Page 1

SERVICE MANUAL

for the

OVER-THE-RANGE

MICROWAVE OVEN HOOD

COMBINATION

1997 “E” Models

March, 1997

Printed in U.S.A. LIT4322167

Page 2

THIS MANUAL CONTAINS INFORMATION NECESSARY FOR SERVICING THE WHIRLPOOL MICROWAVE OVEN HOOD COMBINATION , MODELS:

MH7130XE

MH7135XE

MH9115XE

THE MANUAL IS DESIGNED TO BE USED ONLY BY

QUALIFIED SERVICE PERSONNEL. THE SERVICE

INFORMATION IS ORGANIZED TO HELP YOU EASILY FIND WHAT YOU NEED.

CHECK YOUR LOCAL BUILDING CODE FOR THE

PROPER MODE OF INSTALLATION. IN THE ABSENCE OF LOCAL CODES, THIS UNIT SHOULD BE

INSTALLED IN ACCORDANCE WITH THE

NATIONAL

ELECTRICAL CODE, ANSI/NFPA NO. 70 - 1990, OR

LATEST EDITION, OR C22.1 CANADIAN ELECTRICAL CODE, PART 1

.

This Microwave Service Manual is for authorized WHIRLPOOLSM service technicians only.

Because of the high voltage and the critical nature of the door closure system for the microwave

oven, Whirlpool recommends that customers DO NOT service their own microwave oven.

If you encounter problems with any Whirlpool range having a microwave feature, call your nearest

authorized WHIRLPOOLSM Service Company for service.

ii

Page 3

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page iii

TABLE OF CONTENTS

Page

Important Safety Information ...............................................................................................................................v

Theory Of Operation ......................................................................................................................................... 1-1

Component Access ........................................................................................................................................... 2-1

Component Sections .................................................................................................................................. 2-1

General ...............................................................................................................................................................

Removing The Microwave Oven & Cabinet ............................................................................................ 2-2

The Protection Control System .......................................................................................................................

Removing The Oven Door ......................................................................................................................... 2-4

Removing The Oven Door Components.................................................................................................. 2-5

Removing The Control Panel .................................................................................................................... 2-6

Removing The Line Fuse........................................................................................................................... 2-7

Removing/Adjusting The Interlock Switches .......................................................................................... 2-8

Removing The Base Thermal Fuse........................................................................................................ 2-10

Removing The Magnetron Thermal Fuse .............................................................................................. 2-11

Removing The Convection Thermistor .................................................................................................. 2-12

Removing The Cavity Thermal Fuse ..................................................................................................... 2-14

The Operating Control System......................................................................................................................

Removing The Oven Light Socket.......................................................................................................... 2-15

Removing The Control Circuit Board & The Turntable Indicator Circuit Board ..............................2-16

Removing The Fan Motor ........................................................................................................................ 2-17

Removing The Power Cord .....................................................................................................................2-18

Removing The Blower Motor Capacitor................................................................................................. 2-19

Removing The Convection Heating Element ........................................................................................ 2-20

Removing The Gas Sensor .....................................................................................................................2-22

Removing The Stirrer Motor .................................................................................................................... 2-23

Removing The Turntable Motor .............................................................................................................. 2-24

Removing The Cooktop Light Sockets ..................................................................................................2-25

The High Voltage Components .....................................................................................................................

Accessing The Components.................................................................................................................... 2-26

Removing The Magnetron .......................................................................................................................2-27

Removing The High Voltage Rectifier And The High Voltage Capacitor ......................................... 2-28

Removing The High Voltage Transformer............................................................................................. 2-29

2-2

2-4

2-15

2-26

iii

Page 4

Page

Component Description & Testing .................................................................................................................. 3-1

Important Safety Instructions .................................................................................................................... 3-1

The Thermal Fuses..................................................................................................................................... 3-4

The Blower Motor Capacitor ..................................................................................................................... 3-5

The Gas Sensor .......................................................................................................................................... 3-6

The Convection Thermistor ....................................................................................................................... 3-7

The Convection Heating Element............................................................................................................. 3-8

Motors ........................................................................................................................................................... 3-9

Programming Checks ............................................................................................................................... 3-10

Charts ......................................................................................................................................................... 3-11

Checking The Microwave Power Output ............................................................................................... 3-14

Checking For Microwave Energy Leakage ...........................................................................................3-15

Component Testing ..................................................................................................................................3-18

Control Circuit Board Checklist ..............................................................................................................3-23

Primary, Monitor, & Secondary Switch Checkout Procedure............................................................. 3-24

Tech Tips ............................................................................................................................................................ 4-1

Wiring Diagrams.......................................................................................................................................... 4-1

Strip Circuits ................................................................................................................................................ 4-3

Specifications .............................................................................................................................................. 4-6

Model & Serial Number Explanation ...................................................................................................... 4-15

Whirlpool Microwave Hood Warranty..................................................................................................... 4-16

iv

Page 5

IMPORTANT SAFETY INFORMATION

WARNING

This service manual is intended for factoryservice technicians only. We recommend that

customers DO NOT service their own units,

because of the complexity and risk of highvoltage electrical shock.

The following information is used throughout

this manual, and should be read carefully.

NOTE

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Fire Hazard

Do not obstruct the flow of ventilation air.

Electrical Shock Hazard

It is the customer’s responsibility to:

• Contact a qualified electrical installer.

Page v

Helpful information that explains a more

complicated step, prior to carrying it out.

CAUTION

Information that will help you avoid actions

that could cause product damage (scratches,

dents, etc.) and damage to personal property.

WARNING

Information that alerts you to potentially

dangerous conditions. These conditions can

cause serious personal injury (burns, fire

and electrical shock, etc.) if the suggested

procedures are not observed.

• Assure that electrical installation is adequate and in conformance with the National Electrical Code, ANSl/NFPA 70—

latest edition*, and all local codes and

ordinances.

Failure to do so could result in fire, electrical

shock, or other personal injury.

Take special care when drilling holes into

the wall for venting or electrical wiring. Electrical wires may be concealed behind the

wall covering.

Failure to do so could result In fire, electrical shock, or other personal injury.

• National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

WHIRLPOOL ASSUMES NO RESPONSIBILITY

FOR ANY REPAIRS MADE ON OUR PRODUCTS

BY ANYONE OTHER THAN AUTHORIZED

WHIRLPOOL SERVICE TECHNICIANS.

v

Page 6

CAUTION

WARNING TO SERVICE TECHNICIANS

To avoid possible exposure to microwave radiation or energy, visually check the oven for

damage to the door and door seal before

operating the oven. Use your microwave survey meter to check the amount of leakage

before servicing. In the event that the R.F.

Ieakage exceeds 4 mw/cm

ate repair must be made before continuing to

service the unit. Check interlock function by

operating the door latch. The oven cook cycle

should cut off before the door can be opened.

The door and latching assembly contains the

radio frequency energy within the oven. The

door is protected by three safety interlock

switches. Do not attempt to defeat them. Under no circumstances should you try to operate the oven with the door open.

2

at 5 cm, appropri-

• Proper operation of the microwave ovens

requires that the magnetron be properly

assembled to the waveguide and cavity.

Never operate the magnetron unless it is

properly installed.

• Be sure the “RF” seal is not damaged, and

assembled around the magnetron dome

properly when installing the magnetron.

• Routine service safety procedures should

be exercised at all times.

• Untrained personnel should not attempt

service without a thorough review of the test

procedures and safety information contained

in this manual.

PRECAUTIONS TO BE OBSERVED BEFORE AND DUR-

ING SERVICING TO AVOID POSSIBLE EXPOSURE TO

EXCESSIVE MICROWAVE ENERGY.

1. Do not operate or allow the oven to be

operated with the door open.

2. Make the following safety checks on all

ovens to be serviced before activating the

magnetron or other microwave source,

and make repairs as necessary:

a)Interlock Operation.

b)Proper Door Closing.

c) Seal and Sealing Surfaces (Arcing,

Wear, and Other Damage).

d)Damage to or Loosening of Hinges and

Latches.

e)Evidence of Dropping or Abuse.

3. Before turning on microwave power for

any service test or inspection within the

microwave generating compartments,

check the magnetron, wave guide or transmission line, and cavity for proper alignment, integrity, and connections.

4. Any defective or misadjusted components

in the interlock, monitor, door seal, and

microwave generation and transmission

systems shall be repaired, replaced, or

adjusted by procedures described in this

manual before the oven is released to the

owner.

5. A microwave leakage check to verify compliance with the Federal performance

standard should be performed on each

oven prior to release to the owner.

6. Do not attempt to operate the oven if the

door glass is broken.

vi

Page 7

CAUTION

WARNING

Whirlpool microwave ovens have a monitoring

system designed to assure proper operation

of the safety interlock systems.

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page vii

The interlock monitor switch will immediately

cause the oven fuse to blow if the door is

opened while the following combined failure

exists:

Primary door interlock switch and/or secondary interlock switch contacts failed in a closed

position.

CAUTION: REPLACE BLOWN

FUSE WITH 15 AMPERE CLASS H

FUSE ONLY.

Before replacing the blown oven fuse, test the

upper and lower door interlock switches, cook

relay or latch relay, and interlock monitor switch

(middle switch) for proper operation as described in the component test procedures.

DO NOT ATTEMPT TO REPAIR STICKING

CONTACTS OF ANY INTERLOCK SWITCH,

SAFETY SWITCH, OR COOK (LATCH) RELAY (REPLACE SWITCHES).

Any indication of sticking contacts during component test requires replacement of that component to assure reliability of the safety interlock system.

IF THE FUSE IS BLOWN, THE MONITOR,

PRIMARY INTERLOCK AND SECONDARY

INTERLOCK SWITCHES MUST ALSO BE

REPLACED. BE SURE THEY ARE PROPERLY CONNECTED.

NOTES:

• For proper repair and assembly of the oven

door, refer to pages 2-4 and 2-5.

• Interlock switches are not adjustable individually.

• For proper repair and adjustment of the

interlock switches, refer to page 2-8.

DISCONNECT FROM POWER SUPPLY

BEFORE SERVICING.

CAUTION: HIGH VOLTAGES ARE

PRESENT DURING THE COOK

CYCLE. EXTREME CAUTION

SHOULD BE OBSERVED AT ALL

TIMES.

CAUTION: DO NOT TOUCH

OVEN COMPONENTS OR WIRING DURING OVEN OPERATION.

ATTACH METER LEADS WITH

ALLIGATOR CLIPS WHEN MAKING OPERATIONAL TESTS.

CAUTION: IT IS NEITHER NECESSARY NOR ADVISABLE TO

ATTEMPT MEASUREMENT OF

HIGH VOLTAGES.

CAUTION: BEFORE TOUCHING

ANY OVEN COMPONENTS OR

WIRING, ALWAYS UNPLUG THE

OVEN FROM ITS POWER

SOURCE AND DISCHARGE THE

CAPACITOR BY USING A

20,000-OHM DISCHARGE RESISTOR.

USE AN INSULATED PLASTICHANDLE SCREWDRIVER AND

SHORT ACROSS THE CAPACITOR TERMINALS.

OR

vii

Page 8

R.F. LEAKAGE TEST

CAUTION

EQUIPMENT

• Electromagnetic energy leakage monitor

(NARDA 8100B, HOLADAY H1501).

• 600 ml glass beaker.

• Glass thermometer 100°C or 212° F.

TEST

On every service call, checks for microwave

energy emission must be made according to

the following manner.

1. Remove the cooking rack from the oven

cavity, if the microwave oven is so

equipped.

2. Place a 250 ML (8.0 oz.) glass of water in

the center of the oven bottom.

3. Select “HIGH” cook power, turn the mi-

crowave oven on, and test for R.F. Ieakage

at the following locations using the pattern shown below:

a) Around the cabinet at the front.

b) Around the door.

c) Across the console panel.

d) Horizontally across the door.

e) Vertically across the door.

f) Diagonally across the door.

g) Across the air vents.

h) Across the rear air vent.

i) All lockseams.

j) Weld at bottom.

k) Bottom plate.

I) Oven feet.

4. The scan speed is one inch per second.

When checking for R.F. Ieakage, use an approved R.F. measuring device to assure less

than 4 mw/cm

a maximum scan rate of 2.5 cm/second, in

compliance with U.S. Government Department

of Health, Education and Welfare 21 CFR1030,

performance Standard for Microwave Ovens.

A properly operating door and seal assembly

will normally register small emissions, but they

must be no greater than 4 mw/cm

measurement uncertainty.

NOTE: Enter leakage readings in space BEFORE and AFTER on the service document.

All microwave ovens exceeding the emission

level of 4 mw/cm

Service for microwave ovens immediately and

the owner should be told not to use the microwave oven until it has been repaired completely.

If a microwave oven is found to operate with

the door open, report to Dept. of Service, the

manufacturer and CDRH* immediately. Also

tell the owner not to use the oven.

* CDRH: Center for Device and Radiological Health, Food

and Drug Administration.

The interlock monitor switch acts as the final

safety switch protecting the customer from

microwave radiation. If the interlock monitor

switch operated to blow the fuse when the

interlocks failed you must replace all interlock

switches—primary and secondary interlock

switches and the monitor switch with new

ones because the contacts of those interlock

switches may be melted and welded together.

All repairs must be performed in such a manner that microwave energy emissions are minimal.

Address for CDRH is:

Office of Compliance (HFZ-312) Center for

Devices and Radiological Health

1390 Piccard Drive

Rockville, Maryland 20850

2

emission at 5 cm distance with

2

to allow for

2

must be reported to Dept. of

viii

Page 9

THEORY OF OPERATION

Cooking Products Service Manual

Original March 1997 4322167

© 1997 Whirlpool Corporation

Page 1-1

The microwave oven is powered by the 120volt line. Whenever the door is closed and a

cooking function is programmed through the

control panel’s keypad, relay contacts on the

control board close, and complete a circuit

from the L1 side to the neutral side of the line.

The control board uses five relays to operate

the various functions of the microwave oven

Relay 4 controls the speed of the blower motor

through the contol panel. The base thermal

fuse will also turn the blower motor on to its

low speed if the temperature reaches 133˚F.

The schematic configuration for relay 4 is

shown in the following diagram. The relay is

explained in further detail on the following

page.

L1

(see below). The relays are controlled by the

microcomputer on the control board, and per-

(NC)

(C)

(NO)

form the functions shown below.

RELAY 4

Relay 1 ........................................................ Oven Light/Fan & Stirrer Motors

Relay 2 ........................................................ High Voltage Section

Relay 3 ........................................................ Low-Speed Blower Motor

Relay 4 (N.C. Contacts) ........................... Auto Low-Speed Blower Motor

Relay 4 (N.O. Contacts) ........................... High-Speed Blower Motor

Relay 5 ........................................................ Turntable Motor

BASE

THERMAL

FUSE

BLOWER

MOTOR

(LOW)

(HI)

(C)

CN3

CONTROL

CIRCUIT

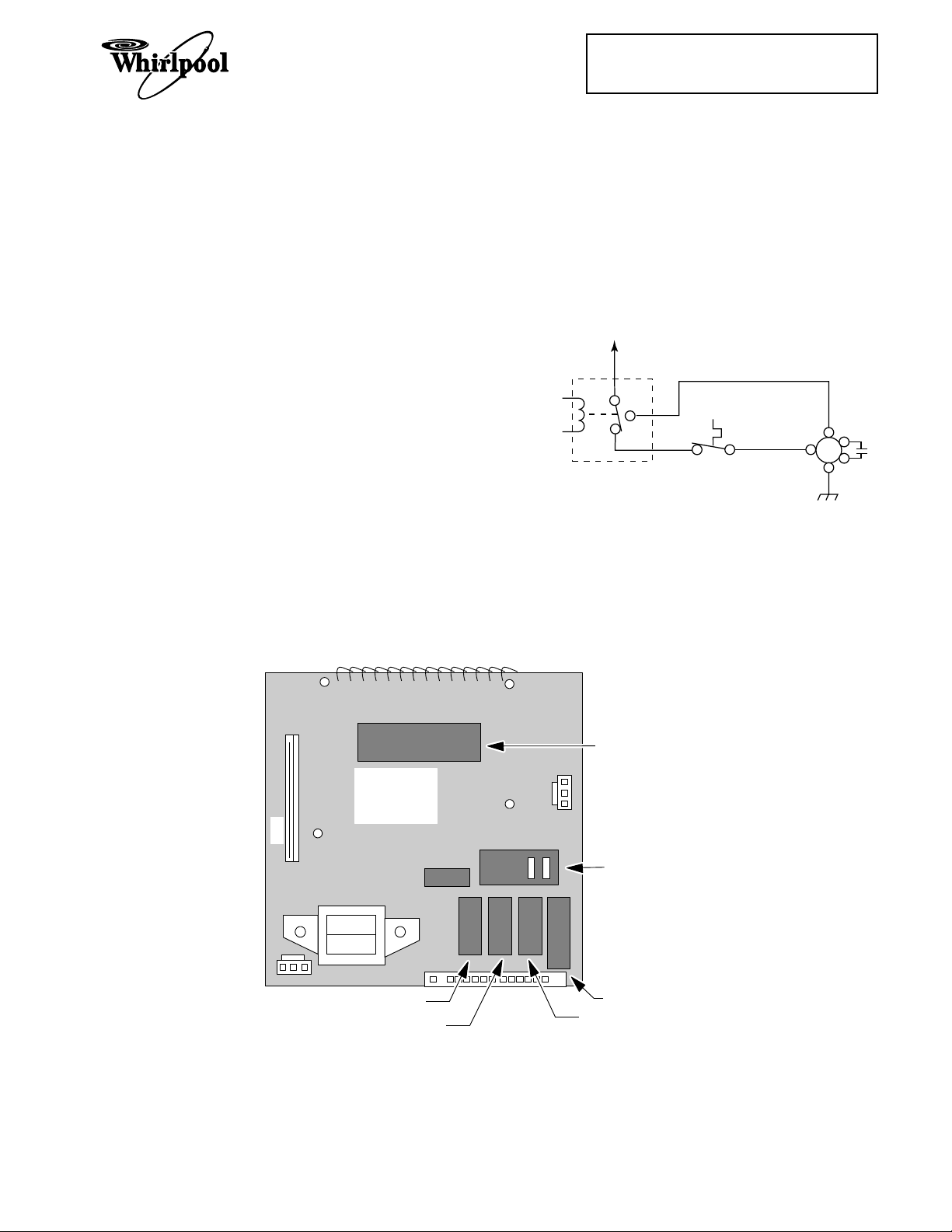

BOARD

RELAY RY1

RELAY RY5

MICROCOMPUTER

RELAY RY2

RELAY RY4

RELAY RY3

1-1

Page 10

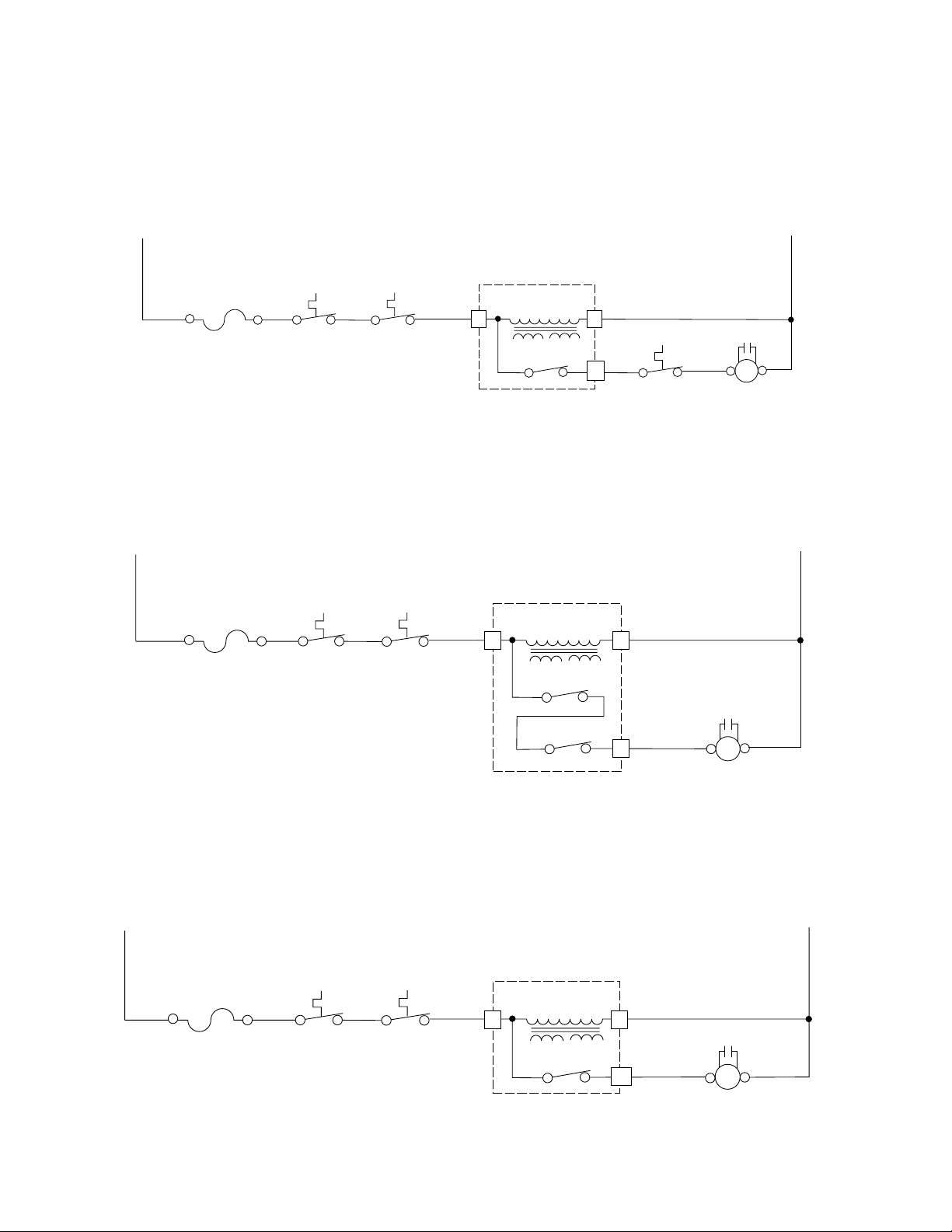

The normally-closed (N.C.) contacts of relay 4 provide a potential circuit for the Base Thermal

Fuse. If the base of the oven exceeds 133˚F, the thermal fuse contacts close, and a circuit for

the low-speed side of the blower motor is completed, which turns the motor on. The low-speed

blower will operate until the base temperature drops below 104˚F and opens the thermal fuse

contacts, and turns off.

L1

BK

20A LINE

FUSE

BK

MAGNETRON

THERMAL

FUSE

BK

CAVITY

THERMAL

FUSE

MICROCOMPUTER

RD

TRANSFORMER

3 1

BOARD

LOW-VOLTAGE

RELAY 4

11

YL

THERMAL

BASE

FUSE

W

CAPACITOR

RD RD

W

BLOWER

MOTOR

N

BL

(C)(HIGH)

When the low-speed fan is selected by the user at the control panel, relay 3 and the normallyclosed (N.C.) contacts of relay 4, complete the circuit to the low-speed windings of the blower

motor and turn it on.

L1

20A LINE

FUSE

RDBK

MAGNETRON

THERMAL

FUSE

BK

CAVITY

THERMAL

USE

MICROCOMPUTER

LOW-VOLTAGE

RD

TRANSFORMER

3 1

BOARD

RELAY 4

RELAY 3

W

CAPACITOR

9

PK/W

(LOW)

BLOWER MOTOR

RDRD

(C)

N

BL

When the high-speed fan is selected by the user at the control panel, the normally-open (N.O.)

contacts of relay 4 complete the circuit to the high-speed windings of the blower motor and turn

it on.

L1

BK

20A LINE

FUSE

RD

MAGNETRON

THERMAL

FUSE

BK

CAVITY

THERMAL

FUSE

MICROCOMPUTER

RD

TRANSFORMER

3 1

BOARD

LOW-VOLTAGE

RELAY 4

13

W

CAPACITOR

RDRD

BK

(HI) (C)

BLOWER MOTOR

N

BL

1-2

Page 11

COMPONENT ACCESS

COMPONENT SECTIONS

This section instructs you on how to service

the individual components in the Microwave

Oven Hood Combination. These components

(shown below) and their sections are as follows:

• General

Cabinet

• The Protection Control System

Oven Door

Oven Door Components

Control Panel

Line Fuse

Interlock Switches

Base Thermal Fuse

Magnetron Thermal Fuse

Convection Thermistor

Cavity Thermal Fuse

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 2-1

• The Operating Control System

Oven Light Socket

Control Circuit Board

Turntable Indicator Circuit Board

Fan Motor

Power Cord

Blower Motor Capacitor

Convection Heating Element

Gas Sensor

Stirrer Motor

Turntable Motor

Cooktop Light Socket

• The High Voltage Components

Magnetron

Rectifier

Capacitor

Transformer

Refer to the section on the following pages for

the component you wish to service.

GAS SENSOR (NOT ON ALL MODELS)

BLOWER MOTOR CAPACITOR

CAVITY THERMAL FUSE

CONVECTION HEATING ELEMENT

(NOT ON ALL MODELS)

BLOWER MOTOR

CONVECTION THERMISTOR

(NOT ON ALL MODELS)

TURNTABLE MOTOR

COOKTOP LIGHTS

SECONDARY INTERLOCK SWITCH

INTERLOCK MONITOR SWITCH

PRIMARY INTERLOCK SWITCH

CONTROL CIRCUIT BOARD

TURNTABLE INDICATOR CIRCUIT BOARD

LINE FUSE

STIRRER MOTOR

OVEN LIGHT

MAGNETRON

THERMAL FUSE

FAN MOTOR

MAGNETRON

HV CAPACITOR

HV RECTIFIER

HV TRANSFORMER

BASE THERMAL FUSE

Base Thermal Fuse ................................................. Closes @ 133˚F/56˚C, resets @ 104˚F/40˚C.

Magnetron Thermal Fuse ...................................... Opens @ 228˚F/109˚C, resets @ 140˚F/60˚C.

Cavity Thermal Fuse .............................................. Opens @ 230˚F/110˚C, resets @ 140˚F/60˚C.

2-1

Page 12

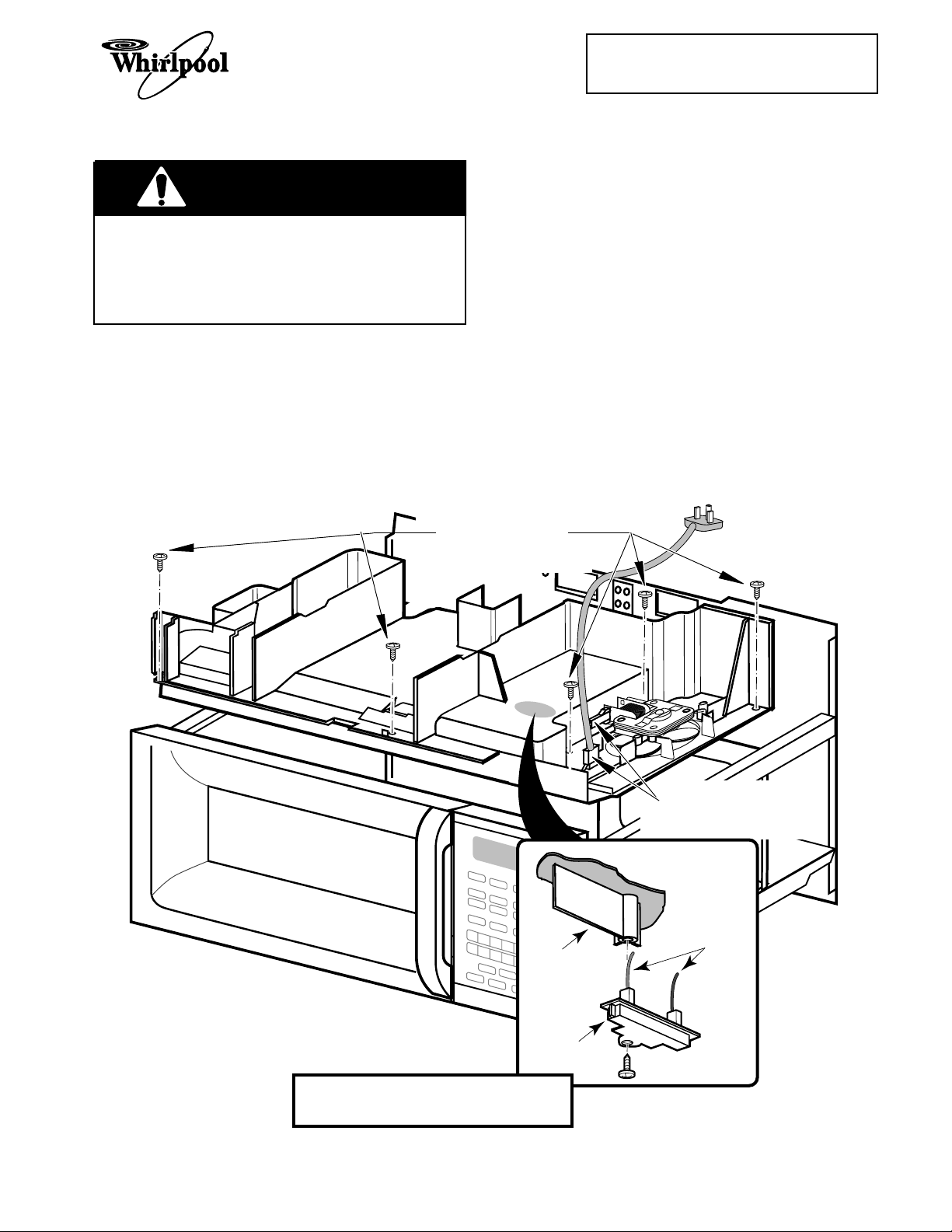

GENERAL

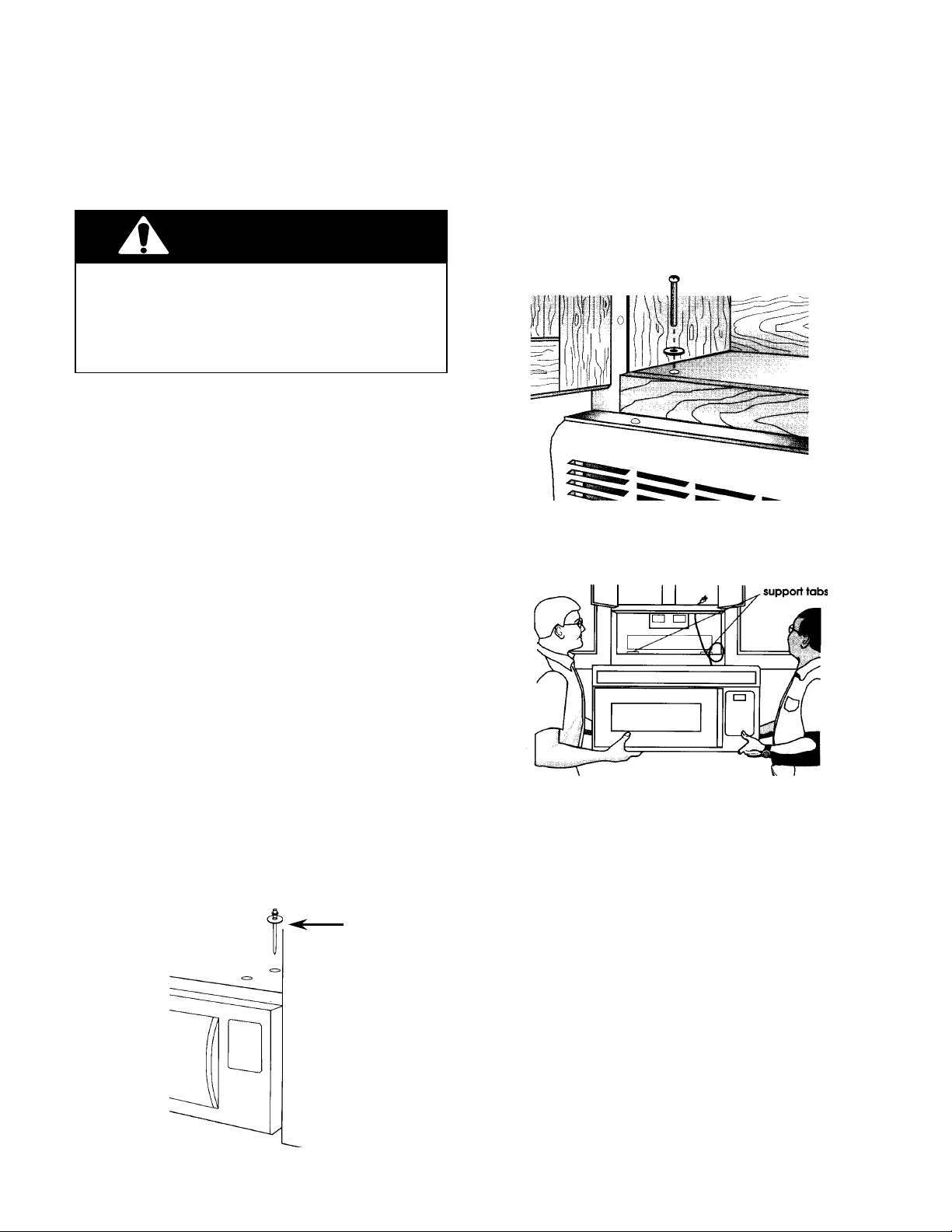

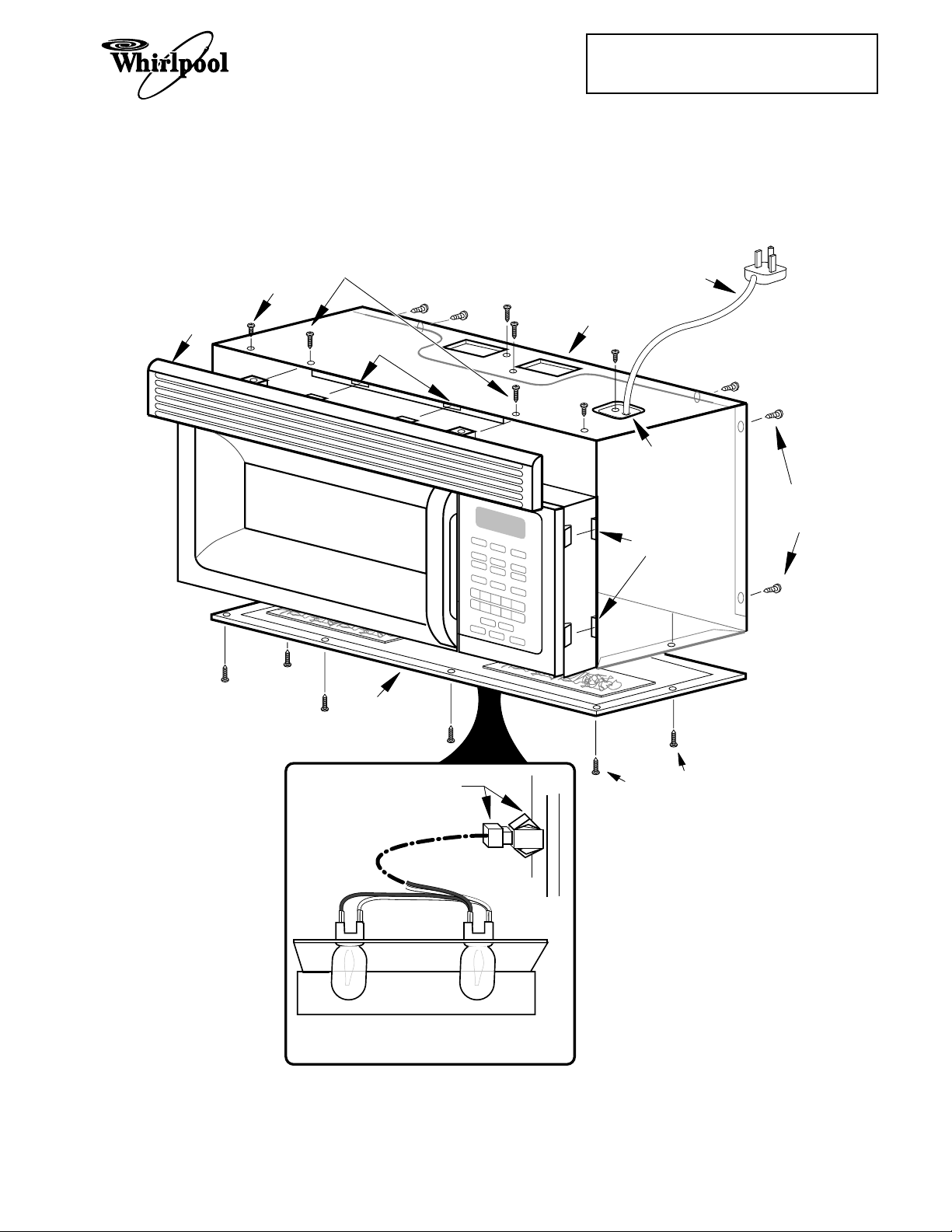

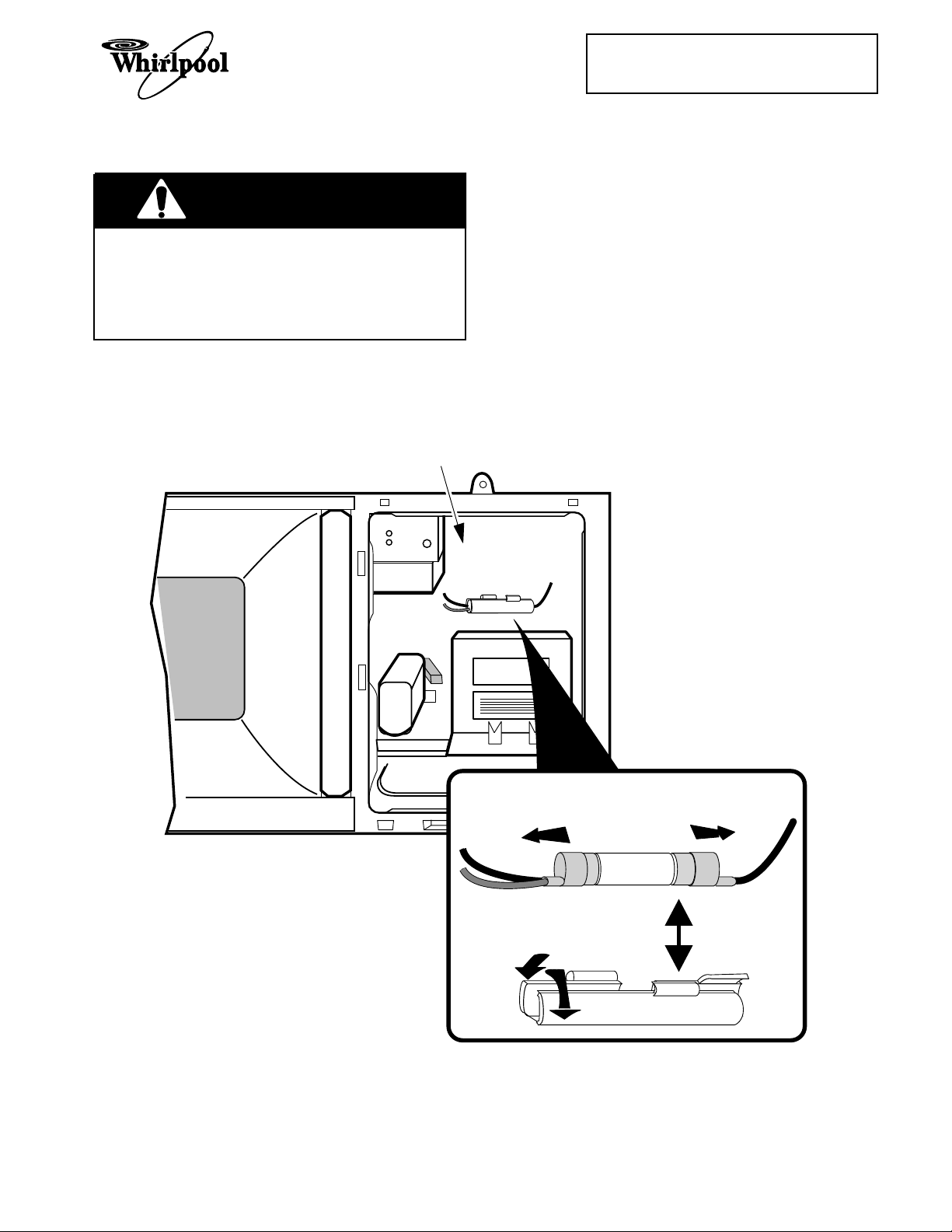

REMOVING THE MICROWAVE OVEN & CABINET

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

IMPORTANT NOTE: Most of the microwave

components can be serviced without removing the unit or its cabinet. They can be accessed by removing the vent grille and the

control panel. Before removing the unit or its

cabinet, first check the procedure for the component you wish to service to see if it is necessary. If it is necessary to remove the unit and

its cabinet to service a component, use the

following procedure.

4. Support the front of the microwave oven

and remove the two bolts and washers

from the top of the oven.

5. Using two people, remove the microwave

oven from its mounting location and set it

on a protected (padded) work surface.

CAUTION: Because of the weight and size of

the microwave oven, two people are required

to safely move and install it. Failure to do so

could result in personal injury.

1. Disconnect the electrical supply to the

microwave oven.

2. Remove the six screws from the base

plate and lower it, (see the illustration on

the next page), then disconnect the

cooktop light connector, and set the base

plate aside.

3. Remove the lock pin and washer from the

top of the microwave oven.

LOCK PIN &

WASHER

6. To remove the vent grille from the microwave oven, remove the two inside screws

from the top of the cabinet, then pull the

top of the vent grille out so the two center

tabs are free of their slots, and remove

the grille.

7. Remove the screw from the power cord

cover and remove the cover.

8. Remove the remaining screws from the

top and rear of the cabinet.

9. Slide the cabinet back and unhook the

sides from the tabs, then slide the power

cord out of the cabinet, and remove the

cabinet.

Proceed to the section for the component you

wish to service.

2-2

Page 13

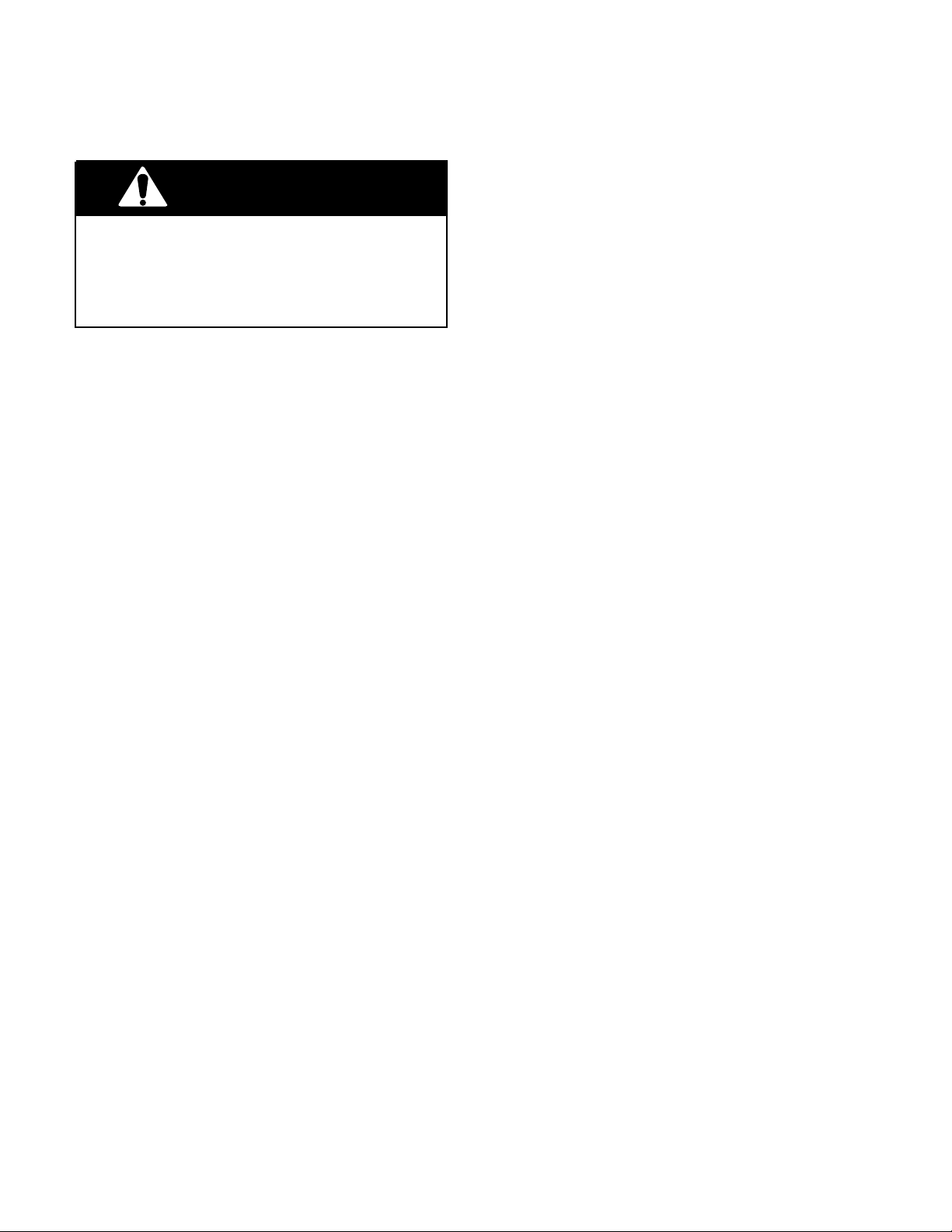

VENT

GRILLE

CABINET

SCREW

VENT

GRILLE

SCREWS (2)

TAB SLOTS

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

CABINET

Page 2-3

POWER

CORD

POWER

CORD COVER

CABINET

SCREWS

BASE

PLATE

CONNECTORS

SLOTS

BASE PLATE

SCREWS

(6)

COOKTOP LIGHT

ASSEMBLY WIRING

Removing The Cabinet

2-3

Page 14

THE PROTECTION CONTROL SYSTEM

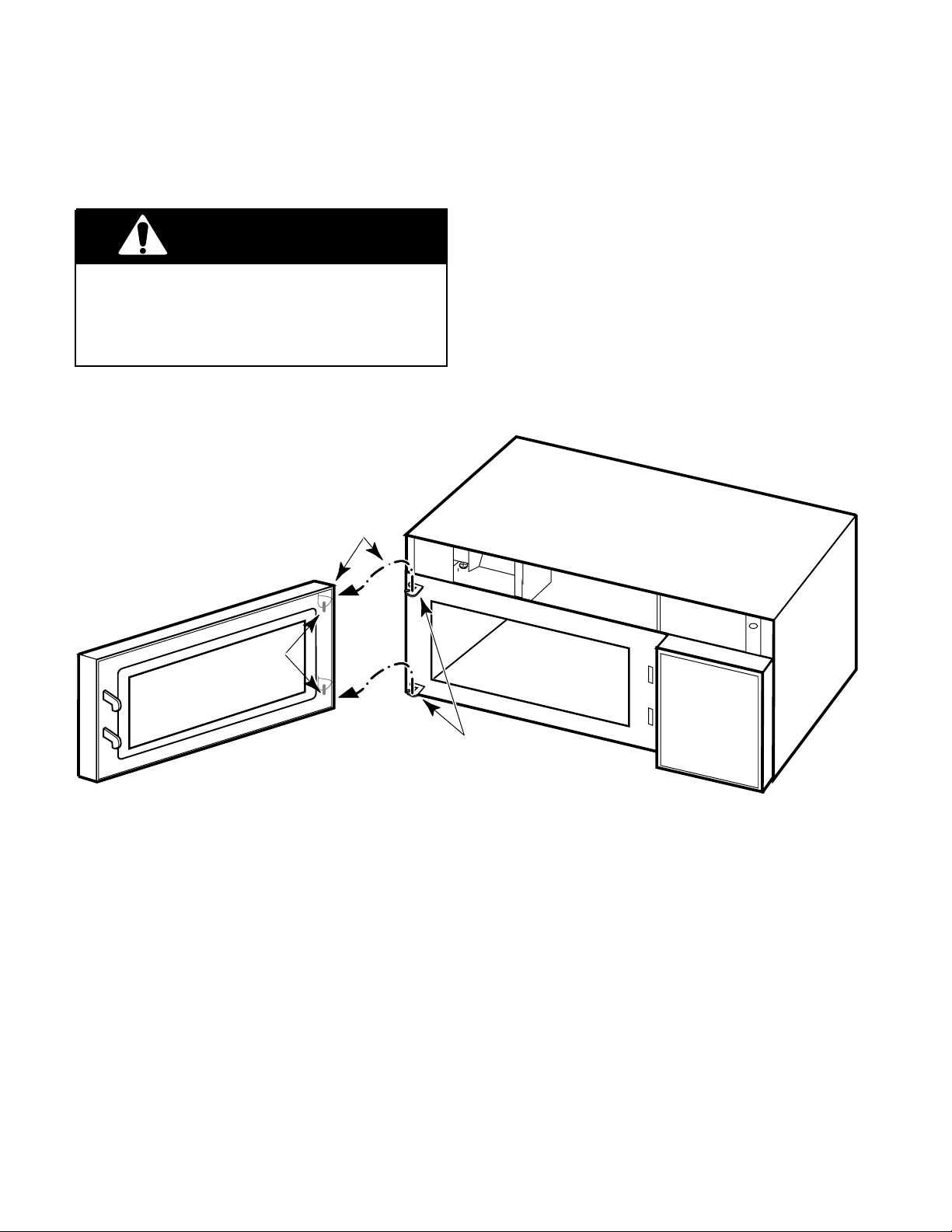

REMOVING THE OVEN DOOR

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

LIFT DOOR PINS

OUT OF HINGE HOLES

2. Remove the two screws from the top of

the cabinet for the vent grille and remove

the grille (see the illustration on page 2-3).

3. Open the oven door all the way, then lift

the door pins out of the hinge holes and

remove it.

4. Install the new oven door and the vent

grille on the microwave oven.

PINS

HINGES

2-4

Page 15

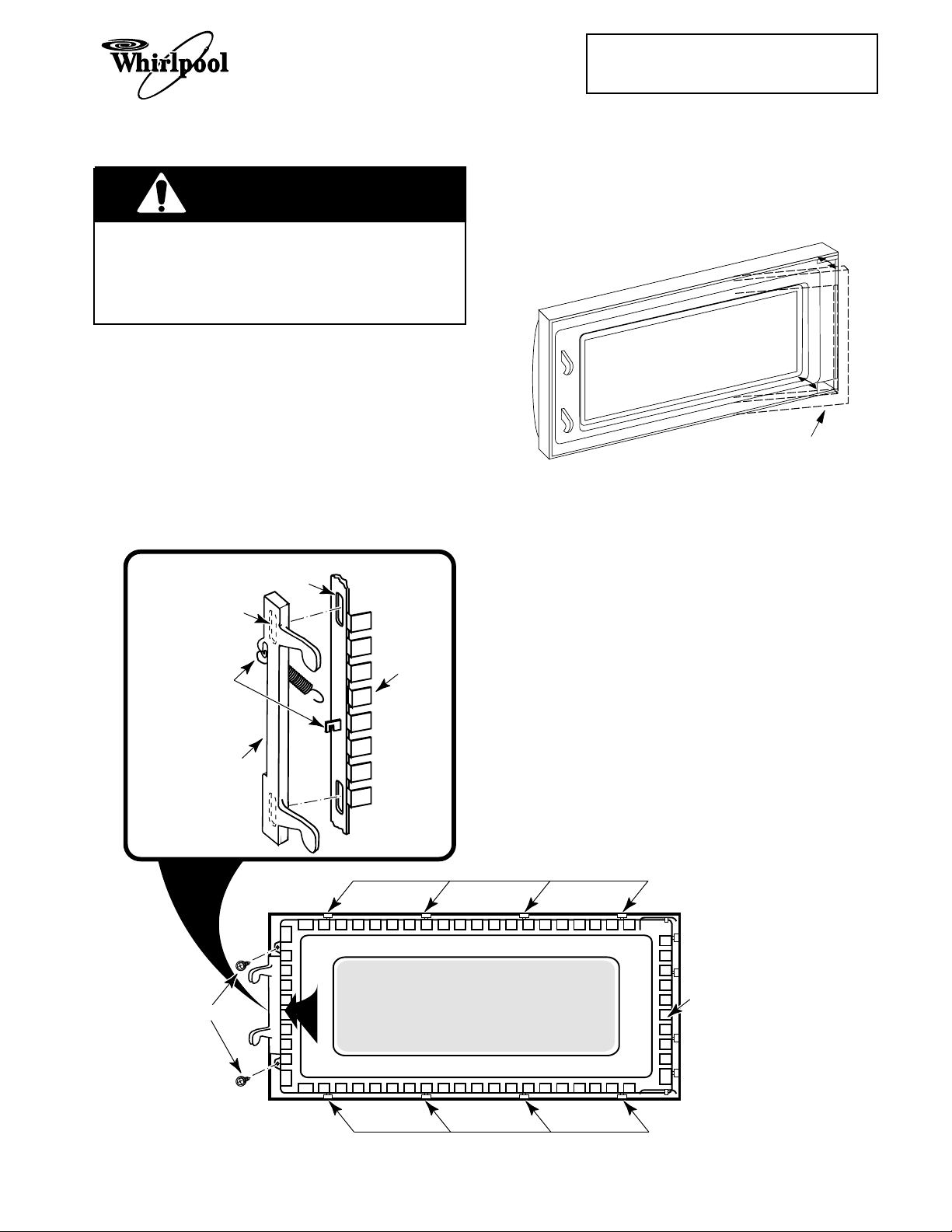

REMOVING THE OVEN DOOR COMPONENTS

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 2-5

4. To remove the oven door choke, use a

putty knife along the edges, and pry the

choke out from around the inside window

frame.

1. Disconnect the electrical supply to the

microwave oven.

2. Remove the two screws from the top of

the cabinet for the vent grille and remove

the grille (see the illustration on page 2-3).

3. Open the oven door all the way, then lift

the door pins out of the hinge holes and

remove it (see the illustration on the previous page).

SLOT

HOOKED TAB

GLASS

HOOK SPRING

OVER TABS

LATCHES

FRAME

OVEN DOOR

PRY OUT CHOKE

5. To replace the latches and door glass

assembly, remove the two mounting

screws from the end of the glass frame,

then push the top and bottom edges of the

door out and unsnap the locking tabs from

the frame and remove the assembly.

6. Slide the latches down and remove the

hooked tabs from the slots in the door

frame, then unhook the ends of the spring

from the door, and remove the latches.

7. Reassemble the oven door.

8. Reinstall the oven door and vent grille on

the microwave oven.

FRAME SCREWS

TOP LOCKING TABS

GLASS

FRAME

BOTTOM LOCKING TABS

2-5

Page 16

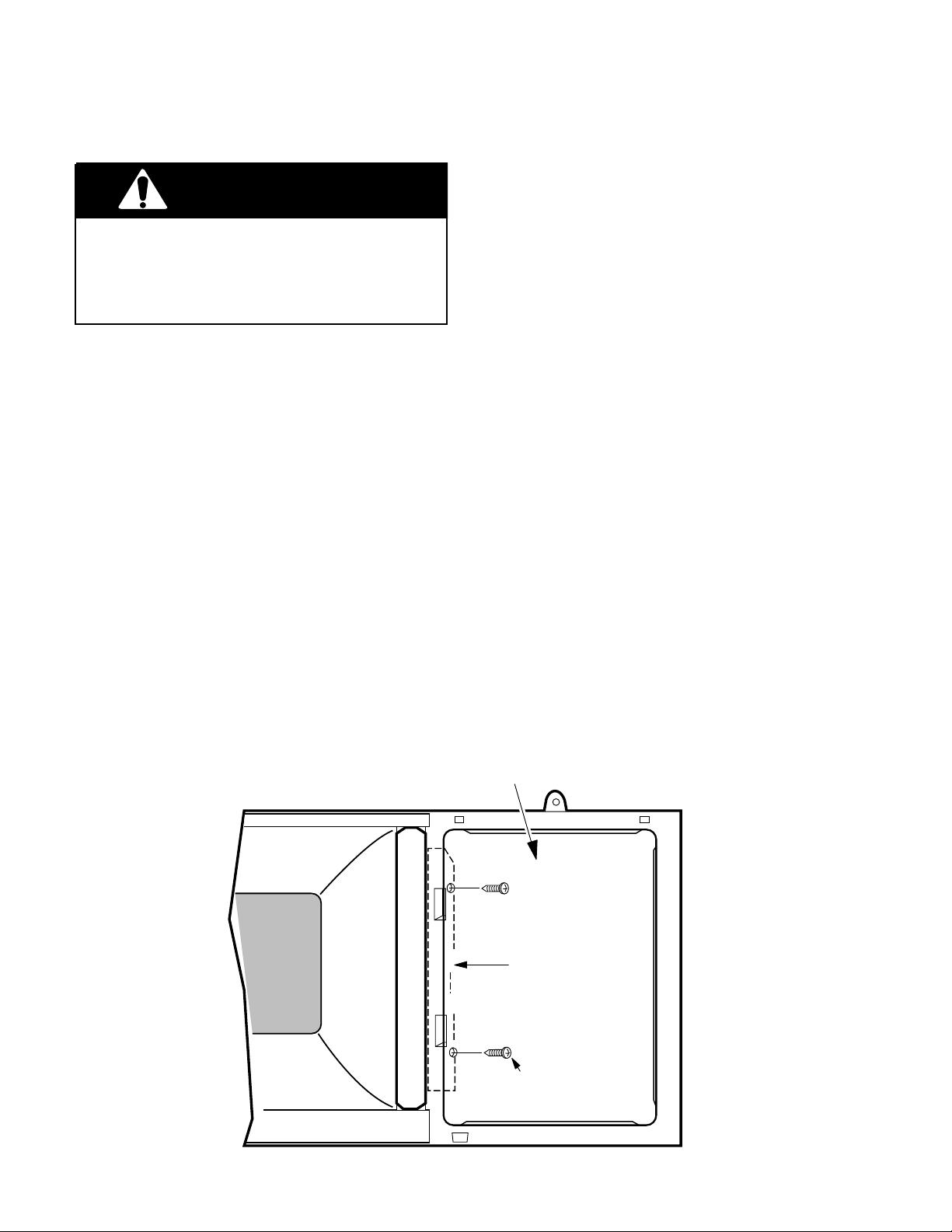

REMOVING THE CONTROL PANEL

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

2. Remove the two screws from the top of

the cabinet for the vent grille and remove

the grille (see the illustration on page

2-3).

3. Remove the screw from the top center tab

of the control panel, then lift the panel so

that the bottom tabs are out of the slots

and pull it forward.

1. Disconnect the electrical supply to the

microwave oven.

TURN PANEL OVER

CONTROL PANEL

4. Turn the panel over and disconnect the

three harness connectors from the board,

then set the control panel aside.

CONTROL

PANEL SCREW

BOTTOM

TABS

BOTTOM

SLOTS

2-6

Page 17

REMOVING THE LINE FUSE

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 2-7

2. Remove the two screws from the top of

the cabinet for the vent grille and remove

the grille (see the illustration on page

2-3).

3. Remove the control panel from the microwave oven (see page 2-6).

4. From inside the control panel opening,

unsnap and open the fuseholder halves.

1. Disconnect the electrical supply to the

microwave oven.

CONTROL PANEL

OPENING

5. Remove the line fuse from the fuseholder

and pull the wire connectors off the ends.

6. Install the new line fuse and reassemble

the microwave oven.

2-7

SLIDE WIRE CONNECTORS

OFF ENDS OF FUSE

LINE FUSE

OPEN FUSEHOLDER

SECTIONS

FUSE HOLDER

Page 18

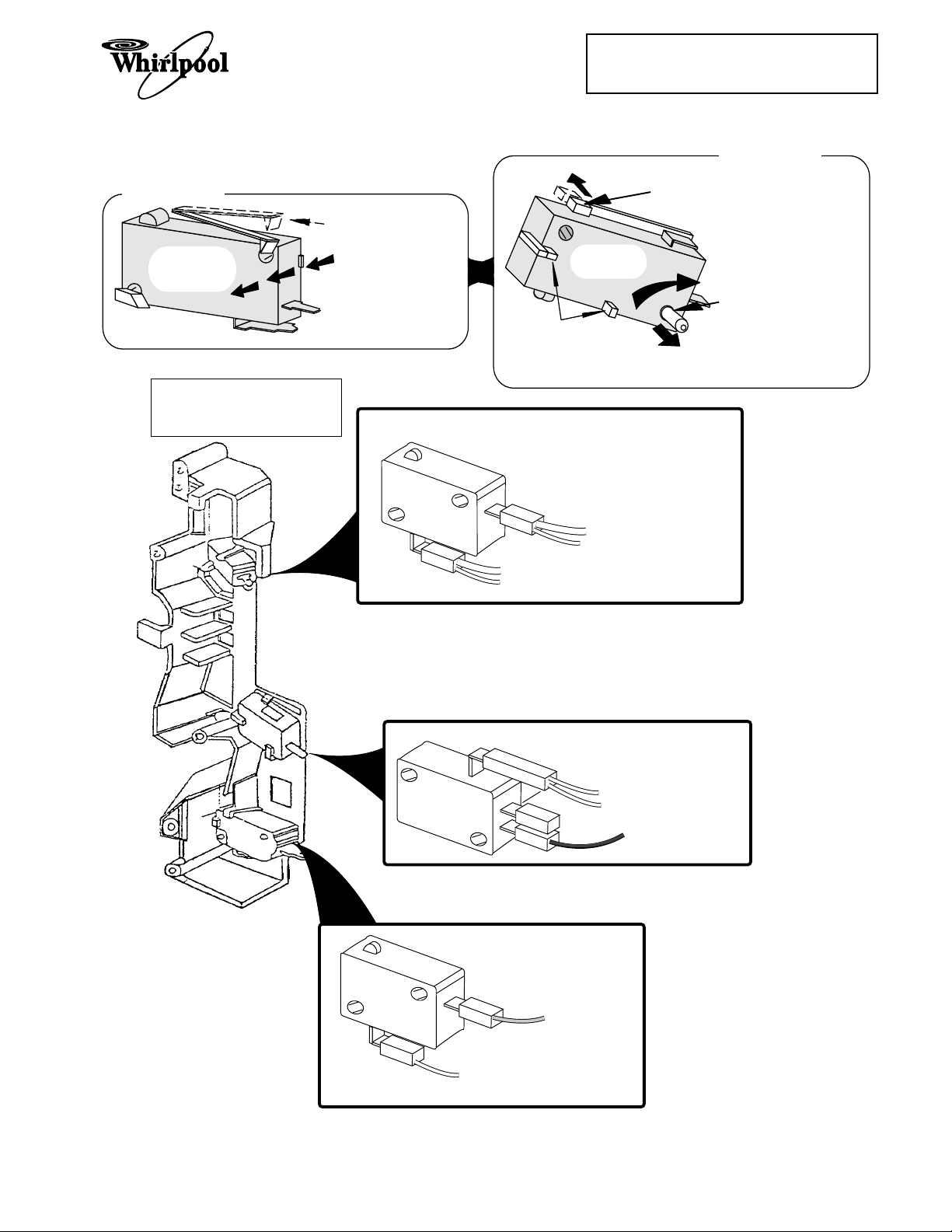

REMOVING/ADJUSTING THE INTERLOCK SWITCHES

6. One at a time, pull the wire connectors off

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

REMOVING A SWITCH

1. Disconnect the electrical supply to the

microwave oven.

2. Remove the two screws from the top of

the cabinet for the vent grille and remove

the grille (see the illustration on page

2-3).

3. Remove the control panel from the microwave oven (see page 2-6).

4. Remove the two mounting screws from

the interlock switch assembly, and position the assembly so you can easily access the switches and wiring.

5. Refer to inset 1 on the next page for the

secondary interlock switch, or inset 2 for

any of the other switches mounted on the

interlock switch housing assembly, and

remove the switch from the housing as

shown.

CONTROL PANEL

OPENING

the defective switch, and reconnect them

to the same terminals on the replacement

switch.

7. Snap the new switch into place on the

switch housing.

8. Mount the interlock switch assembly to

the chassis flange with two screws.

9. Close the housing cover and secure it

with its mounting screw.

MAKING ADJUSTMENTS

1. Plug in the microwave oven and check the

operation of the switches. If necessary,

loosen the two housing screws, and adjust the housing so that the switches operate properly. NOTE: The Interlock Monitor

Switch provides an added safety check on

the Primary and Secondary Interlock

Switches. If the Primary and Secondary

Interlock Switches allow the oven to operate with the door open, the Interlock Monitor Switch will blow the line fuse. Unplug

the oven again when you have completed

the checks.

2. Reassemble the microwave oven.

INTERLOCK

2-8

SCREW

INTERLOCK

SWITCH

HOUSING

INTERLOCK

SCREW

Page 19

INSET 1

SECONDARY

INTERLOCK

SWITCH

INTERLOCK SWITCH

HOUSING ASSEMBLY

1.

RAISE THIS LOCKING

ARM TO RELEASE

SWITCH FROM HOUSING.

2.

PRESS BODY IN

THIS DIRECTION TO

REMOVE SWITCH

FROM HOUSING.

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

INSET 2

ALL OTHER

SWITCHES

NOTE: THESE POSTS

HOLD THE SWITCH IN

PLACE ON THE HOUSING

AND ARE STATIONARY.

SECONDARY INTERLOCK

SWITCH

1.

PUSH THIS LOCKING

ARM BACK TO UNLOCK

SWITCH.

2.

ROTATE SWITCH ON THIS

PIN AND REMOVE

SWITCH FROM HOUSING.

Page 2-9

WHITE (H.V. Transformer)

SMALL WHITE (Monitor Switch)

LARGE WHITE (Power Cord)

SMALL WHITE (Oven Lamp)

INTERLOCK MONITOR

PRIMARY INTERLOCK

SWITCH

SWITCH

WHITE (Turntable Motor)

WHITE (Secondary Switch)

RED (H.V. Transformer)

PINK (CN2 Pin 1)

Blue (CN2 Pin 3)

Interlock Switch Wiring

2-9

Page 20

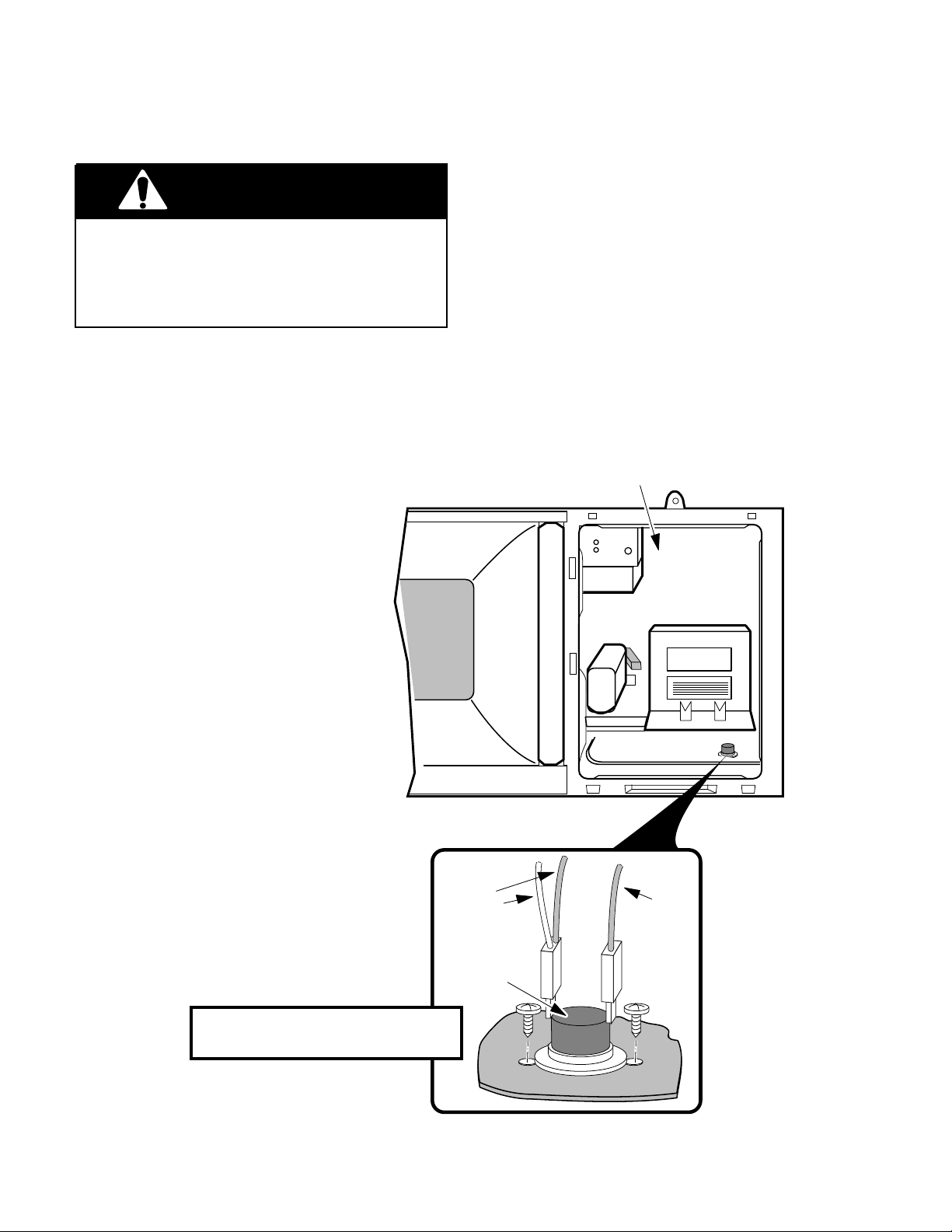

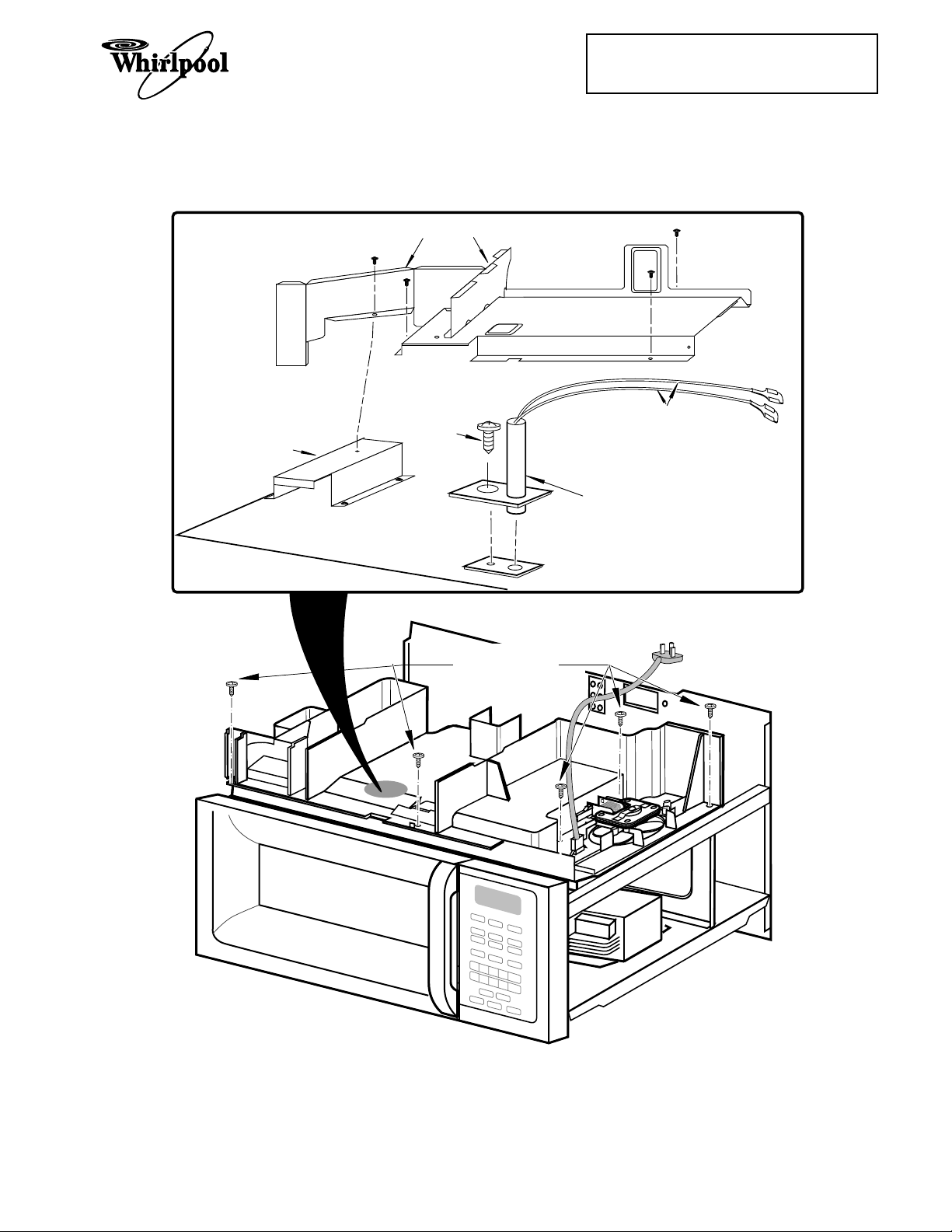

REMOVING THE BASE THERMAL FUSE

CONTROL PANEL

OPENING

YELLOW

PINK

WHITE

BASE

THERMAL FUSE

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

2. Remove the two screws from the top of

the cabinet for the vent grille and remove

the grille (see the illustration on page

2-3).

3. Remove the control panel from the microwave oven (see page 2-6).

4. Remove the mounting screws from the

base thermal fuse and remove it.

1. Disconnect the electrical supply to the

microwave oven.

5. Unplug the connectors from the terminals

of the base thermal fuse.

6. Install the new base thermal fuse and

reassemble the microwave oven.

THE BASE THERMAL FUSE CLOSES

AT 133˚F & RESETS @ 104˚F.

2-10

Page 21

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 2-11

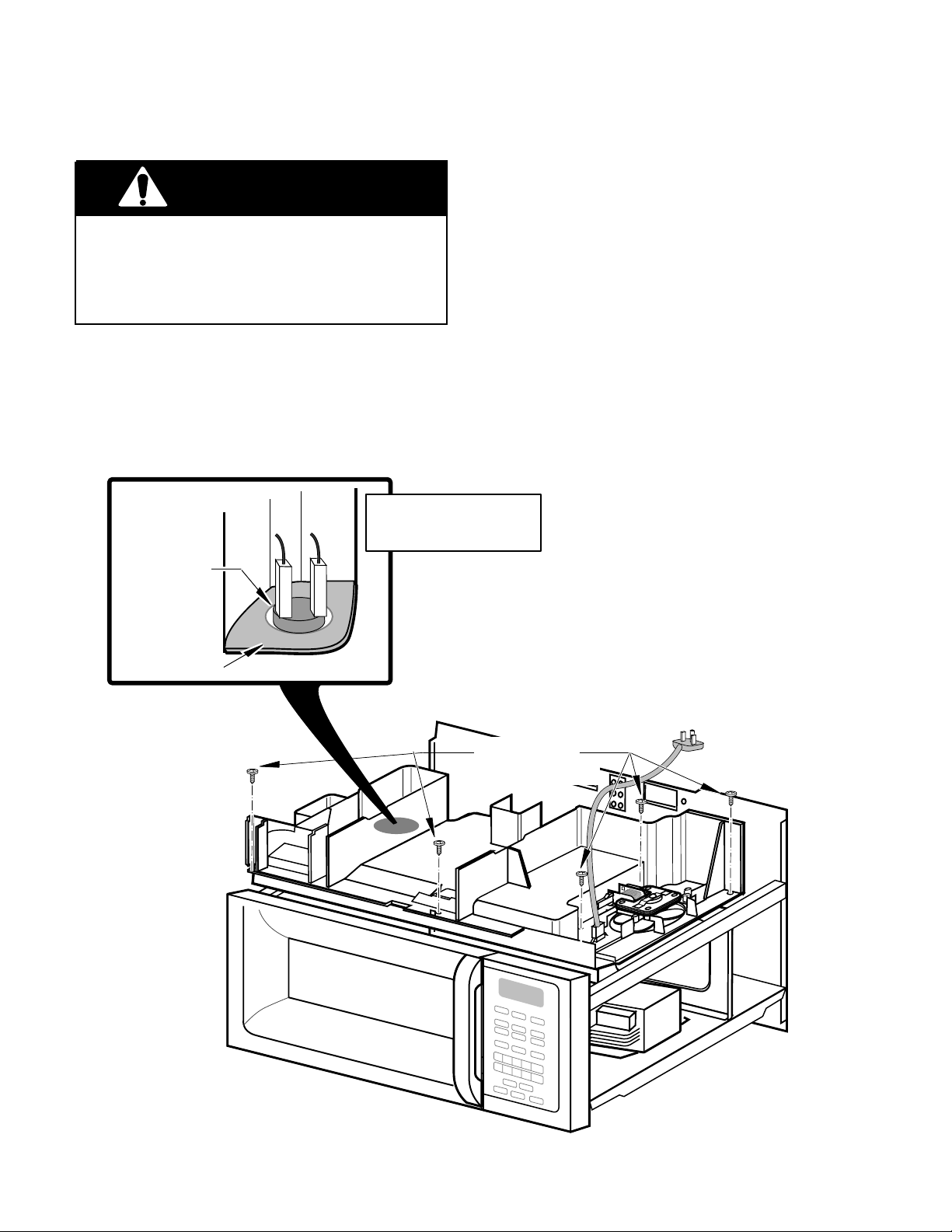

REMOVING THE MAGNETRON THERMAL FUSE

4. Unplug the line cord connector and re-

WARNING

Personal Injury Hazard

move the line cord.

5. Unplug the connector from the terminals

of the fan motor.

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

2. Remove the microwave oven from its

mounting location (see page 2-2).

3. Remove the vent grille and cabinet from

the microwave oven (see the illustration

on page 2-3).

REMOVE FIVE

AIR DUCT SCREWS

6. Remove the five screws from the air duct.

7. Lift the air duct and position it so that you

can access the magnetron thermal fuse,

then remove the mounting screw, and

unplug the connectors from its terminals.

8. Install the new magnetron thermal fuse

on the air duct, and reassemble the microwave oven.

BOTTOM

OF AIR DUCT

MAGNETRON

THERMAL FUSE

THE MAGNETRON THERMAL FUSE

OPENS AT 228˚F & RESETS @ 140˚F.

2-11

UNPLUG POWER

CORD & FAN MOTOR

BLACK & RED

WIRES

Page 22

REMOVING THE CONVECTION THERMISTOR

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

2. Remove the microwave oven from its

mounting location (see page 2-2).

3. Remove the vent grille and cabinet from

the microwave oven (see the illustration

on page 2-3).

4. Remove the five screws from the air duct

and position it so that you can access the

pulley cover underneath.

5. Remove the screws from the circulation

pulley cover and the bracket, then remove the cover and the attached brackets from the top of the oven. Do not remove the brackets from the cover.

6. Remove the screw from the convection

thermistor and remove the thermistor.

7. Cut the two white wires (not the thermistor wires) coming from the control

board next to the splice.

8. Splice the white wires onto the ends of the

new convection thermistor wires. Cover

the spliced wire ends with electrical tape

so that they cannot short to the oven.

9. Mount the new convection thermistor to

the oven and reassemble the microwave

oven.

2-12

Page 23

BRACKETS

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

CIRCULATION

PULLEY COVER

Page 2-13

SENSOR

COVER

PHILLIPS

SCREW

REMOVE FIVE

AIR DUCT SCREWS

WHITE WIRES

CAUTION: WHEN REPLACING THE

THERMISTOR, DO NOT CUT AND SPLICE

THE WHITE WIRES, OR AN IMPROPER

SIGNAL WILL BE SENT FROM THE THERMISTOR

TO THE MICROCOMPUTER BOARD

CONVECTION

THERMISTOR

2-13

Page 24

REMOVING THE CAVITY THERMAL FUSE

3. Remove the vent grille and cabinet from

WARNING

Personal Injury Hazard

the microwave oven (see the illustration

on page 2-3).

4. Remove the five screws from the air duct.

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

2. Remove the microwave oven from its

mounting location (see page 2-2).

THE CAVITY THERMAL

FUSE OPENS AT 230˚F

CAVITY

THERMAL

FUSE

AIR DUCT

AND RESETS AT 140˚F

5. Unplug the connectors from the terminals

of the cavity thermal fuse, then lift the left

side of the air duct, and remove the cavity

thermal fuse. NOTE: There are no mounting screws holding the cavity thermal fuse

in place.

6. Install the new cavity thermal fuse in its

mounting hole, and reassemble the microwave oven.

REMOVE FIVE

AIR DUCT SCREWS

2-14

Page 25

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

THE OPERATING CONTROL SYSTEM

REMOVING THE OVEN LIGHT SOCKET

4. Remove the mounting screw from the light

WARNING

Personal Injury Hazard

cover and remove the cover.

5. Remove the bulb from the oven light

socket.

Page 2-15

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

2. Remove the microwave oven from its

mounting location (see page 2-2).

3. Remove the vent grille and cabinet from

the microwave oven (see the illustration

on page 2-3).

CUT

&

SPLICE

BRACKET

SOCKET

(TWIST TO

REMOVE)

BULB

MOUNTING

POST

& SCREW

LOCKING TAB

6. Cut the wires near the old light socket

body.

7. Push the locking tab and turn the socket

and remove it from the bracket.

1

8. Remove

/2" of insulation from the cut wire

ends of the black and white wires and

then splice them to the wires of the new

socket with two wire nuts.

9. Install the new light socket and its bulb,

and reassemble the microwave oven.

AIRDUCT

2-15

Page 26

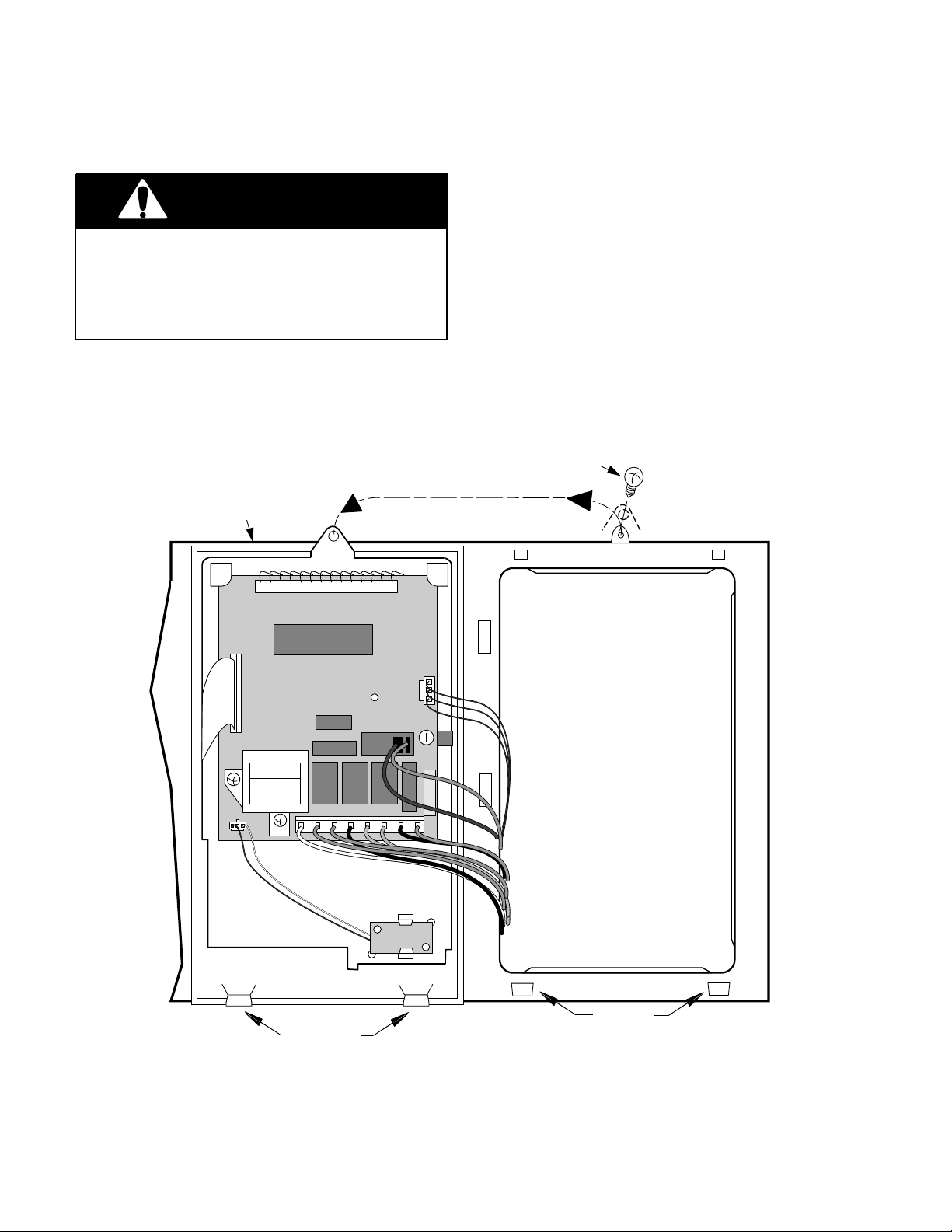

REMOVING THE CONTROL CIRCUIT BOARD

& THE TURNTABLE INDICATOR CIRCUIT BOARD

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

2. Remove the two screws from the top of

the cabinet for the vent grille and remove

the grille (see the illustration on page

2-3).

PANEL SCREW

TURN PANEL OVER

CONTROL BOARD

CONTROL

3. Remove the screw from the top center tab

of the control panel, then lift the panel so

that the bottom tabs are out of the slots

and turn it over.

To remove the control circuit board,

4.

disconnect the three harness connectors

and the ribbon cable (see the inset), and

remove the three mounting screws.

To remove the turntable indicator cir-

5.

cuit board, unplug the connector at CN5,

and unsnap it from the locking arms.

6. Install the new circuit board in its mounting location and reassemble the microwave oven.

CN5

LOCKING ARMS

TURNTABLE

INDICATOR

BOARD

MOUNTING

SCREWS

BOTTOM

TABS

DISCONNECT

THREE HARNESS

CONNECTORS

CN3

BOTTOM

SLOTS

INSERT CABLE INTO

REAR CONTACT SLOT

2-16

RIBBON CABLE

COLLAR

UNSNAP/SNAP LOCKING

ARMS ON COLLAR TO

BOTTOM SIDE OF

CONNECTOR

CONNECTOR

INSET

Page 27

REMOVING THE FAN MOTOR

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

2. Remove the microwave oven from its

mounting location (see page 2-2).

3. Remove the vent grille and cabinet from

the microwave oven (see the illustration

on page 2-3).

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 2-17

4. Pull the fan blade and press-on washer

off the fan motor shaft.

5. Unplug the connector from the fan motor

terminals.

6. Remove the two mounting screws from

the fan motor and remove the motor from

the air duct.

7. Install the new fan motor in its mounting

location and reassemble the microwave

oven.

MOUNTING

SCREW

CONNECTOR

FAN MOTOR

AIR DUCT

FAN BLADE

PRESS-ON WASHER

2-17

Page 28

REMOVING THE POWER CORD

WARNING

3. Remove the vent grille and cabinet from

the microwave oven (see the illustration

on page 2-3).

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

2. Remove the microwave oven from its

mounting location (see page 2-2).

POWER CORD

4. Unplug the connector on the old power

cord from the air duct connector and install the new power cord.

5. Reassemble the microwave oven.

POWER CORD

CONNECTOR

LOCKING

ARM

AIR DUCT

CONNECTOR

2-18

Page 29

REMOVING THE BLOWER MOTOR CAPACITOR

REMOVE FIVE

AIR DUCT SCREWS

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

WIRE NUT

CUT &

SPLICE

WIRES

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 2-19

2. Remove the microwave oven from its

mounting location (see page 2-2).

3. Remove the vent grille and cabinet from

the microwave oven (see the illustration

on page 2-3).

4. Remove the five screws from the air duct.

5. Cut the wires near the body of the blower

motor capacitor.

1

6. Remove

/2" of insulation from the cut wire

ends of the red harness wires and then

splice them to the wires of the new capacitor with two wire nuts.

7. Install the new blower motor capacitor to

the air duct and reassemble the microwave oven.

BLOWER MOTOR

CAPACITOR

AIR DUCT

MOUNTING SCREW

2-19

Page 30

REMOVING THE CONVECTION HEATING ELEMENT

6. Remove the screw from the gas sensor

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

2. Remove the microwave oven from its

mounting location (see page 2-2).

3. Remove the vent grille and cabinet from

the microwave oven (see the illustration

on page 2-3).

4. Remove the five screws from the air duct,

then lift the duct and postion it so you can

access the convection heating element.

5. Remove the three phillips screws from

the circulation pulley cover and the one

from the bracket, and remove the cover

and attached brackets from the top of the

oven. Do not remove the brackets from

the cover.

and position the sensor out of the way.

7. Unhook the drive belt from the circulation

fan pulleys and set it aside.

8. Remove the phillips screw from the convection thermistor that is located on the

top plate. Remove the thermistor and

position it out of the way.

9. Disconnect the wires from the convection

heating element terminals.

10. Remove the phillips screws from the top

cover, remove it from the oven, and turn it

over.

11. Remove the two phillips screws from the

convection heating element bracket.

Unclip the element from the cover and

remove it.

12. Install the new heating element into the

mounting clips in the top cover, and secure the mounting bracket with two phillips

screws.

13. Reassemble the microwave oven.

2-20

Page 31

UNCLIP

ELEMENT

HERE

HEATING ELEMENT

VIEWED FROM UNDER

TOP PLATE

BRACKETS

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

HEATING ELEMENT

MOUNTING SCREWS

CIRCULATION

PULLEY COVER

Page 2-21

GAS SENSOR

CONVECTION

THERMISTOR

SENSOR

COVER

TOP PLATE

MOUNTING SCREWS

TOP PLATE

REMOVE FIVE

AIR DUCT SCREWS

CONVECTION

HEATING

ELEMENT

YELLOW

WIRES

2-21

Page 32

REMOVING THE GAS SENSOR

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

SENSOR

COVER

MOUNTING

SCREW

SENSOR

GAS

BOARD

WH

RD

RED

YL

WHT

YEL

2. Remove the microwave oven from its

mounting location (see page 2-2).

3. Remove the vent grille and cabinet from

the microwave oven (see the illustration

on page 2-3).

4. Remove the five screws from the air duct,

then lift the duct and postion it so you can

access the gas sensor.

5. Remove the screw from the gas sensor

board and remove it from the sensor cover,

then unplug the connector from the control board.

6. Install the new gas sensor board and then

reassemble the microwave oven.

REMOVE FIVE

AIR DUCT SCREWS

2-22

Page 33

REMOVING THE STIRRER MOTOR

REMOVE FIVE

AIR DUCT SCREWS

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

MOUNTING

SCREWS

STIRRER MOTOR

STIRRER

BLADE

COVER

CONNECTOR

TOP

TOP

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 2-23

2. Remove the microwave oven from its

mounting location (see page 2-2).

3. Remove the vent grille and cabinet from

the microwave oven (see the illustration

on page 2-3).

4. Remove the five screws from the air duct

and lift the duct just enough to access the

stirrer motor, then unplug the connector

from the stirrer motor terminals.

5. Remove the two mounting screws from

the stirrer motor, lift the motor straight up

so that the shaft is free of the stirrer

blade, and remove the motor.

6. Install the new stirrer motor so the motor

shaft fits into the hole of the rectangular

pivot on the stirrer blade, and secure the

motor to its mounting location.

7. To access the stirrer blade, unsnap the

two fasteners from the top cover inside

the oven cavity, and lower the cover and

the stirrer blade. NOTE: When you reassemble the cover and stirrer blade, make

sure that you position the blade with the

“TOP” marking facing up.

8. Reassemble the microwave oven.

FASTENERS

2-23

Page 34

REMOVING THE TURNTABLE MOTOR

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

2. From inside the oven cavity, lift the turntable rest off the shaft of the turntable

motor

3. Remove the base plate from the microwave oven and unplug the cooktop light

connector (see the illustration on page

2-3).

4. Unplug the connector and remove the two

mounting screws from the turntable motor, then remove the motor from the bottom of the microwave oven.

5. Mount the new turntable motor and reassemble the microwave oven.

TURNTABLE REST

BOTTOM OF

OVEN

TURNTABLE

MOTOR

CONNECTOR

2-24

Page 35

REMOVING THE COOKTOP LIGHT SOCKETS

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

2. Remove the base plate from the microwave oven and unplug the cooktop light

connector (see the illustration on page

2-3).

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

3. Remove the bulbs from the sockets and

unplug the socket wire connector from

the microwave oven.

4. To remove the sockets, press the locking

tabs near the base of each socket, and

twist the socket until the tabs align with

the slots in the bracket, then remove the

sockets from the bracket.

5. Mount the new sockets to the bracket,

reinstall the bulbs, and reassemble the

microwave oven.

Page 2-25

TWIST SOCKET

TO REMOVE

BASE

BASE

PLATE

PLATE

CONNECTOR

COOKTOP LIGHTS

2-25

Page 36

THE HIGH VOLTAGE COMPONENTS

WARNING

ACCESSING THE COMPONENTS

The components for service in this section

include the:

Magnetron

High Voltage Rectifier

High Voltage Capacitor

High Voltage Transformer

The locations of the high voltage components

are shown below. All of the high voltage components are accessible through the front control panel cutout. However, the cabinet must

be removed to access the mounting screws for

the magnetron. Refer to the following pages

for servicing the high voltage components.

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

Discharge the high voltage capacitor before working inside the oven. Failure to do

so could result in death or electrical shock.

MAGNETRON

HIGH VOLTAGE

CAPACITOR

HIGH VOLTAGE

RECTIFIER

HIGH VOLTAGE

TRANSFORMER

2-26

Page 37

REMOVING THE MAGNETRON

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

2. Discharge the high-voltage capacitor.

3. Remove the microwave oven from its

mounting location, then remove the vent

grille and the cabinet from the oven (see

pages 2-2 and 2-3).

4. Remove the control panel from the microwave oven (see page 2-6).

Page 2-27

1. Disconnect the electrical supply to the

microwave oven.

WARNING

Personal Injury Hazard

Disconnect from power supply before servicing. Discharge the capacitor using a

20,000-ohm discharge resistor, or an insulated plastic-handle screwdriver to short

across the capacitor terminals.

5. From inside the control panel opening,

support the magnetron with one hand,

then remove the four mounting screws

from the magnetron through the four access holes in the top of the air duct.

6. Unplug the wire connector from the back

of the magnetron and remove the magnetron from the oven.

7. Install the new magnetron and reassemble

the microwave oven.

MAGNETRON

MOUNTING

SCREWS

MAGNETRON

2-27

CONNECTOR

Page 38

REMOVING THE HIGH VOLTAGE RECTIFIER

AND THE HIGH VOLTAGE CAPACITOR

2. Discharge the high-voltage capacitor.

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

WARNING

Personal Injury Hazard

Disconnect from power supply before servicing. Discharge the capacitor using a

20,000-ohm discharge resistor, or an insulated plastic-handle screwdriver to short

across the capacitor terminals.

3. Remove the two screws from the top of

the cabinet for the vent grille and remove

the grille (see the illustration on page

2-3).

4. Remove the control panel from the microwave oven (see page 2-6).

5. From inside the control panel opening,

remove the screw from the capacitor

bracket, and remove the bracket and capacitor so that you can access the capacitor terminals.

6. Unplug the wire connectors and the high

voltage rectifier from the capacitor terminals and remove the capacitor and rectifier from the oven.

7. Install the high voltage rectifier and capacitor and reassemble the microwave

oven.

HV RECTIFIER

STRAP

MOUNTING

SCREW

2-28

ORG TO

MAGNETRON

RED TO HV

TRANSFORMER

HV RECTIFIER

Page 39

Cooking Products Service Manual

WARNING

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 2-29

REMOVING THE HIGH VOLTAGE TRANSFORMER

WARNING

Personal Injury Hazard

Disconnect from the electrical supply before servicing the unit. Failure to do so

could result in death or electrical shock.

1. Disconnect the electrical supply to the

microwave oven.

Personal Injury Hazard

Disconnect from power supply before servicing. Discharge the capacitor using a

20,000-ohm discharge resistor, or an insulated plastic-handle screwdriver to short

across the capacitor terminals.

2. Discharge the high-voltage capacitor.

3. Remove the two screws from the top of

the cabinet for the vent grille and remove

the grille (see the illustration on page

2-3).

4. Remove the control panel from the microwave oven (see page 2-6).

5. Disconnect the filament wires from the

magnetron, then disconnect the three remaining wires from the terminals at the

front and back of the high voltage transformer.

6. Remove the three hex nuts from the high

voltage transformer and remove the transformer from the oven.

ORG TO

HV CAP

RED & WHITE

PRIMARY WIRES

7. Install the new high voltage transformer

and reassemble the microwave oven.

FILAMENT TO

MAGNETRON

HV TRANSFORMER

HEX NUTS

2-29

Page 40

— NOTES —

2-30

Page 41

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 3-1

COMPONENT DESCRIPTION & TESTING

IMPORTANT SAFETY INSTRUCTIONS

CAUTION

Warning To Service Technicians!

To avoid possible exposure to microwave radiation or energy, visually check the oven for damage to the

door and door seal before operating any oven. Use a microwave survey meter to check the amount of

leakage before servicing. In the event the R.F. Ieakage exceeds 4 mW/cm at 5 cm, appropriate repair must

be made before continuing to service the unit. Check interlock function by operating the door latch. The

oven cook cycle should cut off before the door can be opened.

The door and latching assembly contains the radio frequency energy within the oven. The door is protected

by three safety interlock switches. Do not attempt to defeat them.

UNDER NO CIRCUMSTANCES SHOULD YOU TRY TO OPERATE THE OVEN WITH THE DOOR OPEN.

• Proper operation of microwave ovens requires that the magnetron be properly assembled to the

waveguide and cavity. Never operate the magnetron unless it is properly installed.

• Be sure the “RF” seal is not damaged and is assembled around the magnetron dome properly when

installing the magnetron.

• Routine service safety procedures should be exercised at all times.

• Untrained personnel should not attempt service without a thorough review of test procedures and safety

information contained in this manual.

PRECAUTIONS TO BE OBSERVED BEFORE AND

DURING SERVICING TO AVOID POSSIBLE EXPOSURE

TO EXCESSIVE MICROWAVE ENERGY

A. Do not operate or allow the oven to be operated with the door open.

B. Make the following safety checks on all ovens to be serviced before activating the magnetron or other

microwave source and make repairs as necessary.

1. Interlock Operation

2. Proper Door Closing

3. Seal and Sealing Surfaces (Arcing, Wear and Other Damage)

4. Damage to or Loosening of Hinges and Latches

5. Evidence of Dropping or Abuse

C. Before turning on the microwave power for any service test or inspection within the microwave

generating components, check the magnetron, wave guide or transmission line and cavity for proper

alignment.

D. Any defective or misadjusted components in the interlock, monitor, door seal and microwave

generation and transmission system shall be repaired or adjusted by procedures described in the

Basic Service Manuals for the specific microwave oven being serviced before the oven is released

to the owner.

E. A microwave leakage check to verify compliance with Federal Performance Standards should be

performed on each oven prior to release to the owner.

F. Do not attempt to operate the oven if the door glass is broken.

3-1

Page 42

Whirlpool microwave ovens have a monitoring system designed to assure proper operation of the safety

interlock systems.

The interlock monitor switch will immediately cause the oven fuse to blow if the door is opened and the

primary door interlock switch and/or the secondary interlock switch contacts fail in a closed position.

CAUTION: REPLACE BLOWN FUSE WITH 15 AMPERE CLASS H FUSE ONLY.

Test the upper and lower door interlock switches, cook relay and interlock monitor switch (middle switch)

for proper operation as described in the component test procedures, before replacing the blown oven fuse.

DO NOT ATTEMPT TO REPAIR STICKING CONTACTS OF ANY INTERLOCK SWITCH, SAFETY

SWITCH OR COOK (LATCH) RELAY. REPLACE THE SWITCHES AND RELAY.

Any indication of sticking contacts during component tests requires replacement of that component to

assure reliability of the safety interlock system.

IF THE FUSE IS BLOWN, THE MONITOR, PRIMARY AND SECONDARY INTERLOCK SWITCHES MUST

BE REPLACED. BE SURE THEY ARE PROPERLY CONNECTED.

Precautions to Avoid Possible Exposure

to Excessive Microwave Energy

DO NOT attempt to operate the oven with the door open since open-door operation can result

in harmful exposure to microwave energy. It is important not to defeat or tamper with the safety

interlocks.

DO NOT place any object between the oven front face and the door or allow soil or cleaner

residue to accumulate on sealing surfaces.

DO NOT operate the oven if it is damaged. It is particularly important that the oven door close

properly and that there is no damage to the:

1. Door (bent).

2. Hinges and Latches (broken or loosened).

3. Door Seals and Sealing Surfaces.

DO NOT operate the microwave oven if the door window is broken.

The microwave oven should be checked for microwave leakage by qualified service personnel

after a repair is made.

The oven should not be adjusted or repaired by anyone except properly qualified service

personnel.

DO NOT operate the microwave oven with the outer cabinet removed.

3-2

Page 43

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 3-3

CAUTION

• High voltages are present during the cook

cycle. Extreme caution should be observed

at all times.

• Abrasive cleansers, steel-wool pads, gritty

wash cloths, etc. can damage the control panel

and the interior and exterior oven surfaces. Use

a sponge with mild detergent or paper towels

with spray glass cleaner. Apply spray glass

cleaner to paper towel. Do not spray directly

on oven.

• Before touching any oven component or wiring, always unplug the oven from its power

source and discharge the capacitor by using a

20,000 ohm discharge resistor or use an insulated plastic handle screwdriver to short across

the capacitor terminals.

• Check that the unit is grounded before troubleshooting. Be careful of the high voltage circuits.

Discharge any static charge from your body by

touching ground before handling any part of the

circuitry on the control board. Electrostatic discharge may damage the control circuit.

• Do not touch oven components or wiring during operation. Attach meter leads with alligator

clips when making operational tests.

• For continued protection against radiation emission, replace only with these types of switches:

Primary (Interlock) Switch: SZM-V16-FA-63 or

VP-533A-OF; Secondary (Interlock) Switch:

SZM-V01-FA-32; Interlock (Monitor) Switch:

SZM-Vl6-FA-62 or VP-532A-OF; Oven Lamp

Switch: SZM-V6-FA-31 or VP-331A-OD.

• It is neither necessary nor advisable to attempt

measurement of high voltage.

WARNING

• Disconnect the oven from electrical supply before servicing. Failure to do so could result in

electrical shock or death.

• Improper use of the grounding plug can result

in a risk of electrical shock. Do not, under any

circumstance, cut or remove the third ground

prong from the power cord plug.

Fire, Electrical Shock, Excessive

Exposure to Microwave Energy,

Personal Injury & Product

Damage Hazard

• Do not block the rear air intake openings or

exhaust vents. Allow a few inches of space at

the back of the oven where intake openings

and exhaust vents are located. Blocking the air

intake openings and exhaust vents can cause

damage to the oven and poor cooking results.

Make sure the microwave oven legs are in

place to ensure proper airflow.

• Do not install the oven next to or over a heat

source (a cooktop or range).

• Do not install oven in any area where excessive heat and steam are generated. This could

cause fire, electrical shock, excessive exposure

to microwave energy, other personal injury or

damage to the outside of the cabinet.

• Attaching the adaptor ground terminal to the

wall receptacle cover screw does not ground

the appliance unless the cover screw is metal

and not insulated and the wall receptacle is

grounded through the house wiring.

3-3

Page 44

THE THERMAL FUSES

There are three thermal fuses in the OTR

Microwave Oven. They are: the magnetron

thermal fuse, the cavity thermal fuse, and the

base thermal fuse. The magnetron and cavity

The base thermal fuse is located directly behind the control panel. It is a normally-open

fuse that, when closed, activates the blower

motor at a low speed.

thermal fuses are located inside the highvoltage section of the oven. These two thermal fuses are normally-closed, and will open

POSSIBLE CUSTOMER COMPLAINT:

The unit turns on by itself.

at a set temperature to disable the oven. Both

of these fuses are resettable.

Magnetron Thermal Fuse Opens @ 228˚F/109˚C Resets @ 140˚F/60˚C

Cavity Thermal Fuse Opens @ 230˚F/110˚C Resets @ 140˚F/60˚C

Base Thermal Fuse Closes @ 133˚F/56˚C Resets @ 104˚F/40˚C

MAGNETRON

CAVITY

THERMAL

FUSE

THERMAL FUSE

3-4

BASE

THERMAL FUSE

Page 45

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

THE BLOWER MOTOR CAPACITOR

Page 3-5

The blower motor capacitor is located below

the air duct at the indicated location. It is in

use any time the blower (vent) motor is oper-

AIR DUCT

BLOWER MOTOR

CAPACITOR

ating. The capacitor helps to maintain a constant voltage to the blower motor so that it

runs more efficiently.

TESTING

1. Set the ohmmeter to the

R x 10K

scale.

2. Measure across the capacitor terminals.

The ohmmeter should indicate several

ohms, then gradually return to infinity.

3-5

Page 46

THE GAS SENSOR

The gas sensor is used during the “Sensor

Cook” operation of the oven. It is located

above the oven and is mounted on the left side

of the sensor cover. The sensor consists of

two circuits housed on a small microcomputer

board that is supplied with a current to keep it

heated. The sensor heat conductivity will vary,

depending upon the humidity of the oven.

Changing humidity conditions, due to the cook-

ing process within the oven cavity, causes a

difference in potential between these two cir-

cuits. This difference is monitored by the mi-

crocomputer during cooking, allowing the mi-

crocomputer to determine the proper cook

time.

NOTE: Always verify that the sensor cover is

not obstructed (proper air flow is passing over

the sensor), and that the fan motor is working

properly, before replacing the gas sensor.

TESTING

SENSOR

COVER

MOUNTING

SCREW

SENSOR

GAS

BOARD

1. Set the ohmmeter to the

R x 1

scale.

2. Remove the 3-pin connector from

the control circuit board and measure the resistance between the:

a)Red & white wire terminals.

You should measure 20 Ω @

WH

RD

RED

YL

WHT

YEL

68˚F.

b)White & yellow wire terminals.

You should measure infinity.

3-6

Page 47

THE CONVECTION THERMISTOR

The convection thermistor is located under

the circulation pulley cover and is used during

the convection operation of the oven. When

the temperature increases, the resistance of

the thermistor decreases. The thermistor resistance is monitored by the microcomputer.

As the oven temperature rises and falls, the

TESTING

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 3-7

thermistor signal going back to the microcomputer causes the heater relay to open and

close, and cycles the heating element on and

off.

NOTE: Verify that the heating element is working correctly before replacing a thermistor.

1. Set the ohmmeter to the

R x 10K

scale.

2. Remove the 6-pin connector from

the control circuit board and measure across terminals 5 & 6.

You should measure 155 kΩ to

350 kΩ @ 68˚F.

BRACKETS

PHILLIPS

SENSOR

COVER

SCREW

CIRCULATION

PULLEY COVER

CONVECTION

THERMISTOR

3-7

Page 48

THE CONVECTION HEATING ELEMENT

The 1400-watt convection heating element is

located under the circulation pulley cover and

the top plate. The heating element heats the

air that is distributed into the oven cavity by

the convection fan. It operates on 120 VAC

and is controlled by the convection thermistor,

UNCLIP

ELEMENT

HERE

HEATING ELEMENT

VIEWED FROM UNDER

TOP PLATE

BRACKETS

and the heater relay on the microcomputer

board. During a convection, or combination

cooking cycle, the heater cycles on and off to

maintain the programmed cavity temperature.

The heating element surrounds the convection fan blade and is not visible through the

oven cavity.

HEATING ELEMENT

MOUNTING SCREWS

CIRCULATION

PULLEY COVER

CONVECTION

THERMISTOR

SENSOR

COVER

TESTING

1. Set the ohmmeter to the

R x 1

scale.

2. Measure across the heating element terminals.

You should measure between

40 Ω and 90 Ω @ 68˚F.

TOP PLATE

CONVECTION

HEATING

ELEMENT

YELLOW

WIRES

3-8

Page 49

MOTORS

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 3-9

Blower Motor

—Removes smoke and odors from the kitchen

cooking area through outside venting or recirculation.

Fan Motor

—Cools the magnetron and circulates air through the

oven during microwave cooking.

Stirrer and Turntable Motors

—Distribute microwave energy

evenly during microwave cooking.

STIRRER MOTOR

TURNTABLE

MOTOR

BLOWER MOTOR

FAN MOTOR

3-9

Page 50

PROGRAMMING CHECKS

TOUCH PANEL CONTINUITY TEST

1. Unplug the microwave oven’s power sup-

ply cord.

2. Open the oven door.

3. Plug the power cord back into the AC

receptical. You should see the following

display if any of the interlock switches are

closed:

– f 2 –

If the sensor is defective, or if the wires are not

properly connected, you will see the following

display:

– f 1 –

3-10

Page 51

CHARTS

Cooking Products Service Manual

Original March, 1997 4322167

© 1997 Whirlpool Corporation

Page 3-11

PROBLEM POSSIBLE CAUSE

Line fuse blows when power

cord is plugged into a wall

receptacle.

Oven will not operate.

Shorted wire in power cord,

wiring harness, or overload

circuit.

1. No power at wall plug. 1. Check fuse or breaker

2. Open wire in power cord

or wiring harness.

3. Control board.

4. Line fuse.

5. Thermal fuses.

Oven cavity light will not turn

on.

1. Bulb is burned out.

2. Lamp socket.

3. Oven lamp switch.

4. Open wiring between the

above components.

5. Control board.

TEST PROCEDURE

OR CORRECTION

1. Check wiring with ohmmeter for continuity.

2. Use separate 15- to 20ampere circuit.

box.

2. Check wiring with ohmmeter for continuity.

3. Check board.

4. Check fuse.

5. Check fuses.

1. Replace bulb.

2. Check lamp socket.

3. Check control board.

4. Repair open wire.

5. Check control board.

Oven will not go into “Cook”

cycle when the door is closed.

Oven goes into “Cook” cycle,

but does not complete the

cycle. Heat is produced in the

oven load.

1. Control board.

2. Line fuse and/or thermal

fuses.

3. Interlock switches.

4. Open wiring between the

above components.

1. Control board.

2. Low line voltage (should

be at least 108-volts

AC).

3. Thermal fuse.

4. Thermal fuse on magnetron.

5. Circuit is overloaded.

1. Check control board.

2. Check line fuse and/or

thermal fuses.

3. Check interlockswitches.

4. Repair open wire.

1. Check control board.

2. Use separate 15- to 20ampere circuit.

3. Check thermal fuse.

4. Check thermal fuse on

magnetron.

5. Use separate 15- to 20ampere circuit.

3-11

Page 52

PROBLEM

POSSIBLE CAUSE

TEST PROCEDURE

OR CORRECTION

Little or no heat is produced

in the oven load.

Oven fuse blows when the

door is opened.

Oven lamp goes on with the

door open, but the light goes

out when the door is closed

with the control on.

The power source fuse blows

when the door starts to open.

1. High voltage transformer.

2. Rectifier diode.

3. High voltage capacitor.

4. Magnetron.

5. Power selector.

1. Primary interlock switch. 1. Check primary interlock

2. Shorted wire harness.

1. Secondary interlock. 1. Check secondary inter-

1. High voltage transformer.

2. Secondary circuit of the

high voltage transformer

is shorted.

3. High voltage capacitor is

shorted.

4. Shorted wiring between

the above components.

1. Check the high voltage

transformer.

2. Check the high voltage

rectifier diode.

3. Check the high voltage

capacitor.

4. Check the magnetron.

5. Check the power selector.

switch.

2. Repair wiring.

lock.