30” Freestanding

Par? No. 76724.CO/4320880

IMPORTANT:

Maller: Leave Installation Instructions

with the homeowner

Homeowner: Keep Installation Instructions

for future reference.

Save Installation Instructions for local electrical

inspector’s use.

Gas Range

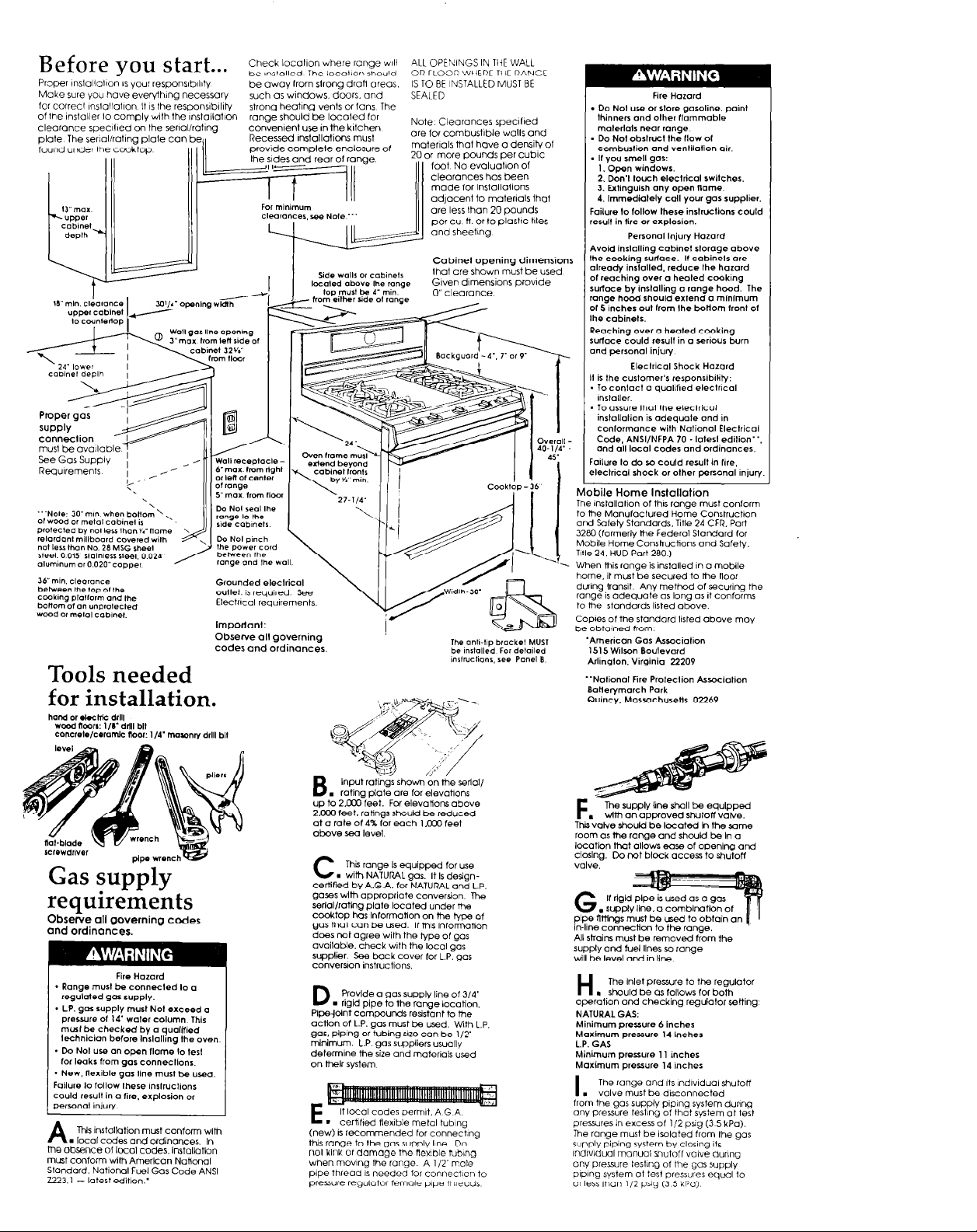

Before you start...

Proper ln~lollol~on IS your resporwbrlrty

Makn sure you have everything “ecessory

lor correcl ~nslollol~on II IS the responsrbrlriy

of the rnsloller lo comply wrlh the ~nslollat~on

cleoronce specrlred on the senalirairng

plate The serroliralrng plate co” be

found under the cooktop

III/l

JI !

I

connection

See Gas Supply

II!

, i~~~h~t

Important:

Observe 011 governing

codes ond ordinances.

Tools needed

for installation.

hard or

&cMc

wood ftoorr: 1/1’drt,, bll

Concrete/cerarr&z “oor: 1 /A’ masenry dr,,, b,,

drll,

Check locahon where range WIII ALL OPENINGS IN THC WALL

be rnslalled The locol10” should

be away lrom strong droti Oreos.

such OS windows. doors. and

strong heatrng vents Or fans The

range should

convenient us

Recessed ~nsl~,,~,,~. I

provide complele en

me s,‘4-e ,.-A 1^^1 -I

be localed for

R rn the krlchen

,4”+ir.mS muS,

I

closure of

llh

or

,bcwe the range

OR FLOOR WHERE THE RANGE

IS TO BE INSTALLED MUST BE

SEALED

Note Clearances specrlred

ore for combustrble walls ond

moterrols that hove o density of

Cabinet opening dimensions

C~bl”dS

lhot ore shown must be used

Given drmensrons provrde

a Do Not use or store gasoline. point

thinners ond other flammable

malerlals near range

. Do Not obstruct the flow of

combuslion and ventilation air.

. If you smell gas:

I, Open windows.

2. Don’1 touch electrical switches.

3. Extinguish any open flame

A. Immediately call your gas supplier.

Failure to follow these instructions could

rest.111 in fire or explosion.

Avoid inslolling cabinel storage above

the cooking surface. If cobinels ore

already inslolled. reduce the hazard

of reaching over o healed cooking

sulloce by rnslalling (1 range hoad. The

range hood should extend o minimum

of 5 inches out lrom Ihe bottom front of

Ihe cabinets.

Reaching over o healed cooking

surface could resull in o serious burn

and personal injury

II is the customer’s responsibility:

. To conlacl CI quaIlfred electrrcal

Installer.

- To assure lhal the electrical

installation is odeauate ond in

conlormance wilh’Nalionol Electrical

Code, ANSI/NFPA 70 lutes.1 edition”.

and a11 local codes and ordinances.

Failure to do so could result in fire,

electrical shock or other personal injuv.

Mobile Home Installation

The rnstallatron of thus range must conform

to the Monufoclured Home Constructron

and Safety Standards. Trtle 24 CFR. Part

3280 (formerly the Federal Standard for

Mobrle Home Conshuct~ons and Safeby.

I

Trtle ‘24, HUD Port 280)

4,

When mis range is lnslalled I” o mobile

home. it must be secured to me floor

durrng transit Any method of securing the

range is adequate os long os It conforms

to the standards lrsted

Copies of the standard listed above may

be obtalned horn:

‘American Gas Association

1515 Wilwn Boulevard

Arlinglon. Virginia 22209

“Notional Fire Proteclion Associolion

Batterymarch Park

Quincy. Massachusetts 02269

Fire Hazard

Personal Injury Hozord

Eleclr~col Shock Hazard

ObOVe.

Gas supply requirements

Observe all governing codes

and ordinances.

. Range must be connecled to a

regulated gas supply.

. LP. gm supply must Not exceed q

prassure of Id’ water column This

must be checked by a quolilied

lechnician before lnslalling the wen

- Do Not use an open flame to tesl

for leaks from gos connections.

- New, flexible gas line must be ured.

Failure lo follow these rnslructions

could result in a fire, explosion or

personal injury

A

. local codes ond ordina”ces. In

me obs?“Ce Of IoCoI CO&S. l”StOllOtlO”

must conform with Amerkon Nonow

Standard. National Fuel Gas Code ANSI

2223.1 - latest edition.’

Fire Hazard

This rnstollotion must conform

with

up to ‘2.m feet. For elevottorx above

2aM) feet. ratings should be reduced

at o rote of A% for each l.CrX feel

above sea level.

This range Is equipped for use

C

. with NATURAL QOS. It

certtned byA.G A. fof NATURAL and L.P

gases with appropriate conversion. The

serlallrating plate located under me

ccektop has lnformonon on

gas that can be used. If this information

does not agree with the type of gos

available. check with the local gas

supplier. See bock cover for L.P. gas

conversro” instructions.

Provide o gas supply line of 314’

D

n

rrgrd prpe to the range location.

Pipeioint compounds resistant to

action of L.P. gos must be used. Wrth L.P.

gas. piping or tubing srze co” be 112

mlnlmum. L.P gas suppliers usuoIIy

deterrrrne the size and materials used

on their system

(new) is recommended for connectzng

this range to the gas supply line

not kink or damage the f&able using

when moving the range. A 112. male

pope thread is needed for conr~ect~~n to

pressure regulator female pipe threads

IS

design-

me type of

me

Do

Thii’voive should be located In the zume

room OS the rorwe and should be In o

location that all&s ease of opening and

closing. Do rwt block access to shutoff

valve.

All strains must be removed from the

supply and fuel lines so range

will be level and in line.

The Inlet pressure to the regulator

H

should be os follows for both

.

operation and checking regulator setting:

NATURAL GAS:

Minimum pressure 6 inches

Maximum pressure IA Inches

L.P. GAS

Minimum pressure 11 inches

Maximum pressure 14 inches

The range and Its lndrvrdual shutoff

I

. valve must be disconnected

from the Qos supply prping system dunng

any pressure lestlng of that system ot test

pressures in excess of 112 PYQ (3 5 kPa).

The range must be rmloted from the gos

supply piping system by closrng Its

IndlVla~~ 1nOnUoi 5hUrOff VOW aUrlnQ

any prewre testi”Q of the Qos supply

prprng system 01 test pressures equo1 to

or less than l/Z ps1g (3 5 kP0)

Electrical requirements

(If model is so equipped.)

Eleclricol Shock Hozord

- Electrical ground k required on this

appllonce.

- Improper conneckon 01 the

equipment-grounding conductor

can result in tire, electrical shock,

or other personal injury.

- Check with o qualitied electrician it

You ore in doubt (II lo whether the

appliance is property grounded. Do

Not modity the power supply cord

plug. iT it will not fit the outlet. have

o proper outlet inslalled bY o

qualified electrician.

. Do Nol use an extension cord wilh

this applionca.

. Do Not have (1 fuse in the neutral or

grounding circtil. A fuse rn the

neutral or grounding circuit could

result in on electrical shock:

Failure lo tallow lhese instructions

could result in fire, electrical shock

or olher personal Injuly.

. ..Gro”“ded cola water ptpe

I-----’

A 1’2OVolt. &Hz. AC-only. 15.Ampere

haed electrical supply ls required

(Hmedeloy tise or &cult breaker Ls

recommended). It Is recommended that

a separate Clrcult serving only Hlls

appliance be ptovlded,

Electronic !gnit!an systems operate tithln

wide voltage Ilmlts. but proper arodina

and pokxiti are necesury: h addition G

checking that the oultet provktes 12Dvdt

power and k correcIiy grounded, the

otiet must be checked by a qwlit?ed

electrkian to zee II It Ir, correcny wired.

A tiring diagram b Included in literature

pcckage. The wiring diagram Is alsa

located on the back of the range.

Recommended

grounding method

DO NOT. UNDER ANY CIRCUMSTANCES.

REMOVE THE POWER SUPPLY CORD

GROUNDING PRONG.

For Your personal safety. mls appliance

must be grounded. MS appliance Is

eaukwed with a power X&Y cord

h&l& a 3pro~~grwndlng plug. To

mlnlrrdze possible shock hazard. tlw cord

nx6t be plugged Into a mating J-prong

groundln@ype wall receptacle,

grcwded In accordawe m the

NaHanal Electrical Code. ANSI/NFPA 70 latest edltlcn”. and all local codes and

ordlnonces. (See Flgws 1.) n a maw

wall receptacle knot cwaUaMe. It Is the

electrklon.

Alternate

grounding method

Do NOT. UNDER ANY CIRCUMSTANCES.

REMOVE THE POWER SUPPLY CORD

GROUNDING PRONG.

Electrical ground is required on this

oppllance.

II changing and properly grounding the

wall receptacle ir impossible and where

local codes permit (consult Your

electrkal inspector). a tempotory

adaptor may be plugged Into the

extstlng 2.prong wall receptacle to mate

tim me

J-prong power y~p@Y cord.

If

mls

is done.You must connect a

saporate copper grounding tire (No.-18

mlnlmum) to a grounded cold water

pipe”’ by rneanr of a clamp and Men

to

me

external grounding connector

screw. Do not ground to a gas supply

pipe or hot water plpe. Do not connect

to electrtcal supply unti appliance is

permonentty grounded.

(see Film 2.)

must have metcl conti”“ltV

to electrlcoi ground and no,

be lnterrup+ed by ploshc.

rubber or other elec+ricoI

I~lanng Connectorssuch

OS hoser. hhrngs. Washers or

gaskets (inciudlng water

meter or pump). Any

electrIcal lnsularlng

cmnector should be

jumped 08 show- with

No.d wire securelv

- . I/..

Now start...

With range in kitchen.

emove racks and oltwr parts

1 R

. fromltideoven.

to tree rear legs. Gently lower range to

floor. Tilt range backwards until front legs

are free

Remove shipplng materials. tape

. and protective film horn range.

3

Do not remove cardboard shipping base

at mis hme.

The backguard may already

be assembled to the range.

g If it Is not. Insert backguard

supports Into holder on the

sides 01 the range. Press

backguard down unltl locked

Into place.

insert backguard electikal

connector plug Into

receptacle In rtght rear 01

Check that wtrlng Is not klnked of plnched

between holders and bockguard.

burner box area

. To prevent tipping. tnstall range

anti-tip bracket.

- Sow these Instollalion Inslructions.

II range is moved to a new location.

the or&tip brackel must be

removed and reinslalled in the

new localion

Lin

cooMop and

5.

16.

4.

Numbers

correspond

to steps.

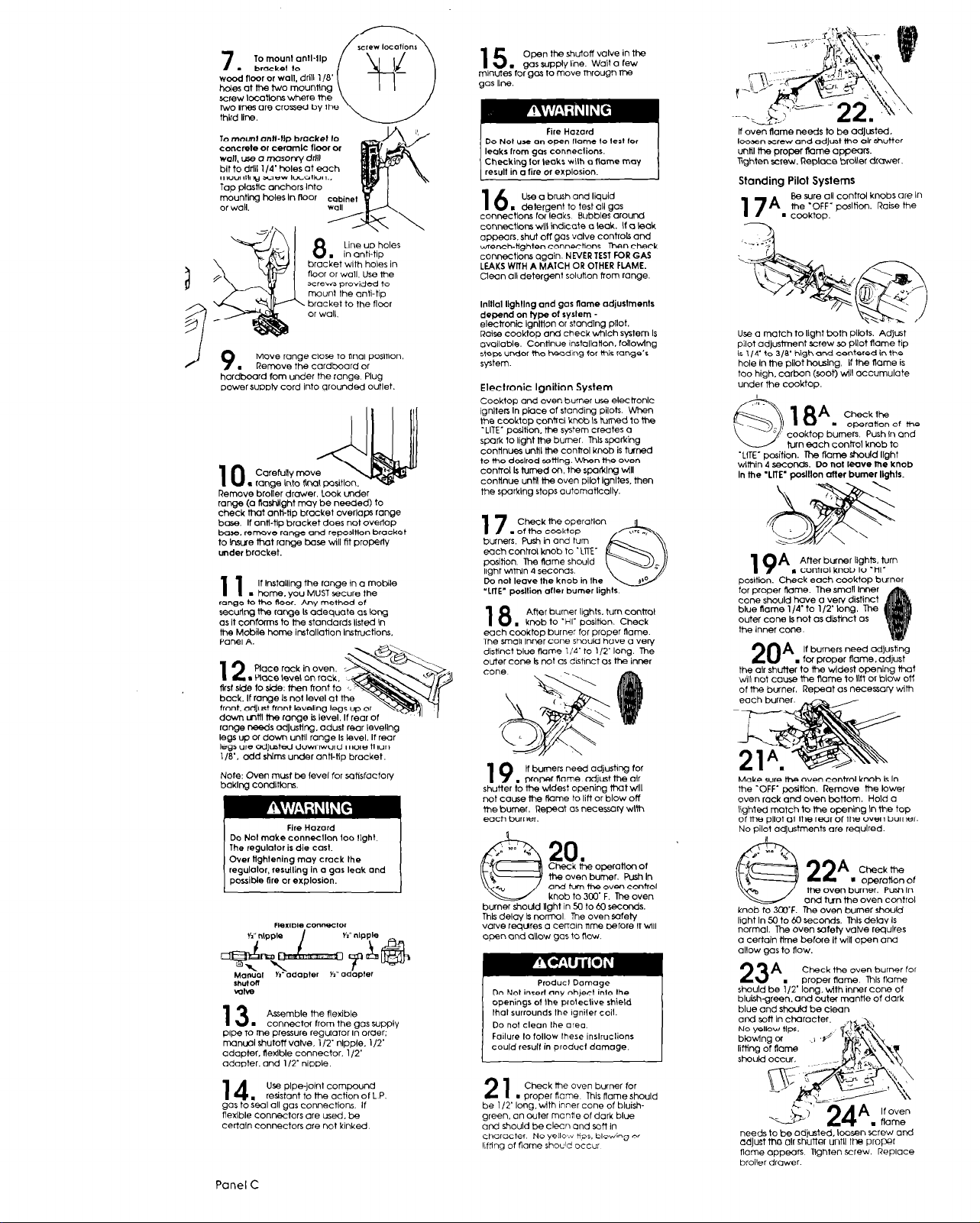

To install anti-tip bracket on wall:

l

Measure and mark a line at the center

ol i% cabinet opening on the rear wall.

Measure and mark lines 12.13/16’ and

13.15116’ tram either the left or right side

of me center line on the rear wall.

Measure and mark on Ihe rear wall a line

3/B’ from the tloor

lo Instoll anti-tlp bracket on 11-r:

a Measure and mark a line at me Center

ol the cabinet opening on the Hoor.

Measure and mark lines 12-13/16’ar?d

13.15/16’ from either the lett or rtght side

of me center line on the Roar. Measue

arc mark on me floor a line I’ from the

rear wall.

Note: II ttwe Is a cabinet on only one side.

the anti-tip bracket must be Installed rw?.i

to the cabinet, using measurements gtven.

Go to Step 7.

II Hw range will Not be Installed

. agolnst a cabinet. the ant+tip

bracket must be Installed.

. Slide range Into final locahon. Mark a

lhne on the Rooi along each side of

range about onehalf me distance from

me rear to the Iront.

To Install anti-ttp brackel on wall:

l

Measure arc mark a lane on H-6 rear

wall at the center of

Measure and mark lines 12-113/l& and

13.15/16’ horn the lett or right sides of

me center line on the rear wall. Measure

and mark on the rear wall a line 310’ horn

me floor.

lo Install antl-tip brackel on Iloor:

. Measure and mark o lane on the noor at

the center of the range locatIon.

Meowreond morkllnes 12.13116’ond

13.15/16’ from the left or rlght’slde of

the center line on me floor. Measure

and mark on the floor a line 1’ horn ti

rear wall.

Go to Step 7.

mhe ran33

location.

Panel B

anti-tip bracket must be installed Anti-hp

bracket may be fastened to the floor

under range or wall behmd range

- Conloct o qualified carpet installer

- Betore moving range across rIoor.

Fo~lure lo totlow lhese instructions

may result in damage to tloor

CoverIng.

Floor Damage

tor the best procedure to drill

mounling holes through your type

01 carpet.

slide range onto cordbxxd or

hordboard.

To mount onll-lip

7.

bracket lo

wood rbor or wall. drill l/8’

hde~ 0t the two mounnng

sc,ew bcatlorls where me

two lines ore craned by the

third line.

To mod onff-lip brockel lo

concrete or ceramk float or

wall, use o mosoru-y drill

bit to drill l/4’ holes at each

mounting screw locatIon..

Tap plostlc anchors Into

mounthg holes In floor

or won.

bracket with holes in

n00r 0, ~011. Use me

screws provided to

mount the anti-tip

bracket to the floor

or wall.

Move range close to flnol position

Remove the cardboard or

hardboord tom under the range. Plug

power supply cord into grounded outlet.

Remove broiler drawer. Look mder

range (a Ilashllght may be needed) to

check ttmt anti-tip bracket overlops range

base If ontl-tip bracket does not oveflop

hose. rerr-ove range one reposltlon bracket

to tmue that range txxe till fit properly

under bracket.

If lnstollrng the range in o mobile

1 1 m home.~ouMUSTsecure

ran@3 to me Root. Any method of

securing the range Is adequate os long

(1s it conforms to lhe standards listed In

the Mobile home Instollofion Irrst~ctions.

Panel A

Place rock in oven.

12

m Race level on rock.

first side to side. then front to

back. If range Is not level at t

front. adJut front leveling leg

down vltll the rome k level,

range reeds odJu&g. odust rear leveling

legs up or down until range Is level. If rear

legs ore od]urted downward more than

118’. odd shlrm under ant+fip bracket.

Note: Oven must be level for xlfisfactory

boklng conditkx6

Do Nol make connecllon loo Ilght

The regulator is die cost.

Over tightening moy crock Ihe

regulalor. resulling in (1 gas leak q nd

possiMe fire or explosion.

13

pipe to the pressure regulator In order.

manual shutotf valve. l/2’ nlpple. 112’

adapter, flexible connector. 1’/2’

adapter. and l/2’ nipple.

1

4.

gas 63 sBoI all gas connections. If

flexible connectors are used. be

certain connectors ore not kinked

Panel

Fire Hazard

Assemble the flexible

. connector from the gos supply

U5-y pipe-joint com,pwnU

resstont to me actron oft P

C

screvl loCalions

the

open tha shutoff valve in the

gas apply line. Wait 0 few

15

minuie;lor gas to move through tiw

gas Ilne

Use o brush and liquid

. detergent to test all gas

16

connections for leaks Bubbles around

connections will indicate o leak. If o leak

oppeors. shut oft gos valve controls and

wrench-tighten connechonr. hen check

connections again. NEVER TEST FOR GAS

LEAKS WfTH A MAICH OR OTHER FLAME.

Clean all detergent soluhon from range.

lnlllal llghllng and gas flame odjuslmenls

depend on type of syslem electronic Ignition or stondlng pIlot.

Rake cooktoo and check wtlch svstem Is

available. Cbntinue wtollaHon. fdllowing

stem under the heodlng for this range’s

system.

Electronic Ignition System

Cooktop and oven burner use elechonlc

igniters In place of standing pilots. When

the cooktop control knob Is timed to the

‘LITE’ position, the system creates Q

spark to light me burner. Thls sparking

continues until the control knob is twned

to the desired setttng. When the Oven

contrd Is fumed on. the spahlng till

continue until H-6 oven pilot Ignites. men

the SparkIng stops outOmotlColt$

Check

1 7

. of the cOOktop

burners. Push in and turn

eOch conhol knob to ‘ITIEposition The flame should

light wittin 4 seconds.

Do not leave the knob in Ihe

‘LITE” podlion after burner lights.

. knob to ‘HI- position. Check

18

each cooktop burner for proper flame.

The small inner cone should hove o vew

distinct blue flame 114’ t0 112’ long. The

outer cone Is not 0s dtstrnct 0s the inner

. proper name. adjust me air

19

shutter to the widest opening ttwt will

not come me Aame to lift or blow off

me burner. Repeat 0s necessorJ

each burner.

burner should lght in 50 to &I seconds.

Thk delay k norm0 The oven safety

valve reqtires 0 certo1n time before It till

open and Qllow QOS to flow.

Do Not insert any object inlo Ihe

openings 01 lhe proleclive shield

lhol surrounds the rgniler coil.

Do no, clean Ihe oreo

Fo~lure lo follow these inslruclions

could result in producl damage.

21

. proper Aome This name should

be l/2’ long. with rnner cone of bluish

green. an outer mantie of dark blue

and should be clew and soft in

cnaroctor, No yellw imps. blowing or

lifting of flame shocld OCCUR

me

OperonOn

After burner lights. turn control

If burners need adjustrng for

llTl *,

‘6

c3

with

ti oven burner. Push In

and ha-n the oven contfol

knob to 3M)’ F. The oven

Producl Damage

Check the oven burner for

loosen screw and adJust the &r shutter

until the proper time appears

TiQhten screw. Replace broiler drawer.

Standing Pilot Systems

17A

--x

Use o match to light both pilots. Adjust

pilot od)ustment screw so @lot flame tip

is l/4’ to 3/B’ high and centered in the

hole In the pllot hou%lng. If the fiome is

too high, curbon (soot) will oCCumulote

under me cooktop.

f3

‘LITE- position. The fTame should light

wlmin 4 second?.. Do not leave the knob

In the ‘LITE’ poslllon otter burner Ilghls.

P

position. Check each cooktop burner

for proper Rome. The small Inner

cone should have o very distinct

blue name 114. to l/2’ long. me

outer cone Is not 0s dbtlnct OS

the inner cone

the olr shutter t0 the widest Opening that

will not cause the name to lltt or blow otf

of me bwner. Repeat OS necenorv tim

Make sure the Oven control knob k In

the ‘OFF’ position. Remove the lower

oven rack and oven bottom. Hold Q

lighted match to the opening In the top

0f me pilot ot me rear 0f the oven burner.

No pilol od]ustments ore required.

knob to 3CO’F.

liclht In 50 to 60

n%mol. me oven safety valve rtiulres

a certain ltme before it will open and

allow gas to flow.

23A

should be 712’ long. ‘.+ith inner cone of

bluishgreen. and outer mantle of dark

blue and should be clean

lifting of Rome

should occur.

needs to be adjusted, looen xlrew and

adlust me air shuner unnl me proper

flame appwrs Tlghten screw. Replace

broiler drawer.

Be sure all control knobs ore In

me ‘OFF. posItion. Raise the

n

ccoktop.

"'-

1 8Am ~~~~~or me

‘,! cooktop burners. Push In and

turn arch control knob to

After burner lights. turn

. control knob to ‘HI’

19A

If burners need cd)usting

. toi proper flame. adjust

20A

N

22A

the oven burner. Push In

or-c hsn me oven control

The oven burner should

~e~0i-d~. mk de10~ IS

Check the oven burner for

proper name. mls flame

Check the

n operation of

finished installing your

new Whirlpool ranae. To aet the

most efficient use from your new

range, read your Whirlpool Use&Care

Congratulations!

Guide. Keep Installation Instructions

and Guide close to range for easy

reference. The instructions will

make reinstalling your Whirlpool

h

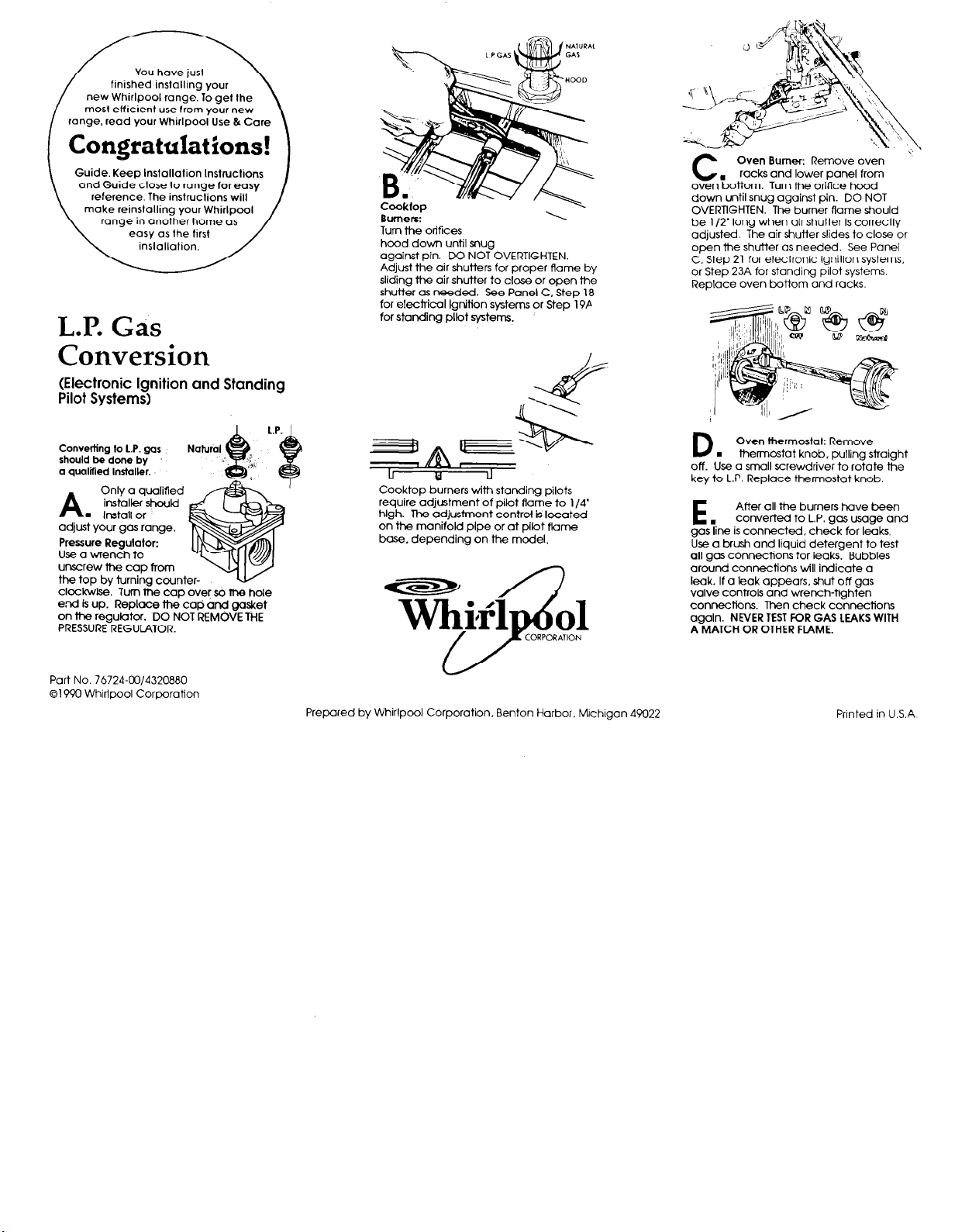

LX Gas

Conversion

(Electronic Ignition and Standing

Pilot Systems)

Converttng to L.P. gos

should be done by

a quaffled Installer.

Only a qualified

installer should

A

n

Install or

adjust your gas range.

Pressure Regulator:

Use a wrench to

unscrew the COD from

the top by turning counterclockwii. Turn the cap over so the hole

end is up. Replace the cop and gasket

on the regutator. DO NOT REMOVE THE

PRESSURE REGULATOR.

Nahml

Burners:

Turn the orifices

hood down until snug

against pin. DO NOT OVERTIGHTEN.

Adjust the air shutters for proper flame by

sliding the air shutter to close or open the

shutter as needed. See Panel C, Step 18

for electricul lgtition systems or Step 19P

for standing pllot systems.

Caoktop burners with standing pilots

require adjustment of pilot flame to l/4’

hlgh. The adjustment control is located

on the manifold plpe or at pilot ftame

base, depending on the model,

TKifl 01

CORPORAllON

Oven Burner: Remove oven

C

oventottom. Turn the orifice hood

down until snug against pin. DO NOT

OVERTIGHTEN. The burner flame should

be l/2’ long when air shutter is correctly

adjusted The air shutter slides to close or

open the shutter OS needed. See Pane

C, Step 21 for electronic ignition systems,

or Step 23A for standing pilot systems.

Replace oven bottom ond rocks.

D

off. Use a small screwdriver to rotate the

key to L.P. Replace thermostat knob.

E

gas~ne is connected, check for leaks.

Use a brush and liquid detergent to test

all gas connections for leaks. Bubbles

around connections will indicate a

leak. If a leak appears, shut off gas

valve controls and wrench-tighten

connections. Then check connections

ogoln. NEVER TEST FOR GAS LEAKS WITH

A MATCH OR OTHER FLAME.

racks and lower panel from

Oven thermostal: Remove

.

thermostat knob. pulling straight

After all the burners have been

converted to L.P. gas usage and

’

Part No. 76724.CQ/4320880

01990 Whirlpool Corporation

2

Prepared by Whirlpool Corporation. Benton Harbor. Michigan 49022

Printed in U.S.A

Loading...

Loading...