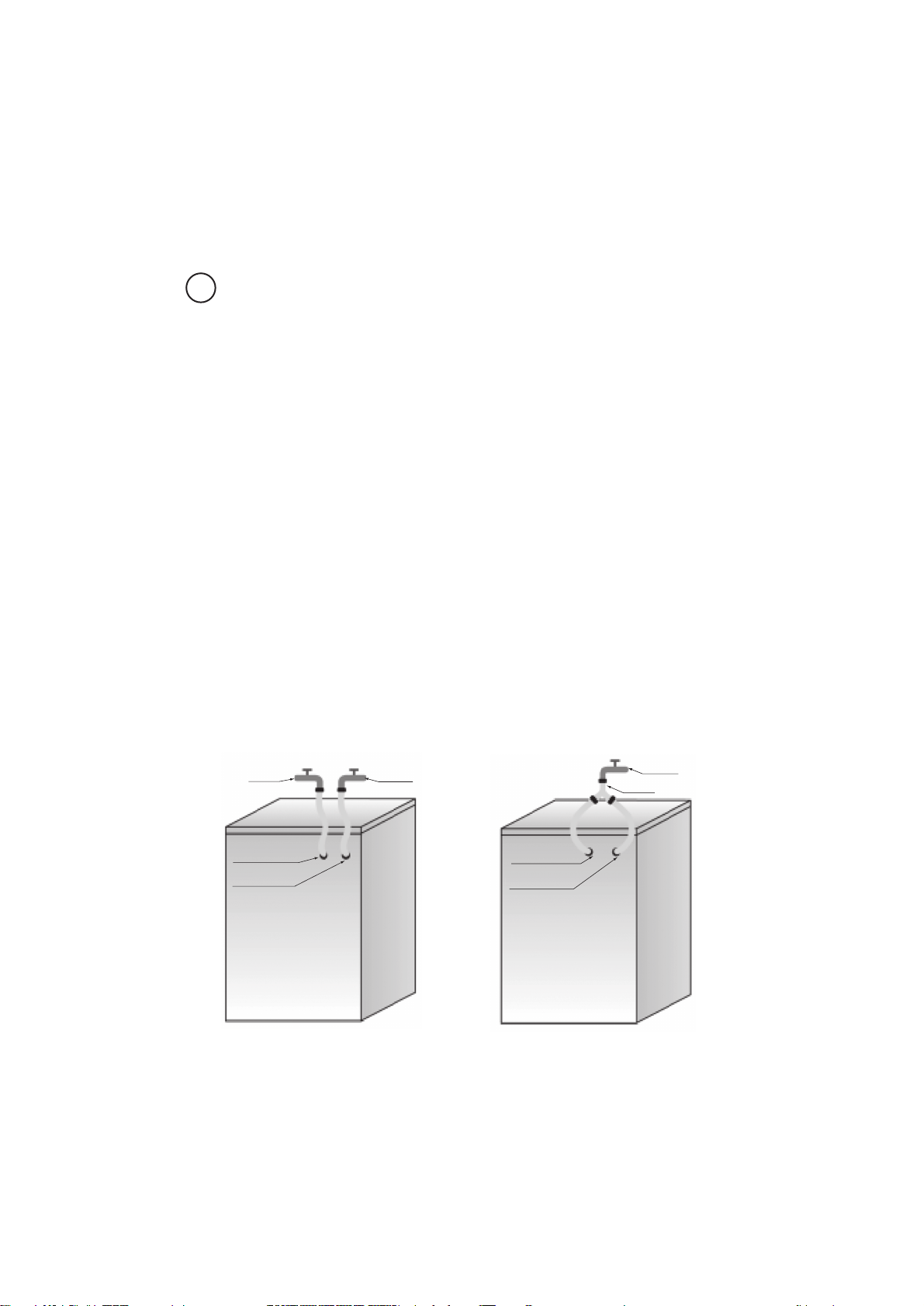

HOT / COLD FILL INSTRUCTION

For Models with Dual Inlets

10

If you wish to connect hot and cold water supply (Fig.1):

1. Fix the red marked inlet hose to the hot water tap and to the inlet valve with the red

filter on the rear side of machine.

2. Fix the other inlet hose to the cold water tap and to the inlet valve with the blue filter

on the rear side of the machine.

Make sure:

a) The connections are tightly fixed

b) Do not invert their position (for example: cold fill into hot inlet valve and vice versa).

If you wish to connect only the cold fill follow the below instructions (Fig. 2):

1. You need a Y-piece connector. This can be purchased from local hardware or

plumbing supplier.

2. Fix the Y-piece connector to the cold fill tap.

3. Connect the two inlet valves present on the rear part of the machine to the Y-piece

connector using the hoses provided.

Ensure that:

All connections are tightly fixed.

Do not allow children to operate, crawl on, be near or inside your washer.

Note that during the wash cycles, the surface temperature of the porthole door

may increase.

Close supervision of children is necessary when the appliance is used near

children.

Hot fill

Red inlet valve

Blue inlet valve

Fig.1

Cold fill

Cold fill

Y-piece

Red inlet valve

Blue inlet valve

Fig.2

Released

In some European factories the letter "W" of the part code

mentioned herein will be automatically replaced by the

number "4000" (e.g. "W12345678" becomes "400012345678")

Loading...

Loading...