AC System Installation Guide

V2 60 Cell Modules

Rev: 10-12-11

Westinghouse Solar AC Installation Guide

Copyright © 2011. Westinghouse Solar. All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording, scanning or otherwise, except as permitted under Section

107 or 108 of the 1976 U.S. Copyright Act, without prior written permission from an officer of Westinghouse Solar.

For permission contact: Westinghouse Solar, 1475 South Bascom Ave. Suite 101, Campbell, CA 95008, Attn: VP of

Marketing.

Trademarks: Westinghouse Solar, Westinghouse Solar Power Systems, Sun for Everyone, and related trade dress

are trade names, trademarks or registered trademarks, and may not be used without written permission.

LIMITATION OF LIABILITY/DISCLAIMER OF WARRANTY. WESTINGHOUSE SOLAR, ITS PARENT, SUBSIDIARIES,

AND THEIR EMPLOYEES, AGENTS, OFFICERS AND DIRECTORS (COLLECTIVELY “AUTHOR”) MAKE NO

REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY OR COMPLETENESS OF THE CONTENTS

OF THIS WORK AND SPECIFICALLY DISCLAIM ALL WARRANTIES, INCLUDING WITHOUT LIMITATION WARRANTIES

OF FITNESS FOR A PARTICULAR PURPOSE. NO WARRANTY MAY BE CREATED OR EXTENDED BY SALES,

PROMOTIONAL MATERIALS OR CUSTOMER SERVICE. THE ADVICE AND STRATEGIES CONTAINED HEREIN MAY

NOT BE SUITABLE FOR EVERY SITUATION. THE CONTENTS OF THIS WORK ARE INTENDED FOR A TARGET

AUDIENCE THAT HAS SOME BASIC CONSTRUCTION AND ELECTRICAL WIRING KNOWLEDGE. THIS WORK IS SOLD

WITH THE UNDERSTANDING THAT THE AUTHOR IS NOT ENGAGED IN RENDERING LEGAL, ACCOUNTING, OR

OTHER PROFESSIONAL SERVICES. IF PROFESSIONAL ASSISTANCE IS REQUIRED, THE SERVICES OF A COMPETENT

PROFESSIONAL PERSON SHOULD BE SOUGHT. IN VIEW OF THE CHANGES IN LOCAL, STATE AND FEDERAL

REGULATIONS, THE READER IS URGED TO REVIEW AND EVALUATE THE INFORMATION PROVIDED BY THEIR

LOCAL, STATE AND FEDERAL REGULATORY AUTHORITY FOR, AMONG OTHER THINGS, ANY RULES, REGULATIONS,

INSTRUCTIONS, REQUIREMENTS, OR PRECAUTIONS RELATED TO THE INSTALLATION OF PV SOLAR ELECTRIC

SYSTEMS. READERS SHOULD CONSULT A LICENSED SOLAR INSTALLATION CONTRACTOR OR ELECTRICIAN WHERE

APPROPRIATE. THE AUTHOR SHALL NOT BE LIABLE FOR DAMAGES ARISING HEREFROM.

Place of Origin. This manual, and the techniques, methods and IP contained within it, were created in the United

States of America. Westinghouse Solar AC Systems contain some foreign made components. Assembly, design and

distribution takes place through operations located within and outside the United States of America.

Protected by U.S. patents (7,406,800; 7,832,157, 7,866,098 and 7,987,641), and foreign patents (2,005,248,343;

243,626; 274,182 and 751,614). Other patents pending.

Copyright © 2011 - Westinghouse Solar

Westinghouse Solar AC Installation Guide

Table of Contents

Section I. Getting Started ...................................................................................................................1

1. Safety Precautions ............................................................................................................................ 1

2. Parts and Tools .................................................................................................................................. 1

3. Solar Power Basics ............................................................................................................................ 2

4. Using this Guide ................................................................................................................................ 3

Section II. Westinghouse Solar AC System Layout and Design ..............................................................5

1. Westinghouse Solar Roof Layout Site Surveys .................................................................................. 7

2. Drafting a Roof Layout ...................................................................................................................... 7

3. Elements of Designing a Solar System Specific to Westinghouse Solar AC Panels........................... 8

4. Westinghouse Solar Mounting and Structural Requirements ........................................................ 10

5. Drafting a Solar Array ...................................................................................................................... 12

Section III. Creating an Electrical Diagram ........................................................................................ 14

1. Westinghouse Solar AC Electrical Requirements ............................................................................ 14

2. Single line diagram preparation ...................................................................................................... 15

3. Electrical Line Diagram .................................................................................................................... 16

4. Grounding ....................................................................................................................................... 16

Section IV. Installation ..................................................................................................................... 18

1. Safety Warnings .............................................................................................................................. 18

2. Layout .............................................................................................................................................. 18

3. Mounting ......................................................................................................................................... 21

4. Module Installation ......................................................................................................................... 23

5. Connecting Westinghouse Solar AC Wiring Harnesses ................................................................... 26

Copyright © 2011 - Westinghouse Solar

Westinghouse Solar AC Installation Guide

6. Grounding ....................................................................................................................................... 29

7. Adding AC Interconnect Parts ......................................................................................................... 30

8. Commissioning Westinghouse Solar AC Systems ........................................................................... 31

Section V. Westinghouse Solar Operations ....................................................................................... 33

1. Troubleshooting .............................................................................................................................. 33

2. Troubleshooting an Inoperable Inverter (For Experienced Installers) ............................................ 34

3. Disconnecting the Inverter from the PV Panel ............................................................................... 34

Section VI. Definitions ...................................................................................................................... 35

Section VII. Appendix ......................................................................................................................... i

Section VIII. Technical Support ........................................................................................................ xiii

Table of Figures .............................................................................................................................. xiv

Copyright © 2011 - Westinghouse Solar

Westinghouse Solar AC Installation Guide

Splice Driver

1/4” Ratchet Wrench

9/16” Combination Wrench

Section I. Getting Started

1. Safety Precautions

• Before installing the Westinghouse Solar AC Module, read all instructions and cautionary

markings in the Westinghouse Solar AC documentation.

• Perform all electrical installations in accordance with all local electrical codes, the National

Electrical Code (NEC), ANSI/NFPA 70 and local utility requirements.

2. Parts and Tools

Required tools include:

Splice Driver (WHS provided)

Grounding Washer

Offset Bracket

(Available from Westinghouse Solar)

(Available from any tool source)

Copyright © 2011 - Westinghouse Solar 1 | Page

(available from any tool source)

Westinghouse Solar AC Installation Guide

3. Solar Power Basics

Background

Rooftop solar power systems have come a long way, and Westinghouse Solar AC panels break new

ground in both performance and safety. Westinghouse Solar AC panels are the first solar panel on

the market to integrate racking, wiring, grounding and inverters directly into the panel. This

section provides an overview of the installation and operation of your Westinghouse Solar Power

System. Please note that the instructions herein are directed towards individuals and

professionals with good knowledge of residential wiring and construction techniques. Do not

undertake the wiring and installation of this product if you are not qualified to work with

household AC voltages, if you are not knowledgeable about construction techniques, and if you

are not experienced in working on rooftops and other dangerous locations.

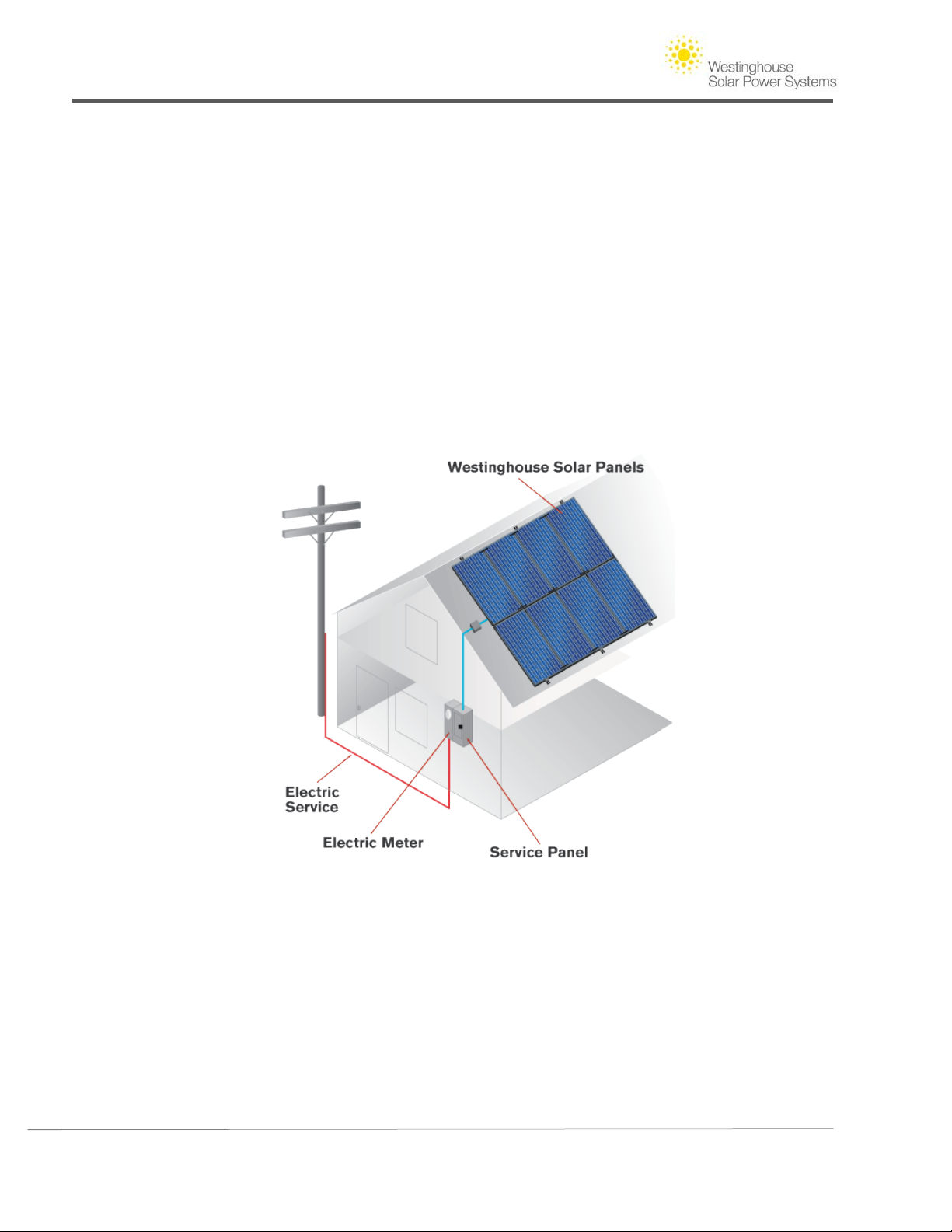

Figure 1 -– Westinghouse Solar AC System

How Westinghouse Solar AC Works

Westinghouse Solar AC panels are installed on a sunny, generally south-facing rooftop or back

yard area. AC output from the solar panels is wired into your home’s electrical service panel via a

dedicated 240 VAC branch circuit. When direct sunlight hits Westinghouse Solar panels, their

built-in inverters produce AC power synchronized to the utility’s grid. This power goes towards use

in your home first. When you produce more electricity on your roof than your home needs, the

excess flows to the grid, running your electric meter backwards. At night or on cloudy days you

Copyright © 2011 - Westinghouse Solar 2 | Page

Westinghouse Solar AC Installation Guide

still draw power from your utility. Your electric bill is reduced because you only pay for the net

amount of electricity you use.

Westinghouse Solar AC Panel Design and Performance

Ordinary solar power systems use a centralized inverter, and require the installation of a separate

racking system to mount the panels. These ordinary systems also require manual interconnection

of high voltage DC wiring, and manual grounding of all panel and racking components. With the

racking, wiring, grounding and inverters built into Westinghouse Solar panels, installation is much

easier, reliability is greater and performance is 5 to 25% higher than ordinary systems.

The rating on each panel indicates the nominal DC power output in watts of a panel when it is in

bright sunlight in 25 degree C conditions, and the sun’s rays are perpendicular to the surface of

the panel. Because the inverter operates at about 95% efficiency, the AC output of the system will

be approximately 5% less than the peak DC output. So at peak conditions, a 235 watt

Westinghouse Solar AC panel will produce up to about 223 watts of power. In real world

conditions throughout the day, as the sun rises, moves across the sky, and then sets, the output of

the panels will increase from essentially zero at dawn to a peak of about 175-214 watts

(depending on season, sun angle, mounting angle and roof orientation), and then decline again to

zero. Each panel operates independently, so if one is shaded or dirty the adjacent panels will still

operate to maximize their energy output.

Westinghouse Solar AC panels use Enphase micro-inverters, which are mounted on the back of

each panel. The easiest way to determine the output from your Westinghouse Solar AC panels is

with the optional Energy Management Unit (EMU). The EMU communicates with Enphase’s

“Englighten” website for real time reporting and analysis on the performance of each of your

Westinghouse Solar panels. The EMU is installed by plugging it into any convenient 120 VAC wall

socket and providing an Ethernet connection to your broadband router or modem. After

installation of the EMU, the full network of Westinghouse Solar AC Panels automatically begins

reporting to Enlighten. Alternatively, you may measure the voltage, current and power output of

each branch circuit of Westinghouse Solar AC panels with conventional electrical instruments,

taking the appropriate cautions when handling live electrical circuitry.

4. Using this Guide

This guide will familiarize you with the fundamentals of design and installation of your

Westinghouse Solar Power System. The guide also serves to illustrate the simplicity and

efficiency of solar design when equipment is developed in unison with each other. Westinghouse

Solar Power Systems consist of hundreds of individual separate parts built into one integrated

solar electric system delivering easier, faster design and installation over ordinary solar

installations.

This guide contains three primary sections. The first section covers the physical properties of solar

design specific to the Westinghouse Solar Power System, including how to layout your

Westinghouse Solar Power System, how to choose components, and the structural requirements

Copyright © 2011 - Westinghouse Solar 3 | Page

Westinghouse Solar AC Installation Guide

involved in the installation process. The second section of this guide covers the creation of an

electrical diagram, electrical site surveys, and elements of designing a solar system specific to

Westinghouse Solar AC panels. Common requirements for solar electrical permit applications are

also reviewed. The final section reviews Westinghouse Solar AC installation best practices and

system commissioning. If you are familiar with residential construction techniques, AC wiring, and

your local permitting requirements you will have the basic skills to install your Westinghouse Solar

Power System. Please note that certain state incentive programs and utility interconnection

regulations may require skills and instruments beyond those noted above, in which case the

services of a professional solar installer may be needed.

The convention we use to describe the orientation of Westinghouse Solar layouts in this guide is

that the north/ south direction describes rows of panels that are aligned vertically where north is

the peak of the roof, and south refers to the gutter. An east / west row describes a horizontal

grouping of panels from left to right. There are different functions that need to be considered

when designing Westinghouse Solar in regards to the horizontal and vertical connection of panels.

Note:

This guide was created by summarizing common requirements of solar design. It serves to prepare

system designers with a basic understanding of the solar design and planning process. Designers are

encouraged to research the specific demands of the permitting jurisdiction and utility governing their

region. Your installation should be performed in full compliance with OSHA safety standards and all

relevant jurisdictional requirements, including if applicable, the U.S. National Electrical Code (“NEC”).

Copyright © 2011 - Westinghouse Solar 4 | Page

Westinghouse Solar AC Installation Guide

Section II. Westinghouse Solar AC System Layout and Design

Westinghouse Solar AC systems require 80% fewer parts than ordinary solar systems; the simplicity of

having fewer parts transfers directly into the ease of the design process. Along with the added

efficiencies of Westinghouse Solar AC panels comes a set of unique parameters that need to be

considered when laying out your design. Westinghouse Solar’s racking system is built directly into the

panel frame. When laying out a single row you should visualize the perimeter of the array for your roof

attachment points. The top and bottom frames of Westinghouse Solar panels is where the "Groove”

(Figure 2) is accessible and will serve as connection between the array and the chosen roof-mounting

solution. The Groove provides full adjustability in the east-west direction of your roof, allowing you to

adapt attachment spacing to nearly every rafter scenario.

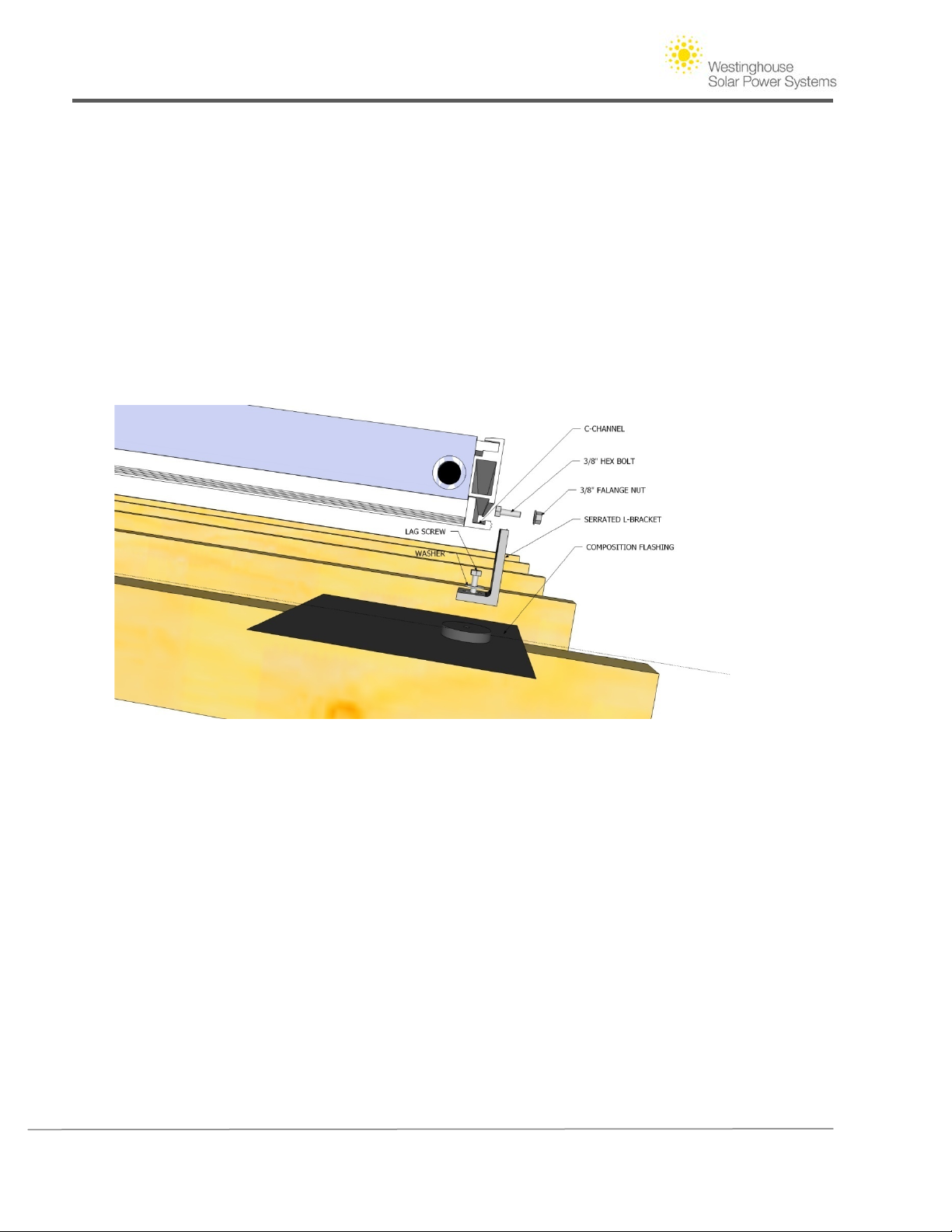

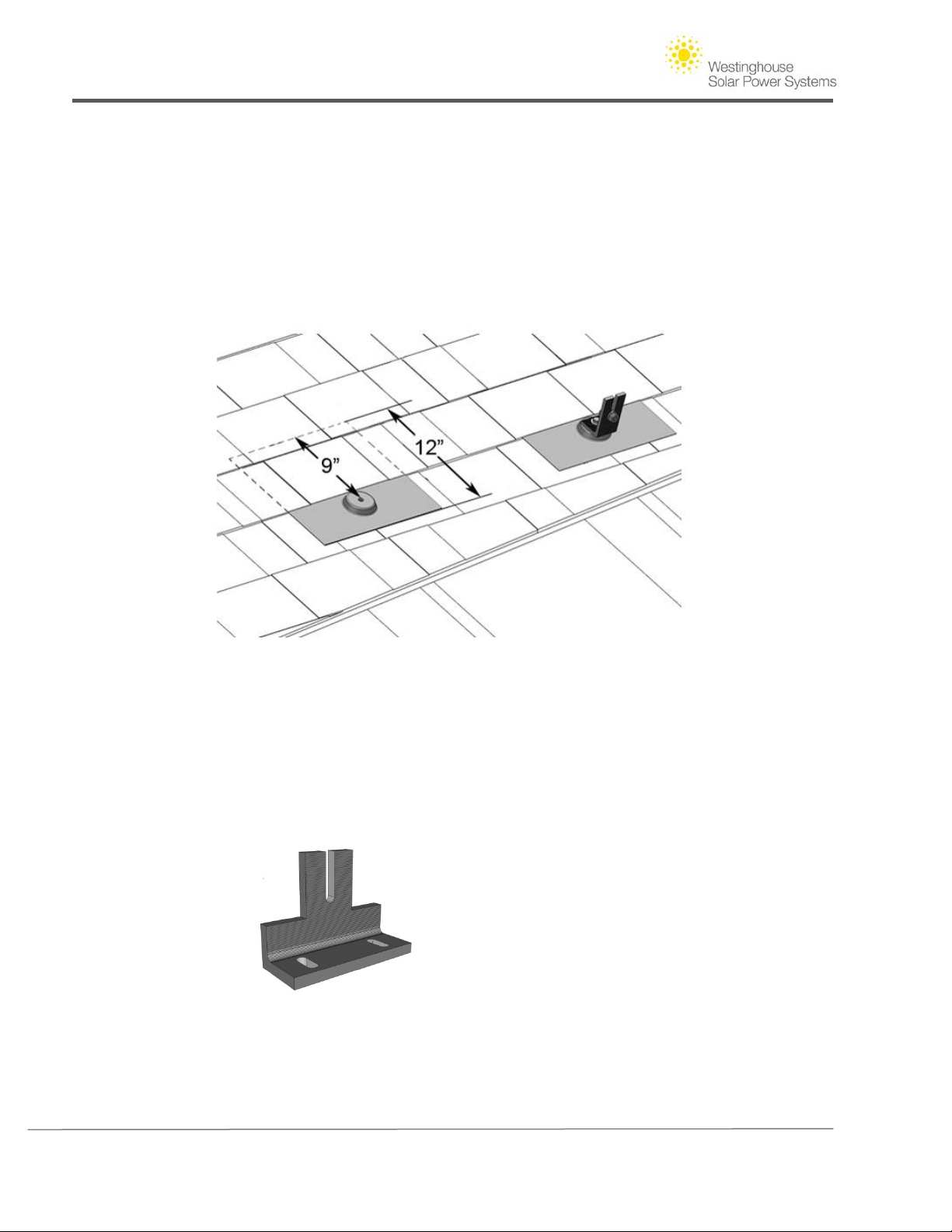

Figure 2 - Roof attachment component s and panel Groove example for composition shingle roof

You may orient the Westinghouse Solar panels in either a “portrait mode” or a “landscape mode”.

Portrait mode minimizes roof penetrations and AC wiring, resulting in faster installation times.

Landscape mode may also be used for added flexibility. The design of the Westinghouse Solar Power

System also accommodates mixed portrait and landscape installations.

Copyright © 2011 - Westinghouse Solar 5 | Page

Westinghouse Solar AC Installation Guide

Figure 3 – Six by two array installed in portrait mode

Figure 4 - Comparably sized four by three array in landscape mode

Copyright © 2011 - Westinghouse Solar 6 | Page

Westinghouse Solar AC Installation Guide

1. Westinghouse Solar Roof Layout Site Surveys

Prepare for the roof layout by surveying your roof to gather the following design information:

A. Roof type. The most common roof type is composition asphalt shingle. Flat Concrete tile

and barrel tile roofs are also compatible with Westinghouse Solar AC panels. This

information will determine your specific roofing kit needed. We have included roof

attachment profiles that can be included in your plans in the appendix of this guide.

B. Underlying structure. Determine the dimension of rafters and the spacing of the rafters.

For example, 2"x 8" @ 24" o.c. describes 2" by 8" rafters that are spaced 24" on center.

This information will determine where you locate your attachment points on your roof

layout. Also, planning departments typically will not ask you to draw individual rafters on

your submitted layout, but they will need this information noted on the plans to confirm the

structure meets code requirements.

C. Roof Pitch. Measure the pitch of your roof in degrees.

D. Roof measurements. Take accurate measurements that can easily be transferred onto a

sheet of graph paper or into the CAD program you are working with to design the layout.

Remember to include any obstacles that will interfere with your array design. When

measuring the peak of the roof, exclude the roof cap in your measurements because this is

an unusable area for solar attachments.

E. Azimuth. This information will help you choose the optimal solar roof surfaces, and is also

crucial to include on documentation when applying for state rebates and incentives. Ideal

orientation is south, but east and west facing roofs are OK with only a slight output penalty.

Panels are designed for flush roof mounting at your existing roof slope.

F. Shading. Using a SunEye or Solar Pathfinder device, determine shading and design a layout

that will maximize system output.

2. Drafting a Roof Layout

This portion of the process can be done using a graph paper or in a more detailed tool such as a

CAD program. Before submitting your layout to your local permitting jurisdiction, request

information from your local building permit office on special requirements for PV design in your

area. These requirements may include roof setbacks and clearances that need to be included in

your design.

Copyright © 2011 - Westinghouse Solar 7 | Page

Westinghouse Solar AC Installation Guide

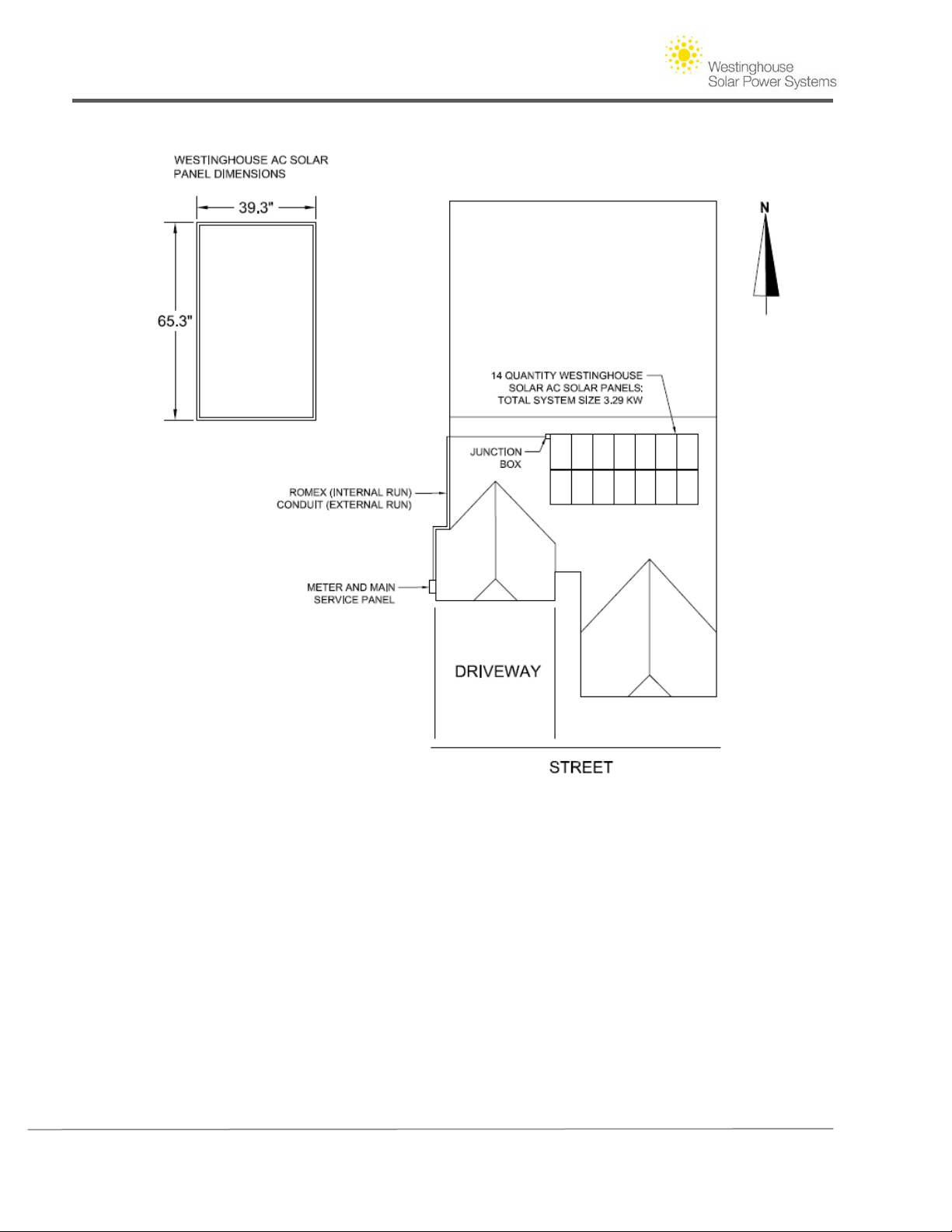

Figure 5 - Sample roof layout and panel dimensions

3. Elements of Designing a Solar System Specific to Westinghouse Solar AC Panels

Before you add the solar array to your roof layout design become familiar with the basic design

principles specific to Westinghouse Solar AC. You should understand the spacing requirements,

mounting methods, and wiring basics that are a part of the Westinghouse Solar AC design. You will

need to follow the equipment specific rules below in order to create a safe and efficient

Westinghouse Solar AC system.

-Westinghouse Solar AC Branch Circuits. -When Westinghouse Solar AC panels are arranged on

a roof layout, they are wired in parallel, and operate independently on a per panel basis. For

this reason, panels can be placed on roofs of varying pitches, orientations, and shading levels.

Copyright © 2011 - Westinghouse Solar 8 | Page

Westinghouse Solar AC Installation Guide

Unlike with ordinary DC solar panels, the performance of Westinghouse Solar panels will not be

compromised by adjacent lower producing panels in the same branch circuit.

-Include Buffer Space Around the Array in your Design. Consider the necessary buffer room

needed around the array for the roof mount to be sufficiently “flashed.” To be flashed is a

roofing term for professionally sealing a penetration by installing a separate metal flashing

underneath the row of shingles above the penetration, as illustrated below. Concrete tile and

barrel tile dimensions are shown in the Appendix.

Figure 6 - Roof top buffer room example on composition shingle roof

Use an Offset L Bracket when modules connect over an attachment point. The Offset L Brackets

allow you to secure two modules together with a splice over an attachment point. Use the

Offset L Bracket instead of a regular L Bracket for an additional 2 inches of mounting flexibility.

Figure 7 - Offset L Bracket

Copyright © 2011 - Westinghouse Solar 9 | Page

Westinghouse Solar AC Installation Guide

4. Westinghouse Solar Mounting and Structural Requirements

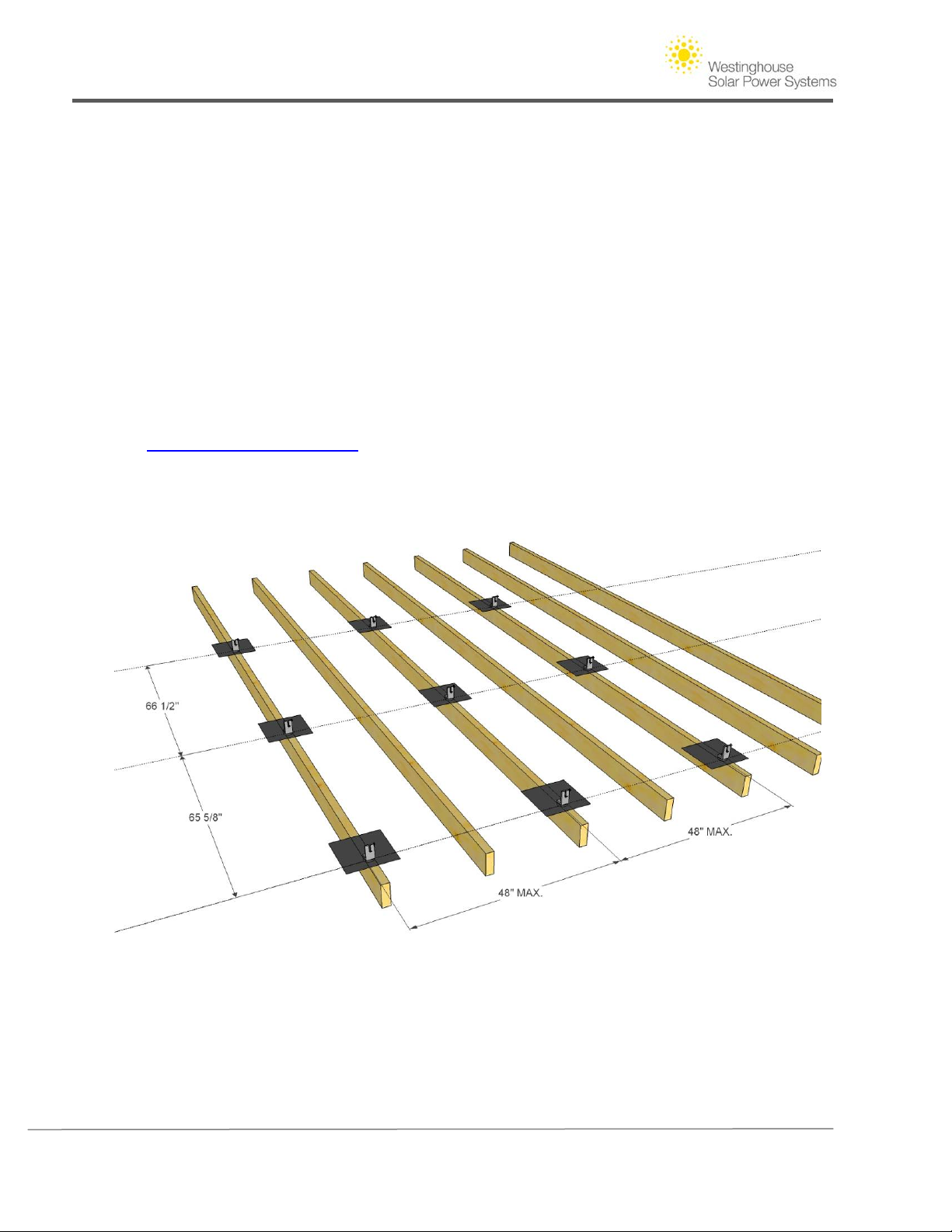

To satisfy Westinghouse Solar's minimal structural requirements there are two simple design rules

that usually dictate the minimum mounting requirements. As Westinghouse Solar AC panels are

connected together they form a rigid structure. The span of the panels between roof attachments

is generally 48”. As per the Technical Engineering Report (available on WestinghouseSolar.com,

greater spans can be used in sheltered wind condition areas, and shorter spans may be necessary

under high wind conditions. These roof attachments are located on both the top and bottom of

your single row array. The second rule requires that panels which overhang the last footing in a

row may stick out no more than a maximum of 16" from that footing. Before finalizing your roof

drawing, check with your local building department to identify any unique wind or snow load

requirements that pertain to your jurisdiction. A combination of shortening the maximum span

between roof attachments and increasing the length of your lags will enhance the wind load

rating of Westinghouse Solar AC panels. Refer to the Technical Engineering Report on

www.westinghousesolar.com to determine maximum allowable anchor spacing.

Figure 8 - Basic Westinghouse Solar attachment point layout

(Refer to Technical Engineering Report on www.westinghousesolar.com)

Copyright © 2011 - Westinghouse Solar 10 | Page

Westinghouse Solar AC Installation Guide

Warning: The Westinghouse Solar AC Solar Panel System must be mounted over a fire

resistant roof covering rated for the application. Attachment points must be properly located

relative to the panel so the brackets do not exert lateral pressure on the frame. Care should

be taken to ensure the mounting points are positioned in accordance with the Westinghouse

Solar AC panel requirements. The measurements in the following diagrams represent distance

between lag bolt penetrations. Westinghouse Solar L-brackets feature an adjustable oblong

base slot that is adjusted to exact panel dimensions as the system is installed. Failure to

adjust the L-Brackets and associated hardware to the exact panel dimensions may cause the

hardware to exert lateral pressure on the Westinghouse Solar Frame voiding the warranty.

Shared Attachment Points

Westinghouse Solar roof layouts that include multiple rows of panels leverage the installation

efficiencies of panel-integrated racking. The stainless steel Westinghouse Solar splices

(Connectors) that ground and connect panels in the east-west direction serve as structural

components. The North-South Bracket serves as a structural connection and enables sharing of

footings between the first and second rows (and all consecutive rows until the top of array).

The Westinghouse Solar North-South Bracket allows the upper row to share the lower rows

upper footing. The Westinghouse Solar AC Solar Power System has been tested and certified at

an accredited laboratory as an integrated system. When designing a multiple row array with

Westinghouse Solar AC, the entire array can be seen as a unified structure, and not single rows

of panels on independent racking systems as with ordinary solar panels.

Figure 9 - Profile of roof attachments with shared center attachment point across two panel rows

Copyright © 2011 - Westinghouse Solar 11 | Page

Westinghouse Solar AC Installation Guide

5. Drafting a Solar Array

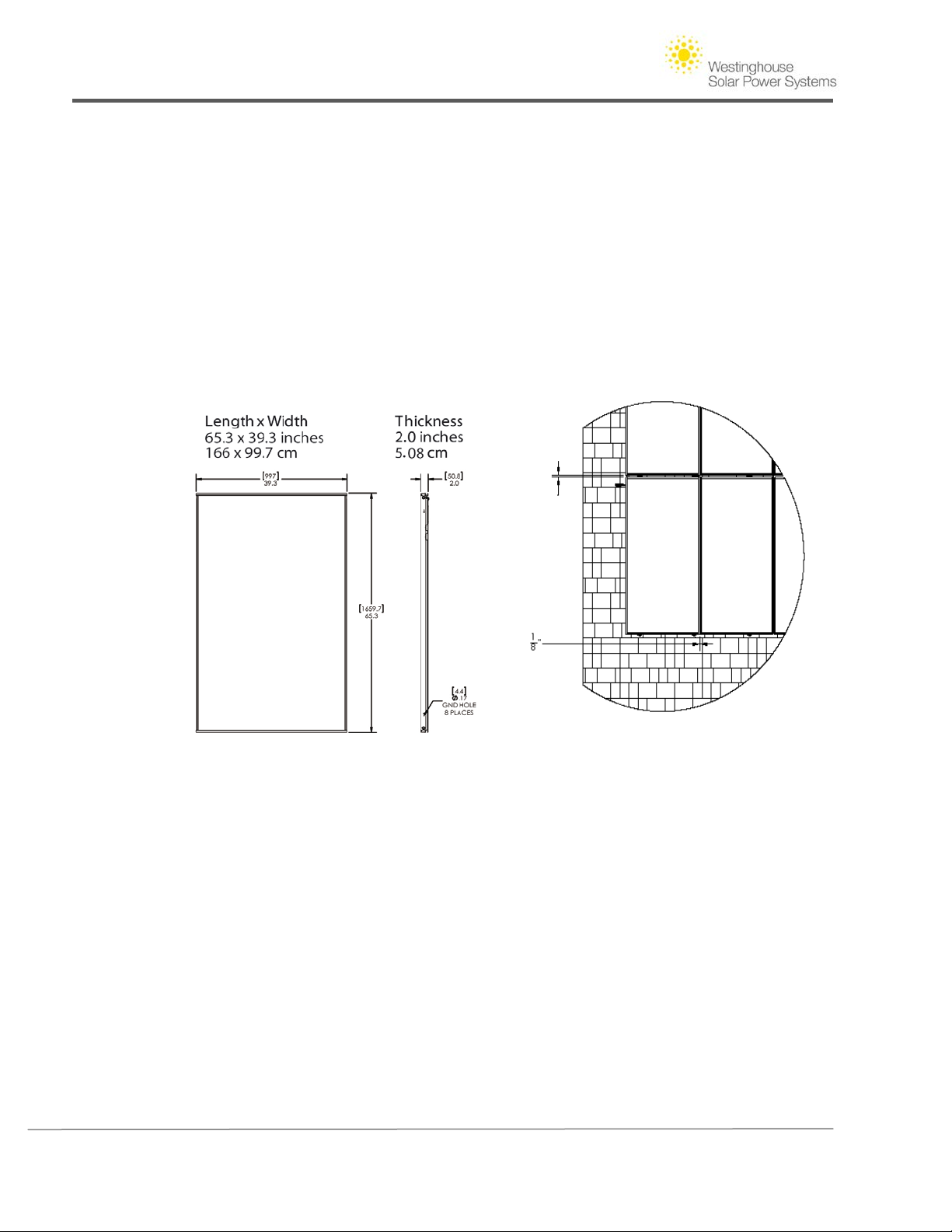

Begin drawing Westinghouse Solar panels on the predetermined solar roofs considering the above

mentioned design parameters. Westinghouse Solar AC panels measure 65.3" long by 39.3” wide.

Include a 1" gap between rows in the north/ south direction to accommodate the installation of the

Westinghouse Solar North-South Bracket. To allow for thermal expansion in large arrays, include a

one inch expansion gap for every 12 Westinghouse Solar panels in a continuous row.

Take time to review how the Westinghouse Solar components you are working with are

developed and organized in the included roof layout. The default roof attachment profiles

included in the Appendices may be attached to your plans for review by local planning and

permitting jurisdictions.

1”

Figure 10 - Westinghouse Solar inter-panel spacing and panel dimensions

Adding Additional Equipment to the Roof Layout

Westinghouse Solar AC Wire Runs

After the roof layout is complete with Westinghouse Solar AC panel locations and the existing

electrical service, identify where conduit or Romex will be run to route the arrays conductors to

the associated equipment on the ground. This can be done by simply drawing a line across your

site map and labeling the material as is seen in the sample roof layout.

Conductors

Conductors will either be run as Romex internally or through an approved conduit externally. If

an external disconnect is required in your jurisdiction, include this location on the roof layout.

Label all equipment and conduit sizes on the roof layout.

Copyright © 2011 - Westinghouse Solar 12 | Page

Westinghouse Solar AC Installation Guide

Other Electrical Equipment

Include junction boxes and disconnects on your roof layout as needed. The conduit will connect

all of this equipment in the same sequence as your electric diagram. For this reason it may be

helpful to finalize the electrical line diagram before finalizing equipment placement on the roof

layout.

Copyright © 2011 - Westinghouse Solar 13 | Page