Page 1

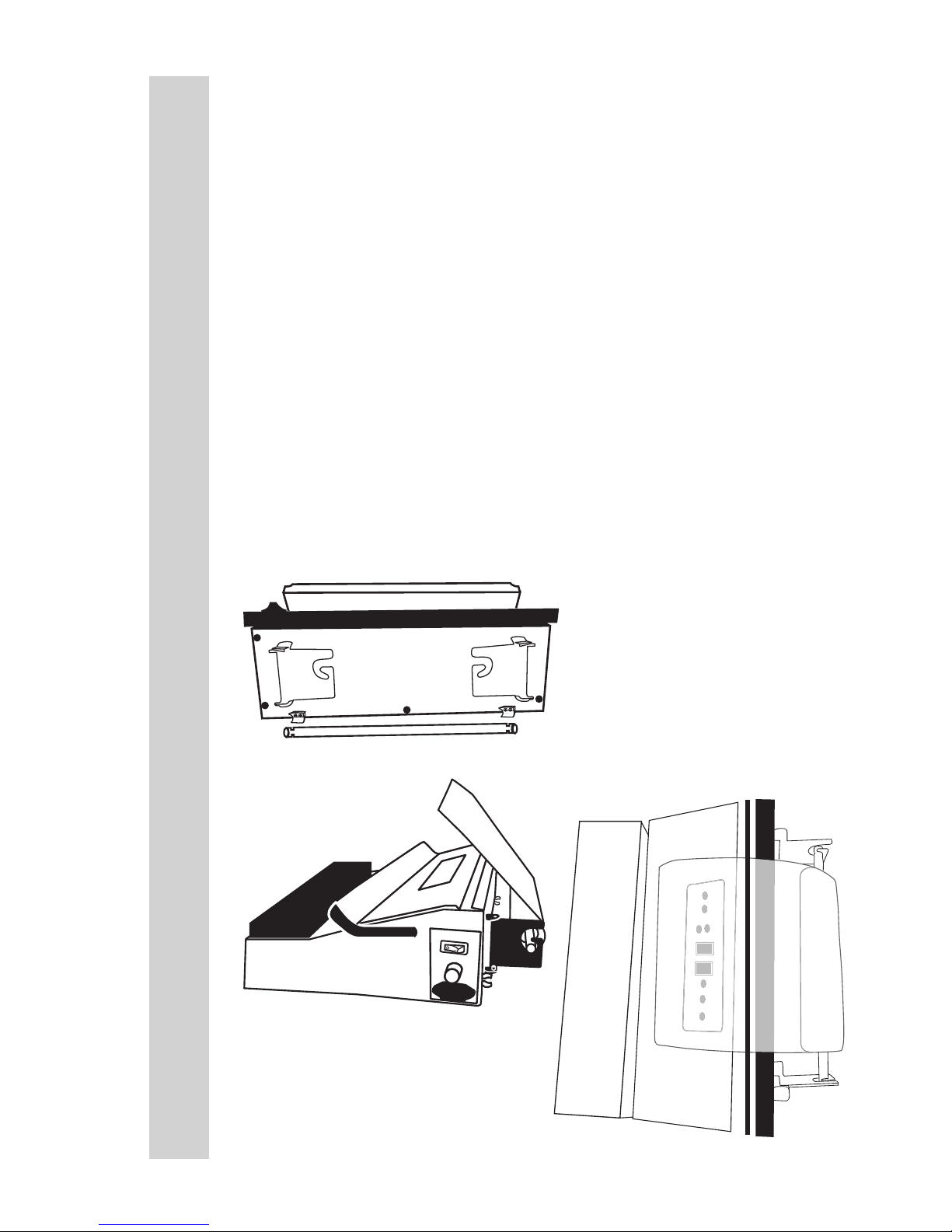

VACUUM SEALER

65-0601-W

DUE TO CONSTANT FACTORY IMPROVEMENTS, THE PRODUCT PICTURED MIGHT DIFFER

SLIGHTLY FROM THE PRODUCT IN THIS BOX. 020915

Page 2

TABLE OF CONTENTS / ÍNDICE / TABLE DES MATIÈRES

2

3

4-5

6

6

7

7

7

7

8

8

9

10

11

12

13

14

15-16

17

18

19

20

22

24

26-27

28

28

29

29

29

29

30

30

31

32

33

34

35

36

37-38

39

40

41

42

44

46

48-49

50

50

51

51

51

51

52

52

53

54

55

56

57

58

59-60

61

62

63

64

66

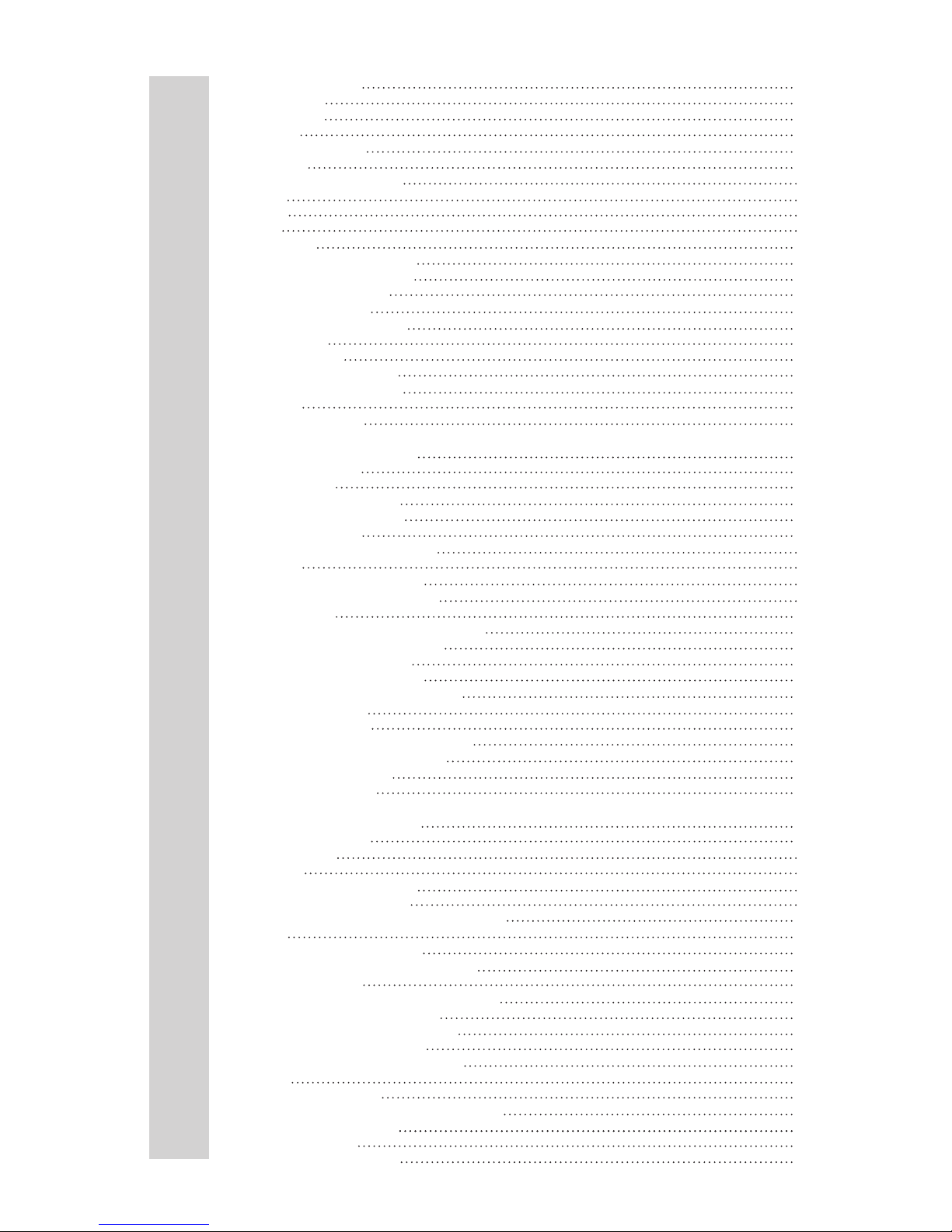

GENERAL SAFETY RULES

COMPONENT LIST

PROTECTIVE TAPE

COOLING FAN

VACUUM CHAMBER SEALS

LIMIT SWITCH

THERMAL OVERLOAD PROTECTOR

ASSEMBLY

GROUNDING

CLEANING

CONTROL PANEL

USING THE ROLL HOLDER & CUTTER

INITIAL TESTING OF THE BAG SEAL

AUTOMATIC MODE OPERATION

MANUAL MODE OPERATION

MAINTENANCE KIT INSTRUCTIONS

TROUBLESHOOTING

REPLACING THE FUSE

STORAGE LIFESPAN GUIDELINES

VACUUM PACKAGING GUIDELINES

FOOD SAFETY

WARRANTY INFORMATION

NORMAS GENERALES DE SEGURIDAD

LISTA DE COMPONENTES

CINTA PROTECTORA

VENTILADOR DE REFRIGERACIÓN

SELLOS DE LA CÁMARA DE VACÍO

INTERRUPTOR DE LÍMITE

PROTECTOR DE SOBRECARGA TÉERMICA

ENSAMBLADO

INSTRUCCIONES PARA HACER TIERRA

INSTRUCCIONES DE CUIDAD Y LIMPIEZA

PANEL DE CONTROL

UTILIZACIÓN DEL PORTAROLLOS Y EL CORTADOR

PRUEBA INICIAL DE SELLADO DE BOLSAS

OPERACIÓN EN MODO AUTOMÁTICO

FUNCIONAMIENTO EN MODO MANUAL

INSTRUCIONES DEL KIT DE MANTENIMIENTO

SOLUCIÓN DE PROBLEMAS

SUSTITUCIÓN DEL FUSIBLE

PAUTAS SOBRE LA VIDA EN ALMACENAMIENTO

LINEAMIENTOS PARA EMPACAR AL VACÍO

SEGURIDAD DE LOS ALIMENTOS

INFORMACIÓN DE GARANTÍA

IMPORTANTED RÈGLES DE SÉCURITÉ

DESCRIPTION DE LA PIÈCE

RUBAN PROTECTEUR

VENTILATEUR

JOINTS DE LA CHAMBRE SOUS VIDE

INTERRUPTEUR DE FIN DE COURSE

PROTECTION CONTRE LES SURCHARGES THERMIQUES

ASSEMBLY

INSTRUCTIONS DE MISE A LA TERRE

INSTRUCTIONS D’ENTRETIEN ET DE NETTOYAGE

PANNEAU DE COMMANDE

UTILISATION DU PORTE-ROULEAU ET DU COUPE-SAC

TEST INTIAL DU SCELLEMENT D’UN SAC

FONCTIONNEMENT EN MODE AUTOMATIQUE

FONCTIONNEMENT EN MODE MANUEL

DIRECTIVES POUR LA TROUSSE D’ENTRETIEN

DÉPANNAGE

REMPLACEMENT SU FUSIBLE

GUIDE DE CONSERVATION DES ALIMENTS EMBALLÉS

GUIDE D’EMBALLAGE SOUS VIDE

SÉCURITÉ ALIMENTAIRE

INFORMATION SUR LA GARANTIE

Page 3

1. ALWAYS DISCONNECT Vacuum

Sealer from power source before

servicing, changing accessories or

cleaning the unit.

2. Plug the Vacuum Sealer into a

standard 120 Volt, 60 Hz wall outlet.

Avoid using extension cords.

3. DO NOT USE the Vacuum Sealer

if the Power Cord, Plug or any other

parts are damaged. If the Power

Cord or the Vacuum Sealer is

damaged, call Customer Service.

DO NOT ATTEMPT TO REPLACE

THE CORD. Be sure to not allow

the Power Cord to drape into your

work area. Check that all parts are

operating properly, and perform the

intended functions. Check for any

other conditions that may affect the

operation.

4. NEVER use any accessories

or parts from other manufacturers.

Doing so will VOID YOUR

WARRANTY and may cause re,

electrical shock or injury.

5. Reduce risk of unintentional

starting. Make sure the Power

Switch is in the “OFF” position before

attaching to the power source.

6. KEEP FINGERS CLEAR of the

Heat Sealing Bar and Seal Bar Tape

AT ALL TIMES, these areas become

HOT. Doing so may cause serious

injury.

7. DO NOT take this appliance

apart; doing so will VOID YOUR

WARRANTY and may result in

personal injury.

GENERAL SAFETY RULES

READ AND FULLY UNDERSTAND ALL INSTRUCTIONS AND WARNINGS

PRIOR TO USING THIS UNIT. YOUR SAFETY IS MOST IMPORTANT!

FAILURE TO COMPLY WITH PROCEDURES AND SAFE GUARDS MAY

RESULT IN SERIOUS INJURY OR PROPERTY DAMAGE. REMEMBER:

YOUR PERSONAL SAFETY IS YOUR RESPONSIBILITY!

8 TO PROTECT AGAINST RISK

OF ELECTRICAL SHOCK: DO NOT

SUBMERGE THE VACUUM SEALER

INTO WATER OR LIQUID. BE

SURE THE VACUUM SEALER IS

DISCONNECTED FROM THE POWER

SOURCE BEFORE CLEANING. Follow

the “Cleaning Instructions” in this booklet.

NEVER rinse appliance Vacuum Sealer

under tap.

9. NEVER LEAVE THE VACUUM

SEALER UNATTENDED. Be safe,

DISCONNECT the Vacuum Sealer from

power source before leaving the work

area. Close supervision is necessary

when any appliance is used near children.

This appliance is NOT to be used by

children.

10. DO NOT let the Power Cord hang

over edge of work surface.

11. Be sure the Vacuum Sealer is on

a stable work surface. Be sure all the

Vacuum Sealer Feet are stable.

12. DO NOT use the Vacuum Sealer

outdoors.

13. DO NOT use the Vacuum Sealer

while under the inuence of drugs,

medications or alcohol.

14. The Vacuum Sealer is ONLY

intended to be used with VACUUM

BAGS. For best results, only use the

recommended vacuum bags. DO NOT

USE HOUSEHOLD BAGS! Any other

uses of the Vacuum Sealer, other than

the uses described in this booklet, could

potentially damage the appliance and

void the warranty!

SAVE THESE INSTRUCTIONS

3

ENGLISH INSTRUCTIONS

Page 4

1

2

3

4

5

6

7

8

9

10

11

12

Vacuum Lid

16

Power

Panel

Upper

Housing

Lower Housing

Vacuum

Chamber

I

O

13

14

ENGLISH INSTRUCTIONS

4

Page 5

COMPONENT LIST

If any components of this unit are broken, the unit does not operate properly or you

need a replacement instruction manual, visit us on the web at

WestonProducts.com

Or call Weston Products LLC Toll Free at 1-800-814-4895

Monday thru Friday 8:00am-5:00pm ET. Outside the U.S. call 001-440-638-3131

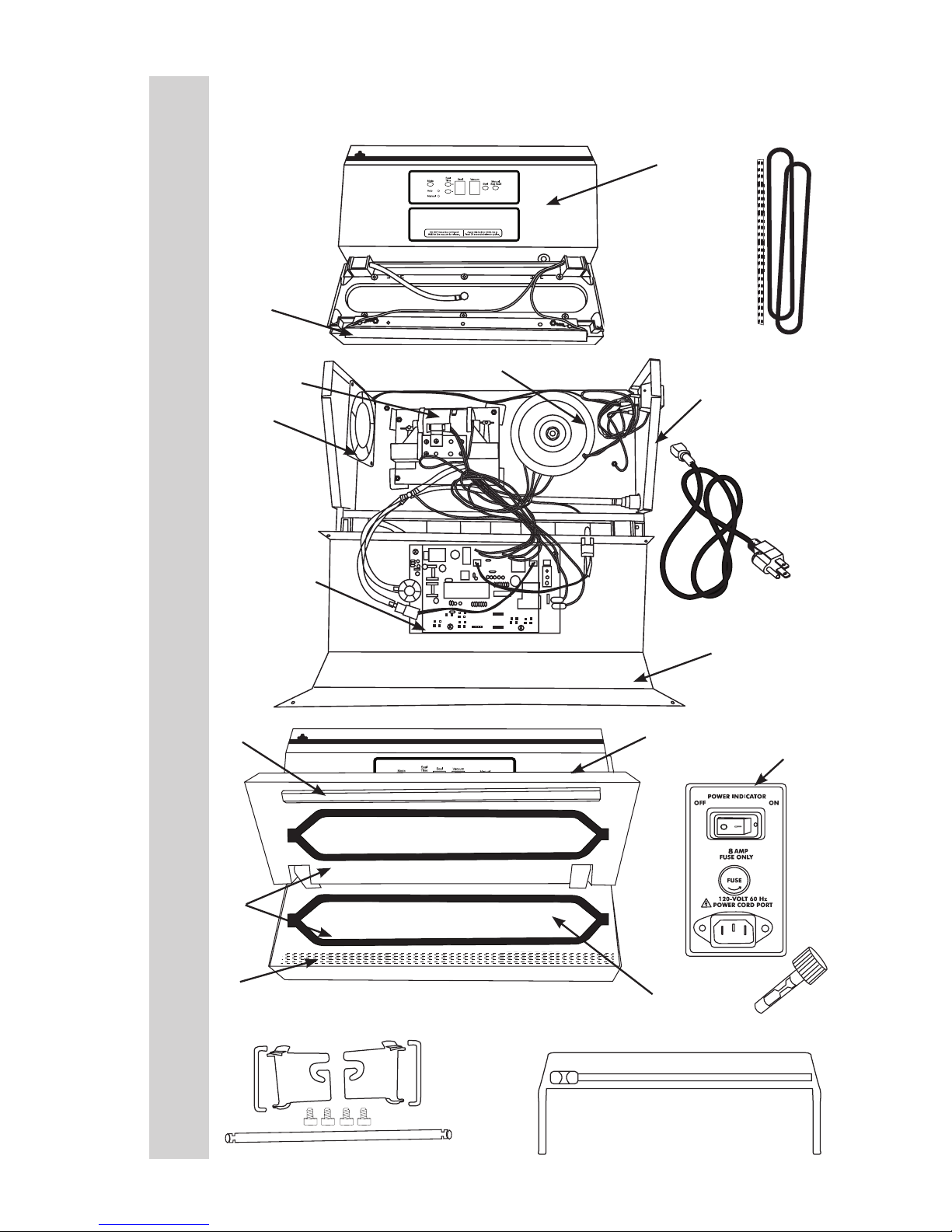

DIAGRAM NUMBER PART DESCRIPTION PART NUMBER

1 SEAL WIRE 08-0627

2 SEAL BAR INSULATOR 08-0625

3 POWER CORD 08-0402

4 FUSE HOLDER 08-0604

5 8-AMP FUSE 08-0605

6 VACUUM PUMP 08-0639

7 TRANSFORMER 08-0641

8 FAN 08-0643

9 CIRCUIT BOARD 65-0638

VACUUM SENSOR 65-0643

10 SEAL BAR TAPE (BLACK) SEE MAINTENANCE

KIT

11 CHAMBER SEAL (2) SEE MAINTENANCE

KIT

12 VACUUM SEALER MAINTENANCE KIT: SEAL

BAR TAPE (BLACK) CHAMBER SEALS(2)

65-0701

13 ROLL HOLDER KIT INCLUDES: ROLL HOLDER

ROD ROD HOLDING ARMS (2) BRACKETS WITH

SCREWS (2 BRACKETS, 4 SCREWS)

65-0639

14 BAG CUTTER KIT INCLUDES: BLADE BLADE

HOLDER

65-0640

15 BLADE 65-0641

16 CONTROL PANEL 65-0642

ENGLISH INSTRUCTIONS

5

Page 6

The Vacuum Sealer has an Internal Cooling Fan that runs whenever

the unit is plugged in and turned on. To save energy, turn the unit

“OFF” and unplug the Power Cord when not in use.

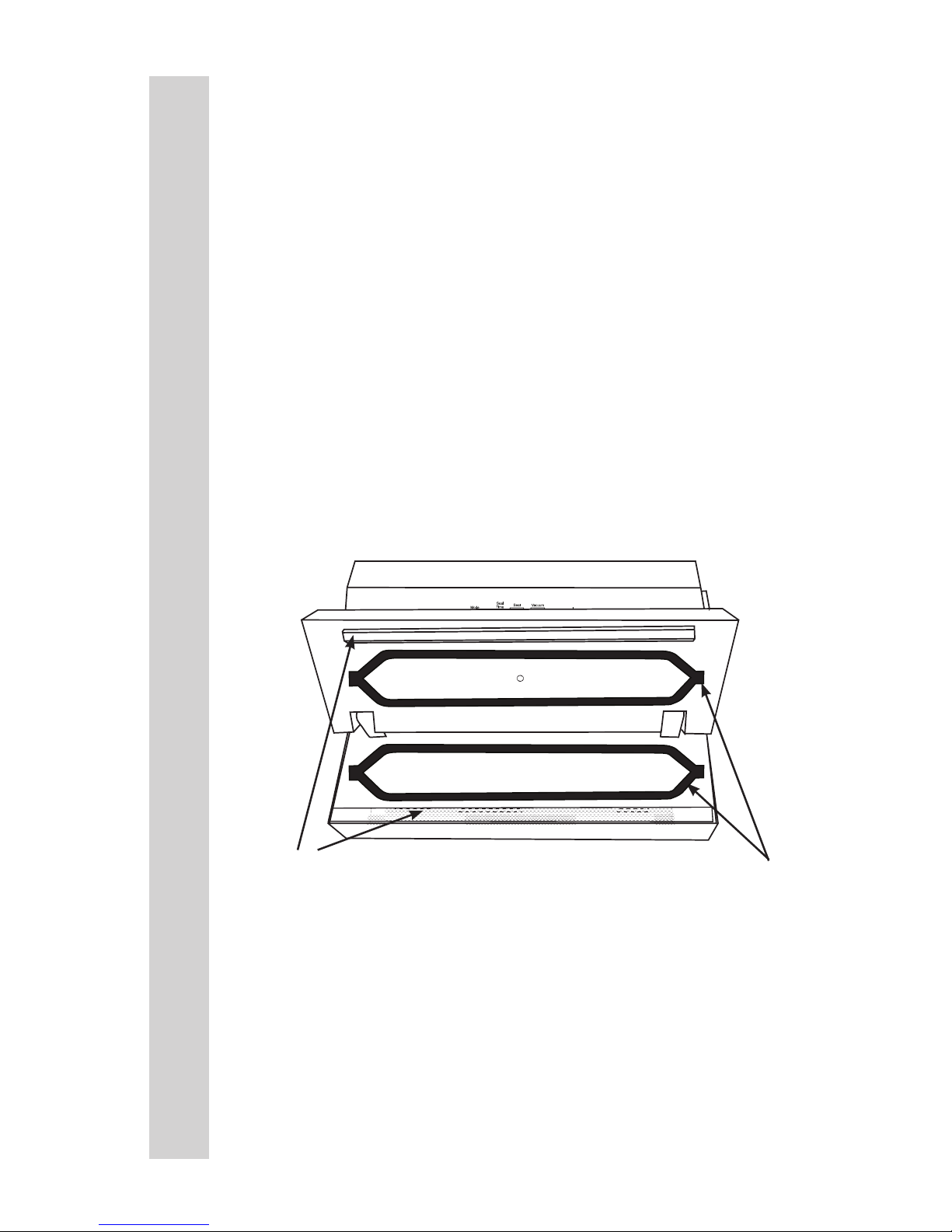

SEAL BAR TAPE

DO NOT

REMOVE!

The Seal Bar Heating Element is covered with Seal Bar Tape to

protect vacuum bags during sealing (Figure 1). DO NOT remove the

Seal Bar Tape. See the “Maintenance Kit” section of this manual for

information on replacing the Seal Bar Tape, if necessary.

OVAL VACUUM CHAMBER SEALS

DO NOT REMOVE!

BEFORE YOU START BAG SEALING

Before using the Vacuum Sealer, familiarize yourself with the bag sealing

functions. A vacuum bag is sealed when the Seal Bar Heating Element is

activated and heats the bag to its melting point, which then permanently

welds the bag layers together, sealing the bag shut. This appliance comes

pre-set from the factory to engage the Seal Bar Heating Element for 3

seconds. This is the correct amount of time required to fully seal Vacuum

Bags. Different brands of vacuum bags may require slightly more or slightly

less sealing time.

Test seal a couple of bags to be sure that the Seal Time is set properly. The

Seal Time may need to be increased (+) or decreased (-) to optimally seal a

bag.

ENGLISH INSTRUCTIONS

6

PROTECTIVE TAPE

There is one factory installed

strip of Seal Bar Tape on the Vacuum Sealer.

DO NOT REMOVE THE TAPE!

FIGURE 1

COOLING FAN

Page 7

There are two factory-installed Oval Vacuum Chamber Seals on the Vacuum

Sealer. When the Vacuum Lid is closed and downward force applied, they

form an airtight seal so the Vacuum Chamber can be evacuated.

The Oval Vacuum Chamber Seals may wear over time and require

replacement. See the “Maintenance Kit” section of this manual for

information on replacing the Oval Vacuum Chamber Seals, if necessary.

THERMAL OVERLOAD PROTECTOR

The Vacuum Sealer will automatically shut down if it overheats. If this occurs,

turn the unit off and open the Vacuum Lid. Resume normal operation after

the unit cools or about 20 minutes.

To help prevent overheating, wait at least 20 seconds between cycles with the

Vacuum Lid open. Avoid touching the Seal Bar Tape. The Seal Bar Tape

will remain hot for a brief period of time after each sealing cycle.

LIMIT SWITCH

The Vacuum Sealer is equipped with a switch to prevent actuation of the Seal

Bar Heating Element in manual mode when the Vacuum Lid is open. When

the Vacuum Lid is closed, heat made by the Seal Bar Heating Element is

absorbed by the vacuum bag and Vacuum Lid Seal.

When the Vacuum Lid is open, there is no means to dissipate the heat and

unit damage may occur.

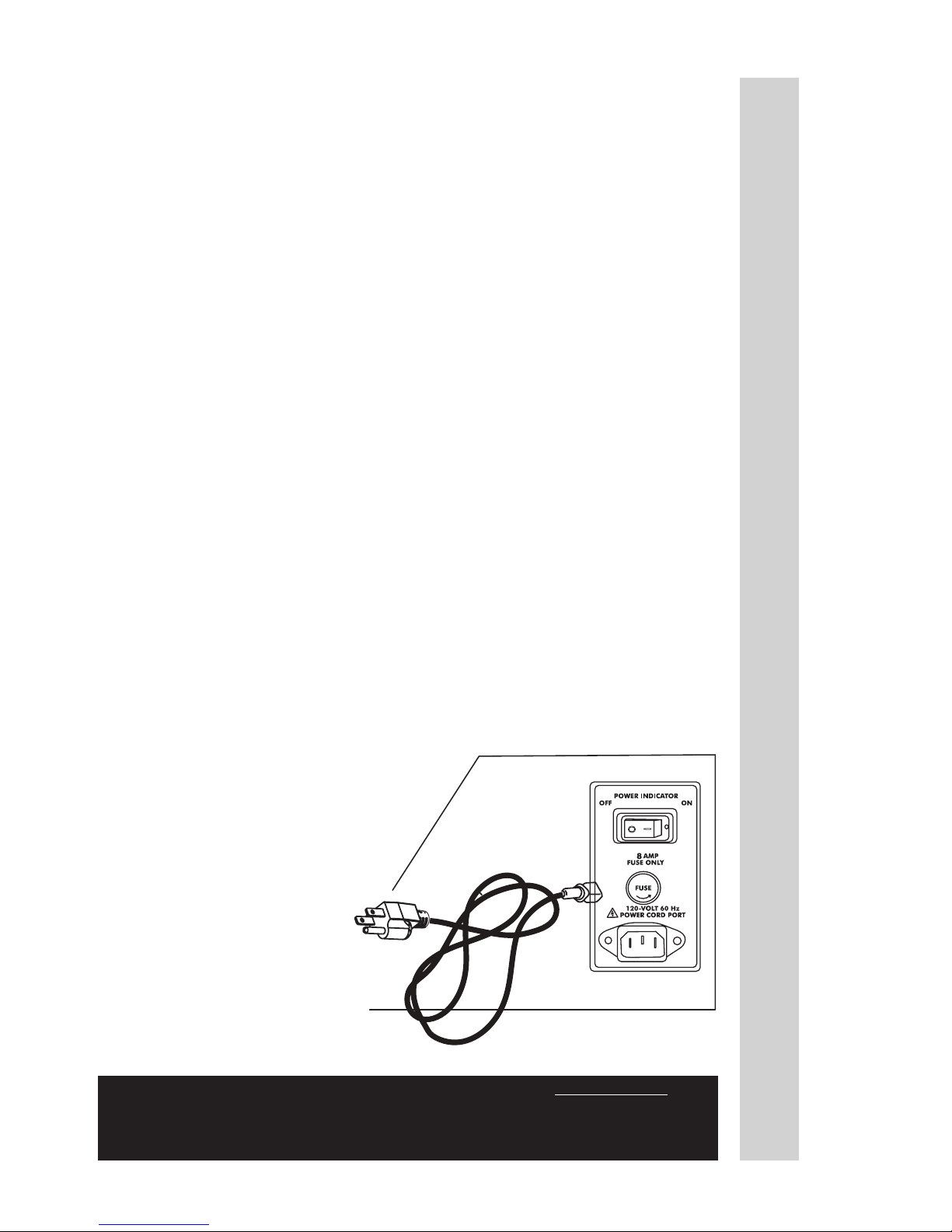

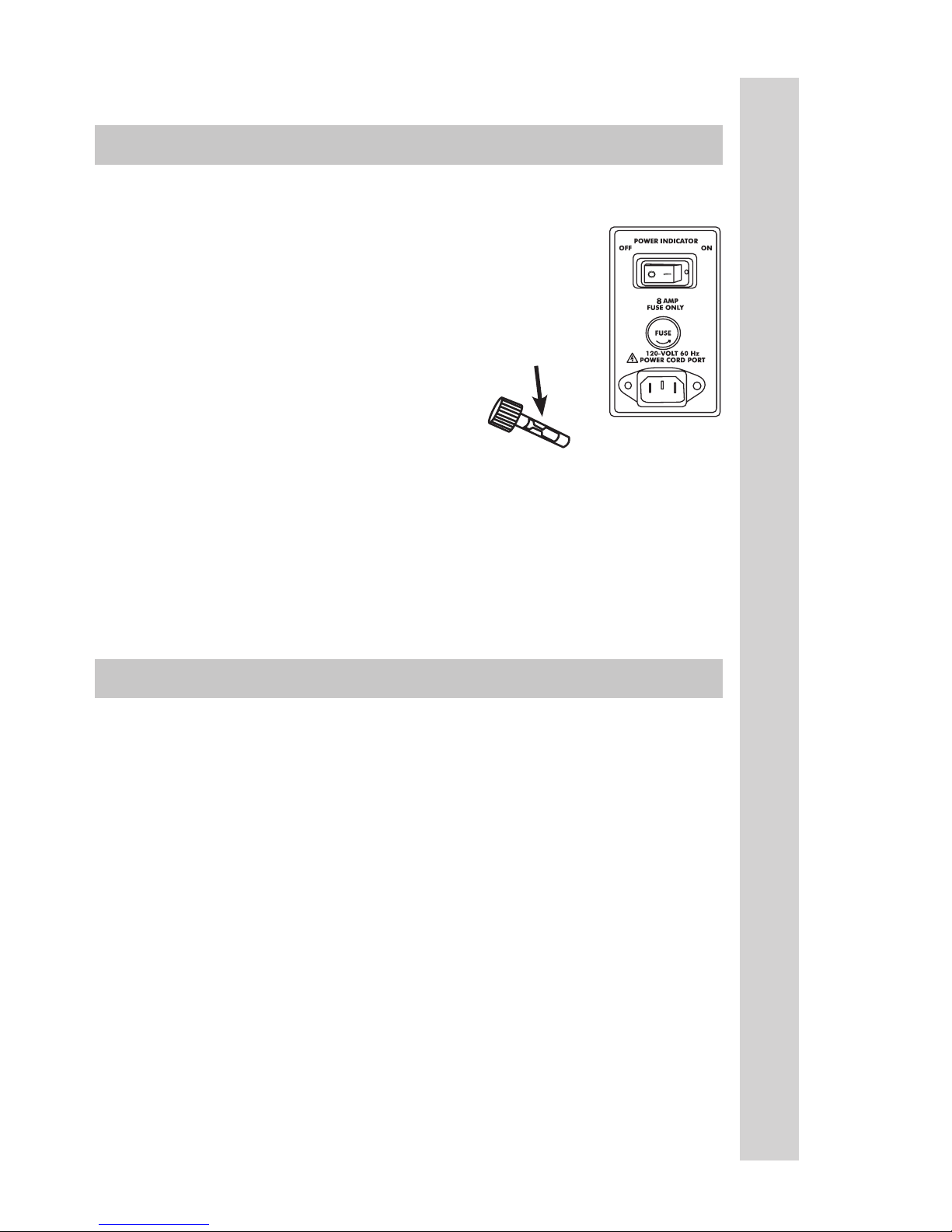

ASSEMBLY

• Place the Vacuum Sealer on

a at, dry surface.

• Plug the female end of the

Power Cord into the Power

Supply Port on the right side of

the appliance (Figure 2).

• Plug the male end of the

Power Cord into a standard,

grounded 120-volt household

electrical outlet. DO NOT

attempt to modify the plug to t

into an unsuitable outlet.

FIGURE 2

I

O

NOTE: The Vacuum Sealer is ONLY intended to be used with VACUUM BAGS. For

best results, only use the recommended vacuum bags with an embossed or mesh lining.

DO NOT USE HOUSEHOLD BAGS! Any other uses of the Vacuum Sealer, other than

the uses described in this booklet, could potentially damage the appliance and void the

warranty!

ENGLISH INSTRUCTIONS

7

VACUUM CHAMBER SEALS

Page 8

· NEVER IMMERSE the Vacuum Sealer in water or other liquid.

· Make sure the Vacuum Sealer has completely cooled before cleaning it.

· Wipe clean all outside surfaces including the Plastic Vacuum Chamber and

Vacuum Lid with a damp cloth or paper towel. Most household spray cleaners

are safe to use. Avoid spraying directly into the vent on the left side of the

unit. DO NOT use abrasive cleansers!

· Be careful while cleaning not to peel or damage the strip of Seal Bar Tape

covering the Seal Bar Heating Element.

· Dry all surfaces and close the Vacuum Lid before storing the Vacuum

Sealer.

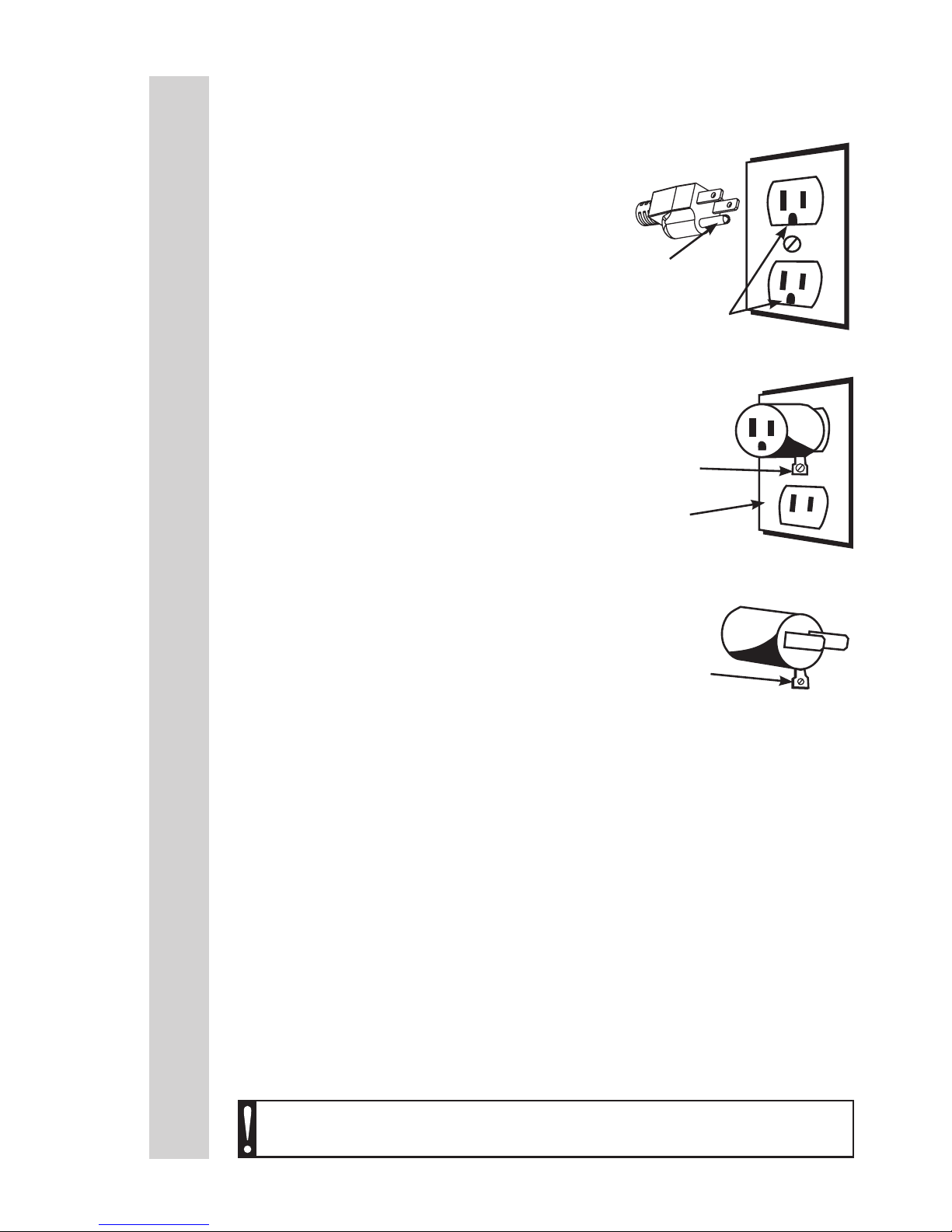

GROUNDING

This appliance must be grounded while in use

to protect the operator from electrical shock.

The appliance is equipped with a 3-conductor

cord and a 3-prong grounding type plug to t

the proper grounding-type receptacle. The

appliance has a plug that looks like Figure

3. An adapter, Figure 4, should be used

for connecting Figure 3 plugs to two-prong

receptacles. The grounding tab which extends

from the adapter must be connected to a

permanent ground such as a properly grounded

outlet box as shown in Figure 5 using a metal

screw.

EXTENSION CORDS

Use only 3-wire extension cords which have

3-prong grounding-type plugs and a 3-pole

cord connector that accepts the plug from the

appliance. Use only extension cords having

an electrical rating not less than the rating of

the appliance. Do not use damaged extension

cords. Examine extension cord before using and

replace if damaged. Do not abuse extension

cord and do not yank on any cord to disconnect.

Keep cord away from heat and sharp edges.

FIGURE 3

FIGURE 4

FIGURE 5

Circuit

Grounding

Conductor

Grounding

Prong

Metal

Grounding

Screw

Cover of

Grounded

Outlet Box

Grounding

Means

AA2220

GROUNDING INSTRUCTIONS

WARNING! Before cleaning, assembling or disassembling the

appliance, make sure the appliance is OFF and the PLUG IS REMOVED

FROM THE OUTLET/POWER SOURCE!

CLEANING INSTRUCTIONS

ENGLISH INSTRUCTIONS

8

Page 9

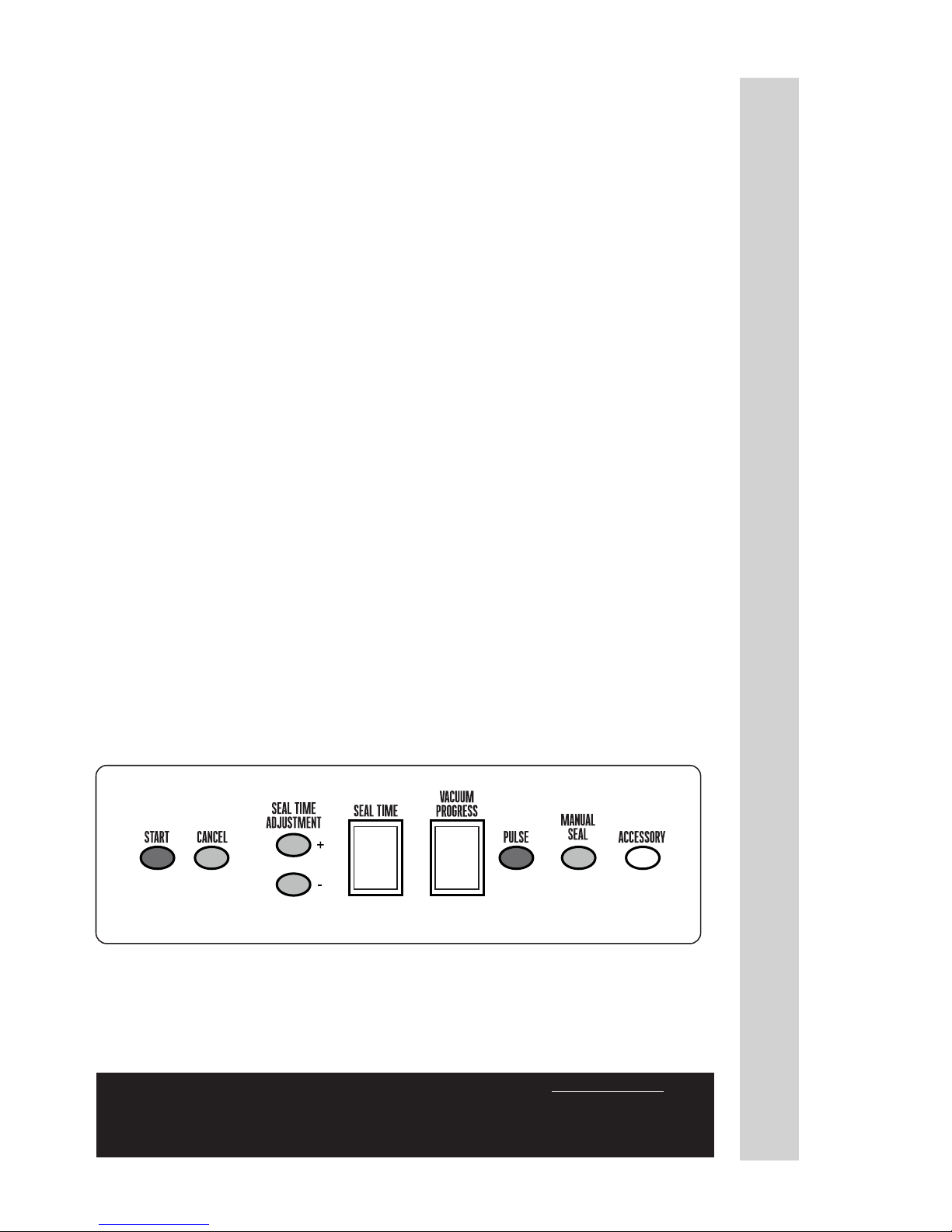

· Start Button: The Start Button starts the 2-Piston Vacuum Pump, which

engages the air evacuation process.

· Cancel Button: This button is used to stop the vacuum cycle at any time.

· Seal Time + and - Buttons: The Seal Time Button adjusts the number of

seconds that the Sealing Bar will apply heat to create the bag’s seal. The

optimal time for different brands of bags can be adjusted using the Plus (+) or

Minus (-) Buttons. See the “Bag Sealing” section in this booklet for further

information on sealing vacuum bags.

· Seal Window: The numeric LED Seal Window indicates the number of

seconds that the Sealing Bar will be activated to apply heat to the bag that

creates the seal. Once the Seal Bar is activated, the display will countdown

to “0”. See the “Bag Sealing” section in this booklet for further information on

sealing vacuum bags.

· Vacuum Window: The numeric LED Vacuum Window indicates the level of

vacuum that the Vacuum Sealer has attained. The display will count up from

“0” to “9”.

·

Pulse Button: The pulse button is for sealing liquids or delicate items, lettnig

you control the vacuum process. When the bag is prepared, press the pulse

button as many times as necessary until you have eliminated the desired

amount of air. Press the manual seal button to seal the bag.

· Manual Bag Seal Button: This button will start the Seal Bar at any time in

Manual Mode. More information about the Manual Mode can be found in the

“Manual Mode” section of his booklet.

· Accessory Button: Press the Accessory Button when using vacuum

canisters (sold separately) to vacuum and seal items stored in a canister.

CONTROL PANEL

NOTE: The Vacuum Sealer is ONLY intended to be used with VACUUM BAGS. For

best results, only use the recommended vacuum bags with an embossed or mesh lining.

DO NOT USE HOUSEHOLD BAGS! Any other uses of the Vacuum Sealer, other than

the uses described in this booklet, could potentially damage the appliance and void the

warranty!

ENGLISH INSTRUCTIONS

9

Page 10

1. To create bags using the roll holder, remove the roll holder rod from the

cilps at the back of the vacuum sealer (FIGURE 6).

2. Slide the rod through the center opening of the roll (will hold bags up to

11” wide).

3. Fold the roll holder arms out and rest the rod in the slots on the roll holder

arms, carefully lining up the notches in the rod with the slots in the arms.

4. It is easier to cut bags from the roll when the bags are rolled over the roll

(as opposed to under the roll) (FIGURE 7).

5. Move the bag cutter towards the lid and pull the vacuum bag over the

cutter slot until you have reached the desired length.

6. Move the bag cutter back over the top of the bag roll, making sure the

blade is to one side.

7. Slide the blade across the bag roll to cut your roll into your custom bag

size (FIGURE 8).

USING THE ROLL HOLDER & CUTTER

FIGURE 6

P

O

W

E

R

I

N

D

I

C

ATO

R

O

N

O

F

F

8 A

M

P

F

U

S

E

O

N

LY

FIGURE 7

FIGURE 8

ENGLISH INSTRUCTIONS

10

Page 11

1. ALWAYS allow the sealing bar to cool for approximately 20 seconds

between bags. Leave the Vacuum Lid OPEN between uses, this allows the

Heating Element to cool more quickly between bags.

2. Place one end of the bag onto the Sealing Bar, leaving about 2” (5 cm) of the

empty part of the bag beyond the inside edge of the Sealing Bar.

3. Be sure not to cover the Vacuum Port with the bag. Covering the Vacuum

Port prevents the proper vacuuming of air from the bag.

4. Close the Vacuum Lid while holding the bag in place. Press down on both

sides of the lid to lock the lid in place. You will hear each side “click” when it is

secured. NOTE: If both sides are NOT securely locked, the lid will NOT release

automatically. To resolve this issue, press down on both sides of the lid twice to

release the locks.

5. Press the Start Button engaging the Vacuum Pump (the Vacuum Pump must be

on for the Seal Bar to heat up).

6. Press the Manual Seal Button immediately after the Vacuum Pump starts.

(Press down on the Vacuum Lid to contact the Sealing Bar.)

7. After the Seal Window counts down to zero (0) the unit will automatically

release the vacuum and enable the Vacuum Lid to open.

8. Remove the bag and inspect the seal. The seal should appear smooth and

consistent all the way across the bag. The seal SHOULD NOT melt through

the bag at any point. Be sure there are no creases or wrinkles that may allow

air to leak into the bag. A properly sealed bag will not pull apart, the bag must

be cut open.

9. Do not form side seals on the bags, the sides are already sealed.

10. If the seal is good, proceed with vacuum packaging. Otherwise:

.

If the seal is melted through the bag trim off the bad seal with scissors and

adjust the Seal Time Down (-) in one second increments and try the test

process again.

.

If the seal has not fully welded the bag closed, trim off the bad seal with

scissors and adjust the Seal Time Up (+) in one second increments and try

the test process again.

INITIAL TESTING OF THE BAG SEAL

NOTE: The Vacuum Sealer is ONLY intended to be used with VACUUM BAGS. For

best results, only use the recommended vacuum bags with an embossed or mesh lining.

DO NOT USE HOUSEHOLD BAGS! Any other uses of the Vacuum Sealer, other than

the uses described in this booklet, could potentially damage the appliance and void the

warranty!

WARNING! Before cleaning, assembling or disassembling the

appliance, make sure the appliance is OFF and the PLUG IS REMOVED

FROM THE OUTLET/POWER SOURCE!

ENGLISH INSTRUCTIONS

11

Page 12

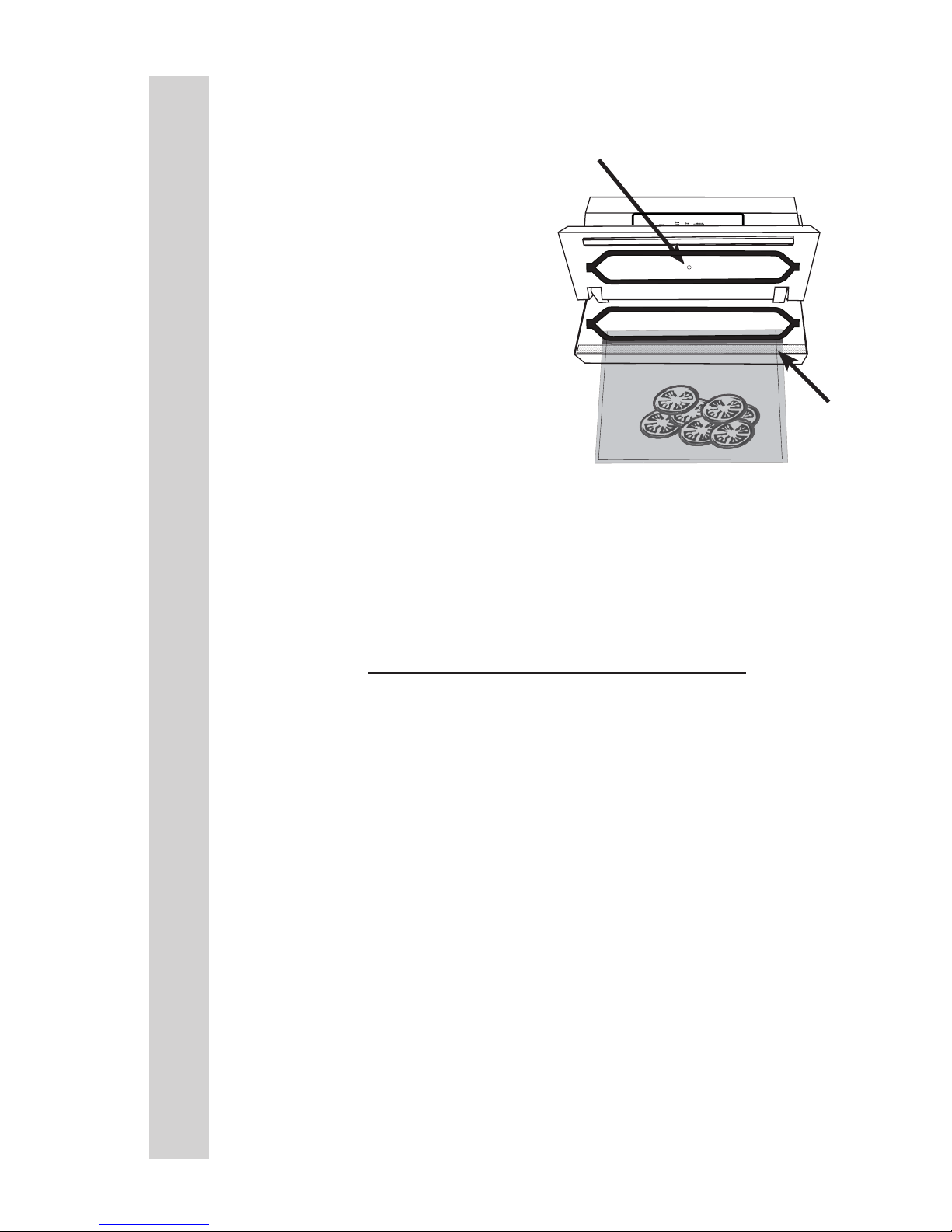

BEFORE ATTEMPTING VACUUM

PACKAGING BE SURE THAT THE

VACUUM SEALER IS SET UP IN

ACCORDANCE WITH ALL OF THE

SAFETY PRECAUTIONS LISTED IN

THIS BOOKLET.

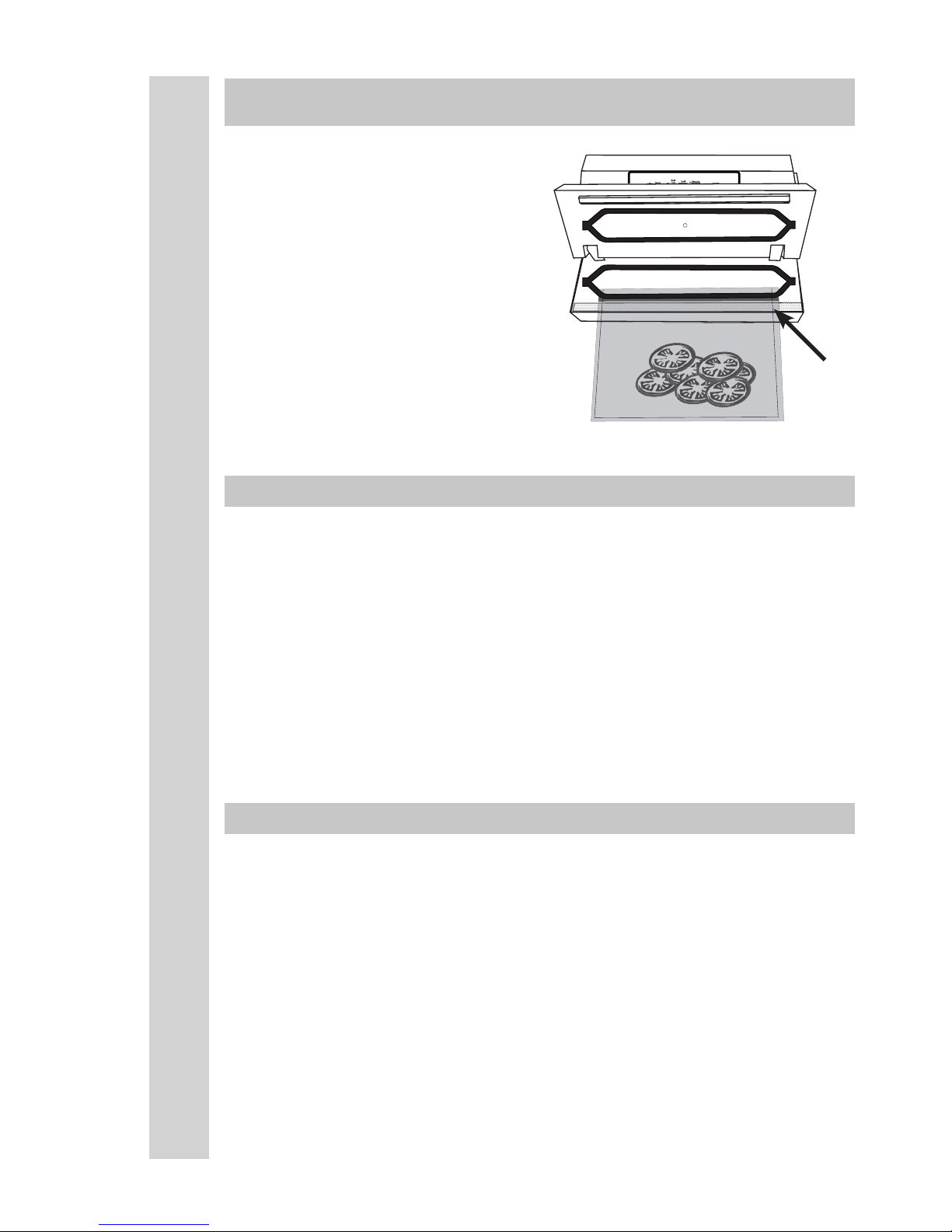

1. Place the items to be vacuum

sealed into a vacuum bag. Allow at

least 2” (5 cm) at the open end of

the bag in order to create enough

seal space. Be sure not to cover the

Vacuum Port (FIGURE 9).

2. Close the Vacuum Lid while holding

the bag in place. Press down on both

sides of the lid to lock the lid in place.

You will hear each side “click” when it is

secured. NOTE: If both sides are NOT

securely locked, the lid will NOT release

automatically. To resolve this issue, press down on both sides of the lid twice to

release the locks.

3. Press and release the Start Button. The 2-Piston Vacuum Pump will begin

removing air from the bag while the LED Vacuum Window begins to count up.

You may need to apply light pressure to the Vacuum Lid during the countup process. The LED Vacuum Window will count up starting at the number

“1” and going thru to the number “9”, before automatically engaging the bag

sealing process. These numbers represent stages, not seconds.

4. Once the LED Vacuum Window displays the number “9”, the sealing

process will begin by counting down from your chosen setting to “0” on the

LED Seal Window.

5. Once the LED Seal Window has reached “0”, the Vacuum Sealer will

automatically stop the 2-Piston Vacuum Pump and release the vacuum

pressure moments later. DO NOT ATTEMPT TO PULL THE VACUUM LID

OPEN BEFORE THE VACUUM HAS BEEN RELEASED, SEVERE DAMAGE

TO THE SEALING BAR WILL RESULT.

AUTOMATIC MODE OPERATION

FIGURE 9

Leave 2”

Seal

Space

Vacuum Port

ENGLISH INSTRUCTIONS

12

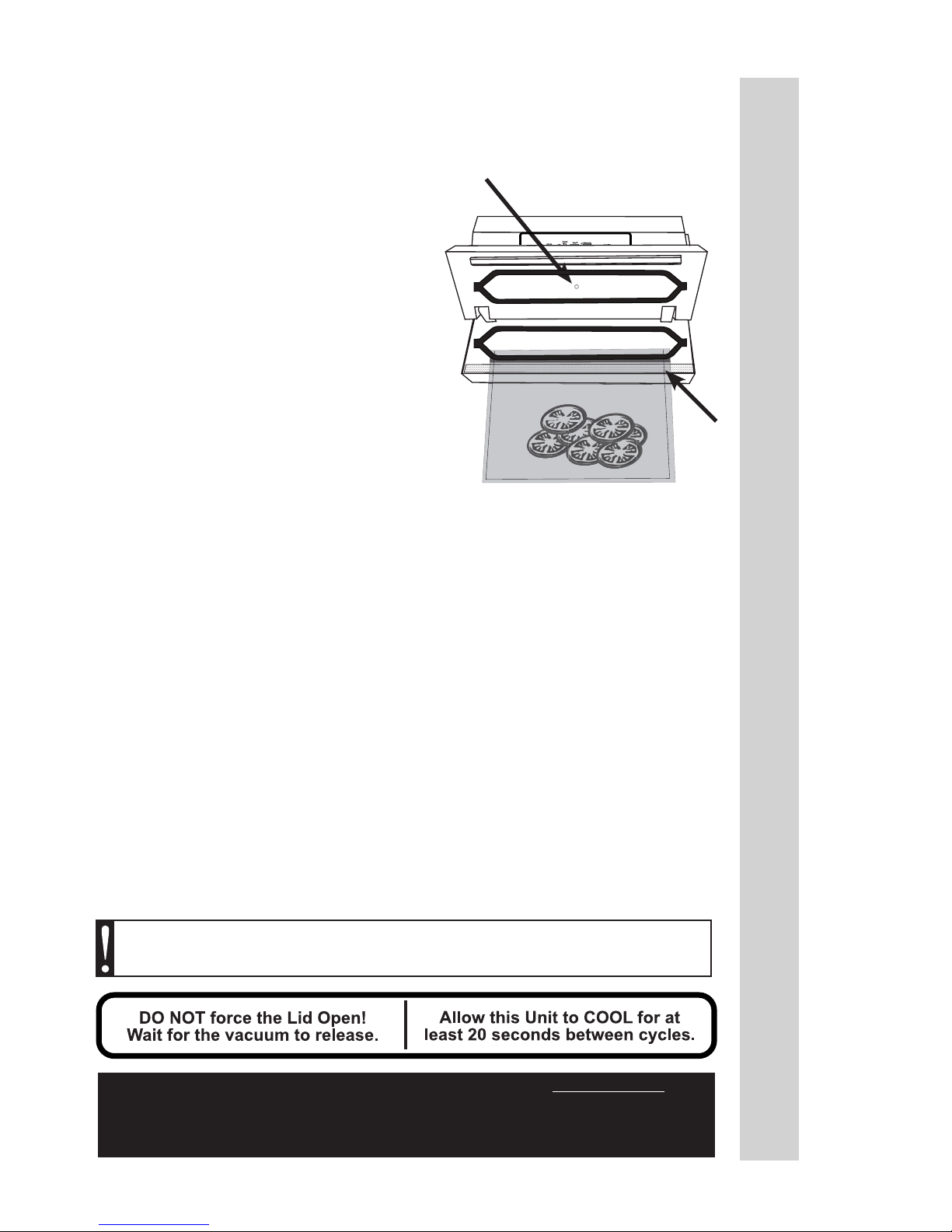

Page 13

BEFORE ATTEMPTING VACUUM

PACKAGING, BE SURE THAT THE

VACUUM SEALER IS SET UP IN

ACCORDANCE WITH ALL OF THE

SAFETY PRECAUTIONS LISTED IN THIS

BOOKLET.

1. Place the items to be vacuum sealed into

a vacuum bag. Allow at least 2” (5 cm) at

the open end of the bag in order to create

enough seal space. Be sure not to cover

the Vacuum Ports (Figure 10).

2. Close the Vacuum Lid while holding the bag

in place. Press down on both sides of the lid

to lock the lid in place. You will hear each side

“click” when it is secured. NOTE: If both sides

are NOT securely locked, the lid will NOT

release automatically. To resolve this issue,

press down on both sides of the lid twice to

release the locks.

3. While monitoring the vacuum bag, press and release START Button.

The 2-Piston Vacuum Pump will begin removing air from the bag. When

the desired level of air has been evacuated from the bag, press and

release the Manual Bag Seal Button. It will start the sealing bag process.

Note: You may need to apply light pressure to the Vacuum Lid during this

process.

Note: It requires some vacuum pressure in the bag to get good seal for the

bag.

4.Once the LED Seal Window has reached “0”, the Vacuum Sealer will

automatically stop the Vacuum Pump and release the vacuum pressure

moments later. DO NOT ATTEMPT TO PULL THE VACUUM LID OPEN

BEFORE THE VACUUM HAS BEEN RELEASED, SEVERE DAMAGE TO

THE SEALING BAR WILL RESULT.

FIGURE 10

Leave 2”

Seal

Space

Vacuum Port

NOTE: The Vacuum Sealer is ONLY intended to be used with VACUUM BAGS. For

best results, only use the recommended vacuum bags with an embossed or mesh lining.

DO NOT USE HOUSEHOLD BAGS! Any other uses of the Vacuum Sealer, other than

the uses described in this booklet, could potentially damage the appliance and void the

warranty!

WARNING! Before cleaning, assembling or disassembling the

appliance, make sure the appliance is OFF and the PLUG IS REMOVED

FROM THE OUTLET/POWER SOURCE!

ENGLISH INSTRUCTIONS

13

MANUAL MODE OPERATION

Page 14

Some parts of the Vacuum Sealer may need replacing after repeated use. The

Vacuum Sealer Maintenance Kit will be necessary for the Vacuum Sealer to

properly function.

REPLACING THE OVAL VACUUM CHAMBER SEALS:

1. Turn “OFF” the Vacuum Sealer and remove the Power Cord from the electrical

outlet.

2. Make sure the unit is completely cool.

3. Open the Vacuum Lid.

4. Remove the Oval Vacuum Chamber Seal from the groove on the underside of

the Vacuum Lid.

5. Remove the Oval Vacuum Chamber Seal from the groove in the Plastic

Vacuum Chamber.

6. Set a new Oval Vacuum Chamber Seal on the groove in the Plastic Vacuum

Chamber. Work the seal into the groove with your ngers until done.

7. Position a new Oval Vacuum Chamber Seal into the groove in the Vacuum

Lid. Work the seal into the groove with your ngers until done.

REPLACING THE SEAL BAR TAPE:

1. Turn “OFF” the Vacuum Sealer and remove the Power Cord from the electrical

outlet.

2. Make sure the unit is completely cool.

3. Open the Vacuum Lid.

4. Pick at either end of the Seal Bar Tape covering the Seal Bar Heating Element

with a ngernail until it lifts slightly. Grasp the loose end and slowly pull

the Seal Bar Tape back over itself until fully removed.

5. Remove the backing from a new strip of Seal Bar Tape. Be careful not to

allow the Seal Bar Tape to contact anything including itself while the adhesive

side is exposed.

6. Hold one end of the Seal Bar Tape in each hand. Stick the left end of the Seal

Bar Tape to the at area on the Plastic Vacuum Chamber just left of the Seal

Bar Heating Element. Apply the Seal Bar Tape from left to right over the Seal

Bar Heating Element until done. Make sure there are no wrinkles or folds in the

Seal Bar Tape once applied. The Seal Bar Tape should fully cover the Seal Bar

Heating Element.

MAINTENANCE KIT INSTRUCTIONS

ENGLISH INSTRUCTIONS

14

Page 15

TROUBLESHOOTING

Q: NOTHING HAPPENS WHEN THE POWER BUTTON IS PRESSED!

1. Make sure that the Power Cord is not

damaged in any way.

2. Be sure that the female end of the Power

Cord is plugged completely into the Power

Supply Port of the Vacuum Sealer, and that

the male end of the Power Cord is firmly

plugged into the wall outlet (Figure 11).

3. If the Vacuum Sealer is properly plugged

in, and the Power Button still does not work,

check the Fuse, located above the Power

Supply Port, on the right side of the Vacuum

Sealer. Twist the Fuse Holder off, then look

at the clear tube to see

if the Fuse is darkened. If the Fuse is

darkened, it will need to be replaced with a

standard 8-Amp Fuse.

4. If the Fuse does not need to be replaced, you will need to be sure the

electrical wall outlet is properly working. Plug in another appliance to see if

that appliance works from the wall outlet. USE ONLY TIME-DELAY FUSES.

Q: MY VACUUM SEALER SHUT OFF AND WILL NOT START AGAIN.

1. The Thermal Overload Protector may have been activated. In this

case, allow the Vacuum Sealer to cool by opening the Vacuum Lid for

approximately 20 minutes. Be sure to leave the Vacuum Lid open between

bag sealing.

2. Be sure that the female end of the Power Cord is plugged completely into

the Power Supply Port of the Vacuum Sealer, and that the male end of the

Power Cord is firmly plugged into the wall outlet.

3. If the Vacuum Sealer is properly plugged in, and the Power Button still

does not work, check the Fuse, located above the Power Supply Port, on

the right side of the Vacuum Sealer. Twist the Fuse Cap off, then look at the

clear tube to see if the Fuse is darkened. If the Fuse is darkened, it will need

to be replaced with a standard 8-Amp Fuse (Figure F).

4. If the Fuse does not need to be replaced, you will need to be sure the

electrical wall outlet is properly working. Plug in another appliance to see if

that appliance works from the wall outlet.

FIGURE 11

Check to see if the

Fuse is darkened.

I

O

ENGLISH INSTRUCTIONS

15

Page 16

Q: THE BAG SEAL PULLS APART.

1. If the seal has not fully welded the bag closed, trim off the bad seal with

scissors and adjust the Seal Time Up (+) in one second increments and try the

test process again.

2. The Vacuum Sealer is only intended to be used with vacuum sealing

bags. For best results, Weston Vacuum Bags should be used. DO NOT USE

HOUSEHOLD BAGS with the Vacuum Sealer.

3. The seal of the bag may be incomplete. If the seal has a crease in it, or if

a liquid or powder has been trapped between the layers of the bag, the layers

may not have been welded together properly. Cut the seal off and wipe the

inside of the bag clean. Then, try to vacuum seal the package again. When

sealing a moist or powdery food, insert a paper towel into the bag above the

food before vacuum packaging. The paper towel will prevent the food from

interfering with the seal. See the “Vacuum Packaging Guidelines” in this

booklet for helpful tips.

FIGURE 12

Q: THE VACUUM PUMP STARTS, BUT NO AIR IS BEING

REMOVE FROM THE VACUUM BAG.

1. For the best results, always use

Weston brand vacuum bags.

2. Be sure that the bag is inserted

properly. Be sure not to cover the

Vacuum Port opening (Figure 12).

3. The bag may have a leak. If there

is a leak in the bag, air will be pulled

into the bag from the outside. Check

for tears or punctures. If you are

using a bag that was made from a roll

of material, double check that the seal

on the end of the bag is welded closed.

Q: THE SEALING BAR MELTS THROUGH THE BAG.

1. The Vacuum Sealer is only intended to be used with vacuum sealing

bags. For best results, Weston Vacuum Bags should be used. DO NOT USE

HOUSEHOLD BAGS with the Vacuum Sealer.

2. Check the condition of the Seal Bar Tape strips. Replace if needed.

3. Open the Vacuum Lid and allow the sealing bar to cool for 5-10 minutes.

Always leave the Vacuum Lid open between bags, and allow at least 20 seconds

between cycles.

4. The Sealing Bar time may need to be lowered. Adjust the Seal Time Down

(-) in one second increments and try the test process again. Refer to the “Initial

Testing of the Bag Seal” instructions in this booklet for more information.

Leave 2”

Seal

Space

ENGLISH INSTRUCTIONS

16

Page 17

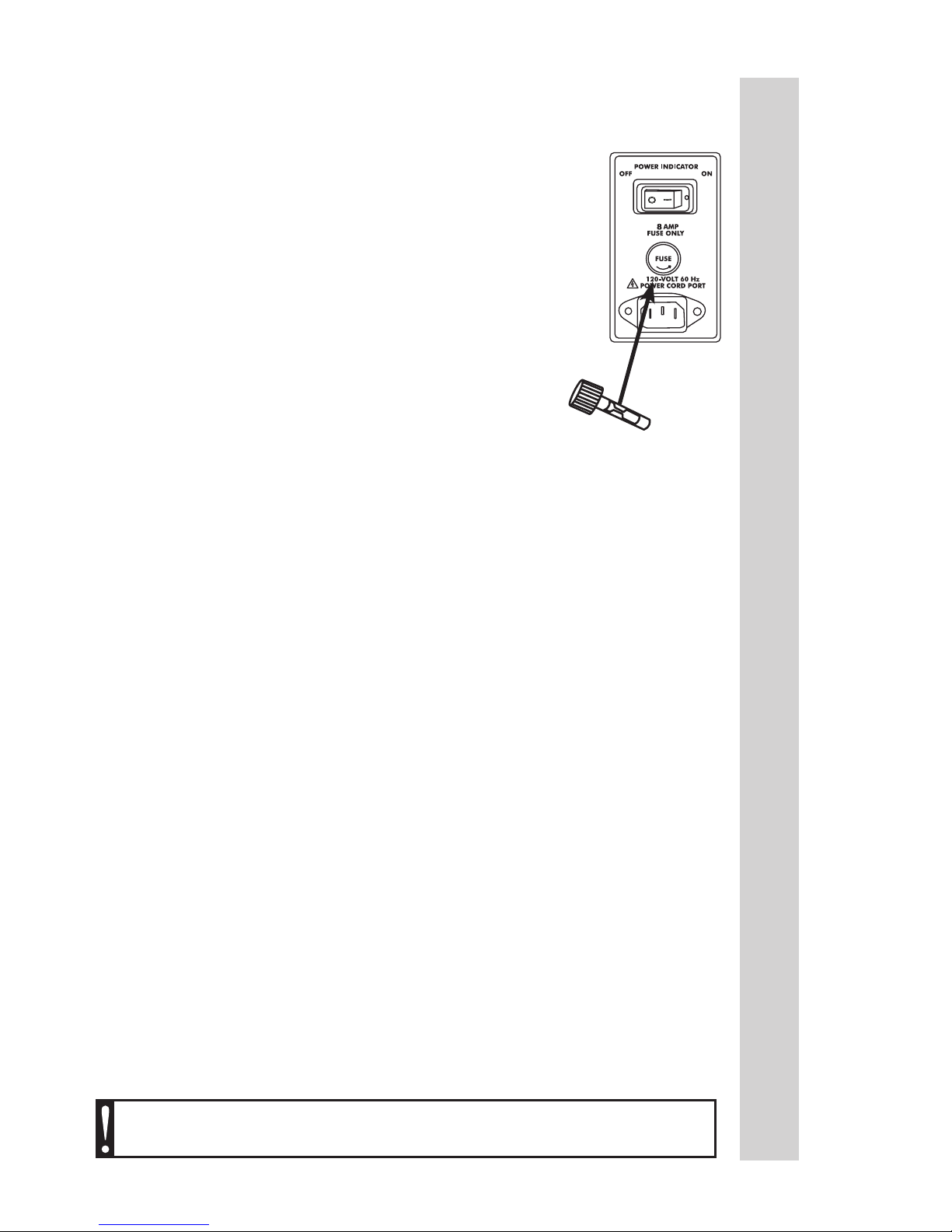

REPLACING THE FUSE

If the Vacuum Sealer does not operate when it is plugged

in and turned on, try any or all of the following:

1. Make sure the Fuse is not blown. The Fuse is located

on the right side of the unit directly above the Power

Cord Port. Turn “OFF” and unplug the Vacuum Sealer.

Twist off and remove the Fuse Holder. Remove and

check the Fuse. The thin metal band in the center of the

Fuse should be clean and unbroken. If it is burned and/or

broken, replace it with a new Fuse (8 Amp). Replace the

Fuse Holder.

2. Make sure the Connector at the end of the Power Cord

is plugged completely into the Power Cord Port.

3. Make sure the Power Cord is not damaged. DO

NOT use a damaged Power Cord. Call the Customer

Service line for information on part replacement.

4. Try connecting the Power Cord Plug to another

electrical outlet.

WARNING! Before cleaning, assembling or disassembling the Vacuum Sealer,

make sure the Vacuum Sealer is OFF and the PLUG IS REMOVED FROM THE

OUTLET/POWER SOURCE!

I

O

FIGURE 13

ENGLISH INSTRUCTIONS

17

Page 18

. IMPORTANT NOTE: Vacuum packaging is NOT a substitute for refrigeration.

Vacuum packed perishable foods still require refrigeration.

. NEVER thaw frozen foods at room temperature. Thaw frozen foods in a

refrigerator or microwave oven.

. In general, the colder the temperature at which foods are stored, the longer the

shelf life.

. Handle vacuum sealer bags with care. Avoid damaging them. A damaged bag

will not hold a seal.

. Only use information in the following chart as a guideline! Refer to the “Vacuum

Packaging Guidelines” and “Food Safety” sections of this manual. Actual storage

life spans may vary. Check all food for spoilage before use.

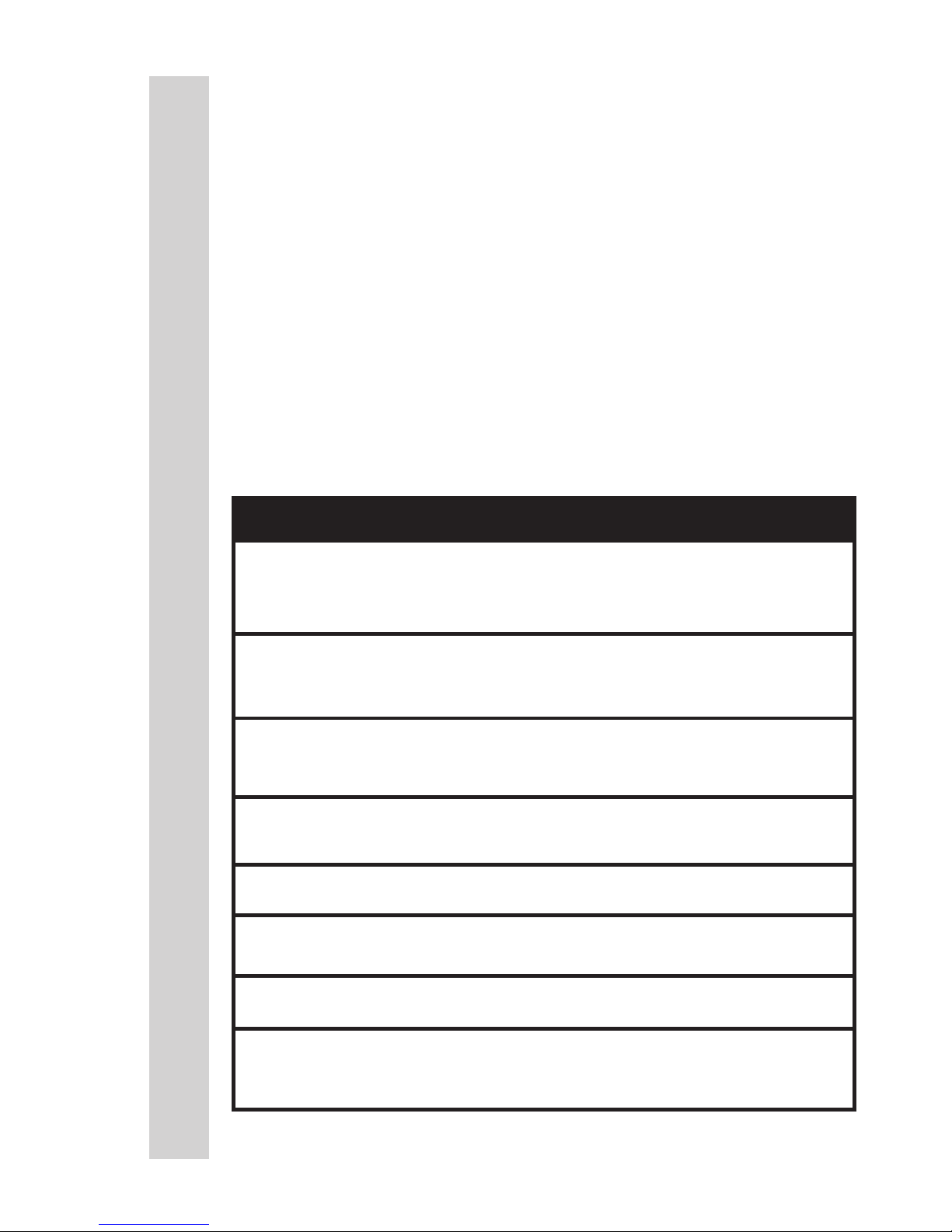

STORAGE LIFESPAN GUIDELINES

FOOD STORAGE NORMAL VACUUM

TYPE LOCATION LIFE PACKED

LIFE

LARGE CUTS OF MEAT Freezer 6 months 2-3 years

GROUND MEAT Freezer 4 months 1 year

FISH Freezer 6 months 2 years

For best results, freeze meats & sh for 1-2 hours before vacuum packing to help prevent moisture

and juices from interfering with the seal of the vacuum bag.

COFFEE BEANS Room temperature 4 weeks 16 months

COFFEE BEANS Freezer 6-9 months 2-3 years

FLOUR, RICE, SUGAR Room Temperature 6 months 1-2 years

For best results, powder or grainy substances should be kept in their original container or bag, then placed in a

vacuum bag for sealing to prevent interfering with the seal of the vacuum bag.

BERRIES strawberries, raspberries, blackberries Refrigerator 1-3 days 1 week

BERRIES cranberries, huckleberries, blueberries Refrigerator 3-6 days 2 weeks

To prevent berries from being crushed by the vacuum sealer, it is best to freeze item before packing. Spread the berries out on a

cookie sheet to allow them to freeze individually. Berries frozen in a large block will be difcult to vacuum seal due to the

many small air pockets that would form between the berries.

CHEESE Refrigerator 1-2 weeks 4-8 months

If vacuum packed cheese is used often, make sure the vacuum bag is long enough to allow for repeated sealing. For shredded

cheese, place a paper towel inside the vacuum bag, on top of the cheese to prevent the cheese from being

sucked into the Vacuum Sealer or interfering with the sealing of the bag.

COOKIES, CRACKERS, BREADS with periodical opening Room Temperature 1-2 weeks 3-6 weeks

Freeze soft airy foods for 1-2 hours prior vacuum packing, to retain shape & texture.

PASTA, GRAINS, DRIED BEANS Room Temperature 6 months 1-1/2 years

NUTS Room Temperature 6 months 2 years

Dried foods with sharp edges should be wrapped in a paper towel or other matter to prevent the sharp edges from puncturing the vacuum bag.

LETTUCE Refrigerator 3-6 days 2 weeks

Wash & thoroughly dry leafy vegetables before vacuum packaging.

VEGETABLES Freezer 8 months 2 1/2 years

To maximize the taste of vegetables, blanch them before vacuum packaging. Blanching cooks the vegetables very briey, sealing

in the avor, color and texture, leaving the vegetables cooked but still crisp. Vegetables can be blanched in boiling water in the microwave,

most vegetables only require 2-3 minutes (corn on the cob requires 6-11 minutes). Then immerse the vegetables in cold water to

stop the cooking process. Dry the vegetables, then vacuum pack.

Table adapted from Dr. G.K.York, Dept. of Food Science & Tech, U of California, Davis.

ENGLISH INSTRUCTIONS

18

Page 19

Powdery Items: When vacuum sealing powdery items, like our, it is best to keep

them in their original packaging before putting them into the vacuum bags.

Sharp or Pointed Items: When vacuum sealing sharp or pointy items, it is best

to cushion the edges so they do not puncture the bag during the vacuum process.

YEAST & BACTERIA

For best results in extending the life of foods, it is important to vacuum package

foods that are fresh. Once food has begun to deteriorate, vacuum packaging may

only slow the deterioration process. Vacuum sealing cannot completely prevent

the growth of mold. Other disease causing microorganisms can still grow in low

oxygen environments and may require further measures to be eliminated.

Yeast: The development of yeast can be slowed by refrigeration and completely

stopped by freezing food at 0oF (-18oC). Yeast causes fermentation, which will give

food an identiable smell.

Bacteria: Freezing cannot eliminate bacteria, but their growth can be stopped.

The growth of bacteria can be easily identied by an offensive odor and sometimes

a slimy texture. Some bacteria, like the one that causes botulism, can grow in low

oxygen environments and cannot be detected by smell, taste or color. Botulism is

very rare, but dangerous. Be sure that all foods are stored and cooked properly

before eating.

COOKING & HEATING

.

Before microwaving vacuum-packed foods, puncture or open the bag to allow

hot airto escape while heating.

.

Vacuum-packed foods can be thawed or cooked in boiling water.

.

Vacuum-packed perishable foods like meats, vegetables and cheeses must

be refrigerated (at or below 34oF (1.1oC)) or frozen, especially acid-free or

low-acid foods.

This is important because although vacuum packaging removes most air from

the bag, bacteria like Clostridium Botulinum, which produces a toxin that causes

the illness botulism, is anaerobic and grows in the absence of oxygen. Refrigeration

and freezing slow the growth of bacteria. It is also important to maintain a clean

working area to reduce the likelihood of packaging harmful bacteria with the food.

VACUUM PACKAGING GUIDELINES

ENGLISH INSTRUCTIONS

19

Page 20

There are basic rules to follow when handling food.

They are COOK, SEPARATE, CLEAN, and CHILL.

COOK

It’s crucial to cook food to a safe internal temperature to destroy bacteria that is present.

The safety of hamburgers and other foods made with ground meat has been receiving a lot

of attention lately, and with good reason. When meat is ground, the bacteria present on the

surface is mixed throughout the ground mixture. If this ground meat is not cooked to at least

160oF to 165oF (71oC to 74oC), bacteria will not be destroyed and there’s a good chance you

will get sick.

Solid pieces of meat like steaks and chops don’t have dangerous bacteria like E. coli on the

inside, so they can be served more rare. Still, any beef cut should be cooked to an internal

temperature of at least 145oF (63oC) (medium rare). The safe temperature for poultry is 165oF

(75oC) and solid cuts of pork should be cooked to 145oF (63oC).

SEPARATE

Foods that will be eaten uncooked and foods that will be cooked before eating MUST

ALWAYS be separated. Cross-contamination occurs when raw meats or eggs come in

contact with foods that will be eaten uncooked. This is a major source of food poisoning.

Always double-wrap raw meats and place them on the lowest shelf in the refrigerator so

there is no way juices can drip onto fresh produce. Then use the raw meats within 1-2 days

of purchase, or freeze for longer storage. Defrost frozen meats in the refrigerator, not on the

counter.

When grilling or cooking raw meats or sh, make sure to place the cooked meat on a clean

platter. Don’t use the same platter you used to carry the food out to the grill. Wash the utensils

used in grilling after the food is turned for the last time on the grill, as well as spatulas and

spoons used for stir-frying or turning meat as it cooks.

Make sure to wash your hands after handling raw meats or raw eggs. Washing hands with

soap and water, or using a pre-moistened antibacterial towelette is absolutely necessary after

you have touched raw meat or raw eggs. Not washing hands and surfaces while cooking is a

major cause of cross-contamination.

CLEAN

Wash your hands and work surfaces frequently when you are cooking. Washing with soap

and warm water for at least 15 seconds, then dry with a paper towel.

CHILL

Chilling food is very important. The danger zone where bacteria multiply is between 40oF and

140oF (4oC and 6oC). Your refrigerator should be set to 40oF (4oC) or below; your freezer should

be 0oF (-17oC) or below. Simple rule: serve hot foods hot, cold foods cold. Use chang dishes

or hot plates to keep food hot while serving. Use ice water baths to keep cold foods cold. Never

let any food sit at room temperature for more than 2 hours - 1 hour if the ambient temperature

is 90oF (32oC) or above. When packing for a picnic, make sure the foods are already chilled

when they go into the insulated hamper. The hamper won’t chill food - it just keeps food cold

when properly packed with ice. Hot cooked foods should be placed in shallow containers and

immediately refrigerated so they cool rapidly. Make sure to cover foods after they are cool.

NOTE: Special considerations must be made when using venison or other wild game, since it

can become heavily contaminated during eld dressing. Venison is often held at temperatures

that could potentially allow bacteria to grow, such as when it is being transported. Refer to

the USDA Meat and Poultry Department for further questions or information on meat and

food safety.

FOOD SAFETY

20

ENGLISH INSTRUCTIONS

Page 21

Page 22

Weston Brands LLC warrants to the ORIGINAL RETAIL PURCHASER of this product that if operated in accordance

with the printed instruction accompanying it, then for a period of 2 year from the date of purchase, the product shall be free

from defects in material and workmanship.

The Warranty Card, along with a copy of the original receipt, must be received by Weston Brands LLC within 30 days

from purchase date for the warranty to apply. Failure to send the completely lled out Warranty Card, along with a copy of

the original receipt, will void the warranty.

The product must be delivered to or shipped freight prepaid to Weston Brands LLC for warranty services, in either

its original packaging or similar packaging affording an equal degree of protection. Damage due to shipping is not the

responsibility of the company. Weston Brands LLC charges a $35.00 per hour bench charge. NOTE: No repairs will

be started without the authorization of the customer. The return shipping cost to the customer will be added to the repair

invoice.

Prior to returning the product for Warranty Repair, the product must be thoroughly cleaned and free from any food

particles or other debris. Failure of the purchaser to comply with this standard will result in the unit being returned without

repair. In some cases, a $50 cleaning surcharge may apply.

Weston Brands LLC will repair (or at its discretion, replace) the product free of charge, if in the judgment of the

company, it has been proven to be defective as to seller’s labor and material, within the warranty period.

New or rebuilt replacements for factory defective parts will be supplied for two (2) year from the date of purchase.

Replacement parts are warranted for the remainder of the original warranty period.

For non-warranty repairs, contact Weston Brands LLC’s Customer Service at 1-800-814-4895 M-F 8am-5pm ET

(outside of the United States 001-440-638-3131) to obtain a Return Merchandise Authorization Number (RMA Number).

Weston Brands LLC will refuse all returns that do not contain this number. DO NOT RETURN THE UNIT WITHOUT

PROPER AUTHORIZATION FROM WESTON BRANDS LLC.

LIMITATIONS: The warranty is void if the product is used for any purpose other than that for which it is designed.

The product must not have been previously altered, repaired, or serviced by anyone else other than Weston Brands

LLC. If applicable, the serial number must not have been altered or removed. The product must not have been subjected

to accident in transit or while in the customer’s possession, misused, abused, or operated contrary to the instructions

contained in the instruction manual. This includes failure caused by neglect of reasonable and necessary maintenance,

improper line voltage and acts of nature. This warranty is not transferable and applies only to U.S. and Canadian sales.

Except to the extent prohibited by applicable law, no other warranties whether expressed or implied, including

warranty merchantability and tness for a particular purpose, shall apply to this product. Under no circumstances shall

Weston Brands LLC be liable for consequential damages sustained in connection with said product and Weston Brands

LLC neither assumes nor authorizes any representative or other person to assume for it any obligation or liability other than

such as is expressly set forth herein. Any applicable implied warranties are also limited to the two (2) year period of the

limited warranty.

This warranty covers only the product and its specic parts, not the food or other products processed in it. Weston is

not responsible for missing or damaged parts on discounted/clearance, resale or nal sale items where the seller may not

be able to guarantee full functionality or completeness of the unit.

CUT ALONG THE DOTTED LINE AND SEND THE WARRANTY CARD ALONG WITH A COPY OF YOUR

ORIGINAL PURCHASE RECEIPT TO:

Weston Brands LLC / WARRANTY

20365 Progress Drive, Strongsville, OH 44149 USA

Customer Name:

Address:

City/State/Zip/Country:

Telephone Number:

E-Mail Address:

Original Date of Purchase:

Product Model #:

Serial # (if applicable):

I have read the warranty information. Initial here:

WESTON WARRANTY INFORMATION

SAVE THIS WARRANTY INFORMATION FOR YOUR RECORDS!

WESTON WARRANTY CARD

SEND THIS CARD ALONG WITH A COPY OF YOUR ORIGINAL PURCHASE RECEIPT TO:

WESTON BRANDS LLC / WARRANTY, 20365 PROGRESS DRIVE, STRONGSVILLE, OH 44149 USA

Copy of Receipt

Included

Page 23

SELLADOR A VACÍO

65-0601-W

DEBIDO A CONSTANTES MEJORAS EN LA FÁBRICA, EL PRODUCTO QUE SE MUESTRA PUEDE

SER LIGERAMENTE DIFERENTE DEL PRODUCTO EN ESTA CAJA. 020915

Page 24

24

1. SIEMPRE DESCONECTE la

selladora al vacío de la fuente de

corriente antes de darle mantenimiento,

cambiarle accesorios o limpiarla.

2. Conecte la selladora al vacío en un

tomacorriente estándar de 120 volts y 60

Hz. Evite usar cables de extensión.

3. NO USE la selladora al vacío si el

cable de corriente, la clavija o cualquier

otra parte estuvieran dañadas. Si

está dañado el cable de corriente o la

selladora al vacío, llame a servicio al

cliente. NO TRATE DE REEMPLAZAR

EL CABLE.

4. NUNCA use accesorios o partes de

otros fabricantes. Hacerlo INVALIDA LA

GARANTÍA y puede causar incendios,

choques eléctricos y lesiones.

5. Reduzca el riesgo de arranques

involuntarios. Asegúrese de que el

interruptor Power (Encendido) esté en

la posición “OFF” (Apagado) antes de

conectar la fuente de alimentación.

6. MANTENGA LOS DEDOS

ALEJADOS de la barra térmica

selladora y la cinta de la barra de sellado

EN TODO MOMENTO. Estas áreas se

CALIENTAN. Podrían causarle lesiones

graves.

7. NO DESARME este aparato; hacerlo

ANULA LA GARANTÍA y puede

provocar lesiones.

8 PARA PROTEGERSE DE

CHOQUES ELÉCTRICOS: NO

SUMERJA EN AGUA U OTRO

LÍQUIDO LA SELLADORA AL VACÍO.

REVISE QUE LA SELLADORA AL

¡GUARDE ESTAS INSTRUCCIONES!

NORMAS GENERALES DE SEGURIDAD

LEA Y COMPRENDA TODAS LAS INSTRUCCIONES Y ADVERTENCIAS

ANTES DE USAR ESTA UNIDAD. ¡SU SEGURIDAD ES PRIMORDIAL! NO

CUMPLIR CON LOS PROCEDIMIENTOS Y MEDIDAS DE SEGURIDAD PUEDE

OCASIONAR LESIONES GRAVES O DAÑOS MATERIALES. RECUERDE:

¡USTED TIENE LA RESPONSABILIDAD SOBRE SU SEGURIDAD PERSONAL!

VACÍO ESTÉ DESCONECTADA

DE LA FUENTE DE CORRIENTE

ANTES DE LIMPIARLA. Siga las

“Instrucciones de limpieza” de este

folleto. NUNCA enjuague la selladora

al vacío bajo el grifo de agua.

9. NUNCA DEJE SIN

SUPERVISIÓN LA SELLADORA

AL VACÍO. Sea prudente:

DESCONECTE LA SELLADORA AL

VACÍO de la fuente de corriente al

salir del área de trabajo. Es necesaria

la supervisión cercana cuando se

use cualquier aparato cerca de niños.

Este aparato NO DEBE ser usado por

niños.

10. NO DEJE que el cable de

corriente cuelgue por el borde de la

supercie de trabajo.

11. Revise que la selladora al vacío

esté en una supercie de trabajo

estable. Revise que estén estables

las patas de la selladora al vacío.

12. NO USE la selladora al vacío en

exteriores.

13. NO USE la selladora al vacío bajo

los efectos de drogas, medicamentos

o alcohol.

14. La selladora al vacío

está diseñada para usarse

EXCLUSIVAMENTE con BOLSAS

AL VACÍO. Para obtener mejores

resultados use exclusivamente las

bolsas recomendadas. ¡NO USE

BOLSAS CASERAS! Cualquier uso

de la selladora al vacío que no sea

de los descritos en este folleto puede

dañar el aparato y anular la garantía.

INSTRUCCIONES EN ESPAÑOL

Page 25

Page 26

1

2

3

4

5

6

7

8

9

10

11

12

Tapa

de vacío

16

Panel de

alimentación

Cubierta

superior

Cubierta inferior

Cámara de

vacío

I

O

13

14

26

INSTRUCCIONES EN ESPAÑOL

Page 27

27

INSTRUCCIONES EN ESPAÑOL

NÚMERO DE DIAGRAMA DESCRIPCIÓN DE LA PIEZA NÚMERO DE PIEZA

1 CABLE DE SELLADO 08-0627

2 AISLANTE DE LA BARRA SELLADORA 08-0625

3 CABLE DE CORRIENTE 08-0402

4 SUJETADOR DEL FUSIBLE 08-0604

5 FUSIBLE DE 8 AMP 08-0605

6 BOMBA DE VACÍO 08-0639

7 TRANSFORMADOR 08-0641

8 VENTILADOR 08-0643

9 TABLERO DE CIRCUITO 65-0638

SENSOR DE VACÍO 65-0643

10 CINTA DE LA BARRA SELLADORA (NEGRA) CONSULTE EL JUEGO

DE MANTENIMIENTO

11 CÁMARA DE SELLADO (2) CONSULTE EL JUEGO

DE MANTENIMIENTO

12 JUEGO DE MANTENIMIENTO DE LA SELLADORA

AL VACÍO CINTA DE LA BARRA SELLADORA

(NEGRA) , SELLOS DE LA CÁMARA (2)

65-0701

13 KIT PORTARROLLOS INCLUYE: VARA

PORTARROLLOS, BRAZOS DE SUJECIÓN DE LA

VARA (2), SOPORTES CON TORNILLOS

(2 SOPORTES, 4 TORNILLOS)

65-0639

14 KIT CORTADOR DE BOLSAS INCLUYE: HOJA

SUJETADOR DE LA HOJA

65-0640

15 HOJA 65-0641

16 PANEL DE CONTROL 65-0642

LISTA DE COMPONENTES

Si cualquier componente de esta unidad está roto, si no funciona debidamente,

o si necesita un instructivo de repuesto, visítenos en la Web en

WestonProducts.com

O llame a Weston Brands LLC larga distancia sin costo 1-800-814-4895

De lunes a viernes, de 8:00 am a 5:00 pm tiempo del ET. Fuera de Estados Unidos

llame al 001-440-638-3131

Page 28

La selladora al vacío cuenta con un ventilador de refrigeración interno

que funciona siempre que la unidad está conectada y encendida.

Para ahorrar energía, coloque la unidad en posición “OFF” (Apagado)

y desconecte el cable de alimentación cuando no esté en uso.

CINTA DE LA BARRA

SELLADORA

¡NO LA QUITE!

El elemento térmico de la barra selladora está cubierto con una cinta

para proteger las bolsas de vacío durante el sellado (FIGURA 1). ¡NO

RETIRE la cinta de la barra selladora! Si necesita reemplazar la cinta

de la barra selladora, consulte la sección “Juego de mantenimiento”

de este manual, si le hace falta.

¡NO QUITE LOS SELLOS OVALADOS DE LA

CÁMARA DE VACÍO!

ANTES DE COMENZAR A SELLAR LA BOLSA

Ante de utilizar la Selladora al vacío, familiarícese con las funciones de

sellado de bolsa. Una bolsa de vacío se sella cuando el Calentador de la

barra de sellado se activa y calienta la bolsa hasta su punto de fusión, que

une permanentemente las capas de la bolsa, y sella la bolsa para cerrarla.

Este electrodoméstico ya viene preestablecido de fábrica para activar el

Calentador de la barra de sellado durante 3 segundos. Esta es la cantidad de

tiempo correcta y necesaria para sellar completamente las bolsas de vacío.

Diferentes marcas de bolsas de vacío pueden requerir un poco más o menos

de tiempo de sellado.

Pruebe sellar un par de bolsas para asegurarse de que el Tiempo de sellado

se establece correctamente. El Tiempo de sellado se puede aumentar (+) o

disminuir (-) para sellar una bolsa de forma óptima.

CINTA PROTECTORA

En la selladora al vacío hay una tira de cinta

para barra selladora instalada de fábrica.

¡NO RETIRE ESA CINTA!

FIGURA 1

VENTILADOR DE REFRIGERACIÓN

28

INSTRUCCIONES EN ESPAÑOL

Page 29

29

INSTRUCCIONES EN ESPAÑOL

La selladora al vacío tiene dos sellos ovalados en la cámara instalados de

fábrica. Cuando se cierra la tapa de vacío, ésta forma un cierro hermético

para que pueda evacuarse la cámara.

Los sellos ovalados de la cámara pueden desgastarse con el tiempo y

necesitan ser reemplazados. Si necesita reemplazar los sellos ovalados de

la cámara de vacío, consulte la sección “Juego de mantenimiento” de este

manual, si le hace falta.

PROTECTOR DE SOBRECARGA TÉRMICA

La selladora al vacío se apaga automáticamente si se sobrecalienta.

Si ocurre esto, apague el aparato y abra la tapa de vacío. Reanude las

operaciones normales cuando se haya enfriado el aparato o unos 20 minutos

después.

Para evitar el sobrecalentamiento espere por lo menos 20 segundos entre

un ciclo y otro con la tapa de vacío abierta. Evite tocar la cinta de la barra

selladora. La cinta de la barra selladora se mantiene caliente por un periodo

breve después de cada ciclo de sellado.

INTERRUPTOR DE LÍMITE

La selladora al vacío está equipada con un interruptor para evitar el

accionamiento del calentador de la barra de sellado en modo manual cuando

la tapa de vacío está abierta. Cuando la tapa de vacío está cerrada, el calor

producido por el calentador de la barra de sellado se absorbe por la bolsa de

vacío y el sello de la tapa de vacío.

Cuando la tapa de vacío está abierta, no hay forma de disipar el calor y la

unidad podría dañarse.

ENSAMBLADO

• Coloque la selladora al

vacío en una superficie lisa y

seca.

• Conecte el extremo hembra

del cable de alimentación

en el puerto de la fuente de

alimentación a la derecha del

electrodoméstico (FIGURA 2).

• Conecte el extremo macho

del cable de alimentación a

un tomacorriente estándar

doméstico de 120 voltios

conectado a tierra. NO intente

modificar el enchufe para que

encaje en un tomacorriente

inadecuado.

FIGURA 2

I

O

SELLOS DE LA CÁMARA DE VACÍO

NOTA: La selladora al vacío está diseñada para usarse EXCLUSIVAMENTE con BOLSAS

AL VACÍO. Obtenga mejores resultados usando solamente las bolsas recomendadas con

forro de malla o estampado.

¡NO USE BOLSAS CASERAS! Cualquier uso de la selladora al vacío que no sea de los

descritos en este folleto puede dañar el aparato y anular la garantía.

Page 30

. NUNCA SUMERJA LA SELLADORA AL VACÍO EN AGUA U OTRO

LÍQUIDO.

. Cerciórese de que la selladora al vacío se haya enfriado por completo antes

de limpiarla

. Frote todas las supercies exteriores, en especial la cámara de vacío de

plástico y la tapa de vacío con un paño o toalla de papel húmedos. Puede

usar la mayoría de los limpiadores caseros en aerosol. Evite rociar en la

ventila del lado izquierdo del aparato. ¡NO USE limpiadores abrasivos!

. Al limpiarla, tenga cuidado de no pelar o dañar la tira de cinta de la barra

selladora que cubre el elemento térmico.

. Seque todas las supercies y cierre la tapa de vacío antes de guardar la

selladora al vacío.

INSTRUCCIONES DE CUIDADO Y LIMPIEZA

30

INSTRUCCIONES EN ESPAÑOL

ATERRIZADO

Este aparato debe estar aterrizado para proteger

al operario de choques eléctricos. El aparato

está equipado con un cable de 3 conductores

y una clavija de tierra de tres patas que entra

en un tomacorriente aterrizado apropiado. El

aparato tiene una clavija que se ve como la

gura 3. Debe usarse un adaptador, gura

4, para conectar la clavija de la gura 3 en

tomacorrientes de dos patas. La pestaña de

tierra que sale del adaptador debe conectarse

a una tierra permanente, por ejemplo, una caja

de conexiones debidamente aterrizada, como la

que se muestra en la gura 5, usando un tornillo

de metal. NO modique la clavija de ninguna

manera.

CABLES DE EXTENSIÓN

Use solamente cables de extensión de 3

alambres que tengan clavijas de tierra de 3

patas y un conector de 3 polos que acepte

la clavija del aparato. Use solamente cables

de extensión que tengan una calibración

eléctrica no menor que la calibración del

aparato. NO USE cables de extensión dañados.

Examine el cable de extensión antes de

usarlo y reemplácelo si está dañado. NO

maltrate el cable de extensión y no lo jale para

desconectarlo. Mantenga el cable alejado del

calor y de bordes losos. NO permita que el

cable cuelgue por el borde del área de trabajo.

FIGURA 3

FIGURA 4

FIGURA 5

Conductor

del circuito

de tierra

Pata de

tierra

Tornillo

metálico de

tierra

Cubierta de

la caja de

conexiones

de tierra

Medios de

aterrizaje

AA2220

INSTRUCCIONES PARA HACER TIERRA

ADVERTENCIA! Antes de limpiar, ensamblar o desarmar la selladora

al vacío, cerciórese de que esté APAGADA y de que LA CLAVIJA ESTÉ

RETIRADA DEL TOMACORRIENTE O FUENTE DE ENERGÍA.

Page 31

31

INSTRUCCIONES EN ESPAÑOL

. Botón Start (Arranque): El botón Start (Arranque) enciende la bomba de vacío

de 2 pistones que activa el proceso de evacuación de aire.

. Botón Cancel (Cancelar): Este botón se utiliza para detener el ciclo de vacío

en cualquier momento.

. Botones + y - de tiempo de sellado: El botón Seal Time (Tiempo de sellado)

ajusta la cantidad de segundos durante la cual la barra de sellado aplicará calor

para crear el sello de la bolsa. El tiempo adecuado para las distintas marcas de

bolsas puede ajustarse con los botones Más (+) o Menos (-). Consulte la sección

“Sellado de bolsas” en este folleto para obtener más información sobre el sellado

de bolsas al vacío.

. Ventana de sellado: La ventana LED numérica de sellado indica la cantidad

de segundos durante la cual la barra de sellado permanecerá activada para

aplicar calor a la bolsa que crea el sello. Una vez que la barra de sellado esté

activada, la pantalla descontará hasta “0”. Consulte la sección “Sellado de

bolsas” en este folleto para obtener más información sobre el sellado de bolsas

al vacío.

. Ventana de vacío: La ventana LED numérica de vacío indica el nivel de vacío

que alcanzó la selladora al vacío. La pantalla comenzará a contar de “0” a “9”.

• Botón de pulso: El botón de pulso se usa al sellar artículos o líquidos

delicados, permitiendo controlar el proceso de vacío. Cuando la bolsa esté

preparada para sellarla al vacío, oprima el botón de pulso una vez para

bloquearla. Después oprima el botón de pulso tantas veces como lo necesite

hasta haber eliminado la cantidad de aire deseada. Oprima el botón de sellado

para sellar la bolsa.

. Botón Manual Bag Seal (Sellado manual de la bolsa): Este botón iniciará

la barra de sellado en cualquier momento en Modo manual. Encontrará más

información sobre el Modo manual en la sección “Modo manual” de este folleto.

. Botón de accesorios: Presione el botón de accesorios al utilizar recipientes

de vacío (se venden por separado) para aspirar y elementos de sellado

almacenados en el recipiente.

PANEL DE CONTROL

NOTA: La selladora al vacío está diseñada para usarse EXCLUSIVAMENTE con BOLSAS

AL VACÍO. Obtenga mejores resultados usando solamente las bolsas recomendadas con

forro de malla o estampado.

¡NO USE BOLSAS CASERAS! Cualquier uso de la selladora al vacío que no sea de los

descritos en este folleto puede dañar el aparato y anular la garantía.

Page 32

1. Para crear bolsas con el portarrollos, extraiga la vara del portarrollos de

los sujetadores en la parte trasera de la selladora al vacío (FIGURA 6).

2. Deslice la vara por la abertura central del rollo (sostiene bolsas de 11” de

ancho).

3. Pliegue los brazos del portarrollos hacia fuera y coloque la vara en las

ranuras de los brazos del portarrollos, alineando con cuidado las muescas en

la vara con las ranuras de los brazos.

4. Es más sencillo cortar las bolsas desde el rollo cuando estas están

enroscadas (y no debajo del rollo) (FIGURA 7).

5. Mueva el cortador de bolsas hacia la tapa y tire de la bolsa de vacío sobre

la ranura del cortador hasta que haya alcanzado la extensión deseada.

6. Mueva el cortador de bolsas hacia atrás sobre la parte superior del rollo de

bolsas y asegúrese de que la hoja esté en uno de los laterales.

7. Deslice la hoja a través del rollo de bolsas para cortar el tamaño de bolsa

que desee (FIGURA 8).

UTILIZACIÓN DEL PORTAROLLOS Y EL CORTADOR

FIGURA 6

P

O

W

E

R

I

N

D

I

C

ATO

R

O

N

O

F

F

8 A

M

P

F

U

S

E

O

N

LY

FIGURA 7

FIGURA 8

32

INSTRUCCIONES EN ESPAÑOL

Page 33

33

INSTRUCCIONES EN ESPAÑOL

1. SIEMPRE permita que se enfríe la barra selladora unos 20 segundos

entre una bolsa y otra. Deje ABIERTA la tapa de vacío entre cada uso; este

permite que el elemento térmico se enfríe más rápidamente entre una bolsa

y otra.

2. Coloque un extremo de la bolsa en la barra selladora, dejando unos 5 cm

(2”) de la parte vacía más allá del borde interno de la barra selladora.

3. Revise que la bolsa no cubra el puerto de vacío. Cubrir el puerto de vacío

impide la salida adecuada del aire de la bolsa.

4. Cierre la tapa de vacío mientras sostiene la bolsa en su lugar. Presione

hacia abajo en ambos lados de la tapa para bloquear la tapa en su lugar.

Usted escuchará cada lado “clic” cuando está asegurada. NOTA: Si ambas

partes no están bien sujetas bloqueadas, la tapa no liberará automáticamente. Para resolver este problema, presione hacia abajo en ambos lados

de la tapa dos veces para liberar los bloqueos.

5. Oprima el botón de arranque para encender la bomba de vacío (la bomba

de vacío debe estar encendida para que se caliente la barra selladora).

6. Presione el botón Manual Seal (Sello manual) inmediatamente luego de

que la bomba de vacío arranque. (Presione la tapa de vacío para que tome

contacto con la barra de sellado.)

7. Cuando la ventana de sellado llegue a 0, el aparato libera automáticamente el vacío y permite que se abra la tapa de vacío.

8. Retire la bolsa e inspeccione el sello. El sello debe verse liso y uniforme

a lo largo de la bolsa. El sello NO DEBE derretirse hacia la bolsa en ningún

punto. Revise que no haya suras o arrugas que permitan la entrada de aire

en la bolsa. Una bolsa sellada debidamente no puede separarse; debe de

cortarse para abrirse.

9. No forme sellos en el costado de las bolsas, éstos ya vienen sellados.

10. Si el sello está bien, continúe con el empaque al vacío. Si no está bien:

• Si el sello está derretido a través de la bolsa, córtelo con unas tijeras y ajuste

el tiempo de sellado hacia abajo (-) en incrementos de un segundo, para probar

nuevamente el proceso.

• Si el sello no soldó por completo la bolsa, córtelo con unas tijeras y ajuste el

tiempo de sellado hacia arriba (+) en incrementos de un segundo, para probar

nuevamente el proceso.

PRUEBA INICIAL DE SELLADO DE BOLSAS

¡NO ABRA a la fuerza la tapa de

vacío! Espere a que el vacío la libere.

Permita que el aparato se ENFRÍE

por lo menos durante 20 segundos

entre un ciclo y otro.

NOTA: La selladora al vacío está diseñada para usarse EXCLUSIVAMENTE

con BOLSAS AL VACÍO. Obtenga mejores resultados usando solamente las

bolsas recomendadas con forro de malla o estampado.

¡NO USE BOLSAS CASERAS! Cualquier uso de la selladora al vacío que no

sea de los descritos en este folleto puede dañar el aparato y anular la garantía.

ADVERTENCIA! Antes de limpiar, ensamblar o desarmar la selladora

al vacío, cerciórese de que esté APAGADA y de que LA CLAVIJA ESTÉ

RETIRADA DEL TOMACORRIENTE O FUENTE DE ENERGÍA.

Page 34

ANTES DE PROBAR EL ENVASADO

AL VACÍO, ASEGÚRESE DE QUE LA

SELLADORA AL VACÍO CUMPLA

CON TODAS LAS PRECAUCIONES

DE SEGURIDAD QUE SE

ENUMERAN

EN ESTE FOLLETO.

1. Coloque los elementos que se

sellarán al vacío dentro de la bolsa

de vacío. Deje al menos 2” (5 cm) en

el extremo abierto de la bolsa para

crear suciente espacio de sellado.

Asegúrese de no cubrir el puerto de

vacío (FIGURA 9).

2. Cierre la tapa de vacío y compruebe

que la abertura de la bolsa esté en

el centro de la cámara de vacío.

Presione hacia abajo en ambos

lados de la tapa para bloquear la tapa en su lugar. Usted escuchará cada

lado “clic” cuando está asegurada. NOTA: Si ambas partes no están bien

sujetas bloqueadas, la tapa no liberará automáticamente. Para resolver este

problema, presione hacia abajo en ambos lados de la tapa dos veces para

liberar los bloqueos.

3. Presione y suelte el botón Start (Arranque). La bomba de vacío de

2 pistones comenzará a extraer el aire de la bolsa mientras la ventana

LED de vacío comienza a contar en forma ascendente. Es probable de

deba presionar levemente la tapa de vacío durante el proceso de cuenta

ascendente. La ventana LED de vacío contará en forma ascendente desde

el número “1” hasta el número “9”, antes de comenzar automáticamente con

el proceso de sellado de la bolsa. Estos números representan etapas, no

segundos.

4. Una vez que la ventana LED de vacío muestra el número “9”, el proceso

de sellado comenzará a descontar desde la conguración establecida hasta

llegar a “0” en la ventana LED de vacío.

5. Una vez que la ventana LED de sellado llegue a “0”, la selladora al vacío

detendrá automáticamente la bomba de vacío de 2 pistones y liberará la

presión al vacío momentos más tarde. NO INTENTE ABRIR LA TAPA DE

VACÍO ANTES DE QUE SE LIBERE EL VACÍO, ESTO PODRÍA CAUSAR

DAÑOS SEVEROS EN LA BARRA DE SELLADO.

OPERACIÓN EN MODO AUTOMÁTICO

FIGURA 9

Deje 5 cm

(2”) de

espacio

para sellar.

Puerto de

vacío

34

INSTRUCCIONES EN ESPAÑOL

¡NO ABRA a la fuerza la tapa de

vacío! Espere a que el vacío la libere.

Permita que el aparato se ENFRÍE

por lo menos durante 20 segundos

entre un ciclo y otro.

NOTA: La selladora al vacío está diseñada para usarse EXCLUSIVAMENTE

con BOLSAS AL VACÍO. Obtenga mejores resultados usando solamente las

bolsas recomendadas con forro de malla o estampado.

¡NO USE BOLSAS CASERAS! Cualquier uso de la selladora al vacío que no

sea de los descritos en este folleto puede dañar el aparato y anular la garantía.

Page 35

35

INSTRUCCIONES EN ESPAÑOL

ANTES DE PROBAR EL ENVASADO

AL VACÍO, ASEGÚRESE DE QUE LA

SELLADORA AL VACÍO CUMPLA

CON TODAS LAS PRECAUCIONES DE

SEGURIDAD QUE SE ENUMERAN EN

ESTE FOLLETO.

1. Coloque los elementos que se sellarán

al vacío dentro de la bolsa de vacío. Deje

al menos 2” (5 cm) en el extremo abierto

de la bolsa para crear suficiente espacio de

sellado. Asegúrese de no cubrir los puertos

de vacío (FIGURA 10).

2. Cierre la tapa de vacío y compruebe que

la abertura de la bolsa esté en el centro de

la cámara de vacío. Presione hacia abajo en

ambos lados de la tapa para bloquear la tapa

en su lugar. Usted escuchará cada lado “clic”

cuando está asegurada. NOTA: Si ambas

partes no están bien sujetas bloqueadas,

la tapa no liberará automáticamente. Para

resolver este problema, presione hacia abajo en ambos lados de la tapa dos

veces para liberar los bloqueos.

3. Mientras supervisa la bolsa de vacío, presione y suelte el botón START

(Arranque). La bomba de vacío de 2 pistones comenzará a extraer el aire de

la bolsa. Cuando se haya extraído la cantidad de aire necesario de la bolsa,

presione y suelte el botón Manual Bag Seal (Sellado manual de la bolsa).

Comenzará con el proceso de sellado de la bolsa.

Nota: Es probable de deba presionar levemente la tapa de vacío durante este

proceso.

Nota: Se requiere algo de presión de vacío dentro de la bolsa para conseguir

un buen sellado.

4. Una vez que la ventana LED de sellado llegue a “0”, la selladora al vacío

detendrá automáticamente la bomba de vacío y liberará la presión de vacío

momentos más tarde. NO INTENTE ABRIR LA TAPA DE VACÍO ANTES DE

QUE SE LIBERE EL VACÍO, ESTO PODRÍA CAUSAR DAÑOS SEVEROS EN

LA BARRA DE SELLADO.

FIGURA 10

Deje

5 cm

(2”) de

espacio

para

sellar.

Puerto de

vacío

FUNCIONAMIENTO EN MODO MANUAL

¡NO ABRA a la fuerza la tapa de

vacío! Espere a que el vacío la libere.

Permita que el aparato se ENFRÍE

por lo menos durante 20 segundos

entre un ciclo y otro.

NOTA: La selladora al vacío está diseñada para usarse EXCLUSIVAMENTE

con BOLSAS AL VACÍO. Obtenga mejores resultados usando solamente las

bolsas recomendadas con forro de malla o estampado.

¡NO USE BOLSAS CASERAS! Cualquier uso de la selladora al vacío que no

sea de los descritos en este folleto puede dañar el aparato y anular la garantía.

ADVERTENCIA! Antes de limpiar, ensamblar o desarmar la selladora

al vacío, cerciórese de que esté APAGADA y de que LA CLAVIJA ESTÉ

RETIRADA DEL TOMACORRIENTE O FUENTE DE ENERGÍA.

Page 36

Algunas piezas de la selladora al vacío quizás deban sustituirse luego de ser

utilizadas repetidamente. El kit de mantenimiento de la selladora al vacío será

necesario para que la selladora al vacío funcione correctamente.

1. Coloque la selladora al vacío en posición “OFF” (Apagado) y extraiga el cable

de alimentación del tomacorriente.

2. Asegúrese de que la unidad esté completamente fría.

3. Abra la tapa de vacío.

4. Extraiga el sello ovalado de la cámara de vacío de la ranura en la parte inferior

de la tapa de vacío.

5. Extraiga el sello ovalado de la cámara de vacío de la ranura de la cámara de

vacío de plástico.

6. Coloque un nuevo sello ovalado de la cámara de vacío en la ranura de la

cámara de vacío de plástico. Coloque el sello en la ranura con los dedos hasta

que esté listo.

7. Coloque un nuevo sello ovalado de la cámara de vacío dentro de la ranura en

la tapa de vacío. Coloque el sello en la ranura con los dedos hasta que esté listo.

SUSTITUCIÓN DE LA CINTA DE LA BARRA DE SELLADO:

1. Coloque la selladora al vacío en posición “OFF” (Apagado) y extraiga el cable

de alimentación del tomacorriente.

2. Asegúrese de que la unidad esté completamente fría.

3. Abra la tapa de vacío.

4. Tome con la uña cualquiera de los extremos de la cinta de la barra de

sellado que cubren el calentador de la barra de sellado hasta que se levante

suavemente. Tome el extremo ojo y tire suavemente

la cinta de la barra de sellado hacia atrás hasta que haya salido completamente.

5. Extraiga la parte trasera de la nueva correa de la cinta de la barra de sellado.

Tenga cuidado de que la cinta de la barra de sellado no tome contacto con nada,

ni consigo misma, cuando el lado del adhesivo quede expuesto.

6. Sostenga un extremo de la cinta de la barra de sellado en cada mano. Pegue

el extremo izquierdo de la cinta de la barra de sellado en el área lisa de la

cámara de vacío de plástico justo a la izquierda del calentador de la barra de

sellado. Coloque la cinta de la barra de sellado de izquierda a derecha sobre

el calentador de la barra de sellado hasta que esté lista. Asegúrese de que no

queden arrugas o dobleces en la cinta de la barra de sellado. La cinta de la barra

de sellado debe cubrir por completo el calentador de la barra de sellado.

INSTRUCIONES DEL KIT DE MANTENIMIENTO

36

INSTRUCCIONES EN ESPAÑOL

Page 37

37

INSTRUCCIONES EN ESPAÑOL

SOLUCIÓN DE PROBLEMAS

PREGUNTA: NO PASA NADA CUANDO PRESIONO EL BOTÓN POWER

(ENCENDIDO).

1. Asegúrese de que el cable de alimentación

no esté para nada dañado.

2. Asegúrese de que el extremo hembra

del cable de alimentación esté conectado

completamente en el puerto de la fuente de

alimentación de la selladora al vacío, y que el

extremo macho del cable de alimentación esté

conectado firmemente al tomacorriente de la

pared (FIGURA 11).

3. Si la selladora al vacío está conectada

correctamente, y el botón Power (Encendido)

aún no funciona, compruebe el estado del

fusible, que se encuentra sobre el puerto de

la fuente de alimentación, a la derecha de la

selladora al vacío. Extraiga el sujetador del fusible y luego observe el tubo

transparente para revisar

si el fusible está oscuro. Si el fusible está oscuro, deberá sustituirse con un

fusible estándar de 8 Amp.

4. Si no es necesario sustituir el fusible, deberá asegurarse de que el

tomacorriente de la pared funcione correctamente. Conecte otro electrodoméstico

al tomacorriente para comprobar si funciona. UTILICE SOLO FUSIBLES CON

RETARDO DE TIEMPO.

PREGUNTA: MI SELLADORA AL VACÍO SE APAGÓ Y NO ARRANCA

NUEVAMENTE.

1. El protector de sobrecarga térmica puede haberse activado. En este caso,

permita que la selladora al vacío se enfríe al abrir la tapa de vacío durante

aproximadamente 20 minutos. Asegúrese de dejar la tapa de vacío abierta

entre la bolsa y el sellado.

2. Asegúrese de que el extremo hembra del cable de alimentación esté

conectado completamente en el puerto de la fuente de alimentación de la

selladora al vacío, y que el extremo macho del cable de alimentación esté

conectado firmemente al tomacorriente de la pared.

3. Si la selladora al vacío está conectada correctamente, y el botón Power

(Encendido) aún no funciona, compruebe el estado del fusible, que se

encuentra sobre el puerto de la fuente de alimentación, a la derecha de la

selladora al vacío. Extraiga la tapa del fusible y observe el tubo transparente

para ver si el fusible está oscuro. Si el fusible está oscuro, deberá sustituirse

con un fusible estándar de 8 Amp.

4. Si no es necesario sustituir el fusible, deberá asegurarse de que

el tomacorriente de la pared funcione correctamente. Conecte otro

electrodoméstico al tomacorriente para comprobar si funciona.

FIGURA 11

Compruebe si el

fusible se oscurece

I

O

Page 38

PREGUNTA: EL SELLO DE LA BOLSA SE SEPARA.

1. Si el sello no soldó por completo la bolsa, córtelo con unas tijeras y ajuste

el tiempo de sellado hacia arriba (+) en incrementos de un segundo, para probar

nuevamente el proceso.

2. La selladora al vacío está diseñada para usarse con bolsas para envasado al

vacío. Para obtener mejores resultados use bolsas al vacío de Weston®. NO USE

BOLSAS CASERAS con la selladora al vacío.

3. El sello de la bolsa puede estar incompleto. Si el sello tiene una fisura o si entre

las capas de la bolsa quedaron atrapados líquidos o polvos, las capas podrían no

haber quedado debidamente soldadas. Corte el sello y limpie el interior de la bolsa.

Después haga la prueba de volver a sellar al vacío el paquete. Cuando envase

un alimento húmedo o en polvo, inserte una toalla de papel en la bolsa antes del

envasado al vacío. La toalla de papel evita que el alimento interfiera con el sellado.

Vea algunos consejos útiles en la sección “Lineamientos de envasado al vacío” de

este folleto.

4. Si ninguna de las medidas anteriores resuelve el problema, comuníquese con

Servicio al cliente.

FIGURA 12

PREGUNTA: LA BOMBA DE VACÍO ARRANCA PERO NO ELIMINA EL AIRE

DE LA BOLSA.

Para obtener mejores resultados use

siempre

bolsas de la marca de Weston®.

1. Revise que la bolsa esté insertada

debidamente. El extremo abierto de

la bolsa debe estar centrado dentro.

Revise que la bolsa no cubra la apertura

del puerto de vacío (FIGURA 12).

2. La bolsa podría tener una fuga. Si

hay una fuga en la bolsa, el aire entra

en la bolsa del exterior. Revise si tiene