Page 1

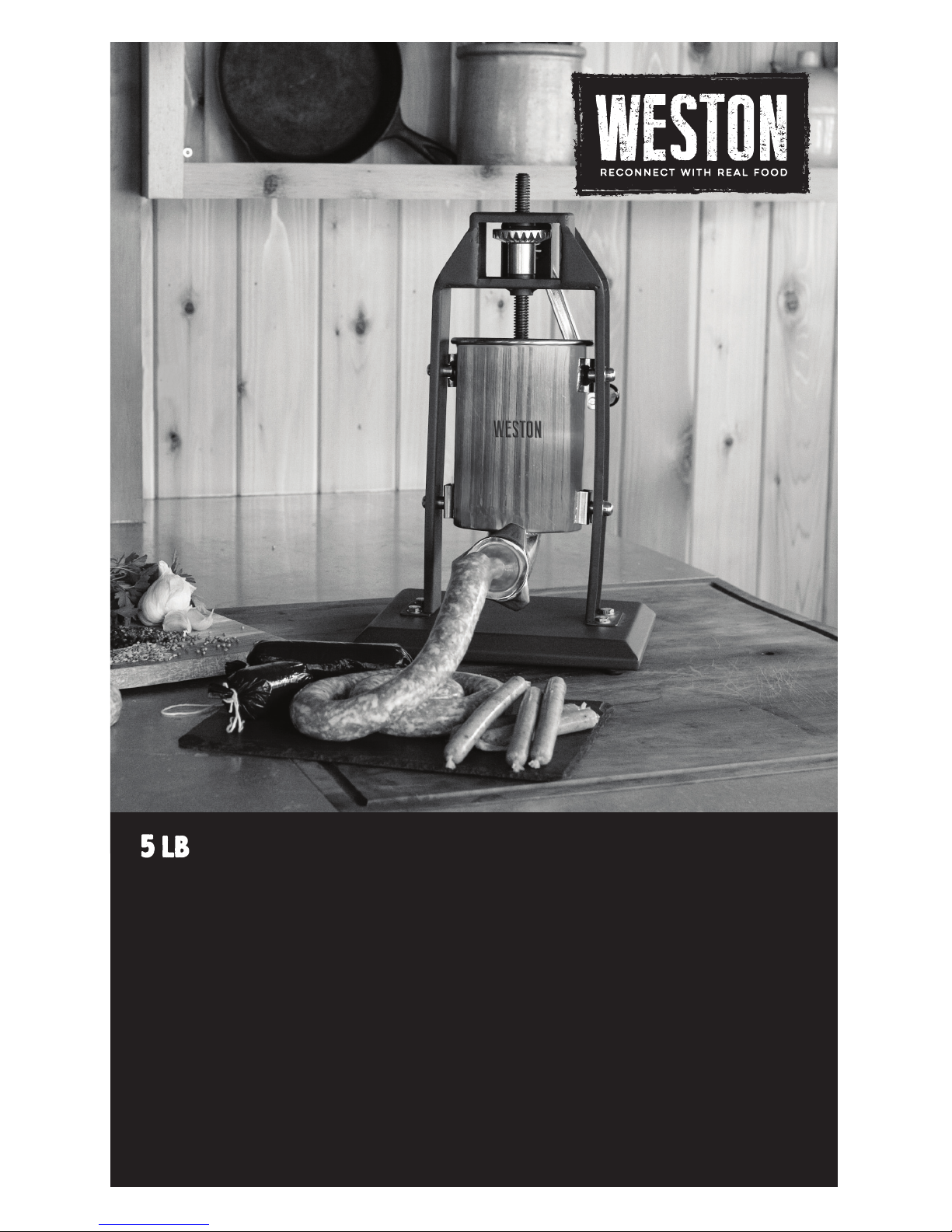

VERTICAL SAUSAGE

STUFFER

73-0501-W

DUE TO CONSTANT FACTORY IMPROVEMENTS, THE PRODUCT PICTURED MIGHT DIFFER

SLIGHTLY FROM THE PRODUCT IN THIS BOX. 060915

Page 2

TABLE OF CONTENTS / ÍNDICE / TABLE DES MATIÈRES

2

GERNERAL SAFETY RULES

COMPONENT LIST

ASSEMBLY

DISASSEMBLY & CLEANING

STUFFING INSTRUCTIONS

FOOD SAFETY

SAUSAGE INFORMATION

WARRANTY

REGLAS IMPORTANTES DE SEGURIDAD

LISTA DE COMPONENTES

ENSAMBLADO

DESARMADO Y LIMPIEZA

INSTRUCCIONES DE RELLENADO

SEGURIDAD DE LOS ALIMENTOS

INFORMACIÓN DE LA SALCHICHA

INFORMACIÓN DE GARANTÍA WESTON

IMPORTANTES RÈGLES DE SÉCURITÉ

DESCRIPTION DE LA PIÈCE

ASSEMBLY

DÉMONTAGE ET NETTOYAGE

INSTRUCTIONS DE BOURRAGE

SÉCURITÉ ALIMENTAIRE

INFORMATIONS SUR LES SAUCISSES

INFORMATION SUR LA GARANTIE

3

4-5

6-7

7

8

9

10

12

14

16-17

18-19

19

20

21

22

24

26

28-29

30-31

31

32

33

34

35

Page 3

CLEANING INSTRUCTIONS

3

ENGLISH INSTRUCTIONS

1. NEVER use any accessories or parts from other manufacturers. Doing so

will void your warranty.

2. Thoroughly clean all parts that will come in contact with food before and

after using the appliance. Wash all parts by hand and thoroughly dry.

3. Before using the Stuffer, always apply a food-grade lubricant to the inside

of the Canister to decrease the friction.

4. KEEP CHILDREN AWAY! Never leave the stuffer unattended. The Stuffer

is not a toy.

5. Be sure the Stuffer is on a stable work area. Be sure all of the Stuffer Feet

are level.

6. WEAR EYE PROTECTION! Everyday eye glasses are not safety glasses.

Safety glasses conform to ANSI Z87.1 requirements. Note: approved safety

glasses have Z87 printed or stamped on them.

7. DO NOT use the Stuffer while under the inuence of drugs or alcohol.

GENERAL SAFETY RULES

READ AND FULLY UNDERSTAND ALL INSTRUCTIONS AND WARNINGS

PRIOR TO USING THIS UNIT. YOUR SAFETY IS MOST IMPORTANT!

FAILURE TO COMPLY WITH PROCEDURES AND SAFE GUARDS MAY

RESULT IN SERIOUS INJURY OR PROPERTY DAMAGE. REMEMBER:

YOUR PERSONAL SAFETY IS YOUR RESPONSIBILITY!

SAVE THESE INSTRUCTIONS

Page 4

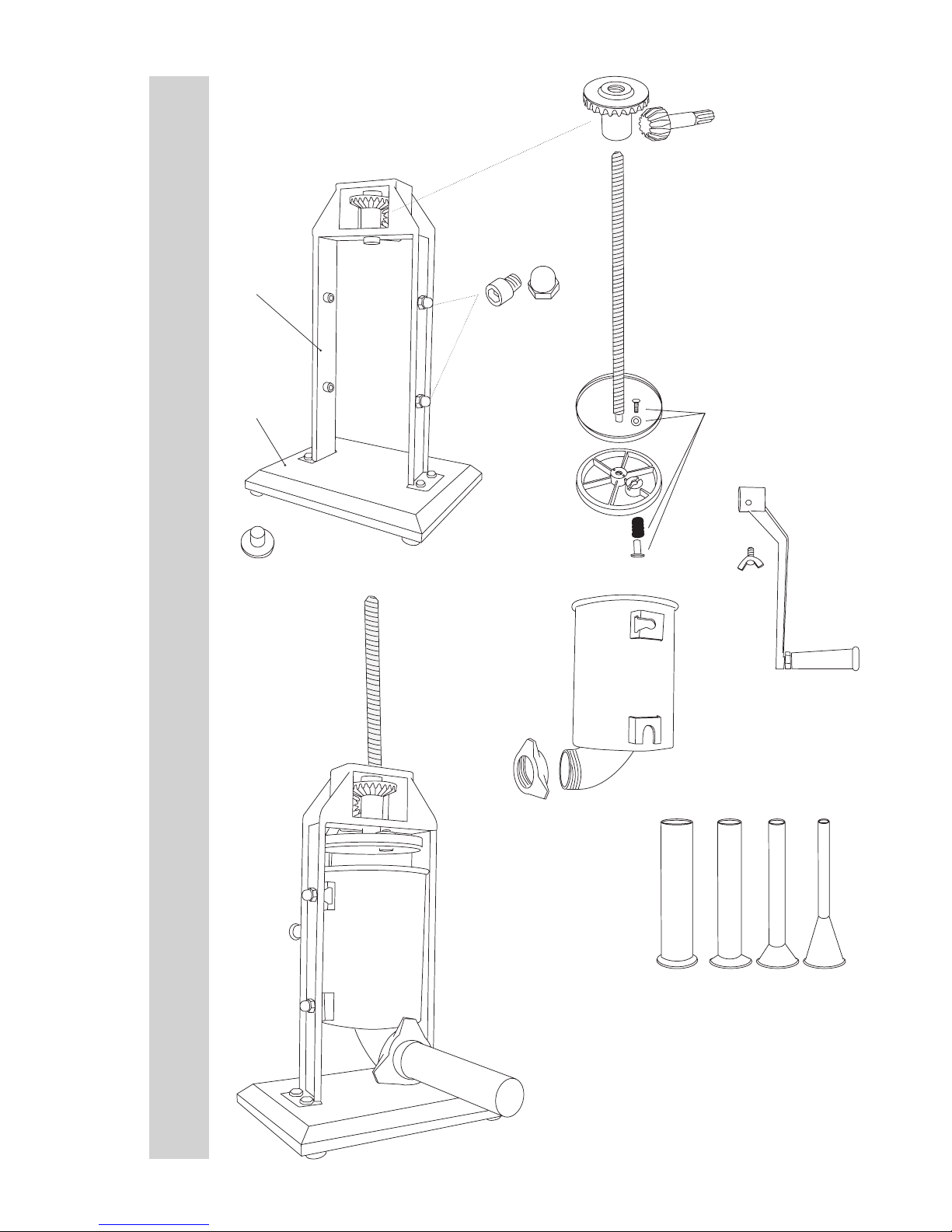

1

2

3

4

6

8

9

10

11

7

5

Stuffer

Sides

Stuffer

Base

ASSEMBLED

5 LB (3 L)

VERTICAL

STUFFER

30 mm 13 mm

40 mm 20 mm

ENGLISH INSTRUCTIONS

4

Page 5

5

ENGLISH INSTRUCTIONS

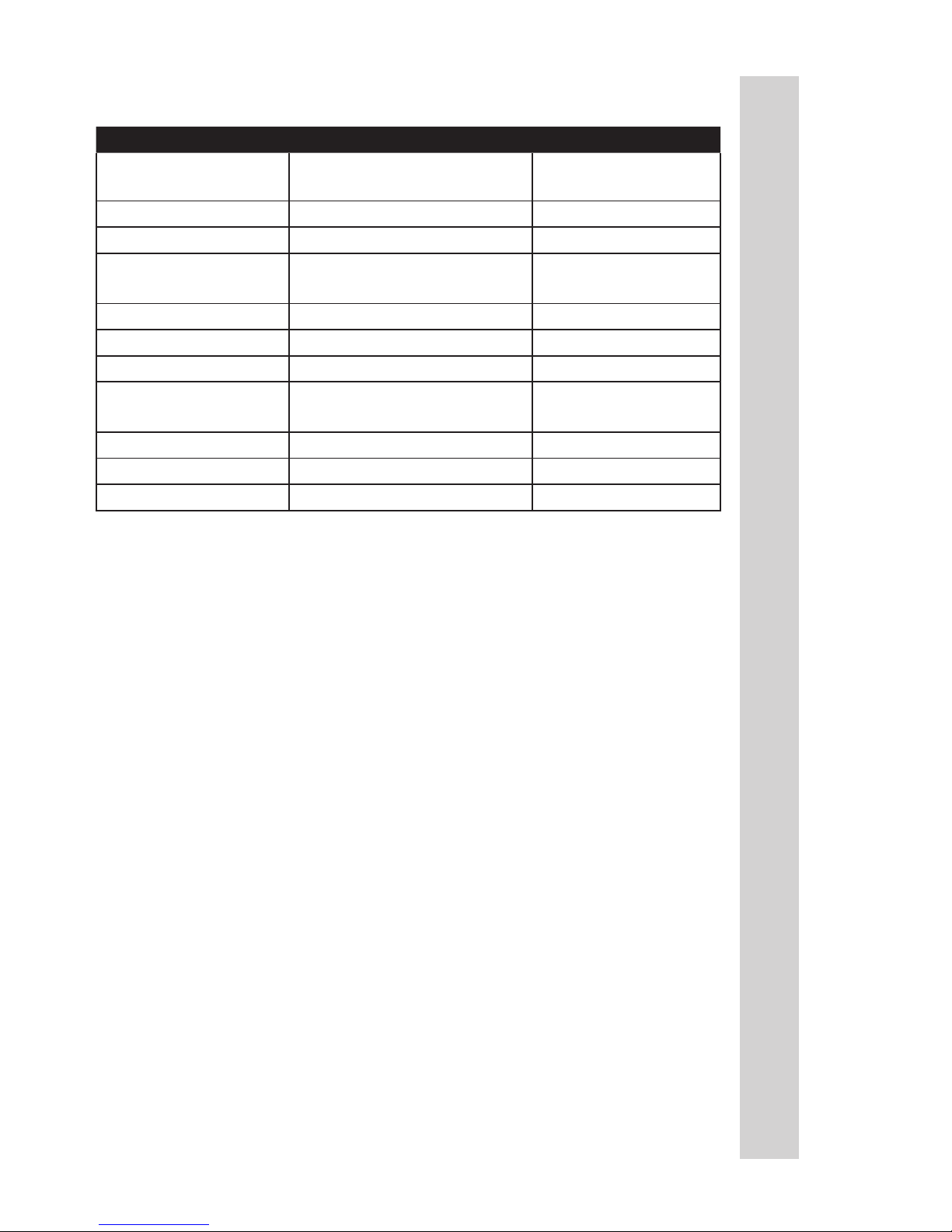

COMPONENT LIST

DIAGRAM NUMBER PART DESCRIPTION PART NUMBER

1 HANDLE WITH WINGNUT

(WINGNUT ONLY 73-0511)

73-0510

2 PLUNGER 73-0514

3 PLUNGER SEAL 73-0516

4 PRESSURE RELEASE VALVE

(4 PIECE SET)

73-0515

5 PLASTIC FUNNEL SET (4 FUNNELS) 73-0520

6 STAINLESS STEEL CANISTER 73-0519

7 FRONT RING NUT 73-0521

8 CANISTER MOUNTING HARDWARE KIT

(4 SETS)

73-0522

9 PLUNGER SHAFT 73-0512

10 GEAR SET (2) 73-0513

11 RUBBER FOOT (4 PIECE SET) N/A

If any components of this unit are broken, the unit does not operate properly or you

need a replacement instruction manual, visit us on the web at

WestonProducts.com

Or call Weston Brands LLC Toll Free at 1-800-814-4895

Monday thru Friday 8:00am-5:00pm ET. Outside the U.S. call 001-440-638-3131

Page 6

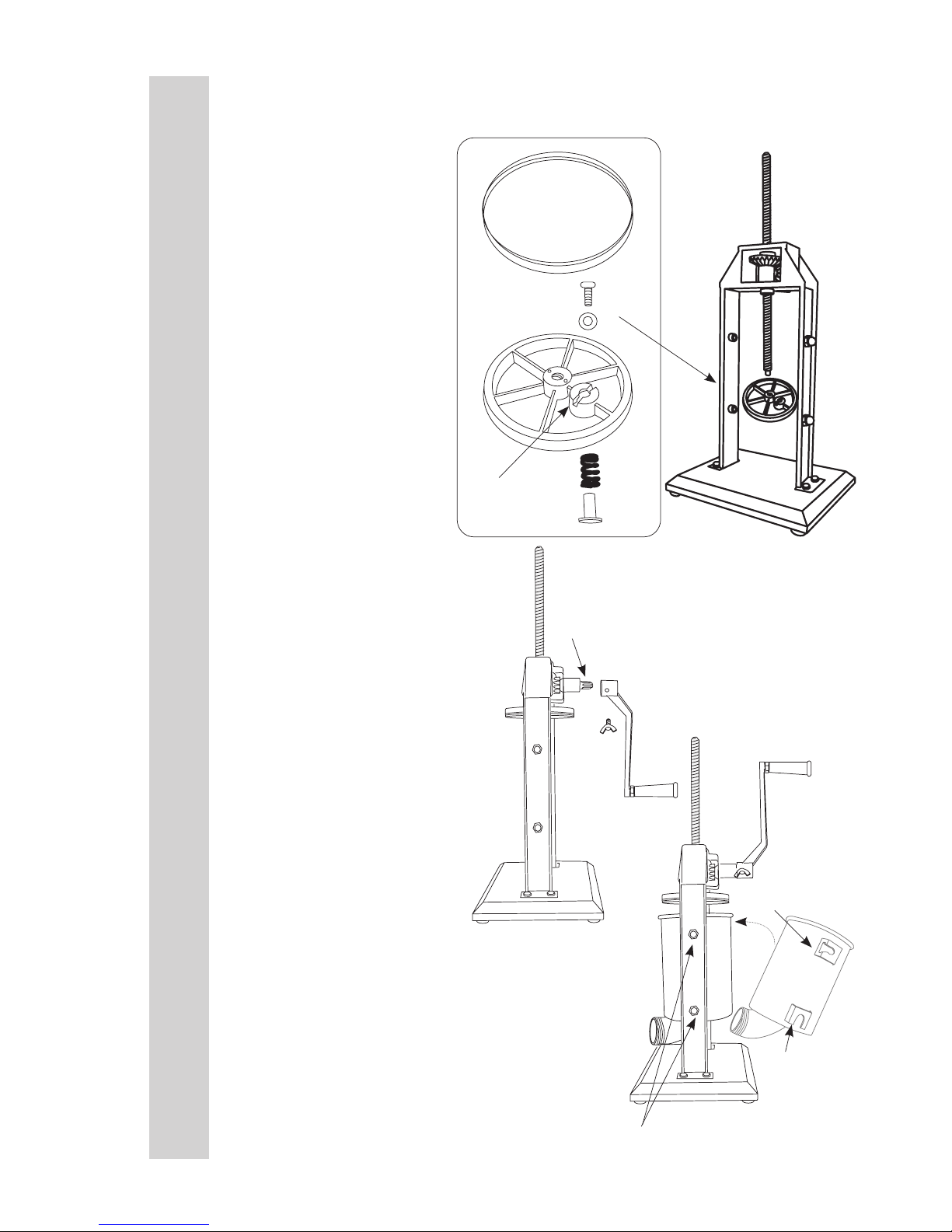

ASSEMBLY

PLUNGER ASSEMBLY

1. Slide the Plunger Seal

onto the Plunger (FIGURE

1).

2. Assemble the Pressure

Release Valve Kit onto

the Plunger. From the top

of the Plunger, place the

Washer onto the Valve

Hole, then insert the

Screw through the Washer

and into the Valve Hole.

From the underside of the

Plunger, place the Spring

onto the end of the Screw,

then place the Valve Cap

onto the end of the Screw

and twist to secure.

3. Place the assembled

Plunger onto the end of the

Plunger Shaft (FIGURE 2).

STUFFER ASSEMBLY

4. Attach the Handle by

sliding it onto the Gear

Shaft and placing the

Wingnut into the hole in the

Handle. Twist to tighten

(FIGURE 3).

5. Crank the Handle

counter-clockwise to bring

the Plunger to the top of

the Stuffer.

6. Rest the Canister’s

Bottom Brackets onto

the Canister Mounts

inside the Housing of the

Stuffer. Pivot the bottom

of the Canister into the

Stuffer Housing. Pivot

the Canister fully into the

Stuffer Housing, snapping

the Top Brackets into the

Canister Mounts (FIGURE

4).

Plunger

Seal

Plunger

Pressure

Release

Valve Kit

Screw

Washer

Spring

Valve Cap

Valve Hole

FIGURE 1

FIGURE 2

FIGURE 3

Gear Shaft

Handle

Wingnut

FIGURE 4

Top Brackets

Bottom Brackets

Outside view of

Canister Mounts

ENGLISH INSTRUCTIONS

6

Page 7

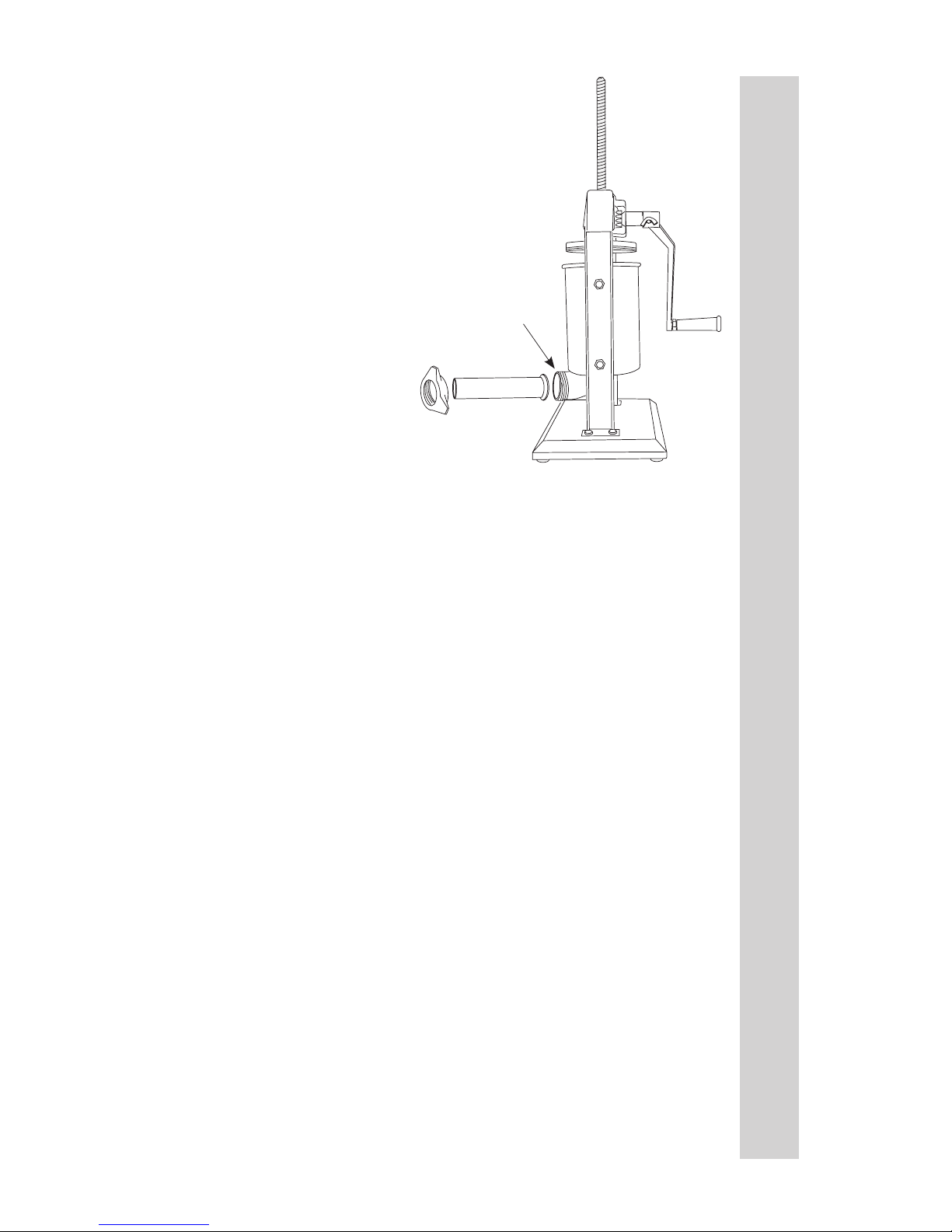

DISASSEMBLY & CLEANING

7. Insert the Stufng Funnel of

your choice through the Front

Ring Nut. Screw the Front Ring

Nut and Stufng Funnel onto the

mouth of the Canister until snug.

DO NOT OVERTIGHTEN the

Front Ring Nut, as it may damage

the Funnel (FIGURE 5).

FIGURE 5

Front

Ring Nut

Funnel

Mouth of the

Canister

1. Remove the Stufng Funnel by unscrewing the Front Ring Nut, and pulling

the Funnel out.

2. Turn the Handle counter-clockwise until the Plunger comes out of the

Canister.

3. Pivot the Canister outward and then pull the Canister up to remove the

Canister from the Stuffer Housing.

4. Unscrew the Plunger from the Plunger Shaft. Disassemble the PressureRelease Valve from the Plunger. Remove the Plunger Seal from the Plunger.

5. Wash all parts that have come in contact with meat in hot soapy water. BE

SURE TO CLEAN THEM IMMEDIATELY AFTER USE. Rinse and thoroughly

dry all parts IMMEDIATELY. Sterilize as needed.

6. Fully lubricate the Shaft, Canister, Pressure Release Valve Components

and the Front Ring Nut with a food-grade lubricant after each use.

FIGURE 1

7

ENGLISH INSTRUCTIONS

Page 8

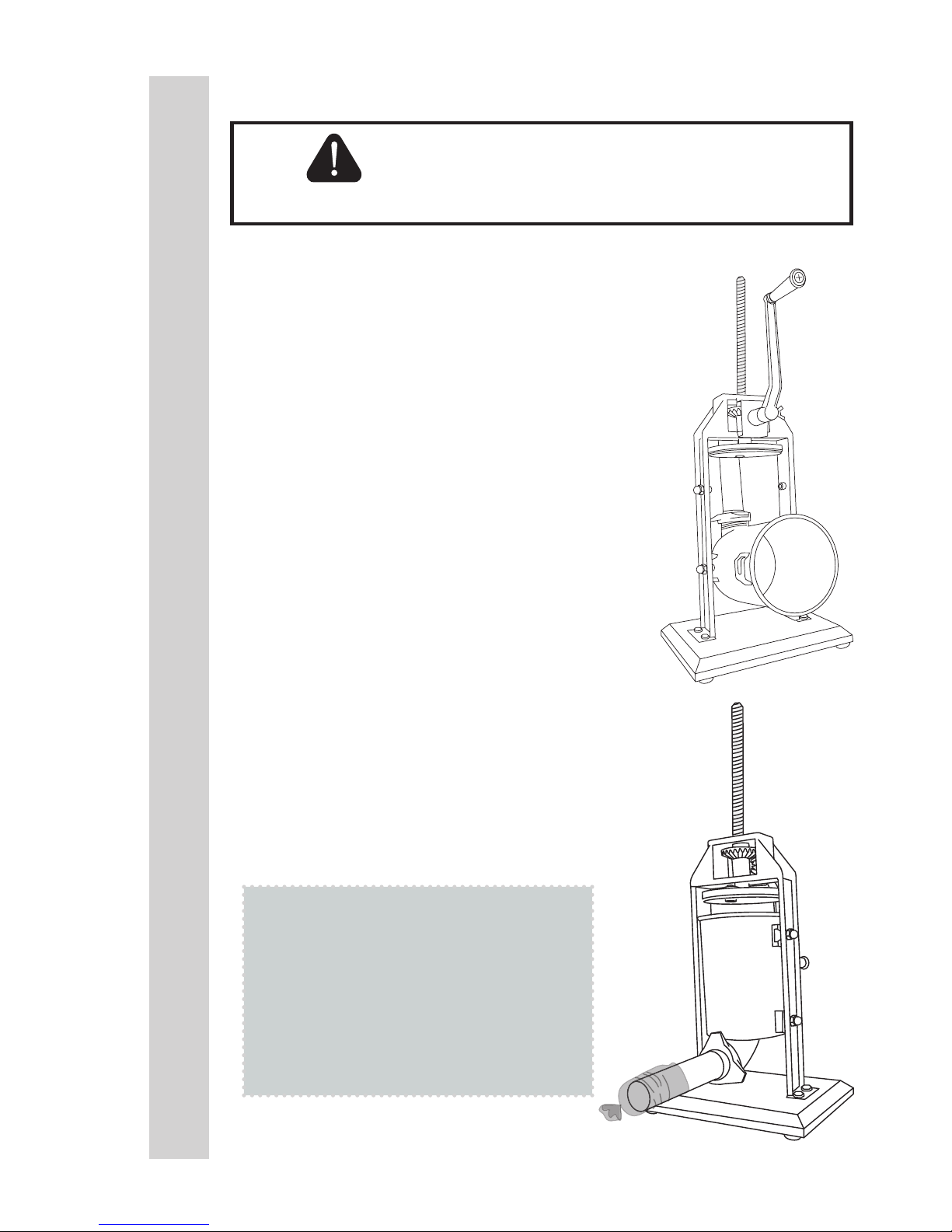

1. Tilt out the Canister.

2. Fill the Canister with your meat and seasoning

mixture (FIGURE 7).

3. Press the mixture down into the Canister rmly

to release any trapped air.

4. Pivot the Canister back into the upright position

and snap the Top Brackets into the Canister

Mounts.

5. Turn the Handle clockwise, until the Plunger

comes in contact with the meat and the mixture is

ready to extrude out the end of the Stufng Funnel.

6. Slip the casing on the end of the Stufng Funnel

until the entire casing has slid onto the Stufng

Funnel (FIGURE 8).

7. Tie, twist or hog ring the end of the casing to seal

it.

8. Turn the Handle clockwise to extrude the

mixture into the casing. For best results, apply

pressure around the casing, close to the end of

the Stufng Funnel. This will hold the casing tight

and will cause the mixture to pack rmly into the

casing.

9. When the end of the casing has been reached,

twist, tie or hog ring the casing to seal the contents

inside.

STUFFING TIPS: The following are

suggestions to help reduce resistance when

stufng with the 13 mm Stufng Funnel.

A. Add water to your meat mixture – up to

1-1/2 cups (0.4 L) of water per every 5 lb

(2.3 kg) of seasoned meat.

B. Add 1/4 cup (60 ml) of vegetable or

olive oil to the meat mixture for better ow.

CAUTION!

CAUTION! Any time you complete stufng or

raise the Plunger out of the Canister, RELEASE THE

HANDLE SLOWLY! Pressure or gravity could cause

the Handle to spin back slightly causing injury!

FIGURE 6

FIGURE 7

Canister

STUFFING INSTRUCTIONS

ENGLISH INSTRUCTIONS

8

Page 9

There are basic rules to follow when handling food.

They are COOK, SEPARATE, CLEAN, and CHILL.

COOK

It’s crucial to cook food to a safe internal temperature to destroy bacteria that is present.

The safety of hamburgers and other foods made with ground meat has been receiving a lot

of attention lately, and with good reason. When meat is ground, the bacteria present on the

surface is mixed throughout the ground mixture. If this ground meat is not cooked to at least

160oF to 165oF (71oC to 74oC), bacteria will not be destroyed and there’s a good chance you

will get sick.

Solid pieces of meat like steaks and chops don’t have dangerous bacteria like E. coli on the

inside, so they can be served more rare. Still, any beef cut should be cooked to an internal

temperature of at least 145oF (63oC) (medium rare). The safe temperature for poultry is 165oF

(75oC) and solid cuts of pork should be cooked to 145oF (63oC).

SEPARATE

Foods that will be eaten uncooked and foods that will be cooked before eating MUST

ALWAYS be separated. Cross-contamination occurs when raw meats or eggs come in

contact with foods that will be eaten uncooked. This is a major source of food poisoning.

Always double-wrap raw meats and place them on the lowest shelf in the refrigerator so

there is no way juices can drip onto fresh produce. Then use the raw meats within 1-2 days

of purchase, or freeze for longer storage. Defrost frozen meats in the refrigerator, not on the

counter.

When grilling or cooking raw meats or sh, make sure to place the cooked meat on a clean

platter. Don’t use the same platter you used to carry the food out to the grill. Wash the utensils

used in grilling after the food is turned for the last time on the grill, as well as spatulas and

spoons used for stir-frying or turning meat as it cooks.

Make sure to wash your hands after handling raw meats or raw eggs. Washing hands with

soap and water, or using a pre-moistened antibacterial towelette is absolutely necessary after

you have touched raw meat or raw eggs. Not washing hands and surfaces while cooking is a

major cause of cross-contamination.

CLEAN

Wash your hands and work surfaces frequently when you are cooking. Washing with soap

and warm water for at least 15 seconds, then dry with a paper towel.

CHILL

Chilling food is very important. The danger zone where bacteria multiply is between 40oF and

140oF (4oC and 6oC). Your refrigerator should be set to 40oF (4oC) or below; your freezer should

be 0oF (-17oC) or below. Simple rule: serve hot foods hot, cold foods cold. Use chang dishes

or hot plates to keep food hot while serving. Use ice water baths to keep cold foods cold. Never

let any food sit at room temperature for more than 2 hours - 1 hour if the ambient temperature

is 90oF (32oC) or above. When packing for a picnic, make sure the foods are already chilled

when they go into the insulated hamper. The hamper won’t chill food - it just keeps food cold

when properly packed with ice. Hot cooked foods should be placed in shallow containers and

immediately refrigerated so they cool rapidly. Make sure to cover foods after they are cool.

NOTE: Special considerations must be made when using venison or other wild game, since it

can become heavily contaminated during eld dressing. Venison is often held at temperatures

that could potentially allow bacteria to grow, such as when it is being transported. Refer to

the USDA Meat and Poultry Department for further questions or information on meat and

food safety.

FOOD SAFETY

9

ENGLISH INSTRUCTIONS

Page 10

SAUSAGE INFORMATION

MEAT SELECTION FOR SAUSAGE MAKING

Sausage making has evolved over many years and generations, and as a result there are countless

types of sausage you can make using the basic ingredients of meat, fat and a few carefully blended

spices. Following are a few simple guidelines that will help you make the best tasting sausage

possible.

Any type of meat can be used for making sausage: pork, beef, bison, moose and caribou, even

antelope make great sausage. It is important when preparing venison or other red game meats to trim

all the fat from the meat, as red game tallow will turn rancid in as few as ve days. Replace the fat with

either pork or beef fat, depending on the type of product you are making, at a ratio of 1 pound (0.5 kg)

of fat for every 4 pounds (1.8 kg) of game meat.

The fat content of your sausage will affect the taste, texture, cooking characteristics and shelf life of

your product. Most commercially made sausage has a fat content of about 20%. Using less than 12%

fat will result in a very dry tasting sausage, while using more than 20% may result in a sticky avorless

sausage that will be difcult to cook.

CURING

It is important to properly cure meats to preserve meat and poultry, and to destroy undesirable

microorganisms on the meat surfaces that cause spoilage and foodbourne illnesses. There are many

steps that help in this process, including smoking, cooking, drying, chilling and the addition of cure

ingredients. The oldest means of accomplishing this is by introducing salt into the meat. The resistance

of bacteria to salt varies widely among different types of bacteria. The growth of some bacteria is

inhibited by salt concentrations as low as 3%, e.g., Salmonella, whereas other types are able to survive

in much higher salt concentrations, e.g., Staphylococcus. Fortunately, the growth of many undesirable

organisms normally found in cured meat and poultry products is inhibited at low concentrations of salt.

Modern curing is based on Nitrates and is very scientic. Purchase Weston Pink Curing Salt

(02-0000-W) and follow the included instructions to ensure that you are properly curing your

homemade sausage.

CASING

Weston offers a complete variety of casings. The right choice depends on personal preference as well

as the type of sausage you wish to make. For most sausages, your choices are natural or collagen.

Don’t let the names fool you; collagen casings are not a synthetic. They are made from beef skin and

other tissues. Collagen casings are uniform in size and texture and require almost no preparation.

“Natural” casings are the intestines of lamb, sheep, hogs or beef. They are less uniform in size and

require preparation. There are also brous non-edible casings that are most commonly used for

summer sausage and ring bologna

TYPES OF SAUSAGE

Most sausages fall into one of four categories: Fresh, Smoked, Cooked or Dried. All sausages, except

dried, require refrigerated storage. There is also a sub-category of uncooked smoked sausages.

Among the fresh and uncooked smoked sausages, you will nd such avors as kielbasa or Polish

sausage, Italian sausage, breakfast sausage and many others. Both fresh and uncooked smoked

sausages require cooking before eating and also require refrigerated storage.

Smoked and cooked sausages include salami, bologna, the ever-popular hot dogs and many others.

Proper smoking requires a smokehouse or smoker. Weston offers Outdoor Propane Smokers in a

variety of sizes (41-0701-W, 41-0301-W, or 41-0401-W). Most smoked sausages are warmed before

serving. Many people think that a smoked sausage will last much longer without spoilage, but this is

not true. Smoked sausages should be treated the same as fresh sausage in terms of storage.

Dried sausages require the longest processing time, as they are air dried over a long period of time.

Dry cured sausages include salami, chorizo, pepperoni, among others. The conditions under which the

meat is dried are very exacting; temperature, time and humidity must all be carefully monitored for a

safe and delicious product.

STORAGE

For the best avors, we recommend vacuum sealing your fresh sausages, then storing them in the

refrigerator (short term) or freezer (long term). Weston manufactures a variety of vacuum sealers. Ask

the retailer from which you purchased this unit for their selection. Store dry cured products in paper or

other breathable wrapping, unrefrigerated.

ENGLISH INSTRUCTIONS

10

Page 11

Page 12

Weston Brands LLC warrants to the ORIGINAL RETAIL PURCHASER of this product that if operated in accordance

with the printed instruction accompanying it, then for a period of 1 year from the date of purchase, the product shall be free

from defects in material and workmanship.

The Warranty Card, along with a copy of the original receipt, must be received by Weston Brands LLC within 30 days

from purchase date for the warranty to apply. Failure to send the completely lled out Warranty Card, along with a copy of

the original receipt, will void the warranty.

The product must be delivered to or shipped freight prepaid to Weston Brands LLC for warranty services, in either

its original packaging or similar packaging affording an equal degree of protection. Damage due to shipping is not the

responsibility of the company. Weston Brands LLC charges a $35.00 per hour bench charge. NOTE: No repairs will

be started without the authorization of the customer. The return shipping cost to the customer will be added to the repair

invoice.

Prior to returning the product for Warranty Repair, the product must be thoroughly cleaned and free from any food

particles or other debris. Failure of the purchaser to comply with this standard will result in the unit being returned without

repair. In some cases, a $50 cleaning surcharge may apply.

Weston Brands LLC will repair (or at its discretion, replace) the product free of charge, if in the judgment of the

company, it has been proven to be defective as to seller’s labor and material, within the warranty period.

New or rebuilt replacements for factory defective parts will be supplied for one (1) year from the date of purchase.

Replacement parts are warranted for the remainder of the original warranty period.

For non-warranty repairs, contact Weston Brands LLC’s Customer Service at 1-800-814-4895 M-F 8am-5pm ET

(outside of the United States 001-440-638-3131) to obtain a Return Merchandise Authorization Number (RMA Number).

Weston Brands LLC will refuse all returns that do not contain this number. DO NOT RETURN THE UNIT WITHOUT

PROPER AUTHORIZATION FROM WESTON BRANDS LLC.

LIMITATIONS: The warranty is void if the product is used for any purpose other than that for which it is designed.

The product must not have been previously altered, repaired, or serviced by anyone else other than Weston Brands

LLC. If applicable, the serial number must not have been altered or removed. The product must not have been subjected

to accident in transit or while in the customer’s possession, misused, abused, or operated contrary to the instructions

contained in the instruction manual. This includes failure caused by neglect of reasonable and necessary maintenance,

improper line voltage and acts of nature. This warranty is not transferable and applies only to U.S. and Canadian sales.

Except to the extent prohibited by applicable law, no other warranties whether expressed or implied, including

warranty merchantability and tness for a particular purpose, shall apply to this product. Under no circumstances shall

Weston Brands LLC be liable for consequential damages sustained in connection with said product and Weston Brands

LLC neither assumes nor authorizes any representative or other person to assume for it any obligation or liability other than

such as is expressly set forth herein. Any applicable implied warranties are also limited to the one (1) year period of the

limited warranty.

This warranty covers only the product and its specic parts, not the food or other products processed in it. Weston is

not responsible for missing or damaged parts on discounted/clearance, resale or nal sale items where the seller may not

be able to guarantee full functionality or completeness of the unit.

CUT ALONG THE DOTTED LINE AND SEND THE WARRANTY CARD ALONG WITH A COPY OF YOUR

ORIGINAL PURCHASE RECEIPT TO:

Weston Brands LLC / WARRANTY

20365 Progress Drive, Strongsville, OH 44149 USA

Customer Name:

Address:

City/State/Zip/Country:

Telephone Number:

E-Mail Address:

Original Date of Purchase:

Product Model #:

Serial # (if applicable):

I have read the warranty information. Initial here:

WESTON WARRANTY INFORMATION

SAVE THIS WARRANTY INFORMATION FOR YOUR RECORDS!

WESTON WARRANTY CARD

SEND THIS CARD ALONG WITH A COPY OF YOUR ORIGINAL PURCHASE RECEIPT TO:

WESTON BRANDS LLC / WARRANTY, 20365 PROGRESS DRIVE, STRONGSVILLE, OH 44149 USA

Copy of Receipt

Included

Page 13

RELLENADORA VERTICAL DE

SALCHICHAS

73-0501-W

DEBIDO A CONSTANTES MEJORAS EN LA FÁBRICA, EL PRODUCTO QUE SE MUESTRA

PUEDE SER LIGERAMENTE DIFERENTE DEL PRODUCTO EN ESTA CAJA. 060915

Page 14

14

INSTRUCCIONES EN ESPAÑOL

1. NUNCA use accesorios o partes de otros fabricantes. Hacerlo puede anular su

garantía.

2. Limpie bien todas las piezas que entran en contacto con los alimentos antes y

después de usar el electrodoméstico. Lave a mano y seque bien todas las partes.

3. Antes de usar la embutidora, aplique siempre un lubricante para uso alimentario

al interior del recipiente para disminuir la fricción.

4. MANTÉNGALO ALEJADO DE LOS NIÑOS. NUNCA DEJE SIN SUPERVISIÓN

EL APARATO. La rellenadora NO ES UN JUGUETE.

5. Revise que la rellenadora esté estable mientras la usa. Las cuatro patas

deben estar rmes en una supercie nivelada. No debe mover la rellenadora

durante su funcionamiento.

6. ¡USE PROTECCIÓN EN LOS OJOS! Los anteojos ópticos no son protección

de seguridad. Las gafas de seguridad cumplen con los requerimientos de la

norma ANSI Z87.1. Nota: Las gafas de seguridad aprobadas tienen impresa o

estampada la clave Z87.

7. NO lo use bajo los efectos de drogas o alcohol.

¡GUARDE ESTAS INSTRUCCIONES!

REGLAS IMPORTANTES DE SEGURIDAD

LEA Y ENTIENDA COMPLETAMENTE TODAS LAS INSTRUCCIONES Y

ADVERTENCIAS ANTES DE UTILIZAR ESTA UNIDAD. ¡SU SEGURIDAD

ES LO MÁS IMPORTANTE! NO SEGUIR LOS PROCEDIMIENTOS

Y PRECAUCIONES PUEDE PROVOCAR LESIONES GRAVES Y

DAÑOS MATERIALES. RECUERDE: ¡SU SEGURIDAD PERSONAL ES

RESPONSABILIDAD DE USTED!

Page 15

Page 16

1

2

3

4

6

8

9

10

11

7

5

Costados

de la

rellenadora

Base de

la

rellenadora

RELLENADORA

VERTICAL

ENSAMBLADA

30 mm 13 mm

40 mm 20 mm

16

INSTRUCCIONES EN ESPAÑOL

Page 17

LISTA DE COMPONENTES

NÚMERO DE DIAGRAMA DESCRIPCIÓN DE LA PIEZA NÚMERO DE PIEZA

1 MANIVELA CON MARIPOSA

(MARIPOSA SOLAMENTE 73-0511)

73-0510

2 ÉMBOLO 73-0514

3 SELLO DEL ÉMBOLO 73-0516

4 VÁLVULA DE LIBERACIÓN DE PRESIÓN

(JUEGO DE 4 PIEZAS)

73-0515

5 JUEGO DE EMBUDOS DE PLÁSTICO

(4 EMBUDOS)

73-0520

6 RECIPIENTE DE ACERO INOXIDABLE 73-0519

7 TUERCA DE ARO FRONTAL 73-0521

8 JUEGO PARA MONTAR LOS ACCESORIOS

DEL RECIPIENTE (4 JUEGOS)

73-0522

9 EJE DEL ÉMBOLO 73-0512

10 JUEGO DE ENGRANES (2) 73-0513

11 PATA DE HULE (JUEGO DE 4 PIEZAS) N/A

Si cualquier componente de esta unidad está roto, si no funciona debidamente, o si necesita

un instructivo de repuesto, visítenos en la Web en

WestonProducts.com

O llame a Weston Brands LLC larga distancia sin costo 1-800-814-4895

De lunes a viernes, de 8:00 am a 5:00 pm tiempo del ET. Fuera de Estados Unidos llame

al 001-440-638-3131

17

INSTRUCCIONES EN ESPAÑOL

Page 18

18

INSTRUCCIONES EN ESPAÑOL

ENSEMBLADO

CONJUNTO DEL

ÉMBOLO

1. Deslice el sello del

émbolo en el émbolo

(FIGURA 1).

2. Ensamble el juego de

la válvula de liberación

de presión en el émbolo.

Desde la parte superior

del émbolo, coloque la

arandela en el agujero de

la válvula, después inserte

el tornillo a través de la

arandela y del agujero de

la válvula. Desde la parte

inferior del émbolo, coloque

el resorte en el extremo del

tornillo, después coloque

la tapa de la válvula en el

extremo del tornillo y gire

para jar.

3. Coloque el émbolo

ensamblado en el extremo

del eje del émbolo

(FIGURA 3).

ENSAMBLE DE LA

RELLENADORA

4. Attach the Handle by

sliding it onto the Gear

Shaft and placing the

Wingnut into the hole in the

Handle. Twist to tighten

(FIGURE 3).

5. Crank the Handle

counter-clockwise to bring

the Plunger to the top of

the Stuffer.

6. Apoye las abrazaderas

del fondo del recipiente en

las monturas del recipiente

adentro del gabinete de

la rellenadora. Haga girar

el fondo del recipiente

en el gabinete de la

rellenadora. Haga girar por

completo el recipiente en el

gabinete de la rellenadora,

enganchando las

abrazaderas superiores en

las monturas del recipiente

(FIGURE 4).

FIGURA 1

FIGURA 2

FIGURA 3

Eje del

engrane

Mango

Mariposa

FIGURA 4

Soporte superior

Ssoporte inferior

Imagen del exterior de las

monturas del recipiente

Sello del

émbolo

Émbolo

Resorte

Tapa de

la válvula

Agujero de la

válvula

Arandela

del tornillo

del juego

de la

válvula de

liberación

de presión

Page 19

19

INSTRUCCIONES EN ESPAÑOL

DESARMADO Y LIMPIEZA

7. Inserte el embudo de rellenado

de su elección a través de la

tuerca de aro frontal. Atornille

la tuerca de aro frontal y el

embudo de rellenado en la boca

del recipiente hasta que estén

apretados. NO APRIETE EN

EXCESO la tuerca de aro frontal

pues podría dañar el embudo

(FIGURE 5).

FIGURA 5

Tuerca de aro

frontal

Funnel

Boca del

recipiente

1. Quite el embudo de rellenado desatornillando la tuerca de aro frontal y

jalando el embudo.

2. Gire el mango hasta que el émbolo suba y salga del recipiente.

3. Gire el recipiente hacia afuera, después tire de él hacia arriba para sacarlo

del gabinete de la rellenadora.

4. Desatornille el émbolo de su eje. Retire la válvula de liberación de presión

del émbolo. Quite el sello del émbolo.

5. Lave con agua jabonosa caliente todas las partes que entren en contacto

con la carne. PROCURE LIMPIAR LAS PARTES INMEDIATAMENTE

DESPUÉS DE USARLAS. Enjuague y seque cuidadosamente todas las

partes inmediatamente. Esterilice si es necesario.

6. Después de cada uso, lubrique por completo los componentes del eje, el

recipiente, la válvula de liberación de presión y la tuerca de aro frontal con un

lubricante para alimento.

Page 20

1. Incline el recipiente hacia afuera.

2. Llene el recipiente con la mezcla de carne y

sazonadores (FIGURA 7).

3. Presione rmemente la mezcla hacia abajo

del recipiente para expulsar el aire que estuviera

atrapado.

4. Gire el recipiente para ponerlo en posición

vertical y enganche las abrazaderas superiores

en las monturas del recipiente.

5. Gire el mango hasta que el émbolo esté en

contacto con la carne y la mezcla esté lista para

ser expulsada por el extremo del embudo de

rellenado.

6. Deslice un forro en el extremo del embudo

de rellenado hasta que se haya deslizado

completamente en el embudo (FIGURA 9).

7. Ate, tuerza o ponga un aro en el extremo del

forro para sellarlo.

8. Gire el mango para expulsar la mezcla en el

forro. Para lograr mejores resultados, aplique

presión alrededor del forro cerca del extremo del

embudo de rellenado. Así mantiene apretado

el forro y hace que la mezcla se empaque

rmemente en el forro.

9. Cuando llegue al extremo del forro ate, tuerza

o ponga un aro en el extremo para sellar el

contenido

CONSEJOS DE RELLENADO: Los

siguientes consejos ayudan a reducir

la resistencia al estar rellenando con el

embudo de rellenado de 13 mm.

A. Agréguele agua a la mezcla de carne:

hasta 1 1/2 tazas (0.4 l) de agua por cada

2.3 kg (5 lb) de carne sazonada.

B. Vierta 1/4 de taza (60 ml) de aceite

vegetal o de oliva por cada 2.3 kg (5 lb) de

carne sazonada para que uya mejor.

CAUTION!

¡ADVERTENCIA! Cuando el émbolo esté salido del

recipiente, SUELTE LENTAMENTE EL MANGO. La

presión y la gravedad pueden hacer que el mango

gire ligeramente hacia atrás y provoque lesiones.

FIGURE 6

FIGURE 7

Recipiente

INSTRUCCIONES DE RELLENADO

20

INSTRUCCIONES EN ESPAÑOL

Page 21

21

INSTRUCCIONES EN ESPAÑOL

Hay que seguir ciertas reglas básicas al manejar alimentos.

Las reglas son COCINAR, SEPARAR, LIMPIAR y ENFRIAR.

COCINAR

Es muy importante cocinar los alimentos a una temperatura interna que destruya cualquier

bacteria que esté presente. Últimamente se ha puesto mucha atención en la higiene de

las hamburguesas y otros alimentos elaborados con carne molida y con razón. Cuando se

muele la carne, las bacterias presentes en la supercie se revuelven en toda la mezcla de la

carne molida. Si la carne molida no se cuece a por lo menos 71°C a 74°C (160°F - 165°F),

no se destruyen las bacterias y hay una buena posibilidad de enfermarse.

Las piezas de carne sólida, como los letes y las chuletas, no tienen en su interior bacterias

peligrosas como le E. coli, por lo que pueden servirse menos cocidas. Aun así, cualquier

corte de vacuno debe cocinarse a una temperatura interna de por lo menos 63°C (145°F)

(medio cocido). La temperatura recomendable para las aves es de 75°C (165°F) y los cortes

sólidos de carne de puerco deben cocinarse a 71°C (160°F).

SEPARAR

SIEMPRE DEBE separar los alimentos que se comen crudos y los que se vayan a cocer

antes de comerse. La contaminación cruzada se presenta cuando la carne o los huevos

crudos entran en contacto con alimentos que se van a consumir sin cocimiento. Ésta es una

importante causa de intoxicaciones. Siempre use una doble envoltura para la carne cruda

y colóquela en la repisa más baja del refrigerador, para que no haya manera de que su

jugo gotee en las verduras frescas. Use la carne cruda 1 o 2 días después de comprarla, o

congélela para guardarla más tiempo. Descongele la carne congelada en el refrigerador, no

en el mesón de la cocina.

Cuando ase o cocine carne o pescado crudo, coloque la carne ya cocida en un platón

limpio. No use el mismo platón que usó para llevar la carne al asador. Lave los utensilios

usados en el asador después de haber volteado los alimentos por última vez, así como las

cucharas y espátulas usadas para freír o para voltear la carne al estarla cocinando.

No olvide lavarse las manos después de manejar carne o huevos crudos. Es absolutamente

necesario lavarse las manos con agua y jabón o usar una toallita húmeda antibacteriana

después de tocar carne o huevos crudos. No lavarse las manos o las supercies cuando se

cocina es una causa importante de contaminación cruzada.

LIMPIAR

Lávese las manos y las supercies de trabajo con frecuencia mientras esté cocinando.

Lávese con agua tibia y jabón durante por lo menos 15 segundos; después séquese con

una toalla de papel.

ENFRIAR

Es muy importante enfriar los alimentos. La zona de peligro para la multiplicación de

bacterias está entre los 4 °C y 60 °C (40 °F - 140 °F). El refrigerador debe estar a 4 °C (40

°F) o menos; el congelador debe estar a -17 °C (0 °F) o menos. Regla básica: sirva calientes

los alimentos calientes y sirva fríos los alimentos fríos. Use platos calientes para mantener

caliente la comida a la hora de servirla. Use baños de agua con hielo para mantener fría

la comida fría. Nunca deje ningún alimento a temperatura ambiente por más de 2 horas;

o por más de 1 hora si la temperatura ambiente es de 32 °C (90 °F) o superior. Cuando

empaque para un picnic, asegúrese de que la comida ya esté fría cuando la meta en la

canasta aislada. La canasta no enfría la comida; sólo la mantiene fría si está debidamente

empacada con hielo. Los alimentos cocidos calientes deben colocarse en recipientes bajos

y refrigerarse de inmediato para que se enfríen rápidamente. No olvide cubrir los alimentos

una vez que se enfríen..

NOTA: Debe tener especial consideración al usar venado y otra carne de caza, ya que

puede contaminarse durante la preparación de campo. El venado suele mantenerse a

temperaturas que podrían permitir el crecimiento de bacterias, como cuando se transporta.

Consulte con el Departamento de Carnes y Aves de la USDA si tiene más preguntas o

quiere más información sobre higiene de carne y alimentos.

SEGURIDAD DE LOS ALIMENTOS

Page 22

22

INSTRUCCIONES EN ESPAÑOL

INFORMACIÓN DE LA SALCHICHA

SELECCIÓN DE CARNE PARA HACER SALCHICHAS

La elaboración de salchichas ha evolucionado a lo largo de muchos años y generaciones, y como resultado,

hay un sinnúmero de tipos de salchichas que puede hacer usando los ingredientes básicos como carne,

grasa y algunas especias cuidadosamente combinadas. A continuación se presentan algunos lineamientos

sencillos que le ayudarán a elaborar salchichas con el mejor sabor posible.

Se puede utilizar cualquier tipo de carne para elaborar embutidos: carne de cerdo, de res, de bisontes, de

alces y de caribúes, incluso con la de antílope se hacen excelentes salchichas. En la preparación de la carne

de venado o de otras carnes rojas de caza es importante quitar toda la grasa de la carne, ya que el sebo de

la carne roja de caza se vuelve rancio en tan sólo cinco días. Reemplace la grasa, con grasa de cerdo o de

vaca, dependiendo del tipo de producto que esté elaborando, en una proporción de 0.5 kg (1 lb) de grasa por

cada 1.8 kg (4 lb) de carne de caza.

El contenido de grasa de la salchicha afectará el sabor, la textura, las características de cocción y la vida

útil de su producto. La mayoría de las salchichas comerciales tienen un contenido de grasa de alrededor del

20%. El uso de menos de 12% de grasa dará lugar a una salchicha muy seca a la degustación, mientras que

con más del 20% puede dar como resultado una salchicha sin sabor y pegajosa que será difícil de cocinar.

CURADO

Es importante curar adecuadamente las carnes para conservarlas, y destruir los microorganismos

indeseables en las supercies de la carne que causan su descomposición así como enfermedades derivadas

de ésta. Hay muchas medidas que son de ayuda en este proceso, como el ahumado, la cocción, el secado,

la refrigeración, y la adición de ingredientes para curado. Los medios más antiguos para lograr esto eran

mediante la introducción de la sal en la carne. La resistencia de las bacterias a la sal varía ampliamente entre

los diferentes tipos de bacterias. El crecimiento de algunas bacterias se inhibe por concentraciones de sal

tan bajas como el 3% en por ejemplo la Salmonela, mientras que otros tipos son capaces de sobrevivir en

concentraciones mucho más altas de sal, por ejemplo el estalococo. Afortunadamente, el crecimiento de

muchos organismos no deseados que normalmente se encuentran en los productos de carne y de aves de

corral curadas se inhibe a concentraciones bajas de sal. El curado moderno se basa en nitratos y es muy

cientíco. Adquiera Sal rosa para curar Weston (02-0000-W) y siga las instrucciones para asegurar que está

curando adecuadamente su salchicha casera.

FORRO

Weston ofrece una variedad completa de envoltorios. La elección correcta depende de su la preferencia

personal, así como del tipo de salchicha que desea elaborar. Para la mayoría de las salchichas, sus opciones

son naturales o de colágeno. No deje que los nombres le engañen; los forros de colágeno no son un producto

sintético. Están hechos de piel de res y otros tejidos. Los forros de colágeno son uniformes en tamaño y

textura y casi no requieren preparación. Los forros “naturales” son los intestinos de cordero, de ovejas, de

cerdos o de res. Son menos uniformes en tamaño y requieren una preparación. También hay forros brosos

no comestibles que se utilizan para algunas variedades de salchichas y mortadelas ahumadas. También hay

envoltorios brosos no comestibles que son usados más comúnmente para salchichón y bolonia

TIPOS DE SALCHICHAS

La mayoría de las salchichas caen dentro de una de cuatro categorías: Frescas, ahumadas, cocidas o secas.

Todas las salchichas, excepto las secas, requieren ser refrigeradas para su almacenamiento. También hay

una subcategoría de salchichas ahumadas crudas.

Entre las salchichas ahumadas frescas y las crudas, encontrará sabores como kielbasa o salchicha polaca,

salchicha italiana, salchichas para desayuno y muchos otros. Las salchichas ahumadas frescas y crudas

requieren cocción antes de comerse y también requieren de almacenamiento refrigerado.

Las salchichas ahumadas y las cocidas incluyen al salami, a la mortadela, a los siempre populares perros

calientes y a muchas otras. El ahumado adecuado requiere un ahumadero o un ahumador. Weston ofrece

ahumadores de propano para estar al aire libre en varios tamaños (41-0701-W, 41-0301-W, o 41-0401-W).

La mayoría de las salchichas ahumadas se calientan antes de servir. Muchas personas piensan que una

salchicha ahumada va a durar mucho más tiempo sin echarse a perder, pero esto no es cierto. Las salchichas

ahumadas deben ser tratadas de la misma manera que las salchichas frescas en cuanto al almacenamiento.

Las salchichas secas requieren un tiempo de procesamiento más largo, ya que se secan al aire durante un

largo período de tiempo. Las salchichas curadas en seco incluyen salami, chorizo y pepperoni, entre otras.

Las condiciones en las que se seca la carne son muy exigentes; la temperatura, el tiempo y la humedad

deben ser monitoreados cuidadosamente para obtener un producto seguro y delicioso.

ALMACENAMIENTO

Recomendamos sellar al vacío sus salchichas frescas, luego almacenarlas en el refrigerador (por corto

tiempo) o en el congelador (por largo tiempo) para obtener el mejor sabor. Weston fabrica diversas selladoras

al vacío. Pida su selección al vendedor donde compró esta unidad. Almacene los productos curados secos y

sin refrigerar en papel u otra envoltura transpirable.

Page 23

Page 24

Weston Brands LLC garantiza al COMPRADOR AL DETALLE ORIGINAL de este producto que si funciona en cumplimiento

con las instrucciones impresas adjuntas, entonces por un período de 1 año desde la fecha de compra, el producto se

considerará libre de defectos respecto del material y mano de obra.

La Tarjeta de Garantía, junto con una copia del recibo original debe ser recibida por Weston Brands LLC dentro de 30 días

desde la fecha de compra para hacer efectiva la garantía. Si no se envía la Tarjeta de Garantía completamente llena, junto

con una copia del recibo original, anulará la garantía.

El producto debe ser enviado o despachado mediante ete prepagado a Weston Brands LLC para efectuar los servicios

establecidos en la garantía, en su envase original o en un envase similar que garantice igual grado de protección. El daño

producto del despacho no es responsabilidad de la compañía. Weston Brands LLC cobra $35.00 por concepto de mesón por

hora. NOTA: Las reparaciones no se iniciarán sin la autorización del cliente. El costo por despacho de devolución al cliente se

agregará a la factura por reparación.

Antes de devolver el producto para la Reparación según la Garantía, el producto debe estar completamente limpio y libre de

partículas de alimentos u otros fragmentos. El incumplimiento del comprador respecto de esta norma resultará en el envío de

la unidad sin reparación. En algunos casos, podría aplicar un sobrecargo de $50 por concepto de limpieza.

Weston Brands LLC reparará (o a su decisión, cambiará) el producto sin cobro, si a juicio de la compañía, se ha demostrado

que está defectuoso respecto de la mano de obra y material del vendedor, dentro del período de garantía.

Los cambios de productos nuevos o reacondicionados por partes defectuosas de fábrica serán suministrados por un (1) año

desde la fecha de compra. Las partes cambiadas están garantizadas por el resto del período original de garantía.

Para las reparaciones que no estén cubiertas en la garantía, comuníquese con Servicio al Cliente de Weston Brands LLC al

1-800-814-4895 de lunes a viernes, desde las 8 a.m. hasta las 5pm ET (Desde fuera de los Estados Unidos comuníquese

al 001-440-638-3131) para solicitar un Número de Autorización de Devolución de la Mercadería (Número RMA). Weston

Brands LLC rechazará todo envío que no contenga este número. NO DEVUELVA LA UNIDAD SIN LA AUTORIZACIÓN DE

WESTON BRANDS LLC.

LIMITACIONES: La garantía queda invalidada si el producto se utiliza para algún objetivo que no sea aquél para el cual

está diseñado. El producto no debe haber sido previamente alterado, reparado, ni tampoco se le debe haber hecho servicio

técnico por cualquier otra persona que no sea de Weston Brands LLC. Si corresponde, no se debe alterar o eliminar el

número de serie. El producto no debe estar sujeto a accidentes durante el transporte o estando en posesión del cliente, no

debe ser mal usado, mal tratado, u operado en forma contraria a las instrucciones de este manual. Esto incluye toda falla

causada por negligencia de mantención razonable o necesaria, voltaje de línea inadecuado o actos de la naturaleza. Esta

garantía es intransferible y sólo se aplica a ventas realizadas en Estados Unidos y Canadá.

Salvo en la medida en que lo prohíba la ley correspondiente, ninguna otra garantía expresa o implícita, incluyendo

comerciabilidad o aptitud de la garantía para un objetivo en particular, aplicará a este producto. Bajo ninguna circunstancia

Weston Brands LLC será responsable de daños emergentes sostenidos en conexión con dicho producto y Weston Brands

LLC no asume ni autoriza a ningún representante u otra persona a asumir por él ninguna obligación o responsabilidad que no

sea aquella expresamente establecida en esta tarjeta de garantía. Toda garantía correspondiente implícita también se limita a

un período de un (1) año de la garantía limitada.

Esta garantía cubre sólo el producto y sus partes especícas, no cubre los alimentos u otros productos procesados en

él. Weston no se hace responsable por partes faltantes o dañadas en productos con descuento/en oferta, reventa, o en

promoción nal, sobre los cuales el vendedor puede no ser capaz de garantizar una funcionalidad completa, o la integridad de

la unidad.

CORTE POR LA LÍNEA PUNTEADA Y ENVÍE LA TARJETA DE GARANTÍA JUNTO CON UNA COPIA DE SU RECIBO DE

COMPRA ORIGINAL A

Weston Brands LLC / WARRANTY

20365 Progress Drive, Strongsville, OH 44149 USA

Nombre del Cliente:

Dirección:

Ciudad/Estado/Código Zip/País:

Número Telefónico:

Dirección de Correo Electrónico:

Fecha de Compra Original:

Modelo del Producto #:

# de Serie (Si corresponde):

INFORMACIÓN DE GARANTÍA WESTON

¡GUARDE ESTA INFORMACIÓN DE GARANTÍA PARA SUS REGISTROS!

TARJETA DE GARANTÍA WESTON

ENVÍE ESTA TARJETA JUNTO CON UNA COPIA DE SU RECIBO DE COMPRA ORIGINAL A:

WESTON BRANDS LLC/WARRANTY, 20365 PROGRESS DRIVE. STRONGSVILLE, OH 44149 USA

Copia del recibo

incluido

Page 25

REMPLISSEUR VERTICAL DE

SAUCISSES

73-0501-W

PARCE QUE NOS PRODUITS BÉNÈFICIENT DE PERFECTIONNEMENTS CONSTANTS

APPORTÉS EN USINE, LES ILLUSTRATIONS PRÉSENTES PEUVENT ÊTRE LÉGÈREMENT

DIFFÉRENTES DU PRODUIT REÇU. 060915

Page 26

1. Ne JAMAIS utiliser d’accessoires ou de pièces provenant d’un autre fabricant.

Cela annulera votre garantie.

2. Nettoyer soigneusement toutes les pièces qui seront en contact avec les

aliments avant et après l’utilisation de l’appareil. Laver toutes les pièces à la main

et les sécher avec soin.

3. Toujours appliquer un lubriant alimentaire à l’intérieur du contenant avant

d’utiliser le poussoir à saucisses, an de diminuer le frottement.

4. TENIR LES ENFANTS À L’ÉCART. NE JAMAIS LAISSER L’APPAREIL SANS

SUPERVISION. Le remplisseur n’est pas un jouet.

5. Utiliser le poussoir à saucisses sur un espace de travail stable. Vérier que

tous les pieds du poussoir à saucisses sont à niveau.

6. PORTER UNE PROTECTION POUR LES YEUX! Les lunettes de vue ne sont

pas des lunettes de sécurité. Les lunettes de sécurité doivent être conformes

aux exigences de la norme ANSI Z87.1. Remarque: Les lunettes de sécurité

agréées ont la marque Z87 imprimée ou gravée dessus.

7. NE PAS utiliser sous l’effet d’alcool et de drogue.

CONSERVER CES DIRECTIVES!

IMPORTANTES RÈGLES DE SÉCURITÉ

LIRE ET COMPRENDRE COMPLÈTEMENT TOUTES LES DIRECTIVES

ET AVERTISSEMENTS AVANT D’UTILISER CE PRODUIT. LE PLUS

IMPORTANT EST VOTRE SÉCURITÉ! LE DÉFAUT D’OBSERVER LES

PROCÉDURES ET MISES EN GARDE PEUT ENTRAINER DES BLESSURES

GRAVES OU DES DOMMAGES MATÉRIELS. N’OUBLIEZ PAS : VOTRE

SÉCURITÉ PERSONNELLE EST VOTRE RESPONSABILITÉ!

INSTRUCTIONS EN FRANÇAIS

26

Page 27

Page 28

INSTRUCTIONS EN FRANÇAIS

28

1

2

3

4

6

8

9

10

11

7

5

30 mm 13 mm

40 mm 20 mm

Côtés du

remplisseur

Base du

remplisseur

REMPLISSEUR

VERTICAL

ASSEMBLÉ

Page 29

DESCRIPTION DE LA PIÈCE

NUMÉRO DE SCHÉMA DESCRIPTION DE LA PIÉCE NUMÉRO DE LA PIÉCE

1 POIGNÉE AVEC ÉCROU À OREILLES

(ÉCROU À OREILLES UNIQUEMENT :

73-0511)

73-0510

2 POUSSOIR 73-0514

3 JOINT DU POUSSOIR 73-0516

4 VALVE DE SURPRESSION

(JEU DE 4 PIÈCES)

73-0515

5 ENSEMBLE D’ENTONNOIRS EN

PLASTIQUE (4 ENTONNOIRS)

73-0520

6 CONTENANT EN ACIERS INOXYDABLE 73-0519

7 ÉCROU ANNULAIRE AVANT 73-0521

8 KIT DE QUINCAILLERIE DE MONTAGE DU

CONTENANT (4 JEUX)

73-0522

9 AXE DU POUSSOIR 73-0512

10 ENSEMBLE D’ÉLÉMENTS DENTÉS (2) 73-0513

11 PIED CAOUTCHOUTÉ (JEU DE 4 PIÈCES) N/A

N’hésitez pas à visiter notre site Web WestonProduct.com/support si un composant est

cassé, l’outil fonctionne mal, ou pour commander un nouveau mode d’emploi.

WestonProducts.com

Veuillez appeler Weston Brands, LLC au numéro sans frais : 1-800-814-4895

Du lundi au vendredi: de 8h00 à 17h00 ET. En dehors des États-Unis, veuillez

appeler le 001-440-638-3131

INSTRUCTIONS EN FRANÇAIS

29

Page 30

INSTRUCTIONS EN FRANÇAIS

30

Brides supérieures

Brides inférieures

Vue de l’extérieur des

supports du contenant

ASSEMBLY

ASSEMBLAGE DU

POUSSOIR

1. Faire glisser le joint du

poussoir dans le poussoir

(FIGURE 1).

2. Assembler le kit de la

soupape de décharge de

pression dans le poussoir.

Depuis le haut du poussoir,

placer la rondelle dans le

trou de la soupape, puis

insérer la vis à travers la

rondelle dans le trou de la

soupape. Depuis la face

inférieure du poussoir, placer

le ressort dans le bout de la

vis, puis placer le capuchon

de la soupape dans la vis et

tourner pour serrer.

3. Placer le poussoir

assemblé dans l’extrémité

de l’arbre du poussoir

(FIGURE 2).

ASSEMBLAGE DU

POUSSOIR À SAUCISSES

4. Fixer la manivelle en la

faisant glisser sur l’arbre

de transmission et placer

l’écrou à oreilles dans le trou

de la manivelle. Tourner

pour serrer (FIGURE 3).

5. Tourner la manivelle dans

le sens antihoraire pour

amener le poussoir vers

le sommet du poussoir à

saucisses.

6. Poser les supports

inférieurs du contenant dans

les supports du contenant

à l’intérieur du boîtier du

poussoir. Faire pivoter le bas

du support dans le boîtier

du poussoir. Faire pivoter le

support entièrement dans

le boîtier du poussoir, en

enclenchant les supports

supérieurs dans les supports

du contenant (FIGURE 4).

Plunger

Seal

Plunger

Pressure

Release

Valve Kit

Screw

Washer

Spring

Valve Cap

Valve Hole

FIGURE 1

FIGURE 2

FIGURE 3

Arbre de

transmission

Poignée

Écrou à

oreilles

FIGURE 4

Page 31

DÉMONTAGE ET NETTOYAGE

7. Insérez l’entonnoir de bourrage

de votre choix par l’écrou

annulaire avant. Vissez l’écrou

annulaire avant et l’entonnoir

de bourrage dans la bouche du

contenant jusqu’au serrage. NE

PAS SERRER AVEC EXCÈS

l’écrou annulaire avant sous

risque d’endommager l’entonnoir

(FIGURE 5).

FIGURE 5

1. Retirez l’entonnoir de bourrage en dévissant l’écrou annulaire avant et

dégageant l’entonnoir.

2. Tournez la manivelle jusqu’à ce que le poussoir remonte et sorte du

contenant.

3. Faites tourner le contenant vers l’extérieur et tirez le contenant vers le haut

pour le dégager du boîtier du remplisseur.

4. Dévissez le poussoir de l’axe du poussoir. Détachez le clapet de

surpression du poussoir. Retirez le joint du poussoir.

5. Lavez toutes les pièces qui entrent en contact avec la viande dans de l’eau

savonneuse. TOUJOURS NETTOYER LES PIÈCES IMMÉDIATEMENT

APRÈS EMPLOI. Rincez et séchez bien toutes les pièces immédiatement.

Stérilisez selon les besoins.

6. Lubriez bien l’axe, le contenant, les composants de la valve de

surpression et l’écrou annulaire avant avec un lubriant de qualité aliment

Écrou annulaire

avant

Entonnoir

Bouche du

contenant

INSTRUCTIONS EN FRANÇAIS

31

Page 32

INSTRUCTIONS EN FRANÇAIS

32

1. Inclinez le contenant vers l’avant.

2. Remplissez le contenant du mélange de

viande et d’assaisonnements (FIGURE 8).

3. Poussez fermement le mélange vers le bas

dans le contenant pour que l’air piégé puisse

s’échapper.

4. Faites tourner le contenant vers l’arrière

en position verticale et enclenchez les brides

supérieures dans les supports du contenant.

5. Tournez la manivelle jusqu’à ce que le

poussoir entre en contact avec la viande et que

le mélange est prêt à sortir de l’autre côté de

l’entonnoir de bourrage.

6. Glissez l’enveloppe sur l’extrémité de

l’entonnoir de bourrage jusqu’à ce que

l’enveloppe entière soit passée sur l’entonnoir

(FIGURE 9).

7. Attachez, tordez ou serrez avec un anneau

l’extrémité de l’enveloppe pour le sceller.

8. Tournez la manivelle pour faire sortir le

mélange et le verser dans l’enveloppe. Pour

faciliter l’opération, exercez une pression autour

de l’enveloppe, près de l’extrémité de l’entonnoir

de bourrage. Ce faisant, l’enveloppe est bien

serrée et le mélange sera emballé fermement

dedans.

9. Lorsque le fond de l’enveloppe est atteint,

tordez ou serrez l’enveloppe avec un anneau

pour sceller le contenant à l’intérieur.

CONSEILS POUR LE BOURRAGE:

Vous trouverez ci-dessous des

suggestions pour réduire la résistance

lors du bourrage avec un entonnoir de

bourrage de 13 mm.

A. Ajoutez de l’eau dans votre mélange

de viandes – jusqu’à 0,4 L (1-1/2 tasses)

d’eau pour 2,3 kg (5 lb) de viande

assaisonnée.

B. Ajoutez 60 ml (1/4 tasse) d’huile

végétale ou d’olive dans le mélange de

viandes pour faciliter le ux.

CAUTION!

ATTENTION ! Lorsque vous relevez le poussoir

pour le sortir du contenant, RELÂCHEZ LA MANIVELLE

LENTEMENT! La pression ou la gravité peuvent forcer

la manivelle à tourner légèrement vers l’arrière ce qui

entraînerait des blessures.

FIGURE 6

FIGURE 7

INSTRUCTIONS DE BOURRAGE

Page 33

Il y a des règles fondamentales à suivre lors de la manipulation d’aliments.

Elles sont CUIRE, SÉPARER, NETTOYER, et REFROIDIR RAPIDEMENT.

CUIRE

Il est crucial de cuire les aliments à une température interne sûre pour détruire les bactéries qui sont

présentes. La sécurité des hamburgers et autres aliments faits avec de la viande hachée a reçu

dernièrement beaucoup d’attention, et pour une bonne raison. Quand la viande est hachée, les bactéries

présentes sur la surface sont mélangées dans l’ensemble du mélange haché. Si cette viande hachée n’est

pas cuite jusqu’à au moins 71oC à 74oC (160oF à 165oF), les bactéries ne seront pas détruites et il y a

une forte chance que cela vous rendra malade.

Des morceaux solides de viande comme des steaks et côtelettes n’ont pas de bactéries dangereuses

comme E. coli à l’intérieur, donc ils peuvent être servis plus saignants. Quand même, tout morceau de

bœuf doit être cuit à une température interne d’au moins 63oC (145oF) (mi-saignant).La température

sûre pour la volaille est 75oC (165oF) et les morceaux de viande entier de porc doivent être cuits à 71oC

(160oF).

SÉPARER

Les aliments qui seront mangés crus et les aliments qui seront cuits avant d’être mangés DOIVENT

TOUJOURS être séparés. La contamination croisée se produit quand des viandes crues ou des œufs

viennent en contact avec des aliments qui seront mangés crus. Ceci est une source principale d’intoxication

alimentaire. Enveloppez toujours deux fois les viandes crues et placez-les sur l’étagère la plus basse dans

le réfrigérateur de manière qu’aucun jus ne puisse goutter sur les fruits et légumes crus. Puis utilisez

les viandes crues entre 1 et 2 jours après l’achat, ou congelez-les pour les conserver plus longtemps.

Décongelez les viandes congelées dans le réfrigérateur, pas sur le comptoir.

Quand vous grillez ou cuisez des viandes ou des poissons crus, assurez-vous de mettre la viande cuite

sur un plat propre. N’utilisez pas le même plat que vous avez utilisé pour transporter les aliments avant de

les mettre sur le grill. Lavez les ustensiles utilisés pour griller après que les aliments sont tournés pour la

dernière fois sur le grill, aussi bien que les spatules et cuillers utilisées pour faire sauter à feu vif en remuant

ou pour tourner la viande au fur et à mesure qu’elle cuit.

Assurez-vous de bien laver vos mains après avoir manipulé des viandes crues ou des œufs crus. Se laver

les mains avec du savon et de l’eau, ou utiliser une lingette antibactérienne pré-humidiée est absolument

nécessaire après avoir touché de la viande crue ou des œufs crus. Ne pas se laver les mains et les

surfaces pendant la cuisine est une cause majeure de contamination croisée.

NETTOYER

Lavez fréquemment vos mains et les surfaces de travail lorsque vous cuisinez. Lavez avec du savon et de

l’eau chaude pendant au moins 15 seconds, puis séchez avec une serviette en papier.

REFROIDIR RAPIDEMENT

La réfrigération rapide des aliments est très importante. La zone de danger où les bactéries se multiplient

est entre 4oC et 60oC (40oF et 140oF). Votre réfrigérateur doit être réglé à 4oC (40oF) ou en-dessous;

votre congélateur doit être à -17oC (0oF) ou en-dessous. Une règle simple : servir chaud les aliments

chauds, servir froid les aliments froids. Utilisez des réchauds ou plaques chauffantes pour garder les

aliments chauds pendant le service. Utilisez des bains d’eau glacée pour garder au froid les aliments

froids. Ne jamais laisser des aliments à la température ambiante pendant plus de deux (2) heures - 1 heure

si la température ambiante est 32oC (90oF) ou au-dessus. Lorsque vous emballez les aliments pour un

pique-nique, assurez-vous que les aliments sont déjà refroidis rapidement lorsqu’ils sont mis dans le panier

à pique-nique isotherme. Le panier à pique-nique ne refroidira pas les aliments – il garde simplement les

aliments froids lorsqu’il est emballé correctement avec de la glace. Les aliments cuits chauds doivent

être placés dans des conteneurs peu profonds et immédiatement réfrigérés pour qu’ils se refroidissent

rapidement. Assurez-vous de bien couvrir les aliments après qu’ils sont froids.

REMARQUE : Des considérations particulières doivent prises lors de l’utilisation de venaison ou d’autre

gibier sauvage, puisqu’ils peuvent devenir très contaminés durant l’opération de dépouille. La venaison est

souvent gardée à des températures qui pourraient potentiellement permettre la croissance de bactéries,

tel que lorsque celle-ci est transportée. Se référer au Département de la viande et de la volaille de l’USDA

(USDA Meat and Poultry Department) pour d’autres questions ou informations sur la sécurité de la viande

et des aliments.

SÉCURITÉ ALIMENTAIRE

INSTRUCTIONS EN FRANÇAIS

33

Page 34

INFORMATIONS SUR LES SAUCISSES

CHOIX DE VIANDE POUR LA FABRICATION DE SAUCISSE

La fabrication de saucisse s’est développée au cours des nombreuses années et générations, et il en résulte

qu’un nombre incalculable de type de saucisses peuvent être fabriquées en utilisant les ingrédients de base

de la viande, matière grasse et quelques épices soigneusement mélangées. Ci-dessous, vous trouverez

quelques indications simples qui vous aideront à faire des saucisses avec le meilleur goût possible.

Tout type de viande peut être utilisé pour faire des saucisses : porc, bœuf, bison, orignal et caribou, même

l’antilope font de la très bonne saucisse. Il est important lors de la préparation de venaison ou d’autres viandes

de gibier rouges d’enlever la matière grasse de la viande, car le suif de gibier rouge rancira en aussi peu que

cinq jours. Remplacez la matière grasse avec soit de la graisse de porc ou de bœuf, suivant le type de produit

que vous faites, à un taux de 0,5 kg (1 livre) de graisse pour chaque 1,8 g (4 livres) de viande de gibier.

La teneur en matière grasse de vos saucisses affectera le goût, la texture, les caractéristiques de cuisson et la

durée de conservation de votre produit. La plupart des saucisses fabriquées commercialement ont une teneur

en matière grasse d’environ 20%. En utilisant moins de 12% de matière grasse, vous obtiendrez des saucisses

avec un goût très sec, alors que si vous utilisez plus de 20%, cela peut résulter en des saucisses collantes et

sans goût qui seront très difciles à cuire.

SAUMURAGE

Il est important de saumurer correctement les viandes pour conserver la viande et la volaille, et pour détruire

les microorganismes indésirables sur les surfaces de la viande qui causent la détérioration et des maladies

d’origine alimentaire. Il y a de nombreuses étapes qui aident à ce processus, y compris la fumaison, la cuisson,

le séchage, le refroidissement rapide et l’addition d’ingrédients de saumure. Le plus ancien moyen d’accomplir

cela est en introduisant le sel dans la viande. La résistance des bactéries au sel varie beaucoup parmi les

différents types de bactéries. Le développement de certaines bactéries est inhibé par des concentrations en

sel aussi basses que 3%, par exemple. Salmonella, alors que d’autres types peuvent survivre dans de plus

hautes concentrations en sel, par exemple, Staphylococcus. Heureusement, le développement de nombreux

microorganismes indésirables normalement trouvés dans les viandes et produits de volaille saumurées est

inhibé à des basses concentrations de sel.

Le saumurage moderne est basé sur les Nitrates et est très scientique. Achetez le sel de salage rose Weston

(02-0000-W) et suivez les instructions fournies pour vous assurer que vous faites correctement votre saucisse

maison.

BOYAUX

Weston offre une variété complète de boyaux. Le bon choix dépend de la préférence personnelle aussi bien

que le type de saucisse que vous désirez faire. Pour la plupart des saucisses, vos choix sont “naturel” ou

“collagène”. Ne laissez pas les noms vous tromper; les boyaux en collagène ne sont pas un produit synthétique.

Ils sont fabriqués à partir de peau de bœuf et d’autres tissus. Les boyaux en collagène sont uniformes en taille

et en texture et ne nécessitent presque aucune préparation. Les boyaux “Naturels” sont les intestins d’agneau,

de mouton, porc ou bœuf. Ils sont moins uniformes en taille et nécessitent une préparation. Il existe également

des boyaux non comestibles en matière breuse qui sont le plus couramment utilisés pour le saucisson d’été

et la mortadelle.

TYPES DE SAUCISSE

La plupart des saucisses se situent dans une des quatre catégories : Fraîche, Fumée, Cuite ou Sèche. Toutes

les saucisses, sauf les sèches, exigent l’entreposage frigorique. Il y a aussi une sous-catégorie de saucisses

fumées non cuites.

Parmi les saucisses fraîches et fumées non cuites, vous trouverez des arômes tels que la kielbasa ou saucisse

polonaise, saucisse italienne, saucisse petit déjeuner et beaucoup d’autres. Les saucisses fraîches aussi

bien que les saucisses fumées non cuites doivent être cuites avant de les manger et elles nécessitent aussi

l’entreposage frigorique.

Les saucisses fumées et cuites comprennent le salami, le saucisson de Bologne, les toujours aussi populaires

hot-dogs et de nombreux autres. La fumaison correcte nécessite un fumoir or appareil pour fumer les aliments.

Ceux-ci peuvent être simplement des structures faites maison à partir de bidonsWeston offre des fumoirs

extérieurs au propane dans une panoplie de grosseurs (41-0701-W, 41-0301-W, ou 41-0401-W). La plupart

des saucisses fumées sont réchauffées avant de servir. Un grand nombre de personnes pensent qu’une

saucisse fumée durera plus longtemps sans altération, mais cela n’est pas vrai. Les saucisses fumées doivent

être traitées de la même manière que les saucisses fraîches en termes d’entreposage.

Les saucisses sèches exigent le temps de transformation le plus long, puisqu’elles sont séchées à l’air pendant

une longue période de temps. Weston offre des fumoirs extérieurs au propane dans une panoplie de grosseurs

(41-0701-W, 41-0301-W, ou 41-0401-W). Les conditions sous lesquelles la viande est séchée sont très

exigeantes; la température, la durée et l’humidité doivent toutes être soigneusement surveillées pour avoir un

produit sûr et délicieux.

ENTREPOSAGE

Pour obtenir de meilleures saveurs, nous recommandons le scellage sous vide pour les saucisses fraîches,

puis de les entreposer dans le réfrigérateur (à court terme) ou au congélateur (à long terme). Weston fabrique

une variété d’appareils d’emballage sous vide. Demandez au détaillant où vous avez acheté cet appareil de

vous parler de sa sélection. Conservez les produits salés à sec dans du papier ou un autre emballage qui

respire, non réfrigéré.

INSTRUCTIONS EN FRANÇAIS

34

Page 35

Weston Brands LLC garantit à l’ACHETEUR AU DÉTAIL D’ORIGINE de ce produit contre tout défaut en matériau

et en main-d’œuvre pendant un (1) an a partir de la date d’achat à condition qu’il soit utilisé conformément aux

directives imprimées qui y sont jointes.

La Carte de Garantie, avec une copie du reçu original, doivent être reçus par Weston Brands LLC dans les trente

(30) jours à partir de la date d’achat pour que la garantie puisse s’appliquer. Le manque d’envoyer la Carte de

Garantie complètement remplie avec une copie du reçu original annulera la garantie.

Le produit doit être livré à ou expédié franco de port à Weston Brands LLC pour les services de garantie, soit dans

son emballage d’origine ou un emballage similaire offrant un degré de protection équivalent. Les dommages causés

par l’expédition ne sont pas la responsabilité de la société. Weston Brands LLC charge 35,00 $ par heure pour frais

de service. REMARQUE : Aucune réparation ne sera commencée sans l’autorisation du client. Les frais d’expédition

de retour seront ajoutés à la facture de réparation.

Avant de renvoyer le produit pour une réparation sous garantie, bien nettoyer le produit pour qu’il soit exempt de

toute particule alimentaire ou autres débris. Si l’acheteur ne respecte pas cette consigne, le produit lui sera renvoyé

sans avoir été réparé. Dans certains, la somme de 50 dollars sera facturée pour le nettoyage.

Weston Brands LLC réparera (ou à sa discrétion, remplacera) le produit sans frais, si à l’opinion de la société, il a

été prouvé être défectueux en matériau et en main d’œuvre dans la période de garantie.

Des remplacements neufs ou remis en état pour les pièces d’usine défectueuses seront fournis pendant un (1)

an à partir de la date d’achat. Les pièces de remplacement sont garanties pour le reste de la période de garantie

originale.

Pour les réparations non garanties, veuillez contacter le Service à la clientèle de Weston Brands LLC au numéro

sans frais 1-800-814-4895, du lundi au vendredi, de 8h00 à 17h00 ET (en dehors des États-Unis : 001-440-638-

3131) pour obtenir une Autorisation de retour d’article (Numéro RMA). Weston Brands LLC refusera tous les retours

qui ne contiennent pas ce numéro. NE PAS RENVOYER CET APPAREIL SANS L’AUTORISATION CORRECTE

DE Weston Brands LLC.

LIMITATIONS : La garantie est annulée si le produit est utilisé pour toute raison autre que pour laquelle il est

conçu. Le produit ne doit pas avoir été antérieurement modié, réparé, ou entretenu par quelqu’un autre que

Weston Brands LLC. Le cas échéant, le numéro de série ne doit pas être modié ou enlevé. Le produit ne doit pas

avoir été soumis à un accident en transit ou pendant qu’il est en la possession du client, mal utilisé, mal traité, ou

utilisé contrairement aux directives contenues dans le manuel d’utilisation. Ceci comprend la défaillance causée

par la négligence d’un entretien raisonnable et nécessaire, une tension de secteur incorrecte et des catastrophes

naturelles. Cette garantie n’est pas transférable et s’applique seulement aux ventes américaines et canadiennes.

À l’exception des cas où la loi en vigueur l’interdit, aucune autre garantie, expresse ou implicite, y compris les

garanties relatives au caractère adéquat pour la commercialisation ou un usage particulier, ne s’appliquera à ce

produit. Weston Brands LLC ne sera en aucun cas responsable des dommages indirects liés au dit produit et

Weston Brands LLC n’a aucune obligation ni responsabilité autre que celles expressément établies dans la présente,

et n’autorise aucun représentant ou autre personne à les assumer pour lui. Toutes garanties implicites applicables

sont aussi limitées à la période d’un (1) an de la garantie limitée.

Cette garantie couvre seulement le produit et ses pièces spéciques, pas les aliments ou autres produits traités

dans celui-ci. Weston n’est pas responsable des pièces manquantes ou endommagées pour les articles réduits/

en solde ou les articles naux de vente où le vendeur peut ne pas être en mesure de garantir l’ensemble de la

fonctionnalité ou l’intégralité de l’unité.

DÉCOUPEZ LE LONG DE LA LIGNE POINTILLÉE ET ENVOYEZ CETTE CARTE DE GARANTIE AVEC UNE

COPIE DE VOTRE REÇU D’ACHAT ORIGINAL À :

Weston Brands LLC / WARRANTY

20365 Progress Drive, Strongsville, OH 44149 USA

INFORMATION SUR LA GARANTIE

CONSERVEZ CETTE INFORMATION SUR LA GARANTIE POUR VOS DOSSIERS!

Nom du Client:

Adresse:

Province/Code postal/Région:

Numéro de téléphone:

Adresse de courrier électronique:

Date d’achat d’origine:

No de modèle du produit:

No de série (s’il y a lieu):

J’ai lu les informations relatives à la garantie. Initiales ici:

CARTE DE GARANTIE

ENVOYEZ CETTE CARTE DE GARANTIE AVEC UNE COPIE DE VOTRE REÇU D’ACHAT ORIGINAL À:

WESTON BRANDS LLC / WARRANTY, 20365 PROGRESS DRIVE, STRONGSVILLE, OH 44149 USA

Copie du reçu incluse

Page 36

ATTENTION!

PLEASE INSPECT THIS PACKAGE THOROUGHLY FOR MISSING PARTS OR ANY PRODUCT DAMAGE.

IF YOUR PRODUCT CONTAINS SHIPPING DAMAGE, PLEASE CONTACT RETAILER FOR ASSISTANCE.

For all other questions regarding product usage, missing parts, product damage, difculty or warranty activation,

please contact the Weston Brands Customer Service Team:

8:00 am to 5:00 pm ET, Monday thru Friday

CustomerService@WestonProducts.com

U.S. Residents Customer Service Line: 1-800-814-4895 (Outside U.S. Call: 001-440-638-3131)

Weston Brands LLC, Cleveland, Ohio 44149

WestonProducts.com

Please DO NOT return this item to the retailer before contacting

Weston Brands Customer Service.

SAVE THESE INSTRUCTIONS!

Refer to them often and use them to instruct others.

ATTENTION!

VEUILLEZ INSPECTER CET EMBALLAGE AVEC SOIN POUR Y DÉTECTER

TOUTE PIÈCE MANQUANTE OU ENDOMMAGÉE.

SI DES PIÈCES ONT ÉTÉ ENDOMMAGÉES PENDANT LE TRANSPORT, VEUILLEZ

COMMUNIQUER AVEC LE DÉTAILLANT POUR OBTENIR DE L’AIDE.

Pour toutes les autres questions concernant l’utilisation du produit, les pièces manquantes, les problèmes ou

l’activation de la garantie, veuillez communiquer avec l’équipe du service clientèle des produits Weston:

de 8:00 à 17:00 HNE, du lundi au vendredi.

CustomerService@WestonProducts.com

Numéro de téléphone du service clientèle pour les résidents des É.-U. : 1-440-638-3131

Numéro de téléphone à l’extérieur des É.-U. : 001-440-638-3131 Weston Brands LLC,

Weston Brands LLC, Cleveland, Ohio 44149

WestonProducts.com

Veuillez communiquer avec le service clientèle des produits Weston AVANT de retourner cet appareil au détaillant.

CONSERVER CES DIRECTIVES!

Veuillez les consulter fréquemment et les utiliser pour la formation.

¡ATENCIÓN!

Revise completamente el envase y compruebe que no falten partes o que algún producto esté dañado.

si el producto está dañado por el transporte, solicite asistencia al distribuidor.

Para todas aquellas preguntas referentes al uso del producto, partes faltantes, daño del producto, dicultad

o activación de la garantía, comuníquese con el equipo de servicio al cliente de weston Brands:

desde las 8:00 am hasta las 5:00 pm ET, de lunes a viernes

CustomerService@WestonProducts.com

Línea de Servicio al Cliente para Residentes de EE.UU.: 1.800.814.4895 (Fuera de EE.UU., llame al: 001-

1-440-638-3131) Weston Brands LLC, Cleveland, Ohio 44149

WestonProducts.com

NO devuelva este artículo al vendedor minorista antes de comunicarse con Servicio al Cliente de

Weston Brands.

¡GUARDE ESTAS INSTRUCCIONES!

Consulte estas instrucciones y úselas para enseñar sobre el uso de este producto a otras personas.

Loading...

Loading...