Whirlpool 29, 27"", 29"" and 27"" Wide Models Installation Instructions Manual

Dryer Installation Instructions

29" and 27" Wide Models

Gas (U.S.A. and Canada) & Electric (Canada Only)

Instructions d’installation de la sécheuse

Modèles de 29" et de 27" de largeur

À gaz (É.-U. et Canada) et

électrique (Canada uniquement)

Para obtener acceso al manual de uso y cuidado en español, o para obtener información adicional acerca de su producto, visite:

www.whirlpool.com

Tenga listo su número de modelo completo. Puede encontrar el número de modelo y de serie dentro de la cavidad superior de la puerta.

Table of Contents

DRYER SAFETY ................................................................2

INSTALLATION REQUIREMENTS .................................... 4

Tools and Parts .................................................................... 4

Location Requirements ...................................................... 5

ELECTRIC DRYER POWER HOOKUP – CANADA ONLY ......... 8

Electrical Requirements ..................................................... 8

GAS DRYER POWER HOOKUP ................................................. 8

Electrical Requirements ..................................................... 8

Gas Supply Requirements .................................................. 9

Install Leveling Legs ......................................................... 10

Make Gas Connection ...................................................... 11

VENTING .................................................................................... 11

Venting Requirements ....................................................... 11

Plan Vent System ............................................................... 12

Venting Kits ........................................................................ 13

Install Vent System ............................................................ 14

Connect Inlet Hoses .......................................................... 14

Connect Vent ..................................................................... 15

LEVEL DRYER ........................................................................... 16

COMPLETE INSTALLATION CHECKLIST ............................... 16

REVERSE DOOR SWING (OPTIONAL) .................................... 17

TROUBLESHOOTING ............................................................... 23

INSTALLATION NOTES

Date of purchase: _________________________________

Date of installation: _______________________________

Installer: ________________________________________

Model number: ___________________________________

Serial number: ___________________________________

Table des matières

SÉCURITÉ DE LA SÉCHEUSE ........................................24

EXIGENCES D’INSTALLATION .......................................26

Outillage et pièces .............................................................26

Exigences d’emplacement ................................................27

RACCORDEMENT DE LA SÉCHEUSE ÉLECTRIQUE –

CANADA SEULEMENT ............................................................. 29

Spécications électriques ................................................. 29

RACCORDEMENT DE LA SÉCHEUSE À GAZ .........................30

Spécications électriques ................................................. 30

Spécications de l’alimentation en gaz ...........................31

Installation des pieds de nivellement ............................... 32

Raccordement au gaz ........................................................33

ÉVACUATION .............................................................................33

Exigences concernant l’évacuation .................................33

Planication du système d’évacuation ............................34

Trousses d’évacuation ...................................................... 35

Installation du circuit d’évacuation ................................. 36

Raccordement des tuyaux de vidange ............................ 37

Raccordement du conduit d’évacuation ..........................38

RÉGLAGE DE L’APLOMB DE LA SÉCHEUSE......................... 39

ACHEVER L’INSTALLATION – LISTE DE VÉRIFICATION ....... 39

INVERSION DU SENS DE L’OUVERTURE DE LA PORTE

(FACULTATIF)

DÉPANNAGE ............................................................................. 47

NOTES CONCERNANT L’INSTALLATION

Date d’achat : _____________________________________

Date d’installation : ________________________________

Installateur : ______________________________________

Numéro de modèle : ________________________________

Numéro de série : __________________________________

............................................................................. 40

W10646607A

W10646608A-SP

1

Dryer Safety

2

3

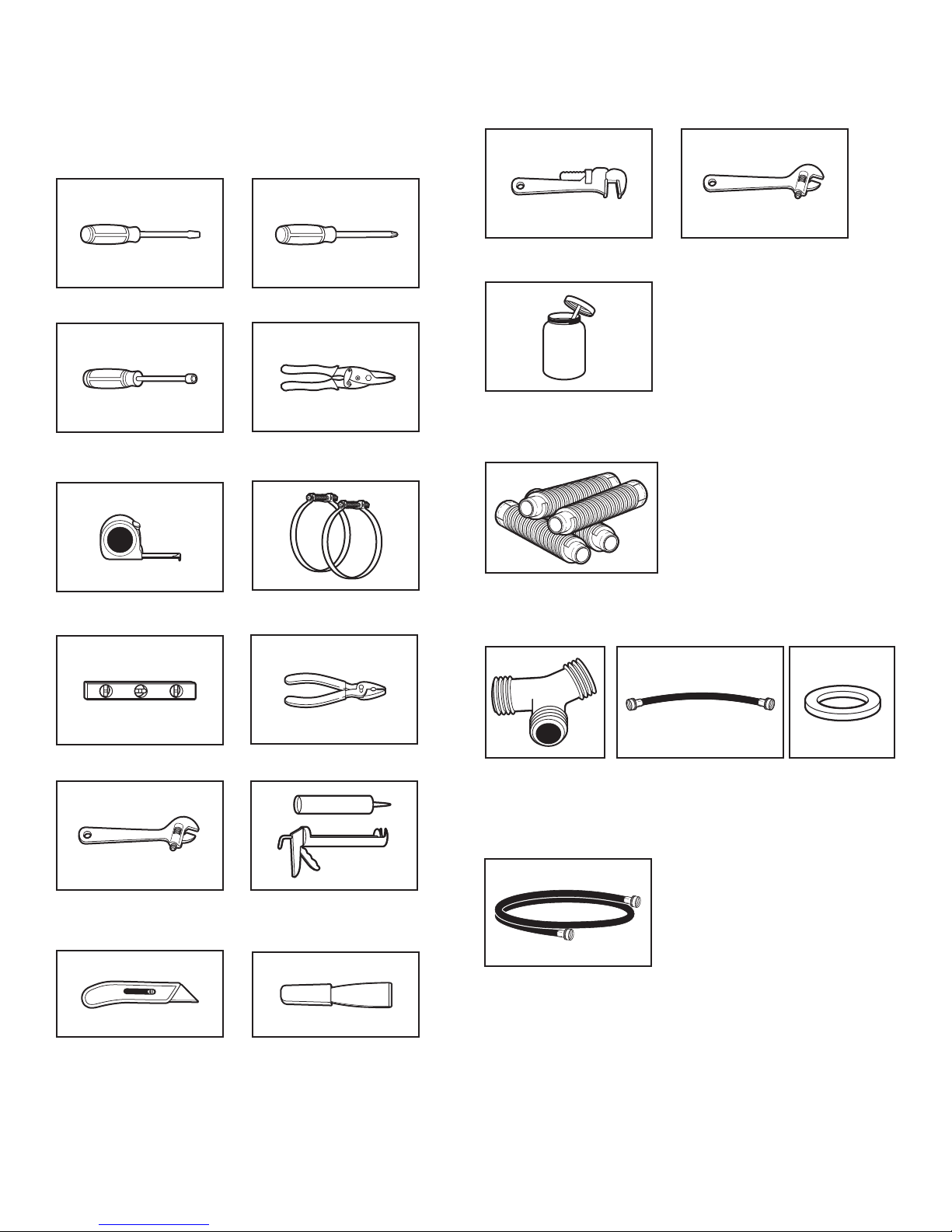

Installation Requirements

Tools and Parts

Gather the required tools and parts before starting installation.

Tools needed for all installations:

Flat-blade screwdriver

1/4" nut driver or socket

wrench (recommended)

#2 Phillips screwdriver

Tin snips (new vent

installations)

Tools needed for gas installations:

8" or 10" pipe wrench

Pipe-joint compound

resistant to LP gas

8" or 10" adjustable wrench

(for gas connections)

Parts supplied:

Tape measure

Level

Adjustable wrench that

opens to 1" (25 mm) or

hex-head socket wrench

Utility knife

4

Vent clamps

Pliers

Caulking gun and

compound (for installing

new exhaust vent)

Putty knife

Leveling legs (4)

Parts supplied (steam models):

“Y” connector

Parts package is located in dryer drum. Check that all parts

are included.

Short inlet hose

Rubber washer

Parts needed (steam models):

5' (1.52 m) inlet hose

Parts needed

Check local codes. Check existing electrical supply and venting.

See “Electrical Requirements” and “Venting Requirements”

before purchasing parts.

Check code requirements. Some codes limit, or do not permit,

installing dryer in garages, closets, mobile homes, or sleeping

quarters. Contact your local building inspector.

Optional Equipment: (Not supplied with dryer)

Refer to your “Use and Care Guide” for information about

accessories available for your dryer.

Location Requirements

You will need:

■ A location allowing for proper exhaust installation.

See “Venting Requirements.”

■ A separate 30 amp circuit for electric dryers.

■ A separate 15 or 20 amp circuit for gas dryers.

■ If you are using power supply cord, a grounded electrical

outlet located within 2 ft. (610 mm) of either side of dryer.

See “Electrical Requirements.”

■ A sturdy oor to support dryer and a total weight (dryer

and load) of 200 lbs. (90.7 kg). The combined weight of a

companion appliance should also be considered.

■ Level oor with maximum slope of 1" (25 mm) under entire

dryer. If slope is greater than 1" (25 mm), install Extended

Dryer Feet Kit, Part Number 279810. If not level, clothes

may not tumble properly and automatic sensor cycles may

not operate correctly.

Do not operate your dryer at temperatures below 45°F (7°C).

At lower temperatures, the dryer might not shut off at the end

of an automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

NOTE: No other fuel-burning appliance can be installed in the

same closet as a dryer.

Installation clearances:

The location must be large enough to allow the dryer door to

open fully.

A minimum of 5½" (140 mm) clearance is required behind

the dryer for the exhaust vent with elbow. See “Venting

Requirements.”

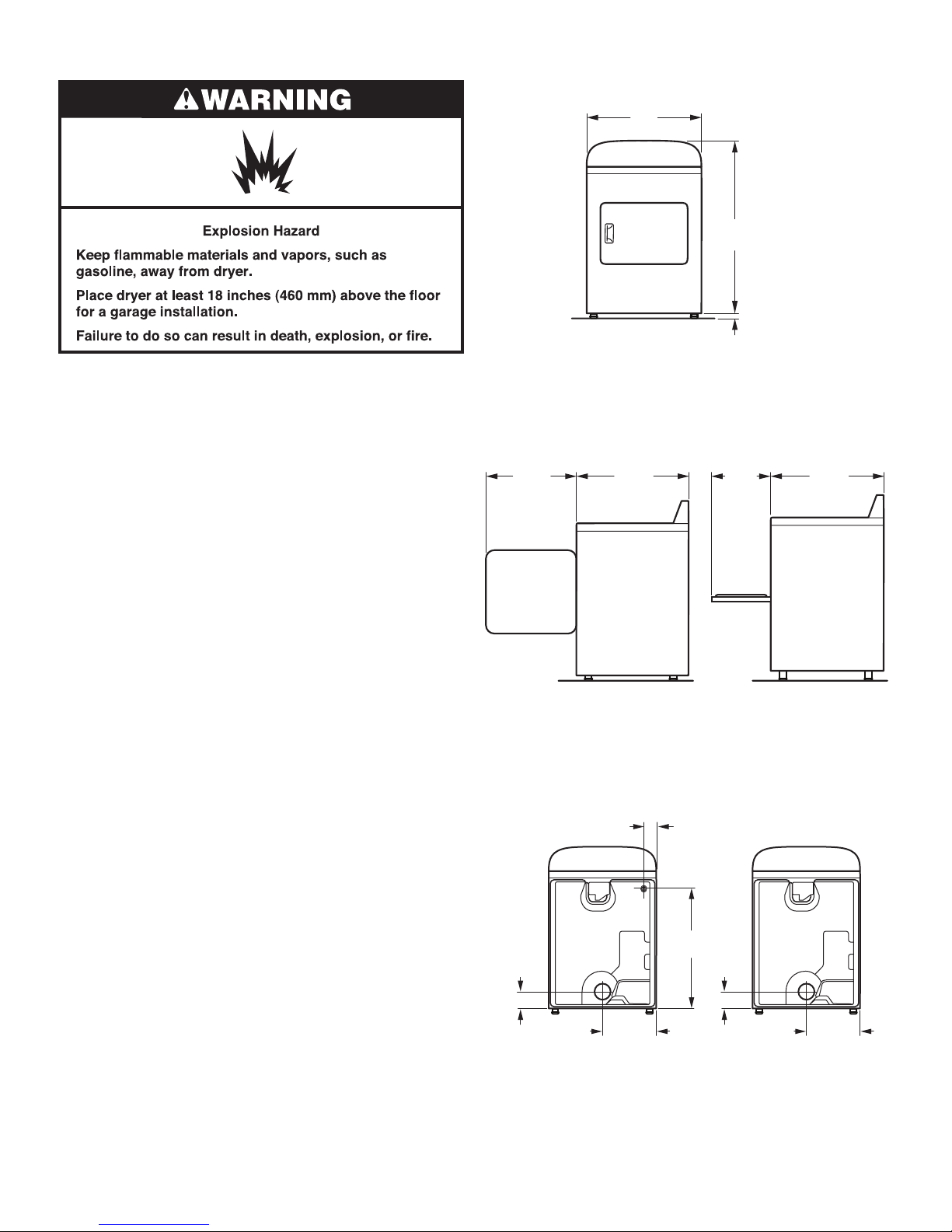

29" Wide Models Dryer Dimensions

Front View

29"

(737 mm)

433/8"

(1102 mm)

1

/2"

(13 mm)

NOTE: Leveling legs should be 1/2" (13 mm) (to match height of

3.6 cu. ft. capacity washer) or 1½" (38 mm) (to match height of

3.8 cu. ft. capacity washer).

Side View

223/4"

(578 mm)

Back View

273/4"

(705 mm)

133/4"

(349 mm)

A B

A. Wide opening side-swing door

B. Wide opening hamper door

4"

(101 mm)

301/4"

(768 mm)

273/4"

(705 mm)

3

4

/4"

(121 mm)

1

14

/2"

(368 mm)

3

4

/4"

(121 mm)

141/2"

(368 mm)

Steam Non-Steam

5

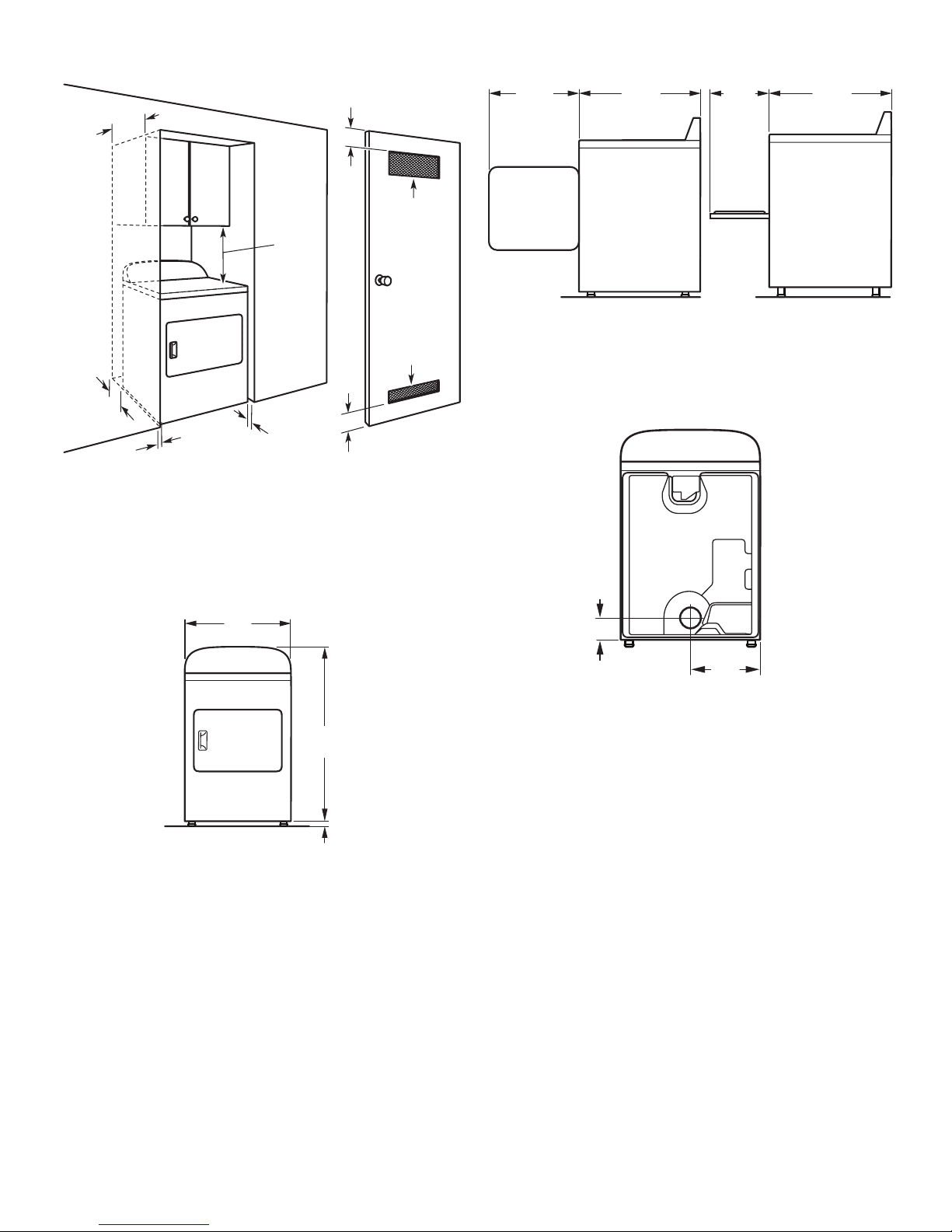

Installation Spacing

3"*

Side View

14"* max.

(356 mm)

51/2"*

(140 mm)

1"*

(25 mm)

*Required spacing

18"*

(457 mm)

1"*

(25 mm)

(76 mm)

3"*

(76 mm)

48 in.2*

(310 cm

24 in.

(155 cm

223/4"

(578 mm)

2

)

2

*

2

)

1

/2"

29

(749 mm)

133/4"

(349 mm)

(749 mm)

A B

291/2"

A. Wide opening side-swing door

B. Wide opening hamper door

Back View

27" Wide Models Dryer Dimensions

Front View

27"

(686 mm)

(1092 mm)

(13 mm)

43"

1

/2"

3

/8"

3

(85 mm)

14"

(356 mm)

Non-Steam

6

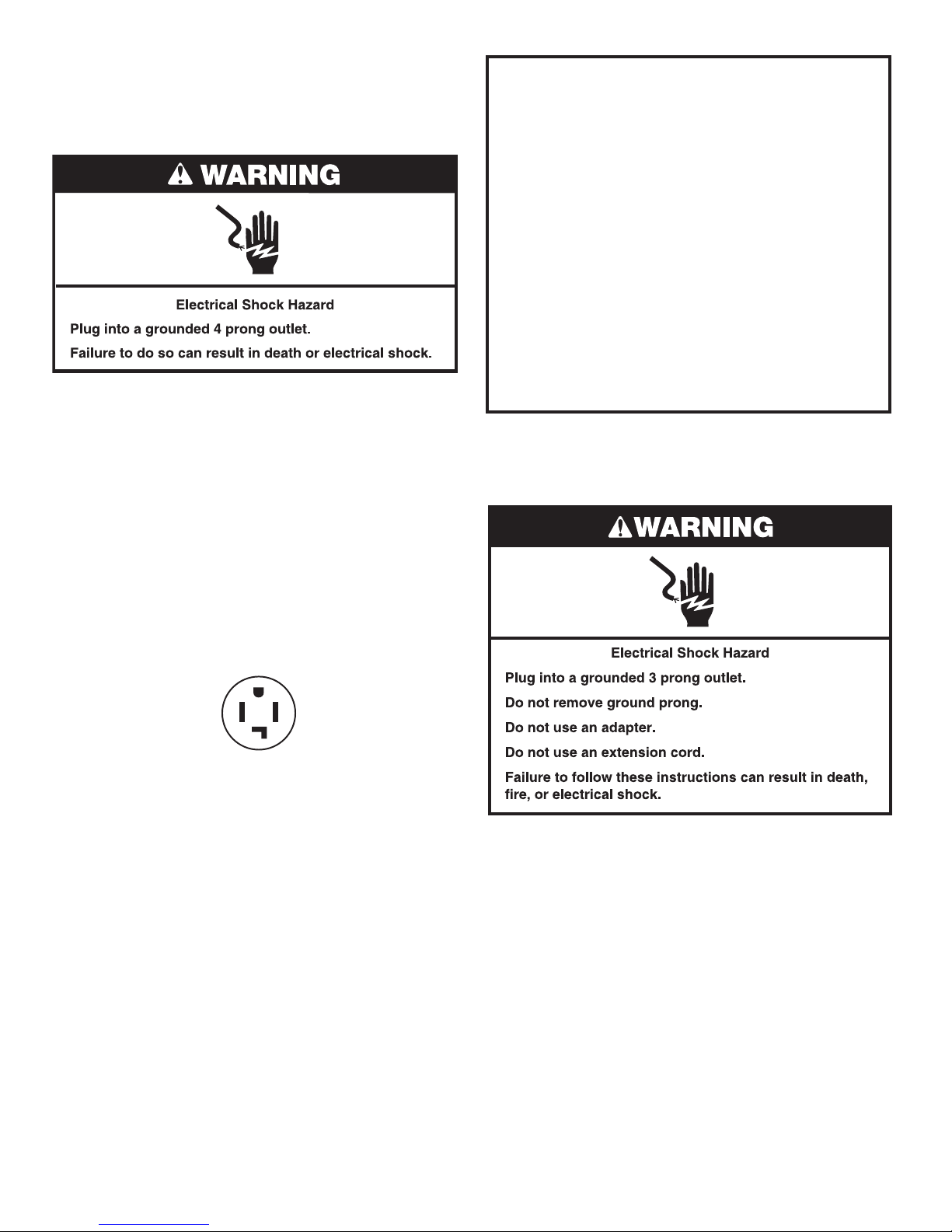

Installation Spacing

14"* max.

(356 mm)

18"*

(457 mm)

3"*

(76 mm)

48 in.2*

(310 cm

Installation spacing for recessed area

or closet

The dimensions shown are for the minimum spacing allowed.

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances might be required for wall, door, and

oor moldings.

2

)

■ Additional spacing of 1" (25 mm) on all sides of the dryer is

recommended to reduce noise transfer.

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

■ Companion appliance spacing should also be considered.

51/2"*

(140 mm)

1"*

(25 mm)

*Required spacing

1"*

(25 mm)

3"*

(76 mm)

2

24 in.

(155 cm2)

*

Mobile home – Additional installation

requirements

This dryer is suitable for mobile home installations. The

installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280) or the Canadian

Manufactured Home Standard CAN/CSA-Z240 MH.

■ Metal exhaust system hardware, available for purchase.

For further information, please reference the “Assistance

or Service” section of the “Use and Care Guide.”

■ Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such

as a nearby window) should be at least twice as large

as the dryer exhaust opening.

7

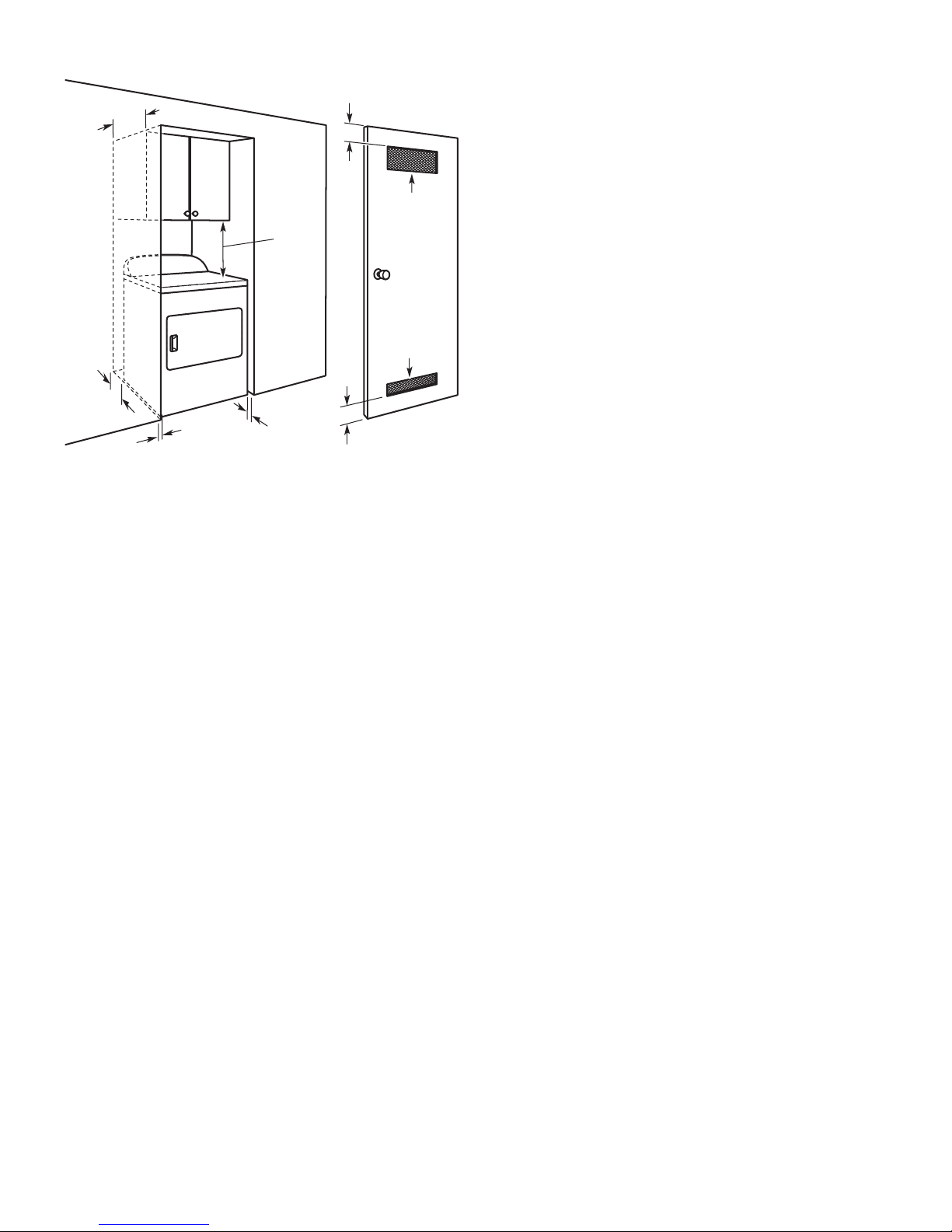

Electric Dryer Power Hookup –

Canada Only

Electrical Requirements

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

It is your responsibility:

■ To contact a qualied electrical installer.

■ To be sure that the electrical connection is adequate

and in conformance with the Canadian Electrical Code,

C22.1-latest edition and all local codes. A copy of the

above codes standard may be obtained from: Canadian

Standards Association, 178 Rexdale Blvd., Toronto, ON

M9W 1R3 CANADA.

■ To supply the required 4 wire, single phase, 120/240 volt,

60 Hz., AC only electrical supply on a separate 30-amp

circuit, fused on both sides of the line. A time-delay fuse or

circuit breaker is recommended. Connect to an individual

branch circuit.

■ This dryer is equipped with a CSA International Certied

Power Cord intended to be plugged into a standard 14-30R

wall receptacle. The cord is 5 ft. (1.52 m) in length. Be sure

wall receptacle is within reach of dryer’s nal location.

WARNING:

grounding conductor can result in a risk of electric shock.

Check with a qualied electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not t the outlet, have a proper outlet

installed by a qualied electrician.

Improper connection of the equipment-

SAVE THESE INSTRUCTIONS

Gas Dryer Power Hookup

Electrical Requirements

4-wire receptacle (14-30R)

■ Do not use an extension cord.

If using a replacement power supply cord, it is recommended

that you use Power Supply Cord Replacement Part Number

8579325. For further information, please reference the

“Assistance or Service” section of the “Use and Care Guide.”

8

■ 120 Volt, 60 Hz., AC only, 15- or 20-amp fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is also recommended that a separate

circuit serving only this dryer be provided.

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING:

grounding conductor can result in a risk of electric shock.

Check with a qualied electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not t the outlet, have a proper outlet

installed by a qualied electrician.

Improper connection of the equipment-

SAVE THESE INSTRUCTIONS

Gas Supply Requirements

LP gas conversion:

Conversion must be made by a qualified technician.

No attempt shall be made to convert the dryer from the gas

specied on the model/serial rating plate for use with a different

gas without consulting the serving gas supplier.

IMPORTANT: The gas installation must conform with local codes,

or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the Canadian Natural Gas and

Propane Installation Code, CSA B149.1.

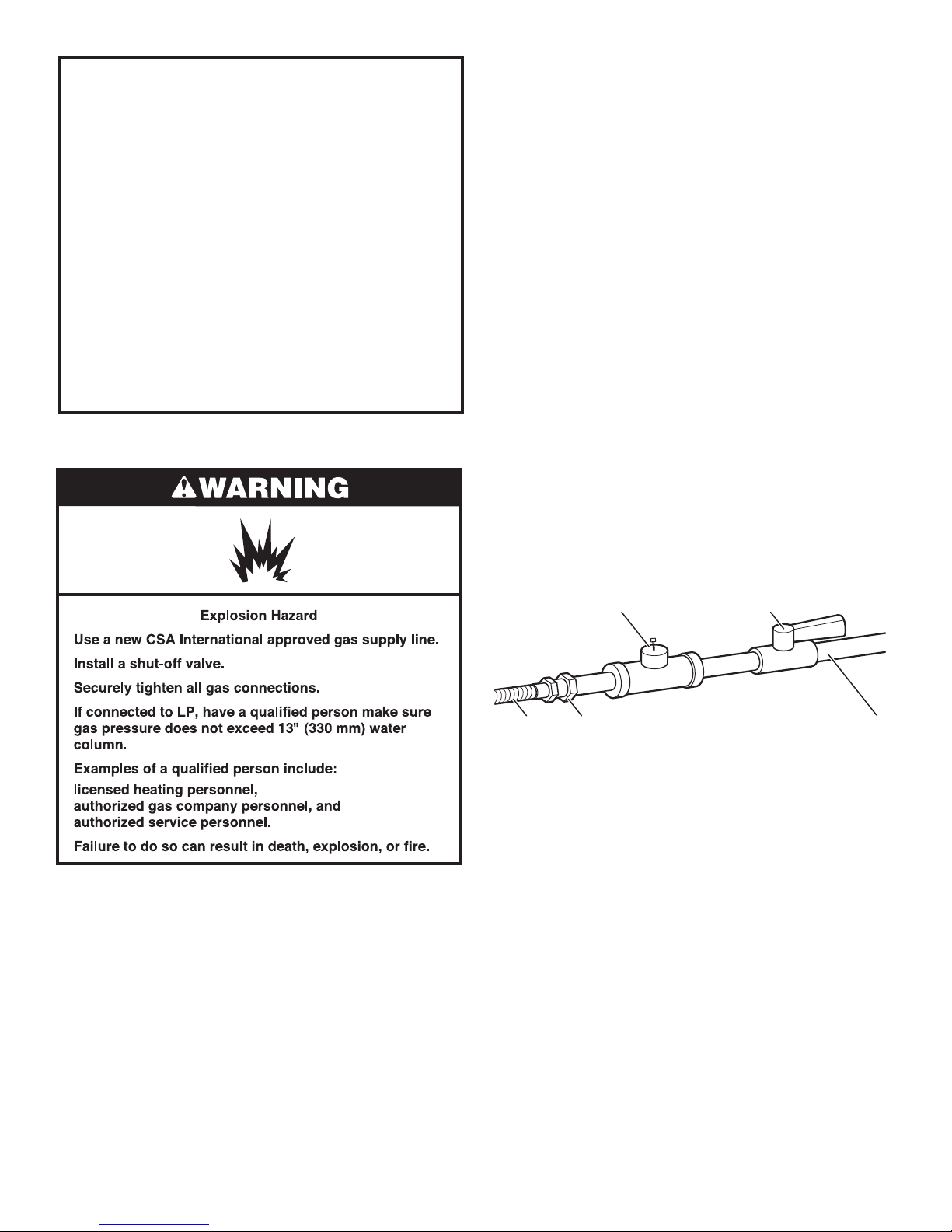

Gas supply line

■ 1/2" NPT pipe is recommended.

■ 3/8" approved tubing is acceptable for lengths under

20 ft. (6.1 m) if local codes and gas supplier permit.

■ Must include 1/8" NPT minimum plugged tapping accessible

for test gauge connection, immediately upstream of the gas

connection to the dryer (see illustration).

■ Must include a shut-off valve:

In the U.S.A.:

An individual manual shut-off valve must be installed within

six (6) feet (1.8 m) of the dryer in accordance with the National

Fuel Gas Code, ANSI Z223.1.

In Canada:

An individual manual shut-off valve must be installed in

accordance with the B149.1, Natural Gas and Propane

Installation Code. It is recommended that an individual manual

shut-off valve be installed within six (6) feet (1.8 m)

of the dryer.

The shut-off valve location should be easy to reach for opening

and closing.

Gas type

Natural gas:

This dryer is equipped for use with Natural Gas. It is designcertied by CSA International for LP (propane or butane) gases

with appropriate conversion.

■ Your dryer must have the correct burner for the type of gas

in your home. Burner information is located on the rating

plate in the door well of your dryer. If this information does

not agree with the type of gas available, please reference the

“Assistance or Service” section of the “Use and Care Guide.”

C

BA

A. 3/8" flexible gas connector

B. 3/8" pipe to flare adapter fitting

C. 1/8" NPT minimum plugged tapping

D. 1/2" NPT gas supply line

E. Gas shut-off valve

E

Gas supply connection requirements

There are many methods by which your gas dryer can be

connected to the gas supply. Listed here are some guidelines

for two different methods of connection.

This dryer must be connected to the gas supply line with

a listed exible gas connector that complies with the standard

for connectors for gas appliances, ANSI Z21.24 or CSA 6.10.

Option 1 (Recommended Method)

Flexible stainless steel gas connector:

■ If local codes permit, use a new exible stainless steel gas

connector (Design Certied by the American Gas Association

or CSA International) to connect your dryer to the rigid gas

supply line. Use an elbow and a 3/8" are x 3/8" NPT adapter

tting between the stainless steel gas connector and the dryer

gas pipe, as needed to prevent kinking.

D

9

Option 2 (Alternate Method)

Approved aluminum or copper tubing:

■ Lengths under 20 ft. (6.1 m) can use 3/8" approved tubing

(if codes and gas supplier permit).

■ If you are using Natural Gas, do not use copper tubing.

■ 3/8" are x 3/8" NPT adapter tting between dryer pipe

and 3/8" approved tubing.

■ Lengths over 20 ft. (6.1 m) should use larger tubing and

a different size adapter tting.

■ If your dryer has been converted to use LP gas, 3/8" LP

compatible copper tubing can be used. If the total length

of the supply line is more than 20 ft. (6.1 m), use larger pipe.

NOTE: Pipe joint compounds that resist the action of LP

gas must be used. Do not use TEFLON®† tape.

Burner input requirements

Elevations up to 10,000 ft. (3,048 m):

■ The design of this dryer is certied by CSA International for

use at altitudes up to 10,000 ft. (3,048 m) above sea level at

the B.T.U. rating indicated on the model/serial number plate.

Burner input adjustments are not required when the dryer is

operated up to this elevation.

Elevations above 10,000 ft. (3,048 m):

■ When installed above 10,000 ft. (3,048 m), a 4% reduction

of the burner B.T.U. rating shown on the model/serial

number plate is required for each 1,000 ft. (305 m)

increase in elevation.

Gas supply pressure testing

■ The dryer must be disconnected from the gas supply piping

system during pressure testing at pressures greater than

1/2 psi.

Dryer gas pipe

■ The gas pipe that comes out through the rear of your dryer

has a 3/8" male pipe thread.

29" Wide Model

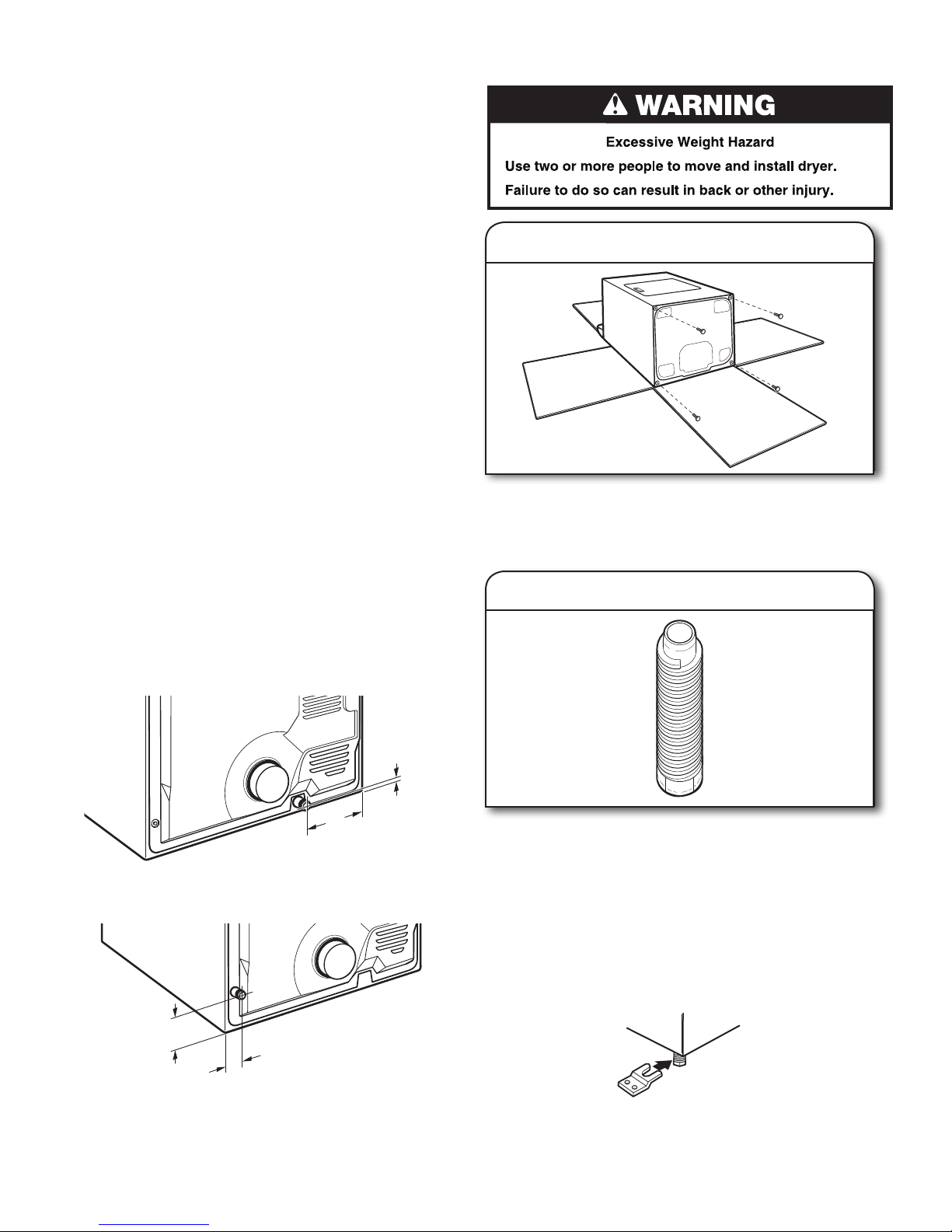

Install Leveling Legs

1.

Prepare dryer for leveling legs

To avoid damaging oor, use a large at piece of cardboard

from dryer carton; place under entire back edge of dryer.

Firmly grasp dryer body (not console panel) and gently lay

dryer down on cardboard.

2.

Screw in leveling legs

(235 mm)

3/8" NPT dryer pipe

27" Wide Model

1

/2"

1

53/4"

(146 mm)

(38 mm)

3/8" NPT dryer pipe

†®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

10

91/4"

1

/4"

1

(32 mm)

Using a wrench and tape measure, screw legs into leg holes

until bottom of foot is approximately 1/2" (13 mm) (to match

height of 3.6 cu. ft. capacity washer) or 1½" (38 mm) (to

match height of 3.8 cu. ft. capacity washer) from bottom of

dryer.

Now stand the dryer on its legs. Slide the dryer until it is

close to its nal location. Leave enough room for electrical

connection and to connect the exhaust vent.

For mobile home use

Gas dryers must be securely fastened to the oor.

Mobile home installations require a Mobile Home Installation

Hold-down Kit. For ordering information, please reference the

“Use and Care Guide.”

A

B

D

C

A

B

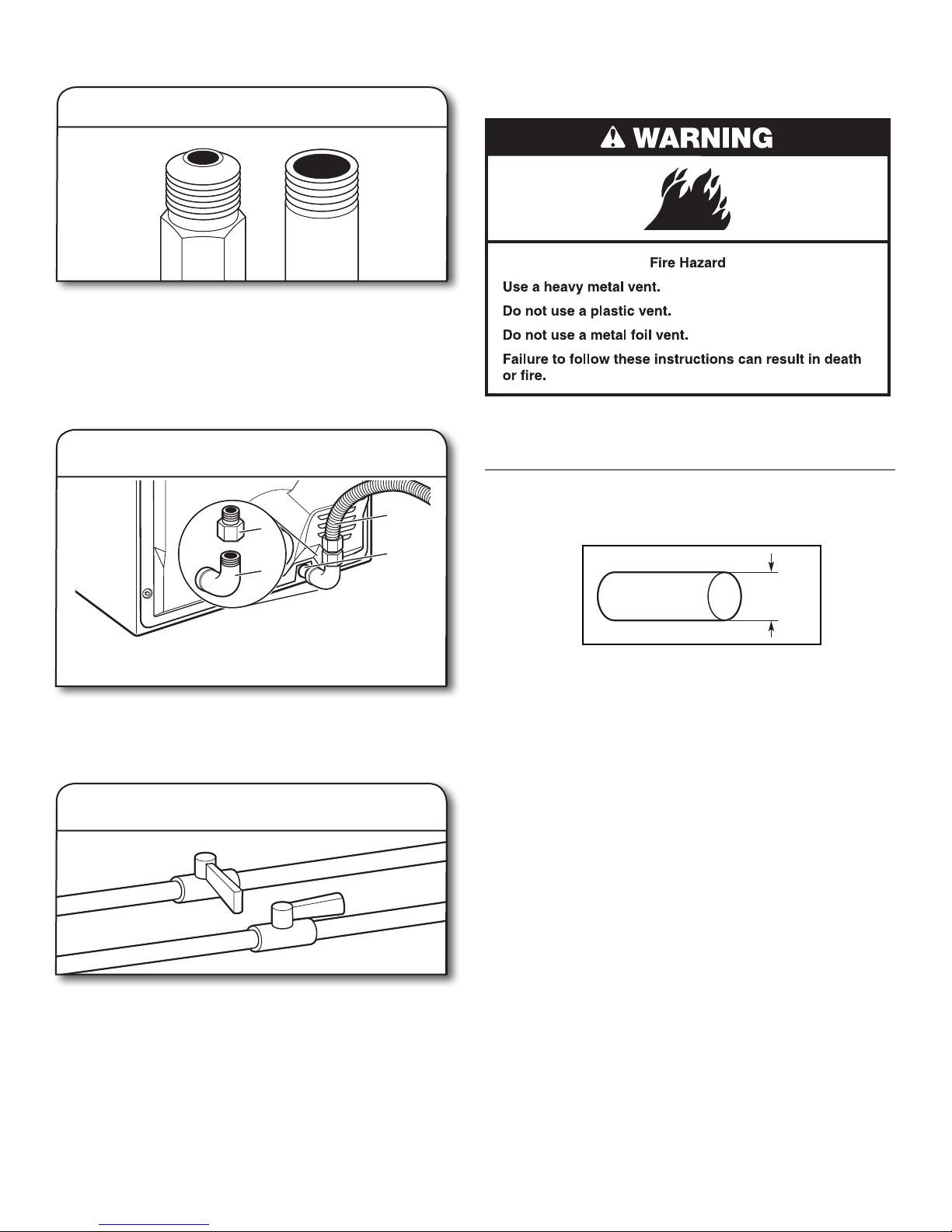

Make Gas Connection

Closed valve

Open valve

Venting

Connect gas supply to dryer

1.

Flared

male tting

Remove red cap from gas pipe. Using a wrench to tighten,

connect gas supply to dryer. Use pipe-joint compound

on threads of all non-ared male ttings. If exible metal

tubing is used, be sure there are no kinks.

NOTE: For LP gas connections, you must use pipe-joint

compound resistant to action of LP gas. Do not use

TEFLON®† tape.

Plan pipe tting connection

2.

Non-ared

male tting

Venting Requirements

WARNING: To reduce the risk of re, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or exible metal vent shall be used for

exhausting.

A. 3/8" exible gas connector

B. 3/8" dryer pipe

A combination of pipe ttings must be used to connect dryer

to existing gas line. A recommended connection is shown.

Your connection may be different, according to supply line

type, size, and location.

Open shut-off valve

3.

Open shut-off valve in supply line; valve is open when handle

is parallel to gas pipe. Then, test all connections by brushing

on an approved noncorrosive leak-detection solution.

Bubbles will show a leak. Correct any leaks found.

C. 3/8" to 3/8" pipe elbow

D. 3/8" pipe-to-are adapter tting

4"

(102 mm)

4" (102 mm) heavy metal exhaust vent

■ Only a 4" (102 mm) heavy metal exhaust vent and clamps may

be used.

■ Do not use plastic or metal foil vent.

Rigid metal vent:

■ Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to

clean)

■ Must be fully extended and supported in nal dryer location.

■ Remove excess to avoid sagging and kinking that may result

in reduced airow and poor performance.

■ Do not install in enclosed walls, ceilings, or oors.

■ The total length should not exceed 7

NOTE: If using an existing vent system, clean lint from entire

length of the system and make sure exhaust hood is not plugged

with lint. Replace plastic or metal foil vents with rigid metal

or exible metal vents. Review “Vent System Chart” and, if

necessary, modify existing vent system to achieve best drying

performance.

3

/4 ft. (2.4 m).

†®TEFLON is a registered trademark of E.I. Dupont De Nemours and Company.

11

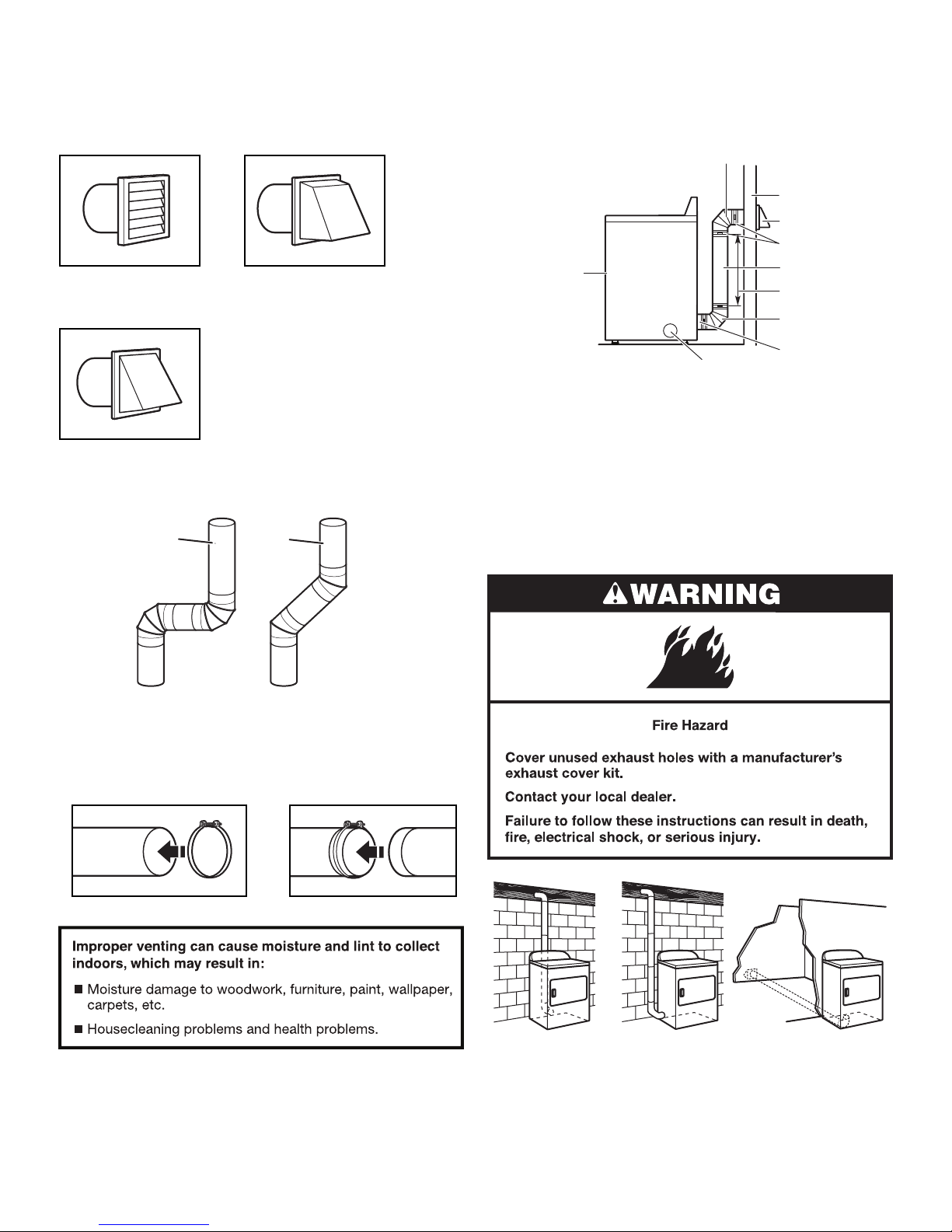

Exhaust hoods:

A

■ Must be at least 12" (305 mm) from ground or any object that

may obstruct exhaust (such as owers, rocks, bushes, or

snow).

Recommended Styles:

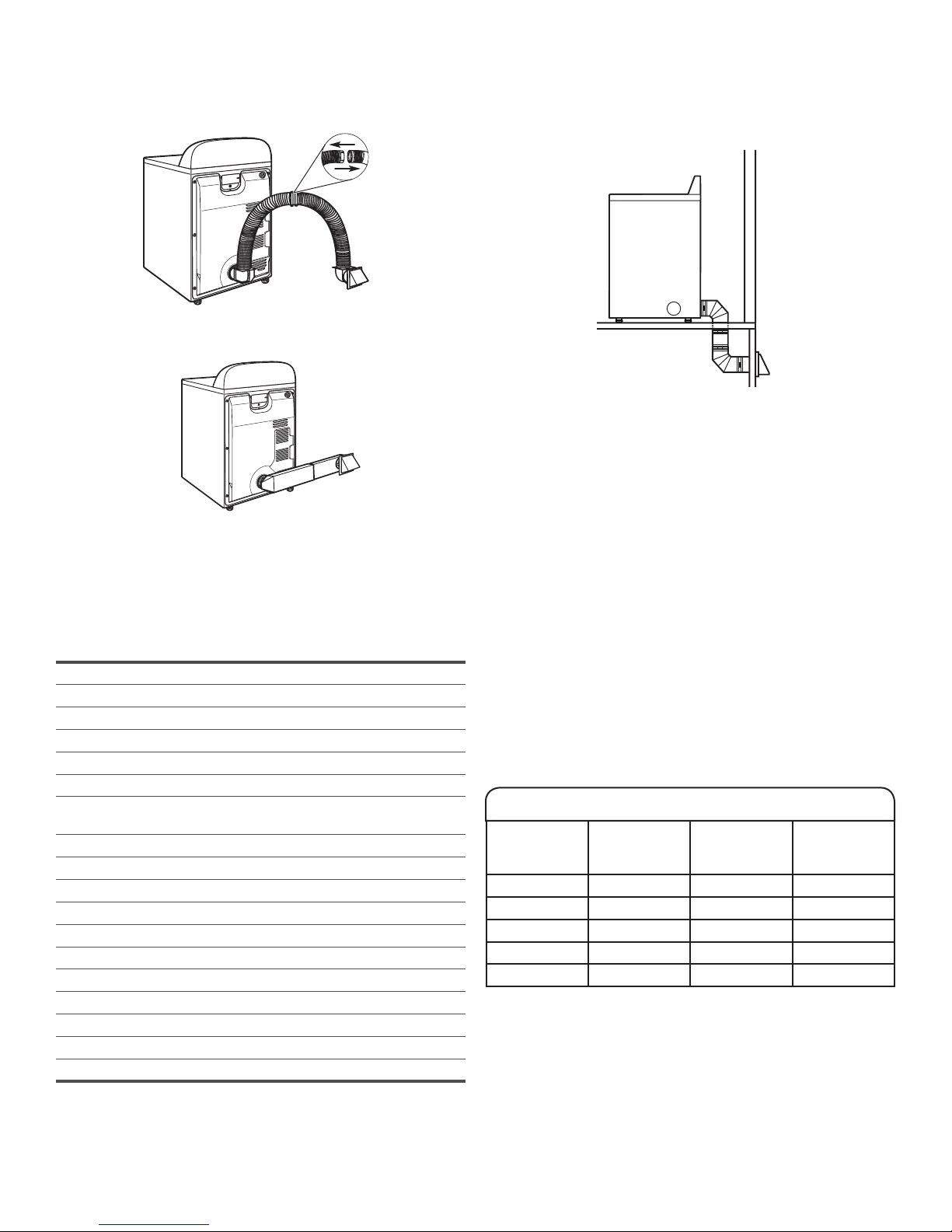

Plan Vent System

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

B

C

D

E

Louvered hood Box hood

Acceptable Style:

Angled hood

Elbows:

■ 45° elbows provide better airow than 90° elbows.

Good

Better

Clamps:

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct

and catch lint. Do not use duct tape.

F

G

B

H

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

I

F. Rigid metal or flexible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

I. Optional side exhaust outlet

E. Clamps

Optional exhaust installations:

27" Wide Models can be converted to exhaust out the right side,

left side, or through the bottom (4-way vent kit). Each kit includes

step-by-step instructions. For ordering information, see “Venting

Kits.”

See “Venting Kits” for more information.

12

A B C

A. Standard rear offset exhaust installation

B. Left- or right-side exhaust installation (27" wide models only)

C. Bottom exhaust installation (27" wide models only)

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best

for your installation. Two close-clearance installations are shown.

Refer to the manufacturer’s instructions.

Over-The-Top installation

(also available with one offset elbow)

Periscope installation

NOTE: The following kits for close clearance alternate

installations are available for purchase.

Venting Kits

For more information, call 1-800-901-2042, or visit us at

www.applianceaccessories.com. In Canada, call

1-800-807-6777 or visit us at www.whirlpoolparts.ca.

Part Number Descriptions

8171587RP 0–5" Metal vent periscope

4396037RP 0"-18" Metal vent periscope

4396011RP 18" - 29" Metal vent periscope

4396014 29" - 50" Metal vent periscope

4392892 In-Wall metal DuraVent™ Periscope

4396028 Sure Connect™ venting kit

(over-the-top installation)

4396009RP 5' Universal connect vent, exible dryer venting

4396010RP 6' SecureConnect™ vent, exible dryer venting

4396013RB Dryer vent installer’s kit

4396033RP 5' exible dryer venting with clamps

4396727RP 8' exible dryer venting with clamps

4396004 Dryer offset elbow

4396005 Wall offset elbow

4396006RW DuraSafe™ close elbow

4396007RW Through-the-wall vent cap

4396008RP 4" steel dryer venting clamps - 2 pack

8212662 Flush mounting louvered vent hood 4"

Special provisions for mobile home

installations:

The exhaust vent must be securely fastened to a noncombustible

portion of the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

Determine vent path:

■ Select route that will provide straightest and most direct path

outdoors.

■ Plan installation to use fewest number of elbows and turns.

■ When using elbows or making turns, allow as much room

as possible.

■ Bend vent gradually to avoid kinking.

■ Use as few 90° turns as possible.

Determine vent length and elbows needed for

best drying performance:

■ Use following “Vent System Chart” to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specied

in “Vent System Chart.” Exhaust systems longer than those

specied will:

■ Shorten life of dryer.

■ Reduce performance, resulting in longer drying times and

increased energy usage.

The “Vent System Chart” provides venting requirements that

will help achieve best drying performance.

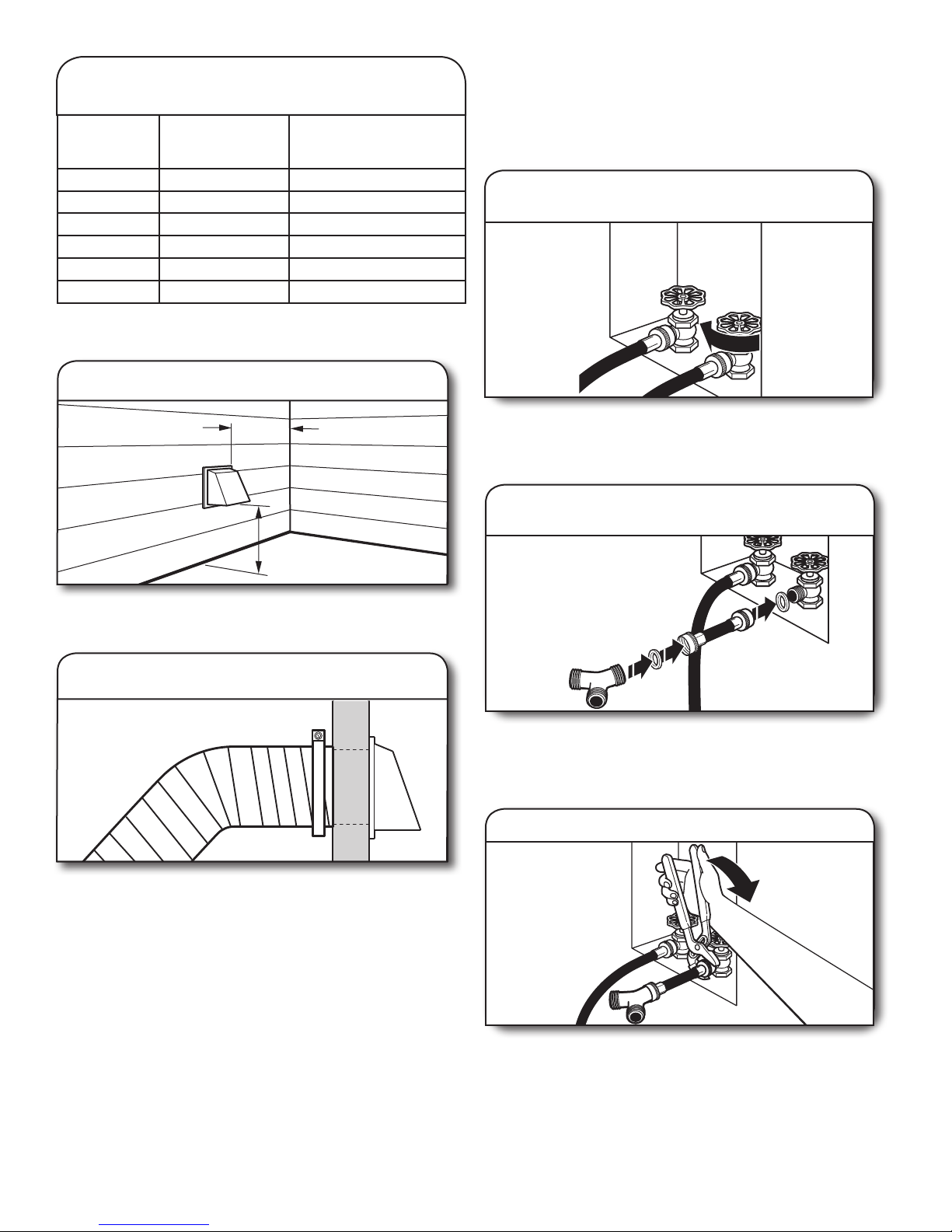

Vent System Chart

Number of

90° turns

or elbows

0 Rigid metal 64 ft. (20 m) 58 ft. (17.7 m)

1 Rigid metal 54 ft. (16.5 m) 48 ft. (14.6 m)

2 Rigid metal 44 ft. (13.4 m) 38 ft. (11.6 m)

3 Rigid metal 35 ft. (10.7 m) 29 ft. (8.8 m)

4 Rigid metal 27 ft. (8.2 m) 21 ft. (6.4 m)

NOTE: Side and bottom exhaust installations for 27" wide

models have a 90º turn inside the dryer. To determine

maximum exhaust length, add one 90º turn to the chart.

Type

of vent

Box/louvered

hoods

Angled

hoods

13

12" min.

(305 mm)

12" min.

(305 mm)

Vent System Chart

(Long Vent Models Only)

Number of

90° turns

or elbows

0 Rigid metal 120 ft. (36.6 m)

1 Rigid metal 110 ft. (33.5 m)

2 Rigid metal 100 ft. (30.5 m)

3 Rigid metal 90 ft. (27.4 m)

4 Rigid metal 80 ft. (24.4 m)

5 Rigid metal 70 ft. (21.3 m)

Type

of vent

Install Vent System

Install exhaust hood

1.

Box/louvered, or

Angled hoods

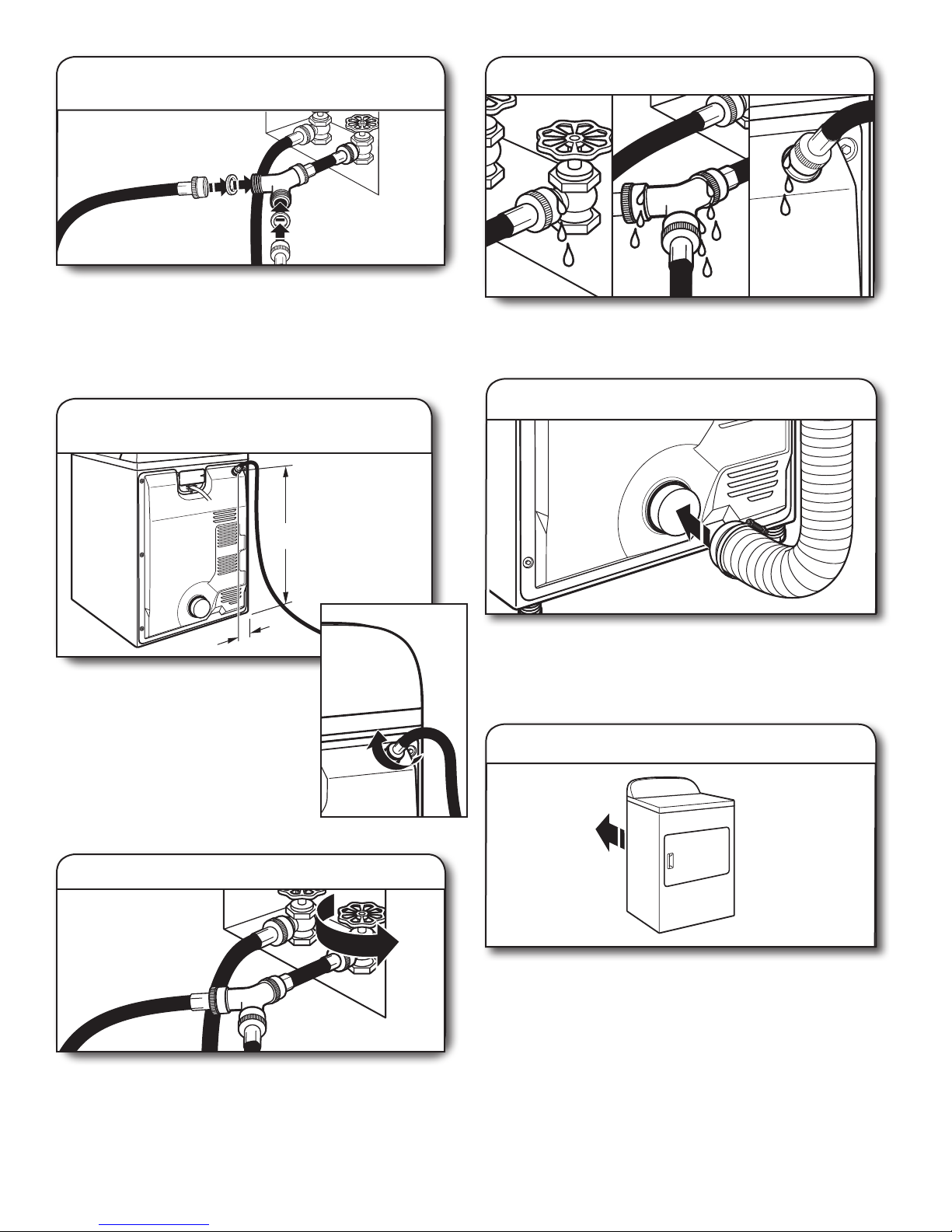

Connect Inlet Hoses

(Steam Models Only)

For non-steam models, skip to “Connect Vent.”

The dryer must be connected to the cold water faucet using

the new inlet hoses. Do not use old hoses.

Turn cold water off, remove and

1.

replace rubber washer

Turn cold water faucet off and remove washer inlet hose.

Remove old rubber washer from inlet hose and replace

with new rubber washer.

Attach short hose and

2.

“Y” connector

Install exhaust hood and use caulking compound to seal

exterior wall opening around exhaust hood.

Connect vent to exhaust hood

2.

Vent must t over the exhaust hood. Secure vent to exhaust

hood with 4" (102 mm) clamp. Run vent to dryer location

using straightest path possible. Avoid 90° turns. Use clamps

to seal all joints. Do not use duct tape, screws, or other

fastening devices that extend into interior of vent to secure

vent, because they can catch lint.

Attach 2 ft (0.6 m) inlet hose to cold water faucet. Screw on

coupling by hand until it is seated on faucet. Then attach

“Y” connector to end of the 2 ft (0.6 m) inlet hose. Screw on

coupling by hand until it is seated on “Y” connector.

Tighten couplings

3.

Using pliers, tighten the couplings with additional two-thirds

turn.

NOTE: Do not overtighten. Damage to the coupling can result.

14

Attach long hose to “Y”

4.

connector and tighten couplings

Attach dryer 5 ft (1.5 m) inlet hose ends to the “Y” connector.

Attach washer cold inlet hose to other side of “Y” connector.

Screw on coupling by hand until it is seated on connector.

Using pliers, tighten the couplings an additional two-thirds

turn.

NOTE: Do not overtighten. Damage to the coupling can result.

Attach long hose to dryer ll

5.

valve and tighten coupling

1

/4"

30

(768 mm)

7.

Check for leaks

Check for leaks around “Y” connector, faucet, and hoses.

Connect Vent

Connect vent to exhaust outlet

1.

(101 mm)

Attach other end of long hose to

ll valve at top of dryer back panel.

Screw on coupling by hand until

it is seated on ll valve connector.

Using pliers, tighten the coupling

an additional two-thirds turn.

NOTE: Do not overtighten. Damage

to the coupling can result.

Turn on cold water faucet

6.

4"

Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure vent is

clean. Dryer vent must t over dryer exhaust outlet and inside

exhaust hood. Check that vent is secured to exhaust hood

with a 4" (102 mm) clamp.

Move dryer to nal location

2.

Move dryer to nal location. Avoid crushing or kinking vent.

Check that the water faucet is turned on.

15

Loading...

Loading...