Whirlpool 8315965 User Manual

Installation Instructions

IMPORTANT:

Read and save

these instructions

IMPORTANT:

Installer: Leave Installation Instructions

with the owner.

Owner: Keep Installation Instructions for

future reference.

Save Installation Instructions for local

electrical inspector’s use.

COMMERCIAL

ELECTRONIC WASHER

120-volt, 60-Hz Models

Part No. 8315965

COMMERCIAL

LAUNDRY

PRODUCTS

®

www.whirlpool.com

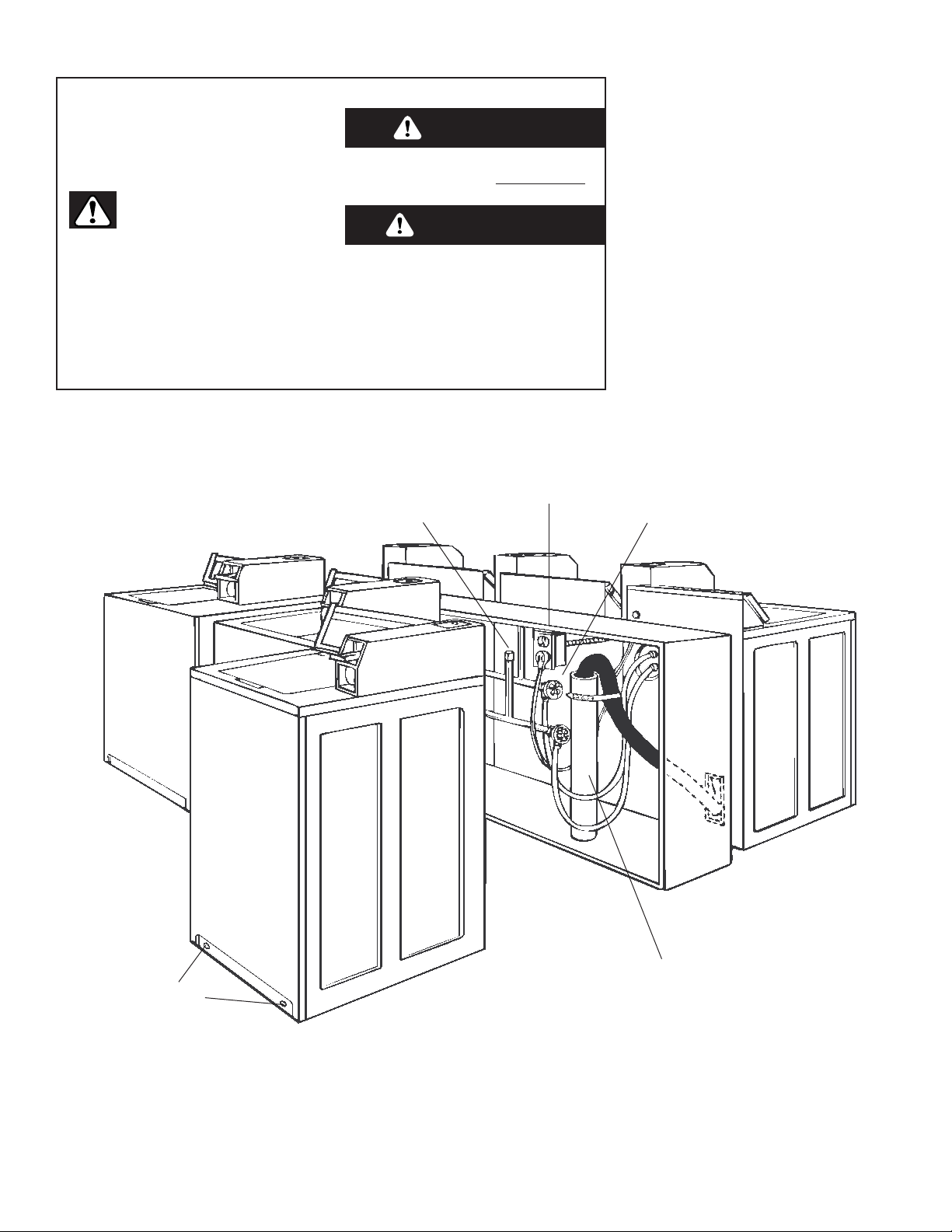

Check location where washer will be

installed. Proper installation is your

responsibility. Make sure you have

everything necessary for correct

installation.

Do Not store or operate washer below

32°F (0°C) (some water may remain in

washer).

Hot and cold water faucets: Must be

within 4 feet (1.2 meters) of the back

of the washer and provide water

pressure 10 - 100 PSI (69-690 kPa). A

pressure reduction valve should be

used in the supply line where inlet

pressure entering the building

exceeds 100 PSI (690 kPa) to prevent

damage to the washer mixing valve.

Grounded

electrical outlet

is required. See

Electrical

requirements.

Single washer

installations require

12-inch (30 cm)

minimum risers to

provide an air

cushion and

prevent noise and

damage to valves.

Untape and

open washer

lid. Remove

packages and

hoses from

washer.

Water heater: Set to

deliver 140°F to 160°F

(60°C-70°C) water to

the washer.

Standpipe drain system: Needs a twoinch (5 cm) minimum carry-away

capacity of 17 gallons (64.4 liters) per

minute. Top of standpipe must be at

least 39 inches (99 cm) high and no

higher than 72 inches (183 cm) from

bottom of washer.

Level floor: Maximum slope

under washer — 1 inch (2.5 cm).

Front access to the pump area is

available by removing 2 No. T20

Torx screws and then removing the

front panel.

Support: Floor must be sturdy

enough to support loaded washer

weight of 315 pounds (143 Kg).

A floor drain should be

provided under the bulkhead.

Prefabricated bulkheads with

electrical outlets, water supply

lines and drain facilities should

be used only where local

codes permit.

Important: Observe all governing

codes and ordinances.

PAGE 2

Before you start...

We have provided many important

safety message in this manual and

on your appliance. Always read

and obey all safety messages.

WARNING

This is the safety alert symbol.

This symbol alerts you to

potential hazards that can kill or

hurt you and others.

All safety messages will be preceded

by the safety alert symbol and the

word “DANGER” or “WARNING”.

These words mean:

All safety messages will tell you

what the potential hazard is, tell you

how to reduce the chance of injury,

and tell you what can happen if the

instructions are not followed.

You can be killed or seriously

injured if you don’t immediately

follow instructions.

You can be killed or seriously

injured if you don’t follow

instructions.

D ANGER

Your safety and the safety of others are very important.

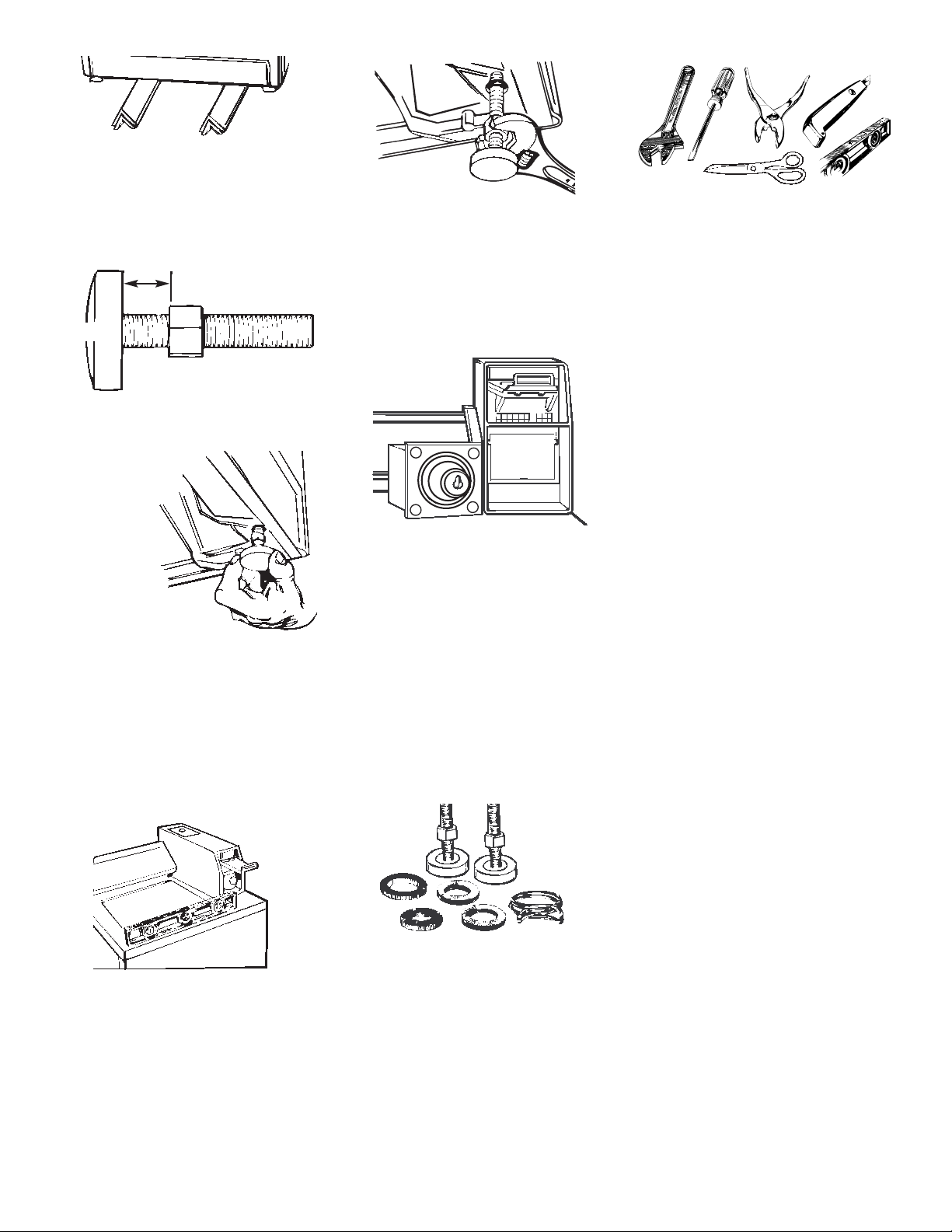

No. T20 TORX

®

screws

® Registered trademark of TEXTRON

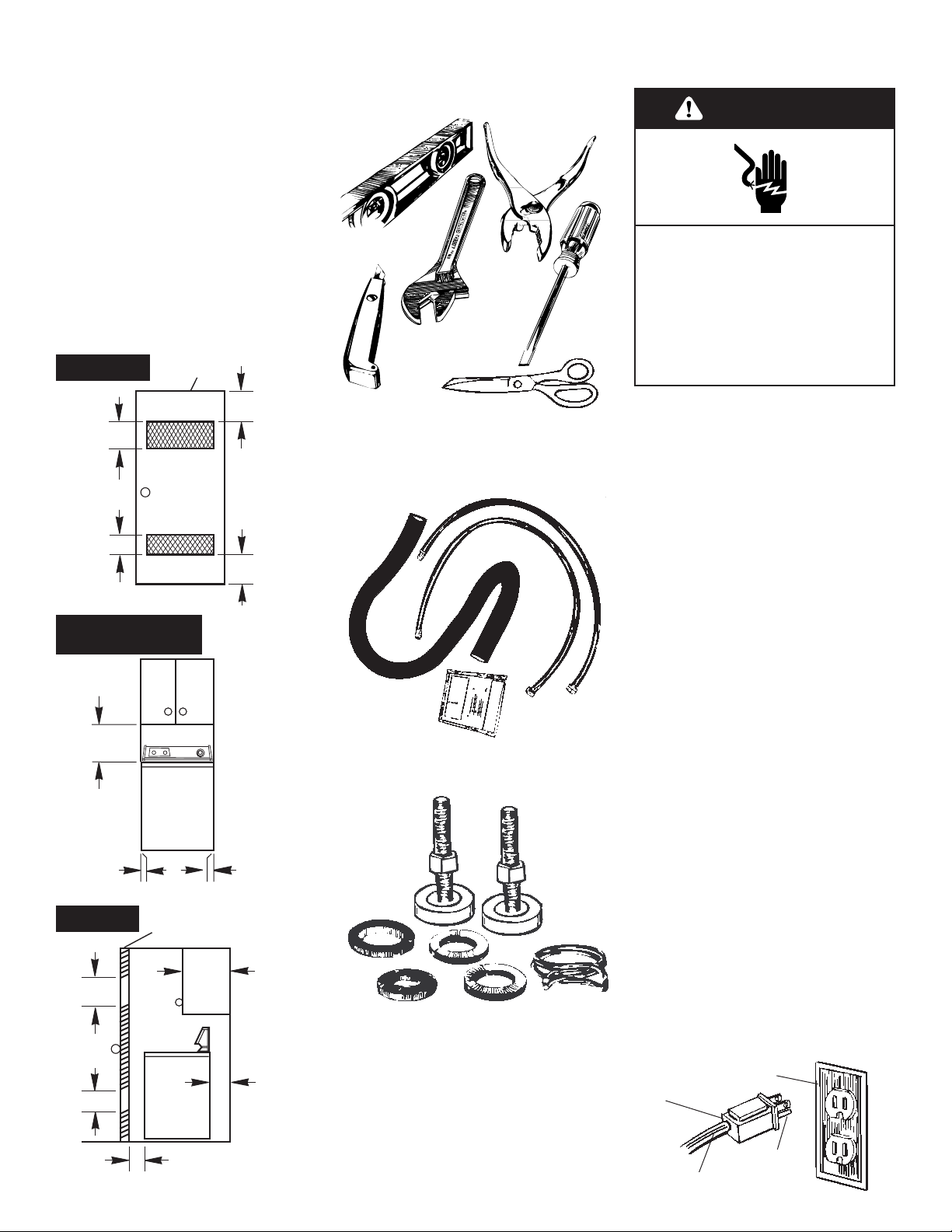

Tools needed for

installation:

level

pliers

utility

knife

wrench

scissors

flat-blade

screwdriver

Electrical requirements

ground

prong

Figure 1

PAGE 3

3-prong groundtype outlet

3-prong

ground

plug

power

supply cord

Plug into a grounded 3-prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions

can result in death, fire, or electrical

shock.

Electrical Shock Hazard

Parts supplied for

installation:

s

Remove parts from packages. Check

that all parts were included.

1 hose clamp

2 inlet hoses

4 flat water hose washers

2 front-leveling legs with nuts

1 drain hose

Recommended

ground method

For your personal safety, this appliance

must be grounded. This appliance is

equipped with a power supply cord

having 3-prong ground plug. To minimize

possible shock hazard, the cord must be

plugged into a mating 3-prong groundtype outlet, grounded in accordance with

local codes and ordinances. See Figure 1.

If a mating outlet is not available, it is the

personal responsibility and obligation of

the customer to have a properly grounded

3-prong outlet installed by a qualified

electrician.

WARNING – Improper connection of the

equipment-grounding conductor can

result in a risk of electric shock. Check with

a qualified electrician or serviceman if you

are in doubt as to whether the appliance is

properly grounded. Do not modify the plug

provided with the appliance – if it will not fit

the outlet, have a proper outlet installed by

a qualified electrician.

WARNING

*0"

*0"

Front view

(door not shown)

Side view

Minimum installation spacing

Recessed area instructions

This washer may be installed in a

recessed area or closet.

The installation dimensions shown are

the minimum spaces allowable.

Additional spacing should be

considered for ease of installation

and servicing. If closet door is

installed, the minimum air openings in

top and bottom of door are required.

Louvered doors with air openings in

top and bottom are acceptable.

Companion appliance spacing

should be considered.

closet door

Front view

closet door

17"

(43 cm)

14"

(35 cm)

max.

4"

(10 cm)

min.

1" (2.5 cm)

min.

3"

(7.6 cm)

3"

(7.6 cm)

24 sq. in.

(155 sq. cm)

48 sq. in.

(310 sq. cm)

24 sq. in.

(155 sq. cm)

48 sq. in.

(310 sq. cm)

If codes permit and a separate ground wire

is used, it is recommended that a qualified

electrician determine that the ground path

is adequate.

Do Not ground to a gas pipe.

Check with a qualified electrician if you are

not sure the washer is properly grounded.

Do Not have a fuse in the neutral or ground

circuit.

A 120-volt, 60-Hz, AC-only, 15- or

20-ampere fused electrical supply is

required. (Time-delay fuse or circuit breaker

is recommended.) It is recommended that

a separate circuit serving only this

appliance be provided.

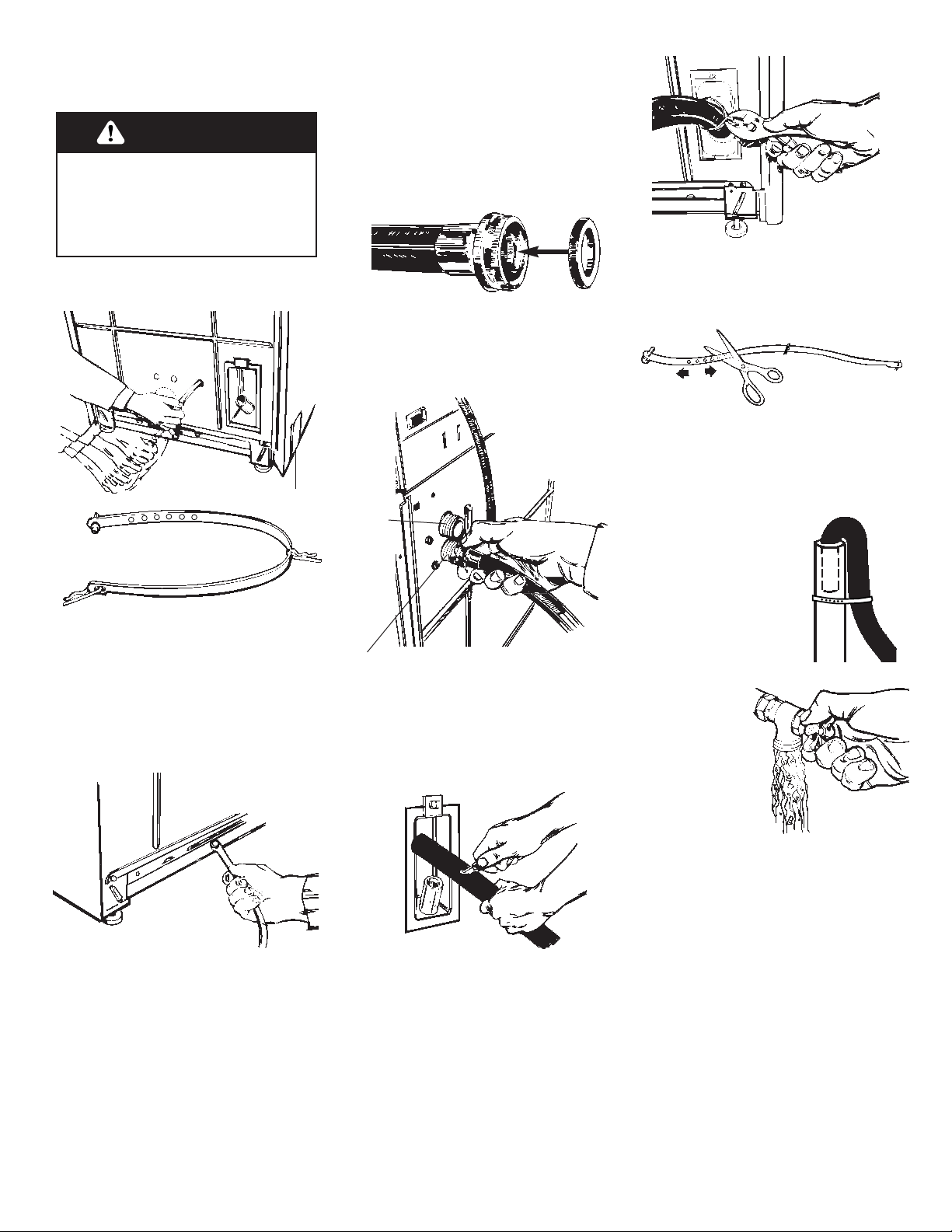

Use new hoses and washers that came

with your Whirlpool washer.

Replace inlet hoses after 5 years of use

to reduce the risk of hose failure.

Inspect and replace inlet hoses if

bulges, kinks, cuts, wear, or leaks are

found. When replacing your inlet hoses,

mark the date of replacement on the

label with a permanent marker.

2.Insert a flat washer into each end

of the inlet hoses. Check that washers

are firmly seated in couplings.

coupling

3.Attach hose to bottom inlet

valve opening first. Then second hose

to top inlet. Tighten couplings by

hand; then use pliers to make an

additional two-thirds turn.

7. Before

attaching water

inlet hoses, run

water through

both faucets into

a bucket. This will

get rid of particles

in water lines that

might clog hoses.

Mark which is the hot water faucet.

8.Attach bottom hose (inlet

marked “H”) to hot water faucet.

Attach top hose (inlet marked “C”) to

cold water faucet. Tighten coupling

to faucet by hand; then use pliers to

make final two-thirds turn.

PAGE 4

Inlets are plastic.

Do Not strip or

crossthread.

hot water

inlet valve

cold

water

inlet

valve

washer

4.Move washer close to final

position. Put “hook” end of drain hose

into standpipe. Estimate length of

drain hose needed when washer is in

final position. Hose must be cut

exactly to length so “hook” end is

held tightly over edge of standpipe. If

drain hose is too long, cut straight end

of hose. (Do Not cut “hook” shaped

end of drain hose.)

DO NOT FORCE EXCESS LENGTH OF

DRAIN HOSE DOWN THE STANDPIPE.

THIS COULD CAUSE SIPHONING. See

Step 6.

5.Place hose clamp over washer

drain connector. Push drain hose onto

washer connector. Use pliers to open

clamp and slide clamp over drain

hose. Check for good fit.

6.Measure and mark a point

approximately 16 inches (40.6 cm)

from the plug end of the shipping

strap. Cut this shipping strap at this

point.

Check that hose is not

twisted or kinked and is

securely in place.

Put “hook” end of drain

hose into standpipe.

Tightly wrap the shipping

strap around the

standpipe. Push plug into

the nearest hole in the

shipping strap.

Now start...

Pull firmly to remove the end of

shipping strap from the back of the

washer. The shipping strap plug must

be completely removed from the

washer for the self-leveling legs to

be released.

Save the shipping strap for use in

Step 6.

Excessive Weight Hazard

Use two or more people to move

and install washer.

Failure to do so can result in back

or other injury.

WARNING

shipping

tape

Pull the strap completely

out of the washer.

1.

Remove tape that covers

shipping strap. Pull to

completely remove the shipping

strap with 2 cotterpins from the inside

of the washer.

16"

(40.6 cm)

1/2"

(1.3 cm)

base

nut

10.Use legs and nuts from parts

package. Screw nut down to within

1/2 inch (1.3 cm) of

base.

11.

Insert legs into correct

holes at each front corner

of washer until nuts touch washer.

Do Not tighten nuts until Step 14.

13.Tilt washer forward raising

back legs 1 inch (2.5 cm) off of floor.

To adjust rear self-leveling legs, gently

lower washer to floor. Check levelness

of the washer by placing a

carpenter’s level on top of the

washer, first side to side; then front to

back.

14.If washer is not level, adjust

the front legs up or down. Make final

check with level.

When washer is level, use wrench

to turn nuts on front legs up tightly

against washer base. If nuts are not

tight against washer base, the washer

may vibrate.

19.Check that you have all of

your tools. Check that the shipping

strap was removed from the back of

the washer and used to secure the

drain hose.

If entire strap is not removed, washer

may vibrate and be noisy.

20.Plug power supply cord into

grounded outlet.

PAGE 5

17.

Check that all parts are now installed.

See parts list, Page 3. If there is an

extra part, go back through steps to

see which step was skipped.

18.Turn on water faucets and

check for leaks. Tighten couplings if

there is leaking. Do Not overtighten;

this could cause damage to faucets.

12.Tilt washer backward and

remove corner posts. Gently lower

washer to floor.

Move washer to its permanent

location. Remove cardboard or

hardboard from under washer.

16 . CHECK ELECTRICAL

REQUIREMENTS. BE SURE YOU HAVE

CORRECT ELECTRICAL SUPPLY AND

RECOMMENDED GROUNDING

METHOD.

9.Stack two corner posts on top of

each other. Tilt washer backwards and

insert corner posts 3 inches (7.6 cm) in

from one side of washer as shown.

Repeat with other corner posts on other

side of washer.

15.Remove the service door of

the meter case. Lift the service door

up at the back and remove. Install

money accepting device (refer to

manufacturers instructions for proper

installation). For machines using coin

slides, use adapter kit (provided with

unit). Replace meter case service

door.

Loading...

Loading...