Whirlpool ADN 112, ADN 108, ADN 109, ADN 117, ADN 118 INSTRUCTION FOR USE

...

ICE CUBES MAKERS Range

SPRAY Technology

CONTENTS

Introduction

Warnings........................................................................................................................................3

Description – Operating Principles.................................................................................................5

Operating principle following the electric diagram..........................................................................6

Specifications

Diagrams of connections and dimensions......................................................................................9

Consumptions, weights, packaged dimensions and volume.........................................................10

Technical Data............................................................................................................................11

Production Figures......................................................................................................................12

Reception of the machine

Packaging - Housing – Specifications plate.................................................................................16

Installation

Required conditions for placement of unit - Water and drainage..................................................17

Connection to water mains (water condensing ) – Connection to drain – Electrical connection....18

Starting

Preliminary checking...................................................................................................................19

Starting.......................................................................................................................................20

Adjustments

Fan pressostat (air condensing)...................................................................................................21

Security pressostat......................................................................................................................22

Maintenance and cleaning instructions and procedures

Maintenance chart.......................................................................................................................23

Water condenser – Air condenser - Evaporator / Water tray........................................................24

Storage bin – Housing - Pipes and nozzles..................................................................................25

Water Filter – Water leaks control...............................................................................................26

Special advises of use R404A Refrigerant................................. ............................................................26

Troubleshooting .....................................................................................................................................27

2

INTRODUCTION

Thank you for choosing ITV's NG DP Ice Cube Maker.

You have purchased one of the most reliable ice-making products on the market today.

Carefully read the instructions contained in this manual since they provide important

information relative to safety during installation, use, and maintenance.

WARNINGS

- This appliance should be installed by approved Technical Service Personnel.

- This plug should be accessible at all times.

- To reduce the risk of electrical shock, ALWAYS disconnect the machine BEFORE

cleaning or maintaining the equipment. Do not attempt to install, service, or modify this

machine.

- Improper use by other than specially trained technicians is extremely dangerous

and may result in a fire or electric shock.

- This product has not been designed for any uses other than producing ice cubes

with drinking water.

- It is extremelly dangerous to modify or try to modify this appliance. Besides it would

automatically cancel the warranty totally.

- This appliance is not intended for use (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the appliance by a person

responsible for their safety.

- Children should be supervised to ensure that they do not play with the appliance.

- This machine should not be placed outdoors or exposed to rain.

- Connect to drinking water mains.

- Connect only with the powerd supply cord supplied with the machine.

- This appliance is not intended to be connected to a fix canalization.

- Please follow the instructions given by the manufacturer in order to guarantee the

efficiency of this machine and a proper operation. THE CLEANING AND MAINTENANCE

should be carried out by trained personnel in most of the cases.

3

IMPORTANT:

- Do not attempt to service this machine yourself. Improper use by other than

specially trained technicians is extremely dangerous and may cause severe damage to the

unit. In case of breakdown contact an authorised distributor. We strongly recommend using

only original replacement parts.

- Waste and other material should be disposed in accordance to local regulations

and procedures for waste disposal.

CLEANING AND MAINTENANCE OPERATIONS ARE NOT COVERED BY THE

WARRANTY AND WILL BE INVOICED BY THE INSTALLER..

4

DESCRIPTION

Main features:

− Stainless steel body AISI 304 and chapa galvanizada.

− Anti-blocking spray nozzles.

− Pump without seals.

− High pressure safety pressostats even in air-cooled machine.

− Large condensers (work well at high ambient temperatures; and reduce cooling water

consumption in water-cooled machines).

− TRANSPARENT CUBES with most of the water mains.

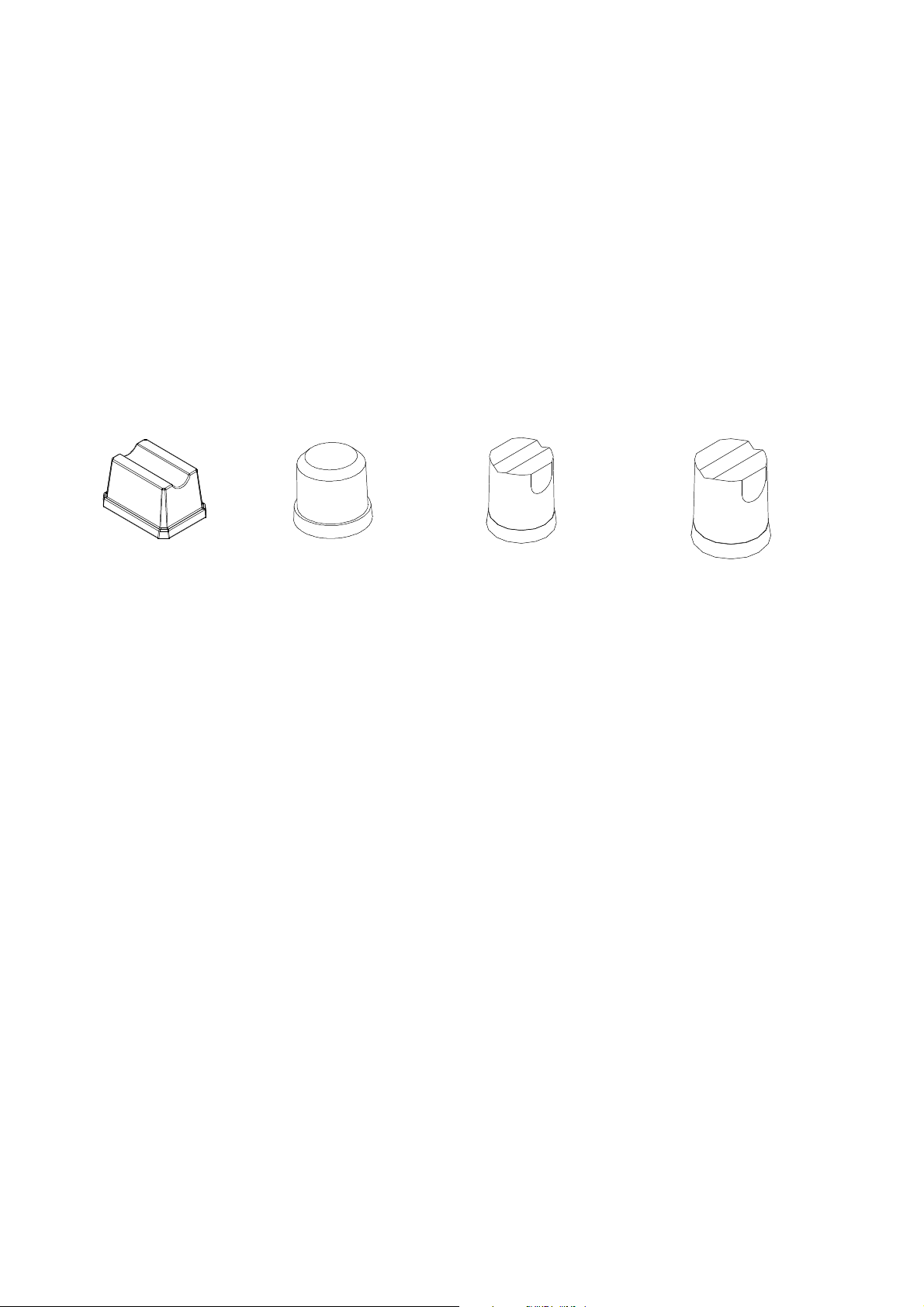

ALFA CUBE GALA CUBE DELTA CUBE SUPER STAR CUBE

OPERATING PRINCIPLE

WHEN SWITCHING ON THE MACHINE FOR THE FIRST TIME, THE MACHINE SHOULD

BE PLACED ON THE DEFROSTING STAGE. To do so, turn the wheels on the timer until

the microswitches are depressed.

- At this moment, the compressor is working; the water inlet valve and hot gas inlet

valve are both open. The water bin fills with water, any excess is lost via the maximum level

overflow.

- After a period of time controlled by the timer the hot gas valve and water inlet valve

are closed. The pump then sends water to the evaporator where the ices cubes are

gradually formed. The evaporation temperature slowly descends until it reaches a point

where the cycle thermostat is connected and starts the timer. Once this time has elapsed,

the defrosting stage (3-4 minutes) begins. The pump is off and the hot gas and water

valves are open. Some water is sent to the top of the evaporator to help the cubes unstick.

- Once the defrosting stage is over, the cycle begins again, and so it continues until

the bin is full of ice, and contact between the bin thermostat situated at the top of the bin

and the ice will stop the machine. The bin thermostat will never stop the machine in midcycle.

5

OPERATING PRINCIPLE FOLLOWING THE ELECTRIC DIAGRAM (TIMER ON

DEFROST - MICROSWITCHES DEPRESSED).

- The ITV model NG has two switches:

1st In the frontal side of the machine (with led). This turns the machine on or off when we

press it.

2nd The second switch is located in the electrical panel. This one stops the condensing unit,

but keeps the hydraulic part in operation and allows to do the cleaning of the machine

(except in NDP20 model).

- Current reaches the machine via the line connecting the blue (1) and brown (2)

terminals. The brown wire connects the compressor and timer motor. The blue wire

connects bin thermostat T1 which closes the circuit with 2. A different blue wire goes to 2

on terminal G1 which at this moment is connecting 1 and 4.

- A red wire connects bin thermostat T1 and micros G1 and G2 which close the

circuit with 4 and provide current via G1 to the timer G.

- At this point the following are connected:

v COMPRESSOR (S)

v WATER INLET VALVE (P)

v HOT GAS VALVE (Q)

v TIMER MOTOR (G)

- Since the motor of the timer (G) is working, during 1÷3 minutes the roler of micro of the

second water inlet coil (cleaning valve drive) is depressed until the pins release the micro,

closing this valve..

- After 2 to 4 minutes micros G1 and G2 will open and close circuits 1-2.

- Via terminal 2 on micro G2, current reaches the pump. Circuit 4 on micro G2 which

provides current to the hot gas valve (Q) and water inlet valve (P) will be interrupted. Since

the thermostat is between 1 and 3 the timer will receive no current. The compressor

continues switched on.

6

- Air-cooled machines have a fan (R) which is controlled by the pressostat (F).

- In water-cooled models without pressostatic valve, pressostat (J) opens and closes

the condenser electrovalve (K).

- Evaporator temperature decreases until the cycle thermostat (T2) set point is

reached, at this temperature circuit 1-2 will be closed and timer motor (G) will switch on.

- Once the cycle is over, the pins on the timer wheels will force the micros to change

circuits, stopping the pump and opening the hot gas valve and water valve. The combined

effect of hot gas and water sprayed on the top of the evaporator will release the ice cubes

and change the position of the cycle thermostat (T2).

- The ice production and defrosting cycle will continue until the ice storage bin is full, at

which point cycle thermostat (T1) will disconnect the machine, but never during a cycle, but

at the beginning of the defrosting stage, since during the production cycle, current will

reach the pump via terminals 1-2 of micro G1.

- The machine will remain disconnected until the level of ice in the bin drops below the

thermostat because of ice consumption. At this point the bin thermostat T1 changes and

the machine will start a new production cycle automatically.

7

8

SPECIFICATIONS

Models:

NDP 20

NG DP 30 - 150.

9

Loading...

Loading...