Page 1

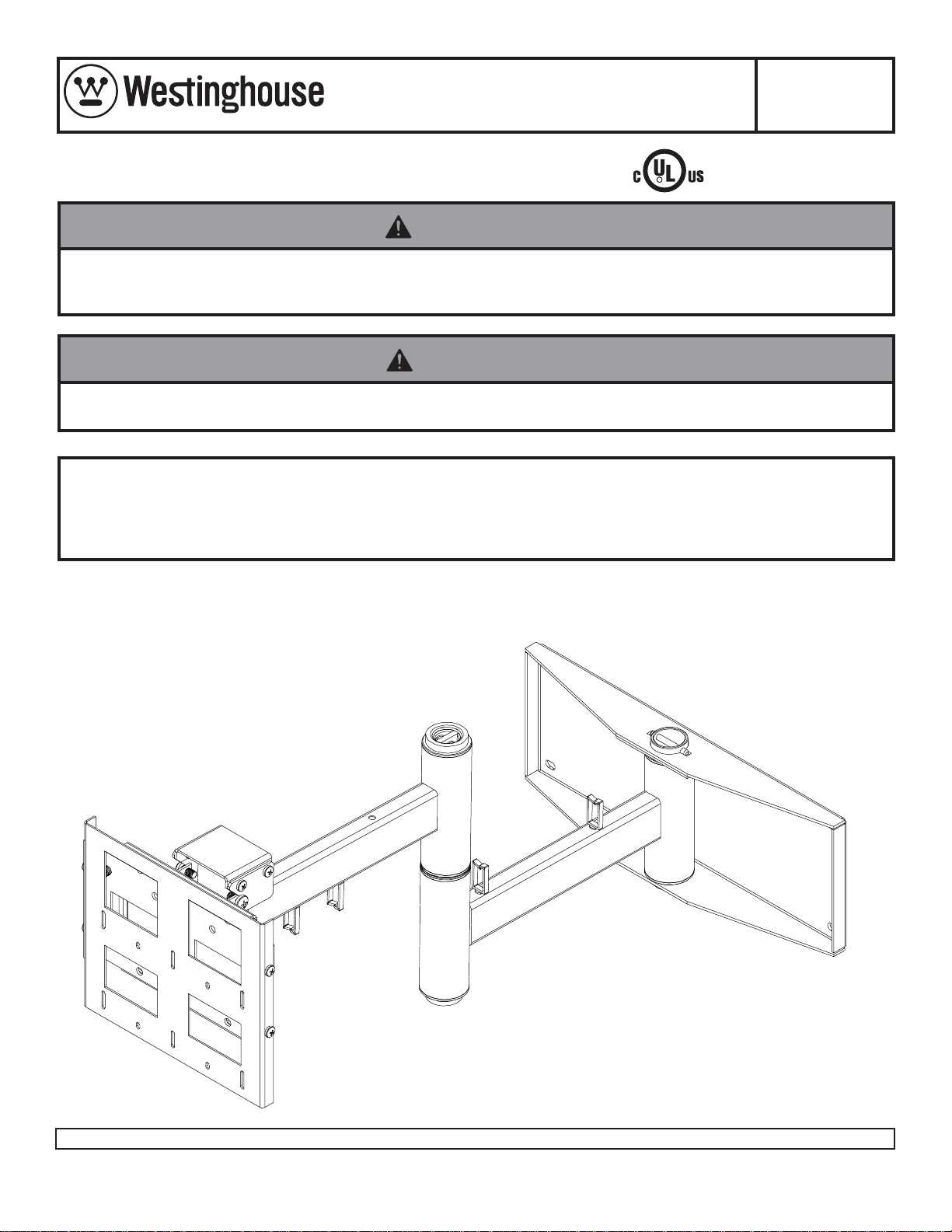

Installation and Assembly - Adjustable Flat

Panel Wall Arm

Model:

MT90 ARM29

IMPORTANT! Read entire instruction sheet

before you start installation and assembly.

MAX LOAD CAPACITY: 90 lb (40.9 kg)

R

This product is UL Listed. It

must be installed by a qualified

professional installer.

WARNING

• Installer must verify that the wall will safely support four times the combined weight of all attached equipment and

hardware.

WARNING

• Always use an assistant or mechanical lifting equipment to safely lift and position the plasma television.

Installations:

To Wood Stud Walls ..........................................................................................................page 3

T o Solid Concrete, Cinder Block, or Brick W alls ................................................................. page 4

1 of 9

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

ISSUED: 05-21-04 SHEET #: 201-9226-1

Page 2

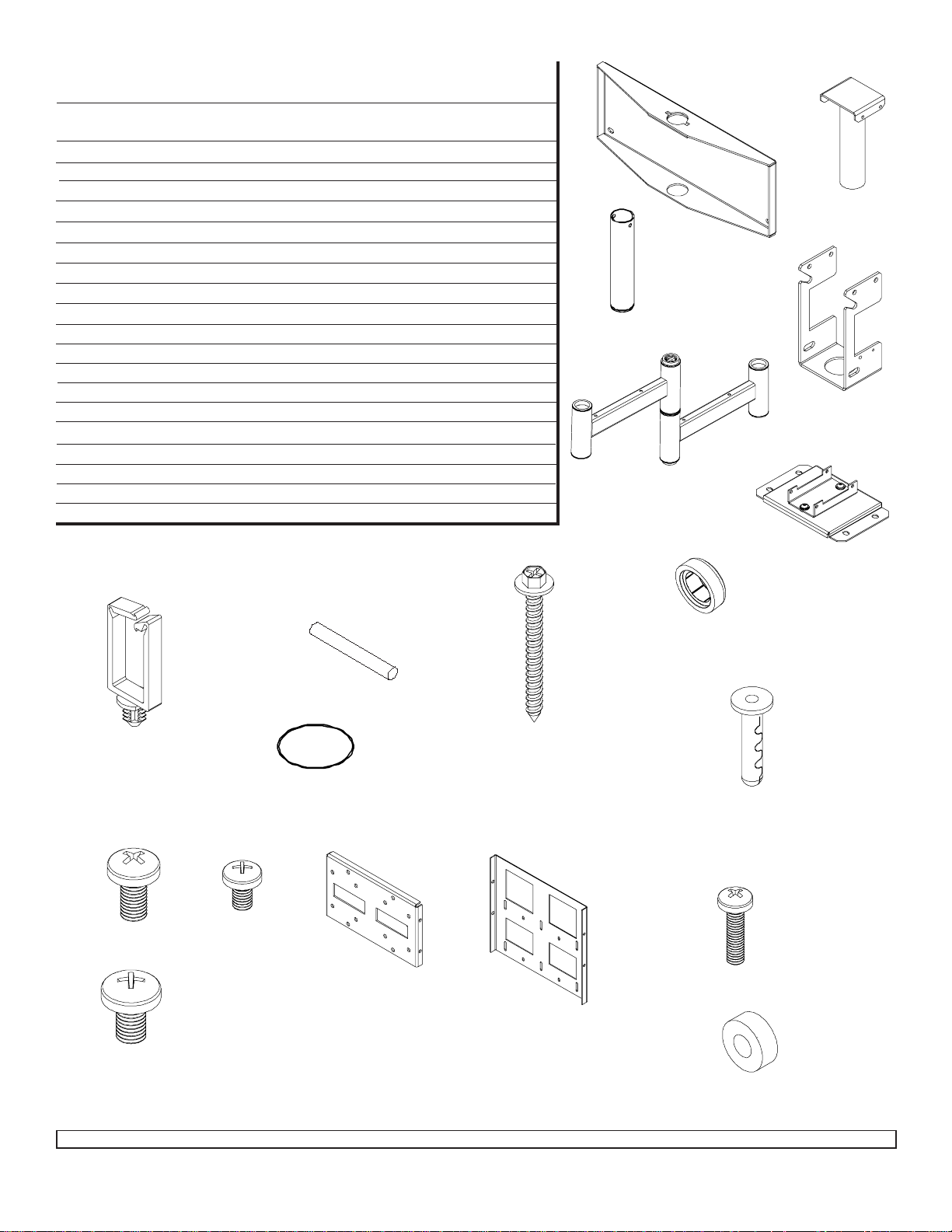

Parts List

PART # QTY. DESCRIPTION

A 200-4413 1 wall bracket

B 200-4418 1 swivel weldment

C 200-1052 1 wall support arm axle

D 200-4483 1 swivel bracket

E 200-0441 1 swing arm assembly

F 200-0547 1 roll pitch assembly

G 590-1089 4 cable clip

H 5M9-025-X02 1 holding pin

I 560-9641 1 snap ring

J 5S1-015-C04 4 #14 x 2.5" hex head phillips screw

K 560-2029 4 3/8" screw head cover

L 520-2051 4 M8 x 16 mm phillips screw

M 520-9524 8 M6 x 10 mm phillips screw

N 590-0097 4 alligator anchor

O 520-2202 4 M10 x 1.5" x 15 mm phillips screw

P 200-4289 1 adapter bracket - top plate

Q 200-4340 1 adapter bracket - bottom plate

R 520-2088 6 M4 x .7 x 16 mm phillips screw

S 590-1116 6 .5 OD x .44 ID x .19 bushing

Some parts may appear slightly different than illustrated.

Before you start make sure all parts

listed are included with your product.

A

B

C

D

E

F

O

G

L

M

K

J

H

N

I

P

Q

R

S

2 of 9 ISSUED: 05-21-04 SHEET #: 201-9226-1

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

Page 3

Installation To Wood Stud Walls

Use wall bracket (A) as a template to mark

and drill four 5/32" (4 mm) dia. holes to a

minimum depth of 2.5" (64 mm). Make sure

wall bracket (A) is level and attach using

#14 x 2 1/2" (6 mm x 38 mm) wood screws

(J) and screw head covers (K). Tighten

screws (J) with phillips screwdriver (not

provided) and push screw head cover over

wood screw heads (J).

K

WARNING

• Tighten wood screws so that wall plate is firmly

attached, but do not overtighten. Overtightening can

damage the screws, greatly reducing their holding

power.

• Never tighten in excess of 80 in • lb (9 N.M.).

• Make sure that mounting screws are anchored into the

center of the studs. The use of an "edge to edge" stud

finder is highly recommended.

J

A

3 of 9

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

ISSUED: 05-21-04 SHEET #: 201-9226-1

Page 4

WARNING

• When installing wall mounts on cinder block, verify that you have a minimum of 1-3/8" of actual concrete surface in

the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount in a solid part of the

block, generally 1" minimum from the side of the block. Cinder block must meet ASTM C-90 specifications. It is

suggested that a standard electric drill on slow setting is used to drill the hole instead of a hammer drill to avoid

breaking out the back of the hole when entering a void or cavity .

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor .

• Make sure that the wall will safely support four times the combined load of the equipment and all attached hardware

and components.

For Concrete Surfaces use wall bracket (A), making sure

that it is level, as a template to mark holes. Drill 1/4" (6

mm) dia. holes to a minimum depth of 2.5" (64 mm). Insert

anchors (N) in holes flush with wall as shown (right). Place

wall bracket (A) over anchors (N) and secure with #14 x

2.5" (6 mm x 65 mm) wood screws (J) and screw head

covers (K). Tighten screws (J) with phillips screwdriver (not

provided) and push screw head covers (K) over wood screw

heads (J).

1

Drill holes and insert anchors (N)

concrete

surface

N

WARNING

• Tighten concrete anchor bolts firmly , but do not

overtighten. Overtightening can damage the bolts,

greatly reducing their holding power.

• Never tighten in excess of 80 in • lb (9 N.M.).

WARNING

• Concrete anchors are not intended for attachment to

concrete wall covered with a layer of plaster , drywall,

or other finishing material. If mounting to concrete wall

covered with plaster/drywall is unavoidable, plaster/

drywall (up to 5/8" thick) must be counterbored as

shown below . If plaster/drywall is thicker than 5/8",

custom fasteners must be supplied by installer .

2

A

N

J

Place plate over anchors (N) and secure with screws (J)

3

Tighten all fasteners (J)

J

INCORRECT

K

CORRECT

mounting

plate

plaster/

CUT AW A Y VIEW

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

dry wall

concrete

mounting

plate

plaster/

dry wall

concrete

A

4 of 9 ISSUED: 05-21-04 SHEET #: 201-9226-1

Page 5

WARNING

• Failure to correctly mount swing arm with plastic cap at top as shown in detail 3 will result in product failure.

• Improperly installed snap rings will result in product failure.

• If you are uncertain that product is properly installed, call customer service.

Insert holding pin (H) into wall support arm axle (C). Insert axle (C) through wall bracket (A) and lower swing arm (E).

Lock axle (C) in place with holding pin (H). IMPORTANT : Be sure swing arm (E) is in correct position shown

below with plastic cap at top.

Next thread snap ring (I) into groove at bottom of axle (C) protruding from wall bracket (A) as shown.

SNAP RING INST ALLA TION: Pull snap ring (I) apart. Wind it around the tube while feeding it into the groove.

Finish by snapping the end of the snap ring into groove.

NOTE: Fit of axle (C) into wall bracket (A) and lower swing arm (E) will be tight.

Gently tap into place with a hammer if necessary.

DETAIL 3

1

groove

H

C

H

C

I

E

2

A

E

I

pre-installed snap ring

Insert swivel weldment (B) through swing arm (E).

Align holes in swivel bracket (D) with holes in swivel weldment (B) and secure with four M6 x 10 mm phillips screws

(M) as shown.

groove

3

I

B

M

E

B

D

D

5 of 9

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

ISSUED: 05-21-04 SHEET #: 201-9226-1

Page 6

FOR VESA 100 MOUNTING P A TTERN

Use four M4 screws (R) and four bushings (S) to

attach bottom plate (Q) to flat panel using phillips

screwdriver (not provided). Use four center holes of

bottom plate (Q) as shown below.

FOR VESA 100 X 200 MOUNTING PA TTERN

Use six M4 screws (R) and six bushings (S) to attach

bottom plate (Q) to flat panel using phillips screwdriver

(not provided). Use six slots on bottom plate (Q) as

shown below. Align upper end of slots with flat panel

mounting holes.

FLAT

PANEL

FLAT

PANEL

S

S

R

VESA 100

MOUNTING

P ATTERN

R

Q

100 x 200

MOUNTING

PATTERN

Q

Use four M6 screws (M) to attach top plate (P) to bottom plate (Q) using phillips screwdriver (not provided).

NOTE: T op plate (P) will have one set of threaded holes on one side and a set of non-threaded holes on the other

side. Bottom plate (Q) will also have one set of threaded holes on one side and a set of non-threaded holes on the

other side. All four M6 screws (M) should pass through non-threaded holes first and into threaded holes.

Q

P

Q

P

6 of 9 ISSUED: 05-21-04 SHEET #: 201-9226-1

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

M

Page 7

Attach roll pitch assembly (F) to top plate (P) using

four M10 x 15 mm phillips screws (O).

BACK OF FLAT

PANEL

P

FLA T PANEL MA Y APPEAR DIFFERENT

THAN ILLUSTRATED

F

O

WARNING

• Always use an assistant or mechanical lifting equipment to safely lift and position the flat panel.

Insert two M8 screws (L) into roll pitch assembly (F). Leave approx. 1/4" of exposed thread as shown

in detail.

L

1/4"

D

L

Hook roll pitch assembly (F)/flat

panel onto swivel bracket (D).

7 of 9

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

Adjust tilt as needed and secure with two M8 x 16

mm screws (L). Use phillips screwdriver (not provided) to tighten screws (L).

ISSUED: 05-21-04 SHEET #: 201-9226-1

Page 8

Snap four cable clips (G) into

swing arm assembly (E) as

shown.

G

E

8 of 9 ISSUED: 05-21-04 SHEET #: 201-9226-1

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

Page 9

Limited Five-Year Warranty

Westinghouse Digital Electronics warrants to original end-users of this Westinghouse television mounting product (the

“Product”) that the Product will be free from defects in material and workmanship, under normal use, for a period of five (5)

years from the date of purchase by the original end-user, subject to the following terms and conditions:

REP AIR OR REPLACEMENT – For a period of five (5) years from the original date of purchase, Westinghouse Digital

Electronics will repair any defect in material or workmanship in the Product, or, at its option, replace a defective Product.

Replacement parts and products will be warranted for either the remainder of the original warranty period or ninety (90)

days from the date of delivery to the end-user, whichever occurs last.

OBT AINING WARRANTY SERVICE – To obtain warranty services, you must either personally deliver or ship the Product

to Westinghouse Digital Electronics, freight prepaid. Please call Westinghouse Digital Electronics at (866) 287-5555 to

obtain a Return Merchandise Authorization (“RMA”) and for other instructions regarding return and replacement or repair of

the Product. Westinghouse Digital Electronics will not accept Products delivered to it without an RMA.

EXCLUSIONS TO WARRANTY – This warranty does not cover damage caused by (a) service or repairs by anyone other

than personnel authorized by Westinghouse Digital Electronics, (b) the failure to utilize proper packing when returning the

product, (c) improper installation or the failure to follow Product instructions or warnings, or (d) misuse or accident, in

transit or otherwise.

PROOF OR ORIGINAL PURCHASE – A sales receipt, invoice, or other proof of purchase specifying the original date of

purchase within the five (5) year warranty period must be presented to obtain warranty service. This warranty extends to

the original purchaser and is not transferable.

EITHER REP AIR OR REPLACEMENT IS YOUR EXCLUSIVE REMEDY UNDER THIS WARRANTY. EXCEPT TO THE

EXTENT PROHIBITED BY LAW, WESTINGHOUSE DIGITAL SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES CLAIMED TO ARISE FROM BREACH OF ANY EXPRESS OR IMPLIED WARRANTY ON

THIS PRODUCT . ANY IMPLIED WARRANTY OF MERCHANT ABILITY OR FITNESS FOR A P ARTICULAR PURPOSE ON

THIS PRODUCT IS LIMITED IN DURATION AND SCOPE T O THE TERMS OF THIS WARRANTY.

Some States do not allow the exclusion or limitation of incidental or consequential damages, or allow limitations on how

long an implied warranty lasts, so the above limitation may not apply to you. This warranty gives specific legal rights, and

you may also have other rights which vary from State to State.

Westinghouse Digital Electronics, LLC

16257 East Gale Ave.

City of Industry , California 91745

T el: (626) 333-9677.

9 of 9

Visit the Westinghouse Web Site at www.westinghousedigital.com For customer service call 1-866-287-5555.

and Westinghouse are trademarks of Westinghouse Electric Corporation and are used under license.

ISSUED: 05-21-04 SHEET #: 201-9226-1

Loading...

Loading...